Page 1

INVERTER

1

2

3

4

5

6

7

8

9

10

FR-E700

INSTRUCTION MANUAL (BASIC)

FR-E720-0.1KSC to 15KSC

FR-E740-0.4KSC to 15KSC

FR-E720S-0.1KSC to 2.2KSC

Thank you for choosing this Mitsubishi Inverter.

This Instruction Manual (B asic) provides handling information and precautions for use of the equipment.

Please forward this Instru ction Manual (Basic) to the e nd user.

CONTENTS

OUTLINE ...................................................................................1

INSTALLATION AND WIRING ...................................................6

PRECAUTIONS FOR USE OF THE INVERTER.........................20

FAILSAFE OF THE SYSTEM WHICH USES THE INVERTER ...22

DRIVING THE MOTOR.............................................................23

ENERGY SAVING OPERATION FOR FANS AND PUMPS ........33

PARAMETERS .........................................................................34

TROUBLESHOOTING ..............................................................39

PRECAUTIONS FOR MAINTENANCE AND INSPECTION ........44

SPECIFICATIONS....................................................................46

To obtain the Instruction Manual (Applied) and the

Safety stop function instruction manual

Contact where you purchased the inverter, your Mitsubishi sales

representative, or the nearest Mitsubishi FA Center for the following

manual:

Instruction Manual (Applied) [IB(NA)-0600277ENG]

Safety stop function instruction manual [BCN-A211508-004]

These manuals are required if you are going to utilize functions and

performance.

The PDF versions of these manuals are also available for download at

"MELFANS Web," the Mitsubishi Electric FA network service on the

world wide web (URL: http://www.MitsubishiElectric.co.jp/melfansweb).

700

1

2

3

4

5

6

7

8

9

10

Page 2

This Instruction Manual (Basic) provides handling information and precautions for use of the equipment.

WARNIN G

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

Please forward this Instruction Manual (Basic) to the end user.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect th e

inverter until you have read through the Inst ruction Manual

(Basic) and appended documents carefully and can use the

equipment correctly. Do not use this product until you have

a full knowledge of the equipment, safety information and

instructions.

In this Instruction Manual (Basic), the safety instruction

levels are classified into "WARNING" and "CAUTION".

Incorrect handling m ay cause

hazardous conditions, resulting in

death or severe injur y.

Incorrect handling m ay cause

hazardous conditions, resulting in

medium or slight injury, or may cause

only material damage.

The level may even lead to a se rious

consequence according to conditions. Both instruction

levels must be followed because these are important to

personal safety.

1. Electric Shock Prevention

While power is ON or when the inverter is running, do not

open the front cover. Otherwise you may g et an electric

shock.

Do not run the inverter with the front cover or wiring cover

removed. Otherwis e you may access the exposed highvoltage terminals or t he charging part of the ci rcuitry and

get an electric shock.

Even if power is OFF, do not remove the front cover

except for wiring or periodic inspection. You may

accidentally touch the charged inverter circuits and get an

electric shock.

Before wiring or inspect ion, power must be sw itched OFF.

To confirm that, LED indication of the operation panel

must be checked. (It must be OFF.) Any person who is

involved in wiring o r inspection shall wait for at least 10

minutes after the power supply has been switched OFF

and check that there are n o residual voltage using a tester

or the like. The capacitor is charged with high voltage for

some time after power OFF, and it is dangerous.

This inverter must be earthed (grounded). Earthing

(grounding) must conform to the requirements of national

and local safety regulations and electrical code (NEC section

250, IEC 536 class 1 and other applicab le standards).

A neutral-point earthed (grounded) power supply for 400V

class inverter in compliance with EN standard must be used.

Any person who is involved in wiring or inspection of this

equipment shall be f ully competent to do the work.

The inverter must be installed before wiring. Otherwise

you may get an elect ric shock or be injured.

Setting dial and key operations must be performed with

dry hands to prevent an electric shock.

Do not subject the c ables to scratches, excess ive stress,

heavy loads or pinchi ng. Otherwise you may get an

electric shock.

Do not change the cooling f an while power is ON. It is

dangerous to change the cooling fan while power is ON.

Do not touch the printed circuit board or handle the

cables with wet hands. Otherwise you may get an electric

shock.

When measuring th e main circuit capacitor ca pacity, the

DC voltage is applied to the motor for 1s at powering OFF.

Never touch the motor terminal, etc. right after powerin g

OFF to prevent an e lectric shock.

2. Fire Prevention

Inverter must be installed on a nonflammable wall without

holes (so that nobody touches the inverter heatsink on the

rear side, etc.). Mounting it to or near flammable material

can cause a fire.

If the inverter has become faulty, the inverter power must

be switched OFF. A continuous flow of large current could

cause a fire.

When using a brake res istor, a sequence that will turn OFF

power when a fault signal is output must be configured.

Otherwise the brak e resistor may overheat due to damage

of the brake transi stor and possibly cause a fire.

Do not connect a resistor directly to the DC terminals P/+

and N/-. Doing so could cause a fire.

3.Injury Prevention

The voltage applied to each terminal must be the ones

specified in the Instruction Manual. Otherwise burst,

damage, etc. may occur.

The cables must be co nnected to the correct terminals.

Otherwise burst, dam age, etc. may occur.

Polarity must be cor rect. Otherwise burst, damage, etc.

may occur.

While power is ON or for some time after power-OFF, do

not touch the inver ter as they will be extremely hot. Doing

so can cause burns.

4. Additional Instructions

Also the following points must be noted to prevent an

accidental failure, injury, electric shoc k, etc.

(1) Transportation and Mounting

The product must be transported in correct method that

corresponds to the weight. Failure to do so may lead to

injuries.

Do not stack the boxes c ontaining inverters higher th an

the number recommended.

The product must be installed to the position where

withstands the weight of the product according to the

information in the Instruction Manual.

Do not install or operate the inverter if it is damaged or

has parts missing.

When carrying the inverter, do not hold it by the front

cover or setting dial; it may fall off or fail.

Do not stand or rest heavy objects on the product.

The inverter mounting orientation must be correct.

Foreign conductive objects must be prevented from

entering the inverter. That includes screws and metal

fragments or other flammable substance such as oil.

As the inverter is a precision instrument, do not drop or

subject it to impact.

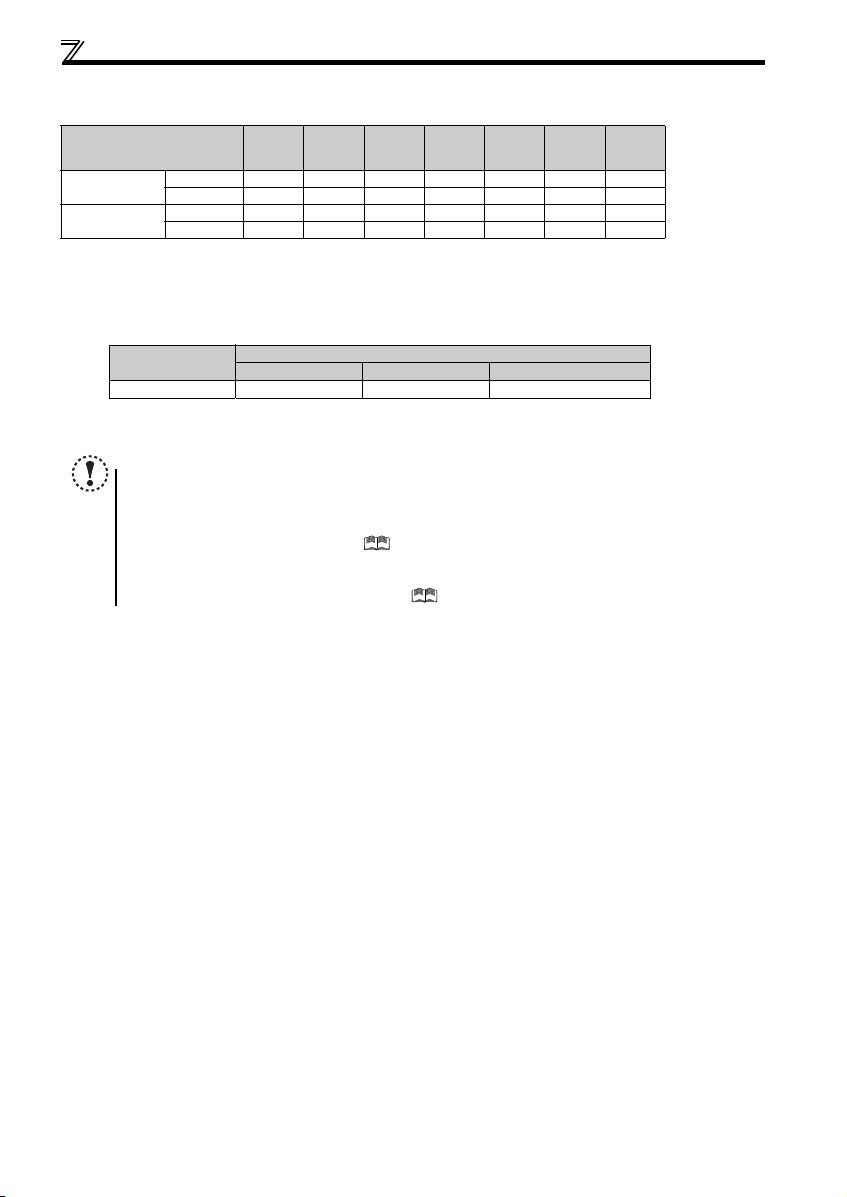

The inverter must be used under the following

environment. Other wise the inverter may be damaged.

Surroundi ng

air

temperature

Ambient

humidity

Storage

temperature

Atmosphere

Environment

Altitude/

vibration

1 Temperature appl icable for a short time, e.g . in transit.

-10°C to +50°C (non-freezing)

90%RH or less (non-condensing)

-20°C to +65°C *1

Indoors (free from corrosi ve gas, flammable gas,

oil mist, dust and dirt)

Maximum 1,000m above sea level.

2

5.9m/s

or less at 10 to 55Hz (directions of X, Y, Z

axes)

A-1

Page 3

(2) Wiring

CAUTION

CAUTION

WARNING

CAUTION

CAUTION

CAUTION

CAUTION

(5) Emergency stop

Do not install a power factor correction capacitor or sur ge

suppressor/capacitor type filter on the inverter output

side. These devices on the inverter output side may be

overheated or burn out.

The connection orientation of the output cables U, V, W to

the motor affects the rotation direction of the motor.

(3) Trial run

Be fore starting operation, each parameter must be

confirmed and adjusted. A failu re to do so may cause

some machines to make unexpected motions.

(4) Usage

An y person must stay away from the equipment wh en the

retry function is set as it will restart suddenly after trip.

S ince pressing key may not stop output dependin g

on the function setting status, separate circ uit and switch

that make an emerg ency stop (power OFF, mechanical

brake operation for emer gency stop, etc.) must be

provided.

OFF status of the start signal must be confirmed before

resetting the inv erter fault. Resettin g inverter alarm wit h

the start signal ON restarts the motor suddenly.

The inverter mu st be used for thre e-phase induction motors.

Connection of any other electrical equipment to the

inverter output may damage the equipment.

Do not modify the equipment.

Do not perform parts removal which is not in structed in this

manual. Doing so may lead to fault or damage of the product.

The electronic thermal relay function does not guarantee

protection of the motor from overheating. It is

recommended to install bo th an external thermal and P TC

thermistor for overh eat protection.

Do not use a magnetic contactor on the inverter input for

frequent starting/stopping of the inverter. Otherwise the

life of the inverter decreases.

T he effect of electrom agnetic interference m ust be

reduced by using a noise filter or by other means.

Otherwise nearby e lectronic equipment may b e affected.

Appr opriate measures must be taken to suppress

harmonics. Otherwise power supply harmonics from the

inverter may heat/dam age the power factor corr ection

capacitor and generator.

W hen driving a 400V class motor by the i nverter, the

motor must be an insulation-enhanced motor or measures

must be taken to suppress surge voltage. Surge voltage

attributable to the wiring constants may occur at the

motor terminals, deteriorating the insulation of the motor.

W hen parameter clear or a ll parameter clear is pe rformed,

the required paramete rs must be set agai n before starting

operations becau se all parameters return t o the initial value.

The inverter can be easily set for high-speed operation.

Before changing its setting, the performances of the

motor and machine must be fully examined.

Stop status cannot be hold by the inverter's brake

function. In addition to t he inverter’s brake function, a

holding device must be installed to ensure safety.

Be fore running an inverter which had been stored for a long

period, inspection and test operation must be performed.

F or prevention of damage due t o static electricity, nearby

metal must be touched before touching this product to

eliminate static electricity from your body.

A s afety backup such as an em ergency brake must be

provided to prevent hazardous condition to the machine

and equipment in ca se of inverter failure.

W hen the breaker on the inverter input side trips, the

wiring must be checked for fault (short circuit), and

internal parts of the inverter for a damage, etc. The cau se

of the trip must be identified and removed before turning

ON the power of the breaker.

W hen any protective function is activated, ap propriate

corrective action must be taken, and the inverter must be

reset before resuming operation.

(6) Maintenance, inspection and parts replacement

Do not carry out a megger (insulation resistance) test on

the control circuit of the inverter. It will cause a failure.

(7) Disposal

T he inverter must be trea ted as industrial waste.

General instruction

Many of the diagrams and dr awings in this Instruction

Manual (Basic) show the inverter without a cover or partially

open for explanation. Never operate the inverter in this

manner. The cover must be alway s reinstalled and the

instruction in this Instruct ion Manual (Basic) must be

followed when operating the inverter.

A-2

Page 4

<Abbreviation>

PU: Operatio n panel and parameter unit (FR-PU04, FR-PU07)

Inverter: Mitsubishi inverter FR-E700 series safety stop function model

FR-E700: Mitsubishi inverter FR-E700 series safety stop function model

Pr.: Parameter number (Number assigned to function)

PU operation: Operation using the PU (operation panel/FR-PU04/FR-PU07)

External operation: Operation using the control circuit signals

Combined operation : Operation using the PU (FR-PU04/FR-PU07) and external operation

Standard motor : SF-JR

Constant torque motor : SF-HRCA

<Trademark>

LONWORKS® is a registered trademark of Echelon Corporation in the U.S.A and other countries.

