Mitsubishi FR-F720-75K, FR-F740-55K, FR-F720P-55K, FR-F720P-75K, FR-F740P-55K Instruction Manual

...

INVERTER

Plug-in option

PRE-OPERATION INSTRUCTIONS

1

FR-A7NF

INSTRUCTION MANUAL

FL remote

function

communication

INSTALLATION

WIRING

INVERTER SETTING

FL REMOTE COMMUNICATION

FUNCTION

CYCLIC TRANSMISSION

MESSAGE TRANSMISSON

DESCRIPTION AND CORRECTIVE

ACTION OF FAULT INDICATION

TROUBLESHOOTING

2

3

4

5

6

7

8

9

Thank you for choosing this Mitsubishi Inverter plug-in option.

This Instruction Manual gives handling information and

precautions for use of this equipment. Incorrect handling might

cause an unexpected fault. Before using the equipment, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about

safety matters

Do not attempt to install, operate, maintain or inspect this

product until you have read through this Instruction Manual and

appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full

knowledge of the equipment, safety information and

instructions.

In this Instruction Manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

Incorrect handling may cause

WARNING

CAUTION

The level may even lead to a serious

consequence according to conditions. Both instruction levels

must be followed because these are important to personal

safety.

CAUTION

hazardous conditions, resulting in

death or severe injury.

Incorrect handling may cause

hazardous conditions, resulting in

medium or slight injury, or may cause

only material damage.

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

• While power is ON or when the inverter is running, do not

open the front cover. You may get an electric shock.

• Do not run the inverter with the front cover or wiring cover

removed. Otherwise, you may accidentally touch the exposed

high-voltage terminals and charging part and get an electric

shock.

• Even if power is OFF, do not remove the front cover except for

wiring or periodic inspection. You may accidentally touch the

charged inverter circuits and get an electric shock.

• Before wiring or inspection, power must be switched OFF. To

confirm that, LED indication of the operation panel must be

checked. (It must be OFF.) Any person who is involved in

wiring or inspection shall wait for at least 10 minutes after the

power supply has been switched OFF and check that there

are no residual voltage using a tester or the like. The

capacitor is charged with high voltage for some time after

power OFF, and it is dangerous.

• Any person who is involved in wiring or inspection of this

equipment shall be fully competent to do the work.

• The plug-in option must be installed before wiring. Otherwise,

you may get an electric shock or be injured.

• Do not touch the plug-in option or handle the cables with wet

hands. Otherwise you may get an electric shock.

• Do not subject the cables to scratches, excessive stress,

heavy loads or pinching. Otherwise you may get an electric

shock.

A-1

2. Injury Prevention

3) Usage

CAUTION

• The voltage applied to each terminal must be the ones

specified in the Instruction Manual. Otherwise burst, damage,

etc. may occur.

• The cables must be connected to the correct terminals.

Otherwise burst, damage, etc. may occur.

• Polarity must be correct. Otherwise burst, damage, etc. may

occur.

• While power is ON or for some time after power-OFF, do not

touch the inverter as they will be extremely hot. Doing so can

cause burns.

3. Additional Instructions

Also the following points must be noted to prevent an accidental

failure, injury, electric shock, etc.

1) Transportation and mounting

CAUTION

• Do not install or operate the plug-in option if it is damaged or

has parts missing.

• Do not stand or rest heavy objects on the product.

• The mounting orientation must be correct.

• Foreign conductive objects must be prevented from entering

the inverter. That includes screws and metal fragments or

other flammable substances such as oil.

2) Trial run

CAUTION

• Before starting operation, each parameter must be confirmed

and adjusted. A failure to do so may cause some machines to

make unexpected motions.

WARNING

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

• Static electricity in your body must be discharged before you

touch the product. Otherwise the product may be damaged.

4) Maintenance, inspection and parts replacement

CAUTION

• Do not test the equipment with a megger (measure insulation

resistance).

5) Disposal

CAUTION

• This inverter plug-in option must be treated as industrial

waste.

6) General instruction

Many of the diagrams and drawings in this Instruction Manual

show the inverter without a cover or partially open for

explanation. Never operate the inverter in this manner. The

cover must be reinstalled and the instructions in the inverter

manual must be followed when operating the inverter.

A-2

— CONTENTS —

1 PRE-OPERATION INSTRUCTIONS 1

1.1 Inverter model ....................................................................................................................................1

1.2 Unpacking and product confirmation ..............................................................................................2

1.2.1 Product confirmation.......................................................................................................................................2

1.2.2 SERIAL number check ...................................................................................................................................3

1.3 Parts ....................................................................................................................................................7

1.4 LED status ..........................................................................................................................................8

1.4.1 Device status LED (DEV), remote status LED (RMT) ....................................................................................9

1.4.2 Transmitting (TX)/receiving (RX) LED ..........................................................................................................10

1.4.3 Communication set status LED (CHG).........................................................................................................10

1.5 Specifications...................................................................................................................................11

1.5.1 Inverter option specifications........................................................................................................................11

1.5.2 Communication specifications......................................................................................................................11

2 INSTALLATION 12

2.1 Pre-installation instructions ...........................................................................................................12

2.2 Installation of the communication option LED display cover .....................................................13

2.3 Installation procedure .....................................................................................................................14

2.4 Node address setting ......................................................................................................................16

3 WIRING 17

3.1 Connection to network ....................................................................................................................17

3.2 Cable specifications ........................................................................................................................18

3.3 Precautions for system configuration ...........................................................................................18

I

3.4 Wiring................................................................................................................................................19

4 INVERTER SETTING 21

4.1 Parameter list ...................................................................................................................................21

4.2 Operation mode setting...................................................................................................................24

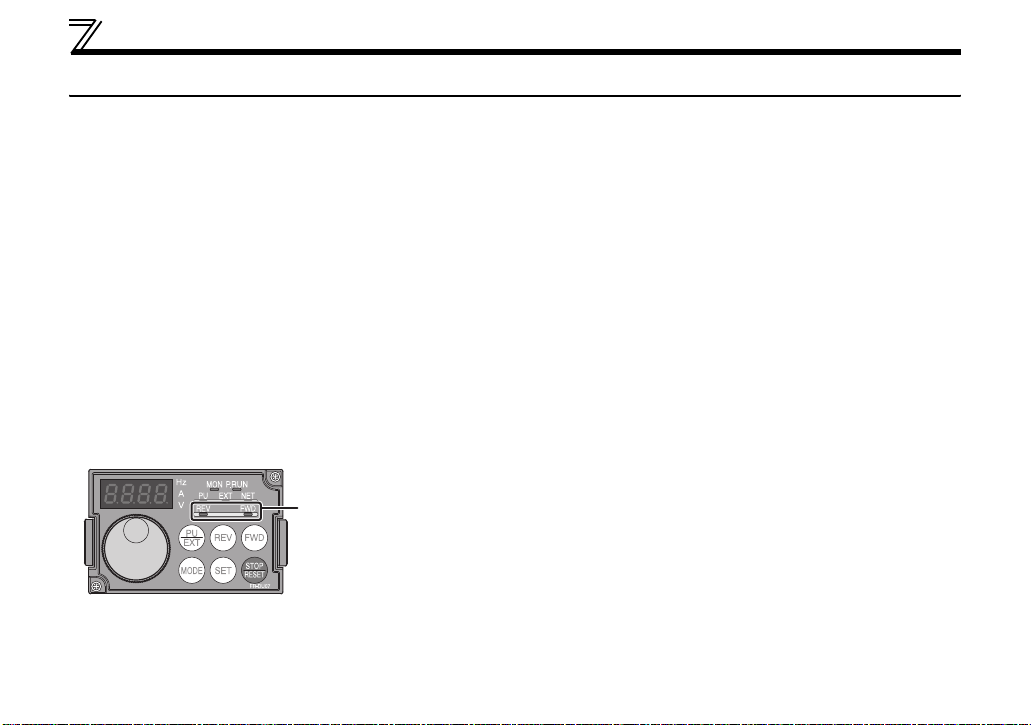

4.2.1 Operation mode indication............................................................................................................................24

4.2.2 Operation mode switchover method.............................................................................................................25

4.3 Selection of control source for the Network operation mode .....................................................30

4.4 Operation at communication error occurrence ............................................................................32

4.4.1 Operation selection at communication error occurrence (Pr. 501, Pr. 502) .................................................32

4.4.2 Fault and measures......................................................................................................................................34

4.5 Inverter reset ....................................................................................................................................36

4.6 Frequency and speed conversion specifications.........................................................................37

5 FL REMOTE COMMUNICATION FUNCTION 38

5.1 Functions..........................................................................................................................................38

5.1.1 Output from the inverter to the network........................................................................................................38

5.1.2 Input to the inverter from the network...........................................................................................................39

5.2 Types of data communication ........................................................................................................40

6 CYCLIC TRANSMISSION 41

6.1 Common memory ............................................................................................................................42

6.1.1 Common memory area 1..............................................................................................................................44

6.1.2 Common memory area 2..............................................................................................................................45

6.2 Output data (master to inverter) .....................................................................................................48

6.2.1 Control input command ................................................................................................................................49

6.2.2 Set frequency ...............................................................................................................................................51

II

6.3 Input data (inverter to master) ........................................................................................................52

6.3.1 Inverter status monitor..................................................................................................................................53

6.3.2 Fault code.....................................................................................................................................................55

6.3.3 Life/warning ..................................................................................................................................................55

6.3.4 Output frequency monitor.............................................................................................................................57

6.3.5 Output current monitor..................................................................................................................................57

7 MESSAGE TRANSMISSON 58

7.1 Error response at word block read/write .......................................................................................61

7.2 Word block read/write .....................................................................................................................62

7.2.1 Virtual address space of word block read/write............................................................................................63

7.2.2 Product information ......................................................................................................................................64

7.2.3 Operation mode............................................................................................................................................66

7.2.4 Inverter status...............................................................................................................................................67

7.2.5 Set frequency ...............................................................................................................................................68

7.2.6 Inverter monitor ............................................................................................................................................69

7.2.7 Parameter.....................................................................................................................................................72

7.2.8 Calibration parameters .................................................................................................................................74

7.2.9 Fault record ..................................................................................................................................................76

