Page 1

INSTRUCTION MANUAL

ORIENTATION CONTROL/PLG FEEDBACK

CONTROL/PULSE TRAIN UNIT

FR-A5AP

TYPE FR-A5AP EIBUN TORISETSU

CODE 1A2H59

IB (NA) 66848-A (9803) MEE

1

Page 2

Thank you for choosing the Mitsubishi transistorized inverter option unit.

C

This instruction manual gives handling information and precautions for use of this product. Incorrect handling might

cause an unexpected fault. Before using the equipment, please read this manual carefully to use it to its optimum.

Please forward this manual to the end user.

Safety Instructions

Do not attempt to install, operate, maintain or inspect this product until you have read through this instruction

manual and appended documents carefully and can use the equipment correctly. Do not use this product until

you have a full knowledge of the equipment, safety information and instructions.

In this manual, the safety instruction levels are classified into "WARNING" and "CAUTION".

WARNING

AUTION

Note that even the CAUTION level may lead to a serious consequence under some circumstances. Please follow the

instructions of both levels as they are important to personnel safety.

Denotes that incorrect handling may cause hazardous conditions, resulting in death or

severe injury.

Denotes that incorrect handling may cause hazardous conditions, resulting in medium or

slight injury, or may cause physical damage only.

2

Page 3

SAFETY INSTRUCTIONS

1. Electric Shock Prevention

WARNING

While power is on or when the inverter is running, do not open the front cover. You may get an electric shock.

Do not run the inverter with the front cover removed. Otherwise, you may access the exposed high-voltage

terminals and charging part and get an electric shock.

If power is off, do not remove the front cover except for wiring or periodic inspection. You may access the

charged inverter circuits and get an electric shock.

Before starting wiring or inspection, switch power off, wait for more than 10 minutes, and check for no residual

voltage with a tester or the like.

Any person who is involved in the wiring or inspection of this equipment should be fully competent to do the

work.

Always install the option unit before wiring. Otherwise, you may get an electric shock or be injured.

Operate the switches with dry hands to prevent an electric shock.

Do not subject the cables to scratches, excessive stress, heavy loads or pinching. Otherwise, you may get an

electric shock.

2. Injury Prevention

CAUTION

Apply only the voltage specified in the instruction manual to each terminal to prevent damage, etc.

Ensure that the cables are connected to the correct terminals.

Otherwise, damage, etc. may occur.

Always make sure that polarity is correct to prevent damage, etc.

While power is on or for some time after power-off, do not touch the inverter as it is hot and you may get burnt.

3

Page 4

3. Additional instructions

Also note the following points to prevent an accidental failure, injury, electric shock, etc.:

(1) Transportation and installation

CAUTION

Do not install or operate the option unit if it is damaged or has parts missing.

Do not stand or rest heavy objects on the product.

Check that the mounting orientation is correct.

Prevent screws, metal fragments, conductive bodies or oil, other flammable substance from entering the inverter.

(2) Test operation and adjustment

CAUTION

Before starting operation, confirm and adjust the parameters. A failure to do so may cause some machines to

make unexpected motions.

(3) Usage

Do not modify the equipment.

WARNING

4

Page 5

CAUTION

When parameter clear or all parameter clear is performed, each parameter returns to the factory setting. Re-set

the required parameters before starting operation.

For prevention of damage due to static electricity, touch nearby metal before touching this product to eliminate

static electricity from your body.

(4) Maintenance, inspection and parts replacement

CAUTION

Do not test the equipment with a megger (measure insulation resistance).

(5) Disposal

CAUTION

Dispose of this product as general industrial waste.

(6) General instruction

All illustrations given in this manual may have been drawn with covers or safety guards removed to provide in-depth

description. Before starting operation of the product, always return the covers and guards into original positions as

specified and operate the equipment in accordance with the manual.

5

Page 6

1 PRE-OPERATION INSTRUCTIONS 8

1.1 Unpacking and Product Confirmation 8

1.2 Packing Confirmation 8

1.3 Structure 9

2 INSTALLATION 10

2.1 Pre-Installation Instructions 10

2.2 Installation Procedure 10

2.3 Wiring 11

3 ORIENTATION CONTROL 12

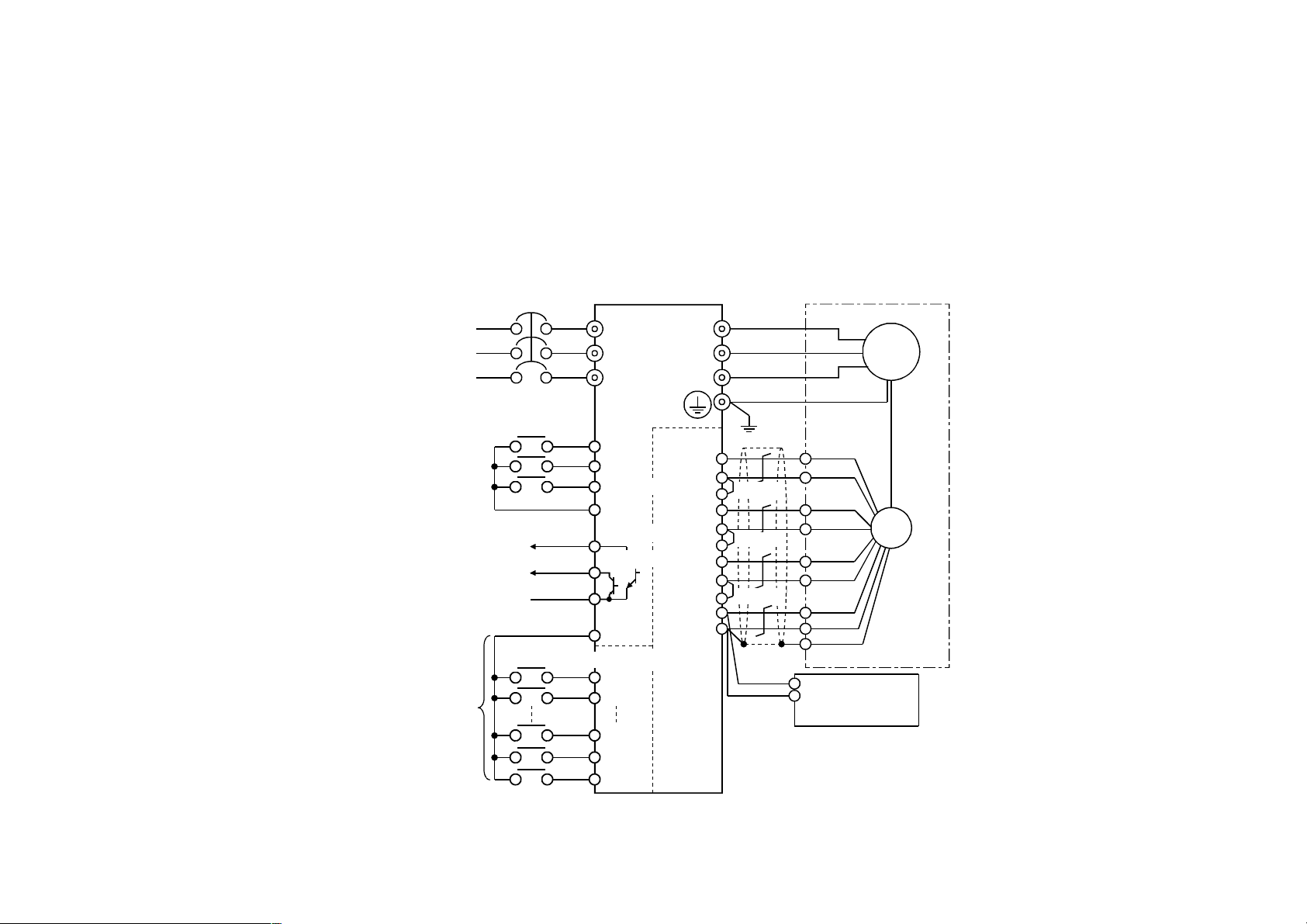

3.1 Wiring Example 12

3.2 Input Circuit 13

3.3 Terminals 14

3.4 Wiring Instructions 17

3.5 Related Parameter List 20

3.6 Pre-Operation Settings 2 1

3.7 Operation 25

3.8 Instructions 32

3.9 Specifications 33

4 PLG FEEDBACK CONTROL 34

4.1 Wiring Example 34

4.2 Input Circuit 35

4.3 Terminals 36

4.4 Wiring Instructions 37

4.5 Related Parameter List 39

4.6 Pre-Operation Settings 4 0

4.7 Control Mode Setting 41

4.8 PLG Feedback Control 42

4.9 Vector control 44

4.10 Additional Functions 51

4.11 Specifications 54

6

Page 7

5 PULSE TRAIN INPUT 55

5.1 Wiring Example 55

5.2 Terminals 55

5.3 Adjustment 56

5.4 Parameter Definition 56

5.5 Setting Example 57

5.6 Specifications 58

7

Page 8

PRE-OPERATION INSTRUCTIONS

1. PRE-OPERATION INSTRUCTIONS

1.1. Unpacking and Product Confirmation

Take the option unit out of the package, check the unit name, and confirm that the product is as you ordered and

intact.

Note: This product may be used with the inverter manufactured during and after February, 1998.

The inverter may be used with this unit if its SERIAL number indicated on the rating plate and package plate

has the following version or later. (The SERIAL number on the package plate uses the 3 most significant

digits of the following 6-digit control number and is indicated in 6 digits including the version symbol.)

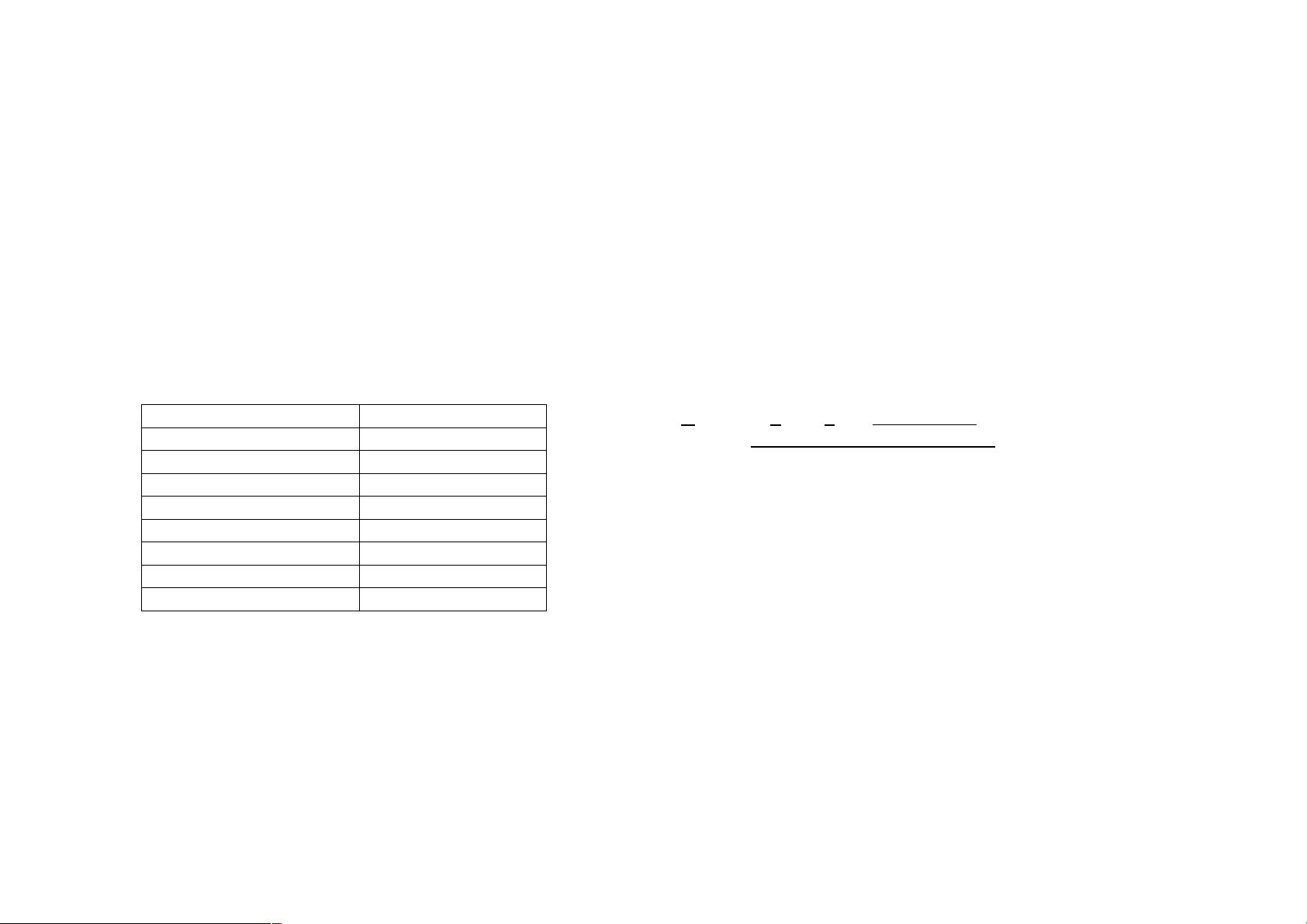

Model SERIAL Number

FR-A520-0.4K, 0.75K U82

FR-A520-1.5K to 11K T82

FR-A520-15K to 22K U82

FR-A520-30K to 55K K82

FR-A540-0.4K to 3.7K L82

FR-A540-5.5K, 7.5K K82

FR-A540-11K to 22K L82

FR-A540-30K to 55K D82

1.2. Packing Confirmation

Make sure that the package includes the following accessories:

Instruction manual 1

Mounting screws M3

Terminal resistor jumpers (Jumpers fitted to the terminal block) 3

10 2

U 8 2

Symbol Year Month Control number

SERIAL number

SERIAL is made up of 1 version symbol and

8 numeric characters as shown above.

