Mitsubishi FR-A720-02880-NA, FR-A720-55K, FR-A740-55K, FR-A740-01100-NA, FR-A740-01800-EC Instruction Manual

...

INVERTER

Plug-in option

PRE-OPERATION INSTRUCTIONS

1

FR-A7NS

INSTRUCTION MANUAL

SSCNET III communication function

INSTALLATION

WIRING

SSCNET III COMMUNICATION

STATUS

INVERTER SETTING AND

DISPLAY

RESTRICTIONS ON THE

FUNCTIONS

PRECAUTIONS

ALARM INDICATION DEFINITIONS

AND CORRECTIVE ACTIONS

TROUBLESHOOTING

2

3

4

5

6

7

8

9

Thank you for choosing this Mitsubishi Inverter plug-in option.

This instruction manual gives handling information and

precautions for use of this equipment. Incorrect handling might

cause an unexpected fault. Before using the equipment, please

read this manual carefully to use the equipment to its optimum.

Please forward this manual to the end user.

This section is specifically about

safety matters

Do not attempt to install, operate, maintain or inspect this

product until you have read through this instruction manual and

appended documents carefully and can use the equipment

correctly. Do not use this product until you have a full

knowledge of the equipment, safety information and

instructions.

In this instruction manual, the safety instruction levels are

classified into "WARNING" and "CAUTION".

Assumes that incorrect handling may

WARNING

CAUTION

Note that even the level may lead to a serious

consequence according to conditions. Please follow the

instructions of both levels because they are important to

personnel safety.

cause hazardous conditions, resulting

in death or severe injury.

Assumes that incorrect handling may

cause hazardous conditions, resulting

in medium or slight injury, or may

cause physical damage only.

CAUTION

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

• While power is on or when the inverter is running, do not

open the front cover. You may get an electric shock.

• Do not run the inverter with the front cover or wiring cover

removed. Otherwise, you may access the exposed highvoltage terminals and charging part and get an electric shock.

• If power is off, do not remove the front cover except for wiring

or periodic inspection. You may access the charged inverter

circuits and get an electric shock.

• Before starting wiring or inspection, check to make sure that

the indication of the inverter operation panel is off, wait for at

least 10 minutes after the power supply has been switched off,

and check that there are no residual voltage using a tester or

the like. The capacitor is charged with high voltage for some

time after power off and it is dangerous.

• Any person who is involved in the wiring or inspection of this

equipment should be fully competent to do the work.

• Always install the plug-in option before wiring. Otherwise,

you may get an electric shock or be injured.

• Do not touch the plug-in option with wet hands. Otherwise

you may get an electric shock.

• Do not subject the cables to scratches, excessive stress,

heavy loads or pinching. Otherwise you may get an electric

shock.

A-1

2. Injury Prevention

3) Usage

CAUTION

• Apply only the voltage specified in the instruction manual to

each terminal. Otherwise, burst, damage, etc. may occur.

• Ensure that the cables are connected to the correct terminals.

Otherwise, burst, damage, etc. may occur.

• Always make sure that polarity is correct to prevent damage, etc.

Otherwise, burst, damage may occur.

• While power is on or for some time after power-off, do not touch

the inverter as it is hot and you may get burnt.

3. Additional Instructions

Also note the following points to prevent an accidental failure,

injury, electric shock, etc.

1) Transportation and mounting

CAUTION

• Do not install or operate the plug-in option if it is damaged or

has parts missing.

• Do not stand or rest heavy objects on the product.

• Check that the mounting orientation is correct.

• Prevent other conductive bodies such as screws and metal

fragments or other flammable substance such as oil from

entering the inverter.

2) Trial run

CAUTION

• Before starting operation, confirm and adjust the parameters.

A failure to do so may cause some machines to make

unexpected motions.

WARNING

• Do not modify the equipment.

• Do not perform parts removal which is not instructed in this

manual. Doing so may lead to fault or damage of the inverter.

CAUTION

• When parameter clear or all parameter clear is performed,

reset the required parameters before starting operations.

Each parameter returns to the initial value.

• For prevention of damage due to static electricity, touch

nearby metal before touching this product to eliminate static

electricity from your body.

4) Maintenance, inspection and parts replacement

CAUTION

• Do not test the equipment with a megger (measure insulation

resistance).

5) Disposal

CAUTION

• Treat as industrial waste.

6) General instruction

All illustrations given in this manual may have been drawn with

covers or safety guards removed to provide in-depth

description. Before starting operation of the product, always

return the covers and guards into original positions as specified

and operate the equipment in accordance with the manual.

A-2

CONTENTS

1 PRE-OPERATION INSTRUCTIONS 1

1.1 Inverter Type ......................................................................................................................................1

1.2 Unpacking and Product Confirmation .............................................................................................2

1.2.1 Packing confirmation ......................................................................................................................................7

1.2.2 Parts ...............................................................................................................................................................8

1.3 Caution................................................................................................................................................9

1.4 Operation Overview .........................................................................................................................10

2 INSTALLATION 12

2.1 Pre-Installation Instructions ...........................................................................................................12

2.2 Shaft number Setting.......................................................................................................................13

2.3 Installation Procedure .....................................................................................................................14

3 WIRING 16

3.1 System configuration (when FR-A7AP is used)............................................................................16

3.2 Wiring example (when FR-A7AP is used)......................................................................................18

3.3 SSCNET III cable ..............................................................................................................................20

3.3.1 SSCNET III cable laying...............................................................................................................................24

3.4 Wiring................................................................................................................................................26

4 SSCNET III COMMUNICATION STATUS 32

I

5 INVERTER SETTING AND DISPLAY 35

5.1 Parameter List ..................................................................................................................................35

5.2 Operation Mode Setting ..................................................................................................................36

5.2.1 Operation mode indication............................................................................................................................36

5.2.2 Operation mode switchover method.............................................................................................................37

5.3 Operation at Communication Error Occurrence...........................................................................40

5.3.1 Alarm and measures ....................................................................................................................................40

5.4 Inverter Reset ...................................................................................................................................41

5.5 Setting SSCNET III communication function ................................................................................42

5.5.1 Pr.499 SSCNET III operation selection........................................................................................................42

5.5.2 Pr.379 SSCNET III rotation direction selection.............................................................................................47

5.5.3 Pr.449 SSCNET III input filter setting ...........................................................................................................48

5.5.4 Pr.52 DU/PU main display data selection.....................................................................................................48

5.5.5 Pr.185 JOG terminal function selection........................................................................................................49

5.5.6 Pr.800 Control method selection..................................................................................................................49

6 RESTRICTIONS ON THE FUNCTIONS 50

6.1 Function Restriction List.................................................................................................................50

6.2 Inverter Parameter List ....................................................................................................................53

6.3 Inverter I/O Terminal Function List ................................................................................................69

6.3.1 Input terminal function..................................................................................................................................69

6.3.2 Output terminal function ...............................................................................................................................72