Company and product names herein are the trademarks and registered trademarks of their respective owners.

<Mark>

REMARKS: Additional helpful contents and relations with other functions are written.

Note: Contents requiring caution or cases when set functions are not activated are written.

POINT: Useful contents and points are written.

<Related document>

Refer to the Instruction Manual (Applied) for further information on the following points.

Removal and reinstallation of the cover

Connection of stand-alone option unit

EMC and leakage currents

Detailed explanation on parameters

Troubleshooting

Check first when you have a trouble

Inspection items (life diagnosis, cooling fan replacement)

Measurement of main circuit voltages, currents and powers

For customers who are replacing the conventional model with this inverter

A-3

Page 5

1

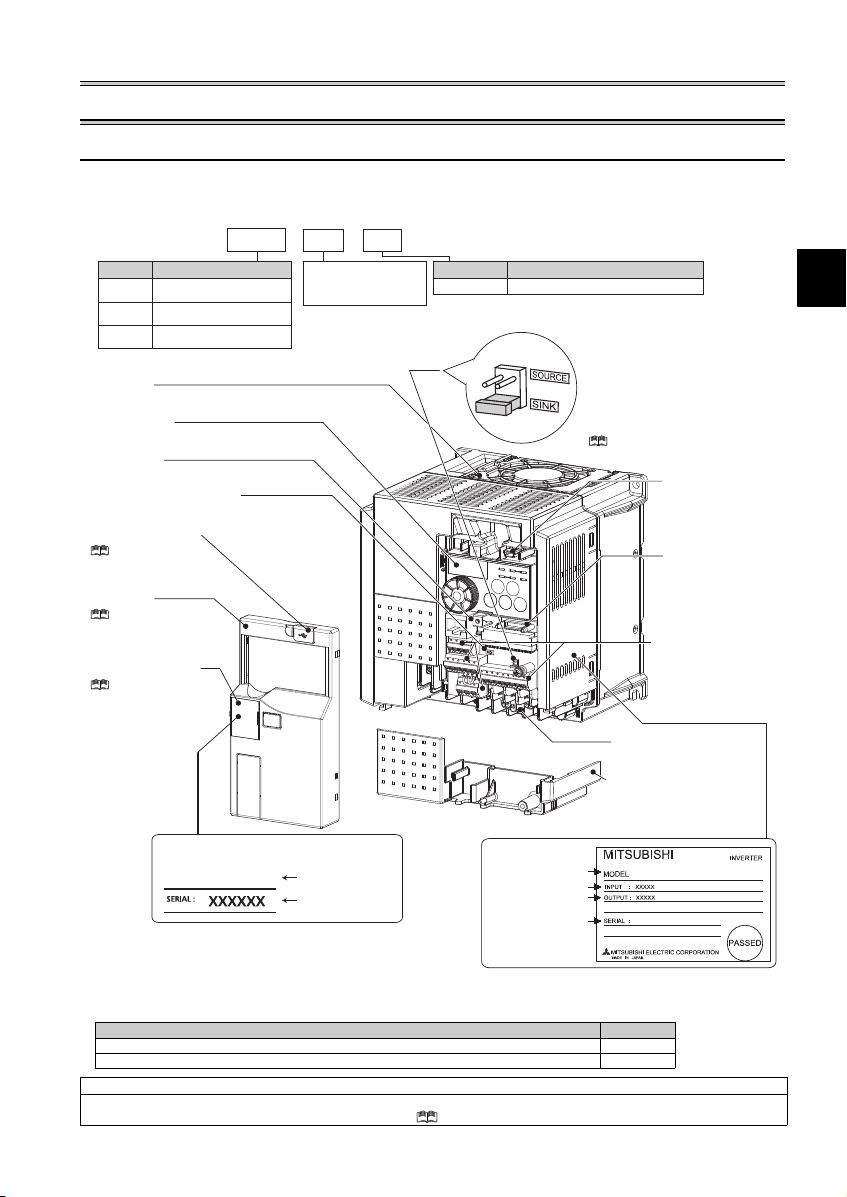

Product checking and parts identification

Cooling fan

The cooling fan is removable.

USB connector

(mini-B conne ctor)

(Refer to page 9)

Control logic switchover jumper

connector

The jumper connector is in the sink logic

(SINK) when shipped from the factory.

Move the jumper connector to change to

the source logic (SOURCE). Always fit the

jumper connector to the either position.

( Refer to the Instruction Manual (Applied))

Combed shaped wiring cover

Refer to the Instruction Manual

(Applied) for installation/removal.

Main circuit terminal block

(Refer to page 10)

PU connector cover

Refer to the

Instruction Manual

(Applied) for how to

open the cover.

Front cover

Refer to the Instruc tion

Manual (Applied) for

installation/removal.

USB connector cover

Refer to the Instruction

Manual (Applied) for how to

open the cover.

Voltage/current input switch

(Refer to page 9)

Operation panel

(Refer to page 2)

PU connector

(Refer to page 9)

Example of FR-E740-3.7KSC

Control circuit terminal

block

(Refer to page 10)

1 OUTLINE

1.1 Product checking and parts identification

Unpack the inverter and check the capacity plate on the front cover and the rating plate on the inverter side face to ensure that

the product agrees with your order and the inverter is intact.

Inverter model

--

No. Voltage class

Three-phase 200V class

E720

Three-phase 400V class

E740

Single-phase 200V class

E720S

E740 3.7 KFR

Represents the

inverter capacity [kW]

SC

Control circuit terminal specificationSymbol

Safety stop function modelSC

Accessory

· Fan cover fixing screws (M3 35mm)

These screws are necessary for compliance with the EU Directive

FR-E720-1.5KSC to 3.7KSC, FR-E740-1.5KSC to 3.7KSC, FR-E720S-0.75KSC to 2.2KSC 1

Harmonic suppression guideline (when inverters are used in Japan)

All models of general -purpose inverters used by specific consumers are covered by "Harmonic suppr ession guideline for cons umers who

receive high voltage or spe cial high voltage". (For furth er details, refer to Chapter 3 of the Instruction Manual (Applied).)

Capacity plate

FR-E740-3.7KSC

Inverter model

Serial number

Rating plate

Inverter model

Input rating

Output rating

Serial number

(Refer to page 49)

Capacity Quantity

FR-E720-5.5KSC to 15KSC, FR-E740-5.5KSC to 15KSC 2

Connector for plug-in

option connection

(Refer to the instruction

manual of options.)

FR-E740-3.7KSC

1

Page 6

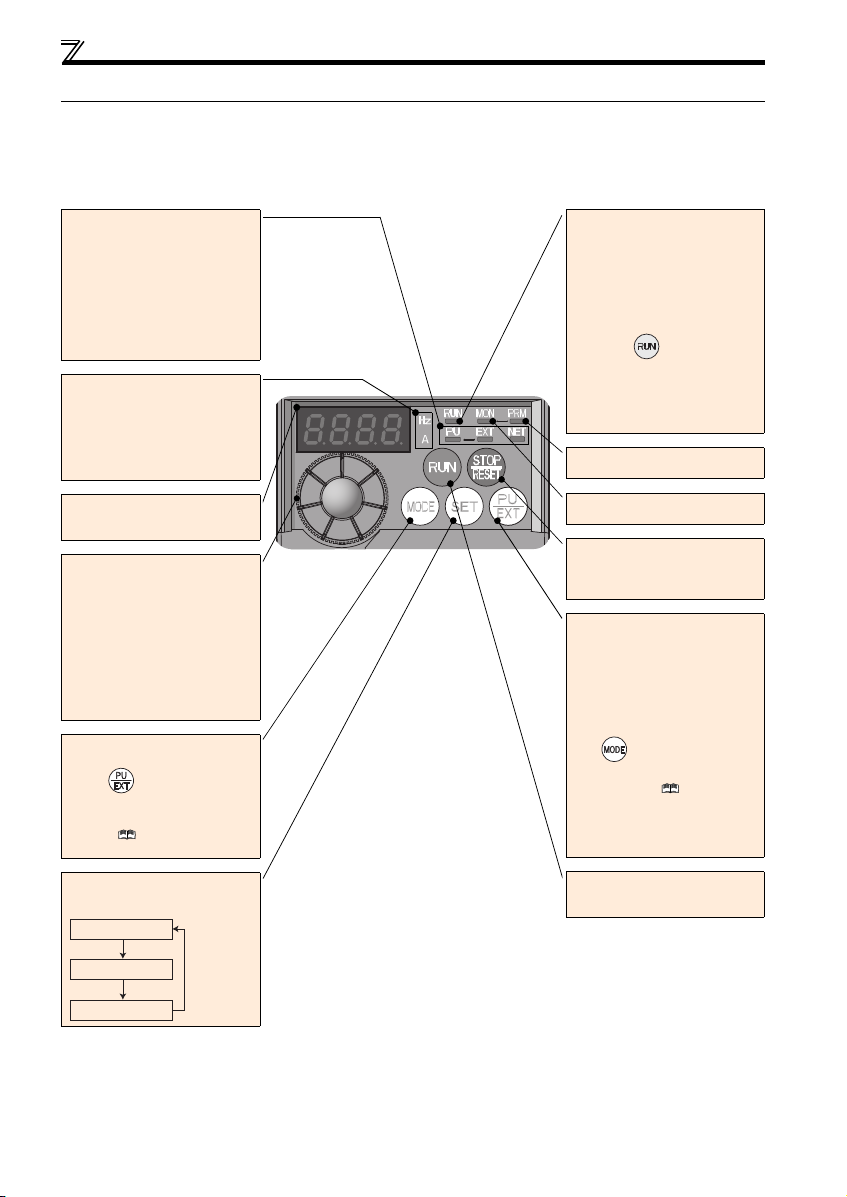

Operation panel

Operation mode indicator

PU: Lit to indicate P U operation mode.

EXT:

Lit to indicate External operation mode.

(Lit at power-ON at initial setting.)

NET: Lit to indicate Network operation

mode.

PU, EXT: Lit to indicate External/PU

combined operation mode 1, 2.

These turn OFF whe n command source is

not on oper ation panel.

Unit indicator

Hz: Lit to indica te frequency.

(Flickers when the set frequency

monitor is displayed.)

A: Lit to indicate current.

(Both "Hz" and "A" turn OFF when other

than the above is displayed.)

Monitor (4-digit LED)

Shows the f requency, parameter numb er,

etc.

Setting dial

(Setting dial: Mitsubishi inverter dial)

Used to change the frequency setting and

parameter settings.

Press to displ ay the following.

Displays the set frequency in the

monitor mode

Present set value is displayed during

calibration

Displays the order in the faults history

mode

Mode switch over

Used to change each setting mode.

Pressing simultaneously changes

the operation mode.

Pressing for a while (2s) can lock

operation. ( Refer to the Instruction

Manual (Applied))

Determination of each setting

If pressed during operation, monitor

changes as below:

Running frequency

Output current

Output voltage

Operating status indicator

Lit or flicker during inverter operation.

* Lit: When the forward rotation operation

is being performed.

Slow flickering (1.4s cycle):

When the reverse operation is being

performed.

Fast flickering (0.2s cycle):

When was pressed or the

start command was given, but the

operation cannot be made.

When the frequency command is less

than the starting frequency.

When the MRS signal is input.

Parameter setting mode

Lit to indicate paramete r setting mode.

Monitor indicator

Lit to indicate monitoring mode.

Stop operation

Used to stop Run command.

Fault can be reset when protective

function is activated (fault).

Operation mode switchover

Used to switch between the PU and

External operation mode.

When using the External operation mode

(operati on using a separa tely connecte d

frequency setting potentiometer and start

signal), press this key to light up t he EXT

indication.

(Press simultaneously (0.5s) o r

change Pr. 79 setting to change to

combined mode .) ( Refer to the

Instruction Manual (Applied))

PU: PU oper ation mode

EXT:External operation mode

Cancels PU stop also.

Start command

The rotation direction can be selected by

setting Pr. 40.

1.2 Operation panel

1.2.1 Names and functions of the operation panel

The operation panel cannot be removed from the inverter.

2

Page 7

1

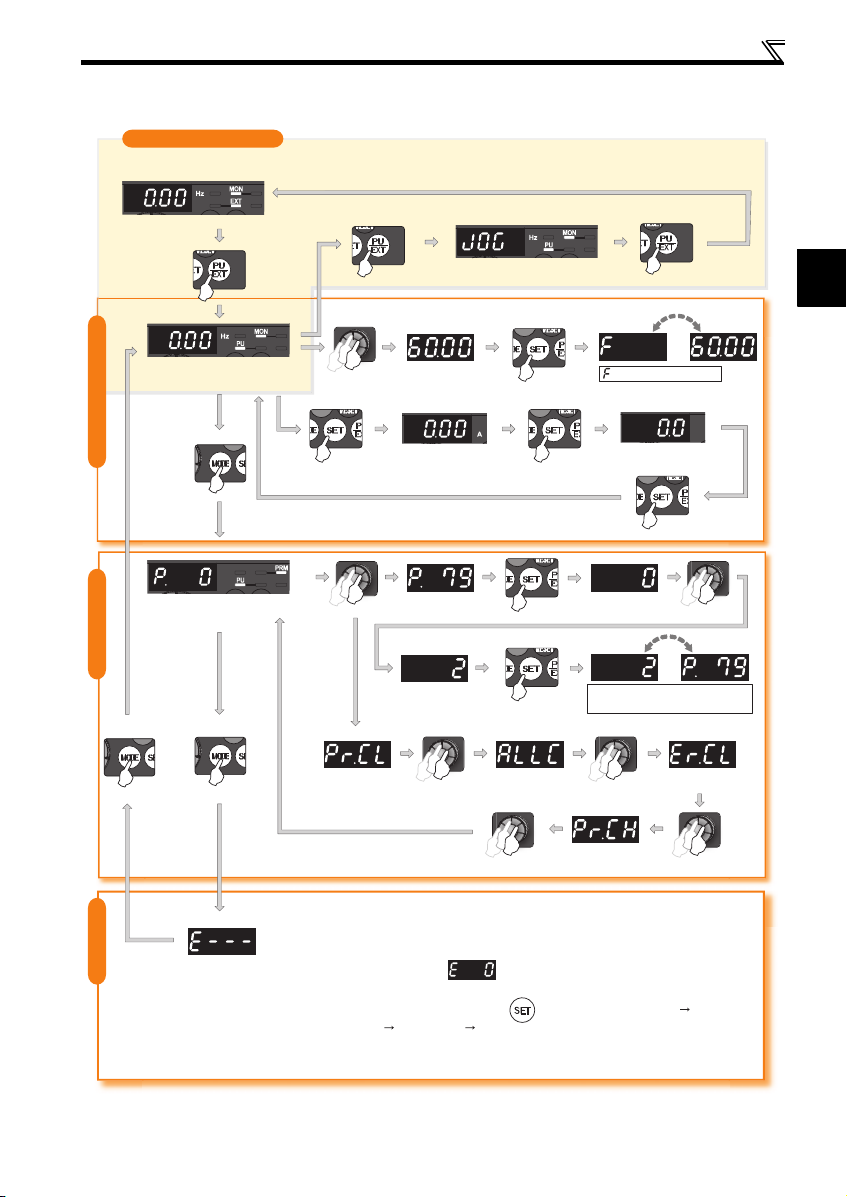

1.2.2 Basic operation (factory setting)

(Refer to page 40)

(Refer to page 4)

Operation mode switchover

At power-ON (External operation mode)

Operation panel

PU Jog operation mode

(Example)

PU operation mode

(output frequency monitor)

Parameter setting mode

Value change

Output current monitor

STOP

and frequency flicker.

