Mitsubishi Electric FR-A700-A1 Instruction Manual

INVERTER

FR-A700-A1

INSTRUCTION MANUAL

Dancer Control Function

Tension Control Function

CONTENTS

OUTLINE OF THE DEDICATED FUNCTIONS.............................................. 1

1

PARAMETER LIST ........................................................................................2

2

DANCER CONTROL/WINDING DIAMETER COMPENSATION ................14

3

3.1 Dedicated specification list ..................................................................................... 14

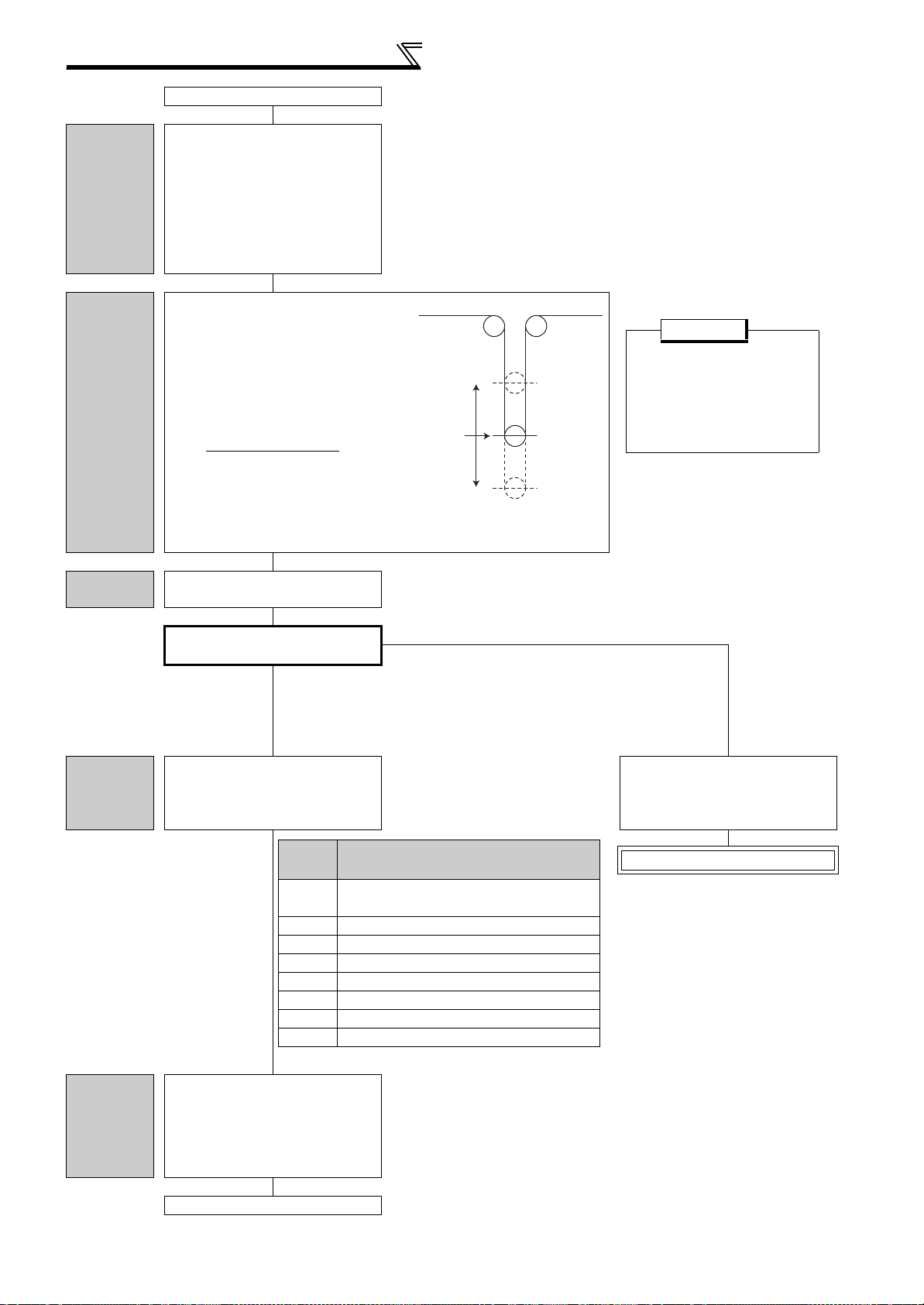

3.2 System configuration example ............................................................................... 15

3.3 Control block diagram............................................................................................. 15

3.4 Dedicated I/O signal ............................................................................................... 16

3.5 Parameter setting procedure for dancer control function ....................................... 19

3.6 Gain adjustment in actual operation ....................................................................... 22

3.7 Dancer control detail ............................................................................................... 25

3.8 Winding diameter compensation function .............................................................. 32

3.9 Main speed setting.................................................................................................. 43

3.10 Dedicated monitor function ..................................................................................... 49

3.11 Regeneration avoidance function (Pr. 882) ............................................................ 53

3.12 Operation command source and speed command source (Pr. 338, Pr. 339) ....... 53

1

2

TENSION CONTROL...................................................................................55

4

4.1 Dedicated function list............................................................................................. 55

4.2 System configuration example ............................................................................... 55

4.3 Block diagram of the control ................................................................................... 56

4.4 Dedicated I/O signal ............................................................................................... 56

4.5 Tension control parameter setting procedure......................................................... 57

4.6 Details of the tension control .................................................................................. 59

APPLICATION EXAMPLE...........................................................................67

5

5.1 Dancer control with winding diameter compensation for printers .......................... 67

5.2 Dancer control with winding diameter compensation for wiredrawing machine .... 70

5.3 Tension control for the winding operation of printers ............................................. 73

APPENDIX ................................................................................................... 74

6

6.1 Compatible plug-in options ..................................................................................... 74

6.2 Differences from the standard inverter ................................................................... 74

6.3 Parameter change when replacing FR-A500-A1 with FR-A700-A1 ...................... 75

6.4 Control mode-based parameter (function) correspondence and

instruction code....................................................................................................... 76

6.5 Index ....................................................................................................................... 80

3

4

5

6

—CONTENTS—

1 OUTLINE OF THE DEDICATED FUNCTIONS 1

2 PARAMETER LIST 2

3 DANCER CONTROL/WINDING DIAMETER COMPENSATION 14

3.1 Dedicated specification list ............................................................................................................. 14

3.2 System configuration example........................................................................................................ 15

3.3 Control block diagram...................................................................................................................... 15

3.4 Dedicated I/O signal ......................................................................................................................... 16

3.4.1 Input signal list ................................................................................................................................................... 16

3.4.2 Output signal list ................................................................................................................................................ 17

3.4.3 Analog input signals and pulse train input signals ............................................................................................. 18

3.5 Parameter setting procedure for dancer control function ............................................................ 19

3.6 Gain adjustment in actual operation............................................................................................... 22

3.6.1 Speed control P/I gain adjustment (Real sensorless vector control/Vector control) ..........................................22

3.6.2 Dancer PID gain adjustment.............................................................................................................................. 24

3.7 Dancer control detail ........................................................................................................................ 25

3.7.1 PID setting (Pr. 128 to Pr. 130, Pr. 134 to Pr. 137, Pr. 709, Pr. 710) ................................................................ 25

3.7.2 Dancer roll target position (Pr. 133, Pr. 702, Pr. 731)........................................................................................ 27

3.7.3 Adjustment of target position input (Pr. 708, C3, C4, C6, C7, C13, C15, C31, C33)......................................... 29

3.7.4 Measured value upper/lower limit detection signal (Pr. 131, Pr. 132) ............................................................... 29

3.7.5 PID gain switchover (Pr. 138, Pr. 270 to Pr. 278, Pr. 464 to Pr. 481, X89 signal, X90 signal) .......................... 29

3.7.6 Speed compensation (Pr. 706, Pr. 798) ............................................................................................................ 31

3.8 Winding diameter compensation function ..................................................................................... 32

3.8.1 Winding diameter calculation and compensation by winding diameter calculation ........................................... 32

3.8.2 Line speed input setting (Pr. 763 to Pr. 768) ..................................................................................................... 33

3.8.3 Setting at driving shaft (Pr. 762, Pr. 773, Pr. 774, X56 signal) .......................................................................... 34

3.8.4 Material thickness, maximum/minimum winding diameter setting

(Pr. 720 to Pr. 727, Pr. 752 to Pr. 755, X53 signal, X54 signal) ........................................................................ 35

3.8.5 Rotation speed at winding diameter calculated value activation (Pr. 797) ........................................................ 36

3.8.6 Storage and clear of winding diameter calculation result (Pr. 781 to Pr. 783, X55 signal)................................ 37

3.8.7 Sampling time and restricted increase of winding diameter (Pr. 707, Pr. 771, Pr. 772, Pr. 786)....................... 38

3.8.8 Filter treatment for compensated main rotation speed by winding diameter calculation (Pr. 769, Pr. 770)....... 38

3.8.9 Winding diameter calculation at start (Pr. 133, Pr. 712, Pr. 790 to Pr. 796)...................................................... 39

3.8.10 Storage and clear of winding/unwinding length (Pr. 279 to Pr. 281, X86 signal, Y53 signal) ............................ 42

3.9 Main speed setting ........................................................................................................................... 43

3.9.1 Input method of main speed command (Pr. 732) .............................................................................................. 43

3.9.2 Main speed command by analog input.............................................................................................................. 44

3.9.3 Main speed command by terminal JOG single-phase pulse train input

(Pr. 384 to Pr. 386, Pr. 703, Pr. 704) ................................................................................................................. 45

3.9.4 Acceleration/deceleration time setting (Pr. 756 to Pr. 761, X51 signal, X52 signal).......................................... 46

3.9.5 Speed control proportional gain selection based on winding diameter compensation result

(Pr. 775 to Pr. 780) ........................................................................................................................................... 47

3.9.6 Target winding diameter achieved signal (Pr. 750, Y52 signal)......................................................................... 48

3.10 Dedicated monitor function ............................................................................................................. 49

3.10.1 Dedicated monitor list ........................................................................................................................................ 49

3.10.2 Terminal 1 input voltage monitor ....................................................................................................................... 50

3.10.3 Winding diameter monitor.................................................................................................................................. 50

3.10.4 Line speed pulse monitor function..................................................................................................................... 50

CONTENTS

I

3.10.5 Multiple monitor (Pr. 52) .....................................................................................................................................50

3.10.6 Analog output signal for dancer tension setting (Pr. 718, Pr. 719, Pr. 733, Pr. 734,

Pr. 785, Pr. 787 to Pr. 789).................................................................................................................................51

3.11 Regeneration avoidance function (Pr. 882).................................................................................... 53

3.12 Operation command source and speed command source (Pr. 338, Pr. 339).............................. 53

4 TENSION CONTROL 55

4.1 Dedicated function list ..................................................................................................................... 55

4.2 System configuration example........................................................................................................ 55

4.3 Block diagram of the control ........................................................................................................... 56

4.3.1 Block diagram of the tension control ..................................................................................................................56

4.4 Dedicated I/O signal ......................................................................................................................... 56

4.4.1 Input signal list....................................................................................................................................................56

4.4.2 Output signal list .................................................................................................................................................56

4.5 Tension control parameter setting procedure ............................................................................... 57

4.6 Details of the tension control .......................................................................................................... 59

4.6.1 Winding diameter calculation during tension control (Pr. 797, X91 signal, Y51 signal)......................................59

4.6.2 Winding taper function (Pr. 717, Pr. 787, Pr. 788)..............................................................................................61

4.6.3 Inertia compensation function (Pr. 713 to Pr. 716, X57 signal, X58 signal, X59 signal).....................................62

4.6.4 Mechanical loss compensation (Pr. 739 to Pr. 749, Pr. 762) .............................................................................64

4.6.5 Stall operation signal (Pr. 737, Pr. 738, Pr. 760, X92 signal).............................................................................65

4.6.6 Tension control monitor output (Pr. 52) ..............................................................................................................66

5 APPLICATION EXAMPLE 67

5.1 Dancer control with winding diameter compensation for printers .............................................. 67

5.2 Dancer control with winding diameter compensation for wiredrawing machine ....................... 70

5.3 Tension control for the winding operation of printers.................................................................. 73

6 APPENDIX 74

6.1 Compatible plug-in options ............................................................................................................. 74

6.2 Differences from the standard inverter .......................................................................................... 74

6.3 Parameter change when replacing FR-A500-A1 with FR-A700-A1............................................... 75

6.4 Control mode-based parameter (function) correspondence and

instruction code ................................................................................................................................ 76

6.5 Index .................................................................................................................................................. 80

II

1

OUTLINE OF THE DEDICATED FUNCTIONS

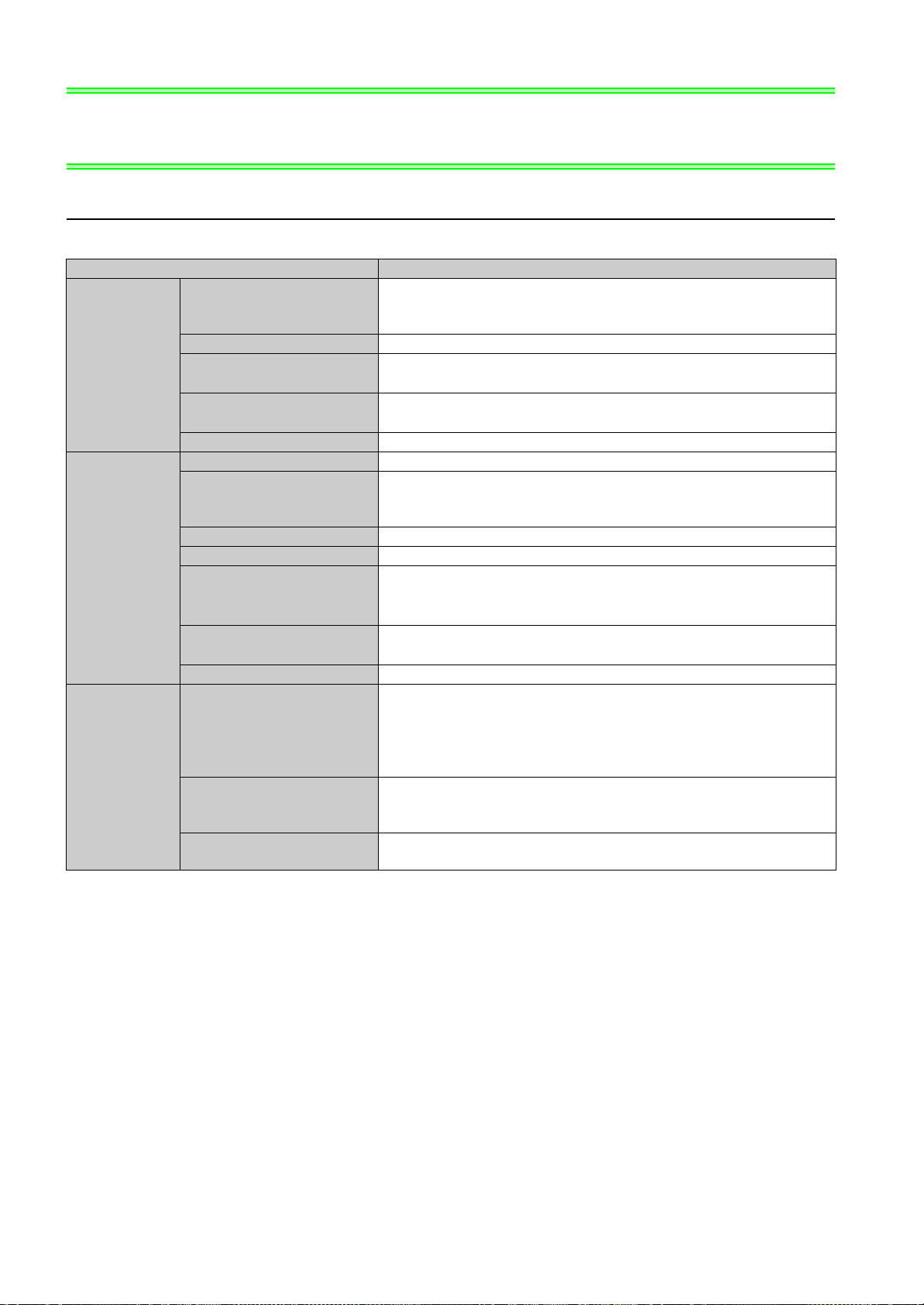

1 OUTLINE OF THE DEDICATED FUNCTIONS

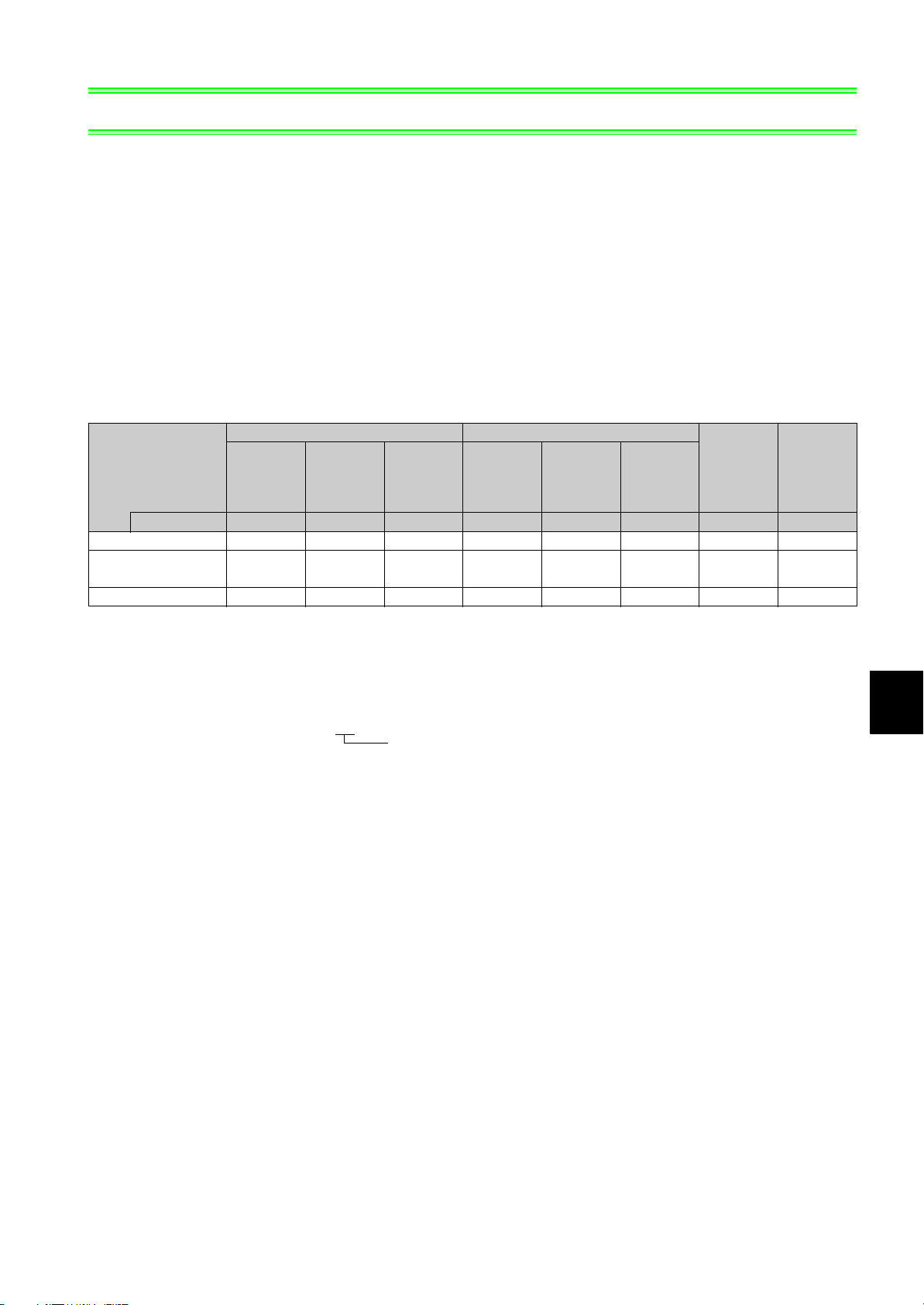

The following dedicated functions for winding and unwinding machine are added to FR-A700 series standard inverter. In this

supplementary instruction manual, specifications of the new functions are included. Refer to the FR-A700 Instruction Manuals

for functions not explained in this supplementary instruction manual.

