S

M

E

S

M

FFDDAA SSeerriieess SSpplliitt SSyysstteemmss

FFDDAA SSeerriieess MMuullttii SSyysstteemms

E

A

A

R

R

N

N

VII

V

U

U

C

C

A

A

E

L

E

L

s

MITSUBISHI HEAVY INDUSTRIES - PAC SERVICE MANUAL

INDEX

MAINTENANCE DATA 2

ERROR CODES 4

PCB INDOOR UNITS 8

ERROR DISPLAY & REMEDY CHART 12

PCB OUTDOOR UNITS 22

ERROR DISPLAY – OUTDOOR UNIT 25

OPERATIONAL DATA CHECK – WIRED CONTROLLER 35

REMOTE CONTROL – WIRED 36

- SETTING FUNCTIONS 37

ERROR DISPLAY – WIRELESS CONTROL 43

REMOTE CONTROL WIRELESS 44

1. MAINTENANCE DATA

1.1 Servicing

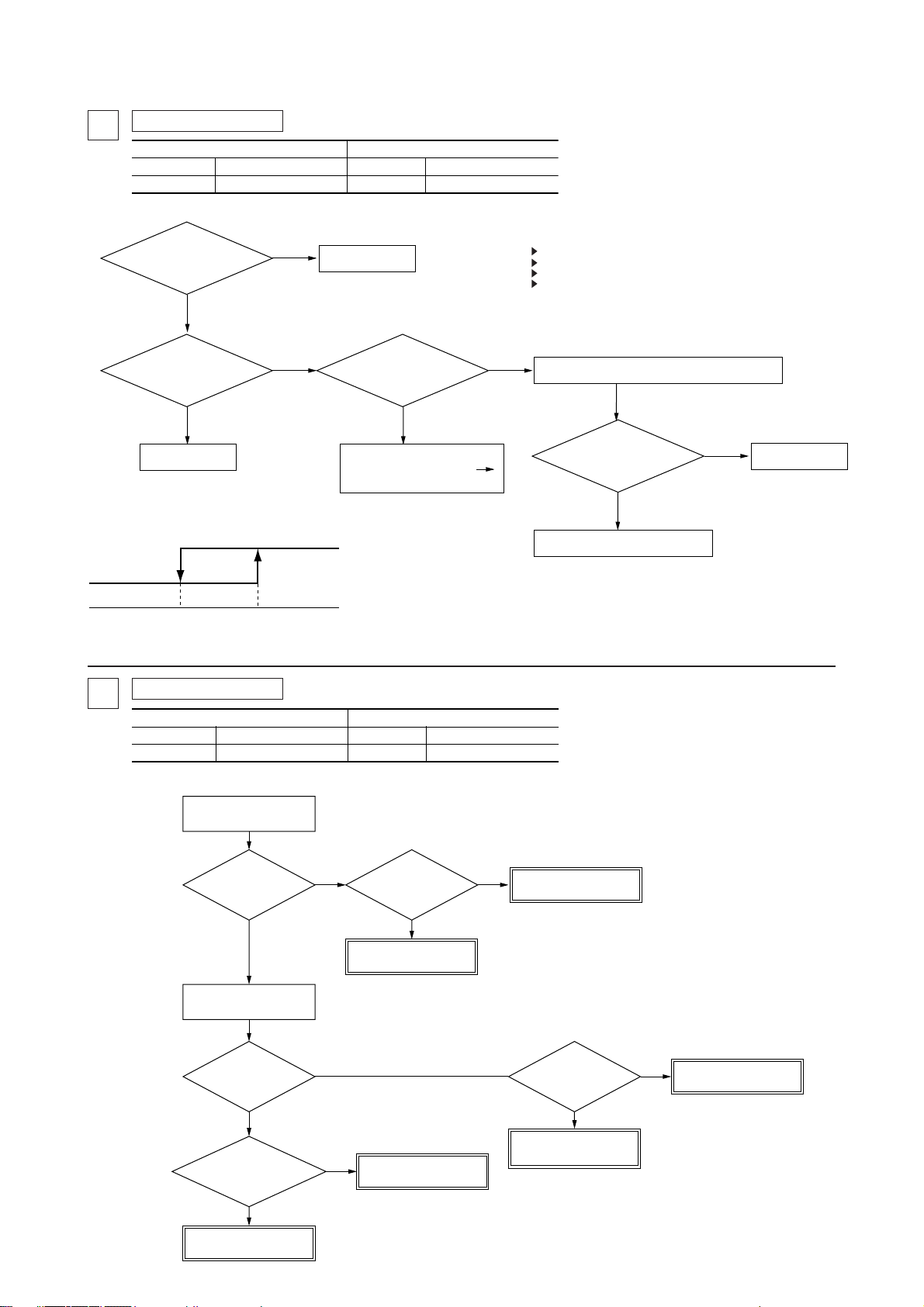

(1) Evacuation

The evacuation is a procedure to purge impurities, such as noncondensable gas, air, moisture from the refrigerant equipment by

using a vacuum pump. Since the refrigerant R410A is very insoluble in water, even a small amount of moisture left in the refriger-

ant equipment will freeze, causing what is called ice clogging.

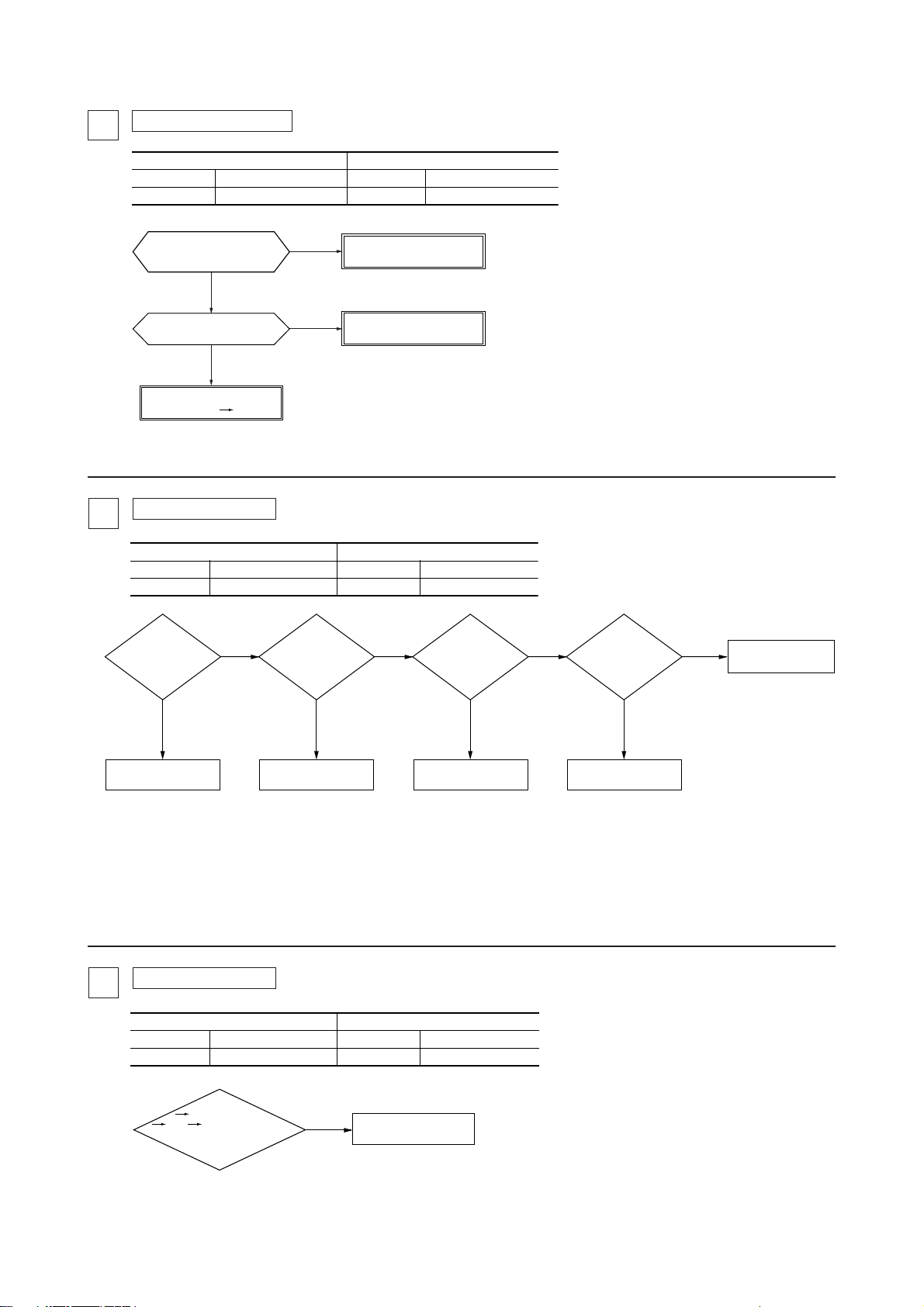

Evacuation procedure

Make sure that the both service valves of gas and liquid line are fully opened.

(a) Check to ensure that there is no internal pres-

sure in the unit. If there is an internal pres-

sure, it should be relived through the service

port.

(b) Connect the charging hose of the gauge mani-

Outdoor unit

fold to the service port of the gas piping.

Close high pressure valve 2 of gange mani-

fold.

(c) Connect the charging hose A to a vacuum

pump.

Repeat evacuation in the following sequence.

Handle Lo

Please run the

vacuum pump for at

least one hour after

the vacuum gauge

Vacuuming begins

shows -101kPa or

lower. (-755mmHg or

lower)

When the vacuum gauge's needle pointer creeps up,

there is moisture left in the system or a leak. Pull air

again after you have checked the system for a leak and

rectified it. Use a reverse flow stop adapter to prevent

the vacuum pump's lubricant oil from flowing into the

refrigerant system.

No increase in the

reading of the

vacuum gauge's

needle pointer.

Vacuuming completed

Vacuum gauge check

Notes (1) Refer to the exterior-view drawing for the position of the service valve.

Notes (2) When connecting of ther service valve, flare connection for both the

Charge hose

(for R410A only)

Charge valve

Vacuum adapter

(for R410A only)

indoor and outdoor unit.

Indoor unit

Gus line

Liquid line

Charge port

Gauge manifold

(for R410A only)

12

Vacuum

pump

Handle Hi

Charge hose A

(for R410A only)

3

Refrigerant

cylinder

Notes (1) Do not use the refrigerant pressure to expel air.

Notes (2) Do not use the compressor for evacuation.

Notes (3) Do not operate the compressor in a vacuum condition.

-

-

2

(2) Refrigerant charging

(a) After the evacuation shown in the above, change the connection of the charge hose A to the refrigerant cylinder.

(b) Purge air from the charge hose A .

First loosen the connecting portion of the charge hose at the gauge manifold side and open valve 3 for a few seconds, and

then immediately retighten it after observing that gas has blown out from loosened connecting portion.

(c) Open valves 1 and 3 then gas refrigerant begins flowing from the cylinder into the unit.

When refrigerant has been charged into the unit to some extent, refrigerant flow becomes stagnant. When that happens, start

the compressor in cooling cycle until the system is filled with the specified amount of gas, then close valves 1 and 3 and

remove the gauge manifold. Cover the service port with caps and tighten them securely.

(d) Check for gas leakage by applying a gas leak detector around the piping connection.

(e) Start the air conditioner and make sure of its operating condition.

1.2 Trouble shooting for refrigerant circuit

(1) Judgement of operating condition by operation pressure and temperature difference

Making an accurate judgement requires a skill that is acquired only after years of experience, one trouble may lead to an another

trouble from a single trouble source and several other troubles may exist at the same time which comes from a undetected different

trouble source.

Filtering out the trouble sources can be done easier by comparing with daily operating conditions. Some good guides are to judge

the operating pressure and the temperature difference between suction air and delivery air.

Following are some pointers,

Pressure

Indi-

Circuit

cation

Too low

A little low

A little

Normal

high

High side ¡

Low side ¡

Too high

1) Excessive overcharging of refrigerant

2) Mixture of non condensable gas (air etc.)

Trouble cause

High side ¡ Ineffective compression

Low side ¡ (defective compressor)

High side ¡

Low side ¡

1) Insufficient refrigerant in circuit

2) Clogging of strainer

3) Gas leakage

4) Clogging of air filter (in cooling)

5) Decrease in heat load (in cooling)

6) Locking of indoor fan (in cooling)

High side ¡

Low side ¡

1) Locking of outdoor unit fan (in cooling)

2) Dirty outdoor heat exchanger (in cooling)

3) Mixture of non condensable gas (air etc.)

