Page 1

INVERTER

FR-E800 Instruction Manual (Communication)

Compact, high functionality inverters

Page 2

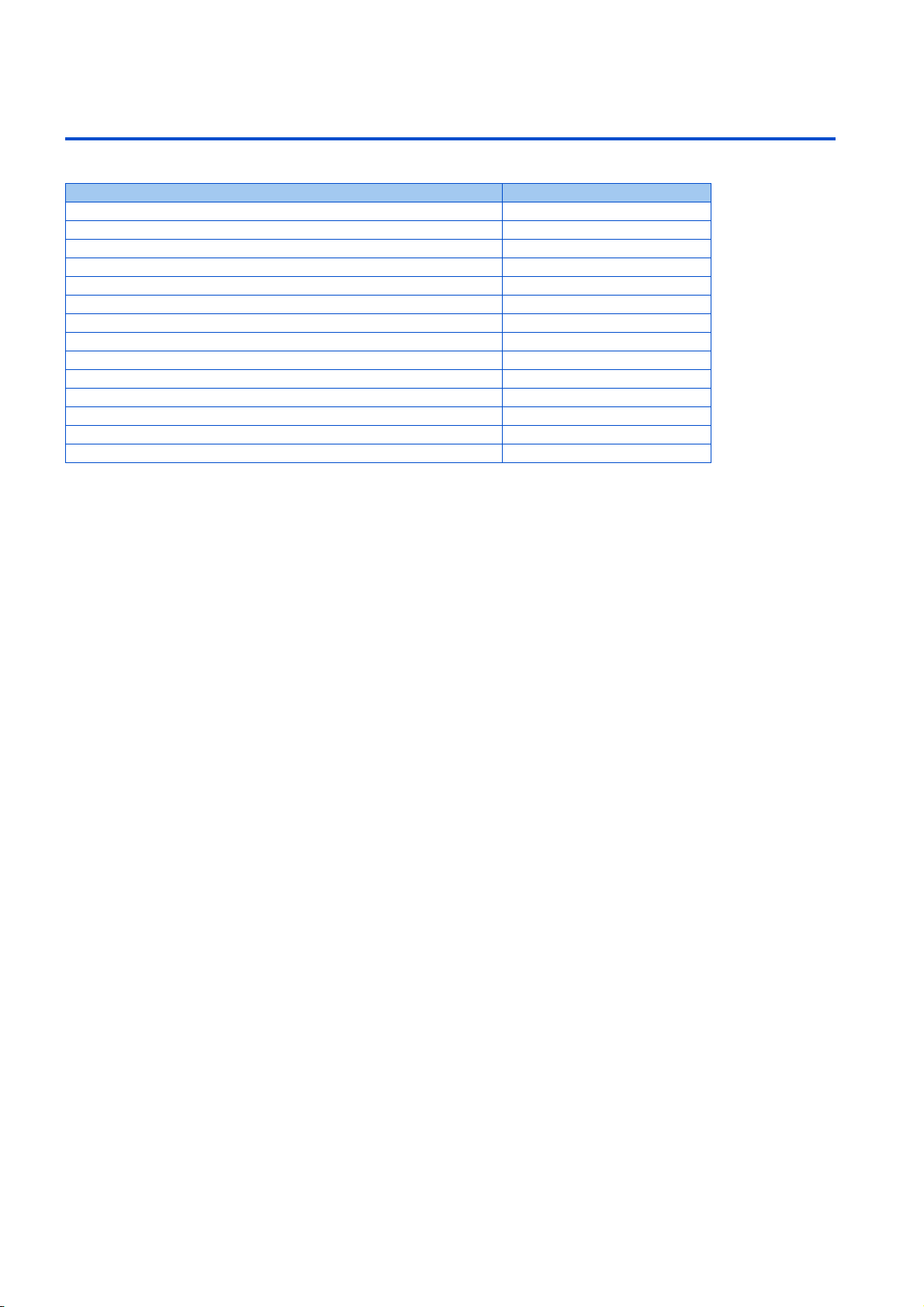

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.1 Product checking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2 Related manuals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2 Ethernet Communication . . . . . . . . . . . . . . . . . . . . . . 12

2.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 System configuration example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.2 Network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.3 Network components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.3 Ethernet cable connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.1 Wiring method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3.2 Wiring precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4 Initial setting for Ethernet communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.5 CC-Link IE TSN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5.2 CC-Link IE TSN configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.5.3 Initial setting for CC-Link IE TSN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.5.4 Parameters related to CC-Link IE TSN. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.6 CC-Link IE Field Network Basic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.6.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.6.2 CC-Link IE Field Network Basic configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.6.3 Initial setting for CC-Link IE Field Network Basic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

2.6.4 Parameters related to CC-Link IE Field Network Basic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.6.5 Group number setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

2.7 MODBUS/TCP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

CONTENTS

2.7.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2.7.2 Initial setting for MODBUS/TCP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

2.7.3 Parameters related to MODBUS/TCP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.8 BACnet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.8.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.8.2 Initial setting for BACnet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

2.8.3 Parameters related to BACnet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

2.9 MELSOFT / FA product connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.9.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.9.2 Initial setting for MELSOFT / FA product connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

2.9.3 Parameters related to MELSOFT / FA product connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

2.10 SLMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.10.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.10.2 Initial setting for SLMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

1

Page 3

2.10.3 Parameters related to SLMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

2.11 EtherNet/IP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .128

2.11.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

2.11.2 Initial setting for EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

2.11.3 Parameters related to EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

2.11.4 Object map definitions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.11.5 Object map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

2.12 PROFINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

2.12.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

2.12.2 PROFINET configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

2.12.3 Initial setting for PROFINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

2.12.4 Parameters related to PROFINET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

2.12.5 Data Exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

2.13 Backup/restore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

2.13.1 Outline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

2.13.2 Initial setting for the backup/restore function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

2.14 Inverter-to-inverter link function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

2.15 Ethernet communication parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Chapter 3 RS-485 Communication . . . . . . . . . . . . . . . . . . . . . . 178

3.1 Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .178

3.2 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

3.2.1 Wiring procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

3.2.2 Connected device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

3.3 Wiring of PU connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .180

3.4 Mitsubishi inverter protocol (computer link communication). . . . . . . . . . . . . . . . . . . . . . . . . . 182

3.5 MODBUS RTU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

Chapter 4 Other Communication Options . . . . . . . . . . . . . . . . 208

4.1 USB device communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

4.2 Automatic connection with GOT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .209

2

Page 4

Chapter 5 Common Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 212

Chapter 6 Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

6.1 How to check specification changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

6.1.1 Details of specification changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

CONTENTS

3

Page 5

4

Page 6

CHAPTER 1

CHAPTER 1

1.1 Product checking ......................................................................................................................................................8

1.2 Related manuals.....................................................................................................................................................10

Introduction

4

5

6

7

8

9

10

5

Page 7

1 Introduction

The contents described in this chapter must be read before using this product.

Always read the instructions before use.

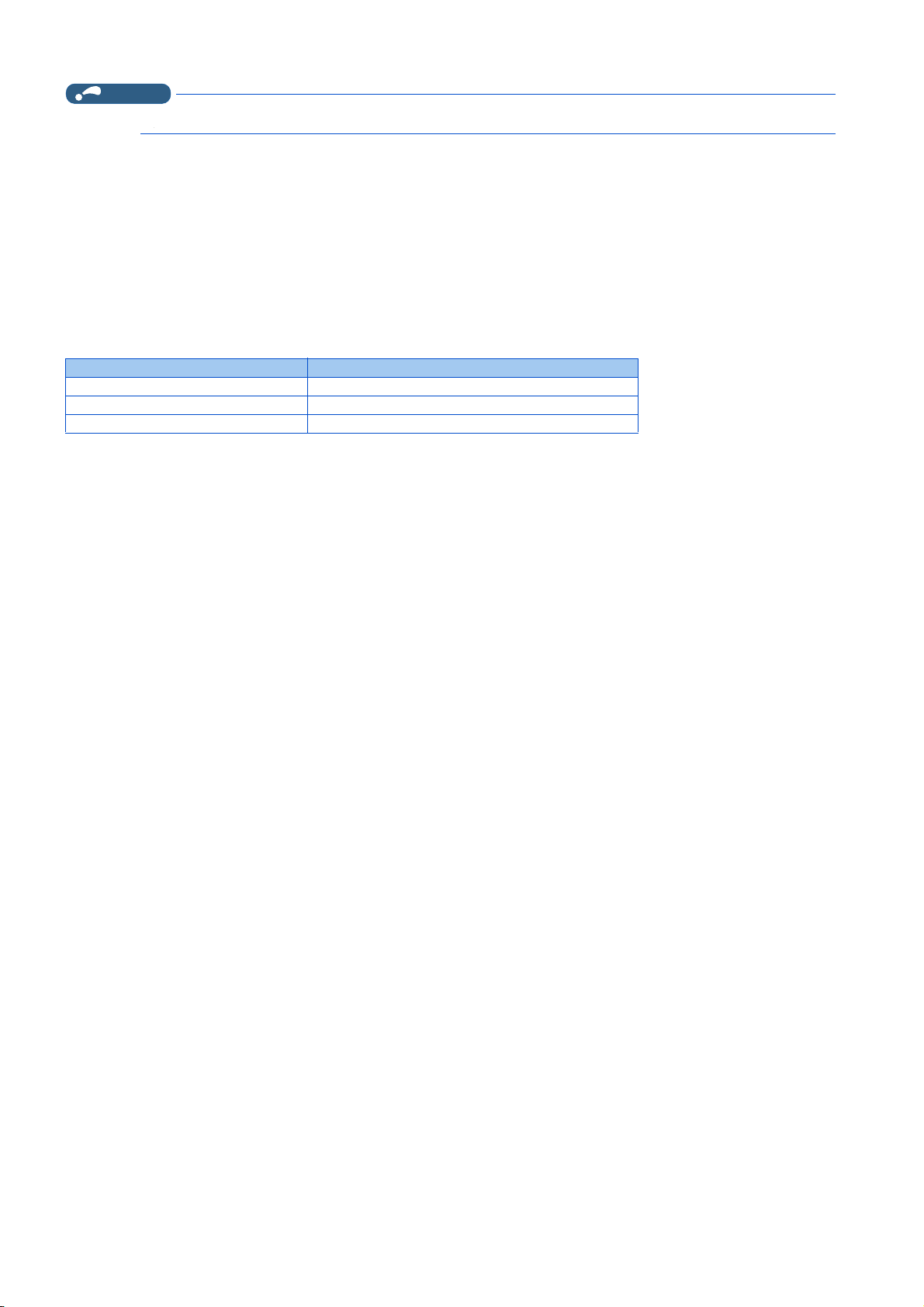

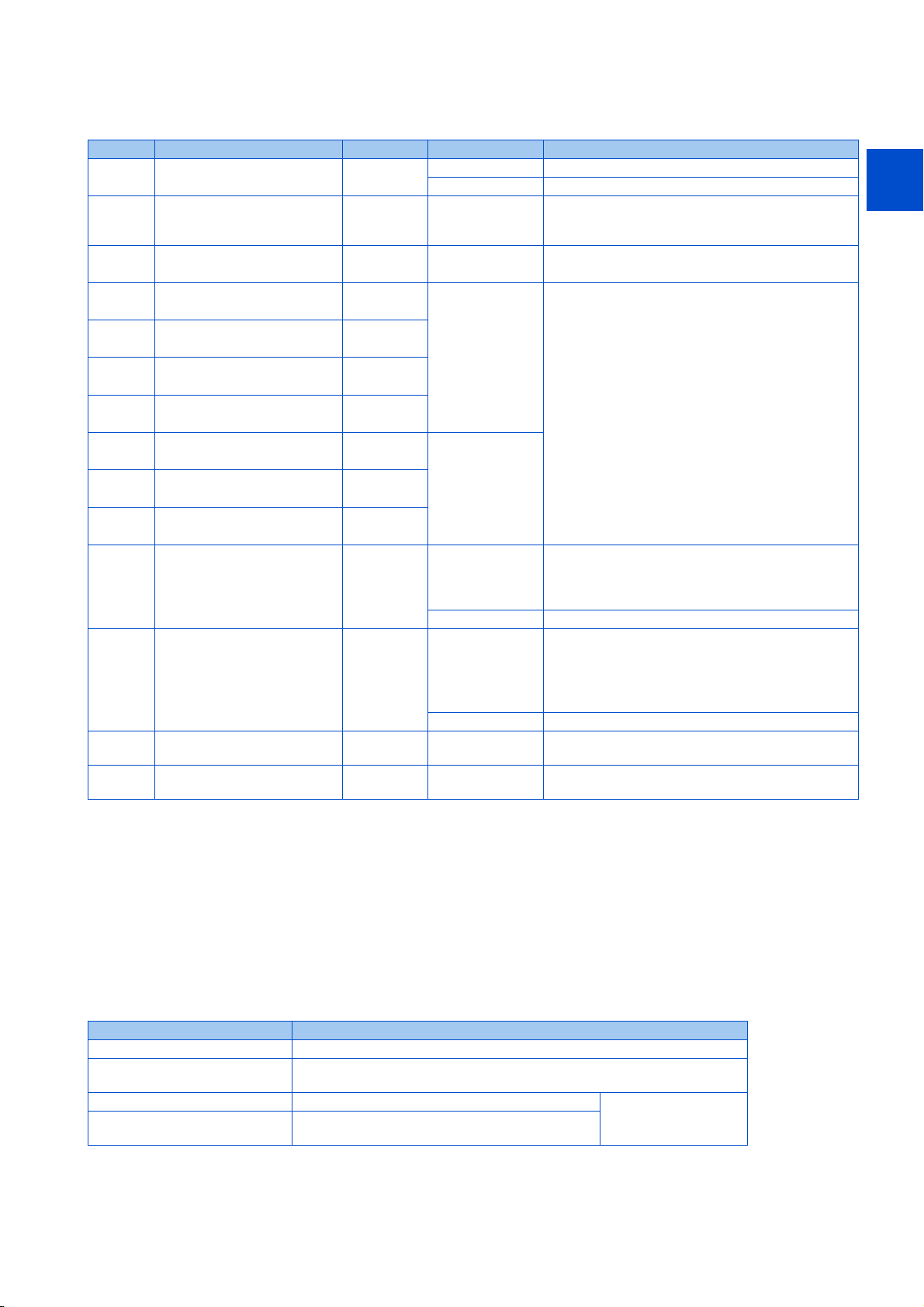

Abbreviations

Item Description

PU

Parameter unit

Inverter Mitsubishi Electric inverter FR-E800 series

E800 Standard model (RS-485 + SIL2/PLd functional safety)

E800-E Ethernet model (Ethernet + SIL2/PLd functional safety)

E800-SCE Safety communication model (Ethernet + SIL3/PLe functional safety)

FM type inverter Standard model with terminal FM (pulse output)

AM type inverter Standard model with terminal AM (voltage output)

Vector control compatible option FR-A8AP E kit

Pr. Parameter number (Number assigned to function)

PU operation Operation using the PU (operation panel / parameter unit)

External operation Operation using the control circuit signals

Combined operation Combined operation using the PU (operation panel / parameter unit) and External operation

Mitsubishi Electric standard

efficiency motor

Mitsubishi Electric constant-torque

motor

Mitsubishi Electric highperformance energy-saving motor

Mitsubishi Electric highperformance energy-saving motor

with encoder

Mitsubishi Electric Vector control

dedicated motor

Mitsubishi Electric geared motor GM-[]

Mitsubishi Electric inverter-driven

geared motor for encoder feedback

control

Operation panel, parameter unit (FR-PU07), LCD operation panel (FR-LU08), and enclosure surface

operation panel (FR-PA07)

Parameter unit (FR-PU07), LCD operation panel (FR-LU08), and enclosure surface operation panel

(FR-PA07)

