Mitsubishi FR-E 520S EC, FR-E 500, FR-E 540 EC Installation Manual

FR-E 500

Frequency Inverter

Installation Manual

FR-E 520S EC

FR-E 540 EC

INDUSTRIAL AUTOMATION

MITSUBISHI ELECTRI

C

MITSUBISHI ELECTRI

C

Art.-No.: 158536

25 02 2004

Version A

2 MITSUBISHI ELECTRIC

Installation Manual

FR-E 520S EC and FR-E 540 EC

Art. No: 158536

Version Changes / Additions / Corrections

A 02/04 pdp – gb First issue

About this Manual

The texts, illustrations, diagrams, and examples contained in this manual are

only intended as aids to help explain the installation, set-up, and starting of the

frequency inverters FR-E 520S EC and FR-E 540 EC.

If you have any questions concerning the programming and operation of the

equipment described in this manual, please contact your relevant sales office

or department (refer to back of cover). Current information and answers to

frequently asked questions are also available through the Internet

(www.mitsubishi-automation.com).

MITSUBISHI ELECTRIC EUROPE B.V. reserves the right to make

changes both to this manual and to the specifications and design of the

hardware at any time without prior notice.

FR-E 500 EC 3

1 Introduction

1.1 General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

2 Specifications

2.1 Model Specifications FR-E 520S EC (1-phase connection). . . . . . . . . . . . . . . . . . . 8

2.2 Model Specifications FR-E 540 EC (3-phase connection) . . . . . . . . . . . . . . . . . . . .9

2.3 Model Specifications FR-E 500 EC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3 Appearance and Structure

3.1 Description of the Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

4 Wiring

4.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2 Wiring of the Main Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2.1 Mains, Motor and Ground Terminal Connections. . . . . . . . . . . . . . . . . . . 14

4.2.2 Main Circuit Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4.3 Wiring of the Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

5 Parameter

5.1 Overview and Setting Ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

6 Protective Functions

6.1 Error Messages and Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

7 Dimensions

7.1 Dimensions of the Frequency Inverters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Safety instructions

For qualified staff only

This manual is only intended for use by properly trained and qualified electrical technicians who

are fully acquainted with automation technology safety standards. All work with the hardware

described, including system design, installation, set-up, maintenance, service and testing, may

only be performed by trained electricaltechnicians withapproved qualifications who arefully ac

-

quainted with the applicable automation technology safety standards and regulations. Any oper

ations or modifications of the hardware and/or software of our products not specifically

described in this manual may only be performed by authorised Mitsubishi staff.

Proper use of equipment

The devices of the FR-E series are only intended for the specific applications explicitly

described in this manual. Please take care to observe all the installation and operating parame

ters specified in the manual. The design, manufacturing, testing and documentation of these

products have all beencarried out instrict accordance with the relevant safety standards. Under

normal circumstances the products described here do not constitute a potential source of injury

to persons or property provided that you precisely observe the instructions and safety informa

tion provided for proper system design, installation and operation. However, unqualified modifi

cation of the hardware or software or failure to observe the warnings on the product and in this

manual can result in serious personal injury and/or damage to property. Only accessories

specifically approved by MITSUBISHI ELECTRIC may be used with the frequency inverters

FR-E 520S EC and FR-E 540 EC. Any other use or application of the products is deemed to be

improper.

Relevant safety regulations

All safety and accident prevention regulations relevant to your specific application must be observed in the system design, installation, setup, maintenance, servicing and testing of these

products.

The regulations listed below are particularly important. This list does not claim to be complete;

however, you are responsible for knowing and applying the regulations applicable to you.

쎲

VDE/EN Standards

–

VDE 0100

(Regulations for electrical installations with rated voltages up to 1,000V)

–

VDE 0105

(Operation of electrical installations)

–

VDE 0113

(Electrical systems with electronic equipment)

–

EN 50178

(Configuration of electrical systems and electrical equipment)

쎲

Fire prevention regulations

쎲

Accident prevention regulations

–

VBG No. 4 (electrical systems and equipment)

4 MITSUBISHI ELECTRIC

General safety informations and precautions

The following safety precautions are intended as a general guideline for using the frequency in

verter together with other equipment. These precautions must always be observed in the de

sign, installation and operation of all control systems.