This product is useful when difference between minimum diameter and maximum diameter is great and when feeding speed

is fast in winding machine with dancer roll.

The inverter torque is controlled by the tension control, inertia compensation and mechanical loss compensation. Thus,

dancer rolls and tension controllers are not required to roll up a sheet of paper when using this product.

This product is also useful for wiredrawing machine and to roll up paper in a printer.

• Dancer control function

• Winding diameter compensation function

• Tension control function

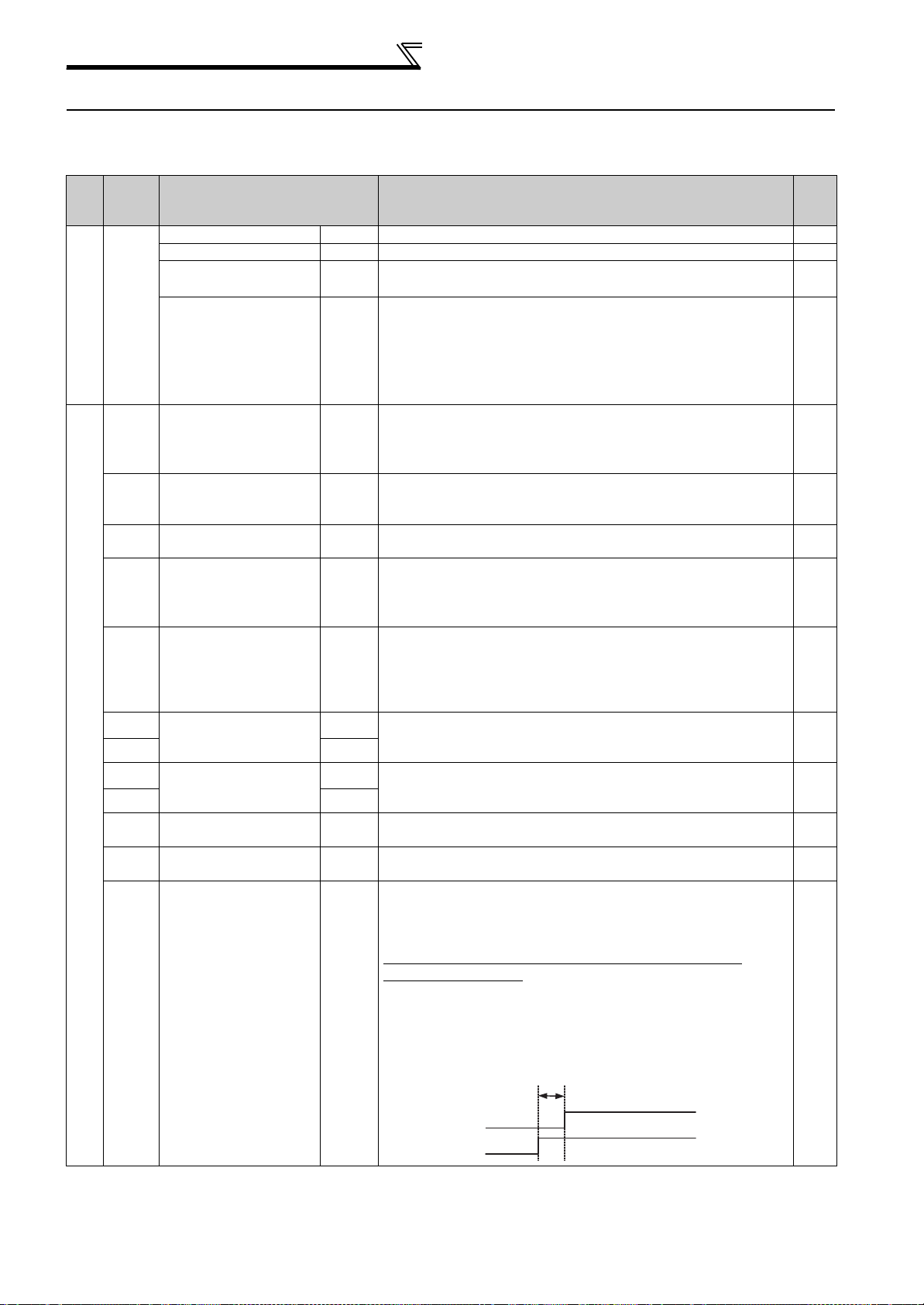

The following table shows valid control methods for each function.

Vector Control Real Sensorless Vector Control

Tensio n

Function

Pr.800 setting 0, 2 1, 2 6 10, 12 11, 12 16 20 20

Dancer control

Winding diameter

compensation function

Tension Control

Speed

Control

Torque

Control

control

(Torque

Control)

Speed

Control

Tor que

Control

Tension

control

(Torque

Control)

Advanced

Magnetic

Flux

Vec to r

Control

: available, : unavailable

V/F

Control

Inverters with dancer control function, winding diameter compensation function and tension control function are indicated with

"-A1" at the end of their model names.

[Example]

FR-A720-1.5K-A1

Inverters with dancer control function, winding

diameter compensation function and tension

control function (for every capacity)

