Page 1

Page 2

Thank you for choosing the Mitsubishi Transistorized inverter.

This instruction manual gives handling information and precautions for use of this

equipment.

Incorrect handling might cause an unexpected fault. Before using the inverter, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This instruction manual uses the International System of Units (SI). The measuring

units in the yard and pound system are indicated in parentheses as reference values.

This section is specifically about safety matters

Do not attempt to install, operate, maintain or inspect the inverter until you have read

through this instruction manual and appended documents carefully and can use the

equipment correctly.

Do not use the inverter until you have a full knowledge of the equipment, safety

information and instructions.

In this manual, the safety instruction levels are classified into "WARNING" and

"CAUTION".

Assumes that incorrect handling may cause hazardous

WARNING

CAUTION

Note that even the CAUTION level may lead to a serious consequence according to

conditions. Please follow the instructions of both levels because they are important

to personnel safety.

conditions, resulting in death or severe injury.

Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or may

cause physical damage only.

A - 1

Page 3

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

!

While power is on or when the inverter is running, do not open the front cover.

You may get an electric shock.

!

Do not run the inverter with the front cover removed. Otherwise, you may access

the exposed high-voltage terminals or the charging part of the circuitry and get

an electric shock.

!

If power is off, do not remove the front cover except for wiring or periodic

inspection. You may access the charged inverter circuits and get an electric

shock.

!

Before starting wiring or inspection, switch power off, wait for more than 10

minutes, and check for residual voltage with a meter (refer to chapter 2 for

further details) etc.

!

Earth the inverter.

!

Any person who is involved in the wiring or inspection of this equipment should

be fully competent to do the work.

!

Always install the inverter before wiring. Otherwise, you may get an electric

shock or be injured.

!

Operate the switches and potentiometers with dry hands to prevent an electric

shock.

!

Do not subject the cables to scratches, excessive stress, heavy loads or

pinching. Otherwise, you may get an electric shock.

!

Do not change the cooling fan while power is on.

It is dangerous to change the cooling fan while power is on.

2. Fire Prevention

CAUTION

!

Mount the inverter and brake resistor on an incombustible surface. Installing the

inverter directly on or near a combustible surface could lead to a fire.

!

If the inverter has become faulty, switch off the inverter power. A continuous

flow of large current could cause a fire.

!

When a brake resistor is used, use an alarm signal to switch power off.

Otherwise, the brake resistor will overheat abnormally due a brake transistor or

other fault, resulting in a fire.

!

Do not connect a resistor directly to the DC terminals P(+), N(−). This could

cause a fire.

A - 2

Page 4

3. Injury Prevention

CAUTION

!

Apply only the voltage specified in the instruction manual to each terminal to

prevent damage etc.

!

Ensure that the cables are connected to the correct terminals. Otherwise,

damage etc. may occur.

!

Always make sure that polarity is correct to prevent damage etc.

!

While power is on and for some time after power-off, do not touch the inverter or

brake resistor as they are hot and you may get burnt.

4. Additional instructions

Also note the following points to prevent an accidental failure, injury, electric shock, etc.

(1)

Transportation and installation

CAUTION

!

When carrying products, use correct lifting gear to prevent injury.

!

Do not stack the inverter boxes higher than the number recommended.

!

Ensure that installation position and material can withstand the weight of the

inverter. Install according to the information in the Instruction Manual.

!

Do not operate if the inverter is damaged or has parts missing.

!

Do not hold the inverter by the front cover or operation panel; it may fall off.

!

Do not stand or rest heavy objects on the inverter.

!

Check the inverter mounting orientation is correct.

!

Prevent screws, wire fragments or other conductive bodies or oil or other

flammable substance from entering the inverter.

!

Do not drop the inverter, or subject it to impact.

!

Use the inverter under the following environmental conditions:

Ambient

temperature

Ambient humidit y 90%RH or less (non-condensing)

Storage

temperature

Ambience

Environment

Altitude, vibration

*Temperatures applicable for a short time, e.g. in transit.

Constant torque : -10°C to +50°C (14°F to 122 °F)

(non-freezing)

-20°C to +65°C * (-4°F to 149 °F)

Indoors (free from corrosive gas, flammable gas, oil mist, dust

and dirt)

Maximum 1000m (3280.80 feet) above sea level for standard

operation. After that derate by 3% for every extra 500m

(1640.40 feet) up to 2500m (8202.00 feet) (91%).

5.9 m/s

2

or less (conforming to JIS C 0911)

A - 3

Page 5

(2)

Wiring

CAUTION

!

Do not fit capacitive equipment such as a power factor correction capacitor,

radio noise filter or surge suppressor to the output of the inverter.

!

The connection orientation of the output cables U, V, W to the motor will affect

the direction of rotation of the motor.

(3)

Trial run

CAUTION

!

Check all parameters, and ensure that the machine will not be damaged by a

sudden start-up.

(4)

Operation

WARNING

!

When you have chosen the retry function, stay away from the equipment as it

will restart suddenly after an alarm stop.

!

The [STOP] key is valid only when the appropriate function setting has been

made. Prepare an emergency stop switch separately.

!

Make sure that the start signal is off before resetting the inverter alarm. A failure

to do so may restart the motor suddenly.

!

The load used should be a three-phase induction motor only. Connection of any

other electrical equipment to the inverter output may damage the equipment.

!

Do not modify the equipment.

CAUTION

!

The electronic overcurrent protection does not guarantee protection of the

motor from overheating.

!

Do not use a magnetic contactor on the inverter input for frequent

starting/stopping of the inverter.

!

Use a noise filter to reduce the effect of electromagnetic interference. Otherwise

nearby electronic equipment may be affected.

!

Take measures to suppress harmonics. Otherwise power harmonics from the

inverter may heat/damage the power capacitor and generator.

A - 4

Page 6

CAUTION

!

When a 400V class motor is inverter-driven, it should be insulation-enhanced or

surge voltages suppressed. Surge voltages attributale to the wiring constants

may occur at the motor terminals, deteriorating the insulation of the motor.

!

When parameter clear or all clear is performed, each parameter returns to the

factory setting. Re-set the required parameters before starting operation.

!

The inverter can be easily set for high-speed operation. Before changing its

setting, fully examine the performances of the motor and machine.

!

In addition to the inverter's holding function, install a holding device to ensure

safety.

!

Before running an inverter which had been stored for a long period, always

perform inspection and test operation.

(5)

Emergency stop

CAUTION

!

Provide a safety backup such as an emergency brake which will prevent the

machine and equipment from hazardous conditions if the inverter fails.

(6)

Maintenance, inspection and parts replacement

CAUTION

!

Do not carry out a megger (insulation resistance) test on the control circuit of

the inverter.

(7)

Disposing of the inverter

CAUTION

!

Treat as industrial waste.

(8) General

Many of the diagrams and drawings in this instruction manual show the inverter

without a cover, or partially open. Never operate the inverter like this. Always

replace the cover and follow this instruction manual when operating the inverter.

instructions

A - 5

Page 7

CONTENTS

1 OUTLINE 1

1.1 Pre-Operation Information ..........................................................................................1

1.1.1 Precautions for operation.....................................................................................1

1.2 Basic Configuration.....................................................................................................3

1.2.1 Basic configuration...............................................................................................3

1.3 Structure .....................................................................................................................4

1.3.1 Appearance and structure....................................................................................4

1.3.2 Removal and reinstallation of the front cover.......................................................5

1.3.3 Removal and reinstallation of the wiring cover.....................................................7

1.3.4 Removal and reinstallation of the accessory cover..............................................8

1.3.5 Reinstallation and removal of the control panel....................................................9

1.3.6 Removal of the control panel (FR-PA02-

1.3.7 Exploded view....................................................................................................11

) front cover .....................................10

02

2 INSTALLATION AND WIRING 12

Contents

2.1 Installation.................................................................................................................12

2.1.1 Instructions for installation..................................................................................12

2.2 Wiring........................................................................................................................14

2.2.1 Terminal connection diagram.............................................................................14

2.2.2 Wiring of the main circuit....................................................................................18

2.2.3 Wiring of the control circuit.................................................................................22

2.2.4 Connection to the PU connector ........................................................................27

2.2.5 Connection of stand-alone option units..............................................................30

2.2.6 Design information .............................................................................................33

2.3 Other Wiring..............................................................................................................34

2.3.1 Power supply harmonics....................................................................................34

2.3.2 Inverter-generated noise and reduction techniques...........................................35

2.3.3 Leakage currents and countermeasures............................................................39

2.3.4 Inverter-driven 400V class motor........................................................................40

2.3.5 Peripheral devices ..............................................................................................41

2.3.6 Instructions for compliance with U.S and Canadian Electrical Codes................45

2.3.7 Instructions for compliance with the European standards..................................46

I

Page 8

3 OPERATION/CONTROL 48

3.1 Pre-Operation Information ........................................................................................48

3.1.1 Types of operation modes..................................................................................48

3.1.2 Power on............................................................................................................50

3.2 About the Control Panel............................................................................................51

3.2.1 Names and functions of the control panel (FR-PA02-

3.2.2 Control panel mode is changed by pressing the

MODE

)....................................51

02

key.................................52

3.2.3 Monitoring...........................................................................................................52

3.2.4 Frequency setting...............................................................................................53

3.2.5 Parameter setting method..................................................................................53

3.2.6 Operation mode..................................................................................................55

3.2.7 Help mode..........................................................................................................55

3.3 Operation..................................................................................................................58

3.3.1 Pre-operation checks .........................................................................................58

3.3.2 External operation mode (Operation using the external

frequency setting potentiometer and external start signal).................................59

3.3.3 PU operation mode (Operation using the control panel)....................................60

3.3.4 Combined operation mode 1

(Operation using both external start signal and control panel)...........................61

3.3.5 Combined operation mode 2..............................................................................62

4 PARAMETERS 63

4.1 Parameter List...........................................................................................................63

4.1.1 Parameter list.....................................................................................................63

4.1.2 List of parameters classified by purpose of use.................................................69

4.1.3 Parameters recommended to be set by the user...............................................71

4.2 Parameter Function Details ......................................................................................72

4.2.1 Torque boost (Pr. 0, Pr. 46)................................................................................72

4.2.2 Output frequency range (Pr. 1, Pr. 2, Pr. 18)......................................................73

4.2.3 Base frequency, base frequency voltage (Pr. 3, Pr. 19, Pr. 47).........................74

4.2.4 Multi-speed operation (Pr. 4, Pr. 5, Pr. 6, Pr. 24 to Pr. 27, Pr. 232 to Pr. 239) .75

4.2.5 Acceleration/deceleration time (Pr. 7, Pr. 8, Pr. 20, Pr. 21, Pr. 44, Pr. 45) .......76

4.2.6 Electronic overcurrent protection (Pr. 9, Pr. 48).................................................78

4.2.7 DC injection brake (Pr. 10 to Pr. 12)...................................................................79

II

Page 9

4.2.8 Starting frequency (Pr. 13).................................................................................80

4.2.9 Load pattern selection (Pr. 14)...........................................................................81

4.2.10 Jog operation (Pr. 15, Pr. 16)...........................................................................82

4.2.11 Stall prevention (Pr. 22, Pr. 23, Pr. 66).............................................................83

4.2.12 Acceleration/deceleration pattern (Pr. 29)........................................................85

4.2.13 Regenerative brake duty (Pr. 30, Pr. 70)..........................................................86

4.2.14 Frequency jump (Pr. 31 to Pr. 36)....................................................................87

4.2.15 Speed display (Pr. 37)......................................................................................88

4.2.16 Frequency at 5V (10V) input (Pr. 38)................................................................89

4.2.17 Frequency at 20mA input (Pr. 39)....................................................................89

4.2.18 Up-to-frequency sensitivity (Pr. 41)..................................................................90

4.2.19 Output frequency detection (Pr. 42, Pr. 43)......................................................90

4.2.20 Monitor display (Pr. 52, Pr. 54, Pr. 158)...........................................................92

4.2.21 Monitoring reference (Pr. 55, Pr. 56)................................................................94

4.2.22 Automatic restart after instantaneous power failure (Pr. 57, Pr. 58).................95

4.2.23 Remote setting function selection (Pr. 59)........................................................97

4.2.24 Shortest acceleration/deceleration mode (Pr. 60 to Pr. 63)..............................99

4.2.25 Retry function (Pr. 65, Pr. 67 to Pr. 69)..........................................................101

Contents

4.2.26 Applied motor (Pr. 71)....................................................................................103

4.2.27 PWM carrier frequency (Pr. 72, Pr. 240)........................................................104

4.2.28 Voltage input (Pr. 73) .....................................................................................105

4.2.29 Input filter time constant (Pr. 74)....................................................................106

4.2.30 Reset selection/disconnected PU detection/PU stop selection (Pr. 75).........106

4.2.31 Parameter write inhibit selection (Pr. 77)........................................................108

4.2.32 Reverse rotation prevention selection (Pr. 78)...............................................109

4.2.33 Operation mode selection (Pr. 79) .................................................................110

4.2.34 General-purpose magnetic flux v ector contr ol selection ( Pr. 80).........................113

4.2.35 Offline auto tuning function (Pr. 82 to Pr. 84, Pr. 90, Pr. 96)..........................115

4.2.36 Computer link operation (Pr. 117 to Pr. 124, Pr. 342)....................................121

4.2.37 PID control (Pr. 128 to Pr. 134)......................................................................134

4.2.38 Output current detection function (Pr. 150, Pr.151)........................................142

4.2.39 Zero current detection (Pr. 152, Pr.153).........................................................143

4.2.40 Stall prevention function and current limit function (Pr. 156)..........................144

4.2.41 User group selection (Pr. 160, Pr. 173 to Pr. 176) .........................................146

4.2.42 Actual operation hour meter clear (Pr. 171)...................................................148

III

Page 10

4.2.43 Input terminal function selection (Pr. 180 to Pr. 183).....................................148

4.2.44 Output terminal function selection (Pr. 190 to Pr. 192)...................................150

4.2.45 Cooling fan operation selection (Pr. 244).......................................................151

4.2.46 Slip compensation (Pr. 245 to Pr. 247) ..........................................................152

4.2.47 Ground fault detection at start (Pr. 249)

(400V class does not have this function)........................................................153