Frequency setting has been

written and completed!!

Output voltage monitor

Display the

present setting

(Example)

Parameter settingFaults history Monitor/frequency setting

Value change

Parameter clear All parameter

clear

Parameter and a setting value

flicker alternately.

Parameter write is completed!!

Faults history clear

Initial value

change list

[Operation for displaying faults history]

Past eight faults can be displayed.

(The latest fault is ended by ".".)

When no fault history exists, is displayed.

While a fault is displayed:

The display shifts as follows by pressing : Output frequency at the fault

Output current Output voltage Energization time.

(After Energization time, it goes back to a fault display.)

Pressing the setting dial shows the fault history number.

3

Page 8

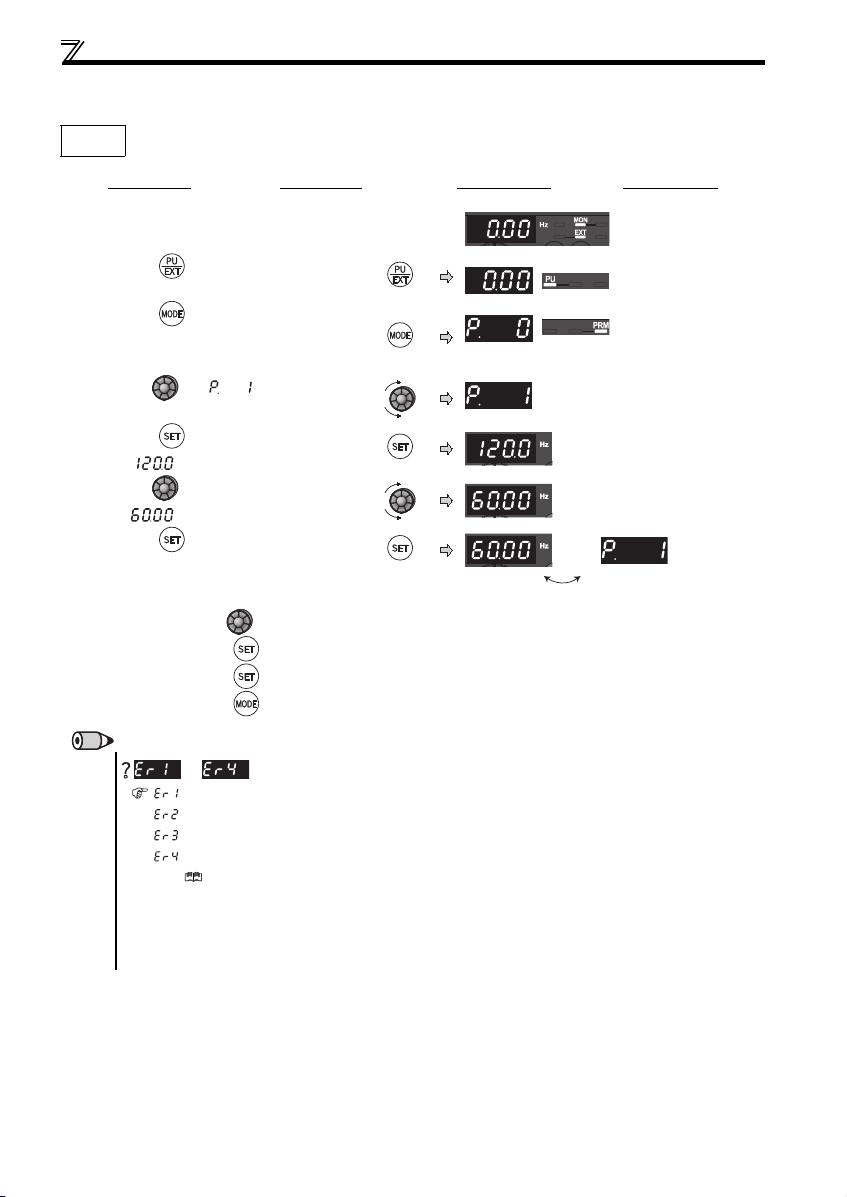

Operation panel

1.2.3 Changing the parameter setting value

Changing

example

Change the Pr. 1 Maximum frequency setting.

Operation Display

1.

Screen at power-ON

The monitor display ap pears.

2. P ress to choose the PU operation mo de.

3. P ress to choose the parameter setting

mode.

4. Turn until (Pr. 1) appears.

5. P ress to read the currently set value.

" "(120.0Hz (initial value) ) appears.

6. Turn to change the set v alue to

" " (60.00Hz).

7. P ress to set.

Turn to read another parameter.

Press to show the setting again.

Press twice to show the next parame ter.

Press twice to return the monito r to frequency monitor.

PU indicator is lit.

PRM indicator is lit.

(The parameter number re ad previously appears.)

Flicker...Parameter setting complete!!

REMARKS

to

appears .................... Write disable error

appears .................... Write error during operat ion

appears ....................Ca libration error

appears ....................M ode designation error

(For details, Refer to the Instruction Manual (Applied) .)

The number of digits displayed on the operation panel is four. Only the upper four digits of values can be displayed and set. If the

values to be displayed have five digits or more including decimal places, the fifth or later numerals can not be displayed nor set.

(Example ) For Pr. 1

When 60Hz is set, 60. 00 is displayed.

When 120Hz is set, 12 0.0 is displayed and second decimal place is not dis played nor set.

is displayed...Why?

4

Page 9

1

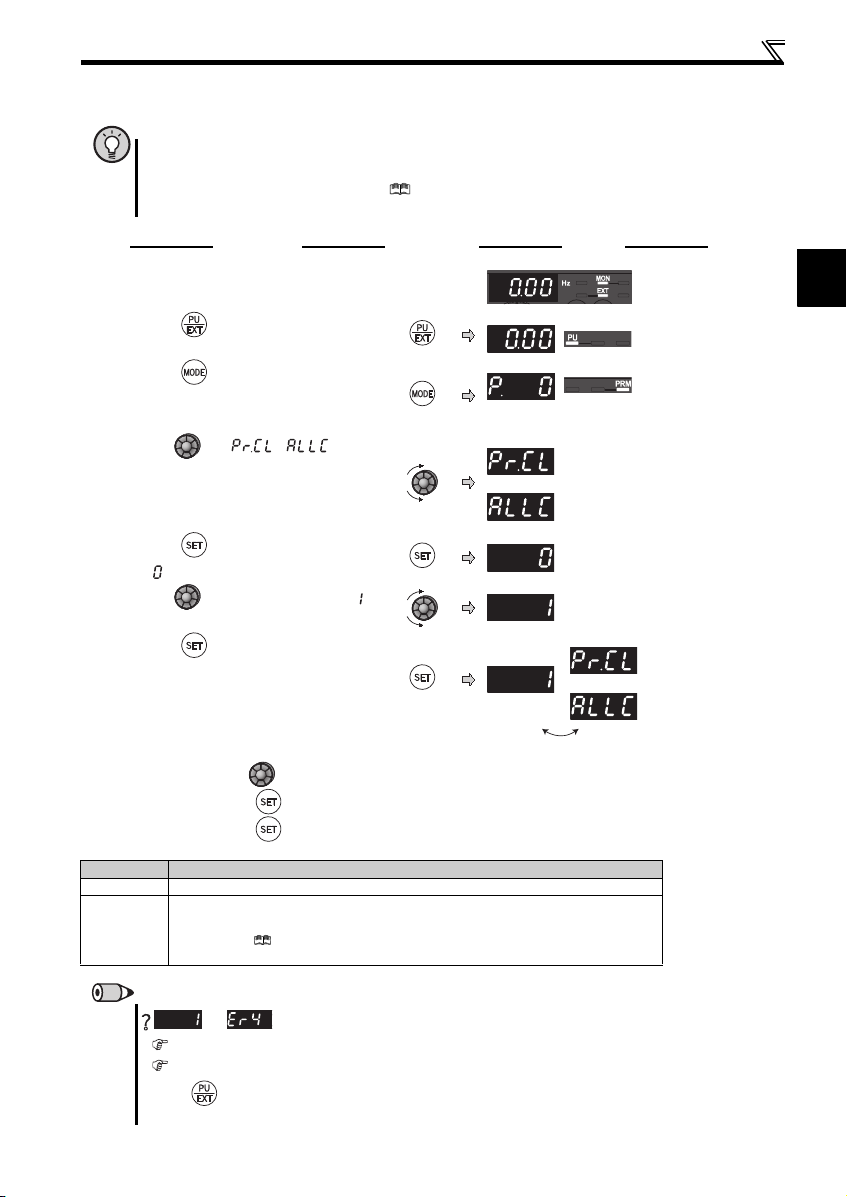

1.2.4 Parameter clear/all parameter clear

and

POINT

Set "1" in Pr.CL Parameter clear, ALLC all parameter clear to initialize all par ameters. (Parameters are not cleared

when "1" is set in Pr. 77 Parameter write selection.)

Refer to the extended parameter list of the Instruction Manual (Applied) for parameters cleared with this

operation.

Operation Display

1.

Screen at power-ON

The monitor display app ears.

2. Press to choose th e PU operation mode.

Operation panel

PU indicator is lit.

3. Press to choose t he parameter setting

mode.

4. Turn until ( ) appears.

PRM indic ator is lit.

(The parameter number r ead previously appears.)

Parameter clear

All parameter clear

5. Press to read the c urrently set value.

" "(initial value) appears.

6. Turn to change it to the set val ue " ".

7. Press to set.

Flicker ··· Parameter setting complete!!

Turn to read another parameter.

Setting Description

0 Not executed.

1

Press to show the setting again.

Press twice to show the next paramet er.

Sets parameters back to the i nitial values. (Paramet er clear sets back all paramete rs except

calibration parameters and term inal function selection parameters to the initial values.) Refer to the

parameter list of the I nstruction Manual (Applied) for availabi lity of parameter clear and a ll

parame ter cl ear.

Parameter clea r

All parameter clear

REMARKS

are displayed alternately ... Why?

The inverter is not in the PU operation mode.

PU connector or USB c onnector is used.

1. Press . [PU] is lit and the monitor (4-digit LED) displays "1". ( When Pr. 79 = "0" (initial value))

2. Carry out operation from step 6 again.

5

Page 10

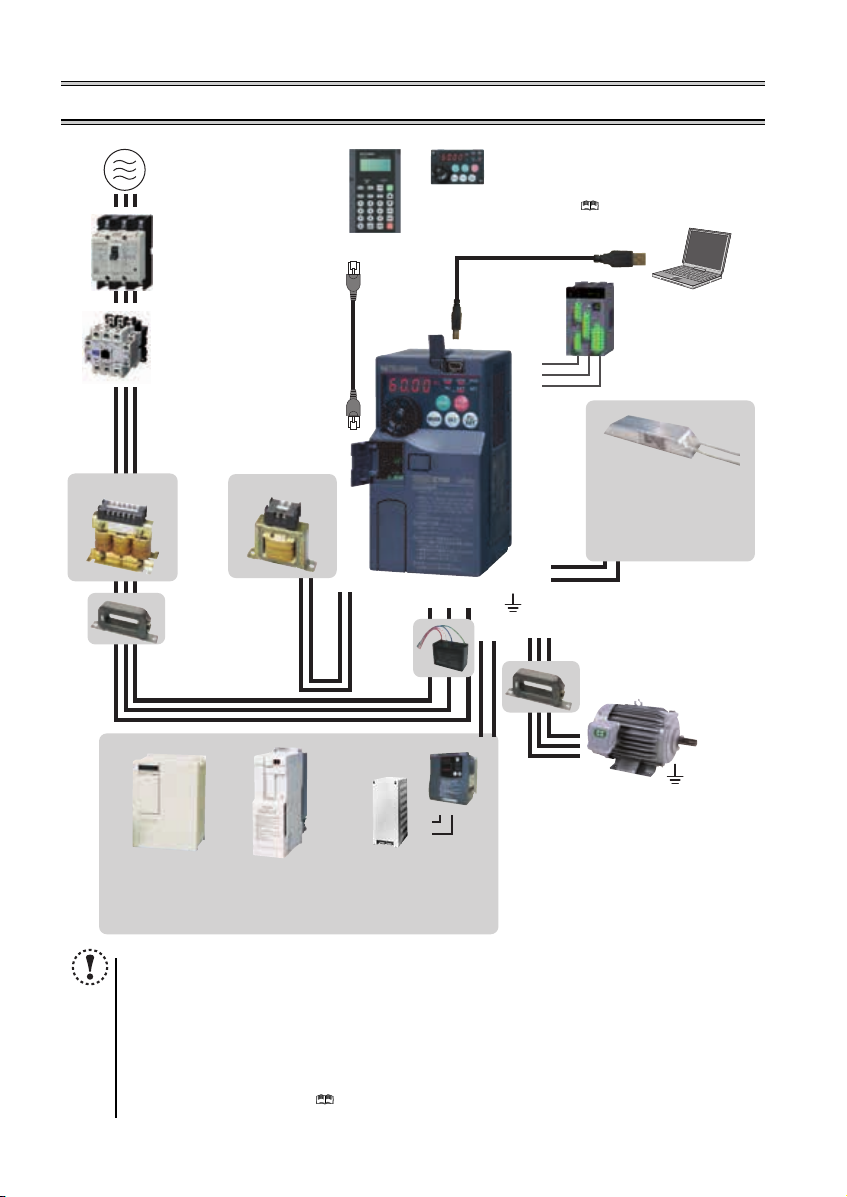

2 INSTALLATION AND WIRING

EMC filter (ferrite core)

(FR-BSF01, FR-BLF)

Install

an EMC filter (ferrite core)

to reduce the electromagnetic

noise generated from the inverter.

