Mitsubishi Electric FR-E720-0.1K, FR-E720-0.75K, FR-E720-1.5K, FR-E720-5.5K, FR-E720-11K Instructions Manual

...

INVERTER

Plug-in option

PRE-OPERATION INSTRUCTIONS

1

FR-A7NP E kit

INSTRUCTION MANUAL

PROFIBUS-DP

communication function

INSTALLATION

2

WIRING

3

INVERTER SETTING

4

FUNCTIONS

5

PROFIBUS DEVICE DATA

6

PPO TYPE SUPPORT SPECIFICATION

7

PPO TYPE NON SUPPORT SPECIFICATION

8

TROUBLESHOOTING

9

Thank you for choosing this Mitsubishi Inverter plug-in option.

This instruction manual gives handling information and

precautions for use of this equipment. Incorrect handling might

cause an unexpected fault. Before using the equipment, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about

safety matters

Do not attempt to install, operate, maintain or inspect this

product until you have read through this instruction manual and

appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full

knowledge of the equipment, safety information and

instructions.

In this instruction manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

Assumes that incorrect handling may

WARNING

CAUTION

Note that even the level may lead to a serious

consequence according to conditions. Please follow the

instructions of both levels because they are important to

personnel safety.

cause hazardous conditions, resulting

in death or severe injury.

Assumes that incorrect handling may

cause hazardous conditions, resulting

in medium or slight injury, or may

cause physical damage only.

CAUTION

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

• While power is on or when the inverter is running, do not

open the front cover. You may get an electric shock.

• Do not run the inverter with the front cover or wiring cover

removed. Otherwise, you may access the exposed highvoltage terminals and charging part and get an electric shock.

• If power is off, do not remove the front cover except for wiring

or periodic inspection. You may access the charged inverter

circuits and get an electric shock.

• Before starting wiring or inspection, check to make sure that

the indication of the inverter operation panel is off, wait for at

least 10 minutes after the power supply has been switched off,

and check that there are no residual voltage using a tester or

the like. The capacitor is charged with high voltage for some

time after power off and it is dangerous.

• Any person who is involved in the wiring or inspection of this

equipment should be fully competent to do the work.

• Always install the plug-in option before wiring. Otherwise,

you may get an electric shock or be injured.

• Do not touch the plug-in option with wet hands. Otherwise

you may get an electric shock.

• Do not subject the cables to scratches, excessive stress,

heavy loads or pinching. Otherwise you may get an electric

shock.

A-1

2. Injury Prevention

3) Usage

CAUTION

• Apply only the voltage specified in the instruction manual to

each terminal. Otherwise, burst, damage, etc. may occur.

• Ensure that the cables are connected to the correct terminals.

Otherwise, burst, damage, etc. may occur.

• Always make sure that polarity is correct to prevent damage, etc.

Otherwise, burst, damage may occur.

• While power is on or for some time after power-off, do not touch

the inverter as it is hot and you may get burnt.

3. Additional Instructions

Also note the following points to prevent an accidental failure,

injury, electric shock, etc.

1) Transportation and mounting

CAUTION

• Do not install or operate the plug-in option if it is damaged or

has parts missing.

• Do not stand or rest heavy objects on the product.

• Check that the mounting orientation is correct.

• Prevent other conductive bodies such as screws and metal

fragments or other flammable substance such as oil from

entering the inverter.

2) Trial run

CAUTION

• Before starting operation, confirm and adjust the parameters.

A failure to do so may cause some machines to make

unexpected motions.

WARNING

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

• When parameter clear or all parameter clear is performed,

reset the required parameters before starting operations.

Each parameter returns to the initial value.

• For prevention of damage due to static electricity, touch

nearby metal before touching this product to eliminate static

electricity from your body.

4) Maintenance, inspection and parts replacement

CAUTION

• Do not test the equipment with a megger (measure insulation

resistance).

5) Disposal

CAUTION

• Treat as industrial waste.

6) General instruction

All illustrations given in this manual may have been drawn with

covers or safety guards removed to provide in-depth

description. Before starting operation of the product, always

return the covers and guards into original positions as specified

and operate the equipment in accordance with the manual.

A-2

CONTENTS

1 PRE-OPERATION INSTRUCTIONS 1

1.1 Unpacking and Product Confirmation .............................................................................................1

1.1.1 SERIAL number..............................................................................................................................................1

1.1.2 Packing confirmation ......................................................................................................................................2

1.1.3 Parts ...............................................................................................................................................................3

1.2 Node Address Setting .......................................................................................................................4

1.3 Specifications.....................................................................................................................................5

1.3.1 Inverter option specifications .......................................................................................................................... 5

1.3.2 Communication specifications........................................................................................................................ 5

2 INSTALLATION 6

2.1 Pre-Installation Instructions .............................................................................................................6

2.2 Installation Procedure .......................................................................................................................6

3WIRING 12

3.1 Terminal Block .................................................................................................................................12

3.2 Wiring ................................................................................................................................................13

4 INVERTER SETTING 18

4.1 Parameter List ..................................................................................................................................18

I

4.2 Operation Mode Setting ..................................................................................................................19

4.2.1 Operation mode indication............................................................................................................................ 19

4.2.2 Operation mode switching and communication startup mode (Pr. 79, Pr. 340) ...........................................20

4.3 Operation and Speed Command Source (Pr. 338, Pr. 339, Pr. 550) ............................................23

4.3.1 Communication EEPROM write selection (Pr. 342) ..................................................................................... 27

4.4 Operation at Communication Error Occurrence ...........................................................................28

4.4.1 Operation selection at communication error occurrence (Pr. 500 to Pr. 502) ..............................................28

4.4.2 Alarm and measures .................................................................................................................................... 32

4.5 Inverter Reset ...................................................................................................................................33

5 FUNCTIONS 35

5.1 Output from the Inverter to the Network........................................................................................35

5.2 Input to the Inverter from the Network...........................................................................................36

6 PROFIBUS DEVICE DATA 37

6.1 Device Data (GSD file) .....................................................................................................................37

6.2 Slave User Parameter ......................................................................................................................41

7 PPO TYPE SUPPORT SPECIFICATION 42

7.1 Profibus Profiles ..............................................................................................................................42

7.2 ID Definitions ....................................................................................................................................43

7.3 Buffer Memory Map .........................................................................................................................44

II

7.4 Buffer Memory Configuration .........................................................................................................45

7.5 Buffer Memory Details .....................................................................................................................46

7.6 Outline of PNU..................................................................................................................................53

7.7 Profibus PNU ....................................................................................................................................54

7.7.1 Real-time monitor .........................................................................................................................................54

7.7.2 Parameter clear ............................................................................................................................................ 55

7.7.3 Operation mode read/write...........................................................................................................................55

7.7.4 Set frequency read....................................................................................................................................... 55

7.7.5 Terminal input read.......................................................................................................................................56

7.7.6 Inverter reset ................................................................................................................................................ 56

7.7.7 Node address read.......................................................................................................................................56

7.7.8 Alarm definition read.....................................................................................................................................57

7.7.9 PNU list read ................................................................................................................................................ 61

7.8 Standard Parameters .......................................................................................................................62

8 PPO TYPE NON SUPPORT SPECIFICATION 64

8.1 Profibus Profiles ..............................................................................................................................64

8.2 ID Definitions ....................................................................................................................................65

8.3 Buffer Memory Map .........................................................................................................................65

8.4 Buffer Memory Configuration .........................................................................................................66

8.5 Buffer Memory Details .....................................................................................................................67

8.6 Outline of PNU..................................................................................................................................72

8.7 Profibus PNU (Module Type E5NP) ................................................................................................73

8.7.1 Real time monitor area (IND=0000H (IND=00H, PP=00H)) .........................................................................73

III

8.7.2 System environment variable (sev) area (IND = 01PPH (IND = 01H, PP = 00H, 01H)) ..............................74

8.8 Standard Parameters .......................................................................................................................78

8.8.1 Normal parameter area (IND = 0200H (IND = 02H, PP = 00H)) ..................................................................78

8.8.2 Pr. 900 to calibration parameter (frequency) area (IND=0300H (IND=03H, PP=00H))................................79

8.8.3 Pr. 900 to calibration parameter (%) area (IND=0400H (IND=04H, PP=00H)) ............................................80

9 TROUBLESHOOTING 81

IV

1 PRE-OPERATION INSTRUCTIONS

1.1 Unpacking and Product Confirmation

Take the plug-in option out of the package, check the product name, and confirm that the product is as you

ordered and intact.

