Mitsubishi FDCVA302HENR, FDTCA151R, FDTA151R, FDTVA302HEN1R, FDENVA302HEN1R User Manual

...

Collection data

PACKAGED AIR-CONDITIONER

(Split system, Air to air heat pump type)

CEILING RECESSED TYPE

FDTVA302HEN1R

Manual No. '06•PAC-T-109

CEILING SUSPENDED TYPE

FDENVA302HEN1R

SATELLITE DUCTED TYPE

FDUMVA302HEN2R

MULTI-TYPE (V-MULTI)

PACKAGED AIR-CONDITIONER

(OUTDOOR UNIT)

FDCVA302HENR

(INDOOR UNIT)

FDTCA151R

FDTA151R

FDENA151R

FDKNA151R

-

1

-

TABLE OF CONTENTS

1. PACKAGED AIR-CONDITIONER......................................................................................... 2

2. MULTI-TYPE (V MULTI) PACKAGED AIR-CONDITIONER ............................................ 122

3. WIRELESS KIT (OPTIONAL PARTS) .............................................................................. 190

-

2

-

1. PACKAGED AIR-CONDITIONER

CONTENTS

1.1 GENERAL INFORMATION ............................................................................... 4

1.1.1 Specific features .......................................................................................... 4

1.1.2 How to read the model name....................................................................... 4

1.2 SELECTION DATA ........................................................................................... 5

1.2.1 Specifications ............................................................................................... 5

(1) Ceiling recessed type (FDT) ......................................................................... 5

(2) Ceiling suspended type (FDEN) ................................................................... 6

(3) Satellite ducted type (FDUM)........................................................................ 7

1.2.2 Range of usage & limitations ....................................................................... 8

1.2.3 Exterior dimensions ..................................................................................... 9

(1) Indoor unit ..................................................................................................... 9

(2) Remote controller (Optional parts) ............................................................. 12

(3) Outdoor unit ................................................................................................ 14

1.2.4 Inside view ................................................................................................. 15

1.2.5 Exterior appearance .................................................................................. 16

1.2.6 Piping system ............................................................................................ 17

1.2.7 Selection chart ........................................................................................... 18

1.2.8 Characteristics of fan ................................................................................. 23

1.2.9 Noise level ................................................................................................. 23

(1) Indoor unit ................................................................................................... 23

(2) Outdoor unit ................................................................................................ 24

1.3 ELECTRICAL DATA ....................................................................................... 25

1.3.1 Electrical wiring .......................................................................................... 25

(1) Indoor unit ................................................................................................... 25

(2) Outdoor unit ................................................................................................ 28

1.4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER .................. 29

(1) Remote controller ....................................................................................... 29

(2) Operation control function by the indoor unit controller .............................. 31

(3) Operation control function by the wired remote controller .......................... 38

(4) Operation control function by the outdoor unit controller ............................ 39

-

3

-

1.5 APPLICATION DATA ...................................................................................... 49

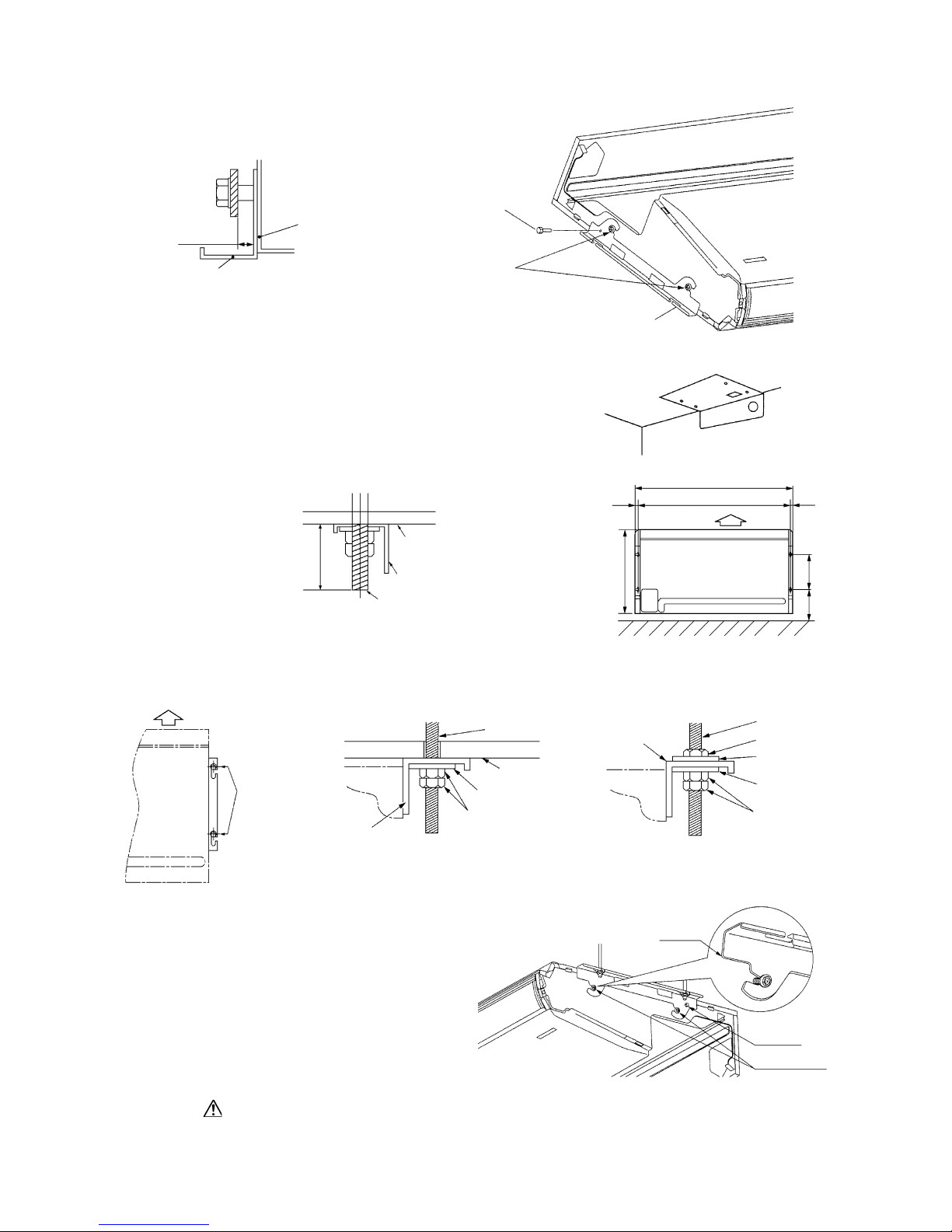

1.5.1 Installation of indoor unit ........................................................................... 50

(1) Ceiling recessed type (FDT) ....................................................................... 50

(2) Ceiling suspended type (FDEN) ................................................................. 56

(3) Satellite ducted type (FDUM)...................................................................... 61

1.5.2 Installation of wired remote controller ....................................................... 68

1.5.3 Installation of outdoor unit ......................................................................... 69

(1) Installation................................................................................................... 69

(2) Refrigerant piping work ............................................................................... 71

(3) Air tightness test and air purge ................................................................... 72

(4) Refrigerant quantity .................................................................................... 73

(5) Drain piping work ........................................................................................ 73

(6) Electrical wiring ........................................................................................... 74

(7) Setting functions using the wired remote controller .................................... 76

(8) Checking operation data ............................................................................. 80

(9) Test run ....................................................................................................... 81

1.6 MAINTENANCE DATA ................................................................................... 82

1.6.1 Servicing ................................................................................................... 82

1.6.2 Trouble shooting for refrigerant circuit ....................................................... 83

1.6.3 Diagnosing of microcomputer circuit ......................................................... 84

(1) Selfdiagnosis function ................................................................................. 84

(2) Procedures of trouble diagnosis ................................................................. 87

(3) Error diagnosis procedures at the indoor unit side ..................................... 87

(4) Error diagnosis procedures at the outdoor unit side ................................. 104

(5)

Check method in the case of the failure display in the remote controller ..............

119

(6)

Check abnormal operation data with the wired remote controller .........................

120

1.6.4

Check display on wireless specification models (FDEN · FDT)....................

121

-

4

-

Example: FDT V A 30 2 H EN 1 R

1.1 GENERAL INFORMATION

1.1.1 Specific features

(1) A new refrigerant, R410A, which causes no damage to the earth’s ozone layer, is used. R410A is a pseudoazeotropic refrigerant, so

there is little formation of separate vapor and liquid layers, and it is possible to add refrigerant on-site.

(2) Less refrigerant charge amount due to use of double phase refrigerant flow system. The total refrigerant charge amount has been

reduced by more than 50%.

(3) The microcomputer chip is installed in the indoor unit and outdoor unit. There is no need for the unit to communicate between the

outdoor and indoor units so the unit is more resistant to electromagnetic noise thus the incidence of microcomputer malfunction

has been reduced. The compressor in the outdoor unit has its own self protection function, that reacts according to abnormal high

pressure and excessive high temperature.

(4) There are only three power lines between the outdoor and indoor unit. One cabtyre cable with 3 wires encased in one sheath is

enough for conducting the wiring work between the outdoor unit and the indoor unit. This contributes to simpler wiring work in the

field.

(5) All air supply ports have auto swing louvers. (Only case of FDT and FDEN models). The indoor fan motor has three speeds of

high, medium and low.

(6) All models have service valves protruding from the outdoor unit for faster flare connection work in the field.

(7) The size and weight of the outdoor units in the FDCVA 302 series have been greatly reduced. Use of an inverter has also improved

energy conservation and economy.

1.1.2 How to read the model name

RoHS specification

Applicable power source ... See the specifications

Heat pump type

Series No.

Product capacity

R410A models

V: Inverter specification

Model name

FDT :

FDEN :

FDUM

:

FDC :

Ceiling recessed type unit with wired

remote controller

Ceiling suspended type unit with

wireless remote controller

Satellite ducted type unit with wired

remote controller

Outdoor unit

-

5

-

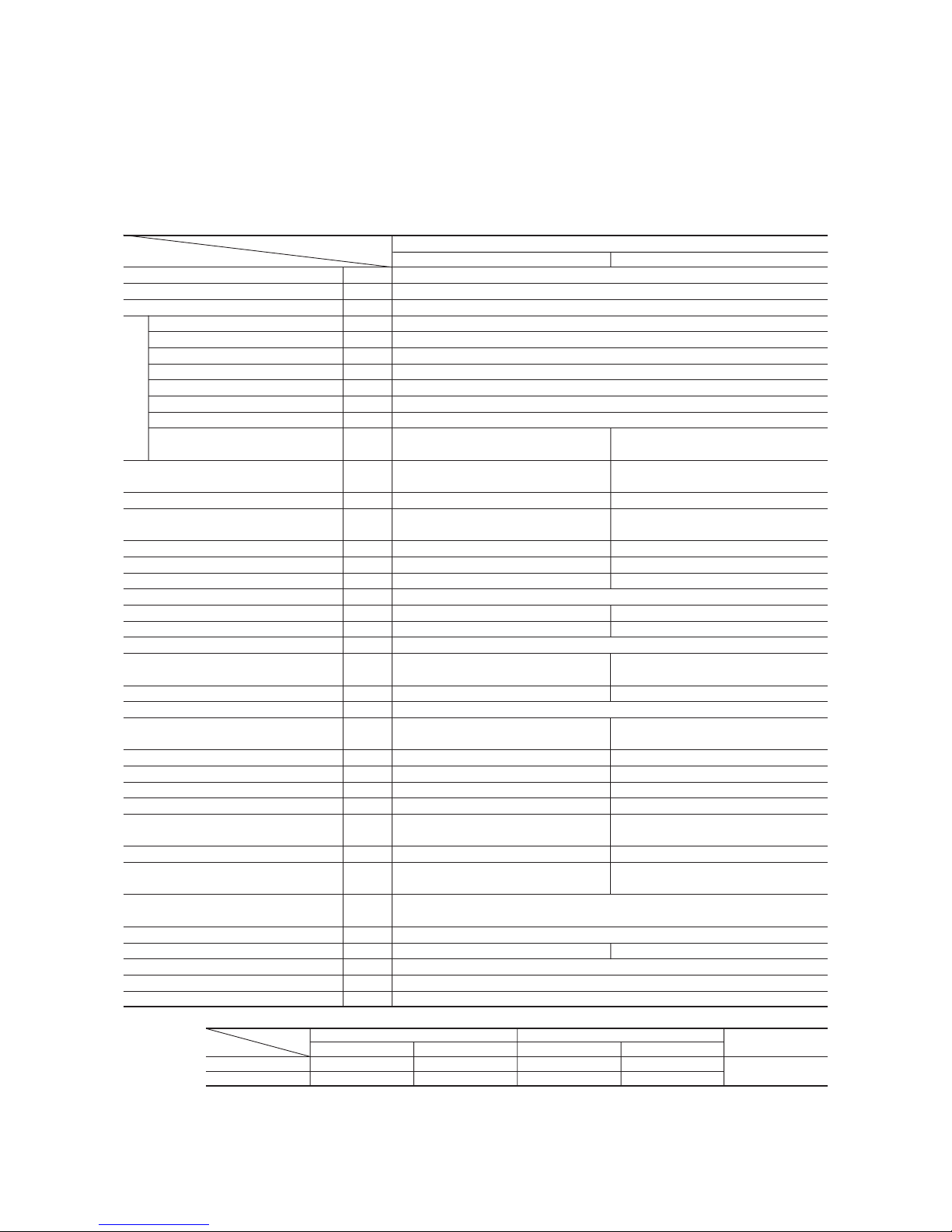

Item

Model

FDTA301R FDCVA302HENR

Nominal cooling capacity

(1)

kW 7.1[3.9~8.0]

Nominal heating capacity

(1)

kW 8.0[4.0~9.0]

Power source 1 Phase, 220/230/240V 50Hz

Cooling power consumption kW 1.90

Running current (Cooling) A 8.3

Power factor (Cooling) % 99

Heating power consumption kW 2.07

Running current (Heating) A 9.0

Power factor (Heating) % 99

Inrush current (L.R.A) A 5

Noise level dB(A)

35 52

Exterior dimensions

mm

Unit 270 × 840 × 840

750 × 880 (+88) × 340

Height × Width × Depth Panel 30 × 950 × 950

Net weight kg 31 (Unit:24 Panel:7) 60

Refrigerant equipment

– 2YC45DXD 1

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

2.95 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.65 (FVC50K)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Turbo fan × 1 Propeller fan × 1

Motor W 20 × 1 120 × 1

Starting method Direct line start

Air flow CMM Cooling:60 Heating:48.5

Outside air intake Available –

Air filter, Q’ty Long life filter ×1(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control Wired remote control switch (Optional : RC-E1R)

Operation switch

Wireless remote control switch (Optional : RCN-T-35W-ER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Abnormal discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Decorative Panel

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 230V 50Hz.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDTVA302HEN1R

Model FDTVA302HEN1R

Powerful mode Hi:38 Me:35 Lo:33

Mild mode Hi:35 Me:33 Lo:31

Powerful mode Hi:20 Me:17 Lo:15

Mild mode Hi:17 Me:15 Lo:13

48

(1) Ceiling recessed type (FDT)

1.2 SELECTION DATA

1.2.1 Specifications

-

6

-

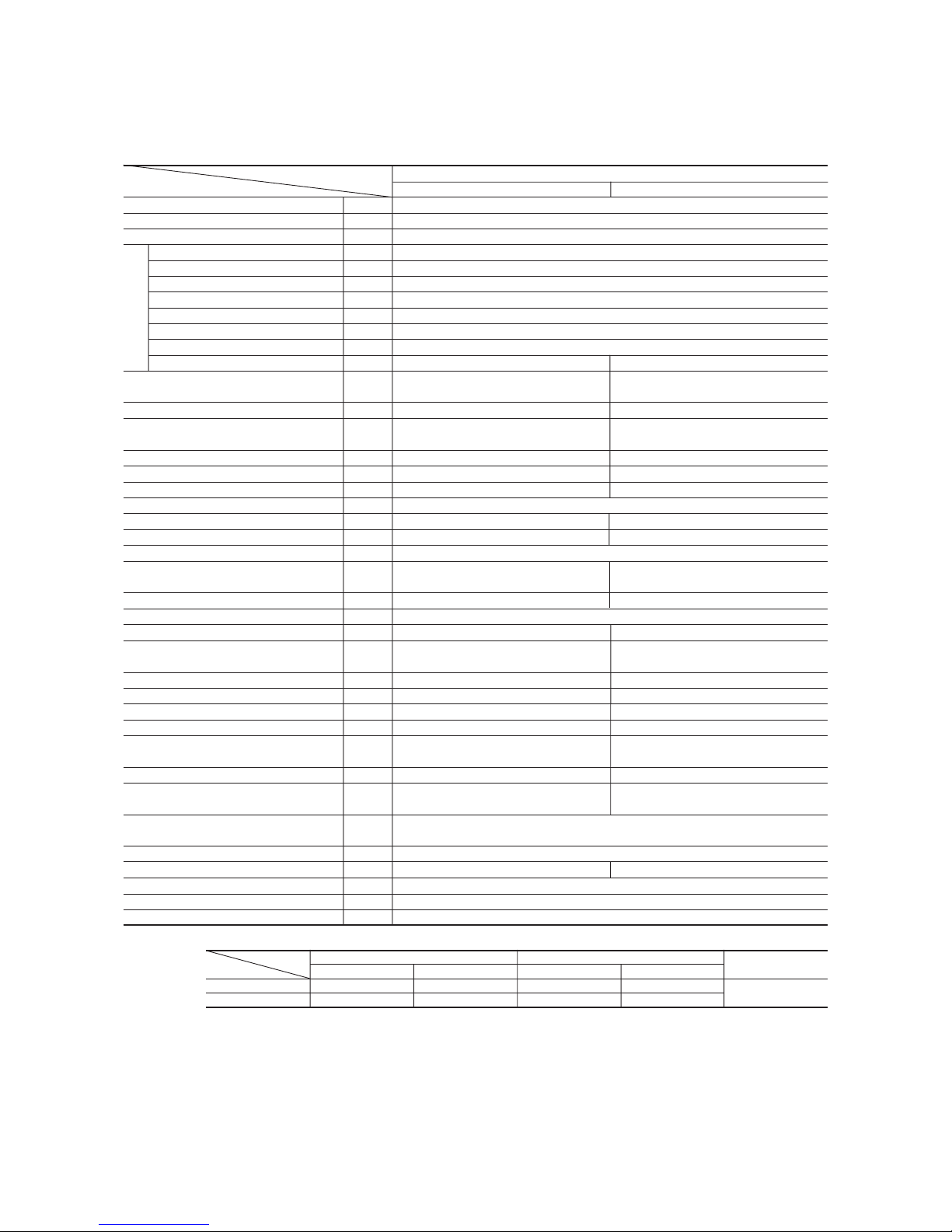

Item

Model

FDENA301R FDCVA302HENR

Nominal cooling capacity

(1)

kW 7.1[3.5~8.0]