II

7 PRECAUTIONS 74

8 ALARM INDICATION DEFINITIONS AND CORRECTIVE ACTIONS 75

9 TROUBLESHOOTING 79

III

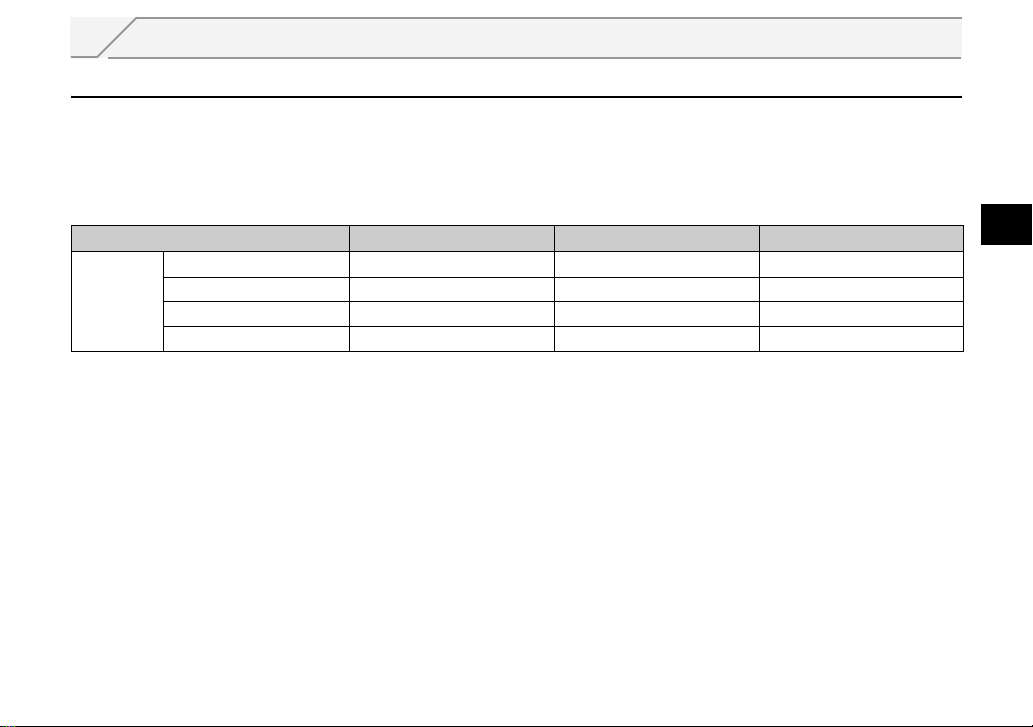

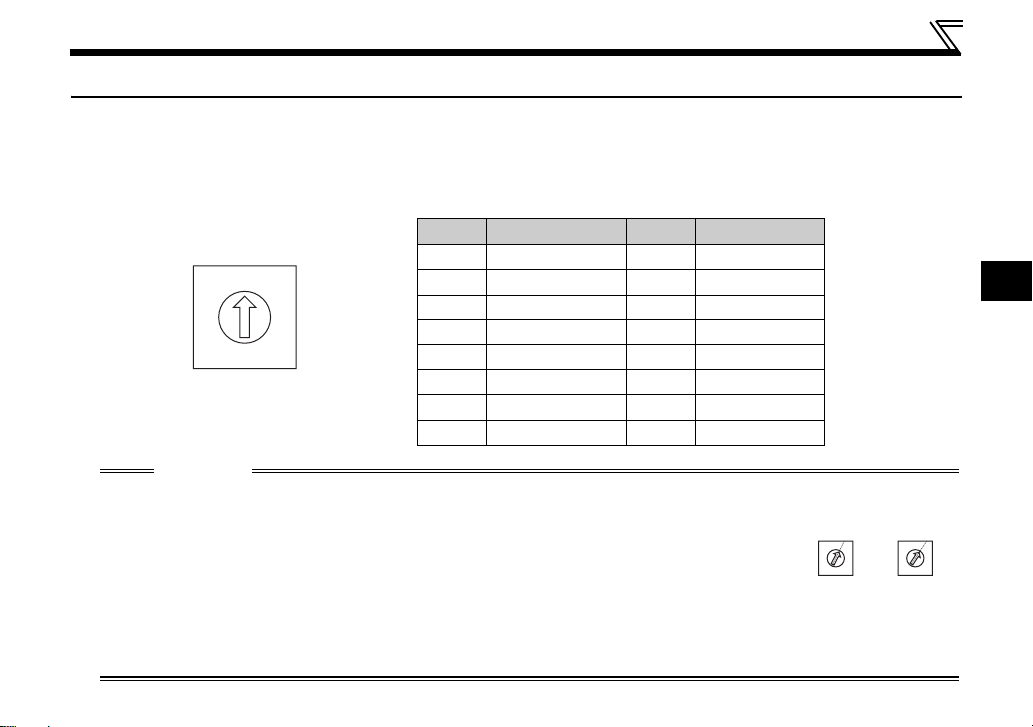

1 PRE-OPERATION INSTRUCTIONS

1.1 Inverter Type

The inverter type, 55K and 75K stated in this Instruction Manual differs according to each -NA, -EC, -CH(T)

versions. Refer to the following correspondence table for each inverter type. (Refer to the instruction manual

of each inverter for the inverter type.)

For example, "for the 75K or more" indicates "for the FR-A740-01440-NA or more" in the case of FR-A740

of NA version.

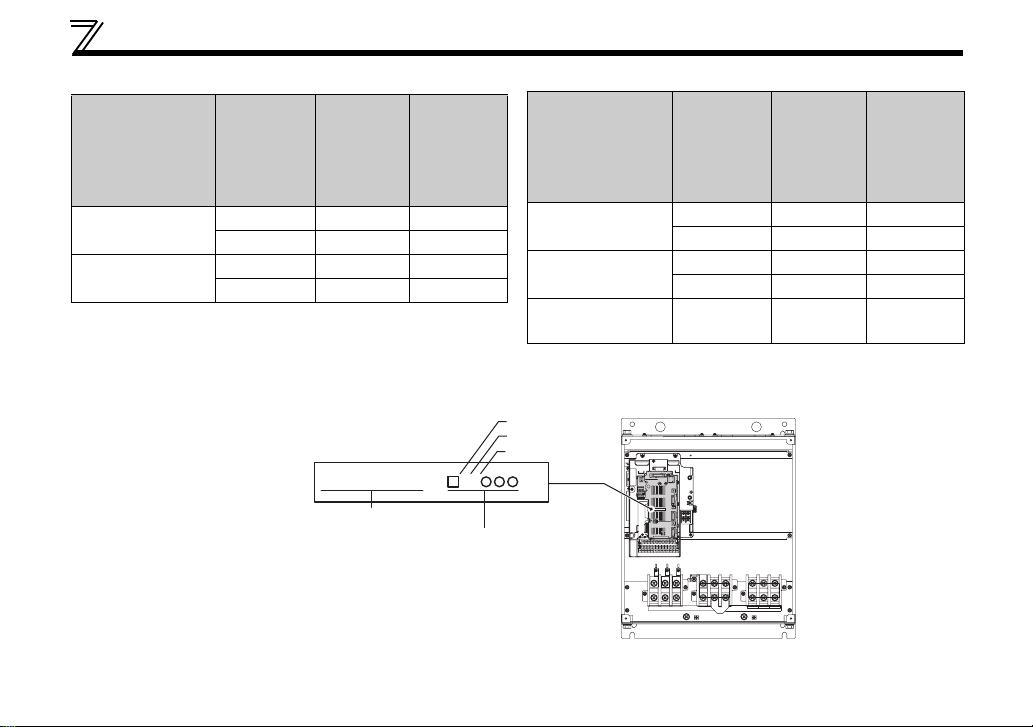

NA EC CH

FR-A720-55K FR-A720-02150-NA

A700

FR-A720-75K FR-A720-02880-NA

FR-A740-55K FR-A740-01100-NA FR-A740-01800-EC FR-A740-55K-CHT

FR-A740-75K FR-A740-01440-NA FR-A740-02160-EC FR-A740-75K-CHT

1

1

PRE-OPERATION INSTRUCTIONS

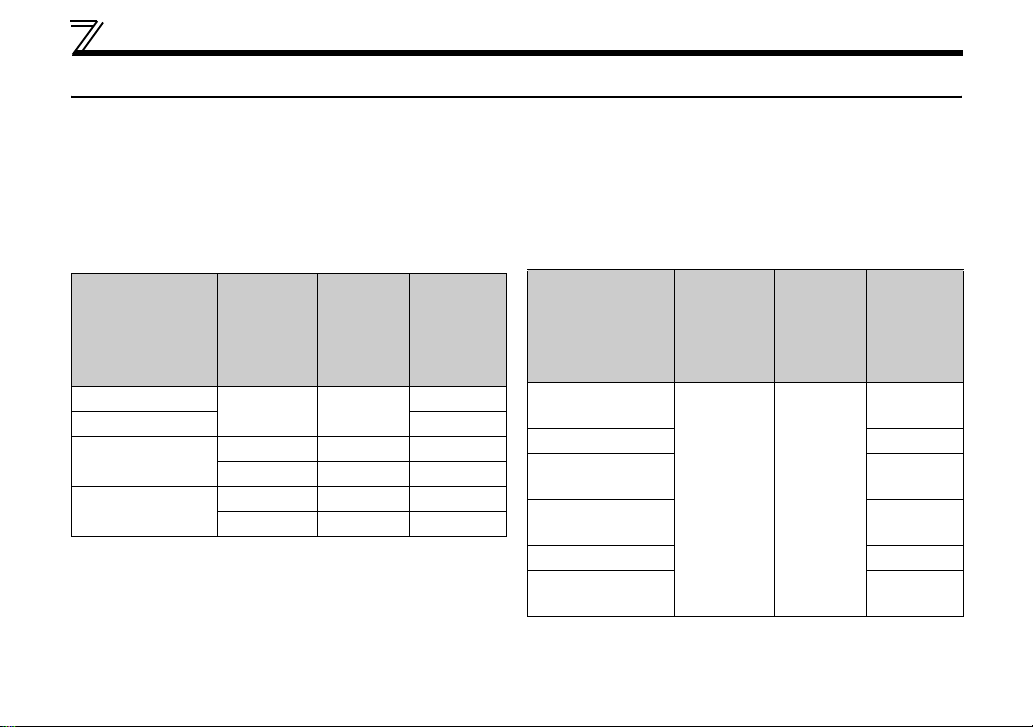

1.2 Unpacking and Product Confirmation

Take the plug-in option out of the package, check the unit name, and confirm that the product is as you

ordered and intact.