7.3 Network parameter read ..................................................................................................................82

7.4 Log data read ...................................................................................................................................85

7.5 Log data clear...................................................................................................................................88

7.6 Profile read .......................................................................................................................................89

7.7 Message loopback ...........................................................................................................................93

8 DESCRIPTION AND CORRECTIVE ACTION OF FAULT INDICATION 94

9 TROUBLESHOOTING 95

III

1 PRE-OPERATION INSTRUCTIONS

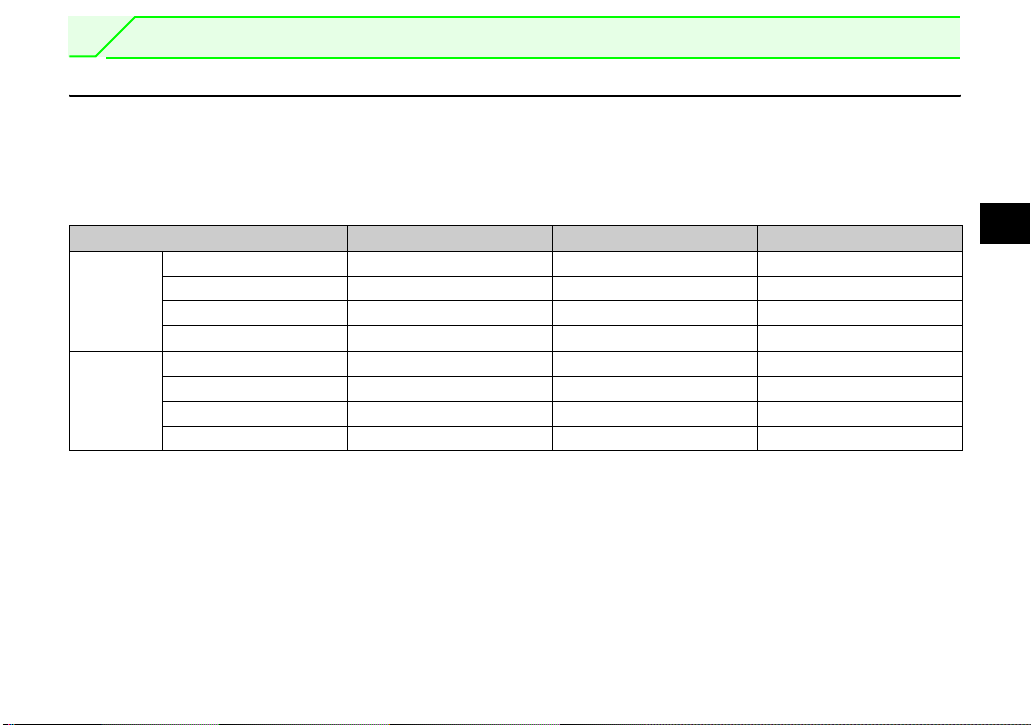

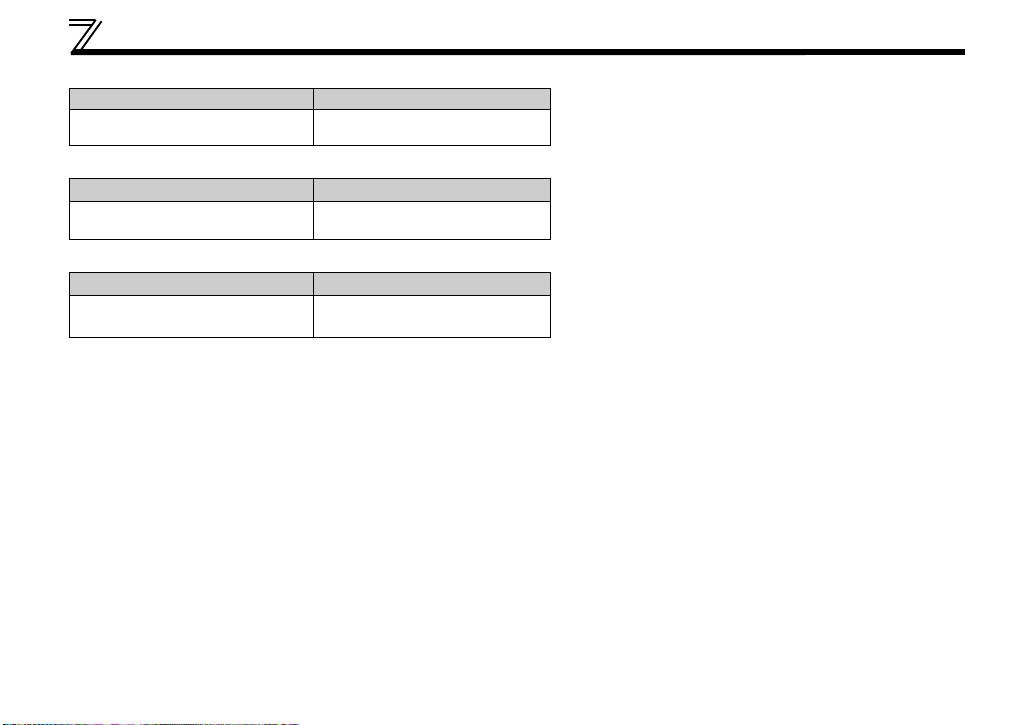

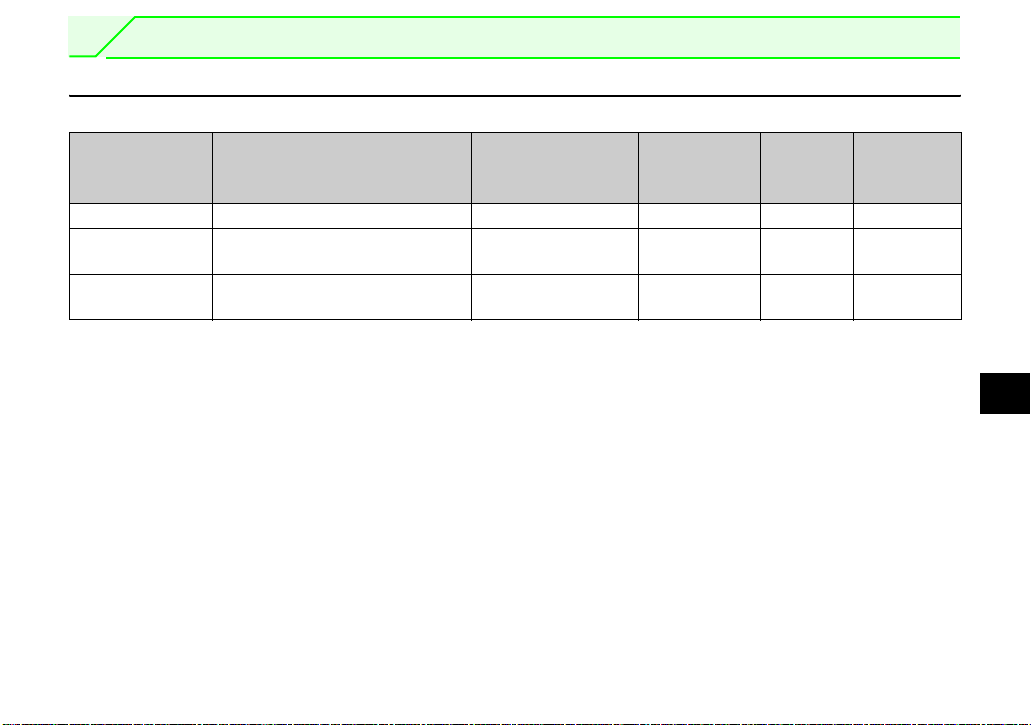

1.1 Inverter model

The inverter model, 55K and 75K stated in this Instruction Manual differs according to each -NA, -EC, CH(T) versions. Refer to the following correspondence table for each inverter model. (Refer to the Instruction

Manual of each inverter for the inverter model.)

For example, "for the 75K or higher" indicates "for the FR-A740-01440-NA or higher" in the case of FRA740 of NA version.

NA EC CH

FR-F720(P)-55K FR-F720-02330-NA ⎯⎯

F700

A700

FR-F720(P)-75K FR-F720-03160-NA ⎯⎯

FR-F740(P)-55K FR-F740-01160-NA FR-F740-01160-EC FR-F740-55K-CH(T)

FR-F740(P)-75K FR-F740-01800-NA FR-F740-01800-EC FR-F740-S75K-CH(T)

FR-A720-55K FR-A720-02150-NA ⎯⎯

FR-A720-75K FR-A720-02880-NA ⎯⎯

FR-A740-55K FR-A740-01100-NA FR-A740-01800-EC FR-A740-55K-CHT

FR-A740-75K FR-A740-01440-NA FR-A740-02160-EC FR-A740-75K-CHT

1

1

PRE-OPERATION INSTRUCTIONS

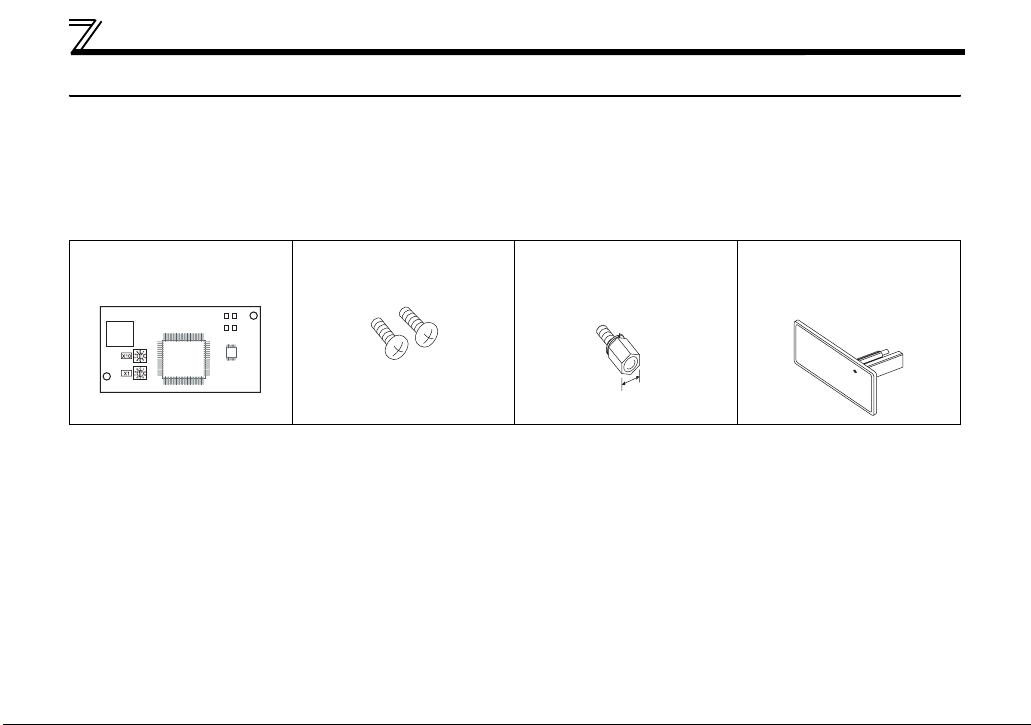

1.2 Unpacking and product confirmation

Take the plug-in option out of the package, check the product name, and confirm that the product is as you

ordered and intact.