High side ¡

Low side ¡

1) Too high temperature of room

-

-

3

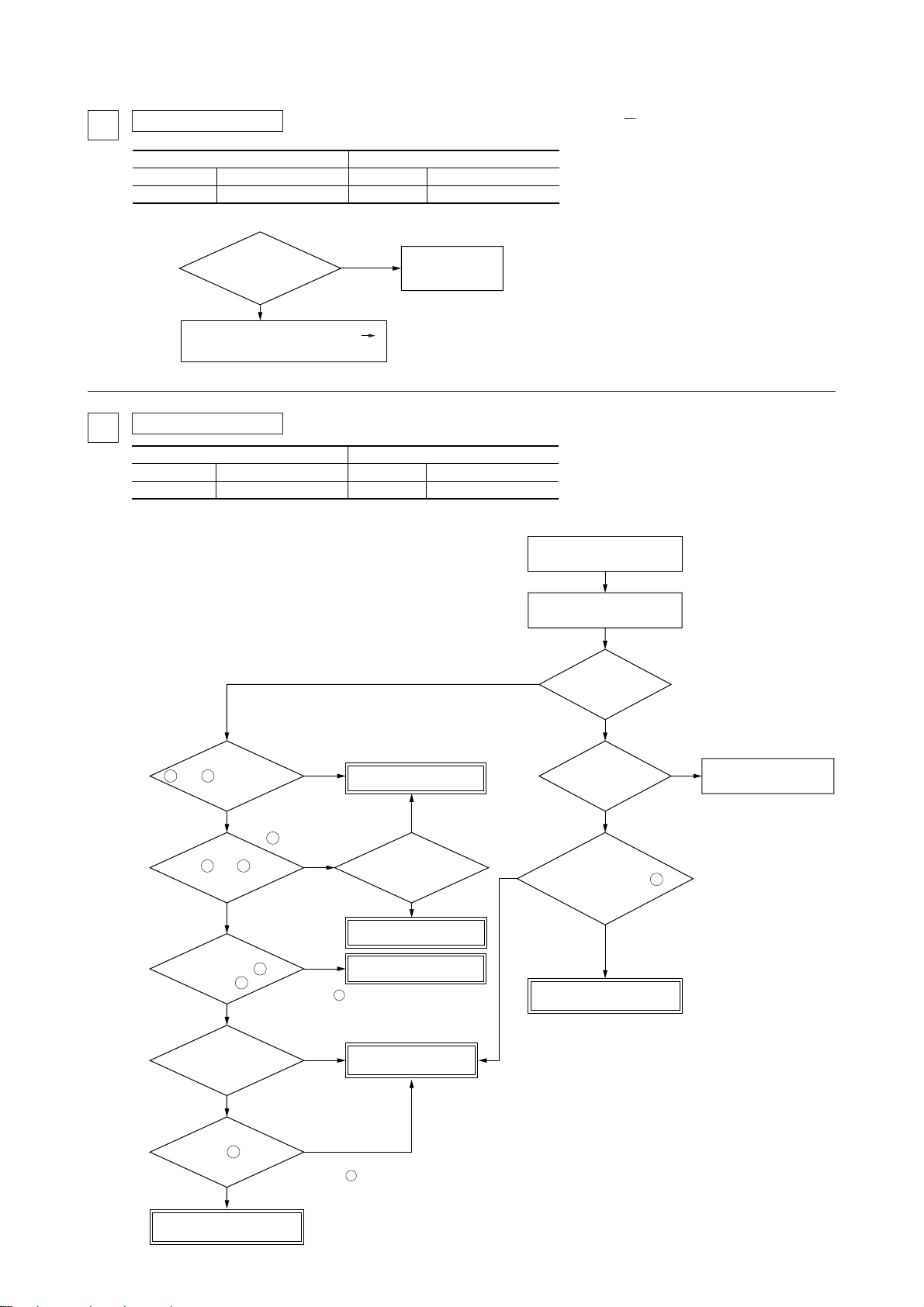

(1) Selfdiagnosis function

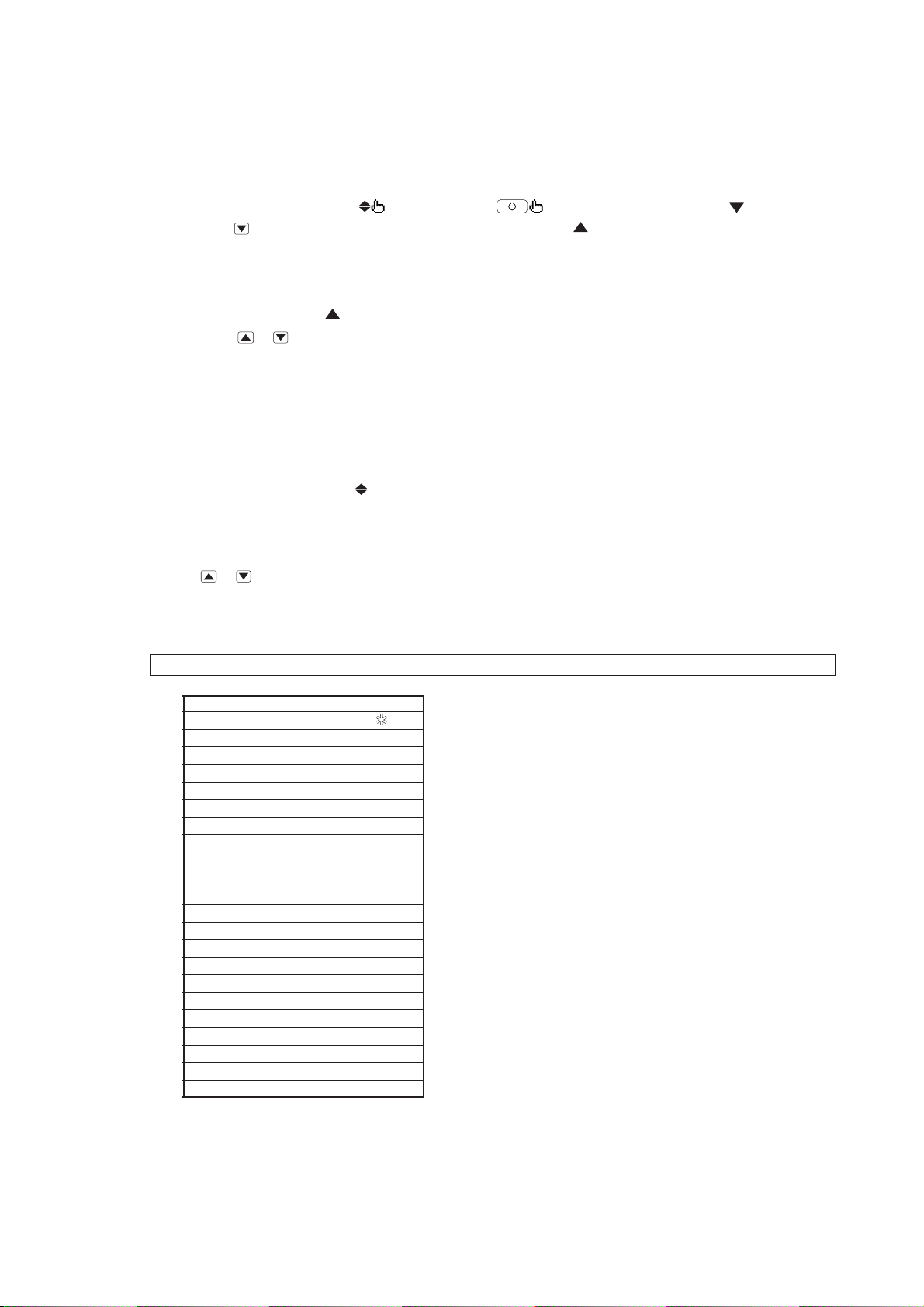

(a) Check Indicator Table

Whether a failure exists or not on the indoor unit and outdoor unit can be know by the contents of remote controller eroor code

and microcomputer normality pilot lamp) or red LED (check pilot lamp).

1) Indoor unit side

1.3 Diagnosing of microcomputer circuit

, indoor/outdoor unit green LED (power pilot lamp

Remote

controller

error code

No-indication

LCD flashes

continuously

or is off.

-

4

Green

Keeps flashing

Stays OFF Stays OFF Stays OFF

Keeps flashing

Keeps flashing

Keeps flashing Keeps flashingStays OFF 2 time flash

Keeps flashing

Red

Stays OFF

Stays OFF

*3 time flash

Stays OFF

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

-

E1

E5

E6

E7

E8

E9

E10

E16

E28

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Stay OFF or Lights

continously

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing Keeps flashing1 time flash Stays OFF

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Stay OFF

Stay OFF

2 time flash

2 time flash

2 time flash

1 time flash

1 time flash

1 time flash

Stays OFF

Stays OFF

Stays OFF

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Outdoor unit LEDIndoor unit LED

Green

Stays OFF

Red

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

2 time flash

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Cause

Normal

Power OFF, L phase wiring is open, power source failure

Indoor unit microcomputer failure

Remote controller wires X and Y are reversely connected. *For wire breaking at

power ON, the LED is OFF. Remote controller wire is open. (X wire breaking : A

beep is produced and no indication is made. Z wire breaking : No beep and no

indication) The remote controller wires Y and Z are reversely connected.

Poor connection or disconnection in wires connecting the indoor and outdoor

units.

When multiple remote controllers are used for control, the power supply to some

indoor units is OFF.

Indoor unit PCB fault

The remote controller wire Y is open. The remote controller wires X and Y are

reversely connected. Noise is penetrating the remote control lines. The remote

controller or indoor control PCB is faulty. (The communications circuit is faulty.)

Indoor / outdoor transmission error.

Outdoor unit control PCB is faulty when the power is turned on, or the inverter

parts are faulty (FDCVA 151~251 type).

Outdoor unit microcomputer failure

Indoor unit heat exchanger thermistor failure

Indoor unit return air thermistor failure

Heating overload (indoor heat exchanger temperature is abnormally high) and

indoor heat exchanger thermistor is faulty.

The float SW operates (with FS only). Drain up kit wiring fault.

When multi-unit control by remote controller is performed, the number of units is

over (more than 17 units). Two remote controller are provided for one controller is

performed.

Fan motor is faulty (FDTA 501, 601 type, FDKN type).

Remote controller thermistor failure

Outdoor unit LEDIndoor unit LED

Green

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Keeps flashing

Red Green

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

Stays OFF

1 time flash

1 time flash

1 time flash

1 time flash

1 time flash

1 time flash

1 time flash

1 time flash

1 time flash

1 time flash

Red

Wiring is open or reversal phase (FDCA 301~601 type)

Abnormal current cut of compressor (FDCA 301~601 type)

52C secondary side L3-phase wiring is open. (FDCA 301~601 type)

Discharge temperature abnormality.

Discharge pipe thermistor failure

63H1 operation (FDCA 301~601 type)

Outdoor air temperature thermistor failure

Inverter Over-voltage Trouble. (FDCVA 151~251 type)

DC fan motor abnormal. (FDCVA 151~251 type)

Remote

controller

error code

E32

E33

E34

E36

E37

E38

E39

E40

E47

E48

Cause

Keeps flashing Keeps flashing

Stays OFF 1 time flash

E35

Keeps flashing

Stays OFF 1 time flash

Current (Abnormalities in a compressor over current)

E42

Keeps flashing Keeps flashing

Stays OFF Lights contiously

52C abnormal. (FDCA 301~601 type)

E52

Keeps flashing

Keeps flashing

Stays OFF 1 time flash

Power transistor thermistor is faulty or disconnection or connector

connections are poor. (FDCVA 151~251 type)

E56

Keeps flashing

Stays OFF 1 time flash

Insufficient refrigerant.

E57

1 time flash

Keeps flashing

Stays OFF 2 time flash

Compressor startup error (FDCVA 151~251 type)

E59

3 time flash

Keeps flashing

Stays OFF 1 time flash

Compressor loader position detection error. (FDCVA 151~251 type)

E60

Outdoor unit heat exchanger thermistor

failure

Outdoor heat exchanger temperature is high or outdoor heat exchanger thermistor

is faulty.

Inverter primary side current is abnormal. (FDCVA151~251 type)

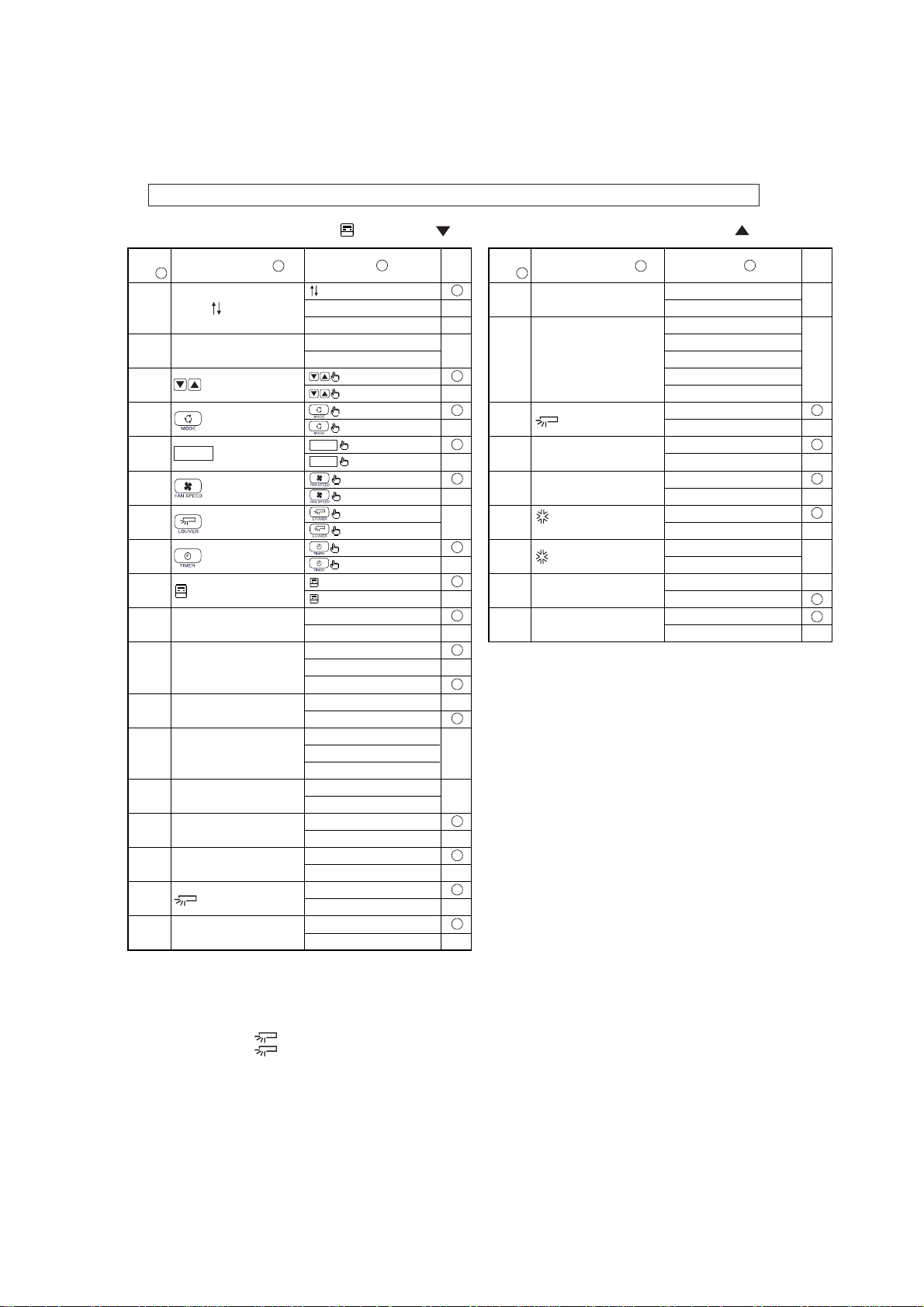

2) Outdoor unit side

-

5

-

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

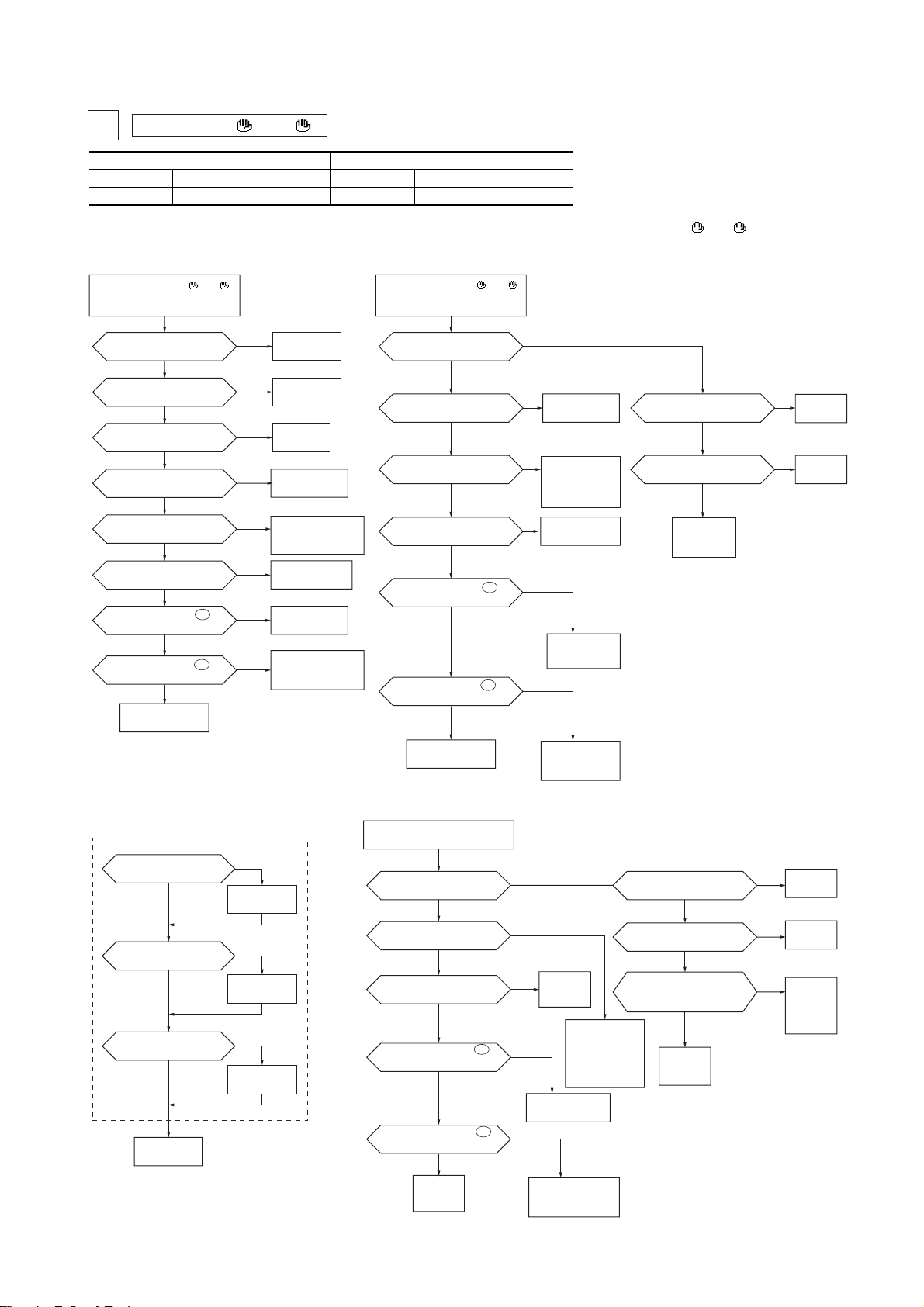

(b) Display sequence of error, inspection display lamp

1) One kind error

Display corresponding to the error is shown.

2) More than one errors.

Section Display section

Error code of remote controller

Inspection LED (red) of indoor unit PCB

Inspection LED (red) of outdoor unit PCB

• Displays the error of higher priority (When plural errors are persisting)

• Displays the present errors.

(When a new error has occurred after the former error was reset.)

3) Timing of error detection

● Indoor unit side.

Error detail Error code Timing of error detection

······················

Drain error (float switch motion)

Wrong connection between the indoor and

outdoor units.

Transmission error of remote controller

indoor unit

Transmission error between indoor/outdoor

units

The number of connected indoor units

exceeds the connection limit (when

multiple units are control by a single remote

controller).

Broken wire of indoor unit return air

thermistor

Broken wire of heat exchanger thermistor

● Outdoor unit side.

Error detail Error code Timing of error detection

Broken wire of outdoor air temperature

thermistor

Broken wire of heat exchanger thermister

Broken wire of discharge pipe thermistor

Broken wire of power transistor

thermistor

“ Wait ”

Normally, 30 seconds after the power is turned ON.

No communications even once with the outdoor unit.

After 1 or more communications of the indoor unit with the remote controller

following power on, transmission errors cause an interruption for 2 minutes.

After communications with the outdoor unit 1 or more times, communications

are abnormal continuously for 2 minutes.

Normally after the power is turned ON (during communications).

When an input temperature of –50°C or lower is measured by the return air

thermistor is measured for 5 seconds or longer within 60 minutes after the

first detection.

When an input temperature of –50°C or lower is measured by the heat

exchanger thermistor is measured for 5 seconds or longer within 60 minutes

after the first detection.

When a thermistor input temperature of –30°C or lower is measured for 5

seconds or longer 3 times within 40 (60) minutes after the 1st detection

between 2 minutes and 2 minutes 20 seconds after compressor operation

starts.

When a thermistor input temperature of –30°C or lower is measured for 5

seconds or longer 3 times within 40 (60) minutes after the 1st detection

between 2 minutes and 2 minutes 20 seconds after compressor operation

starts.

When a thermistor input temperature of –10°C or lower is measured for 5

seconds or longer 3 times within 40 (60) minutes after the 1st detection

between 10 minutes and 10 minutes 20 seconds (between 2 minutes and 2

minutes 20 seconds) after compressor operation starts.

When the under-dome thermistor input temperature of –10°C is measured for

5 seconds or longer 3 times within 40 minutes after the 1st detection between

10 minutes and 10 minutes 20 seconds after compressor operation starts.

