Page 1

RFID

Intreface

Module

EQ

-

V680D1

EQ

-

V680D2

User,s

Manual

Page 2

A - 1 A - 1

SAFETY PRECAUTIONS

(Always read these precautions prior to use.)

Before using this product, please read this manual and the relevant manuals introduced in this manual

carefully and pay full attention to safety to ensure that the product is used correctly.

The precautions presented in this manual are concerned with this product only. For programmable

controller system safety precautions, refer to the user’s manual of the CPU module used.

In this manual, the safety precautions are ranked as “WARNING” and “CAUTION.”

WARNING

Indicates that incorrect handling may cause hazardous

conditions, resulting in death or severe injury.

CAUTION

Indicates that incorrect handling may cause hazardous

conditions, resulting in medium or minor injury and/or property

damage.

Note that failure to observe the

CAUTION level instructions may lead to a serious consequence

according to the circumstances. Always follow the precautions of both levels because they are important

to personal safety.

Please keep this manual in an easy-to-access location for future reference, and be sure to deliver the

manual to the end user.

[DESIGN PRECAUTIONS]

CAUTION

Provide a safety circuit outside the programmable controller to ensure that the overall system

operates safely in the event of an error in the external power supply or failure of the

programmable controller itself. Failure to do so results in the risk of erroneous output and

malfunction, resulting in module failure.

Configure the circuitry so that the external power supply is activated after the power supply of the

programmable controller itself. Activating the external power supply first results in the risk of

erroneous output and malfunction, resulting in module failure.

When installing the RFID interface module and amplifier/antenna cables, do not bundle the

cables with or install the cables close to the main circuit, power lines, or the like. Be sure to

separate the cables and lines by about 100mm or more. Failure to do so will cause noise,

resulting in malfunction.

Page 3

A - 2 A - 2

[DESIGN PRECAUTIONS]

CAUTION

When storing the product, be sure to observe the defined storage ambient temperature and

humidity. Failure to do so will lead to module malfunction and failure.

Look the control panel so that only those who are trained and have acquired enough knowledge

of electric facilities can open control panel.

Install the emergency stop switch outside the control panel so that workers can operate it easily.

[INSTALLATION PRECAUTIONS]

CAUTION

Use the programmable controller in an environment that reflects the general specifications stated

in the user’s manual of the CPU module used. Using the programmable controller in an

environment out of the general specification range results in the risk of electric shock, fire,

malfunction, and product damage or deterioration.

During installation, fully insert the tabs used to secure the module into the holes of the base unit

while pressing down the module mounting lever located at the bottom of the module, using the unit

holes as support points. An incorrectly mounted module results in the risk of malfunction, failure,

and dropping. When used in an environment of high oscillation, secure the module with screws.

Tighten the screws within the specified torque range. If a screw is too loose, a dropped module,

short circuit, or malfunction may result. If a screw is too tight, screw and/or module damage may

occur, resulting in a dropped module, short circuit, or malfunction.

Be sure to shut off all phases of the external power supply used by the system before module

installation or removal.

Failure to do so results in the risk of product damage.

Do not directly touch a powered section or electronic component of the module. Doing so results

in the risk of module malfunction and failure.

[WIRING PRECAUTIONS]

CAUTION

After the installation and wiring work, be sure to install the provided terminal cover on the product when

you want to activate and operate the module. Failure to do so results in the risk of electric shock.

Fully mount the antenna cable to the module connector. After mounting, check for separation.

Insufficient contact results in the risk of erroneous input and output.

Be sure to place the communication cables and power cables connected to the module in a duct,

or secure them with clamps. Failure to do so results in the risk of cable movement and drift,

module or cable damage caused by careless pulling, and malfunction caused by insufficient

cable contact.

Page 4

A - 3 A - 3

[WIRING PRECAUTIONS]

CAUTION

When connecting a cable, first verify the connection interface type and then connect the cable

properly. Connecting a cable to a wrong interface or miswiring a cable results in the risk of

module and external device malfunction.

Tighten the screws within the specified torque range. If a screw is too loose, a short circuit or

malfunction may result. If a screw is too tight, screw and/or module damage may occur, resulting

in a short circuit or malfunction.

When removing a communication cable or power cable connected to the module, do not pull the

cable section. For cables with connectors, hold the connector of the section connected to the

module during removal. For terminal block cables, loosen the screws of the terminal block and

then remove the cable. Pulling a cable while it is connected to the module results in the risk of

malfunction and module and cable damage.

Be careful to prevent foreign matter such as dust or wiring chips from entering the module

interior. Failure to do so results in the risk of fire, failure, and malfunction.

A protective film is attached to the top of the module to prevent foreign matter, such as wire

chips, from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

Do not connect the power supply in reverse. Doing so results in risk of failure.

Use the module after confirming that the external input DC power supply is within the rated

power supply voltage.

Failure to do so results in the risk of failure and malfunction.

Do not bundle the control or communication cables with or install the cables close to the main

circuit, power lines, or the like. Be sure to separate the cables and lines by about 100mm or more.

[STARTUP AND MAINTENANCE PRECAUTIONS]

CAUTION

Do not disassemble or modify the module. Doing so results in the risk of failure, malfunction,

injury, and fire.

Be sure to shut off all phases of the external power supply used by the system before module

installation or removal. Failure to do so results in the risk of module failure and malfunction.

After product use begins, be sure the number of times the module, base, and terminal block are

installed and removed does not exceed 50 (JIS B 3502 compliant). Exceeding 50 results in the

risk of malfunction.

Do not touch the terminals while the module is powered. Doing so results in the risk of

malfunction.

Page 5

A - 4 A - 4

[STARTUP AND MAINTENANCE PRECAUTIONS]

CAUTION

Be sure to shut off all phases of the external power supply used in the system before cleaning or

tightening terminal screws or module screws. Failure to do so results in the risk of module failure

and malfunction. If a screw is too loose, a dropped module, short circuit, or malfunction may

result. If a screw is too tight, screw and/or module damage may occur, resulting in a dropped

module, short circuit, or malfunction.

The module case is made of plastic. Do not drop the case or expose the case to strong impact.

Doing so results in the risk of module damage.

Before touching the module, be sure to touch grounded metal or the like to release the static

electricity from your body. Failure to do so results in the risk of module failure or malfunction.

When cleaning, do not use thinner, benzene, acetone, or kerosene. Doing so results in the risk of

module damage.

Do not insert water or wire through the gaps in the case. Doing so results in the risk of fire or

electric shock.

This product cannot be used as a detector for physical protection. Erroneous output or

malfunction may result in an accident.

When installing or removing the antenna from the amplifier, first turn OFF the module power

supply. Failure to do so results in the risk of module failure and malfunction.

Installation of multiple antennas may result in a decrease in communication performance due to

mutual interference. Refer to the description of mutual interference between antennas in the

antenna user’s manual.

In the unlikely event that you feel something is wrong with the product, stop using the product

immediately, turn OFF the power supply, and consult with your local Mitsubishi service center or

representative. Continued use as is results in the risk of module failure and malfunction.

Do not use the product in locations where chemical products and oil are scattered. Doing so

results in the risk of module failure and malfunction.

When using the product, be sure to observe the defined ambient temperature and humidity.

Failure to do so results in the risk of module failure and malfunction.

Do not touch any connectors when the module is powered. Doing so results in the risk of module

malfunction caused by the static electricity in your body.

[DISPOSAL PRECAUTIONS]

CAUTION

At the time of disposal, treat the product as industrial waste.

Page 6

A - 5 A - 5

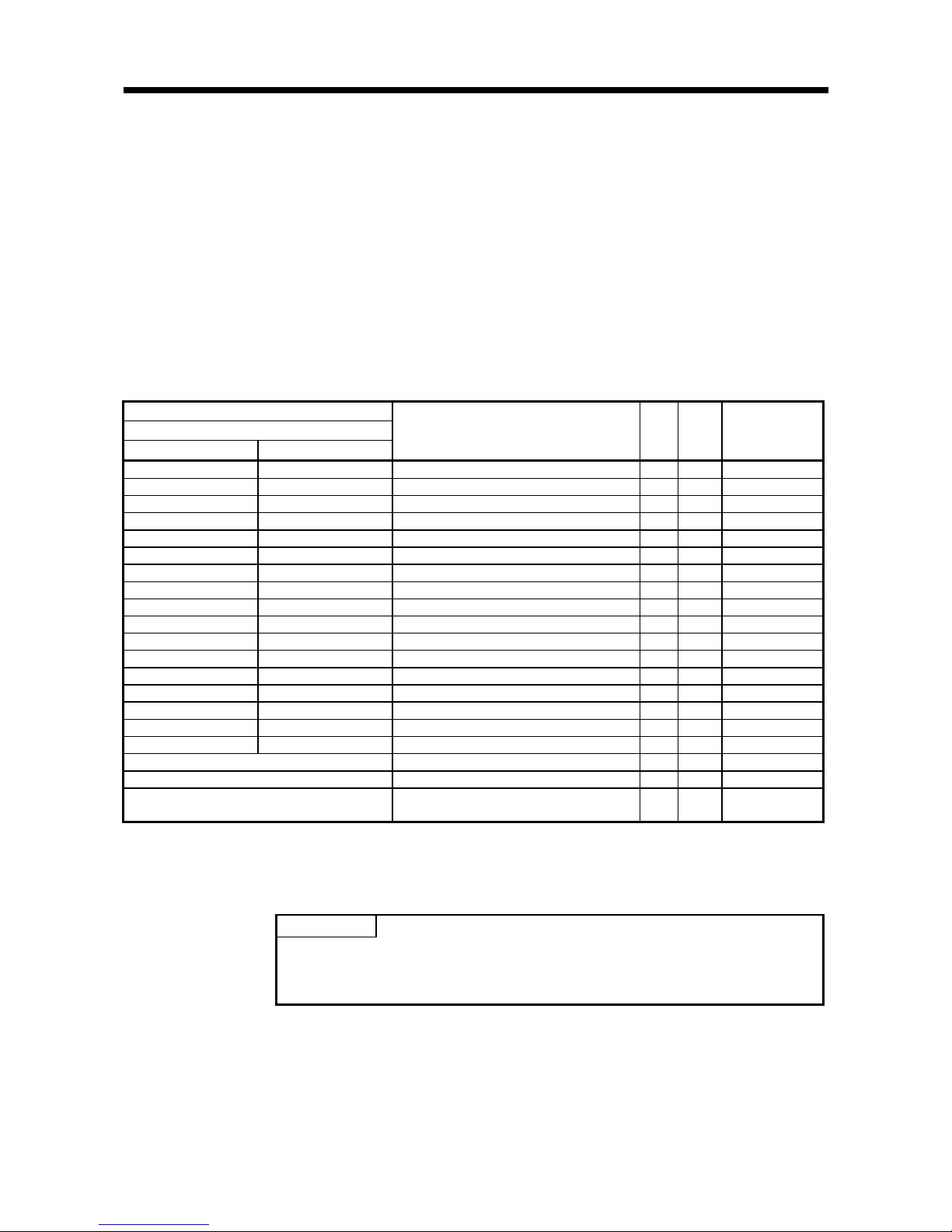

REVISIONS

*The manual number is given on the bottom left of the back cover.