4.2.48 Stop selection (Pr. 250)..................................................................................154

4.2.49 Output phase failure protection selection (Pr. 251)........................................155

4.2.50 Meter (frequency meter) calibration (Pr. 900) (200V class, 100V class).......156

4.2.51 Meter (frequency meter) calibration (Pr. 901) (400V class)............................158

4.2.52 Biases and gains of the frequency setting voltage (current)

(Pr. 902 to Pr. 905)...........................................................................................160

5 PROTECTIVE FUNCTIONS 166

5.1 Errors (Alarms)........................................................................................................166

5.1.1 Error (alarm) definitions....................................................................................166

5.1.2 To know the operating status at the occurrence of alarm.................................174

5.1.3 Correspondence between digital and actual characters...................................174

5.1.4 Resetting the inverter.......................................................................................174

5.2 Troubleshooting......................................................................................................175

5.2.1 Motor remains stopped.....................................................................................175

5.2.2 Motor rotates in opposite direction...................................................................175

5.2.3 Speed greatly differs from the setting...............................................................176

5.2.4 Acceleration/deceleration is not smooth...........................................................176

5.2.5 Motor current is large........................................................................................ 176

5.2.6 Speed does not increase..................................................................................176

5.2.7 Speed varies during operation..........................................................................176

5.2.8 Operation mode is not changed properly.........................................................177

5.2.9 Control panel display is not operating ..............................................................177

5.2.10 POWER lamp is not lit....................................................................................177

5.2.11 Parameter write cannot be performed............................................................177

5.3 Precautions for Maintenance and Inspection..........................................................178

5.3.1 Precautions for maintenance and inspection ...................................................178

5.3.2 Check items......................................................................................................178

5.3.3 Periodic inspection...........................................................................................178

IV

Page 11

5.3.4 Insulation resistance test using megger...........................................................179

5.3.5 Pressure test....................................................................................................179

5.3.6 Daily and Periodic Inspection...........................................................................180

5.3.7 Replacement of parts.......................................................................................183

5.3.8 Measurement of main circuit voltages, currents and powers............................188

6 SPECIFICATIONS 191

6.1 Standard Specifications..........................................................................................191

6.1.1 Model specifications.........................................................................................191

6.1.2 Common specifications....................................................................................194

6.1.3 Outline drawings...............................................................................................196

APPENDIX 202

Appendix 1 Data Code List...........................................................................................202

Contents

V

Page 12

C H A P T E R 1

CHAPTER 1

O U T L I N E

OUTLINE

This chapter gives information on the basic "outline" of this

product.

Always read the instructions before using the equipment.

1.1 Pre-Operation Information ..........................................1

1.2 Basic Configuration.....................................................3

1.3 Structure.....................................................................4

<Abbreviations>

!

PU

Control panel and parameter

unit (FR-PU04)

!

Inverter

Mitsubishi transistorized inverter

FR-E500 series

!

Pr.

Parameter number

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Page 13

1.1 Pre-Operation Information

OUTLINE

1 OUTLINE

1.1 Pre-Operation Information

1.1.1 Precautions for operation

This manual is written for the FR-E500 series transistorized inverters.

Incorrect handling may cause the inverter to operate incorrectly, causing its life to be

reduced considerably, or at the worst, the inverter to be damaged. Handle the inverter

properly in accordance with the information in each section as well as the precautions

and instructions of this manual to use it correctly.

For handling information on the parameter unit (FR-PU04), stand-alone options, etc.,

refer to the corresponding manuals.

(1)

Unpacking and product check

Unpack the inverter and check the capacity plate on the front cover and the rating plate

on the inverter side face to ensure that the product agrees with your order and the

inverter is intact.

1) Inverter type

Capacity plate

FR-E520-0.1K-NA/

Inverter type

"

Inverter type

FR -

Symbol Voltage Class

E520

E540

E510W

E520

Three-phase

200V class

Three-phase

400V class

Single-phase

100V class

Capacity plate

Serial number

Rating plate

MITSUBISHI

Rating plate

Input rating

Output rating

Serial number

MODEL

FR-E520-0.1K-NA

INPUT :

XXXXX

OUTPUT :

XXXXX

SERIAL :

-0.1K - NA

Represents the

inverter capacity

".

"kW

INVERTER

Inverter type

PASSED

2) Accessory

Instruction manual

If you have found any discrepancy, damage, etc., please contact your sales

representative.

1

Page 14

OUTLINE

(2)

Preparation of instruments and parts requi r ed for operation

Instruments and parts to be prepared depend on how the inverter is operated. Prepare

equipment and parts as necessary. (Refer to page 48.)

(3)

Installation

To operate the inverter with high performance for a long time, install the inverter in a

proper place, in the correct direction, with proper clearances. (Refer to page 12.)

(4)

Wiring

Connect the power supply, motor and operation signals (control signals) to the terminal

block. Note that incorrect connection may damage the inverter and peripheral devices.

(See page 14.)

1

2

Page 15

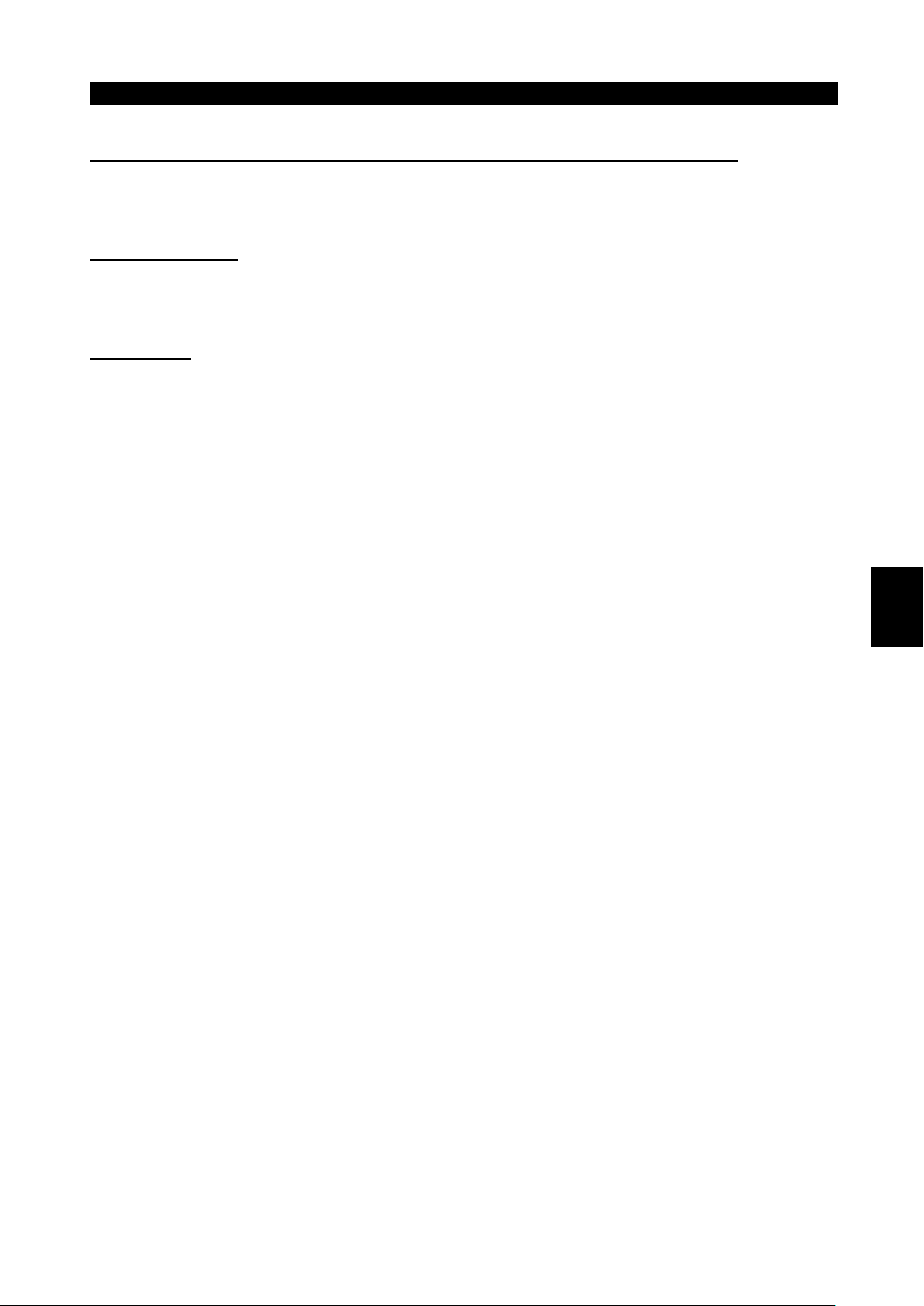

1.2 Basic Configuration

A

(

)

OUTLINE

1.2 Basic Configuration

1.2.1 Basic configuration

The following devices are required to operate the inverter. Proper peripheral devices

must be selected and correct connections made to ensure proper operation. Incorrect

system configuration and connections can cause the inverter to operate improperly, its

life to be reduced considerably, and in the worst case, the inverter to be damaged.

Please handle the inverter properly in accordance with the information in each section

as well as the precautions and instructions of this manual. (For connections of the

peripheral devices, refer to the corresponding manuals.)

Name Description

Use the power supply within the

permissible power supply specifications

of the inverter. (Refer to page 191.)

The breaker should be selected with

care since a large inrush current flows

in the inverter at power on. (Refer to

page 41.)

Do not use this magnetic contactor to

start or stop the inverter. It might reduce

the inverter life. (Refer to page 41.)

The reactors must be used when the

power factor is to be improved or the

inverter is installed near a large power

supply system (1000KVA or more and

wiring distance within 10m (32.81 feet)).

Make selection carefully.

•

The inverter life is influenced by

ambient temperature. The ambient

temperature should be as low as

possible within the permissible range.

This must be noted especially when

the inverter is installed in an enclosure.

(Refer to page 12.)

•

Wrong wiring might lead to inverter

damage. The control signal lines should

be kept away from the main circuit to

protect them from noise. (Refer to page

14.)

Do not connect a power capacitor,

surge suppressor or radio noise

filter to the output side.

To prevent an electric shock, always

ground the motor and inverter.

The ground wiring from the power line

of the inverter as an induction noise

reduction technique is recommended to

be run by returning it to the ground

terminal of the inverter. (Refer to page

38.)

(NFB)

(ELB)

C reactor

FR-BAL

or

(MC)

Ground

Power

supply

Earth leakage

circuit breaker

or no-fuse

breaker

Magnetic

contactor

Reactors

DC reactor

(FR-BEL)

Inverter

Ground

Devices

connected

to the output

Ground

3

Page 16

1.3 Structure

(

)

g

(

)

1.3 Structure

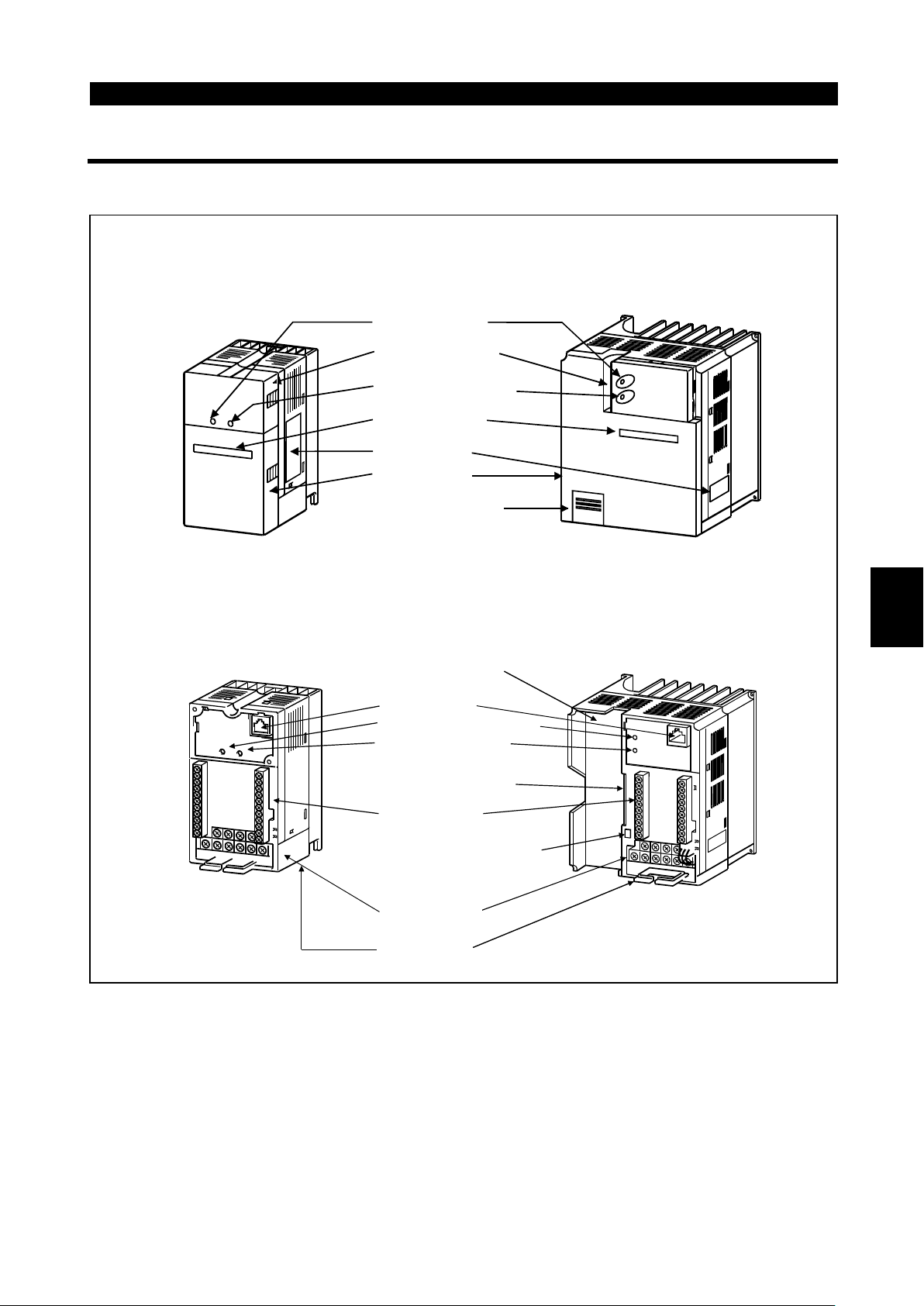

1.3.1 Appearance and structure

(1) Front view

OUTLINE

100V class, 200V class

POWER lamp

(yellow)

Accessory cover

ALARM lamp (red)

Capacity plate

Rating plate

Front cover

Wiring port cover

for option

(2) Without accessory cover and front cover

100V class, 200V class

Inboard option

mounting position

PU conector*

POWER lamp (yellow)

ALARM lamp (red)

Connector for connection

of inboard option

(400V class only)

Control circuit

terminal block

Control logic changing

connector

(400V class only)

Main circuit

terminal block

(400V class)

1

(400V class)

Wirin

cover

*Use the PU connector for the FR-PA02

-02

or FR-PU04 option and RS-485

communication.