This product is a plug-in option for the FR-E700 series inverter.

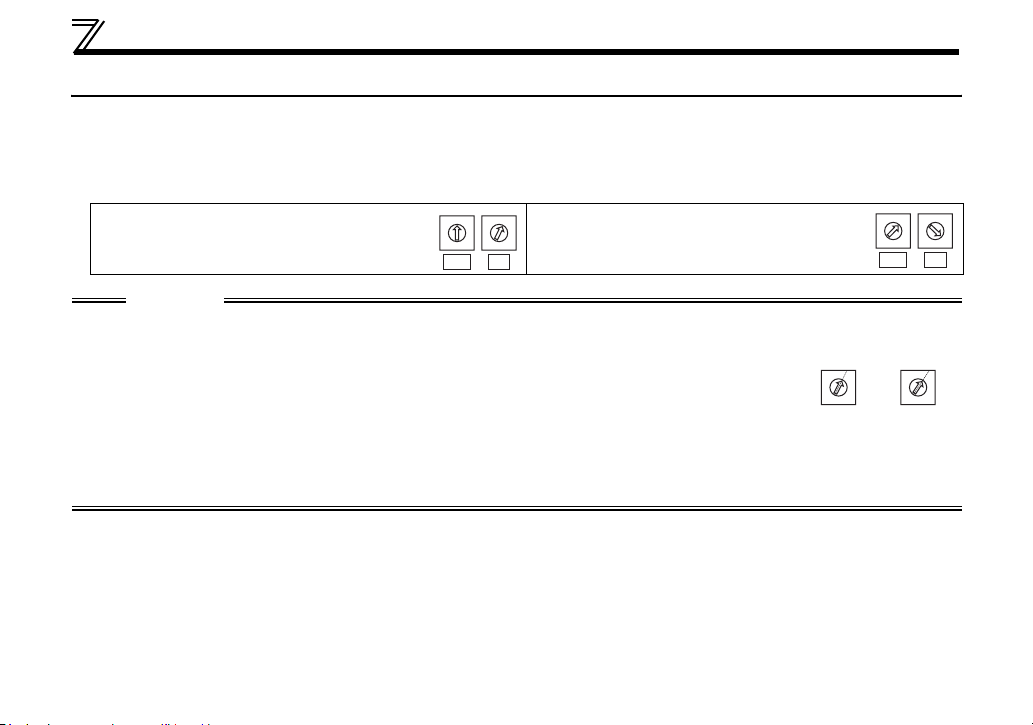

1.1.1 SERIAL number

Check the SERIAL number indicated on the inverter rating plate or package.

For the 200V class of FR-E700, this option can be used with the inverter having the following SERIAL

number or later. (For the 400V class of FR-E700, this option can be used with all inverters regardless of

SERIAL number.)

Typ e SERIAL number

FR-E720-0.1K to 0.75K J7Y{{{{{{

FR-E720-1.5K to 5.5K K7Y{{{{{{

FR-E720-7.5K L7Y{{{{{{

FR-E720-11K, 15K G7Y{{{{{{

z SERIAL number check

Refer to the inverter manual for the location of the rating plate.

Rating plate example

Symbol Year Month Control number

7 Y {{{{{{

SERIAL number

The SERIAL consists of 1 version symbol, 2 numeric characters or 1 numeric

character and 1 alphabet letter indicating year and month, and 6 numeric

characters indicating control number.

Month is indicated as 1 to 9, X (October), Y (November), and Z (December).

1

1

PRE-OPERATION INSTRUCTIONS

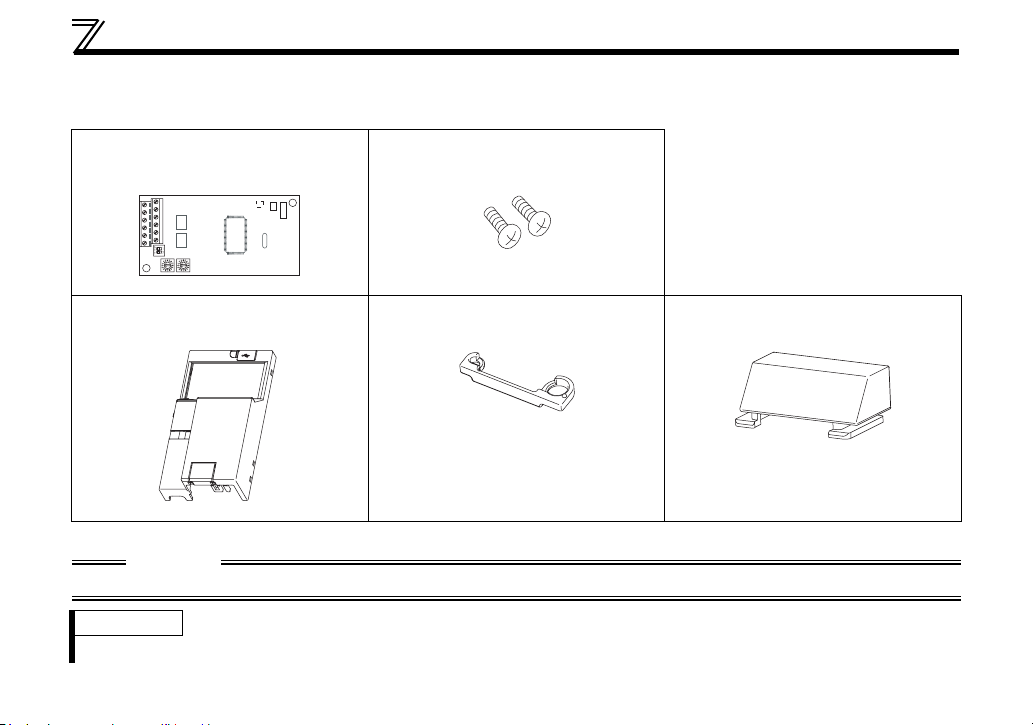

1.1.2 Packing confirmation

Check the enclosed items.

Plug-in option

......................................................... 1

Mounting screw (M3 × 6mm)

........................ 2 (Refer to page 8, 10.)

Front cover for plug-in option

......................................................... 1

* Used with the FR-E720-3.7K (FR-E720-175) or less and FR-E740-7.5K (FR-E740-170) or less.

Option protective cover

.......................................................1

Option small cover (Not used)

..........................................................1

*

CAUTION

• In place of the inverter front cover, install a provided front cover for plug-in option.

REMARKS

•PROFIBUS is a registered trademark of PROFIBUS User Organization.