SF-JR

SF-HRCA

SF-PR

SF-PR-SC

SF-V5RU

GM-DZ, GM-DP

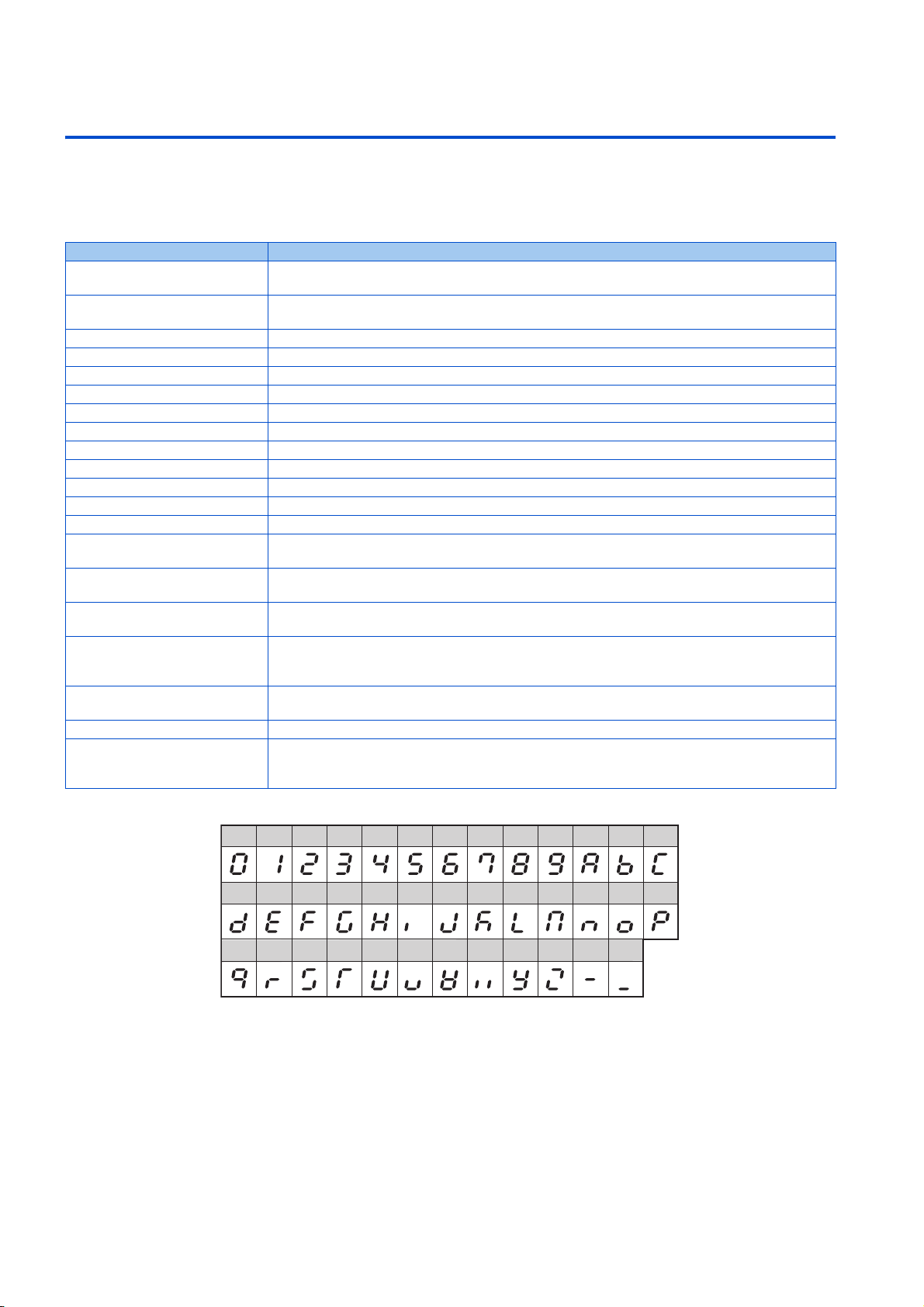

Digital characters and their corresponding printed equivalents

0123456789ABC

DEFGH I J KLMNOP

QRSTUVWXYZ - _

Trademarks

• Ethernet is a registered trademark of Fuji Xerox Corporation in Japan.

• MODBUS is a registered trademark of SCHNEIDER ELECTRIC USA, INC.

• BACnet is a registered trademark of the American Society of Heating, Refrigerating and Air-Conditioning Engineers

(ASHRAE).

• DeviceNet and EtherNet/IP are registered trademarks of ODVA (Open DeviceNet Vendor Association, INC).

• PROFIBUS and PROFINET are either trademarks or registered trademarks of PROFIBUS & PROFINET International.

• CC-Link IE TSN and CC-Link IE Field Network Basic are registered trademarks of CC-Link Partner Association.

• Other company and product names herein are the trademarks and registered trademarks of their respective owners.

1. Introduction

6

Page 8

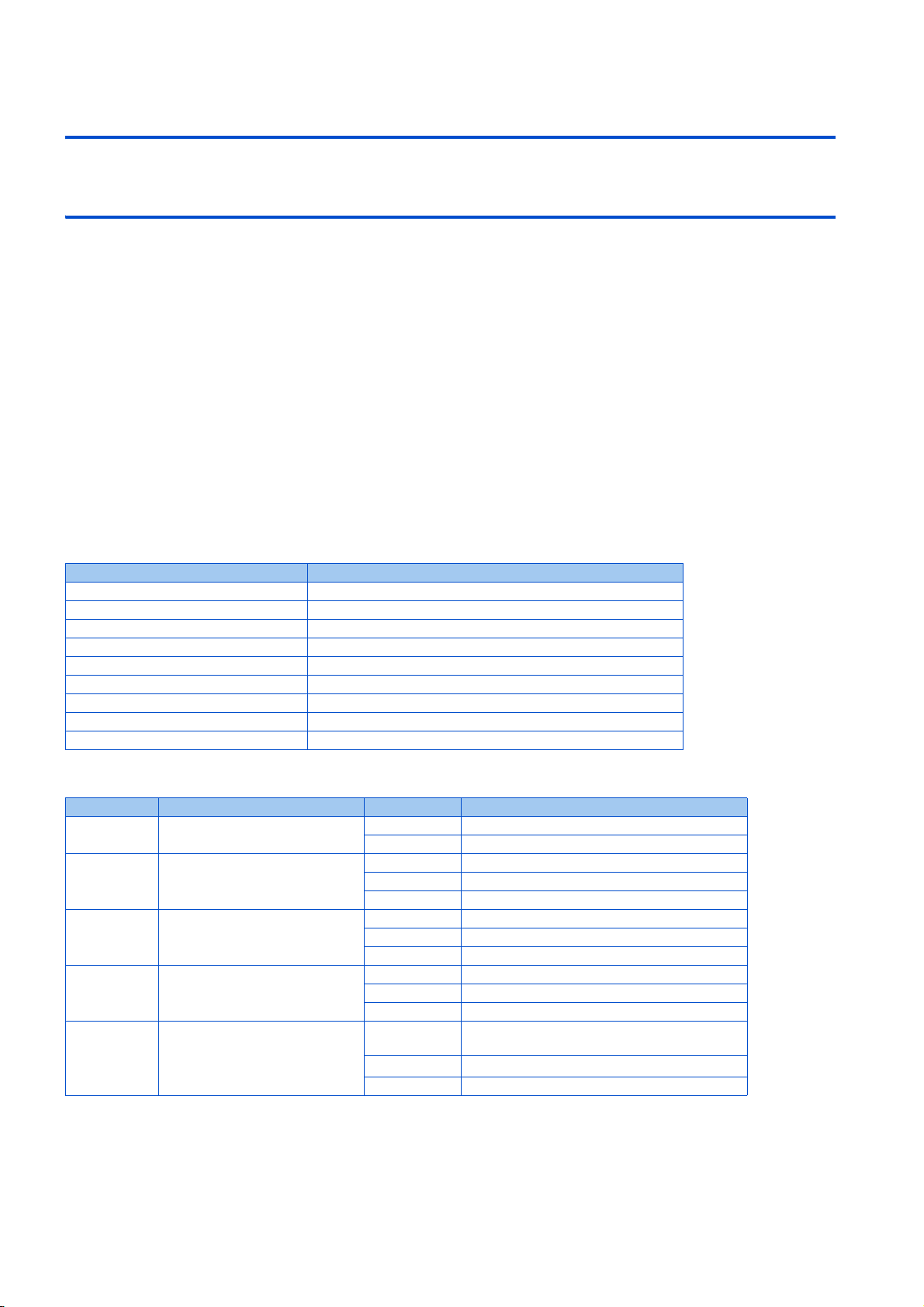

Notes on descriptions in this Instruction Manual

• Connection diagrams in this Instruction Manual appear with the control logic of the input terminals as sink logic, unless

otherwise specified. (Refer to the FR-E800 Instruction Manual (Connection) for the switching of the control logic of the

inverter.)

1

2

Precautions

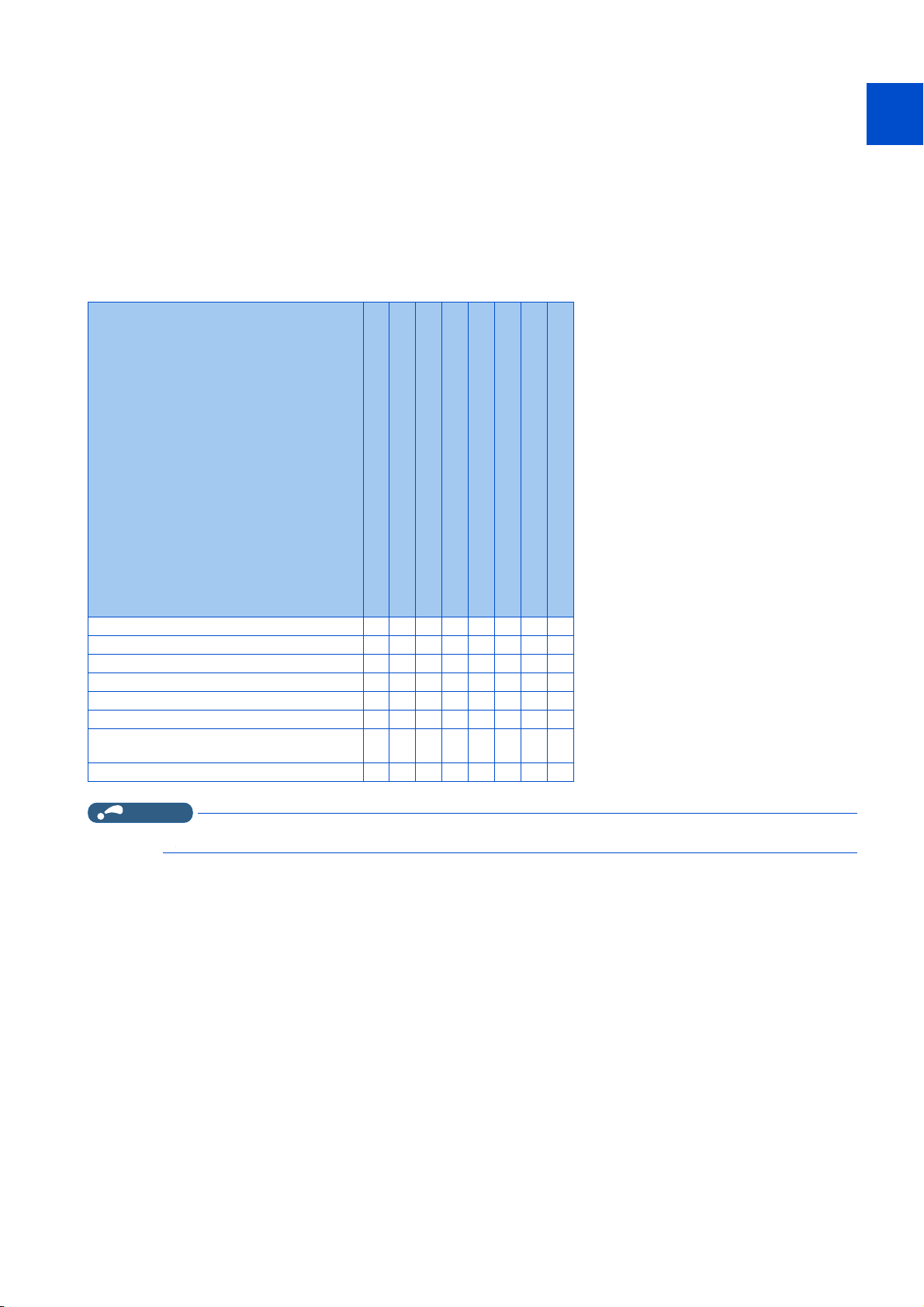

• Some of the communication protocols and the plug-in options cannot be used together as shown in the following table. For

the application and protocol settings, refer to page 173.

CC-Link IE TSN

BACnet/IP

CC-Link IE Field Network Basic

CC-Link IE TSN — × × × ×

CC-Link IE Field Network Basic × — ×

BACnet/IP — ×

EtherNet/IP × — ×

PROFINET × × × —

CC-Link (when the FR-A8NC E kit is installed) × × — × ×

PROFIBUS-DP (when the FR-A8NP E kit is

installed)

DeviceNet (when the FR-A8ND E kit is installed) × × —

EtherNet/IP

PROFINET

CC-Link (when the FR-A8NC E kit is installed)

×—×

DeviceNet (when the FR-A8ND E kit is installed)

PROFIBUS-DP (when the FR-A8NP E kit is installed)

3

4

5

6

7

8

9

10

NOTE

• FR Configurator2 can be used for any communication protocol or plug-in option.