4

Page 17

OUTLINE

)2)3)

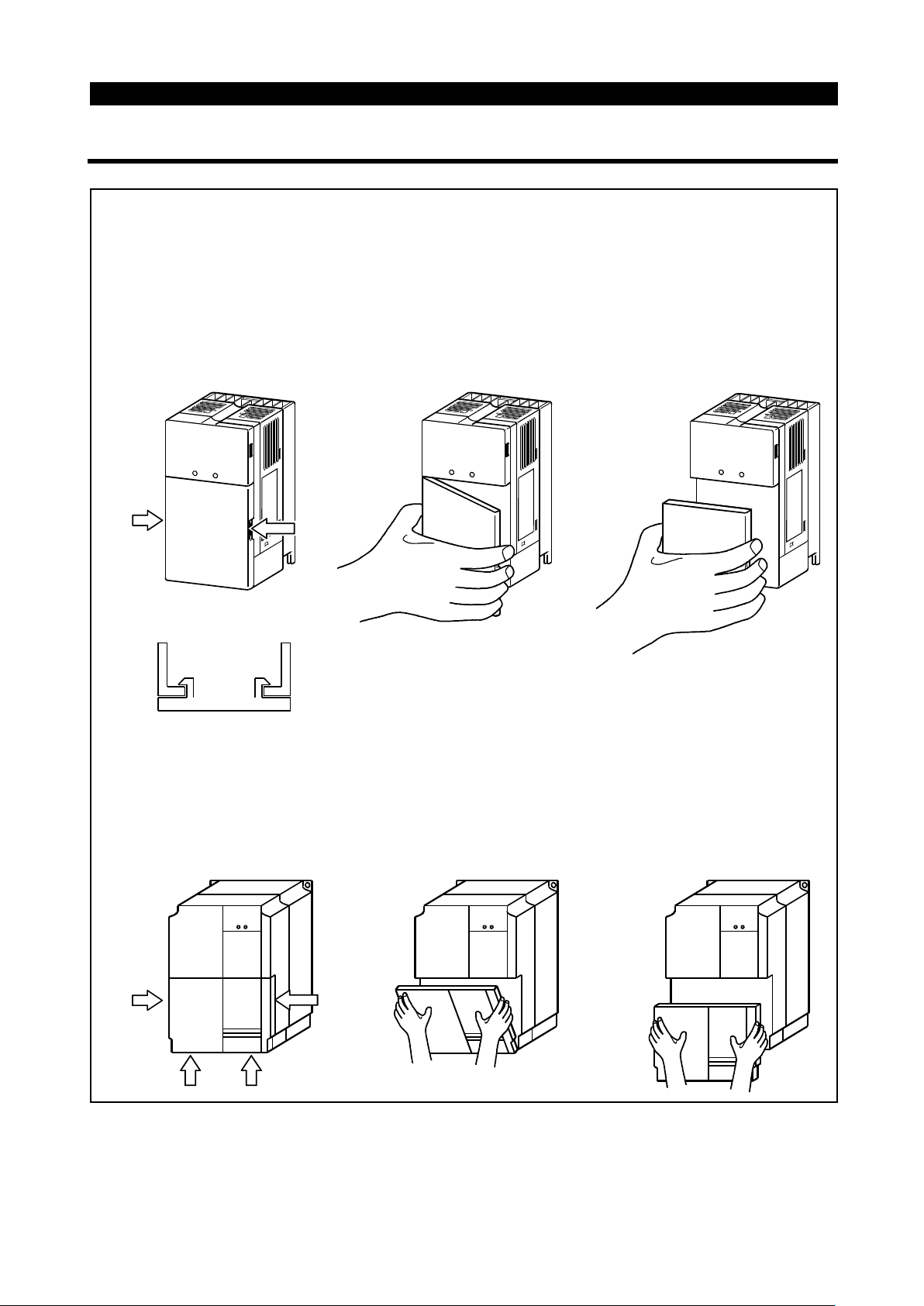

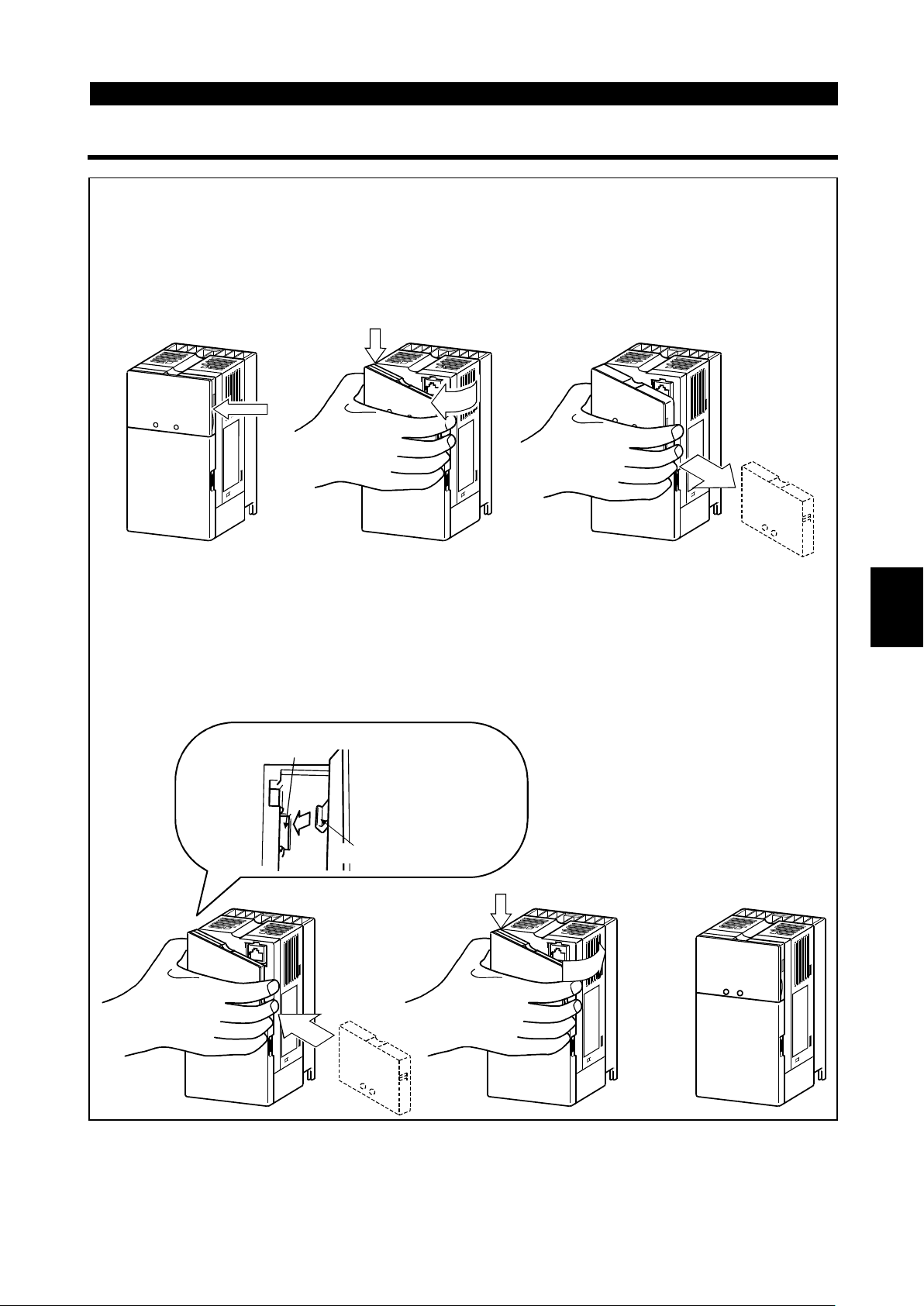

1.3.2 Removal and reinstallation of the front cover

""""

Removal

(For the FR-E520-0.1K to 3.7K-NA, FR-E510W-0.1K to 0.75K-NA)

The front cover is secured by catches in positions A and B as shown below.

Push either A or B in the direction of arrows, and using the other end as a

support, pull the front cover toward you to remove.

1

A

B

(For the FR-E520-5.5K, 7.5K-NA)

The front cover is fixed with catches in positions A, B and C.

Push A and B in the directions of arrows at the same time and remove the

cover using C as supporting points.

1) 2) 3)

A

C

C

B

5

Page 18

OUTLINE

)

(For the FR-E540-0.4K to 7.5K-NA)

The front cover is fixed with catches in positions A, B and C.

Push A and B in the directions of arrows at the same time and remove the

cover using C as supporting points.

1

A B

C

"

" Reinstallation

""

C

2) 3)

When reinstalling the front cover after wiring, fix the catches securely.

With the front cover removed, do not switch power on.

Note:1. Make sure that the front cover has been reinstalled securely.

1

2. The same serial number is printed on the capacity plate of the front cover

and the rating plate of the inverter. Before reinstalling the front cover, check

the serial numbers to ensure that the cover removed is reinstalled to the

inverter from where it was removed.

