Mitsubishi Electric FR-A7NC E kit-SC Instruction Manual

INVERTER

PRE-OPERATION INSTRUCTIONS

1

FR-A7NC E kit-SC

INSTRUCTION MANUAL

communication function

HOW TO CHECK FOR ERROR USING THE LEDS

INSTALLATION

2

WIRING

3

INVERTER SETTING

4

FUNCTION OVERVIEW

5

I/O SIGNAL LIST

6

DETAILS OF INPUT AND OUTPUT SIGNALS

7

PROGRAMMING EXAMPLES

8

9

Thank you for choosing this Mitsubishi Inverter plug-in option.

WARNING

CAUTION

CAUTION

This Instruction Manual gives handling information and

precautions for use of this equipment. Incorrect handling might

cause an unexpected fault. Before using the equipment, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about

safety matters

Do not attempt to install, operate, maintain or inspect this

product until you have read through this Instruction Manual and

appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full

knowledge of the equipment, safety information and

instructions.

In this Instruction Manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

Incorrect handling may cause

hazardous conditions, resulting in

death or severe injury.

Incorrect handling may cause

hazardous conditions, resulting in

medium or slight injury, or may cause

only material damage.

The level may even lead to a serious

consequence according to conditions. Both instruction levels

must be followed because these are important to personal

safety.

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

While power is ON or when the inverter is running, do not

open the front cover. You may get an electric shock.

Do not run the inverter with the front cover or wiring cover

removed. Otherwise, you may access the exposed highvoltage terminals and charging part and get an electric shock.

Even if power is OFF, do not remove the front cover except for

wiring or periodic inspection. You may accidentally touch the

charged inverter circuits and get an electric shock.

Before wiring or inspection, power must be switched OFF. To

confirm that, LED indication of the operation panel must be

checked. (It must be OFF.) Any person who is involved in

wiring or inspection shall wait for at least 10 minutes after the

power supply has been switched OFF and check that there

are no residual voltage using a tester or the like. The

capacitor is charged with high voltage for some time after

power OFF, and it is dangerous.

Any person who is involved in wiring or inspection of this

equipment shall be fully competent to do the work.

The plug-in option must be installed before wiring. Otherwise,

you may get an electric shock or be injured.

Do not touch the plug-in option or handle the cables with wet

hands. Otherwise you may get an electric shock.

Do not subject the cables to scratches, excessive stress,

heavy loads or pinching. Otherwise you may get an electric

shock.

A-1

2. Injury Prevention

3) Usage

CAUTION

The voltage applied to each terminal must be the ones

specified in the Instruction Manual. Otherwise burst, damage,

etc. may occur.

The cables must be connected to the correct terminals.

Otherwise burst, damage, etc. may occur.

Polarity must be correct. Otherwise burst, damage, etc. may

occur.

While power is ON or for some time after power-OFF, do not

touch the inverter as they will be extremely hot. Doing so can

cause burns.

3. Additional Instructions

Also the following points must be noted to prevent an accidental

failure, injury, electric shock, etc.

1) Transportation and mounting

CAUTION

Do not install or operate the plug-in option if it is damaged or

has parts missing.

Do not stand or rest heavy objects on the product.

The mounting orientation must be correct.

Foreign conductive objects must be prevented from entering

the inverter. That includes screws and metal fragments or

other flammable substances such as oil.

2) Trial run

CAUTION

Before starting operation, each parameter must be confirmed

and adjusted. A failure to do so may cause some machines to

make unexpected motions.

WARNING

Do not modify the equipment.

Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

When parameter clear or all parameter clear is performed, the

required parameters must be set again before starting operations

because all parameters return to the initial value.

For prevention of damage due to static electricity, nearby

metal must be touched before touching this product to

eliminate static electricity from your body.

4) Maintenance, inspection and parts replacement

CAUTION

Do not test the equipment with a megger (measure insulation

resistance).

5) Disposal

CAUTION

This inverter plug-in option must be treated as industrial

waste.

6) General instruction

Many of the diagrams and drawings in this Instruction Manual

show the inverter without a cover or partially open for

explanation. Never operate the inverter in this manner. The

cover must be reinstalled and the instructions in the inverter

manual must be followed when operating the inverter.

A-2

— CONTENTS —

1 PRE-OPERATION INSTRUCTIONS 1

1.1 Unpacking and product confirmation ..............................................................................................1

1.1.1 Product confirmation....................................................................................................................................... 1

1.2 Parts ....................................................................................................................................................2

1.3 Inverter option specifications...........................................................................................................4

1.4 CC-Link version .................................................................................................................................5

1.4.1 CC-Link ver. 1.10............................................................................................................................................ 5

1.4.2 CC-Link ver. 2................................................................................................................................................. 5

2 INSTALLATION 6

2.1 Pre-installation instructions .............................................................................................................6

2.2 Installation procedure .......................................................................................................................6

3WIRING 12

3.1 System configuration example.......................................................................................................12

3.2 Connection of several inverters .....................................................................................................13

3.3 Connection cable .............................................................................................................................16

3.4 Wiring ................................................................................................................................................16

4 INVERTER SETTING 19

I

4.1 Parameter list ...................................................................................................................................19

4.2 Operation Mode Setting ..................................................................................................................20

4.2.1 Operation mode indicator.............................................................................................................................20

4.2.2 Operation mode switching and communication startup mode (Pr. 79, Pr. 340) ...........................................21

4.3 Start and Speed Command Sources (Pr. 338, Pr. 339, Pr. 550) ...................................................24

4.3.1 Communication EEPROM write selection (Pr. 342) ..................................................................................... 28

4.4 Operation at Communication Error Occurrence ...........................................................................29

4.4.1 Operation selection at communication error occurrence (Pr. 500 to Pr. 502) ..............................................29

4.4.2 Fault and measures...................................................................................................................................... 33

4.5 Inverter Reset ...................................................................................................................................34

4.6 CC-Link function setting .................................................................................................................36

4.6.1 Station number setting (Pr. 542)...................................................................................................................36

4.6.2 Baud rate setting (Pr. 543) ...........................................................................................................................37

4.6.3 Frequency command with sign (Pr. 541)......................................................................................................38

5 FUNCTION OVERVIEW 39

5.1 Function block diagram ..................................................................................................................39

5.2 Output from the inverter to the network ........................................................................................40

5.3 Input to the inverter from the network ...........................................................................................41

6 I/O SIGNAL LIST 42

6.1 CC-Link extended setting (Pr. 544) ................................................................................................42

6.2 I/O signal list.....................................................................................................................................43

II

6.2.1 I/O signal when CC-Link ver.1 one station (FR-E500 series compatible) is occupied (Pr. 544 = 0) ............43

6.2.2 I/O signal when CC-Link ver.1 one station is occupied (Pr. 544 = "1") ........................................................46

6.2.3 I/O signal when CC-Link ver.2 double setting is selected (Pr. 544 = "12")...................................................47

6.2.4 I/O signal when CC-Link ver.2 quadruple setting is selected (Pr. 544 = "14") ............................................. 48

6.2.5 I/O signal when CC-Link ver.2 octuple setting is selected (Pr. 544 = "18") ..................................................49

7 DETAILS OF INPUT AND OUTPUT SIGNALS 51

7.1 Details of remote input and output signals ...................................................................................51

7.1.1 Output signals (master module to inverter (FR-A7NC)) ...............................................................................51

7.1.2 Input signals (inverter (FR-A7NC) to master module) ..................................................................................53

7.2 Details of remote register................................................................................................................55

7.2.1 Remote register (master module to inverter (FR-A7NC)).............................................................................55

7.2.2 Remote register (inverter (FR-A7NC) to master module) .............................................................................58

7.2.3 Instruction codes ..........................................................................................................................................61

7.2.4 Monitor codes ...............................................................................................................................................66

8 PROGRAMMING EXAMPLES 68

8.1 Program example for reading the inverter status.........................................................................71

8.2 Program example for setting the operation mode........................................................................72

8.3 Program example for setting the operation commands ..............................................................73

8.4 Program example for monitoring the output frequency ..............................................................74

8.5 Program example for parameter reading.......................................................................................75

8.6 Program example for parameter writing ........................................................................................76

8.7 Program example for setting the running frequency ...................................................................77

III

8.8 Program example for fault record reading ....................................................................................79

8.9 Program example for resetting the inverter at inverter error ......................................................80

8.10 Instructions ......................................................................................................................................81

9 HOW TO CHECK FOR ERROR USING THE LEDS 83

9.1 When one inverter is connected.....................................................................................................83

9.2 When two or more inverters are connected ..................................................................................85

9.3 Communication stops during operation........................................................................................87

IV

1 PRE-OPERATION INSTRUCTIONS

1.1 Unpacking and product confirmation

Take the plug-in option out of the package, check the product name, and confirm that the product is as you

ordered and intact.