1. Introduction

7

Page 9

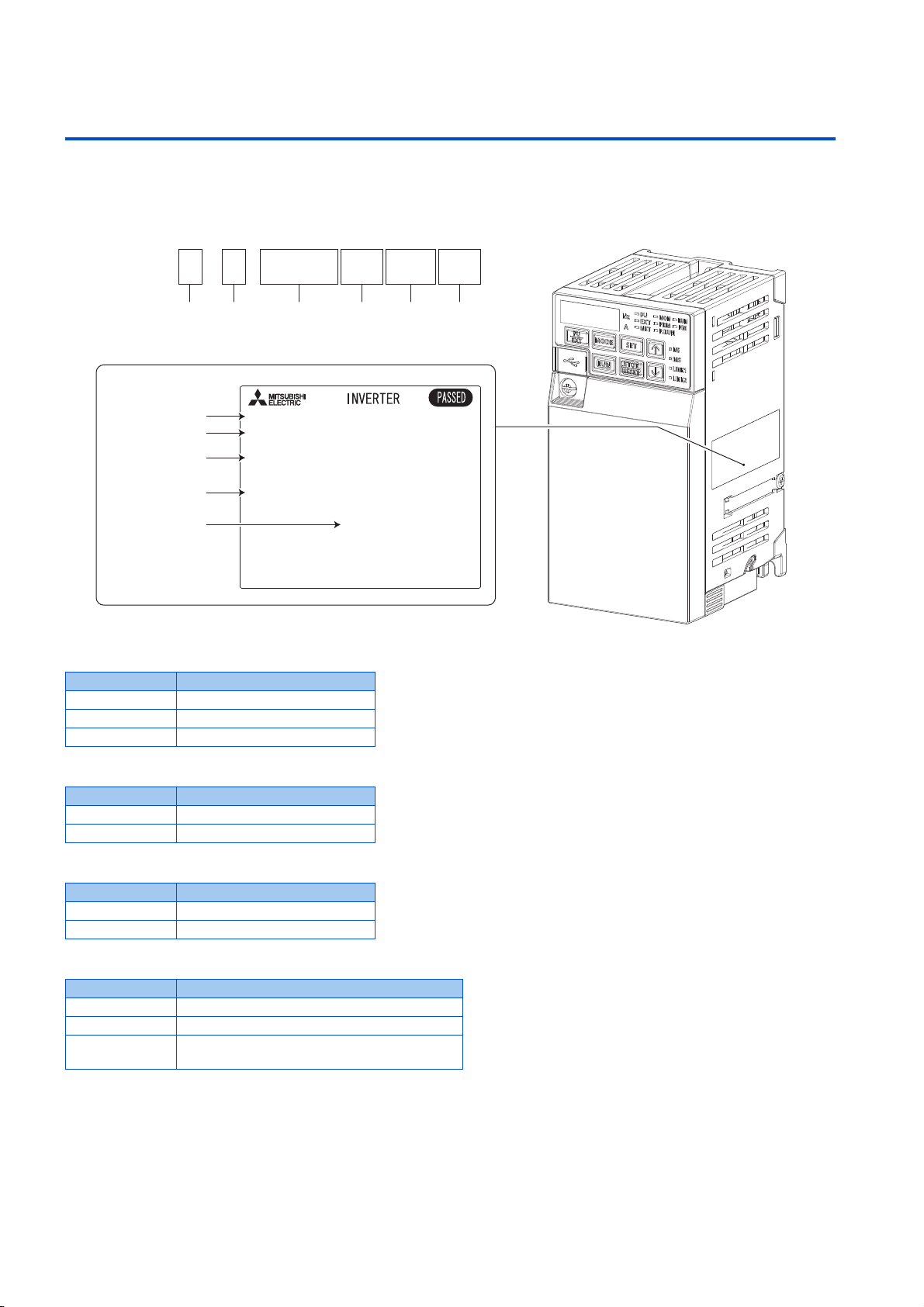

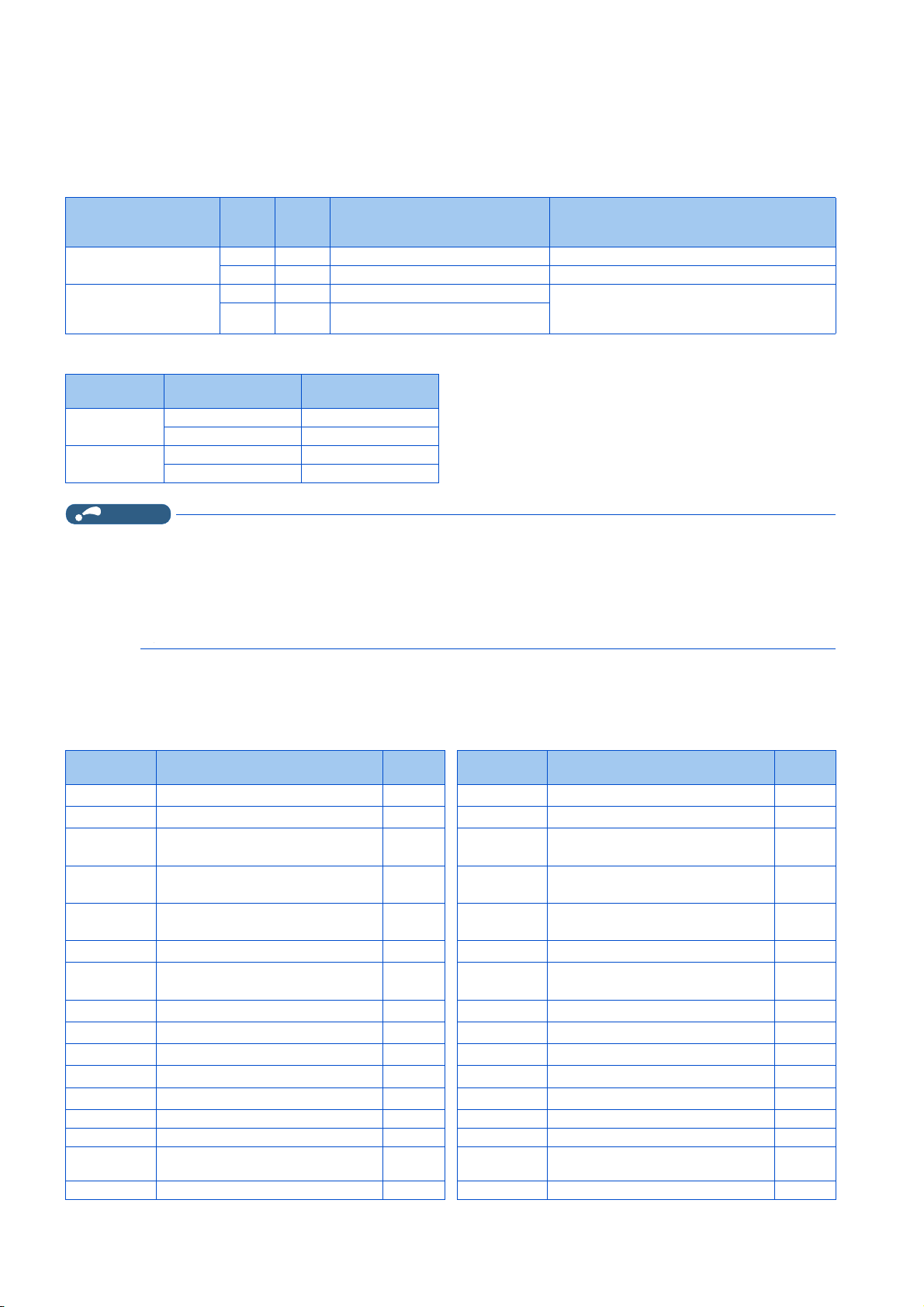

1.1 Product checking

FR-E8 0 -

A B C D E F

00082EPA

Rating plate

Input rating

Output rating

SERIAL

Inverter model

INPUT :XXXXX

MODEL :FR-E820-0008EPA

OUTPUT:XXXXX

SERIAL:XXXXXXXXXXX

MADE IN XXXXX

Country of origin

Inverter model

• A: The voltage class is shown.

Symbol Voltage class

2 200 V class

4 400 V class

6 575 V class

• B: The number of phases of the power source is shown.

Symbol Description

None Three-phase input

S Single-phase input

• C: The inverter rated capacity or the inverter rated current is shown.

Symbol Description

0.1K to 22K Inverter ND rated capacity (kW)

0008 to 0900 Inverter ND rated current (A)

• D: The communication type and the functional safety specification are shown.

Symbol Communication / functional safety

None Standard model (RS-485 + SIL2/PLd)

E Ethernet model (Ethernet + SIL2/PLd)

SCE

Safety communication model (Ethernet + SIL3/

PLe)

1. Introduction

8

1.1 Product checking

Page 10

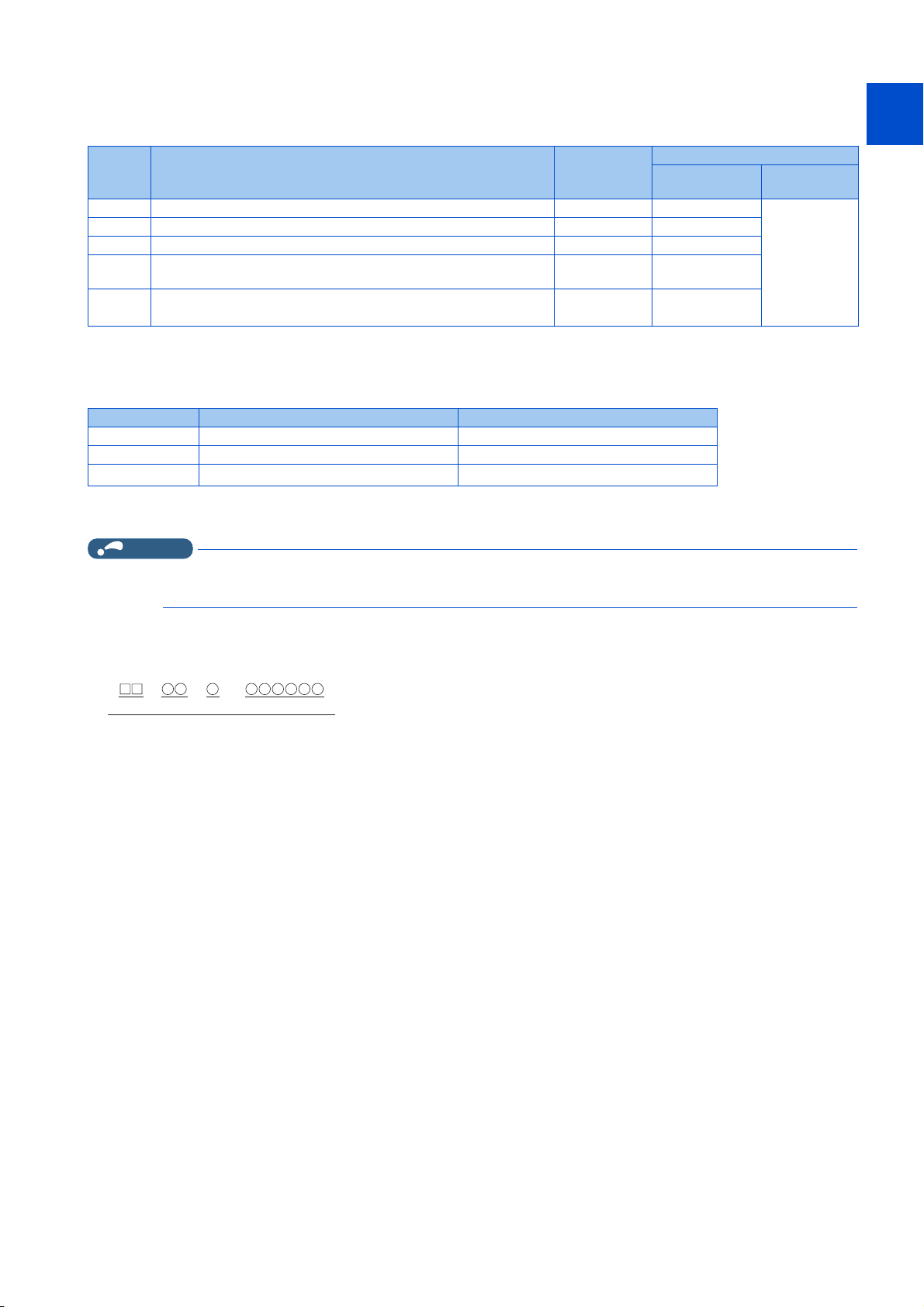

• E: The output specification for monitoring and the rated frequency are shown for the standard model, and the

NOTE

Rating plate example

Symbol Year Month Control number

SERIAL

communication protocol group is shown for the Ethernet model and the safety communication model. The control logic is

fixed to the source logic for the safety communication model.

1

Rated

Symbol Monitoring/protocol specifications

-1 Pulse (terminal FM) 60 Hz Sink logic

-4 Voltage (terminal AM) 50 Hz Source logic

-5 Voltage (terminal AM) 60 Hz Sink logic

PA

PB

• F: Availability of circuit board coating / plated conductors is shown.

None Without coating Without plated conductors

-60 With coating Without plated conductors

-06

Protocol group A (CC-Link IE TSN, CC-Link IE Field Network Basic,

MODBUS/TCP, EtherNet/IP, and BACnet/IP)

Protocol group B (CC-Link IE TSN, CC-Link IE Field Network Basic,

MODBUS/TCP, PROFINET)

*1 The initial status of the control logic differs depending on the inverter model.

Sink logic for the models indicated with the rated capacity (kW)

Source logic for the models indicated with the rated current (A).

Symbol Circuit board coating

*2

*1 Conforming to IEC 60721-3-3 3C2

*2 Applicable for the FR-E820-0470(11K) or higher, and the FR-E840-0230(11K) or higher.

With coating With plated conductors

• In this Instruction Manual, the inverter model name consists of the applicable motor capacity and the rated current.

(Example) FR-E820-0008(0.1K)

*1

frequency

(initial setting)

60 Hz Sink logic

50 Hz

Plated conductor

Input signal

(initial status)

Sink logic / source

*1

logic

Control logic

Safety stop

Source logic

(fixed)

signal

2

3

4

5

6

7

8

How to read the SERIAL number

The SERIAL consists of two symbols, three characters indicating the production

year and month, and six characters indicating the control number.

The last two digits of the production year are indicated as the Year, and the Month

is indicated by 1 to 9, X (October), Y (November), or Z (December).

9

10

1. Introduction

1.1 Product checking

9

Page 11

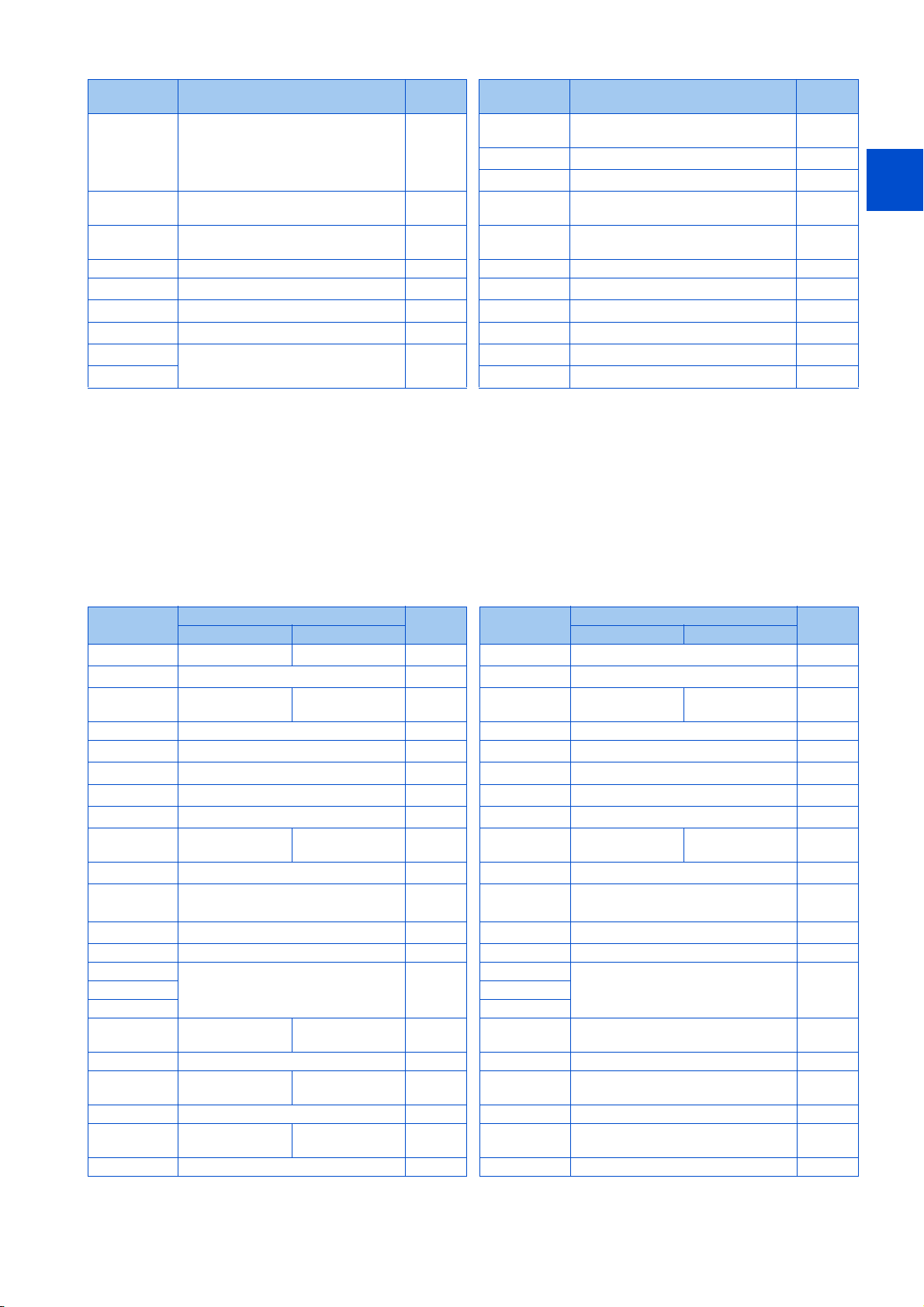

1.2 Related manuals

Manuals related to the FR-E800 inverter are shown in the following table.

Name Manual number

FR-E800 Inverter Safety Guideline IB-0600857ENG

FR-E860 Inverter Safety Guideline IB-0600862ENG

FR-E800-E Inverter Safety Guideline IB-0600860ENG

FR-E860-E Inverter Safety Guideline IB-0600863ENG

FR-E800-SCE Inverter Safety Guideline IB-0600921ENG

FR-E860-SCE Inverter Safety Guideline IB-0600924ENG

FR-E800 Instruction Manual (Connection) IB-0600865ENG

FR-E860 Instruction Manual (Connection) IB-0600906ENG

FR-E800 Instruction Manual (Function) IB-0600868ENG

FR-E800 Instruction Manual (Maintenance) IB-0600874ENG

FR-E800 Instruction Manual (Functional Safety) BCN-A23488-000

FR-E800-SCE Instruction Manual (Functional safety) BCN-A23488-004

FR Configurator2 Instruction Manual IB-0600516ENG

PLC Function Programming Manual IB-0600492ENG

1. Introduction

10

1.2 Related manuals

Page 12

CHAPTER 2

CHAPTER 2

2.1 Outline ....................................................................................................................................................................12

2.2 Wiring......................................................................................................................................................................13

2.3 Ethernet cable connection ......................................................................................................................................15

2.4 Initial setting for Ethernet communication...............................................................................................................17

2.5 CC-Link IE TSN ......................................................................................................................................................18

2.6 CC-Link IE Field Network Basic..............................................................................................................................52

2.7 MODBUS/TCP........................................................................................................................................................81

2.8 BACnet/IP ...............................................................................................................................................................97

2.9 MELSOFT / FA product connection......................................................................................................................110

2.10 SLMP ....................................................................................................................................................................113

2.11 EtherNet/IP ...........................................................................................................................................................128

2.12 PROFINET............................................................................................................................................................149

2.13 Backup/restore......................................................................................................................................................167

2.14 Inverter-to-inverter link function ............................................................................................................................169

2.15 Ethernet communication parameters ....................................................................................................................172

Ethernet Communication

4

5

6

7

8

9

10

11

Page 13

2 Ethernet Communication

2.1 Outline

Ethernet communication is available for the Ethernet model and the safety communication model.

Precautions for communication

• To maintain the security (confidentiality, integrity, and availability) of the inverter and the system against unauthorized

access, DoS*1attacks, computer viruses, and other cyberattacks from external devices via network, take appropriate

measures such as firewalls, virtual private networks (VPNs), and antivirus solutions. We shall have no responsibility or

liability for any problems involving inverter trouble and system trouble by DoS attacks, unauthorized access, computer

viruses, and other cyberattacks.

• Depending on the network environment, the inverter may not operate as intended due to delays or disconnection in

communication. Carefully consider what type of environment the inverter will be used in and any safety issues related to

its use.

*1 DoS: A denial-of-service (DoS) attack disrupts services by overloading systems or exploiting vulnerabilities, resulting in a denial-of-service (DoS)

state.