8

Page 9

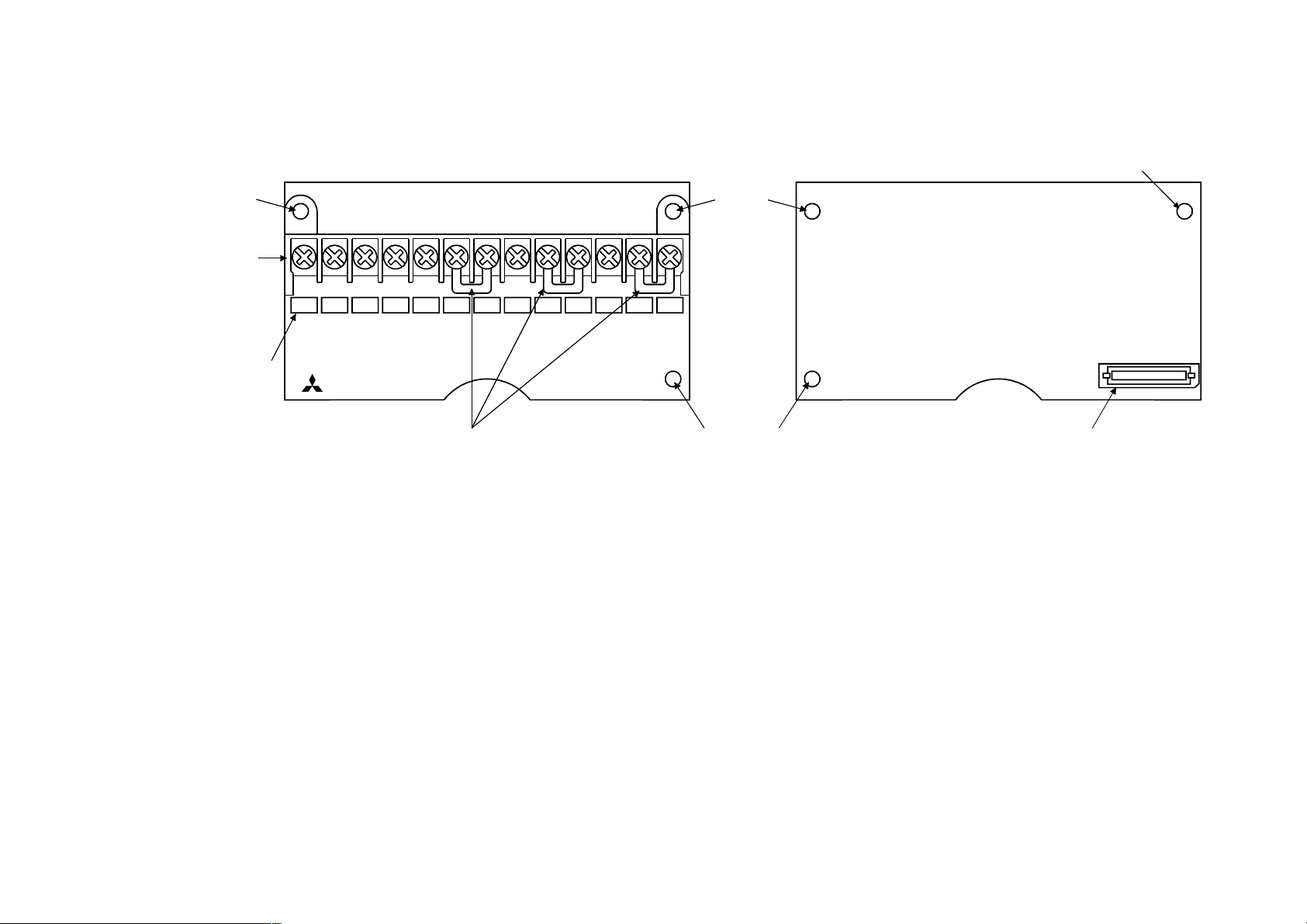

1.3. Structure

T

y

j

g

g

g

Mounting hole

erminal block

screw size M3

Front view

Mountin

holes

Rear view

Mountin

hole

Terminal s

mbol

PIN PO 5V PA2

SG PA1

FR-A5AP

Terminal resistor

PAR

PB1 PB2 PBR PC1 PC2

umpers

PCR

Option fixin

holes

Connector

9

Page 10

I.ISTALLATION

2.INSTALLAT ION

2.1. Pre-Installation Instructions

(1) Make sure that the input power of the inverter is off and make sure the charge light is off.

(2) When the FR-A5AP unit is used for PLG feedback control or orientation control, a PLG (motor with PLG) and

external power supply are required.

When PLG feedback control and orientation control are used together, the PLG (motor with PLG) and external power

supply are shared between these controls.

(3) When the FR-A5AP unit is fitted, the programmed operation function is made invalid.

CAUTION

With input power on, do not install or remove the option unit. Otherwise, the inverter and option unit

may be damaged.

2.2. Installation Procedure

(1) Securely insert the connector of the option unit far into the connector of the inverter. At this time, also fit the option

fixing holes securely.

(2) Securely fix the option unit to the inverter on both sides with the accessory mounting screws. If the screw holes

do not match, the connector may not have been connected correctly. Check for loose connections.

CAUTION

When installing the inverter front cover, the cables to the inverter's control circuit terminals and option

terminals should be routed properly in the wiring space to prevent them from being caught between the

inverter and its cover.

10

Page 11

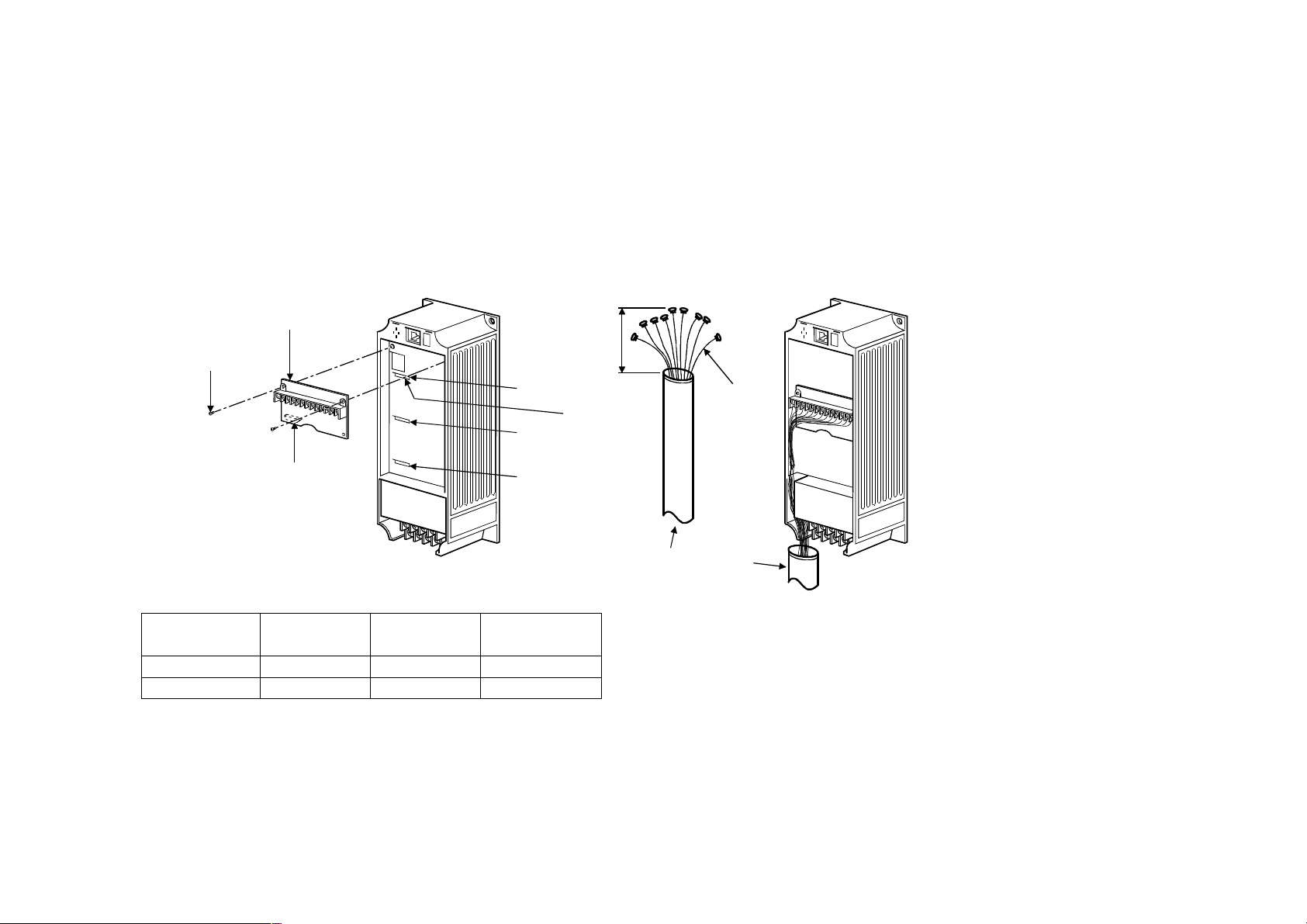

2.3. Wiring

y

(

)

g

(

)

Route the cables so that they do not take up a large space in the control circuit terminal block wiring area of the

option unit.

Wire the twisted pair shielded cable after stripping its sheath to make its cables loose. Also, protect the shield cable

of the twisted pair shielded cable to ensure that it will not make contact with the conductive area.

Note: During wiring, do not leave wire off-cuts in the inverter. They can cause a fault, failure or malfunction.

Accessor

2 pcs.

Option unit

screw

Inverter

Without cover

Slot 1

Slot 2

L

Shield cable

Inverter side

connector

Cable routin

Option side

connector

Slot 3

Twisted pair shielded cable

Sheath Stripping Dimensions for Shield Cable

Inverter

Capacity

0.4K to 3.7K L: 350mm L: 300mm L: 250mm

5.5K to 55K L: 270mm L: 220m m L: 170mm

Slot 1 Slot 2 Slot 3

I.ORIENTATION CONTROL

11

Page 12

3. ORIENTATION CONTROL

)

y

(

)

(

)

(

)

(

)

(

)

y

)

(

)

(

)

(

)

(

)

This function is used with a position detector (PLG) installed to the spindle of a machine tool (or the motor) to allow a

rotary shaft to be stopped at the specified position (oriented).

Pr. 350 "stop position command selection" is factory-set to "9999" to make the orientation control function invalid.

3.1. Wiring Example

Power suppl

NFB

R

S

T

Inverter

Standard motor with PLG (SF-JR

U

V

W

Note 1

IM

Forward rotation

Reverse rotation

Orientation command

In position

Orientation fault

Output common

External stop command

STF

STR

Note 5

X22

SD

Note 6

ORA

Note 6

ORM

SE

SD

FR-A5AX

X11

X10

X1

X0

DY

FR-A5AP

PA1

PA2

PAR

PB1

PB2

PBR

PC1

PC2

PCR

5V

SG

Note 7

Note 4

Note 4

Note 4

Note 1

C

R

A

N

B

P

H

K

E

5VDC

5V

0

power suppl

(Note 2

PLG

12

Page 13

Note:1. When the motor with a PLG used is other than the standard motor with PLG (SF-JR), the pin numbers

are different. To reduce radiated noise, connect the shield wires of the PLG cables to the CG.

2. When orientation control is used with PLG feedback control, the PLG and 5V power supply may be

shared between these controls.

3. Couple the PLG in line with the motor with a speed ratio of 1 to 1 without any mechanical looseness.

4. Keep the accessory jumpers connected. However, when the same PLG is shared between the FR-A5AP

and another unit (e.g. NC) which is connected with a terminal resistor, the built-in terminal resistors are

not required and should be removed. (Terminal resistors: 100)

5. Assign this function to any of the input terminals using Pr. 180 to Pr. 186 "input terminal function

selection".

6. Assign this function to any of the output terminals using Pr. 190 to Pr. 195 "output terminal function

selection".