This product is a plug-in option dedicated for the FR-E700-SC series

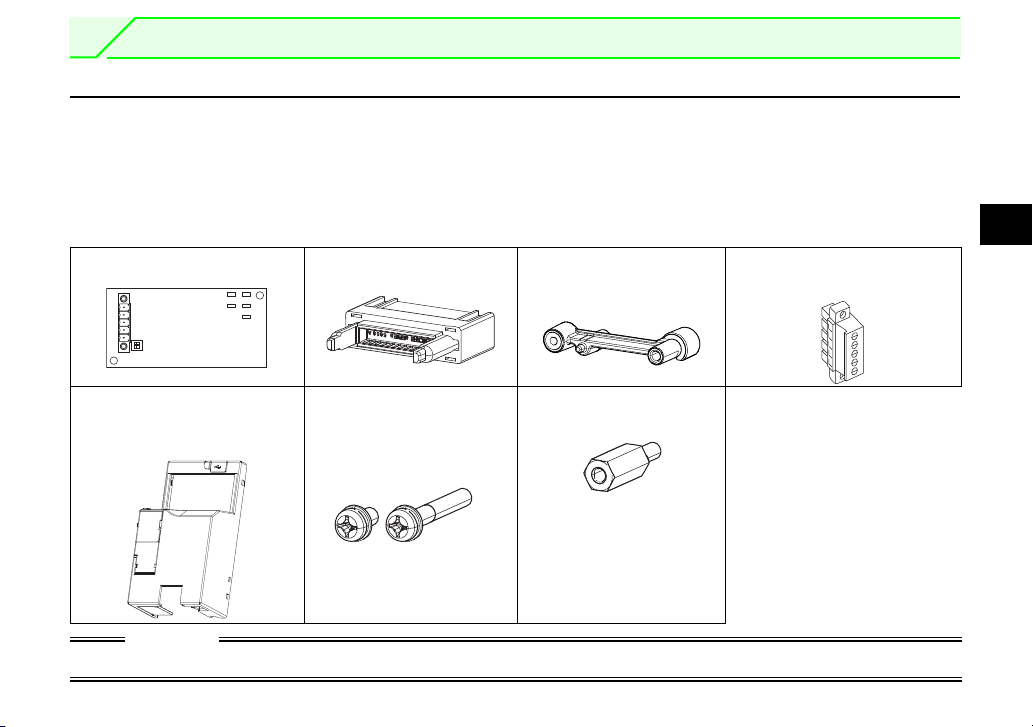

1.1.1 Product confirmation

Check the enclosed items.

Plug-in option ................... 1 Junction connector...........1

SD

L.RUN

RD

L.ERR

ON

12

SW2

RUN

(Refer to page 7, 9.)

Spacer for plug-in option

mounting....................1

(Refer to page 7, 9.)

(Safety stop function model).

Terminal block................... 1

(Refer to page 16)

1

Front cover for plug-in option

......................................... 1

(Refer to page 7, 9.)

M3 mounting screw

(Long) (M3 20mm).......1

(Short) (M3 6mm)........1

Hexagon spacer..............1

(Refer to page 7, 9.)

(Refer to page 7, 9.)

CAUTION

Install a provided front cover for plug-in option, in place of the inverter front cover .

1

PRE-OPERATION INSTRUCTIONS

(Refer to page 13.)

(Refer to page 3.)

(Refer to page 16.)

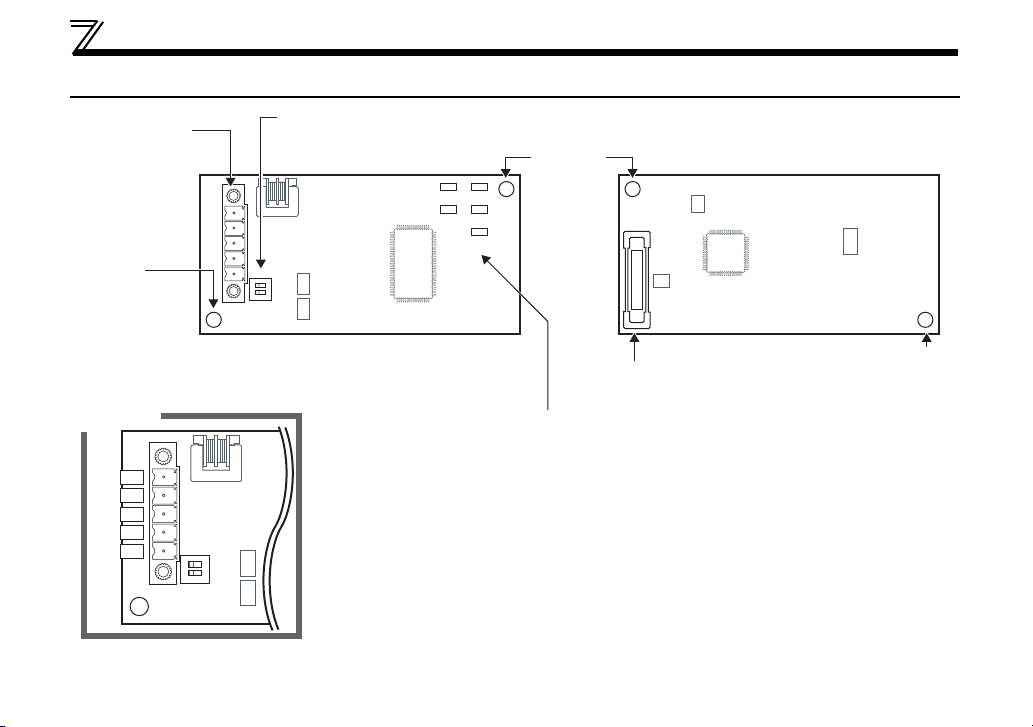

1.2 Parts

Connector for

communication

Mount the

accessory

terminal block to

connect to the

network.

Mounting

hole

Terminal

layout

DA

DB

DG

SLD

FG

Terminating resistor selection switch

Select the resistor value of the terminating resistor.

Front view Rear view

SD

L.RUN

RD

L.ERR

RUN

ON

12

SW2

Mounting

hole

Mounting hole

Connector

Connect to the inverter option connector.

Operation status indication LED

Lit/flicker of the LED indicate operation status.

ON

12

SW2

2

PRE-OPERATION INSTRUCTIONS

Operation status indication LED

LED Description

L.RUN

L.ERR

RUN

SD Turns OFF when no data is transmitted.

RD Lit when the received data carrier is detected.

REMARKS

Set transmission baud rate using Pr.543 Baud rate selection (CC-Link). (Refer to page 37.)

Lit when refresh data is properly received. Turns OFF when a data transmission is stopped for a

certain period of time.

Lit when a communication error occurs in the own station and flickers when settings of switch, etc.

are changed while power is ON.

Flickers when the Pr. 542 or Pr. 543 setting is changed.

Turn the power ON again or turn the RES signal ON. (Refer to page 36, 37.)

Lit during normal operation (5V is supplied in the board) (Lit even in the noncommunication status.)

Flickers when the master station is CC-Link ver.1 and the FR-A7NC is CC-Link ver.2 compatible.

(Refer to page 5.)

Set the station number using Pr. 542 Communication station number (CC-Link). (Refer to page 36.)

1

3

PRE-OPERATION INSTRUCTIONS

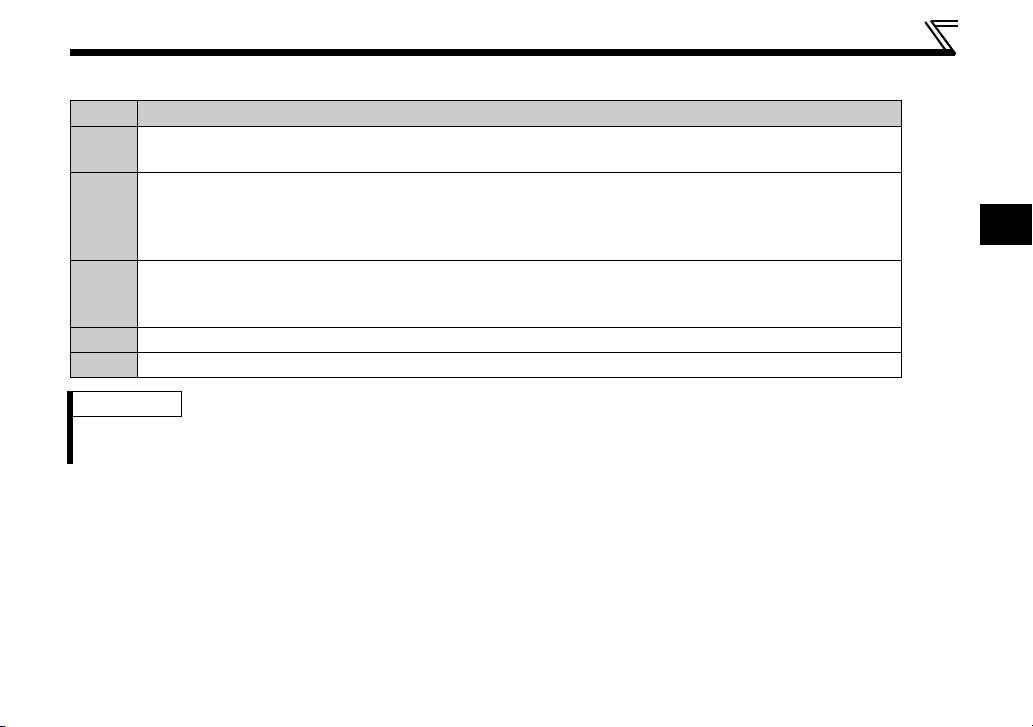

1.3 Inverter option specifications

Typ e Inverter plug-in option type, terminal block connectable

Power supply 5VDC supplied from the inverter

Number of units

connected

Cable size

Station type Remote device station

Number of stations

occupied

Communication cable CC-Link dedicated cable, CC-Link ver. 1.10 compatible CC-Link dedicated cable

42 units max. (Refer to page 42 for the number of stations occupied.) May be used with other

equipment.