2

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

0

F

E

D

C

B

A

9

8

7

6

5

4

3

2

1

1

O

F

F

2

SW2

SW3

SW1

X1

X16

D+

DVD-

CNTR

FG

V+

D+

DD+

V-

FG

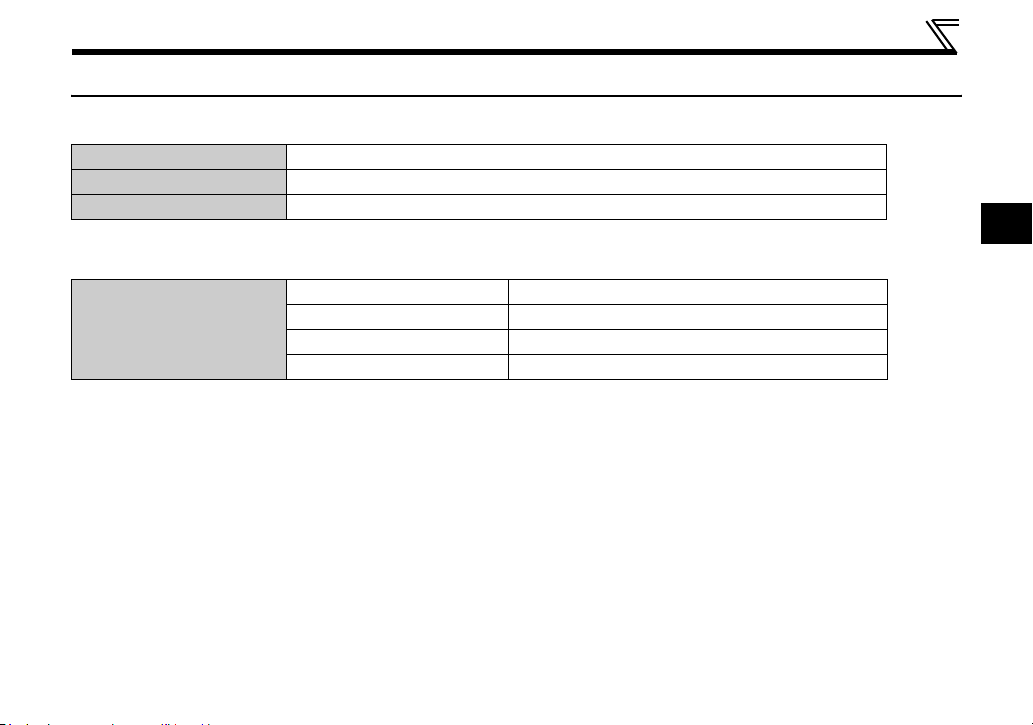

1.1.3 Parts

Switch for manufacturer setting

O

Terminal block

Connect

the communication

cable.

1

Do not change from

F

2

F

initially-set status (1, 2:OFF).

Front view Rear view

FR-A7NP

SW2

O

1

F

2

F

SW1

SW3

5

5

4

4

6

6

3

3

7

7

2

2

8

8

1

1

9

9

0

0

A

A

F

F

B

B

E

E

C

C

D

D

X1X16

Mounting hole

Node address switch

Mount on the inverter with an accessory mounting screw.

Terminal

(Refer to page 8, 10.)

layout

PRE-OPERATION INSTRUCTIONS

Operation status indication LED

Lit/off of the LED indicate inverter operation status.

Mounting

STATUS

LED1

(Refer to page 4.)

Name Function

Node address

switch

Operation status

indication LED

hole

Connector

Connect to the inverter option connector.

Set the inverter address within the range of 00H to

7DH.

Off Inverter power off

Red is lit

A communication error with the master

occurred

Green is lit During communication with the master

1

Mounting hole

3

PRE-OPERATION INSTRUCTIONS

1.2 Node Address Setting

Set the node address between "00H to 7DH" using node address switches on the FR-A7NP (refer to page 3).

The setting is reflected at the next power-on or inverter reset.

Set the arrow (×) of the corresponding switches to the number and alphabet to set a desired address.

• Setting example

Node address 1:

Set the "

× " of X16(SW3) to "0" and the "×

" of X1(SW1) to "1".

0

1

F

2

E

3

D

4

5

C

B

6

7

A

8

9

X16 X1

Node address 38 (26H):

0

1

F

2

E

3

D

4

5

C

B

6

7

A

Set the "

8

9

"

× " of X1(SW1) to "6".

×" of X16(SW3) to "2" and the

CAUTION

• Set the node address switch to the switch number (alphabet) position correctly. If the

switch is set between numbers, normal data communication can not be made.

• Do not set the node address to 7EH through FFH.

• Depending on the master module, 00H, 01H, 02H, 7CH, 7DH of node address may not

be used.

• You cannot set the same node address to other devices on the network. (Doing so disables proper

communication.)

• Set the inverter node address before switching on the inverter and do not change the setting while power is

on. Otherwise you may get an electric shock.

Good

example

1

0

F

2

E

3

D

4

5

C

B

6

7

A

8

9

0

1

F

F

2

E

E

3

D

D

4

5

C

C

B

B

6

7

A

A

8

9

X16 X1

Bad

example

1

0

F

2

E

3

D

4

5

C

B

6

7

A

8

9

0

1

2

3

4

5

6

7

8

9

4

PRE-OPERATION INSTRUCTIONS

1.3 Specifications

1.3.1 Inverter option specifications

Type Inverter plug-in option type

Number of nodes occupied One inverter occupies one node.

Connection cable Cable which supports 12.0Mbps communication (EEIA-485(RS-485) standard)

1.3.2 Communication specifications

Wiring length 1200m or less 9600bps, 19.2Kbps, 93.75Kbps

Communication speed

Wiring length 600m or less 187.5Kbps

Wiring length 200m or less 500Kbps, 1.5Mbps

Wiring length 100m or less 3.0Mbps, 6.0Mbps, 12.0Mbps

1

5

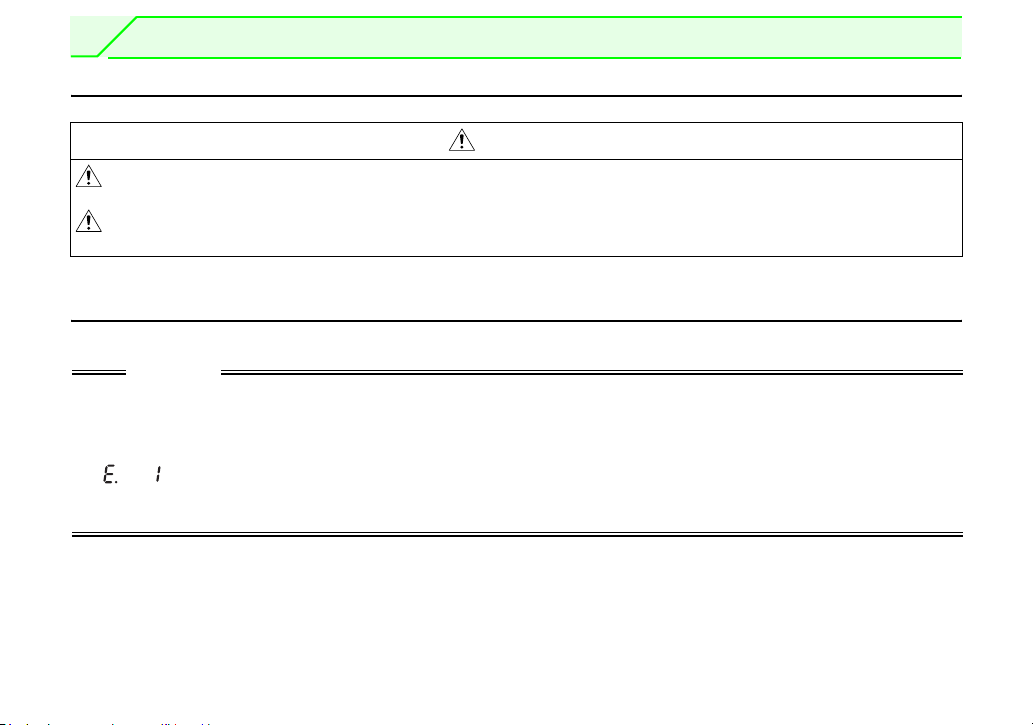

2 INSTALLATION

2.1 Pre-Installation Instructions

Make sure that the input power of the inverter is off.