This product is a plug-in option for the FR-A700/F700(P) series inverter.

1.2.1 Product confirmation

Check the enclosed items.

Plug-in option

.........................................1

Mounting screw (M3 × 6mm)

............ 2 (Refer to page 14.)

Hex-head screw for option

mounting (5.5mm)

............. 1 (Refer to page 14.)

5.5mm

Communication option LED

display cover

............ 1 (Refer to page 13.)

2

PRE-OPERATION INSTRUCTIONS

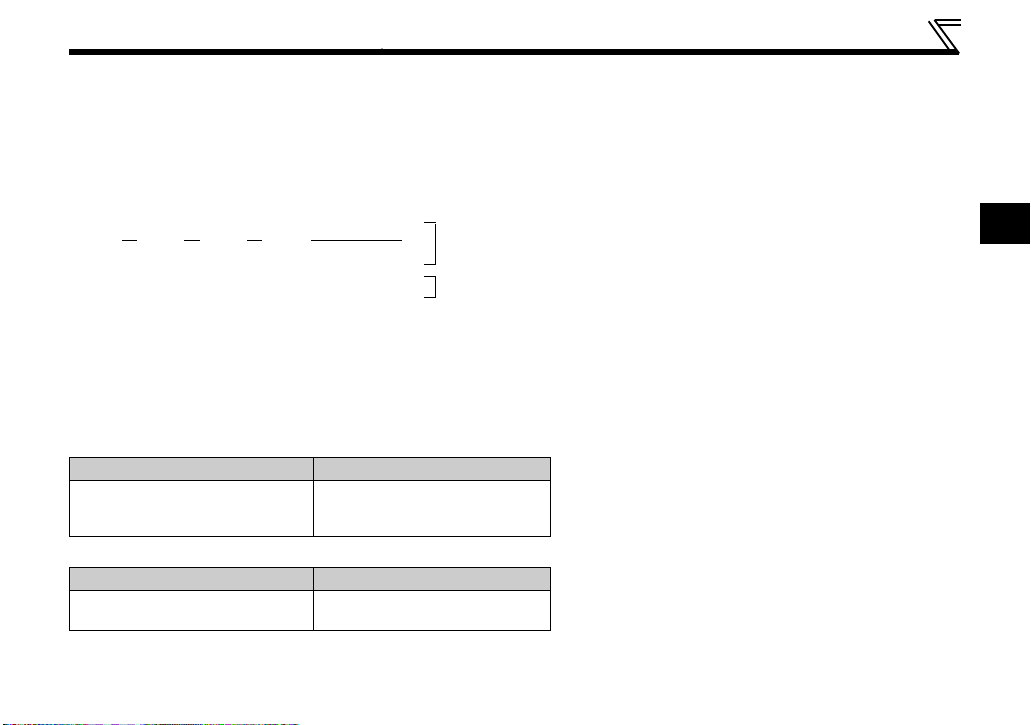

1.2.2 SERIAL number check

The plug-in option is compatible with the inverter having the following SERIAL number or later.

Check the SERIAL number indicated on the inverter rating plate or package.

z SERIAL number check

Refer to the inverter manual for the location of the rating plate.

Rating plate example

Symbol Year Month Control number

The SERIAL consists of one symbol, two characters indicating production year and month, and six characters indicating control number.

The last digit of the production year is indicated as the Year, and the Month is indicated by 1 to 9, X (October), Y (November), or Z (December.)

(1) PU/NET operation switchover (X65 signal) specification

The inverters with the following SERIAL are operated in the PU/NET operation switchover (X65 signal)

specification when connected with FR-A7NF.

z FR-A700 series

FR-A720-(-NA),

FR-A740FR-CA70-EC, FR-CA70-ECT

z FR-F700 series Japanese specification

FR-F720-0.75K to 110K,

FR-F740-0.75K to 560K

Regardless of their SERIAL numbers, all FR-F700P series inverters are operated with the PU operation interlock

(X12 signal) specification.

{ { {{{{{{

TC{{{A{{{G{{ TC number

Model SERIAL number

(-NA)(-EC)(-CHT),

Model SERIAL number

7X{{{{{{ to

03{{{{{{

91{{{{{{ or later

SERIAL

1

3

PRE-OPERATION INSTRUCTIONS

z FR-F700 series NA specification

Model SERIAL number

FR-F720-00046 to 04750-NA,

FR-F740-00023 to 12120-NA

z FR-F700 series EC specification

Model SERIAL number

FR-F740-00023 to 00620-EC,

FR-CF70-EC, FR-CF70-ECT

z FR-F700 series CHT specification

Model SERIAL number

FR-F740-0.75K to 55K-CHT,

FR-F740-S75K to S630K-CHT

91{{{{{{ or later

95{{{{{{ or later

93{{{{{{ or later

4

PRE-OPERATION INSTRUCTIONS

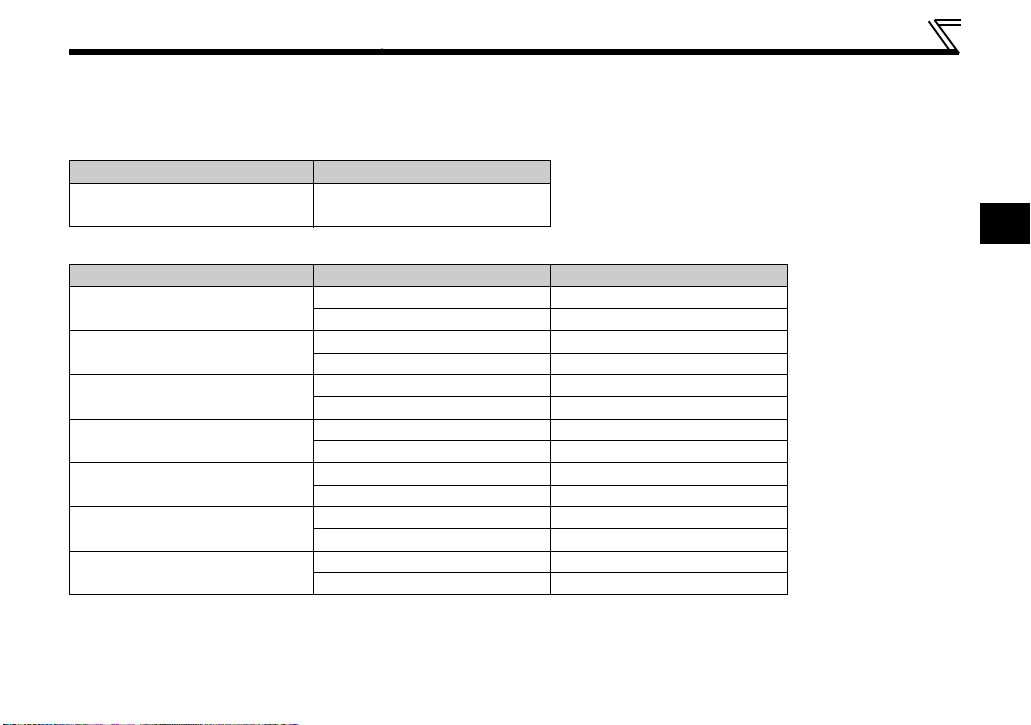

(2) PU operation interlock (X12 signal) specification

The FR-F700P series and the inverters with the following TC and SERIAL numbers are operated in the PU

operation interlock (X12 signal) specification when connected with FR-A7NF.

z FR-A700 series Japanese and NA specification

Model SERIAL number

FR-A720- (-NA)

FR-A740-

(-NA)

04{{{{{{

z FR-A700 series EC specification

Model TC number SERIAL number

FR-A740-00023 to 00052-EC

FR-A740-00083/00126-EC

FR-A740-00170/00250-EC

FR-A740-00310/00380-EC

FR-A740-00470/00620-EC

FR-CA70-EC

(Control unit)

FR-CA70-ECT

(Control unit)

TC{{{A{{{G7{ C0{{{{{{{ or later

TC{{{A{{{G8{ A0{{{{{{{ or later

TC{{{A{{{G7{ C0{{{{{{{ or later

TC{{{A{{{G8{ B0{{{{{{{ or later

TC{{{A{{{G7{ Y0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ Z0{{{{{{{ or later