Print Date *Manual Number Revision

Oct. 2011 50CM-D180057-B First edition

Nov. 2012 50CM-D180057-C Partial correction

Section 6.5 changed to Section 6.6

Addition

Section 6.5

Apr. 2014 50CM-D180057-D Partial correction

EMC Directive and Low Voltage Directive Compliance, Section 2.1,

Section 2.3, Section 4.6

Oct. 2014 50CM-D180057-E Partial correction

Section 2.1, Section 2.5, Section 4.7, Section 5.2, APPENDIX 1,

APPENDIX 2

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any

patent licenses. Mitsubishi Electric Engineering cannot be held responsible for any problems involving

industrial property rights which may occur as a result of using the contents noted in this manual.

2011 MITSUBISHI ELECTRIC ENGINEERING COMPANY LIMITED

Page 7

A - 6 A - 6

INTRODUCTION

Thank you for purchasing the RFID interface module manufactured by Mitsubishi Electric Engineering

Company, Ltd.

Prior to use, please read this manual carefully to develop full familiarity with the functions and performance of

the MELSEC-Q series programmable controller to ensure correct use.

CONTENTS

SAFETY PRECAUTIONS ······································································································ A- 1

REVISIONS ························································································································ A- 5

INTRODUCTION ·················································································································· A- 6

CONTENTS ························································································································ A- 6

EMC Directive and Low Voltage Directive Compliance ································································· A- 9

Manuals ····························································································································· A-10

Generic Terms and Abbreviations ···························································································· A-10

Product Portfolio ··················································································································· A-10

Chapter 1 OVERVIEW 1- 1 to 1- 2

1.1 RFID Interface Module Overview ························································································· 1- 1

1.2 RFID Interface Module Features ·························································································· 1- 2

Chapter 2 SYSTEM CONFIGURATION 2- 1 to 2- 8

2.1 Application System ··········································································································· 2- 1

2.2 Verifying the Function Version ····························································································· 2- 4

2.3 Identification of the UL/cUL authorization acquisition item ························································· 2- 5

2.4 Overall Configuration ········································································································· 2- 6

2.4.1 System that uses a separate amplifier type antenna ··························································· 2- 6

2.4.2 System that uses a built-in amplifier type antenna ····························································· 2- 7

2.5 Component List ················································································································ 2- 8

Chapter 3 SPECIFICATIONS 3- 1 to 3-13

3.1 Performance Specifications ································································································ 3- 1

3.2 Functions ························································································································ 3- 2

3.2.1 RUN mode ················································································································ 3- 2

3.2.2 TEST mode ··············································································································· 3- 3

3.3 Programmable Controller CPU IO Signals ············································································· 3- 4

3.3.1 IO signal list ··············································································································· 3- 4

3.3.2 IO signal details ·········································································································· 3- 5

3.4 Buffer Memory ················································································································· 3- 8

3.4.1 Buffer memory list ······································································································· 3- 8

3.4.2 Buffer memory details ·································································································· 3- 8

Page 8

A - 7 A - 7

Chapter 4 SETUP AND PROCEDURES PRIOR TO OPERATION 4- 1 to 4- 9

4.1 Usage Precautions ··········································································································· 4- 1

4.2 Installation Environment ····································································································· 4- 2

4.3 Cable Installation ·············································································································· 4- 2

4.4 Setup and Procedures Prior to Operation ·············································································· 4- 3

4.5 Names of Parts ················································································································ 4- 4

4.6 Wiring ···························································································································· 4- 5

4.6.1 Wiring precautions ······································································································ 4- 5

4.6.2 Wiring the external power supply terminal ········································································ 4- 5

4.6.3 Inserting and removing the antenna cable ········································································ 4- 7

4.7 Intelligent Function Module Switch Settings ··········································································· 4- 8

Chapter 5 THINGS YOU NEED TO KNOW BEFORE PROGRAMMING 5- 1 to 5-24

5.1 Operation Mode ··············································································································· 5- 1

5.1.1 Switching the operation mode ························································································ 5- 1

5.1.2 RUN mode ················································································································ 5- 1

5.1.3 TEST mode ··············································································································· 5- 1

5.2 ID Tag Memory ················································································································ 5- 8

5.3 Write Protect Function ······································································································ 5-10

5.3.1 How to set write protect ······························································································· 5-10

5.3.2 How to cancel write protect ·························································································· 5-15

5.4 ID Tag Number of Writes Management Function (EEPROM Type Only) ····································· 5-16

5.4.1 Manage Number of Writes 1 (Write life = Preset number of writes) ······································· 5-16

5.4.2 Manage Number of Writes 2 (Write life = Arbitrary number of writes) ···································· 5-19

5.5 ID Tag Data Check Function ······························································································ 5-21

5.6 ID Tag Memory Error Correction Function ············································································ 5-24

Chapter 6 HOW TO COMMUNICATE WITH ID TAGS 6- 1~6-84

6.1 Programming Precautions ·································································································· 6- 1

6.2 Instruction/Specification List ································································································ 6- 2

6.2.1 Read ························································································································ 6- 2

6.2.2 Write ························································································································ 6- 2

6.2.3 Set bit ······················································································································· 6- 3

6.2.4 Clear bit ···················································································································· 6- 4

6.2.5 Write mask bit ············································································································ 6- 5

6.2.6 Write calculation ········································································································· 6- 7

6.2.7 Fill data ····················································································································· 6- 8

6.2.8 Check data ················································································································ 6- 9

6.2.9 Control number of writes ····························································································· 6-10

6.2.10 Copy ······················································································································ 6-11

6.2.11 Read with error correction ·························································································· 6-12

6.2.12 Write with error correction ·························································································· 6-13

6.2.13 Read UID ··············································································································· 6-13

6.2.14 Measure noise ········································································································· 6-13

6.3 Control Methods According to Communication Specification ···················································· 6-14

6.3.1 Trigger ····················································································································· 6-14

Page 9

A - 8 A - 8

6.3.2 Auto ························································································································ 6-15

6.3.3 Repeat auto ·············································································································· 6-16

6.3.4 FIFO trigger ·············································································································· 6-17

6.3.5 FIFO repeat ·············································································································· 6-18

6.3.6 Multi-trigger ·············································································································· 6-19

6.3.7 Multi-repeat ·············································································································· 6-20

6.4 Sample Programs ············································································································ 6-21

6.4.1 Set parameters ·········································································································· 6-23

6.4.2 Read ······················································································································· 6-25

6.4.3 Write ······················································································································· 6-28

6.4.4 Set bit ······················································································································ 6-31

6.4.5 Clear bit ··················································································································· 6-34

6.4.6 Write mask bit ··········································································································· 6-37

6.4.7 Write calculation ········································································································ 6-40

6.4.8 Fill data ···················································································································· 6-44

6.4.9 Check data ··············································································································· 6-47

6.4.10 Control number of writes ···························································································· 6-50

6.4.11 Copy ······················································································································ 6-53

6.4.12 Read with error correction ·························································································· 6-56

6.4.13 Write with error correction ·························································································· 6-59

6.4.14 Read UID ··············································································································· 6-62

6.4.15 Measure noise ········································································································· 6-65

6.4.16 Read module status ·································································································· 6-68

6.5 Specialized Sample Program for Read/Write of ID Tags with the Trigger Communication ·············· 6-70

6.5.1 Sample program ········································································································ 6-70

6.6 For Use in Remote I/O Network ·························································································· 6-76

6.6.1 Sample program for use in remote I/O Network ································································ 6-76

6.6.2. Attention and limitation using the RFID module at MELSECNET/H remote I/O station ············· 6-84

Chapter 7. TROUBLESHOOTING 7- 1~7- 5

7.1 Error Details List ··············································································································· 7- 1

7.2 Troubleshooting ··············································································································· 7- 2

7.2.1 Troubleshooting flow ··································································································· 7- 2

7.2.2 Flow when “RUN” LED turns OFF ·················································································· 7- 3

7.2.3 Flow when the “EXT.PW” LED turns OFF ········································································ 7- 4

7.2.4 Flow when the “ERR.” LED turns ON ·············································································· 7- 5

APPENDICES App- 1~App- 8

APPENDIX 1 COMMUNICATION TIME (Reference) ································································ App- 1

APPENDIX 2 PROCESSING TIME (Reference) ······································································ App- 3

APPENDIX 3 EXTERNAL DIMENSIONS ··············································································· App- 7

INDEX Ind- 1~Ind- 2

Page 10

A - 9 A - 9

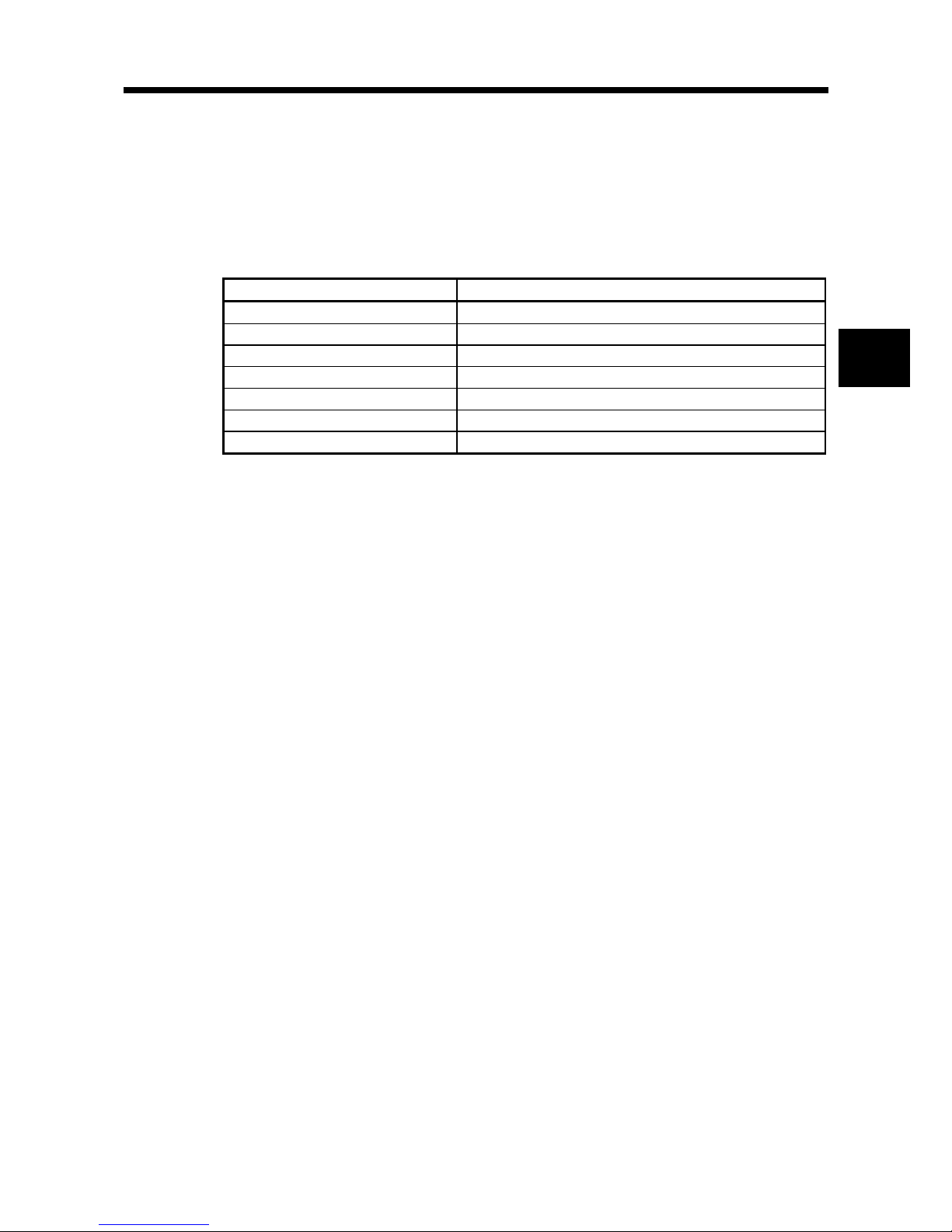

EMC Directive and Low Voltage Directive Compliance

(1) Programmable controller system

When you want to incorporate an EMC Directive and Low Voltage Directive compliant

programmable controller into your product to ensure directive compliance, refer to

Chapter 9, “EMC Directive and Low Voltage Directive”, of the QCPU User’s Manual

(Hardware Design, Maintenance, and Inspection). A programmable controller that is

compliant with the EMC Directive and Low Voltage Directive has a CE mark printed on

the rating plate of the main unit.