7.When the stop position command is entered from outside the inverter (externally), the FR-A5AX inboard

option is required.

3.2. Input Circuit

1k

+

+

+

-

-

-

1000pF

1000pF

1000pF

1000pF

1000pF

1000pF

100

100

100

100

100

100

1k

1k

1k

1k

1k

100

100

100

1F

PA1

PAR

PA2

PB1

PBR

PB2

PC1

PCR

PC2

5V

SG

Jumpers

13

Page 14

3.3. Terminals

SymbolTerminal Remarks Description

PA1 PLG A-phase signal input terminal

PA2 PLG A-phase inverse signal input

terminal

PB1 PLG B-phase signal input terminal

PB2 PLG B-phase inverse signal input

terminal

PC1 PLG C(Z)-phase signal input terminal

PC2 PLG C(Z)-phase inverse signal input

terminal

PAR A-phase terminal resistor terminal Factory-connected with "PA2" by the

PBR B-phase terminal resistor terminal Factory-connected with "PB2" by the

PCR C(Z)-phase terminal resistor terminal Factory-connected with "PC2" by the

5V DC power (positive) input terminal

SG DC power ground terminal

For information on t he

pulse signals, refer to

page 11.

4.75 to 6VDC (Current

consumption 50mA)

A-, B- and C(Z)-phase signals are input

from the PLG

jumper. Remove the jumper when the

terminal resistor is not needed

jumper. Remove the jumper when the

terminal resistor is not needed

jumper. Remove the jumper when the

terminal resistor is not needed

PLG power supply common terminals.

Input PLG power. Connect the positive

side to 5V and the ground side to SG.

Also, connect the shield of the shield wire

to SG.

14

Page 15

<Inverter I/O terminals>

Symbol Terminal Remarks Description

(Note 1)

X22

SD Common terminal Common terminal for the orientation

ORA

(Note 2)

ORM

(Note 2)

SE Open collector output

Note:1. Assign the function of the X22 signal to any of the input terminals using Pr. 180 to Pr. 186 "input terminal

function selection".

2. Assign the functions of the ORA/ORM signal to any of the output terminals using Pr. 190 to Pr. 195

"output terminal function selection".

Orientation command input

terminal

In-position signal output

terminal

Orientation fault signal output

terminal

common terminal

Open collector output.

Permissible load

24VDC, 0.1A

Open collector output.

Permissible load

24VDC, 0.1A

Used to enter an orientation signal.

signal.

Switched low if the orientation has

stopped within the in-position zone while

the start and orientation signals are input.

Switched low if the orientation has not

stopped within the in-position zone while

the start and orientation signals are input.

Common terminal for the ORA and ORM

open collector output terminals. I s olated

from the common terminal of the control

circuit.

15

Page 16

<FR-A5AX, inverter input ter mi nals>

g

Symbol Terminal Remarks Descripti on

X0

to

X11

FRA5AX

input

terminal

s

Inverter

input

terminal

s

How to use terminal DY (when the stop position is specified from outside the inverter (externally) ).

DYData read timing

SD Common

PC External

Digital signal

input terminals

input signal

terminal (sink)

transistor

common

terminal (source)

DY

Position data

Use a micro current switching

contact relay for the relay

contact. A transistor with the

following specifications should

be selected for the open

collector signal:

Electrical characteristics of the

transistor used;

10mA

I

C

V

Leakage current 100A max.

If I

voltage is 3V max.

Position command latch

30V

CE

10mA, V

C

200ms or lon

CE(sat)

er

Used to input digital signals through either relays or

open collector transistors.

As the command signals are ent ered, speed or position

commands are selected using Pr. 360.

Used when a digital signal read timing signal is

necessary. Data is only read while terminals DY-SD are

shorted. By opening terminals DY-SD, the data before

opening is retained.

Common terminal for digital signal input terminals and

data read timing signals

When connecting the transistor output (open collector

output) of a programmable controller (PC), etc., connect

the external power common (positive) to this terminal to

prevent a fault occurring due to leakage current

When terminals DY-SD are open, the inverter does not import data. Therefore, if the input status of the X0-X11

signals change, the stop position data before opening of terminals DY-SD is valid.

Also, the position data is imported on the leading edge of the DY signal.

Note: Pr. 300 to Pr. 304 settings for the FR-A5AX are made invalid when the stop position is set to be specified

from outside the inverter (externally), with the FR-A5AP (orientation control option) fitted to the inverter and

when orientation control is used.

Pr. 300 to Pr. 305 of the FR-A5AX are made valid when the stop position is not set from outside the inverter.

16

Page 17

3.4. Wiring Instructions

(1) Connection with the position detector (PLG).

2

Use twisted pair shielded cables (0.2mm

Cables to terminals 5V and SG should be connected in parallel or be larger in size according to the cable length

table as indicated below.

To protect the cables from noise, run them (at least 10cm) away from any source of noise (e.g. the main circuit

and power supply voltage).

Note: If the cable size is too large to connect the terminals to the terminal block or if the number of cables is

increased due to parallel connection and they cannot be contained in the wiring space, provide a junction terminal

block, for example.

(2) Cable length.

1) Cable length within 30m.

or larger) to connect the FR-A5AP and position detector (PLG).

Cable Length

Within 10m At least 2 cables

Within 20m At least 4 cables

Within 30m At least 6 cables

Number of Parallel Cables of 0.2mm

Required

2) Cable length of more than 30m.

Use a power supply slightly higher than 5V (approximately 5.5V) in addition to 6 or more parallel cables of

2

0.2mm

or cables of 1.25mm2 or more. This allows the cable length to be increased up to 100m. Note that the

voltage applied

across terminals 5V-SG must not exceed 6V.

2

Larger-Size Cable

0.4mm

0.75mm

1.25mm

or larger

2

or larger

2

or larger

2

17

Page 18

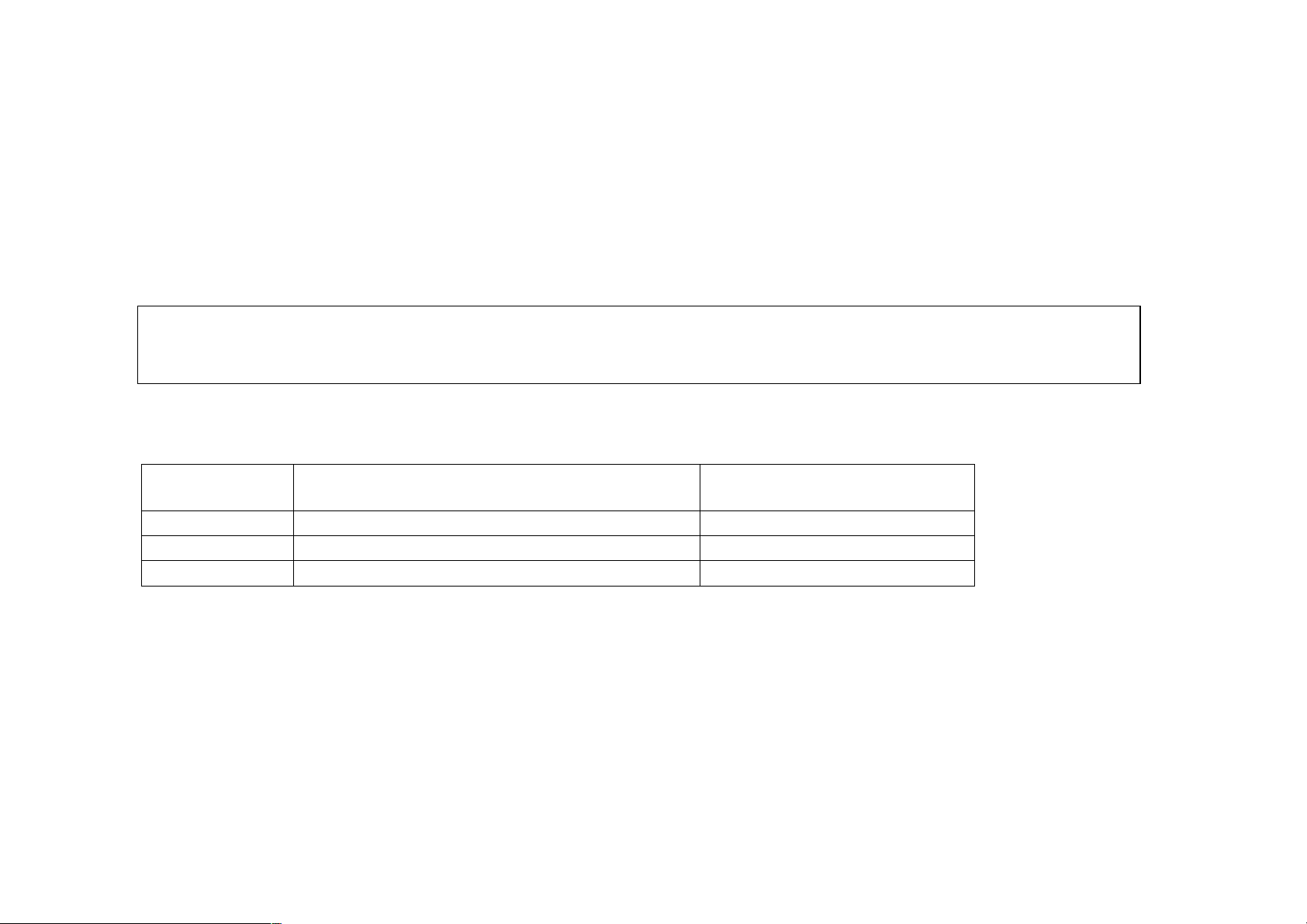

3) Connection with NC. (Or similar device)

(

)

When one position detector is shared between the FR-A5AP and NC (or another device), its output signals

should be connected as shown below. In this case, the cable length between the FR-A5AP and NC should be

as short as possible, within 5m.

Position detector

PLG

Inverter

FR-A5AP

NC

Max. 5m

2 parallel cables

(3) Connection of terminal resistors.

Use the jumpers across PA2-PAR, PB2-PBR and PC2-PCR to connect terminal resistors to the A, B and C(Z)phases of the PLG. Normally, keep the jumpers fitted.

However, remove the jumpers when the same PLG is shared between the FR-A5AP and the other unit (e.g. NC)

which is connected with a terminal resistor.

18

Page 19

(4) Position detector (PLG).

r

Line driver LED type PLG

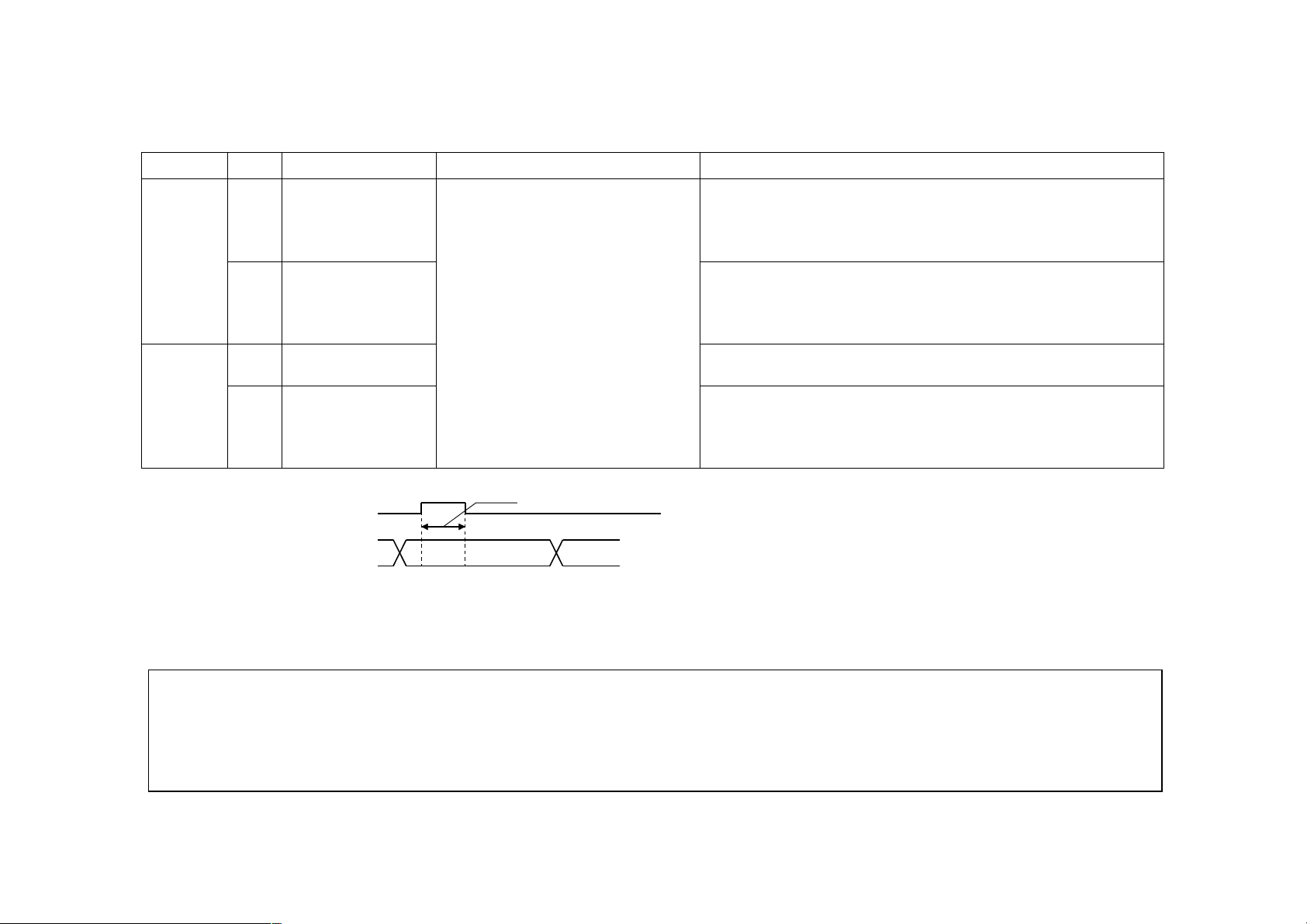

A. A signal 1000ppr to 4096ppr

B. B signal 1000ppr to 4096ppr

C(Z).C(Z) signal 1ppr Output pulse specifications

P

abcd

A

A

B

B

C

C

a, b, c and d should be (1/4 1/8)P when rotation is clockwise as viewed from the shaft

end of the PLG.