Effective in the range from about

1MHz to 10MHz. A wire should be

wound four turns at a maximum.

Motor

Earth (Ground)

Earth (Ground)

Devices connected to the output

Do not install a power factor correction capacitor,

surge suppressor or capacitor type filter on the output

side of the inverter. When installing a moulded case

circuit breaker on the output side of the inverter,

contact each manufacturer for selection of the

moulded case circuit breaker.

The regenerative braking capability

of the inverter can be exhibited fully.

Install this as required.

Power supply harmonics

can be greatly suppressed.

Install this as required.

High power factor

converter (FR-HC)

Power regeneration

common converter

(FR-CV)

Earth (Ground)

R/L1 S/L2T/L3

P1

UW

PR

V

Great braking capability

is obtained.

Install this as required.

EMC filter (ferrite core) *

(FR-BSF01, FR-BLF)

AC power supply

Use within the permissible power supply

specifications of the inverter. To ensure

safety, use a moulded case circuit breaker,

earth leakage circuit breaker or magnetic

contactor to switch power ON/OFF.

Magnetic contactor (MC)

Install the magnetic contactor to ensure

safety. Do not use this magnetic contactor

to start and stop the inverter. Doing so will

cause the inverter life to be shorten.

Moulded case circuit breaker

(MCCB) or earth leakage circuit

breaker (ELB), fuse

The breaker must be selected carefully

since an in-rush current flows in the

inverter at power ON.

Install

an EMC filter (ferrite core)

to reduce the electromagnetic

noise generated from the

inverter. Effective in the range

from about 1MHz to 10MHz.

When more wires are passed

through, a more effective result

can be obtained. A wire should

be wound four turns or more.

To prevent an electric shock, always earth (ground)

the motor and inverter. For reduction of induction noise

from the power line of the inverter, it is recommended

to wire the earthing cable by returning it to the earth

(ground) terminal of the inverter.

AC reactor (FR -HAL)

DC reactor (FR-HEL) *

EMC filter

(capacitor) *

(FR-BIF)

P/+

P/+

PR

PR

Brake unit

(FR-BU2)

Reduces the

radio noise.

Resistor unit (FR-BR)

Discharging resistor (GZG, GRZG)

Inverter (FR-E700)

* Filterpack (FR-BFP2), which contains DC reactor and EMC filter in one package, is also available.

Approved safety

relay module

Required for

compliance with

safety standard.

S1

S2

SC

Parameter unit

(FR-PU07)

USB connector

A personal computer and an inverter

can be connected with a

USB (Ver1. 1) cable.

Enclosure surface operation panel

(FR-PA07)

By connecting the connection cable (FRCB2) to the PU connector, operation can

be performed from FR-PU07, FR-PA07.

Reactor (FR-HAL, FR-HEL option)

Reactors (option) must be used when

power harmonics measures are taken,

the power factor is to be improved or the

inverter is installed near a large power

supply system (500kVA or more). The

inverter may be damaged if you do not

use reactors. Select the reactor according

to the model. Remove the jumpers across

terminals P/+ and P1 to connect the DC reactor.

P/+

P/+

P/+

N/-

(Refer to page 46)

(Refer to page 7)

(Refer to page 7)

( Refer to Chapter 4 of the

Instruction Manual (Applied))

Brake resistor

(FR-ABR, MRS type, MYS type)

Braking capabili ty can be improved. (0.4K

or higher)

Always install a t hermal relay when using

a brake resistor whose capacity is 11K or

higher.

(Refer to page 19)

NOTE

The life of the inverter is influenced by surrounding air temperature. The surrounding air temperature should be as low as

6

possible within the p ermissible range. This m ust be noted especi ally when the inverter is installed in an enclosur e. (Refer

to page 8)

Wrong wiring might lead to damage of the inverter. The control signal lines must be kept fully away from the main circuit

to protect them from noise. (Refer to page 9)

Do not install a power factor correction capacitor, surge suppressor or capacitor type filter on the inverter output side.

This will cause the i nverter to trip or the c apacitor and surge suppress or to be damaged. I f any of the above dev ices are

connected, immediately remove them.

Electromagne tic wave interference

The input/output (main circuit) of the inverter includes high frequency components, which may interfere with the

communication devices (such as AM radios) used near the inverter. In this case, install options among the capacitor type

EMC filter FR-BIF (for use in the input side only), the ferrite core type EMC filter FR-BSF01/FR-BLF, filterpack, and EMC

filter to minimize the interferen ce. ( Refer to Chapter 3 of the Instruction Manual (Applied)).

Refer to the instructi on manual of each option and peripher al devices for details of peripheral devi ces.

Page 11

2

Peripheral devices

MCCB INV

MCCB INV

IM

IM

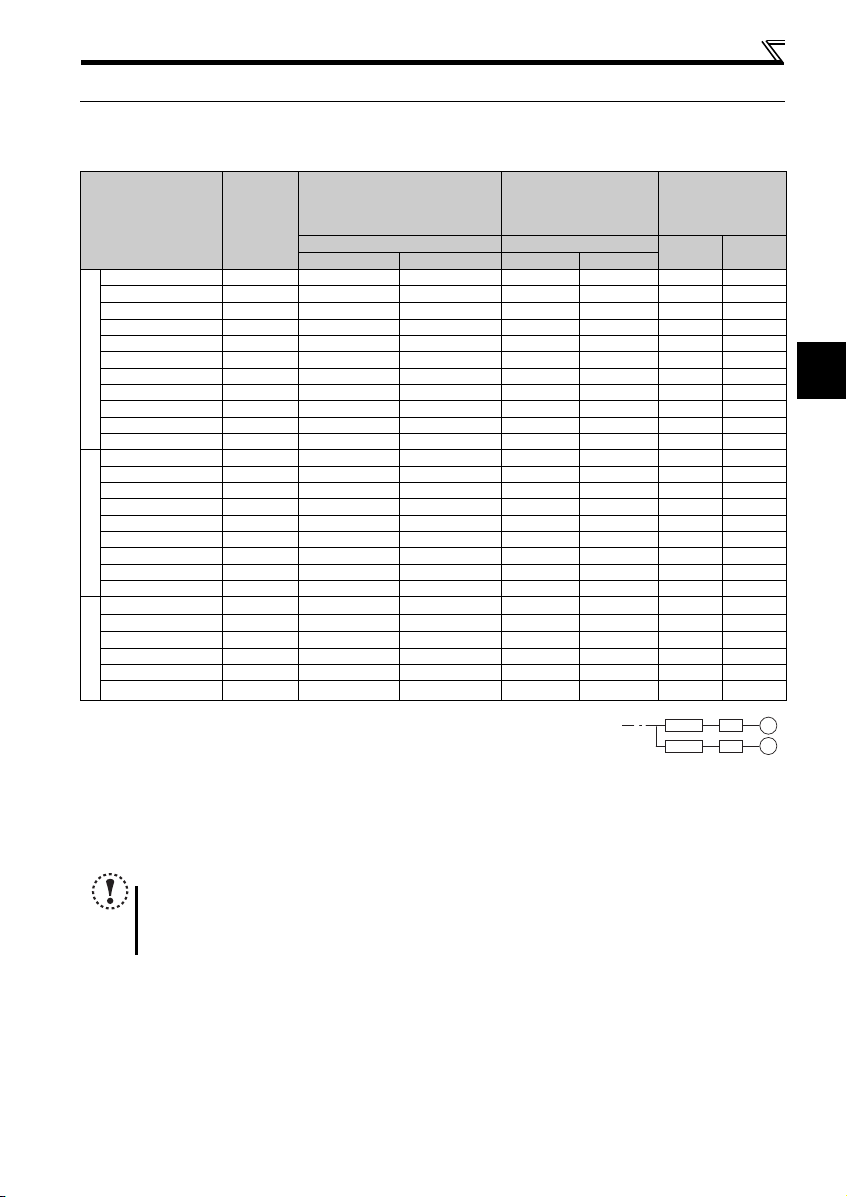

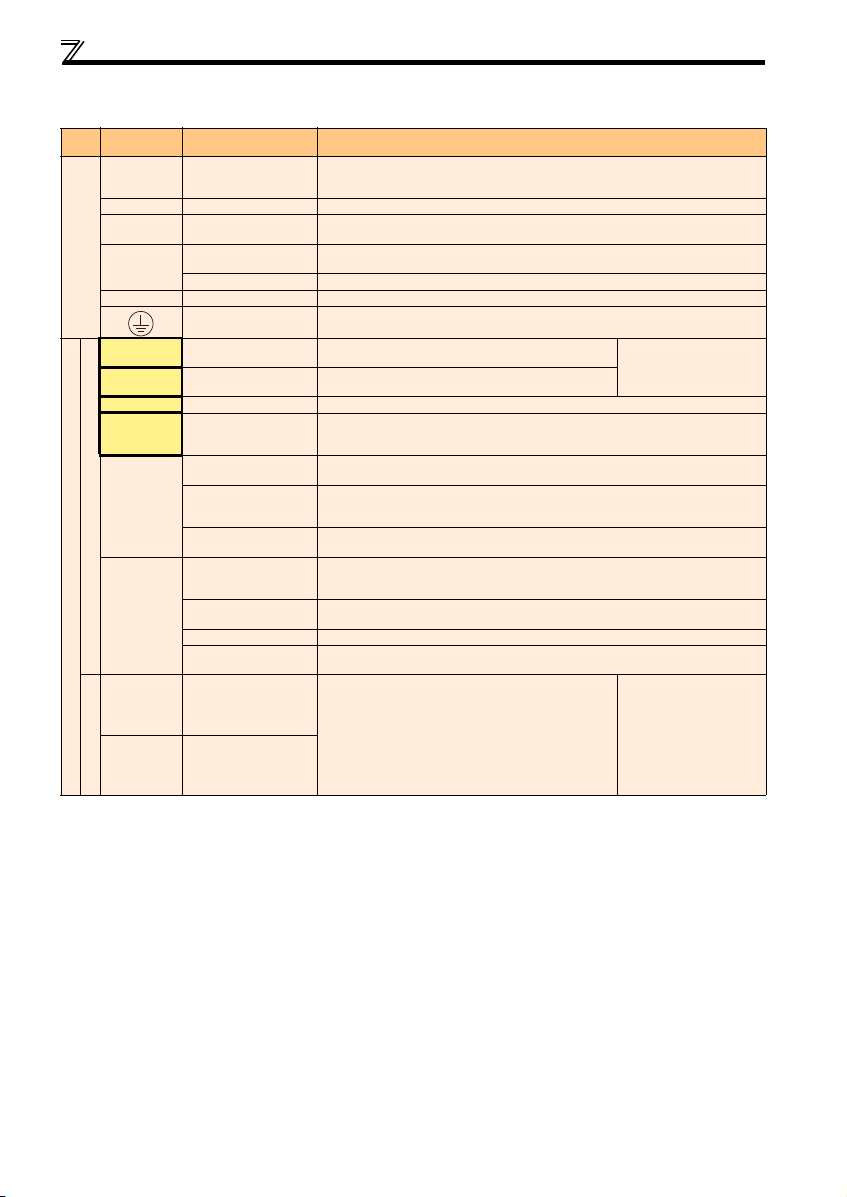

2.1 Peripheral devices

Check the inverter model of the inverter you purchased. Appropriate peripheral devices must be selected according to the capacity.

Refer to the following list and prepare appropriate peripheral devices.

Moulded Case Circuit Breaker

Applicable Inverter

Model

Motor

Output

(kW)

or Earth Leakage Circuit Breaker

(MCCB)

(ELB)

Reactor connection Reactor connection

without with without with

FR-E720-0.1KSC 0.1 5A 5A S-N10 S-N10 0.4K 0.4K

FR-E720-0.2KSC 0.2 5A 5A S-N10 S-N10 0.4K

FR-E720-0.4KSC 0.4 5A 5A S-N10 S-N10 0.4K 0.4K

FR-E720-0.75KSC 0.75 10A 10A S-N10 S-N10 0.75K 0.75K

FR-E720-1.5KSC 1.5 15A 15A S-N10 S -N10 1.5K 1.5K

FR-E720-2.2KSC 2.2 20A 15A S-N10 S -N10 2.2K 2.2K

FR-E720-3.7KSC 3.7 30A 30A S-N20, S-N21 S-N 10 3.7K 3.7K

FR-E720-5.5KSC 5.5 50A 40A S-N25 S-N20, S-N21 5.5K 5.5K

Three-Phase 200V

FR-E720-7.5KSC 7.5 60A 50A S-N25 S -N25 7.5K 7.5K

FR-E720-11KSC 11 75A 75A S-N35 S-N35 11K 11K

FR-E720-15KSC 15 125A 100A S-N50 S-N50 15K 15K

FR-E740-0.4KSC 0.4 5A 5A S-N10 S-N10 H0.4K H0.4K

FR-E740-0.75KSC 0.75 5A 5A S-N10 S -N10 H0.75K H0.75K

FR-E740-1.5KSC 1.5 10A 10A S-N10 S -N10 H1.5K H1.5K

FR-E740-2.2KSC 2.2 15A 10A S-N10 S -N10 H2.2K H2.2K

FR-E740-3.7KSC 3.7 20A 15A S-N10 S -N10 H3.7K H3.7K

FR-E740-5.5KSC 5.5 30A 20A S-N20, S-N21 S-N11, S-N12 H5. 5K H5.5K

FR-E740-7.5KSC 7.5 30A 30A S-N20, S-N21 S-N20, S-N21 H7.5K H7.5K

Three-Phase 400V

FR-E740-11KSC 11 50A 40A S-N20, S-N21 S-N2 0, S-N21 H11K H11K

FR-E740-15KSC 15 60A 50A S-N25 S-N20, S-N21 H15K H15K

FR-E720S-0.1KSC 0.1 5A 5A S-N10 S-N10

FR-E720S-0.2KSC 0.2 5A 5A S-N10 S-N10

FR-E720S-0.4KSC 0.4 10A 10A S-N10 S-N10

FR-E720S-0.75KSC 0.75 1 5A 10A S -N10 S-N10 1.5K 1.5K

FR-E720S-1.5KSC 1.5 20A 20A S-N10 S-N10 2.2K 2.2K

FR-E720S-2.2KSC 2.2 40A 30A S-N20, S-N21 S-N 10 3.7K 3.7K

Single-Phase 200V

Select an MCCB according to the power supply capacity.