This product is a plug-in option for the FR-A700 series inverter assembled in and after January 2007.

Refer to the table below to check the SERIAL (Serial No.) indicated on the inverter rating plate or package.

(1) NA specification

z200V class

Label on

Inverter Type

FR-A720-00030-NA

FR-A720-00050-NA P71

FR-A720-00080/

00110-NA

FR-A720-00175-NA

Product

Package

Identification

Symbol

Without G5

Without G5 Q71

<G> G7 D71

Without G5 R71

<G> G7 D71

Lower Third

and Second

Number of

TC Number

on Rating

Plate

SERIAL

(Upper

Three

Numbers of

SERIAL)

Q71

Label on

Inverter Type

FR-A720-00240/

00330-NA

FR-A720-00460-NA P71

FR-A720-00610 to

00900-NA

FR-A720-01150 to

01750-NA

FR-A720-02150-NA P71

FR-A720-02880/

03460-NA

Product

Package

Identification

Symbol

Without G5

Lower Third

and Second

Number of

TC Number

on Rating

Plate

SERIAL

(Upper

Three

Numbers of

SERIAL)

Q71

R71

Q71

M71

2

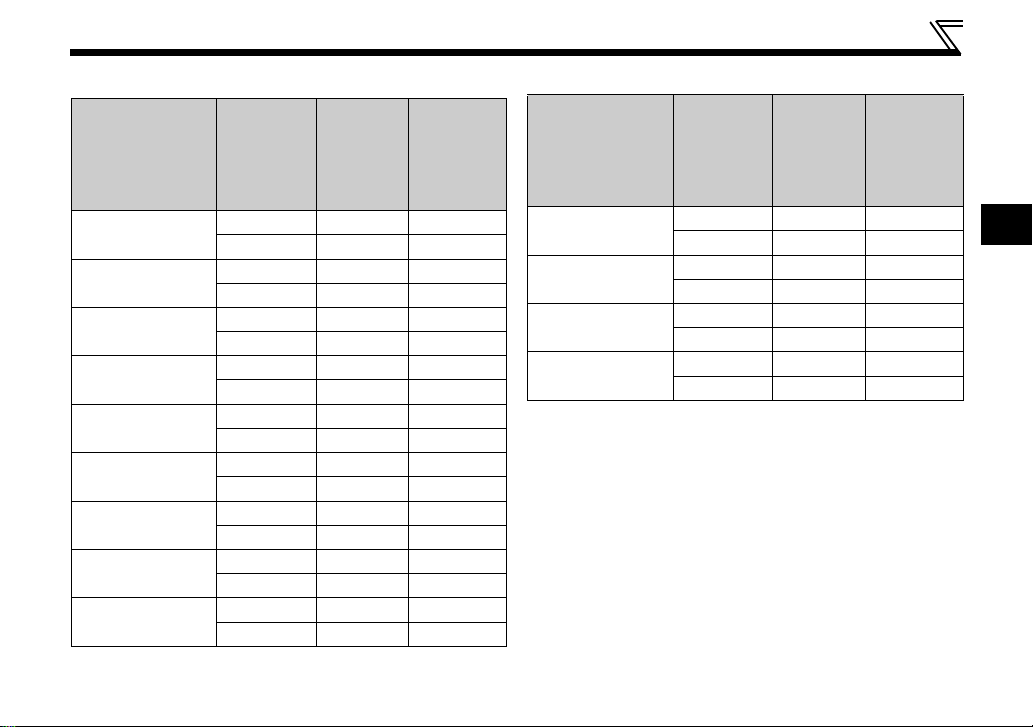

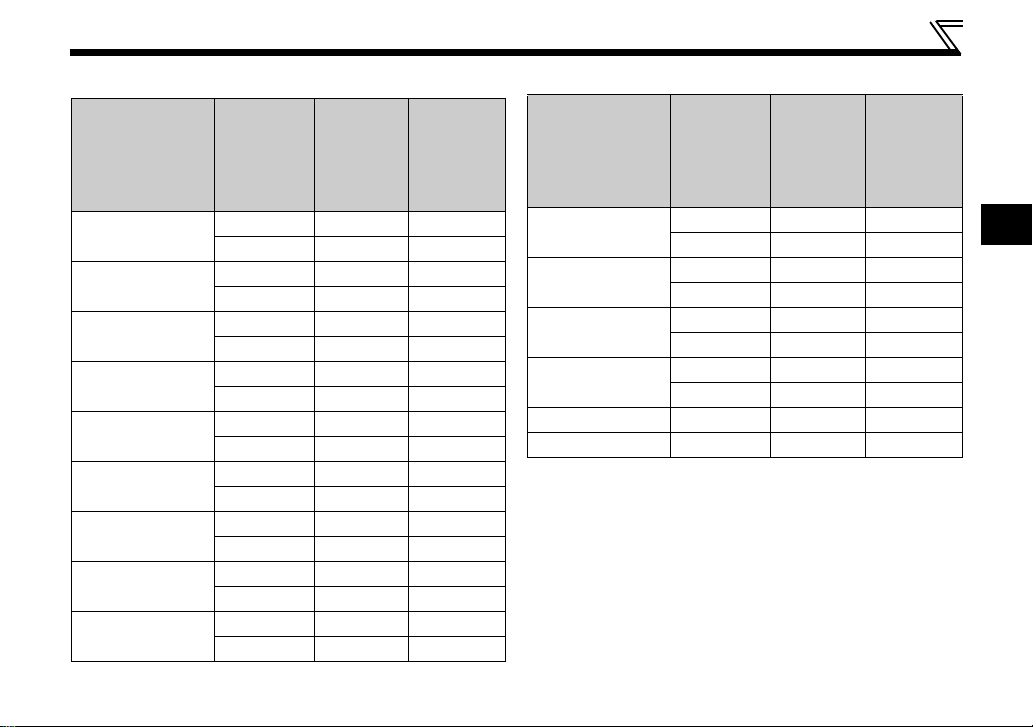

z400V class

Inverter Type

FR-A740-00015 to

00310-NA

FR-A740-00380/

00440-NA

FR-A740-00570 to

00860-NA

FR-A740-01100-NA

FR-A740-01440

to 02660-NA

FR-A740-03250-NA

FR-A740-03610-NA

FR-A740-04320/

04810-NA

FR-A740-05470-NA

Label on

Product

Package

Identification

Symbol

Without G5 Q71

<G> G7 E71

Without G5 Q71

<G> G7 F71

Without G5 P71

<G> G7 E71

Without G5 P71

<G> G7 D71

Without G5 M71

<G> G7 E71

Without G5 N71

<G> G7 F71

Without G5 M71

<G> G7 F71

Without G5 M71

<G> G7 E71

Without G5 N71

<G> G7 E71

Lower Third

and Second

Number of

TC Number

on Rating

Plate

Numbers of

SERIAL

(Upper

Three

SERIAL)

PRE-OPERATION INSTRUCTIONS

Inverter Type

FR-A740-06100-NA

FR-A740-06830-NA

FR-A740-07700/

08600-NA

FR-A740-09620-NA

Label on

Product

Package

Identification

Symbol

Without G5 M71

<G> G7 D71

Without G5 J71

<G> G7 D71

Without G5 M71

<G> G7 D71

Without G5 N71

<G> G7 D71

Lower Third

and Second

Number of

TC Number

on Rating

Plate

Numbers of

SERIAL

(Upper

Three

SERIAL)

1

3

PRE-OPERATION INSTRUCTIONS

(2) EC specification

Label on

Product

Inverter Type

Package

Identification

Symbol

FR-A740-00023 to

00126-EC

FR-A740-00170/

00250-EC

* For the FR-A740-00770 to 12120-EC

Check the SERIAL indicated on the Serial number sticker shown below.