E

CAUTION:

All relevant electrical and physical specifications must be strictly observed and

maintained for all the frequency inverters in the installation.

The load used should be a three-phase induction motor only. Connection of any

other electrical equipment to the inverter output may damage the equipment.

FR-E 500 EC 5

P

DANGER:

쎲

Observe all safety and accident prevention regulations applicable to your specific

application. Installation, wiring and opening of the assemblies, components and

devices may only be performed with all power supplies disconnected.

쎲

Assemblies, components and devices must always be installed in a shockproof

housing fitted with a proper cover and protective equipment.

쎲

Devices with a permanent connection to the mains power supply must be inte

grated in the building installations with an all-pole disconnection switch and a

suitable fuse.

쎲

Check power cables and lines connected to the equipment regularly for breaks

and insulation damage. If cable damage is found, immediately disconnect the

equipment and the cables from the power supply and replace the defective ca

bling.

쎲

Before using the equipment for the first time check that the power supply rating

matches that of the local mains power.

쎲

Residual current protective devices pursuant to DIN VDE Standard 0641 Parts 1–3

are not adequate on their own as protection against indirect contact for installations with frequency inverter systems. Additional and/or other protection facilities are essential for such installations.

쎲

EMERGENCY OFF facilities pursuant to VDE 0113 must remain fully operative at

all times and in all control system operating modes.The EMERGENCY OFF facility

reset function must be designed so that it cannot cause an uncontrolled or undefined restart.

쎲

You must also implement hardware and software safety precautions to prevent

the possibility of undefined control system states caused by signal line cable or

core breaks.

Safety warnings

In this manual special warnings that are important for the proper and safe use of the products are

clearly identified as follows:

P

DANGER:

Personnelhealth and injury warnings. Failure to observe the precautions described

here can result in serious health and injury hazards.

E

CAUTION:

Equipment and property damage warnings. Failure to observe the precautions

described here can result in serious damage to the equipment or other property.

6 MITSUBISHI ELECTRIC

1 Introduction

This Installation Manual includes a brief summaryof the mainspecifications of theFR-E 500 fre

quency inverters, which should be sufficient to enable experienced usersto install and configure

the inverter. For further information on the functions and parametrization please refer to the In

struction Manual of the frequency inverter FR-E 500. This Installation Manual is intended exclu

sively as an installation and setup guide and a brief reference. It does not replace the main

product manual.

1.1 General Description

The inverters of the FR-E 520S EC series are available with outputs from 0.4 to 2.2kW

(1-phase). The inverters of the FR-E 540 EC series are available with outputs from 0.4 to 7.5kW

(3-phase). The output frequency ranges from 0.2 to 400Hz.

Features of the frequency inverters

쎲

Communication ability and networking

For the integration in an automation plant a serial interface RS485 is included as standard

equipment. Through this interface up to 32 inverters can be linked up. Open communications with standardised industrial bus systems as Profibus/DP, DeviceNet, CC-Link, CAN

Open, or Modbus Plus can be realised easily via optional interface cards.

쎲 Compatibility with a lot of new applications

– PID Control

The inverter can be used to exercise process control, e.g. flow rate for pumps

– Stop function selection (terminal MRS)

This function isused to select the stoppingmethod (deceleration to astop or coasting).