Notes (1) Values in ( ) show for the FDCA301~601 models.

(2) The power transistor temperature sensor is used in the FDCVA151~251 models only.

-

6

-

4) Recording and reset of error

Error display Memory Reset

Error code of remote

controller

Indoor unit inspection lamp

(red)

Outdoor unit inspection lamp

(red)

Notes (1) Priority is in the order of E1 > ... > E10 > ... > E60.

• Saves in memory the mode

priority

• Cannot save in memory

• Saves in memory the mode

priority

(1)

of higher

(1)

of higher

• Stop the unit operation by pressing the ON/OFF switch of remote

controller.

• Operation can be started again if the error has been reset.

Indoor unit

: Press the ON/OFF button on the remote controller. Or disconnect and reconnect the power supply connector

(CNW1 or CNW0) on the indoor unit control PCB or turn the main power supply OFF.

Outdoor unit

: Turn the main power supply OFF.

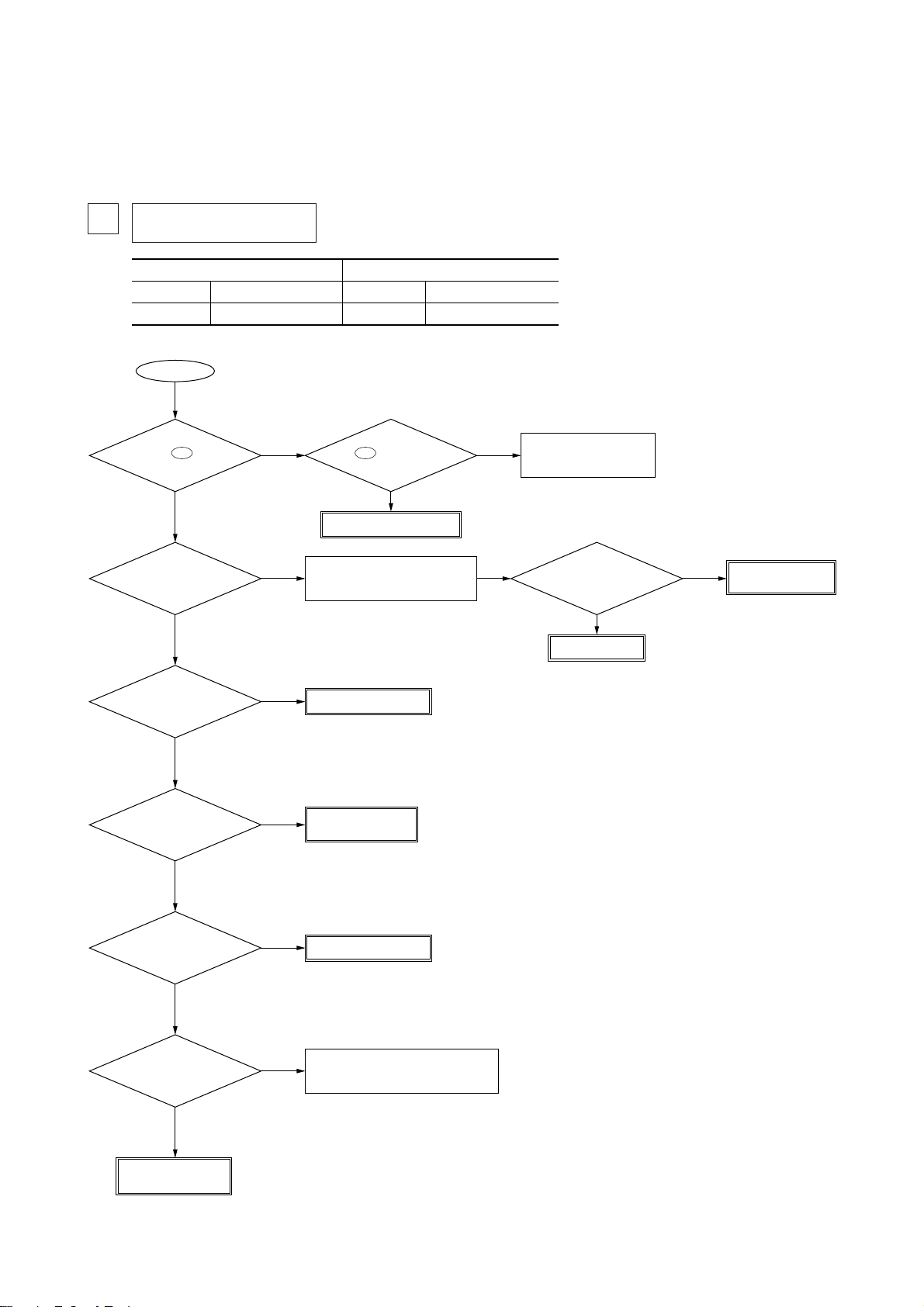

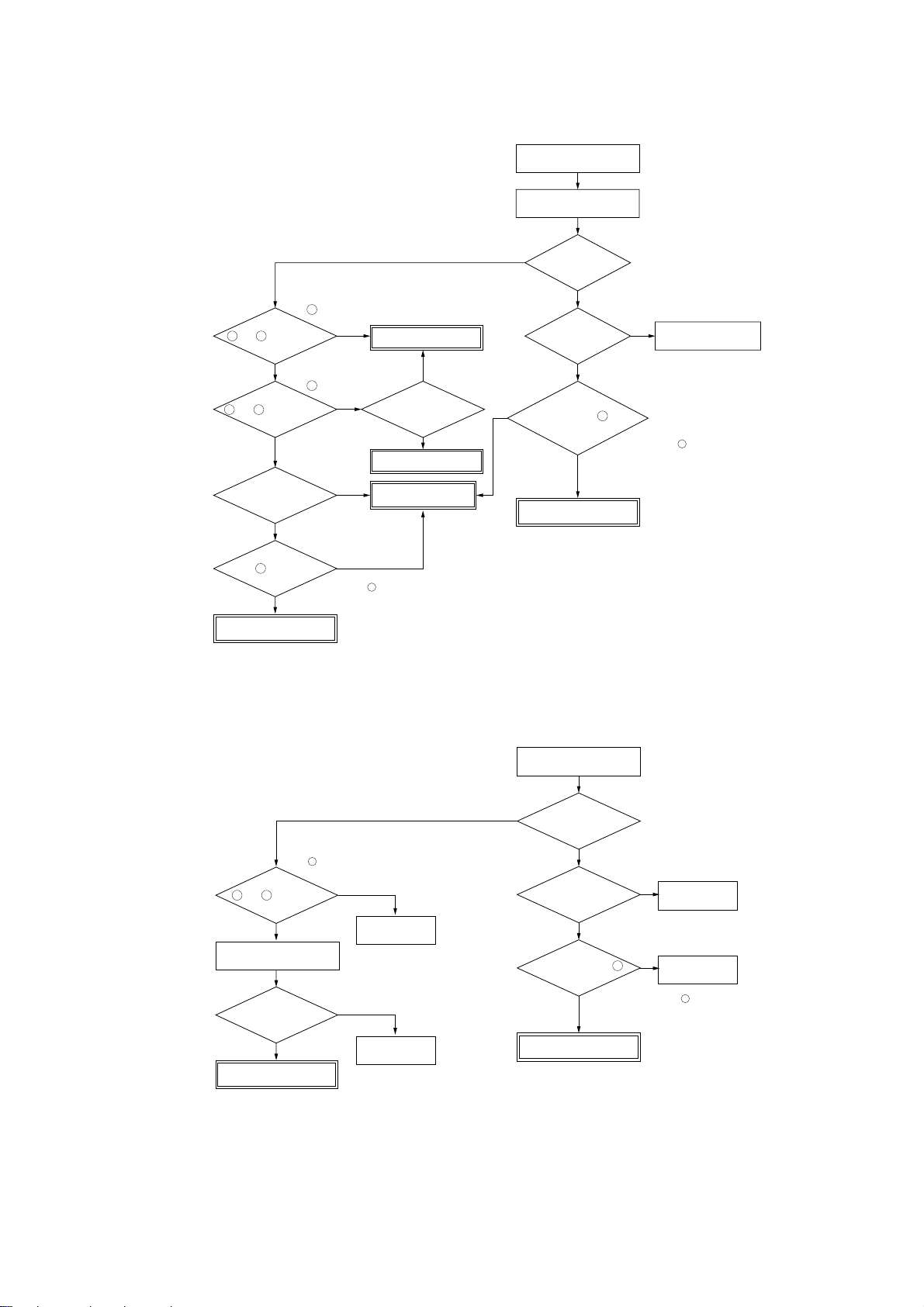

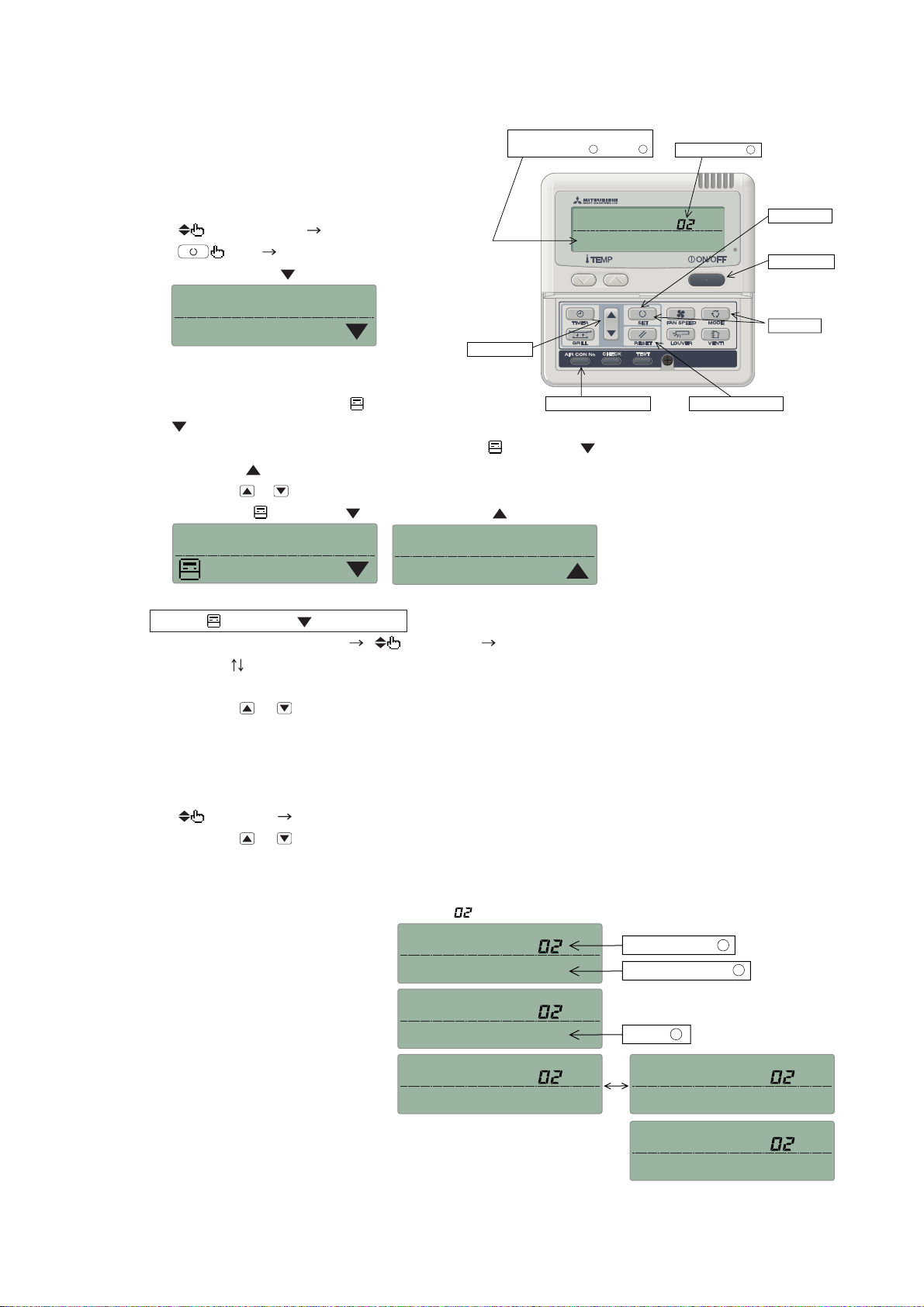

(2) Procedures of trouble diagnosis

When any error occurs, inspect in following sequence. Detailed explanation on each step is given later in this text.

Error Power supply reset

Replacement or repair of defective

parts Test run/adjustment

Note (1) It means the operation to turn off the power and back on again more than 1 min. later in order to reset the malfunction of microcomputer due to the

effect of power supply conditions or accidental noise.

Power supply check

(indoor/outdoor unit)

Check of inspection display [In-

door/outdoor unit PCB, remote

controller or Indication board]

Check of unit

controller

(1)

Check of inspection display [In-

door/outdoor unit PCB, remote

controller or Indication board]

(3) Error diagnosis procedures at the indoor unit side

To diagnose the error, measure the voltage (AC, DC), resistance, etc. at each connector around the circuit board of indoor unit

based on the inspection display or the operation state of unit (no operation of compressor or blower, no switching of 4-way valve,

etc.) If any defective parts are discoverd, replace with the assembly of parts as shown below.

(a) Single-unit replacement parts for circuit board of indoor unit. (Peripheral electric parts for circuit board.)

Indoor unit printed circuit board, thermistor (return, heat exchanger), operating switches, limit switches, transformers, fuses.

Note (1) Use normal inspection methods to determine the condition of strong electrical circuits and frozen cycle parts.

(b) Replacement procedure of indoor unit microcomputer printed circuit board

Microcomputer printed circuit board can be replaced with following procedure.

(i) Confirm the parts numbers. (Refer to the following parts layout drawing for the location of parts number.)