Install one MCCB per inverter.

For the use in the United States or Canada, select a UL and cUL certified fuse with Class T fuse equivalent cut-off

speed or faster with the appropriate rating for branch circuit protection. Alternatively, select a UL489 molded case circuit breaker (MCCB). (Refer to page 52)

Magnetic contactor is selected based on the AC-1 class. The electrical durability of magnetic contactor is 500,000 times. When the magnetic contactor is

used for emergency stop during motor driving, the electrical durability is 25 times.

When using the MC for emergency stop during motor driving or using on the motor side during commercial-power supply operation, select the MC with c lass

AC-3 rated current for the motor rated current.

The power factor may be slightly lower.

NOTE

When the inver ter capacity is larger than t he motor capacity, select an MCCB and a m agnetic contactor according t o

the inverter model and cable and reactor according to the motor output.

When the breaker on the inverter input side trips, check for the wiring fault (short circuit), damage to internal parts of

the inverter, etc. Identify the ca use of the trip, then rem ove the cause and power O N the breaker.

Magnetic Contactor (MC)

Reactor

FR-HAL FR-HEL

0.4K

0.4K

0.4K

0.4K

0.4K

0.75K

0. 75K

7

Page 12

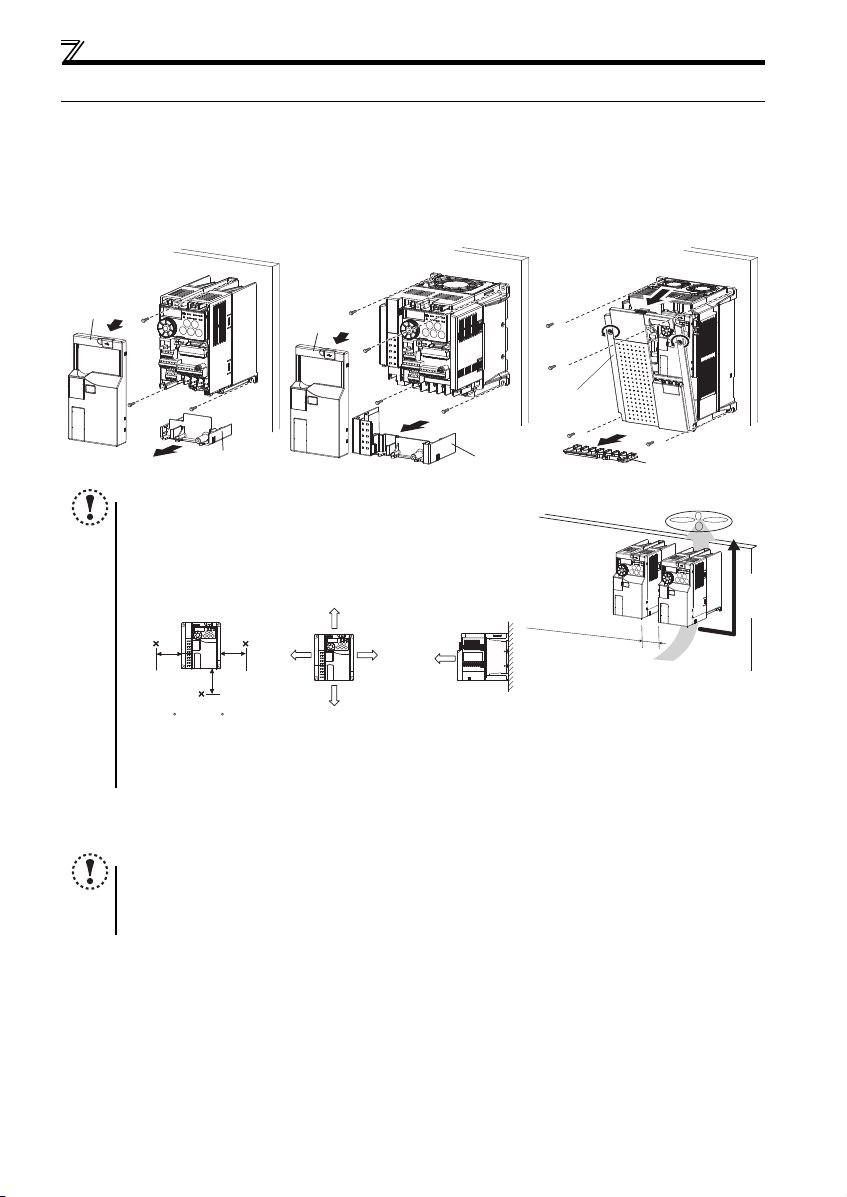

Installation of the inverter and instructions

Front cover

Wiring cover

Front cover

Wiring cover

FR-E720-0.1KSC to 0.75KSC

FR-E720S-0.1KSC to 0.4KSC

FR-E720-1.5KSC to 3.7KSC

FR-E740-0.4KSC to 7.5KSC

FR-E720S-0.75KSC or higher

Front cover 1

FR-E720-5.5KSC to 15KSC

FR-E740-11KSC, 15KSC

Wiring cover

Refer to the clearances

shown on the left.

Vertical

10cm or more

10cm or more

Measurement

position

Measurement

position

5cm

5cm

5cm

-10 C to +50 C

(non-freezing)

1cm or

more

∗1, ∗2

1cm or

more

∗1, ∗2

1cm or

more

∗1

2.2 Installation of the inverter and instructions

(1) Installation of the inverter

Enclosure surface mounting

Remove the front cover and wiring cover to fix the inverter to the surface. (Remove the covers in the directions of the arrows.)

Note

When encasing multi ple inverters, install them in parallel as a cooling

measure.

Install the inverter ve rtically.

For heat dissipation and maintenance, tak e at least the clear ances

shown in the table below from the inverter to the other devices and to

the enclosure surface .

Take 5cm or more clearances for 5.5K or higher.

When using the inverters at the surrounding air temperature of 40C or less, the inverters can be installed without any clearance between

(2) Environment

Before installation, che ck that the environment meets the specifications on page 47.

Note

Install the inverter on a strong surface securely and vertically with bolts.

Leave enough clearances and take cooling measures.

Avoid places where the inverter is subjected to direct sunlight, high temperature and high humidity.

8

Install the inverter on a nonflammable wall surface.

them (0cm clearance).

Page 13

2

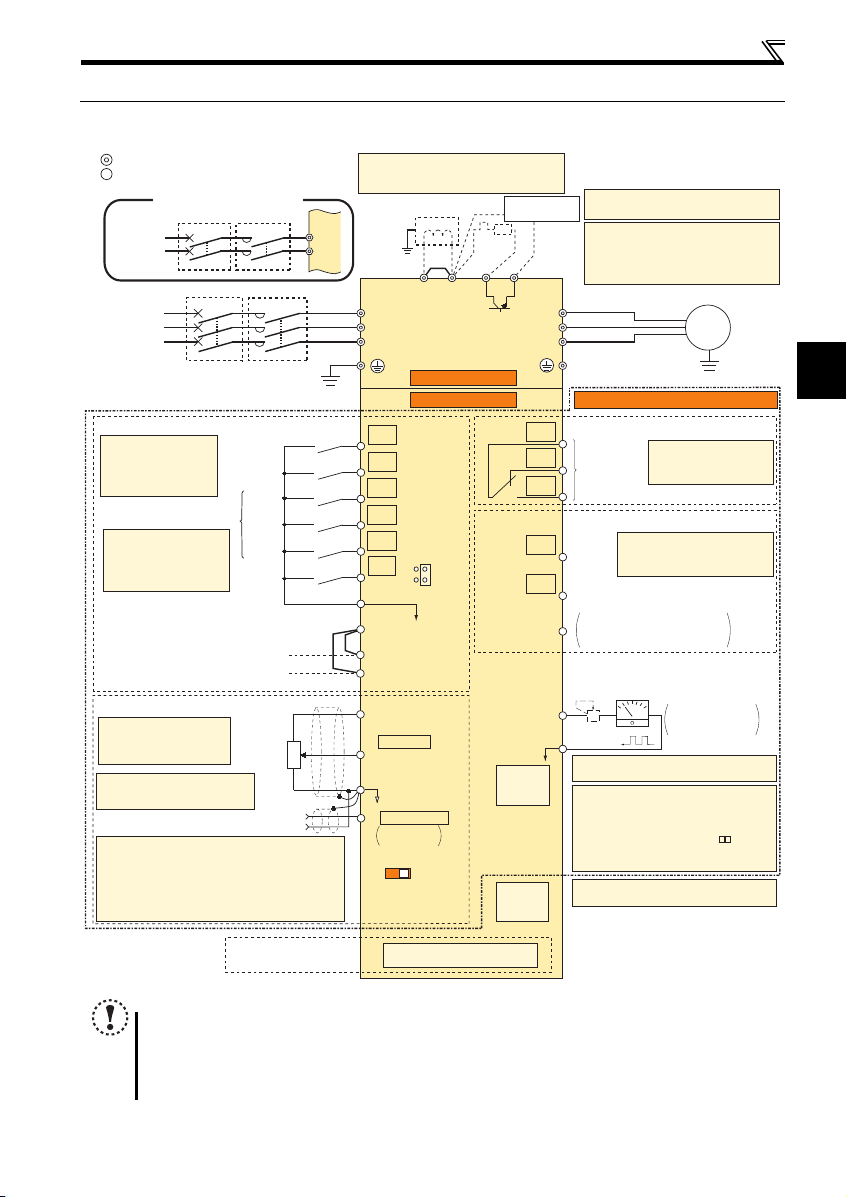

2.3 Wiring

Earth

(Ground)

Motor

IM

Earth (Ground)

Three-phase

AC power

supply

MCCB MC

R/L1

P1 P/+

PR

N/-

S/L2

T/L3

U

V

W

Earth

(Ground)

*7 Brake resistor (FR-ABR, MRS, MYS type)

Install a thermal relay to prevent an

overheat and burnout of the brake resistor.

(The brake resistor can not be connected

to the 0.1K and 0.2K.)

*6 A brake transistor is not built-in to the 0.1K

and 0.2K.

Forward

rotation start

Reverse

rotation start

Middle

speed

High

speed

Low

speed

Reset

Control input signals (No voltage input allowed)

Contact input common

STR

STF

RH

RM

RL

RES

Relay output

Running

Frequency detection

Open collector output

Open collector output common

Sink/source common

FU

RUN

SE

A

B

C

FM

SD

Indicator

(Frequency meter, etc.)

+

-

Moving-coil type

1mA full-scale

Calibration resistor

Frequency setting signals (Analog)

2 0 to 5VDC

10(+5V)

2

3

1

Frequency

setting

potentiometer

1/2W1kΩ

5(Analog common)

*4

Connector for

plug-in option connection

Option connector

*3 Terminal input specifications

can be changed by analog

input specifications

switchover (Pr. 73).

*2 When using terminals PC-

SD as a 24VDC power

supply, take care not to

short across terminals

PC-SD.

PU

connector

*1. DC reactor (FR-HEL)

When connecting a DC reactor, remove the

jumper across P1 and P/+.

Control circuit terminal

Main circuit terminal

Sink logic

Jumper

*1

*7

*6

*3

*8

*9

USB

connector

*10

Terminal functions vary

with the input terminal

assignment (Pr. 178 to

Pr. 182 and Pr. 184)

Multi-speed selection

Terminal functions vary with

the output terminal assignment

(Pr. 190 and Pr. 191)

Terminal functions vary

by Pr. 192 A,B,C terminal

function selection

SINK

SOURCE

VI

*5

(0 to 10VDC)

Voltage/current

input switch

Main circuit

Control circuit

Safety stop function model

R

SD

Relay output

(Fault output)

Brake unit

(Option)

Single-phase

AC power

supply

MCCB MC

R/L1

S/L2

Single-phase power input

24VDC power supply

(Common for external power supply transistor)

Safety stop input common terminal

PC

*2

S1

S2

Safety stop input (Channel 1)

Shorting wire

Safety stop input (Channel 2)

Terminal 4 input

(Current input)

(+)

(-)

4 4 to 20mADC

*5

0 to 5VDC

0 to 10VDC

*5 Terminal input specifications can be changed by analog

input specifications switchover (Pr. 267). Set the

voltage/current input switch in the "V" position to select

voltage input (0 to 5V/0 to10V) and "I" (initial value) to

select current input (4 to 20mA).

To use terminal 4 (initial setting is current input), set "4"

in any of Pr.178 to Pr.184 (input terminal function selection)

to assign the function, and turn ON AU signal.

*4 It is recommended to use 2W1kΩ

when the frequency setting signal

is changed frequently.

*9 Operation and parameter setting can be

done from the parameter unit (FR-PU07)

and the enclosure surface operation panel

(FR-PA07).

(Use the option cable (FR-CB2 ).)

RS-485 communication can be utilized from

a personal computer and other devices.

*8 It is not necessary when calibrating the

indicator from the operation panel.

*10 A personal computer and an inverter can be

connected with a USB (Ver1.1) cable.

2.3.1 Terminal connection diagram

Wiring

NOTE

To prevent a malfunction caus ed by noise, separate the signal c ables more than 10cm from the power cables. Also

After wiring, wire off cuts must not be left in the inverter.

The output of the single-phase power input model is three-phase 200V.

separate the main circuit w ire of the input side and t he output side.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean. When drilling mounting holes

in an enclosure etc., take ca re not to allow chips and other foreign matter to enter the inverter.