Without G5 or G6 M71

<G> G7 or G8 F71

Without G5 or G6 N71

<G> G7 or G8 F71

Serial number sticker example

The SERIAL consists of 1 version symbol, 2 numeric characters

or 1 numeric character and 1 alphabet letter indicating year and

month, and 3 numeric characters indicating control number.

Month is indicated as 1 to 9, X (October), Y (November), and Z

(December).

To check the SERIAL, the front cover must be removed.

For the removal of the front cover, refer to the inverter manual.

Lower Third

and Second

Number of

TC Number

on Rating

Plate

FR-CA70-EC 71

SERIAL

(Upper

Three

Numbers of

SERIAL)

SERIAL

Control unit type

SERIAL (Serial No.)

Symbol

Yea r

Month

Inverter Type

FR-A740-00310/

00380-EC

FR-A740-00470/

00620-EC

FR-A740-00770 to

12120-EC*

Label on

Product

Package

Identification

Symbol

Lower Third

and Second

Number of

TC Number

on Rating

Plate

Numbers of

Without G5 or G6 M71

<G> G7 or G8 F71

Without G5 N71

<G> G7 G71

VUW

SERIAL

(Upper

Three

SERIAL)

L71 or F71

4

(3) CHT specification

Label on

Inverter Type

FR-A740-0.4K/

0.75K-CHT

FR-A740-1.5K to

15K-CHT

FR-A740-18.5K/

22K-CHT

FR-A740-30K to

45K-CHT

FR-A740-55K-CHT

FR-A740-75K to

132K-CHT

FR-A740-160K-CHT

FR-A740-185K-CHT

FR-A740-220K/

250K-CHT

Product

Package

Identification

Symbol

Without G5 or G6 S71

<G> G7 or G8 E71

Without G5 or G6 T71

<G> G7 or G8 E71

Without G5 or G6 U71

<G> G7 or G8 F71

Without G5 or G6 Q71

<G> G7 or G8 E71

Without G5 or G6 Q71

<G> G7 or G8 D71

Without G5 M71

<G> G7 E71

Without G5 N71

<G> G7 F71

Without G5 M71

<G> G7 F71

Without G5 M71

<G> G7 E71

Lower Third

and Second

Number of

TC Number

on Rating

Plate

SERIAL

(Upper

Three

Numbers of

SERIAL)

PRE-OPERATION INSTRUCTIONS

Inverter Type

FR-A740-280K-CHT

FR-A740-315K-CHT

FR-A740-355K-CHT

FR-A740-400K-CHT

FR-A740-450K-CHT

FR-A740-500K-CHT

Label on

Product

Package

Identification

Symbol

Without G5 N71

<G> G7 E71

Without G5 M71

<G> G7 D71

Without G5 K71

<G> G7 D71

Without G5 M71

<G> G7 D71

Without G5 M71

Without G5 N71

Lower Third

and Second

Number of

TC Number

on Rating

Plate

Numbers of

SERIAL

(Upper

Three

SERIAL)

1

5

PRE-OPERATION INSTRUCTIONS

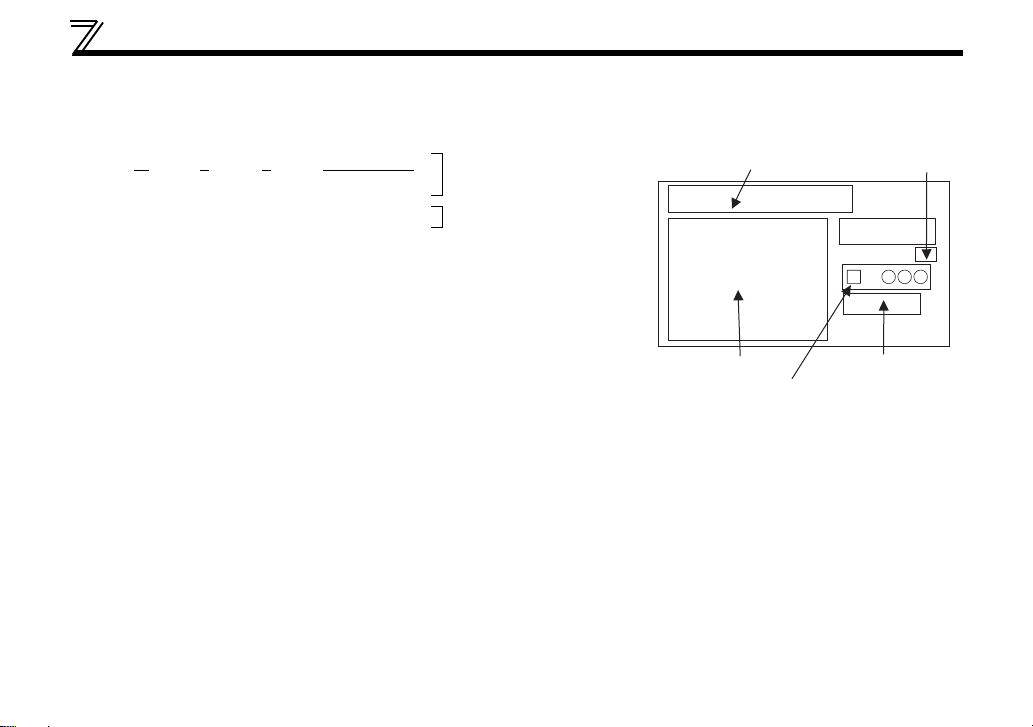

z SERIAL number check

Refer to the inverter manual for the location of the rating plate.

Rating plate example

Symbol Year Month Control number

The SERIAL consists of 1 version symbol, 2 numeric characters or 1 numeric character

and 1 alphabet letter indicating year and month, and 6 numeric characters indicating

control number.

Month is indicated as 1 to 9, X (October), Y (November), and Z (December).

7 1 {{{{{{

SERIAL (Serial No.)

TC{{{A{{{G{{ TC number

Label on the product package

Inverter Type

Identification Symbol

71

Bar code

SERIAL (Serial No.)

The SERIAL (Serial No.) indicated on the

label of the product package consists of

six digits including the first three digits of

the control number and a symbol.

Input rating

6

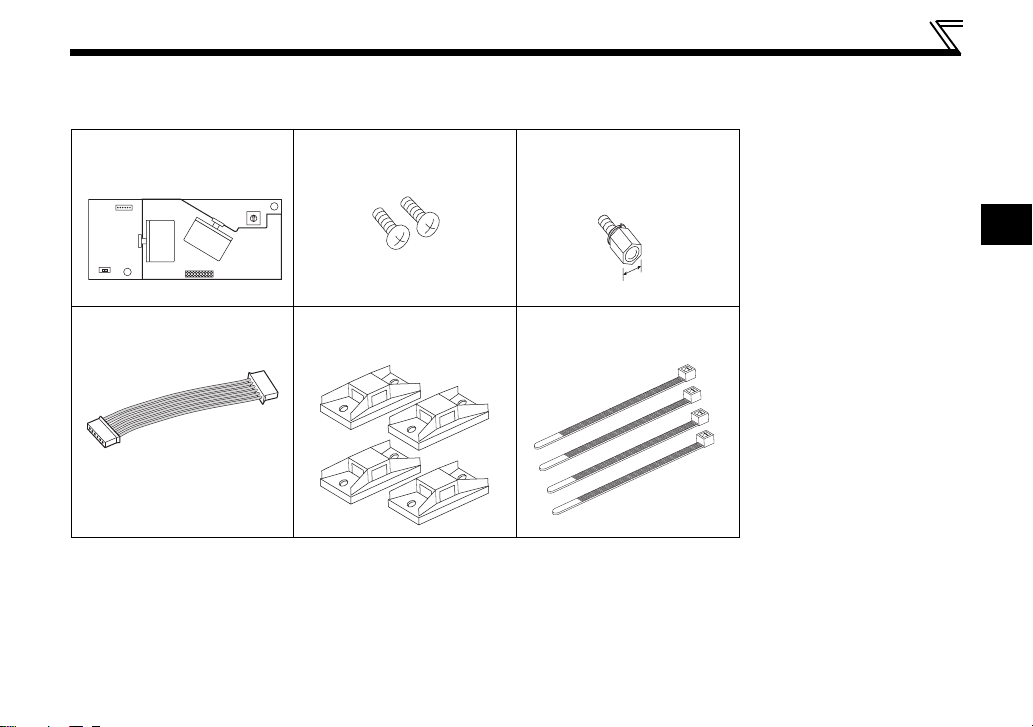

1.2.1 Packing confirmation

Check the enclosed items.