2.4 to 5.25V

H

L

0 to 0.4V

1000ppr to 4096pp

1000ppr to 4096ppr

1000ppr to 4096ppr

1000ppr to 4096ppr

1ppr

1ppr

<Example of PLG

available on the market>

Tamagawa Seiki:

TS1508N207,

TS5008N122,

TS5108N122

Pin Numbers of PLG Output Signals (Tamagawa Seiki, TS1508N207)

Pin Number Output Signal Pin Number Output Signal

C A-phase signal H +5V power supply

R A-phase inverse signal K Power supply common

A B-phase signal E Case earth

N B-phase inverse signal

B C(Z )-phase signal

P C(Z )-phase inverse

signal

Note: When PLG feedback control and orientation control are used together, the PLG is shared between these

controls.

Use a PLG which has a pulse count of 1000 to 4096ppr (pulses per revolution).

19

Page 20

3.5. Related Parameter List

Parameter

Number

350 Stop position command

selection

351 Orientation speed 0 to 30Hz 0.01Hz 2Hz

352 Creep speed 0 to 10Hz 0.01Hz 0.5Hz

353 Creep select position 0 to 16383 (Note) 1 511

354 Position loop select

position

355 DC dynamic braking start

position

356 Internal stop position

command

357 In-position zone 0 to 255 1 5

358 Servo torque selection 0 to 13 1 1

359 PLG rotation direction 0, 1 1 1

360 12-bit data selection 0, 1, 2 to 127 1 0 0: Speed command,

361 Position shift 0 to 16383 (Note) 1 0

362 Position loop gain 1 to 10 1 1

363 In-position signal output

delay time

364 PLG stop check time 0 to 5 sec. 0.1 sec. 0.5 sec.

365 Orientation time limit 0 to 60 sec., 9999 1 sec. 9999 9999: 120 sec. setting

366 Recheck time 0 to 5 sec., 9999 0.1 sec. 9999 9999: No check

369 PLG pulse count 0 to 4096 1 1024 Number of pulses before it is

Name Setting Range Minimum Setting

Increments

0, 1, 9999 1 9999 9999: No orientation

0 to 8191 1 96

0 to 255 1 5

0 to 16383 (Note) 1 0

0 to 5 sec. 0.1 sec. 0.5 sec.

Factory

Setting

Remarks

Set using with respect to the stop

position.

Set using with respect to the stop

position.

Set using with respect to the stop

position.

1: Position command,

2 to 127: Number of stop positions 1

multiplied by 4

Note: When the FR-DU04 is used, up to 9999 may be set. When the FR-PU04 is used, up to 16383 may be set.

20

Page 21

3.6. Pre-Operation Settings

W

(1) Pr. 350 "stop position command selection".

For the stop position command, either the internal stop position command or the external stop position

command using external signals (12-bit data) may be selected.

Set "9999" in Pr. 350 to make orientation control invalid.

Pr. 350 Setting Description

0 Internal stop position command

1 External stop position command

9999 Orientation control invalid (factory setting)

(2) Pr. 369 "number of PLG pulses".

Set the number of PLG pulses.

Set the number of pulses before it is multiplied by 4.

Example:Set "1024" for 1024 pulses per revolution (ppr).

(3) Pr. 359 "PLG rotation direction".

Indicates the direction in which the PLG rotates.

Pr. 359=0 Pr. 359=1 (factory setting)

CCW

PLG

C

A

Forward rotation is clockwise rotation

when viewed from A.

Forward rotation is counterclockwise

rotation when viewed from A.

Note: When the FR-A5AP is fitted and Pr. 350 "stop position command selection" is set to make orientation control

valid, the PU (FR-DU04/FR-PU04) shows the rotation direction of the PLG.

Make the setting of Pr. 359 so that FWD is displayed when the STF signal switches on or REV displayed

when the STR signal switches on.

21

Page 22

(4) Pr. 356 "internal stop position command".

)

Set "0" in Pr. 350 "stop position command selection" to choose the internal position command mode.

In the internal position command mode, the value set in Pr. 356 is processed as the stop position command.

When the PLG pulse count is 1024ppr, one revolution of the PLG (360 degrees) is divided into 4096 positions,

i.e. 360 degrees/4096 = 0.0879 degrees per address (see below). The stop positions (addresses) are indicated in

parentheses.

Origin (0)

CW

CCW

Origin (0)

270

(3072)

180(2048)

Pr. 359=0

90

(1024)

90

(1024)

180(2048)

Pr. 359=1

270

(3072

(5) Pr. 360 "12-bit data selection".

When "1" is set in Pr. 350 "stop position command selection" and the FR-A5AX option is used with the FR-A5AP, set

stop positions using 12-bit data.

The value set in Pr. 360 should be the number of stop positions less 1.

<Example>

When the number of stop positions is 20 (divided at intervals of 18 degrees), 20 1 = 19. Hence, set "19".

The stop position command is entered in binary when using the FR-A5AX.

Pr. 360 Setting Description

0 Speed command

1 Position command

2 to 127 The external stop position command may be used to set up to 128 stop positions at

regular intervals. If the external stop command entered is greater than the setting, the

stop positions are the same as those in the maximum external stop command value.

22

Page 23

[Example 1]

(2)

(1)

g

)

(

)

(6)

(5)

(1)

(3)

(4)

(2)

)

(

)

(

)

(

)

(

)

)

4 stop positions

Ori

270

3 or more

180

in (0

CW

90

7 or more

Pr. 360 = "3"

Relationships between stop position command and 12-bit data

[Example 2]

8 stop positions

Origin (0

315

270

225

180

45

135

Pr. 360 = "7"

90

Pr. 360

"stop position

command selection"

"12-bit data

selection"

Stop position

command

[Example 3]

120 stop positions

Origin (0

CW

270

H5A

At intervals

of 3

180

H3C

90

Pr. 360 = "119"

Note: Values in parentheses

indicate binary data entered

from the input terminals of

the FR-A5AX. If the position

H1E

signal monitoring (Pr. 52 =

19) is selected, the data

monitored is not the number

of stop positions but is 0 to

4095 pulses.

Operating StatusPr. 350

12-bit data Speed command

0: Internal 0: Speed command Internal Speed command 12-bit data

0: Internal 1, 2 to 127: Position

command

Internal Invalid External command (or

PU)

1: External 0: Speed command Internal Speed command 12-bit data

1: External 1, 2 to 127: Position

command

External (Internal when

FR-A5AX is not fitted)

Position command External command (or

PU)

(6) Pr. 361 "position shift".

The stop positions are those defined by the position command plus the value set in Pr. 361.

<Position shift function>

Electrically shifts the origin (the inverters reference point for the origin) without changing the origin of the

position detector (PLG) (i.e. without any physical movement).

23

Page 24

(7) Pr. 363 "in-position signal output delay time".

When the motor shaft enters the in-position zone, the in-position signal is output after a delay of the time set in

Pr. 363. Also, when the motor shaft comes out of the in-position zone, the in-position signal is switched off after a

delay of the time set in Pr. 363.

(8) Pr. 364 "PLG stop check time".

When the in-position signal has not yet been output in orientation operation, the orientation fault signal is output if

orientation cannot be completed and the PLG is stopped for the period of time set in Pr. 364. When the inposition signal has been output once, the orientation fault signal is output if the orientation cannot be completed

again within the time set in Pr. 364.

(9) Pr. 365 "orientation time limit".

If orientation cannot be completed within the time set in Pr. 365, which is measured from when the current

position signal has passed the creep select position, the orientation fault signal is output.

(10) Pr. 366 "recheck time".

If the start signal is switched off with the orientation command ON after the PLG is stopped under orientation

control, the current position is checked again after the time set in Pr. 366 has elapsed and the in-position signal

or orientation fault signal is output according to the check result.

24

Page 25

3.7. Operation

(1) Orientation starting during rotation.

1) The orientation command (X22) causes the motor to decelerate to the orientation speed set in Pr. 351.

2) After the orientation speed is reached, the motor decelerates to the creep speed set in Pr. 352 as soon as the

current position signal reaches the creep select position set in Pr. 353.

3) Furthermore, the position loop begins to work as soon as the current position signal reaches the position loop

select position set in Pr. 354.

4) After the position loop is selected, the motor keeps decelerating until the current position signal reaches the

DC dynamic braking start position set in Pr. 355, at which time DC dynamic braking is started to stop the

motor.

5) When the motor has stopped within the in-position zone set in Pr. 357, the in-position signal (ORA) is output

with a delay of the in-position signal output delay time set in Pr. 363. If the current position signal comes out of

the in-position zone due to external force etc., the in-position signal is switched off with a delay of the inposition signal output delay time set in Pr. 363.

6) The orientation fault signal (ORM) is output if the orientation cannot be completed within the time set in Pr. 365

after the current position signal has passed the creep select position.

7) If the orientation (once started) has been stopped by an external force etc. before the in-position zone is

reached and the in-position signal (ORA) is not yet output, the orientation fault signal (ORM) is output after the

PLG stop check time set in Pr. 364 has elapsed. If the current position signal comes out of the in-position zone

due to an external force etc. after the output of the in-position signal (ORA), the in-position signal (ORA) is

switched off after a delay of the in-position signal output delay time set in Pr. 363. If the orientation cannot be

completed within the PLG stop check time set in

Pr. 364, the orientation fault signal (ORM) is output.

8) When the start signal (STF or STR) is switched off with the orientation command on after the in-position signal

(ORA) or orientation fault signal (ORM) has been output once, the in-position signal (ORA) or orientation fault

signal (ORM) is output again after the recheck time set in Pr. 366 has elapsed.

25

Page 26

9) The in-position signal (ORA) and orientation fault signal (ORM) are not output if the orientation command is off.

g

y

(

)

(

)

g

y

(

)

)

(

)

(

)

(

)

(

)

g

(

)

CAUTION If the orientation command is switched off with the start signal on, the motor accelerates to

the command speed.

Orientation

speed

Creep selection

Position loop

Ori

Creep speed

Operation Timing Chart

Spindle speed

PLG

Start signal

across STF/STR-SD

Orientation command

across X22-SD

Current position signal

Ori

in signal

namic brake

DC d

in

Orientation

namic braking start position

DC d

Position loop selection

0

Orientation speed

DC dynamic

start position

brakin

set in Pr. 355

set in Pr. 351

Creep speed (set in Pr. 352

Creep select position

set in Pr. 353

Position loop select position

set in Pr. 354

Stop position command

ON

In-position signal

across ORA-SE

ON

Note: A high level refers to a signal being ON.

26

Page 27

(2) Orientation starting during stop.

(

)

g

(

)

(

)

(

)

Switch on the orientation command (X22), then switch on the start signal to start and accelerate the motor to the

orientation speed set in Pr. 351 and perform orientation using the same procedure as in Section (1). Note that if

the current position signal is within the DC dynamic braking start position, the spindle speed will not rise to the

orientation speed and the DC dynamic brake is applied.

Operation Timing Chart

Orientation speed

Creep speed

Spindle speed

PLG

Start si

across STF/STR-SD

Orientation command

across X22-SD

DC dynamic brake

nal

OFF

OFF

OFF

ON

ON

ON

OFF

OFF

OFF

In-position signal

across ORA-SE

OFF

ON

OFF

27

Page 28

(3) Multi-position orientation.