9

Page 14

Wiring

2.3.2 Terminal specifications

Ter mina l

Typ e

Symbol

R/L1, S/L2,

T/L3 *

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

P/+, PR Brake resistor conn ection

P/+, N/-

Main circuit

P/+, P1 DC reactor connection Remove the jumper across terminals P/+ and P1 and connect a DC reactor.

STF Forward ro tation start

STR Reverse rotation start

RH, RM, RL Mu lti-speed selection Multi-speed can be selected according to the combination of RH, RM and RL signals.

RES Reset

SD

Contact input

PC

Control circuit/input signal

S1

S2

Safety stop function *

For more details, refer to the Safety stop function instruction manual (BCN-A211508-004). (Refer to the front cover for how to obtain the manual.)

Term inal Na me Description

AC power input

Brake unit connection

DC power input

Earth (Ground)

Contact input common

(sink) (initial setting)

External transistor

common (source)

24VDC power supply

common

External transistor

common

(sink) (initial setting)

Contact input common

(source)

24VDC power supply

Safety stop input terminal

common

Safety stop input

(Channel 1)

Safety stop input

(Channel 2)

Connect to the commercial power supply. Keep these terminals open when using the high

power factor converter (FR-HC) or power regeneration common converter (FR-CV).

When using single-phase power input, terminals are R/L1 and S/L2.

Connect a brake resistor (MRS type, MYS type, FR-ABR) across terminals P/+ and PR.

(The brake resistor can not be connected to the 0.1K or 0.2K)

Connect the brake unit (FR-BU2), power regeneration common converter (FR-CV) or high

power factor converter (FR-HC).

Connect t he plus sid e of the pow er supply t o terminal P/+ and minu s side to t erminal N/ -.

For earthing (grounding) the inverter chassis. Must be earthed (grounded).

Turn ON the STF signal to start forward rotation and turn it OFF

to stop.

Turn ON the STR signal to start reverse rotation and turn it OFF

to stop.

Used to reset alarm output provided when protective circuit is activated. Turn ON the RES

signal for more t han 0.1s, then tu rn it OFF. Initial setting is fo r reset always. By setting Pr. 75,

reset can be set to enabled only at fault occurrence. Recover about 1s after reset is cancelled.

Common terminal for contact input terminal (sink logic) and terminal FM.

Connect this terminal to the power supply common terminal of a transistor output (open

collector output) device, such as a programmable controller, in the source logic to avoid

malfunction by undesirable current.

Common output terminal for 24VDC 0.1A power supply (PC terminal).

Isolated from terminals 5 and SE.

Connect this terminal to the power supply common terminal of a transistor output (open

collector output) device, such as a programmable controller, in the sink logic to avoid

malfunction by undesirable current.

Common terminal for contact input terminal (source logic).

Can be used as 24VDC 0.1A power supply.

Common terminal for safety stop input terminals S1 and S2.

S1/S2 are safety stop signals for use with in conjunction with

an approved external safety unit. Both S1/S2 must be used in

dual channel form. Inverter output is shutoff depending on

shorting/opening between S1 and PC, S2 and PC.

In the initial status, terminal S1 and S2 are shorted with

terminal PC by shorting wire.

Remove the shorting wire and connect the safety relay module

when using the safety stop function.

When the STF and STR

signals are turned ON

simultaneously, the stop

command i s given.

Input resistance 4.7k

Voltage when contacts are

open

21 to 26VDC

When contacts are shortcircuited

4 to 6mADC

10

Page 15

2

Typ e

Voltage input

Current input

(initial status)

Control circuit/input signa l

Frequency setting

Term ina l

Symbol

10

2

4

Terminal Name Description

Frequency setting power

supply

Frequency setting

(voltage)

Frequency setting

(current)

Used as power supply when connecting potentiometer for

frequency setting (speed setting) from outside of the inverter.

Inputting 0 to 5VDC (or 0 to 10V) provides the maximum output

frequency at 5V (10V) and makes input and output

proportional. Use Pr. 73 to switch betw een input 0 to 5VD C

(initial setting) and 0 to 10VD C input.

Inputting 0 to 20mADC (or 0 to 5V / 0 to 10V) provides the

maximum output frequency at 20mA and makes input and

output proportional. This input signal is valid only when the AU

signal is ON (terminal 2 input is invalid). To use terminal 4

(initial setting is current input), set "4" to any of Pr.178 to Pr.184

(input terminal function selection), a nd turn AU signal O N. Use

Pr. 267 to switch among input 4 to 20mA (initial setting), 0 to

5VDC, and 0 to 10VDC. Set the voltage/current input switch in

the "V" position to select voltage in put (0 to 5V/0 t o 10V).

Wiring

5VDC

permissible load current 10mA

Input resistance 10k ± 1k

Permissible maximum voltage

20VDC

Voltage input:

Input resistance 10k ± 1k

Permissible maximum voltage

20VDC

Current input:

Input resistance 233 ± 5

Maximum permissible current

30mA.

5

A, B, C

Relay

RUN Inverter running

FU Frequency detection

Open collector

Control circuit/output signal

SE

FM For meter

Pulse

— PU co nnector

— USB connector

Communication

Frequency setting

common

Relay output

(fault output)

Open collector

output common

Common terminal for the frequency setting signals (terminals 2 and 4). Do not earth (ground).

1 changeover contact output indicates that the inverter fault occurs.

Fault: discontinuity across B and C (continuity across A and C),

Normal: continuity across B and C (discontinuity across A and C)

Contact capacity 230VAC 0.3A (power factor = 0.4) 30VDC 0.3A

Switched Low when the inverter output frequency is equal to or

higher than the starting frequency (initial value 0.5Hz).

Switched High during stop or DC injection brake operation.

Switched Low when the inverter output frequency is equal to or

higher than the preset detected frequency and High when less

than the pr eset detect ed frequency.

Common terminal of terminal RUN and FU.

Used to output a selected monitored item (such as Output

frequency) among several monitored items. (Not output during

inverter reset.)The output signal is proportional to the

magnitude of the corresponding monitoring item.

With the PU connector, RS-485 communication can be established.

· Conforming standard: EIA-485 (RS-485) · Transmission format: Multi-drop link

· Communication speed: 4800 to 38400bps · Overall extension: 500m

A personal computer and an inverter can be connected with a USB (Ver1.1) cable.

· Interface: conforms to USB1.1 · Transmission Speed: 12Mbps

· Connector: USB mini B connector (receptacle mini B type)

Permissible load 24VDC

(Maximum 27VDC) 0.1A

(a voltage drop is 3.4V

maximum when the signal is

ON)

Low is when the open

collector output transistor is

ON (conducts). High is when

the transistor is OFF (does

not conduct).

Permissible load current 1mA

1440 pulses/s at 60Hz

Note

Set Pr. 267 and a voltage/current input switch correctly, then input an analog signal in accordance with the setting.

Applying a voltage with voltage/current input switch in "I" position (current input is selected) or a current with switch

in "V" position (voltage input is selected) could cause component damage of the inverter or analog circuit of output

devices.

The inverter will b e damaged if power is applied to t he inverter output terminals (U, V, W). Never perform such wiring.

indicates that terminal functions can be selected using Pr. 178 to Pr. 182, Pr. 184 and Pr. 190 to Pr. 192 (I/O terminal

function selection).

Terminal names and termina l functions are those of t he factory set.

When connecting the DC power supply, be sure to connect the plus side of the power supply to terminal P/+ and

minus side to terminal N/-. Opposite polarity will damage the inverter.

11

Page 16

Wiring

MotorPower supply

N/-

P/+ PR

IM

R/L1 S/L2 T/L3

Jumper

Motor

Power supply

IM

N/-

P/+

PR

R/L1 S/L2 T/L3

Jumper

MotorPower supply

N/-

P/+ PR

IM

R/L1 S/L2

Jumper

Motor

Power supply

N/-

P/+

PR

IM

R/L1 S/L2

Jumper

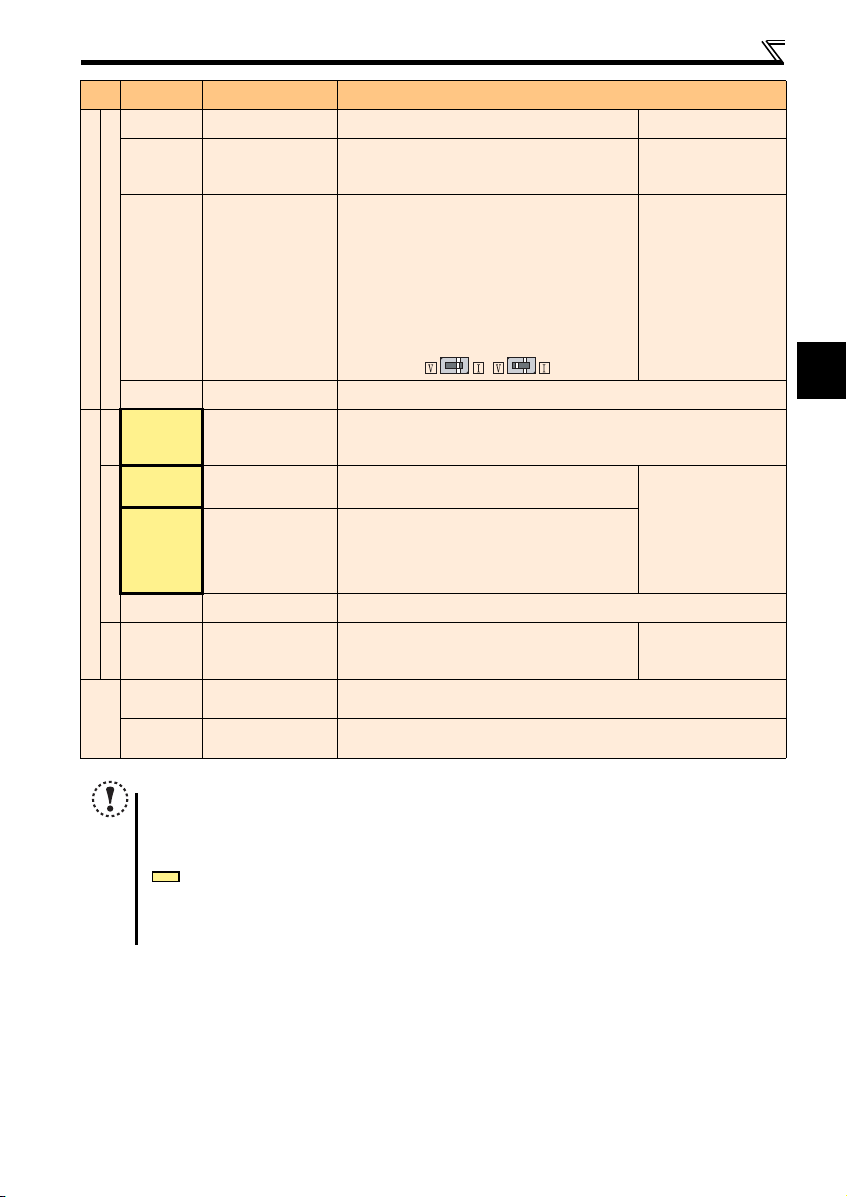

2.3.3 Terminal arrangement of the main circuit terminal, power supply and the motor wiring

Three-phase 200V/400V class

FR-E720-0.1KSC to 0.7 5KSC FR-E720-1.5KSC to 3.7K SC

FR-E740-0.4KSC to 3.7K SC

N/-

P/+

PR

Jumper

R/L1 S/L2 T/L3

IM

Motor

FR-E720-5.5KSC, 7.5K SC FR-E740-5.5KSC, 7.5K SC

R/L1 S/L2 T/L3

N/-

P/+

Jumper

PR

N/-

P/+

Power supply

R/L1 S/L2 T/L3

PR

Jumper

IM

Power supply

FR-E720-11KSC, 15KSC FR-E740-11KSC, 15KSC

R/L1 S/L2 T/L3

N/-

P/+

Motor

PR

Jumper

IM

MotorPower supply

Single-phase 200V class

FR-E720S-0.1KSC to 0 .4KSC FR-E720S-0.75KSC to 2.2KSC

NOTE

Make sure the power cables are connected to the R/L1, S/L2, and T/L3. (Phase need not be matched.) Never connect

12

the power cables to the U, V, and W of the inverter. Doing so will damage the inverter.

Connect the motor to U, V, and W. Turning ON the forward rotation switch (signal) at this time rotates the motor

counterclockwise when viewed from the load shaft.

IM

MotorPower supply

Page 17

2

Wiring

3 × wire resistance[mΩ/m] × wiring distance[m] × current[A]

1000

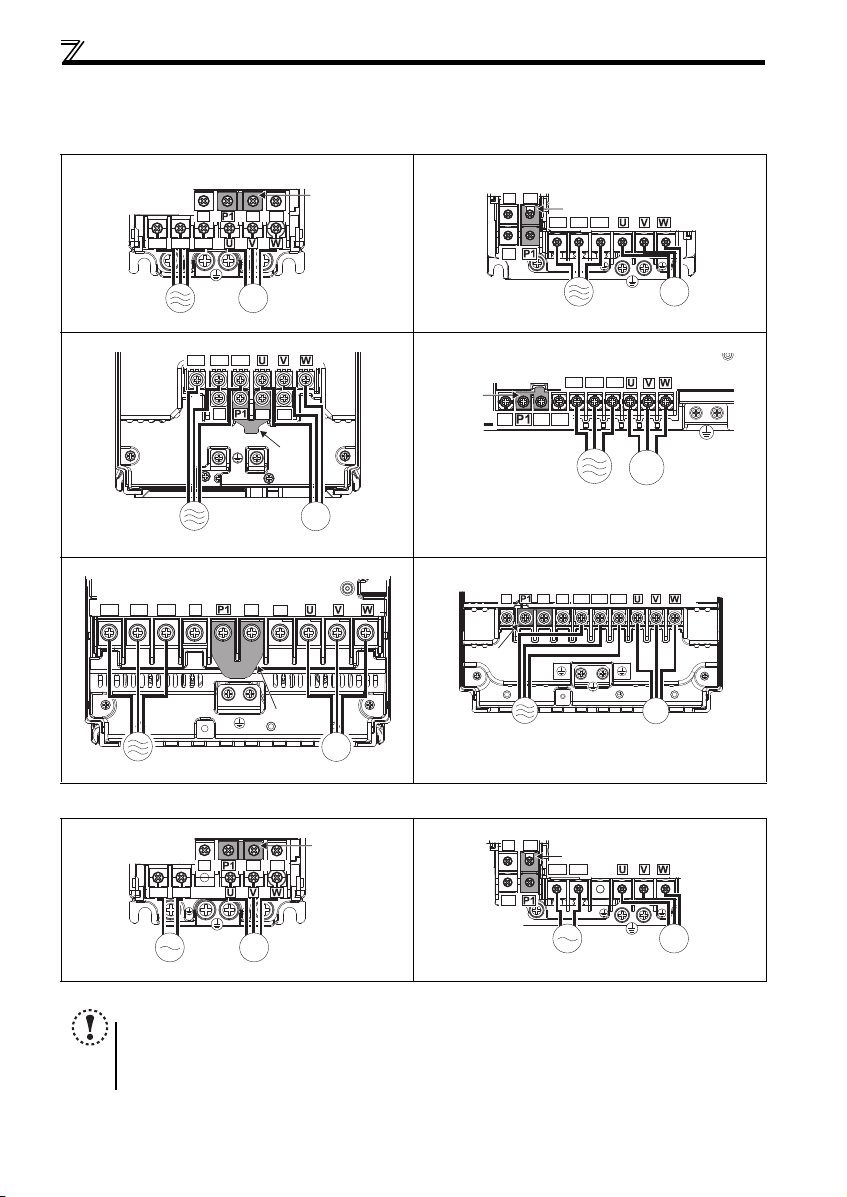

(1) Cable size and other specifications of the main circuit terminals and the earthing terminal

Select the recommended cable size to ensure that a voltage drop will be 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor torque to

decrease especially at the output of a low frequency.