Authorized representative in Europe

Authorized representative in Europe si shown below

Name: Mitsubishi Electric Europe B.V.

Address: Gothaer strasse 8, 40880 Ratingen, Germany

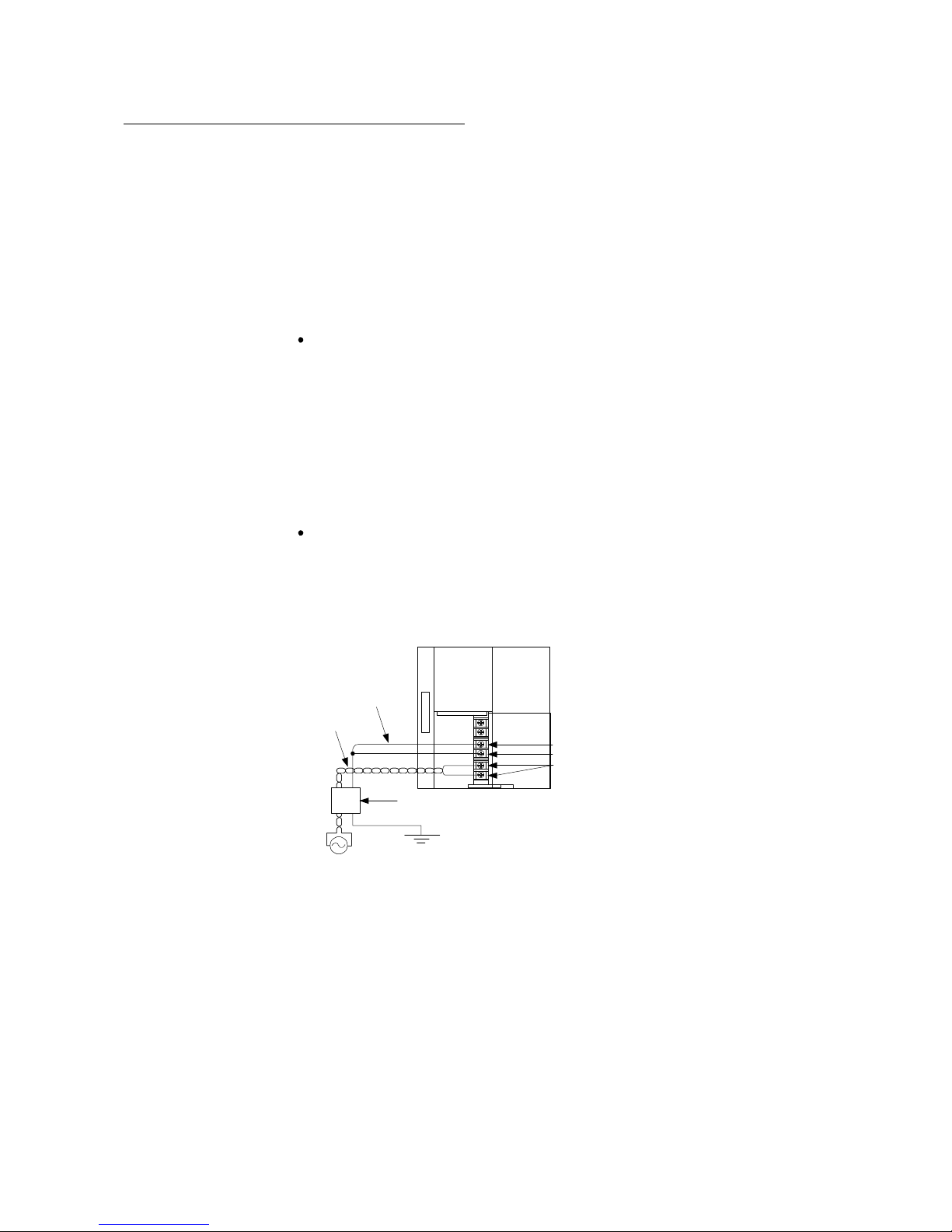

(2) This product

To make this product compliant with the EMC Directive and Low Voltage Directive,

the following countermeasure is required.

To suppress radiation noise, use a ferrite core. The method of use is as follows:

Bring together the power supply cable of the programmable controller power supply

module and the grounding wire and route them through the ferrite core. The target

position of the ferrite core is within 10cm from the power supply module.

FG

LG

INPUT

100-240VAC

Programmable controller

Power

supply

CPU

module

Ferrite core

(within 10cm from the power supply contact)

Grounding

wire

Power suppl

y

cable

Page 11

A - 10 A - 10

Manuals

The manuals related to this product include the following.

Direct any inquiries to your local sales store, Mitsubishi Electric Engineering service

office, or any Mitsubishi Electric product dealer, as necessary.

Detailed manuals

Included manual

Manual Title Manual Number

RFID Interface Module User's Manual (Hardware)

50CM-D180056

Manufactured by

Mitsubishi Electric Corporation Mitsubishi general-purpose programmable controller MELSEC-Q series manual

Manual Title

Manual Number

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

SH-080483ENG

Generic Terms and Abbreviations

This manual uses the following generic terms and abbreviations in product

explanations, unless otherwise specified.

Generic Term / Abbreviation Description

RFID interface module A generic term for an EQ-V680D1/EQ-V680D2 RFID interface module.

GX Developer

A generic product name for product models SWnD5C-GPPW-E, SWnD5C-GPPW-EA,

SWnD5C-GPPW-EV, and SWnD5C-GPPW-EVA (where n indicates version 4 or later).

-A indicates a multiple license product, and -V indicates a version upgrade product.

QCPU (Q mode)

A generic term for Q00JCPU, Q00CPU, Q01CPU, Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU,

Q25HCPU, Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU, Q12PRHCPU, Q25PRHCPU,

Q02UCPU, Q03UDCPU, Q04UDHCPU, Q06UDHCPU, Q13UDHCPU, Q26UDHCPU,

Q03UDECPU, Q04UDEHCPU, Q06UDEHCPU, Q13UDEHCPU, and Q26UDEHCPU.

Product Portfolio

The following indicates the product portfolio of this product.

Model Product Name Quantity

EQ-V680D1

EQ-V680D1 RFID interface module (for one channel) 1

User’s Manual (Hardware) (Included with module) 1

Ferrite core (Included with module) 1

EQ-V680D2

EQ-V680D2 RFID interface module (for two channels) 1

User’s Manual (Hardware) (Included with module) 1

Ferrite core (Included with module) 1

Page 12

1 - 1 1 - 1

1. OVERVIEW

Chapter 1 OVERVIEW

This user’s manual describes the specifications, use, ID tag communication method,

and other information related to the EQ-V680D1/EQ-V680D2 RFID interface module

(hereinafter “RFID interface module”).

The RFID interface module is mounted on a base unit of the Mitsubishi

general-purpose programmable controller MELSEC-Q series, enabling reading and

writing with Omron RFID system V680 series ID tags.

When utilizing the program examples introduced in this manual in an actual system, be

sure to fully verify that use will not be problematic in the control of the target system.

1.1 RFID Interface Module Overview

The RFID interface module has one or two channels that connect to a V680 series

antenna, and fulfills the role as an interface for V680 series ID tag reading and writing

and the programmable controller CPU.

Programmable

controller CPU

Amplifier

Antenna

ID tag

RFID interface

module

Data reading and

writing with ID tag

by electromagnetic

induction (non-contact)

1

Page 13

1 - 2 1 - 2

1. OVERVIEW

1.2 RFID Interface Module Features

The following describes the features of the RFID interface module.

(1) The RFID interface module uses a rich group of Mitsubishi Electric MELSEC-Q series

products, and is capable of controlling Omron RFID system V680 series products.

(2) The two-channel RFID interface module enables independent antenna operation per

channel.

(Setup)

(Finishing and inspection)

CH1

CH2

(3) The two-channel RFID interface module allows you to the module allows you to copy

data between ID tags using the Copy Data command.

Data

Copy

(4) The one-channel RFID interface module enables use of an amplifier built-in type

antenna.

(5) The module is provided with various test functions as standard.

The communication test function allows you to check whether or not

communication with an ID tag is possible without operating the sequence program.

The distance level measurement function measures the distance between the

antenna and ID tag with respect to the communication area, dividing the margin

into six stages.

The communication success rate measurement function executes

communication with a static ID tag 100 times, and measures the repeated

communication success rate.

The speed level measurement function measures the number of times

communication can be performed continuously according to the speed of an ID

tag that moves within the antenna communication area.

The noise level measurement function measures the noise level in the area

surrounding the antenna installation location.

(6) The module allows you to simply develop programs by downloading an FB (function

block) library that can be used with Mitsubishi Electric MELSOFT GX Works 2 from

the Mitsubishi Electric Corporation FA device information site MELFANSweb.

1

Page 14

2 - 1 2 - 1

2. SYSTEM CONFIGURATION

Chapter 2 SYSTEM CONFIGURATION

The following describes the system configuration of the RFID interface module.

2.1 Application System

The following describes the application system.