Ethernet communication specifications

The communication specification varies depending on the specification of the master or the communication protocol.

Item Description

Category 100BASE-TX/10BASE-T

Data transmission speed 100 Mbps (100BASE-TX) / 10 Mbps (10BASE-T)

Transmission method Baseband

Maximum segment length 100 m between the hub and the inverter

Number of cascade connection stages Up to 2 (100BASE-TX) / up to 4 (10BASE-T)

Topology Line, star, or a combination of line and star

Interface RJ-45

Number of interfaces available 2

IP version IPv4

Operation status LEDs

LED name Description LED status Remarks

NS Communication status

MS Inverter status

LINK1

LINK2

NET

Connector for communication

(PORT1) status

Connector for communication

(PORT2) status

SLMP command request message

reception status

OFF Duplicate IP address not detected

Red Duplicate IP address detected

OFF Power-OFF / during inverter reset

Green Operating properly

Red Fault detected

OFF Power-OFF/link-down

Blinking green Link-up (Data reception in progress)

Solid green Link-up

OFF Power-OFF/link-down

Blinking green Link-up (Data reception in progress)

Solid green Link-up

OFF

Blinking green

Solid green Network operation mode

Power-OFF / inverter identification disabled /

inverter identification paused

Inverter identification in progress

*1

*1 While "1 (initial value)" is set in Pr.1399 Inverter identification enable/disable selection, this LED blinks when the MAC/IP address of the

2. Ethernet Communication

12

2.1 Outline

inverter match to the MAC/IP address specified by using engineering software such as FR Configurator2.

Page 14

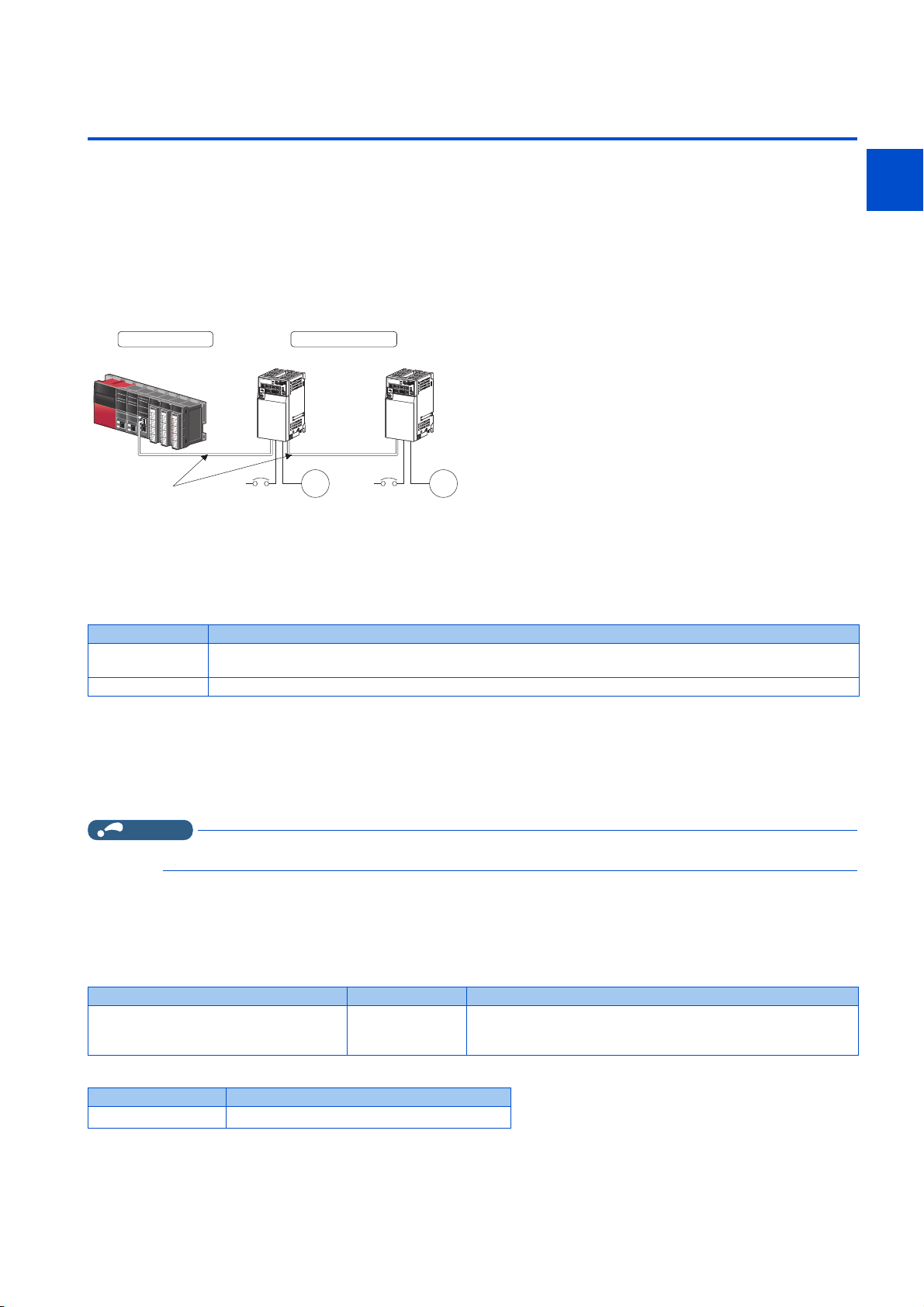

2.2 Wiring

Inverter

Motor

Power

supply

Inverter

Motor

Power

supply

Slave station

Ethernet cable

Master station

1

2.2.1 System configuration example

1. Select the connection method. (Refer to page 13.)

2. Prepare the equipment required for wiring. (Refer to page 13.)

3. Turn OFF the power of the programmable controller and the inverter.

4. Connect the master station and the inverters with Ethernet cables. (Refer to page 15.)

2.2.2 Network configuration

Network topology

The network can be wired into star topology or line topology. A network can consist of a combination of star and line topologies.

2

3

4

5

6

7

8

Item Description

Star topology

Line topology Modules are configured into a line with Ethernet cables. A switching hub is not required.

Modules are configured into a star using a switching hub and Ethernet cables. Slave stations can be easily added in a

star topology. Furthermore, data link continues among normally-operating stations in a star topology.

Station number and connection position

Modules can be connected in any order regardless of the station number.

Replacing CC-Link IE TSN devices

For star topology, slave stations can be replaced without powering off the whole system.

NOTE

• Refer to the Master Module User's Manual for detailed network configurations.

2.2.3 Network components

Connection cable

Use Ethernet cables compliant with the following standards.

Ethernet cable Connector Type

Category 5 or higher straight cable (double

shielded / STP)

• Recommended product (as of April 2019)

RJ-45 connector

The following conditioning cables:

• IEEE 802.3 (100BASE-TX)

• ANSI/TIA/EIA-568-B (Category 5)

9

10

Model Manufacturer

SC-E5EW series

*1 SC-E5EW cable is for in-enclosure and indoor uses. SC-E5EW-L cable is for outdoor use.

*1

Mitsubishi Electric System & Service Co., Ltd.

2. Ethernet Communication

2.2 Wiring

13

Page 15

NOTE

• Depending on the cable connector shape, the cable may not be connected to the inverter.

Hubs

Use hubs that meet the following conditions. Operation is not guaranteed if the hubs do not meet these conditions.

• Compliance with the IEEE 802.3 (100BASE-TX)

• Support of the auto MDI/MDI-X function

• Support of the auto-negotiation function

• Switching hub (layer 2 switch)

*1 A repeater hub is not available.

Industrial switching hub

Model Manufacturer

NZ2EHG-T8N Mitsubishi Electric Corporation

NZ2EHG-T8 (discontinued product) Mitsubishi Electric Corporation

DT135TX Mitsubishi Electric System & Service Co., Ltd.

*1

2. Ethernet Communication

14

2.2 Wiring

Page 16

2.3 Ethernet cable connection

This section explains Ethernet cable connection and the relevant precautions. For the details of the network configuration and

the cables and hubs used for wiring, refer to page 13 onwards.

1

2

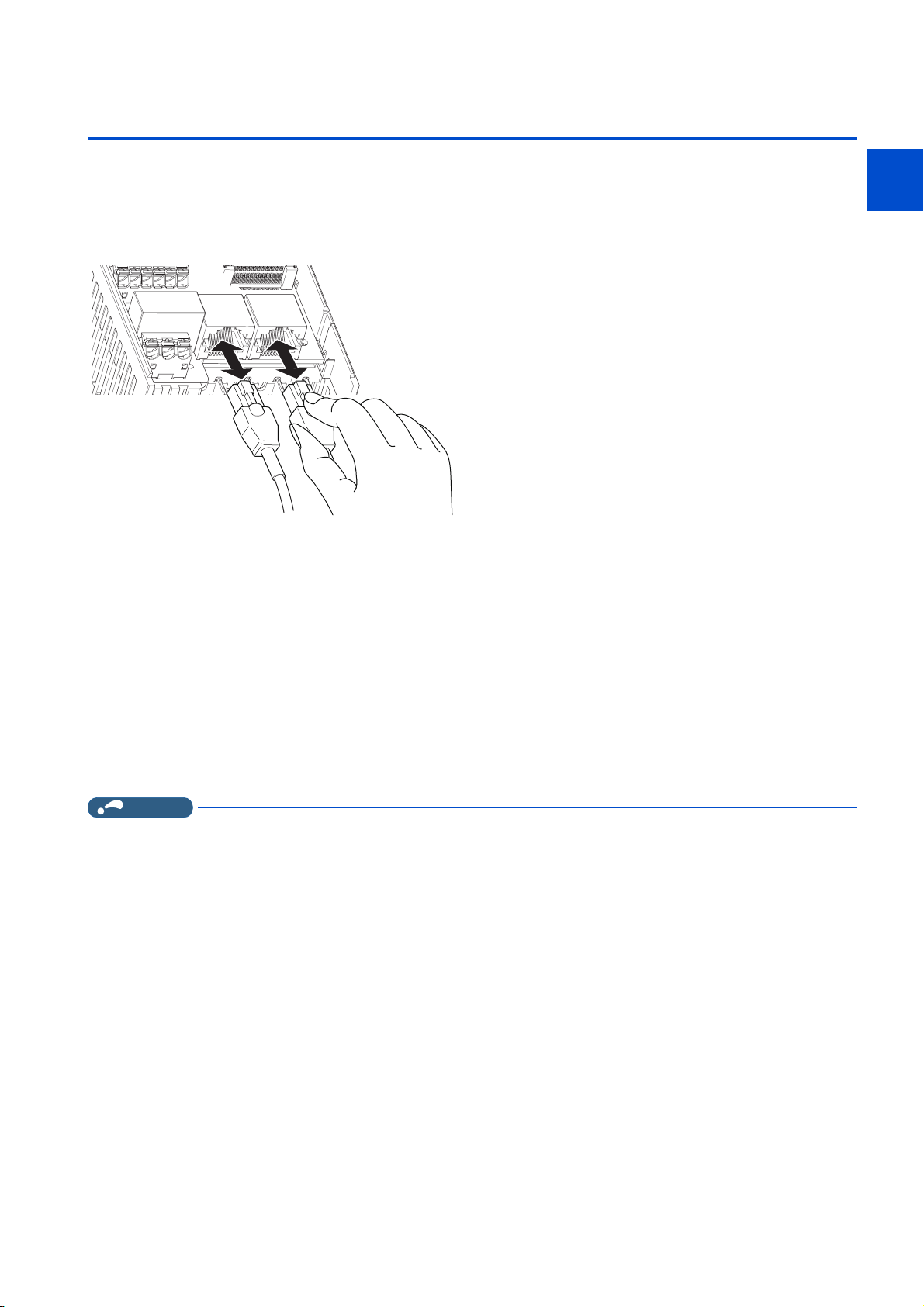

2.3.1 Wiring method

Reinstallation

1. Turn OFF the power of the programmable controller and the inverter.

2. Remove the inverter front cover.

3. Check the orientation of the connectors. Insert the connector part of the Ethernet cable to the communication

connector until it clicks.

Disconnection

1. Turn OFF the power of the programmable controller and the inverter.

3

4

5

6

7

8

9

10

2. Remove the inverter front cover.

3. Hold down the latch on the Ethernet cable connector, and pull out the cable while holding the latch.

NOTE

• There is no need to distinguish between PORT1 and PORT2 on the inverter (except for PROFINET).

• When only one connector is used in star topology, either PORT1 or PORT2 is applicable. (Use PORT1 for PROFINET.)

• When using two connectors for line topology, an Ethernet cable can be connected to the connectors in any combination. For

example, the cable can be connected across two of PORT1 or across PORT1 and PORT2. (For PROFINET, use PORT1

for connection with the master, and use PORT2 for connection with PORT1 of the adjacent inverter.)

2. Ethernet Communication

2.3 Ethernet cable connection

15

Page 17

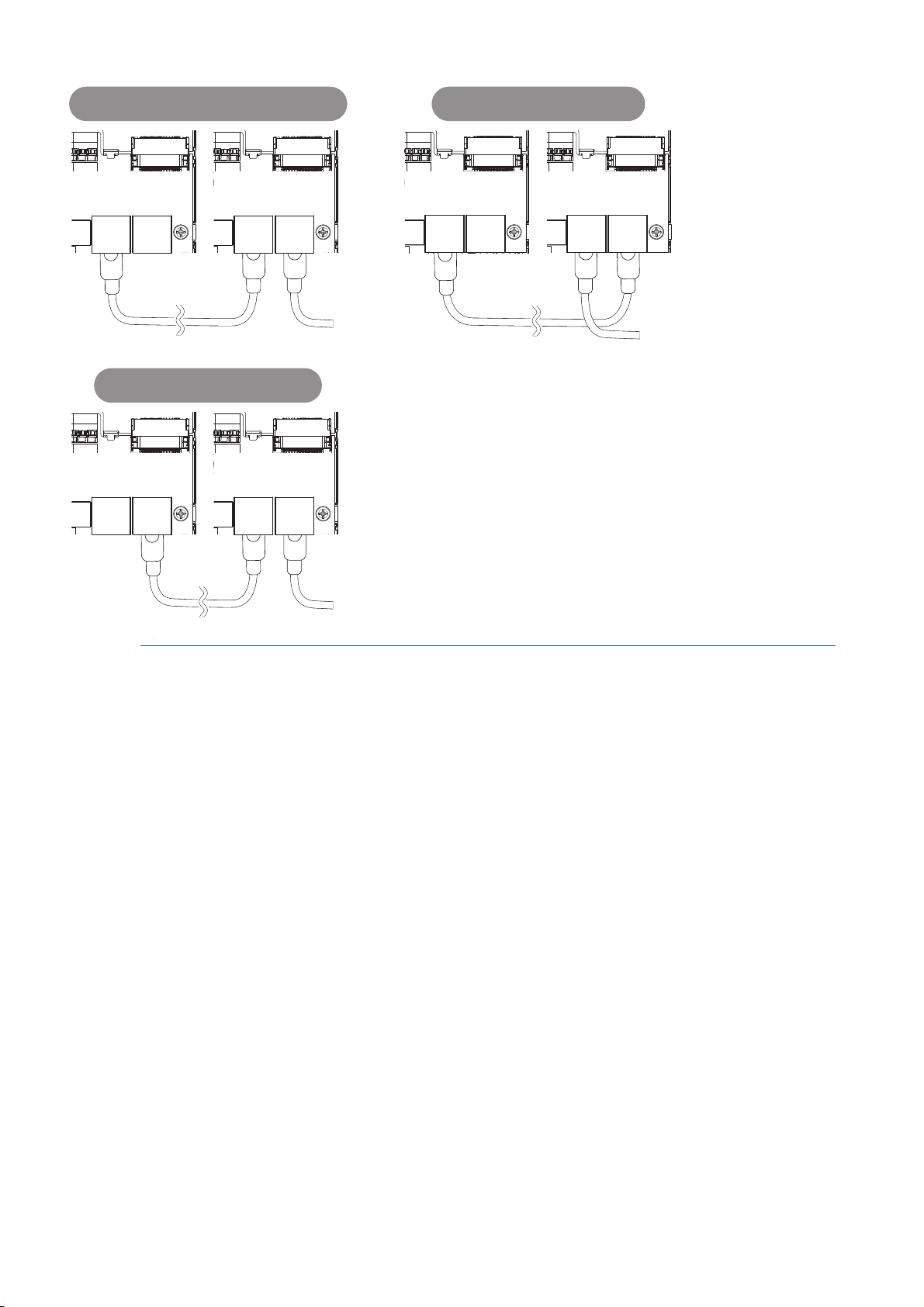

2.3.2 Wiring precautions

Connection between

PORT1 and PORT1, PORT2 and PORT2

Connection between

PORT1 and PORT2

Connector

for

communication

(PORT2)

Connector

for

communication

(PORT1)

Connector

for

communication

(PORT2)

Connector

for

communication

(PORT1)

Connector

for

communication

(PORT2)

Connector

for

communication

(PORT1)

Connector

for

communication

(PORT2)

Connector

for

communication

(PORT1)

Connector

for

communication

(PORT2)

Connector

for

communication

(PORT1)

Connector

for

communication

(PORT2)

Connector

for

communication

(PORT1)

To the next

connector for

communication

(PORT2)

To the next

connector for

communication

(PORT2)

Connection between

PORT2 and PORT1 (PROFINET)

To the next

connector for

communication

(PORT1)

This section explains Ethernet cable connection and the relevant precautions.