(

)

g

q

g

g

q

Orientation starting with orientation command and STF/STR kept on

(Orientation starting in the servo-in state)

Orientation speed

Creep speed

Spindle speed

PLG

Start signal

Orientation command

In-pos ition si

Position si

Position data is read on the leading edge of DY (refer to the FR-A5AX instruction manual).

If the current position signal is within the creep select position, the spindle speed rises not to the orientation

nal

DY

nal

Servo

tor

ue

Servo

ue

tor

200ms or lon

Position command latch Position command latch

er

speed but to the creep speed.

If the current position signal is outside the creep select position, the spindle speed rises to the orientation

speed.

If the current position signal is within the DC dynamic braking start position, the DC dynamic brake is applied.

28

Page 29

(4) Pr. 358 "servo torque selection"

Pr. 358 Setting

Function

1) Selection of servo torque

function until output of in-

012345678910111213

XOOOOXOXOXOXXOO:Servo torque function valid

X:Servo torque f unction invalid

Remarks

position signal

2) Retry function selection XXXXXXXOXXXOXXO:Retry function valid

X:Retry function invalid

3) Output freq uency is

compensated for when motor

shaft stops outside in-position

zone.

4) DC dynamic braking or servo

torque is selected when the

XXOOXOOXXXXXOOO:Frequency compensation

valid

X:Frequency compensation

invalid

OXXXXOOOOOOOOOO:DC dynamic braking selected

X:Servo torque selected

motor shaft comes out of the inposition zone after the inposition signal is output.

5) Selection of DC dynamic

braking or orientat ion

termination timing

O O O X X O O O O X X X X X O:Start signal (STF, STR) or

orientation command is

switched off

X:Orientation comm and is

switched off

6) Selection of in-position signal

OFF; when motor shaft comes

out of in-position zone after inposition signal is output once.

OOOOOXXXXXXXXXO:In-position signal is switched

off when motor shaft com es out

of in-position zone.

X:In-position signal r em ains on

if motor shaft comes out of inposition zone. (Orientation f ault

signal is not output.)

Note: If the orientation command is switched off with the start signal remaining on, the motor accelerates toward

the command speed.

29

Page 30

1) Selection of servo torque function until the in-position signal is output.

Set Pr. 358 "servo torque selection" to determine whether servo torque is required or not. When the current

position signal is between the orientation stop position and DC dynamic braking start position, servo torque is

not generated. The shaft is held by DC dynamic braking. If the current position signal comes out of this zone

due to external force, etc., servo torque is generated to return the current position signal to within the zone.

Once the in-position signal is output, operation is performed in accordance with the setting in 4).

2) Retry function.

Set Pr. 358 "servo torque selection" to determine whether the retry function is required or not. Note that this

function cannot be used with the servo torque function. If the motor shaft is confirmed to have stopped but is

not in the in-position zone, the retry function causes the shaft to be oriented again.

This retry is made three times, including the first orientation, but no more than three times. (The orientation

fault signal is not output during retry operation.)

3) Frequency compensation function for use when the motor shaft has stopped outside the in-position zone.

When the motor shaft has been stopped by external force, etc. before entering the in-position zone, the output

frequency is increased to move the shaft to the orientation stop position. This output frequency rises gradually

to the creep speed set in Pr. 352. This function cannot be used with the retry function.

4) Selection of whether DC dynamic braking or servo torque is started when the motor shaft comes out of the inposition zone after the in-position signal has been output once.

You can select whether to start DC dynamic braking to lock the shaft or to start servo torque to return the shaft

to the orientation stop position if the motor shaft comes out of the in-position zone due to external force, etc.

after the output of the in-position signal.

5) Selection of DC dynamic braking, servo torque or orientation termination timing.

To terminate orientation, switch off the start signal (STF or STR) and then switch off the orientation command

(X22). At this time, you can select the point of switching off the in-position signal between when the start signal

is switched off or when the orientation command is switched off.

6) In-position signal OFF selection; for use when the motor shaft comes out of the in-position zone after the inposition signal is output once. You can select either the mode in which the in-position signal is switched off

when the motor shaft comes out of thein-position zone or the mode in which the in-position signal remains on

(orientation fault signal is not output) when the motor shaft comes out of the in-position zone.

30

Page 31

(5) Pr. 362 "position loop gain"

When Pr. 358 "servo torque selection" value has been set to choose the servo torque function, the output

frequency provided to generate servo torque rises gradually up to the creep speed set in Pr. 352 according to the

inclination set in Pr. 362 "position loop gain". Increasing the setting will increase the operation speed but may

cause the machine to hunt.

(6) Monitoring functions

Monitoring Description

Position signal monitoring Set "19" in Pr. 52 to display the position signal on the PU

instead of the voltage (Displayed only when the FR-A5AP is

fitted.)

Set "22" in Pr. 52 to display the orientation status on the PU

instead of the output voltage. (Displayed only when the FRA5AP is fitted.)

0 - Orientation not selected (i.e. orientation mode has not

been activated) or orientation speed has not been reached.

1 - Orientation speed reached.

Orientation status

2 - Creep speed reached.

3 - Position loop reached.

4 - In-position.

5 - Orientation fault (pulse stop).

6 - Orientation fault (orientation time limit elapsed).

7 - Orientation fault (recheck).

8 - Positioning orientation in progress.

Servo torque will return the motor to the stop position (if enough torque can be provided) if it is moved from the

stop position. Servo torque is available in all modes vector, V/f, etc. When orientation control is selected.

31

Page 32

3.8. Instructions

(1) T he PLG should be coupled with the motor shaft or the spindle oriented with a speed ratio of 1 to 1 without any

mechanical looseness.

(2) The DC dynamic brake operated for positioning must be released in the shortest time (within several seconds).

Operating the brake continuously can cause the motor to generate heat and burn out.

(3) The servo lock function is not available after positioning stop. If the spindle must be held securely, prepare an

appropriate holding means such as a mechanical brake or a dowel pin.

(4) To ensure correct positioning, the PLG must be set in the proper rotation direction and the A and B phases

connected correctly.

(5) The orientation fault signal may be output if the pulse signal is not given from the PLG during orientation due to

an open cable, etc.

(6) When orientation control is exercised, orientation cannot be completed if "no DC dynamic brake operation" is set

in the DC dynamic brake adjusting (voltage, frequency, time) parameters. These parameters must be set to

operate the DC dynamic brake.

(7) To terminate orientation, the start signal (STF or STR) must be first switched off and the orientation signal (X22)

must be switched off. As soon as this orientation signal is switched off, orientation control ends. (Depending on

the setting of

Pr. 358 "servo torque selection", when the orientation signal remains on, orientation will continue even if the DC

dynamic brake is released as soon as the start signal is switched off. Hence, the orientation status monitored is

not set to 0.)

(8) When the retry function has been selected in Pr. 358 "servo torque selection", retry is made three times.

(Note: The first orientation counts as 1 retry.)

(9) For orientation control, set correct values in Pr. 350 "stop position command selection" and Pr. 360 "12-bit data

selection". If the values set are incorrect, proper orientation control will not be performed.

(10)The value set in Pr. 11 (DC dynamic brake operation time) should be any of 1 to 10. If "8888" (DC dynamic brake

external selection) is set in Pr. 11, the DC dynamic brake is not operated unless the X13 terminal signal is

switched on. For orientation control the DC dynamic brake is operated independently of the X12 signal.

(11)When orientation control is exercised, PID control is invalid.

32

Page 33

3.9. Specifications

Stop position accuracy

Permissible rotation speed PLG-mounted shaft speed (6000r/min)

Functions

Holding force after positioning Without servo lock function (However, when "2" is set in Pr. 370 to choose vector

Input signals (contact input)

Output signals (open collector output)

DC power supply Prepare a 5VDC power supply for the PLG.

1.5 degrees

Note: Depends on t he load torque, load GD

position loop select position, etc.

Note: The motor and PLG-mounted shaft must be coupled directly or via a belt

without any slip. A gear change type cannot be used.

Orientation and creep speed setting.

Stop position comm and selection.

DC dynamic brake start position setting.

Creep speed and position loop select position setting.

Position shift.

In-position zone.

Position signal monitoring, etc.

Note: Set the above functions from the parameter unit.

control, the servo lock function is valid.)

Orientation command.

Forward and reverse rotation commands.

Stop position comm and (open collector signal may also be entered). Maximum 12-

bit binary signal.

In-position signal.

Orientation fault signal.

(Usually a

5V, 50mA is also required for the opt ion.

Supply power from the NC or use a general power supply.

Example: NEMIC LAMBDA ES15-5 (5V, 3A)

*When PLG feedback control and orientation control are used together, the 5V

power supply is shared between these controls.

oximately 350mA)

ppr

, orientation speed, creep speed,

2

33

Page 34

I.PLG FEEDBACK CONTROL

(

)

(L1)S (L2)T (L3)

y

q

(

)

(

)

(

)

y

)

(

)

4. PLG FEEDBACK CONTROL

This function is used with a speed detector (PLG) to allow the motor speed to be detected by the speed detector and

fed back to the inverter so that the output frequency of the inverter is controlled to keep the motor speed constant to

load variations. Pr. 367 "speed feedback range" is factory-set to "9999" and Pr. 370 "control mode selection" to "0",

making this function invalid.

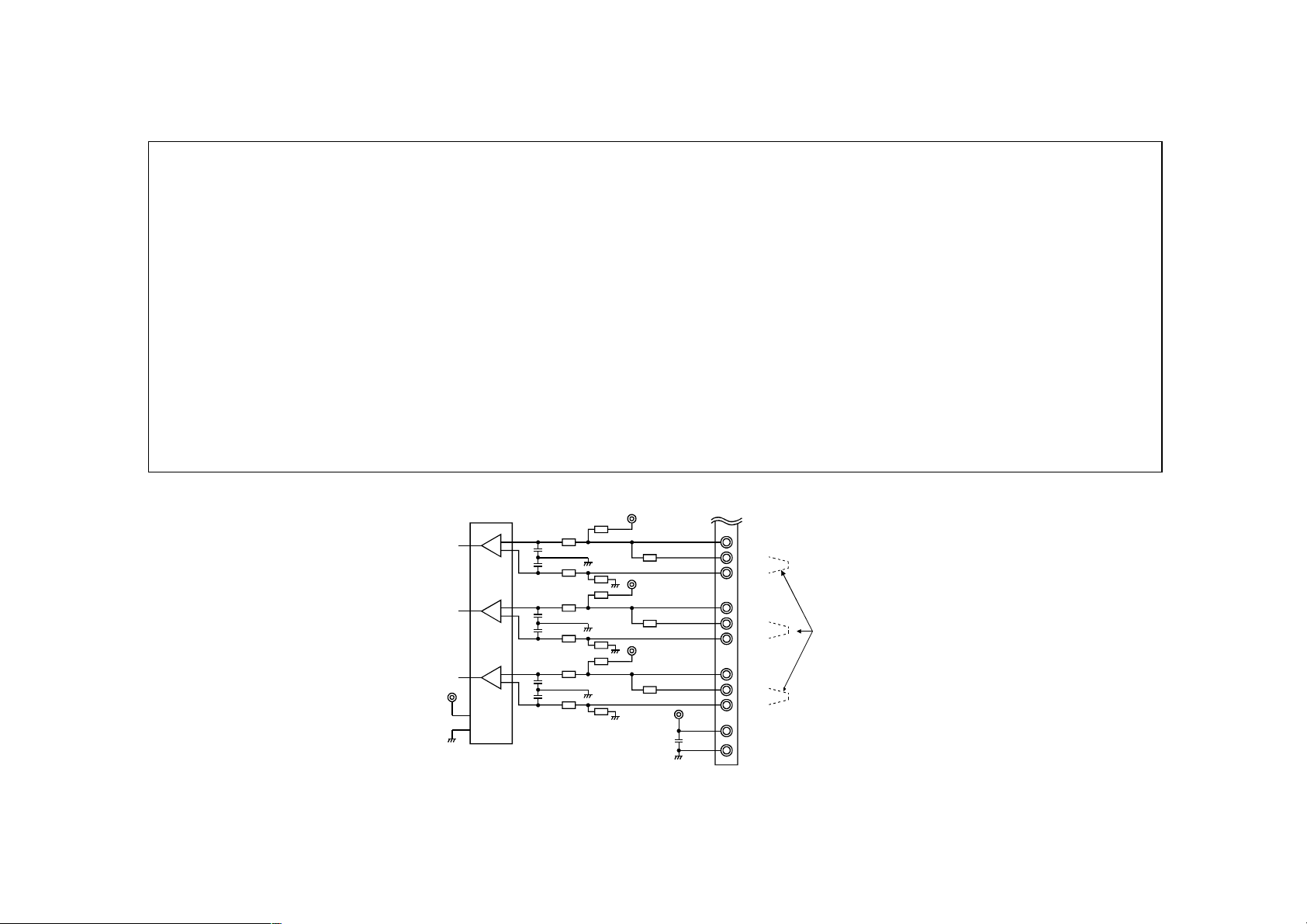

4.1. Wiring Example

SF-JR

Note 1

IM

PLG

Power suppl

Forward rotation

Reverse rotation

uency setting

Fre

potentiometer

NFB

R

STF

STR

SD

10

2

5

Inverter

FR-A5AP

U

V

W

PA1

PA2

PAR

PB1

PB2

PBR

5V

SG

Standard motor with PLG

C

R

Note 4

A

N

Note 4

H

K

E

Note 1

5V

5VDC

0

power suppl

(Note 2

34

Page 35

Note: 1. When the motor with PLG used is other than the standard motor with PLG (SF-JR), the pin numbers are

different. To reduce radiation noise, connect the shield wires of the PLG cables to the case earth pin.