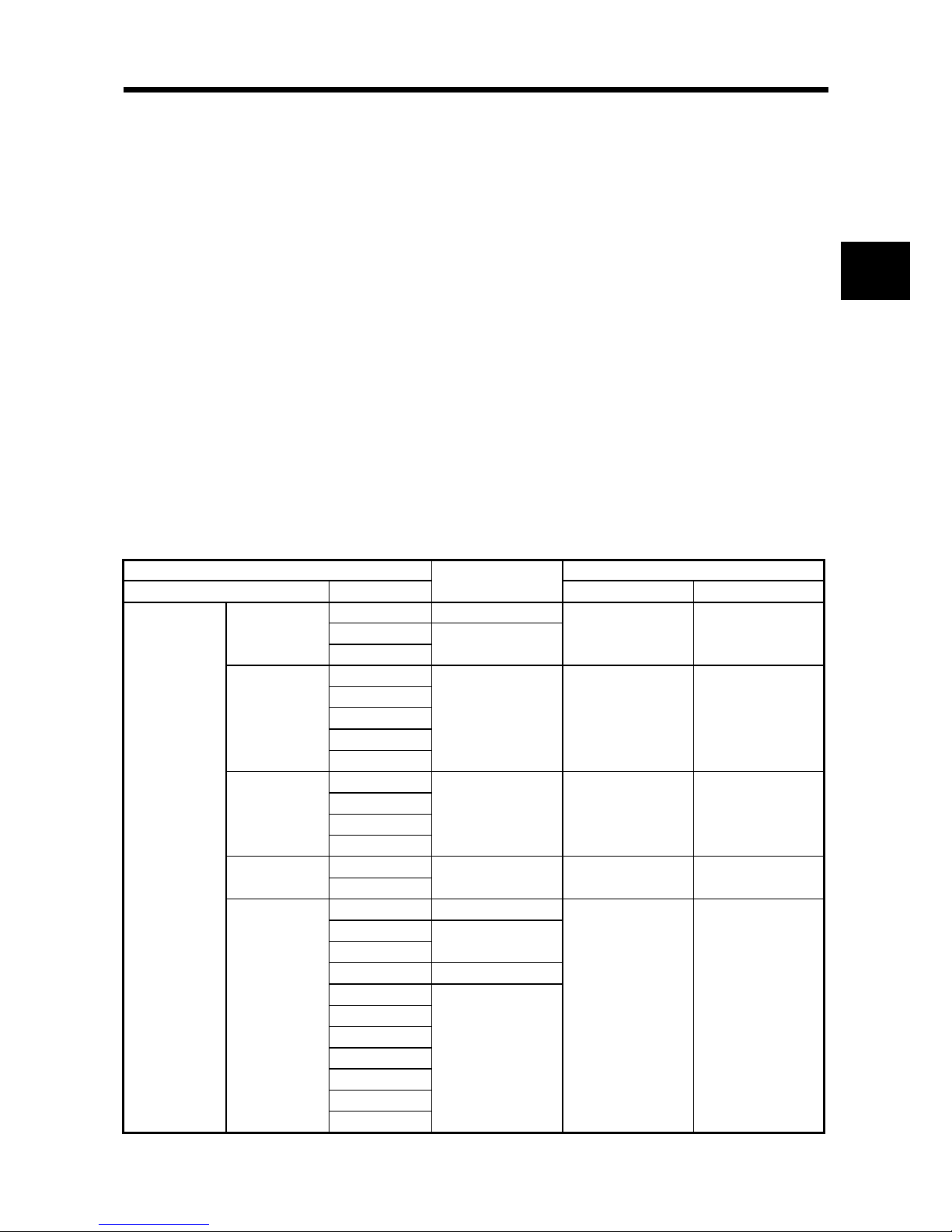

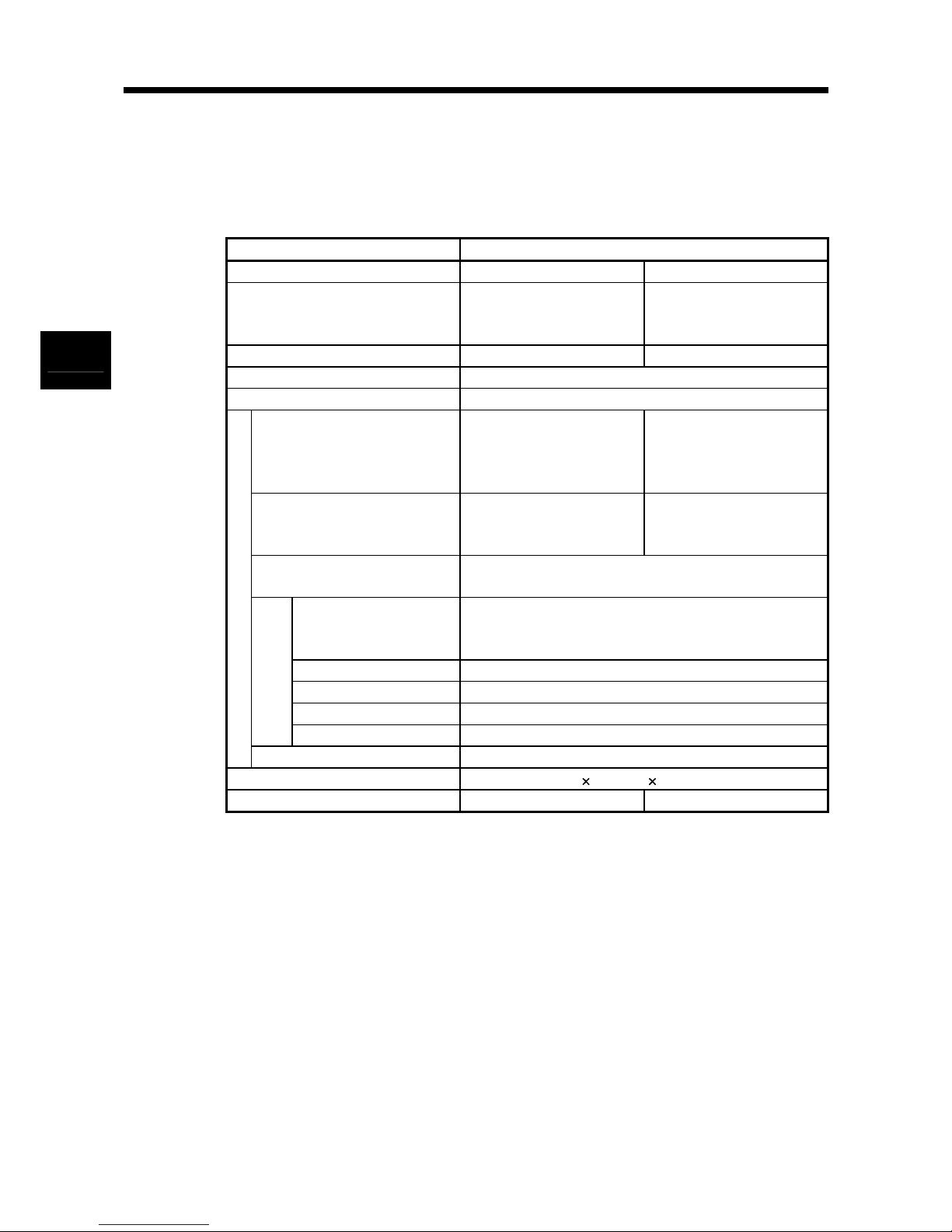

(1) Mountable modules, mountable quantities, and mountable base units

(a) When mounted with a CPU module

The table below indicates the mountable CPU modules, mountable quantities,

and mountable base units for the RFID interface module.

Note that, depending on the combination with other mounted modules and the

number of modules mounted, the power supply capacity may be insufficient.

When mounting the modules, be sure to take the power supply capacity into

consideration.

In the event the power supply capacity is insufficient, investigate the combination

of the mounted modules.