Model

FDTA 151~401

FDTA 501, 601

FDE

Parts number

PJA505A122ZD

PJA505A122ZC

PJA505A128ZF

Model

FDKA 151~251

FDKA 301

FDUR

-

-

7

Parts number

PHA505A018ZF

PHA505A018ZG

PJA505A131ZC

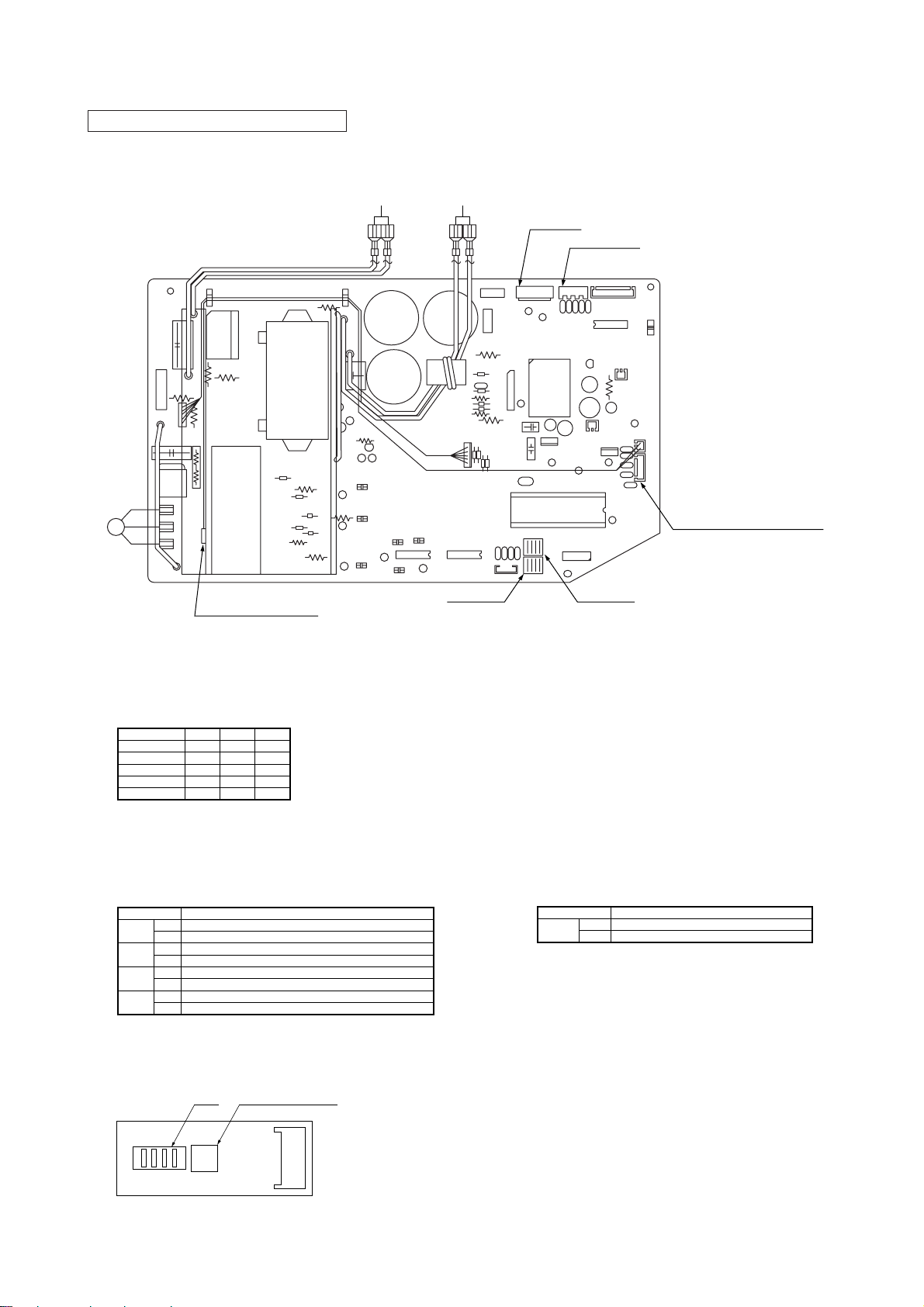

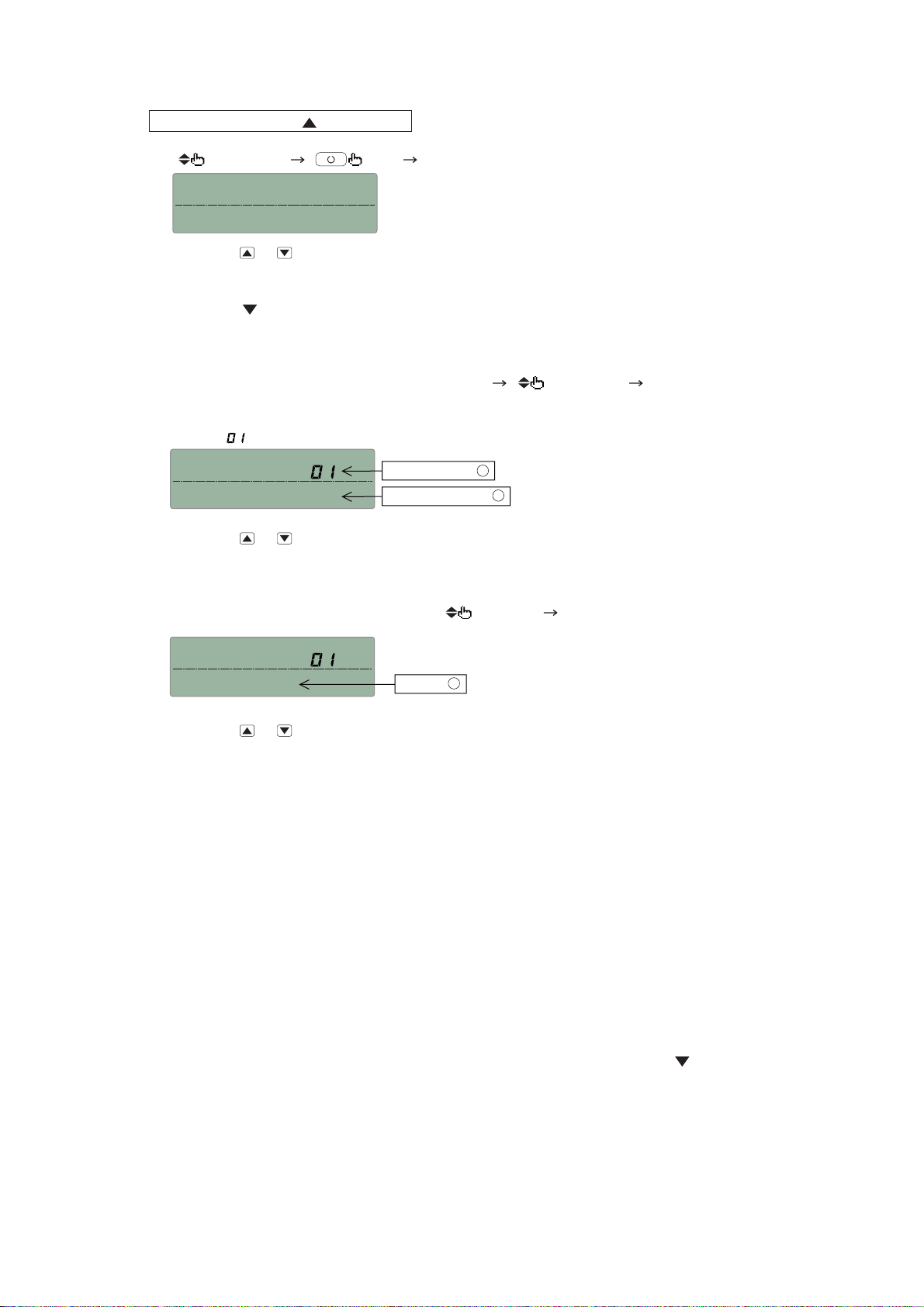

Parts layout on the indoor unit PCB

Model: FDT series

To power supply PCB

(501, 601) (CNW9)

Fan motor

(501, 601)

Power supply PCB

(CNW8)

Connector

(CNT)

Address switch

(SW2)

Heat exchanger thermistor,

Return air thermistor

(Thi-R1, Thi-A)

CNT

CNM2

C13

CNW8

CNY

PC5

L1

C58

CNW9

C12

C1

IC2

IC3

C2

C3

IC9

CNI

Heat exchanger

thermistor

(Thi-R2)

CNM3

52X6 52X1 52X2 52X3

PC3

C4

SW2

CNH CNN1

IC12

X1

J8

J10

J9~J11

(SW10)

Fan motor

(151~401)

CNR

52X4

CNG

LED2

C5

SW10

J11

J12

1234

SW5

J5J6J7

LED1

ON

52X8-2

CNE

SW8

J8

SW7

J1J2J3

1234

C41

J4

ON

SW9

DIP switch

(SW5)

KN1

TVS1

J5~J6

(SW8)

CNV

IC8

IC11

F1

F2

J1~J4

(SW7)

DIP switch

(SW9)

Z2D

52X7

To power supply

(CNW7)

L2

R17

IC7

D2

ZD1

R16

CNJ

Remote

controller

Louver motor

CNW7

C23

TM1

52X8-1

PC2 PC1

C11

CNB

Z3D

Z4D

Z5D

● Change by the jumper wire

Name Function

J1 (SW7-1)

J2 (SW7-2)

J3 (SW7-3)

J4 (SW7-4)

J5 (SW8-1)

J6 (SW8-2)

“None” means that jumper wire is not provided on the PCB or the

Note (1)

connection is cut

The replacement board is not equipped with jumpers J1 ~ J6. Instead,

(2)

SW7 and 8, with the same functions as jumpers J1~J6, are used in the

position where the jumpers were previously. Set SW7 and 8 locally in

accordance with the above table.

With

Input signal - Reverse invalid

(1)

None

Input signal - Rus stop

With

Heating thermostat OFF-Lo

(1)

None

Heating thermostat OFF-Stop, Lo

With

Normal operation operable

(1)

None

Operation permission prohibited

With

Normal

(1)

None

Heating temp. +3

With

Louver free stop control - Invalid

(1)

None

Louver free stop control - Effective

With

Freeze prevention fan control activated.

(1)

None

Freeze prevention fan control deactivated.

● Control change switch (SW5, SW9, SW10)

Function of DIP switch SW5 (Usually all turned OFF)

Switch Function

ON

SW5-4SW5-3

OFF

Setting time : 1000hrs. (Unit stop)

ON

Setting time : 1000hrs. (Display)

OFF

Setting time : 600hrs. (Display)

ON

Setting time : 180hrs. (when shipped from factory)

OFF

Function of DIP switch SW9 (Usually all turned OFF)

Switch Function

SW9-3

SW9-4

Note (1) It is normally ON only in the case of SW9-4.

Emergency operation

ON

Normal

OFF

Fan control : Powerful mode

ON

Fan control : Mild mode

OFF

Function of DIP switch SW10 (Usually all turned OFF)

SW10-1 (J9)

SW10-2

(J10)

Switch Function

OFF

SW10-3

(J11)

ON

Auto swing fanction - None

OFF

Auto swing function - With

ON

Remote controller air flow –

OFF

Remote controller air flow 1 speed

ON

Remote controller air flow 2 speed

OFF

Remote controller air flow 3 speed

ON

-

-

8

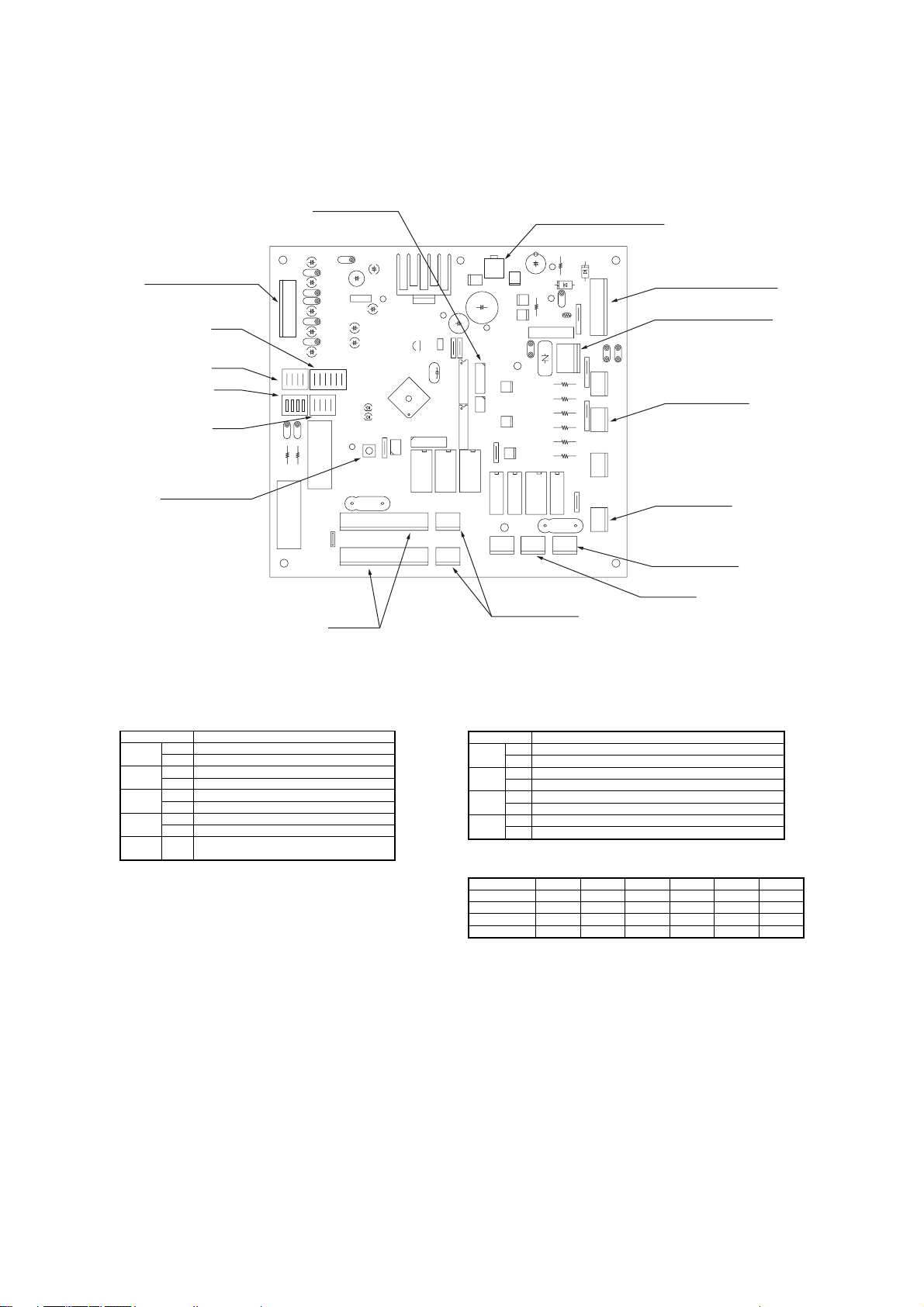

Model: FDEN series

Fan motor

CNJ2CNM3CNRCNV

PCB power supply connector

(Primary side)

Power supply

L2

CNW1

52X5

52X352X252X252X652X4

CNW0

CNM1

L3

F1

ZNR

L1

IC8IC7

PCB power supply

connector

(Secondary side)

Remote controller

52X8-2

52X8-1

KN1

52X7

C57

CNQ CNT

Connector

(CNT)

Heat exchanger thermistor,

Return air thermistor

(Thl-R1, Thl-A)

● Change by the jumper wire

Name Function

J1 (SW7-1)

J2 (SW7-2)

J3 (SW7-3)

J4 (SW7-4)

J5 (SW8-1)

J6 (SW8-2)

“None” means that jumper wire is not provided on the PCB or the

Note (1)

connection is cut

The replacement board is not equipped with jumpers J1 ~ J6. Instead,

(2)

SW7 and 8, with the same functions as jumpers J1~J6, are used in the

position where the jumpers were previously. Set SW7 and 8 locally in

accordance with the above table.

With

Input signal - Reverse invalid

(1)

None

Input signal - Rus stop

With

Heating thermostat OFF-Lo

(1)

None

Heating thermostat OFF-Stop, Lo

With

Normal operation operable

(1)

None

Operation permission prohibited

With

Normal

(1)

None

Heating temp. +3

With

Louver free stop control - Invalid

(1)

None

Louver free stop control - Effective

With

Freeze prevention fan control activated.

(1)

None

Freeze prevention fan control deactivated.

CNE

LED1

LED2

CNB CNW2

DIP switch

(SW5)

SW2 SW5

CNH CNN1

SW8

SW7SW9SW10

J5, J6

(SW8)

J1~J4

(SW7)

DIP switch

Address switch

(SW2)

J9~J11

(SW10)

(SW9)

Heat exchanger thermistor

(Thl-R2)

● Control change switch (SW5, SW9, SW10)

Function of DIP switch SW5 (Usually all turned OFF)

Switch Function

ON

SW5-4SW5-3

OFF

Setting time : 1000hrs. (Unit stop)

ON

Setting time : 1000hrs. (Display)

OFF

Setting time : 600hrs. (Display)

ON

Setting time : 180hrs. (when shipped from factory)

OFF

Function of DIP switch SW9 (Usually all turned OFF)

Switch Function

SW9-3

SW9-4

Note (1) It is normally ON only in the case of SW9-4.

Emergency operation

ON

Normal

OFF

Fan control : Powerful mode

ON

Fan control : Mild mode

OFF

Function of DIP switch SW10 (Usually all turned OFF)

SW10-1 (J9)

SW10-2

(J10)

Switch Function

OFF

SW10-3

(J11)

ON

Auto swing fanction - None

OFF

Auto swing function - With

ON

Remote controller air flow –

OFF

Remote controller air flow 1 speed

ON

Remote controller air flow 2 speed

OFF

Remote controller air flow 3 speed

ON

-

-

9

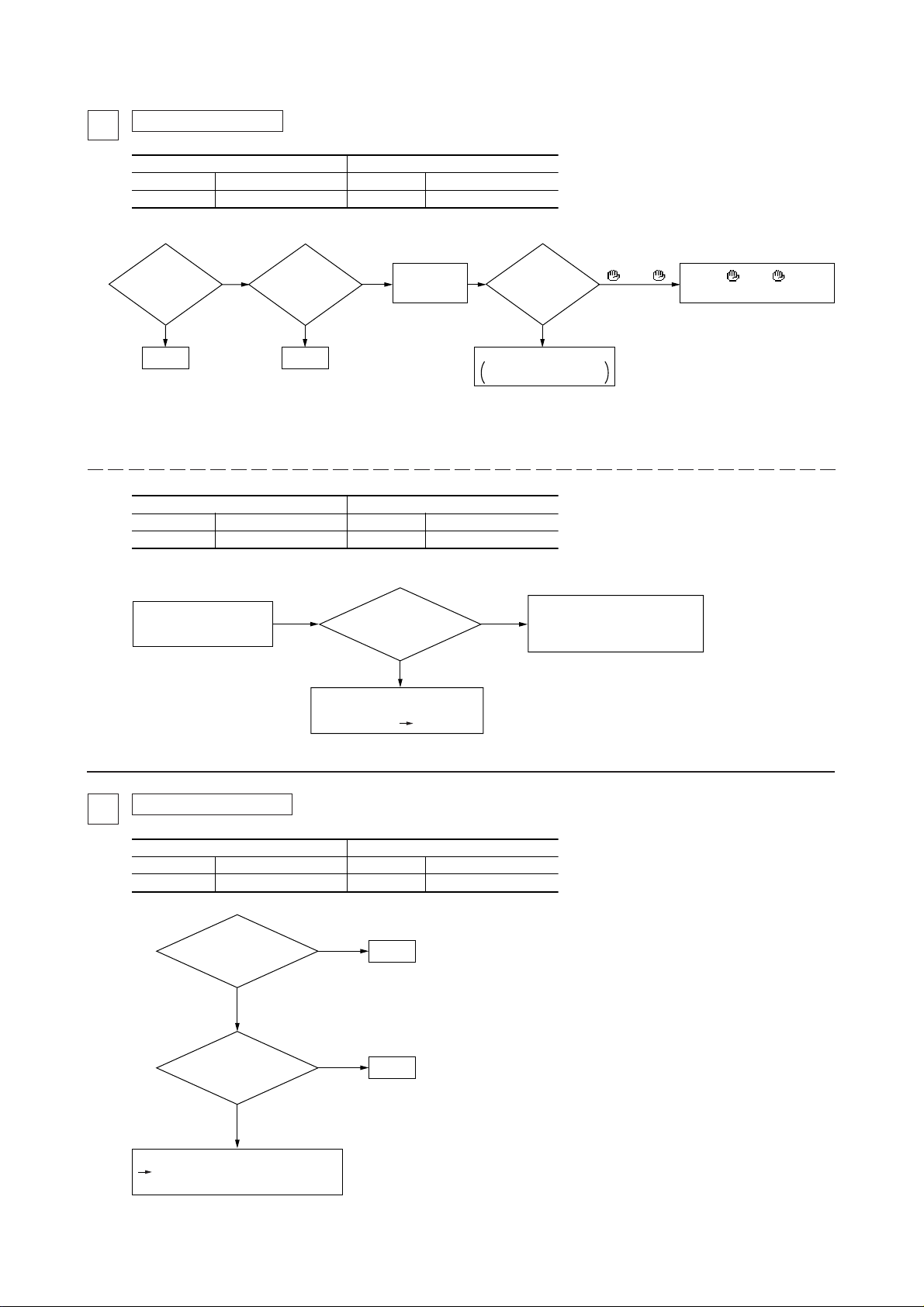

Model: FDKN series

This diagram shows the PCB for the 151~251. The component layout on the 301 PCB is different, but the functions are the

same.