CAUTION

With input power on, do not install or remove the plug-in option. Otherwise, the inverter and

plug-in option may be damaged.

For prevention of damage due to static electricity, touch nearby metal before touching this

product to eliminate static electricity from your body.

2.2 Installation Procedure

The FR-E700 series has one connection connector for the plug-in option.

CAUTION

• Always perform wiring to the main circuit terminals and control circuit terminals before installing the

option. Wiring cannot be performed after installing the option.

• When the inverter can not recognize that the option unit is mounted due to improper installation, etc.,

" " (option alarm) is displayed.

• Take care not to drop a mounting screw during mounting and removal.

• Pull out the option straight to remove. Otherwise, the connector may be damaged.

6

INSTALLATION

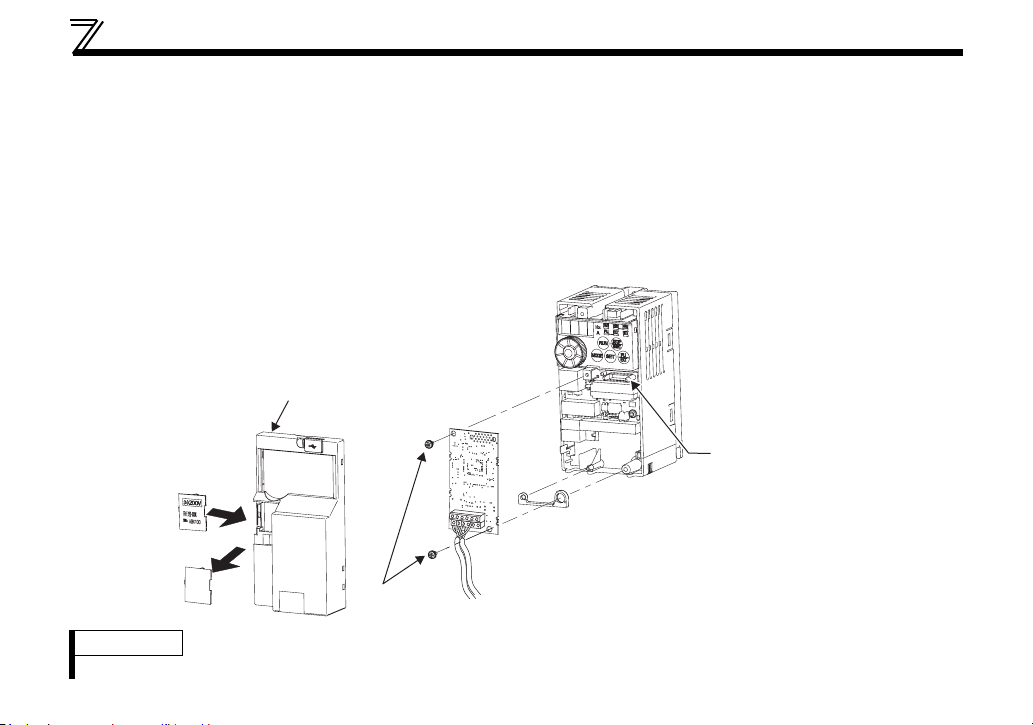

z For FR-E720-3.7K (FR-E720-175) or less and FR-E740-7.5K (FR-E740-170) or less

(1) Remove the front cover from the inverter. (For removing the front cover, refer to the FR-E700

instruction manual.)

(2) Remove the PU cover from the front cover. Open the PU cover with a driver, etc. and remove it in the

direction of arrow as shown below.

(1) Front cover

2

*

* Open the PU cover, then open it toward the arrow

direction to remove.

(2) PU cover

REMARKS

• Because the voltage class, model name and serial (only voltage class is labeled for FR-E740-5.5K (FR-E740-120)

or more) are stated on the PU cover, replace a PU cover of a plug-in option front cover with the removed PU cover

from the inverter.

7

INSTALLATION

(3) Install the option protective cover.

(4) Securely fit the connector of the plug-in option to the inverter connector along the guides.

(5) Securely fix the both top and bottom of the plug-in option to the inverter with the accessory mounting

screws. (tightening torque 0.45N

•m to 0.55N•m) If the screw holes do not line-up, the connector may

not have been plugged snugly. Check for loose plugging.

(6) Remove the PU cover provided on the front cover for plug-in option and install the other PU cover,

which was removed in (2).

(7) Loosen the terminal screw and insert the cable into the terminal. Tighten each cable with fixing screws

to the recommended tightening torque. (Refer to the chapter 3 for wiring.)

(8) Install the front cover for plug-in option to the inverter.

(6) Replace

(8)

Front cover

for plug-in option

Mounting

screws

(5)

(3) Option protective cover

(7)

(4)

Option

connector

of inverter

REMARKS

• When the option protective cover is not installed, the protective structure (JEM1030) changes to open type (IP00).