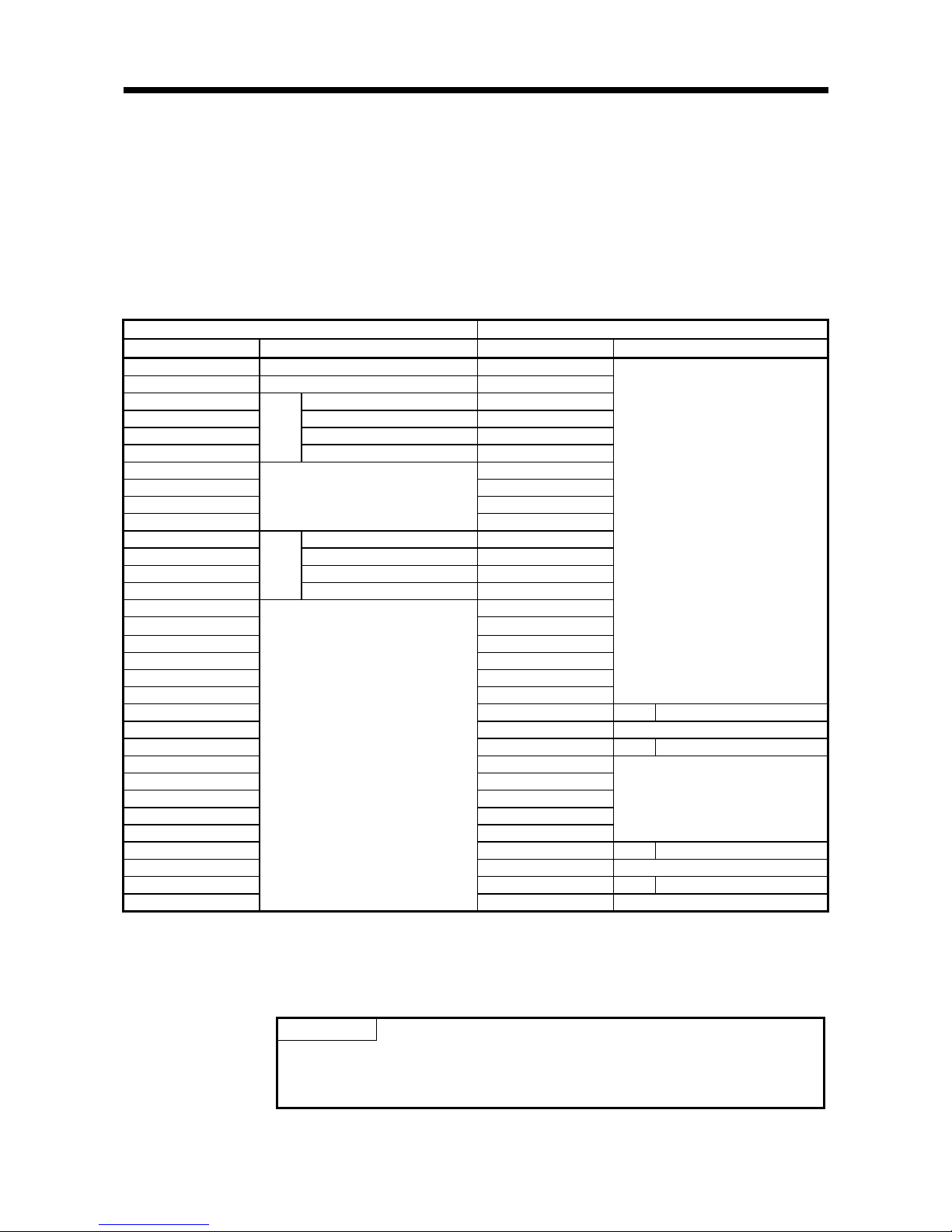

Table 2.1 Application system

Mountable CPU Module

Mountable Quantity*

1

Mountable Base Unit*2

CPU Type CPU Model Main Base Unit Extension Base Unit

Programmable

controller CPU

Basic model

QCPU

Q00JCPU 8, maximum

○ ○

Q00CPU

24, maximum

Q01CPU

High

performance

model QCPU

Q02CPU

64, maximum

○ ○

Q02HCPU

Q06HCPU

Q12HCPU

Q25HCPU

Process CPU

Q02PHCPU

64, maximum

○ ○

Q06PHCPU

Q12PHCPU

Q25PHCPU

Dual CPU

Q12PRHCPU

53, maximum

× ○

Q25PRHCPU

Universal

model CPU

Q00UJCPU 8, maximum

○ ○

Q00UCPU

24, maximum

Q01UCPU

Q02UCPU 36, maximum

Q03UDCPU

64, maximum

Q04UDHCPU

Q06UDHCPU

Q10UDHCPU

Q13UDHCPU

Q20UDHCPU

Q26UDHCPU

2

Page 15

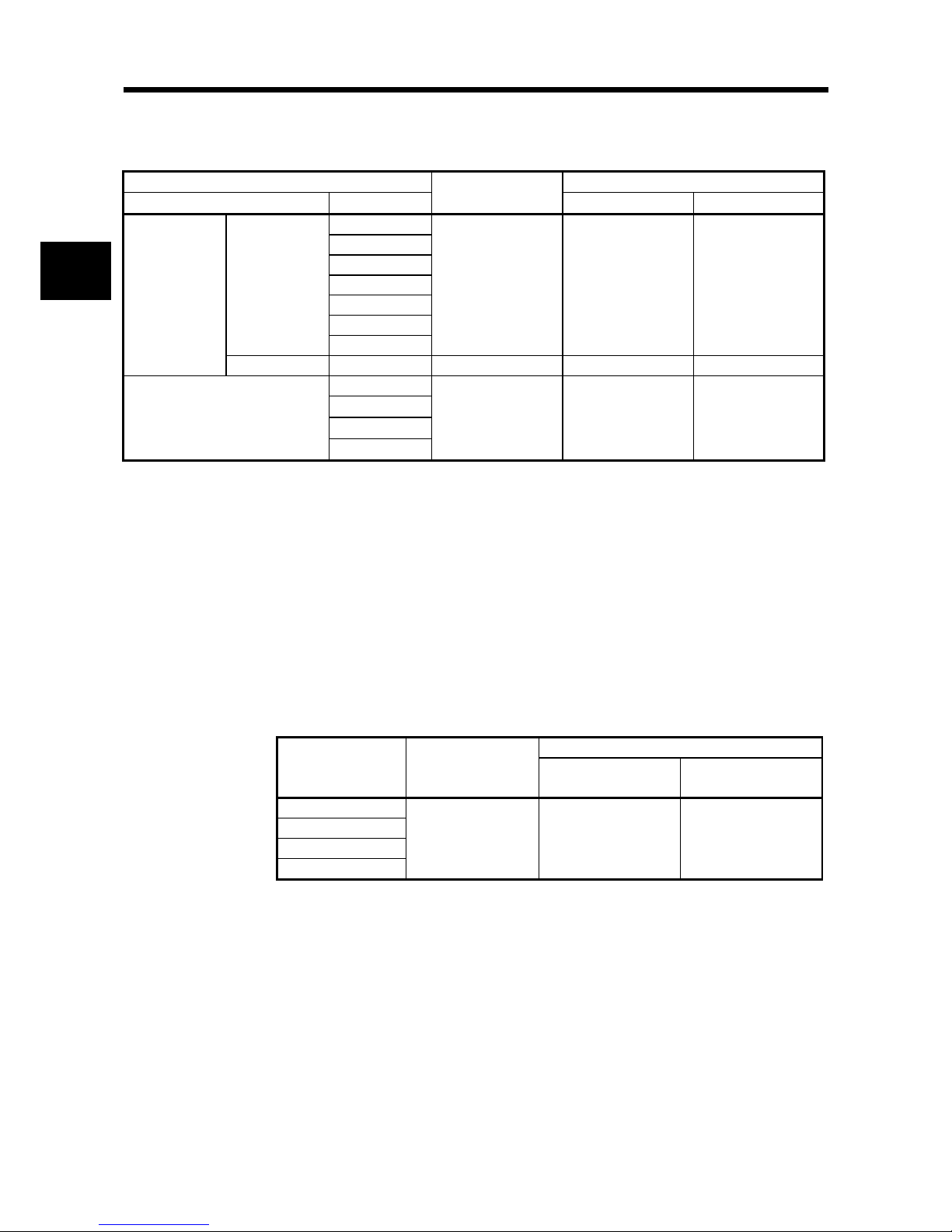

2 - 2 2 - 2

2. SYSTEM CONFIGURATION

Table 2.1 Application system (Continued)

Mountable CPU Module

Mountable Quantity*

1

Mountable Base Unit*

2

CPU Type CPU Model Main Base Unit Extension Base Unit

Programmable

controller CPU

Universal

model CPU

Q03UDECPU

64, maximum

○ ○

Q04UDEHCPU

Q06UDEHCPU

Q10UDEHCPU

Q13UDEHCPU

Q20UDEHCPU

Q26UDEHCPU

Safety CPU QS001CPU Not mountable

× ×

*

3

C-language controller module

Q06CCPU-V-H01

Not mountable

× ×

Q06CCPU-V

Q06CCPU-V-B

Q12DCCPU-V

○

:Mountable, ×:Not mountable

*1. Limited to within the range of the number of IO points of the CPU module.

*2. Mountable in any IO slot of a mountable base unit.

*3. An extension base unit cannot be connected to a safety CPU.

(b) Mounting to a MELSECNET/H remote I/O station

The table below shows the network modules and base units applicable to the

RFID interface module and quantities for each network module model.

Depending on the combination with other modules or the number of mounted

modules, power supply capacity may be insufficient.

Pay attention to the power supply capacity before mounting modules, and if the

power supply capacity is insufficient, change the combination of the modules.

Applicable network

module

No. of modules*

1

Base unit*

2

Main base unit of

remote I/O station

Extension base unit of

remote I/O station

QJ72LP25-25

Up to 64

○ ○

QJ72LP25G

QJ72LP25GE

QJ72BR15

○

:Applicable, ×:N/A

*1. Limited within the range of I/O points for network module.

*2. Can be installed to any I/O slot of a base unit.

2

Page 16

2 - 3 2 - 3

2. SYSTEM CONFIGURATION

(2) Compatibility with multiple CPU systems

When you want to use the RFID interface module in a multiple CPU system, be

sure to first refer to the manual below:

QCPU User’s Manual (Multiple CPU System)

(a) Compatible RFID interface modules

The RFID interface module has supported a multiple CPU system from the

beginning with function version B.

(b) Intelligent function module parameters

Execute programmable controller writing of intelligent function module

parameters to the control CPU of the RFID interface module only.

(3) Omron RFID system V680 series dedicated use

The RFID interface module connects with amplifiers and antennas of the Omron

RFID system V680 series, enabling reading and writing with V680 series ID tags.

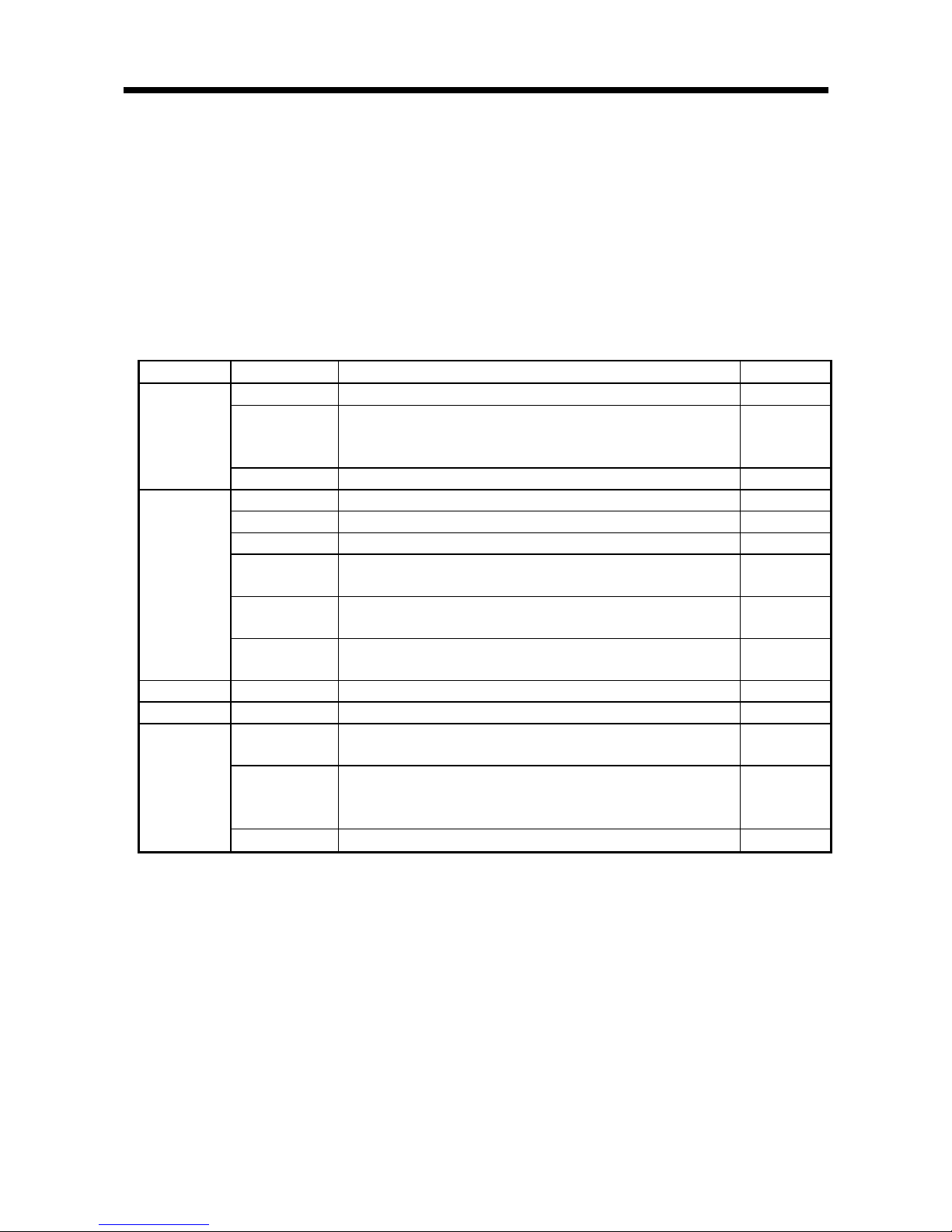

(4) Compatible software packages

The following table indicates the compatibility between systems that use the RFID

interface module and software packages.

When using an RFID interface module, GX Developer is required.