2. When PLG feedback control is used with orientation control, the PLG and 5V power supply may be shared

between these controls.

3. Couple the PLG in line with the motor with a speed ratio of 1 to 1 without any mechanical looseness.

4. Keep the accessory jumpers connected. However, when the same PLG is shared between the FR-A5AP

and the other unit (e.g. NC) which is connected with a terminal resistor, the built-in terminal resistors are

not required and should be removed. (Terminal resistors; 100)

4.2. Input Circuit

‚‹

1

1000pF

+

-

+

-

1000pF

1000pF

1000pF

100

100

100

100

‚‹

1

‚‹

1

‚‹

1

100

100

1F

PA1

PAR

PA2

Jumpers

PB1

PBR

PB2

5V

SG

35

Page 36

4.3. Terminals

Symbol Terminal Remarks Description

PA1 PLG A-phase signal input terminal

PA2 PLG A-phase inverse signal input

terminal

PB1 PLG B-phase signal input terminal

PB2 PLG B-phase inverse signal input

terminal

PAR A-phase terminal resistor terminal Factory-connected with "PA2" by the

PBR B-phase terminal resistor terminal Factory-connected with "PB2" by the

5V DC power (positive) input terminal

SG DC power ground terminal

For information on t he

pulse signals, refer to

page 30.

4.75 to 6VDC

(Current consumption

50mA)

A and B-phase signals are input from

the PLG.

jumper. Remove the jumper when the

terminal resistor is not needed.

jumper. Remove the jumper when the

terminal resistor is not needed.

PLG power supply common terminals.

Input PLG power. Connect the positive

side to 5V and the ground side to SG.

Also, connect the shield of the shield

wire to SG.

36

Page 37

4.4. Wiring Instructions

(1) Connection with the speed detector (PLG).

2

Use twisted pair shielded cables (0.2mm

to terminals 5V and SG should be connected in parallel or be larger in size according to the cable length table as

indicated below. To protect the cables from noise, run them (at least 10cm) away from any source of noise (e.g.

the main circuit and power supply voltage).

(2) Cable length.

1) Cable length within 30m.

Cable Length Number of Parallel Cables

of 0.2mm

Within 10m At least 2 cables

Within 20m At least 4 cables

Within 30m At least 6 cables

2) Cable length of more than 30m

Use a power supply slightly higher than 5V (approximately 5.5V) in addition to 6 or more parallel cables of

2

0.2mm

or cables of 1.25mm2 or more. This allows the cable length to be increased up to 100m. Note that the

voltage applied across terminals 5V-SG must not exceed 6V.

(3) Connection of terminal resistors

Use the jumpers across PA2-PAR and PB2-PBR to connect terminal resistors to the A and B-phases of the PLG.

Normally, keep the jumpers fitted. However, remove the jumpers when the same PLG is shared between the FRA5AP and the other unit (e.g. NC) which is connected with a terminal resistor.

or larger) to connect the FR-A5AP and speed detector (PLG). Cables

Larger-Size Cable

2

0.4mm

0.75mm

1.25mm

or larger

2

or larger

2

or larger

2

37

Page 38

(4) Speed detector (PLG)

(High)

)

Line driver LED type PLG

A. A signal 1000ppr to 4096ppr

B. B signal 1000ppr to 4096ppr Output pulse specifications

P

abcd

A

A

B

B

2.4 to 5.2V

a, b, c and d should be (1/4 1/8)P when rotation is clockwise as viewed from

the shaft end of the PLG.

0 to 0.4V (Low

<Example of PLG available on the market>

Tamagawa Seiki:

TS1508N207, TS5008N122, TS5108N122

Pin Numbers of PLG Output Signals (Tamagawa Seiki, TS1508N207)

Pin Number Output Signal Pin Number Output Signal

C A-phase signal H +5V power supply

R A-phase inverse signal K Power supply common

A B-phase signal E Case earth

N B-phase inverse signal

Note: When PLG feedback control and orientation control are used together, the PLG is shared between these

controls. Use the PLG with a pulse count is 1000 to 4096ppr.

38

Page 39

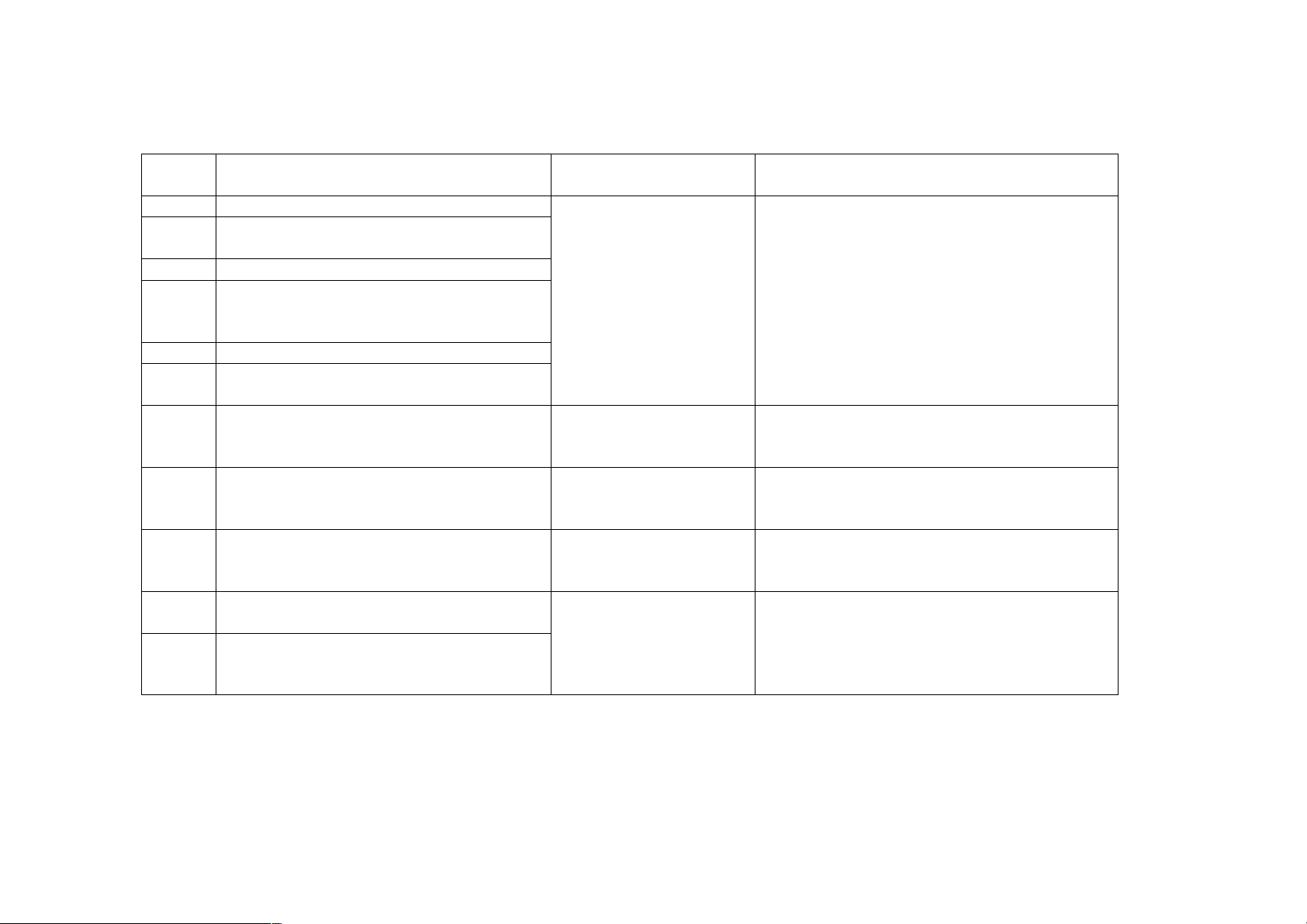

4.5. Related Parameter List

Setting Range Minimum

Number Name

22 Torque limit level (Stall prevention

operation level) (Note 1)

29 Acceleration/deceleration pattern 0, 1, 2, 3, 4 1 0

144 Number of motor poles (Speed

setting switch-over) (Note 1)

162 Automatic restart after

instantaneous power failure

selection

285 Overspeed detection frequency 0 to 30Hz, 9999 0.01Hz 9999

359 PLG rotation direction 0, 1 1 1

367 Speed feedback range 0 to 400Hz,

368 Feedback gain 0 to 100 0.1 1

369 Number of PLG pulses 0 to 4096 1 1024

370 Control mode selection 0, 1, 2 1 0

371 Torque characteristic selection 0, 1 1 1

372 Speed control P gain 0 to 200% 0.1% 100%

373 Speed control I gain 0 to 200% 0.1% 20%

374 Overspeed detection level 0 to 400Hz 0.01Hz 120Hz

375 Servo lock gain 0 to 150 1 20

380 Acceleration S pattern 1 0 to 50% 1% 0%

381 Deceleration S pattern 1 0 to 50% 1% 0%

382 Acceleration S pattern 2 0 to 50% 1% 0%

383 Deceleration S pattern 2 0 to 50% 1% 0%

0 to 200%, 9999 0.1% 150%

0, 2, 4, 6, 8, 10,

102, 104, 106,

108, 110

0, 1, 2 1 0

9999

Setting

Increments

14

0.01Hz 9999

Factory

Setting

Control ModeParameter

PLG feedback

control

(Note 3)

(Note 4)

Vector

control

(Note 4)

Note:1. When the FR-A5AP is not fitted, the function names in parentheses are used.

2. • in the Control Mode field indicates that the corresponding function is valid.

3. Functions as the stall prevention operation level.

4. The acceleration/deceleration pattern C setting (Pr. 29 = 4) is made valid when the FR-A5AP is fitted.

39

Page 40

4.6. Pre-Operation Settings

(1) Pr. 144 "number of motor poles (PLG)".

The either of the following motors may be used. Set the number of motor poles according to the motor used:

Standard motor (with PLG) : SF-JR 0.2kW to 55kW

Constant-torque motor (with PLG): SF-JRCA 0.4kW to 55kW

Note:1. For vector control, this parameter value is made invalid and the setting of Pr. 81 "number of motor poles"

is made valid.

2. If you set this parameter value to "0, 10 or 110" and operate the inverter, any of E.OP1 to E.OP3 occurs.

3. If you set "102, 104, 106 or 108", that value minus 100 is set as the number of poles.

(2) Pr. 369 "number of PLG pulses".

Set the number of PLG pulses.

Set the number of pulses before it is multiplied by 4.

Example:Set "1024" for 1024 pulses per revolution (ppr).

(3) Pr. 359 "PLG rotation direction".

Indicates the direction in which the PLG rotates.

Pr. 359=0 Pr. 359=1 (facto ry setting)

CCW

PLG

A

Forward rotation is clockwise

rotation when viewed from A.

CW

Forward rotation is counterclockwise

rotation when viewed from A.

Note: When the FR-A5AP is fitted and PLG feedback control or vector control is selected, the PU (FR-DU04/FR-

PU04) shows the rotation direction of the PLG. Make the setting so that FWD is displayed when the STF

signal switches on or REV displayed when the STR signal switches on.