Plug-in option

......................................... 1

Mounting screw (M3 × 6mm)

............ 2 (Refer to page 13.)

0

1

F

2

E

3

D

4

C

5

B

6

A

7

9

8

PRE-OPERATION INSTRUCTIONS

Hex-head screw for option

mounting (5.5mm)

............. 1 (Refer to page 13.)

1

5.5mm

FR-A7AP connection cable

............ 1 (Refer to page 14.)

Cable clamp

............ 4 (Refer to page 31.)

Cable tie

............ 4 (Refer to page 31.)

Microsoft and Windows are registered trademark or trademark of Microsoft Corporation in the United States and/or

other countries.

®

The formal name of Windows

The formal name of Windows

2000 is Microsoft® Windows® 2000 operating system.

®

XP is Microsoft® Windows® XP operating system.

Company and product names herein are the trademarks or registered trademarks of their respective owners.

7

PRE-OPERATION INSTRUCTIONS

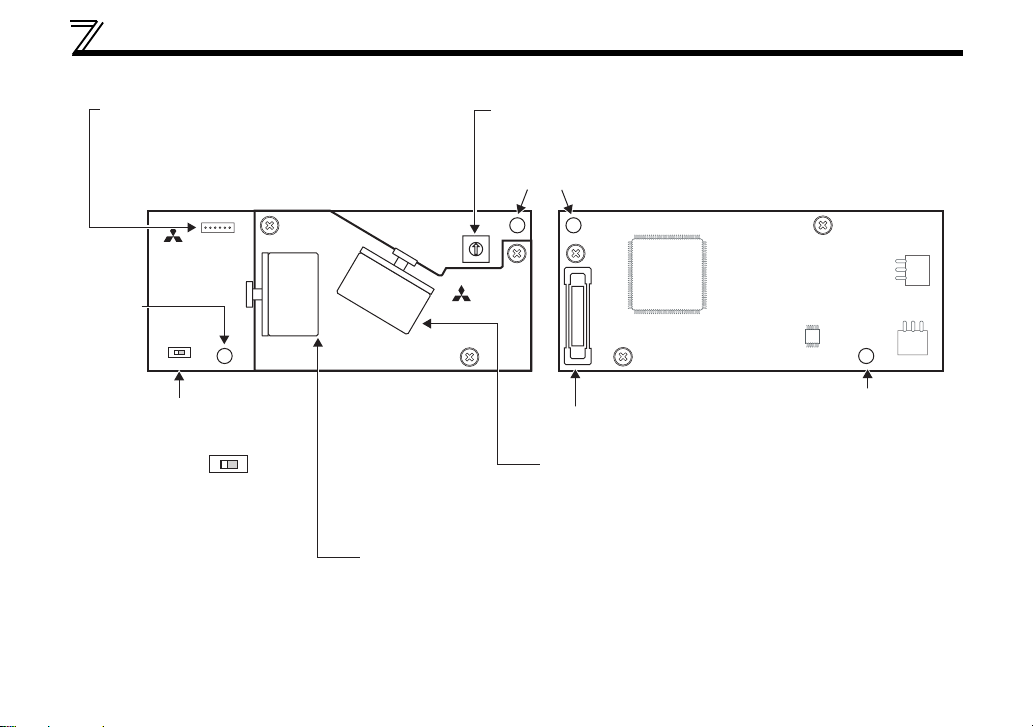

1.2.2 Parts

FR-A7AP connector

Use this connector to connect to the FR-A7AP/

FR-A7AL. Connecting to the FR-A7AP/FR-A7AL

enables the inverter to receive encoder feedback

data.

(Refer to page 14.)

Front view Rear view

FR-A7NS_B

Shaft number switch

Set the shaft number.

(Refer to page 12.)

Mounting

hole

0

1

2

F

3

E

4

D

5

C

6

B

7

A

9

8

Mounting

hole

1

2

O

N

SW1

Switch for manufacturer

setting

Do not change from initially-

1

set status (1: ).

8

O

N

FR-A7NS

2

FR-A7NS_T

Connector

Connect to the inverter option connector.

SSCNET III cable connector (CN1A)

Connect the servo system controller, the preceding

axis inverter or the servo amplifier.

SSCNET III cable connector (CN1B)

(Refer to page 26.)

Connect the following axis inverter or the servo amplifier.

For the final axis, puts a cap.

Mounting hole

(Refer to page 26.)

PRE-OPERATION INSTRUCTIONS

1.3 Caution

(1) Refer to the following manuals or software HELP for full information on the servo system controller.

y Q173DCPU/Q172DCPU user's manual ................................................... IB-0300133

y Q173DCPU/Q172DCPU motion controller (SV13/SV22)

programming manual (real mode version)................................................ IB-0300136

y Q173DCPU/Q172DCPU motion controller

programming manual (common mode version)........................................ IB-0300134

y Q173DCPU/Q172DCPU motion controller (SV13/SV22)

programming manual (Motion SFC version)............................................. IB-0300135

y Q173DCPU/Q172DCPU motion controller (SV22)

programming manual (virtual mode version)............................................ IB-0300137

(2) Servo System Controller NETwork ΙΙΙ is abbreviated to SSCNET ΙΙΙ in this manual.

1

9

PRE-OPERATION INSTRUCTIONS

1.4 Operation Overview

In communication with the Mitsubishi servo system controller, the inverter operation (speed control or

position control or torque control under vector control with encoder) or monitoring can be performed from a

program on the servo system controller.

Application of optical communication method greatly improved the communication speed and noise

resistance of the SSCNET ΙΙΙ as compared with the conventional SSCNET. In addition, 50m of the

maximum wiring length between stations is realized.

Servo system controller

Motion control

Position command

Speed command

Torque command

Control command

Emergency stop

Monitor data

Parameter

*1 When the emergency stop signal is input, the inverter shuts off the output and the motor coasts.

*2 Please contact your sales representative when performing torque control.

*2

*1

SSCNETΙΙΙ

interface

FR-A700

FR-A7NS

SSCNETΙΙΙ

interface

FR-A7AP/

FR-A7AL

Encoder

interface

Torque command

Speed command

Position

command

Current

monitor

Speed monitor/feedback pulse monitor

Position

control

Speed

control

Emergency stop

output shutoff

Torque

*2

control

IM

Encoder

10

PRE-OPERATION INSTRUCTIONS

CAUTION

y Mounting both the FR-A7NS and FR-A7AP/FR-A7AL and performing vector control enables SSCNET ΙΙΙ

communication.

When operating the inverter with the FR-A7NS mounted and without FR-A7AP/FR-A7AL, option alarm

(E.OPT) occurs. (Refer to page 77.) Also option alarm (E.OPT) occurs when the FR-A7AP and FR-A7NS are not

connected with the FR-A7AP connection cable (the FR-A7AL and FR-A7NS are not connected with the FRA7NS connection cable) during a stop of the inverter. (Refer to page 77.) (In those conditions, however, option

fault (E.OPT) does not occur when Pr.800 Control method selection = "9" (vector control test operation) (refer to

page 49) or when Pr.499 SSCNET III operation selection = "9999" (operation invalid). (refer to page 42))

y An alarm such as overcurrent shut off (E.OC3) and position error large (E.OD) may occur depending on the

status of the motor current and droop pulses during inverter operation.