Handling of the Ethernet cable

• Do not touch the conductors of the cable or the connector on the inverter. Keep the conductors free of dust or dirt. If oil

from your hand, dirt or dust is attached to the core, it can increase transmission loss, arising a problem in data link.

• Check the following:

Is any Ethernet cable disconnected?

Is any of the Ethernet cables shorted?

Are the connectors securely connected?

• Do not use Ethernet cables with broken latches. Doing so may cause the cable to unplug or malfunction.

• The maximum station-to-station distance is 100 m. However, the distance may be shorter depending on the operating

environment of the cable. For details of the cable, contact your cable manufacturer.

Connecting and disconnecting of the Ethernet cable

Hold the connector part when connecting and disconnecting the Ethernet cable. Pulling a cable connected to the inverter may

damage the inverter or cable, or result in malfunction due to poor contact.

Network configuration

Check the network configuration before wiring, and perform correct wiring. For example, using ring topology may cause system

failure.

16

2. Ethernet Communication

2.3 Ethernet cable connection

Page 18

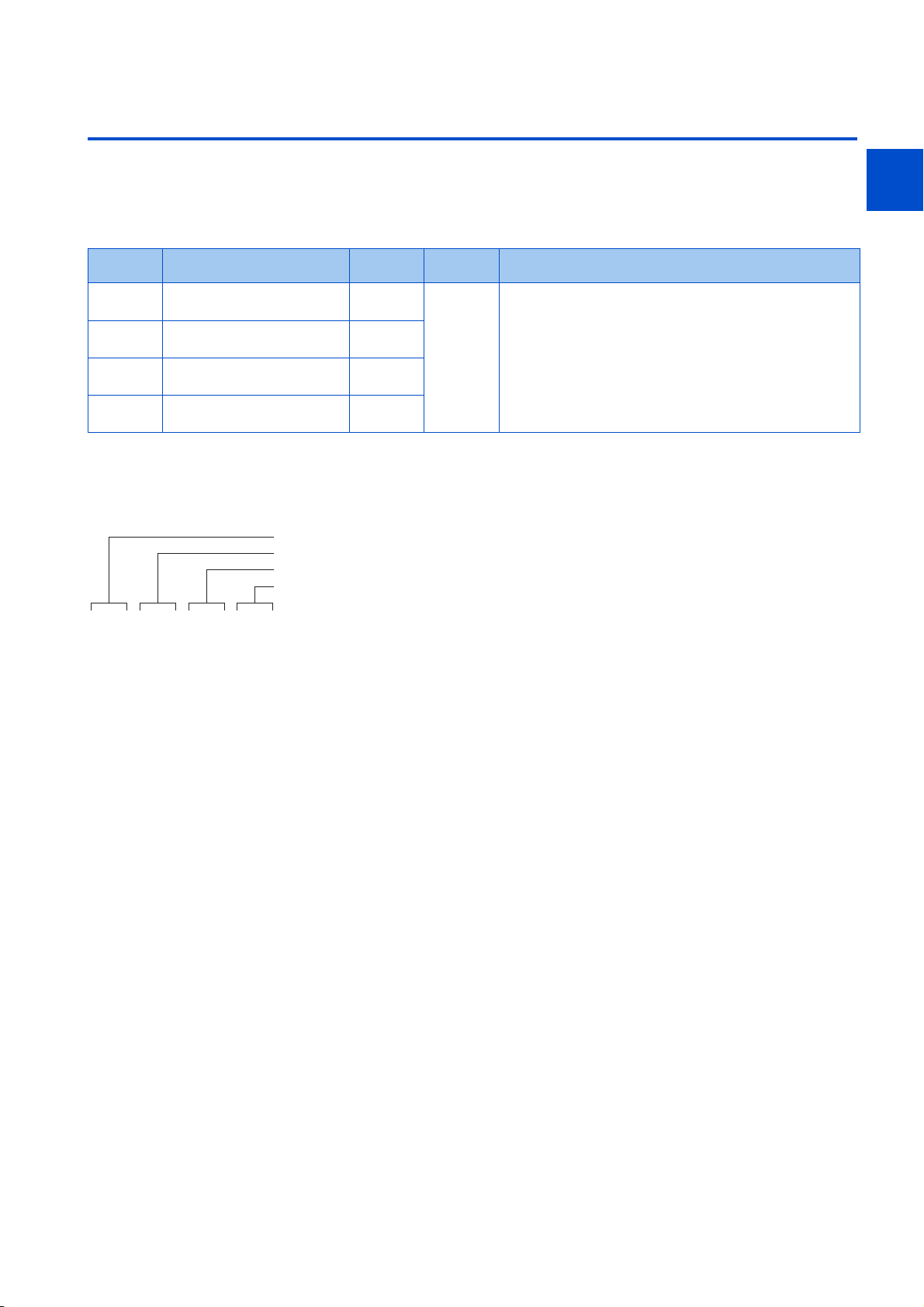

2.4 Initial setting for Ethernet communication

* * * . * * * . * * * . * * *

Set the value in the first octet in Pr.1434.

Set the value in the second octet in Pr.1435.

Set the value in the third octet in Pr.1436.

Set the value in the fourth octet in Pr.1437.

Use the following parameters to perform required settings for Ethernet communication between the inverter and other devices.

To make communication between other devices and the inverter, perform the initial settings of the inverter parameters to match

the communication specifications of the devices. Data communication cannot be made if the initial settings are not made or if

there is any setting error.

Pr. Name

1434

N600

1435

N601

1436

N602

1437

N603

IP address 1 (Ethernet) 192

*1

IP address 2 (Ethernet) 168

*1

IP address 3 (Ethernet) 50

*1

IP address 4 (Ethernet) 1

*1

*1 The setting is applied after an inverter reset or next power-ON.

Initial

value

IP address (Pr.1434 to Pr.1437)

Enter the IP address of the inverter to be connected to Ethernet in Pr.1434 to Pr.1437. (Enter the IP address assigned by the

network administrator.)

Setting

range

0 to 255 Enter the IP address of the inverter to be connected to Ethernet.

Description

1

2

3

4

5

6

7

8

9

10

2. Ethernet Communication

2.4 Initial setting for Ethernet communication

17

Page 19

2.5 CC-Link IE TSN

NOTE

2.5.1 Outline

Data can be transmitted to IT systems while performing real-time cyclic communication control.

Some functions are not supported depending on the date of manufacture of the inverter. For details of specification changes,

refer to page 220.

CC-Link IE TSN authentication classes

• Devices (nodes) and switches on the CC-Link IE TSN network are classified into different authentication classes according

to their functionality and performance. There are two authentication classes: A and B. For details of the authentication class

of each product, check the information on the web site of the CC-Link Partner Association, or refer to catalogs and manuals

of each product. Different functions and system configurations are available depending on the authentication class of the

devices to be used. For example, use authentication class B devices to construct a high-speed motion control system. For

details of system construction such as mixing devices of both class A and class B, check the manuals of the applicable

master device.

Communication specifications

The communication specification varies depending on the specification of the master.

Item Description

Transmission speed 100 Mbps (10 Mbps is not supported.)

Minimum synchronization cycle 5000.00 μs

Authentication class Authentication class A

Communication method Time sharing method

Synchronization function Conforms to IEEE 1588v2

Maximum number of connected units 121 units (sum of master and slave stations)

Maximum number of branches No upper limit on the same Ethernet network

Connection cable

Topology

Node type Slave station

RX 32 bits

Maximum cyclic size (of

one node)

*1 Ring topology will be supported later.

• To use the CC-Link IE TSN, do not install the FR-A8NC to the inverter. (Installing the FR-A8NC E kit disables CC-Link IE TSN.)

RY 32 bits

RWr 32 words

RWw 32 words

Ethernet cable (IEEE 802.3 100BASE-TX compliant cable or ANSI/TIA/EIA-568-B (Category 5)

compliant shielded 4-pair branched cable)

Line, star, or a combination of line and star

*1

2. Ethernet Communication

18

2.5 CC-Link IE TSN

Page 20

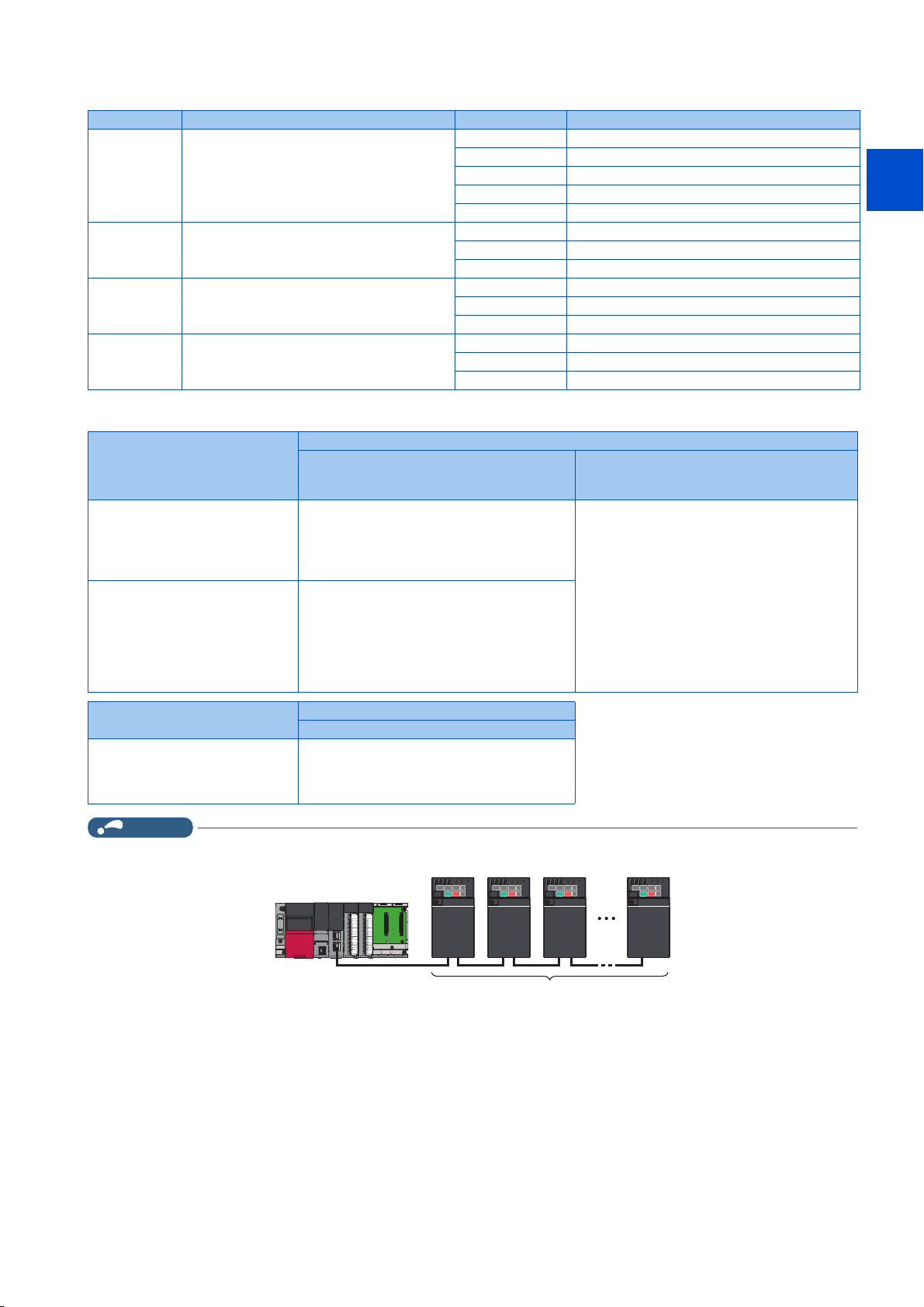

Operation status LEDs

RJ71GN11-T2

Communication speed 100 Mbps

FR-E800 (authentication class A)

Communication speed 100 Mbps

120 units maximum

LED name Description LED status Remarks

OFF Power-OFF

Blinking green Data transmission not performed

NS Communication status

MS Inverter status

LINK1 Connector for communication (PORT1) status

LINK2 Connector for communication (PORT2) status

Solid green Data transmission in progress

Blinking red Communication interrupted

Solid red Duplicate IP address detected

OFF Power-OFF / during inverter reset

Green Operating properly

Red Fault detected

OFF Power-OFF/link-down

Blinking green Link-up (Data reception in progress)

Solid green Link-up

OFF Power-OFF/link-down

Blinking green Link-up (Data reception in progress)

Solid green Link-up

Network configuration

1

2

3

4

5

Master station

MELSEC iQ-R series master/local

module RJ71GN11-T2 or a master

station that supports both 1 Gbps

and 100 Mbps communication

speeds

MELSEC iQ-F series master/local

module FX5-CCLGN-MS or a master

station that supports 1 Gbps

communication speed only

Master station

MELSEC iQ-R series Motion module

RD78G[]/GH[]

NOTE

• When all slave stations are authentication class A products, up to 120 units can be connected.

Slave station

FR-E800 (authentication class A) only

Line topology, star topology, or a combination of

line and star

Set 100 Mbps for the communication speed of the

master station.

Star topology or a combination of line and star

(Line topology only is not supported.)

Connection sequence: Master station →

General-purpose switching hub → FR-E800

(authentication class A)

Line topology is available for connection starting

from the FR-E800.

Slave station

FR-E800 (authentication class A) only

Connection sequence: Master station → FRE800 (authentication class A)

Line topology is available for connection starting

from the FR-E800.

Mixture of FR-E800 (authentication class A)

and FR-A800-GN or other device

(authentication class B)

Star topology or a combination of line and star

(Line topology only is not supported.)

Connection sequence: Master station → Slave

station (authentication class B) → Generalpurpose switching hub → FR-E800 (authentication

class A)

Line topology is available for connection starting

from the FR-E800.

6

7

8

9

10

2. Ethernet Communication

2.5 CC-Link IE TSN

19

Page 21

• When both authentication class B and class A products are used, the data size of all class A units must not exceed 2k bytes

RJ71GN11-T2

Communication

speed 1 Gbps

FR-E800 (authentication class A)

Communication speed 100 Mbps

10 units maximum

Remote I/O

(authentication

class B)

Communication

speed 1 Gbps

General-purpose

switching hub

FR-E800 (authentication class A)

Communication speed 100 Mbps

Remote I/O

(authentication

class B)

Communication

speed 1 Gbps

General-purpose

switching hub

Port 1

Port 2

Total number of

slave stations:

120 units maximum

RJ71GN11-T2

(firmware version

"12" or later)

Communication

speed 1 Gbps

for cyclic transmission. Up to 10 authentication class A units can be connected per port on the master station.

• When the master station has more than one port, use separate ports for both authentication classes to enable connection of

up to 120 slave station units. For example, use port 1 for authentication class B products only, and port 2 for class A products

only.

• For details of network configurations, refer to the Master Module User's Manual.