8

INSTALLATION

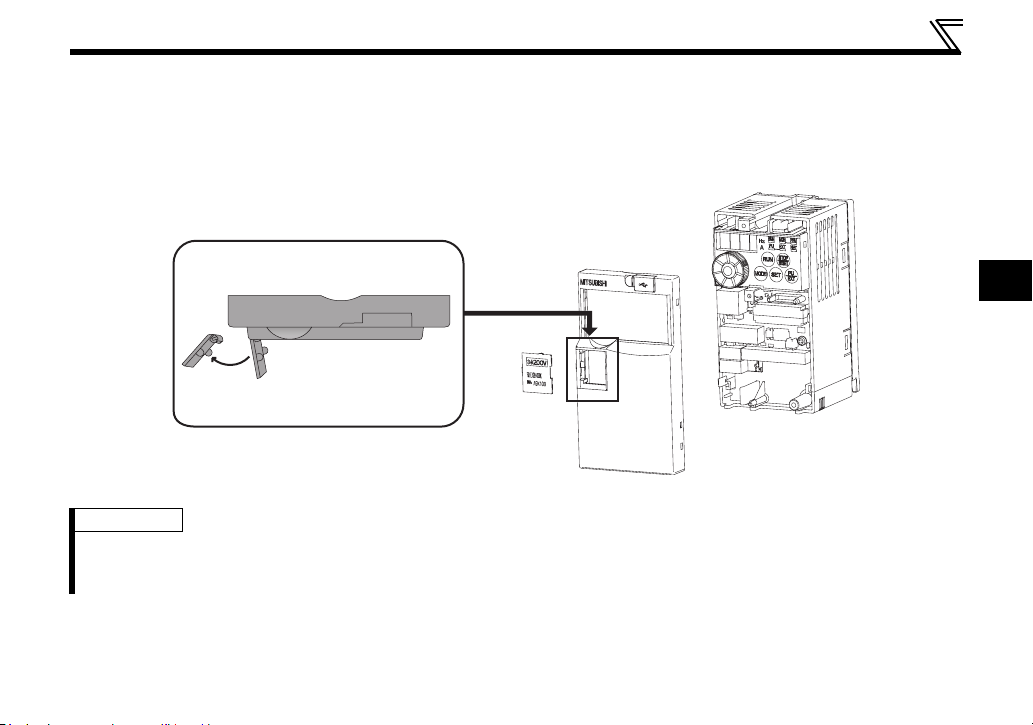

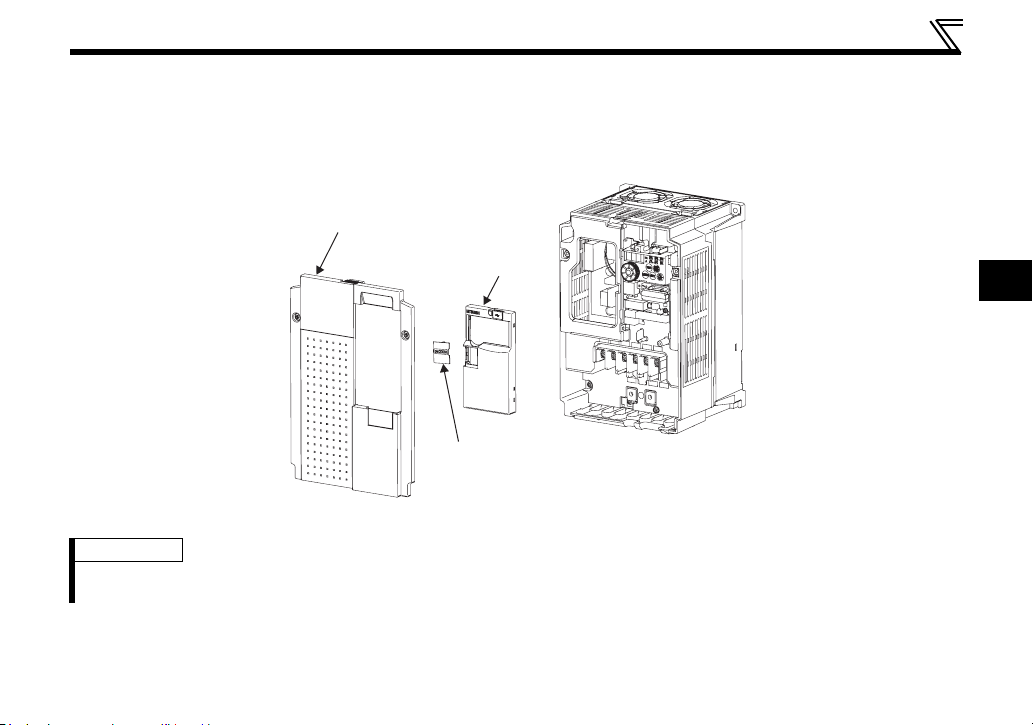

z For FR-E720-5.5K (FR-E720-240) or more and FR-E740-11K (FR-E740-230) or more

(1) Remove the front cover 1 and 2 from the inverter. (For removing the front cover, refer to the FR-E700

instruction manual.)

(2) Remove the PU cover from the front cover 2. For removing the PU cover, refer to page 7.

Front cover 1

(1)

Front cover 2

(1)

(2)

PU cover

REMARKS

• Because the voltage class is stated on the PU cover, replace a PU cover of a plug-in option front cover with the

removed PU cover from the inverter.

2

9

INSTALLATION

(3) Install the front cover 1 to the inverter.

(4) Securely fit the connector of the plug-in option to the inverter connector along the guides.

(5) Securely fix the both top and bottom of the plug-in option to the inverter with the accessory mounting

screws. (tightening torque 0.45N

not have been plugged snugly. Check for loose plugging.

(6) Remove the PU cover provided on the front cover for plug-in option and install the other PU cover,

which was removed in (2).

(7) Loosen the terminal screw and insert the cable into the terminal. Tighten each cable with fixing screws

to the recommended tightening torque. (Refer to the chapter 3 for wiring.)

(8) Install the front cover for plug-in option to the inverter.

•m to 0.55N•m) If the screw holes do not line-up, the connector may

10

(6)

Replace

INSTALLATION

(4) Option connector of inverter

(3)

Front cover for

plug-in option

(8)

2

(7)