6

Page 19

OUTLINE

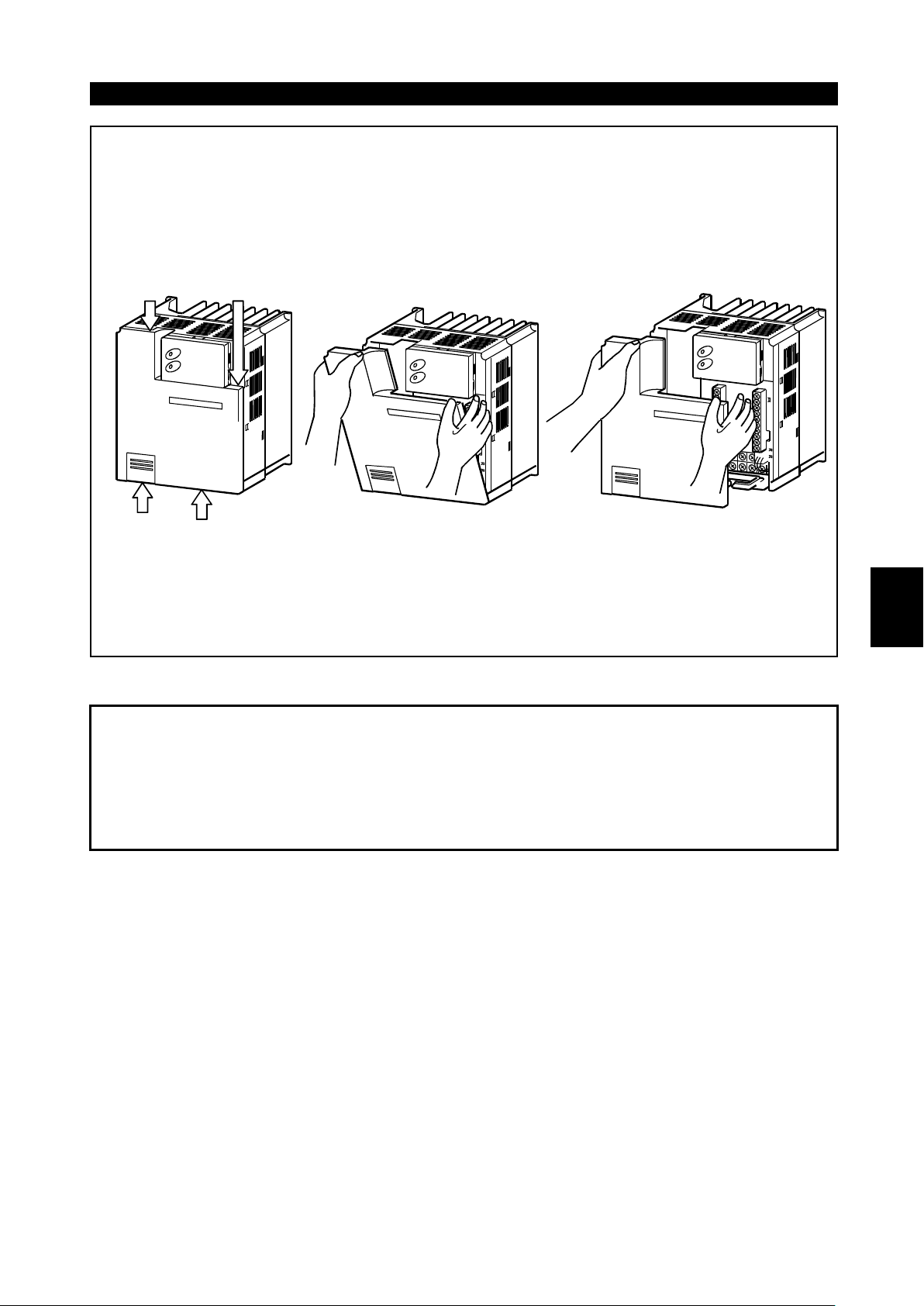

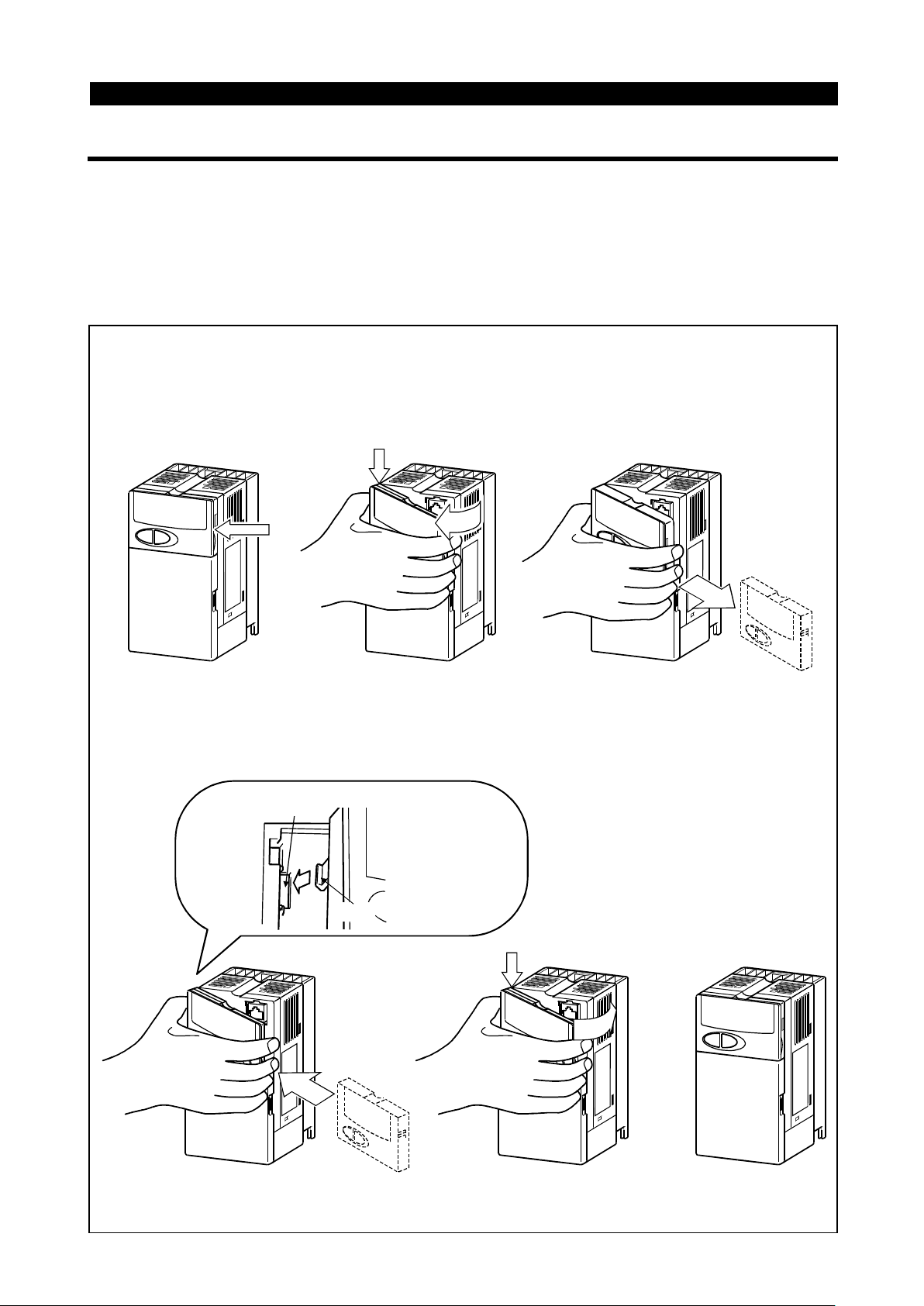

1.3.3 Removal and reinstallation of the wiring cover

""""

Removal

(For the FR-E520-0.1K to 7.5K-NA, FR-E510W-0.1K to 0.75K-NA)

The wiring cover is fixed by catches in positions 1) and 2).

Push either 1) or 2) in the direction of arrows and pull the wiring cover

downward to remove.

1)

2)

(For the FR-E540-0.4K to 7.5K-NA)

Remove the wiring cover by pulling it in the direction of arrow A.

Wiring hole

A

Wiring hole

""""

Reinstallation

Pass the cables through the wiring hole and reinstall the cover in the original

position.

7

Page 20

OUTLINE

1.3.4 Removal and reinstallation of the accessory cover

""""

Removal of the accessory cover

Hold down the portion A indicated by the arrow and lift the right hand side using

the portion B indicated by the arrow as a support, and pull out the accessory

cover to the right.

1)

""""

Reinstallation of the accessory cover

2)

A

B

3)

Insert the mounting catch (left hand side) of the accessory cover into the

mounting position of the inverter and push in the right hand side mounting

catch to install the accessory cover.

Mounting position

1

1)

Accessory cover

Catch

2)

A

3)

8

Page 21

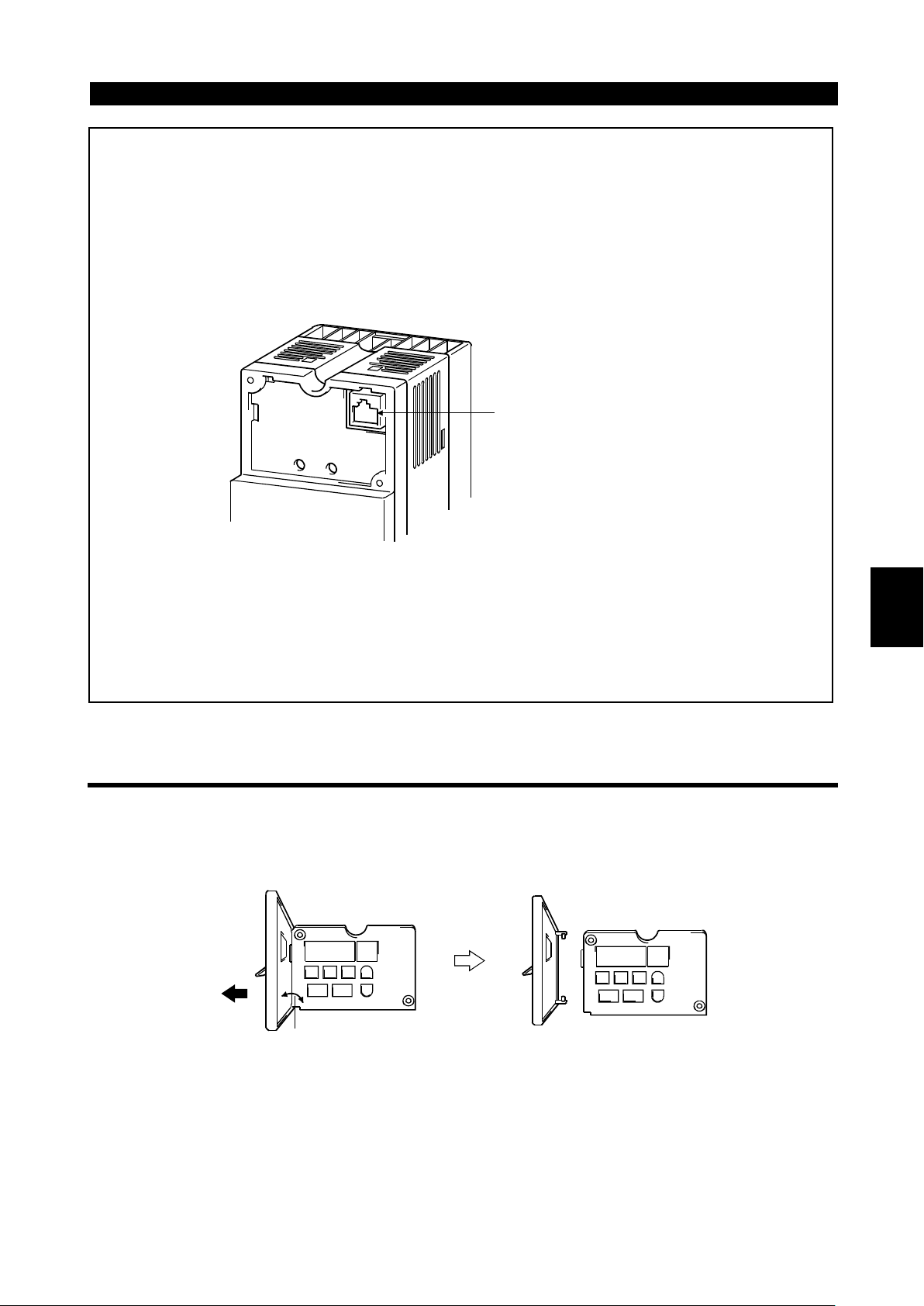

OUTLINE

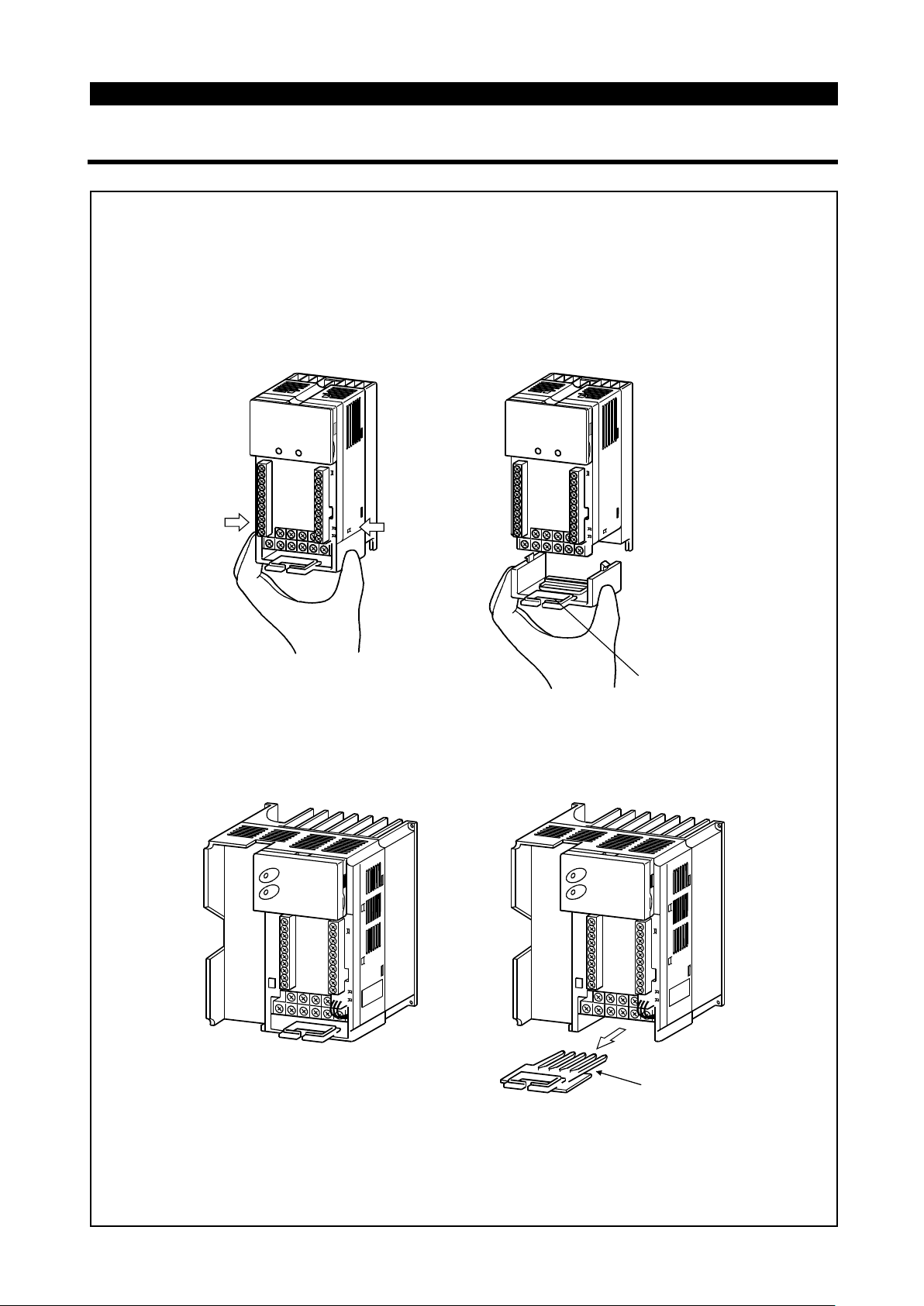

1.3.5 Reinstalla tion and removal of the control panel

To ensure safety, reinstall and removal the optional control panel (FR-PA02-02) after

switching power off.