1

PARAMETER LIST

2 PARAMETER LIST

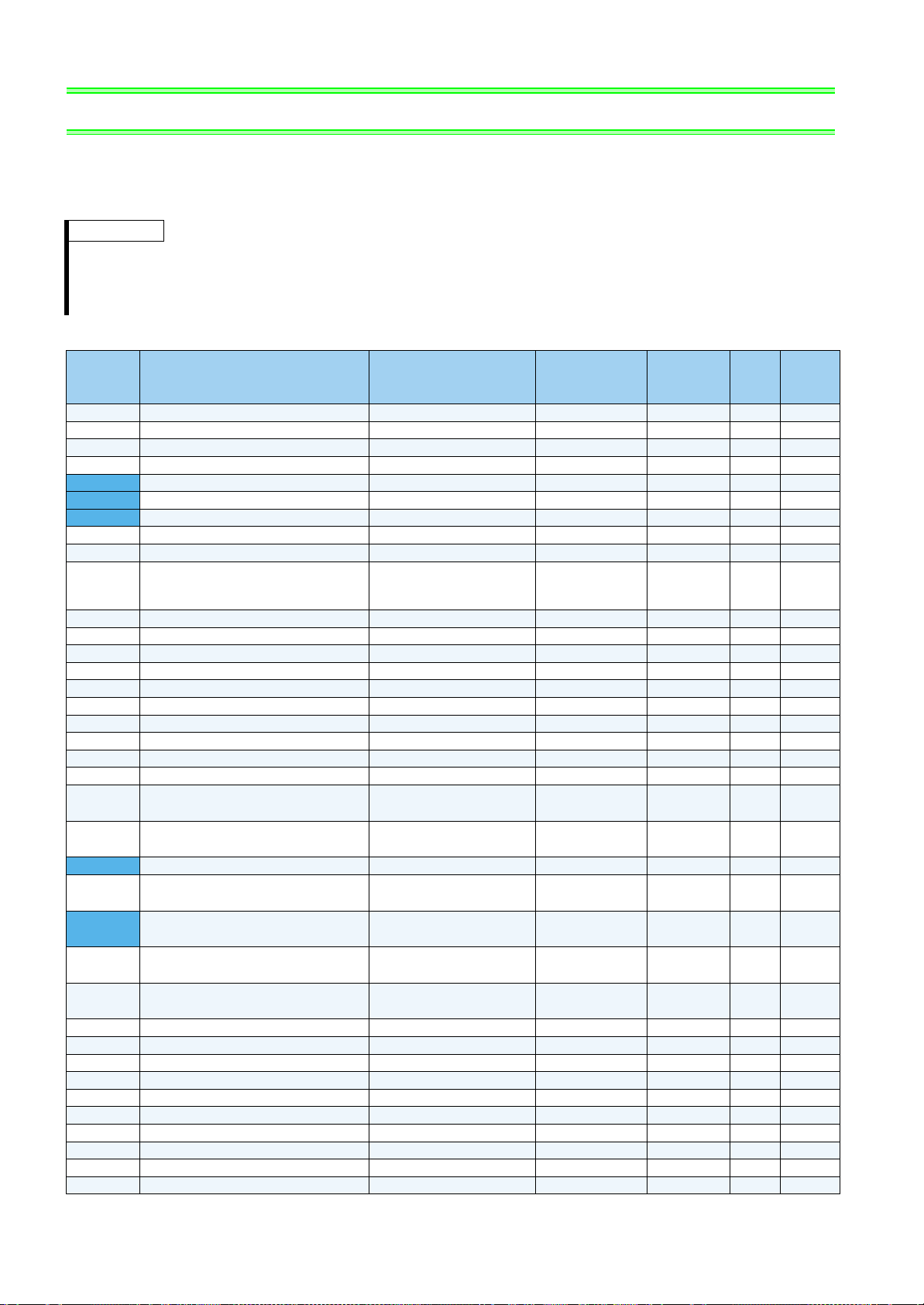

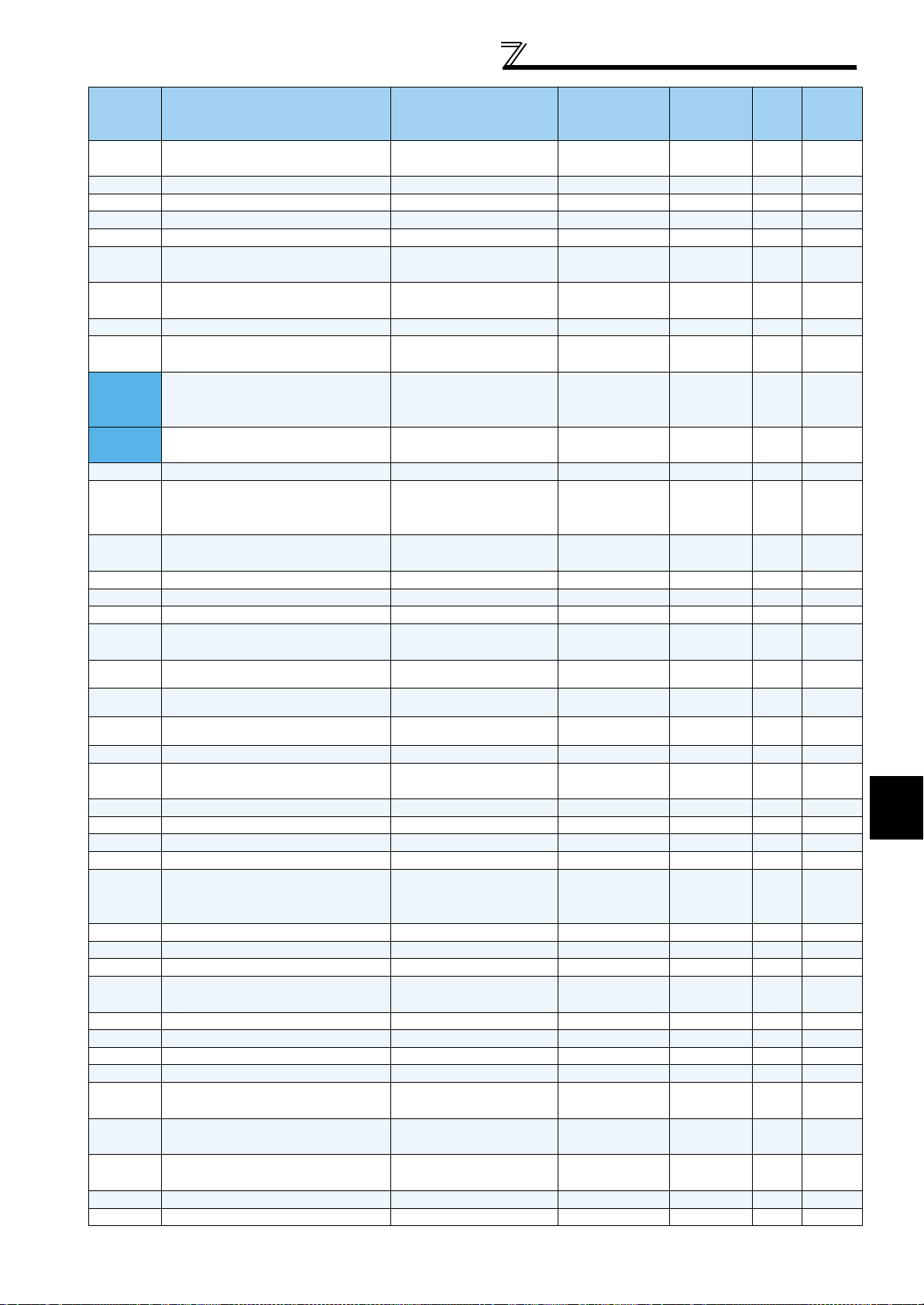

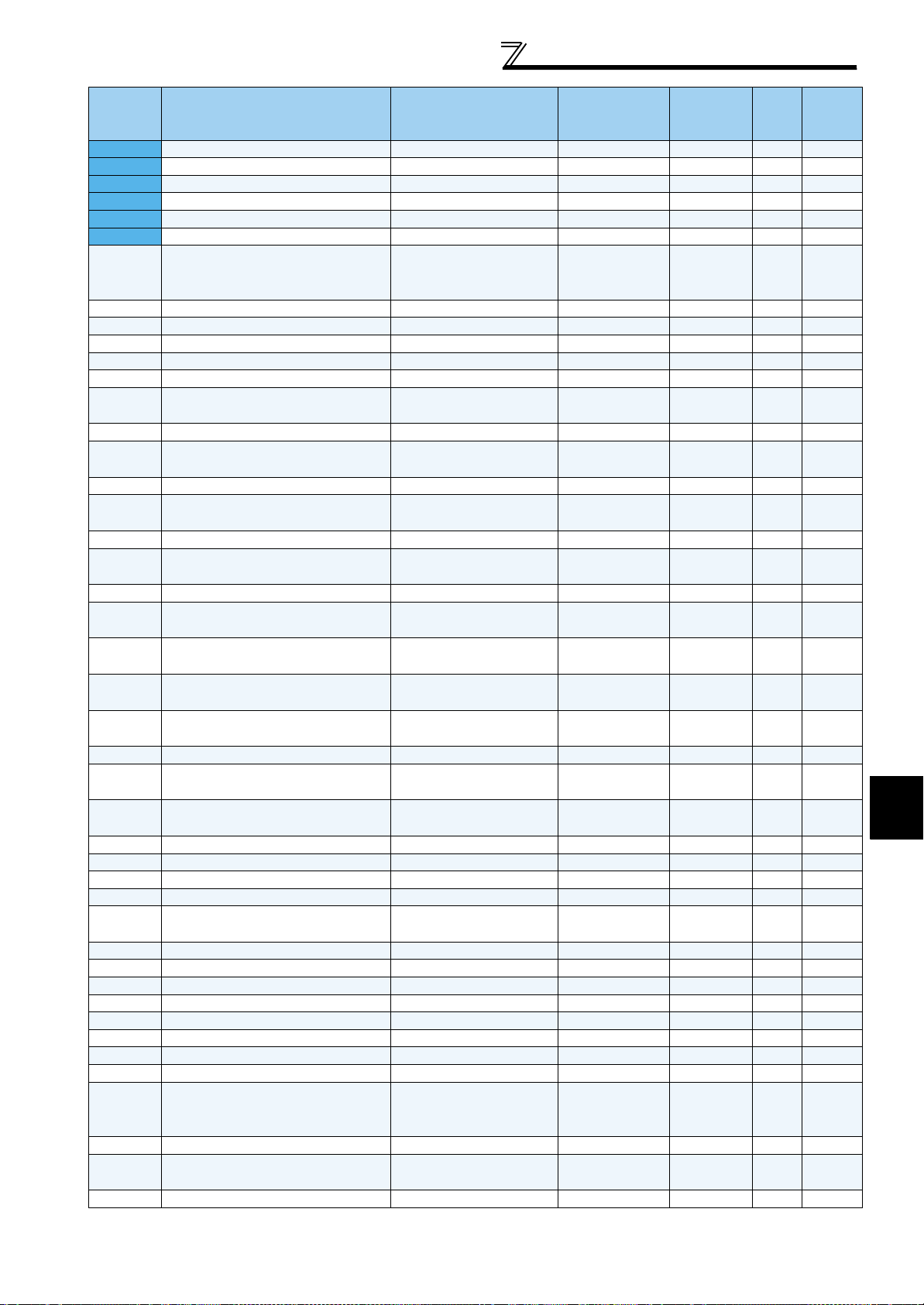

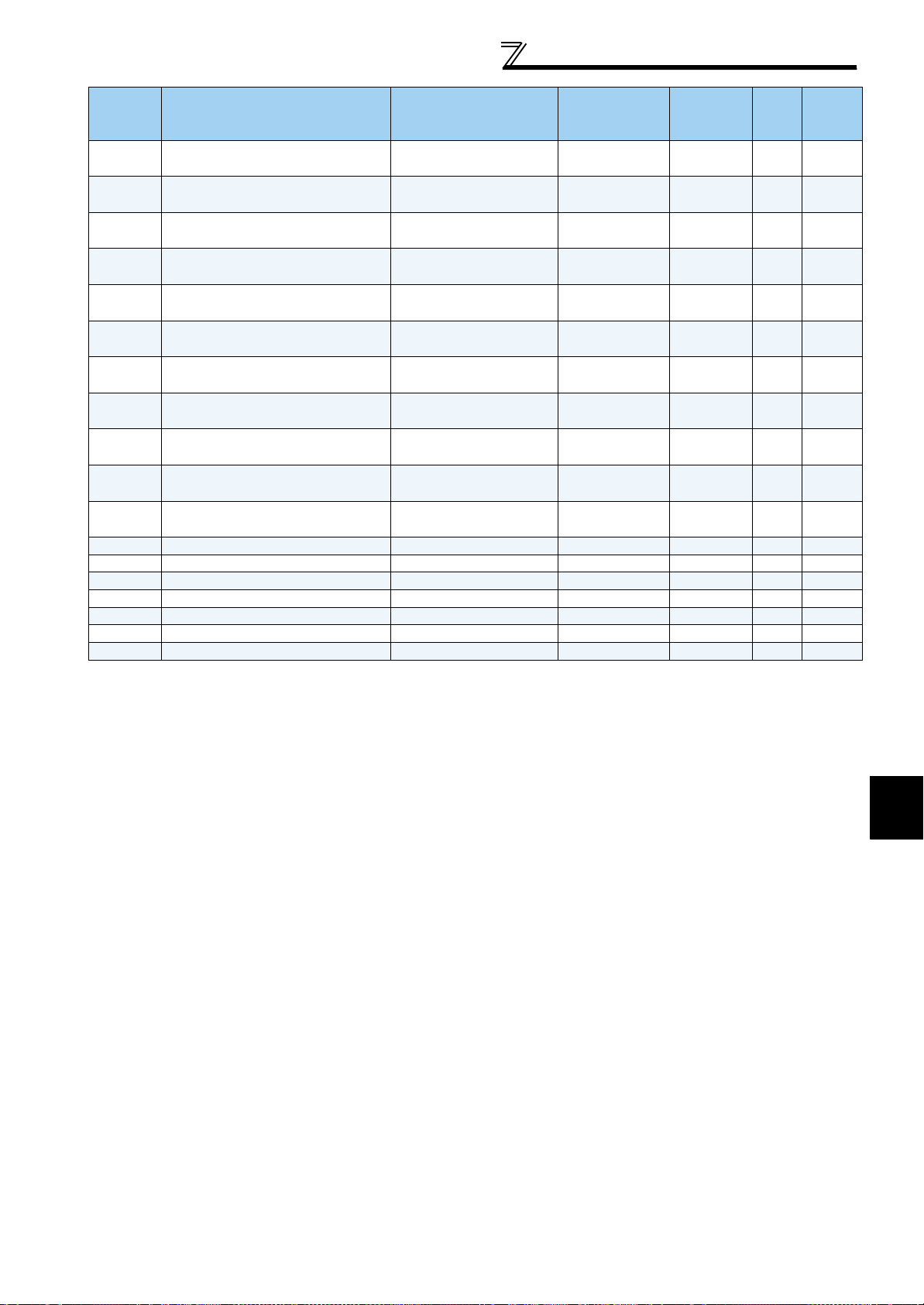

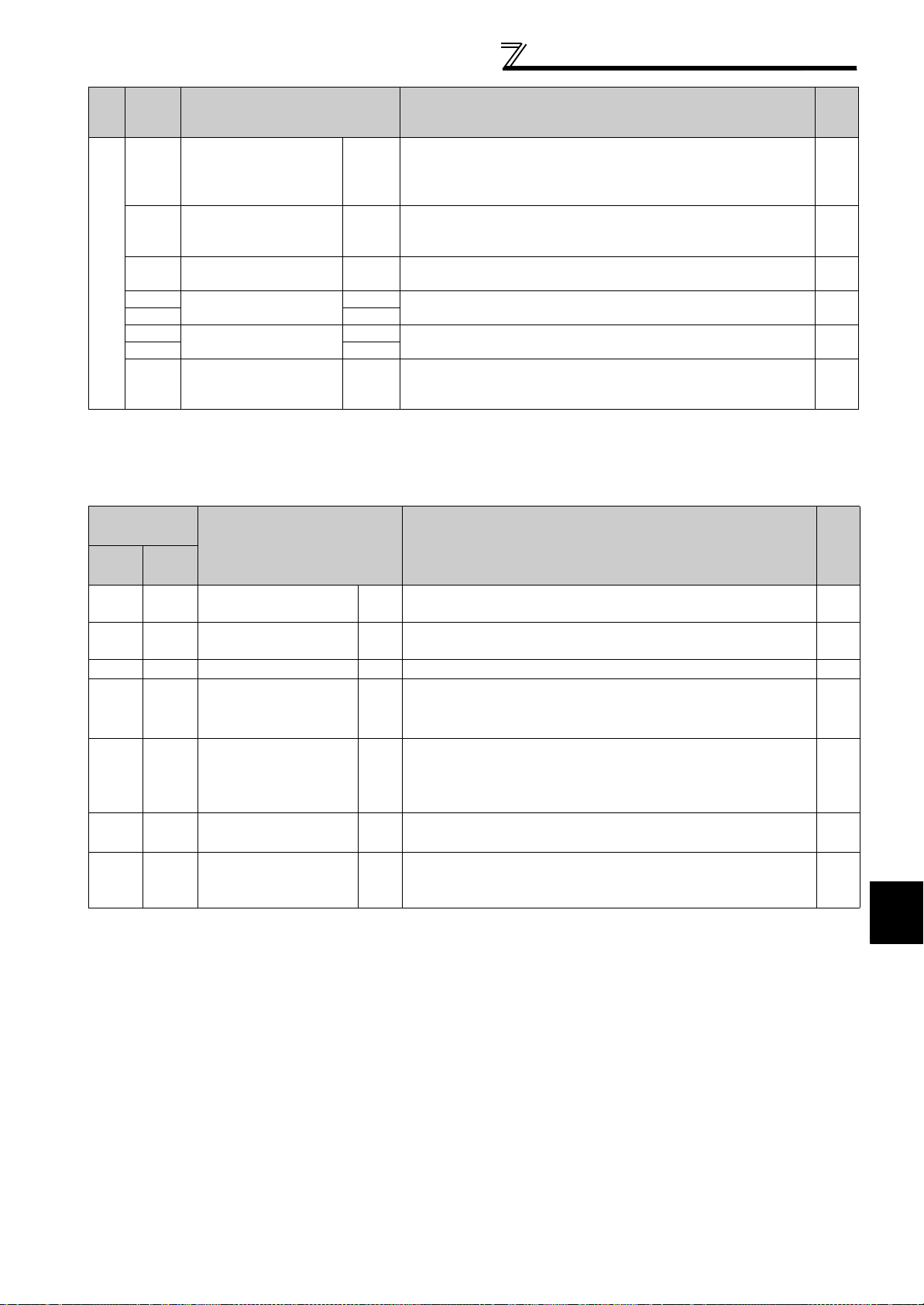

Set the necessary parameters to meet the load and operational specifications. Parameter setting, change and check can be

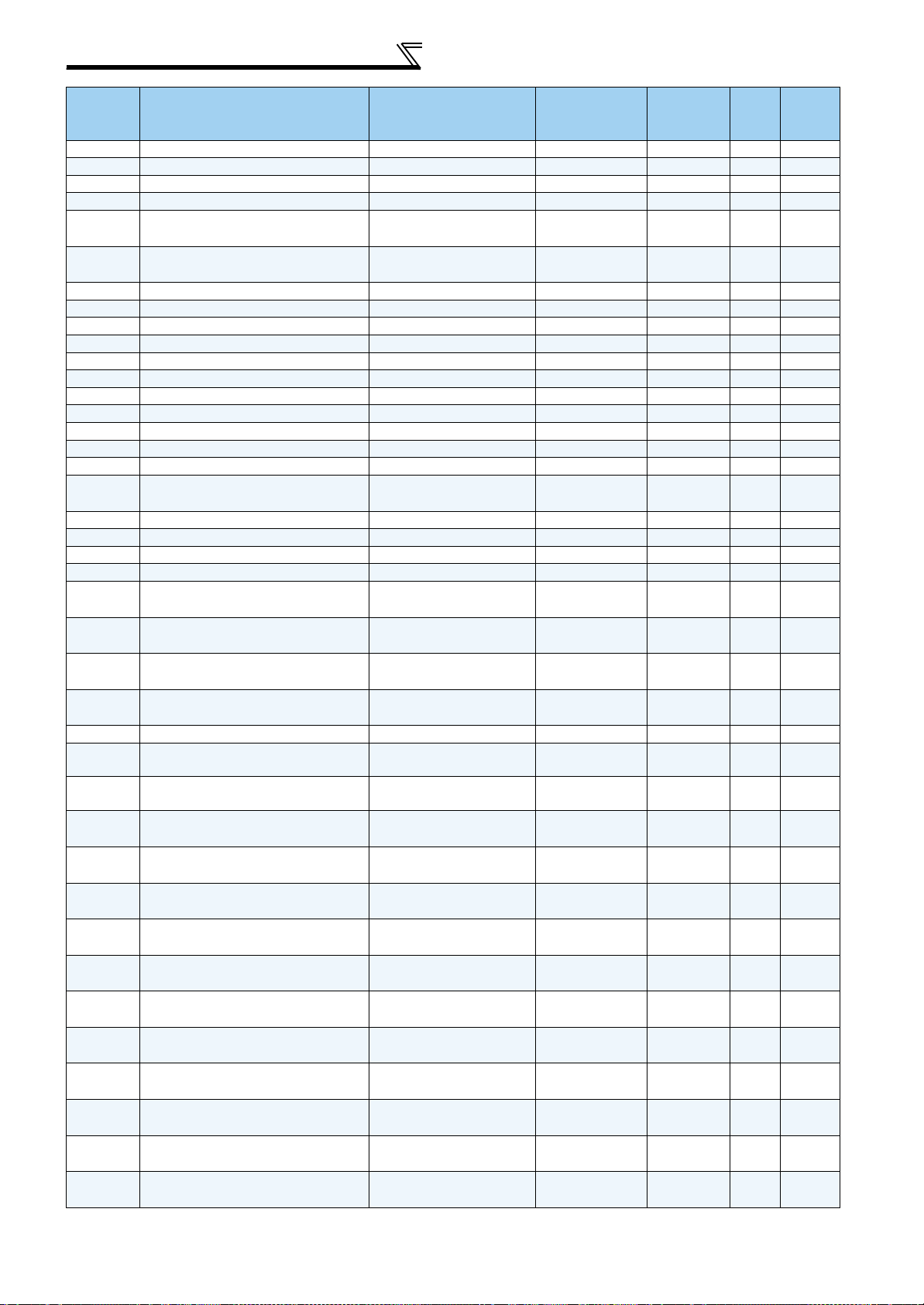

made from the operation panel (FR-DU07). For the parameters not described in this Instruction Manual, refer to the Instruction

Manual of FR-A700 series.

REMARKS

• The shaded parameters in the table allow their settings to be changed during operation even if "0" (initial value) is set in Pr. 77 Parameter

write selection.

• Refer to the page 76 for instruction codes for communication and availability of parameter clear, all clear, and parameter copy of each

parameter.

Parameter

Name Setting Range

Setting

Increments

0 Torque boost 0 to 30% 0.1% 6/4/3/2/1% *1 —

1 Maximum frequency 0 to 120Hz 0.01Hz 120/60Hz *2 —

2 Minimum frequency 0 to 120Hz 0.01Hz 0Hz —

3 Base frequency 0 to 400Hz 0.01Hz 60Hz —

4 Multi-speed setting (high speed) 0 to 400Hz 0.01Hz 60Hz —

5 Multi-speed setting (middle speed) 0 to 400Hz 0.01Hz 30Hz —

6 Multi-speed setting (low speed) 0 to 400Hz 0.01Hz 10Hz —

7 Acceleration time 0 to 3600/360s 0.1/0.01s 5/15s *3 —

8 Deceleration time 0 to 3600/360s 0.1/0.01s 5/15s *3 —

Minimum

9 Electronic thermal O/L relay 0 to 500/0 to 3600A *2 0.01

10 DC injection brake operation frequency 0 to 120Hz, 9999 0.01Hz 3Hz —

11 DC injection brake operation time 0 to 10s, 8888 0.1s 0.5s —

12 DC injection brake operation voltage 0 to 30% 0.1% 4/2/1% *4 —

13 Starting frequency 0 to 60Hz 0.01Hz 0.5Hz —

14 Load pattern selection 0 to 5 1 0 —

15 Jog frequency 0 to 400Hz 0.01Hz 5Hz —

16 Jog acceleration/deceleration time 0 to 3600/360s 0.1/0.01s 0.5s —

17 MRS input selection 0, 2, 4 1 0 —

18 High speed maximum frequency 120 to 400Hz 0.01Hz 120/60Hz *2 —

19 Base frequency voltage 0 to 1000V, 8888, 9999 0.1V 9999 —

20

21

22 Stall prevention operation level 0 to 400% 0.1% 150% —

23

24 to 27

28

29

30 Regenerative function selection 0, 1, 2, 10, 11, 20, 21 1 0 —

31 Frequency jump 1A 0 to 400Hz, 9999 0.01Hz 9999 —

32 Frequency jump 1B 0 to 400Hz, 9999 0.01Hz 9999 —

33 Frequency jump 2A 0 to 400Hz, 9999 0.01Hz 9999 —

34 Frequency jump 2B 0 to 400Hz, 9999 0.01Hz 9999 —

35 Frequency jump 3A 0 to 400Hz, 9999 0.01Hz 9999 —

36 Frequency jump 3B 0 to 400Hz, 9999 0.01Hz 9999 —

37 Speed display 0, 1 to 9998 1 0 —

41 Up-to-frequency sensitivity 0 to 100% 0.1% 10% —

42 Output frequency detection 0 to 400Hz 0.01Hz 6Hz —

Acceleration/deceleration reference

frequency

Acceleration/deceleration time

increments

Stall prevention operation level

compensation factor at double speed

Multi-speed setting (4 speed to 7

speed)