Installation completed

(5) Mounting screws

11

3 WIRING

A

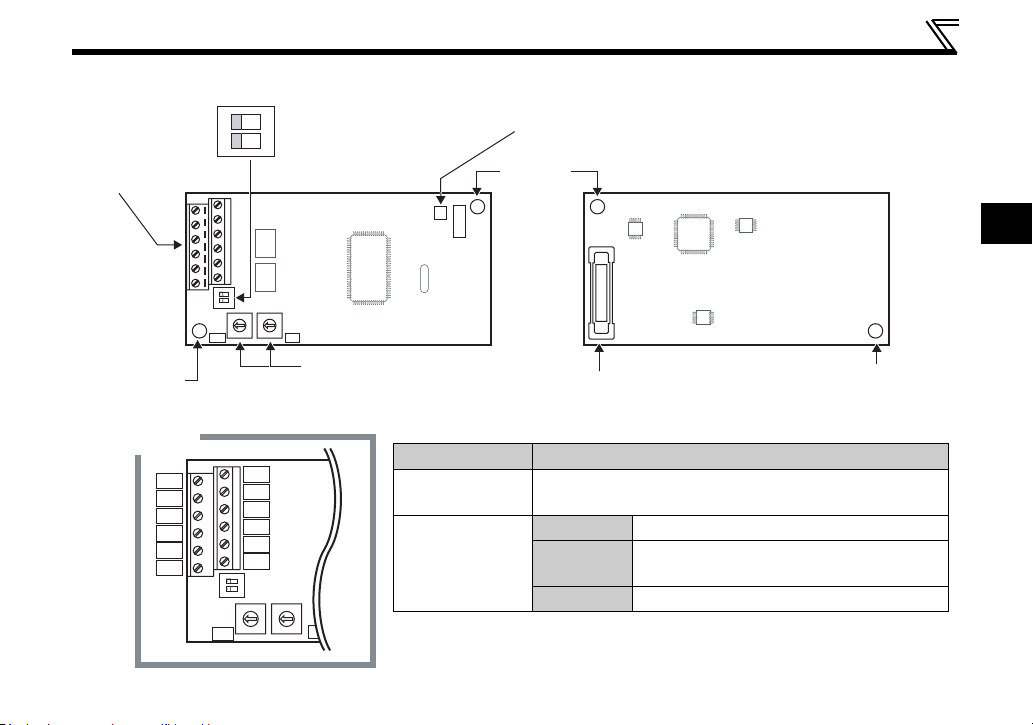

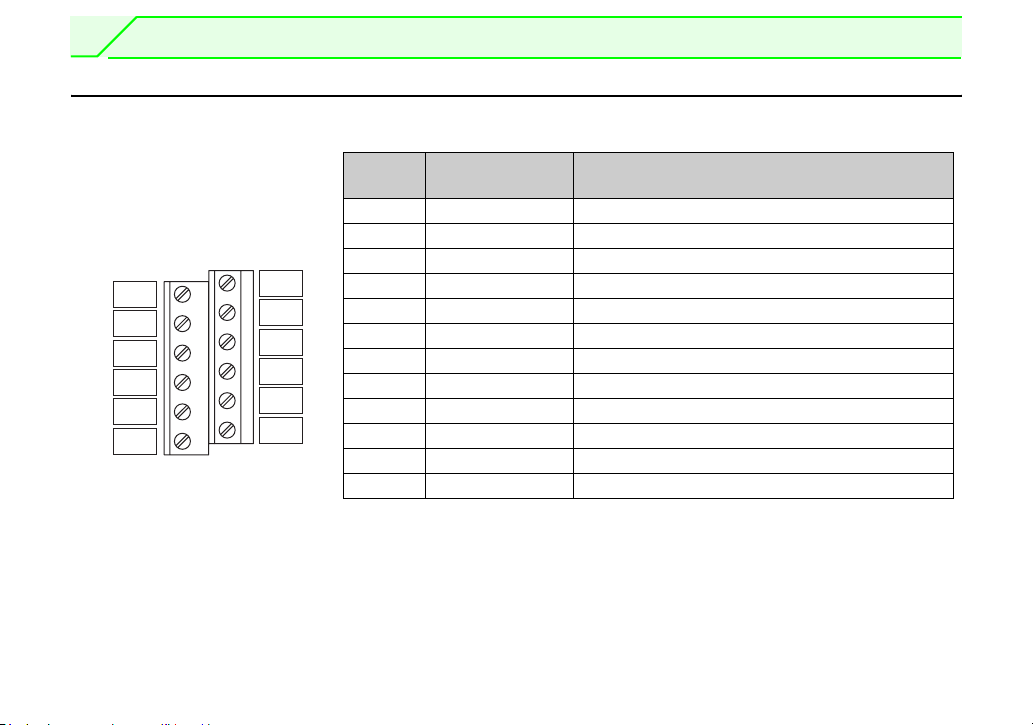

3.1 Terminal Block

Terminal block layout

12

B

1

2

3

4

5

CNTR

6

D+

D-

V-

D-

FG

Ter minal

No.

1-A V+ (VP)

1-B D+ (RXD/TXD-P) Send and receive profibus signal+

2-A D+ (RXD/TXD-P) Send and receive profibus signal+

V+

1

2

D+

D-

3

D+

4

V-

5

FG

6

2-B D+ (RXD/TXD-N) Send and receive profibus signal-

3-A D+ (RXD/TXD-N) Send and receive profibus signal-

3-B V- (DGND)

4-A D+ (RXD/TXD-P) Send and receive profibus signal+

4-B D+ (RXD/TXD-N) Send and receive profibus signal-

5-A V- (DGND)

5-B CNTR

6-A FG (connected to the earth of the inverter unit)

6-B FG (connected to the earth of the inverter unit)

*1 Use when selecting a terminating resistor. (Refer to page 15)

*2 It may not be necessary depending on the master used.

Ter mi na l N am e Definition

*1 Voltage output (approx. 5V to V-)

*1 GND of D+/D-

*1 GND of D+/D-

*2 Control signal (sending request from the inverter)

WIRING

3.2 Wiring

Use the network connection cable which supports 12.0Mbps communication.

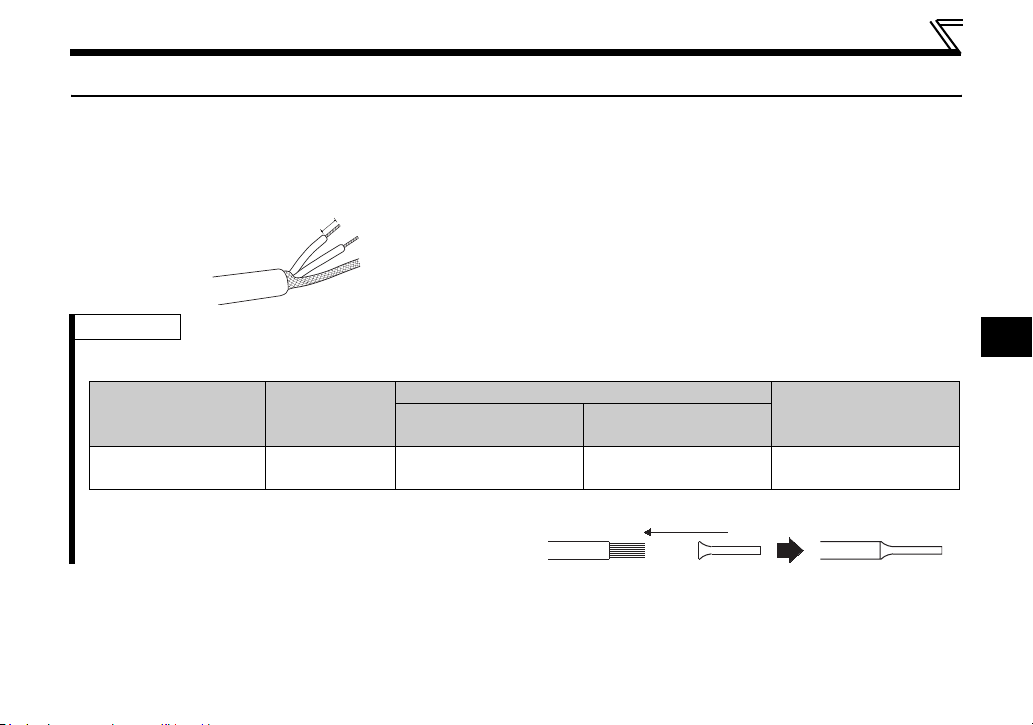

(1) Strip off the sheath of the PROFIBUS communication dedicated cable and wind wires and shield cables

to use. If the length of the sheath pealed is too long, a short circuit may occur among neighboring wires.

If the length is too short, cables and shield cables might come off.

Cable stripping size

Approx 5mm

Wire the stripped cable after twisting it to prevent it from

becoming loose.

(Do not solder it.)

Use a bar type terminal as required.

REMARKS

yInformation on bar terminals...recommended product (as of September, 2006)

Terminal Screw Size

M2 0.3 to 0.5 Al 0,5-6WH A 0,5-6

Bar terminal crimping tool: CRIMPFOX ZA3 (Phoenix Contact Co., Ltd.)

When using the bar terminal (without insulation sleeve), use

care so that the twisted wires do not come out.

Cable Size

2

(mm

)

With insulation

Bar Terminal Model

sleeve

Without insulation

sleeve

3

Maker

Phoenix Contact

Co.,Ltd.

13

WIRING

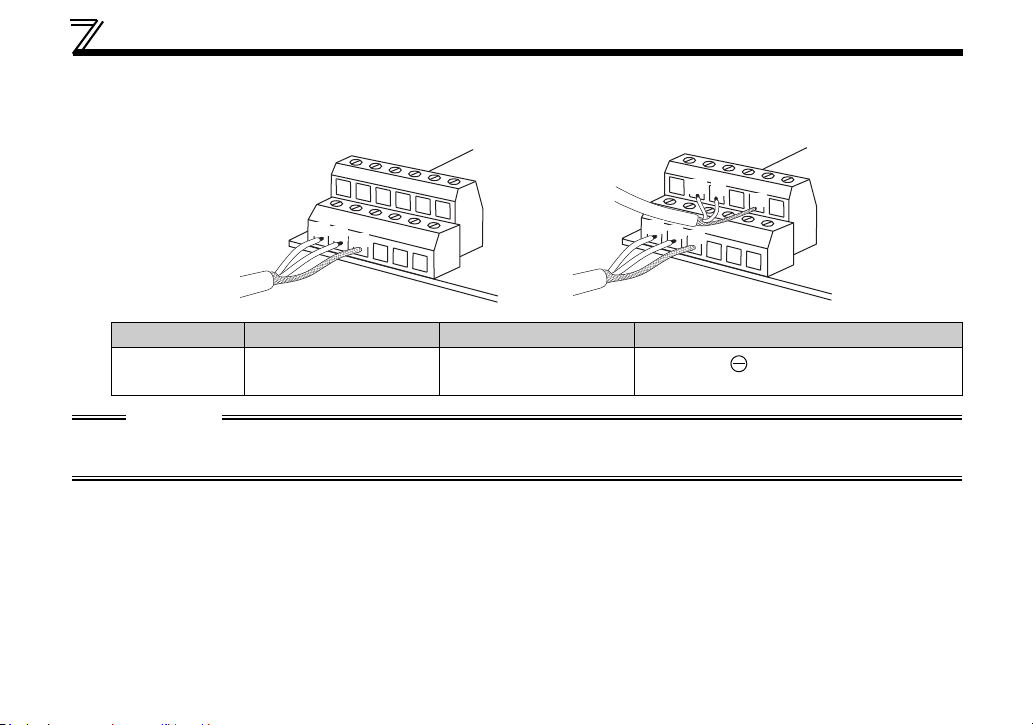

(2) Loosen the terminal screw and insert the cable into the terminal.