TC{{{A{{{G8{ B0{{{{{{{ or later

TC{{{A{{{G7{ Y0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ V0{{

TC{{{A{{{G8{ E0{{{{{{{ or later

TC{{{A{{{G7{ S0{{{{{{{ or later

TC{{{A{{{G8{ E0{{{{{{{ or later

{{{{{ or later

1

5

PRE-OPERATION INSTRUCTIONS

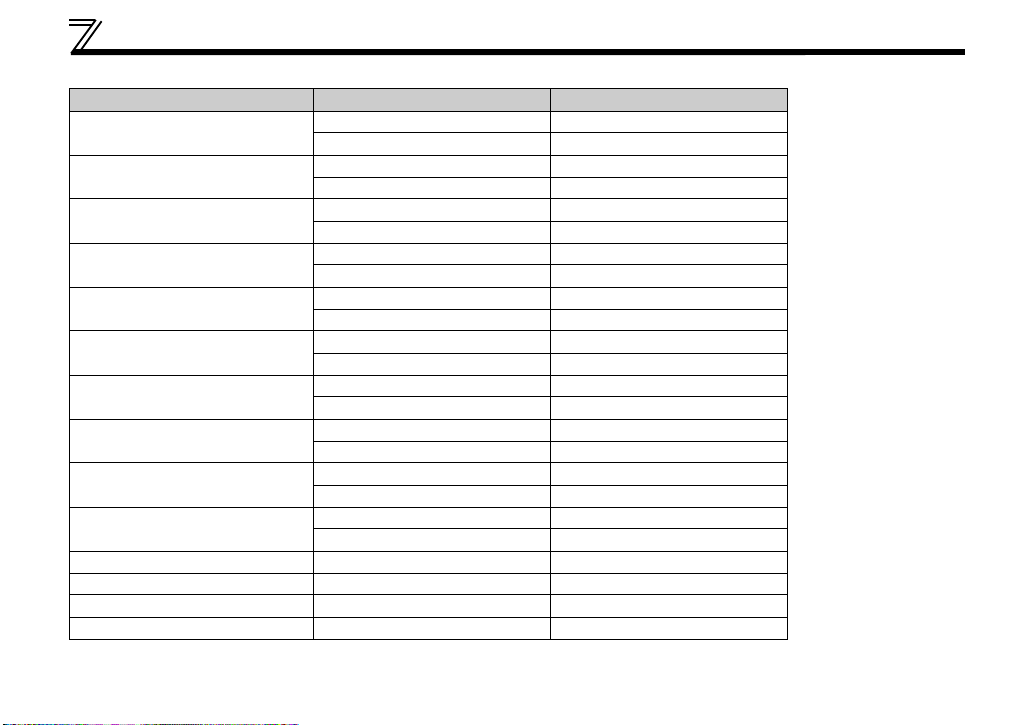

z FR-A700 series CHT specification

Model TC number SERIAL number

FR-A740-0.4K to 1.5K-CHT

FR-A740-2.2K/3.7K-CHT

FR-A740-5.5K/7.5K-CHT

FR-A740-11K/15K-CHT

FR-A740-18.5/22K-CHT

FR-A740-30K to 45K-CHT

FR-A740-55K-CHT

FR-A740-75K/90K-CHT

FR-A740-110K-CHT

FR-A740-132K-CHT

FR-A740-160K/185K-CHT TC{{{A{{{G7{ W0{{{{{{{ or later

FR-A740-220K to 280K-CHT TC{{{A{{{G7{ V0{{

FR-A740-315K/355K-CHT TC{{{A{{{G7{ U0{{{{{{{ or later

FR-A740-400K to 500K-CHT TC{{{A{{{G7{ R0{{{{{{{ or later

TC{{{A{{{G7{ A0{{{{{{{ or later

TC{{{A{{{G8{ Y0{{{{{{{ or later

TC{{{A{{{G7{ A0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ X0{{{{{{{ or later

TC{{{A{{{G7{ X0{{{{{{{ or later

TC{{{A{{{G8{ Z0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ X0{{{{{{{ or later

TC{{{A{{{G7{ X0{{

TC{{{A{{{G8{ V0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ V0{{{{{{{ or later

TC{{{A{{{G7{ V0{{{{{{{ or later

TC{{{A{{{G8{ F0{{{{{{{ or later

TC{{{A{{{G7{ X0{{{{{{{ or later

TC{{{A{{{G8{ G0{{{{{{{ or later

TC{{{A{{{G7{ W0{{{{{{{ or later

TC{{{A{{{G8{ G0{{{{{{{ or later

{{{{{ or later

{{{{{ or later

6

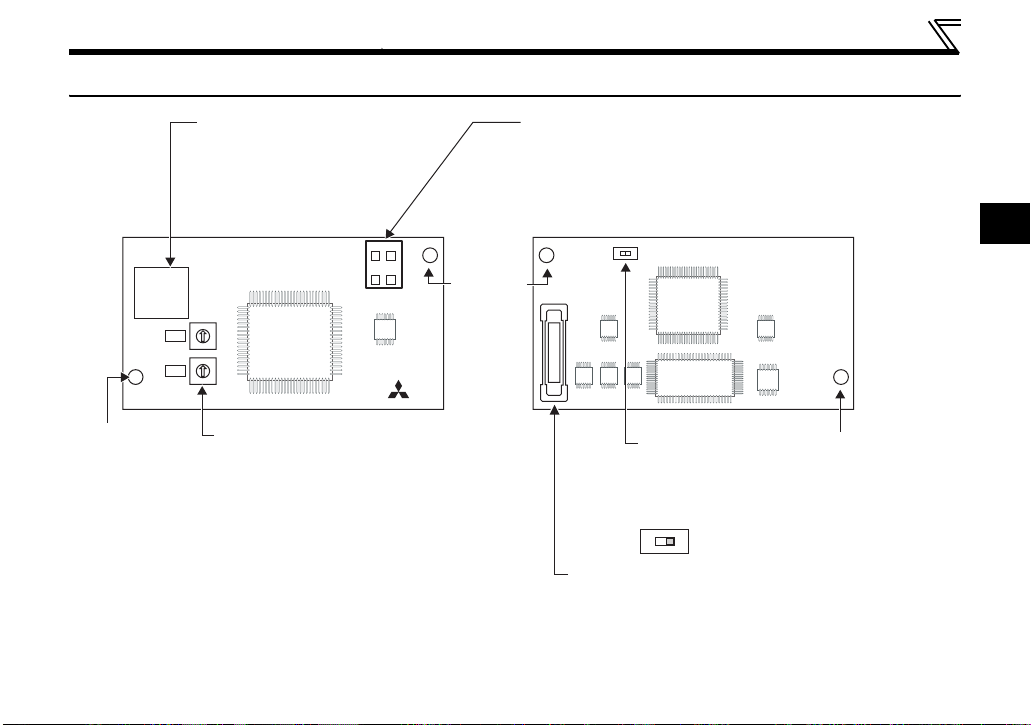

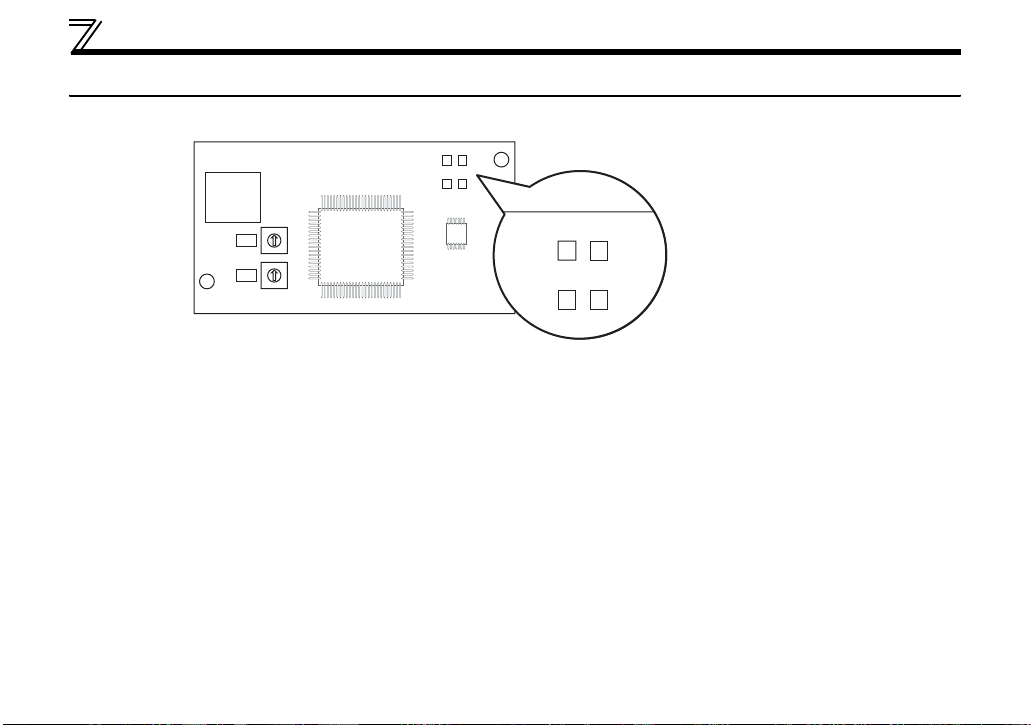

1.3 Parts

PRE-OPERATION INSTRUCTIONS

FR-A7NF

Mounting

hole

Connector for communication

Connect to the network by

connecting a FL-net dedicated

LED (operation status indication)

Lit/flicker/OFF of the LED indicate inverter

operation status.

cable.

Front view Rear view

D1 D2

SW2

0

1

9

2

8

3

X10

7

4

6

5

0

1

9

2

8

3

X1

7

4

6

5

SW1

Node address switch

Set the node address.

(Refer to page 16)

D3 D4

Mounting

hole

Connector

Connect to the inverter option connector.

(Refer to page 8)

SW3

Switch for manufacturer

setting

Do not change from

initially-set status (OFF).

SW3

N

2

L

O

1

Mounting

hole

7

PRE-OPERATION INSTRUCTIONS

D1 D2

S

D3 D4

1.4 LED status

Each LED indicates the operating status of the option unit and network according to the indication status.