Multi-speed input compensation

selection

Acceleration/deceleration pattern

selection

1 to 400Hz 0.01Hz 60Hz —

0, 1 1 0 —

0 to 200%, 9999 0.1% 9999 —

0 to 400Hz, 9999 0.01Hz 9999 —

0, 1 1 0 —

0 to 5 1 0 —

/0.1

A *2

Initial

Value

Rated

inverter

current

Refer

to

Page

—

Customer

Setting

2

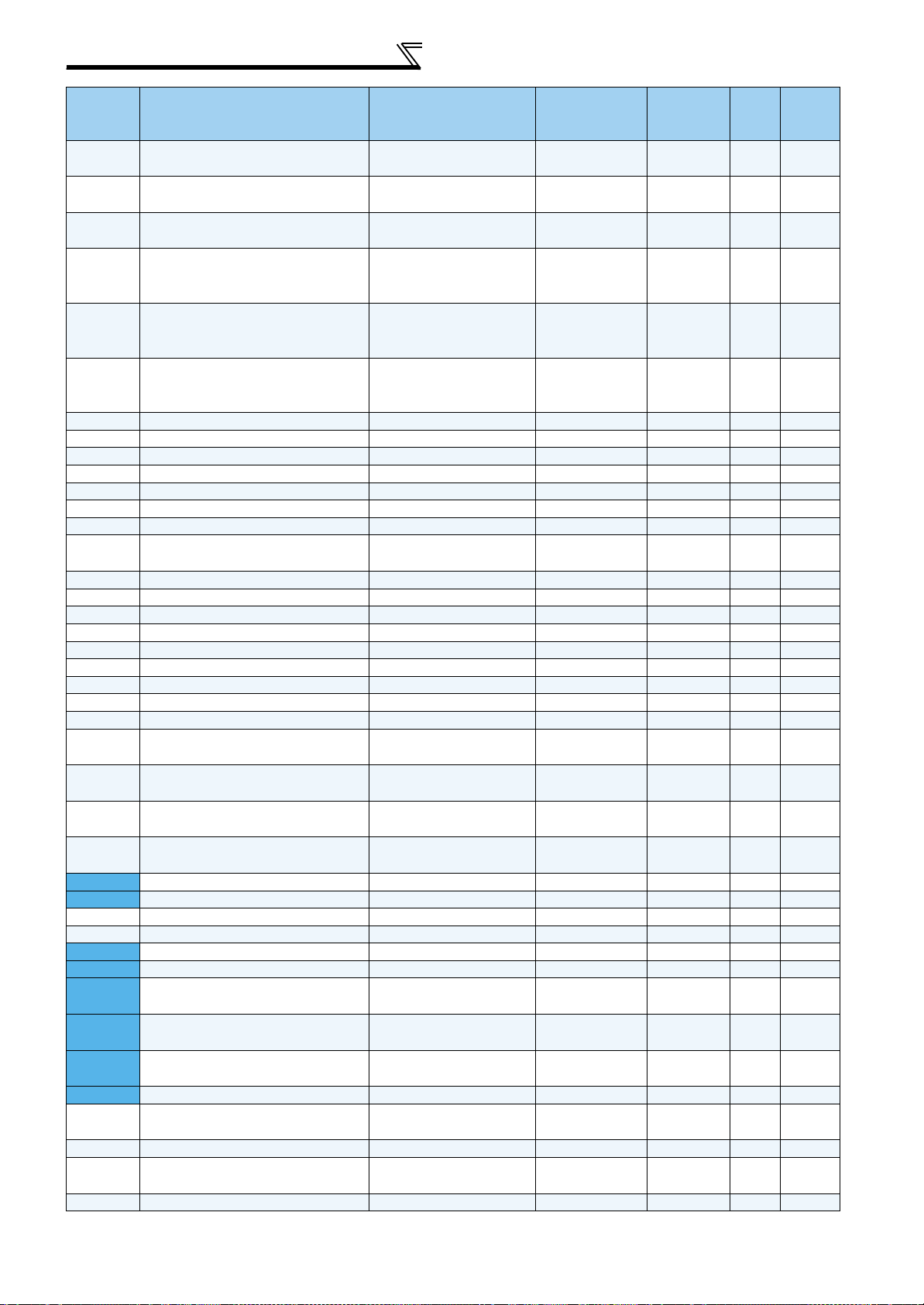

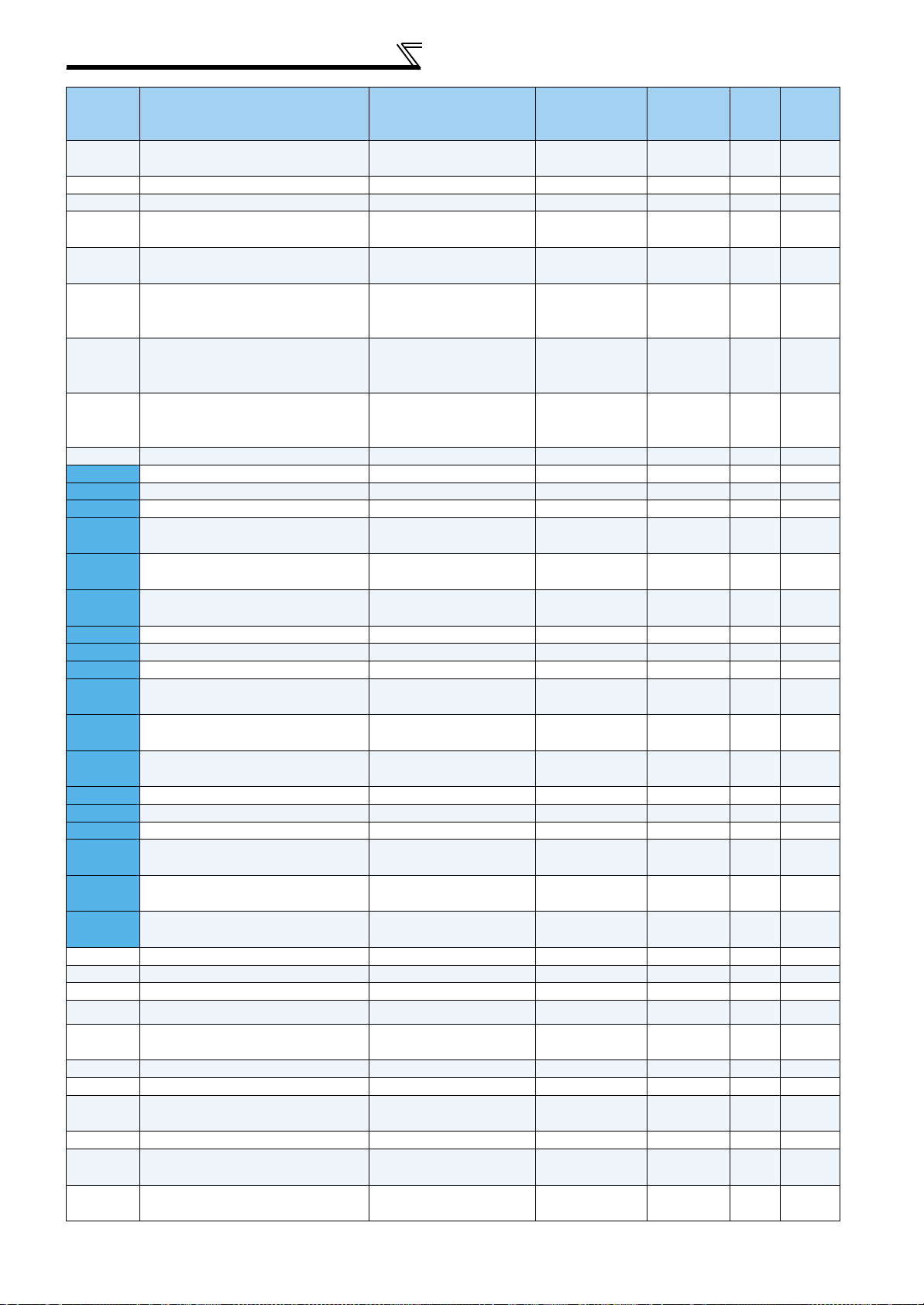

PARAMETER LIST

2

PARAMETER LIST

Minimum

Parameter

Name Setting Range

Setting

Increments

43

44 Second acceleration/deceleration time 0 to 3600/360s 0.1/0.01s 5s —

45 Second deceleration time 0 to 3600/360s, 9999 0.1/0.01s 9999 —

46 Second torque boost 0 to 30%, 9999 0.1% 9999 —

47 Second V/F (base frequency) 0 to 400Hz, 9999 0.01Hz 9999 —

48

49

50 Second output frequency detection 0 to 400Hz 0.01Hz 30Hz —

51 Second electronic thermal O/L relay

52 DU/PU main display data selection

54 FM terminal function selection

55 Frequency monitoring reference 0 to 400Hz 0.01Hz 60Hz —

56 Current monitoring reference 0 to 500/0 to 3600A *2 0.01/0.1A *2

57 Restart coasting time

58 Restart cushion time 0 to 60s 0.1s 1s —

59 Remote function selection 0, 1, 2, 3 1 0 —

60 Energy saving control selection 0, 4 1 0 —

61 Reference current

62 Reference value at acceleration 0 to 220%, 9999 0.1% 9999 —

Output frequency detection for reverse

rotation

Second stall prevention operation

current

Second stall prevention operation

frequency

0 to 400Hz, 9999 0.01Hz 9999 —

0 to 220% 0.1% 150% —

0 to 400Hz, 9999 0.01Hz 0Hz —

0 to 500A, 9999/

0 to 3600A, 9999

0, 5 to 14, 17, 18, 20, 21,

23 to 27, 32 to 35, 39 to 46,

52 to 57, 62 to 65, 100

1 to 3, 5 to 14, 17, 18, 21,

24, 32 to 34, 39 to 44, 46

0, 0.1 to 5s, 9999/

0, 0.1 to 30s, 9999

0 to 500A, 9999/

0 to 3600A, 9999

*2

*2

*2

0.01/0.1A *2 9999 —

1 0 49

1149

0.1s 9999 —

0.01/0.1A *2 9999 —

Initial

Value

Rated

inverter

current

Refer

to

Page

—

Customer

Setting

63 Reference value at deceleration 0 to 220%, 9999 0.1% 9999 —

64 Starting frequency for elevator mode 0 to 10Hz, 9999 0.01Hz 9999 —

65 Retry selection 0 to 5 1 0 —

66

67 Number of retries at fault occurrence 0 to 10, 101 to 110 1 0 —

68 Retry waiting time 0 to 10s 0.1s 1s —

69 Retry count display erase 0 1 0 —

70 Special regenerative brake duty 0 to 30%/0 to 10% *2 0.1% 0% —

71 Applied motor

72 PWM frequency selection 0 to 15/0 to 6, 25 *2 12—

73 Analog input selection 0 to 7, 10 to 17 1 1 —

74 Input filter time constant 0 to 8 1 1 —

75

76 Fault code output selection 0, 1, 2 1 0 —

77 Parameter write selection 0, 1, 2 1 0 —

78 Reverse rotation prevention selection 0, 1, 2 1 0 —

79 Operation mode selection 0, 1, 2, 3, 4, 6, 7 1 0 —

80 Motor capacity

81 Number of motor poles

82 Motor excitation current

83 Rated motor voltage 0 to 1000V 0.1V 200/400V *5 —

84 Rated motor frequency 10 to 120Hz 0.01Hz 60Hz —

Stall prevention operation reduction

starting frequency

Reset selection/disconnected PU

detection/PU stop selection

0 to 400Hz 0.01Hz 60Hz —

0, 1, 3 to 8, 13 to 18, 20, 23,

24, 30, 33, 34, 40, 43, 44,

50, 53, 54

0 to 3, 14 to 17 1 14 —

0.4 to 55kW, 9999/

0 to 3600kW, 9999

2, 4, 6, 8, 10, 12, 14, 16, 18,

20, 9999

0 to 500A, 9999/

0 to 3600A, 9999

*2

*2

1 0 —

0.01/0.1kW *2 9999 —

1 9999 —

0.01/0.1A *2 9999 —

3

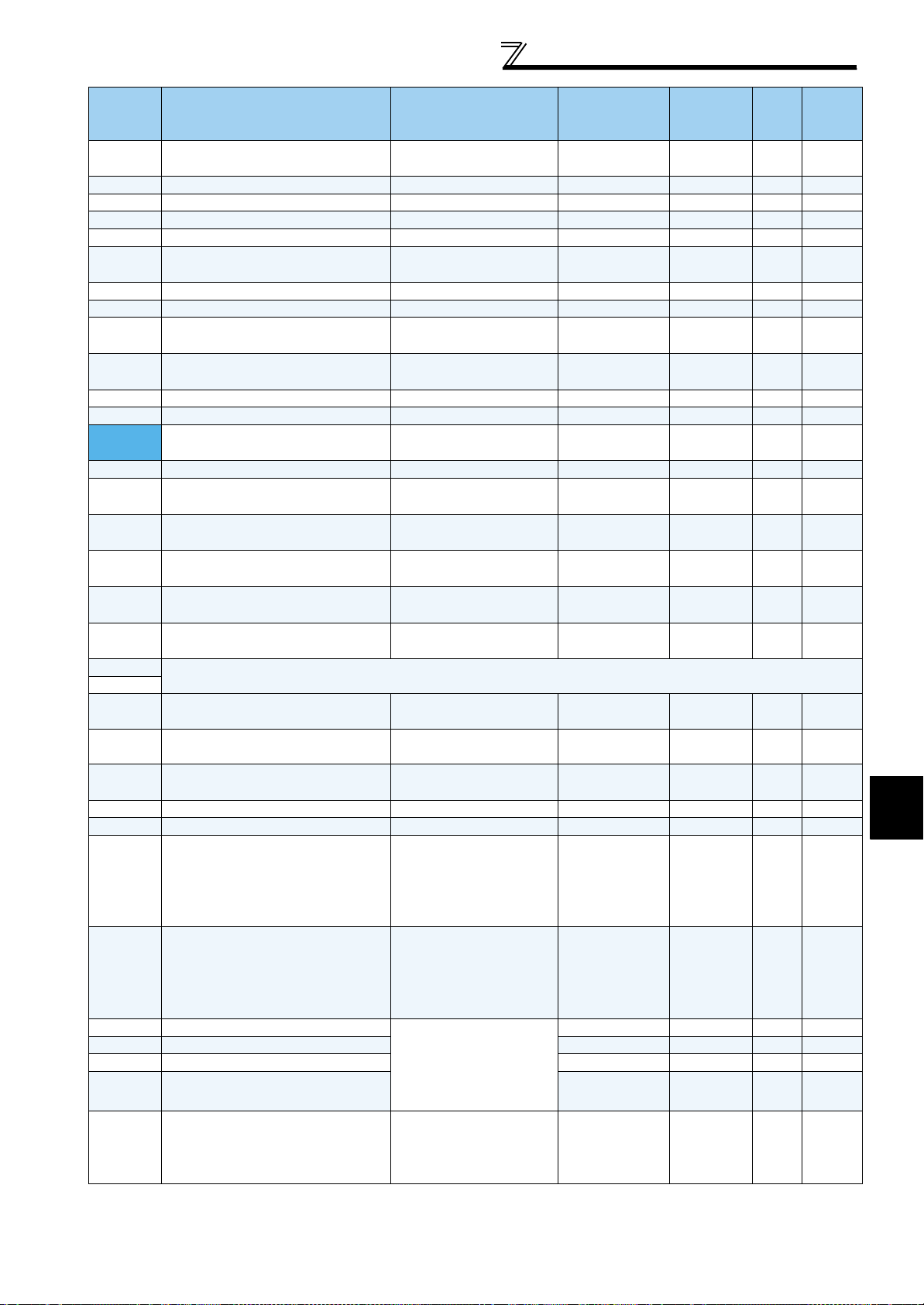

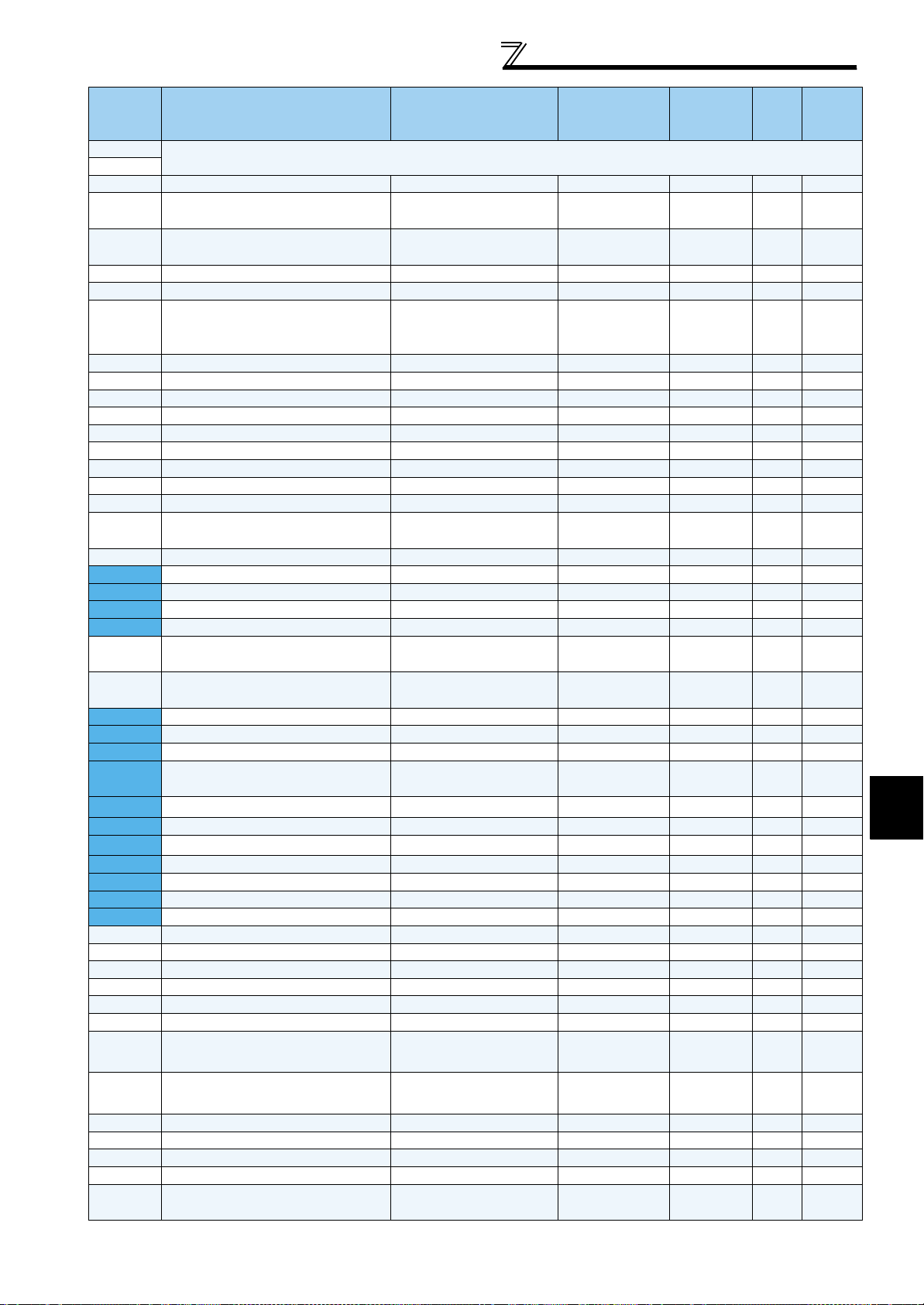

PARAMETER LIST

Parameter

89

90 Motor constant (R1)

91 Motor constant (R2)

92 Motor constant (L1)

93 Motor constant (L2)

94 Motor constant (X)

Speed control gain (advanced magnetic

flux vector)

Name Setting Range

0 to 200%, 9999 0.1% 9999 —

0 to 50, 9999/

0 to 400m, 9999

0 to 50, 9999/

0 to 400m, 9999

0 to 50(0 to 1000mH),

9999/0 to 3600m(0 to

400mH), 9999

0 to 50(0 to 1000mH),

9999/0 to 3600m(0 to

400mH), 9999

0 to 500(0 to 100%),

9999/0 to 100(0 to

100%), 9999

*2

*2

*2

*2

*2

Minimum

Setting

Increments

0.001/0.01m *2 9999 —

0.001/

*2

0.01m

0.001(0.1mH)/

0.01m(0.01mH)

*2

0.001(0.1mH)/

0.01m(0.01mH)

*2

0.01(0.1%)/

0.01(0.01%)