The following table indicates a selection example for the wiring length of 20m.

Three-phase 200V class (when input power supply is 220V)

cable

cable

cable

Cable Size

AWG

R/L1

S/L2

U, V, W

T/L3

Cable Size

AWG

R/L1

S/L2

U, V, W

T/L3

Cable Size

AWG

R/L1

U, V, W

S/L2

PVC Cables, etc. (mm2)

R/L1

S/L2

T/L3

PVC Cables, etc. (mm2)

R/L1

S/L2

T/L3

PVC Cables, etc. (mm2)

R/L1

S/L2

U, V, W

U, V, W

U, V, W

Earthing

cable

Earthing

cable

Earthing

cable

Crimping

N·m

Ter min al

R/L1

S/L2

T/L3

Ter mi nal

Applicable Inverter

Model

FR-E720-0.1KSC to 0.7 5KSC M 3.5 1.2 2-3.5 2-3.5 2 2 2 14 14 2.5 2.5 2.5

FR-E720-1.5KSC, 2.2K SC M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-E720-3.7KSC M4 1.5 5.5-4 5.5 -4 3.5 3.5 3.5 12 12 4 4 4

FR-E720-5.5KSC M5 2.5 5.5-5 5.5 -5 5.5 5.5 5.5 10 10 6 6 6

FR-E720-7.5KSC M5 2.5 14-5 8-5 14 8 5.5 6 8 16 10 6

FR-E720-11KSC M5 2.5 14-5 14-5 14 14 14 6 6 16 16 16

FR-E720-15KSC M6(M5) 4.4 2 2-6 22-6 22 22 14 4 4 2 5 25 16

Screw

Size

Tightening

Torque

HIV Cables, etc. (mm2)

R/L1

U, V, W

S/L2

T/L3

U, V, W

Earthing

Three-phase 400V class (when input power supply is 440V)

Crimping

N·m

Ter min al

R/L1

S/L2

T/L3

Ter mi nal

Applicable Inverter

Model

FR-E740-0.4KSC to 3.7 KSC M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-E740-5.5KSC M4 1.5 5.5-4 2-4 3.5 2 3.5 12 14 4 2.5 4

FR-E740-7.5KSC M4 1.5 5.5-4 5.5 -4 3.5 3.5 3.5 12 12 4 4 4

FR-E740-11KSC M4 1.5 5.5-4 5.5-4 5.5 5.5 8 10 10 6 6 10

FR-E740-15KSC M5 2. 5 8-5 8-5 8 8 8 8 8 1 0 10 10

Screw

Size

Tightening

Torque

HIV Cables, etc. (mm2)

R/L1

U, V, W

S/L2

T/L3

U, V, W

Earthing

Single-phase 200V class (when input power supply is 220V)

N·m

Crimping

Ter min al

R/L1

S/L2

HIV Cables, etc. (mm2)

R/L1

U, V, W

S/L2

U, V, W

Earthing

Ter mi nal

Applicable Inverter

Model

FR-E720S-0.1KSC to 0.4KS C M3.5 1. 2 2-3.5 2-3.5 2 2 2 14 14 2.5 2.5 2.5

FR-E720S-0.75KSC M4 1. 5 2-4 2-4 2 2 2 1 4 14 2.5 2.5 2.5

FR-E720S-1.5KSC M4 1.5 2-4 2-4 2 2 2 14 14 2.5 2.5 2.5

FR-E720S-2.2KSC M4 1.5 5.5-4 2-4 3.5 2 2 12 14 4 2.5 2.5

The cable size is that of the cable (HIV cable (600V class 2 vinyl-insulated cable) etc.) with continuous maximum permissible temperature of 75°C. Assumes

that the surrounding air temperature is 50°C or less and the wiring distance is 20m or less.

The recommended cable size is that of the cable (THHW cable) with continuous maximum permissible temperature of 75°C. Assumes that the surrounding air

temperature is 40°C or less and the wiring distance is 20m or less. (Selection example for use mainly in the United States.)

The recommended cable size is that of the cable (PVC cable) with continuous maximum permissible temperature of 70°C. Assumes that the surrounding air

temperature is 40°C or less and the wiring distance is 20m or less. (Selection example for use mainly in Europe.)

The terminal screw size indicates the terminal size for R/L1, S/L2, T/L3, U, V, W, and a screw for earthing (grounding).

A screw for earthing (grounding) of the FR-E720-15KSC is indicated in ( ).

For single-phase power input, the terminal screw size indicates the size of terminal screw for R/L1, S/L2, U, V, W, PR, P/+, N/-, P1 and a screw for earthing

(grounding).

Screw

Size

Tightening

Torque

NOTE

Tighten the terminal screw to the specified torque. A screw that has been tighten too loosely c an cause a short circuit

or malfunction. A screw that has been tighten too tightly can cause a short circuit or malfunction due to the unit

breakage.

Use crimping terminals with insulation sleeve to wire the power supply and motor.

The line voltage drop can be calculated by the following formula:

Line voltage drop [V]=

Use a larger diameter cable when the wiring distance is long or when it is desired to decrease the voltage drop (torque

reduction) in the low speed range.

13

Page 18

Wiring

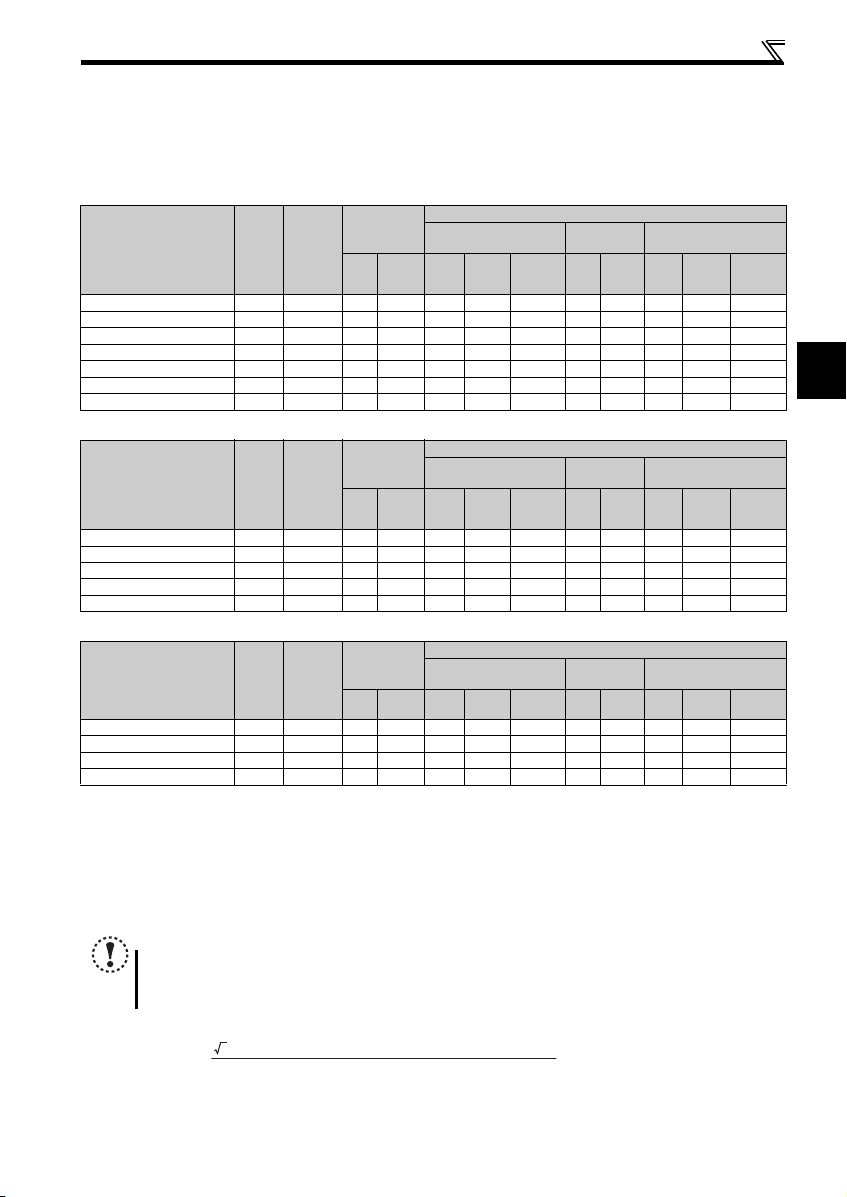

(2) Total wiring length

The overall wiring length for connection of a single motor or multiple motors should be within the value in the table below.

Pr. 72 PWM frequency selection

Setting

(carrier frequency)

1 (1kHz) or less

2 to15

(2kHz to 14.5kHz)

200V class 200m 200m 3 00m 500m 500m 500m 500m

400V class - - 200m 200m 300m 50 0m 500m

200V class 30m 1 00m 200m 300m 500m 500m 500m

400V class - - 30m 100m 200m 300m 500 m

0.1K 0.2K 0.4K 0.75K 1.5K 2.2K

When driving a 400V class motor by the inverter, surge voltages attributable to the wiring constants may occur at the motor

terminals, deteriorating the insulation of the motor. Take the following measures 1) or 2) in this case.

1) Use a "400V class inverter-driven insulation-enhanced motor" and set frequency in Pr. 72 PWM frequency selection

according to wir ing length.

Carrier frequency 14.5kHz or less 8kHz or less 2kHz or less

50m or less 50m to 100m Exceeding 100m

Wiring Length

2) Connect the surge voltage su ppression filter (FR-ASF-H/FR-BMF-H) o n the inverter output side.

NOTE

Especially for long-distance wiring, the inverter may be affected by a charging current caused by the stray

capacitances of the wiring, leading to a malfunction of the overcurrent protective function, fast response current limit

function, or stall prevention function or a malfunction or fault of the equipment connected on the inverter output side.

If malfunction of fast-response current limit function occurs, disable this function. If malfunction of stall prevention

function occurs, increase the stall level. ( Pr. 22 Stall prevention operation level and Pr. 156 Stall prevention operation

selection in Chapter 4 of the Instruction Manual (Applied))

When using the automatic restart after instantaneous power failure function with the wiring length exceeding 100m,

select without frequen cy search (Pr. 162 = "1, 11"). (

Refer to Chapter 4 of the Instruction Manu al (Applied))

3.7K

or More

14

Page 19

2

2.3.4 Wiring of control circuit

(1) Control circuit terminal layout

Recommend wire size:

0.3mm

2

to 0.75mm

2

Wiring

10 2 5 4

RUN SEFU S1 S2

PC

RL

RES

FM

CBA

RHRM

STF

SD

SD

STR

(2) Wiring method

Wiring

Use a blade terminal and a wire with a sheath stripped off for the control circuit wiring. For a single wire, strip off the sheath of

the wire and apply directly.

Insert the blade terminal or the single wire into a socket of the terminal.

1) Strip off the sheath about the size below. If the length of the sheath peeled is too long, a short circuit may occur

among neighboring wires. If the length is too short, wires might come off.

Wire the stripped wire after twisting it to prevent it from becoming loose. In addition, do not solder it.

Wire stripping length

10mm

2) Crimp the blade terminal.

Insert wires to a blade terminal, and check that the wires come out for about 0 to 0.5 mm from a sleeve.

Check the condition of the blade ter minal after crimping. Do not use a bla de terminal of which the crimping is

inappropriate, or the face is damaged.

Unstranded

Wire

Sleeve

0 to 0.5mm

Shell

Damaged

Crumpled tip

Blade terminals available on the market: (as of Jan. 2010)

Phoenix Contact Co.,Ltd.

Wire Size (mm2)

0.3 AI 0,5-10WH — —

0.5 AI 0,5-10WH — AI 0,5-10WH-GB

0.75 AI 0,75-10GY A 0,75-10 AI 0,75-10GY-GB

1 A I 1-10RD A1-10 AI 1-10RD/1000GB

1.25, 1.5 AI 1,5-10BK A1,5-10 AI 1,5-10BK/ 1000GB

0.75 (for two wires) AI-TWIN 2 x 0,75-10GY — —

A bl ade terminal with an insulation sleeve compatible with MTW wire which has a thick wire insulation

Applicable for terminal ABC.

with insulation sleeve without insulation sleeve for UL wire

Blade Terminal Model

NICHIFU Co.,Ltd.

Wire Size (mm2)

0.3 to 0.75 BT 0.75-11 VC 0.75 NH 67

Blade terminal product

number

Insulation product number

wires

Wires are not inserted

into the shell

Blade terminal

crimping tool

Blade terminal

crimping tool

CRIMPFOX 6

15

Page 20

Wiring

Flathead screwdriver

Open/close button

r

NOTE

Pulling out the terminal block forcefully without pushing

the open/close button all the way down may damage the

terminal block.