쎲

Large number of protective functions for safe operation

–

Automatic restart after instantaneous power failure

–

Built-in overcurrent protection

–

Retry function after alarm occurence

쎲

Compatibility with numerous I/O's

–

Multi-speed operation

(15 different pre-selected speeds are available)

–

0/4 to 20mA (0–10V) control input

–

Multi-input terminals:

select 4 inputs from 11 possible input types (e.g. digital potentiometer)

–

Multi-output terminals:

select three outputs from 12 possible output types

–

24V external power supply output

(permissible values: 24V DC/0.1A)

Introduction

FR-E 500 EC 7

2 Specifications

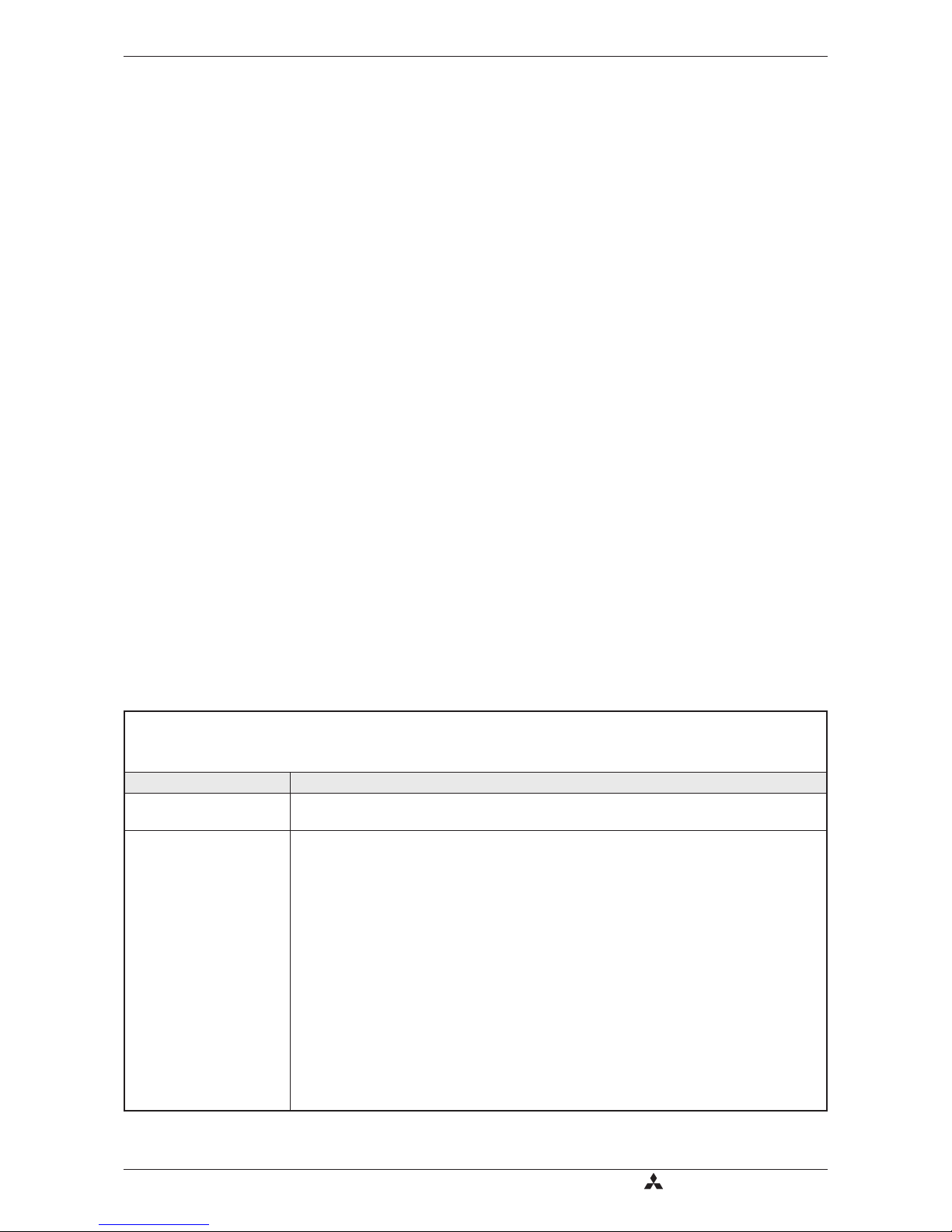

2.1 Model Specifications FR-E 520S EC

(1-phase connection)

NOTES Special notes referring to the table:

The applicable motor capacity refers to a motor voltage of 230V.