Initial

Value

9999 —

9999 —

9999 —

*2

9999 —

95 Online auto tuning selection 0 to 2 1 0 —

96 Auto tuning setting/status 0, 1, 101 1 0 —

110 Third acceleration/deceleration time 0 to 3600/360s, 9999 0.1/0.01s 9999 —

111 Third deceleration time 0 to 3600/360s, 9999 0.1/0.01s 9999 —

112 Third torque boost 0 to 30%, 9999 0.1% 9999 —

113 Third V/F (base frequency) 0 to 400Hz, 9999 0.01Hz 9999 —

114 Third stall prevention operation current 0 to 220% 0.1% 150% —

115

Third stall prevention operation

frequency

0 to 400Hz 0.01Hz 0 —

116 Third output frequency detection 0 to 400Hz 0.01Hz 60Hz —

117 PU communication station number 0 to 31 1 0 —

118 PU communication speed 48, 96, 192, 384 1 192 —

119 PU communication stop bit length 0, 1, 10, 11 1 1 —

120 PU communication parity check 0, 1, 2 1 2 —

121 Number of PU communication retries 0 to 10, 9999 1 1 —

122 PU communication check time interval 0, 0.1 to 999.8s, 9999 0.1s 9999 —

123 PU communication waiting time setting 0 to 150ms, 9999 1 9999 —

124 PU communication CR/LF selection 0, 1, 2 1 1 —

125

126

127

128 PID action selection

Terminal 2 frequency setting gain

frequency

Terminal 4 frequency setting gain

frequency

PID control automatic switchover

frequency

0 to 400Hz 0.01Hz 60Hz —

0 to 400Hz 0.01Hz 60Hz —

0 to 400Hz, 9999 0.01Hz 9999 —

10, 11, 40, 41, 50, 51, 60,

61

1 40 25

129 PID proportional band 0.1 to 1000%, 9999 0.1% 100% 25

130 PID integral time 0.1 to 3600s, 9999 0.1s 1s 25

131 PID upper limit 400 to 600%, 9999 0.1% 9999 29

132 PID lower limit 400 to 600%, 9999 0.1% 9999 29

133 Target dancer position 400 to 600%, 9999 0.01% 500% 27, 39

134 PID differential time 0.01 to 10.00s, 9999 0.01s 9999 26

135

136

137

PID proportional band for under-set

point value

PID integral time for under-set point

value

PID differential time for under-set point

value

0.1 to 1000%, 9999 0.1% 9999 26

0.1 to 3600s, 9999 0.1s 9999 26

0.01 to 10.00s, 9999 0.01s 9999 26

138 Integral control presence/absence 0 to 3 1 0 30

140

Backlash acceleration stopping

frequency

0 to 400Hz 0.01Hz 1Hz —

141 Backlash acceleration stopping time 0 to 360s 0.1s 0.5s —

142

Backlash deceleration stopping

frequency

0 to 400Hz 0.01Hz 1Hz —

143 Backlash deceleration stopping time 0 to 360s 0.1s 0.5s —

Refer

to

Page

Customer

Setting

4

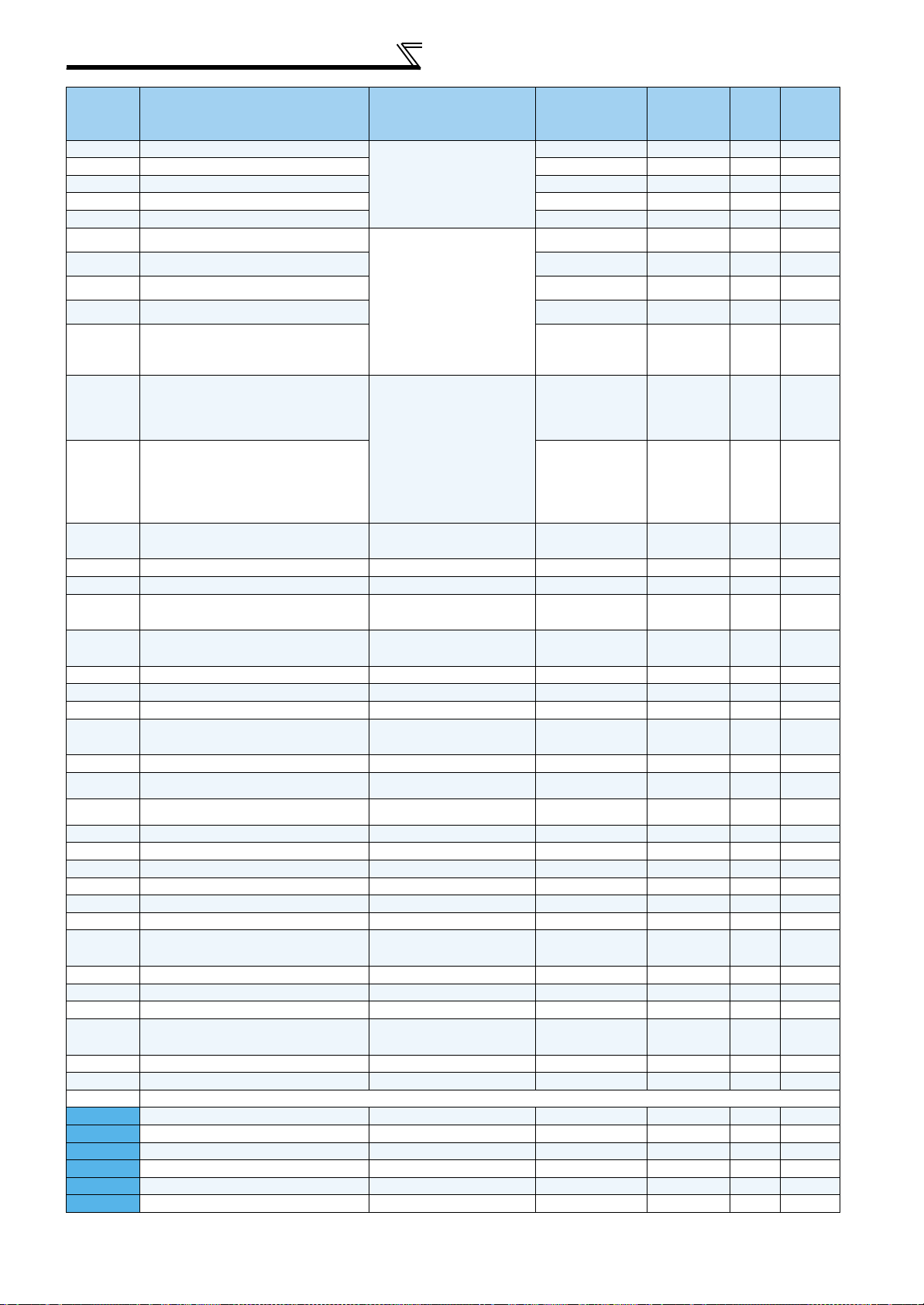

PARAMETER LIST

2

PARAMETER LIST

Minimum

Parameter

Name Setting Range

Setting

Increments

144 Speed setting switchover

145 PU display language selection 0 to 7 1 0 —

148 Stall prevention level at 0V input 0 to 220% 0.1% 150% —

149 Stall prevention level at 10V input 0 to 220% 0.1% 200% —

150 Output current detection level 0 to 220% 0.1% 150% —

151

152 Zero current detection level 0 to 220% 0.1% 5% —

153 Zero current detection time 0 to 1s 0.01s 0.5s —

154

155

156 Stall prevention operation selection 0 to 31, 100, 101 1 0 —

157 OL signal output timer 0 to 25s, 9999 0.1s 0s —

158 AM terminal function selection

160 User group read selection 0, 1, 9999 1 0 —

161

162

165

166

167

168

169

170 Watt-hour meter clear 0, 10, 9999 1 9999 —

Output current detection signal delay

time

Voltage reduction selection during stall

prevention operation

RT signal function validity condition

selection

Frequency setting/key lock operation

selection

Automatic restart after instantaneous

power failure selection

Stall prevention operation level for

restart

Output current detection signal

retention time

Output current detection operation

selection

Parameter for manufacturer setting. Do not set.

0, 2, 4, 6, 8, 10, 102, 104,

106, 108, 110

0 to 10s 0.1s 0s —

0, 1 1 1 —

0, 10 1 0 —

1 to 3, 5 to 14, 17, 18, 21,

24, 32 to 34, 39 to 44, 46

0, 1, 10, 11 1 0 —

0, 1, 2, 10, 11, 12 1 0 —

0 to 220% 0.1% 150% —

0 to 10s, 9999 0.1s 0.1s —

0, 1 1 0 —

14—

1149

Initial

Value

Refer

to

Page

Customer

Setting

171 Operation hour meter clear 0, 9999 1 9999 —

172

173 User group registration 0 to 999, 9999 1 9999 —

174 User group clear 0 to 999, 9999 1 9999 —

178 STF terminal function selection

179 STR terminal function selection

180 RL terminal function selection 0 to 14, 16 to 18, 20,

181 RM terminal function selection 1 1 16

182 RH terminal function selection 1 2 16

183 RT terminal function selection 1 3 16

184 AU terminal function selection

User group registered display/batch

clear

9999, (0 to 16) 1 0 —

0 to 14, 16 to 18, 20,

22 to 28, 30, 32 to 35,

42 to 44, 51 to 60, 62,

64 to 67, 70, 71, 83 to 93,

9999

0 to 14, 16 to 18, 20,

23 to 28, 30, 32 to 35,

42 to 44, 51 to 59, 61, 62,

64 to 67, 70, 71, 83 to 93,

9999

23 to 28, 30, 32 to 35,

42 to 44, 51 to 59, 62,

64 to 67, 70, 71, 83 to 93,

9999

0 to 14, 16 to 18, 20,

23 to 28, 30, 32 to 35,

42 to 44, 51 to 59, 62 to 67,

70, 71, 74, 83 to 93, 9999

16016

1 61 16

1016

1416

5

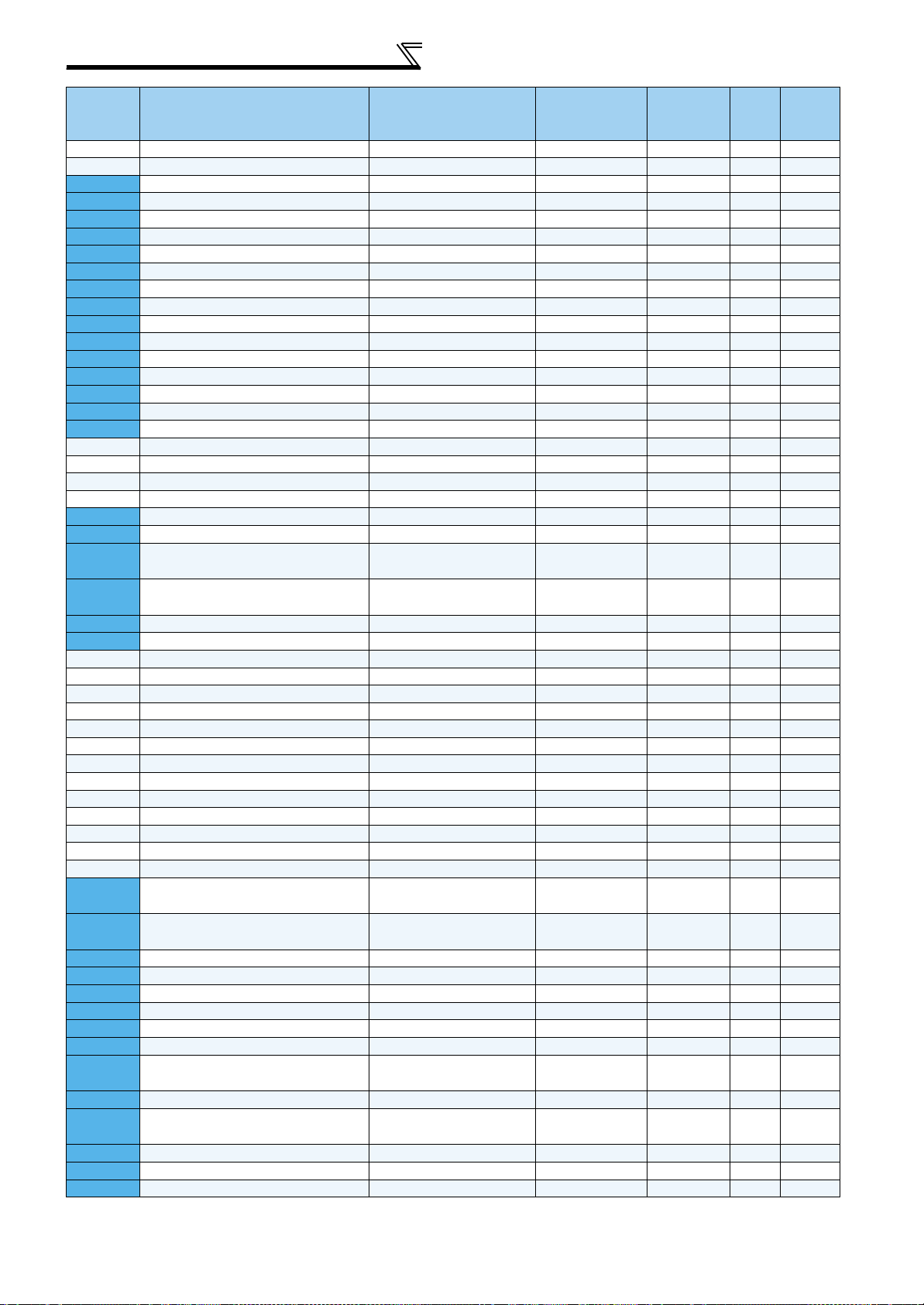

PARAMETER LIST

Minimum

Parameter

Name Setting Range

Setting

Increments

185 JOG terminal function selection

186 CS terminal function selection 1 6 16

187 MRS terminal function selection 1 24 16

188 STOP terminal function selection 1 25 16

189 RES terminal function selection 1 62 16

190 RUN terminal function selection

191 SU terminal function selection 1 1 17

192 IPF terminal function selection 1 2 17

193 OL terminal function selection 1 3 17

194 FU terminal function selection 1 4 17

195 ABC1 terminal function selection

196 ABC2 terminal function selection 1 9999 17

232 to 239

240 Soft-PWM operation selection 0, 1 1 1 —

241 Analog input display unit switchover 0, 1 1 0 —

242

243

244 Cooling fan operation selection 0, 1 1 1 —

245 Rated slip 0 to 50%, 9999 0.01% 9999 —

246 Slip compensation time constant 0.01 to 10s 0.01s 0.5s —

247

251 Output phase loss protection selection 0, 1 1 1 —

252 Override bias 0 to 1000% 0.1% 50% 44

Multi-speed setting (8 speed to 15

speed)

Terminal 1 added compensation

amount (terminal 2)

Terminal 1 added compensation

amount (terminal 4)

Constant-power range slip

compensation selection

0 to 20, 22 to 28, 30,

32 to 35, 42 to 44, 62,

64 to 71, 74, 76, 83, 9999

0 to 8, 10 to 16, 25, 26,

30 to 35, 39, 41 to 47,

50 to 54, 64, 70, 85, 90, 91,

93 to 99, 100 to 108,

110 to 116, 125, 126,

130 to 135, 139, 141 to 147,

150 to 154, 164, 170, 185,

190, 191, 193 to 199, 9999

0 to 8, 10 to 16, 25, 26,

30 to 35, 39, 41 to 47,

50 to 54, 64, 70, 85, 90, 91,

94 to 99, 100 to 108,

110 to 116, 125, 126,

130 to 135, 139, 141 to 147,

150 to 154, 164, 170, 185,

190, 191, 194 to 199, 9999

0 to 400Hz, 9999 0.01Hz 9999 —

0 to 100% 0.1% 100% —

0 to 100% 0.1% 75% —

0, 9999 1 9999 —

1 5 16

1017

1 99 17

Initial

Value

Refer

to

Page

Customer

Setting

253 Override gain 0 to 1000% 0.1% 150% 44

255 Life alarm status display (0 to 15) 1 0 —

256 Inrush current limit circuit life display (0 to 100%) 1% 100% —

257 Control circuit capacitor life display (0 to 100%) 1% 100% —

258 Main circuit capacitor life display (0 to 100%) 1% 100% —

259 Main circuit capacitor life measuring 0, 1 1 0 —

261 Power failure stop selection 0, 1, 2, 11, 12 1 0 —

262

263 Subtraction starting frequency 0 to 120Hz, 9999 0.01Hz 60Hz —

264 Power-failure deceleration time 1 0 to 3600/ 360s 0.1/0.01s 5s —

265 Power-failure deceleration time 2 0 to 3600/ 360s, 9999 0.1/0.01s 9999 —

266

267 Terminal 4 input selection 0, 1, 2 1 0 —

268 Monitor decimal digits selection 0, 1, 9999 1 9999 —

269 Parameter for manufacturer setting. Do not set.

270 Dancer position A 400.1% to 600% 0.1% 600% 30

271 Dancer position B 400% to 599.9% 0.1% 400% 30

272 Dancer position C1 400.1% to 599.9%, 9999 0.1% 9999 30

273 Dancer position C2 400.1% to 599.9%, 9999 0.1% 9999 30

274 PID position gain A 0.1 to 1000%, 9999 0.1% 9999 30

275 PID position gain B 0.1 to 1000%, 9999 0.1% 9999 30

Subtracted frequency at deceleration

start

Power failure deceleration time

switchover frequency

0 to 20Hz 0.01Hz 3Hz —

0 to 400Hz 0.01Hz 60Hz —

6

PARAMETER LIST

2

PARAMETER LIST

Minimum

Parameter

Name Setting Range

Setting

Increments

276 PID position gain C1 0.1 to 1000%, 9999 0.1% 9999 30

277 PID position gain C2 0.1 to 1000%, 9999 0.1% 9999 30

278 PID position gain D 0.1 to 1000%, 9999 0.1% 9999 30

279 Winding/unwinding length detection 0 to 9999 1 1000 42

280 Winding/unwinding length unit 0, 1, 2, 3 1 0 42

281 Stored winding/unwinding length 0 to 9999 1 0 42

Overspeed detection frequency

285

286 Droop gain 0 to 100% 0.1% 0% —

287 Droop filter time constant 0 to 1s 0.01s 0.3s —

288 Droop function activation selection 0, 1, 2, 10, 11 1 0 —

291 Pulse train I/O selection 0, 1, 10, 11, 20, 21, 100 1 0 —

292 Automatic acceleration/deceleration 0, 1, 3, 5, 6, 11 1 0 —

293

294 UV avoidance voltage gain 0 to 200% 0.1% 100% —

299

331 RS-485 communication station number 0 to 31(0 to 247) 1 0 —

332 RS-485 communication speed

333 RS-485 communication stop bit length 0, 1, 10, 11 1 1 —

334

335 RS-485 communication retry count 0 to 10, 9999 1 1 —

336

337

338

339

340 Communication startup mode selection 0, 1, 2, 10, 12 1 0 —

341

342

343 Communication error count — 1 0 —

359 *6 Encoder rotation direction 0, 1 1 1 —

369 *6 Number of encoder pulses 0 to 4096 1 1024 —

374 Overspeed detection level 0 to 400Hz 0.01Hz 140Hz —

376 *6

380 Acceleration S-pattern 1 0 to 50% 1% 0 —

381 Deceleration S-pattern 1 0 to 50% 1% 0 —

382 Acceleration S-pattern 2 0 to 50% 1% 0 —

383 Deceleration S-pattern 2 0 to 50% 1% 0 —

384 Input pulse division scaling factor 0 to 250 1 0 45

385 Frequency for zero input pulse 0 to 400Hz 0.01Hz 0 45

386 Frequency for maximum input pulse 0 to 400Hz 0.01Hz 60Hz 45

428 *6 Command pulse selection 0 to 5 1 0 —

450 Second applied motor

451 Second motor control method selection 10, 11, 12, 20, 9999 1 9999 —

453 Second motor capacity

454 Number of second motor poles 2, 4, 6, 8, 10, 9999 1 9999 —

(Excessive speed deviation detection

frequency)