2

to 0.75mm

0.3mm

CC-Link ver.1: occupies one station

CC-Link ver.2: occupies one station (selectable from among double, quadruple and octuple)

2

4

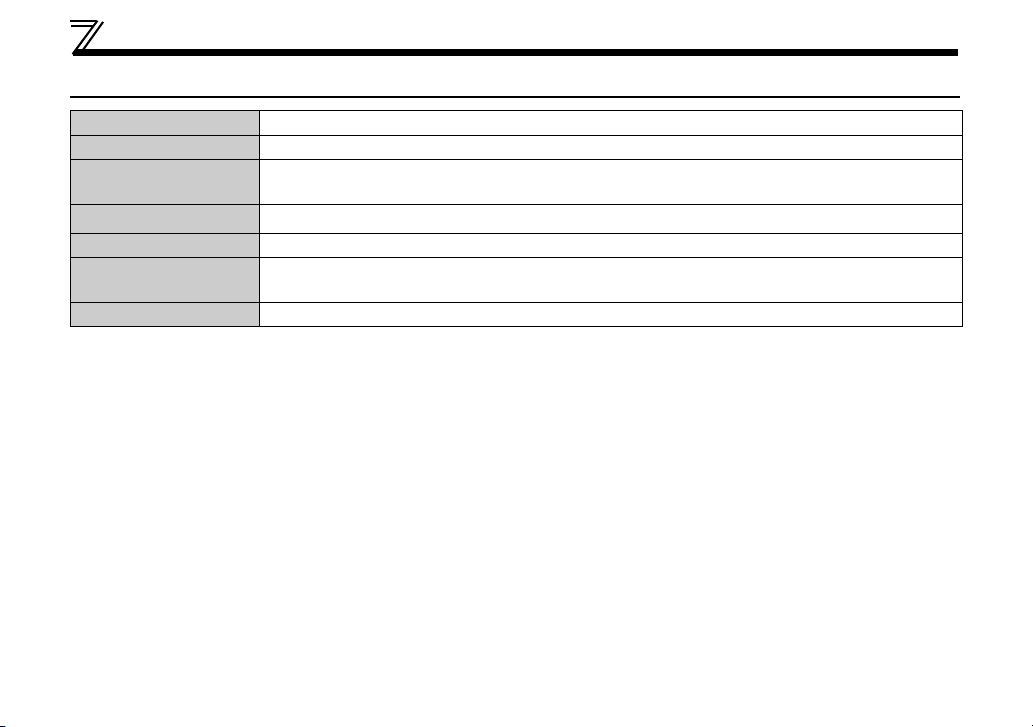

1.4 CC-Link version

Master station

(CC-Link ver.1)

Master station

(CC-Link ver.2)

CC-Link ver.1

setting

CC-Link ver.1

setting

CC-Link ver.2

setting

CC-Link ver.2

setting

Communication

enabled

Communication

enabled

Communication

disabled

("RUN" LED flickers)

1.4.1 CC-Link ver. 1.10

The conventional CC-Link products, whose inter-station cable lengths have equally been changed to 20cm

(7.87 inch) or more to improve the inter-station cable length restriction, are defined as CC-Link ver. 1.10. In

comparison, the conventional products are defined as CC-Link ver. 1.00.

Refer to the CC-Link Master Module Manual for the maximum overall cable lengths and inter-station cable

lengths of CC-Link ver. 1.00 and ver. 1.10.

CC-Link ver. 1.10 compatibility conditions

1)All modules that comprise a CC-Link system should be compatible with CC-Link ver. 1.10.

2)All data link cables should be CC-Link ver. 1.10 compatible, CC-Link dedicated cables.

(CC-Link ver. 1.10 compatible cables have a logo or ver. 1.10 indication.)

In a system that uses the CC-Link ver. 1.00 and ver. 1.10 modules and cables together, the maximum overall

cable length and inter-station cable length are as specified for CC-Link ver. 1.00.

1.4.2 CC-Link ver. 2

The FR-A7NC is compatible with CCLink ver.2.

When using the CC-Link ver.2 setting

with the FR-A7NC, the master station

needs to be compatible with the CCLink ver.2.

For CC-Link ver.2, double, quadruple

and octuple settings can be used to

increase the remote register (RWr/w)

points.

CAUTION

PRE-OPERATION INSTRUCTIONS

1

5

2 INSTALLATION

2.1 Pre-installation instructions

Make sure that the input power of the inverter is OFF.

CAUTION

With input power ON, do not install or remove the plug-in option. Otherwise, the inverter and

plug-in option may be damaged.

For prevention of damage due to static electricity, touch nearby metal before touching this

product to eliminate static electricity from your body.

2.2 Installation procedure

CAUTION

Always perform wiring to the main circuit terminals and control circuit terminals before installing the

option. Wiring cannot be performed after installing the option.

When mounting the plug-in option, do not let wires get caught in the plug-in option or the spacer for option

mounting. If a wire gets caught, the inverter and the plug-in option may be damaged.

When the inverter cannot recognize that the option unit is mounted due to improper installation, etc.,

" " (option fault) is displayed.

When mounting/removing an option, hold the sides of the circuit board. Do not press on the parts on the

circuit board. Stress applied to the parts by pressing, etc. may cause a failure.

Take caution not to drop mounting screws during the mounting and removal of the option.

Pull the option straight out when removing. Pressure applied to the connector and to the circuit board may

break the option.

REMARKS

Because the voltage class, model name and serial number (only voltage class is labeled for FR-E720-5.5KSC (FR-

E720-240SC), FR-E740-5.5KSC (FR-E740-120SC) or higher) are written on the PU cover, replace the PU cover of

the plug-in option with the removed PU cover of the inverter.