Nominal heating capacity

(1)

kW 8.0[4.0~9.0]

Power source 1 Phase, 220/230/240V 50Hz

Cooling power consumption kW 2.06

Running current (Cooling) A 9.1

Power factor (Cooling) % 98

Heating power consumption kW 2.21

Running current (Heating) A 9.8

Power factor (Heating) % 98

Inrush current (L.R.A) A 5

Noise level dB(A)

Exterior dimensions

mm 210 × 1320 × 690 750 × 880 (+88) × 340

Height × Width × Depth

Net weight kg 36 60

Refrigerant equipment

– 2YC45DXD 1

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

2.95 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.65 (FVC50K)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Multiblade centrifugal fan × 4 Propeller fan × 1

Motor W 25 × 2 120 × 1

Starting method Direct line start

Air flow CMM Cooling:60 Heating:48.5

Outside air intake Unavailable –

Air filter, Q’ty Polypropylene net ×2(washable) –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20 (Crank case heater)

Operation control

Wireless remote control switch (Optional: RCN-E1R)

Operation switch Wired remote control switch (Optional: RC-E1R)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Abnormal discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP20 (I.D.20mm, O.D.26mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts –

Model FDENVA302HEN1R

Operation data

(3)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard. ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 230V 50Hz.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

FDENVA302HEN1R-SB

48

Powerful mode Hi:44 Me:41 Lo:39

Mild mode Hi:41 Me:39 Lo:38

Powerful mode Hi:20 Me:18 Lo:14

Mild mode Hi:18 Me:14 Lo:12

(2) Ceiling suspended type (FDEN)

-

7

-

Model FDUMVA302HEN2R

Item

Model

FDUMA302R FDCVA302HENR

Nominal cooling capacity

(1)

kW 7.1[3.5~8.0]

Nominal heating capacity

(1)

kW 8.0[4.0~9.0]

Power source 1 Phase, 220/230/240V, 50Hz

Cooling power consumption kW 2.08

Running current (Cooling) A 9.2

Power factor (Cooling) % 98

Heating power consumption kW 2.21

Running current (Heating) A 10.2

Power factor (Heating) % 94

Inrush current (L.R.A) A 5

Noise level dB(A) Hi:35 Me:32 Lo:29

Exterior dimensions

mm 299 × 950 × 635 750× 880 (+88)× 340

Height × Width × Depth

Net weight kg 40 60

Refrigerant equipment

–

2YC45DXD × 1

Compressor type & Q’ty

Starting method – Direct line start

Heat exchanger Louver fin & inner grooved tubing Straight fin & inner grooved tubing

Refrigerant control – Electronic expansion valve

Refrigerant R410A

Quantity kg –

2.95 [Pre-charged up to the piping length of 30m]

Refrigerant oil r – 0.48 (BR68A)

Defrost control Microcomputer controlled de-icer

Air handling equipment

Fan type & Q’ty

Multiblade centrifugal fan × 2 Propeller fan × 1

Motor W 100 × 1 120 × 1

Starting method Direct line start

Air flow CMM Hi: 20 Me:18 Lo:15 Cooling:60 Heating:48.5

Available static pressure

Pa Standard: 50, Max: 85 –

Outside air intake – –

Air filter, Q’ty – –

Shock & vibration absorber Rubber sleeve (for fan motor) Rubber mount (for compressor)

Electric heater W – 20(Crank case heater)

Operation control Wired remote control switch (Optional: RC-E1R)

Operation switch Wireless kit (Optional: RCND-KIT-HER)

– (Indoor unit side)

Room temperature control Thermostat by electronics –

Safety equipment Internal thermostat for fan motor. Internal thermostat for fan motor.

Frost protection thermostat. Abnormal discharge temperature protection.

Installation data mm

Liquid line: φ9.52 (3/8″) Gas line: φ15.88 (5/8″)

Refrigerant piping size (in)

Connecting method Flare piping

Drain hose Connectable with VP25 (I.D.25mm, O.D.32mm) –

Insulation for piping Necessary (both Liquid & Gas lines)

Accessories Mounting kit. Drain hose

Optional parts Filter kit (UM-FL2E)

(2) This packaged air-conditioner is manufactured and tested in conformity with the following standard.

ISO-T1 “UNITARY AIR-CONDITIONERS”

(3) The operation data indicate when the air-conditioner is operated at 230V 50Hz.

Notes (1) The data are measured at the following conditions.

Item Indoor air temperature Outdoor air temperature

Standards

Operation DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

Heating 20˚C – 7˚C 6˚C

ISO-T1

Operation data

(3)

FDUMVA302HEN2R

48

(3) Satellite ducted type (FDUM)

-

8

-

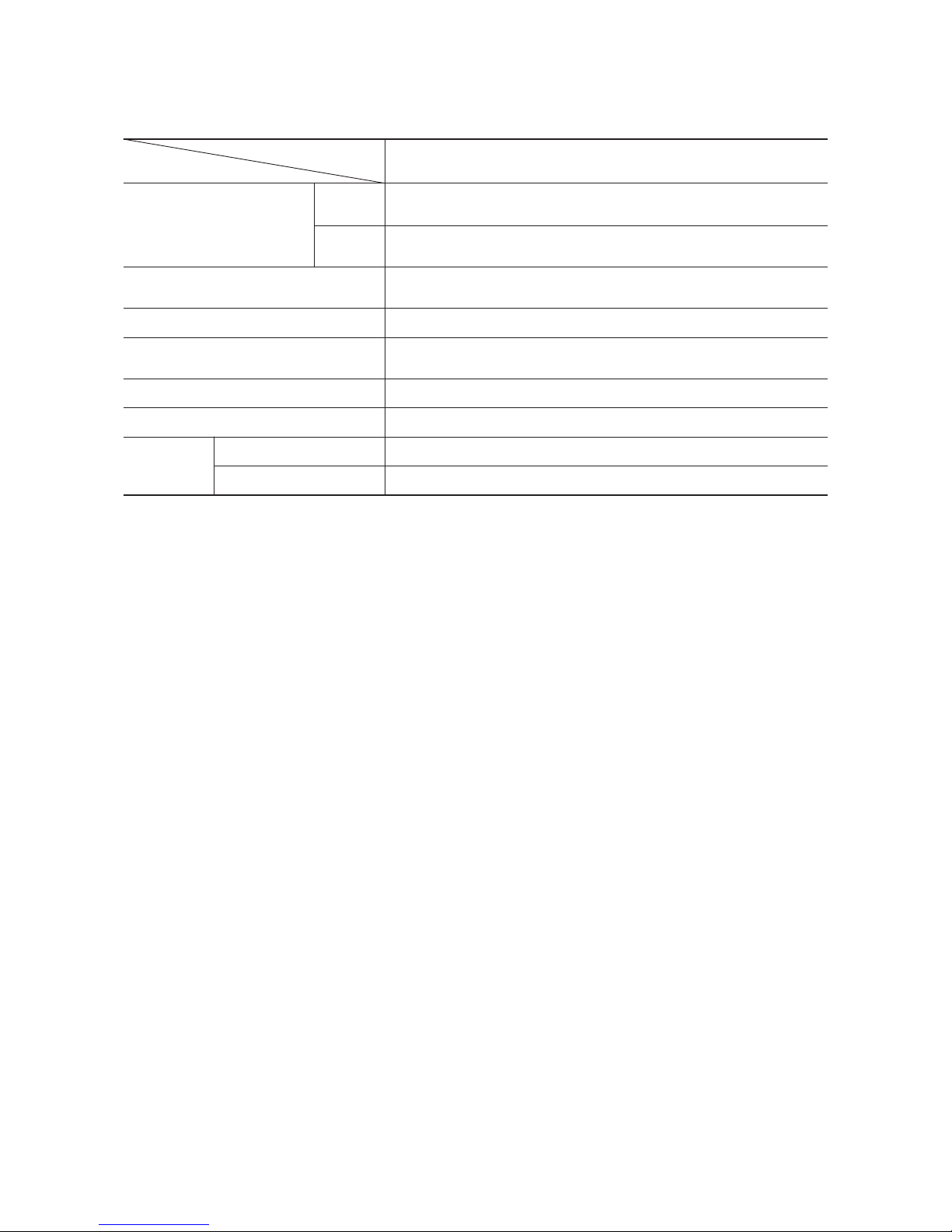

1.2.2 Range of usage & limitations

Model

302 series

Item

Limitations

Return air temp

Indoor unit atmosphere (behind ceiling)

temperature and humidity

Refrigerant line (one way) length

Vertical height difference between

outdoor unit and indoor unit

Power source voltage

Voltage at starting

Cycle Time

Stop Time

Dew point temperature: 28˚C or less, relative humidity: 80% or less

Indoor unit:18~30˚CD.B Outdoor unit:-15~43˚CD.B

Max. 50m

7 minutes or more (4 minutes or more from start to stop) or (3 minutes or more from stop to start)

3 minutes or more

Min. 85% of rating

Rating ± 10%

Compressor

stop/start

Frequency

Max. 30m (Outdoor unit is higher)

Max. 15m (Outdoor unit is lower)

Cooling

Heating Indoor unit:18~30˚CD.B Outdoor unit:-10~24˚CD.B

-

9

-

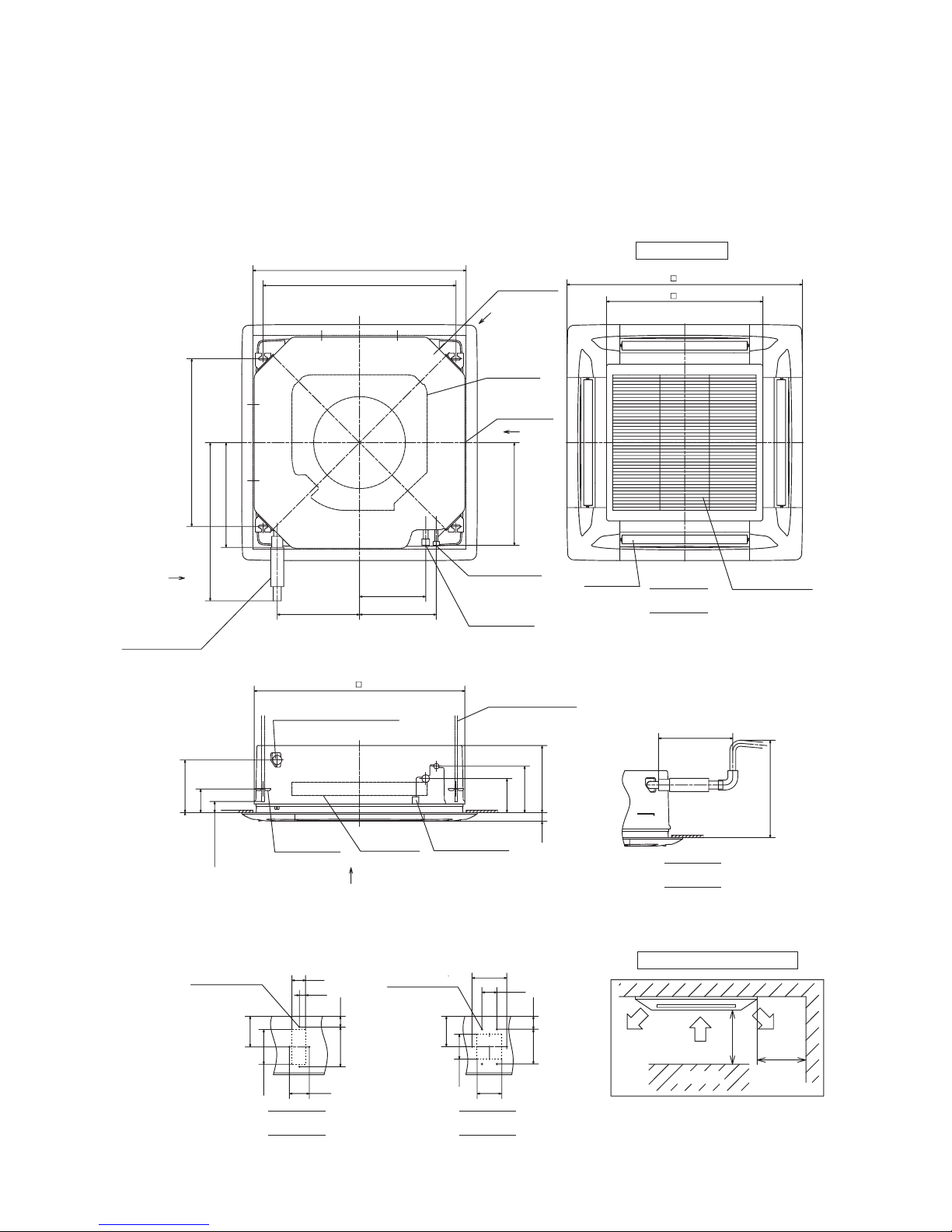

Air supply

Air return grille

VIEW A

VIEW B

VIEW C VIEW D

Decorative Panel

700

or less

(Max. Drain up)

Drain hose piece

(Accessory)

(Installed at site)

Hole for wiring

840

212

95

45

35 270

187

137

332

637

422

420

310

267

950

630

295~325

122

100

25

55

123

140

80 100

160 43

60

140

140 52

ø15.88(5/8")

A

6-ø4

4-ø4

860~890

(Ceiling hole size)

780

(Suspension bolts pitch)

675

(Suspension bolts pitch)

Control box

Outside air

opening for

ducting

Exhaust air

opening for

ducting

Control box

Gas piping

ø9.52(3/8")

Liquid piping

or more

Lug for

suspension bolts

Space for installation and service

If you are mounting units close together,

leave a space of 4000 or greater between unit.

Obstacle

Holes for

tapping screws

Holes for

tapping screws

Holes

Holes

Suspension bolts

B

D

C

Drain

(Connectable with VP25)

1000

or more

2500 or more

Model FDTA301R

unit : mm

1.2.3 Exterior dimensions

(1) Indoor unit

(a) Ceiling recessed type (FDT)

-

10

-

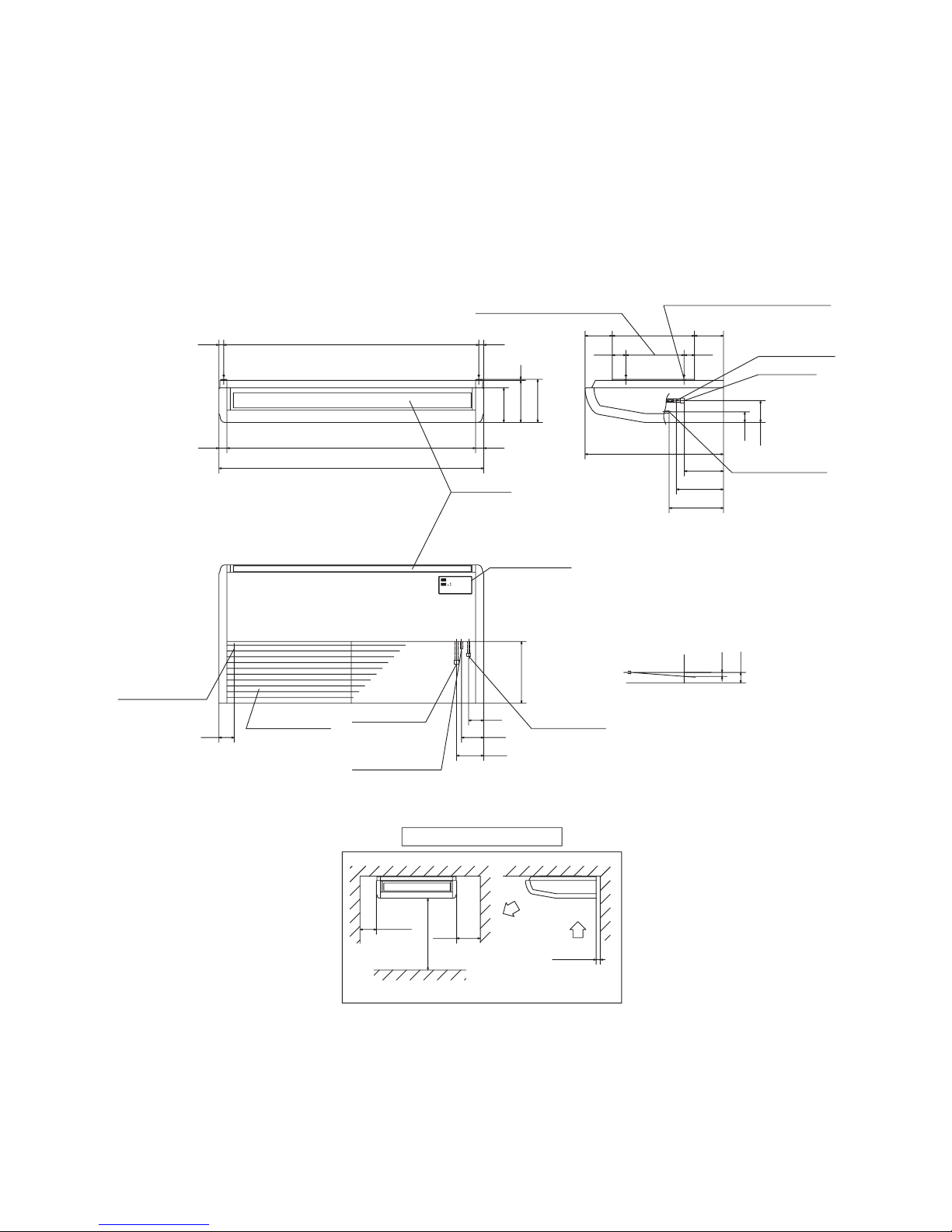

(b) Ceiling suspended type (FDEN)

Model FDENA301R

100

300or more

150

5

75

110

135

308

4040 1240

1320

173

210 5

215

2424

690

195

235

271

53

109

5268

410135

10

53

145

76

1272(Suspension bolts pitch)

290(Suspension bolts pitch)

Air supply

Indication board

ø9.52(3/8")

ø15.88(5/8")

Holes for suspension bolts

(M8 to M10

×

4pcs.Not included)

Liquid piping

Gas piping

Liquid piping

Gas piping

Space for installation and service

or more

or more

or more

Obstacles

Air ireturn grille

Drain hose piece

connection

(1)

Drain hose piece

connection

(1)

Drain hose piece

connection

(1)

(VP20)

(VP20)

(VP20)

Note(1) The slope of drain piping inside the unit is

able to take incline of 10mm.