Acceleration/deceleration separate

selection

Rotation direction detection selection at

restarting

RS-485 communication parity check

selection

RS-485 communication check time

interval

RS-485 communication waiting time

setting

Communication operation command

source

Communication speed command

source

RS-485 communication CR/LF

selection

Communication EEPROM write

selection

Encoder signal loss detection enable/

disable selection

0 to 30Hz, 9999 0.01Hz 9999 —

0 to 2 1 0 —

0, 1, 9999 1 0 —

3, 6, 12, 24, 48, 96, 192,

384

0, 1, 2 1 2 —

0 to 999.8s, 9999 0.1s 0s —

0 to 150ms, 9999 1 9999 —

0, 1 1 0 —

0, 1, 2 1 0 —

0, 1, 2 1 1 —

0, 1 1 0 —

0, 1 1 0 —

0, 1, 3 to 8, 13 to 18, 20,

23, 24, 30, 33, 34, 40, 43,

44, 50, 53, 54, 9999

0.4 to 55kW, 9999/

0 to 3600kW, 9999

*2

1 96 —

1 9999 —

0.01kW/0.1kW *2 9999 —

Initial

Value

Refer

to

Page

Customer

Setting

7

PARAMETER LIST

Parameter

Name Setting Range

455 Second motor excitation current

0 to 500A, 9999/

0 to 3600A, 9999

Minimum

Setting

Increments

*2

0.01/0.1A *2 9999 —

Initial

Value

456 Rated second motor voltage 0 to 1000V 0.1V 200/400V*5 —

457 Rated second motor frequency 10 to 120Hz 0.01Hz 60Hz —

458 Second motor constant (R1)

459 Second motor constant (R2)

460 Second motor constant (L1)

461 Second motor constant (L2)

462 Second motor constant (X)

0 to 50, 9999/

0 to 400m, 9999

*2

0 to 50, 9999/

0 to 400m, 9999

*2

0 to 50(0 to 1000mH),

9999/0 to 3600m(0 to

400mH), 9999

*2

0 to 50(0 to 1000mH),

9999/0 to 3600m(0 to

400mH), 9999

*2

0 to 500(0 to 100%),

9999/0 to 100(0 to 100%),

9999

*2

0.001/0.01m *2 9999 —

0.001/

0.01m

*2

9999 —

0.001(0.1mH)/

9999 —

0.01m(0.01mH)

*2

0.001(0.1mH)/

0.01m(0.01mH)

*2

0.01(0.1%)/

0.01(0.01%)

*2

9999 —

9999 —

463 Second motor auto tuning setting/status 0, 1, 101 1 0 —

464 Second PID proportional band 0.1 to 1000%, 9999 0.1% 9999 29

465 Second PID integral time 0.1 to 3600s, 9999 0.1s 9999 29

466 Second PID differential time 0.01 to 10s, 9999 0.01s 9999 29

467

468

469

Second PID proportional band for

under-set point value

Second PID integral time for under-set

point value

Second PID differential time for under-

set point value

0.1 to 1000%, 9999 0.1% 9999 29

0.1 to 3600s, 9999 0.1s 9999 29

0.01 to 10s, 9999 0.01s 9999 29

470 Third PID proportional band 0.1 to 1000%, 9999 0.1% 9999 29

471 Third PID integral time 0.1 to 3600s, 9999 0.1s 9999 29

472 Third PID differential time 0.01 to 10s, 9999 0.01s 9999 29

473

474

475

Third PID proportional band for under-

set point value

Third PID integral time for under-set

point value

Third PID differential time for under-set

point value

0.1 to 1000%, 9999 0.1% 9999 29

0.1 to 3600s, 9999 0.1s 9999 29

0.01 to 10s, 9999 0.01s 9999 29

476 Fourth PID proportional band 0.1 to 1000%, 9999 0.1% 9999 29

477 Fourth PID integral time 0.1 to 3600s, 9999 0.1s 9999 29

478 Fourth PID differential time 0.01 to 10s, 9999 0.01s 9999 29

479

480

481

Fourth PID proportional band for under-

set point value

Fourth PID integral time for under-set

point value

Fourth PID differential time for under-

set point value

0.1 to 1000%, 9999 0.1% 9999 29

0.1 to 3600s, 9999 0.1s 9999 29

0.01 to 10s, 9999 0.01s 9999 29

495 Remote output selection 0, 1, 10, 11 1 0 —

496 Remote output data 1 0 to 4095 1 0 —

497 Remote output data 2 0 to 4095 1 0 —

503 Maintenance timer 0(1 to 9998) 1 0 —

504

Maintenance timer alarm output set

time

0 to 9998, 9999 1 9999 —

505 Speed setting reference 1 to 120Hz 0.01Hz 60Hz —

516 S-pattern time at a start of acceleration 0.1 to 2.5s 0.1s 0.1s —

517

S-pattern time at a completion of

acceleration

0.1 to 2.5s 0.1s 0.1s —

518 S-pattern time at a start of deceleration 0.1 to 2.5s 0.1s 0.1s —

519

539

S-pattern time at a completion of

deceleration

Modbus-RTU communication check

time interval

0.1 to 2.5s 0.1s 0.1s —

0 to 999.8s, 9999 0.1s 9999 —

Refer

to

Page

Customer

Setting

8

PARAMETER LIST

2

PARAMETER LIST

Minimum

Parameter

Name Setting Range

Setting

Increments

547

548

549 Protocol selection 0, 1 1 0 —

550

551

555 Current average time 0.1 to 1s 0.1s 1s —

556 Data output mask time 0 to 20s 0.1s 0s —

557

563 Energization time carrying-over times (0 to 65535) 1 0 —

564 Operating time carrying-over times (0 to 65535) 1 0 —

569 Second motor speed control gain 0 to 200%, 9999 0.1% 9999 —

571 Holding time at a start 0 to 10s, 9999 0.1s 9999 —

574 Second motor online auto tuning 0, 1 1 0 —

575 Output interruption detection time 0 to 3600s, 9999 0.1s 9999 —

576 Output interruption detection level 0 to 400Hz 0.01Hz 0Hz —

577 Output interruption cancel level 900 to 1100% 0.1% 1000% —

611 Acceleration time at a restart 0 to 3600s, 9999 0.1s 5/15s *2 —

665

684 Tuning data unit switchover 0, 1 1 0 —

702 Dancer position detection level 0 to 100% 0.01% 10% 27

703 Minimum number of input pulse 0 to 100kpps 0.01kpps 0kpps 45

704 Maximum number of input pulse 0 to 100kpps 0.01kpps 100kpps 45

706 Speed compensation gain 0 to 200% 0.1% 0% 31

707

708

709 Integral clamp (positive polarity) 0 to 100%, 9999 0.1% 9999 26

710 Integral clamp (negative polarity) 0 to 100%, 9999 0.1% 9999 26

711 Signal loss detection stationary time 0 to 100s, 9999 0.01s 9999 28

712

713 Initial inertia moment

714 Roll width 0 to 5000mm 1mm 0mm 62

715 Material specific gravity

716 Inertia compensation cushion time 0 to 360s 0.01s 0s 62

717 Tension command cushion time 0 to 360s 0.01s 0s 61

718 Dancer tension setting bias 0 to 200% 0.1% 0% 51

719 Dancer tension setting gain 0 to 200% 0.1% 100% 51

720 Maximum winding diameter 1 1 to 6553mm 1mm 2mm 35

721 Minimum winding diameter 1 1 to 6553mm 1mm 1mm 35

722 Maximum winding diameter 2 1 to 6553mm 1mm 2mm 35

723 Minimum winding diameter 2 1 to 6553mm 1mm 1mm 35

724 Maximum winding diameter 3 1 to 6553mm 1mm 2mm 35

725 Minimum winding diameter 3 1 to 6553mm 1mm 1mm 35

Parameter for manufacturer setting. Do not set.

NET mode operation command source

selection

PU mode operation command source

selection

Current average value monitor signal

output reference current

Regeneration avoidance frequency

gain

Sampling time for winding diameter

calculation

Filter time constant for dancer control

input

Initial winding diameter calculation

dead zone 2

0, 1, 9999 1 9999 —

1, 2, 3 1 2 —

0 to 500/0 to 3600A*2 0.01/0.1A*2

0 to 200% 0.1% 100% —

0.01 to 1s, 9999 0.01s 9999 38

0 to 5s 0.001s 0s 27

0 to 50%, 9999 0.1% 9999 40

0 to 500kg · m

0 to 20g/cm

2

3

0.01kg · m

0.001g/cm

2

3

Initial

Value

Rated

inverter

current

0kg · m

0g/cm

2

3

Refer

to

Page

—

62

62

Customer

Setting

726 Maximum winding diameter 4 1 to 6553mm 1mm 2mm 35

727 Minimum winding diameter 4 1 to 6553mm 1mm 1mm 35

728 Main speed analog gain 2 0 to 400Hz, 9999 0.01Hz 9999 44

729 Main speed analog gain 3 0 to 400Hz, 9999 0.01Hz 9999 44

730 Main speed analog gain 4 0 to 400Hz, 9999 0.01Hz 9999 44

731 Dancer signal input selection 3 to 6 1 5 27

732

Dancer main speed command input

selection

0 to 7 1 0 43

9

PARAMETER LIST

Minimum

Parameter

Name Setting Range

Setting

Increments

733 Taper setting analog input selection 3 to 6, 9999 1 9999 51

734 Dancer tension setting input selection 3 to 6, 9999 1 9999 51

737 Stall torque setting 0 to 200% 0.1% 20% 65

738 Speed limit for stall operation 0 to 60Hz 0.01Hz 1Hz 65

739 Mechanical loss setting frequency bias 400 to 600% 1% 500% 64

740 Mechanical loss setting frequency 1 0 to 400Hz, 9999 0.01Hz 9999 64

741 Mechanical loss 1 400 to 600% 1% 500% 64

742 Mechanical loss setting frequency 2 0 to 400Hz, 9999 0.01Hz 9999 64

743 Mechanical loss 2 400 to 600% 1% 500% 64

744 Mechanical loss setting frequency 3 0 to 400Hz, 9999 0.01Hz 9999 64

745 Mechanical loss 3 400 to 600% 1% 500% 64

746 Mechanical loss setting frequency 4 0 to 400Hz, 9999 0.01Hz 9999 64

747 Mechanical loss 4 400 to 600% 1% 500% 64

748 Mechanical loss setting frequency 5 0 to 400Hz, 9999 0.01Hz 9999 64

749 Mechanical loss 5 400 to 600% 1% 500% 64

750 Target winding diameter 1 to 6553mm 1mm 1mm 48

751 Dancer input offset 400 to 600% 0.01% 500% 16

752 Material thickness d1 0 to 20mm, 9999 0.001mm 9999 35

753 Material thickness d2 0 to 20mm 0.001mm 1mm 35

754 Material thickness d3 0 to 20mm 0.001mm 1mm 35

755 Material thickness d4 0 to 20mm 0.001mm 1mm 35

756 First acceleration time for main speed 0 to 3600s/360s 0.1s/0.01s 15s 46

757 First deceleration time for main speed 0 to 3600s/360s 0.1s/0.01s 15s 46

758

759

760 Third acceleration time for main speed 0 to 3600s/360s 0.1s/0.01s 15s 46, 65

761 Third deceleration time for main speed 0 to 3600s/360s 0.1s/0.01s 15s 46

762 Winding/unwinding selection 0, 1 1 0 34, 64

763 Line speed input selection 0 to 7 1 0 33

764 Pulse reference for line speed input 0.01 to 200 0.01kpps 30kpps 33

765 Voltage reference for line speed input 0.1 to 100% 0.1% 50% 33

766 Line speed reference 1 to 6553.4 0.1 1000 33, 49

767 Line speed unit 0, 1, 2, 3 1 0 33, 49

768 Line speed input filter time constant 0 to 5s 0.001s 0.025s 33

769 Filter treatment waiting time 0 to 100s 0.01s 0s 38

770 Filter time constant 0 to 100s 0.01s 0s 38

771 r-r' limit value (diameter) 0 to 9.998, 9999 0.001mm 1mm 38

772 r-r' limit disable time 0 to 100s 0.01s 0s 38

773 Gear ratio numerator (driver side) 1 to 65534 1 1 34

774 Gear ratio denominator (follower side) 1 to 65534 1 1 34

775

776

777 Speed control proportional gain 1 0 to 1000%, 9999 1% 9999 47

778 Speed control proportional gain 2 0 to 1000%, 9999 1% 9999 47

779 Speed control proportional gain 3 0 to 1000%, 9999 1% 9999 47

780 Speed control proportional gain 4 0 to 1000%, 9999 1% 9999 47

781 Winding diameter storage selection 0, 1 1 0 37

782 Stored winding diameter 1 to 6553 1mm 1mm 37

783

785 Terminal 4 function setting 1, 2, 9999 1 9999 44, 51

786

787 Taper ratio setting 0 to 100%, 9999 0.1% 0% 51, 61

788 Winding diameter at taper start 1 to 6553mm, 9999 1mm 9999 51, 61

789 Dancer tension setting 1 to 100, 9999 0.1 100.0 51

Second acceleration time for main

speed

Second deceleration time for main

speed

Speed control proportion term applied

diameter 1

Speed control proportion term applied

diameter 2

Operation time with stored winding

diameter

Number of averaging for winding

diameter calculation

0 to 3600s/360s 0.1s/0.01s 15s 46

0 to 3600s/360s 0.1s/0.01s 15s 46

1 to 99%, 9999 1% 9999 47

1 to 99%, 9999 1% 9999 47

0 to 100s 0.01s 0s 37

0 to 10 1 4 38

Initial

Value

Refer

to

Page

Customer

Setting

10

PARAMETER LIST

2

PARAMETER LIST

Minimum

Parameter

Name Setting Range

Setting

Increments

790

791

792 Accumulated amount 1 to 5000mm, 8888, 9999 1mm 160mm 39

793 Speed control P gain at a start 0 to 1000% 1% 60% 40

794 Speed control integral time at start 0 to 20s 0.001s 2s 40

795 Integral term limit at a start 0 to 100% 0.1% 2.5% 41

796 PID term limit at a start 0 to 100% 0.1% 2.5% 41

797

798 Speed compensation bias 0 to 200% 0.1% 60% 31

799 Winding diameter monitor reference 1 to 6553mm 1mm 1000mm 49

800 Control method selection 0, 1, 2, 6, 9 to 12, 16, 20 1 20 —

802 *6 Pre-excitation selection 0, 1 1 0 —

803

804 Torque command source selection 0 to 6 1 0 —

805 Torque command value (RAM) 600 to 1400% 1% 1000% —

806

807 Speed limit selection 0, 1, 2 1 0 —

808 Forward rotation speed limit 0 to 120Hz 0.01Hz 60Hz —

809 Reverse rotation speed limit 0 to 120Hz, 9999 0.01Hz 9999 —

810 Torque limit input method selection 0, 1 1 0 —

811 Set resolution switchover 0, 1, 10, 11 1 0 —

812 Torque limit level (regeneration) 0 to 400%, 9999 0.1% 9999 —

813 Torque limit level (3rd quadrant) 0 to 400%, 9999 0.1% 9999 —

814 Torque limit level (4th quadrant) 0 to 400%, 9999 0.1% 9999 —

815 Torque limit level 2 0 to 400%, 9999 0.1% 9999 —

816 Torque limit level during acceleration 0 to 400%, 9999 0.1% 9999 —

817 Torque limit level during deceleration 0 to 400%, 9999 0.1% 9999 —

818 Easy gain tuning response level setting 1 to 15 1 2 —

819 Easy gain tuning selection 0 to 2 1 0 —

820 Speed control P gain 1 0 to 1000% 1% 60% —

821 Speed control integral time 1 0 to 20s 0.001s 0.333s —

822 Speed setting filter 1 0 to 5s, 9999 0.001s 9999 —

823 *6 Speed detection filter 1 0 to 0.1s 0.001s 0.001s —

824 Torque control P gain 1 0 to 200% 1% 100% —

825 Torque control integral time 1 0 to 500ms 0.1ms 5ms —

826 Torque setting filter 1 0 to 5s, 9999 0.001s 9999 —

827 Torque detection filter 1 0 to 0.1s 0.001s 0s —

828 Model speed control gain 0 to 1000% 1% 60% —

830 Speed control P gain 2 0 to 1000%, 9999 1% 9999 —

831 Speed control integral time 2 0 to 20s, 9999 0.001s 9999 —

832 Speed setting filter 2 0 to 5s, 9999 0.001s 9999 —

833 *6 Speed detection filter 2 0 to 0.1s, 9999 0.001s 9999 —

834 Torque control P gain 2 0 to 200%, 9999 1% 9999 —

835 Torque control integral time 2 0 to 500ms, 9999 0.1ms 9999 —

836 Torque setting filter 2 0 to 5s, 9999 0.001s 9999 —

837 Torque detection filter 2 0 to 0.1s, 9999 0.001s 9999 —

840 *6 Torque bias selection 0 to 3, 9999 1 9999 —

841 *6 Torque bias 1 600 to 1400%, 9999 1% 9999 —

842 *6 Torque bias 2 600 to 1400%, 9999 1% 9999 —

843 *6 Torque bias 3 600 to 1400%, 9999 1% 9999 —

844 *6 Torque bias filter 0 to 5s, 9999 0.001s 9999 —

845 *6 Torque bias operation time 0 to 5s, 9999 0.01s 9999 —

846 *6 Torque bias balance compensation 0 to 10V, 9999 0.1V 9999 —

847 *6 Fall-time torque bias terminal 1 bias 0 to 400%, 9999 1% 9999 —

848 *6 Fall-time torque bias terminal 1 gain 0 to 400%, 9999 1% 9999 —

849 Analog input offset adjustment 0 to 200% 0.1% 100% —

Initial winding diameter calculation start

point

Initial winding diameter calculation

dead zone

Rotation speed at winding diameter

calculated value activation

Constant power range torque

characteristic selection

Torque command value

(RAM,EEPROM)