6

INSTALLATION

2

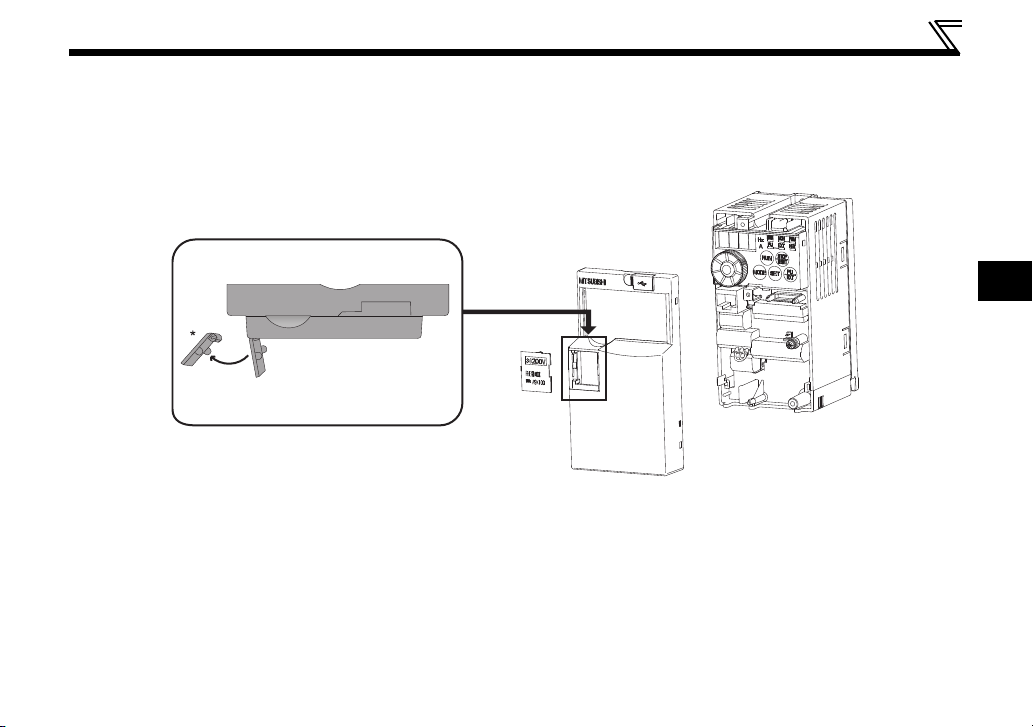

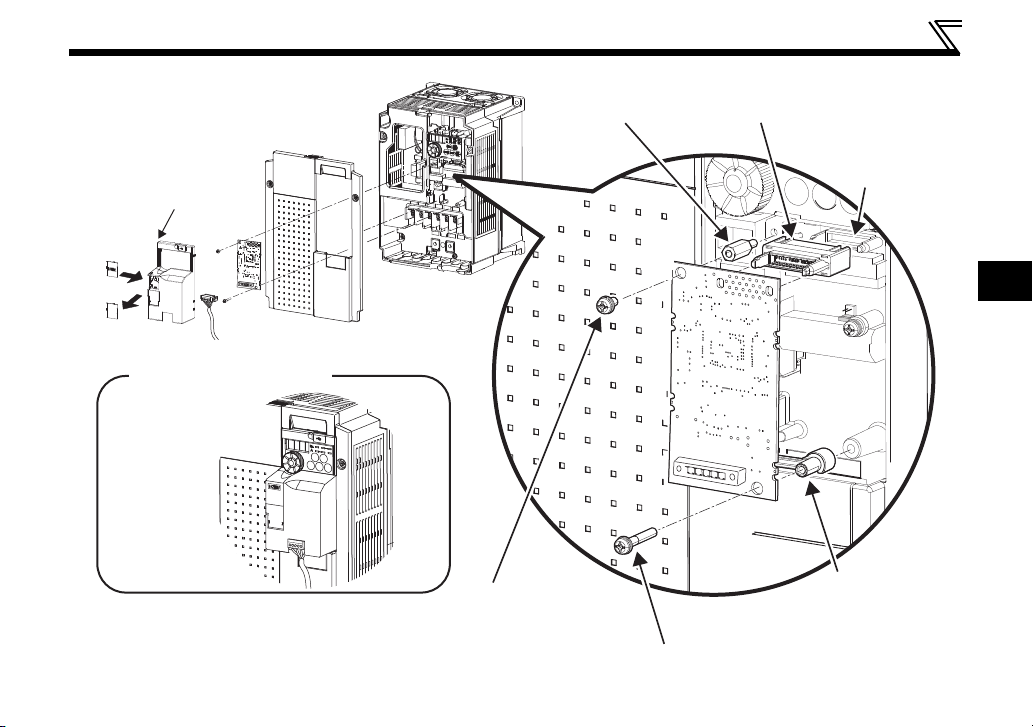

(1) Front cover

(2) PU cover

* Open the PU cover, then open it toward the arrow

direction to remove.

Inverter with one front cover

(1) Remove the front cover from the inverter. (For removing the front cover, refer to the FR-E700

instruction manual.)

(2) Remove the PU cover from the front cover. Open the PU cover with a driver, etc. and remove it in the

direction of arrow as shown below.

(3) Mount the spacer for plug-in option mounting, the hexagon spacer, and the junction connector. Fit the

junction connector to the guide of the connector at the inverter side, and insert the junction connector

as far as it goes.

(4) Fit the connector of the plug-in option to the guide of the junction connector, and insert the plug-in

option as far as it goes.

(5) Fix the plug-in option securely by using the supplied mounting screw (short) to the upper screw hole

and the other supplied mounting screw (long) to the lower screw hole of the plug-in option. If the screw

holes do not line up, the connector may not have been plugged properly. Check for loose plugging.

Tightening torque: 0.33 to 0.4Nm

7

INSTALLATION

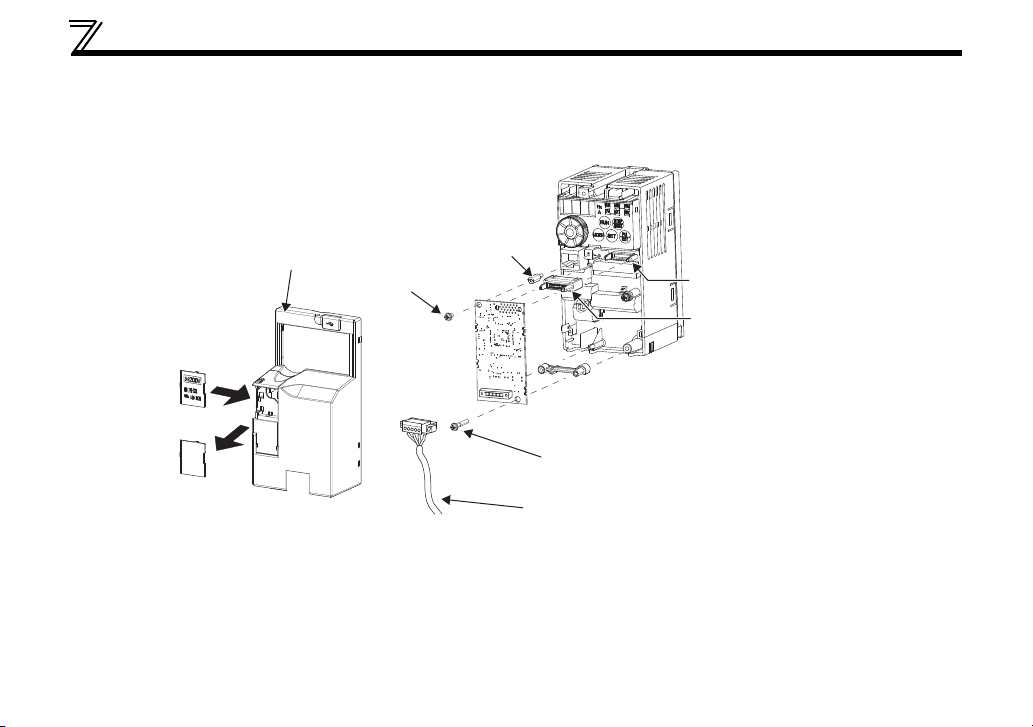

(7)

(3) Hexagon

spacer

(3) Junction connector

(5) Mounting screws

(short)

(5) Mounting screw (long)

(7) CC-Link communication cable

(8)

(4)

(3) Plug-in option connector

of inverter

(3) Spacer for plug-in option mounting

(6) Replace

Front cover

for plug-in option

(6) Remove the PU cover provided on the front cover for plug-in option and install the other PU cover,

which was removed in (2).

(7) Mount the already wired terminal block to the plug-in option. (Refer to Chapter 3 for wiring.)

(8) Install the front cover for plug-in option to the inverter.

8

INSTALLATION

2

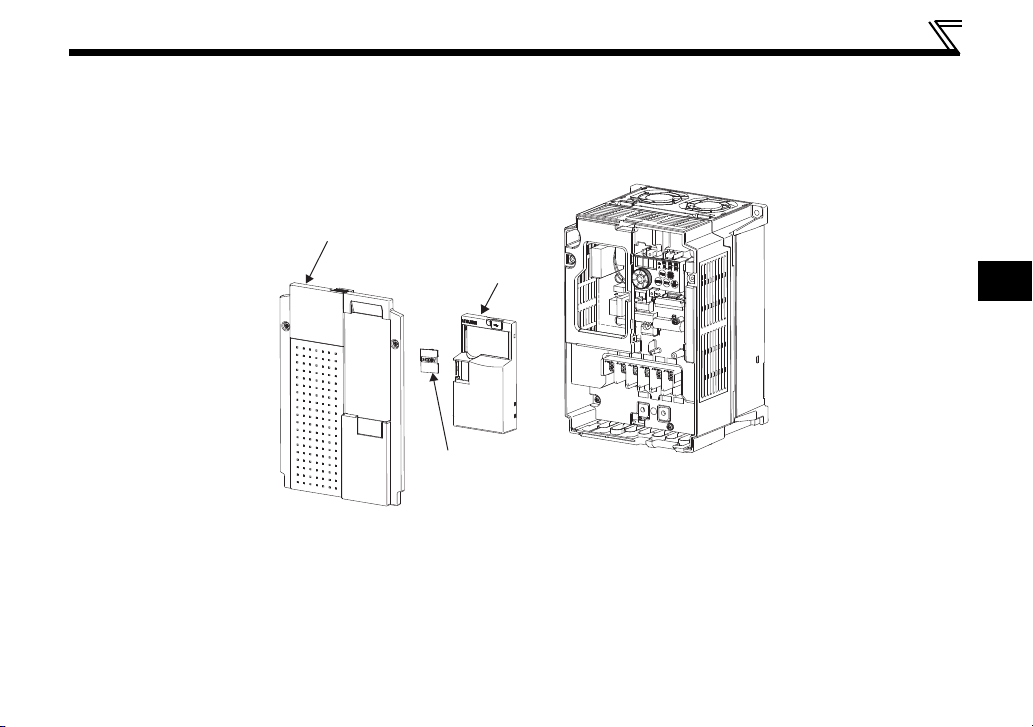

Front cover 1

Front cover 2

(1)

(2)

PU cover

(1)

Inverter with front covers 1 and 2

(1) Remove the front covers 1 and 2 from the inverter. (For removing the front cover, refer to the FR-E700

instruction manual.)

(2) Remove the PU cover from the front cover 2. For removing the PU cover, refer to page 7.

9

INSTALLATION

(3) Install the front cover 1 to the inverter.

(4) Mount the spacer for plug-in option mounting, the hexagon spacer, and the junction connector. Fit the

junction connector to the guide of the connector at the inverter side, and insert the junction connector

as far as it goes.

(5) Fit the connector of the plug-in option to the guide of the junction connector, and insert the plug-in

option as far as it goes.

(6) Fix the plug-in option securely by using the supplied mounting screw (short) to the upper screw hole

and the other supplied mounting screw (long) to the lower screw hole of the plug-in option. If the screw

holes do not line up, the connector may not have been plugged properly. Check for loose plugging.

Tightening torque: 0.33 to 0.4Nm

(7) Remove the PU cover provided on the front cover for plug in option and install the other PU cover,

which was removed in (2).

(8) Mount the already wired terminal block to the plug-in option. (Refer to Chapter 3 for wiring.)

Pass the CC-Link cable over the front cover 1 of the inverter. (Refer to the finished installation figure in

the next page.) If a CC-Link cable is passed through underneath the front cover 1, the bending radius

of the cable shortens, stressing the cable.