The overload capacity indicated in % is the ratio of the overload current to the inverter’s rated

current. For repeated duty, allow time for the inverter and motor to return to or below the tem

-

peratures under 100% load.

The maximum output voltage cannot exceed the power supply voltage. The maximum output

voltage may be set as desired below the power supply voltage.

The power supply capacity changes with the values of the power supply side inverter im

-

pedances (including those of the input reactor and cables).

Specifications

8 MITSUBISHI ELECTRIC

Type

FR-E 520S EC

0.4 k 0.75 k 1.5 k 2.2 k

Rated motor

capacity [kW]

150% Overload

capacity

0.75 1.1 2.2 3

200% Overload

capacity

0.4 0.75 1.5 2.2

Output

Rated

current [A]

150% Overload

capacity

3.6 5 9.6 12

200% Overload

capacity

2.5 4 7 10

Rated output capacity [kVA]

0.95 1.5 2.7 3.8

Overload

capacity

150% of rated motor capacity for 0.5s; 120% for 1min

(max. ambiente temperature 40°C)

200% of rated motor capacity for 0.5s; 150% for 1min

(max. ambiente temperature 50°C)

Voltage

3-phase, 0V up to power supply voltage

Input

Power supply voltage

1-phase, 200–240V AC, −15% / +10%

Permissible AC voltage fluctuation

170–264V AC at 50 / 60Hz

Power supply frequency

50 / 60Hz ± 5%

Rated input capacity [kVA]

1.5 2.3 4.0 5.2

Protection

IP 20

Cooling

Self-cooling Fan-cooling

Weight [kg]