400% to 600% 0.01% 400% 39

0 to 50% 0.1% 1% 40

0 to 400Hz 0.01Hz 3Hz 36, 59

0, 1 1 0 —

600 to 1400% 1% 1000% —

Initial

Value

Refer

to

Page

Customer

Setting

11

PARAMETER LIST

Parameter

Name Setting Range

Minimum

Setting

Increments

Initial

Value

850 Brake operation selection 0, 1 1 0 —

853 *6 Speed deviation time 0 to 100s 0.1s 1s —

854 Excitation ratio 0 to 100% 1% 100% —

858 Terminal 4 function assignment 0, 1, 4, 9999 1 0 —

859 Torque current

860 Second motor torque current

0 to 500A, 9999/

0 to 3600A, 9999

0 to 500A, 9999/

0 to 3600A, 9999

*2

*2

0.01/0.1A*2 9999 —

0.01/0.1A*2 9999 —

862 Notch filter time constant 0 to 60 1 0 —

863 Notch filter depth 0 to 3 1 0 —

864 Torque detection 0 to 400% 0.1% 150% —

865 Low speed detection 0 to 400Hz 0.01Hz 1.5Hz —

866 Torque monitoring reference 0 to 400% 0.1% 150% —

867 AM output filter 0 to 5s 0.01s 0.01s —

868 Terminal 1 function assignment 0 to 6, 9999 1 0 —

872 Input phase loss protection selection 0, 1 1 0 —

873 *6 Speed limit 0 to 120Hz 0.01Hz 20Hz —

874 OLT level setting 0 to 200% 0.1% 150% —

875 Fault definition 0, 1 1 0 —

877

Speed feed forward control/model

adaptive speed control selection

0, 1, 2 1 0 —

878 Speed feed forward filter 0 to 1s 0.01s 0s —

879 Speed feed forward torque limit 0 to 400% 0.1% 150% —

880 Load inertia ratio 0 to 200times 0.1times 7times —

881 Speed feed forward gain 0 to 1000% 1% 0% —

882

883

884

885

Regeneration avoidance operation

selection

Regeneration avoidance operation

level

Regeneration avoidance at

deceleration detection sensitivity

Regeneration avoidance compensation

frequency limit value

0 to 3 1 0 53

300 to 800V 0.1V 380/760V *2 —

0 to 5 1 0 —

0 to 10Hz, 9999 0.01Hz 6Hz —

886 Regeneration avoidance voltage gain 0 to 200% 0.1% 100% —

888 Free parameter 1 0 to 9999 1 9999 —

Refer

to

Page

Customer

Setting

889 Free parameter 2 0 to 9999 1 9999 —

C0

(900)

C1

(901)

C2

(902)

C3

(902)

125

(903)

C4

(903)

C5

(904)

C6

(904)

126

(905)

C7

(905)

C12

(917)

FM terminal calibration — — — —

*7

AM terminal calibration — — — —

*7

Terminal 2 frequency setting bias

*7

frequency

Terminal 2 frequency setting bias 0 to 300% 0.1% 0% —

*7

Terminal 2 frequency setting gain

*7

frequency

Terminal 2 frequency setting gain 0 to 300% 0.1% 100% —

*7

Terminal 4 frequency setting bias

*7

frequency

Terminal 4 frequency setting bias 0 to 300% 0.1% 20% —

*7

Terminal 4 frequency setting gain

*7

frequency

Terminal 4 frequency setting gain 0 to 300% 0.1% 100% —

*7

Terminal 1 bias frequency (speed) 0 to 400Hz 0.01Hz 0Hz —

*7

0 to 400Hz 0.01Hz 0Hz —

0 to 400Hz 0.01Hz 60Hz —

0 to 400Hz 0.01Hz 0Hz —

0 to 400Hz 0.01Hz 60Hz —

12

PARAMETER LIST

2

PARAMETER LIST

Parameter

C13

*7

(917)

C14

(918)

*7

C15

*7

(918)

C16

*7

(919)

C17

*7

(919)

C18

*7

(920)

C19

*7

(920)

C38

*7

(932)

C39

*7

(932)

C40

*7

(933)

C41

*7

(933)

Minimum

Name Setting Range

Setting

Increments

Terminal 1 bias (speed) 0 to 300% 0.1% 0% —

Terminal 1 gain frequency (speed) 0 to 400Hz 0.01Hz 60Hz —

Terminal 1 gain (speed) 0 to 300% 0.1% 100% —

Terminal 1 bias command (torque/

magnetic flux)

Terminal 1 bias (torque/magnetic flux) 0 to 300% 0.1% 0% —

Terminal 1 gain command (torque/

magnetic flux)

Terminal 1 gain (torque/magnetic flux) 0 to 300% 0.1% 100% —

Terminal 4 bias command (torque/

magnetic flux)

Terminal 4 bias (torque/magnetic flux) 0 to 300% 0.1% 20% —

Terminal 4 gain command (torque/

magnetic flux)

Terminal 4 gain (torque/magnetic flux) 0 to 300% 0.1% 100% —

0 to 400% 0.1% 0% —

0 to 400% 0.1% 150% —

0 to 400% 0.1% 0% —

0 to 400% 0.1% 150% —

Initial

Value

989 Parameter copy alarm release 10/100 1 10/100 *2 —

990 PU buzzer control 0, 1 1 1 —

991 PU contrast adjustment 0 to 63 1 58 —

Pr.CL Parameter clear 0, 1 1 0 —

ALLC All parameter clear 0, 1 1 0 —

Er.CL Faults history clear 0, 1 1 0 —

PCPY Parameter copy 0 to 3 1 0 —

*1 Differ according to capacities. 6%: 0.4K, 0.75K, 4%: 1.5K to 3.7K, 3%: 5.5K, 7.5K, 2%: 11K to 55K, 1%: 75K or higher

*2 Differ according to capacities. (55K or lower/75K or higher)

*3 Differ according to capacities. (7.5K or lower/11K or higher)

*4 Differ according to capacities. 4% for 7.5K or higher, 2% for 11K to 55K, 1% for 75K or higher

*5 Differs according to the voltage class. (200V class/400V class)

*6 Setting can be made only when the FR-A7AP/FR-A7AL is mounted.

*7 The parameter number in parentheses is the one for use with the parameter unit (FR-PU04/FR-PU07).

Refer

to

Page

Customer

Setting

13

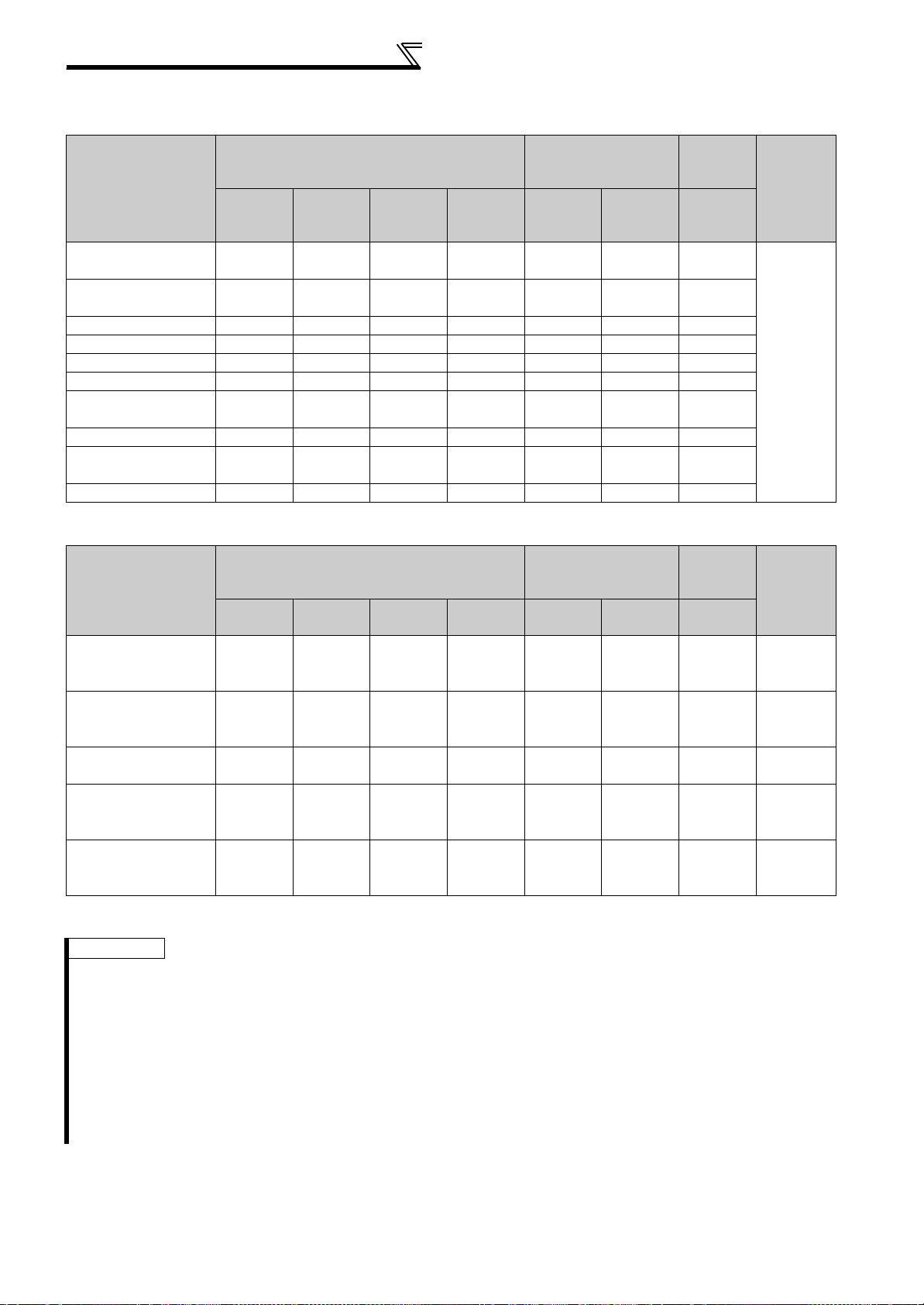

Dedicated specification list

3 DANCER CONTROL/WINDING DIAMETER

COMPENSATION

3.1 Dedicated specification list

Item Description

PID control, PI control, P control, and PD control can be selected.

Gain switchover by dancer position is available. Gain switchover by external

terminal input is available.

Set a point with parameter.

Analog voltage 10V (terminal 1)

Available. Three patterns are selectable with external contact signal.

Calculation method by line speed detection and rotation speed of motor, and

calculation method by material thickness and rotation number of motor are

selectable.

Pulse train input (A/B phase, single phase) and analog input are selectable.

Available

Available. Four patterns are selectable with external signal.

Available. Straight movement (with three turns) against the roll diameter can be

performed.

Dancer/tension control selection, winding diameter compensation selection, PID

gain switchover, PID integral term reset (P control selection), speed

compensation gain selection, main speed acceleration/deceleration time

selection, winding diameter selection, winding diameter storage clear, winding/

unwinding selection.

Upper limit signal, lower limit signal, dancer roll position signal, signal loss

detection, initial winding diameter calculation completion, target winding diameter

achieved, winding/unwinding completion.

Set point, measured value, deviation, main speed, winding diameter, line speed,

compensation speed, winding length.

Dancer control

Winding

diameter

compensation

Common

Control method

Dancer roll position setting

Dancer roll position detection

signal

Main speed acceleration/

deceleration function

Additional function Material break detection

Constant line speed control Available

Winding diameter calculator

Line speed detection

Gear ratio setting

Maximum winding diameter/

minimum winding diameter

setting

Speed control proportional

gain compensation

Winding diameter storage Available

Dedicated input signal

Dedicated output signal

Dedicated monitor

14

3

DANCER CONTROL/WINDING DIAMETER COMPENSATION

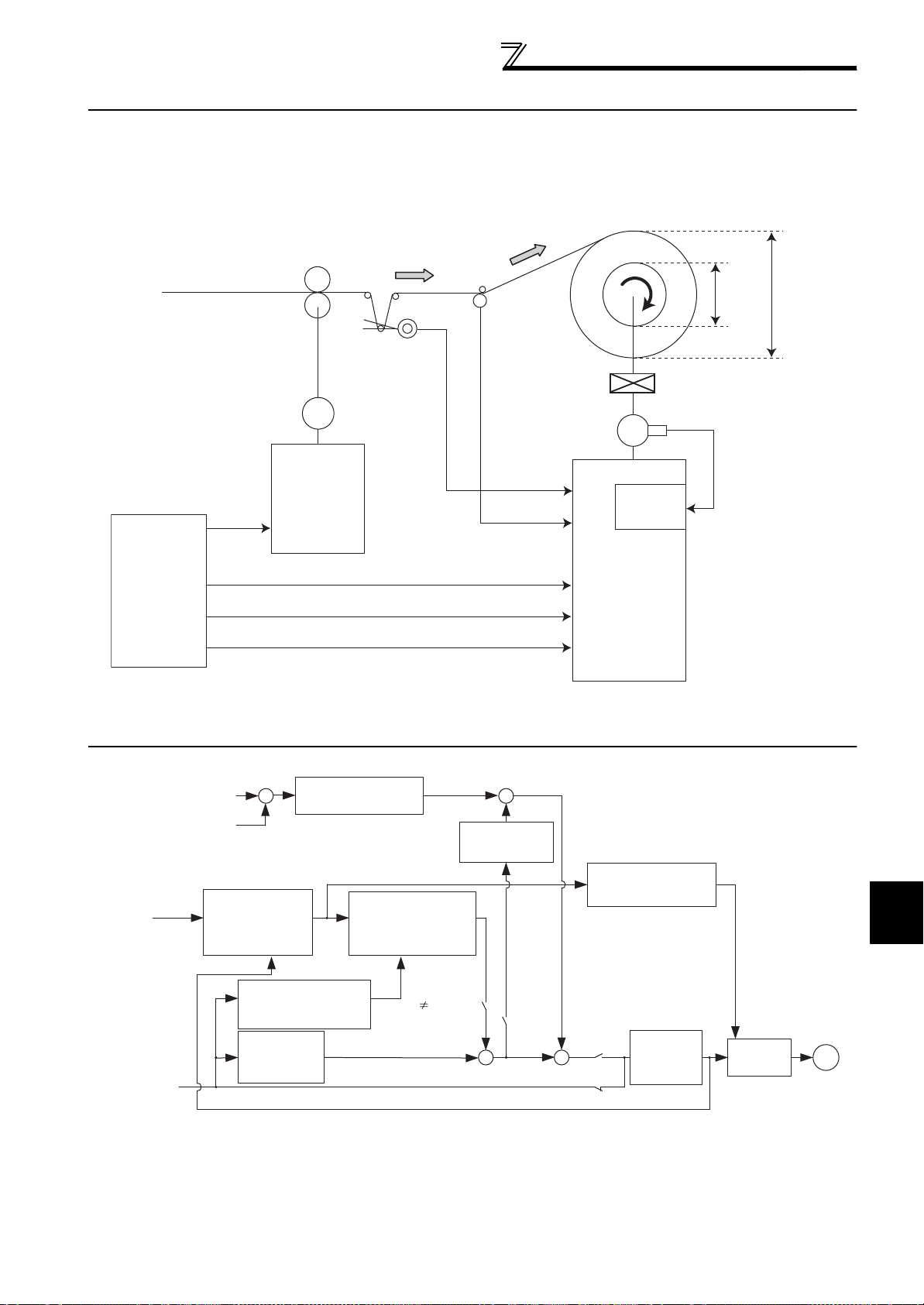

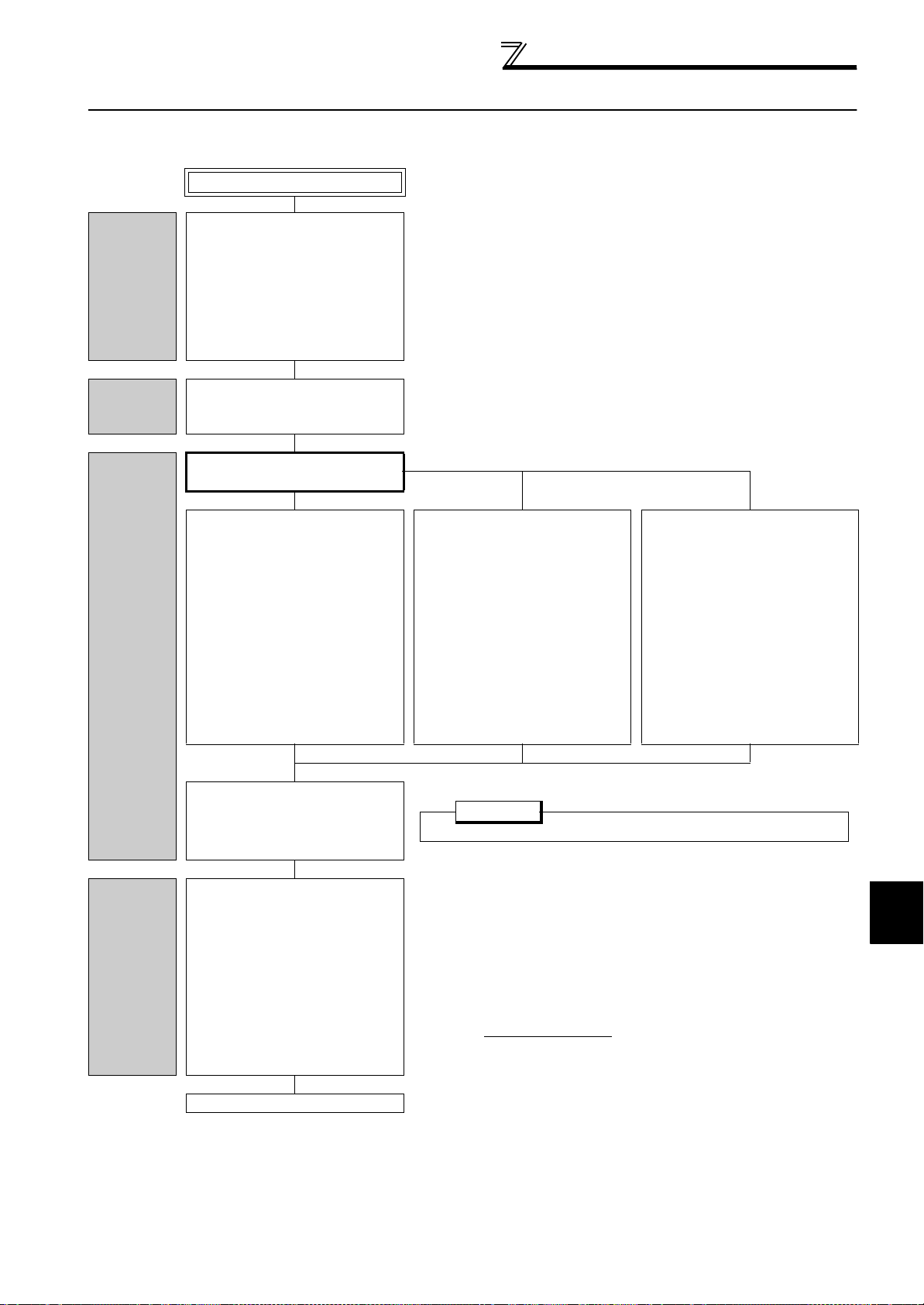

3.2 System configuration example

Vector Control

Dancer roll

(no-contact

potentiometer)

Dancer roll

position

(-10 to 10V)

Winding

IM

FR-A700

Encoder

IM

FR-A7AP

1

4

RL (X83)

Line speed *

Min.

diameter

Max. diameter

FR-A700-A1

2

Programmable

controller

Main speed setting

Line speed

STF/STR

Start signal

Dancer control selection (X83)

2

Feeder

Reduction gear

Line speed

detector

* Input line speed using line speed detector.