D1 D2

D3 D4

SW2

0

1

9

2

8

3

X10

7

4

6

5

0

1

9

2

8

3

X1

7

4

6

5

SW1

FR-A7NF

D1: Communication set status LED (CHG)

D2: Device status LED (DEV)

D3: Reception/transmission LED (TX/RX)

D4: Remote status LED (RMT)

8

PRE-OPERATION INSTRUCTIONS

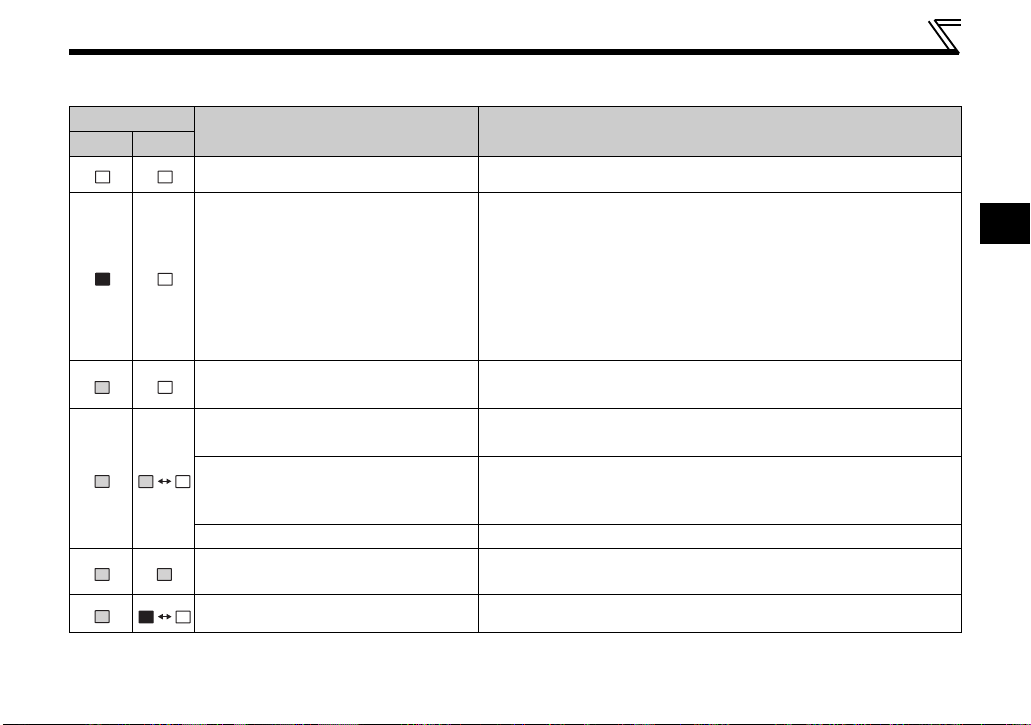

1.4.1 Device status LED (DEV), remote status LED (RMT)

LED Status

DEV RMT

Node Status Description

Power is OFF The inverter power is OFF.

· Node address is out of range (other than 1 to 64).

· Optional board fault

· When mounted to the inverter which is not compatible with

Hardware fault

FL remote network is not connected

FL remote network at a remote stop

FL remote network

during remote connection

processing

Master is not present When the master is disconnected from FL remote network.

FL remote network

during remote operation

Own node is disconnected When the own node is disconnected from FL remote network.

the FR-A7NF (Refer to page 3 for the inverter which is

compatible with the FR-A7NF)

· When a contact fault occurs in an option connector between

the inverter and communication option.

Although hardware is normal, it is not connected to the FL

remote network.

It is correctly set to connect to the FL remote network and

waiting for remote I/O control.

Although remote I/O control started, initial processing is in

progress.

During remote I/O control

1

9

PRE-OPERATION INSTRUCTIONS

LED Status

DEV RMT

Node Status Description

Setting error

Duplicate node When node address is duplicate with other node address

Although it is connected to the FL remote, setting error is found.

(When the slave is not the one the master is expected.)

:OFF, : red is lit, : green is lit, :red is flickering, : green is flickering,

: red and green are alternately flickering

1.4.2 Transmitting (TX)/receiving (RX) LED

LED Status Node Status Description

Not transmitting (TX)/not receiving

(RX)

Transmitting (TX)/receiving (RX) Flickers at high speed during continuous transmitting/receiving

———

:OFF, : green is lit

1.4.3 Communication set status LED (CHG)

LED Status Node Status Description

Communication setting is not changed

Communication setting is changed

:OFF, : red is flickering

The red LED flickers when the applied setting and the node

address switch setting differ. The setting value of the node

address switch is applied by re-powering ON the inverter in this

status, then communication setting status LED turns OFF.

———

10

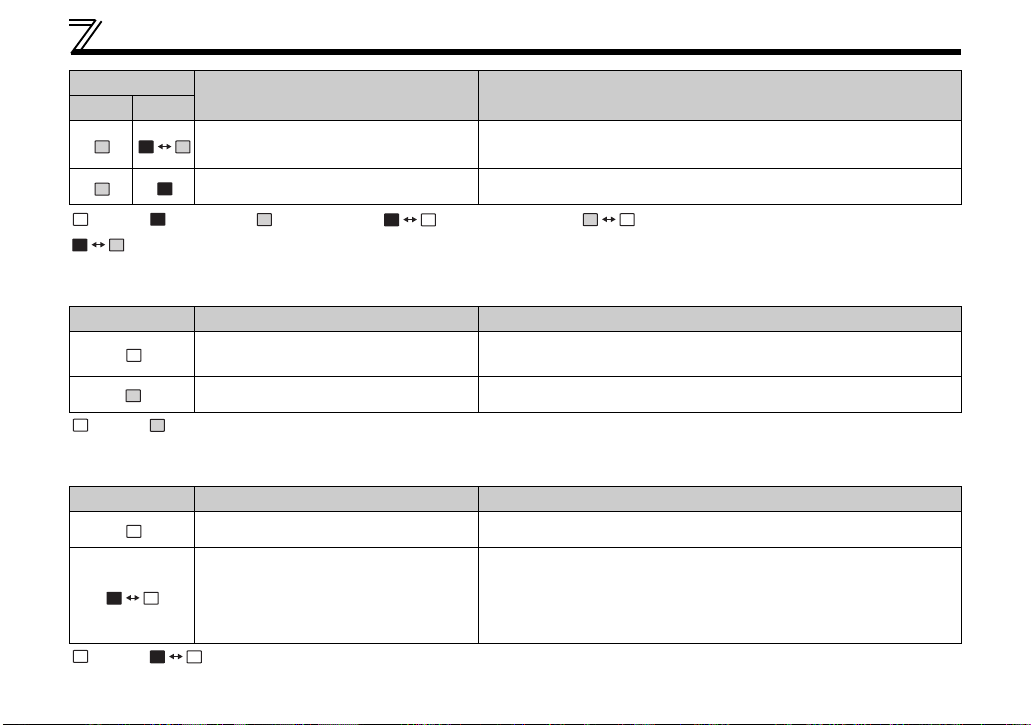

PRE-OPERATION INSTRUCTIONS

1.5 Specifications

1.5.1 Inverter option specifications

Power supply Supplied from the inverter

Typ e Inverter plug-in option (can be mounted/dismounted to/from the inverter front face)

FL-net dedicated cable Refer to page 18

1.5.2 Communication specifications

Maximum number of

connectable inverters

Communication speed Auto negotiation (auto detection) (10Mbps/100Mbps)

Topology

Communication

distance

Electrical interface Conforms to IEEE802.3u (conforms to CSMA/CD)

Transmission protocol FL remote

Node address setting

I/O points Input 64 points, output 64 points

64 units maximum

· Star (connection with a hub in the center)

· Star bus (connection with multiple hubs)

· Between node ⇔ hub: 100m maximum (Node indicate master and inverters.)

· Between hubs: 100m maximum

· Overall length: 2000m maximum

Can be set with node address switch (Refer to page 16).

The setting is applied to IP address as well.

(192.168.250.node address)

1

11

2 INSTALLATION

2.1 Pre-installation instructions

Make sure that the input power of the inverter is OFF.

CAUTION

With input power ON, do not install or remove the plug-in option. Otherwise, the inverter and

plug-in option may be damaged.

Static electricity in your body must be discharged before you touch the product. Otherwise the

product may be damaged.

12

INSTALLATION

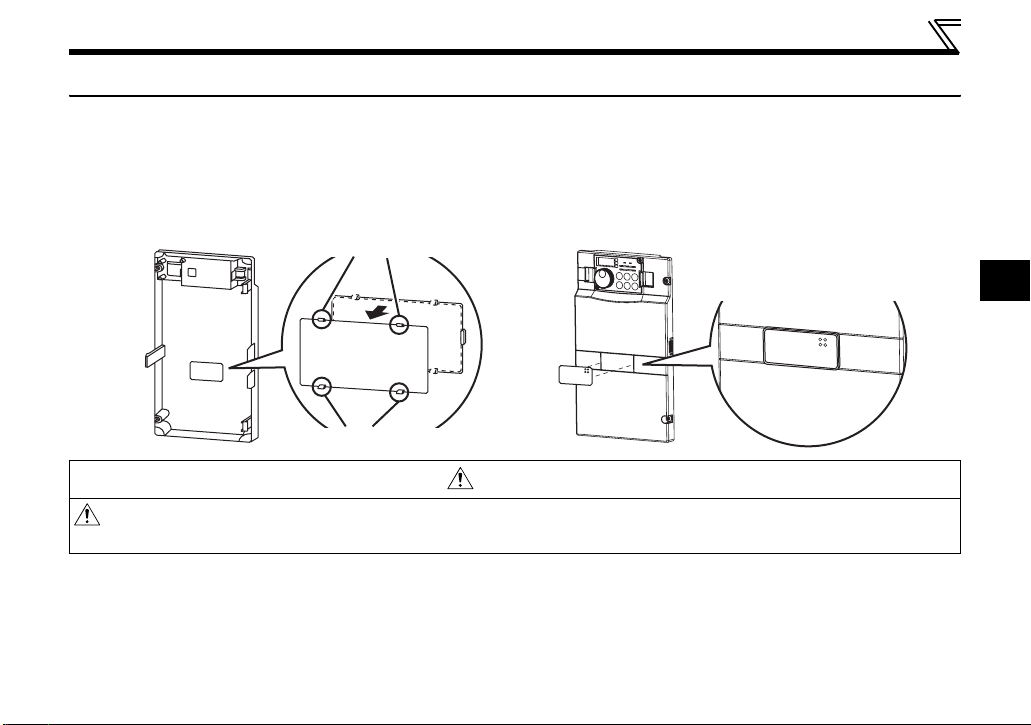

2.2 Installation of the communication option LED display cover

Mount the cover for displaying the operation status indication LED for the communication option on the

inverter front cover.

1)

Cut off hooks on the rear of the inverter front

cover with nipper, etc. and open a window for

fitting the LED display cover.

Cut off with a nipper, etc.