Heat exchanger thermistor,

Dip switch

(SW5)

J9~J11

(SW10)

Dip switch

(SW9)

J5~J8

(SW8)

J1~J4(SW7)

Adress switch

(SW2)

CNZ

SW10

J10

J11

J9

SW8

J5J6J7

J8

SW2

IC9 IC10

LED1

SW5

SW9

J1J2J3

CNE

CNH

IC11

C2

R62

BZ

Return air thermistor

(Thl-R1, Thl-A)

R17

L1

CNW1

CNM

Heat exchanger thermistor

J31

(Thl-R2)

CNN1

CNB

J31

J4

SW7

L4

CNL

C92

CNG

CNY CNJ

IC8

CNT

R16

L2

R151

C104

Remote controller

PCB power supply

connector

(Primary side)

PCB power supply

connector

(Secondary side)

TB,3

TB,2

TB,1

G

● Change by the jumper wire

Name Function

J1 (SW7-1)

J2 (SW7-2)

J3 (SW7-3)

J4 (SW7-4)

J5 (SW8-1)

J6 (SW8-2)

J8 (SW8-4)

“None” means that jumper wire is not provided on the PCB or the

Note (1)

connection is cut

The replacement board is not equipped with jumpers J1 ~ J8. Instead,

(2)

SW7 and 8, with the same functions as jumpers J1~J8, are used in the

position where the jumpers were previously. Set SW7 and 8 locally in

accordance with the above table.

With

Input signal - Reverse invalid

(1)

None

Input signal - Rus stop

With

Heating thermostat OFF-Lo

(1)

None

Heating thermostat OFF-Stop, Lo

With

Normal operation operable

(1)

None

Operation permission prohibited

With

Normal

(1)

None

Heating temp. +3

With

Louver free stop control - Invalid

(1)

None

Louver free stop control - Effective

With

Freeze prevention fan control activated.

(1)

None

Freeze prevention fan control deactivated.

With

Model 151~251

(1)

None

Model 301

Louver motor

(CNT)

Fan motorConnector

● Control change switch (SW5, SW9, SW10)

Function of DIP switch SW5 (Usually all turned OFF)

Switch Function

ON

SW5-4SW5-3

OFF

Setting time : 1000hrs. (Unit stop)

ON

Setting time : 1000hrs. (Display)

OFF

Setting time : 600hrs. (Display)

ON

Setting time : 180hrs. (when shipped from factory)

OFF

Function of DIP switch SW9 (Usually all turned OFF)

Switch Function

SW9-1

SW9-2

SW9-3

SW9-4

Note (1) It is normally ON only in the case of SW9-4.

Custom code - Change

OFF

Custom code - Normal

ON

Power failure security - Effective

OFF

Power failure security - Invalid

ON

Emergency operation

ON

Normal

OFF

Fan control : Powerful mode

ON

Fan control : Mild mode

OFF

Function of DIP switch SW10 (Usually all turned OFF)

SW10-1 (J9)

SW10-2

(J10)

Switch Function

OFF

SW10-3

(J11)

ON

Auto swing fanction - None

OFF

Auto swing function - With

ON

Remote controller air flow –

OFF

Remote controller air flow 1 speed

ON

Remote controller air flow 2 speed

OFF

Remote controller air flow 3 speed

ON

-

10

-

Model: FDUR series

Drain motor

CNT

Connector

(CNT)

Heat exchanger thermistor,

Return air thermistor

(Thl-R1, Thl-A)

Heat exchanger thermistor

(Thl-R2)

CNN1

CNH

CNV

CNO

Remote controller

CNF

CNN2

CNB

CNQ

Address swith

(SW2)

DIP switch

(SW5)

SW2 SW10

SW5 SW7

LED2

J10~J11

(SW10)

J6

(SW8)

DIP switch

(SW9)

J1~J4

Float switch

(SW7)

CNZ CNI

SW9SW8

CNO

52X5 52X4

CNJ2 CNR

L3L2

52X3

52X2 52X1 52X6

CNW1

CNM3

PCB power supply connector

(Primary side)

● Change by the jumper wire

Name Function

J1 (SW7-1)

J2 (SW7-2)

J3 (SW7-3)

J4 (SW7-4)

J6 (SW8-2)

“None” means that jumper wire is not provided on the PCB or the

Note (1)

connection is cut

The replacement board is not equipped with jumpers J1 ~ J4, J6.

(2)

Instead, SW7 and 8, with the same functions as jumpers J1~J4, J6, are

used in the position where the jumpers were previously. Set SW7 and 8

locally in accordance with the above table.

With

Input signal - Reverse invalid

(1)

None

Input signal - Rus stop

With

Heating thermostat OFF-Lo

(1)

None

Heating thermostat OFF-Stop, Lo

With

Normal operation operable

(1)

None

Operation permission prohibited

With

Normal

(1)

None

Heating temp. +3

With

Freeze prevention fan control activated

(1)

None

Freeze prevention fan control deactivated

LED1

L4

F1

L1

CNW0

CNE

CNG

Power supply

CNW2

PCB power supply connector

F2

CNK2CNK1

CNA

F3

(Secondary side)

● Control change switch (SW5, SW9, SW10)

Function of DIP switch SW5 (Usually all turned OFF)

Switch Function

ON

SW5-4SW5-3

OFF

Setting time : 1000hrs. (Unit stop)

ON

Setting time : 1000hrs. (Display)

OFF

Setting time : 600hrs. (Display)

ON

Setting time : 180hrs. (when shipped from factory)

OFF

Function of DIP switch SW9 (Usually all turned OFF)

Switch Function

SW9-3

SW9-4

Emergency operation

ON

Normal

OFF

Fan control : High speed (High Ceiling)

ON

Fan control : Standard

OFF

-

11

Function of DIP switch SW10 (Usually all turned OFF)

Switch Function

(J10)

OFF

ON

SW10-3

(J11)

SW10-2

Remote controller air flow –

OFF

Remote controller air flow 1 speed

ON

Remote controller air flow 2 speed

OFF

Remote controller air flow 3 speed

ON

-

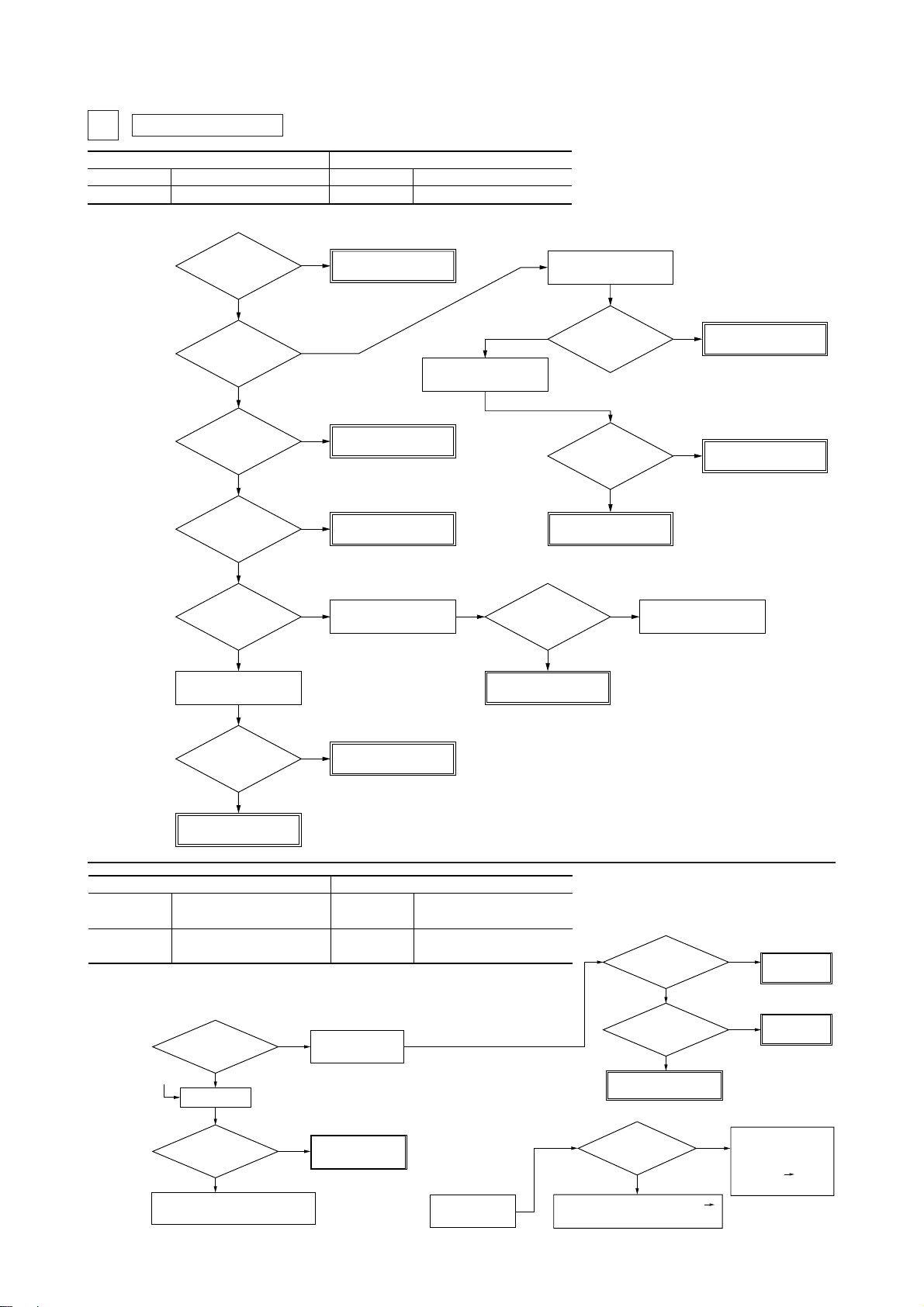

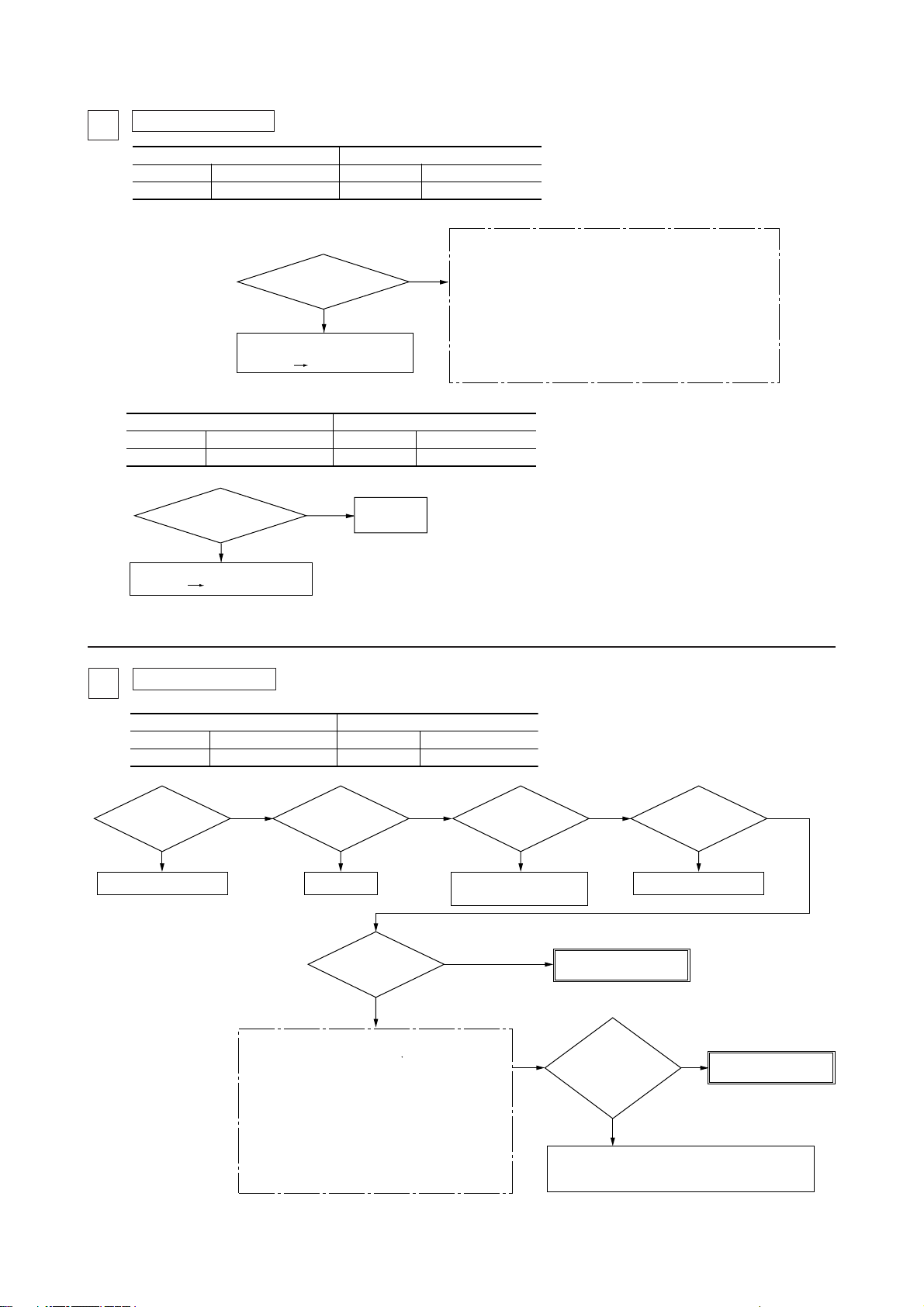

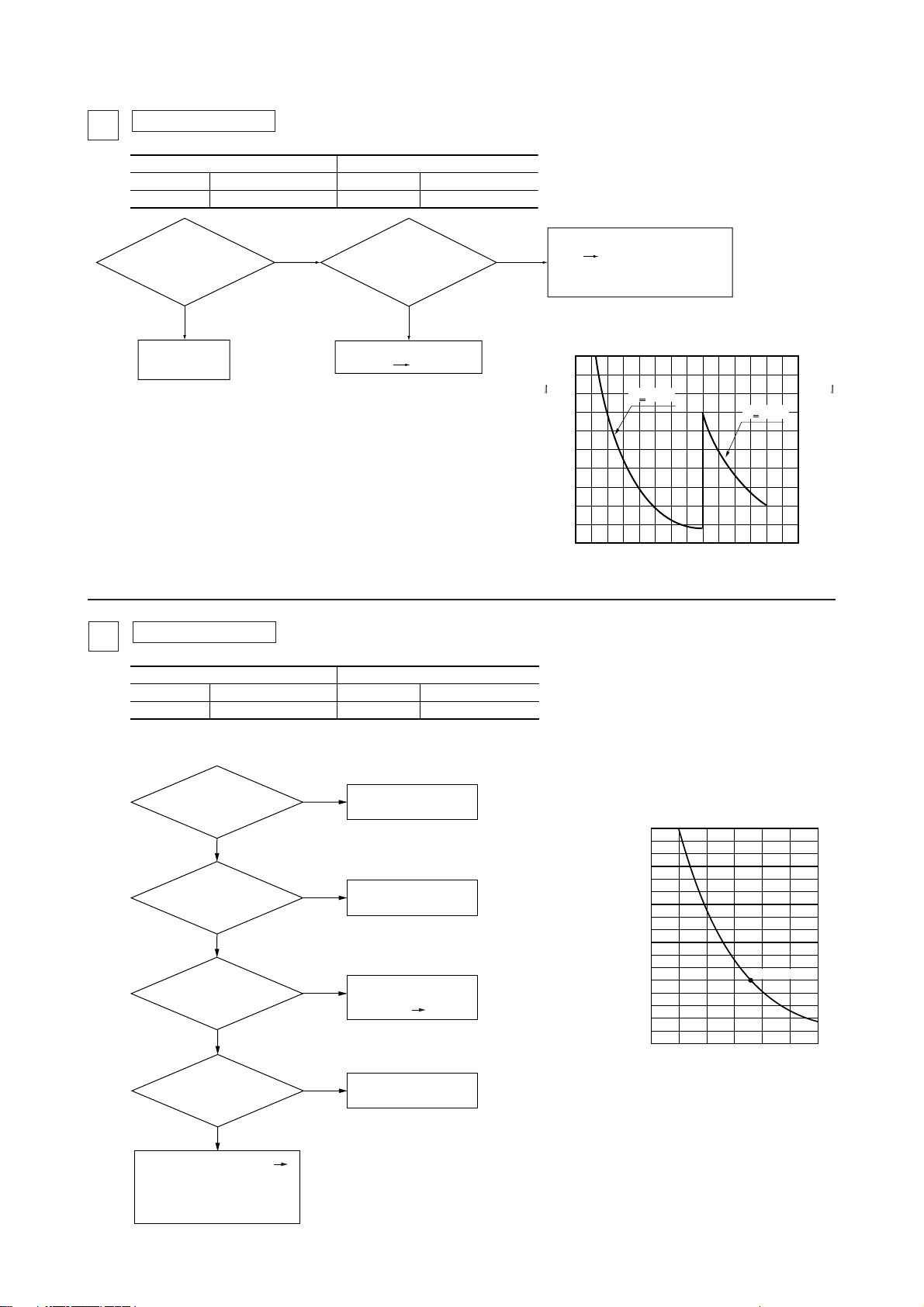

(c) Check method when the error code is display

Remote controller or Indication board: Inspection LED, error code

Indoor unit PCB: Red LED (inspection display), Green LED (CPU. normal display)

Outdoor unit PCB: ARed LED (inspection display), Green LED (CPU. normal display)

Error display : No display

1

LCD display : No display

[Power supply line error]

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Stays OFF

Stays OFF

Red LED

Green LED

Outdoor unit

Start

Is the voltage

between 1 and 2/N of the indoor

unit’s terminal block

AC220/240V?