Table 2.2 Compatible software packages list

Software Version

GX Developer

Q00J/Q00/Q01CPU

Single CPU system Version 7 or later

Multiple CPU system Version 8 or later

Q02/Q02H/Q06H/Q12H/

Q25HCPU

Single CPU system Version 4 or later

Multiple CPU system Version 6 or later

Q02PH/Q06PHCPU

Single CPU system

Version 8.68W or later

Multiple CPU system

Q12PH/Q25PHCPU

Single CPU system

Version 7.10L or later

Multiple CPU system

Q12PRH/Q25PRHCPU Dual system Version 8.45X or later

Q00UJ/Q00U/Q01UCPU

Single CPU system

Version 8.76E or later

Multiple CPU system

Q02U/Q03UD/Q04UDH/

Q06UDHCPU

Single CPU system

Version 8.48A or later

Multiple CPU system

Q10UDH/Q20UDHCPU

Single CPU system

Version 8.76E or later

Multiple CPU system

Q13UDH/Q26UDHCPU

Single CPU system

Version 8.62Q or later

Multiple CPU system

Q03UDE/Q04UDEH/Q06UDEH/

Q13UDEH/Q26UDEHCPU

Single CPU system

Version 8.68W or later

Multiple CPU system

Q10UDEH/Q20UDEHCPU

Single CPU system

Version 8.76E or later

Multiple CPU system

Page 17

2 - 4 2 - 4

2. SYSTEM CONFIGURATION

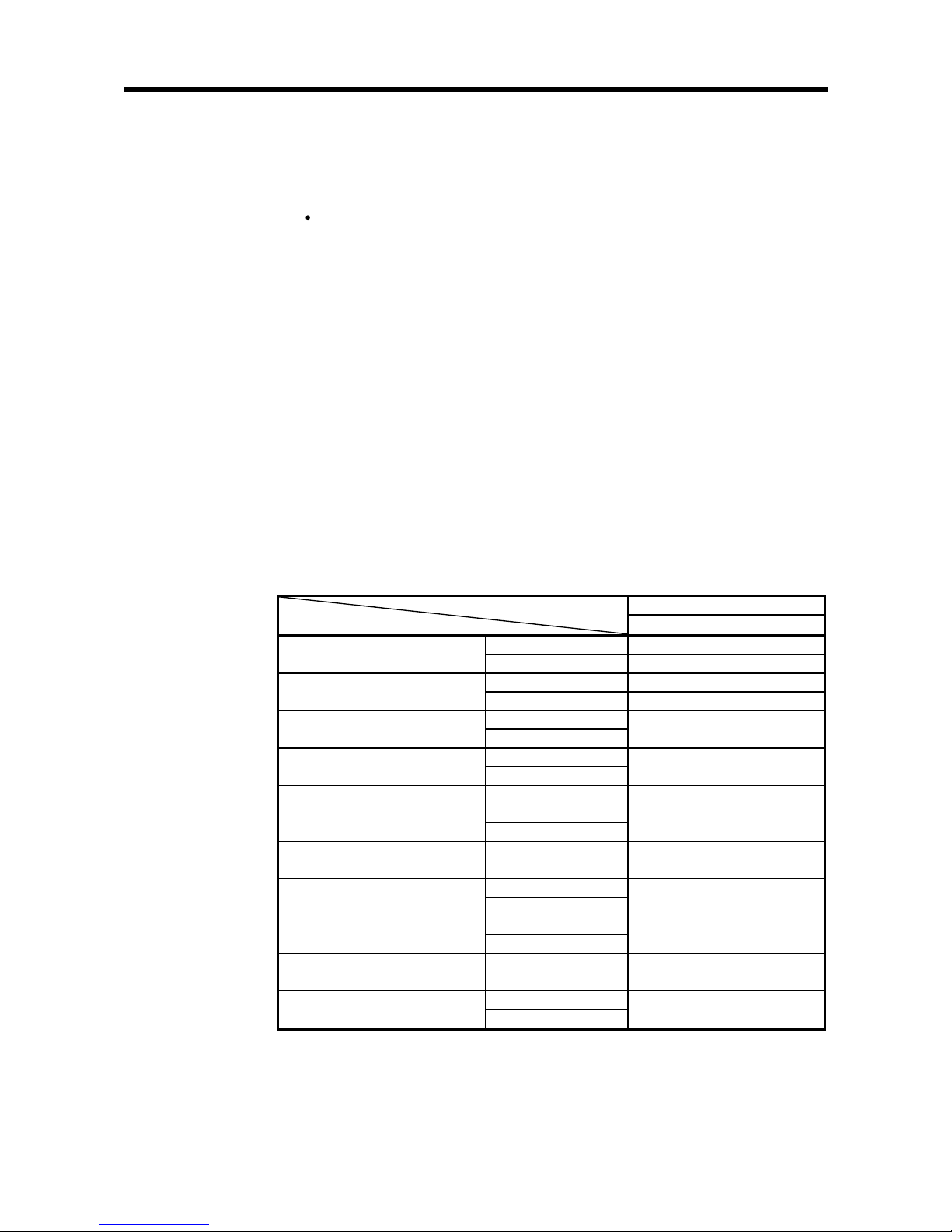

2.2 Verifying the Function Version

The following describes the method used to verify the function version of the RFID

interface module.

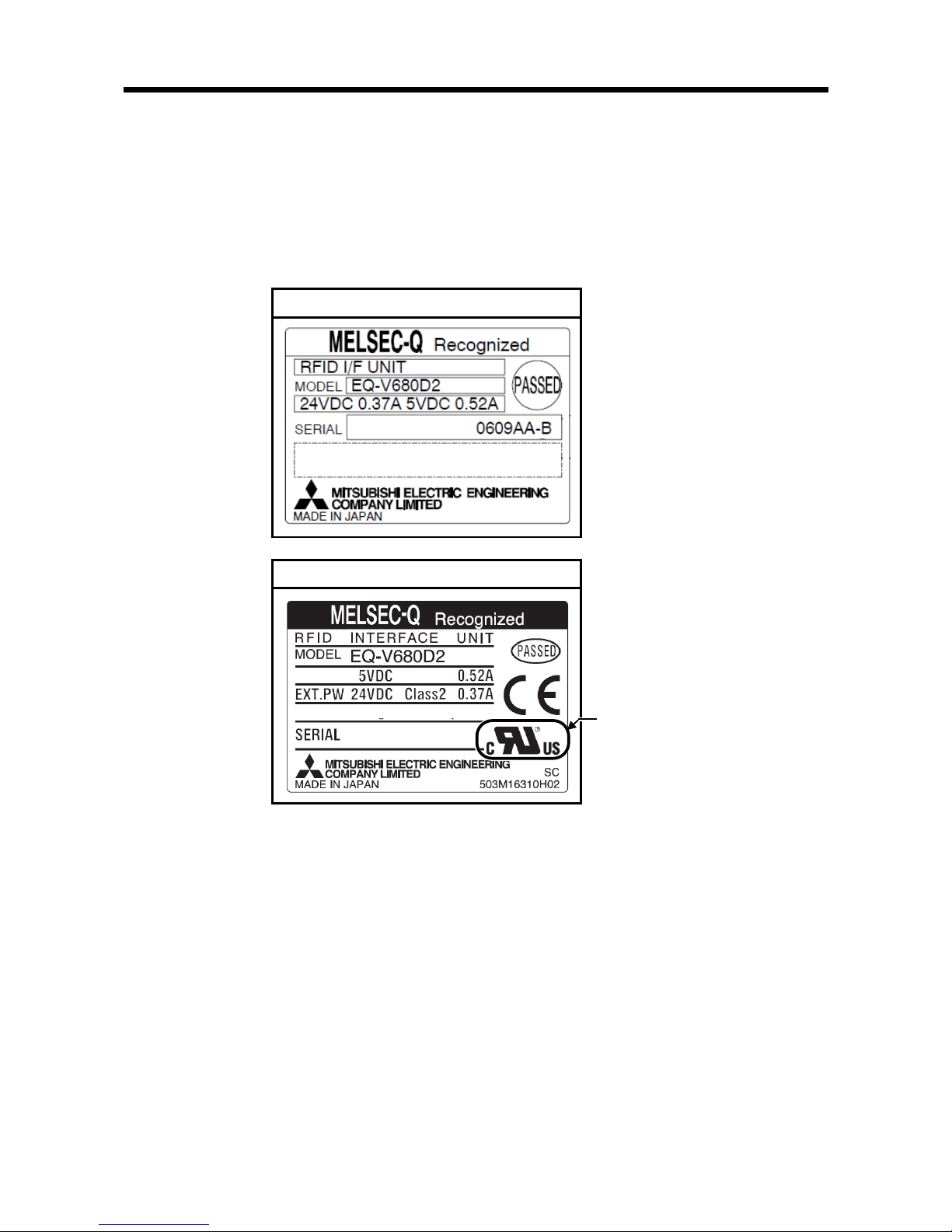

(1) Verifying the function version of the RFID interface module

(a) When verifying the version by viewing the “SERIAL” area of the rating plate on

the side of the module

・

EQ-V680D1

・

EQ-V680D2

(b) When verifying the version by viewing the system monitor (product information

list)

To view the system monitor, select “Diagnostics” -> “System Monitor” in GX

Developer, and click the Product Information List button.

Function version

1109BA-B

1109BA-B

Function version

Function version

S/W version

S/W version

Page 18

2 - 5 2 - 5

2. SYSTEM CONFIGURATION

2.3 Identification of the UL/cUL authorization acquisition item

The RFID interface module produced after September, 2011 is shipped as the UL/cUL

authorization acquisition item.

The RFID interface module can distinguish the UL/cUL authorization acquisition item

by the rating plate on the side of the module.

Before August, 2011(Not acquisition)

After September, 2011(Acquisition)

UL/cUL authorization acquisition

1109BA-B

Page 19

2 - 6 2 - 6

2. SYSTEM CONFIGURATION

2.4 Overall Configuration

The following indicates the overall configuration of the RFID system.

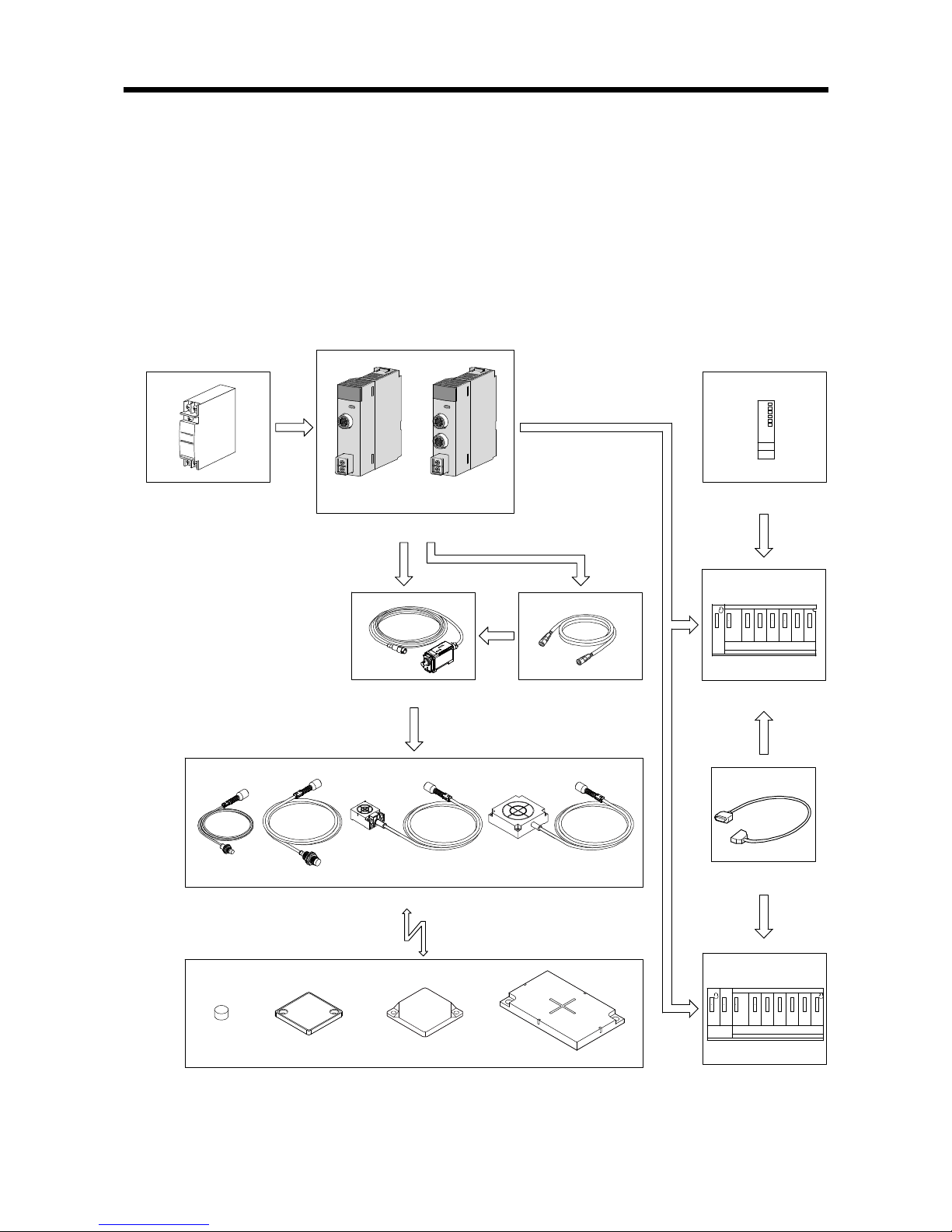

2.4.1 System that uses a separate amplifier type antenna

The following illustrates a system that uses a separate amplifier type antenna.