2)

Fit the communication option LED display

cover to the front of the inverter front cover

and push it into until fixed with hooks.

Fit it so that the position of

lenses is in the upper-right

of the LED display cover.

Fitting drawing

Cut off with a nipper, etc.

CAUTION

Take caution not to hurt your hand and such with portions left by cutting hooks of the rear of

the front cover.

2

13

INSTALLATION

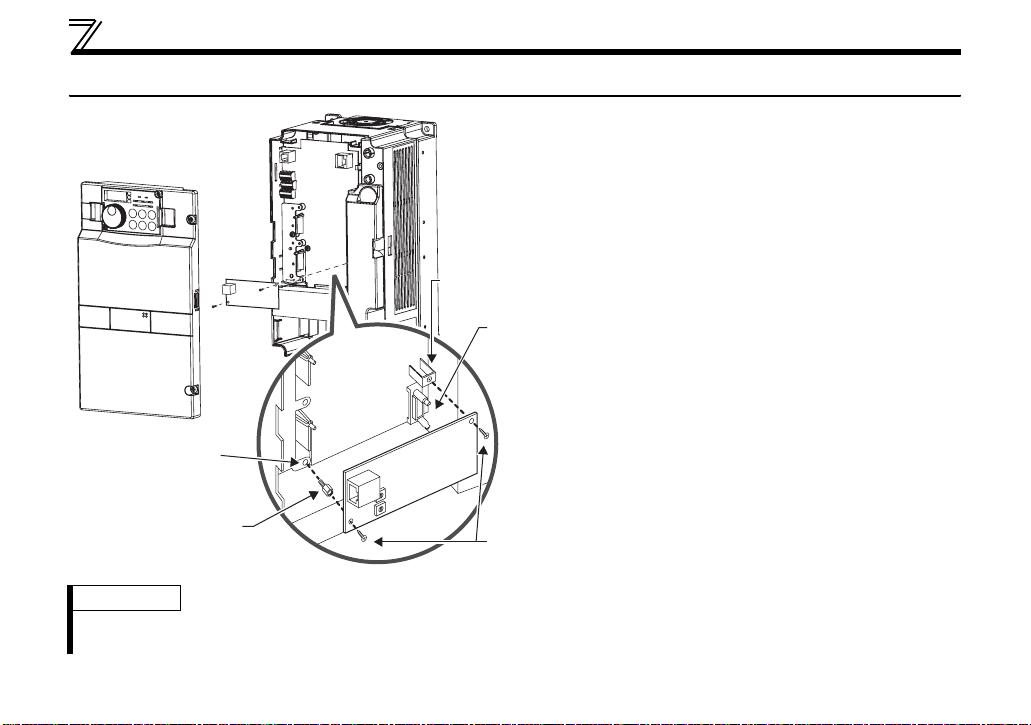

2.3 Installation procedure

1) Remove the inverter front cover.

1)

2) Mount the hex-head screw for option

mounting into the inverter screw hole

(on earth plate) (size 5.5mm, tightening

torque 0.56Nxm to 0.75Nxm).

Screw hole for

option mounting

Inverter side

option

connector

3) Securely fit the connector of the plug-in

option to the inverter connector along

the guides.

4) Securely fix the both right and left sides

of the plug-in option to the inverter with

the accessory mounting screws.

(Tightening torque 0.33Nxm to

0.40Nxm)

If the screw holes do not line up, the

connector may not have been plugged

securely. Check for loose plugging.

Screw hole for

option mounting

(on earth plate)

Hex-head screw

for option mounting

2)

3)

1

2

0

3

9

4

8

5

7

6

1

2

0

3

9

4

8

5

7

6

4)

Mounting

screws

REMARKS

• Remove a plug-in option after removing two screws on both left and right sides.

(The plug-in option is easily removed if the control circuit terminal block is removed before.)

14

INSTALLATION

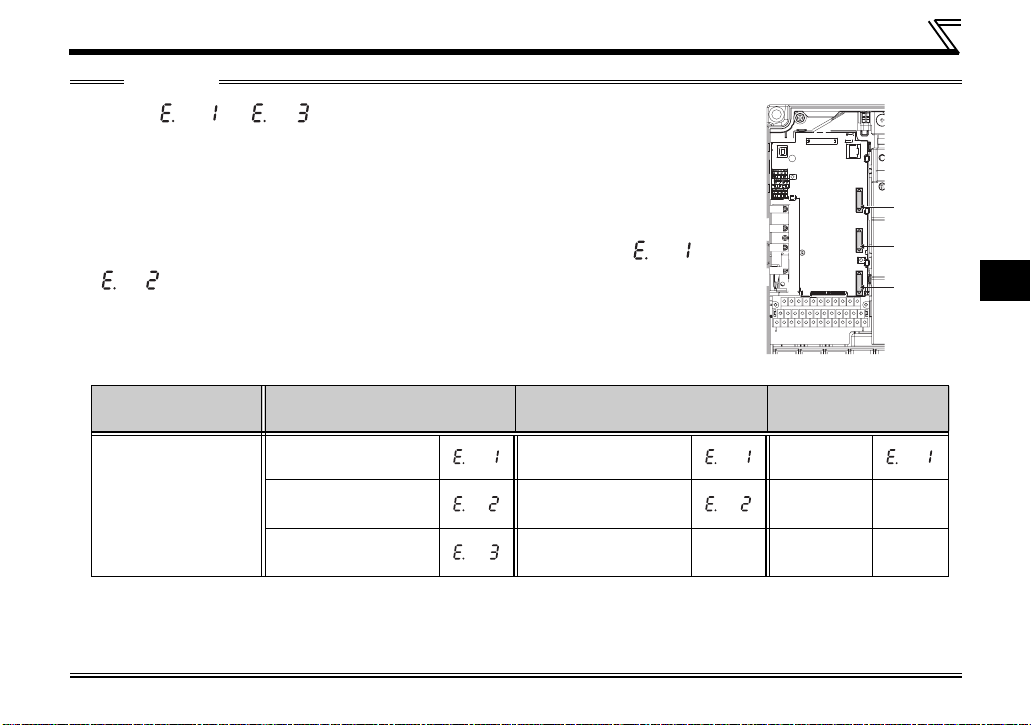

CAUTION

• One of " to " (option fault) appears when the inverter cannot rec-

ognize the option because it is improperly mounted, etc. One of the faults also

appears when an incompatible option is mounted to the inverter. Different indication will appear according to the mounted position (connector 1, 2, or 3).

• For an inverter having several option connectors, use the bottom connector to

mount the option.

If it is connected to a connector other than the bottom connector, " " or

" " (option fault) will appear and its operation will be disabled. Different

indication will appear according to the mounted position (connector 1 or 2).

• The number of option connectors differs by the model. The table below shows

how the fault indication differs according to the number of connectors and their

positions.

Number of option

connectors

Mounting position

and fault indication

3 2 1

Connector 1

(top connector)

Connector 2

(middle connector)

Connector 3

(bottom connector)

Connector 1

(top connector)

Connector 2

(bottom connector)

⎯⎯⎯⎯

Example of FR-A700

Connector 1

⎯⎯

(Refer to Chapter 1 of the inverter's Instruction Manual for the number of option connectors.

• Take caution not to drop a hex-head screw for option mounting or mounting screw during mounting and

removal.

• Pull out the option straight to remove. Otherwise, the connector may be damaged.

Connector 1

Connector 2

Connector 3

2

15

INSTALLATION

2.4 Node address setting

Set the node address between "1 to 64" using node address switches on the FR-A7NF (Refer to page 7).

The setting is applied when the power turns OFF once, then ON again.

Set the arrow (×) of the corresponding switches to the number to set a desired address.

z Setting example

Node address 1:

Set the "×" of X10(SW1) to "0" and the

X10

"×" of X1(SW2) to "1".

X1

CAUTION

• Set the node address switch to the switch number position correctly. If the switch

is set between numbers, normal data communication can not be established.

• If the node address switch is set to a value other than "1 to 64", it is invalid due to outside of setting

range. In this case, DEV LED of the option is lit red and E.OPT appears on the operation panel of the

inverter.

• You cannot set the same node address to other devices on the network. (Doing so disables proper

communication.)

• Set the inverter node address before switching ON the inverter and do not change the setting while

power is ON. Otherwise you may get an electric shock.

• Changes in the node address setting are applied only at the next power-ON. Therefore, if the node

address setting is changed, make sure to power OFF and ON the inverter power.

Node address 26:

0

1

9

2

8

3

7

4

Set the "×" of X10(SW1) to "2" and the

6

5

"×" of X1(SW2) to "6".

0

1

9

2

8

3

7

4

6

5

Good

example

0

1

9

2

8

3

7

4

6

5

X10

X1

Bad

example

9

8

7

6

0

1

9

2

8

3

7

4

6

5

0

1

9

2

8

3

7

4

6

5

0

1

2

3

4

5

16

3 WIRING

3.1 Connection to network

(1) Be sure to check the following before connecting the inverter to the network.