1.9 1.9 2.0 2.0

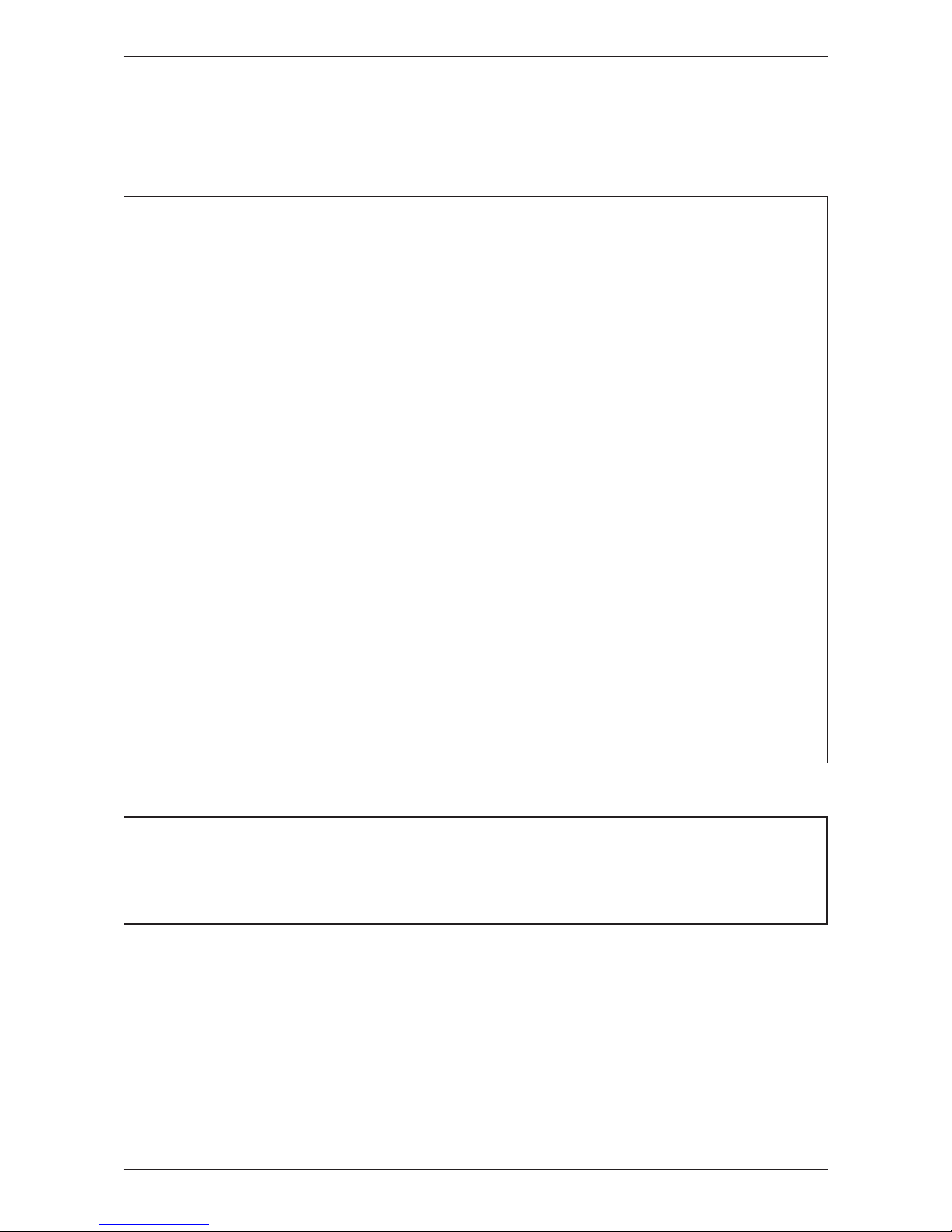

2.2 Model Specifications FR-E 540 EC

(3-phase connection)

NOTES Special notes referring to the table:

The applicable motor capacity refers to a motor voltage of 400V.

The overload capacity indicated in % is the ratio of the overload current to the inverter’s rated

current. For repeated duty, allow time for the inverter and motor to return to or below the tem

-

peratures under 100% load.

The maximum output voltage cannot exceed the power supply voltage. The maximum output

voltage may be set as desired below the power supply voltage.

The power supply capacity changes with the values of the power supply side inverter im

-

pedances (including those of the input reactor and cables).

The rated output current in the parentheses applies when low acoustic noise operation is to

be performed at an ambient temperature higher than 40°C with the parameter 72 value set

to 2kHz or higher.

Specifications

FR-E 500 EC 9

Type

FR-E 540 EC

0.4 k 0.75 k 1.5 k 2.2 k 3.7 k 5.5 k 7.5 k

Rated motor

capacity [kW]

150% Overload

capacity

0.75 1.1 2.2 3 4 7.5 11

200% Overload

capacity

0.4 0.75 1.5 2.2 4 5.5 7.5

Output

Rated

current [A]

150% Overload

capacity

1.8 3 4.9 6.7 9.5 14 21

200 % Overload

capacity

1.6 (1.4) 2.6 (2.2) 4 (3.8) 6 (5.4) 9.5 (8.7) 12 17

Rated output capacity [kVA]

1.2 2.0 3.0 4.6 7.2 9.1 13.0

Overload

capacity

150% of rated motor capacity for 0.5s; 120% for 1min

(max. ambient temperature 40°C )

200% of rated motor capacity for 0.5s; 150% for 1min

(max. ambient temperature 50°C)

Voltage

3-phase, 0V up to power supply voltage

Input

Power supply voltage

3-phase, 380–480V AC, −15% / +10%

Voltage range

323–528V AC at 50 / 60Hz

Frequency range

50 / 60Hz ± 5%

Rated input capacity [kVA]

1.5 2.5 4.5 5.5 9 12 17

Protection

IP 20

Cooling

Self-cooling Fan-cooling

Weight [kg]