The charging area and control printed board are exposed on the rear surface of the

control panel. When removing the control panel, always fit the rear cover option

FR-E5P. Never touch the control printed board because touching it can cause the

inverter to fail.

""""

Reinstallation of the control panel

Insert the mounting catch (left hand side) of the control panel into the

mounting position of the inverter and push in the right hand side mounting

catch to install the control panel.

1) 2)

A

B

3)

""""

Removal of the control panel

Hold down the portion A indicated by the arrow and lift the right hand side

using the portion B indicated by the arrow as a support, and pull out the

control panel to the right.

Mounting position

2)

02

A

3)

FR-PA02-

Catch

1)

(If the above procedure is not used for removal, the internal connector may be

damaged by the force applied.)

9

Page 22

OUTLINE

(

)

"

" Using the connection cable for operation

""

1) Fit the rear cover option FR-E5P to the back surface of the optional control

panel.

2) Securely plug one end of the connection cable into the PU connector of the

inverter and the other end into the adaptor of the FR-E5P option to connect it

to the control panel. (For the connection cable of the FR-E5P, refer to page

27.)

PU connector

RS-485 cable specifications

"

" Mounting the control panel on an enclosure

""

When you open the control panel front cover, the screw mounting guides for

fixing the control panel to an enclosure appear on the top left and bottom right.

Fit the rear cover of the FR-E5P option, drill holes in the control panel mounting

guides, and securely mount the control panel on the enclosure with screws.

1.3.6 Removal of the control panel (FR-PA02-02) front cover

1) Open the control panel front cover to 90 degrees.

2) Pull out the control panel front cover to the left to remove it.

1

90 degrees

10

Page 23

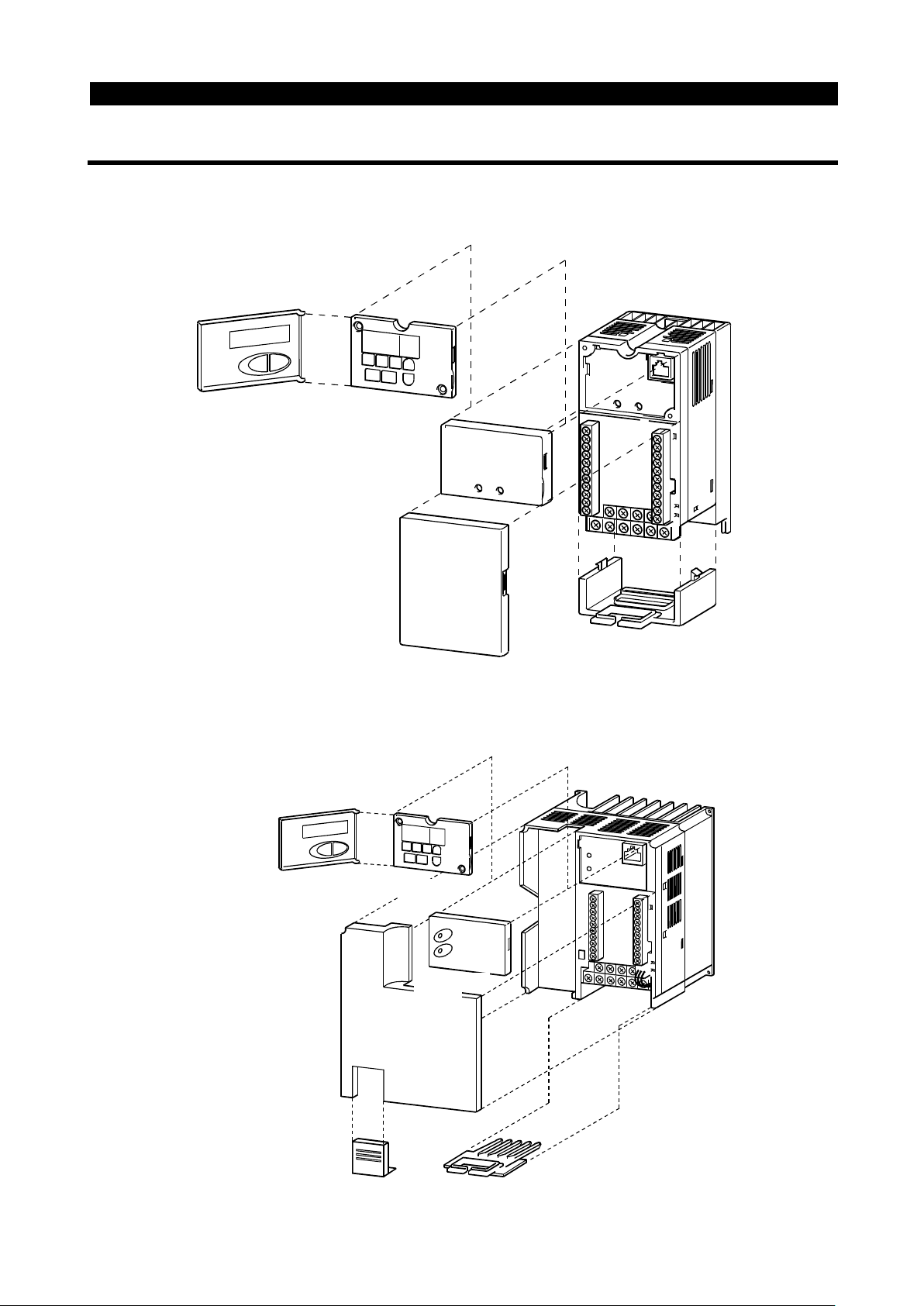

1.3.7 Exploded view

ont cove

W

f

""""

FR-E520-0.1K to 7.5K-NA

""""

FR-E510W-0.1K to 0.75K-NA

OUTLINE

Control panel (FR-PA02 )

""""

FR-E540-0.4K to 7.5K-NA

-02

Accessory cover

Fr

Wiring cover

r

Control panel (FR-PA02-02)

Front cover

iring port cover

or option

Accessory

cover

Wiring cover

11

Page 24

C H A P T E R 2

CHAPTER 2

INSTALLATION AND

INSTALLATIONAND

WIRINNG

WIRING

This chapter gives information on the basic "installation and

wiring" for use of this product.

Always read the instructions in this chapter before using the

equipment.

2.1 Installation ....................................................................12

2.2 Wiring ...........................................................................14

2.3 Other Wiring ................................................................. 34

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

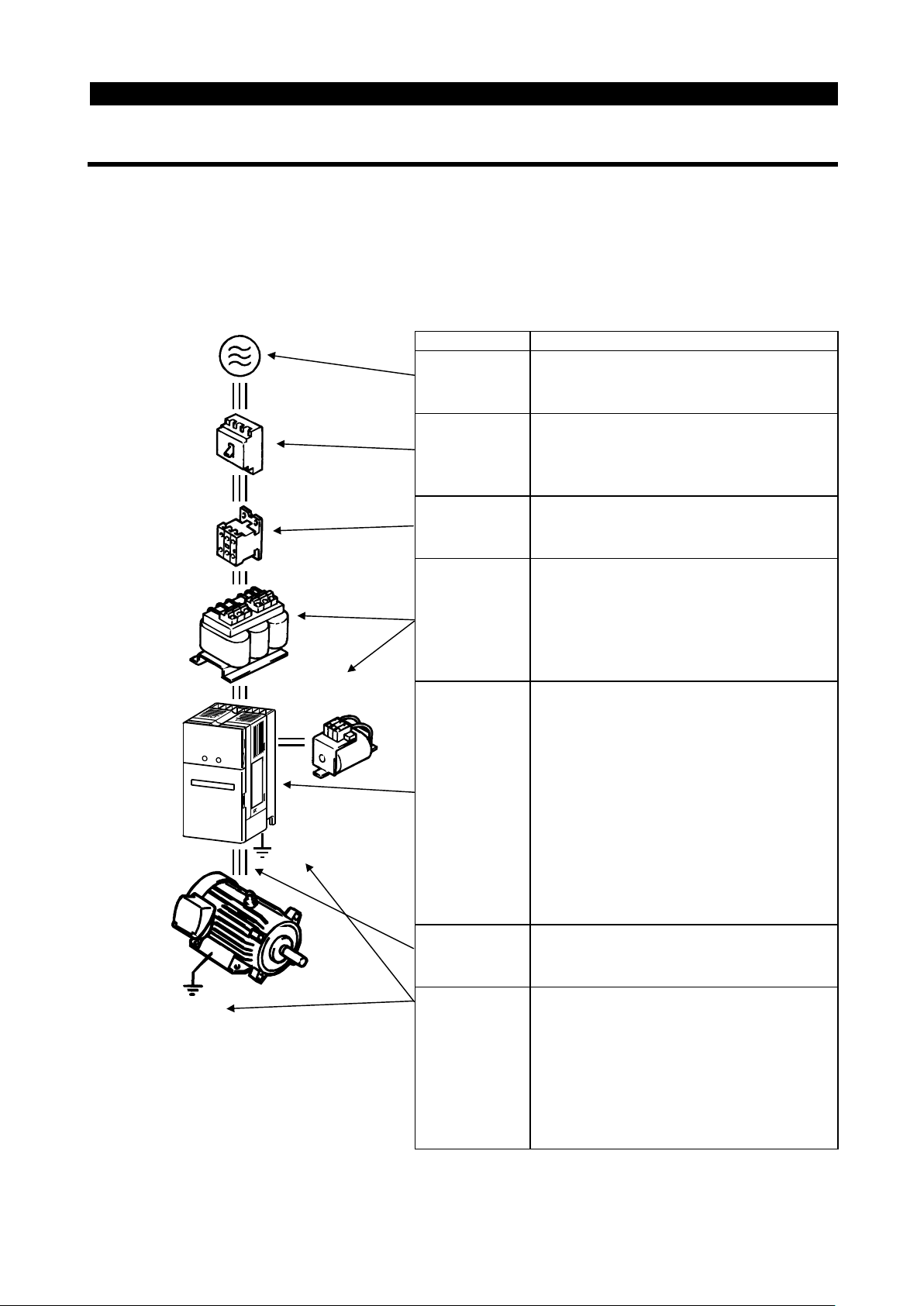

Page 25

2.1 Installation

)>

INSTALLATION AND WIRING

2 INSTALLATION AND WIRING

2.1 Installation

2.1.1 Instructions for installation

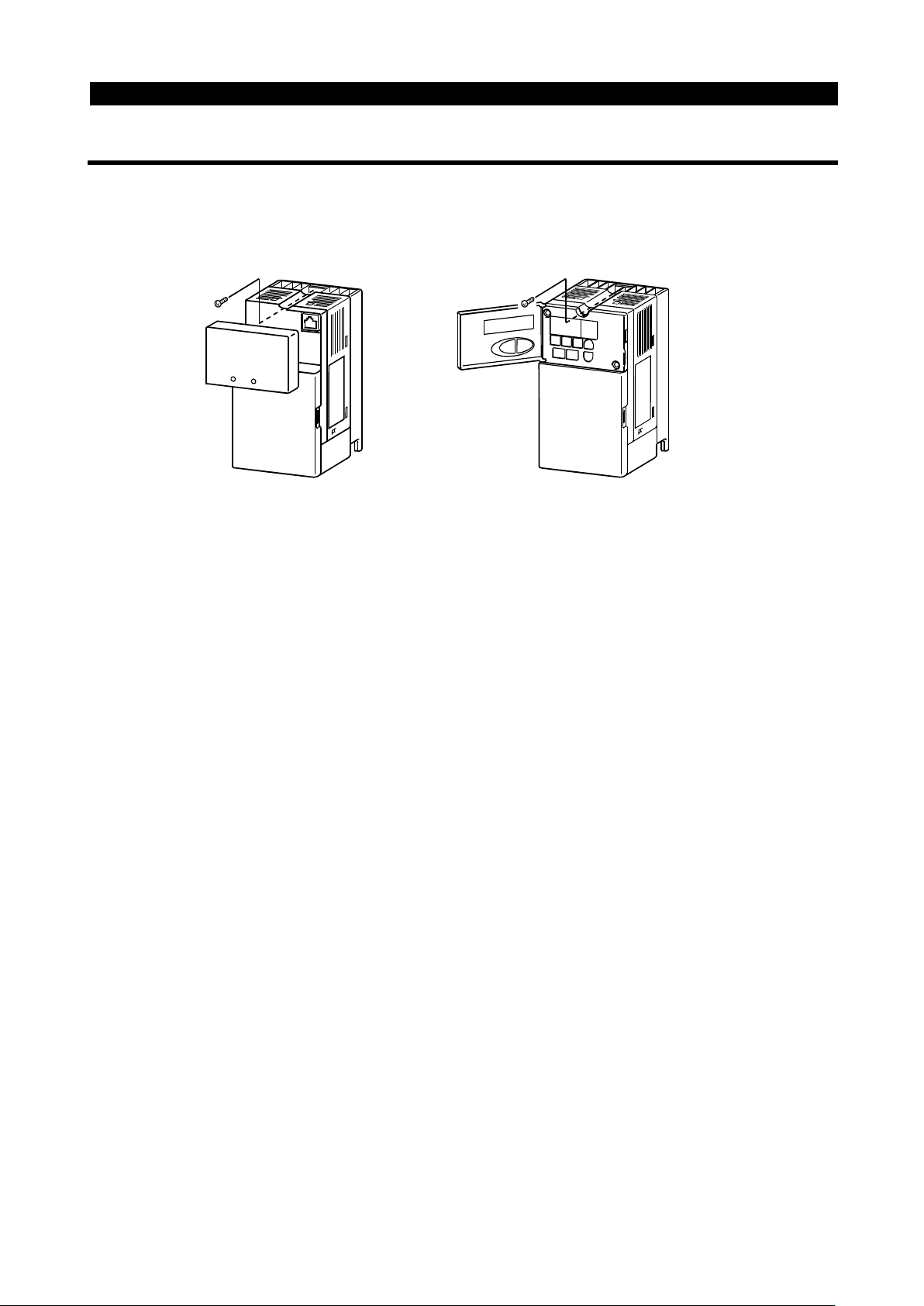

For the FR-E520-0.1K to 0.75K-NA and FR-E510W-0.1K to 0.4K-NA, install the

02

inverter with the accessory cover or control panel (FR-PA02-

) front cover open.