Related manuals

Name Manual number

MELSEC iQ-R CC-Link IE TSN User's Manual (Startup) SH-082127ENG

MELSEC iQ-R CC-Link IE TSN User's Manual (Application) SH-082129ENG

MELSEC iQ-F FX5 User's Manual (CC-Link IE TSN) SH-082215ENG

MELSEC iQ-R Motion Module User's Manual (Startup) IB-0300406ENG

MELSEC iQ-R Motion Module User's Manual (Application) IB-0300411ENG

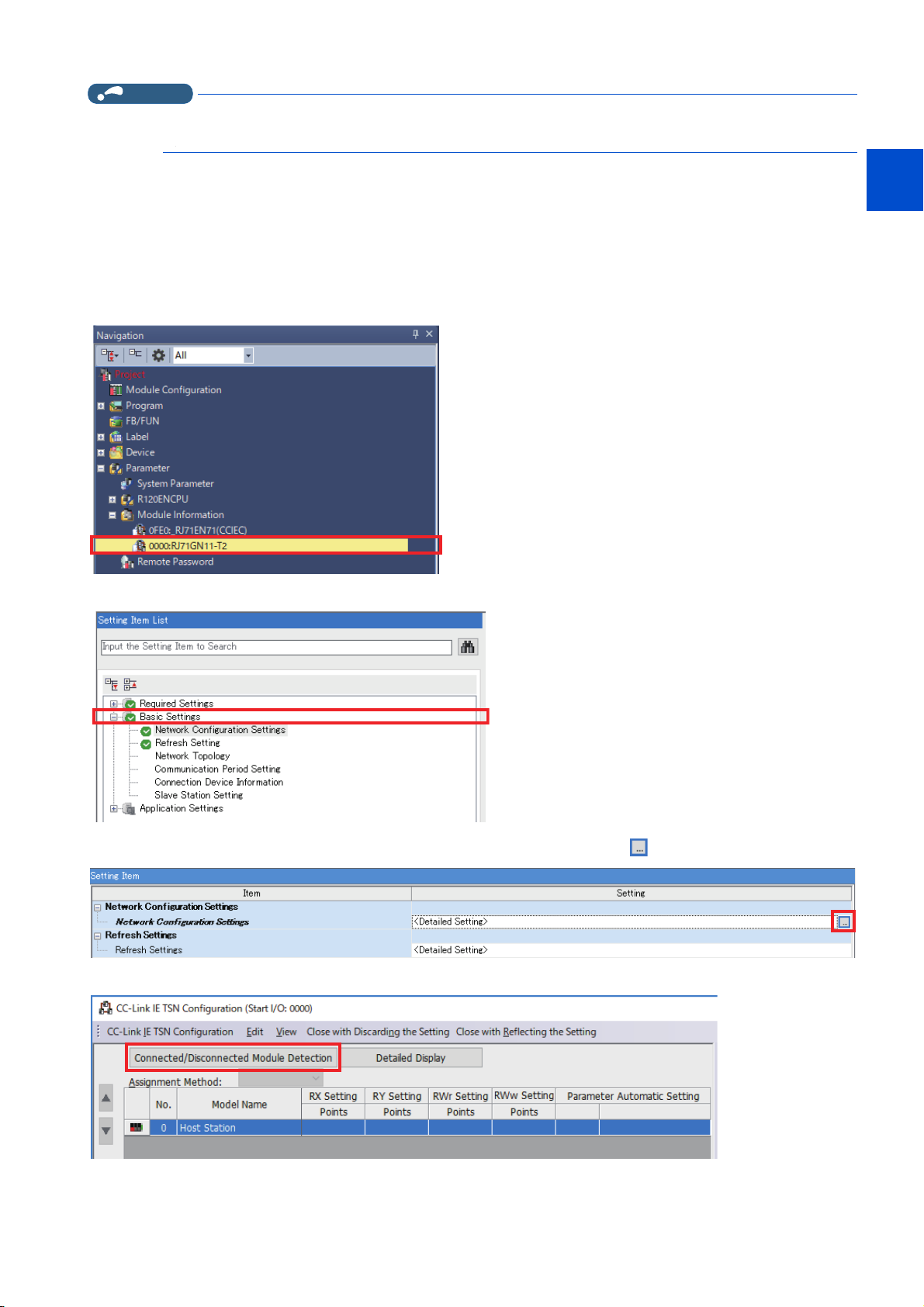

2.5.2 CC-Link IE TSN configuration

Procedure

The following shows the procedure to connect the inverter with a Mitsubishi Electric master device.

Before communication

1. Connect each unit with an Ethernet cable. (Refer to page 15.)

2. Enter the IP address (Pr.1434 to Pr.1437). (Refer to page 17.)

3. Set "45238" (CC-Link IE TSN) in any of Pr.1427 to Pr.1430 Ethernet function selection 1 to 4. (Refer to page 26.)

In the initial status, Pr.1429 = "45238" (CC-Link IE TSN) and setting is not required.

Registering a profile

2. Ethernet Communication

20

2.5 CC-Link IE TSN

4. Reset the inverter, or turn OFF and then ON the power.

1. Start the engineering software (GX Works3).

2. On the menu bar, select [Tool] > [Profile Management] > [Register...].

3. Select a CSP+ file to be registered on the "Register Profile" screen, and click the [Register] button.

Page 22

NOTE

• A profile is a compressed file (such as *.zip, *.ipar, and *.cspp). Register a profile without decompressing the file.

• Profile registration is not required for the next time onwards.

1

Creating a project file

1. For information on creating and opening a project, go to [Help] > [GX Works3 Help].

Detecting an Inverter

Detection is not possible when the data link is not established with the master module. For details, refer to the Master Module

User's Manual.

1. In the "Navigation" window, select [Parameter] > [Module Information] then select the module name.

2. Select [Basic Settings] in the "Setting Item List" window.

2

3

4

5

6

7

8

3. In the "Setting Item" window, go to [Network Configuration Settings] then click next to the [Detailed Setting] field.

4. Click [Connected/Disconnected Module Detection] in the "CC-Link IE TSN configuration" window.

9

10

2. Ethernet Communication

2.5 CC-Link IE TSN

21

Page 23

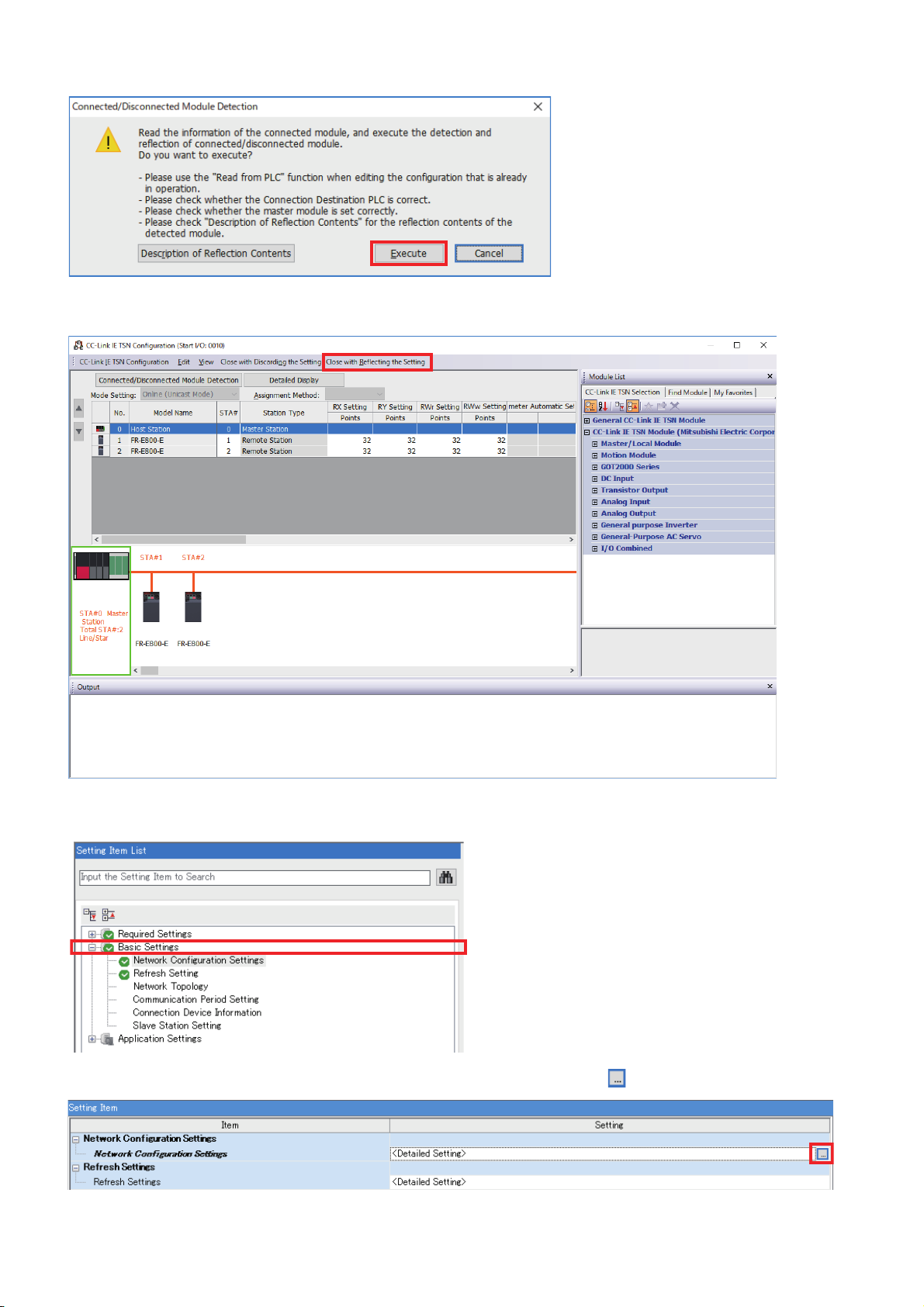

5. Read the cautions in the "Connected/Disconnected Module Detection" window and click [Execute].

HostStation

6. The FR-E800-E or the FR-E800-SCE will appear on the screen when it is detected. (FR-E800-E inverters are

displayed in the following example.) Click [Close with Reflecting the Setting] to close the window.

System setting window (communication speed setting of the master: 1 Gbps)

1. Select [Basic Settings] in the "Setting Item List" window.

2. In the "Setting Item" window, go to [Network Configuration Settings] then click next to the [Detailed Setting] field.

2. Ethernet Communication

22

2.5 CC-Link IE TSN

Page 24

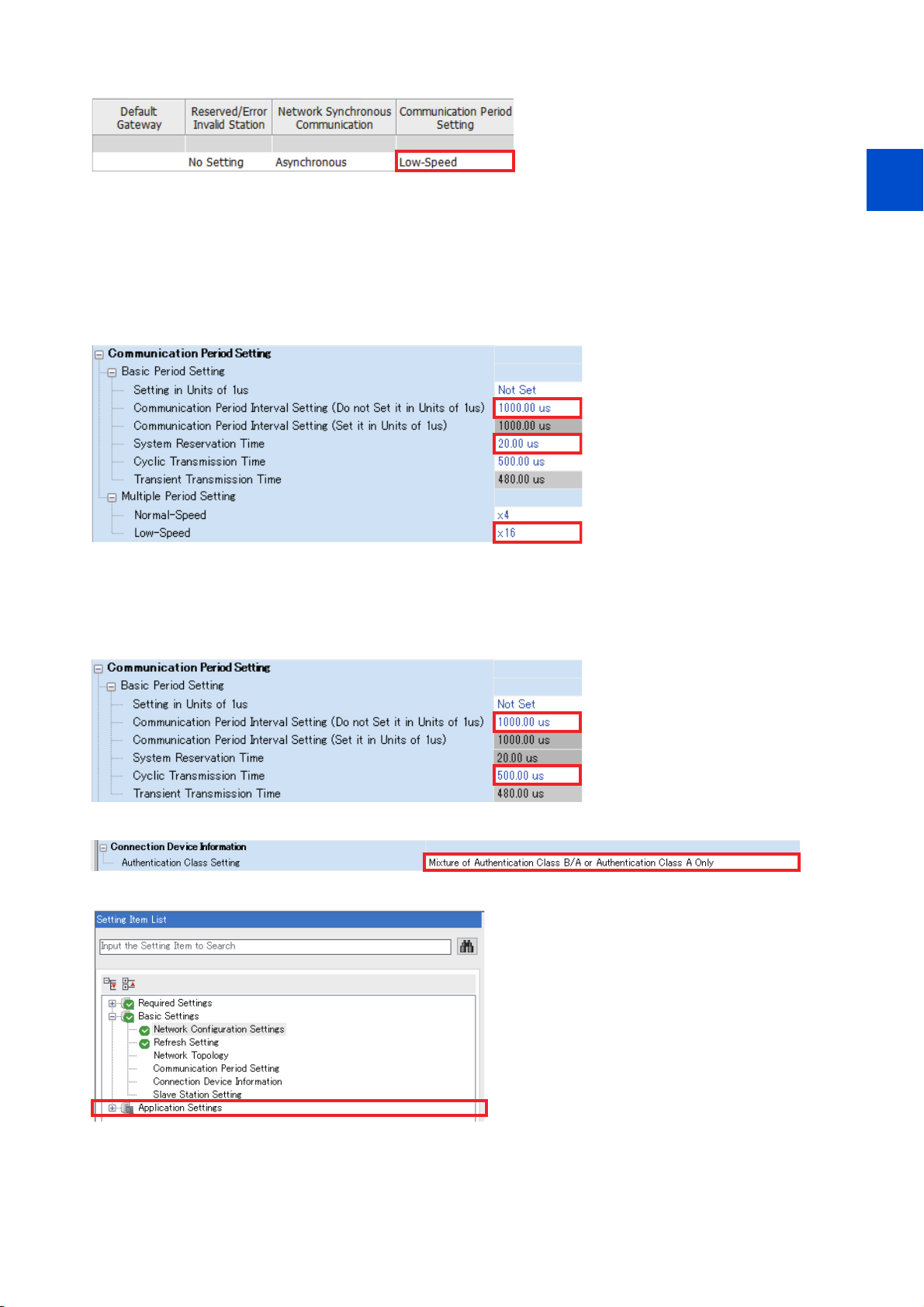

3.

In the "CC-Link IE TSN Configuration" window, set "Low-Speed" for [Communication Period Setting].

4. Set "1000.00 μs" (initial value) for [Communication Period Interval Setting (Do not Set it in Units of 1us)].

• When RJ71GN11-T2 is the master

Set "20.00 μs" (initial value) for [System Reservation Time].

Consider the scaling factor in [Multiple Period Setting] - [Low-Speed] to change the settings for [Basic Period Setting]. Refer to

the following examples.

[Communication Period Interval Setting] = "5000.00 μs" / "16 (initial value)" (minimum value)

[System Reservation Time] = "200.00 μs" / "16 (initial value)" (minimum value)

1

2

3

4

5

6

7

• When FX5-CCLGN-MS is the master

Set "500.00 μs" (initial value) for [Cyclic Transmission Time].

Consider the scaling factor in [Multiple Period Setting] - [Low-Speed] to change the settings for [Basic Period Setting]. Refer to

the following example.

[Communication Period Interval Setting] = "5000.00 μs" / "16 (fixed)" (minimum value)

5. Set "Mixture of Authentication Class B/A or Authentication Class A Only" for [Authentication Class Setting].

6. Select [Application Settings] in the "Setting Item List" window.

8

9

10

2. Ethernet Communication

2.5 CC-Link IE TSN

23

Page 25

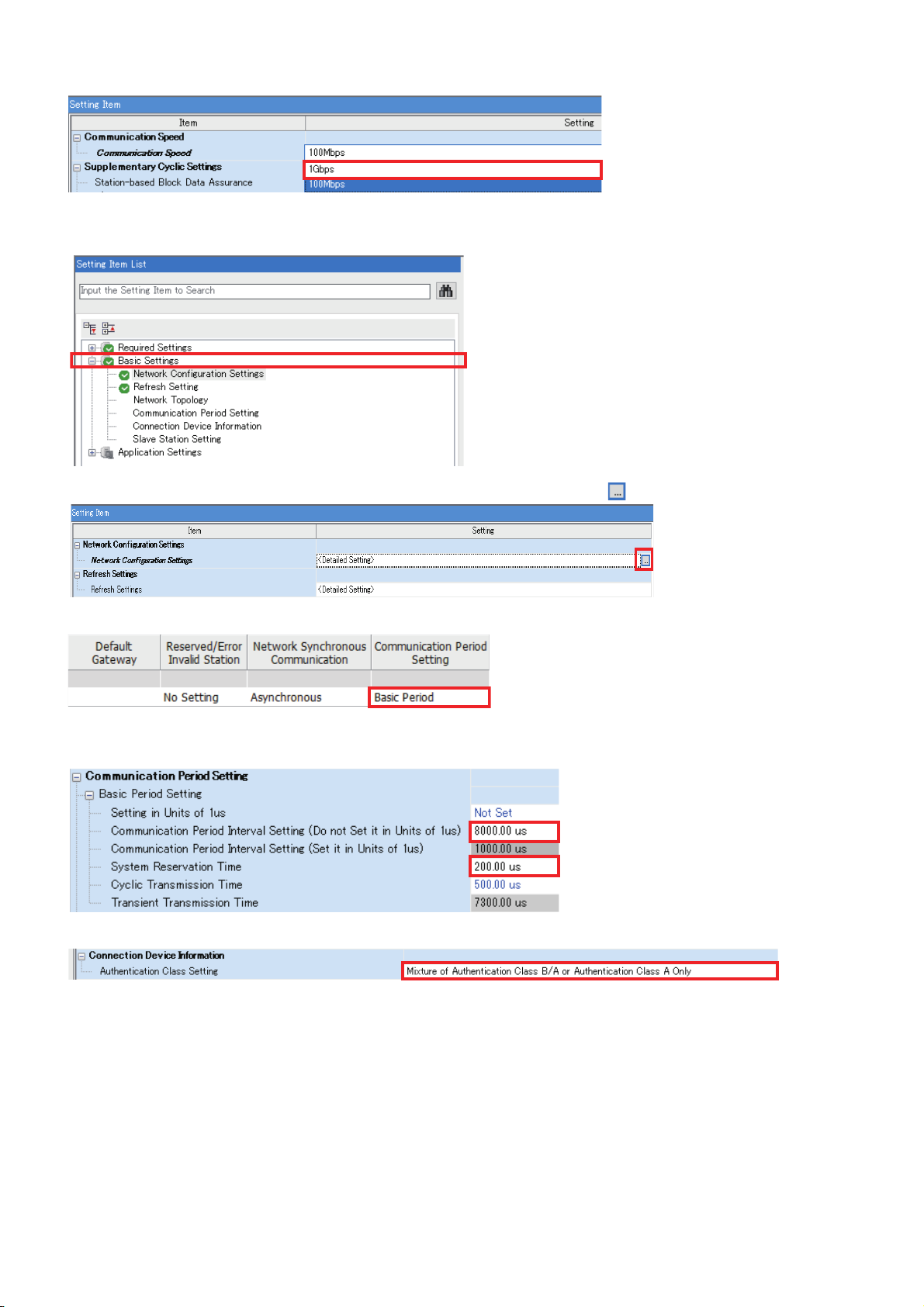

7. Set "1 Gbps" for [Communication Speed].

System setting window (communication speed setting of the master: 100 Mbps)

1. Select [Basic Settings] in the "Setting Item List" window.

2. In the "Setting Item" window, go to [Network Configuration Settings] then click next to the [Detailed Setting] field.

3. In the "CC-Link IE TSN Configuration" window, set "Basic Period" for [Communication Period Setting].

4. Set "5000.00 μs" or larger value for [Communication Period Interval Setting (Do not Set it in Units of 1us)].

Set "200.00 μs" for [System Reservation Time].