YES

NO YES

Voltage between

1 and 2/N of the outdoor unit’s

terminal block is

AC220/240V.

NO

Outdoor unit check

Fuse

OK?

YES

Is the voltage at

CNW3 or 10

(1)

transformer’s secondary side

(red – red) on the

14 V or higher?

YES

NO NO

NO

Disconnect the transformer’s primary side

(CNW1) and measure the resistance on

both ends of CNW1 (using a tester, etc.).

Notes (1) In models other than FDT, replace the fuse.

(2) FDT only

Transformer exchange

Note (1) In models other than FDT, it is CNW2.

Stays OFF

Stays OFF

Control lines connected

wrong or disconnected.

Several 10K Ω or higher.

YES

Fuse exchange

Replacement indoor unit

power supply PCB

Is the voltage

between CNW5 2 and 3

DC 12V?

YES

Is the voltage

between CNW8 2 and 3

DC 12V?

YES

Does it return

to normal when the power

supply is reset?

NO

Replacement indoor unit

control PCB

(1)(2)

(1)(2)

NO

NO

YES

Replacement indoor unit

power supply PCB

Note (1) 3 is GND

Harness disconnection

Unit is normal.

(Malfunction was due to noise, etc.)

-

-

12

Indoor unit

Red LED 3 time flash

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Keeps flashing

Red LED Stays OFF

Green LED

Outdoor unit

Keeps flashing

Remote

controller wiring

connect check (Red·

White·Black)

OK

Approximately

(1)

10 ~ 11 V between

X and Z.

Note (1) Z is GND.

NO

Remote controller wire

is removed

YES

Remeasure

between X~Z.

10~11V.

NO

(2)

Is the voltage

between CNW8 1-3

12V?

YES

NO

YES

YES

Remote controller wire short circuit?

Remote controller defective

NO

Note (2) 3 is GND.

Correction

Power supply reset

Check the

CNW5-8 harness.

NG

Harness exchange

OK

Normal?

NO

YES

Maltifunction by

accidental noise

Only case of FDT

Replacement indoor unit power

supply PCB

Remote controller wire

disconnection?

Remote controller defective

Replacement indoor

unit control PCB

-

13

-

Indoor – outdoor communications trouble

2

Red LED

Green LED

Notes (1)

Error display “ WAIT

Indoor unit

Stays OFF

Keeps flashing

If trouble occurs during communications, the error code E5 is displayed (Outdoor, Red LED flashes 2 times). The check procedure is as shown below. (However, excluding

”

(Initial (when the power is turned on)

Outdoor unit

Red LED

Green LED

connection related problems) Also, if the power supply is reset after E5 occurs, if the trouble is intermittent, it will be displayed in the LCD(“ WAIT ”).

The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

(2)

● 151~251 ● 301~601

The remote controller’s LCD(“ WAIT ”)

display remains unchanged after waiting 2

minutes after the power is turned on.

YES

Is the outdoor unit controller's

power fuse F5 (20A) blown?

YES

YES

(1)

(1)

Is the voltage at the secondary side

of the noise filter AC220/240V?

Are the wires connecting to the

noise filter board OK?

YES

Is the indoor unit’s green LED

flashing?

YES

Is the outdoor unit’s control red

LED flashing 2 times?

YES

Are the wires connecting the indoor

and outdoor units connected

according to specifications?

Measure the voltage between 2/N and

3 of the outdoor unit’s terminal block.

Measure the voltage between 2/N and

3 of the indoor unit’s terminal block.

YES

DC 20V

Approx.

0V DC

Approx.

0V DC

DC 20V

Indoor unit control

PCB defect

Note (1) 1 phase is removed.

NO

Power supply

fuse exchange

NO

Noise filter

exchange

NO

Connects

corrently

NO

Indoor unit control

PCB defect

Indoor/outdoor unit control PCB

NO

defect Remote controller defect

Remote controller wire

disconnection (Y)

Repair the wires

NO

connecting the indoor

and outdoor units.

Outdoor unit

control PCB defect

Connection wires are

faulty (disconnection)

Noise

The remote controller’s LCD (“ WAIT ”)

display remains unchanged after waiting 2

minutes after the power is turned on.

*

Is the outdoor green LED

Is the indoor green LED

Is the outdoor red LED

flashing 2 times?

Are the wires connecting the indoor

and outdoor units connected according

to specifications?

Measure the voltage between 2/N and

3 of the outdoor unit’s terminal block.

Measure the voltage between 2/N and

3 of the indoor unit’s terminal block.

Keeps flashing

YES

flashing?

YES

flashing?

YES

YES

YES

DC 20V

Approx.

20V DC

2 time flash

NO

NO

Indoor unit control

PCB defect

NO

Indoor unit control PCB

defect

Remote controller defect

Remote controller wire

disconnection (Y)

Repair the wires

NO

connecting the indoor

and outdoor units.

Approx.

0V DC

Outdoor unit

control PCB

Approx.

0V DC

defect

Is the fuse (10A) OK?

YES

Is the voltage on the outdoor unit’s

transformer secondary side (red –

red) 14 V?

YES

Outdoor unit

control PCB

defect

NO

Fuse

exchange

(1)

NO

Transformer

defect

Inverter check before replacing the power supply fuse.

Is the noise filter out of

phase or short circuited?

YES

Are there any cracks or burnouts in

the power module or diode stack?

YES

Is the reactor abnormal?

YES

Power supply

fuse exchange

NO

Nois filter

exchange

NO

Replacement outdoor

unit control PCB

NO

Reactor

exchange

Indoor unit control

PCB defect

Remote controller does not display

after the power is turned on.

YES

Is the indoor green LED

flashing?

YES

Is the outdoor red LED

flashing 2 times?

YES

Are the wires connecting the indoor

and outdoor units connected according

to specifications?

YES

Measure the voltage between 2/N

and 3 of the outdoor unit’s

terminal block.

Approx. 20V DC

Measure the voltage between 2/N

and 3 of the indoor unit’s

terminal block.

Approx. 20V DC

Indoor unit

control PCB

defect

Connection wires are

faulty (disconnection)

NO

NO

Repair the

NO

connection

lines.

Approx.

0V DC

Outdoor unit control

PCB defect

Approx. 0V DC

Connection wires are

faulty (disconnection)

Noise

Noise

Is the fuse on the indoor unit

Is the voltage on the outdoor

unit’s transformer secondary

side (red – red) AC15V?

Is the voltage between the red and

black wires in the remote

controller DC10~11V when the

remote controller is disconnected?

The indoor/outdoor

control board is faulty.

The remote controller

is faulty.

The X or Z lines in the

remote controller are

disconnected.

control PCB OK?

YES

YES

YES

Remote

controller

defect

NO

NO

NO

Fuse

exchange

Transformer

defect

The remote

controller

wires are

short

circuited.

-

14

-

Error display :

3

e1

[Communication error between remote controller~Indoor unit]

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Stays OFF

Keeps flashing

Voltage

between X and Z

approximately

10~11 V?

Red LED

Green LED

YES

Replacement remote

Outdoor unit

controller

NO

Voltage

fluctuates between

5~11 V between

Y and Z.

NO

Power supply OFF

YES

Voltage

fluctuates between

5~10 V between

Y and Z

indoors.

NO

Remote controller

wire disconnection

YES

Voltage

fluctuates between

5~10 V between

CNB Y and Z.

NO

Terminal block CNB

harness is defective.

YES

Indoor unit

resets every

4 minutes.

YES

NO

❇

❇

After the green LED lights up once,

it begins flashing again continuously.

The louver moves once in the

Power supply reset

close direction.

Stays OFF

Keeps flashing

Replacement remote

Remote controller

wire is removed

Is the

YES

resistance between

Y~Z on the remote controller

approximately

10kΩ?

Resistance is

approximately 10kΩ

between indoor

Y~Z.

YES

Remote controller

wire short circuit

YES

Normal?

NO

controller

NO

NO

Replacement

remote controller

Replacement indoor

unit control PCB

Noise?Power supply reset

YES

Normal?

Noise

NO

Replacement indoor

unit control PCB

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Stays OFF

Stays OFF or Lights

continuously

Red LED

Green LED

Outdoor unit

● Only case of FDT

Stays OFF

Lighting

Is the voltage

between CNW8

2-3 12V?

YES

Power supply reset

NO

Check the CNW5CNW8 harness.

● Cases of other than FDT

NO

Normal

YES

The unit is normal.

(The malfunction is due to noise, etc.)

Replacement indoor

unit control PCB

Power supply

reset

-

15

Stays OFF

Keeps flashing

-

Disconnection ?

NO

Is the

voltage at the transfomer's

secondary side (red-red) 15V

or higher?

YES

Replacement indoor unit

power supply PCB

Is it normalized?

NO

Defective indoor unit control PCB

Replace. (Defective CPU)

YES

NO

YES

(Runaway of indoor

unit CPU due to

noise, etc.

Transient trouble)

Harness

exchange

Transformer

exchange

Unit is normal.

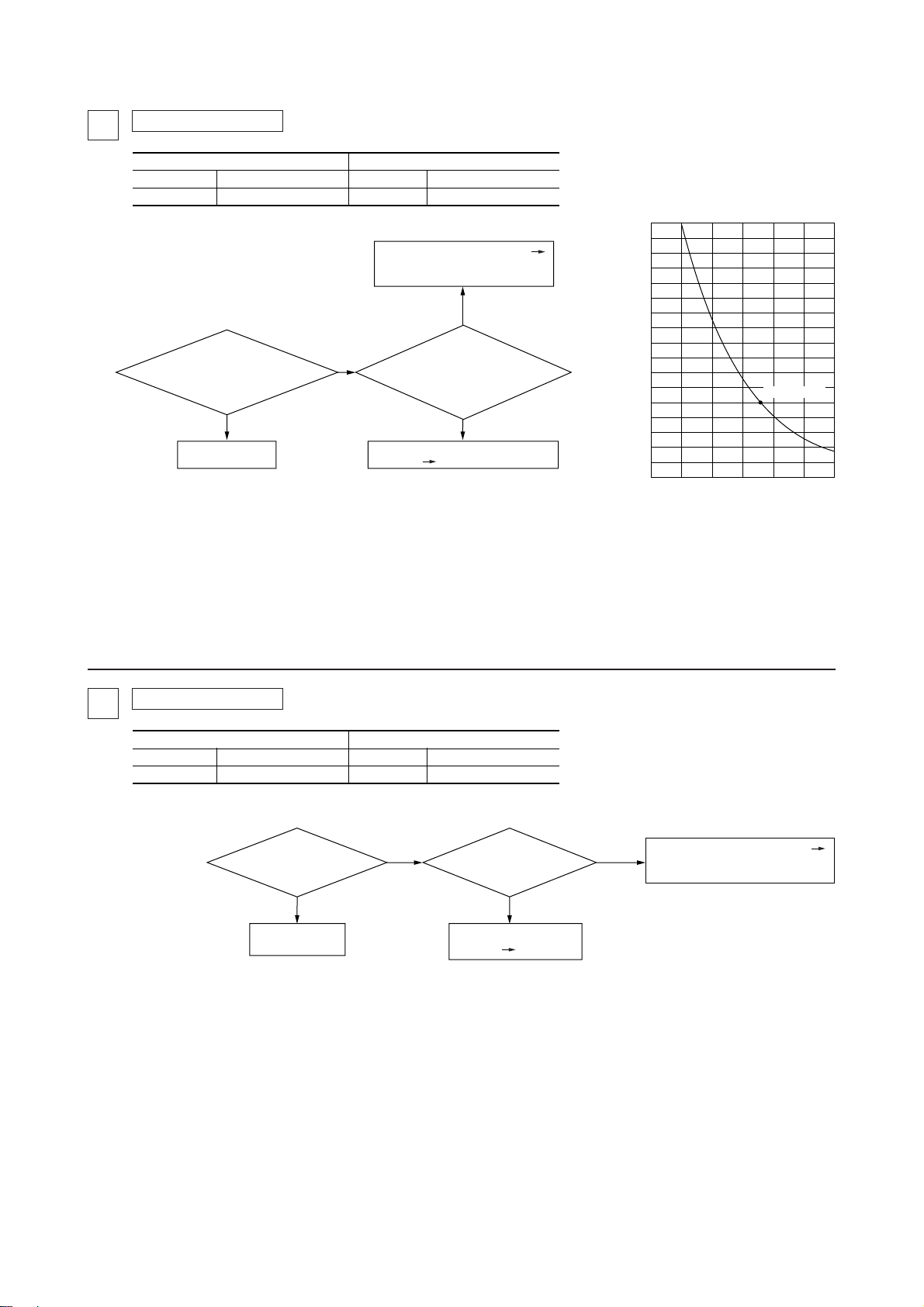

Error display :

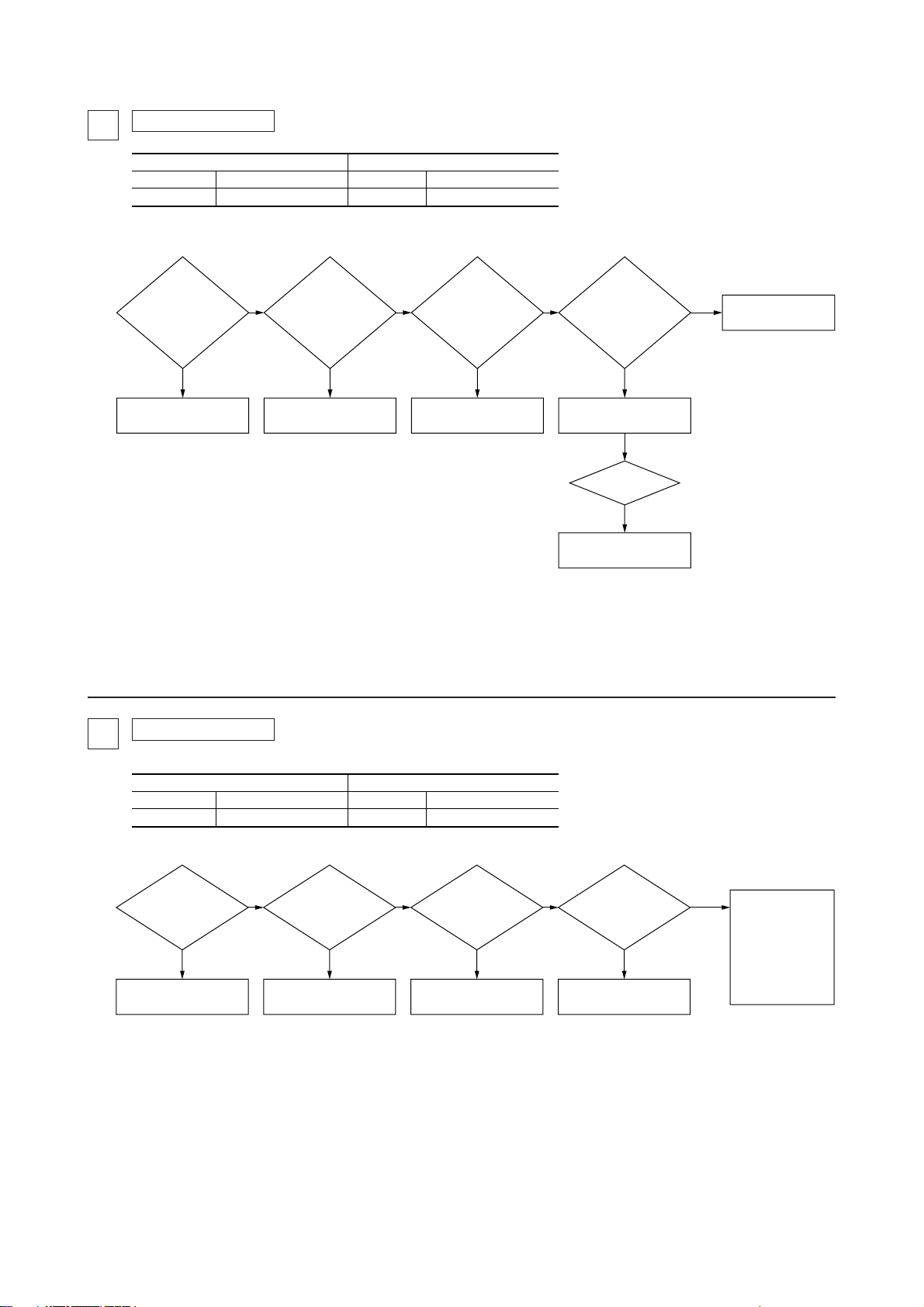

4

e6

[Defective indoor unit heat exchanger thermistor]

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Is the indoor

unit heat exchanger

thermistor connector

connection OK?