Unit : mm

If you are mounting units close together,

leave a space of 4500 or greater between unit.

-

11

-

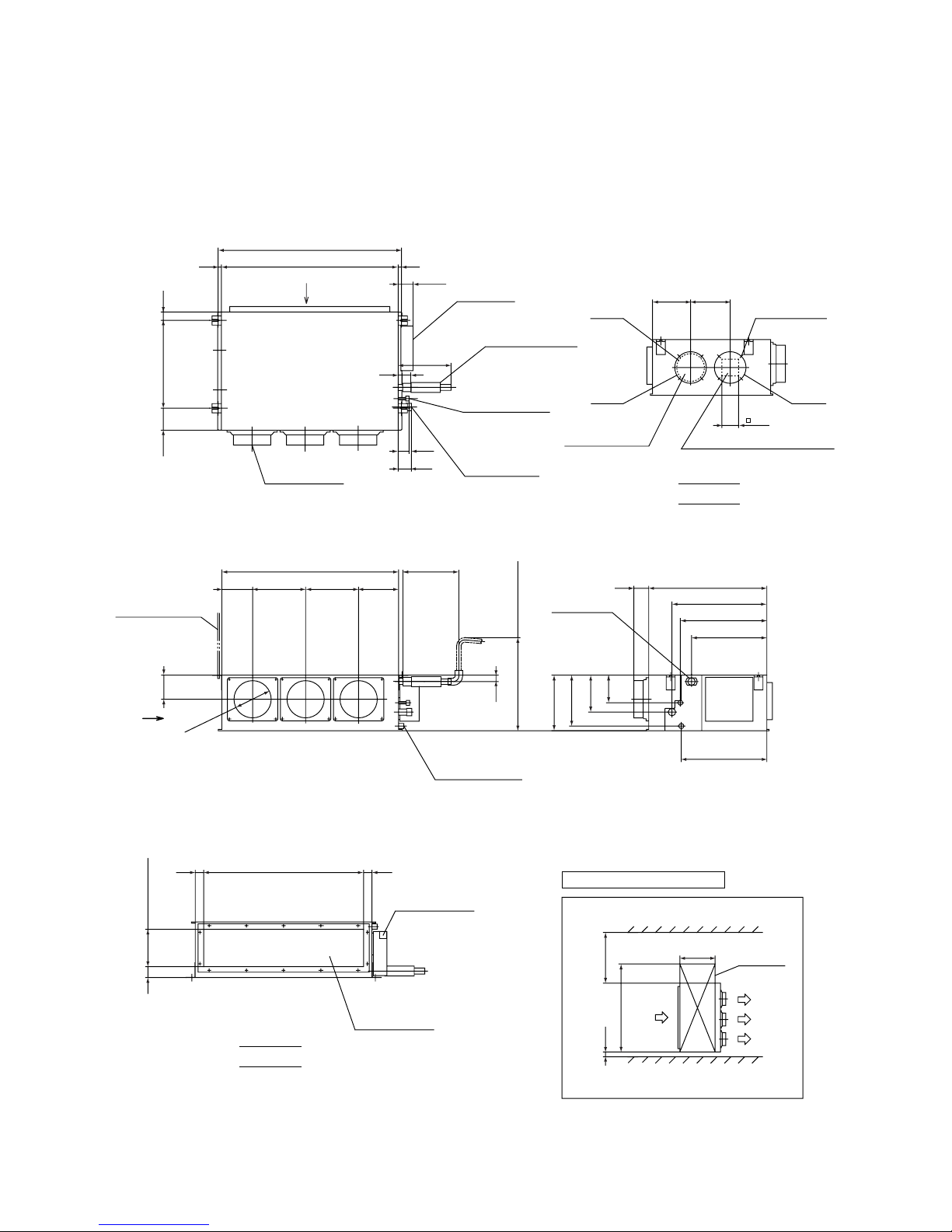

(C) Satellite ducted type (FDUM)

Model FDUMA302R

69

Space for installation and service

620

100

600

1300

45

860

45

59

200

130

165 285

950

285 215

465

510

80

635

405

460

35

149

274

299

199

VIEW B

295~325

(Gravity drainage)

(M10×4pcs.)

600 or less

Suspension bolts

Air return duct

Drain(VP20)

Hole for wiring

Inspection

space

ø200

80.5

18

213205

59

71

950

18

45118

284

986 (Suspension bolts pitch)

Unit : mm

VIEW A

Liquid piping

ø9.52(3/8")

472

(Suspension bolts pitch)

Drain hose piece

(Accessory)

(Installed at site)

Gas piping

ø15.88(5/8")

Fresh air opening

for ducting

(Knock out)

Exhaust air opening for ducting

(Knock out)

A

90

Control box

Air supply duct

B

4-ø4

Holes of

tapping screws

ø149

ø170

ø170

Max.Drain up

Drain

(Connectable

with VP20)

(Duct flange

inner dimeter)

(Duct flange inner dimeter)

-

12

-

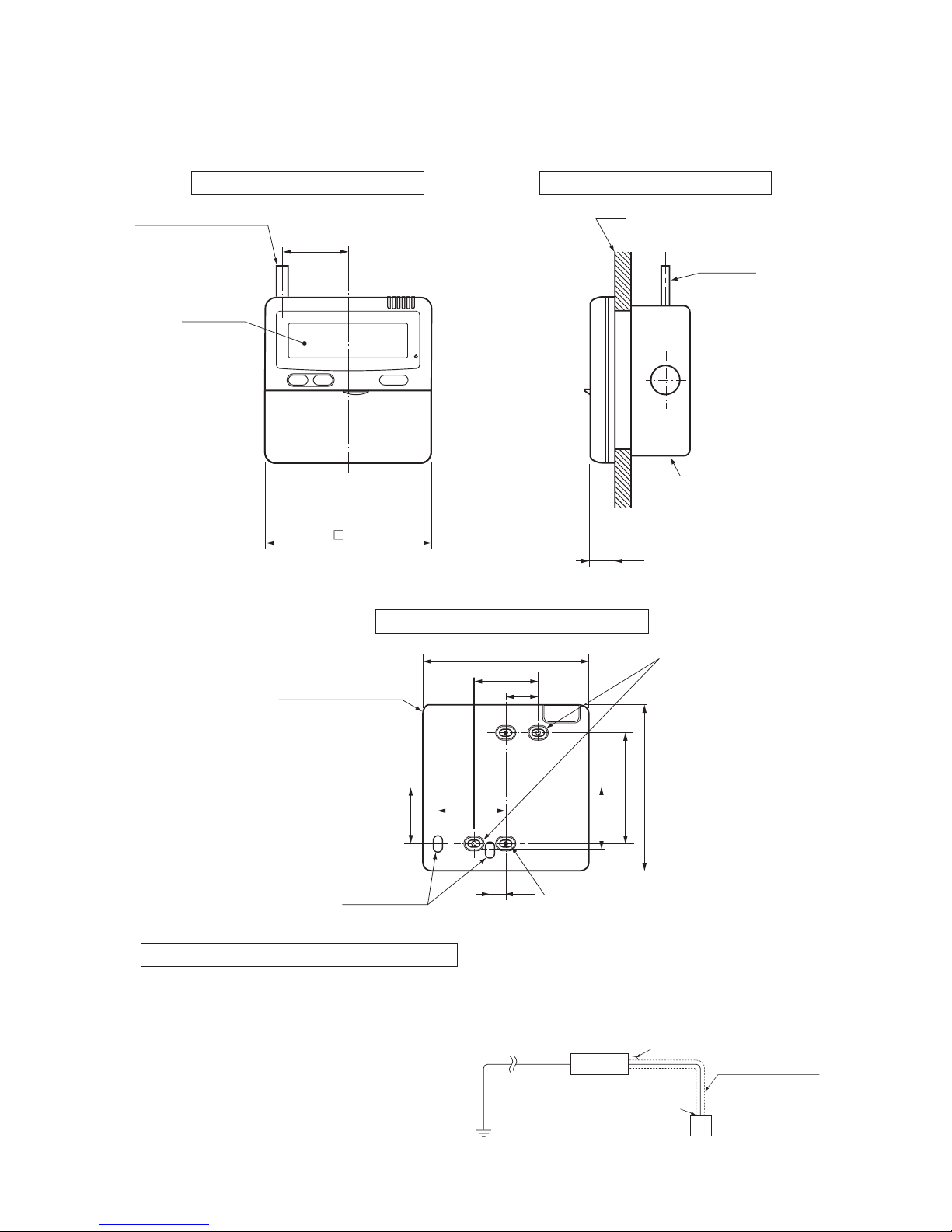

(2) Remote controller (Optional parts)

(a) Wired remote controller

Unit : mm

0.3mm2, 3cores (O.D.ø5.6)

LCD display

120

Wall

Wire

(Recessed)

Electrical box

(Locally Purchased)

19

23

46

11.5

44

Remote controller

outline

120

45

83.5

42

120

Remote controller mounting dimensions

For the passage

after wiring

Attachment hole

12×7 Long hole

9×4.5 Long hole(4 pcs.)

48

Installation with wiring exposed Installation with wiring recessed

Cut off with a knife or the

like thin walled parts intended for screw holes, and then

fix it with screws.

(This side is not grounded)

Earth wiring

Remote control switch

Remote control cord

(Shielded wire)

Precation in Extending the Remote control cord

The cord should be a shielded wire.

● For all types : 0.3mm

2

3 cores

Note: (1) Use cables up to 0.5mm

2

(maximum) for those laid inside the remote control unit casing and connect to a different size

cable at a vicinity point outside the remote control unit, if necessary.

● The shielded wire should be grounded at one side only.

Maximum total extension 600m.

Within 100-200m

…………

Within 300m

…………

Within 400m

…………

Within 600m

…………

0.5 mm

2

0.75 mm

2

1.25 mm

2

2.0 mm

2

3 cores

3 cores

3 cores

3 cores

▼

Indoor unit

-

13

-

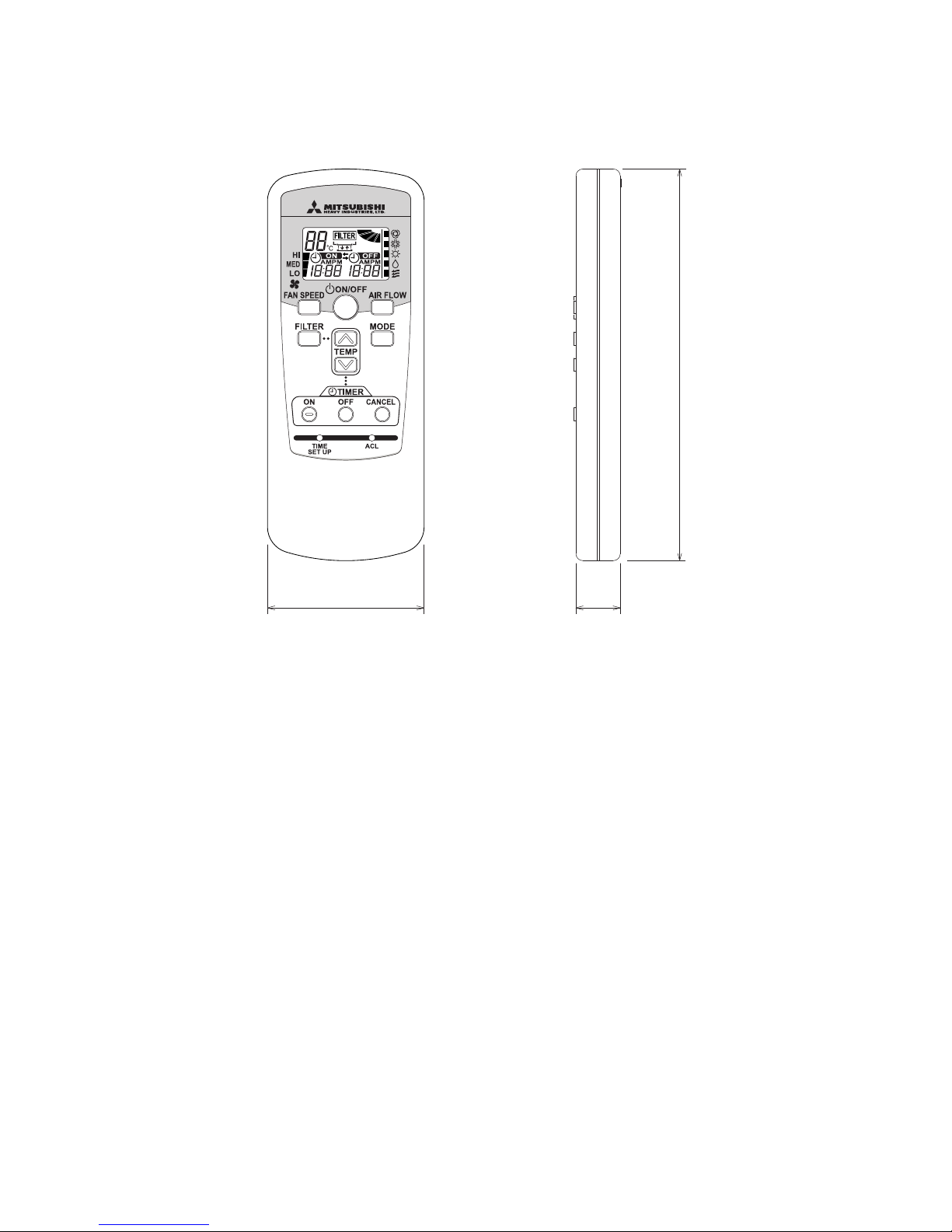

(b) Wireless remote controller

60 17

150

-

14

-

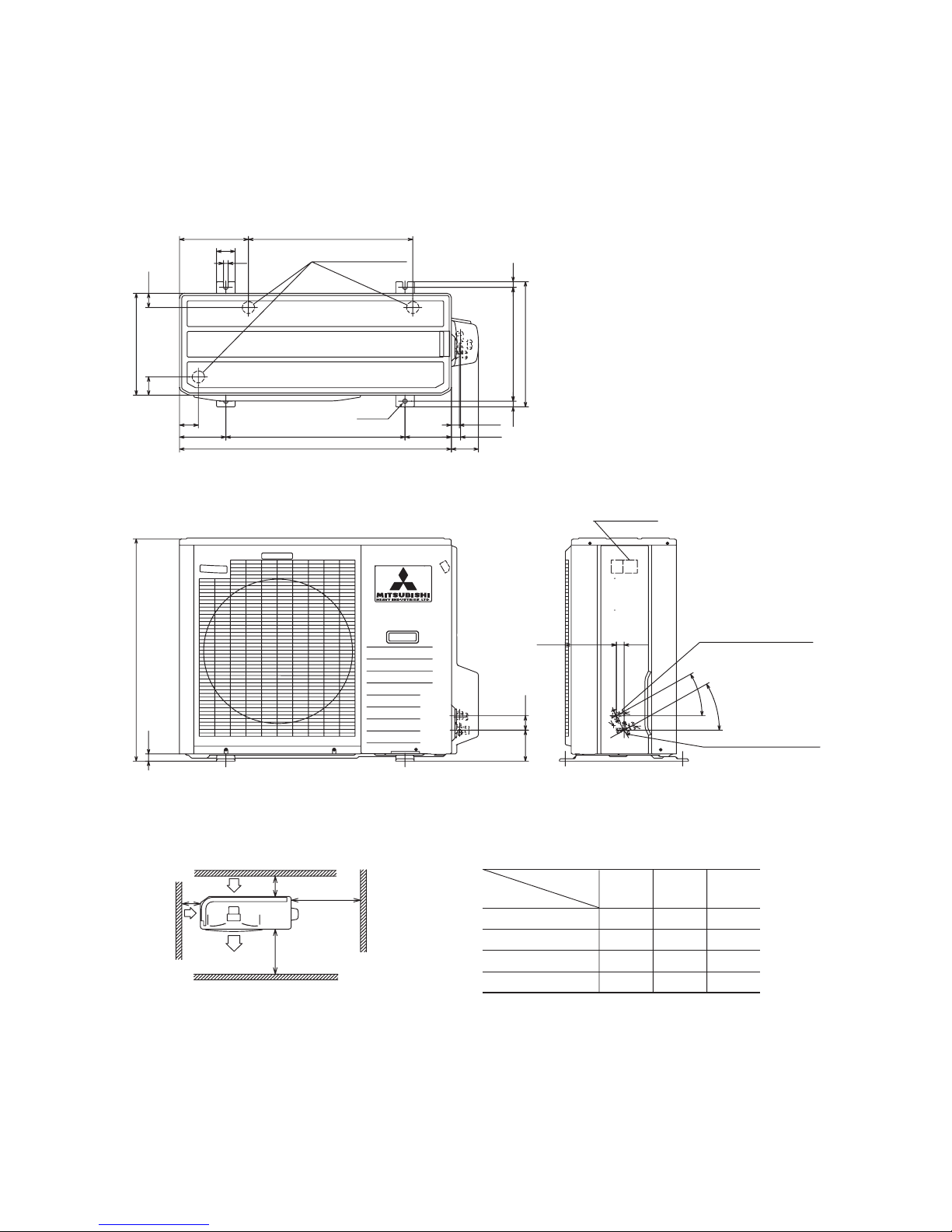

(3) Outdoor unit

Model FDCVA302HENR

Unit: mm

Terminal block

Gas piping ø15.88 (5/8")

Liquid piping ø9.52(3/8")

(Flare connecting)

(Flare connecting)

25.1165.5

30

°

30°

48.5103.3

750

24.1

Holes for drain

2-ø15

25.8

29.8

87.9

880

150580150

61

532

223

60

15

340

61 47.5

19 380 19

418

Required space for maintenance and air flow Minimum allowable space to the obstacles

Unit:mm

Mark

123

L1 Open Open

500

L2 300 250 Open

L3 100 150

100

L4 250 250 250

Installation

type

Notes

(1) It is prohibited to install in a space enclosed with walls

at four sides.

(2) Unit must be secured with anchor bolts.

Anchor bolt should not protrude more than 15 mm above

the surface.

(3) Where strong winds blow,the blow outlet must be

oriented at right angle against the wind direction.

(4) Secure a space of 1 m or more above the unit.

(5) Barrier standing in front of the blow outlet mustbe lower

than the height of unit.

L2

L1

L3

L4

Air inlet

Air outlet

Maintenance

space

( )

Air

inlet

(ø20×3 pcs.)