5. Set "Mixture of Authentication Class B/A or Authentication Class A Only" for [Authentication Class Setting].

2. Ethernet Communication

24

2.5 CC-Link IE TSN

Page 26

6.

XXX.XXX.XXX.XXX

XX-XX-XX-XX-XX-XX

Select [Application Settings] in the "Setting Item List" window.

7. Set "100 Mbps" for [Communication Speed].

1

2

3

4

5

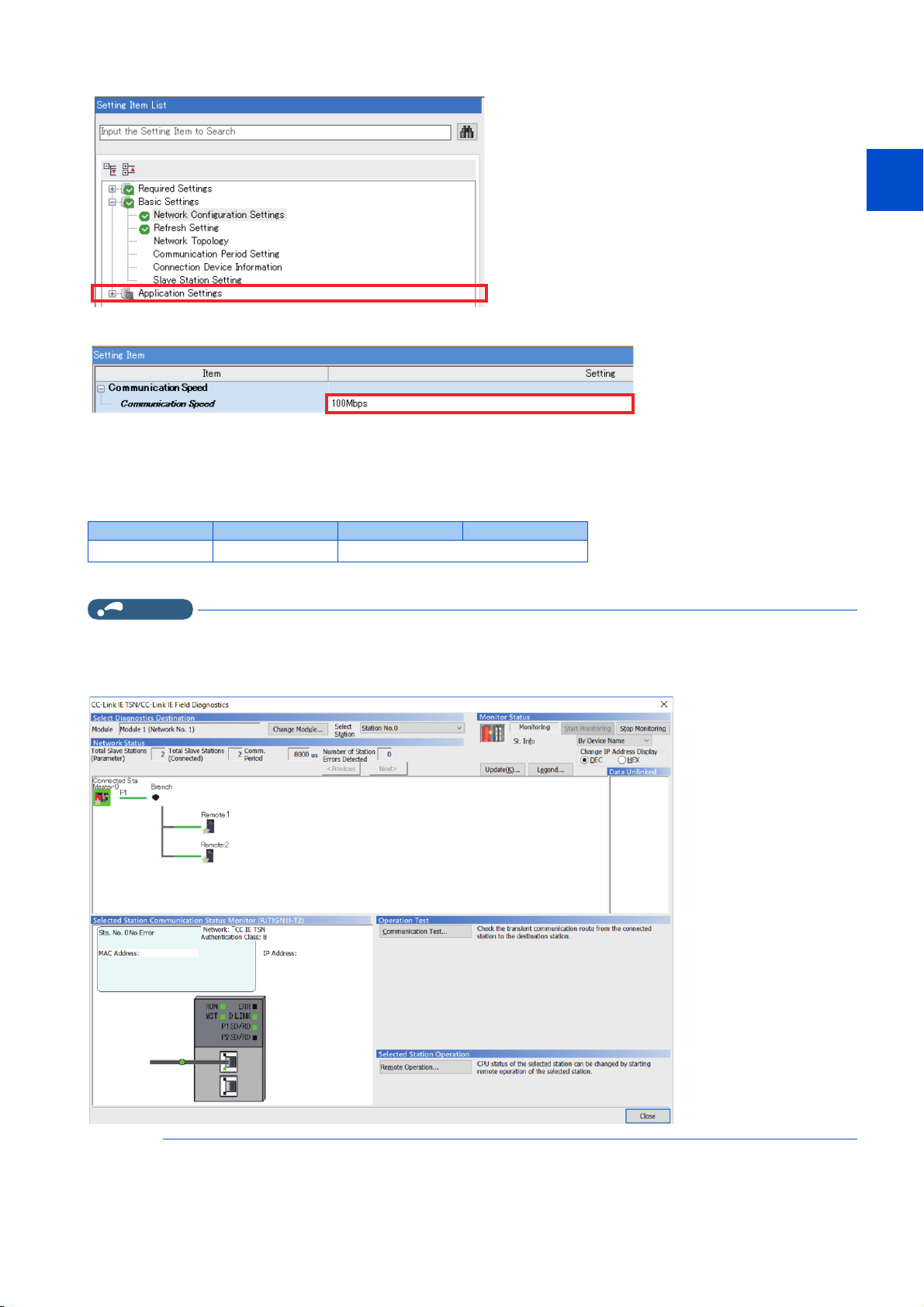

Checking communication

The following table shows the status of the LEDs when the programmable controller and the inverter are connected

successfully. Check the [CC Link IE TSN / CC Link IE Field Diagnostics] window to confirm that the communication is

established between them.

NS MS LINK1 LINK2

Solid green Solid green

*1 The LED on either LINK1 or LINK2 will blink depending on the port (port 1 or 2) the Ethernet cable is connected to.

NOTE

• If the FR-E800-(SC)E cannot be detected, on the menu bar select [Diagnostics (D)] → [CC Link IE TSN / CC Link IE Field

Diagnostics]. The "CC Link IE TSN / CC Link IE Field Diagnostics" window will be displayed. Broken or disconnected wires

can be detected.

• The network configuration diagram is displayed in star topology even if the devices are connected in line topology.

Blinking green

*1

6

7

8

9

10

2. Ethernet Communication

2.5 CC-Link IE TSN

25

Page 27

2.5.3 Initial setting for CC-Link IE TSN

NOTE

Use the following parameters to perform required settings for Ethernet communication between the inverter and other devices.

To make communication between other devices and the inverter, perform the initial settings of the inverter parameters to match

the communication specifications of the devices. Data communication cannot be made if the initial settings are not made or if

there is any setting error.

Pr. Name

1427

N630

1428

N631

1429

N632

1430

N633

Ethernet function

*1

selection 1

Ethernet function

*1

selection 2

Ethernet function

*1

selection 3

Ethernet function

*1

selection 4

*1 The setting is applied after an inverter reset or next power-ON.

*2 The setting is available only for the FR-E800-EPA and the FR-E800-SCEPA.

*3 The setting is available only for the FR-E800-EPB and the FR-E800-SCEPB.

Initial

value

5001

45237

45238

9999

Setting range Description

502, 5000 to 5002, 5006

to 5008, 5010 to 5013,

9999, 34962

45237, 45238, 47808

61450

*3

, 44818*2,

Set the application, protocol, etc.

*2

,

Ethernet function selection (Pr.1427 to Pr.1430)

To select CC-Link IE TSN for the application, set "45238" (CC-Link IE TSN) in any of Pr.1427 to Pr.1430 Ethernet function

selection 1 to 4. In the initial status, Pr.1429 = "45238" (CC-Link IE TSN) and setting is not required.

• Change the setting if selected communication protocols cannot be used together. (Refer to page 7 and page 173.)

2. Ethernet Communication

26

2.5 CC-Link IE TSN

Page 28

2.5.4 Parameters related to CC-Link IE TSN

The following parameters are used for CC-Link IE TSN communication. Set the parameters as required.

Pr. Name Initial value Setting range Description

541

N100

544

*1

N103

1426

*1

N641

1442

*1

N660

1443

*1

N661

1444

*1

N662

1445

*1

N663

1446

*1

N664

1447

*1

N665

1448

*1

N666

1320 to

1329

N810 to

*1

N819

1330 to

1343

N850 to

*1

N863

804

D400

810

H700

Frequency command sign

selection

CC-Link extended setting 0

Link speed and duplex mode

selection

IP filter address 1 (Ethernet) 0

IP filter address 2 (Ethernet) 0

IP filter address 3 (Ethernet) 0

IP filter address 4 (Ethernet) 0

IP filter address 2 range

specification (Ethernet)

IP filter address 3 range

specification (Ethernet)

IP filter address 4 range

specification (Ethernet)

User Defined Cyclic

Communication Input 1 to 10

Mapping

User Defined Cyclic

Communication Output 1 to 14

Mapping

Torque command source

selection

Torque limit input method

selection

*1 The setting is applied after an inverter reset or next power-ON.

*2 The setting is available only for the FR-E800-EPB and the FR-E800-SCEPB.

0

0 0 to 4

9999

9999

9999

9999

9999

0 0, 1, 3 to 6

0 0 to 2 The torque limit input method can be selected.

0 Signed frequency command value

1 Unsigned frequency command value

0, 1, 12, 14, 18, 38,

100, 112, 114, 118,

138

0 to 255

0 to 255, 9999

*2

, 100*2, 12288 to

5

13787, 20488,

20489

9999 Function disabled

*2

, 101*2, 12288 to

6

13787, 16384 to

16483, 20488,

20489, 20981 to

20990

9999 Function disabled

Use this parameter to extend the function of the remote

registers for the CC-Link IE TSN.

Set the communication speed and the communication

mode (full-duplex/half-duplex).

Set the range of connectable IP addresses for the

network devices. (When Pr.1442 to Pr.1445 = "0 (initial

value)", the function is invalid.)

Set the index number for inverter parameters and

inverter control parameters. Functions can be assigned

to remote registers RWwn+4 to RWwn+17 when Pr.544

= "38".

Set the index number for inverter parameters, monitor

data, and inverter control parameters. Functions can be

assigned to remote registers RWrn+4 to RWrn+1F when

Pr.544 = "38".

In the torque control mode, the torque command source

can be selected.

1

2

3

4

5

6

7

8

9

10

Precautions for CC-Link IE TSN communication

• For CC-Link IE TSN, do not change initial values of Pr.1449 to Pr.1454 used to specify the Ethernet IP address range for

command source selection as the IP address is not used. Setting a value other than the initial value in any of the above

parameters may cause an Ethernet communication fault (E.EHR). If the fault occurs, reset the setting of the relevant

parameter to the initial value, or set "9999" in Pr.1432 Ethernet communication check time interval.

CC-Link extended setting (Pr.544)

• Use this parameter to select the function of the remote registers for the CC-Link IE TSN.

Pr.544 setting Description

0 (initial value), 1, 12, 14, 18 Compatible with the octuple setting of CC-Link Ver.2

38

100, 112, 114, 118 Compatible with the octuple setting of CC-Link Ver.2

138

*1 Refer to the PLC Function Programming Manual.

Compatible with the octuple setting of CC-Link Ver.2, user defined cyclic

communication data selected

Compatible with the octuple setting of CC-Link Ver.2,

user defined cyclic communication data selected

PLC function

*1

2. Ethernet Communication

2.5 CC-Link IE TSN

27

Page 29

Frequency command with sign (Pr.541)

NOTE

• The start command (forward/reverse rotation) can be inverted by adding a plus or minus sign to the value of the frequency

command sent through the CC-Link IE TSN.

•The Pr.541 Frequency command sign selection setting is applied to the frequency command from RWw1. (Refer to

page 35.)

Rotations per minute

(machine speed) setting

using Pr.37 and Pr.53

Disabled

Pr.541

setting

Sign Setting range Actual frequency command

0 Without 0 to 59000 0 to 590.00 Hz

1 With -32768 to 32767 (two's complement) -327.68 to 327.67 Hz

0 Without 0 to 65535 The rotation speed command or the machine

Enabled

1 With -32768 to 32767 (two's complement)

• Relationship between the start command and sign (Pr.541 = "1")

Start

command

Forward

rotation

Reverse

rotation

Sign of the frequency

command

Actual operation

command

+ Forward rotation

- Reverse rotation

+ Reverse rotation

- Forward rotation

• When Pr.541 = "1" (with sign)

• When EEPROM write is specified by turning ON of RYE, write mode error (error code H01) will occur.

• When both RYD and RYE are turned ON, RYD has precedence.

• When power is turned ON (inverter reset), the initial setting status of the sign bit is "positive" and the set frequency is 0 Hz.

(The motor does not operate at the frequency set before turning OFF the power (inverter reset).)

• When set frequency is written with the instruction code of HED or HEE, the sign of the frequency command is not changed.

speed command is selected depending on the

Pr.37 and Pr.53 settings. (1 increments)

I/O signal list

When Pr.544 = "0, 1, 12, 14, or 18"

• Remote I/O signals

Device No.

RYn0

RYn1

RYn2

RYn3

RYn4

RYn5

RYn6

RYn7

RYn8

RYn9

RYnA

RYnB

*7

Signal

Forward rotation command

Reverse rotation command

High-speed operation command

(terminal RH function)

*1

Middle-speed operation command

(terminal RM function)

*1

Low-speed operation command

(terminal RL function)

JOG operation selection 2

Second function selection

Current input selection

*1

*2

*2

*2

Pr.185 assignment function (NET X1)

Output stop (terminal MRS function)

Pr.186 assignment function (NET X2)

Pr.184 assignment function (RES)

*2

*2

RYnC Monitor command 33 RXnC Monitoring 34

RYnD Frequency setting command (RAM) 33 RXnD Frequency setting completion (RAM) 34

RYnE

Frequency setting command (RAM,

EEPROM)

RYnF Instruction code execution request 33 RXnF Instruction code execution completed 34

Refer to

page

Device No.

*7

Signal

32 RXn0 Forward running 34

32 RXn1 Reverse running 34

33 RXn2

33 RXn3

33 RXn4

33 RXn5

33 RXn6

33 RXn7

*5

33 RXn8

*1

33 RXn9

*5

33 RXnA

*5

33 RXnB

33 RXnE

Running (terminal RUN function)

Up to frequency

Overload warning

*2

*2

Pr.193 assignment function (NET Y1)

Frequency detection (terminal FU

function)

*3

Fault (terminal ABC function)

Pr.194 assignment function (NET Y2)

Pr.313 assignment function (DO0)

Pr.314 assignment function (DO1)

Pr.315 assignment function (DO2)

Frequency setting completion (RAM,

EEPROM)

*3

*6

*3

*6

*4

*4

*4

Refer to

page

34

34

34

34

34

34

34

34

34

34

34

2. Ethernet Communication

28

2.5 CC-Link IE TSN

Page 30

Device No.

RY(n+1)0 to

RY(n+1)7

RY(n+1)8

RY(n+1)9

RY(n+1)A Error reset request flag 33 RX(n+1)A Error status flag 34

RY(n+1)B

RY(n+1)C

RY(n+1)D

RY(n+1)E

RY(n+1)F RX(n+1)F

*7

Reserved —

Not used (initial data process

completion flag)

Not used (initial data process request

flag)

Pr.187 assignment function (NET X3)

Pr.188 assignment function (NET X4)

Pr.189 assignment function (NET X5)

Reserved —

*1 These signals are set in the initial setting. Using Pr.180 to Pr.183, input signals assigned to the device numbers can be changed.

For details of Pr.180 to Pr.183, refer to the FR-E800 Instruction Manual (Function).

*2 The signals are fixed. They cannot be changed using parameters.

*3 These signals are set in the initial setting. Using Pr.190 to Pr.192, output signals assigned to the device numbers can be changed.

For details of Pr.190 to Pr.192, refer to the FR-E800 Instruction Manual (Function).

*4 Output signals can be assigned using Pr.313 to Pr.315.

For details, refer to the description of Pr.190 to Pr.196 (Output terminal function selection) in the FR-E800 Instruction Manual (Function).

*5 Input signals can be assigned using Pr.184 to Pr.189.

For details, refer to the description of Pr.184 to Pr.189 (Input terminal function selection) in the FR-E800 Instruction Manual (Function).

*6 Output signals can be assigned using Pr.193 to Pr.196.

For details, refer to the description of Pr.193 to Pr.196 (Output terminal function selection) in the FR-E800 Instruction Manual (Function).

*7 "n" indicates a value determined by the station number.

Signal

Refer to

page

— RX(n+1)8

— RX(n+1)9

*5

33 RX(n+1)B Remote station ready 34

*5

33 RX(n+1)C

*5

33 RX(n+1)D

Device No.