<For the accessory cover> <For the control panel (FR-PA02

-02

1) Handle the unit carefully.

The inverter uses plastic parts. Handle it gently to protect it from damage.

Also, hold the unit with even strength and do not apply too much strength to the front

cover alone.

2) Install the inverter in a place where it is not affected by vibration easily (5.9m/s

maximum).

Note the vibration of a cart, press, etc.

2

3) Note on ambient temperature.

The inverter life is under great influence of ambient temperature. In the place of

installation, the ambient temperature must be within the permissible range -10°C to

+50°C (14°F to 122°F). Check that the ambient temperature is within that range in

the positions shown in figure 3).

4) Install the inverter on a non-combustible surface.

The inverter will be very hot (maximum about 150°C (302°F)). Install it on a noncombustible surface (e.g. metal). Also leave sufficient clearances around the

inverter.

5) Avoid high temperatures and high humidity.

Avoid direct sunlight and places of high temperature and high humidity.

6) Avoid places where the inverter is exposed to oil mist, flammable gases, fluff, dust,

dirt etc.

Install the inverter in a clean place or inside a "totally enclosed" panel which does

not accept any suspended matter.

12

Page 26

INSTALLATION AND WIRING

(

)

(

)

7) Note the cooling method when the inverter is installed in an enclosure.

When two or more inverters are installed or a ventilation fan is mounted in an

enclosure, the inverters and ventilation fan must be installed in proper positions with

extreme care taken to keep the ambient temperatures of the inverters with the

permissible values. If they are installed in improper positions, the ambient

temperatures of the inverters will rise and ventilation effect will be reduced.

8) Install the inverter securely in the vertical direction with screws or bolts.

3) Note on ambient

temperatures

Measurement

position

5cm

1.97inch

5cm

1.97inch

FR-E500

Measurement position

5cm

(1.97inch)

7) For installation in an enclosure

Ventilation

fan

Inverter

(Correct example) (Incorrect example)

Position of Ventilation Fan

Inverter

4) Clearances around the inverter

10cm (3.94inch)

or more

1cm (0.39inch)

or more*

These cleara nc es ar e a ls o necessary for cha nging the cooling fan.

Inverter

FR-E500

*5cm (1.97inch) or mor e for 5.5K and 7.5K

Built-in cooling fan

(Correct example)

1cm (0.39inch)

or more*

10cm (3.94inch)

or more

Inverter

Leave sufficient

clearances above

and under the

inverter to ensure

adequate ventilation.

Cooling fan

built in the

inverter

Inverter

Inverter

(Incorrect example)

Cooling air

2

8) Vertical mounting

13

Page 27

2.2 Wiring

g

p

)

q

q

p

2.2 Wiri ng

2.2.1 Terminal connection diagram

""""

3-phase 200V power input

""""

3-phase 400V power input

INSTALLATION AND WIRING

3-phase

AC power

supply

24VDC power output and

external transistor commo n

Multi-speed selection

Control input signals

(no voltage input allowed)

Frequency setting signals (analog)

(Note 1)

Frequency

setting

potentiometer

1/2W1k

NFB

Forward rotation start

Reverse rotation start

Contact input common

3

1

Current input(-)

Ω

4 to 20mADC(+)

MC

High

Middle

Low

Output stop

Reset

2

)

R(L

1

)

S(L

2

3

T(L

)

PC

Note 5

STF

STR

RH

RM

RL

MRS

RES

SD

Note 4

10(+5V)

0 to 5VDC

2

0 to 10VDC

5(Common)

Note 4

4(4 to 20mADC)

Selected

PU connector

(RS-485)

P1

(+)P

PR

(-)N

Note 2

RUN

FU

SE

Note 3

FM

SD

Note 3

AM

U

V

W

Jumper

Remove this jumper when

using the optional power-factor

improving DC reactor.

Brake resistor connection

A

B

C

5

Alarm

output

Running

Frequency detection

Open collector

output common)

(e.g. frequency meter)

+

Calibration

resistor (Note 6)

Ground

Main circuit termina l

Control circuit input terminal

Control circuit output terminal

Meter

Moving-coil

type1mA

full-scale

Analog signal

(+)

output

(−)

(0 to 10VDC)

Motor

IM

Ground

Open

collector outputs

For 200V

and100V

class

inverters

For 400V

class

inverter

Note:1. If the potentiometer is to be operated often, use a 2W1kΩ potentiometer.

2. 0.1K and 0.2K do not contain a transistor.

3. Terminals SD and SE are isolated.

4. Terminals SD and 5 are common terminals. Do not earth them to the

round. Terminals SD and 5 are not isolated. (Those of the 400V class are

isolated.)

5. When terminals PC-SD are used as a 24VDC

ower supply, be careful not

to short these terminals. If they are shorted, the inverter will be damaged.

02

6. Not needed when the control panel (FR-PA-02-

PU04

fre

the fre

is used for calibration. Used when calibration must be made near the

uency meter for such a reason as a remote frequency meter. However,

uency meter needle may not deflect to full-scale if the calibration

) or parameter unit (FR-

resistor is connected. In this case, use this resistor and the control

parameter unit together.

14

anel or

Page 28

"

" Single-phase 100V power input

""

INSTALLATION AND WIRING

NFB

Power supply

MC

R (L

S (L

)

1

)

2

U

V

W

Motor

IM

Ground

Note:1. To ensure safety, connect the power input to the inverter via a magnetic

contactor and earth leakage circuit breaker or no-fuse breaker, and use the

magnetic contactor to switch power on-off.

2. The output is three-phase 200V.

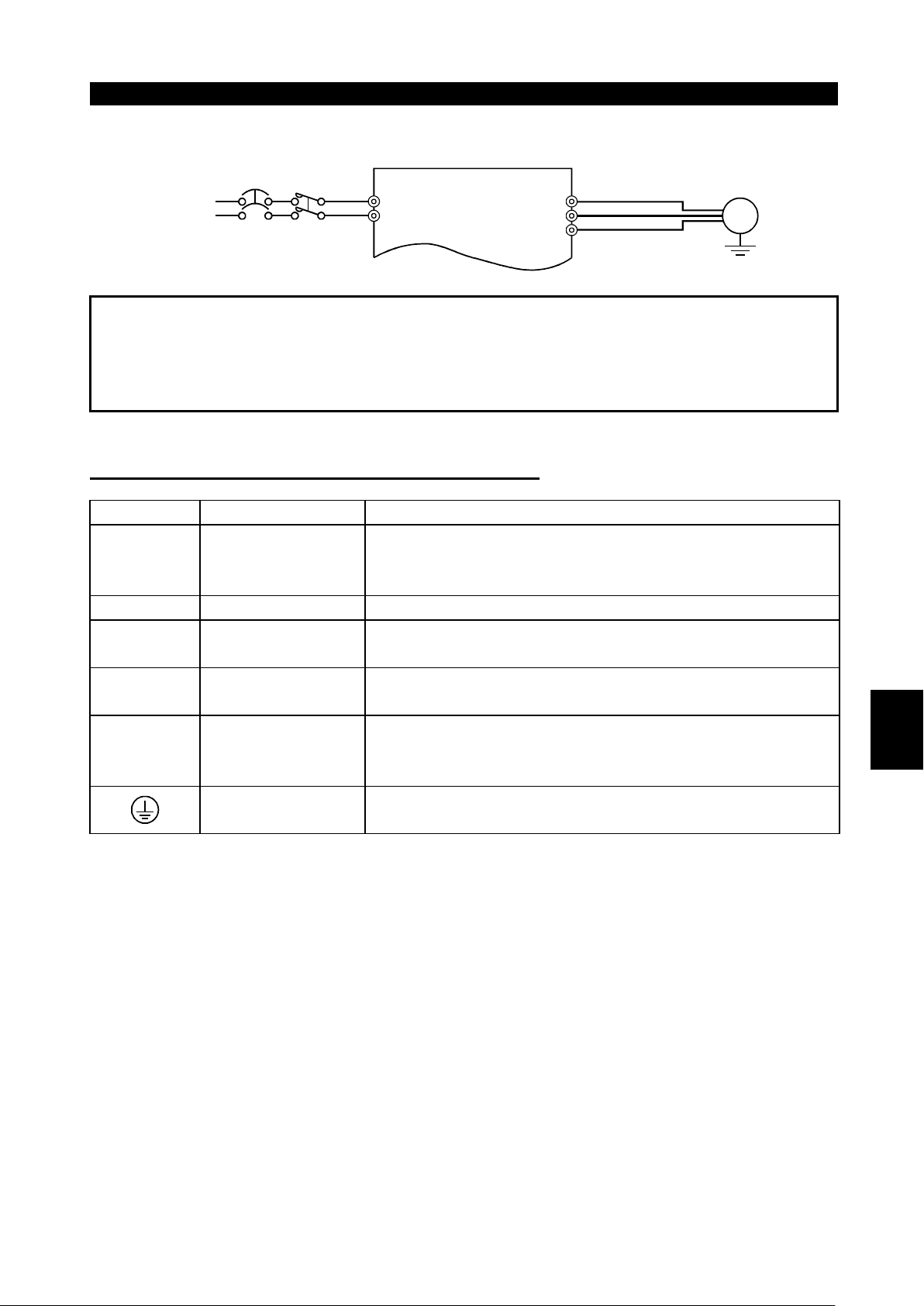

(1)

Description of the main circuit terminals

Symbol Terminal Name Description

R, S, T

, L2, L3)

(L

1

AC power input

(Note)

U, V, W Inverter output Connect a three-phase squirrel-cage motor.

P (+), PR

P (+), N (−)

Brake resistor

connection

Brake unit

connection

Power factor

P (+), P1

improving DC

reactor connection

Connect to the commercial power supply. Keep these

terminals unconnected when using the high power factor

converter.

Connect the optional brake resistor across term inals P-PR

(+ - PR) (not for 0.1K and 0.2K).

Connect the optional brake unit or high power factor

converter.

Disconnect the jumper f rom terminals P-P1 (+ - P1) and

connect the optional power factor improving DC reactor.

2

Ground For grounding the inverter chassis. Must be earthed.

Note: R, S (L1, L2) terminals for single-phase power input.

15

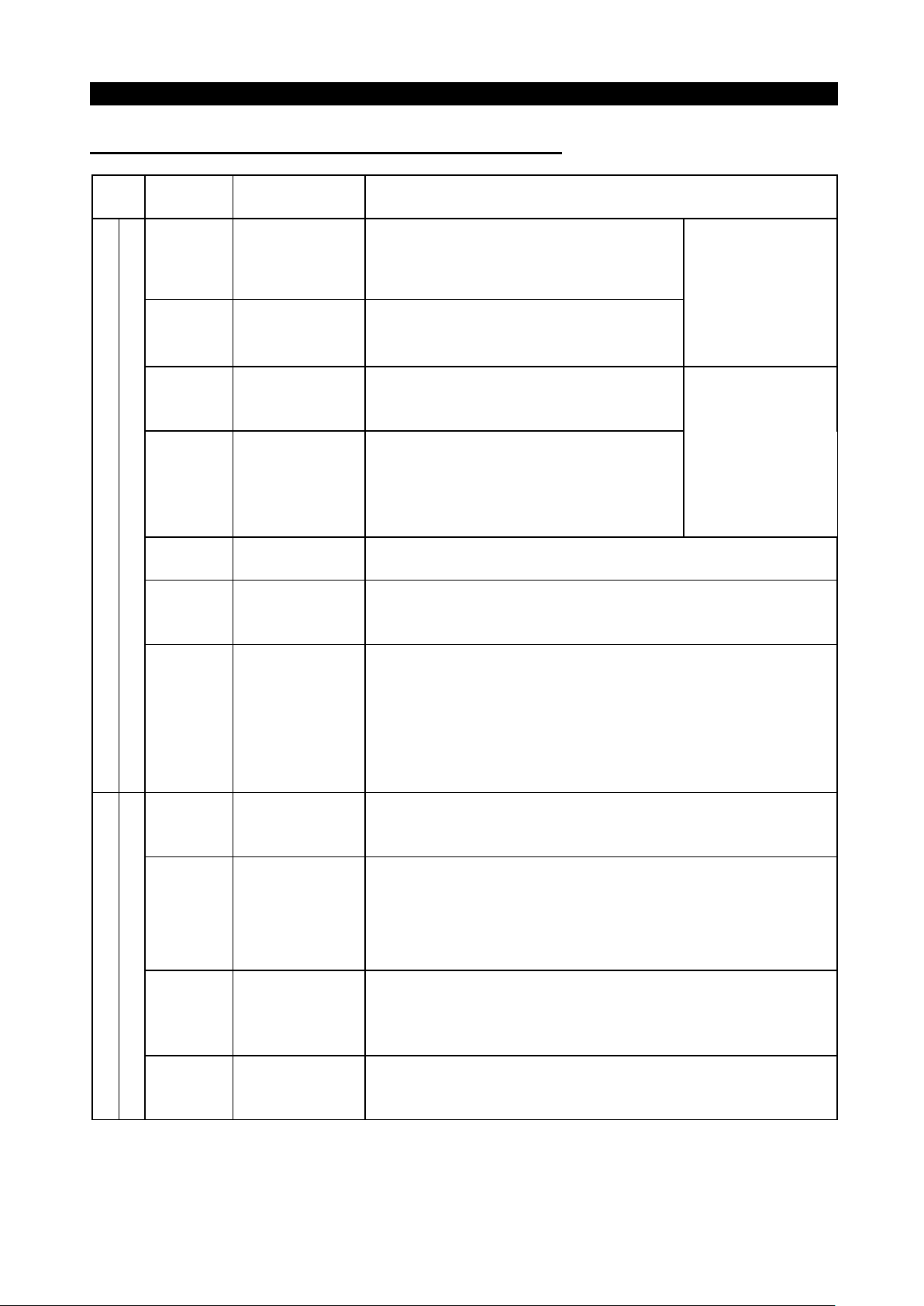

Page 29

(2)

Description of the control circuit terminals

INSTALLATION AND WIRING

Type Symbol

STF

STR

RH, RM,RLMulti-speed

MRS Output stop

Input signals

Analog

RES Reset

SD

Contacts, e.g. start (STF), stop (STOP) etc

PC

10

2

4

Frequency setting

5

Terminal

Name

Forward

rotation start

Reverse

rotation start

selection

Contact input

common

(sink*)

Power output

and external

transistor

common

Contact input

common

(source*)

Frequency

setting power

supply

Frequency

setting

(voltage)

Frequency

setting

(current)

Frequency

setting input

common

Description

When the STF

Turn on the STF signal to start forward

rotation and turn it off to stop.