Tighten each cable with fixing screws to the recommended tightening torque.

<Cable connection example>

<Connection example of multiple inverters>

To next inverter

D+

D-

V-

To master

D+

D-

V-

D+

D-

V-

Screw Size Tightening Torque Cable Size Screwdriver

M2 0.22N•m to 0.25N•m

0.3mm

2

to 0.75mm

2

Small flat-blade screwdriver

(Tip thickness: 0.4mm /tip width: 2.5mm)

CAUTION

• Undertightening can cause cable disconnection or malfunction. Overtightening can cause a short circuit or

malfunction due to damage to the screw or unit.

14

WIRING

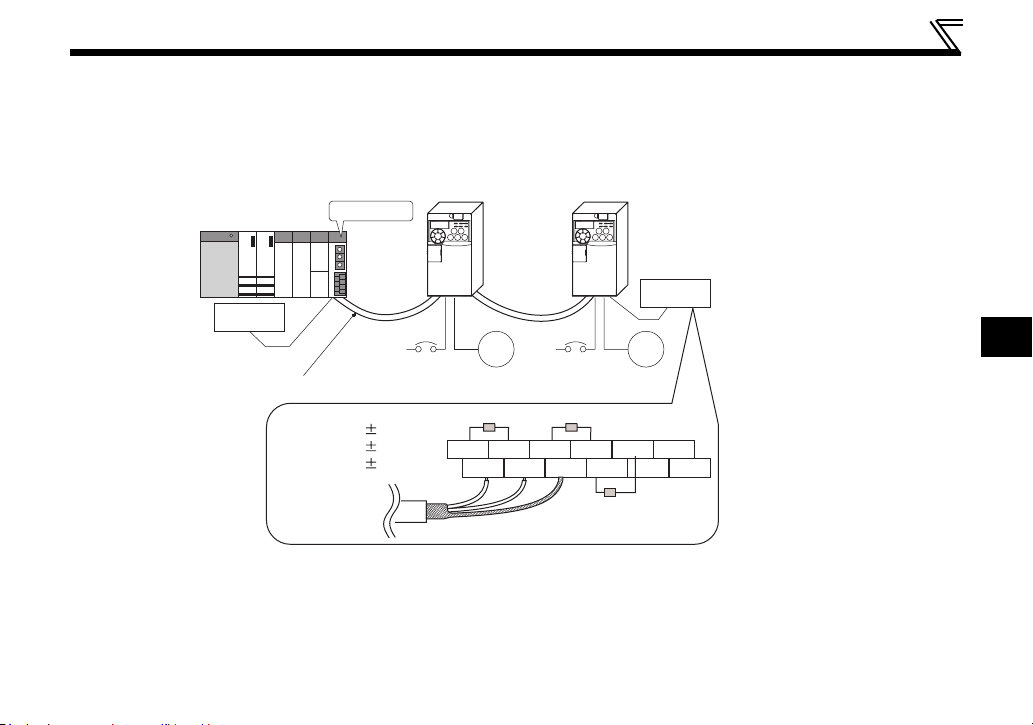

(3) Terminating resistor

If the node at both ends of the network are the FR-A7NP and inverter, connect a connector with a

built-in terminating resistor.

Connection example

Programmable

controller etc.

Terminating

resistor

Master station

Power

supply

Profibus communication cable

R1=390Ω 2% 1/4W

R2=220Ω 2% 1/4W

R3=390Ω 2% 1/4W

Inverter

Motor Motor

R1 R2

V+ D+ D- D+D-V-

Power

supply

Inverter

Terminating

resistor

3

To other inverter

(node)

R3

15

WIRING

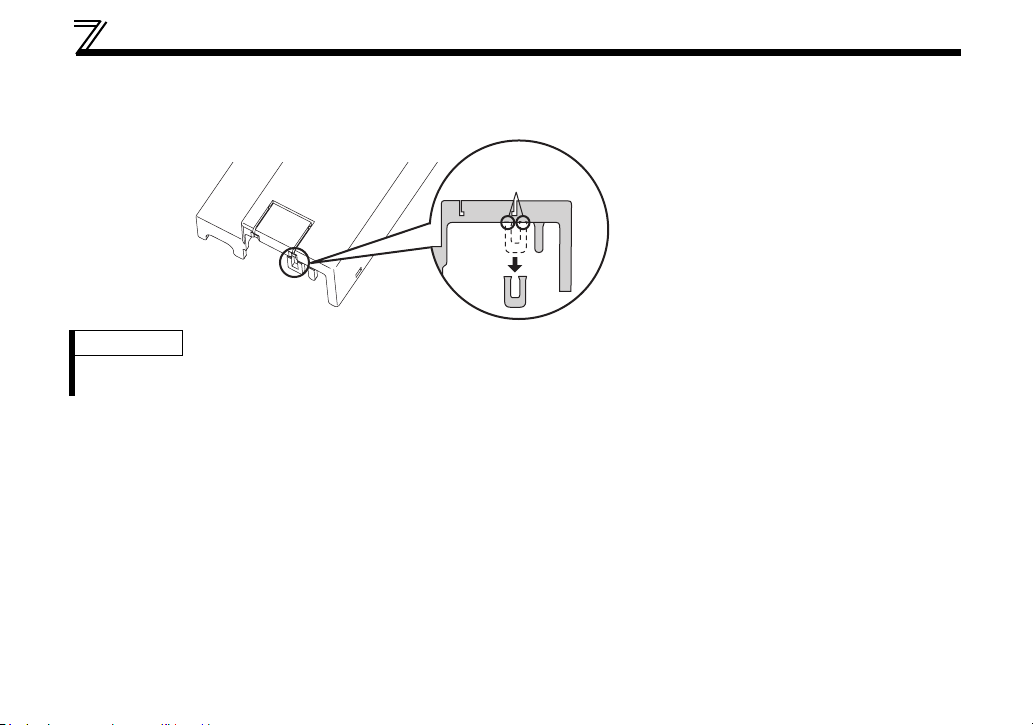

(4) When wiring, if a hook of the front cover of the plug-in option impedes wiring, cut off the hook and

perform wiring.

Cut off with a

nipper, etc.

Cut off a hook at the bottom

of the option cover.

(Cut off so that no portion is left.)

REMARKS

• When the option protective cover is not fitted or wire is not passed through even if the hook of the front cover of the

plug-in option has been cut off, the protective structure (JEM1030) changes to open type (IP00).

16

WIRING

(5) For wiring of FR-E720-5.5K (FR-E720-240) or more and FR-E740-11K (FR-E740-230) or more, pass

a cable on the inverter front cover as shown below. If a PROFIBUS communication dedicated cable is

passed through inside the inverter front cover, the bending radius of the cable becomes small, stressing

the cable.

CAUTION

When wiring, take care not to subject the cable to stress.

After wiring, wire offcuts must not be left in the inverter. They may cause a fault, failure or

malfunction.