40

Page 41

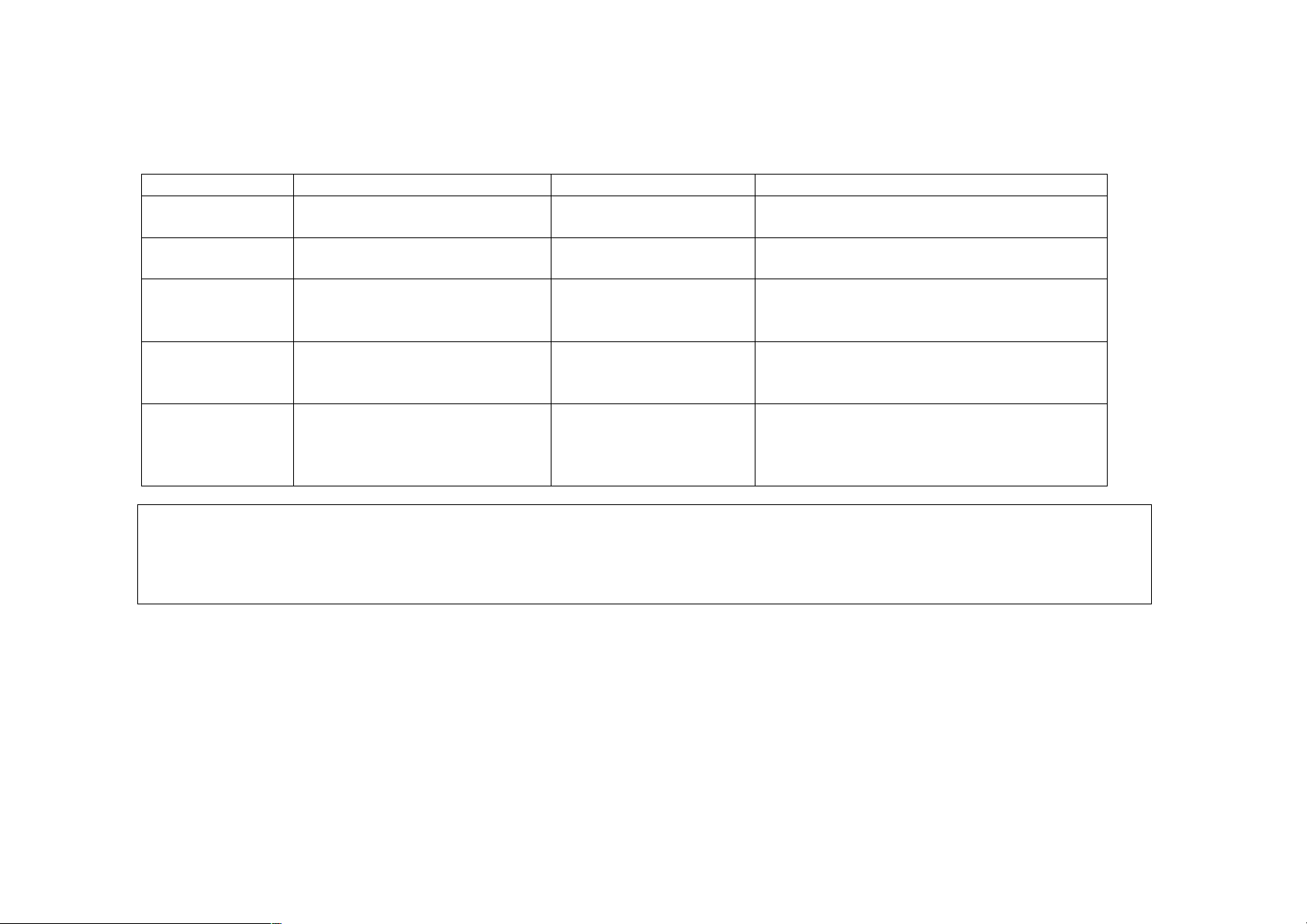

4.7. Control Mode Setting

By setting the Pr. 370 "control mode selection" value, you can choose any of PLG feedback control (V/F control,

advanced magnetic flux vector control) and vector control.

Torque control and position control are not performed. (However, torque limit can be done in the vector control

mode.) When holding torque is required during a stop, choose vector control (zero speed control or servo lock).

Control Mode Motor Pr. 80, Pr.

81 Setting

Standard

V/F control

PLG

feedback

control

Vector control (Note 1)

Advanced

magnetic

flux vector

control

motor with

PLG (same

capacity)

Standard

motor with

PLG (same

capacity)

Standard

motor with

PLG (same

capacity)

9999 0 (1,2)

Other than

9999

Other than

9999 1

Other than

9999 2

Pr. 370

Setting

(Note 2)

0 Other than

Pr. 367

Setting

Other than

9999

9999

Zero

Speed

Control

Servo Lock Torque

Limit

Note:1. When a speed control range of 1:1000 is required, choose vector control.

If vector control has been chosen, torque control and position control are not performed. The frequency

response of vector control is 10 to 20rad/s.

2. When Pr. 80 and Pr. 81 = "9999", PLG feedback control (V/F control) is valid if "1" or "2" is set in Pr. 370.

3. The RT terminal may be used to select between V/F control, PLG feedback control + advanced magnetic

flux vector control and vector control during a stop only.

41

Page 42

4.8. PLG Feedback Control

S

(

)

Driven load

Regenerative load

Make sure that Pr. 80 "motor capacity", Pr. 81 "number of motor poles", Pr. 144 "number of motor poles", Pr. 369

"number of PLG pulses", Pr. 359 "PLG rotation direction" and Pr. 370 "control mode" values are set properly. (Refer

to Section 4.6 "Pre-Operation Settings and 4.7 "Control Mode Setting".)

(1) Pr. 367 "speed feedback range".

This parameter is used to make the PLG feedback function valid.

Set the speed feedback control range.

(When Pr. 367 = 9999 (factory setting), the PLG feedback function is invalid.)

<Setting>

Define the upper and lower limits in reference to the set value (frequency at which the motor is to be rotated at

constant speed). Normally, set the frequency converted from the rated motor speed (rated load) and slip (r/min).

Too large setting will result in slow response.

Example: Rated speed of a 4-pole motor is 1740r/min (60Hz)

Slip Nsp = synchronous speed - rated speed

= 1800 - 1740 = 60 (r/min)

Frequency equivalent to slip (fsp)

Nsp - number of poles

fsp =

peed feedback range

Set command

120 120

Set value

=

60 x 4

= 2(Hz)

42

Page 43

(2) Pr. 368 "feedback gain".

This parameter is valid when PLG feedback control is valid.

Set if rotation is instable or response is slow.

When the setting is greater than 1, response is faster but overcurrent or rotational instability is more liable to

occur.

When the setting is less than 1, response is slower but rotation is more stable.

(3) Instructions for PLG feedback control.

1) The number of motor poles used must be checked before starting operation. The number of poles set must be

correct to ensure proper control of the motor.

2) The PLG should be coupled in line with the motor shaft without any mechanical looseness with a speed ratio of

1 to 1.

3) Make sure that the PLG has been set to the correct rotation direction on the rotation direction display of the

parameter unit. If the rotation direction is not correct, PLG feedback control cannot be carried out (the inverter

can be operated).

4) During acceleration or deceleration, PLG feedback control is not performed to prevent instability such as

hunting. PLG feedback control is started after the output frequency has once reached the [set speed] [speed

feedback range].

5) If any of the following conditions occurs during PLG feedback control operation, the inverter is run at the output

frequency of [set speed] [speed feedback range] without coming to an alarm stop and does not follow up the

motor speed:

The pulse signal from the PLG is switched off due to an open cable, etc.

An accurate pulse signal cannot be detected due to induction noise, etc.

The motor is forced to accelerate (regenerative operation) or decelerate (e.g. motor lock) by large external

force.

6) When opening the brake of the motor with brake, use the RUN (running) signal. (The brake may not be

opened if the FU (output frequency detection) signal is used.)

7) During PLG feedback control, do not switch off the 5V power of the PLG. If the power is switched off, normal

PLG feedback control cannot be exercised.

8) Programmed operation cannot be performed in the PLG feedback control mode (when the FR-A5AP is fitted).

43

Page 44

9) Set Pr. 285 "overspeed detection frequency" to prevent misoperation caused if an accurate signal cannot be

detected from the PLG. This shuts off the output and gives an inverter alarm (E.MB1) when;

(detection frequency) - (output frequency) > Pr.

285.

4.9. Vector control

Vector control can be performed using the standard motor with PLG.

Make sure that Pr. 80 "motor capacity", Pr. 81 "number of motor poles", Pr. 144 "number of motor poles", Pr. 369

"number of PLG pulses", Pr. 359 "PLG rotation direction" and Pr. 370 "control mode" values are set properly. (Refer

to Section 4.6 "Pre-Operation Settings and 4.7 "Control Mode Setting".) Servo lock will resist and attempts to move it

from the stop position, the limitation is the amount of torque that can be provided. Servo lock is only available in

vector control mode (when using a PLG).

(1) Zero speed control and servo lock

<Zero speed control>

When the Pr. 370 value is "1" and Pr. 80 and Pr. 81 values are not "9999", zero speed control is made valid so

that torque may be generated at zero speed.

Use Pr. 22 to set the torque limit level in the zero speed control mode. (150% torque (short duration) is possible.)

<Servo lock>

When the Pr. 370 value is "2" and Pr. 80 and Pr. 81 values are not "9999", servo lock is made valid.

Use Pr. 22 to set the torque limit level in the servo lock mode. (150% torque (short duration) is possible.)

Also, use Pr. 375 "servo lock gain" to set the servo lock gain.

A high setting will make response faster but increase the probability of instability.

When GD

2

(inertia) is large, a high servo lock gain setting will increase the probability of instability.

44

Page 45

<Zero speed control and servo lock timing charts>

(

)

q

y

Z

o

y

y

(

)

y

y

1) Zero speed control or servo lock is made valid when the auxiliary exciting terminal (LX) is ON without the start

signal (STF, STR) being entered into the inverter (during a stop). Assign the function of the auxiliary exciting

terminal (LX) to any of the terminals using Pr. 180 to Pr. 186.

LX

ON

STF

STR

Output fre

ero speed control

r servo lock

uenc

OFF

OFF

namic brake

DC d

operation frequenc

2) Zero speed control or servo lock is made valid when the frequency command is 0Hz (not more than the

starting frequency) with the start signal being entered.

LX

STF

STR

Output frequenc

Zero speed control

or servo lock

namic brake

DC d

operation time

OFF

OFF

OFF

If a start is made during zero speed control or servo lock, online auto tuning is not activated.

45

Page 46

3) Zero speed control or servo lock is made valid when the frequency command is not more than the DC

(

)

y

y

q

y

dynamic brake frequency during deceleration of the inverter. The position at the DC dynamic brake operation

frequency is held.

LX

OFF

STF

STR

Output frequenc

Zero speed control

or servo lock

OFF

namic brake

DC d

operation fre

OFF

DC dynamic brake

operation time

uenc

46

Page 47

(2) Pr. 22 "torque limit level"

(

)

(

)

(5)

ge (

)

Torque limit may be activated only when vector control is selected. The second and third functions are Pr. 48

"second torque limit level" and Pr. 144 "third torque limit level". When vector control is not selected, the stall

prevention functions are activated. Use the same parameter numbers for setting. The Pr. 22 setting may be

changed during operation. When Pr. 22 = "9999", the torque limit level may be set by entering a signal into the

No. 1 terminal. At this time, the auxiliary input override function of the No. 1 terminal is not activated.

The variable torque limit level analog signal can be limited.

Pr. 22=9999

200%

150%

Pr.149

Torque limit level

Pr.148

0V

Input volta

across terminals 1-5

10

V

(3) Pr. 371 "torque characteristic selection"

Used to change the torque characteristic according to the machine characteristics.

Pr. 371 Setting Standard Motor with PLG (e.g. SF-JR)

0

Cyclic operation mode

1 (factory setting) Continuous operation mode

(Note)

Note: When the cyclic operation mode is used, the inverter capacity must be made one rank higher than the motor

capacity.

47

Page 48

]

(

)

q

(

)

)

]

(

)

q

(

)

q

Torque Characteristic of the Standard Motor with PLG (Example: SF-JR Standard Motor with PLG (4 poles))

With Reference to 1800r/min (60Hz) Torqu e

Cyclic operation mode setting

[When the inverter used has a capacity one rank higher

than that of the motor and the rated voltage is input]

Short-duration

maximum tor

150

1.5kW or less

100

50%ED (Note 2

ue

2.2kW or more

Note 3

[ When the inverter used has the same capacity as

that of the motor and the rated voltage is input]

150

100

75

Continuous operation mode setting

Short-duration

maximum tor

1.5kW or less

Continuous

operation tor

ue

ue

2.2kW or more

Note 4

Torque [%]

30

20

0 900 1800 3600

Speed [r/min

Note 1

Torque [%]

30

20

0 1800 36001500600

Note 1

Speed [r/min

Note: 1.The maximum speed is 1) 0.4kW to 7.5kW: 3600r/m in, 2) 11kW to 30kW: 3000r/min, 3) 37kW to 55kW: 1950r/min.

2.Continuous, repetitive operation of 50%ED can be performed in cycle time of 10 minutes. Note that the maximum

continuous operation time is 5 minutes.

3.Use the constant-torque motor (SF-JRCA with PLG) when 50%ED with 100% torque is required for 2.2kW or more

at 900r/min or less.

4.Use the constant-torque motor (SF-JRCA with PLG) when continuous 100% torque is required for 2. 2kW or more at

600r/min or less.

5.To provide 150% torque from 0Hz to the rated speed of the motor the inverter should be one rank higher than t he

motor.

6.Cyclic operation when the inverter and motor have the same capacity is possible but typically only 50% torque can

be produced.

7.Continuous operation when the inverter capacity is one rank higher than the motor will produce the same results as

when the inverter and motor capacity are the same (as shown above).

48

Page 49

(4) Pr. 372 "speed control P gain".

Used to set the proportional gain of the speed loop.