The antennas, amplifier and ID tags can be used in certain combinations. Refer to the

Omron RFID system V680 series catalog.

Extension cable

1CH type 2CH type

RFID interface module

Programmable

controller CPU

Main base

Extension cable

Extension base

Amplifier

Antennas

ID tags

24V external power supply

power supply

Page 20

2 - 7 2 - 7

2. SYSTEM CONFIGURATION

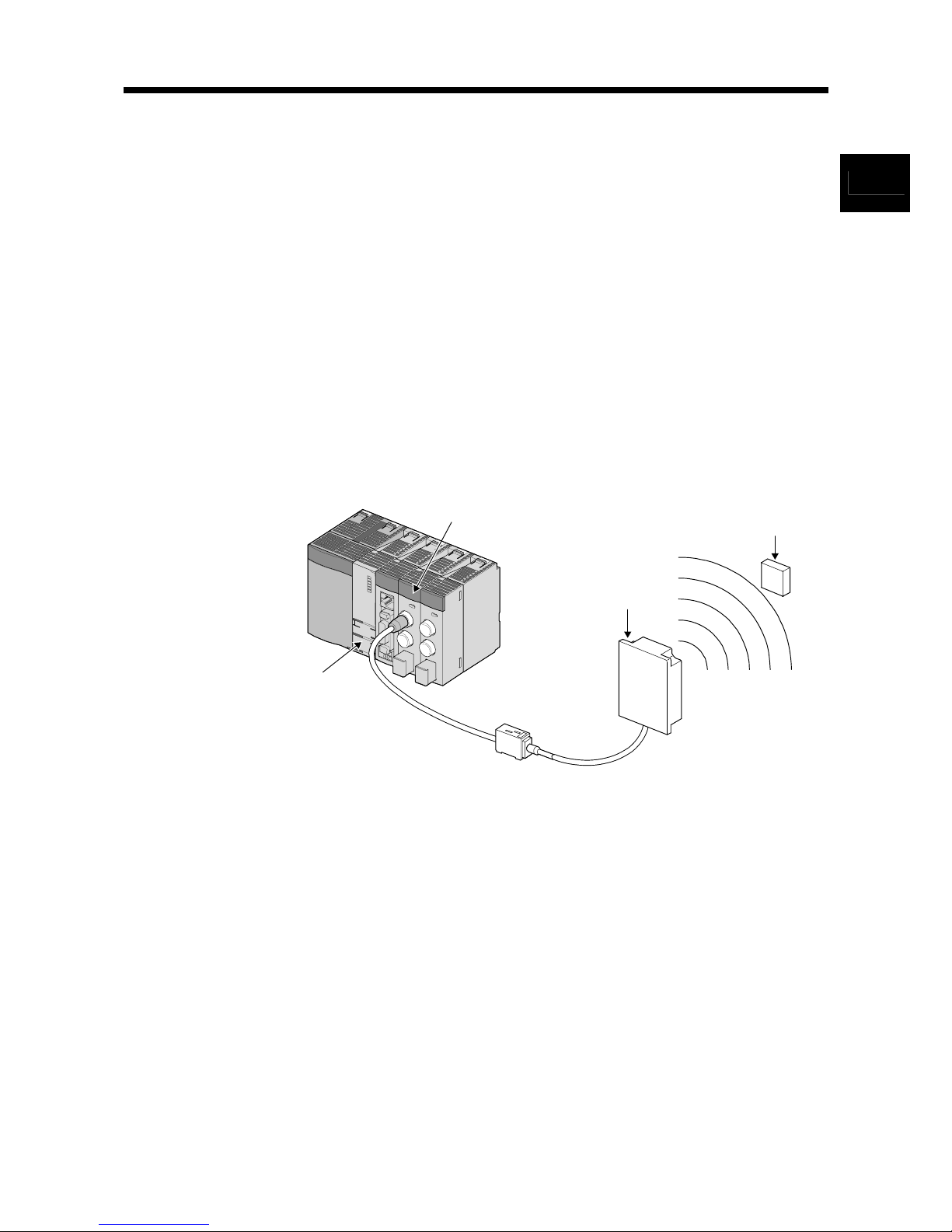

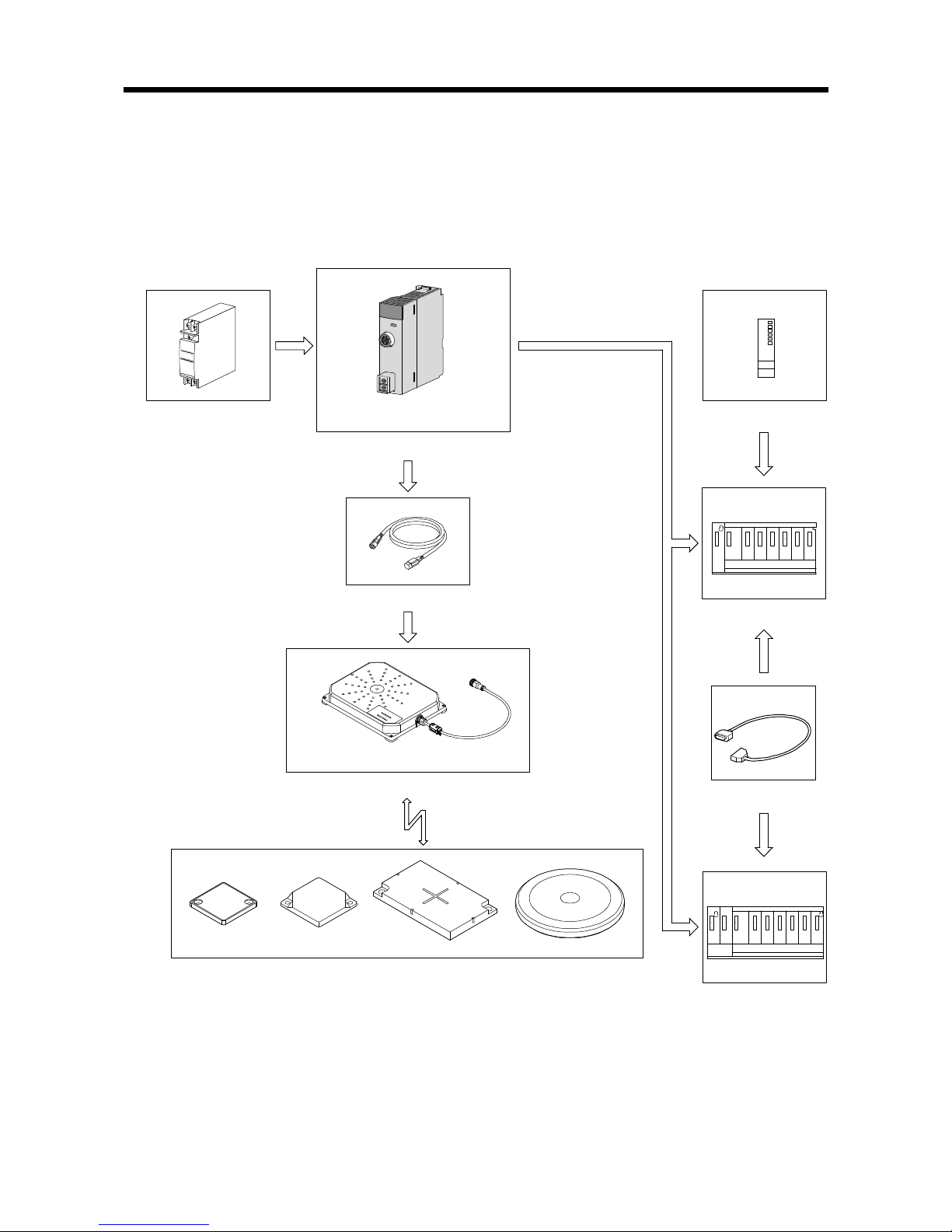

2.4.2 System that uses a built-in amplifier type antenna

The following illustrates a system that uses a built-in amplifier type antenna.

The antennas and ID tags can be used in certain combinations. Refer to the Omron

RFID system V680 series user’s catalog.

1CH type*1

RFID interface module

Programmable

controller CPU

Main base

Extension cable

Extension base

Built-in amplifier type antenna

ID tags

*1. A 2CH type cannot be used.

24V external power supply

power supply

Extension cable

Page 21

2 - 8 2 - 8

2. SYSTEM CONFIGURATION

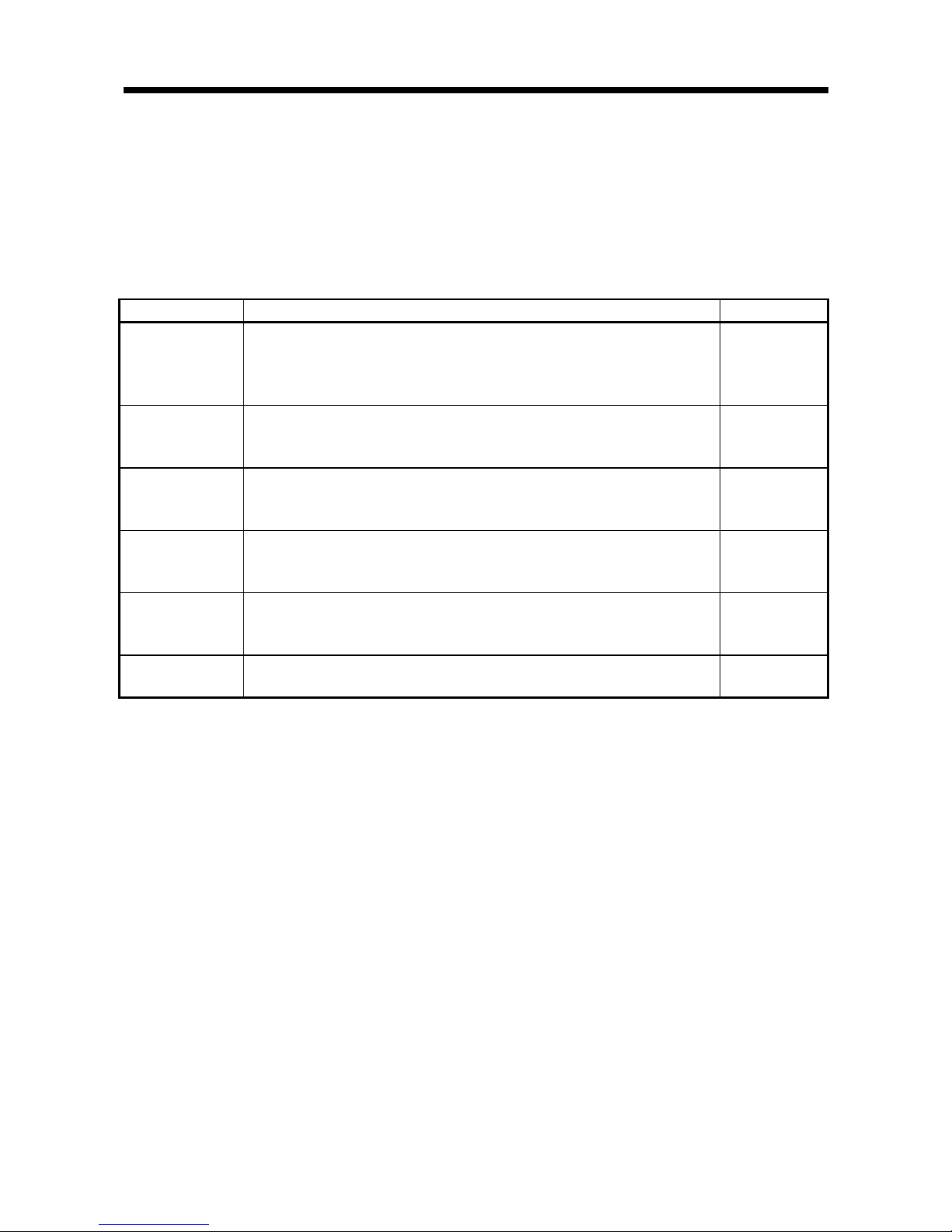

2.5 Component List

The component lists the required equipment for using the RFID interface module.