(9) Install the front cover for plug-in option to the inverter.

10

INSTALLATION

2

(9)

(3)

(5)

Installation completed

(7)

Replace

Front cover for

plug-in option

(4) Plug-in option

connector

of inverter

(8) CC-Link communication cable

(4) Hexagon

spacer

(4) Junction

connector

(6) Mounting screws

(short)

(4) Spacer for

plug-in option

mounting

(6) Mounting screw (long)

11

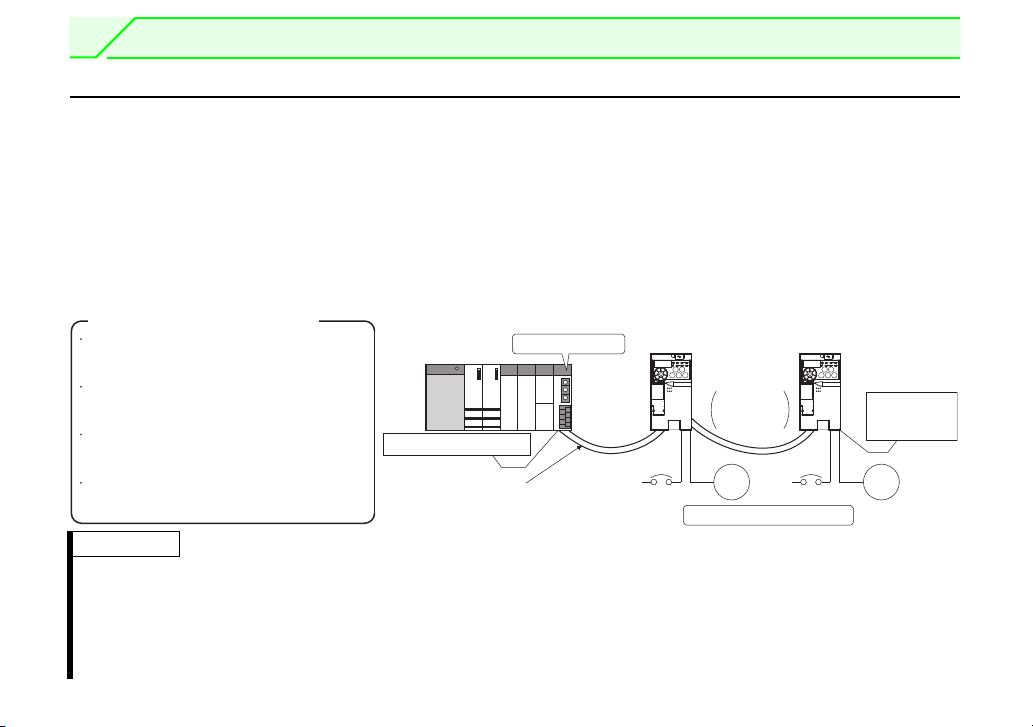

3 WIRING

3.1 System configuration example

(1) Programmable controller side

Mount the "QJ61BT11N", "AJ61QBT11", "A1SJ61QBT11", "AJ61BT11", "A1SJ61BT11" or "LJ61BT11" "CC-

Link system master/local module" on the main or extension base unit having the programmable controller

CPU used as the master station.

(2) Inverter side

Mount the option (FR-A7NC) on the inverter.

(3) Connect the programmable controller CC-Link module master station and the terminal block supplied with the

FR-A7NC with the CC-Link dedicated cable. After connecting the terminal block to the FR-A7NC, fit the front

cover.

Manual of the CC-Link master station

QJ61BT11N type

CC-Link System Master/Local Module

User's Manual ...SH-080394E

AJ61QBT11/A1SJ61QBT11 type

Control & Communication Link System

Master/Local Module User's Manual ...IB-66722

AJ61BT11/A1SJ61BT11 type

Control & Communication Link System

Master/Local Module User's Manual ...IB-66721

LJ61BT11 type

CC-Link System Master/Local Module User's

Manual ...SH-080895ENG

Master station

Terminating resistor

CC-Link dedicated cable

QJ61BT11N,

etc.

Power

supply

Inverter

Up to 42

units can be

connected

when only

inverters are

connected

Motor

Remote device station

REMARKS

• When the CPU has automatic refresh function (example: QnA series CPU)

When the END instruction is executed by the programmable controller CPU, the buffer memory is automatically refreshed to

enable communication with a remote device.

• When the CPU does not have automatic refresh function (example: AnA series CPU)

Sequence ladder logic is configured to perform direct communication with the buffer memory of the master station and to

enable communication with a remote device.

Power

supply

Inverter

Terminating

resistor

Motor

12

3

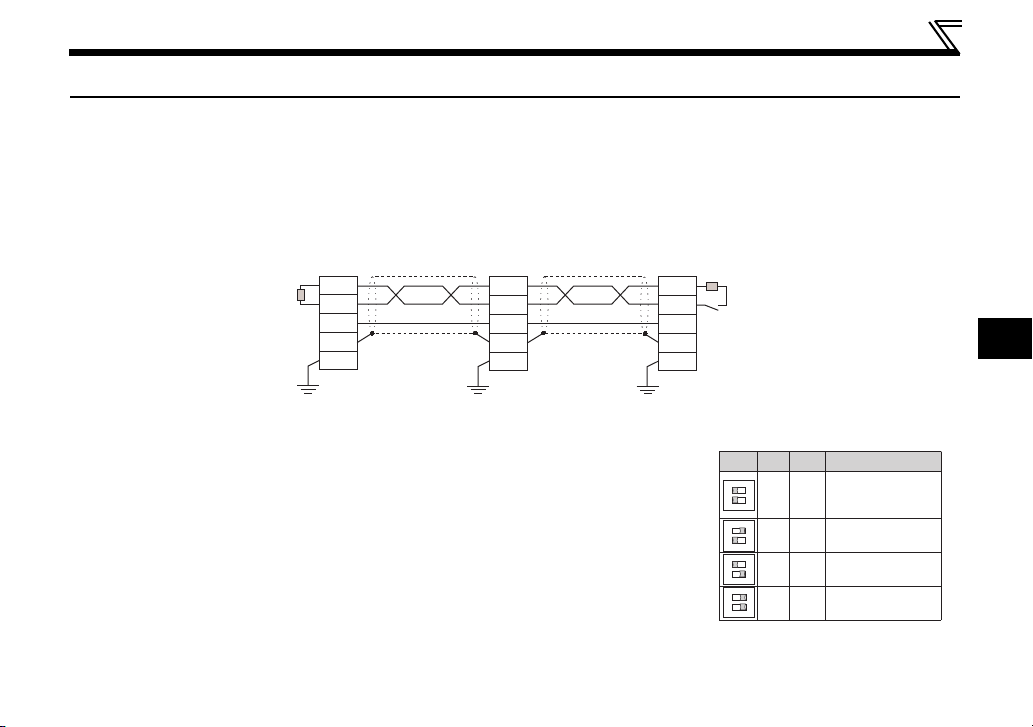

3.2 Connection of several inverters

Shielded

twisted cable

DA

DB

DG

SLD

FG

Terminating

resistor

*1

Terminating

resistor

selection

switch (SW2)

*3

Master module

Blue

White

Yellow

FR-A7NC*2

FR-A7NC

Shielded

twisted cable

DA

DB

DG

SLD

FG

DA

DB

DG

SLD

FG

Blue

White

Yellow

130 is a resistance value for the CC-Link

ver.1.00 dedicated high performance

cable.

An inverter can join the link system as a CC-Link remote device station, and such device stations can be

controlled and monitored with a user program of a programmable controller. These devices can be useful

components of an automated factory.

For the shield cable of the CC-Link dedicated cable, connect it to "SLD" of each unit and always earth

(ground) it via "FG".

Terminals SLD and FG are connected inside the unit.

*1 Use the terminating resistors supplied with the programmable controller.

*2 For the unit in the middle, set 1 and 2 of SW2 to OFF (without terminating resistor).

*3 Perform setting of the terminating resistor selection switch (SW2).

(Refer to page 2 for the position of the switch.)

When connecting a terminating resistor separately, do not use a built-in

terminating resistor. (SW2 1-OFF, 2-OFF)

12

12

12

12

12

ON

OFFOFF

ON

ON OFF

ON

OFF ON

ON

ON ON

WIRING

Description

Without

terminating

resistor

Do not use.

130Ω

110 Ω

13

Cut

Cut the tube

Tube

If any other units are included, the number of stations occupied depends on the unit

and therefore the following conditions must be satisfied:

{(1 a) + (2 b) + (3 c) + (4 d)} 64

a: Number of units occupying 1 station c: Number of units occupying 3 stations

b: Number of units occupying 2 stations d: Number of units occupying 4 stations

{(16 A) + (54 B) + (88 C)} 2304

A: Number of remote I/O 64

B: Number of remote device stations 42

C: Number of local, standby master and intelligent device stations 26

WIRING

REMARKS

When performing online exchange

The built-in terminating resistor cannot be exchanged online since the terminating resistor is on the FR-A7NC board

and disconnected when the terminal block is removed from the FR-A7NC connector for communication. When

changing the FR-A7NC online, connect a terminating resistor supplied with a programmable controller master module

to the FR-A7NC after modifying it and do not use the internal terminating resistor (SW2 1-OFF, 2-OFF).