-

15

-

1.2.4 Inside view

Outdoor unit

Control box

4way valve

High pressure

switch

(63H1)

Low pressure

sensor

(PSL)

Electronic

expansion valve

(EEVH)

Electronic

expansion valve

(EEVC)

Solenoid valve

(SV1)

Compressor

Service valve

(Liquid side)

Service valve

(Gas side)

-

16

-

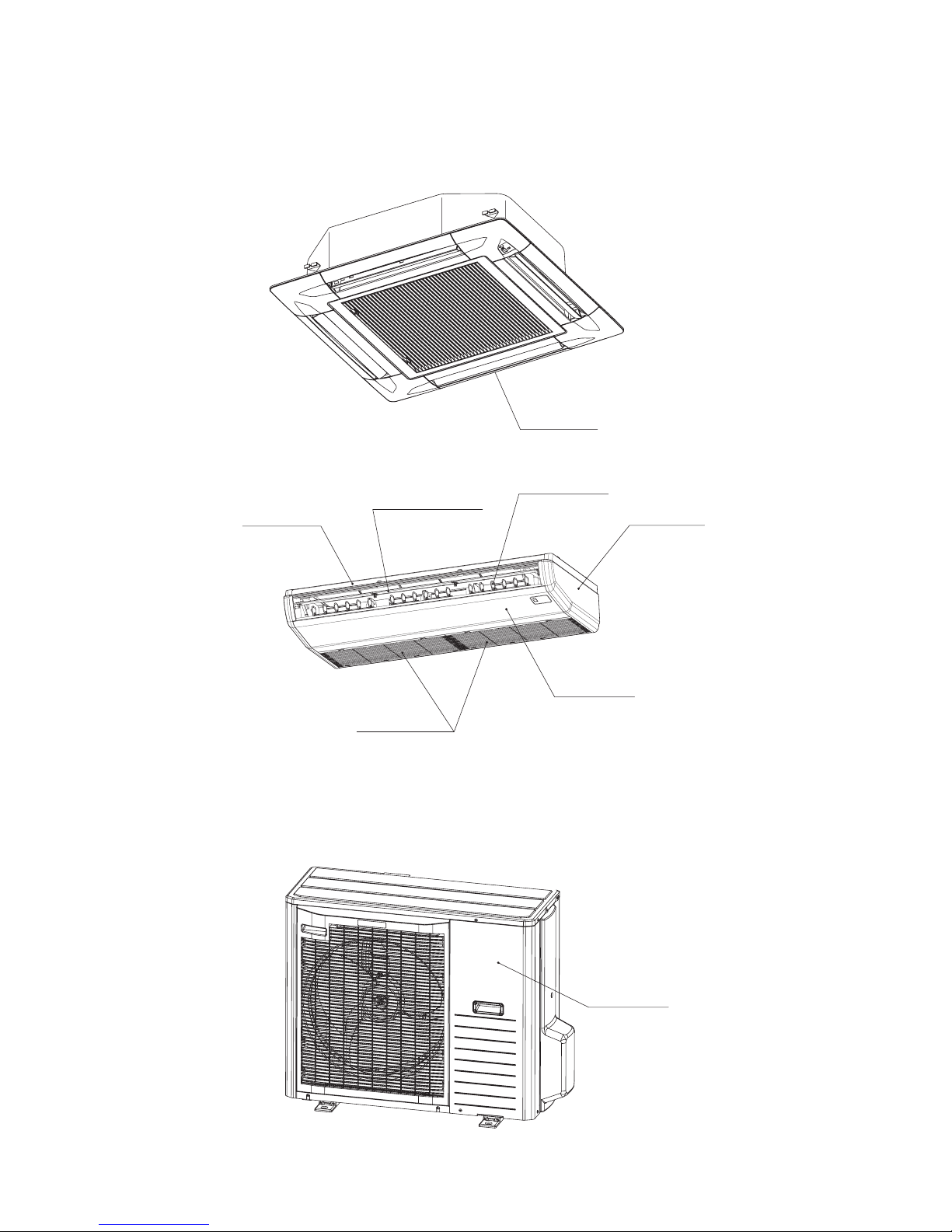

1.2.5 Exterior appearance

(1) Indoor unit

(a) Ceiling recessed type (FDT)

Plaster white

Plaster white

Plaster white

Plaster white

(Front panel)

(Front panel)

(Side panel)

(Vertical louver)

(Horizontal louver)

Light gray

Light gray

(Air return grille)

Plaster white

(b) Ceiling suspended type (FDEN)

(c) Satellite ducted type (FDUM)……Zinc steel plate

(2) Outdoor unit

Stucco white

-

17

-

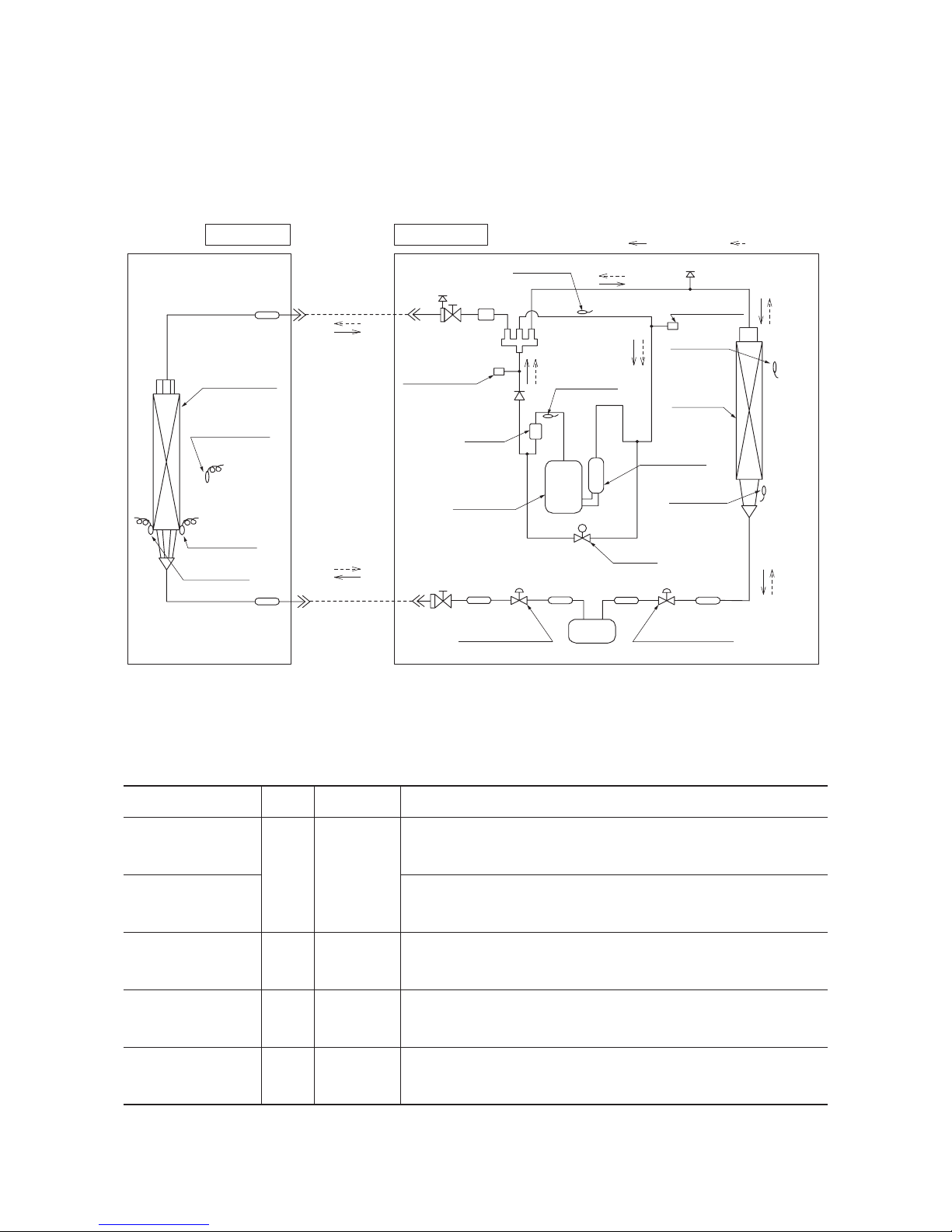

1.2.6 Piping system

Model 302 series

Cooling cycle

Heating cycle

Thermistor

(Th

I

-R2)

Thermistor

(Th

I

-R1)

Thermistor

(Th

O

-D)

Thermistor

(Th

O

-S)

Thermistor

(Th

O

-A)

Service valve

(Flare connecting)

Service valve

(Flare connecting)

High pressure

switch

Low pressure

sensor

(63H1)

(LPT)

(SV1)

Thermistor

(Th

O

-R)

(EEVH)

Thermistor

(Th

I

-A)

Heat exchanger

Heat

exchanger

Solenoid

valve

Strainer

Strainer

Strainer

Strainer

Liquid line

(ø9.52)

Gas line

(ø15.88)

4way valve

Muffler

Muffler

Compressor

Compressor

accumlator

Check joint

Check joint

Check valve

Indoor unit

Outdoor unit

Electronic

expansion valve

Electronic

expansion valve

(EEVC)

Strainer

Strainer

Receiver

Parts name

Mark

Thermistor

(for protection overloading in heating)

Thermistor

(for frost prevention)

Thermistor

(for detecting discharge pipe temp.)

High pressure switch

(for protection)

OFF 63

℃

ON 56

℃

Equipped

unit

Th

I

-R

Th

o

-D

63H1

Indoor unit

Outdoor unit

Outdoor unit

OFF 1.0

℃

ON 10

℃

302 series

OFF 4.15MPa

ON 3.15MPa

Low pressure sensor

(for protection)

LPT

Outdoor unit

OFF 0.227MPa

ON 0.079MPa

OFF 115

℃

ON 85

℃

Preset point of the protective devices

Note(1) A FDEN type strainer only should be used for the indoor unit

-

18

-

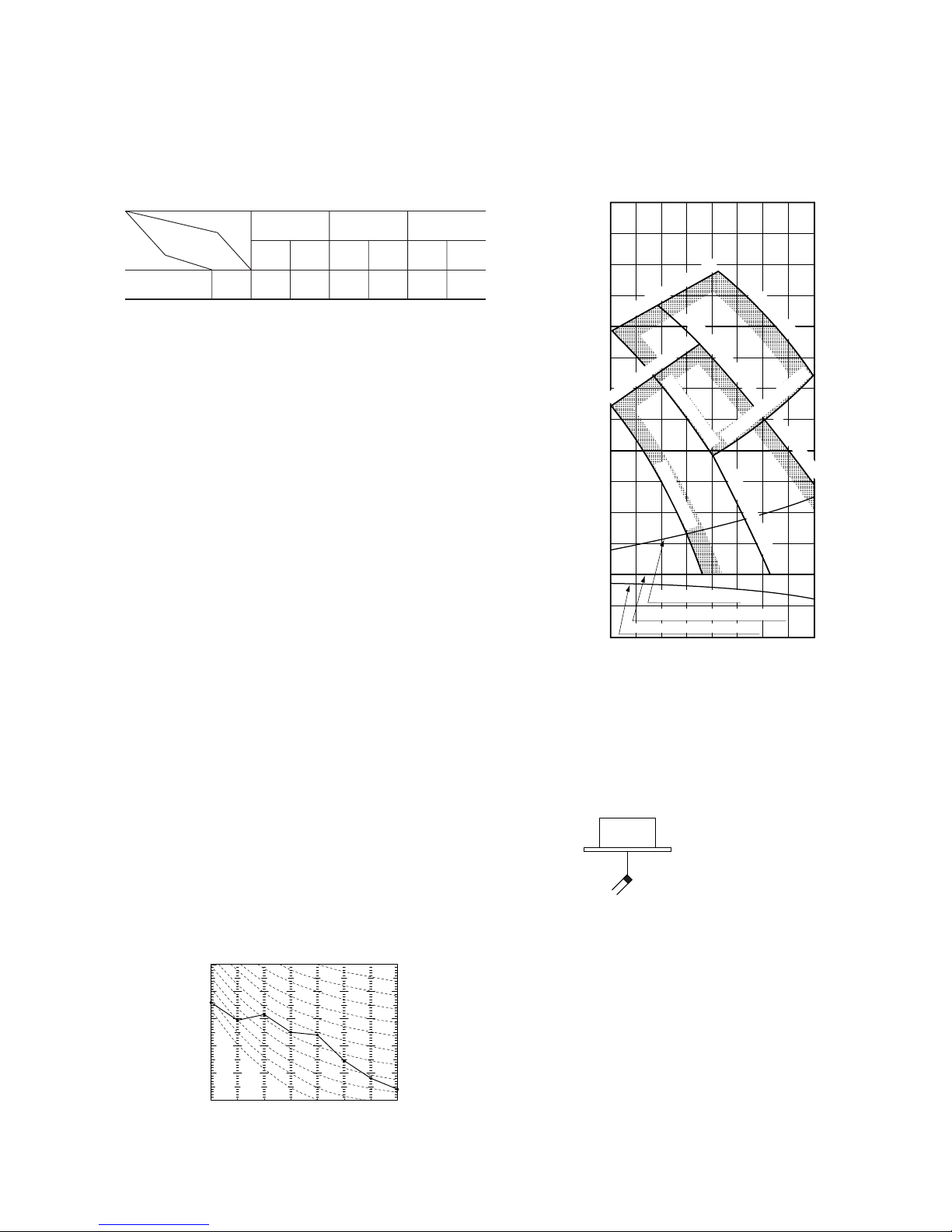

1.2.7 Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specification × Correction factors as follows.

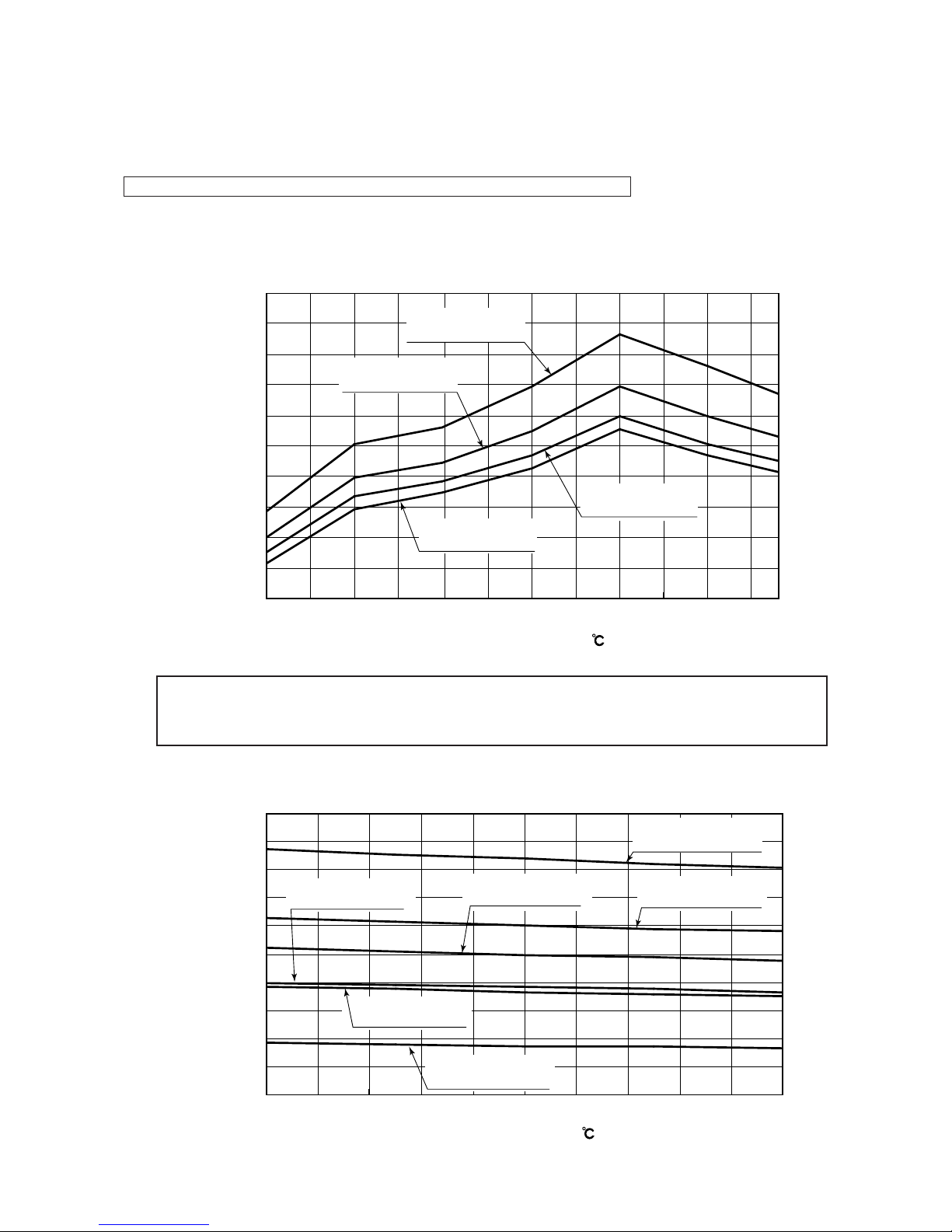

(1) Coefficient of cooling and heating capacity in relation to temperatures

(a) Capacity compensation coeffcient

1) Cooling

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

1.40

-

15-10

-

50 51015202530354043

Outdoor air temperature ( DB)

Capacity compensation coeffcient

Indoor air

temperture 24℃W.B

Indoor air

temperture 19

℃

W.B

Indoor air

temperture 12

℃

W.B

Indoor air

temperture 16

℃

W.B

2) Heating

15 16 17 18 19 20 21 22 2423 25

Indoor air temperature ( DB)

Capacity compensation coeffcient

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.40

1.30

1.50

Outdoor air

temperture 18.5

℃W.B

Outdoor air

temperture 6

℃W.B

Outdoor air

temperture 10

℃W.B

Outdoor air

temperture 1

℃W.B

Outdoor air

temperture -10

℃W.B

Outdoor air

temperture 0

℃W.B

If a cooling operation is done when the outdoor air temperature is -5˚C or lower, as much as possible, the outdoor unit should be

installed in a condition where it is not going to be influenced by natural wind. If it is hit by the wind, the compressor stop

frequency will be high because of the drop in the low pressure, the capacity will drop even further and it could cause the unit to

break down.