• Pr. 180 = "83"

• Pr. 762 = "0"

• Pr. 763 = "4"

• Pr. 267 = "1" or "2"

• Voltage/current input selection switch 1 = OFF

Winding diameter

calculation

X83-ON

X35

X83-OFF

Pr. 771 "9999"

Main speed

acceleration/

deceleration

Target line speed

calculation

Pr. 756, Pr. 757

PID calculation

Pr. 129, Pr. 130, Pr. 134

Winding diameter

Speed limit

+

+

+

+

X

IM

Line speed

Speed setting

Dancer roll position detection

Dancer roll set point

Pr. 133

-

+

Acceleration

/deceleration

processing

Pr. 7, Pr. 8

Speed

control

Speed control proportional

gain compensation

Main speed compensation

frequency calculation

based on winding diameter

Pr. 777 to Pr. 780

Speed

compensation gain

Pr. 706, Pr. 798

Pr. 773, Pr. 774

Pr. 720, Pr. 721,

Pr. 773, Pr. 774

Pr. 720, Pr. 721,

Pr. 773, Pr. 774

System configuration example

3.3 Control block diagram

15

Dedicated I/O signal

STF

X83

20ms or more

3.4 Dedicated I/O signal

3.4.1 Input signal list

Use contact input signals by assigning them to Pr. 178 to Pr. 189 (Input terminal function selection).

Pr. 178 to

Pr. 189

Typ e

setting

Dancer roll target position

Dancer roll position detection

Main speed setting

—

Analog/Pulse

Line speed detection

PID integral term reset

30

input

PID differential term

32

reset input

Offset displacement

33

storage

Integral term activation

34

signal

Speed compensation

35

gain

selection

Acceleration/

51

deceleration time

52 X52

selection

Minimum/maximum

53

winding diameter

54 X54

selection

Contact input

Stored winding diameter

55

clear

Winding/unwinding

56

selection

Dancer/tension control

83

function selection

Signal Description

— Set the target position with parameter. (Pr. 133) 27

Terminal 1

Terminal

2, etc.

Input dancer roll position detection signal. 29

Set the main speed which becomes the line speed. 43

Input detection signal of line speed. Input method can be selected from below.

Same as the main speed.

Pulse train input

—

(single-phase pulse from terminal JOG and FR-A7AL, encoder pulse* from

FR-A7AP/FR-A7AL)

Analog input (terminal 2, terminal 4)

* Encoder pulse train inputs are not available during vector control.

Turn ON X30 signal to reset integral term.

OFF: Does not reset integral term.

X30

ON: Resets integral term.

Integral term can be reset with MRS signal input when terminal is not assigned.

Turn ON X32 signal to reset differential term.

X32

OFF: Does not reset differential term.

ON: Resets differential term.

X33

Set an analog value, which is input to terminal 1, to

Turn X34 signal ON/OFF to enable/disable the control by integral term.

OFF: Disables integral term.

X34

ON: Enables integral term.

Integral term is enabled when X34 signal is not assigned.

Turn ON to select compensation by main rotation speed command.

OFF:Speed compensation gain does not change regardless of main speed.

X35

ON: Speed compensation gain changes with main speed.

Speed compensation gain changes with main speed when X35 signal is

not assigned.

X51

Acceleration/deceleration time of main speed can be switched. 46

X53

Select minimum/maximum winding diameter. 35

X55 Clears stored winding diameter calculation results. 37

X56 Select whether winding or unwinding shaft. 34

Select dancer control and winding diameter compensation function.

OFF: Normal operation.

ON:Activates dancer control and winding diameter compensation function.

Normal operation is performed when X83 signal is not assigned.

Always set when using dancer control and winding diameter

compensation function.

Turn ON/OFF the X83 in a stop status to switch between the dancer

control operation and normal operation. After turning ON the X83 signal,

X83

wait 20ms or longer to input a start command (STF/STR).

Pr. 751

as offset.

Refer

to

page

33

—

—

—

—

31

25, 32

16

Dedicated I/O signal

3

DANCER CONTROL/WINDING DIAMETER COMPENSATION

Pr. 178 to

Typ e

Pr. 189

Signal Description

setting

Select to enable/disable winding diameter compensation. When X84 is

Winding diameter

84

compensation selection

Dancer control

85

selection

Winding/unwinding

86

length clear

87

Contact input

Analog input gain

selection

88 X88

89

PID gain switchover

90 X90

ON, winding diameter compensation is disabled (winding diameter is

X84

retained), and only the dancer control operates.

(Input of X83 signal is necessary)

Select to enable/disable dancer control. When X85 signal is ON, dancer

X85

control is disabled, and only winding diameter compensation operates.

(Input of X83 signal is necessary)

X86 Clears measured winding/unwinding length. 42

X87

Changes the gain of analog input for main speed. 44

X89

PID gain can be switched with external terminal input. 29

Speed control

93

proportional gain

X93 Disables the settings of Pr. 777 to Pr. 780 (Speed control proportional gain). 47

disabled

3.4.2 Output signal list

Use output signals by assigning them to Pr. 190 to Pr. 196 (output terminal function selection).

Pr. 190 to Pr. 196

setting

Positive

Negative

logic

14 114 PID lower limit FDN

15 115

50 150

logic

PID upper limit FUP

Signal loss detection Y50 Output when dancer roll is in abnormal condition. 28

Winding diameter

51 151

52 152

53 153

54 154

calculation completion

Target winding diameter

Winding/unwinding

Dancer position

Signal Description

Output when dancer roll position goes lower than the setting in Pr. 132 PID

lower limit

Output when dancer roll position goes higher than the setting in Pr. 131

PID upper limit.

Output when winding diameter calculation is completed at an operation

Y51

at a start

achieved

completion

detection

start.

Output when winding diameter achieves the setting in Pr. 750 or becomes

longer for winding.

Y52

Output when winding diameter achieves the setting in Pr. 750 or becomes

shorter for unwinding.

Output when winding/unwinding length reaches the setting in Pr. 279 or

Y53

longer.

Output when dancer roll position is commanded, and the position of

Y54

dancer roll is within the set range of Pr. 702. This signal is also output when

inverter is at a stop.

Refer

to

page

25

32

Refer

to

page

29

29

41

48

42

27

17

Dedicated I/O signal

3.4.3 Analog input signals and pulse train input signals

Analog input

Function

Terminal 1

Pr. 868

Frequency (speed)

command

Frequency setting

auxiliary

Override 1

Magnetic flux command 1

Regenerative torque limit 2 2

Torque command 3, 4 3, 4

Stall prevention operation

level

Torque limit 4 4

Forward/reverse rotation

speed limit

Torque bias 6 6

10

0 1

4 4

5 5

Terminal 2

Terminal 4

Pr. 785

Terminal 6

(FR-A7AZ)

Pr. 406

Analog input

Function

Terminal 1 Terminal 2 Terminal 4

Dancer signal input selec-

tion

Pr. 731

Dancer main speed com-

mand input selection

Pr. 732

Line speed input selection

Pr. 763

Taper setting analog input

selection

Pr. 733

Dancer ten sion setting input

selection

Pr. 734

*1 Can be set when Pr. 291= "1, 11, 21, or 100".

*2 Setting Pr. 785 = "2" sets the taper ratio setting as the terminal 4 input regardless the Pr. 733 setting.

5346 27

5346

53461

534

5346 51

*2 6 51, 61

Terminal 6

FR-A7AZ

Single-phase pulse

train input

Terminal

JOG

FR-A7AL

Pr. 291

1, 11, 21,

100

: Setting available, : Setting not available

Single-phase pulse

train input

Terminal

JOG

1

*1

*1 7233

FR-A7AL

7243

Encoder

pulse train

input

FR-A7AP/

FR-A7AL

Encoder

pulse train

input

FR-A7AP/

FR-A7AL

: Setting not available

Refer to

page

Refer to the

Instruction

Manual

(Applied) of

FR-A700 series

Refer to

page

REMARKS

• While the dancer/tension control selection X83 signal is ON, the setting values of Pr. 731 to Pr. 734 and Pr. 763 have higher precedence

over the other assigned terminal settings such as Pr. 868, Pr. 785 = "1", and Pr. 406. (Example: When Pr. 731 = "5" and Pr. 868 = "0", the

terminal 1 is set to the dancer signal input.)

• For the taper setting analog input, the setting of Pr. 785 Terminal 4 function setting has higher precedence.

• While tension control is valid (Pr. 800 = "6 or 16"), the following parameter settings are invalid: Pr. 731 Dancer signal input selection,

Pr. 732 Dancer main speed command input selection, and Pr. 734 Dancer tension setting input selection.

• The dedicated-function parameters take the following precedence over each other. When several functions are assigned to a terminal,

input to the function of lower precedence is regarded as 0.

Terminal 4 function setting (Pr. 785 = "2") > Pr. 731 Dancer signal input selection > Pr. 763 Line speed input selection > Pr. 732 Dancer main speed

command input selection > Pr. 733 Taper setting analog input selection > Pr. 734 Dancer tension setting input selection.

18

Parameter setting procedure for dancer

3

DANCER CONTROL/WINDING DIAMETER COMPENSATION

POINT

Set X83 signal ON to activate dancer control.

*2 Maximum rotation number: max

Maximum number of rotation at the fastest line speed with minimum diameter

(maximum diameter) for winding (unwinding).

max =

V

max

r/min

Dmin (Dmax) Z

control function

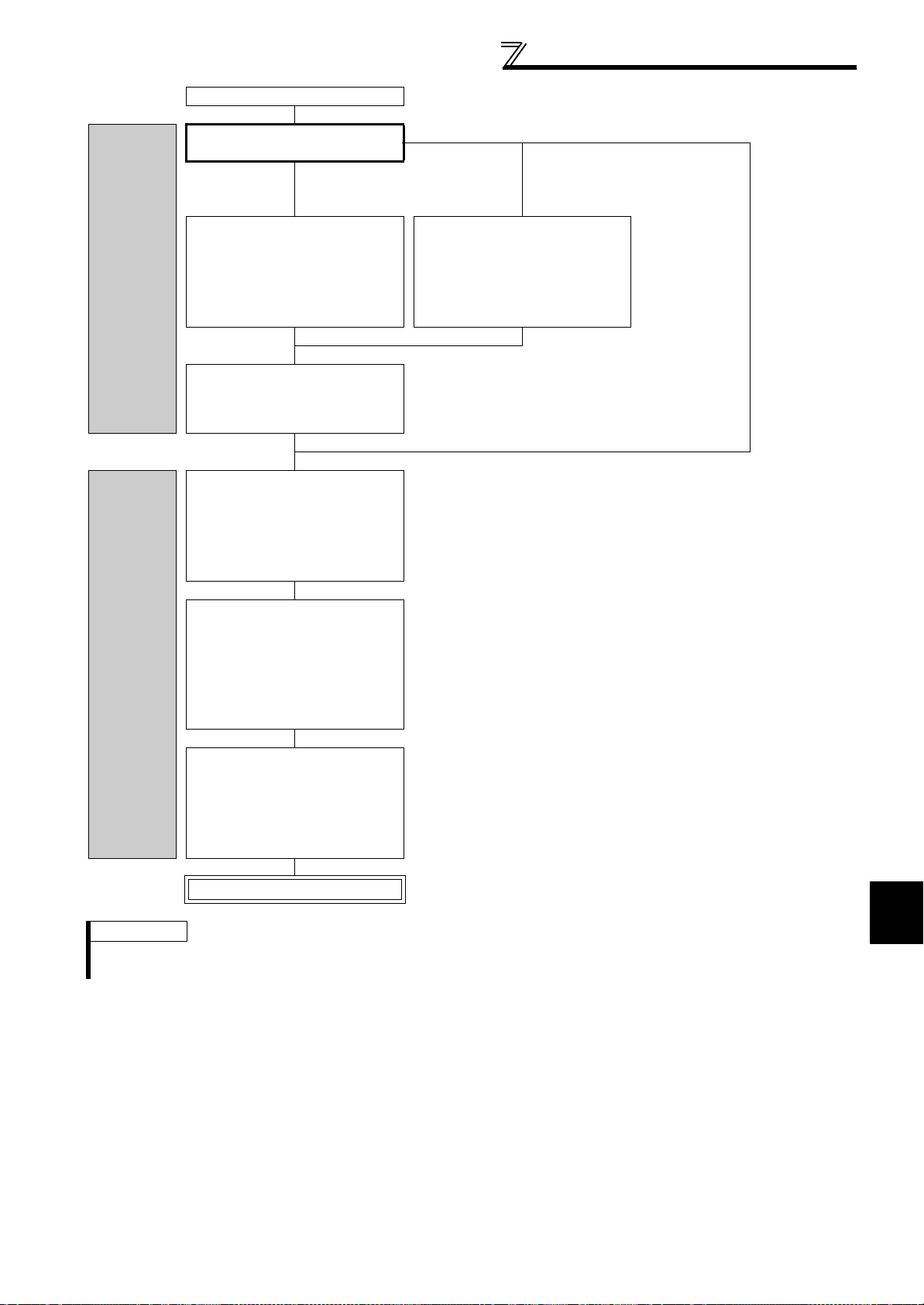

3.5 Parameter setting procedure for dancer control function

The following flowchart shows the parameter setting example for the dancer control.

Start

Basic setting

Gain

adjustment of

speed control

Input signal

setting

Select control method according to

the application and the motor.

Applied motor selection (Pr. 71)

Motor capacity (Pr. 80)

Number of motor poles (Pr. 81)

Control method selection (Pr. 800)

Number of encoder pulses (Pr. 369)

Adjust gain of speed control.

Main speed setting

(Refer to page 43 )

Setting with analog input voltage

(terminal 2) *1

Set parameters below.

C2 Terminal 2 frequency setting bias

frequency = "0r/min"

Pr. 125 Terminal 2 frequency setting

gain frequency = "Maximum speed"

*2

C3 Terminal 2 frequency setting bias =

"0%"

C4 Terminal 2 frequency setting gain =

"100%"

Select any of V/F control, Advanced magnetic flux vector control, Real

sensorless vector control (speed control), or vector control (speed control) to

perform winding with dancer control.

Refer to page 22 for gain adjustment of speed control with Real sensorless

vector control/Vector control.

Setting with pulse train input

(terminal JOG)

Set parameters below according to

the input pulse frequency.

Pr. 384 Input pulse division scaling

"0"

factor

Pr. 385 Frequency for zero input pulse

= "0r/min"

Pr. 386 Frequency for maximum input

pulse = "Maximum speed"

Pr. 703 Minimum number of input

pulse = "0"

Pr.704 Maximum number of input pulse

= "Maximum number of pulses"

*1

Setting with digital input

(FR-A7AX)

Set parameters below according to

BCD and binary code signals.

Pr. 304 Digital input and analog input

compensation enable/disable selection

Pr. 300 BCD input bias

Pr. 301 BCD input gain

Pr. 302 BIN input bias

Pr. 303 BIN input gain

Pr. 305

Read timing operation selection

Pr. 329 Digital input unit selection

Assign X83 by setting "83" in any of

Input terminal function selection (Pr. 178

to Pr. 189).

Set action determined by polarity of

dancer roll position detection signal

Dancer

control

function

selection

(terminal 1 input

action selection

(Refer to page 25 )

Set Pr. 762 Winding/unwinding

selection. (Refer to page 34 )

For winding : Pr. 762 = "0"

For unwinding : Pr. 762 = "1"

*3) with Pr. 128 PID

See the next page.

Set Pr. 128 = "40" to accelerate when dancer roll position detection signal

(terminal 1 input

Set Pr. 128 = "41" to accelerate when dancer roll position detection signal

(terminal 1 input

*1 Use Pr. 732 to change the input terminal for the main speed commands.

*3 Use Pr. 731 to change the terminal for the dancer roll position detection.

*3) is negative.

*3) is positive.

19

Parameter setting procedure for dancer

Pr.133=

% at upper limit - % at lower limit

% at

lowest

2

POINT

Turn ON the start signal when

operation X83 is ON and main

speed = 0r/min, and move the

dancer roll up and down to

check compensation directions

of the dancer.

Pr. 763

setting

Line speed input signal

0

Without line speed input signal

(Main speed is the line speed.)

1 Single-phase pulse train input (terminal JOG)

2 Encoder pulse train input (FR-A7AP)

3 Analog Input (Terminal 2)

4 Analog Input (Terminal 4)

5 Analog Input (Terminal 1)

6 Analog Input (FR-A7AZ Terminal 6)

7 Single-phase pulse train input (FR-A7AL)

control function

Continued from the last page.

Acce

leration/

Deceleration

time setting

Target dancer

position

(Pr. 133)

setting

Operation

check

Set acceleration/deceleration time as

below.

(Refer to page 46)

Pr. 7 Acceleration time = "0s"

Pr. 8 Deceleration time = "0s"

Pr.

756 First acceleration time for main

= "Acceleration time of the line"

speed

Pr.757 First deceleration time for main

speed

= "Deceleration time of the line

Set Pr. 52 ="27" (monitor voltage % of

terminal 1 input).

And record,

Value when the dancer position is

at the upper limit

Value when the dancer position is

at the lower limit

Set the value obtained from

Alternatively, move the dancer roll to

the center position, and set the

monitored value of terminal 1 input

voltage % to Pr. 133.

Adjust the gain of dancer control (PID

control). (Refer to page 24 )

"

Pr. 756, Pr. 757:

When cushion time is considered in main speed command, set 0s.

Upper limit %

Target position

of

dancer roll

(Pr. 133)

Lower limit %

Refer to page 24 for gain adjustment of dancer control (PID control).

Dancer roll

upper limit

Dancer roll

lower limit

Compensation by winding

diameter calculation

(Winding/

Unwinding shafts)

Winding

diameter

calculator

setting

20

Gear ratio

setting

Set Pr. 763 Line speed input selection.

(Refer to page 33 )

Set gear ratio with Pr. 773 Gear ratio

numerator (driver side), Pr. 774 Gear

ratio denominator (follower side) when

a reduction gear is installed between

rolling shaft and motor output shaft.

(Refer to page 34 )

See next page

Perform winding

diameter

compensation

(Intermediate shafts)

Do not perform

winding diameter

compensation

Set

Pr. 771

r-r' limit value (diameter)

"9999" to inactivate winding diameter

calculator.

(Refer to page 38)

=

Test r un

3

DANCER CONTROL/WINDING DIAMETER COMPENSATION

Continued from the last page.

Input method for line speed