Use a small flathead scr ewdriver (Tip thickness: 0.4mm/

tip width: 2.5mm) .

If a flathead screwdriver with a narrow tip is used,

terminal block may be damaged.

Products available on the market :(as of Jan. 2010)

Place the flath ead screwdriver vertical t o the open/close

button. In case the blade tip slips, it may cause to damage of inverter or in jury.

Product Ty pe Maker

Flathead

screwdriver

SZF 0- 0,4 x 2,5 Phoenix Co ntact Co.,Ltd.

3) Insert the wire into a socket.

When using a single wire or a stranded wire without a blade terminal, push an

open/close button all the way down with a flathead screw driver, and insert the wire.

NOTE

When using a stranded wire without a blade terminal, twist enough to avoid short circuit with a nearby terminals or

wires.

Place the flathea d screwdriver vertical to the open/clo se button. In case t he blade tip slips, it ma y cause to damage of

inverter or injury.

Wire removal

Pull the wire with pushing the open/close button all the

way down firmly with a flat head screwdr iver.

Open/close button

Flathead screwdrive

(3) Control circuit common terminals (SD, 5, SE)

Terminals SD, SE and 5 are common terminals for I/O signals. (All common terminals are isolated from each other.) Do not

earth them. Avoid connecting the terminals SD and 5 and the terminals SE and 5.

Terminal SD is a common terminal for the contact input terminals (STF, STR, RH, RM, RL, RES) and frequency output signal

(FM). The open collector circuit is isolated from the internal control circuit by photocoupler.

Terminal 5 is a common terminal for the frequency setting signals (terminal 2 or 4). It should be protected from external noise

using a shielded or twisted wire.

Terminal SE is a common terminal for the open collector output terminal (RUN, FU). The contact input circuit is isolated from

the internal control circuit by photocoupler.

(4) Wiring instructions

1) It is recommended to use the wires of 0.3mm2 to 0.75mm2 gauge for connection to the control circuit terminals.

2) The maximum wiring length should be 30m ( 200m for terminal FM).

3) Do not short terminals PC and SD. Inverter may be damaged.

4) Use two or more parallel micro-signal contacts or twin contacts to prevent

contact faults wh en using contact inputs since the control circui t input signals

are micro-currents.

5) Use shielded or twisted wires for connection to the control circuit terminals and

run them away from the main and power circuits (including the 200V relay

sequence circuit).

6) Do not apply a voltage to the contact input terminals (e.g. STF) of the control

circuit.

7) Always apply a voltage to the fault output terminals (A, B, C) via a relay coil, lamp, etc.

16

Micro signal contacts Twin contacts

Page 21

2

Wiring

S2

S1

PC

Inverter

START/RESET

+24V

QS90SR2SN-Q

K1

X0 X1

COM0

COM1

24G

XS0

XS1

Z10

Z00

Z20

Z11 Z01 Z21

K2

DC24V

RUN(SAFE2)

R S T

U V W

MITSUBISHI MELSEC Safety relay module

IM

SE

STF

STR(STOP)

STF

STOP

SD

I/O control

FU(SAFE)

monitor

*1

*1

*2

*2

Internal

Safety

Circuit

Output shutoff

circuit

*1 Output signals differ by the setting of Pr.190 and

Pr.191 (Output terminal function selection).

*2 Input signals differ by the setting of Pr178 to Pr.182

(Input terminal function selection).

Emergency

stop button

2.3.5 Safety stop function

(1) Description of the function

The terminals related to the safety stop function are shown below.

Terminal Symbol Description

S1

S2

PC

FU

RUN

SE Common terminal for open col lector outputs (terminal RUN and FU)

In the initial status, terminal S1 and S2 are shorted with terminal PC by shortening wire. Remove the shortening wire and connect the safety relay module

when using the safety stop function.

In the initial setting, output frequency detection (FU signal) is assigned to terminal FU. Set "80" to Pr.191 FU terminal function selection to assign SAFE signal.

The function can be assigned to other terminals by setting "80 (positive logic) or 180 (negative logic)" to any of Pr.190 to Pr.192 (Output terminal function

selection). ( Refer to the Instruction Manual (Applied))

In the initial setting, inverter running (RUN signal) is assigned to terminal RUN. Set "81" to Pr.190 RUN terminal function selection to assign SAFE2 signal. The

function can be assigned to other terminals by setting "81 (positive logic) or 181 (negative logic)" to any of Pr.190 to Pr.192 (Output terminal function selection).

( Refer to the Instruction Manual (Applied))

At an internal safety circuit failure, one of E.SAF, E.6, E.7, and E.CPU is displayed on the operation panel.

For input of safety stop c hannel 1.

For input of safety stop c hannel 2.

Common terminal for termi nal S1 and S2.

Outputs the safety stop s tatus

SAFE

The signal is output when i nverter output is shut off due to the

signal

safety stop function.

SAFE2

Outputs when an alarm or failure is detected.

The signal is output when no internal safety circuit failure

signal

NOTE

Hold the ON or OFF status for 2ms or longer to input signal to terminal S1 or S2. Signal input shorter than 2ms is not

recognized.

Use SAFE signal to monitor safety stop status. SAFE signal cannot be used as safety stop input signal to other

devices (other than the safety relay module).

SAFE 2 signal can only be used to output an alarm or to prevent restart of an inverter. The signal cannot be used as

safety stop input sig nal to other devices.

(2) Wiring connection diagram

To prevent restart at fault occurrence, connect terminals RUN (SAFE 2 signal) and SE to terminals XS0 and XS1, which are

the feedback input terminals of the safety relay module.

By setting Pr. 190 RUN terminal function selection = "81 (SAFE2 signal)", terminal RUN is turned OFF at fault occurrence.

Between S1 and PC / S2 and PC

Open: In safety stop state .

Short: Other than safety s top state.

OFF: Drive enabled or dr ive stop (at an internal

safety circuit failure

ON: Drive stop (no interna l safety circuit failure

OFF: Internal safety circ uit failure

exists.

ON : No internal safety cir cuit failure

)

)

NOTE

Changing the terminal assignment using Pr. 190 to Pr. 192 (output terminal function selection) may affect the other

functions. Set parameters after confirming the function of each terminal.

17

Page 22

Wiring

(3) Safety stop function operation

Input

power

OFF — — — OFF OFF Output shutoff (Safe state)

ON

At an internal safety circuit failure, one of E.SAF, E.6, E.7, and E.CPU is displayed on the operation panel.

SA is displayed when both of the S1 and S2 signals are in open status and no internal safety circuit failure exists.

ON: Transistor used for an open collector output is conducted.

OFF: Transistor used for an open collector output is not conducted.

For more details, refer to the Safety stop function instruction manual (BCN-A211508-004). (Please contact your sales

representative for the manual.)

Input sign al

S1-PC S2-PC SAFE SAFE2

Short Short

Open Open

Short Open Failure OFF O FF Output shu toff (Safe state)

Open

Short Failure OFF OF F Output shu toff (Safe state)

Internal safety circuit

No failure OFF ON Drive enabled

Failure OFF OFF Output shutoff (Safe state)

No failure ON O N Output shutoff (Safe state)

Failure OFF OFF Output shutoff (Safe state)

Output signal

Inverter operation enable signal

18

Page 23

2

Connection of a dedicated external brake resistor (MRS type, MYS type, FR-ABR)

Thermal relay

(OCR) (*1)

*2

Thermal re lay

(OCR) (*1)

*2

r

2.4 Connection of a dedicated external brake resistor (MRS type, MYS type, FR-ABR)

Install a dedicated brake resistor (MRS type, MYS type, FR-ABR) outside when the motor driven by the inverter is made to run

by the load, quick deceleration is required, etc. Connect a dedicated brake resistor (MRS type, MYS type, FR-ABR) to

terminals P/+ and PR. (For the locations of terminals P/+ and PR, refer to the terminal block layout (page 12).)

Set parameters below. (

Connected Brake Resistor Pr. 30 Regenerative function selection Setting Pr. 70 Special regenerative brake duty Setting

MRS type, MYS type 0 (initial value) —

MYS type

(used at 100% torque/6% ED)

FR-ABR 1

It is recommended to configure a sequence, which shuts off power in the input side of the inverter by the external thermal

relay as shown below, to prevent overheat and burnout of the brake resistor (MRS, MYS) and high duty brake resistor (FR-

ABR) in case the regenerative brake transistor is damaged. (The brake resistor can not be connected to the 0.1K or 0.2K.)

<Example 1>

Power supply

F

ON

MC

Refer to the table below for the type number of each capacity of thermal relay and the diagram below for t he connection.

(Always install a thermal relay when using a brake resistor whose capacity is 11K or higher.)

When the power supply is 400V class, install a step-down transformer.

Power Supply

Vol ta ge

MRS120W200 TH-N20CXHZ-0.7A

MRS120W100 TH-N20CXHZ-1.3A

200V

MRS120W60 TH-N20CXHZ-2.1A

MRS120W40 TH-N20CXHZ-3.6A

MYS220W50 (two

units in parallel)

Power Supply

Vol ta ge

FR-ABR-0.4K TH-N20CXHZ-0.7A

FR-ABR-0.75K TH-N20CXHZ-1.3A

FR-ABR-2.2K TH-N20CXHZ-2.1A

200V

FR-ABR-3.7K TH-N20CXHZ-3.6A

FR-ABR-5.5K TH-N20CXHZ-5A

FR-ABR-7.5K TH-N20CXHZ-6.6A

FR-ABR-11K TH-N20CXHZ-11A

FR-ABR-15K TH-N20CXHZ-11A

FR-ABR-H0.4K TH-N20CXHZ-0.24A

FR-ABR-H0.75K TH-N20CXHZ-0.35A

FR-ABR-H1.5K TH-N20CXHZ-0.9A

FR-ABR-H2.2K TH-N20CXHZ-1.3A

400V

FR-ABR-H3.7K TH-N20CXHZ-2.1A

FR-ABR-H5.5K TH-N20CXHZ-2.5A

FR-ABR-H7.5K TH-N20CXHZ-3.6A

FR-ABR-H11K TH-N20CXHZ-6.6A

FR-ABR-H15K TH-N20CXHZ-6.6A

Note

The brake resistor connected should only be the dedicated brake resistor.

Perform wiri ng and operation accor ding to the Instruction M anual of each option un it.

Brake resistor can not be used with the brake unit, high power factor converter, power supply regeneration converter,

etc.

Do not use the brake resistor (MRS type, MYS type) with a lead wire extended.

Do not connect the resistor directly to t he terminals P/+ and N/- . This could cause a fire.

Refer to the Instruction Manual (Applied) for the parameter details.)

16%

MC

R/L1

S/L2

T/L3

T

MC

OFF

OCR

Contact

Brake Resistor

Inverter

P/+

PR

Thermal Relay Type

(Mitsubishi product)

High-duty brake

resistor (FR-ABR)

R

<Example 2>

Power supply

F

ON

MC

Contact Rati ng

110VAC 5A,

220VAC 2A (AC11 class)

110VDC 0.5A,

220VDC 0.25A (DC11 class)

Contact Rating

Brake Resistor

TH-N20CXHZ-5A

Thermal Relay Type

(Mitsubishi product)

110VAC 5A

220VAC 2A (AC11 class)

110VDC 0.5A,

220VDC 0.25A (DC11 class)

7.5K or lower 10%

11K or higher 6%

MC

Inverter

P/+

R/L1

S/L2

PR

T/L3

T

B

MC

OFF

C

OCR

Contact

1/L1 5/L3

2/T1 6/T3

To the inverter

terminal P/+

High-duty brake

resistor (FR-ABR)

R

TH-N20

To a resisto

19

Page 24

PRECAUTIONS FOR USE OF THE INVERTER

3 PRECAUTIONS FOR USE OF THE INVERTER

The FR-E700 s eries is a highly reliable product, but incorrect peripheral circuit making or operation/handling method may

shorten the product life or damage the product.

Before starting operation, always recheck the following points.

(1) Use crimping terminals with insulation sleeve to wire the power supply and motor.

(2) Application of power to the output terminals (U, V, W) of the inverter will damage the inverter. Never perform

such wiring.

(3) After wiring, wire offcuts must not be left in the inverter.

Wire offcuts can cause an alarm, failure or malfunction. Always keep the inverter clean.

When drilling mounting holes in an enclosure etc., take care not to allow chips and other foreign matter to enter the

inverter.

(4) Use cables of the size to make a voltage drop 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable voltage drop will cause the motor torque

to decrease especially at the output of a low frequency.

Refer to page 13 for the recommende d wire sizes.

(5) The overall wiring length should be 500m or less.

Especially for long distance wiring, the fast-response current limit function may decrease or the equipment connected to

the secondary side may malfunction or become faulty under the influence of a charging current due to the stray capacity

of the wiring. Therefore, note the overall wiring length. (Refer to page 14)

(6) Electromagnetic wave interference

The input/output (main circuit) of the inverter includes high frequency components, which may interfere with the

communication devices (such as AM radios) used near the inverter. In this case, install options among the capacitor type

EMC filter FR-BIF (for use in the input side only), the ferrite core type EMC filter FR-BSF01/FR-BLF, filterpack, and EMC

filter to minimize the interference.

(7) Do not install a power factor correct ion capacitor, surge s uppressor or capacitor type filter on the in verter

output side.

This will cause the inverter to trip or the capacitor and surge suppressor to be damaged. If any of the above devices are

connected, immediately re move them. (When using capacitor type filter (FR-BIF) for si ngle-phase power input model,

make sure of secure insulation of T-phase, and connect to the input side of the inverter.)

(8) For some short time after the power is switched OFF, a high voltage remains in the smoothing capacitor.

When accessing the inverter for inspection, wait for at least 10 minutes after the power supply has been switched OFF,

and then make sure that the voltage across the main circuit terminals P/+ and N/- of the inverter is not more t han 30VDC

using a tester, etc. The capacitor is charged with high voltage fo r some time after power OFF and it is dangerous.

(9) If "EV" is displayed on the operation panel, turn off the 24V external power supply before wiring and inspection.

(10) A short circuit or earth (ground) fault on the inverter output side may damage the inverter modules.

Fully check the insulation resistance of the circuit prior to inverter operation since repeated short circuits caused by