1

11

2 INSTALLATION

2.1 Pre-Installation Instructions

Make sure that the input power of the inverter is off.

CAUTION

With input power on, do not install or remove the plug-in option. Otherwise, the inverter and

plug-in option may be damaged.

For prevention of damage due to static electricity, touch nearby metal before touching this

product to eliminate static electricity from your body.

12

INSTALLATION

2.2 Shaft number Setting

ySetting with shaft number switch

Set the shaft number between "0H to FH" using shaft number switches on the FR-A7NS (refer to page 4).

The setting is reflected at the next power-on or inverter reset.

Set the arrow (×) of the corresponding switches to the number and alphabet to set a desired shaft

number.

No. Definition No. Definition

0 1st axis 8 9th axis

0

1

F

2

E

3

C

D

4

5

B

6

7

A

8

9

Initial status

CAUTION

y Set the shaft number switch to the switch number (alphabet) position correctly. If

the switch is set between numbers, normal data communication can not be

made.

y You cannot set the same shaft number to other devices on the network. (Doing so disables proper

communication.)

y Set the inverter shaft number before switching on the inverter and do not change the setting while

power is on. Otherwise you may get an electric shock.

1 2nd axis 9 10th axis

2 3rd axis A 11th axis

3 4th axis B 12th axis

4 5th axis C 13th axis

5 6th axis D 14th axis

6 7th axis E 15th axis

7 8th axis F 16th axis

Good

example

1

0

F

2

E

3

D

4

5

C

B

6

7

A

8

9

example

Bad

0

F

E

D

C

B

A

9

2

1

2

3

4

5

6

7

8

13

INSTALLATION

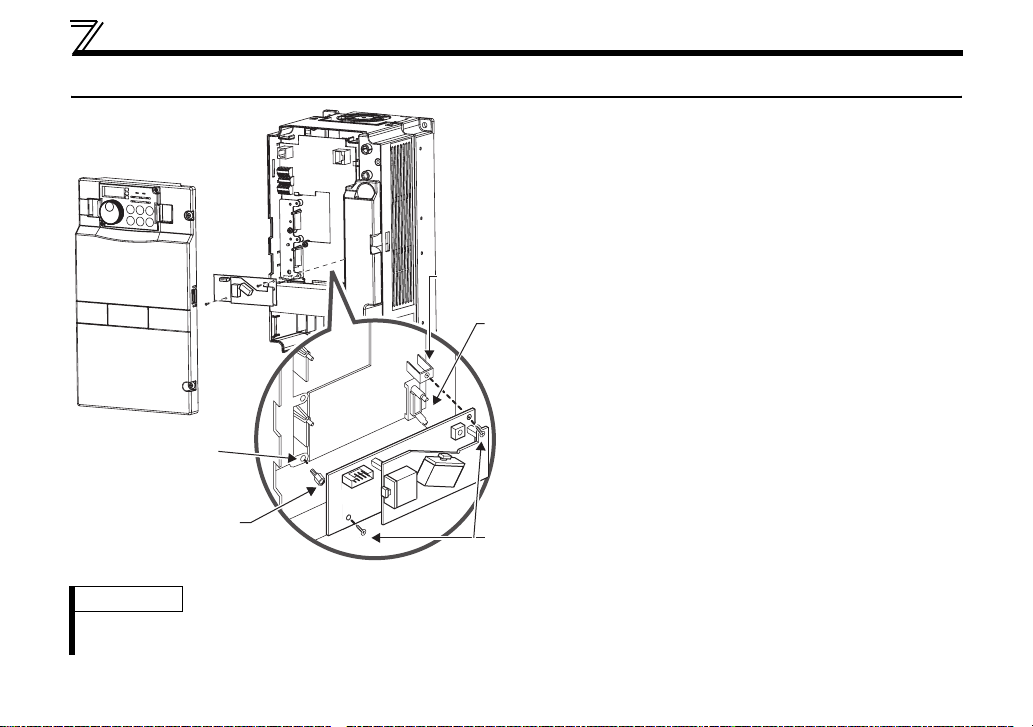

2.3 Installation Procedure

1)Remove the inverter front cover.

1)

Screw hole for

option mounting

Inverter side

option

connector

3)

Screw hole for

option mounting

(on earth plate)

Hex-head screw

for option mounting

REMARKS

y Remove a plug-in option after removing two screws on both left and right sides.

(The plug-in option is easily removed if the control circuit terminal block is removed before.)

2)

4) Mounting

screws

2)Mount the hex-head screw for option

mounting into the inverter screw hole

(on earth plate). (size 5.5mm,

tightening torque 0.56N⋅m to 0.75N⋅m)

3)Securely fit the connector of the plug-in

option to the inverter connector along

the guides.

4)Securely fix the both right and left sides

of the plug-in option to the inverter with

the accessory mounting screws.

(Tightening torque 0.45N⋅m to

0.55N⋅m) If the screw holes do not lineup, the connector may not have been

plugged snugly. Check for loose

plugging.

14

INSTALLATION

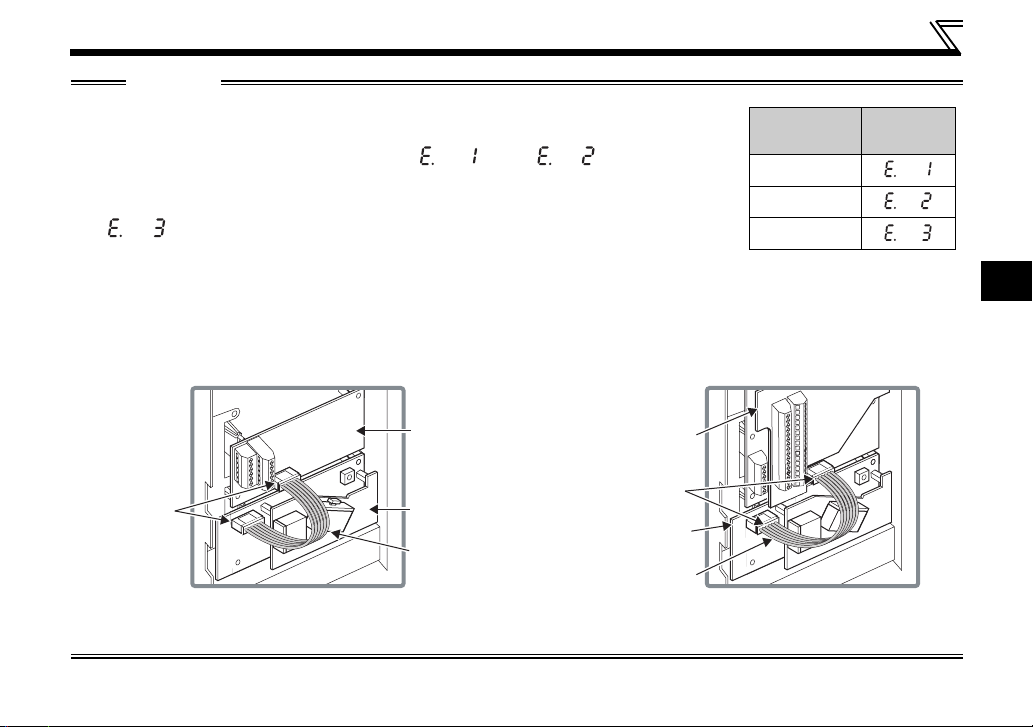

CAUTION

y When using this option unit, mount it in the "option connector 3 (lowermost

connector)" of the inverter.

If it is fitted in option connector 1 or 2, " " or " " (option alarm)

is displayed and the inverter will not function. In addition, when the inverter can

not recognize that the option is mounted due to improper installation, etc.,

" " (option alarm) is displayed even if the option is fitted in the option

connector 3.

y Mount the FR-A7AP/FR-A7AL to the "option connector 2" of the inverter.

y After mounting both of the FR-A7NS and FR-A7AP/FR-A7AL, connect each external connector using the FR-

A7AP connection cable (Refer to page 3) / FR-A7NS connection cable (enclosed in FR-A7AL, refer to the instruction

manual of FR-A7AL.) respectively.