A high setting will make the speed response faster but if the setting is too high this will cause vibrations and

noise.

(5) Pr. 373 "speed control I gain".

Used to set the integral gain of the speed loop.

A high setting will shorten restoration time at occurrence of speed variation but if the setting is too high this will

cause speed overshooting.

(6) Driving/regenerative status signal output.

When vector control is selected, the driving/regenerative status is output as a signal.

Assign the function of the output signal to any of the output terminals using Pr. 190 to Pr. 195 "output terminal

function selection".

(7) Instructions for vector control.

1) When using vector control, perform offline auto tuning in the motor rotation mode (whilst the motor is running).

2) Before starting operation, always confirm that the correct number of poles of the motor used. Proper speed

control cannot be performed if the number of motor poles is incorrect.

3) Couple the PLG in line with the motor shaft with a speed ratio of 1 to 1 without any mechanical looseness.

4) Make sure that the PLG has been set to the correct rotation direction on the rotation direction display of the

parameter unit. If the rotation direction is not correct, vector control cannot be carried out.

5) In the vector control mode, vector control is also exercised during acceleration/deceleration.

6) When opening the brake of a motor with brake, use the RY2 (operation ready 2) signal. (The brake may not be

opened if the FU (output frequency detection) signal is used.)

7) In the vector control mode, the maximum speed is 3600r/min (120Hz). If the speed is increased above that

value, it is clamped (limited to 120Hz (3600r/min) ).

8) Do not switch off the 5V power of the PLG during vector control. Proper vector control cannot be performed if

that power is switched off.

9) Proper vector control cannot be performed if the pulse signal from the PLG is lost due to an open cable, etc.

49

Page 50

10) In the vector control mode, the carrier frequency is as follows:

Pr. 72 Setting Carrier Frequency

V/F control, advanced

magnetic flux vector

control

0 0.7kHz

1 1kHz

2 2kHz

3 3kHz

4 4kHz

5 5kHz

6 6kHz

7 7kHz

8 8kHz

9 9kHz

10 10kHz

11 11kHz

12 12kHz

13 13kHz

14 14kHz

15 14.5kHz

Vector control

Approximately 1kHz

Approximately 3kHz

Approximately 6kHz

(Note 1)

Note:1. When the capacity of the inverter is the same as that of the motor, do not set "6" or a higher value in Pr.

72 "PWM frequency selection".

When the capacity of the inverter is one rank higher than that of the motor, "6" (appoximately 6KHz) or a

higher value may be set in Pr. 72 "PWM frequency selection".

2. In the vector control mode, set the Pr. 72 "PWM frequency selection" value during a stop.

50

Page 51

4.10. Additional Functions

(1) Pr. 162 "selection of automatic restart after instantaneous power failure selection".

By setting "2" in Pr. 162, automatic restart after instantaneous power failure can be made at the frequency

detected from the PLG. In the vector control mode, automatic restart is made with the PLG detection frequency

searched for, independently of the Pr. 162 setting.

Pr. 162 Setting Description

0 (factory setting) With frequency search

1 Without frequency search

2 PLG detection frequency search

(2) Pr. 285 "overspeed detection frequency".

If (detection frequency) (output frequency) > (Pr. 285 setting), E.MB1 occurs and the output is shut off.

When Pr. 285 = 9999, overspeed detection is not performed.

51

Page 52

(3) Pr. 374 "overspeed detection level".

)

(

)

Used to limit the maximum speed. (0 to 400Hz)

Any speed higher than the speed set in Pr. 374 is judged as overspeed and the corresponding signal is output.

If overspeed is detected, the inverter will not come to an alarm stop.

Speed (r/min

Speed set in Pr. 374

Pr.374

Time

Overspeed detection

output

Y29) (Note

OFF ON

Note: Assign the function to any of the terminals using Pr. 190 to Pr. 195 "output terminal function selection".

(4) Forward/reverse running signal output.

Whether forward or reverse rotation is being made is output as a signal according to the actual speed.

Assign the function of the output signal to any of the terminals using Pr. 190 to Pr. 195 "output terminal function

selection".

52

Page 53

(5) S-shaped acceleration/deceleration C

S

d

s

When the FR-A5AP is fitted, S-shaped acceleration/deceleration C can be selected by setting "4" in Pr. 29

"acceleration/deceleration pattern". The S-shaped acceleration/deceleration C function allows the speeds of Sshaped acceleration/deceleration to be set in the corresponding parameters and the required parameter to be

selected by the S-shaped acceleration/deceleration C switching terminal (X20).

Assign the function of the S-shaped acceleration/deceleration C switching terminal (X20) to any of the terminals

using Pr. 180 to Pr. 186 "input terminal function selection".

Operation During Acceleration During Deceleration

S-Pattern

Switching Terminal

OFF Pr. 380 "S-shaped

ON Pr. 382 "S-shaped

acceleration 1"

acceleration 2"

Pr. 381 "S-shaped

deceleration 1"

Pr. 383 "S-shaped

deceleration 2"

-shaped acceleration/

eceleration C

witching terminal X20

Pr.380

Pr.380

ON

OFF

Pr.382

Pr.382

Pr.381

Pr.381

Pr.383

Pr.383

Also, Pr. 380 to Pr. 383 are used to set the ratio of the S-shaped acceleration/deceleration time (Ts) to the

acceleration/deceleration time (T) in %.

S-shaped acceleration

Linear acceleration

Ts

T

Note: During acceleration/deceleration, switching cannot be made using the S-shaped acceleration/deceleration C

switching terminal (X20). When X20 is switched either ON or OFF during either acceleration or deceleration, the

effect of the switch (to select a different acceleration or deceleration shape) does not take effect until either the

acceleration or deceleration has stopped (i.e. a stable speed has been reached).

53

Page 54

4.11. Specifications

Speed variation ratio

Speed control range 1:1000 in vector control mode.

Functions

DC power supply A 5VDC power supply is required for the PLG and option unit.

Maximum speed 3600r/min (120Hz) in vector control mode.

Frequency response 10 to 20rad/s.

0.02% of the maximum speed (3600r/min) in vector control mode

(load variation 0 to 100% at 6Hz or more).

Speed feedback range setting.

Feedback gain setting.

PLG rotation direction setting.

The 5V power supply can be shared between orientation control and PLG feedback control.

This power supply is optional.

Power supply 5VDC, current capacity 400mA or more.

(Normally approximately 350mA for PLG and 50mA for opt ion unit)

<Power supply example> NEMIC LAMBDA ES15-5 (5V 3A)

(Note 1)

Note: 1. Load variation 100% indicates the maximum continuous operation torque value of the motor output

characteristic (refer to the relevent catalog or technical information) to the running frequency.

54

Page 55

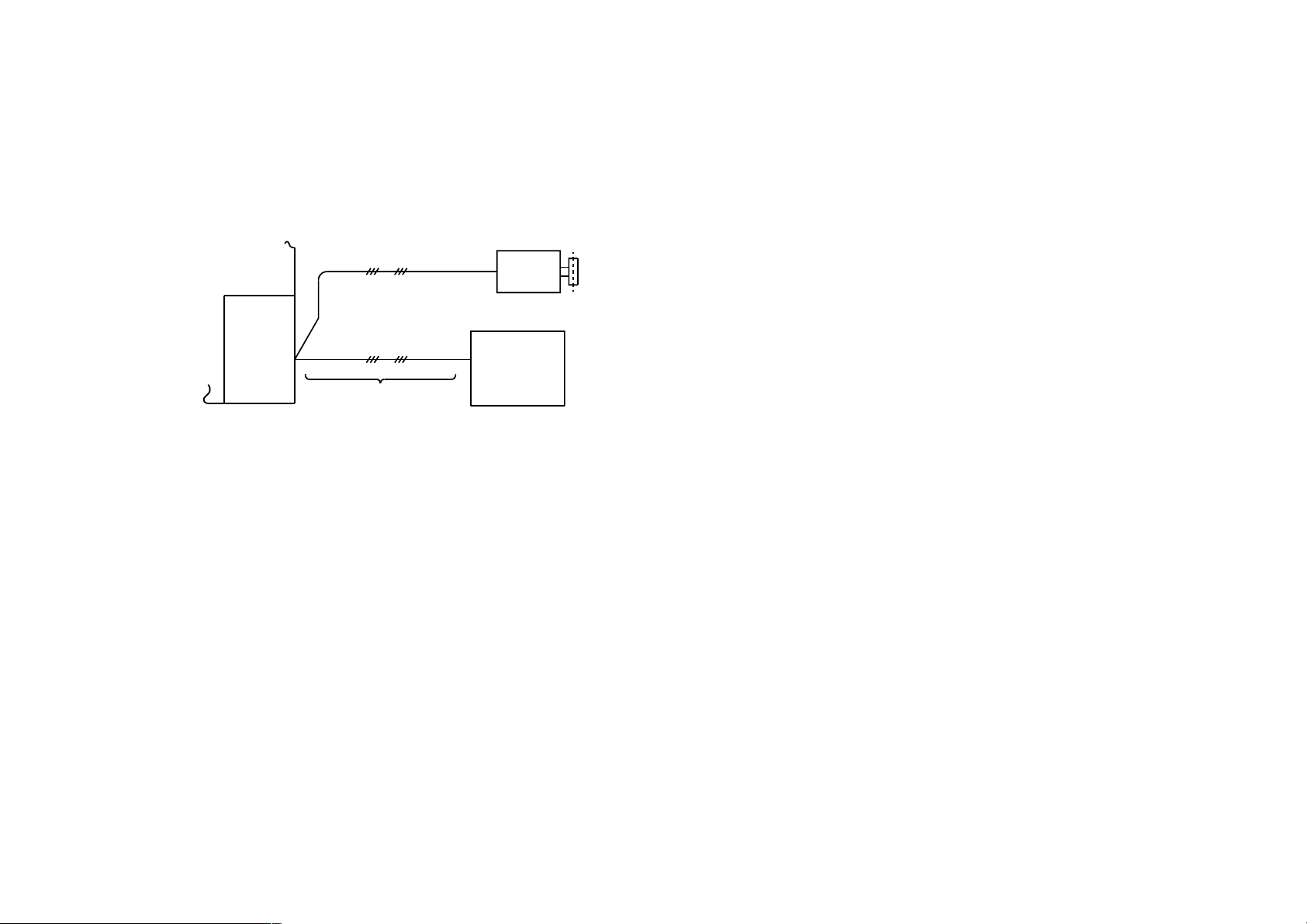

5. Wiring Example

(L1)S (L2)T (L3)

(L1)S (L2)T (L3)

y

y

I. PULSE TRAIN INPUT

A pulse train signal can be used to enter the speed setting of the inverter.

Pr. 384 is factory set to "0" to make this function invalid.

5.1. Wiring Example

NFB

Power

suppl

R

Inverter

W

U

V

Motor

IM

Power

suppl

NFB

R

Inverter

W

U

V

Motor

IM

or

Input pulses

Open

collector

input

PC

PIN

PO

SD

FR-A5AP

Input pulses

Open collector input

PC

FR-A5AP

PIN

PO

SD

Note: This option unit must be wired using the open collector system to operate it properly.

5.2. Terminals

Symbol Terminal Description

PIN Pulse input terminal 1

PO Pulse input terminal 2

Terminal used to enter a pulse train of 0 to 100kpps

Terminal used to enter a pulse train of 0 to 100kpps

Note: Whether an input pulse is entered into PIN or PO depends on the wiring. Refer to Section 5.1 "Wiring

Example".

(Note)

(Note)

55

Page 56

5.3. Adjustment

(

)

y

g

(

)

Factor

60Hz

settin

Note: Maximum number of input pulses: 100kpps

Note: Number of input pulses are multiplied by 2

internally

Output frequency

Bias

Pr.385

Pr.386

Gain

0

Input pulses

Maximum number of pulses

PPS

5.4. Parameter Definition

Parameter No. Name Setting Range Minimum Increments Factory Setting

(Note 1)

384

385 Zero-input pulse frequency 0 to 400Hz 0.01Hz 0

386 Maximum-input pulse frequency 0 to 400Hz 0.01Hz 60

Input pulse frequency division ratio 0 to 250 1 0

Note:1. Indicates the frequency division ratio for the input pulses. The frequency resolution to the input pulses

varies with the setting.

2. When the Pr. 384 value is "0" (factory setting), Pr. 385 and Pr. 386 do not function even if their values

have been set.

CAUTION

It should be noted that if the pulse train input command is not given, the motor will start at the preset

frequency by merely switching on the start signal.

56

Page 57

5.5. Setting Ex ample

y

g

g

y

(L1)

(L2)

(L3)

When the frequency is set to 0 to 60Hz at the input pulse frequency setting of 0 to 50kpps.

NFB

Power suppl

Frequency setting potentiometer

e.

. pulse

enerator

0 to 50kpps

Inverter

R

S

T

FR-A5AP

U

V

W

Motor

IM

0 to 60Hz

Hz

60

Preset frequency

0

Input pulse frequenc