Caution:

-

19

-

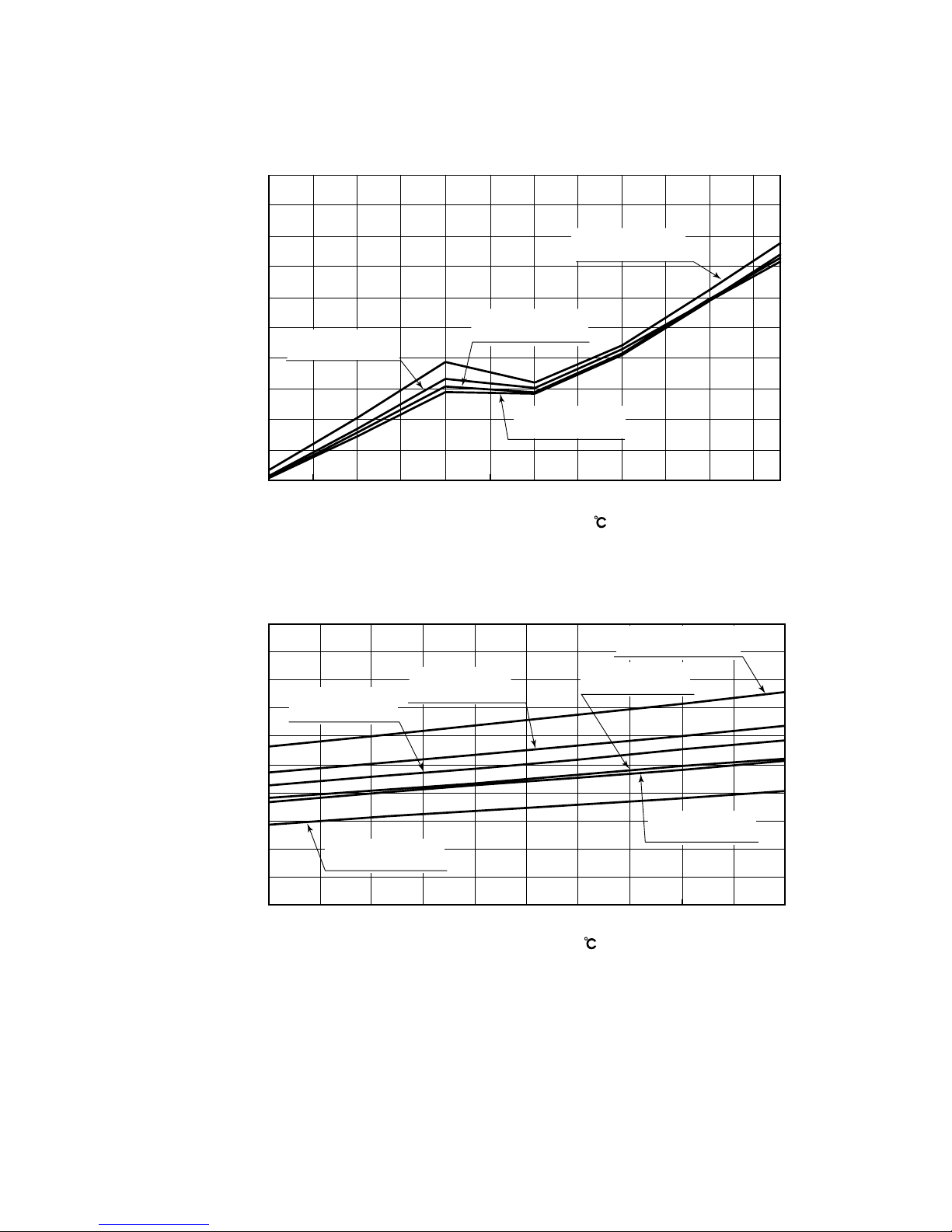

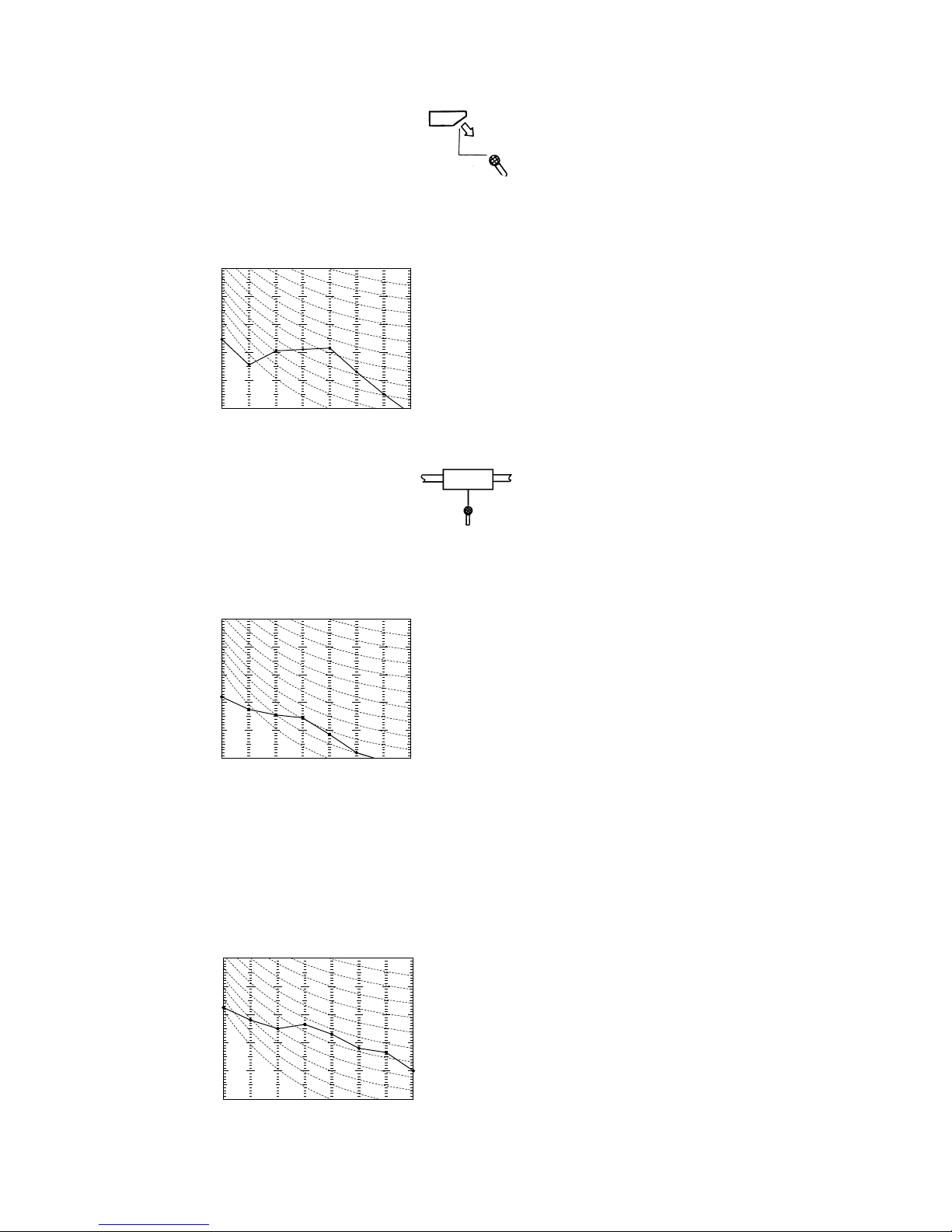

(b) Power consumption correction factor

1) Cooling

2) Heating

Outdoor air temperature ( DB)

Power consumption correction factor

0.40

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.30

1.40

-

15-10

-

50 5 1015202530354043

Indoor air

temperture 24

℃

W.B

Indoor air

temperture 19

℃

W.B

Indoor air

temperture 12

℃

W.B

Indoor air

temperture 16

℃

W.B

Indoor air temperature ( DB)

Power consumption correction factor

0.50

0.60

0.70

0.80

0.90

1.00

1.10

1.20

1.40

1.30

1.50

15 16 18 20 22 2417 19 21 23 25

Outdoor air

temperture 18.5

℃W.B

Outdoor air

temperture 6

℃W.B

Outdoor air

temperture 10

℃W.B

Outdoor air

temperture 1

℃W.B

Outdoor air

temperture -10

℃W.B

Outdoor air

temperture 0

℃W.B

-

20

-

(c) Sensible heat factor

Outdoor air temperature ( DB)

Sensible heat factor

0.60

0.65

0.70

0.75

0.80

0.85

0.90

0.95

1.00

1.05

-

15-10

-

50 5 1015202530354043

Indoor air

temperture 12℃W.B

Indoor air

temperture 24

℃

W.B

Indoor air

temperture 19

℃

W.B

Indoor air

temperture 16

℃

W.B

-

21

-

(3) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

It is necessary to correct the cooling and heating capacity in relation to the one way equivalent piping length between the indoor

and outdoor units.

(4) When the outdoor unit is located at a lower height than the indoor unit in cooling operation and when the outdoor unit is located

at a higher height than the indoor unit in heating operation, the following values should be subtracted from the values in the

above table.

Height difference between the indoor unit and

outdoor unit in the vertical height difference

5m 10m 15m 20m 25m 30m

Adjustment coefficient 0.01 0.02 0.03 0.04 0.05 0.06

(2) Correction of cooling and heating capacity in relation to air flow rate control (fan speed)

Coefficient: 1.00 at High, 0.95 at Low

Note (1) Calculate the equivalent length using the following formula.

However, install the piping so that the equivalent length is within +5 m of the piping distance limit (actual length) for each respective piping system.

● Equivalent length = Actual length + (equivalent length of bends x number of bends in the piping)

Equivalent length for 1 bend

0.15

ø9.52 ø15.88

0.25

Gas pipe diameter (mm)

Bend equivalent length

Equivalent piping length

(1)

(m) 7.5 10 15 20 25 30 35 40 45 50 55

Heating 1 1 1 1 1 0.998 0.998 0.993 0.993 0.988 0.988

ø 15.88 1 0.996

0.989 0.982 0.975 0.968 0.961 0.954 0.947

0.940 0.933

ø 19.05

1.008 1.006 1.003 1 0.997 0.994 0.991 0.988 0.985 0.982 0.979

Cooling

• Outdoor air temperature degree 5˚C or more

Equivalent piping length

(1)

(m) 7.5 10 15 20 25 30 35 40 45 50 55

Heating 1 1 1 1 1 0.998 0.998 0.993 0.993 0.988 0.988

ø 15.88 0.800 0.793

0.779 0.765 0.751 0.738 0.724 0.710 0.696

0.682 0.669

ø 19.05

0.806 0.798 0.786 0.774 0.762 0.750 0.738 0.727 0.715 0.703 0.691

Cooling

• Outdoor air temperature degree -5˚C or more

Equivalent piping length

(1)

(m) 7.5 10 15 20 25 30 35 40 45 50 55

Heating 1 1 1 1 1 0.998 0.998 0.993 0.993 0.988 0.988

ø 15.88 0.600 0.590

0.569 0.549 0.528 0.507 0.487 0.466 0.446

0.425 0.404

ø 19.05

0.605 0.590 0.569 0.548 0.527 0.507 0.486 0.465 0.444 0.424 0.403

Cooling

• Outdoor air temperature degree -15˚C or more

-

22

-

Item

Model

302 servies

Max. one way piping length 50m

Max. vertical height difference Outdoor unit is higher 30m Outdoor unit is lower 15m

Piping length limitations

How to obtain the cooling and heating capacity

Example : The net cooling capacity of the model FDTVA302HEN1R with the air flow “High”, the piping length of 15m, the outdoor unit

located 5m lower than the indoor unit, indoor wet-bulb temperature at 19.0 ˚C and outdoor dry-bulb temperature 35 ˚C is

Net cooling capacity = 7.1 × 1.00 × (0.989 - 0.01) × 1.0 ≒ 7.0 kW

Factor by air

temperatures

FDTVA302HEN1R Air flow

“High”

Length 15m.

Height difference 5 m

Note (1) Values in the table indicate

the one way piping length

between the indoor and

outdoor units.

-

23

-

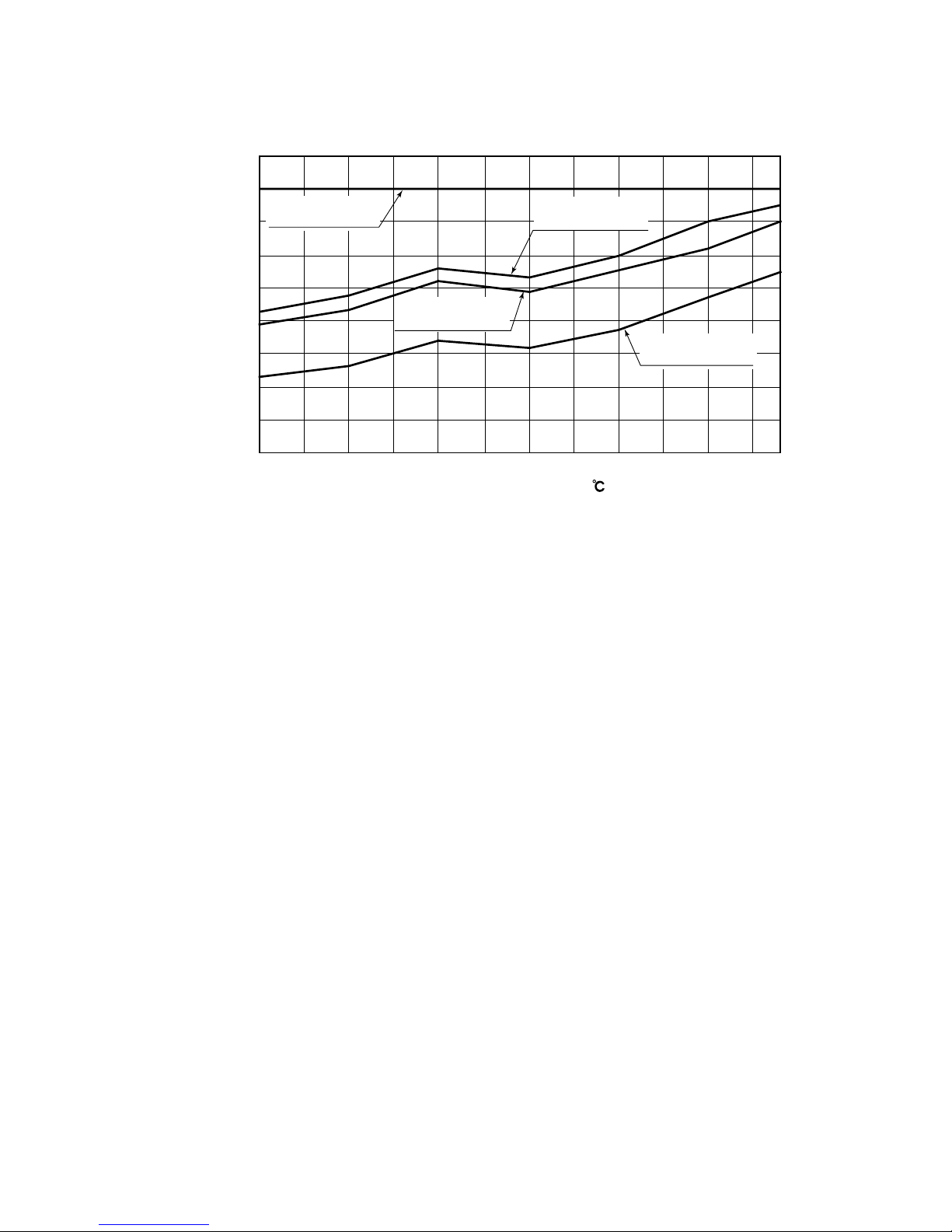

100

120

80

60

40

20

0

−10

14 17 20 22

Air flow(m3/min)

Lower

limit

Uppe

r

limit

[Standard]3-spot blower internal resistance

Square duct blower internal resistance

High speed・Upper limit

Standard

・

Upper limit

High speed

・

Low limit

High speed

・

High

High speed

・

Medium

High speed

・

Low

Standard

・

Low

Standard

・

Medium

Standard

・

High

Static pressure (Pa)

2-spot blower internal resistance

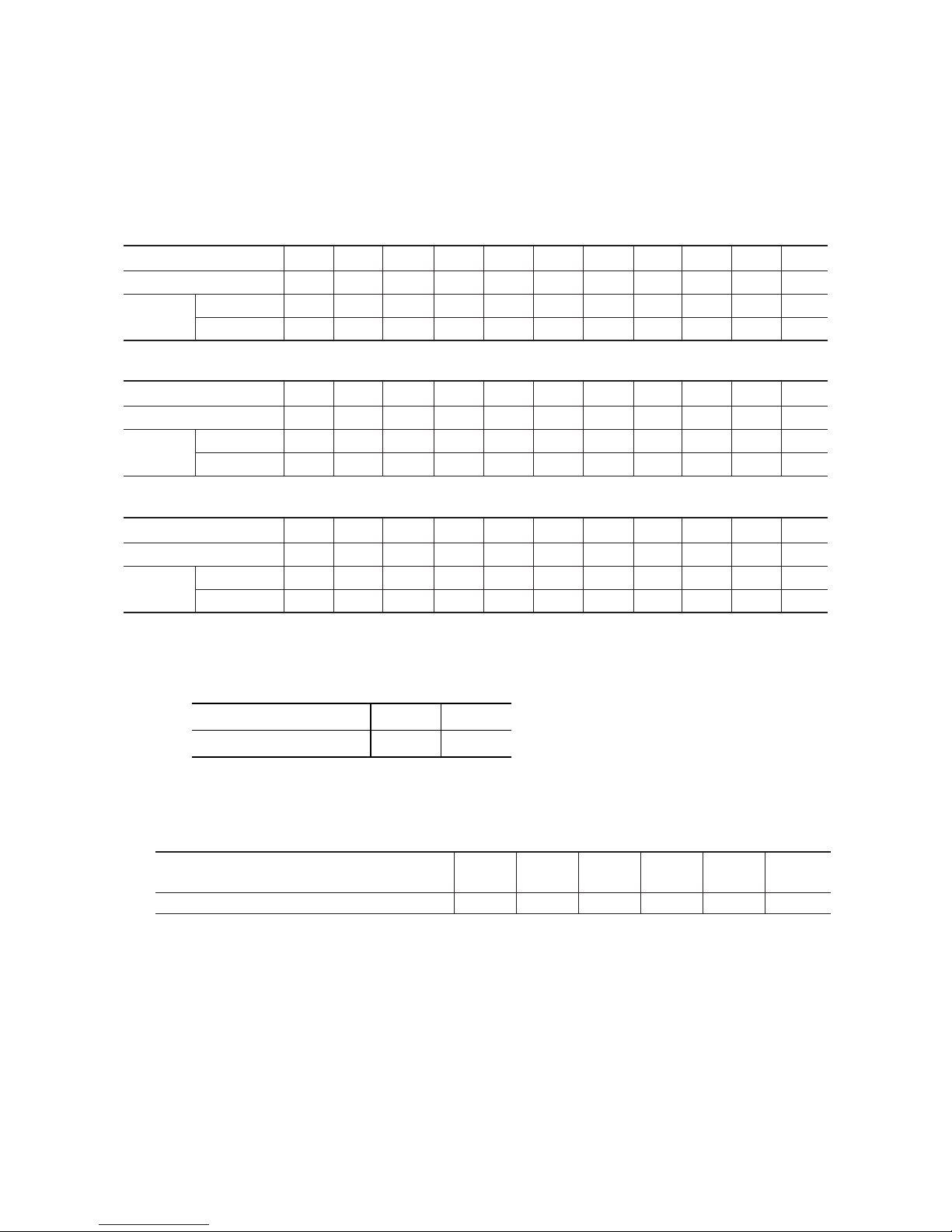

1.2.9 Noise level

Notes (1) The data are based on the following conditions.