Connection with the terminating resistor

Connect the terminating resistor between terminals

DA-DB of the FR-A7NC at the end.

Modify the terminating resistors supplied with the

programmable controller to use.

When a resistor is not supplied with the master

module, use a resistor with 110 1/2W available on the market.

(1) Maximum number of units connected to one master station (CC-Link ver.1.10)

42 units (when connections are inverters only)

14

3

(2) Maximum number of units connected to one master station (CC-Link ver.2.00)

If any other units are included, the number of stations occupied depends on the unit and

therefore the following conditions must be satisfied:

• {(a + a2 + a4 + a8) + (b + b2 + b4 + b8) 2 + (c + c2 + c4 + c8) 3 + (d + d2 + d4 + d8) 4} 64

•{(a 32 + a2 32 + a4 64 + a8 128) + (b 64 + b2 96 + b4 192 + b8 384) + (c

96 + c2 160 + c4 320 + c8 640) + (d 128 + d2 224 + d4 448 + d8 896)} 8192

•{(a 4 + a2 8 + a4 16 + a8 32) + (b 8 + b2 16 + b4 32 + b8 64) + (c 12 +

c2 24 + c4 48 + c8 96) + (d 16 + d2 32 + d4 64 + d8 128)} 2048

a: Number of single setting devices occupying one station

b: Number of single setting devices occupying two stations

c: Number of single setting devices occupying three stations

d: Number of single setting devices occupying four stations

a2: Number of double setting devices occupying one station

b2: Number of double setting devices occupying two stations

c2: Number of double setting devices occupying three stations

d2: Number of double setting devices occupying four stations

a4: Number of quadruple setting devices occupying one station

b4: Number of quadruple setting devices occupying two stations

c4: Number of quadruple setting devices occupying three stations

d4: Number of quadruple setting devices occupying four stations

a8: Number of octuple setting devices occupying one station

b8: Number of octuple setting devices occupying two stations

c8: Number of octuple setting devices occupying three stations

d8: Number of octuple setting devices occupying four stations

• 16 A + 54 B + 88 C 2304

A: Numbers of remote I/O 64

B: Number of remote device stations 42

C: Number of local and intelligent device stations 26

42 units (when connections are inverter only)

WIRING

15

WIRING

6.5mm

3.3 Connection cable

In the CC-Link system, use CC-Link dedicated cables.

If the cable used is other than the CC-Link dedicated cable, the performance of the CC-Link system is not

guaranteed.

For the specifications of the CC-Link dedicated cable, refer to the website of the CC-Link Partner

Association.

Website of the CC-Link Partner Association http://www.cc-link.org/

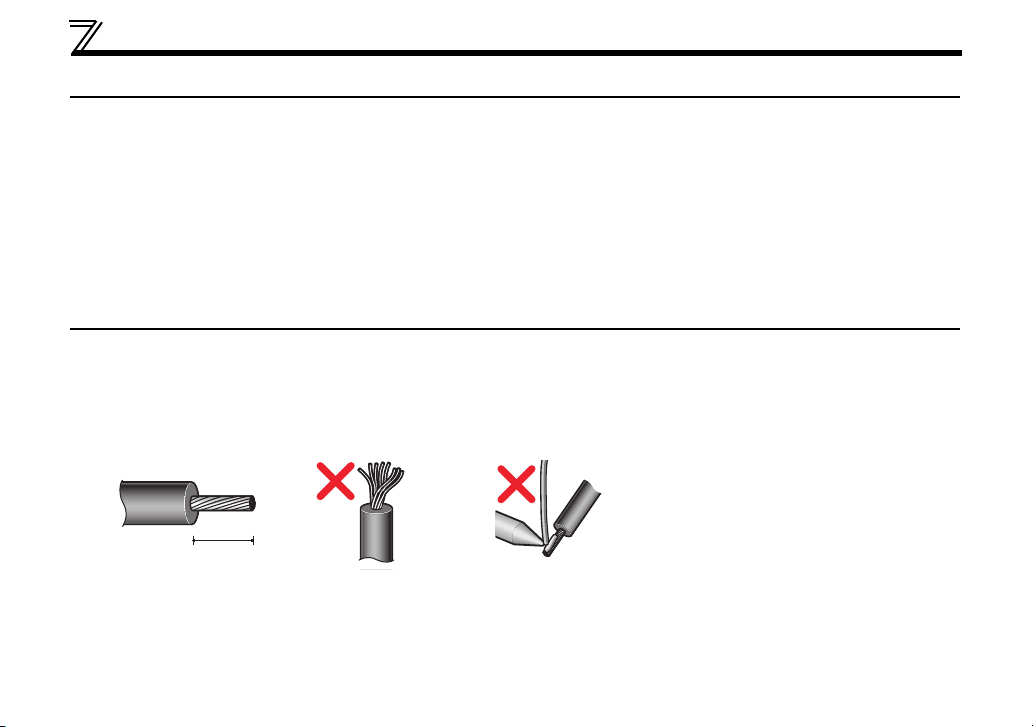

3.4 Wiring

(1) Strip off the sheath of the CC-Link dedicated cable and twist wires to use. If the length of the sheath

pealed is too long, a short circuit may occur among neighboring wires. If the length is too short, wires

might come off.

Use recommended cables. (Refer to page 16.) Recommended tightening torque : 0.22Nm to 0.25Nm

Wire the stripped cable after twisting it to prevent it from becoming loose. (Do not solder it.)

Cable stripping length

Use a blade type terminal as required.

16

WIRING

3

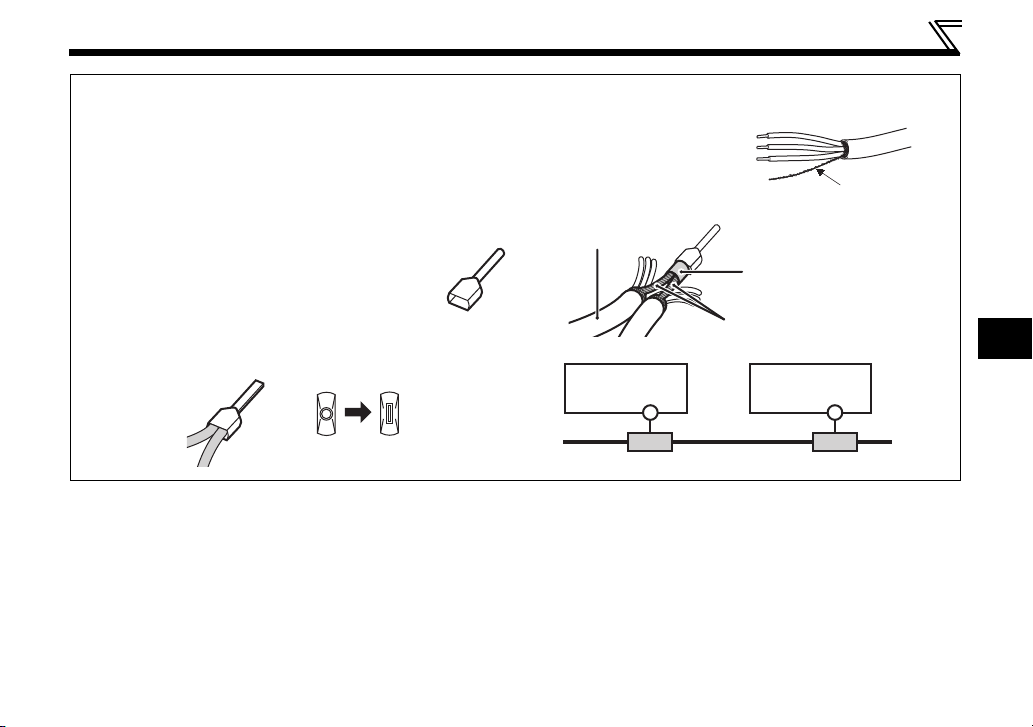

Recommended blade terminal

For wiring of the CC-link communication signal, two CCLink dedicated cables need to be twisted to wire to one

terminal block.

It is recommended to use the following blade terminal and

tool.

Recommended products (as of February 2012):

Phoenix Contact Co.,Ltd.

Blade terminal model: AI-TWIN2

Blade terminal crimping tool: CRIMPFOX 6

Note the crimping method.

Hold the long side in a longitudinal direction and insert it

into the terminal block.

0,5-8WH

Connection of the shielding wires of the

CC-Link dedicated cable

Twist the shielding wires and

wire to the terminal SLD.

Use a compression tube and

junction terminal block.

Use of a compression tube

CC-Link dedicated

cable

Prevent looseness with

a compression tube

Shielding wires

Use of a junction terminal block

FR-A7NC

SLD

Junction terminal block Junction terminal block

FR-A7NC

Shielding wires

SLD

17

WIRING

(2) Loosen the terminal screw and insert the cable into the terminal.

Screw Size Tightening Torque Cable Size Screwdriver

M2

0.22N

m to 0.25Nm

0.3mm

2

to 0.75mm

2

Small flat-blade screwdriver

(Tip thickness: 0.4mm /tip width:

2.5mm)

CAUTION

Undertightening can cause cable disconnection or malfunction. Overtightening can cause a short circuit or

malfunction due to damage to the screw or unit.