1.9 1.9 2.0 2.1 2.1 3.8 3.8

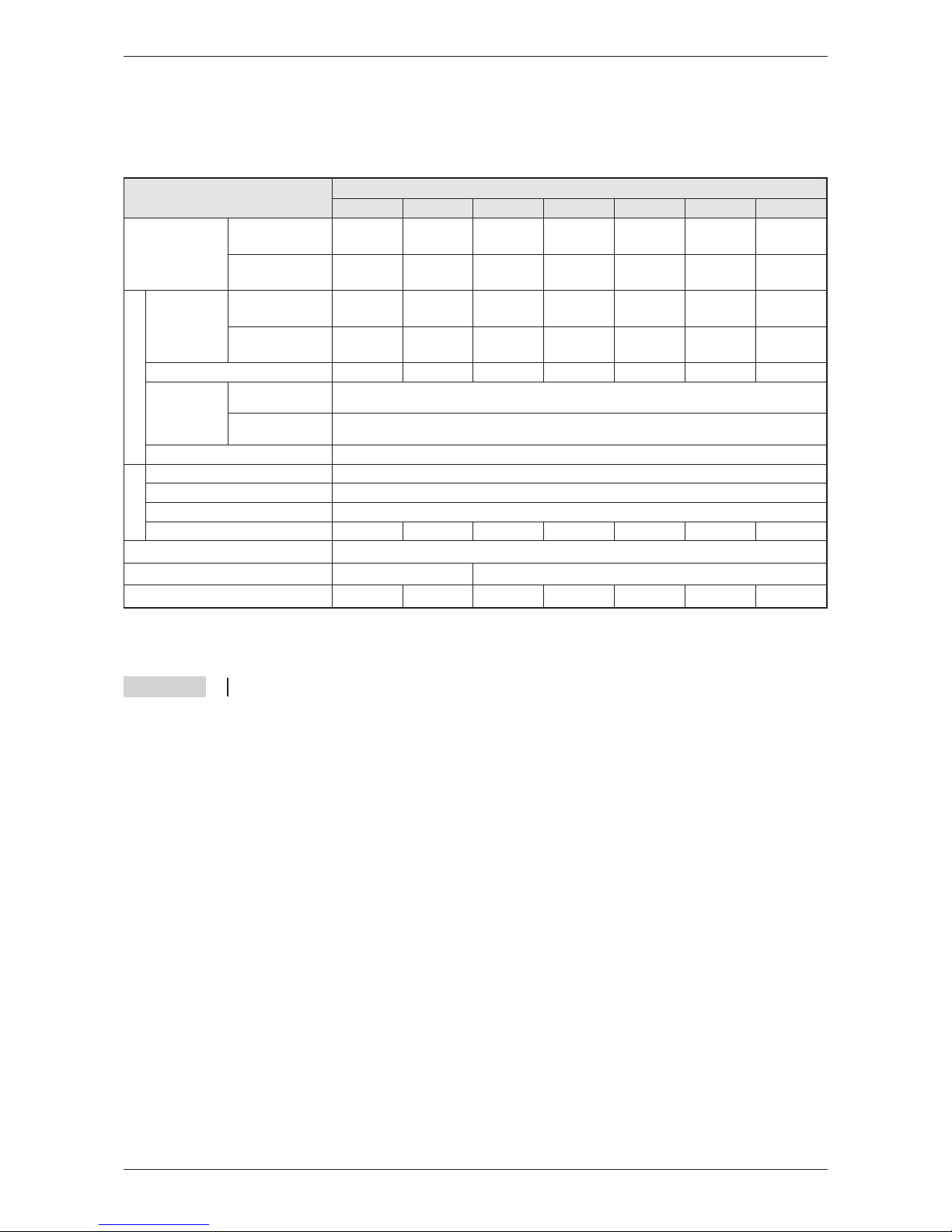

Loading...

Loading...