Mounting

Position

Connector 1

Connector 2

Connector 3

Error

Display

2

When using FR-A7AP

FR-A7AP

External

connector

y Take care not to drop a hex-head screw for option mounting or mounting screw during mounting and removal.

y Pull out the option straight to remove. Otherwise, the connector may be damaged.

FR-A7NS

FR-A7AP

connection

cable

FR-A7AL

External

connector

FR-A7NS

FR-A7NS

connection

cable

When using FR-A7AL

15

3 WIRING

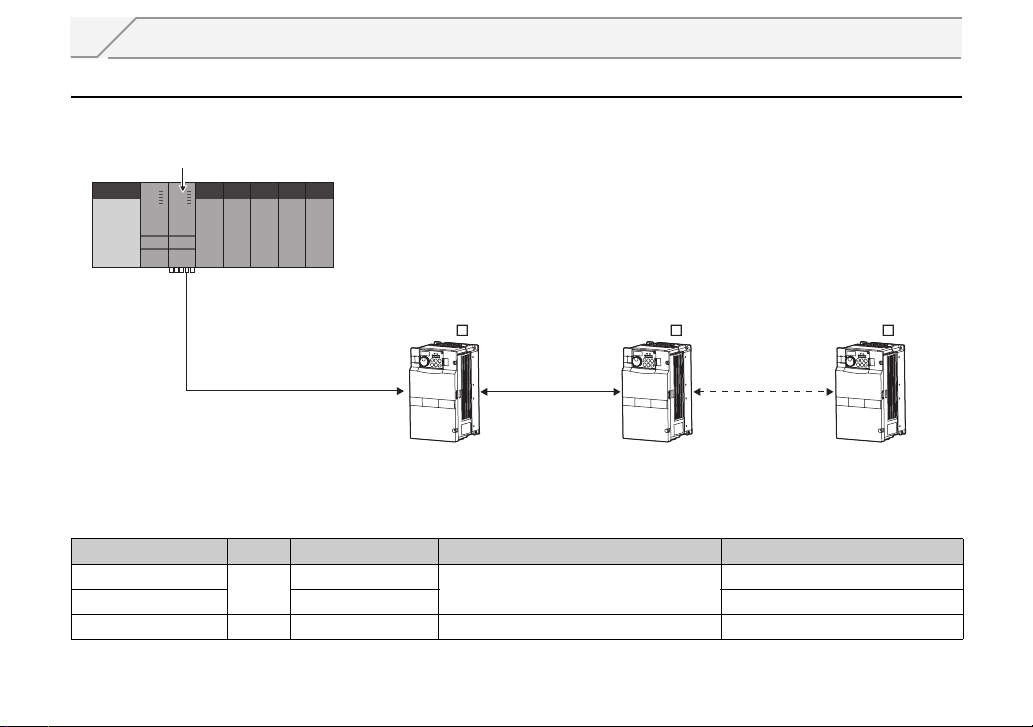

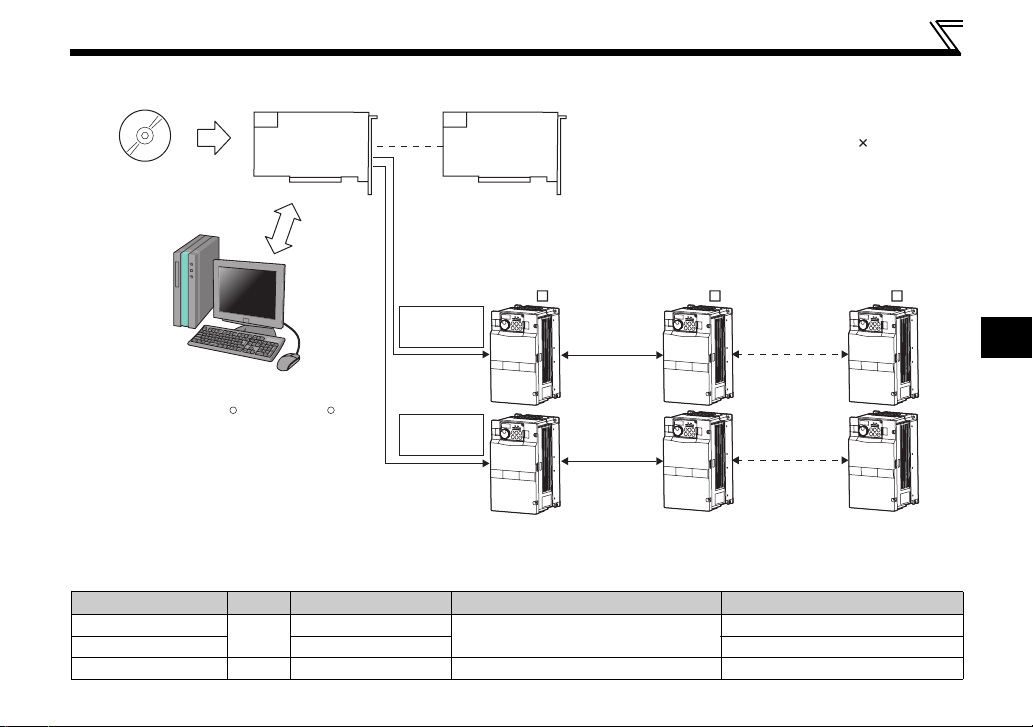

3.1 System configuration (when FR-A7AP is used)

zConnecting with the motion controller

Motion controller

(Q173DCPU/Q172DCPU)

Inverter

FR-A700 series

+ FR-A7NS + FR-A7AP

(or servo amplifier

MR-J3- B)

SSCNET ΙΙΙ cable *2 SSCNET ΙΙΙ cable *2 SSCNET ΙΙΙ cable *2

1st axis 2nd axis 16th axis *1

*1 The maximum number of inverter (or servo amplifier) connected differs depending on the type of motion controller

(Q173DCPU/Q172DCPU).

*2 For the distance between electrodes of SSCNET ΙΙΙ cable, refer to the following table.

Cable Model Name Type Cable Length (m) Distance Between Electrodes (m)

MR-J3BUSM

MR-J3BUSM-A 5 to 20 Standard cable outside panel

MR-J3BUSM-B HPCF 30 to 50 50 Long-distance cable

POF

0.15 to 3

20

Inverter

FR-A700 series

+ FR-A7NS + FR-A7AP

(or servo amplifier

MR-J3- B)

Inverter

FR-A700 series

+ FR-A7NS + FR-A7AP

(or servo amplifier

MR-J3- B)

Applications

Standard code inside panel

16

zConnecting with the motion board

Motion board(Q111BD-SSC/Q110BD-SSC)

Inverter OS software

(For the A7NS)

WIRING

Number of mountable boards:

4 boards maximum (128 axis total (32 axis 4 boards))

Specify board ID using the board ID setting switch of the

motion board.

PCI bus

Personal computer

(PC/AT compatible)

(Windows 2000 /Windows XP )

R R

Inverter

FR-A700 series

+ FR-A7NS + FR-A7AP

(or servo amplifier

MR-J3- B)

SSCNET ΙΙΙ

(Line 1)

SSCNET ΙΙΙ

cable *2

SSCNET ΙΙΙ

(Line 2)

SSCNET ΙΙΙ

cable *2

SSCNET ΙΙΙ

cable *2

SSCNET ΙΙΙ

cable *2

1st axis 2nd axis 16th axis *1

Inverter

FR-A700 series

+ FR-A7NS + FR-A7AP

(or servo amplifier

MR-J3- B)

SSCNET ΙΙΙ

cable *2

SSCNET ΙΙΙ

cable *2

Inverter

FR-A700 series

+ FR-A7NS + FR-A7AP

(or servo amplifier

MR-J3- B)

*1 The maximum number of inverter (or servo amplifier) connected differs depending on the type of motion board

(Q111BD-SSC/Q110BD-SSC).

*2 For the distance between electrodes of SSCNET ΙΙΙ cable, refer to the following table.