· Check that the FR-A7NF is correctly mounted to the inverter. (Refer to page 14)

· Check that the correct node address is set. (Refer to page 16)

· Check that the FL-net dedicated cable is correctly connected to the FR-A7NF. (Refer to page 18)

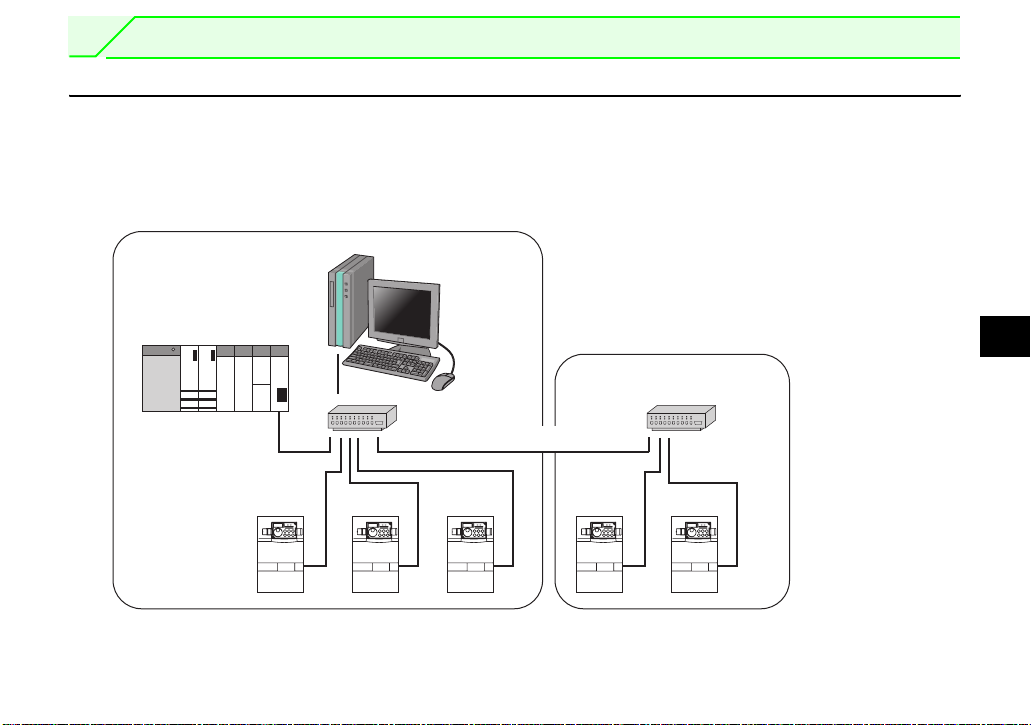

(2) System configuration

Segment 1

Master

100m maximum)

(

Personal computer

Segment 2

Hub

Cascade connection (100m maximum)

Inverter Inverter Inverter Inverter Inverter

Overall length: 2000m maximum

3

Hub

17

WIRING

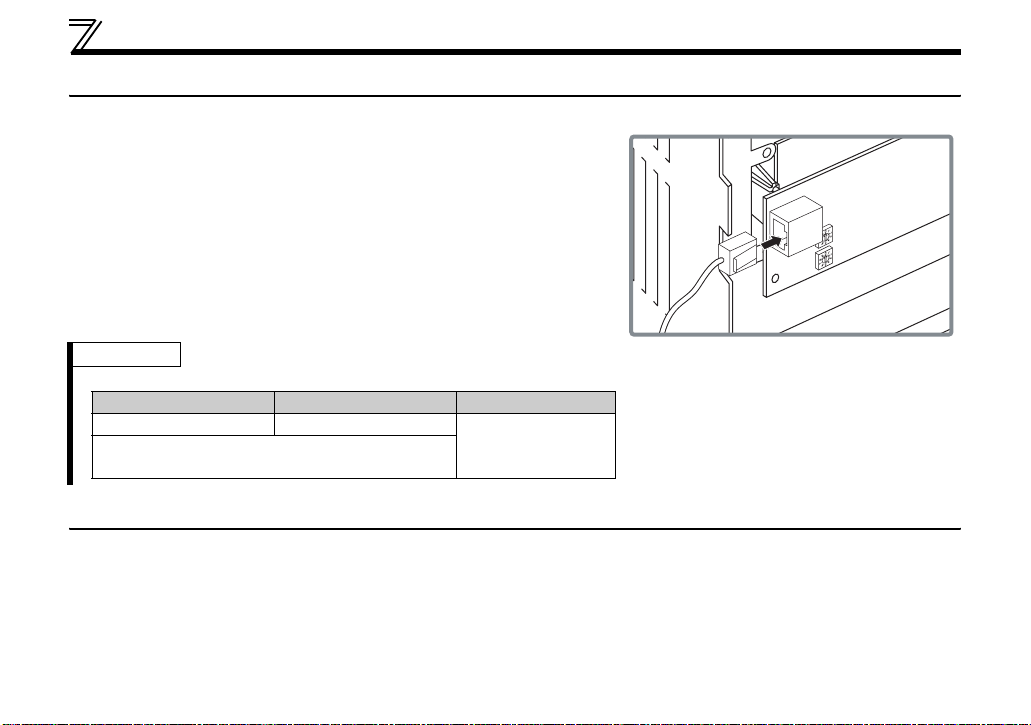

3.2 Cable specifications

Connect the FR-A7NF option unit to the FL remote network using the FL-net dedicated cable below.

Cables : TPCC5 or more (Twisted Pair Communication Cable

for LAN Category 5)

For the shape, use STP (Shielded Twisted Pair)

(according to the 100BASE-TX(IEEE802.3u)

standard)

Maximum wiring length:100m maximum between hub and inverter.

(according to the 100BASE-TX

(IEEE802.3u) standard)

REMARKS

y FL-net dedicated cable...recommended product (as of July 2011)

Typ e Cable Length (m) Maker

FLG-S-{{{ 1m to 100m

(Example: when the cable length is 1m)

FLG-S-010

Shinwa Co., Ltd.

3.3 Precautions for system configuration

Enough safety measures are necessary when installing the FL-net dedicated cable and connecting to the

FL remote network.

Consult the network provider and network administrator (person in charge of network planning and IP

address management) including terminal treatment of connection cable, construction of trunk cable, etc.

We are not responsible for system troubles from connecting to the FL remote network.

18

WIRING

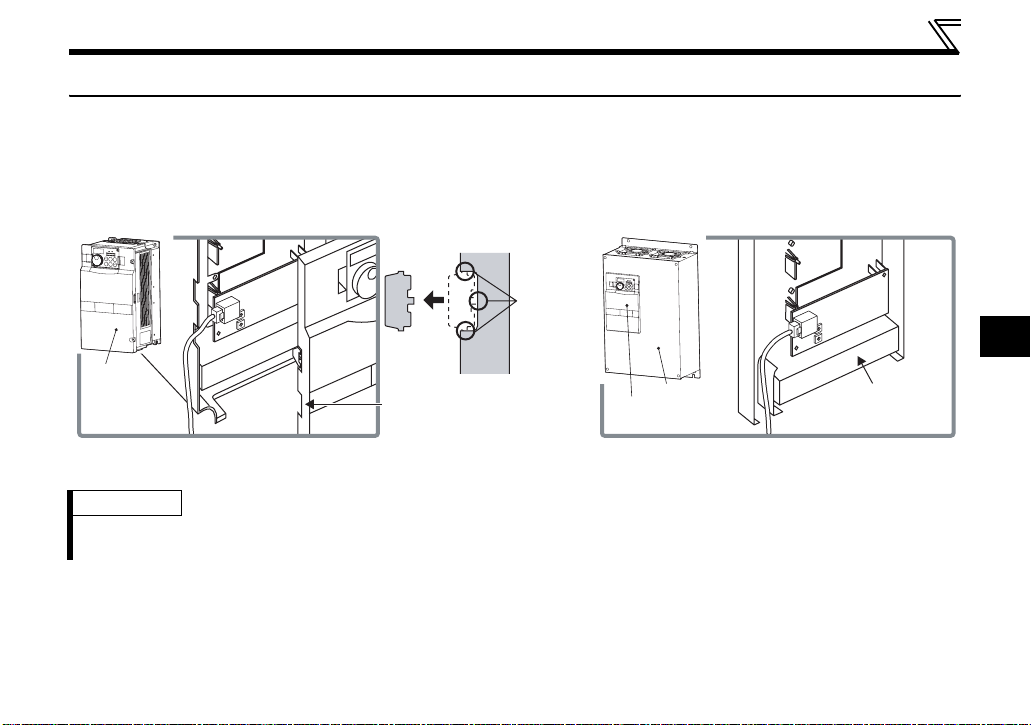

3.4 Wiring

For wiring of the inverter which has one front cover, route wires between the control circuit terminal block

and front cover. If cables can not be routed between the control circuit terminal block and front cover (about

7mm), remove a hook of the front cover and use a space become available.

For wiring of the inverter which has front cover 1 and 2, use the space on the left side of the control circuit

terminal block.

Cut off

1

2

0

3

9

4

8

5

7

6

1

2

0

3

9

4

8

5

7

6

Front cover

Cut off a hook on the inverter

front cover side surface.

(Cut off so that no portion is left.)

Inverter which has one front cover Inverter which has front cover 1 and 2

REMARKS

⋅ When the hook of the inverter front cover is cut off for wiring, the protective structure (JEM1030) changes to open

type (IP00).

with a

nipper,

etc.

Front cover 1

Front cover 2

1

2

0

3

9

4

8

5

7

6

1

2

0

3

9

4

8

5

7

6

Control circuit

terminal block

3

19

WIRING

C

AUTION

Do not connect the parameter unit (FR-PU07, etc.) to the FR-A7NF communication connector.

Doing so will damage the option.

When performing wiring using the space between the inverter front cover and control circuit

terminal block, take care not to subject the cable to stress.

After wiring, wire offcuts must not be left in the inverter. They may cause an error, failure or

malfunction.

20

4 INVERTER SETTING

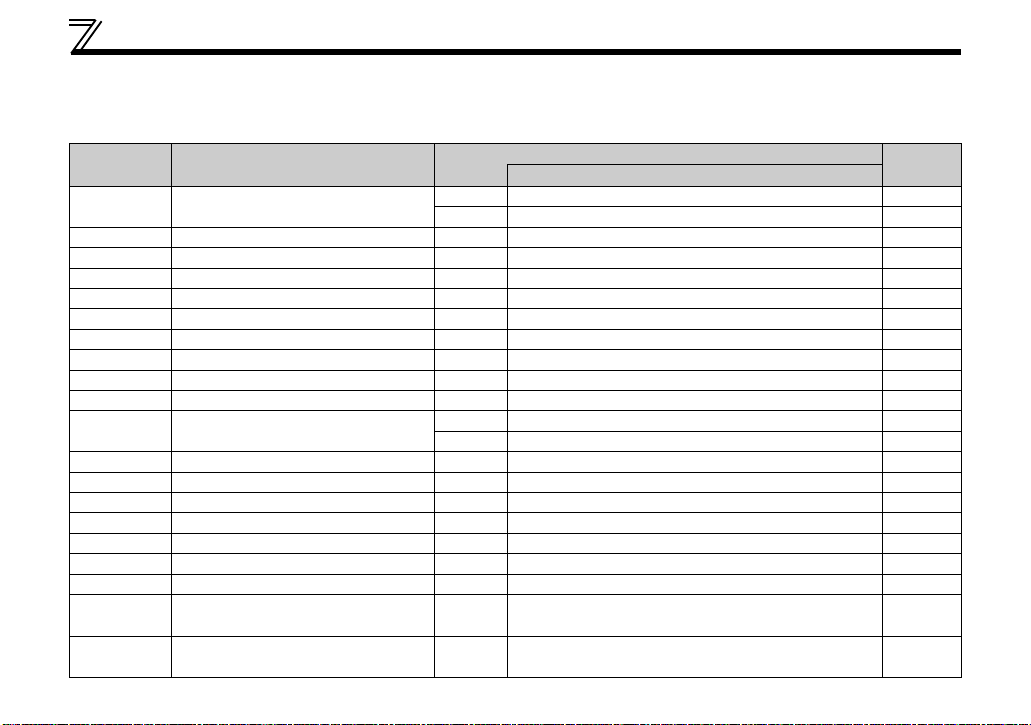

4.1 Parameter list

zThe following parameters are used for the communication option (FR-A7NF)

Parameter

Number

37 Speed display 0, 1 to 9998 1 0 37

144 Speed setting switchover

501

*

* Parameters which can be displayed when the plug-in option (FR-A7NF) is mounted.