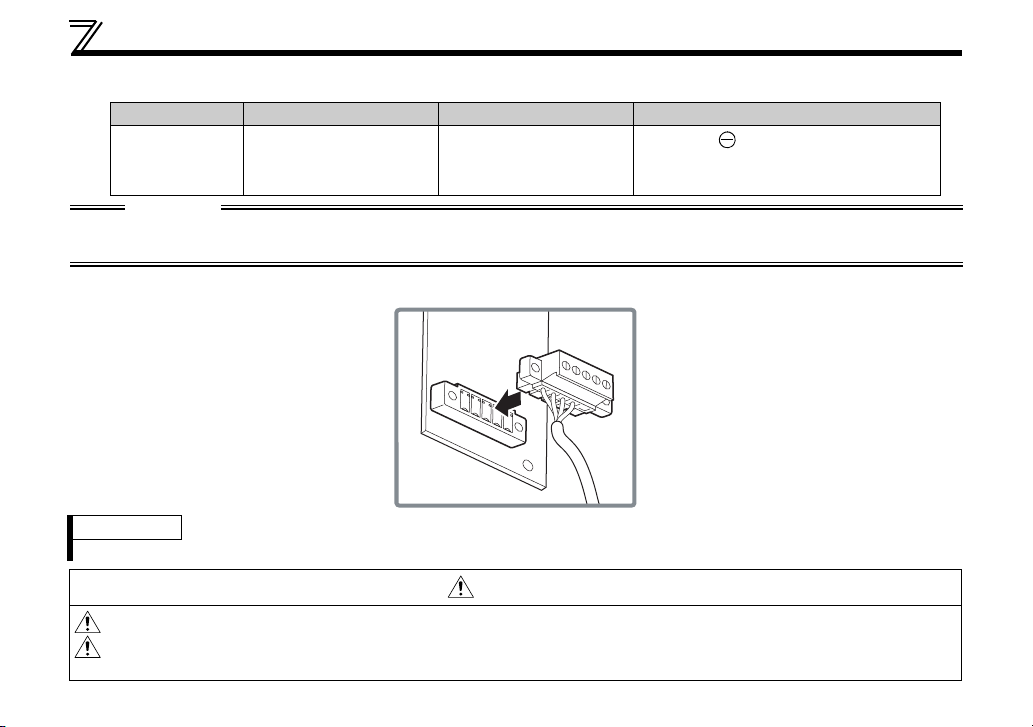

(3) Connect the terminal block to the connector for communication of the communication option.

REMARKS

• If the terminal block of the FR-A7NC is removed, the built-in terminating resistor cannot be used. (Refer to page 13.)

CAUTION

When wiring, take care not to subject the cable to stress.

After wiring, wire offcuts must not be left in the inverter. They may cause a fault, failure or

malfunction.

18

4

4 INVERTER SETTING

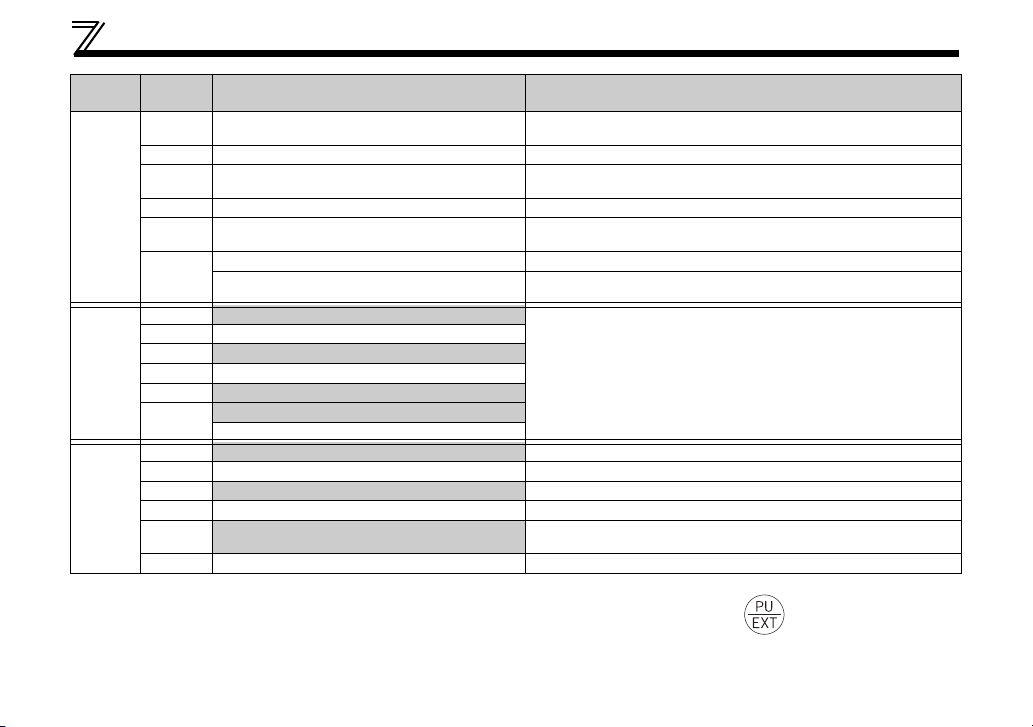

4.1 Parameter list

The following parameters are used for the plug-in option (FR-A7NC).

Set the values according to need.

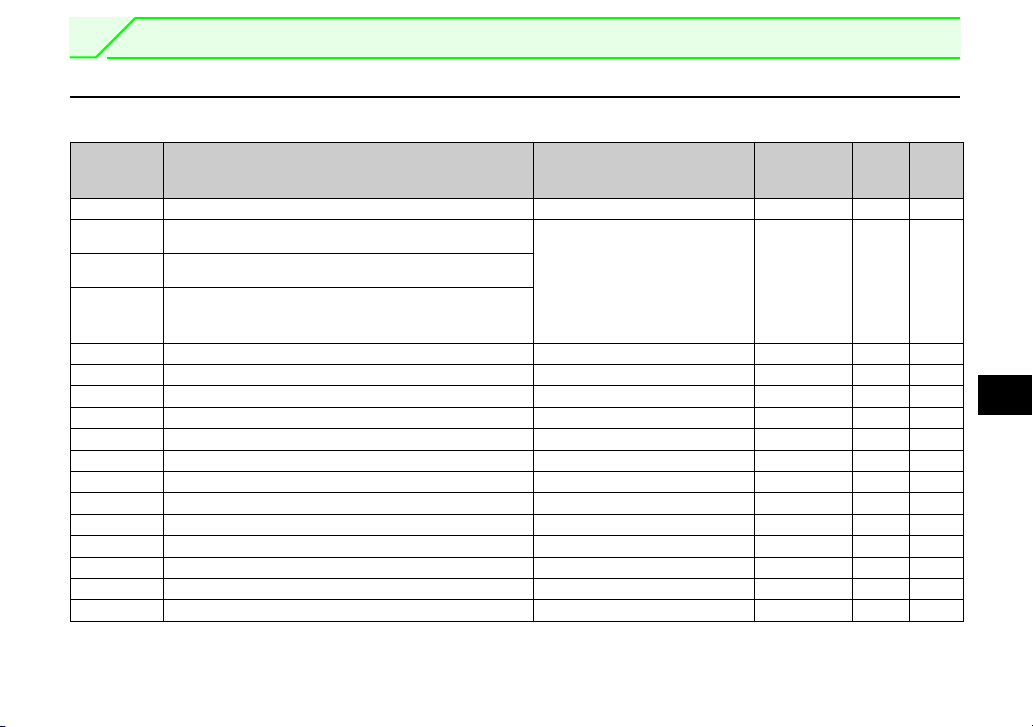

Parameter

Number

Name Setting Range

79 Operation mode selection 0 to 4, 6, 7 1 0 21

313

*1 DO0 output selection

*1 DO1 output selection

314

0, 1, 3, 4, 7, 8, 11 to 16, 20, 25,

26, 46, 47, 64, 80, 81, 90, 91,

93, 95, 96, 98, 99, 100, 101,

103, 104, 107, 108, 111 to 116,

120, 125, 126, 146, 147, 164,

315

*1 DO2 output selection

180, 181, 190, 191, 193, 195,

196, 198, 199, 9999

338 Communication operation command source 0, 1 1 0 24

339 Communication speed command source 0, 1, 2 1 0 24

340 Communication startup mode selection 0, 1, 10 1 0 21

342 Communication EEPROM write selection 0, 1 1 0 28

349

*1 Communication reset selection 0, 1 1 0 34

*1 Communication error execution waiting time 0 to 999.8s 0.1s 0s 29

500

501

*1 Communication error occurrence count display 0 1 0 30

502

*2 Stop mode selection at communication error 0 to 3 1 0 31

*1 Frequency command sign selection (CC-Link) 0, 1 1 0 38

541

542

*1, *2, *3 Communication station number (CC-Link) 1 to 64 1 1 36

543

*1, *2, *3 Baud rate selection (CC-Link) 0 to 4 1 0 37

*1, *2 CC-Link extended setting 0, 1, 12, 14, 18 1 0 42

544

550

*2 NET mode operation command source selection 0, 2, 9999 1 9999 24

*1 Parameters which can be displayed when the plug-in option (FR-A7NC) is mounted.

*2 The setting is applied after inverter reset or at the next power-ON.