Cable Model Name Type Cable Length (m)

MR-J3BUSM

MR-J3BUSM-A 5 to 20 Standard cable outside panel

POF

0.15 to 3

Distance Between Electrodes (m)

20

Application

Standard code inside panel

MR-J3BUSM-B HPCF 30 to 50 50 Long-distance cable

17

3

WIRING

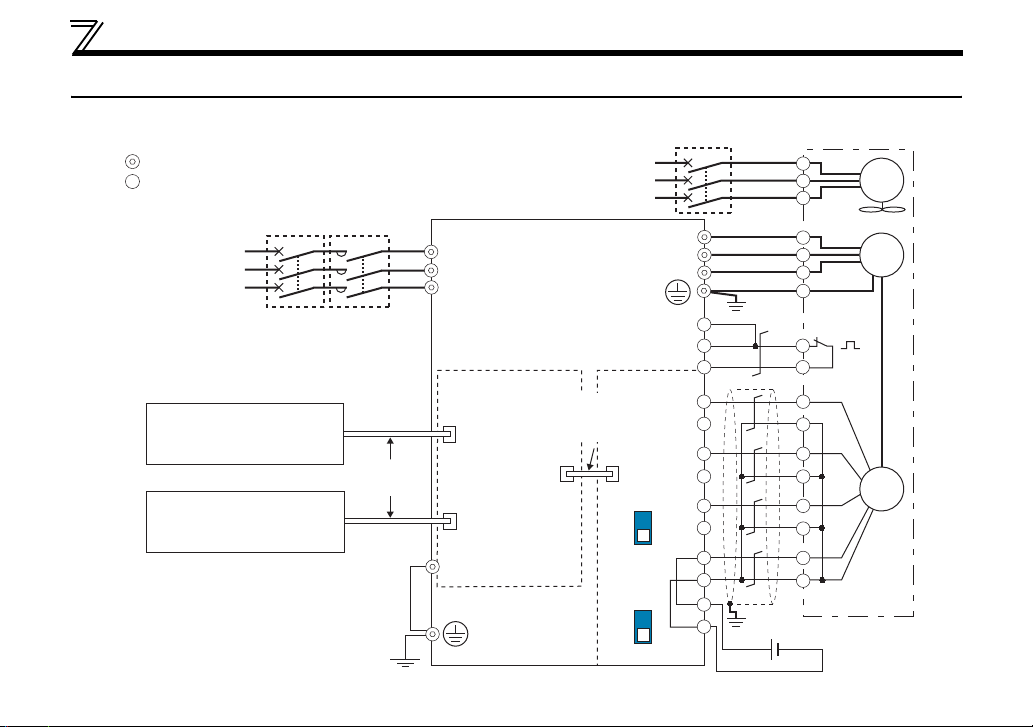

3.2 Wiring example (when FR-A7AP is used)

zVector control dedicated motor (SF-V5RU, SF-THY), 12V complementary

*1

*2

CS(OH)

PA1

PA2

PB1

PB2

PZ1

Differential

PZ2

resistor

ON

OFF

MCCB

W

PC

SD

PG

SD

PG

SD

*8*6

Sink logic

Main circuit terminal

Control circuit terminal

Three-phase

AC power supply

Servo system controller,

preceding axis inverter

(servo amplifier)

Following axis inverter

(servo amplifier)

MCCB

MC

SSCNET ΙΙΙ

cable

Three-phase

AC power supply

R/L1

S/L2

T/L3

SSCNET ΙΙΙ unit

FR-A7NS

SSCNET III

cable connector

(CN1A)

FR-A7AP

connector

SSCNET III

cable connector

(CN1B)

Earth terminal

Inverter

External

thermal

relay input

FR-A7AP

FR-A7AP

connection

cable

Complementary

Terminating

U

V

SF-V5RU, SF-THY

A

B

C

U

V

W

E

Earth

Thermal relay

(Ground)

2W1kΩ

*5

(+) (-) 12VDC power supply

G1

G2

A

B

C

D

F

G

S

R

protector

*3

FAN

IM

Encoder

*4

*7

18

WIRING

*1 For the fan of the 7.5kW or less dedicated motor, the power supply is single phase. (200V/50Hz, 200 to 230V/

60Hz)

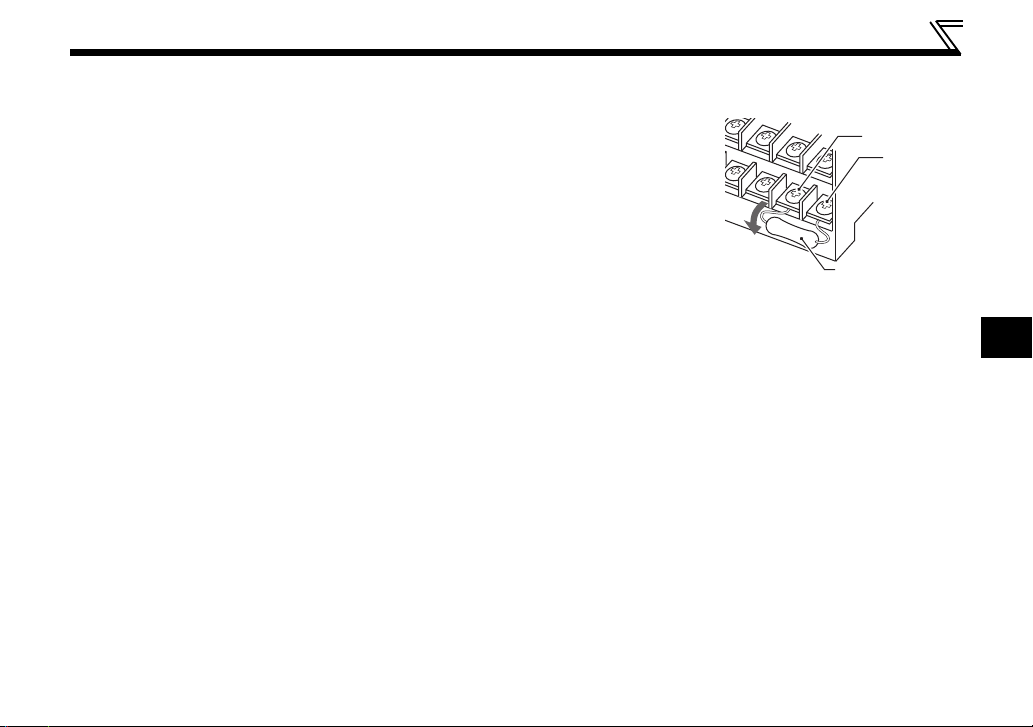

*2 Assign OH (external thermal input) signal to the terminal CS. (Set "7" in Pr. 186 )

Connect a 2W1kΩ resistor between the terminal PC and CS (OH). Install the

resistor pushing against the bottom part of the terminal block so as to avoid a

contact with other cables.

Refer to FR-A700 Instruction Manual (Applied) for details of Pr.186 CS terminal

function selection.

CS(OH)

PC

Control circuit

terminal block

Resistor (2W1kΩ)

*3 The pin number differs according to the encoder used.

Speed control and torque control are properly performed even without connecting Z phase.

*4 Connect the encoder so that there is no looseness between the motor and motor shaft. Speed ratio should be 1:1.

*5 Earth (Ground) the shielded cable of the encoder cable to the enclosure with a P clip, etc.

(Refer to FR-A7AP Instruction Manual.)

*6 For the complementary, set the terminating resistor selection switch to off position.

(Refer to FR-A7AP Instruction Manual.)

*7 A separate power supply of 5V/12V/15V/24V is necessary according to the encoder power specification.

*8 For terminal compatibility of the FR-JCBL, FR-V7CBL and FR-A7AP, refer to FR-A7AP Instruction Manual.

19

3

WIRING

3.3 SSCNET III cable

Use our optional SSCNET ΙΙΙ connection cables.

(1) Cable type

Cable Model Name *1 Type Cable Length (m) Flex Life Application

MR-J3BUSM

MR-J3BUSM-A 5, 10, 20 Standard

MR-J3BUSM-B *2 HPCF 30, 40, 50 Long flex

*1 in the type represents the cable length.

Symbol 015 03 05 1 3 5 10 20 30 40 50

Cable Length (m) 0.15 0.3 0.5 1 3 5 10 20 30 40 50

*2 For cable of 30m or less, contact our company.

POF

0.15, 0.3, 0.5, 1, 3 Standard

Standard code inside panel

Standard cable outside panel

Long-distance cable

20

Loading...

Loading...