Correction

1 time flash

Keeps flashing

NO

Red LED

Green LED

YES

Outdoor unit

Stays OFF

Keeps flashing

Defective indoor unit control PCB

Replace-ment (Defective indoor unit

heat exchanger thermistor input circuit)

YES

Are characteristics

of indoor unit heat

exchanger thermistor OK

or is there any

broken wire?

NO

Defective indoor unit heat exchanger

thermistor Replacement

Return air thermistor (Th

Indoor unit heat exchanger thermistor

(ThI-R1, R2)

Resistance temperature characteristics

15

10

Resistance (kΩ)

5

010 304020 50

Temperature (˚C)

Note (1) 22.5 kΩ at -6˚C

● Display condition

If a temperature of –50ºC or lower is detected continuously for 5 seconds or longer by the thermistor, the compres-

sor stops. After a 3 minute delay, the compressor restarts. If this state is detected again within 60 minutes after the

first detection.

I-

A)

5kΩ at 25˚C

Error display :

5

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

e7

Indoor unit

1 time flash

Keeps flashing

Is the return air

thermistor connector

connection OK?

[Detective return air thermistor]

Outdoor unit

Red LED

Green LED

YES YES

NO

Correction

● Display condition

If a temperature of –50ºC or lower is detected continuously for 5 seconds or longer by the thermistor, the compres-

sor stops. After a 3 minute delay, the compressor restarts. If this state is detected again within 60 minutes after the

first detection.

Stays OFF

Keeps flashing

Is the return air

thermistor characteristics

OK or is there a

broken wire?

NO

Defective return air

thermistor Replacement

Defective indoor unit control PCB

Replacement (Defective return air

thermistor input circuit)

Note (1) Characteristics as per the above

graph.

-

16

-

Error display :

6

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

e8

Indoor unit

1 time flash

Keeps flashing

[Heating overload]

Outdoor unit

Red LED

Green LED

Stays OFF

Keeps flashing

Is the air filter clogged?

NO

Are the connections to

the indoor heat exchanger thermistor

OK?

NO

Repair

YES

YES

Clean it.

Are the characteristics of

the indoor heat exchanger thermistor

OK?

NO

Defective indoor unit heat

exchanger thermistor

Replacement

● Abnormal Temperature Detection

Abnormal stop

Heating is

possible.

● Display condition

An abnormal stop occurs if this state is detected 5 times within 60 minutes of the

56

63

first detection, or if the overload state is detected continuously for 6 minutes.

Indoor unit heat exchanger temp. (˚C)

Error display :

7

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

e9

Indoor unit

1 time flash

Keeps flashing

[Drain trouble]

Outdoor unit

Red LED

Green LED

Notes (1) Check if the overload state exists or not using the following check points.

Is there a short circuit?

Is the indoor heat exchanger dirty or clogged?

Is the outdoor unit’s fan control normal?

((

Is the indoor or outdoor air temperature too high?

(2) See the figure page 142 for indoor heat exchanger thermistor characteristics.

YES

Stays OFF

Keeps flashing

Check the remote controller for abnormal data.

Does the heating

overload state exist?

NO

Check the cooling system.

YES

((

Adjust

Abnormal data check

in remote controller

Is there any

overflow?

YES

Drain motor ON from

remote controller.

DM

operation

YES

Is drain

piping unclogged?

Is the slop OK?

YES

DM check

NO

NO

NO

DC 12 V

at both terminals

of CNI?

YES

Float switch check

Correction

-

17

NO

Replacement indoor

unit PCB

AC 220/240 V

at both terminals

of CNR?

YES

DM check of

motor wiring

NO

Replacement indoor

unit control PCB

-

Error display :

8

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

e10

Indoor unit

Stays OFF

Keeps flashing

[Control of 1 remote controller VS multiple units

Excessive number of units (more than 17 units) ]

Outdoor unit

Red LED

Green LED

Stays OFF

Keeps flashing

Are more

than 17 units connected

to a remote

controller?

NO

Defective indoor unit control PCB

Replacement

Error display :

9

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

e16

Indoor unit

Keeps flashing

[Fan motor abnormalities]

Stays OFF

YES

Red LED

Green LED

Reduce to 16 units

or less

Outdoor unit

S Only case of FDTA501, 601 types

Stays OFF

Keeps flashing

NO

Abnormal data check

with remote controller

After check reset,

fan runs on weak.

Fan ON?

CNM1

1 and 3 (Red – White)

DC280V?

CNW9

1 and 3

DC15V?

DC 15V

between CNW9- 3 and

CNM2 4 ?

Does the

fan motor turn

smoothly by

hand?

Is the voltage

at CNM2 3 DC 1V

or higher?

White is GND.

YES YES

3 is GND.

YES

Note (1) CNW9- 3 is GND.

YES

YES

(2)

NO

NO

NO

(1)

NO

NO

YES

Note (2) CNW9- 3 is GND.

Replacement indoor

unit power supply PCB

side of transformer

Replacement transformer

Replacement indoor

unit control PCB

Detective fan motor

Secondary

(red-red) 15V

or more

NO

YES

NO

Was it reproduced?

YES

When the

motor is turning, does

the voltage at CNM2 2

fluctuate between

0 ~ 15 V?

YES

Replacement indoor

unit control PCB

NO

Check the

circumstances.

● Display conditions

If an indoor unit fan motor’s speed is detected to be less than

200 rpm continuously for 30 seconds, the fan motor stops for 2

seconds. After 2 seconds, it starts again, but this occurs 4 times

within a period of 1 hour.

Replacement indoor

unit control PCB

-

18

-

S Only case of FDKN

Only case of 151~251 types

Abnormal data check

with remote controller

After check reset,

fan runs on Me.

3 (Black) is GND.

CNM

1 and 3 (Red – Black)

DC280V?

YES YES

3 (Black) is GND.

CNM

4 and 3 (White-Black)

DC15V?

YES

Does the

fan motor turn

smoothly by

hand?

YES

Is the voltage

at CNM 5 (Yellow) DC 1V

or higher?

Replacement indoor

unit control PCB

(2)

Note (2) CNM 3 (Black) is GND.

NO

NO

Replacement indoor

NO

side of transformer

Replacement transformer

NO

Detective fan motor

YES

unit control PCB

Secondary

(red-red) 14V

or more

NO

NO

NO

Fan ON?

YES

Was it reproduced?

YES

When the

motor is turning, does

the voltage at CNM 6 (Blue)

fluctuate between

DC 0 ~ 15 V?

Replacement indoor

unit control PCB

(1)

YES

NO

Note (1) CNM 3 (Black) is GND.

Check the

circumstances.

● Display conditions

If an indoor unit fan motor’s speed is detected to be less than

200 rpm continuously for 30 seconds, the fan motor stops for 2

seconds. After 2 seconds, it starts again, but this occurs 4 times

within a period of 1 hour.

Only case of 301 type

CNM

1 and 4 (Red-Blue)

DC 0~60V ?

NO

Turn the power off and wait

a short time (30 min. ~ 1 hr.)

YES

When tried again,

the fan goes ON.

YES

Replacement indoor

unit control PCB

3 (black) is GND.

YES

YES

Replacement fan

motor

Check the

circumstances.

After check reset,

fan runs on Me.

NO

NO

Fan ON ?

YES

Was it reproduced?

YES

When

the motor is turning,

does the voltage at CNM 5

(White) fluctuate between

DC 0 ~ 15 V?

YES

Replacement indoor

unit control PCB

NO

(1)

NO

Note (1) CNM 4 (Blue) is GND.

Check the

circumstances.

Replacement fan

motor

● Display conditions

If an indoor unit fan motor’s speed is detected to be less than

200 rpm continuously for 30 seconds, the fan motor stops for 2

seconds. After 2 seconds, it starts again, but this occurs 4 times

within a period of 1 hour.

-

19

-

10

Error display :

e28

[Directive remote controller thermistor.]

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Is the remote controller

thermistor connector connection OK?

Resistance-temperature characteristic of remote controller thermister

Temperrature(°C)

Resistance value (kΩ)

0

1

2

4

6

8

10

12

Stays OFF

Keeps flashing

NO

Correction

65

62

59

53

48

44

40

36

YES

Temperrature(°C)

14

16

18

20

22

24

26

28

Red LED

Green LED

Resistance value (kΩ)

Outdoor unit

Stays OFF

Keeps flashing

Are characteristics of

remote controller thermistor OK or is there any

broken wire?

NO

Detective remote controller

thermistor Replacement

Temperrature(°C)

33

30

27

25

23

21

19

18

30

32

34

36

38

40

42

44

YES

Resistance value (kΩ)

16

15

14

13

12

11

9.9

9.2

Detectivie remote controller PCB

Replacement (Detective remote thermistor input circuit)

Temperrature(°C)

Resistance value (kΩ)

46

48

50

52

54

56

58

60

8.5

7.8

7.3

6.7

6.3

5.8

5.4

5.0

-

20

-

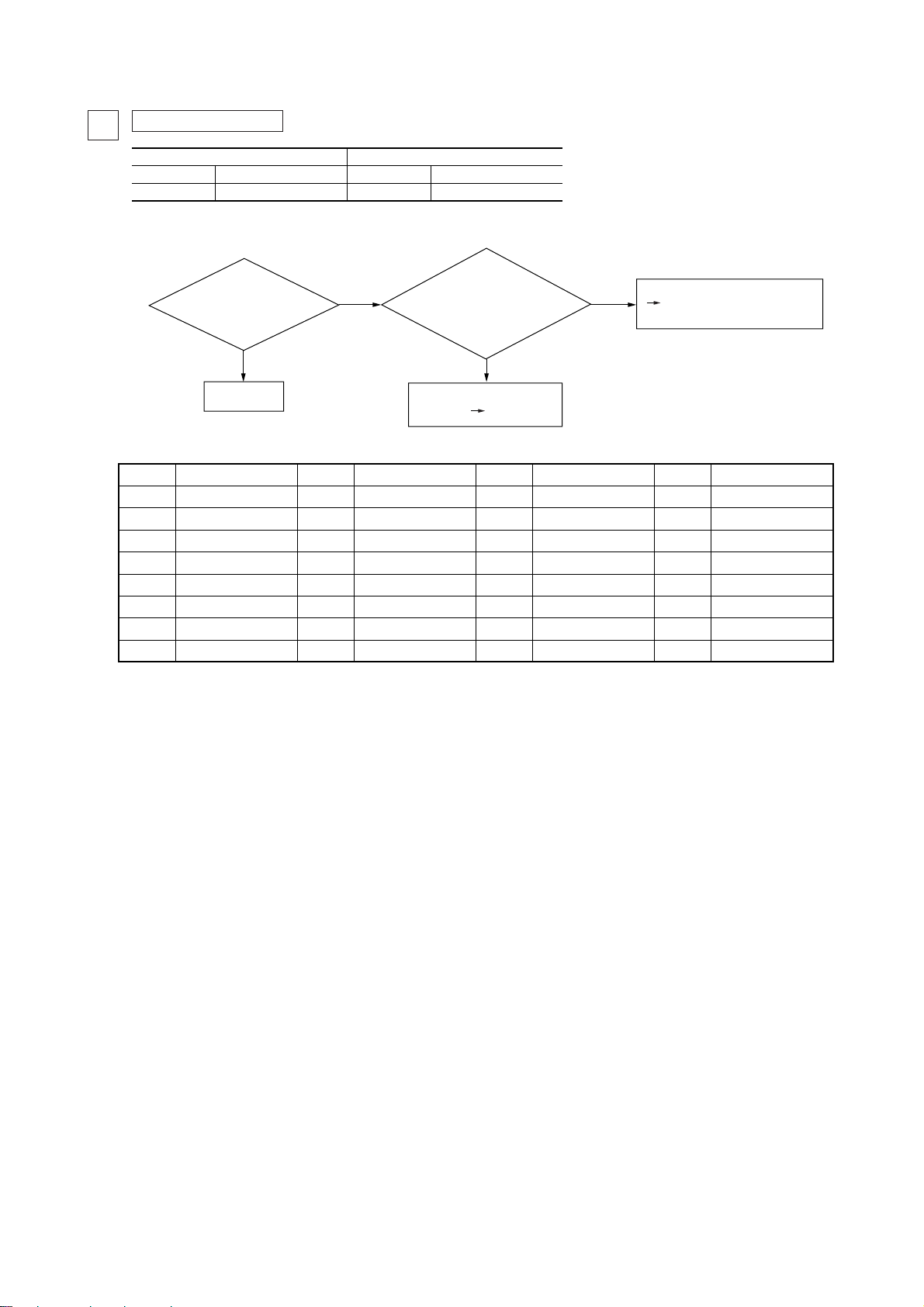

(4) Error diagnosis procedures at the outdoor units side

At the error diagnosis related to the outdoor unit, check at first the error code of remote controller and the illumination patterns of

norma1 and inspection display lamps in the same manner as the case of indoor unit.

Then estimate the outline, the cause and the location of error based on the pattern and proceed to the inspcetion and repair.

Since the self diagnosis function by means of the microcomputers of indoor/outdoor units provide the judgement of error of

microcomputers them selves irregularity power supply line, overload, etc. caused by the installation space, inadequate volume of

refrigerant etc., the location and cause of trouble will be discovered without difficulty.

In addition, the display lamps error code of indoor/outdoor unit is kept flashing, (except when the power supply is iterrupted) after

the irregularity is automatically recovered to give irregularity information to the service presonnel. If any mode of higher priority

than the error retained in memory occurs after the reset of error, it is switched to that mode and saved in the memory.

(a) Replacement parts assembly related to the outdoor unit controller

Outdoor unit PCB, power transistor module, capacitor, noise filter, thermistor, (heat exchanger, discharge pipe, outdoor

temperature, power transistor), fuse, transformer, etc.

(b) Replacement procedure of outdoor unit microcomputer printed circuit board.

Microcomputer printed circuit board can replaced with following procedure.

1) Confirm the parts numbers. (Refer to the following parts layout drawing for the location of parts number.)

Parts No.

PCA505A080Z

PCA505A065ZN

PCA505A065ZS

FDCVA151HEN, 201HEN, 251HEN

FDCA301HEN, 401HEN

FDCA301HES, 401HES, 501HES, 601HES

Applicable Model

2) Set the model using the model setting switch (SW6). (In the case of the 151~251 only).

Switch Setting Table (All switches are set in the OFF position when shipped from the factory.)

Model

151 201 251

Switch Setting Table

Set the switches ON or

OFF for each switch

No.

( ON, OFF)

1 2 3 4

ON

1 2 3 4

ON

ON

1 2 3 4

3) Set the overcurrent value using the overcurrent setting switch for CM (SW3). (In the case of the 301~601 only)

Switch Setting Table (All switches are set in the OFF position when shipped from the factory.)

Model

Setting Value (A)

Switch Setting Table

Set the switches ON or

OFF for each switch

No.

( ON, OFF)

301HEN 301HES 401HEN

17 2710

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

ON

401HES 501HES 601HES

11 1412

1 2 3 4 5 6

ON

1 2 3 4 5 6

1 2 3 4 5 6

ON

1 2 3 4 5 6

ON

4) Set the control select switch to match the previously set settings on the previous board.

If the previously set settings were set with jumper wires, the control select switch should be set in the ON position if there

was a jumper wire and in the OFF position if there wasn’t a jumper wire.

5) Connect the faston terminals and connectors to the control board.

When connecting the wires to the faston terminals, connect each wire to the terminal printed with the same color on the

board.

Note (1) When connecting the faston terminals to the control board, connect them so that there is no deformation of the far end of the circuit board.

-

-

21

Parts layout on the outdoor unit PCB

S FDCVA151~251 type

Sub PCB

(Noise filter)

Reactor

Fan motor

Stepping motor

T2

T4

F2

CNI

T8

W

T7

VU

CN

T6

Power transistor thermistor

(Tho-IPM)

● Change by the jumper wire

Model

JA1 (SW7-1)

JA5 (SW6-1)

JA6 (SW6-2)

JA7 (SW6-3)

JA8 (SW6-4)

151 201 251

None

None

None

None

With

None

None

None

With

With

CNM

F3

T5

T1

F1

CNQ

SW7

SW6

DIP switch

(SW6)

None

Notes (1) “None” means that jumper wire is not provided on the PCB or the connection is cut

None

Notes (2) The replacement PCB is not equipped with jumper wires JA1 and JA5~JA8. Instead, SW6 and 7

None

With

With

are mounted in the same position and have the same functions as jumper wires JA1 and JA5~JA8.

Carry out the local settings in accordance with the table using SW6 and 7.