Ambient air temperature: Indoor unit 27˚C DB, 19˚C WB. Outdoor unit 35˚C DB.

Notes (2) The data in the chart are measured in an unechonic room.

Notes (3) The noise levels measured in the field are usually higher than the data because of reflection.

Notes (4) Noise levels for the FDT and FDEN series show the noise level when in the Powerful mode.

(1) Indoor unit

(a) Ceiling recessed type (FDT)

Measured based on JIS B 8616

Mike position as right

1.5m

Mike (center & low points)

Model FDTA301R

Noise level 38 dB (A) at HIGH

35 dB (A) at MEDIUM

33 dB (A) at LOW

N60

40

50

40

50

63

125

250 500 1000 2000 4000 8000

10

20

30

10

20

30

N50

N40

N30

N20

60

60

N10

Souud Pressure Level

(standard 0.0002µ bar)

Mid Octave Band Frequency (Hz)

1.2.8 Characteristics of fan

(1) Satellite ducted type (FDUM)

Model FDUMA302R

Duct specs.

1 spot

closing

Stan

-

dard

Stan

-

dard

Stan

-

dard

High

speed

Standard Square duct

Unit : Pa

External static pressure table

Model

20 30 65 50 85 55 90

FDUMA302R

Air flow

(m

3

/min)

(4)

High

speed

(4)

High

speed

(1)

Notes (1) 1 spot closing: Round duct flange at center is removed and shield with a

special panel (option).

(2) Standard: ø200 duct are installed at all blowout holes.

(3) Square duct: All round ducts are removed and replaced with special

square duct flanges (option).

(4) When using the high speed setting, turn the dip swich SW9-4 on the

indoor PCB to the ON position.

(When setting from the remote controller, select “Hi CEILING 1” )

-

24

-

Model FDENA301R

Noise level 44 dB (A) at HIGH

41 dB (A) at MEDIUM

39 dB (A) at LOW

Souud Pressure Level

(standard 0.0002µ bar)

Mid Octave Band Frequency (Hz)

N30

N40

N20

N50

N60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

(b) Ceiling suspended type (FDEN)

Measured based on JIS B 8616

Mike position as right

Unit

1 m

1 m

Mike (front & at low point)

(c) Satellite ducted type (FDUM)

Measured based on JIS B 8616

Mike position as right

Model FDUMA302R

Noise level 35 dB (A) at HIGH

32 dB (A) at MEDIUM

29 dB (A) at LOW

(2) Outdoor unit

Measured based on JIS B 8616

Mike position: at highest noise level in position as below

Distance from front side 1m

Height 1m

Model FDCVA302HENR

Noise level 48 dB (A)

1.5 m

Unit

Mike (center & low points)

N30

N40

N20

N50

N60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

Souud Pressure Level

(standard 0.0002µ bar)

Mid Octave Band Frequency (Hz)

N30

N40

N20

N50

N60

N70

63 125 250 500 1000 2000 4000 8000

20

30

40

50

60

70

20

30

40

50

60

70

Souud Pressure Level

(standard 0.0002µ bar)

Mid Octave Band Frequency (Hz)

-

25

-

1

3

2/N

X

Y

Z

X

Y

Z

Y/GN

RD

RD

RD

RD

WH

WH

BK

BK

BL

RD

BR

WH

BR

BK

BL

RD

WH

BR

BK

BL

RD

WH

RD

P

BR

OR

RD

WH

BL

OR

OR

WH

BL

Y/GN

CnW1

TB

CnW4

CnW7

CnN4

CnH

X6

X1

X2

X3

X4

CnT

CnJ

CnJ2

CnB

ThC

TB

CnI

CnI2

CnV CnY

CnR

CnR2

CnM3

CnF

CFI

DM

FS

LM1

XR1

XR3

XR2

XR4

XR5

ThI-A

ThI-R1

Option

LM2

LM3

LM4

TrI

To outdoor unit

Power line

Signal line

220/240V 15V

F(3.15A)

F(0.16A)

1

3

5

C

UH

H

M

L

Remote

controller

FMI

CFI

DM

FS

LM1~4

ThI-A

ThI-R1

ThI-R2

ThC

SW2

Fan motor

Capacitor for FMI

Drain motor

Float switch

Louver motor

Thermistor

Thermistor

Thermistor

Thermistor

Remote controller communication address

SW5-3,4

SW9-3

TrI

F

LED1

LED2

XR1

XR2

XR3

XR4

Filter sign

Emergency operation

Transformer

Fuse

Indication lamp(Red)

Indication lamp(Green)

Operation output(DC12V output)

Heating output(DC12V output)

Thermo ON output(DC12V output)

Inspection output(DC12V output)

XR5

X1,2,3,6

X4

TB

CnB~Z

mark

Remote operation input(volt-free contact)

Auxiliary relay(For FM)

Auxiliary relay(For DM)

Terminal block( mark)

Connector

Closed-end connector

Mark Parts nameMark Parts nameMark Parts name

Meaning of marks

Color marks

BK

BL

BR

OR

P

RD

WH

Y

Y/GN

Black

Blue

Brown

Orange

Pink

Red

White

Yellow

Yellow/Green

Mark Color

SW5

SW9

SW2

LED • 2

LED • 1

Power board

Printed circuit

board

1

31

3795

1

1

1

1

1

1

2

3

4

3

5

2

34

23456

2345

2

3

BK

BK

BK

BK

BK

BK

CnN3

CnN1

ThI-R2

FMI

1

3

2/N

Blower fan tap switch

SW9-4

ON

OFF

Fan control, powerful mode

Fan control, mild mode

Function number

A

Function description

B

Setting

C

1 Set SW9-4 provided on the indoor unit PCB to OFF.

Use one of the two methods to set the fan tap.

01

Hi CEILING SET STANDARD

(Mild mode)

BK

BK

RD

RD

CnW2

CnW10

CnW8

CnW5

Select the “STANDARD (Mild mode)” setting for “

C ” in #01 of

“I/U FUNCTION

▲” (indoor unit function) by using remote

controller function setting.

2

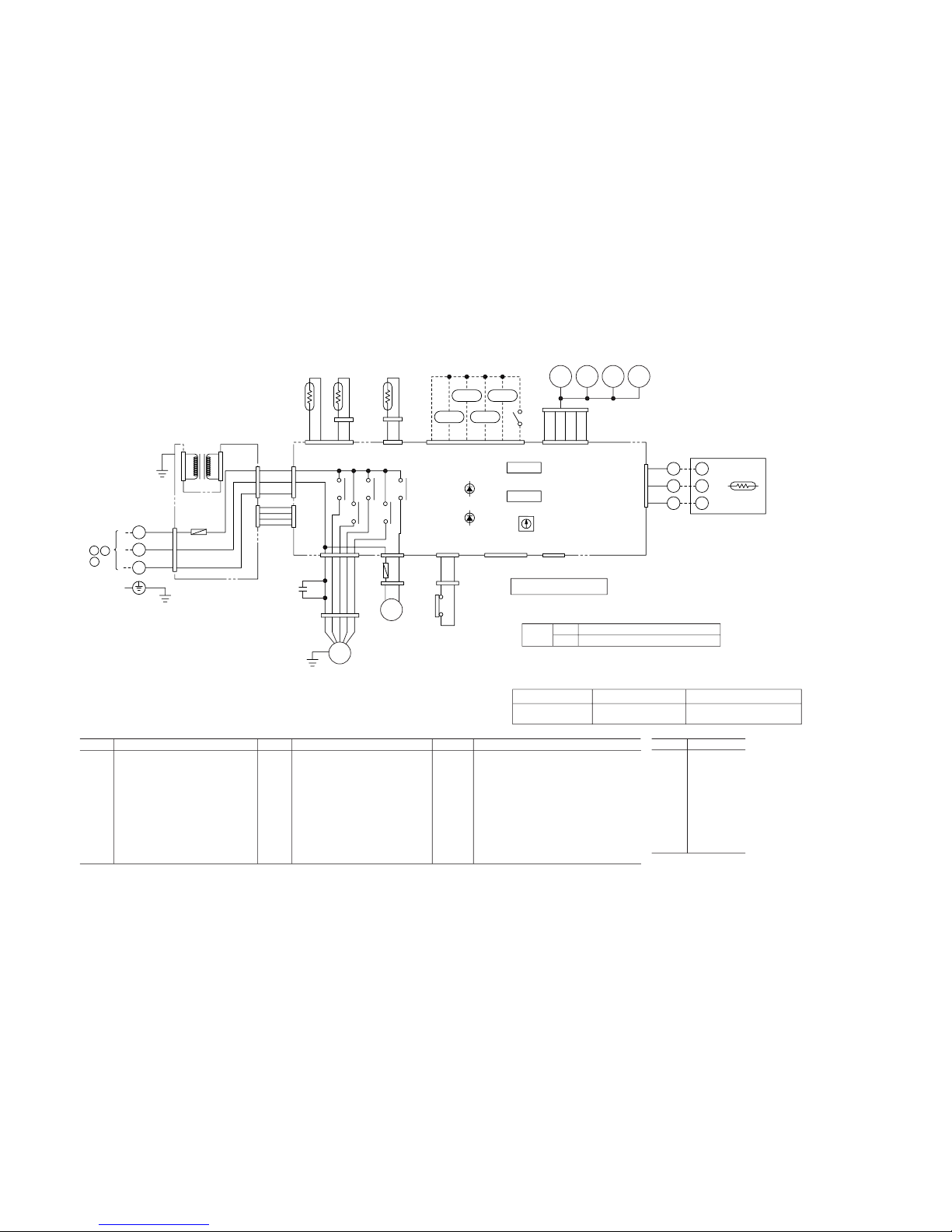

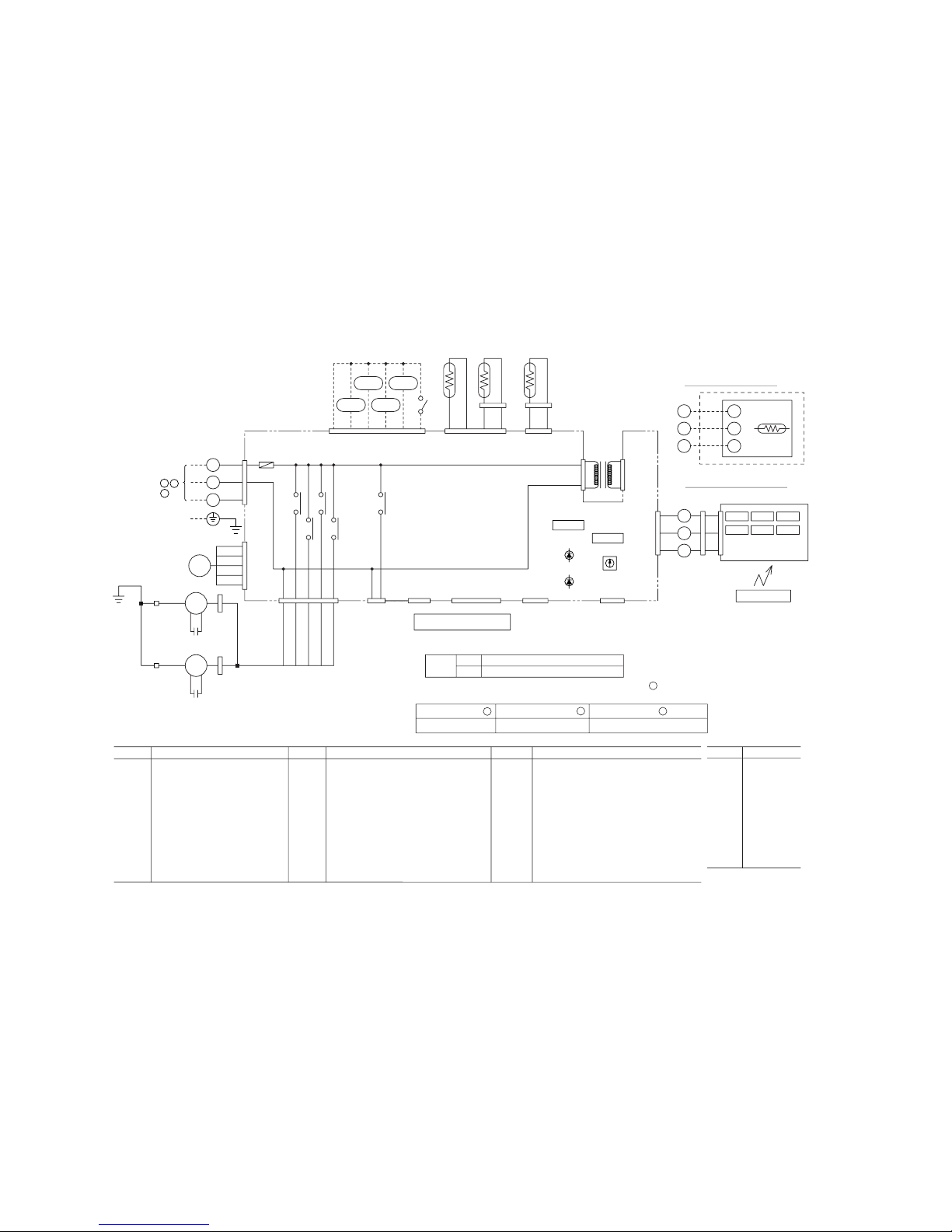

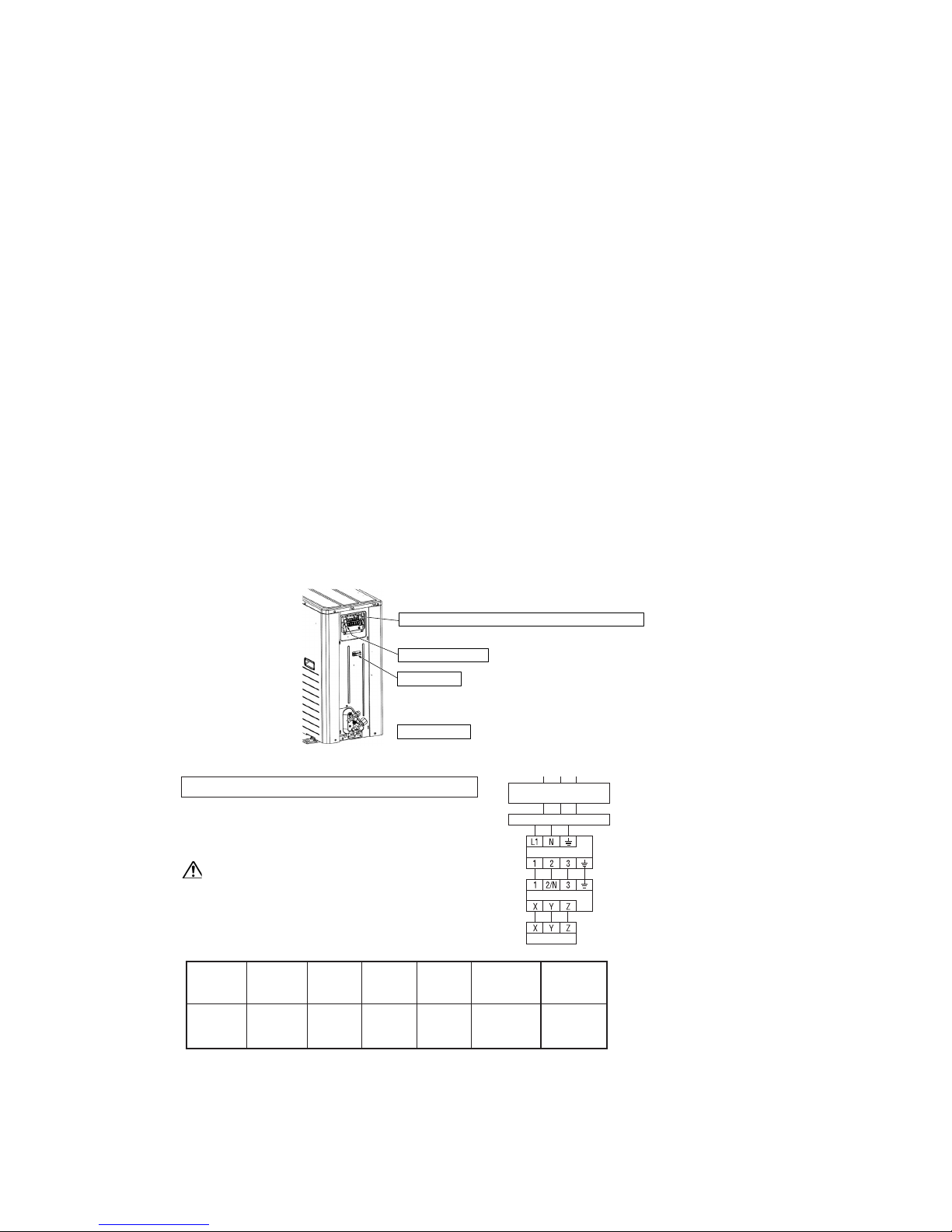

1.3 ELECTRICAL DATA

1.3.1 Electrical wiring

(1) Indoor unit

(a) Ceiling recessed type (FDT)

Model FDTA301R

-

26

-

F (3.15A)

Remote controller

X

CnB CnB2

AMP SW2 SW1

LED3 LED1 LED2

Z

Y

TB

CFI2

CnF2

FMI2

CFI1

FMI1

CnF1

CnR

CnM3

CnI

1

2/N

WH

RD

WH

BR

BK

BL

RD

BK

BK

BK

BK

BK

BK

XR1

XR4

XR5

XR2

XR3

CnT

CnO

CnY

CnV

CnW1

CnW2

TrI

BK RD

BK RD

3

4

1

2

CnN3

CnH

ThI-R1ThI-A

CnN1

ThI-R2

CnN2

1

2

3

11234345621

3

5

1

RD

WH

BK

31

97531

CUHH M L

X6

X1 X3

X2 X4

Option

CnW0

Printed circuit board

TB

220/240V

15V

Y/GN

Y/GN

3

BL

To outdoor unit

Power line

Signal line

1

3

2/N

BL

P

BR

OR

RD

LM

1

2

3

4

5

CnJ1

SW5

SW9

SW2

LED • 2

LED • 1

FMI1,2

CFI1,2

LM

ThI-A

ThI-R1

ThI-R2

ThC

SW2

SW5-3,4

SW9-3

TrI

Fan motor

Capacitor for FMI

Louver motor

Thermistor

Thermistor

Thermistor

Thermistor

Remote controller communication address

Filter sign

Emergency operation

Transformer

F

LED1

LED2

XR1

XR2

XR3

XR4

XR5

X1,2,3,6

TB

CnB~Z

Fuse

Indication lamp(Red)

Indication lamp(Green)

Operation output(DC12V output)

Heating output(DC12V output)

Thermo ON output(DC12V output)

Inspection output(DC12V output)

Remote operation input(volt-free contact)

Auxiliary relay(For FM)

Terminal block( mark)

Connector

mark

LED•1

LED•2

LED•3

SW1

SW2

Closed-end connector

Indication lamp(Green-Operation)

Indication lamp(Yellow-Timer/Check)

7-segement indicator(For check)

Switch(For setting)

Backup switch(Operation/Stop)

Mark Parts nameMark Parts nameMark Parts name

Meaning of marks

Color marks

Wireless specification

BK

BL

BR

OR

P

RD

WH

Y

Y/GN

Black

Blue

Brown

Orange

Pink

Red

White

Yellow

Yellow/Green

Mark Color

Y/GN

Blower fan tap switch

SW9-4

ON

OFF

Fan control, powerful mode

Fan control, mild mode

A

B

C

Function number Function description Setting

1 Set SW9-4 provided on the indoor unit PCB to OFF.

01

Hi CEILING SET STANDARD

(Mild mode)

Wired specification

Remote

controller

ThC

XX

Z

Y

Z

Y

TB

RD

WH

BK

C

Use one of the two methods to set the fan tap.