*3 "L.ERR" LED flickers if the setting is changed. If the inverter is reset, the setting is applied and the LED turns OFF.

Minimum

Setting

Increments

1 9999 53

Initial

Value

Refer

to

Page

19

INVERTER SETTING

)

4.2 Operation Mode Setting

The inverter mounted with a communication option has three operation modes.

(1) PU operation [PU].............. Controls the inverter from the keys of the operation panel on the inverter or

parameter unit (FR-PU07/FR-PA07).

(2) External operation [EXT] ...Controls the inverter by switching ON/OFF external signals connected to

the control circuit terminals of the inverter.

(The inverter is factory-set to this mode.)

(3) Network operation [NET] ... Controls the inverter with instructions from the network via the

communication option.

(The operation signal and running frequency can be entered from the

control circuit terminals depending on the Pr. 338 Communication operation

command source and Pr. 339 Communication speed command source settings.

Refer to page 25.)

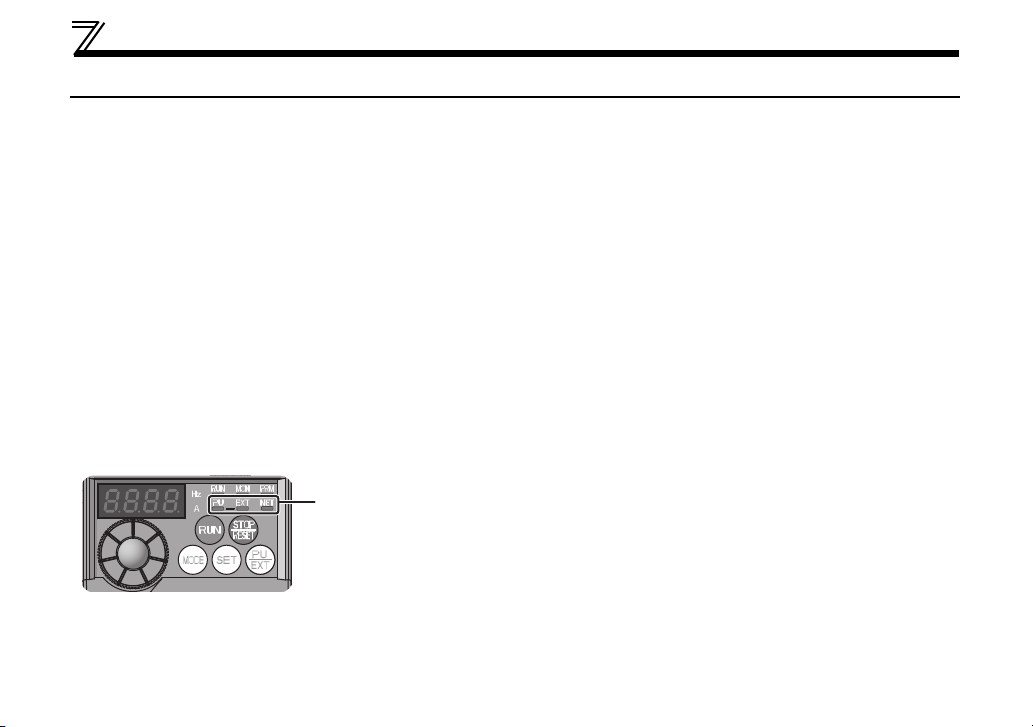

4.2.1 Operation mode indicator

Operation panel

Operation mode indicators

(The inverter operates according to the LED lit mode.

PU: PU operation mode

EXT: External operation mode

NET: Network operation mode

20

INVERTER SETTING

4

4.2.2

(1) Operation mode switching conditions

Before switching the operation mode, check that:

1) The inverter is at a stop;

2) Both the STF and STR signals are OFF; and

3) The Pr. 79 Operation mode selection setting is correct.

(Set using the operation panel of the inverter or parameter unit (FR-PU07/FR-PA07).)

Refer to the Inverter Manual for details of Pr. 79.

(2) Operation mode selection at power ON and at restoration from instantaneous power

The operation mode at power ON and at restoration from instantaneous power failure can be selected.

Set a value other than "0" in Pr. 340 to select the Network operation mode.

After started in Network operation mode, parameter write from the network is enabled. (Refer to page 76 for

a program example for parameter write.)

REMARKS

• Change of the Pr. 340 setting is applied valid power ON or an inverter reset.

• Pr. 340 can be changed with the operation panel in any operation mode.

Operation mode switching and communication startup mode (Pr. 79, Pr. 340)

failure

21

INVERTER SETTING

Pr. 340

Setting

(initial

value)

10

Pr. 79

Setting

0 (initial

value)

0

3, 4 External/PU combined operation mode Operation mode switching is disallowed

1

3, 4 External/PU combined operation mode

3, 4 External/PU combined operation mode Same as when Pr. 340 = "0"

Operation Mode at Power ON or Power

External operation mode

1 PU operation mode PU operation mode fixed

2 External operation mode

6 External operation mode

X12 (MRS) signal ON

7

X12 (MRS) signal OFF

0 NET operation mode

1 PU operation mode

NET operation mode

2

NET operation mode

6

X12 (MRS) signal ON .... NET operation mode

7

X12 (MRS) signal OFF

0 NET operation mode Switching between the PU and NET operation mode is enabled *2

1 PU operation mode Same as when Pr. 340 = "0"

2

NET operation mode NET operation mode fixed

NET operation mode

6

7 External operation mode Same as when Pr. 340 = "0"

Restoration

..... External operation mode

... External operation mode

... External operation mode

Switching among the External, PU, and NET operation mode is

*1

enabled

Switching between the external and NET operation mode is enabled

Switching to the PU operation mode is disallowed

Switching among the External, PU, and NET operation mode is

enabled while running.

Switching among the External, PU, and NET operation mode is enabled

External operation mode fixed (Forcibly switched to External

operation mode.)

Same as when Pr. 340 = "0"

Switching between the PU and NET operation mode is enabled while

*2

running

Operation Mode Switchover

*1 Operation mode cannot be directly changed between the PU operation mode and Network operation mode.

*2 Operation mode can be changed between the PU operation mode and Network operation mode with of the operation panel and

X65 signal.

*1

22

4

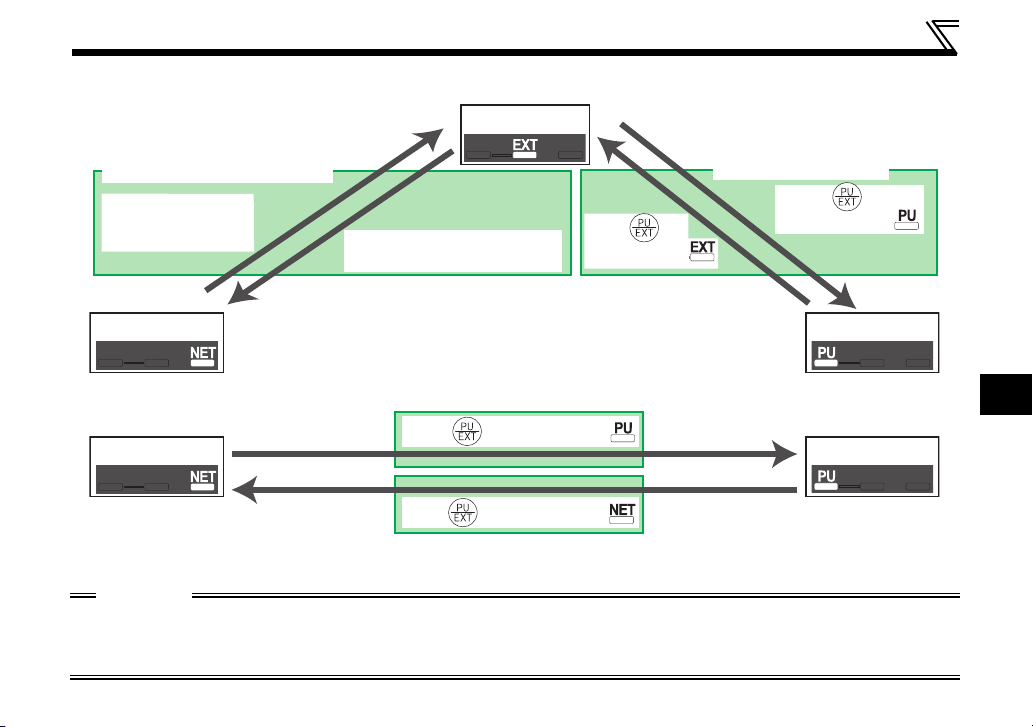

(3) Operation mode switching method

INVERTER SETTING

When "0 or 1" is set in Pr. 340

Switching through the network

Switch to External

operation mode

through the network.

Network operation PU operation

Switch to Network operation

mode through the network.

When "10" is set in Pr. 340

Network operation PU operation

For the switching method with the external terminal, refer to the Inverter Manual.

Refer to page 61 for the switching method through the network.

External operation

Press on

the PU to light

Press on the PU to light

Press on the PU to light

Switching with the PU

Press on

the PU to light

CAUTION

• When starting the inverter in Network operation mode at power ON or an inverter reset, set a value other

than "0" in Pr. 340. (Refer to page 21)

• When setting a value other than "0" in Pr. 340, make sure that the initial settings of the inverter are correct.

23

Loading...

Loading...