3

17

4 INVERTER SETTING

4.1 Parameter List

The following parameters are used for the communication option (FR-A7NP)

Set the values according to need.

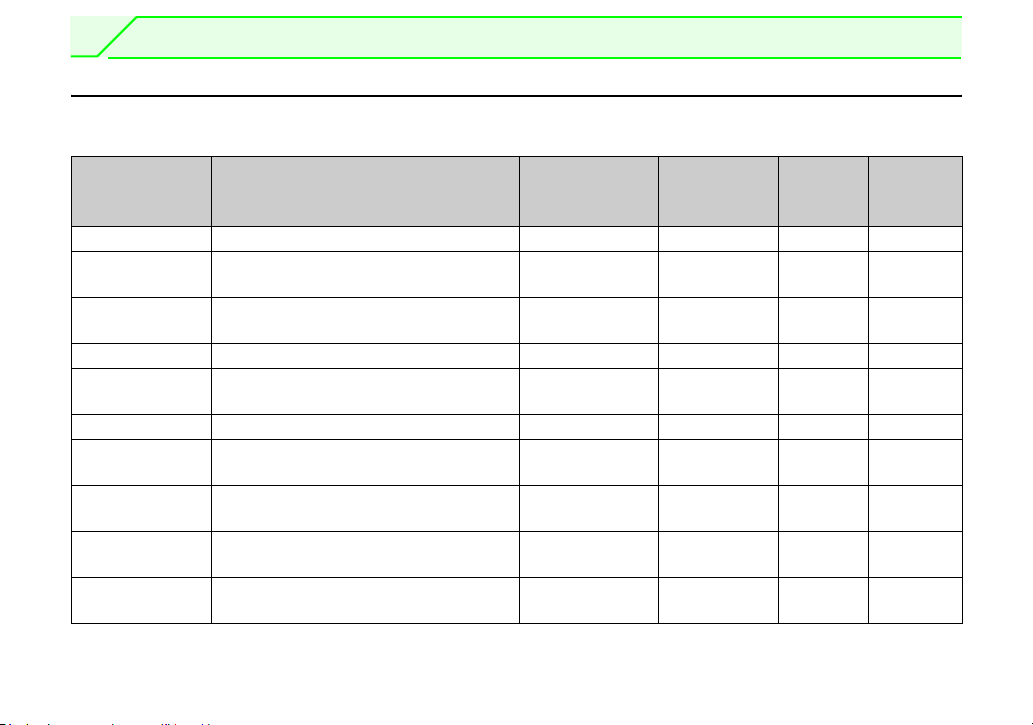

Parameter

Number

79 Operation mode selection 0 to 4, 6, 7 1 0 20

338

339

340 Communication startup mode selection 0, 1, 10 1 0 20

342

*1 Communication reset selection 0, 1 1 0 34

349

*1

500

501

*1

502

*2

550

*2

*1 Parameters which can be displayed when the plug-in option (FR-A7NP) is mounted.

*2 The setting is reflected after inverter reset or at the next power-on.

Communication operation command

source

Communication speed command

source

Communication EEPROM write

selection

Communication error execution waiting

time

Communication error occurrence count

display

Stop mode selection at communication

error

NET mode operation command source

selection

Name Setting Range

0, 1 1 0 23

0, 1, 2 1 0 23

0, 1 1 0 27

0 to 999.8s 0.1s 0 28

01029

0, 1, 2, 3 1 0 30

0, 2, 9999 1 9999 23

Minimum

Setting

Increments

Initial

Value

Refer to

page

18

INVERTER SETTING

4.2 Operation Mode Setting

The inverter mounted with a communication option has three operation modes.

(1) PU operation [PU].............. Controls the inverter from the key of the operation panel on the inverter or

parameter unit (FR-PU07/FR-PA07).

(2) External operation [EXT] ...Controls the inverter by switching on/off external signals connected to the

control circuit terminals of the inverter.

(The inverter is factory-set to this mode.)

(3) Network operation [NET] ... Controls the inverter with instructions from the network via the

communication option.

(The operation signal and running frequency can be entered from the

control circuit terminals depending on the Pr. 338 Communication operation

command source and Pr. 339 Communication speed command source setting.

Refer to page 24.)

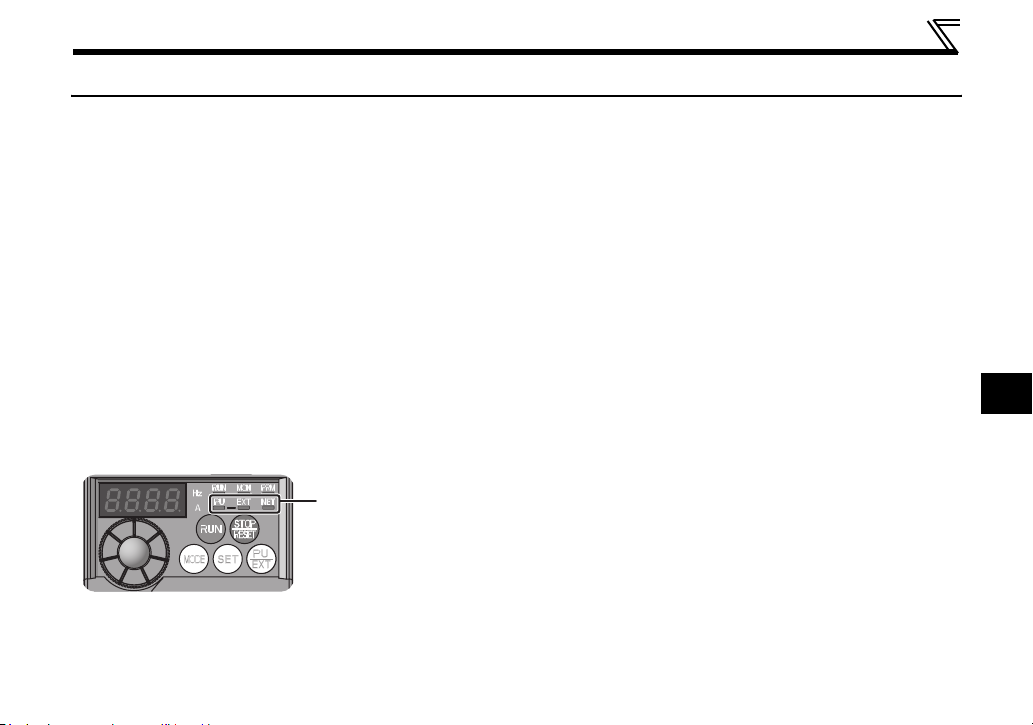

4.2.1 Operation mode indication

Operation panel

Operation mode indication

(The inverter operates according to the LED lit mode.)

PU: PU operation mode

EXT: External operation mode

NET: Network operation mode

4

19

INVERTER SETTING

4.2.2

Operation mode switching and communication startup mode (Pr. 79, Pr. 340)

(1) Operation mode switching conditions

Before switching the operation mode, check that:

1) The inverter is at a stop;

2) Both the STF and STR signals are off; and

3) The Pr. 79 Operation mode selection setting is correct.

(Set using the operation panel of the inverter or parameter unit (FR-PU07/FR-PA07).)

Refer to the inverter manual for details of Pr. 79.

(2) Operation mode selection at power on and at restoration from instantaneous power failure

The operation mode at power on and at restoration from instantaneous power failure can be selected.

Set a value other than "0" in Pr. 340 to select the network operation mode.

After started in network operation mode, parameter write from the network is enabled.

REMARKS

• Change of the Pr. 340 setting is made valid when powering on or resetting the inverter.

• Pr. 340 can be changed with the operation panel independently of the operation mode.

20

Loading...

Loading...