Select the “STANDARD (Mild mode)” setting for “ ” in #01 of

“I/U FUNCTION

▲” (indoor unit function) by using remote controller function setting.

2

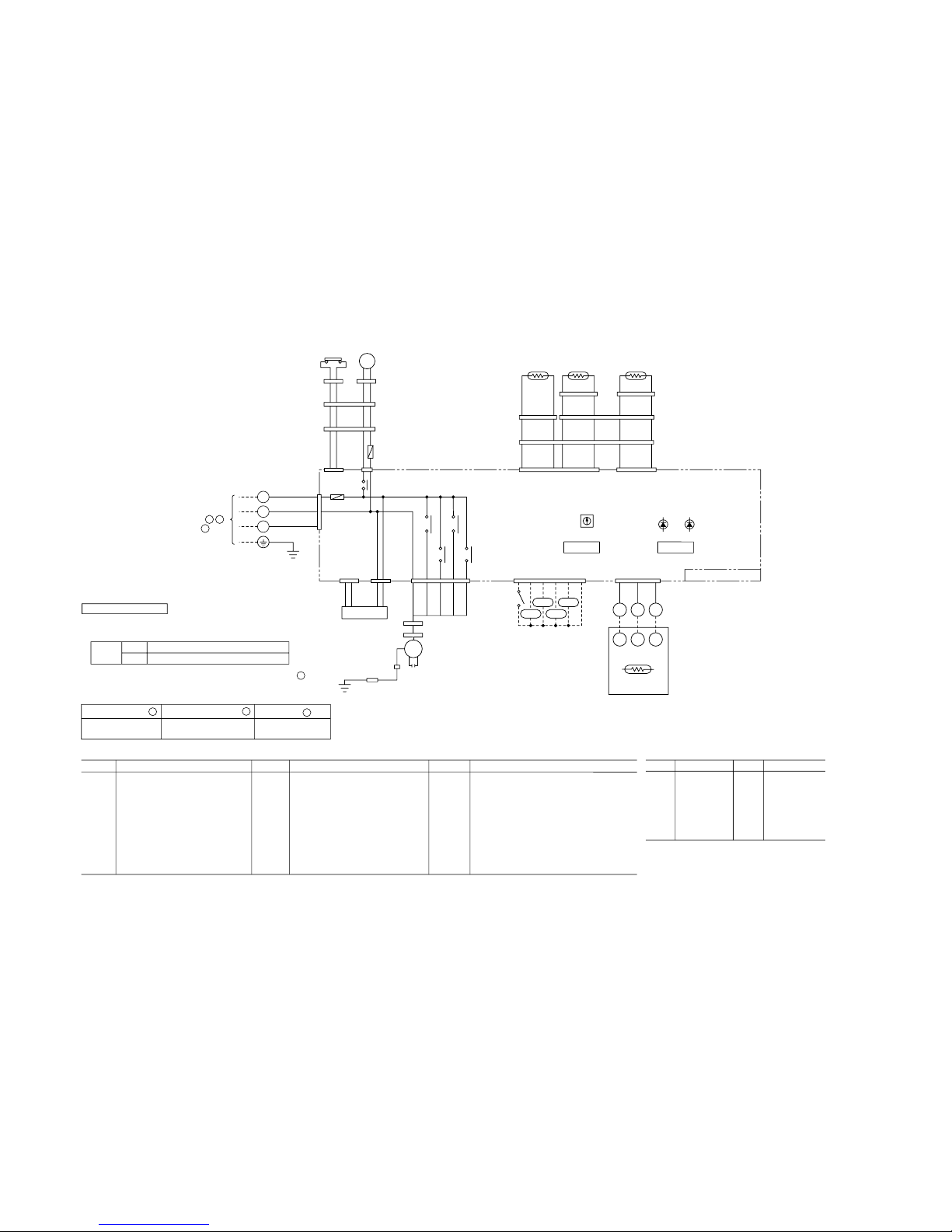

(b) Ceiling suspended type (FDEN)

Model FDENA301R

-

27

-

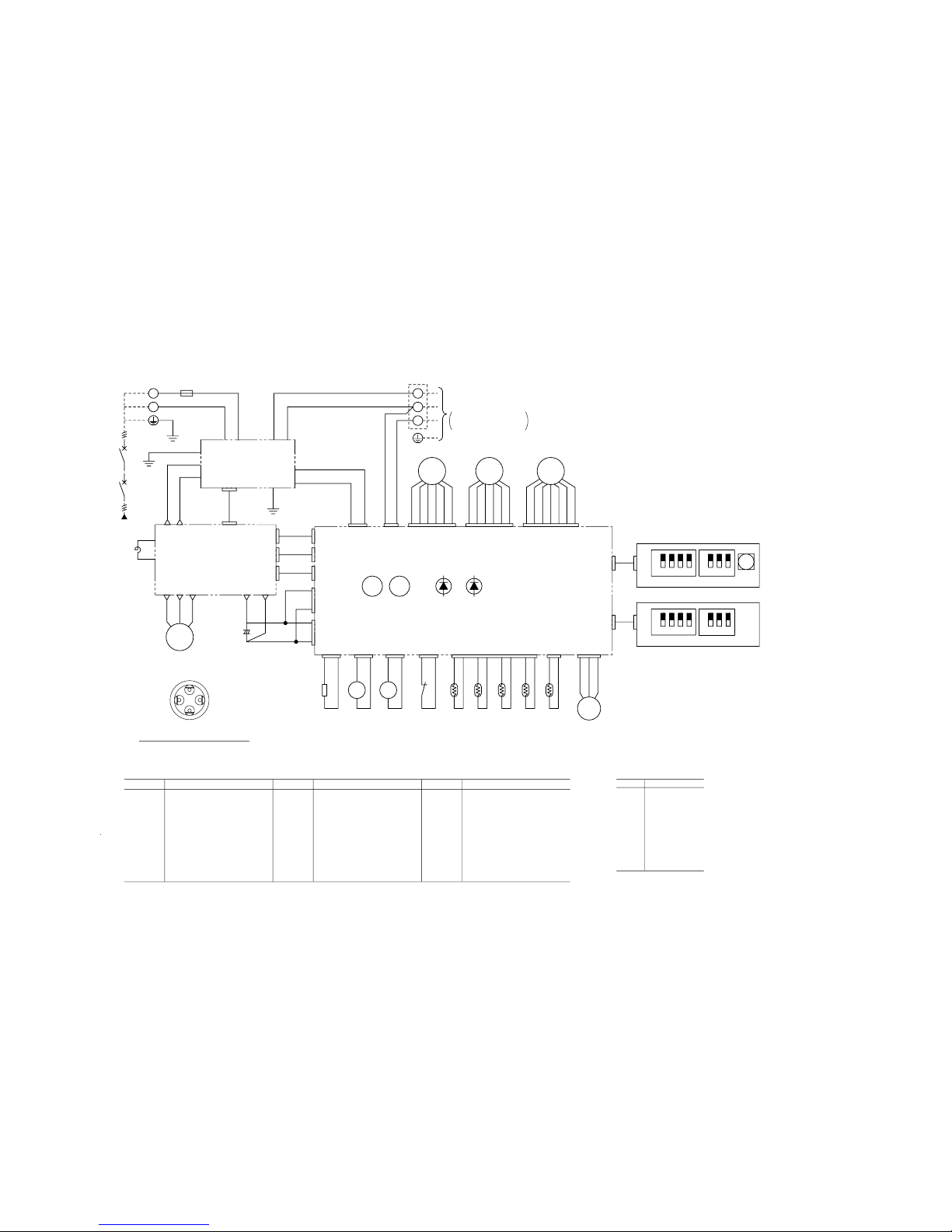

(c) Satellite ducted type (FDUM)

Model FDUMA302R

1

2/N

3

C

To outdoor unit

Power wires

Signal wire

SW9

SW5

CnI2

CnR2

CnRI1

CnRI

CnI

CnR

CnH

CnH2

CnN3

CnNZ

CnN1

CnN6

CnN5

CnW0

CnW2 CnW1

SW2

LED

•

1

LED

•

2

RD

WH

BL

TB

1

2/N

3

Y/GN

Y/GN

Y/GN

F(3.15A)

F(0.16A)

FS

DM

X4

X6 X2

X1 X3

WHWH

BR

BR

BK

BK

BK

BK

BK

BK

RD/Y

BL/Y

BK

Y

OR

RD

RD

BK

BK

BR/Y

WH

RD

RDRD

RDRD

RD

RD

RD

RD

RD

RD

RD

RD

RD RD

RD

RD

RD

ThI-A ThI-R1 ThI-R2

XR3 XR1

XR5

XR2XR4

CnT

CnM3

CnF3

CnF3

CnG

CnS

Option

CUH H M L

FMI1

CFI1

TrI

15V

220/

240V

Printed circuid board

FMI1

CFI1

DM

FS

ThI-A

ThI-R1

ThI-R2

ThC

Fan motor

Capacitor for FMI

Drain motor

Float switch

Thermistor

Thermistor

Thermistor

Thermistor

SW5-3,4

SW9-3

TrI

F

LED

•

1

LED

•

2

XR1

Filter sign

SW2

Remote control communications address

Emerqency operation

Transformer

Fuse

Indication lamp(Red:inspection)

Indication lamp(Green:normal operation)

Operation output(DC12V output)

XR2

XR3

XR4

XR5

X1,2,3,6

X4

TB

CnA~Z

mark

Heating output(DC12V output)

Thermo ON output(DC12V output)

Inspection output(DC12V output)

Remote operation input(volt-free contact)

Auxiliary relay(For FM)

Auxiliary relay(For DM)

Terminal block( mark)

Connector(

□

mark)

Closed-end connector

Mark

Mark

Mark Parts name Parts name Parts name

Meaning of marks

Color marks

BK

BL

BL/Y

BR

BR/Y

Black

Blue

Blue/Yellow

Brown

Brown/Yellow

OR

RD

RD/Y

WH

Y

Y/GN

Orange

Red

Red/Yellow

White

Yellow

Yellow/Green

Mark Color

Mark Color

XYZ

XYZ

RD

RD

WH

WH

BK

BK

CnB

ThC

TB

Remote

controller

1

21 31

3421

65

432 1

123

1

3

579

3

5

Blower fan tap switch

SW9-4

ON

OFF

Fan control, high speed (High ceiling)

Fan control, standard

A

B

C

Function number Function description

Setting

Use one of the two methods to set the fan tap.

1Set SW9-4 provided on the indoor unit PCB to ON.

01

Hi CEILING SET

Hi CEILING 1

2Select the “Hi CEILING 1 (High-speed tap)

”

setting for “ ”

in #01 of

“

I/U FUNCTION

▲”

(Indoor unit fuction) by using

remote controller function setting.

-

28

-

(2) Outdoor unit

Model FDCVA302HENR

RD

WH

RD

N

L1

CM

BL

BL

RD

WH

CNG1

CH

CNR

BR

BR

20S

BK

CNS

BK

52X1

PWB1

52X3

CNW

RD

WH

CNW2

GR

BR

OR

CNFANCNEEV1CNEEV2

THo-D

CNTH

63H1

CNH

BK

BK

THo-R1

BK

BK

BK

BK

LED2LED1

132

SW5

BK

BK

CNQ1

CNQ1

CNQ2

4

ON

THo-ATHo-S THo-IP

RD

RD

Y

CNIP

BK

Y

BK

LPT

CNPS

WH

BK

RD

SW9

3

SW8

12

ON

132

SW3

CNQ2

4

ON

3

SW7

12

ON

BL

756

Y

WH

243 1

BR

BL

OR

RD

45623

OR

Y

WH

BR

BL

189

RD

P

GR

65 14

WH

Y

RD

BK

FMO1

Yellow/Green

Color

Position of compressor terminals

WH White

GR

Y

Y/GN

Gray

P Pink

Yellow

Mark

Color marks

BR

OR

RD

BK

BL

Red

Orange

Brown

Blue

Black

Auxillary relay (for 20S)

Expansion valve for cooling

Solenoid valve for 4 way valve

Auxillary relay (for CH)

Parts name

Crankcase heater

SM1

20S

52X3

CH

52X1

Fan motor

Compressor motor

FMO1

Mark

Meaning of marks

CM

High pressure switch

Thermistor (H.X. temp.)

Thermistor (discharge temp.)

Low pressure sensor

Thermistor (suction temp.)

Thermistor (Outdoor air temp.)

Solnoid valve

Thermistor (IPM)Tho-IP

SV1

LPT

Tho-R1

Tho-D

Tho-S

Tho-A

Expansion valve for heating

Parts name

SM2

63H1

Mark

Local setting switch

Indication lamp (GREEN)

Indication lamp (RED)

Reactor

Pump down switch

Diode module

L1

LED1

DM

LED2

SW9

SW3,5,7,8

Terminal block

Fuse

ConnectorCnA~Z

TB

F

Parts nameMark

GR

CNI1

BK

Y

BL

CNI2

CNG2

CNO1

CNO2

PWB2 Inverter

PWB3 N/F

RD

BL

RD

BL

F(20A)

CNA1

CNA2

Y/GN

Y/GN

Y/GN

RD

WH

TB

3

TB

1

2

S.M2 S.M1

Power source

1Phase 220-240V

To indoor unit

Power wires

12

Signal wire 3

SV1

BK

CNS

BK

L1

C1

CNI3

BL

CNI4

T27T26WVU

T25

T24

T21 T22

T13

T11

T10

T9T8T1T2

T4

T5

T6

RD

BK

U(RD)

V(WH)

W(BL)

DON'T

CONNECT

-

29

-

1.4 OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER

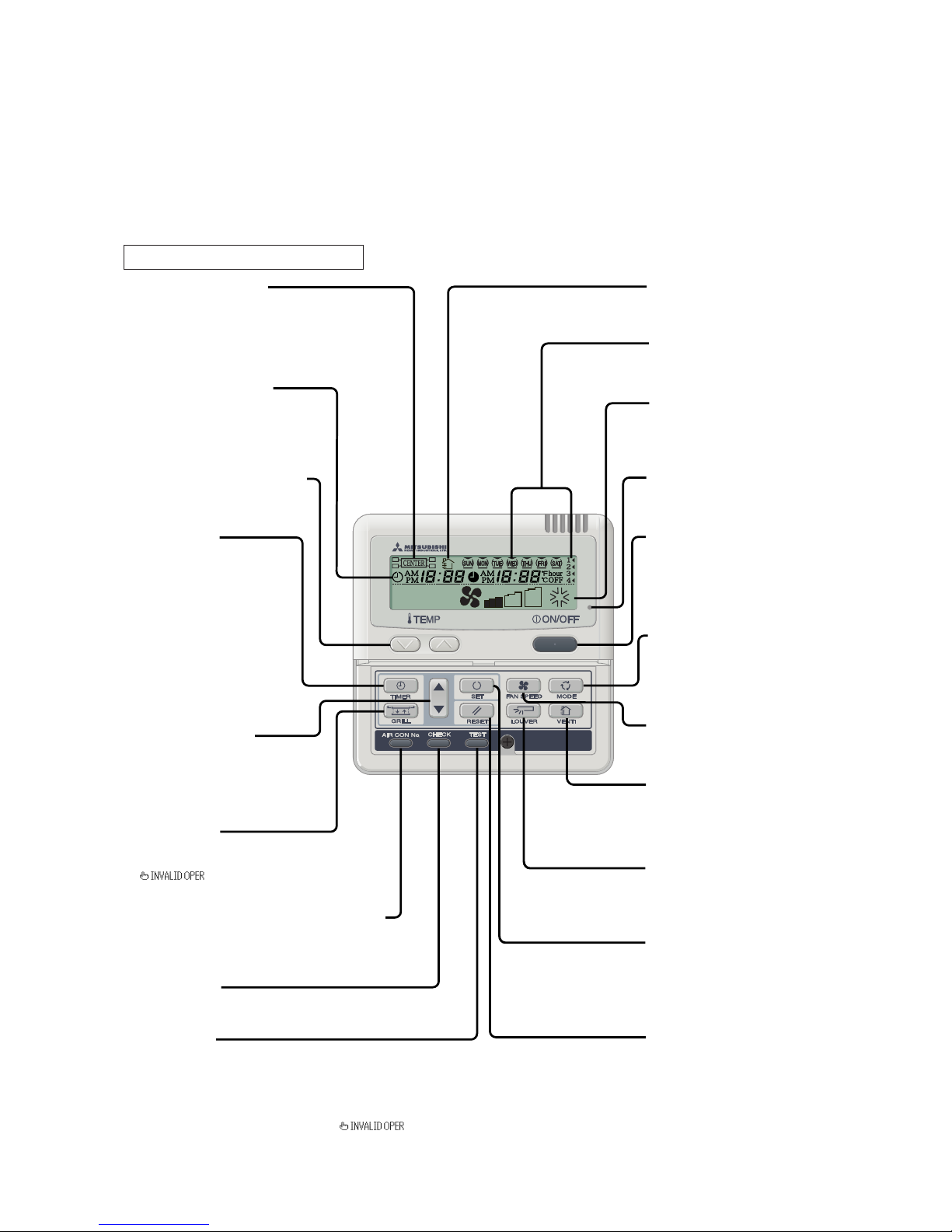

(1) Remote controller

(a) Wired remote controller

The figure below shows the remote controller with the cover opened. Note that all the items that may be displayed in the

liquid crystal display area are shown in the figure for the sake of explanation.