Communication error occurrence

count display

Name Setting Range

0, 2, 4, 6, 8, 10, 102,

104, 106, 108, 110

01032

Minimum

Setting

Increments

1437

Initial

Value

Refer to

Page

4

21

INVERTER SETTING

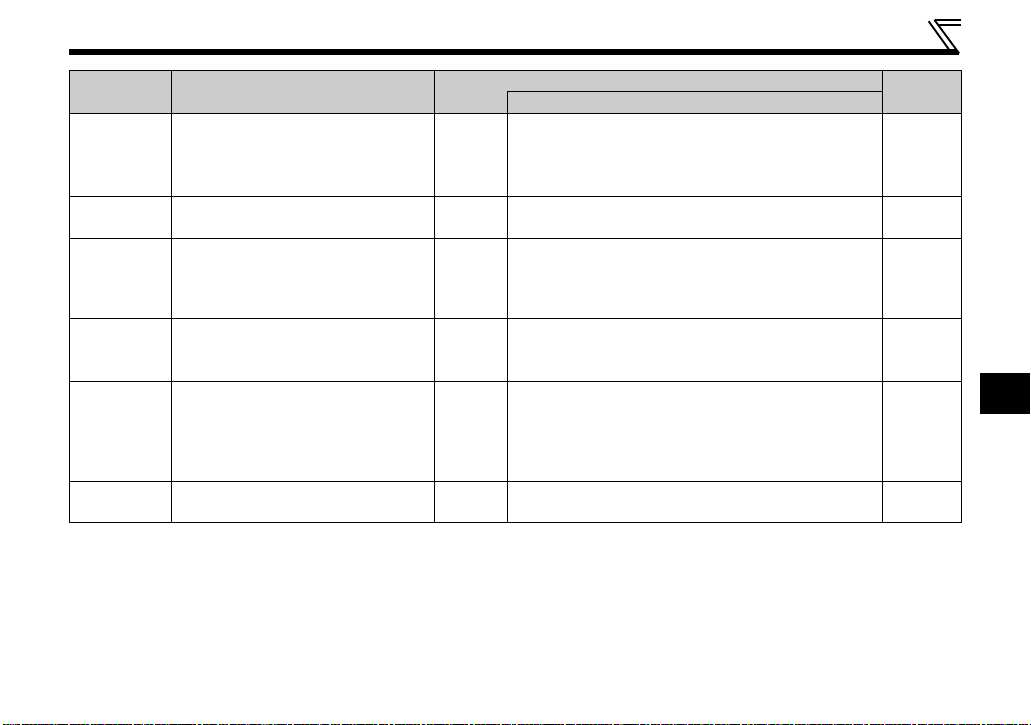

zParameters whose functions are always the same

When the FR-A7NF is mounted to the inverter, following parameter functions are always the same.

(Changed setting is invalid even if the setting value is changed.)

Parameter

Number

79 Operation mode selection

180 RL terminal function selection 0 Low-speed operation command

181 RM terminal function selection 1 Middle-speed operation command

182 RH terminal function selection 2 High-speed operation command

183 RT terminal function selection 3 Second function selection

184 AU terminal function selection 9999 — (no function)

185 JOG terminal function selection 9999 — (no function)

186 CS terminal function selection 9999 — (no function)

187 MRS terminal function selection 24 Output stop

188 STOP terminal function selection 9999 — (no function)

189 RES terminal function selection

190 RUN terminal function selection 0 Inverter running

191 SU terminal function selection 1 Up to frequency

192 IPF terminal function selection 2 Instantaneous power failure/undervoltage

193 OL terminal function selection 3 Overload alarm

194 FU terminal function selection 4 Output frequency detection

195 ABC1 terminal function selection 99 Fault output

196 ABC2 terminal function selection 9999 — (no function)

338

339

Communication operation

command source

Communication speed command

source

Name Setting

*3 Network operation mode 25

0

7

*4 PU operation interlock 25

*3 PU/NET operation switchover

65

12 *4 PU operation interlock

0 Operation command source communication 30

0 Speed command source communication 30

Function

Refer

to Page

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

— *2

22

INVERTER SETTING

Parameter

Number

340

342

500 *1

502 *1

550

551

*1 Parameters which can be displayed when the plug-in option (FR-A7NF) is mounted.

*2 Refer to the inverter manual for details.

*3 This setting is for the inverters with the PU/NET operation switchover (X65 signal) specification.

*4 This setting is for the inverters with the PU operation interlock (X12 signal) specification. (Refer to page 5)

The X12 signal is valid only when it is input via FL remote communication. (Refer to page 50) (It is invalid when input

from a control circuit terminal of the inverter.)

Communication startup mode

selection

Communication EEPROM write

selection

Communication error execution

waiting time

Stop mode selection at

communication error

NET mode operation command

source selection

PU mode operation command

source selection

Name Setting

10

0

0

1

9999

2

Function

Started in Network operation mode. Operation

mode can be changed between the PU

operation mode and Network operation mode

from the operation panel.

Parameter values written by communication are

written to the EEPROM and RAM.

There is no waiting time since the communication

line fault occurrence until communication error

(0s). Note that actual time depends on the

detection time on FL remote network.

The inverter decelerates to stop at

communication fault occurrence, when provide

a fault output.

Automatic communication option recognition

Normally, control source of the RS-485 terminal

is valid. When a communication option is

mounted, the control source of the

communication option is valid.

Selects the PU connector as the PU operation

mode operation source.

(Refer to page 3)

Refer

to Page

25

— *2

— *2

33

4

— *2

— *2

23

INVERTER SETTING

4.2 Operation mode setting

Powering ON the inverter with the communication option (FR-A7NF) mounted starts the inverter in Network

operation mode.

(1) Network operation [NET] ... Controls the inverter with instructions from the network via the

communication option.

Functions of Pr.79 and Pr.340 are always the same when the FR-A7NF is

mounted.

(2) PU operation [PU].............. Controls the inverter from the key of the operation panel (FR-DU07)

mounted on the inverter or parameter unit (FR-PU07/FR-PU04).

(3) External operation [EXT] ...Controls the inverter by switching ON/OFF external signals connected to

the control circuit terminals of the inverter.

(The operation mode can not be changed to External operation mode when

the FR-A7NF is mounted.)

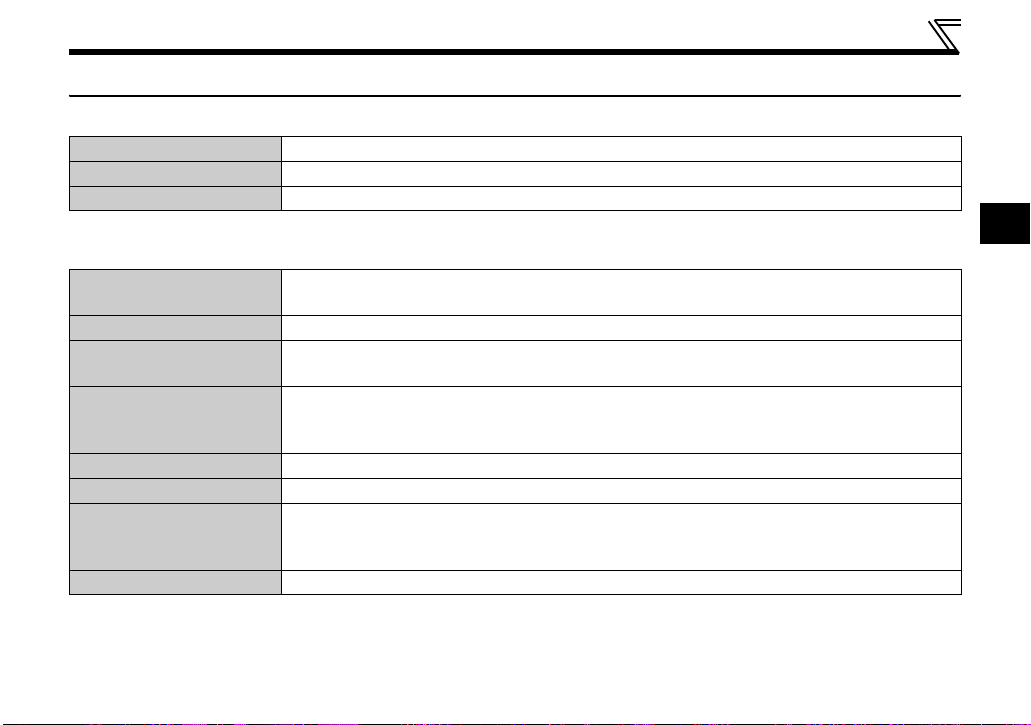

4.2.1 Operation mode indication

FR-DU07

Operation mode indication

(The inverter operates according to the LED lit mode.)

PU: PU operation mode

EXT: External operation mode

NET: Network operation mode *2

*1 The operation mode can not be changed to External operation mode when the FR-A7NF is mounted.

*2 "NET" is displayed when the FR-A7NF is mounted.

*1

24

Loading...

Loading...