Turn on the STR signal to start reverse

rotation and turn it off to stop.

Combine the RH, RM and RL signals

as appropriate to select multiple

speeds.

Turn on the MRS signal (20ms or

longer) to stop the inverter output.

Used to shut off the inverter output to

bring the motor to a stop by the

electromagnetic brake.

Used to reset the protective circuit activated. Turn on the

RES signal for more than 0.1 second then turn it off.

Common to the contact input terminals and terminal FM.

Common output terminal for 24VDC 0.1A power output

(PC terminal).

When transist or output (open collector output), such as a

programmable controller (PLC), is connected, connect the

external power supply common for transistor output to this

terminal to prevent a fault caused by undesirable current.

This terminal can be used as a 24VDC, 0.1A power

output.

5VDC, permissible load current 10m A

By entering 0 to 5VDC (0 to 10VDC), the maximum output

frequency is reached at 5V (or 10V) and I/O are

proportional. Use Pr. 73 to switch between input 0 to

5VDC (factory setting) and 0 to 10VDC. Input resistance

10kΩ. Maximum permissible voltage 20V.

By entering 4 to 20mADC, the m aximum output frequency

is reached at 20mA and I/O are proportional. This input

signal is valid only when the AU signal is on. Input

resistance 250Ω. Maximum permissible current 30mA.

Common to the frequency setting signals (terminal 2, 1 or 4).

Do not connect to the earth.

and STR signals

are turned on

simultaneously,

the stop

command is

given.

Input terminal

function choices

(Pr. 180 to

Pr. 183) change

terminal functions.

Note: Assign the AU signal to any of the terminals using the input terminal function

selection (Pr. 180 to Pr. 183).

* Used as a contact input signal common terminal for the 400V class by switching

between sink logic and source logic. (Refer to page 23).

16

Page 30

INSTALLATION AND WIRING

Type Symbol

A, B, C Alarm output

Contact

RUN

FU

Open collector

Output signals

SE

FM

(200V

and

100V

Pulse

class

inverters)

AM

(400V

class

Analog

only)

Terminal

Name

Inverter

running

Frequency

detection

Open collector

output

common

For meter

Analog signal

output

Description

Contact output indicating that t he output has

been stopped by the inverter protective

function activated. 230VAC 0.3A, 30VDC

0.3A. Alarm: discontinuity across B-C

(continuity across A-C), normal: continuity

across B-C (discontinuity across A-C).

Switched low when the inverter output

frequency is equal to or higher than the

starting frequency (factory set to 0.5Hz,

variable). Switched high during stop or DC

injection brake operation (*1).

Permissible load 24VDC 0.1A.

Switched low when the output frequency has

reached or exceeded the detection frequency

set as appropriate. Switched high when below

the detection frequency (*1).

Permissible load 24VDC 0.1A

Common to t he RUN and FU terminals.

Factory setting of output item:

One selected from output

frequency, motor current

and output voltage is

output (*2). The output

signal is proportional to

the magnitude of each

monitoring item.

Frequency

Permissible load current 1mA

1440 pulses/s at 60Hz

Factory setting of output item:

Frequency

Output signal 0 to 10 VDC

Permissible load current 1mA

Output

terminal

function

choices

(Pr. 190 to

Pr. 192)

change

terminal

functions.

2

With the control panel connector, communication can be

made using the RS-485 protocol.

Conforming Standard : EIA Standard RS-485

!

Transmission format : Multi-drop link

!

Communication speed : Maximum 19200 bps

!

Overall length : 500m (1640.40 feet)

!

Communication

RS-485

PU connector

*1: Low indicates that the open collector output transistor is on (conducts). High

indicates that the transistor is off (does not conduct).

*2: Not output during inverter resetting.

17

Page 31

INSTALLATION AND WIRING

3

)

2.2.2 Wiring of the main circuit

(1)

Wiring instructions

1) It is recommended to use insulation-sleeved solderless terminals for power supply

and motor wiring.

2) Power must not be applied to the output terminals (U, V, W) of the inverter.

Otherwise the inverter will be damaged.

3) After wiring, wire off-cuts must not be left in the inverter.

Wire off-cuts can cause an alarm, failure or malfunction. Always keep the inverter

clean.

When drilling mounting holes in a control box etc., be careful so that chips and

others do not enter the inverter.

4) Use thick cables to make the voltage drop 2% or less.

If the wiring distance is long between the inverter and motor, a main circuit cable

voltage drop will cause the motor torque to decrease, especially at the output of a

low frequency. (A selection example for the wiring length of 20m (65.62 feet) is

shown on page 21.)

5) For long distance wiring, the overcurrent protection may be activated improperly or

the devices connected to the output side may misoperate or become faulty under

the influence of a charging current due to the stray capacitance of the wiring.

Therefore, the maximum overall wiring length should be as indicated in the following

table. If the wiring length exceeds the value, it is recommended to set "1" in Pr. 156 to

make the fast-response current limit function invalid. (When two or more motors are

connected to the inverter, the total wiring length should be within the indicated value.)

Inverter Capacity 0.1K 0.2K 0.4K 0.75K 1.5K 2.2K

Non-low

acoustic noise

mode

Low acoustic

noise mode

100V,

200V

class

400V

class

100V,

200V

class

400V

class

200

(656.16)

——

30

(98.42)

——

200

(656.16)

100

(328.08)

300

(984.24 )

200

(656.16)

200

(656.16)

30

(98.42)

500

(1640.40)

200

(656.16)

300

(984.24)

100

(328.08)

500

(1640.40)

300

(984.24)

500

(1640.40)

200

(656.16)

(1640.40)

(1640.40)

(1640.40)

(984.24)

Overall wiring length (3.7K or more)

500m (1640.40 feet)

maximum

300m

(984.24 feet)

300m

(984.24 feet)

500

500

500

300

(Unit: m (feet))

3.7K or

more

500

(1640.40)

500

(1640.40)

500

(1640.40)

500

(1640.40)

00m (984.24 feet)+300m (984.24 feet)=600m (1968.48 feet

18

Page 32

INSTALLATION AND WIRING

g

g

)

pp

g

g

q

p

g

6) Connect only the recommended optional brake resistor between the terminals P-PR

(+ - PR). Keep terminals P-PR (+ - PR) of 0.1K or 0.2K open.

These terminals must not be shorted.

0.1K and 0.2K do not accept the brake resistor. Keep terminals P-PR (+ - PR) open.

Also, never short these terminals.

7) Electromagnetic wave interference

The input/output (main circuit) of the inverter includes harmonic components, which

may interfere with the communication devices (such as AM radios) used near the

inverter. In this case, install the FR-BIF optional radio noise filter (for use in the input

side only) or FR-BSF01 or FR-BLF line noise filter to minimize interference.

8) Do not install a power capacitor, surge suppressor or radio noise filter (FR-BIF

option) in the output side of the inverter.

This will cause the inverter to trip or the capacitor and surge suppressor to be

damaged. If any of the above devices are installed, immediately remove them.

(When using the FR-BIF radio noise filter with a single-phase power supply, connect

it to the input side of the inverter after isolating the T phase securely.)

9) W hen rewiring after operation, make sure that the POWER lamp has gone off, and

when more than 10 minutes has elapsed after power-off, check with a meter etc.

that the voltage is zero. After that, start rewiring work. For some time after power-off,

there is a dangerous voltage in the capacitor.

Notes on Grounding

"

Leaka

and motor must be grounded.

"

Use the dedicated

in the case, chassis, etc.

aluminium and co

contain zinc. When ti

the aluminium frame.

"

The

e

as short as

inverter to minimize the ground cable length.

2.2kW (3HP) or less 2 (2.5)

3.7kW (5HP)

5.5kW (7. 5HP), 7.5kW (10HP)

To meet the Low Volta

specified size in brackets ( ).

e currents flow in the inverter. To prevent an electric shock, the inverter

round terminal to ground the inverter. (Do not use the screw

For the earth connection avoid direct contact between

er. Tin-plated cable lugs can be used if the plating does not

htening the screws take care not to damage the thread in

round cable should be as thick as possible. Use the cable whose gauge is

ual to or larger than those indicated in the following table, and make its length

ossible. The grounding point should be as near as possible to the

(Unit: mm2)

Ground Cable Gauge

100V class

200V class 400V class

2 (2.5) 2 (2.5)

3.5 (4) 2 (4)

e Directive, use PVC insulated cables larger than

2

"

Ground the motor on the inverter side using one wire of the 4-core cable.

19

Page 33

(2)

(

)

(

)

(

)

)

Terminal block layout of the power circ ui t

INSTALLATION AND WIRING

FR-E520-0.1K-NA, 0.2K-NA, 0.4K-NA,

0.75K-NA

P1N/- P/+ PR

UVW

R/L1S/L2T/L

3

Screw size (M3 . 5 )

TB1

Screw size

M3.5

FR-E520-5.5K-NA, 7.5K-NA

R/L1S/L2T/L3N/-

P1

Screw size (M5)

PR V WP/+

U

TB1

Screw size

(M5)

FR-E540-0.4K to 7.5K-NA

P1N/- P/+ PR

R/L1S/L2T/L

3

UVW

TB1

Screw size (M4 )

FR-E520-1.5K-NA, 2.2K-NA, 3.7K-NA

N/- P/+

P1

PR

TB2

Screw size (M4 )

R/L1S/L2T/L

3

UVW

Screw size (M4 )

TB1

Screw size (M4 )

Screw size (M4 )

FR-E510W-0.1K-NA, 0.2K-NA, 0.4K-NA

P1N/- P/+ PR

R/L1S/L

2

Screw size

UVW

TB1

Screw size

M3.5

M3.5

FR-E510W-0.75K-NA

N/- P/+

P1

PR

TB2

Screw size (M4)

R/L1S/L

2

Screw size (M4)

UVW

TB1

Screw size (M4

20

Page 34

INSTALLATION AND WIRING

(3)

Cables, crimping terminals, etc.

The following table lists the cables and crimping terminals used with the inputs (R (L1),

2

S (L

), T (L3)) and outputs (U, V, W) of the inverter and the torques for tightening the

screws:

1) FR-E520-0.1K-NA to 7.5K-NA

Applicable

Inverter Type

FR-E520-0.1K-NA

to 0.75K-NA

FR-E520-1.5K-NA,

2.2K-NA

FR-E520-3.7K-NA M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 2.5

FR-E520-5.5K-NA M5 2.5 5.5-5 5.5-5 5.5 5.5 10 10 6 4

FR-E520-7.5K-NA M5 2.5 14-5 8-5 14 8 6 8 16 6

Terminal

Screw

Size

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

Tight-

ening

Torque

N

m

⋅⋅⋅⋅

Crimping

Terminals

R, S, T

(L1, L2, L3)

U, V, W

mm

R, S, T

(L1, L2, L3)

Cables

2

U, V, W

AWG mm

R, S, T

(L1, L2, L3)

U, V, W

PVC insulated

Cables

R, S, T

(L1, L2, L3)

2

U, V, W

2) FR-E540-0.4K-NA to 7.5K-NA

Applicable

Inverter Type

FR-E540-0.4K-NA M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

FR-E540-0.75K-NA M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

FR-E540-1.5K-NA M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

FR-E540-2.2K-NA M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

FR-E540-3.7K-NA M4 1.5 2-4 2-4 2 2 14 14 2.5 2.5

FR-E540-5.5K-NA M4 1.5 5.5-4 2-4 3.5 2 12 14 4 2.5

FR-E540-7.5K-NA M4 1.5 5.5-4 5.5-4 3.5 3.5 12 12 4 4

Terminal

Screw

Size

Tight-

ening

Torque

N

m

⋅⋅⋅⋅

Crimping

Terminals

R, S, T

(L1, L2, L3)

U, V, W

mm

R, S, T

(L1, L2, L3)

Cables

2

U, V, W

AWG mm

R, S, T

(L1, L2, L3)

U, V, W

PVC insulated

Cables

R, S, T

(L1, L2, L3)

2

U, V, W

2

3) FR-E510W-0.1K-NA to 0.75K-NA

Cables

2

U, V, W

AWG mm

R, S

(L1, L2)

Applicable

Inverter Type

FR-E510W-0.1K

-NA to 0.4K-NA

FR-E510W-0.75K

-NA

Terminal

Screw

Size

M3.5 1.2 2-3.5 2-3.5 2 2 14 14 2.5 2.5

M4 1.5 5.5-4 2-4 3.5 2 12 14 4 2.5

Tight-

ening

Torque

N

m

⋅⋅⋅⋅

Crimping

Terminals

R, S

(L1, L2)

U, V, W

mm

R, S,

(L1, L2)

Note:1. The cables used should be 75°C (167°F) copper cables.