Characters displayed with dots in the liquid crystal display area are abbreviated.

Pull the cover downward to open it.

*If you press any of the switches above and " " is display, the switch has no function.

But it does not mean a failure.

Weekly timer display

Displays the settings of

the weekly timer.

Vent Indicator

Indicates operation in the

Ventilation mode.

ON/OFF switch

This switch is used to operate and

stop the air conditioning system.

Press the switch once to operate

the system and press it once again to

stop the system.

MODE switch

This switch is used to switch between

operation modes.

Operation setting display area

Displays setting temperature,

airflow volume, operation mode and

operation message.

Operation/Check indicator light

During operation: Lit in green

In case of error: Flashing in red

FAN SPEED switch

This switch is used to set the

airflow volume.

SET switch

This switch is used to apply the timer

operation setting.

This switch is also used to make silent

mode operation settings.

RESET switch

The switch which returns to

a previous step.

Central control display

Displayed when the air conditioning

system is controlled by the option controller.

Timer operation display

Displays the settings related to

timer operation.

AIR CON No. (Air conditioning system No.) switch

Displays the number of the connected

air conditioning system.

CHECK switch

This switch is used at servicing.

TEST switch

This switch is used during test operation.

Temperature setting switches

These switches are used to set

the temperature of the room.

VENT switch

Switch that operates the

connected ventilator.

Timer setting switches

These switches are used to set

the timer mode and time.

TIMER switch

This switch is used to select

a timer mode.

GRILL switch

This switch has no function.

When this switch is pressed,

(Invalid Operation)

is displayed, but it does not mean a failure.

LOUVER switch

This switch is used to operate/stop

the swing louver.

27

˚

C

-

30

-

(b) Wireless remote controller

Indication section

FAN SPEED indicator

Indicates the selected blow rate.

ON-TIMER indicator

Indicated when ON-TIMER is set.

ROOM TEMP. indicator

Indicates set temperature.

AIR FLOW indicator

Indicates the condition of swing flap.

ON-TIMER setting time indicator

Indicates the ON-TIMER setting time.

Indicates nothing when ON-TIMER is not set.

OFF-TIMER indicator

Indicated when OFF-TIMER set.

OFF-TIMER setting time indicator

Indicates OFF-TIMER setting time. Indicates

the current time when the OFF-TIMER is not set.

OPERATION MODE indicator

Indicates selected operation with lamp.

FILTER indicator

Indicates for 2 seconds when FILTER button

is pressed.

Operation section

FAN SPEED button

Every time when the button is pressed,

the mode is sequentially changed in

order.

HILOMED

OPERATION MODE select button

The operation mode on the side of the

indicator is the currently selected operation mode. It will switch in order.

ON-TIMER button

This button selects ON-TIMER operation.

OFF-TIMER button

This button selects OFF-TIMER operation.

TIME SET UP switch

This switch for setting the time.

ROOM TEMP. button

Press either the or

but ton to set the room temperature.

ACL switch

This is a switch to reset the microcomputer

.

TIMER CANCEL button

This button cancels the timer settings.

FILTER button

Used to reset (turn off) the filter sign.

Press the button only after completing

the filter cleaning.

Signal sender

Signal are sent to the air conditioner

from here.

AIR FLOW button

Used to start or stop the swing flap.

ON/OFF button

When the button is pressed, the air conditioner is started, and when the button is

pressed once again, it is stopped.

(FAN)

(AUTO) (COOL)

(DRY)

(HEAT)

-

31

-

Cooling Fan Heating Dry

Control part

Compressor

4-way valve

Outdoor fan

Indoor fan

/

/

Louver motor

/

Condensate motor

(5min. ON) (5min. ON)

(5min. ON)

(5min. ON)

Note (1) :ON

:OFF

/ × :According to control other than temperature control.

Thermostat

ON

(c) Control parts operation during cooling and heating

Function

–

Temperature difference between thermostat set temp.

and return air temp. (Detected by ThI-A)

Temperature difference between thermostat set

temp. and return air temp. (Detected by Th

I

-A)

Heating operation

OFF

+1

-1

Set temp.by thermostat

Cooling operation

OFF

+1

-1

Set temp.by thermostat

ON

(2) Operation control function by the indoor unit controller

(a) Room temperature control (Differential of thermostat)

(b) Automatic operation

If the Auto mode is selected on the remote control device, the selection of cooling or heating can be made automatically

depending on the room temperature (and the temperature of indoor heat exchanger). (When the switching between the

cooling and the heating is made within 3 minutes, the compressor will not operate for 3 minutes.) This will make much easier

the switching of cooling/heating at the change of season and can be adapted to the unmanned operation at bank cash dis-

penser.

Notes (1) During the automatic switching of cooling/heating the room

temperature is controlled based on the setting of room temperature.

Notes (2) If the temperature of indoor heat exchanger rises beyond 59˚C during

the heating operation, it is switched automatically to the cooling

operation. For an hour after this switching, the heating operation is

suspended regardless of the temperature as shown at left.

Heating operation

Cooling operation

Setting room temp.

Room temp. (detected at Th

I

-A) [deg]

Ready for

heating

Suspended heating operation

Indoor heat exchanger temperature (˚C)

59

56

Thermostat

OFF

Thermostat

ON

Thermostat

OFF

Hot start

(Defrost)

Thermostat

ON

Thermostat

OFF

-

32

-

(d) Dehumidifying operation (“THERMAL DRY”)

The compressor, the indoor fan motor and the outdoor fan

motor are operated intermittently under thermistor (Th

I-A)

control according to the appropriate operation block, to pro-

vide cooling operation for the dehumidifying.

Notes (1) Blocks A and B: Normal cooling operation for 16 minutes after operation starts, then when the set temperature is reached,

the thermostat stops. 16 minutes later, it switches to normal operation.

Blocks C and D: The operation mode shown in the table above is performed for 8 minutes. After 8

minutes, it switches to normal operation.

Notes (2) Under normal operation, the temperature is checked every 8 minutes after normal operation starts to determine which block is operating,

then the operation mode is decided.

Operation block

DCBA

Set temp. by thermostat

Pattern of operation

Operation

block

Thermal drying starting

(for 8 or 16 minutes after operation started)

A

(16 minutes)

• The air flow is set at 1 speed lower than the set air flow.

(8 minutes)

Continuous cooling operation (FMI:Lo)

B

(8 minutes)

CM, FM0

FMI

C

(8 minutes)

CM, FM0

FMI

(8 minutes)

CM, FM0

FMI

D

(8 minutes) All stoppage

(e) Timer Operation

1) Simple Timer

This sets the amount of time from the current time that the air conditioner goes OFF.

The off time can be selected in 10 steps, from “Off 1 hour from now” to “Off 10 hours from now.” After the simple timer

is set, the number of hours until the air conditioning goes off is displayed in one hour units from the current time.

2) Time Off Timer

The time the air conditioner goes OFF can be set in 10-minute increments.

3) Time On Timer

The time the air conditioner goes ON can be set in 10-minute increments. The set temperature can also be set at the same

time.

CM, FMO: ON FMI : ON

Normal thermal dry operation

(after completion of thermal drying)

Low

-2

+3

High

Normal cooling operation

-

33

-

4) Weekly timer

Each day, it is possible to set this timer's operation up to 4 times (ON time, or OFF timer).

5) Possible joint use timer operation setting combinations

Simple timer

Time OFF timer

Time ON timer

Weekly timer

Simple timer

Time OFF timer

Time ON timer

Weekly timer

(f) Hot start (Cold draft prevention during heating)

When heating operation starts, when the thermostat is reset, during a defrosting operation or when resetting a heating opera-

tion, in order to prevent a cold draft, the indoor heat exchanger (sensed by ThI-R1 and R2) control the indoor fan.

Heating start thermostat judgment

Normal state, set air flow

Indoor heat exchanger (˚C) Indoor heat exchanger (˚C)

25 35

Lo

Fan

OFF

35

Fan

Lo

Set air flow

Indoor heat exchanger (˚C)

20

30

Fan

OFF

Set air flow

Indoor heat exchanger (˚C)

40

45

Fan

Lo

(1)

Set air flow

Set air flow

Heat exchanger temperature 35˚C or above, or 7 minutes passesHeat exchanger temperature 35˚C or above, or 7 minutes passes

Compressor ON Defrosting ends

Thermostat ONThermostat OFF

Defrosting startsCompressor OFF

Notes (1) If J2 starts, it changes from OFF to Lo for 5 minutes.

Notes (2) During Hot Start (the compressor is operating and the indoor fan is not operating at the set air flow), Heating preparation is displayed.

(g) FM control with the heating thermostat turned off (For cold draft prevention)

In order to prevent a cold draft while the heating thermostat is turned off, the indoor blower is controlled in response to the

temperature of the indoor heat exchanger as illustrated below. It should be noted that if jumer wire J2 (SW7-2) on the indoor

PCB is turned off, the indoor blower will stop so far as the temperature of the indoor heat exchanger is lower than 40°C. It

will be turned to the Lo operation 5 minutes later.

Note (1) After the thermostat is reset, it returns to the hot start

control.

(Setting air flow)

Indoor heat exchanger temperature (˚C)

40 45

Lo

Note (1) : Possible, : Impossible

-

34

-

(h) Room temperature sensing temperature compensation during heating

In the standard specifications, the temperature set on the thermostat is used to turn the compressor on and off, but in cases

where the warm air easily escapes to the ceiling and the thermostat ends up turning off too soon, Jumper wire J4 (SW7-4) on

the indoor PCB can be disconnected. When this is done, the compressor can be turned ON and OFF at the set temperature +3

degrees, and the feeling that the room is heated can be improved. However, the upper limit for the set temperature is 30°C.

(i) Filter sign

If operating time (the length of time the ON/OFF switch is ON) totals 180 hours

(1)

, “FILTER CLEANING” is displayed on

the remote control unit. (This is displayed whether the system is running or not, when the unit is broken down, and when

there is central control.)

Notes (1) The following controls are enabled by the combination of the ON/OFF settings of 2 switches on the indoor unit PCB, SW5-3 and SW5-4.

(They are switched OFF when the unit is shipped from the factory. The setting time is 180 hours.)

Operation

Room temperature (deg)

—

1

+ 1

Stop

Standard

Compressor

Operation

Set temperatureSet temperature

Room temperature (deg)

+ 4+2

Stop

If J4 (SW7-4) is disconnected

(if it is turned ON),

Compressor

SW5-3 OFF

SW5-4 OFF

SW5-3 OFF

SW5-4 ON

SW5-3 ON

SW5-4 OFF

SW5-3 ON

SW5-4 ON

Setting time: 180 hrs. (when shipped from factory)

Setting time: 600 hrs. (Display)

Setting time: 1000 hrs. (Display)

Setting time: 1000 hrs. (Unit stop)

FunctionSwitch

Notes (2) When SW5-3, SW5-4 is switched ON, the message “FILTER CLEANING” is displayed after the setting time has passed, then the unit stops after

another 24 hours have passed (including stop time).

(j) Auto swing control (Except the FDUR model)

1) Louver Control

a) While the air conditioner is operating, press the “LOUVER” switch.

“AU TO

” is displayed for 3 seconds and the swing louvers move up and down continuously.

b) When fixing the position of the swing louvers, press the “LOUVER” switch once while the swing louvers are moving. 4

stop positions are displayed in sequence at 1-second intervals.

When the display comes to the position where you would like to stop the louvers, press the “LOUVER” switch once

more. The display will stop the message (ex. “STOP

”) will be displayed for 3 seconds, then the swing louvers will

stop.

c) Louver operation when the louver 4-position controller’s power goes On

When the power is turned ON, the louvers automatically swing 1 time automatically (without remote control operation).

This is done so that the microcomputer can confirm the louver’s position and input the louver motor’s (LM) position to

the microcomputer.

Note (1) When the “LOUVER” switch is turned ON, the louver position LCD display displays the swing operation for 10 seconds.

Then “AUTO

” is displayed for 3 seconds.

2) Auto louver horizontal set during heating

During display of “

” (Heating Preparation) (during hot start and heating thermostat OFF), the louvers are in the

horizontal position regardless of the operation of the auto swing switch (auto swing and louver stop). (In order to prevent

cold drafts.) Also, the louver position display LCD continues the previous display from before this control started.

If the “

” (Heating Preparation) display goes off, the LCD display also returns to the original display.

3) Louver free stop control

Setting an open circuit with jumper wire J5 (SW8-1), used for setting louver free stop, causes the louver motor to stop if

there is a stop signal from the remote control unit and saves the position of the louver in memory. Then if there is an auto

swing signal from the remote control unit, auto swing control starts from the previous stop position.

-

35

-

(k) Condensate pump motor (DM) Control [FDT and FDUM models only]

(a) Drain motor is started no sooner than the compressor is turned ON during cooling or dehumidifying operation. The drain

motor continues to operate for 5 minutes after the stop of unit operation, stop with the error stop, thermostat stop and at

switching from cooling or dehumidifying operation to blowing or heating operation. When there is any unit subjected to oil

return control, the drain motor is operated for 5 minutes at such occasion.

(b) Overflow detection is performed by the float switch at all times regardless of the operating mode. If the float switch

circuit is detected to be open continuously for 3 seconds (or when the float switch is disconnected or a wire is broken), an

abnormal stop (E9) is performed and the condensate pump motor runs until the float switch recovers.

(l) Air flow mode control

Air flow mode control can be changed using DIP switch SW9-4 on the indoor PCB.

Abnormal stop

63

Indoor heat exchanger temperature(˚C)

56

Heating operation possible

Cooling operation

10

Indoor heat exchanger temperature (˚C)

1.0

Fan operation

SW9-4 OFF

(Mild Mode Control)

SW9-4 ON

(Powerful mode Control)

Air flow mode

Item

DIP SW

FDT, FDEN models

Hi, Me, Lo UHi, Hi, Me

(m) Compressor inching prevention control

1) 3-minute timer

If the compressor stops due to operation of the thermostat, the Run switch on the remote controller or some trouble, it is not

restarted after 3 minutes. However, when the power is turned ON, the 3-minute timer becomes inactive.

2) 3-minute forced operation timer

a) For 3 minutes after the compressor goes ON, it does not stop. However, it will stop if the Run/Stop button is pressed

and through a change in the operation mode, it sill stop immediately when the thermostat goes OFF.

b) During 3-minute forced operation timer control in heating operation, if the thermostat goes OFF, the louver position

is set in the horizontal position.

Note (1) The compressor stops when protection control starts.

(n) Heating overload porotection

If an overload condition is sensed continuously for 2 seconds by the indoor heat exchanger temperature during heating

(sensed by Thi-R1 or R2), the compressor is stopped. After a 3-minute delay, the compressor is restarted. If the overload is

sensed 5 times within 60 minutes of the first time it was detected, an abnormal stop is performed (E8). Also, if the overload

state is sensed continuously for 6 minutes, it results in an abnormal stop.

(o) Frost prevention during cooling, dehumidification

In order to prevent frost during cooling and dehumidification, 3 minutes after compressor operation starts, if the indoor heat

exchanger temperature (sensed by Thi-R1 or R2) is 3.5˚C or lower for 30 seconds, the compressor’s speed is lowered. 30

seconds later, if the indoor heat exchanger temperature is 3.5˚C or lower, the speed is reduced still more. If the temperature

becomes lower than 3.5˚C continuously, this control is terminated. Furthermore, even if the compressor’s speed is lowered, if

the indoor heat exchanger becomes as shown in the diagram below, the unit switches to fan operation.

(p) Thermistor (Air return, heat exchanger) disconnected wire detection.

If the temperature sensed by the thermistor is –50°C or lower continuously for 5 seconds, the compressor stops. After a 3-

minute delay, the compressor is restarted, but if a recurrence is detected within 60 minutes of the 1st time, or if it is sensed

continuously for 6 minutes, it results in an abnormal stop (E6, E7).

Notes (1) When the unit is shipped, SW9-4 is turned ON.

Notes (2) If SW9-4 is ON, the fan operates in Me even during hot start and

when the heating thermostat is OFF.

SW9-4 OFF

(Standard)

SW9-4 ON

(High speed)

Air flow mode

Item

DIP SW

FDUM model

Hi, Me, Lo UHi, Hi, Me

Notes (1) When the unit is shipped, SW9-4 is turned OFF.

Notes (2) If SW9-4 is ON, the fan operates in Hi even during hot start and

when the heating thermostat is OFF.

-

36

-

(q) Using 1 remote controller to control multiple units (indoor units - up to 16 units)

1) Function

A single remote control switch can be used for group control of multiple units (indoor units - up to 16 units). All units in

the group that have had the remote control switch set at [Operating Mode] can be turned on and off in order of the unit

number.

This functions independently of the thermostat and protection functions of each unit.

2) Display to remote controller

a) Remote or center and heating preparation: Displays for the youngest unit for the remote mode (center mode

if there is no remote mode) of the units in operation.

b) Inspection and filter sign: Displays either to the first corresponding unit.

3) Confirmation of connected units

Pressing the “AIR CON No.” switch on the remote control unit displays the indoor unit address. Pressing the

or

button

displays the indoor units in the order of lowest to highest assigned No.

4) Error

a) If an error occurs (protection device activation) with some of the units in the group, those units will have an error

stop, but the properly operating units will continue operation.

b) Wiring outline

Route the wire connecting each of the indoor and outdoor units as it would be for each unit. Use the terminal block

(X, Y, Z) for the remote control for the group controller and use a jumper wire among each of the rooms.

(r) External control (remote display) /control of input signal

1) External control (remote display) output

Following output connectors (CnT) are provided on the control PCB of indoor unit.

● Operation output: Power to engage DC 12V relay (provided by the customer) is outputted during operation.

● Heating output: Power to engage DC 12V relay (provided by the customer) is outputted during the heating operation.

● Compressor ON output: Power to engage DC 12V relay (provided by the customer) is outputted while the compressor

is operating.

● Error output: When any error occurs, the power to engage DC 12V relay (provided by the customer) is outputted.

2) Control of input signal

(Make sure to connect the standard remote control unit. Control of input signal is not available without the standard

remote controller.)

Control of input signal (switch input, timer input) connectors (CnT) are provided on the control PCB of the indoor unit.

However, when the operation of air conditioner is under the Center Mode, the remote control by CnT is invalid.