RX(n+1)0 to

RX(n+1)5

RX(n+1)6

RX(n+1)7

RX(n+1)E

*7

Reserved —

Pr.195 assignment function (NET Y3)

Pr.196 assignment function (NET Y4)

Not used (initial data process request

flag)

Not used (initial data process

completion flag)

In-position

During position command operation

Home position return completed

Home position return failure

Signal

*2

*2

*2

*6

34

*6

34

—

—

34

*2

34

34

34

• Remote registers

Refer to

page

1

2

3

4

5

6

7

8

Address

RWwn Monitor code 2 Monitor code 1 34 RWrn

RWwn+1

RWwn+2

RWwn+3 Data to be written 35 RWrn+3 Data to be read 36

RWwn+4 Monitor code 3 35 RWrn+4

RWwn+5 Monitor code 4 35 RWrn+5

RWwn+6 Monitor code 5 35 RWrn+6

RWwn+7 Monitor code 6 35 RWrn+7

RWwn+8 Fault history No. H00

RWwn+9

RWwn+A PID measured value (0.01%

RWwn+B

RWwn+C Torque command or torque limit 35, 42 RWrn+C Fault record (energization time) 36

RWwn+D

RWwn+F RWrn+F

RWwn+10

RWwn+11 Data to be written 35 RWrn+11 Data to be read 36

RWwn+12

RWwn+13 Data to be written 35 RWrn+13 Data to be read 36

RWwn+14

RWwn+15 Data to be written 35 RWrn+15 Data to be read 36

*5

Upper 8 bits Lower 8 bits Upper 8 bits Lower 8 bits

Set frequency (0.01 Hz increments)

Link parameter

extended setting

PID set point (0.01% increments)

increments)

PID deviation (0.01% increments)

H00 (Free) —

Link parameter

extended setting

Link parameter

extended setting

Link parameter

extended setting

Description

Instruction code 35 RWrn+2 Reply code 2 Reply code 1 36

*1

*1

Instruction code 35 RWrn+10 Reply code 36

Instruction code 35 RWrn+12 Reply code 36

Instruction code 35 RWrn+14 Reply code 36

Refer to

page

*2

35 RWrn+1

35

35

35

*1

35 RWrn+B Fault record (output voltage) 36

Address

RWrn+8 Fault history No. Fault record (fault

RWrn+9

RWrn+A Fault record (output current)

RWrn+D

*5

First monitor value

Second monitor value

Third monitor value

Fourth monitor value

Fifth monitor value

Sixth monitor value

Fault record (output frequency)

H00 (Free) —RWwn+E RWrn+E

Description

*3

*3

*3

*3

*3

*3

data)

36

36

36

36

36

36

36

*4

36

36

Refer to

page

9

10

2. Ethernet Communication

2.5 CC-Link IE TSN

29

Page 31

Address

RWwn+16

*5

Description

Upper 8 bits Lower 8 bits Upper 8 bits Lower 8 bits

Link parameter

extended setting

Instruction code 35 RWrn+16 Reply code 36

Refer to

page

Address

*5

Description

RWwn+17 Data to be written 35 RWrn+17 Data to be read 36

RWwn+18

Link parameter

extended setting

Instruction code 35 RWrn+18 Reply code 36

RWwn+19 Data to be written 35 RWrn+19 Data to be read 36

RWwn+1A

RWrn+1A

RWwn+1B RWrn+1B

RWwn+1C RWrn+1C

RWwn+1D RWrn+1D

H00 (Free) —

H00 (Free) —

RWwn+1E RWrn+1E

RWwn+1F RWrn+1F

*1 When Pr.128 = "50, 51, 60, or 61", the register is valid. When Pr.128 = "1000 to 2011", the register is valid depending on the setting in Pr.609 or

Pr.610.

*2 The display can be changed to rotations per minute (machine speed) using Pr.37 and Pr.53.

*3 When the item displayed in frequency is selected, the Pr.37 and Pr.53 settings are invalid.

*4 The frequency is always displayed regardless of the settings in Pr.37 and Pr.53.

*5 "n" indicates a value determined by the station number.

When Pr.544 = "38" (user defined cyclic communication data selection)

• Remote I/O signals

Refer to

page

Device No.

RYn0

RYn1

RYn2

RYn3

RYn4

RYn5

RYn6

RYn7

RYn8

RYn9

RYnA

RYnB

*7

Signal

Forward rotation command

Reverse rotation command

High-speed operation command

(terminal RH function)

*1

Middle-speed operation command

(terminal RM function)

*1

Low-speed operation command

(terminal RL function)

JOG operation selection 2

Second function selection

Current input selection

*1

*2

*2

*2

Pr.185 assignment function (NET X1)

Output stop (terminal MRS function)

Pr.186 assignment function (NET X2)

Pr.184 assignment function (RES)

*2

*2

Refer to

page

Device No.

*7

Signal

32 RXn0 Forward running 34

32 RXn1 Reverse running 34

33 RXn2

33 RXn3

33 RXn4

33 RXn5

33 RXn6

33 RXn7

*5

33 RXn8

*1

33 RXn9

*5

33 RXnA

*5

33 RXnB

Running (terminal RUN function)

Up to frequency

Overload warning

*2

*2

Pr.193 assignment function (NET Y1)

Frequency detection (terminal FU

function)

*3

Fault (terminal ABC function)

Pr.194 assignment function (NET Y2)

Pr.313 assignment function (DO0)

Pr.314 assignment function (DO1)

Pr.315 assignment function (DO2)

*3

34

34

34

*6

34

34

*3

34

*6

34

*4

34

*4

34

*4

34

RYnC Monitor command 33 RXnC Monitoring 34

RYnD Frequency setting command (RAM) 33 RXnD Frequency setting completion (RAM) 34

RYnE

Frequency setting command (RAM,

EEPROM)

33 RXnE

Frequency setting completion (RAM,

EEPROM)

34

RYnF Instruction code execution request 33 RXnF Instruction code execution completed 34

RY(n+1)0 to

RY(n+1)7

RY(n+1)8

RY(n+1)9

Reserved —

Not used (initial data process

completion flag)

Not used (initial data process request

flag)

RX(n+1)0 to

RX(n+1)5

RX(n+1)6

RX(n+1)7

— RX(n+1)8

— RX(n+1)9

Reserved —

Pr.195 assignment function (NET Y3)

Pr.196 assignment function (NET Y4)

*6

*6

Not used (initial data process request

flag)

Not used (initial data process

completion flag)

34

34

—

—

RY(n+1)A Error reset request flag 33 RX(n+1)A Error status flag 34

RY(n+1)B

RY(n+1)C

RY(n+1)D

RY(n+1)E

Pr.187 assignment function (NET X3)

Pr.188 assignment function (NET X4)

Pr.189 assignment function (NET X5)

User defined cyclic communication

input writing request

*5

33 RX(n+1)B Remote station ready 34

*5

33 RX(n+1)C

*5

33 RX(n+1)D

33 RX(n+1)E

In-position

During position command operation

Home position return completed

*2

*2

34

*2

34

34

Refer to

page

2. Ethernet Communication

30

2.5 CC-Link IE TSN

Page 32

Device No.

RY(n+1)F Reserved — RX(n+1)F

*7

*1 The signal initially assigned to the terminal. Using Pr.180 to Pr.183, input signals assigned to the device numbers can be changed.

For details of Pr.180 to Pr.183, refer to the FR-E800 Instruction Manual (Function).

*2 The signals are fixed. They cannot be changed using parameters.

*3 These signals are set in the initial setting. Using Pr.190 to Pr.192, output signals assigned to the device numbers can be changed.

For details of Pr.190 to Pr.192, refer to the FR-E800 Instruction Manual (Function).

*4 Output signals can be assigned using Pr.313 to Pr.315.

For details, refer to the description of Pr.190 to Pr.196 (Output terminal function selection) in the FR-E800 Instruction Manual (Function).

*5 Input signals can be assigned using Pr.184 to Pr.189.

For details, refer to the description of Pr.184 to Pr.189 (Input terminal function selection) in the FR-E800 Instruction Manual (Function).

*6 Output signals can be assigned using Pr.193 to Pr.196.

For details, refer to the description of Pr.193 to Pr.196 (Output terminal function selection) in the FR-E800 Instruction Manual (Function).

*7 "n" indicates a value determined by the station number.

Signal

Refer to

page

Device No.

• Remote registers

*7

Home position return failure

Signal

Refer to

page

*2

34

1

2

3

4

Address

RWwn Monitor code 2 Monitor code 1 35 RWrn

RWwn+1

RWwn+2

RWwn+3 Data to be written 36 RWrn+3 Data to be read 37

RWwn+4

RWwn+5

RWwn+6

RWwn+7

RWwn+8

RWwn+9

RWwn+A

RWwn+B

RWwn+C

RWwn+D

RWwn+E

RWwn+F

RWwn+10

RWwn+11

*3

Upper 8 bits Lower 8 bits Upper 8 bits Lower 8 bits

Set frequency (0.01 Hz increments)

Link parameter

extended setting

User Defined Cyclic Communication

Input 1 Mapping (Pr.1320), lower 16 bits

User Defined Cyclic Communication

Input 1 Mapping (Pr.1320), upper 16

bits

User Defined Cyclic Communication

Input 2 Mapping (Pr.1321), lower 16 bits

User Defined Cyclic Communication

Input 2 Mapping (Pr.1321), upper 16

bits

User Defined Cyclic Communication

Input 3 Mapping (Pr.1322), lower 16 bits

User Defined Cyclic Communication

Input 3 Mapping (Pr.1322), upper 16

bits

User Defined Cyclic Communication

Input 4 Mapping (Pr.1323), lower 16 bits

User Defined Cyclic Communication

Input 4 Mapping (Pr.1323), upper 16

bits

User Defined Cyclic Communication

Input 5 Mapping (Pr.1324), lower 16 bits

User Defined Cyclic Communication

Input 5 Mapping (Pr.1324), upper 16

bits

User Defined Cyclic Communication

Input 6 Mapping (Pr.1325), lower 16 bits

User Defined Cyclic Communication

Input 6 Mapping (Pr.1325), upper 16

bits

User Defined Cyclic Communication

Input 7 Mapping (Pr.1326), lower 16 bits

User Defined Cyclic Communication

Input 7 Mapping (Pr.1326), upper 16

bits

Description

Instruction code 36 RWrn+2 Reply code 2 Reply code 1 37

Refer to

page

*1

36 RWrn+1

36 RWrn+4

36 RWrn+5

36 RWrn+6

36 RWrn+7

36 RWrn+8

36 RWrn+9

36 RWrn+A

36 RWrn+B

36 RWrn+C

36 RWrn+D

36 RWrn+E

36 RWrn+F

36 RWrn+10

36 RWrn+11

Address

*3

First monitor value

Second monitor value

User Defined Cyclic Communication

Output 1 Mapping (Pr.1330), lower 16

bits

User Defined Cyclic Communication

Output 1 Mapping (Pr.1330), upper 16

bits

User Defined Cyclic Communication

Output 2 Mapping (Pr.1331), lower 16

bits

User Defined Cyclic Communication

Output 2 Mapping (Pr.1331), upper 16

bits

User Defined Cyclic Communication

Output 3 Mapping (Pr.1332), lower 16

bits

User Defined Cyclic Communication

Output 3 Mapping (Pr.1332), upper 16

bits

User Defined Cyclic Communication

Output 4 Mapping (Pr.1333)

bits

User Defined Cyclic Communication

Output 4 Mapping (Pr.1333), upper 16

bits

User Defined Cyclic Communication

Output 5 Mapping (Pr.1334), lower 16

bits

User Defined Cyclic Communication

Output 5 Mapping (Pr.1334), upper 16

bits

User Defined Cyclic Communication

Output 6 Mapping (Pr.1335), lower 16

bits

User Defined Cyclic Communication

Output 6 Mapping (Pr.1335), upper 16

bits

User Defined Cyclic Communication

Output 7 Mapping (Pr.1336), lower 16

bits

User Defined Cyclic Communication

Output 7 Mapping (Pr.1336), upper 16

bits

Description

*2

*2

, lower 16

37

37

37

37

37

37

37

37

37

37

37

37

37

37

37

37

Refer to

page

5

6

7

8

9

10

2. Ethernet Communication

2.5 CC-Link IE TSN

31

Page 33

Address

RWwn+12

RWwn+13

RWwn+14

RWwn+15

RWwn+16

RWwn+17

RWwn+18

RWwn+19 RWrn+19

RWwn+1A RWrn+1A

RWwn+1B RWrn+1B

RWwn+1C RWrn+1C

RWwn+1D RWrn+1D

RWwn+1E RWrn+1E

RWwn+1F RWrn+1F

*3

Upper 8 bits Lower 8 bits Upper 8 bits Lower 8 bits

User Defined Cyclic Communication

Input 8 Mapping (Pr.1327), lower 16 bits

User Defined Cyclic Communication

Input 8 Mapping (Pr.1327), upper 16

bits

User Defined Cyclic Communication

Input 9 Mapping (Pr.1328), lower 16 bits

User Defined Cyclic Communication

Input 9 Mapping (Pr.1328), upper 16

bits

User Defined Cyclic Communication

Input 10 Mapping (Pr.1329), lower 16

bits

User Defined Cyclic Communication

Input 10 Mapping (Pr.1329), upper 16

bits

H00 (Free) —

*1 The display can be changed to rotations per minute (machine speed) using Pr.37 and Pr.53.

*2 When the item displayed in frequency is selected, the Pr.37 and Pr.53 settings are invalid.

*3 "n" indicates a value determined by the station number.

Description

Refer to

page

36 RWrn+12

36 RWrn+13

36 RWrn+14

36 RWrn+15

36 RWrn+16

36 RWrn+17

Address

RWrn+18

*3

User Defined Cyclic Communication

Output 8 Mapping (Pr.1337), lower 16

bits

User Defined Cyclic Communication

Output 8 Mapping (Pr.1337), upper 16

bits

User Defined Cyclic Communication

Output 9 Mapping (Pr.1338), lower 16

bits

User Defined Cyclic Communication

Output 9 Mapping (Pr.1338), upper 16

bits

User Defined Cyclic Communication

Output 10 Mapping (Pr.1339), lower 16

bits

User Defined Cyclic Communication

Output 10 Mapping (Pr.1339), upper 16

bits

User Defined Cyclic Communication

Output 11 Mapping (Pr.1340), lower 16

bits

User Defined Cyclic Communication

Output 11 Mapping (Pr.1340), upper 16

bits

User Defined Cyclic Communication

Output 12 Mapping (Pr.1341)

bits

User Defined Cyclic Communication

Output 12 Mapping (Pr.1341), upper 16

bits

User Defined Cyclic Communication

Output 13 Mapping (Pr.1342), lower 16

bits

User Defined Cyclic Communication

Output 13 Mapping (Pr.1342), upper 16

bits

User Defined Cyclic Communication

Output 14 Mapping (Pr.1343), lower 16

bits

User Defined Cyclic Communication

Output 14 Mapping (Pr.1343), upper 16

bits

Description

, lower 16

Refer to

page

37

37

37

37

37

37

37

37

37

37

37

37

37

37

Details of the I/O signals

The device numbers described in this section are for the station number 1. For the station number 2 and later, the device

numbers are different. (Refer to the manual for the CC-Link master module for the correspondence between device numbers

and station numbers.)

Output signals (from the master module to the inverter)

Output signals from the master module are as follows. (Input signals to the inverter)

Device No. Signal Description

0: Stop

RY0

RY1

2. Ethernet Communication

32

2.5 CC-Link IE TSN

Forward rotation command

Reverse rotation command

*2

*2

command

1: Forward

rotation start

0: Stop

command

1: Reverse

rotation start

When "1" is set, a start command is input to the inverter.

When "1" is set in RY0 and RY1, a stop command is input.

Page 34

Device No. Signal Description

RY2

RY4

RY5

RY6

RY7

RY8

RY9

RYA

RYB

RYC Monitor command

RYD

RYE

RYF Instruction code execution request

RY1A Error reset request flag

RY1B

RY1D

RY1E

*1 These signals are set in the initial setting. Using Pr.180 to Pr.183, input signals assigned to the device numbers can be changed. Some signals

*2 The signals are fixed. They cannot be changed using parameters.

*3 No signal is assigned in the initial setting. Use Pr.184 to Pr.189 to assign signals to RY8, RYA, RYB, and RY1B to RY1D.

*4 While "1" is set in the frequency setting command (RYD), the set frequency (RWw1) is always applied.

*5 Refer to page 217 for operation conditions of inverter reset.

*6 Torque control cannot be performed with a PM motor.

High-speed operation command (terminal

RH function)

Middle-speed operation command

(terminal RM function)

Low-speed operation command (terminal

RL function)

JOG operation selection 2

Second function selection

Current input selection

— (terminal NET X1 function)

Output stop (terminal MRS function)