CNI2CNV1

CNW

CNI3

CNL CNTR

CNE

DIP switch

(SW7)

Outdoor air temp. thermistor,

Outdoor heat exchanger themistor,

Discharge pipe thermistor

(Tho-A, Tho-R, Tho-D)

● Function of DIP switches (SW5) (Usually all turned OFF)

Switch Function

ON

SW5-1

SW5-2

SW5-3

SW5-4

Defrost Setting Select For cold regions.

OFF

Normal

Snow-guard fan control-Effective

ON

Snow-guard fan control-Invalid

OFF

ON

Low refrigerant protection control-Effective

OFF

Low refrigerant protection control-Invalid

ON

Test run operation-Heating

OFF

Test run operation-Cooling

External PCB

SW5 SW9

Test run operation switch

SW9

SW5

1234

CNQ1

-

22

● Change by the JA3

Switch Function

with

JA3

(SW7-3)

Model selection-Energy saving

None

Model selection-Standerd

Note (1) “None” means that jumper wire is not provided on the

PCB or the connection is cut.

-

S FDCA301~601 type

Outdoor air thermistor,

Outdoor heat exchanger

thermistor,

Discharge pipe thermistor

(Tho-A, Tho-D, Tho-R1, 2)

SW3

SW6

SW5

SW4

SW2

(Test run operation switch)

SW5

L11

CNL

1234

CT1

SW6

J5

J8J7J6

L12

Stepping motor

L5

C6

L6

C13

C7

IC12

L7

C6

C8

L8

C9

L10

C10

SW3

J14

J13

J12

J11

J15

J16

SW4

J4J3J2

J1

CT2

Fan motor

PCB power supply connector

(Secondary side)

C5

CNA2

C3

Outdoor unit power supplly

C1

CNV1

X07 X05 X01 X06

CNS CNO

CNQ

CNE

X04 X03 X02

HT1

CNM3

CNM4

C2

C4

C11

C12

LED-R

LED-G

SW2

KN1

CNM1

CNM2

CNW

PCB power supply connector

(Primary side)

CNA1

High pressure switch

(63H1)

CNRCNP3CNP1CNP2

KN2

Crankcase heater

Magnetic contactor

(52C)

4 way valve

Capacitor for FMo

● Change by the jumper wire ● Function of DIP switches (SW5) (Usually all turned OFF)

Switch Function

J1

(SW4-1)

J2

(SW4-2)

J6

(SW6-2)

J7

(SW6-3)

J8

(SW6-4)

1 Phase

with

(1)

None

3 Phase

Cooling

with

(1)

None

Heating

Defrost recovery temperature 14ºC

with

(1)

Defrost recovery temperature (See page 88)

None

Defrost prohibited temperature 45 min.

with

(1)

Defrost prohibited temperature 37 min.

None

(1)

None

-

Switch Function

SW5-1

SW5-2

SW5-3

SW5-4

Defrost Setting Select For cold regions.

ON

Normal

OFF

Snow-guard fan control-Effective

ON

Snow-guard fan control-Invalid

OFF

Low refrigerant protection control-Effective

ON

Low refrigerant protection control-Invalid

OFF

Test run operation-Heating

ON

Test run operation-Cooling

OFF

● Overcurrent Setting

Notes (1) “None” means that jumper wire is not provided on the

PCB or the connection is cut

Notes (2) The replacement board is not equipped with jumper

wires JA1~JA8. Instead, SW4 and 6 are mounted in

the same position and have the same functions as

jumper wires JA1~JA8. Carry out the local settings in

accordance with the above table using SW4 and 6.

Model

Setting Value (A)

J11 (SW3-1)

J12 (SW3-2)

J13 (SW3-3)

301HEN17301HES10401HEN27401HES11501HES12601HES

With

With

None

None

(1)

(1)

None

None

(1)

(1)

With

None

With

(1)

With

None

With

(1)

With

With

None

14

With

With

(1)

With

Notes (1) “None” means that jumper wire is not provided on the PCB or the

connection is cut

Notes (2) The replacement board is not equipped with jumper wires J11~J13.

Instead, SW3 is mounted in the same position and has the same functions as jumper wires J11~J13. Carry out the local settings in accordance with the above table using SW3.

(3) The overcurrent setting value becomes the above setting value (A)

automatically in accordance with the settings on J11(SW3-1) ~

J13(SW3-3) and J1(SW4-1).

-

23

-

L

N

E

TB

TB

Red

White

Y/NG

LED1

Red

T1 T5

Red

White

Black

Orange

Yellow

UVW

T6 T7 T8

CM

F2 (250V 20A)

CnTR

Control PCB

Power transistor module

CNI3 T2 T4

6

DC280V

F3 (250V 1A)

F5

(

20A

)

4321

CNI2

FM

0

T21

T22

Sub PCB

(Noise filter)

T24

T25

T26

T30

T27T28CNI1

Orange

Gray To indoor unit

Brown

Temperature

[

T

]

(

˚C

)

T

<

80˚C

T

>

80˚C

100

50

0

10

5

0

Thermistor resistance (kΩ)

[

T

<

=

80˚C

]

Thermistor resistance (kΩ)

[

T

>

=

80˚C

]

0 20 50 80 100 120

Power transistor thermistor temperature and

resistance characteristics check

Power transistor module

check: Is there a short circuit, open circuit or damage? (See 160 page for the

check procedure.)

DC Reactor Continuity

Check: 50 mΩ or higher,

less than 100 mΩ.

Fuse Check: There should be continuity.

If faulty, replace the control PCB.

When the outdoor

unit fan motor is

abnormal:

(Refer to page 157)

Noise Filter Check:

There should be continuity.

There should be no shorts between phases.

LED1 (Red) Check

Light continuously :

Keeps flashing :

1~3 time flash :

Normal

EEV

Refer to 131 page

Power Supply Check

Measure the power supply at L.N.

(It is normal if it is AC 220/240V.)

❇

Fuse Check: There should be

continuity.

●

Outdoor unit check points

Check items with the *mark when the power is ON.

Outdoor Unit controller failure diagnosis circuit diagram

FDCVA151~251 type

-

24

-

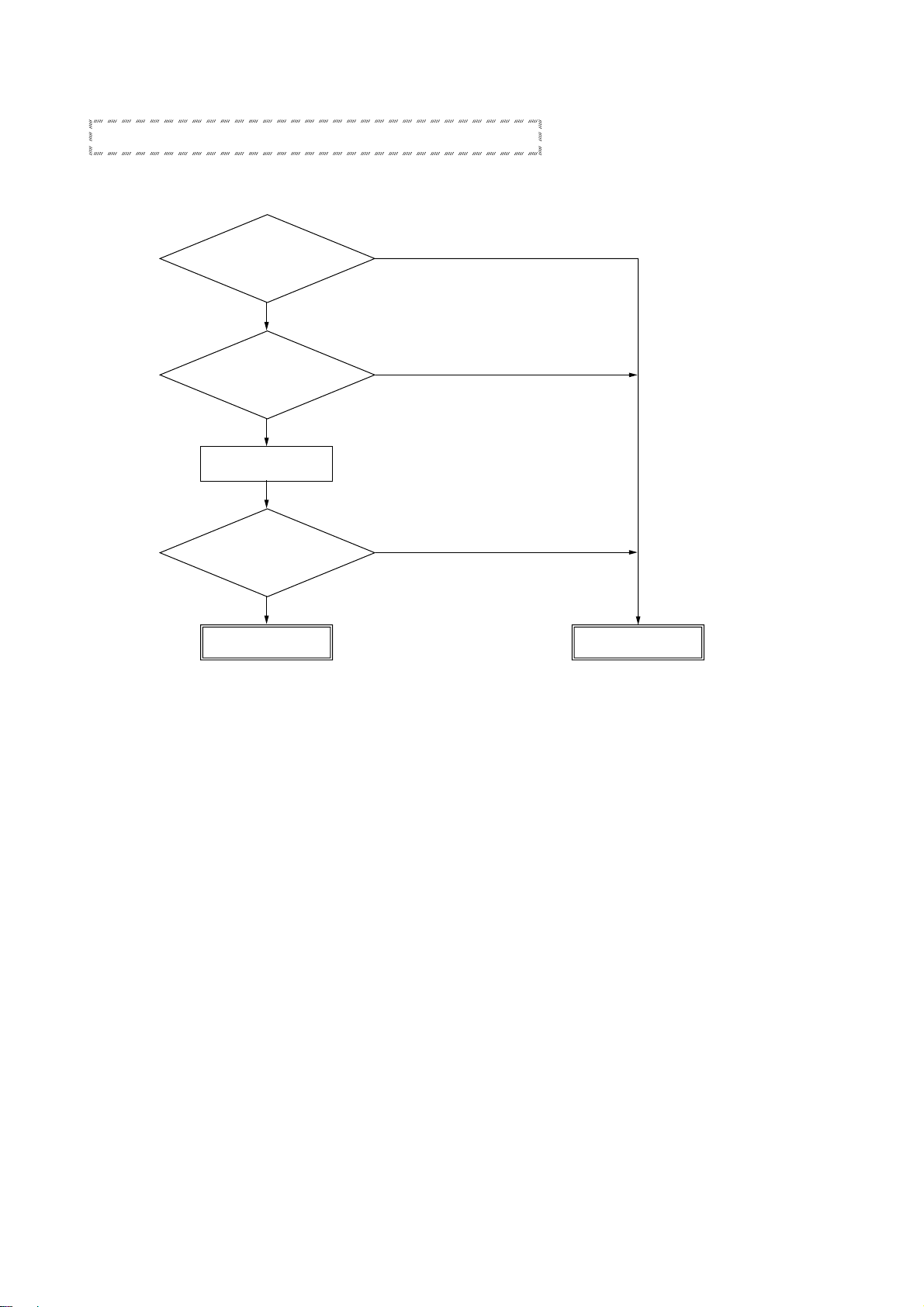

Error display :

1

e5

[Communications error during operation]

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Is the connection

of the signal wires at the

outdoor unit poor?

YES

Repair Repair

Notes (1) Check for poor connections (disconnection, looseness) on the outdoor unit’s terminal block.

(2) Check for poor connections or disconnection of the signal lines between the indoor and outdoor units.

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Reset power supply.

2 time flash

Keeps flashing

(1) (2)

NO

Indoor unit

Is the connection

of the signal wires at the

indoor unit poor?

YES YES

2 time flash

Keeps flashing

Did it return to normal?

Red LED

Green LED

NO

Red LED

Green LED

Outdoor unit

Reset power

supply.

Outdoor unit

NO

2 time flash

Keeps flashing

Did the remote

controller’s LCD return

to normal?

The unit is normal.

Malfunction was due to

transient noise, etc.

Stays OFF

Keeps flashing

YES

(The outdoor unit’s CPU went

out of control due to noise during

power on.)

Malfunction is due to noise, etc.

“ WAIT ”

“ WAIT ”

Go to display diagnosis (page 140).

Error display :

2

Red LED

Green LED

e32

Indoor unit

Stays OFF

Keeps flashing

Are the power supply

phases reversed?

NO

Are the connections

to the reverse phase detection

circuit lines correct?

YES

[Power supply phases reversed] [Only case of 301~601 type]

Outdoor unit’s control PCB is

faulty. (Network communications

circuit is faulty.) Replace

Outdoor unit

1 time flash

Keeps flashing

YES

NO

Red LED

Green LED

Repair

Repair

Outdoor unit’s control PCB is faulty.

Replace

(Reverse phase detection circuit is faulty.)

-

25

-

Error display :

3

e33

[Inverter primary current abnormal] [Only case of 151~251 type]

Indoor unit

Red LED

Green LED

Is the power supply normal?

Is the voltage within

the specified range?

Is there any foreign matter

such as dust or dirt on the control

PCB soldered surfaces?

Replace the control PCB.

Stays OFF

Keeps flashing

NO

YES

NO

YES

NO

YES

Red LED

Restore it to the

normal state.

Restore it to the

normal state.

Remove any foreign matter

such as dust or dirt.

Outdoor unit

1 time flash

● Display Conditions

If the inverter’s primary current exceeds the set value for 3 sec-

onds, the compressor stops. After a 3 minute delay, it restarts, but

when this occurs 5 times within 60 minutes.

[Compressor overcurrent trouble] [Only case of 301~601 type]

Outdoor unit

1 time flash

Keeps flashing

Red LED

Green LED

Indoor unit

Stays OFF

Keeps flashing

Red LED

Green LED

Is the voltage

AC220/240V between the

L1 and L3 phases and between the L2

and L3 phases on the 52C

secondary side?

YES

Is there overcurrent

at the compressor?

NO

Outdoor unit control PCB is

faulty. Replace

(The CT input circuit is faulty.)

NO

(1)

YES

Out of phase between the

L1 and L2 phases.

•

Is the power supply voltage proper? (Isn’t it too low?)

•

Are the power lines proper? (Aren’t they too thin?)

•

Is the overcurrent setting correct? (SW3 setting)

•

Is the compressor running with an overload?

• Is the compressor locked?

Notes (1) Measure the overcurrent value to make sure.

Also make sure the overcurrent setting set with SW3 and SW4-1 on the outdoor unit control PCB

is not incorrect.

• 52C is faulty.

• There is a disconnection between

52C and CM or in the L1 and L2

phases between TB1 and 52C.

Check the unit side.

• During cooling: Is FMo turning?

• During heating: Is FM

Is the service valve (gas side) fully open?

Is the filter clogged?

• Is there an overcharge?

• Is the installation space for the indoor and

outdoor units proper?

•

Is there a short circuit in the indoor or outdoor units?

• Compressor is faulty. Replace

I

turning?

-

26

-

Error display :

4

[Open phase at L3 phase of 52C secondary side] (Only case of 301~601 type)

e34

Indoor unit

Red LED

Green LED

secondary side L3 phase

52C

open?

Stays OFF

Keeps flashing

(1)

NO

Red LED

Green LED

YES

(2)

Outdoor unit

Repair

The outdoor unit control PCB is faulty.

(The CT circuit is faulty) Replace

Error display :

5

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Are the

characteristics of the

outdoor heat exchanger thermistor

normal?

[Cooling overload operation]

e35

Stays OFF

Keeps flashing

YES

Red LED

Green LED

Is there cooling overload

operation?

Outdoor unit

NO

Replace the outdoor heat

exchanger thermistor.

Is the unit normal?

NO

Abnormal Temperature Detection

Error stop

Is high pressure control

normal?

Abnormal temperature detection

Is it (the actual measurement) correct?

NO

The outdoor control PCB

is faulty. Replace

Return

1 time flash

Keeps flashing

Notes (1) Also check if there is voltage at the L3 phase on the 52C primary

side, but no voltage on the secondary side (coil wire disconnec-

tion or faulty contacts).

(2) If there is voltage at the L3 phase on the 52C primary side and it

is not abnormal, the outdoor unit control PCB is faulty.

AAA

AAAAAAAAAAAAAAAAAAAAAAAA

If the unit is operated with the service valve closed, 49C (internal thermostat) operates. E34 may also be displayed. Check the service valve.

AAAAAAAAAAAAAAAAAAAAAAAA

1 time flash

Keeps flashing

Check the unit side.

• Is there a short circuit in the outdoor unit?

• Is the installation space proper?

• Is the refrigerant level too high?

• Is the heat exchanger dirty or clogged?

(1)

The compressor’s speed drops when all the following conditions are met

(151~251). In the case of the 301~601, expansion valve control is performed.

1

Outdoor heat exchanger temperature: A˚C or higher

2

Outdoor air temperature: 41ºC or higher

3

The outdoor unit’s fan runs at 7 speed (UHi)

30 seconds or longer.

(2) Control is cancelled when the temperature drops to BºC or lower.

Model

less than 88

88 to less than 108

108 or higher

151~251 type

Compressor

speed

(rps)

301~601 type

Note (1) Values in ( ) show for the case of the 301~601 models.

Item

(1)

continuously for

A

58.5

53.5

48.5

58

53.5

48.5

43.5

AAA

B

53

(1)

48 65

Outdoor air temp. (ºC)

Note (1) In the case of the 151 ~

251, the abnormal stop

temperature differs

depending on the

compressor’s speed.

Compressor speed

(rps)

less than 88

88 to less than 108

108 or higher

Indoor heat exchanger

temprature (˚C)

65 or more

60 or more

55 or more

-

27

● Display Conditions

If the outdoor heat

exchanger temperature

becomes 65ºC 5 times

within 60 minutes,

including while the

compressor is stopped,

or if it continues at that

temperature for 10

minutes or longer.

-

Outdoor unit heat exchanger

themistor (Tho-R)

Resistancetemperature characteristics

15

10

(kΩ)

Resistance

5

010 304020 50

5kΩ at 25°C

Temperature (°C)

Error display :

6

[Discharge temperature error]

e36

Indoor unit

Red LED

Green LED

Note (1) The green LED in the outdoor unit is used in the FDCA301 ~ 601 models only.

Is the

discharge pipe ther-

mistror characteristics

normal?

Stays OFF

Keeps flashing

Discharge

temperature error?

YES

(At cooling/heating

operation)

Red LED

Green LED

Outdoor unit

1 time flash

Keeps flashing

Check the unit side.

Insufficient refrigerant

Charge the refrigerant (measure)

Is it the oveload operation?

NO

Discharge pipe thermistor replacement

Is the unit

normalized

NO

Is discharge temperature

control normal?

Abnormal temperature sensed

Is the (actual measurement) normal?

NO

Defective outdoor unit PCB

Replacement

● Display conditions

If the discharge temperature is as shown at left 2 (5) times within 60