2. Tighten the terminal screws to the specified torques.

Undertightening can cause a short or misoperation.

Overtightening can cause the screws and unit to be damaged, resulting in a

short or misoperation.

21

U, V, W

PVC insulated

Cables

2

R, S

(L1, L2)

U, V, W

Page 35

(4)

T

t

s

(

Connection of the power suppl y and motor

"

" Three-phase power input

""

Three-phase

power supply 200V

Three-phase

power supply 400V

No-fuse

breaker

Ground

terminal

Ground

R

)S(L2)T(L3)

(L

1

R

(L1)S(L2)T(L3)

UVW

U

INSTALLATION AND WIRING

W

Motor

Ground

V

he power supply cables must be connected

o R, S, T (L , L , L ). If the y ar e connected to

U, V, W, the inverter will be damaged. (Phase

equence need not be matched.)

"

" Single-phase power input

""

1 2 3

Single-phase power

supply 100V

Ground

No-fuse

breaker

terminal

Ground

R

(L1)S(L2)

R

1

(L

)S(L2)

Note:1. To ensure safety, connect the power input to the inverter via a

magnetic contactor and earth leakage circuit breaker or no-fuse

breaker, and use the magnetic contactor to switch power on-off.

2. The output is three-phase 200V.

Connect the motor to U, V, W.

connection, turning on the forward rotation switch (signal)

rotates the motor in the counterclockwise

when viewed from the load shaft.

UVW

UVW

Motor

In the above

arrow) direction

Ground

2.2.3 Wiring of the control circuit

(1)

Wiring instructions

1) Terminals SD, SE and 5 are common to the I/O signals. These common terminals

must not be earthed to the ground.

Terminals SD and 5 are not isolated. (Those of the 400V class are isolated.)

2) Use shielded or twisted cables for connection to the control circuit terminals and run

them away from the main and power circuits (including the 200V relay sequence

circuit).

3) The frequency input signals to the control circuit are micro currents. W hen contacts

are required, use two or more parallel micro signal contacts or a twin contact to

prevent a contact fault.

4) It is recommended to use the cables of 0.3mm2 to 0.75mm2 gauge for connection to

the control circuit terminals.

5) W hen bar terminals and solid wires are used for wiring, their diameters should be

0.9mm (0.04 inches) maximum If they are larger, the screw threads may be

damaged during tightening.

22

Page 36

INSTALLATION AND WIRING

)

(2)

Terminal block layout

In the control circuit of the inverter, the terminals are arranged as shown below:

Terminal screw size: M2.5

(200V class, 100V class) (400V class)Terminal layout of control circuit

RH

RM

RL

MRS

RES

SD

FM*

PC

SE

RUN

FU

A

B

C

10

2

5

4

SD

STF

STR

SD

*AM for the 400V class inverter.

(3)

Wiring method

1) For wiring the control circuit, use cables after stripping their sheaths.

Refer to the gauge printed on the inverter and strip the sheaths to the following

dimensions. If the sheath is stripped too much, its cable may be shorted with the

adjoining cable. If the sheath is stripped too little, the cable may come off.

2

7mm±1mm (0.28inches± 0.04inches

2) When using bar terminals and solid wires for wiring, their diameters should be

0.9mm maximum. If they are larger, the threads may be damaged during tightening.

3) Loosen the terminal screw and insert the cable into the terminal.

4) Tighten the screw to the specified torque.

Undertightening can cause cable disconnection or misoperation. Overtightening can

cause damage to the screw or unit, leading to short circuit or misoperation.

⋅

Tightening torque: 0.25 N

m to 0.49 N⋅m

* Use a size 0 screwdriver.

Note: When routing the stripped cables, twist them so that they do not become loose.

In addition, do not solder them.

(4) Control logic changing (400V class only)

For the 200V and 100V class inverters, the logic cannot be changed.

The input signal logic is factory-set to the sink mode.

To change the control logic, the position of the connector beside the control circuit

terminal block must be changed.

23

Page 37

INSTALLATION AND WIRING

1) Use tweezers etc. to remove the connector in the sink logic position and fit it in the

source logic position.

Do this position changing before switching power on.

Note:1. Make sure that the front cover has been installed securely.

2. The front cover has a capacity plate and the inverter a rating plate on it.

Since these plates have the same serial numbers, always reinstall the

removed cover to the inverter from where it was removed.

3. Always install the sink-source logic changing connector in either of the

positions. If two connectors are installed in these positions at the same time,

the inverter may be damaged.

2) Sink logic type

•

In this logic, a signal switches on when a current flows out of the corresponding

signal input terminal.

Terminal SD is common to the contact input signals. Terminal SE common to the

open collector output signals.

•

Current

STF

STR

SD

R

R

Current flow related to

RUN signal

Inverter

RUN

SE

24VDC

AX40

1

9

R

R

24

Page 38

INSTALLATION AND WIRING

C

•

When using an external power supply for transistor output, use terminal PC as a

common to prevent misoperation caused by undesirable current.

(Do not connect terminal SD of the inverter with terminal 0V of the external power

supply. When using terminals PC-SD as a 24VDC power supply, do not install the

power supply in parallel outside the inverter. Doing so may cause misoperation due

to undesirable current.)

Y40 type

ransistor

utput module

Inverter

24VD

(SD)

10

1

STF

2

STR

3

RH

4

RM

5

RL

6

RES

9

PC

24VDC

SD

3) Source logic type

•

In this logic, a signal switches on when a current flows into the corresponding signal

input terminal.

Terminal PC is common to the contact input signals. Terminal SE common to the

open collector output signals.

2

• Current flow related to

Current

PC

STF

STR

RUN signal

R

R

Inverter

RUN

SE

24VDC

AX80

1

9

R

R

25

Page 39

INSTALLATION AND WIRING

C

(

)

•

When using an external power supply for transistor output, use terminal SD as a

common to prevent misoperation caused by undesirable current.

24VDC

PC

STF

STR

SD

Inverter

24VD

(SD)

AY-80

9

1

2

10

(5) How to use the STOP signal

The following connection example shows how to self-hold the start signals (forward

rotation, reverse rotation).

Use Pr. 180 to Pr. 183 (input terminal function selection) to assign the STOP signal.

RL

(STOP)

Stop

Forward

rotation

Reverse

rotation

MRS

RES

SD

STF

STR

Wiring example for sink logic

26

Page 40

INSTALLATION AND WIRING

2.2.4 Connection to the PU connector

(1)

When connecting the control panel or parameter unit using a cable

Use the option FR-CB2# or the following connector and commercially available cable:

<Connection cable>

!

Connector : RJ45 connector

Example: 5-554720-3, Tyco Electronics Corporation

!

Cable : Cable conforming to EIA568 (e.g. 10BASE-T cable)

Example: SGLPEV 0.5mm×4P (Twisted pair cable, 4 pairs),

MITSUBISHI CABLE INDUSTRIES, LTD.

<When using the control panel>

Note: The rear cover and junction adaptor are required since the circuit board is

exposed in the back of the control panel.

Use the FR-E5P option (cover and adaptor available as a set).

<Maximum w iring length>

!

Control panel (FR-PA02-

!

Parameter unit (FR-PU04): 20m (65.62 feet)

(2)

For RS-485 communication

02

): 20m (65.62 feet)

The PU connector can be used for communication

operation from a personal computer etc.

When the PU connector is connected with a

personal, FA or other computer by a

communication cable, a user program allows the

1) SG

2) P5S

3) RDA

4) SDB

8) to 1)

5) SDA

6) RDB

7) SG

8) P5S

inverter to be run and monitored and the parameter

values to be read and written.

<PU connector pin-outs>

Viewed from the inverter (receptacle side) front

Note: 1. Do not connect the PU connector to a computer's LAN board, FAX modem

socket or telephone modular connector. Otherwise, the product may be

damaged due to electrical specification differences.

2. Pins 2) and 8) (P5S) provide power to the control panel or parameter unit.

Do not use these pins for RS-485 communication.

2

27

Page 41

INSTALLATION AND WIRING

n

<System configuration examples>

1) When a computer having a RS-485 interface is used with several inverters

Computer

RS-485

interface/terminal

Computer

Station 1

Inverter

PU connector

(Note1)

Distribution

terminal

10BASE-T cable (Note 2)

Station 2

Inverter

PU connector

(Note1)

Station n

Inverter

PU connector

(Note1)

Use the connectors and cables which are available on the market.

Note:1. Connector: RJ45 connector

Example: 5-554720-3, Tyco Electronics Corporation

2. Cable :Cable conforming to EIA568 (such as 10BASE-T cable)

Example: SGLPEV 0.5mm × 4P (Twisted pair cable, 4 pairs),

Mitsubishi Cable Industries, Ltd.

2) When a computer having a RS-232C interface is used with inverters

Termination

resistor

Computer

RS-232C

connector

RS-232C

cable

RS-485

terminal

*Commercially available converter is required. (Note 3)

Max. 15m

(49.21 feet)

Converter*

Distribution

terminal

10BASE-T ca ble (Note 2)

Station 1

Inverter

PU connector

(Note1)

Use the connectors, cables and converter which are available on the market.

Note:1. Connector: RJ45 connector

Example: 5-554720-3, Tyco Electronics Corporation

2. Cable : Cable conforming to EIA568 (such as 10BASE-T cable)

Example: SGLPEV 0.5mm × 4P (Twisted pair cable, 4 pairs),

Mitsubishi Cable Industries, Ltd.

3.*Commercially available converter examples

Model: FA-T-RS40

Converter

Nagoya Sales Office, Mitsubishi Electric Engineering Co., Ltd.

Station 2

Inverter

PU connector

(Note1)

Station n

Inverter

PU connector

(Note1)

Terminatio

resistor

28

Page 42

<Wiring methods>

1) Wiring of one RS-485 computer and one inverter

INSTALLATION AND WIRING

Computer Side Terminals

Signal name Description

RDA

RDB

SDA

SDB

RSA

RSB

CSA

CSB

SG

FG

Receive data

Receive data

Send data

Send data

Request to send

Request to send

Clear to send

Clear to send

Signal ground

Frame ground

Cable connection and signal direction

10 BASE-T Cable

(Note 1)

0.3mm or more

2

PU connector

2) Wiring of one RS-485 computer and "n" inverters (several inverters)

Cable connection and signal direction

Computer

RDA

RDB

SDA

SDB

RSA

RSB

CSA

CSB

SG

FG

(Note 1)

RDB

SG

Station 1

Inverter Inverter Inverter

10 BASE-T Cable

RDA

SDB

SDA

RDB

RDA

SG

Station 2

SDB

SDA

RDB

RDA

SG

Station n

Inverter

SDA

SDB

RDA

RDB

SG

SDB

SDA

Termination

resistor

(Note 2)

2

Note:1. Make connections in accordance with the instruction manual of the

computer used.

Fully check the terminal numbers of the computer as they differ between

models.

2. There may be the influence of reflection depending on the transmission

speed and/or transmission distance. If this reflection hinders

communication, provide a termination resistor. If the PU connector is used

to make a connection, use the distributor as a termination resistor cannot be

fitted.

Connect the termination resistor to only the inverter remotest from the

computer. (Termination resistor: 100Ω)

29

Page 43

INSTALLATION AND WIRING

r

2.2.5 Connection of stand-alone option unit s

The inverter accepts a variety of stand-alone option units as required.

Incorrect connection will cause inverter damage or an accident. Connect and operate

the option unit carefully in accordance with the corresponding option unit manual.

(1)

Connection of the dedicated external brake resistor (option)

(Cannot be connected to 0.1K and 0.2K)

Connect a brake resistor across terminals P (+) and PR. Connect a dedicated brake

resistor only.

(For the positions of terminals P (+) and PR, refer to the terminal block layout (page 20).)

⋅

FR-E520-0.4K to 0.75K, 5.5K, 7.5K-NA

⋅

FR-E540-0.4K to 7.5K-NA

⋅

FR-E510W-0.4K-NA

PPR

P1N

Brake resistor

⋅

FR-E520-1.5K to 3.7K-NA

⋅

FR-E510W-0.75K-NA

P

PR

Brake resisto

30

Page 44

(2)

Connection of the BU brake unit (option)

INSTALLATION AND WIRING

Connect the BU brake unit correctly

as shown on the right. Incorrect

connection will damage the inverter.

NFB

MC

T (Note 3)

Brake unit

HC HB

Inverter

R (L

S (L

T (L

P (+)

P

BU brake unit

OFF

U

)

1

V

)

2

W

)

3

N (-)

PC

Constantvoltage

power

supply

ON

MC

Motor

IM

Remove jumpers.

Discharge resistor

HCHBHA

TB

OCR

+

MC

PR

OCR

-

N

Comparator

Note: 1. The wiring distance between the inverter, brake unit and discharge resistor

should be within 2m (6.56 feet). If twisted wires are used, the distance

should be within 5m (16.40 feet).

2. If the transistors in the brake unit should fail, the resistor will be extremely

hot, causing a fire. Therefore, install a magnetic contactor on the inverter's

power supply side to shut off current in case of failure.

3. When the power supply is 400V class, install a step-down transformer.

2

31

Page 45