Table 2.3 Component List

Product Name Model Remarks

RFID interface

module

EQ-V680D1 V680 series RFID interface module; one antenna connected

EQ-V680D2 V680 series RFID interface module; two antennas connected

Amplifier

V680-HA63A For EEPROM-type ID tags (V680-D1KP

)

V680-HA63B For FRAM-type ID tags (V680-D2KF/V680-D8KF/V680-D32KF)

Antenna

(separate

amplifier type)

V680-HS51 For ID tag communication;

Ф

18mm type

Cable length: 2m/12.5m

V680-HS52 For ID tag communication; Ф22mm type

Cable length: 2m/12.5m

V680-HS63 For ID tag communication; 40x53mm type

Cable length: 2m/12.5m

V680-HS65 For ID tag communication; 100x100mm type Cable length: 2m/12.5m

Antenna

(built-in

amplifier type)

V680-H01-V2 For ID tag communication; 250x200mm type Cable length: 0.5m

EEPROM-type

ID tag

V680-D1KP52MT Memory capacity: 1kbytes (1,000 bytes);

Ф

8mm type; metal embedding permitted

V680-D1KP53M Memory capacity: 1kbytes (1,000 bytes); Ф10mm type; metal embedding permitted

V680-D1KP66MT Memory capacity: 1kbytes (1,000 bytes); 34x34mm type; metal installation permitted

V680-D1KP66T Memory capacity: 1kbytes (1,000 bytes); 34x34mm type

V680-D1KP66T-SP

Memory capacity: 1kbytes (1,000 bytes);

oil-proof and chemical resistant specifications

V680-D1KP58HT Memory capacity: 1kbytes (1,000 bytes); Ф80mm type; heat resistant specifications

FRAM-type ID

tag

V680-D2KF52M Memory capacity: 2kbytes (2,000 bytes);

Ф

8mm type; metal embedding permitted

V680-D2KF67M Memory capacity: 2kbytes (2,000 bytes); 40x40mm type; metal installation permitted

V680-D2KF67 Memory capacity: 2kbytes (2,000 bytes); 40x40mm type

V680S-D2KF67M Memory capacity: 2kbytes (2,000 bytes); 40x40mm type; metal installation permitted

V680S-D2KF67 Memory capacity: 2kbytes (2,000 bytes); 40x40mm type

V680S-D2KF68M Memory capacity: 2kbytes (2,000 bytes); 86x54mm type; metal installation permitted

V680S-D2KF68 Memory capacity: 2kbytes (2,000 bytes); 86x54mm type

V680-D8KF67M Memory capacity: 8kbytes (8,192 bytes); 40x40mm type; metal installation possible

V680-D8KF67 Memory capacity: 8kbytes (8,192 bytes); 40x40mm type

V680S-D8KF67M Memory capacity: 8kbytes (8,192 bytes); 40x40mm type; metal installation possible

V680S-D8KF67 Memory capacity: 8kbytes (8,192 bytes); 40x40mm type

V680-D8KF68 Memory capacity: 8kbytes (8,192 bytes); 86x54mm type

V680S-D8KF68M Memory capacity: 8kbytes (8,192 bytes); 86x54mm type; metal installation possible

V680S-D8KF68 Memory capacity: 8kbytes (8,192 bytes); 86x54mm type

V680-D32KF68 Memory capacity: 32kbytes (32,744 bytes); 86x54mm type

Extension

cable

V700-A43 For V680-HA63A/63B amplifier connection Cable length: 10m

V700-A44 For V680-HA63A/63B amplifier connection Cable length: 20m

V700-A40-W

For V680-H01-V2 built-in amplifier type antenna connection

Cable length: 2m/5m/10m/20m/30m

* For amplifier, antenna, and ID tag combinations, refer to the Omron RFID system

V680 series catalog.

* For V680S-D8KF, use an RFID interface module of S/W version B or later as

stated on the rating nameplate, or with 16093 or thereafter as the first five digits of

the serial number displayed on the system monitor (Product Information List). For

information on how to verify the S/W number, refer to Section 2.2.

Page 22

3 - 1 3 - 1

3. SPECIFICATIONS

Chapter 3 SPECIFICATIONS

The following describes the RFID interface module performance specifications,

programmable controller CPU input/output signals, and buffer memory specifications.

The following table shows the general specifications of the RFID interface module.

Item Specifications

Operating temperature

0 to 55℃(Maximum surrounding air temperature 55℃)

Operating humidity 5 to 95%RH

Pollution degree 2

Operating ambience No corrosive gases

Operating altitude 0 to 2000m

Overvoltage category

Ⅱ

Enclosure open type equipment (Must be mounted within an enclosure.)

3

Page 23

3 - 2 3 - 2

3. SPECIFICATIONS

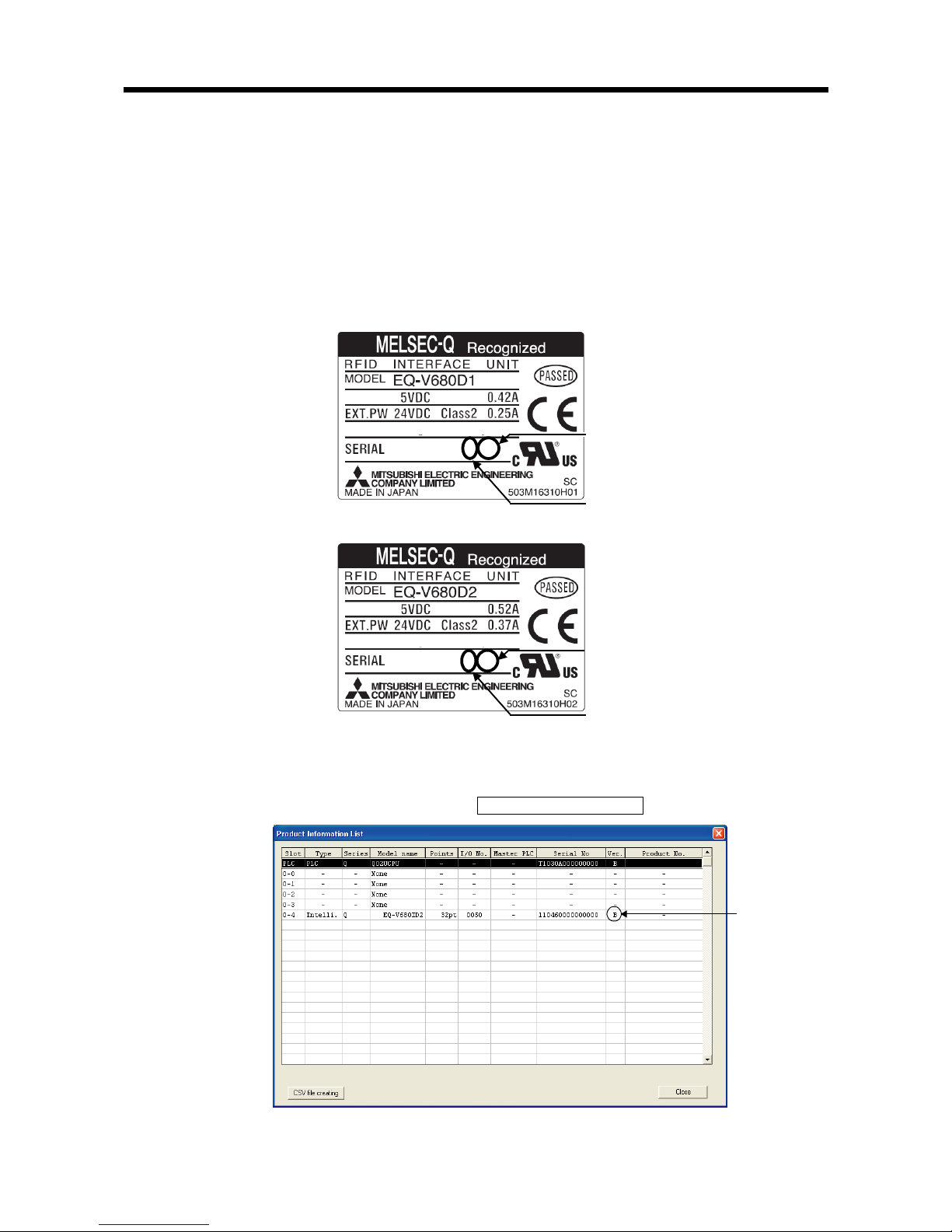

3.1 Performance Specifications

The following describes the performance specifications of the RFID interface module.

Table 3.1 Performance specifications

Item Specifications

Model EQ-V680D1 EQ-V680D2

Manufactured by Omron Corporation

Connectable antenna

V680-HA63A+V680-HS□□

V680-HA63B+V680-HS□□

V680-H01-V2

V680-HA63A+V680-HS□□

V680-HA63B+V680-HS□□

No. of connectable antennas 1 antenna 2 antennas

No. of occupied IO points 32 points (IO assignments: 32 intelligent module points)

Data transfer volume 2,048 bytes, maximum

Internal power supply

Current consumption

5VDC (supplied from inside

the programmable controller) *1

0.42A 0.52A

External power supply*2

Current consumption

24VDC (20.4 to 26.4VDC)

0.25A 0.37A

External power supply connection

terminal

2-point terminal block

Wire standard

Heat Resistant PVC Insulated Wire

JIS C 3316 HKIV,JIS C 3317 HIV,

UL 758 Style No.1007or1015

Temperature rating

Minimum 75℃

Voltage rating 300V to 600V

Conductors wire size AWG18(0.75mm2, 0.9mm2)

Wiring

recommendations

Conductors metal Stranded copper

Power supply

Compatible crimp Contact lugs 1.25-3, R1.25-3

Outer dimensions 98(H) 27.4(W) 106.5(D) [mm]

Weight 0.2kg 0.2kg

*1. “The Power Supply shall comply with the requirements in the standard for an

isolated secondary limited voltage, limited current (LVLC) circuit, defined by

UL508.” or equivalent.

*2. For external power supply details, refer to Section 4.6.2.

3

Page 24

3 - 3 3 - 3

3. SPECIFICATIONS

3.2 Functions

The RFID interface module has two operation modes: RUN mode and TEST mode.

The following describes the functions of each mode.

3.2.1 RUN mode

RUN mode is used during programmable controller operation.

To set the mode to RUN mode, set the test switch located on the front of the RFID

interface module to “RUN”.

Table 3.2 RUN mode functions list

Function Command Description Reference

Read Reads data from an ID tag. Section 6.2.1

Read with Error

Correction

Reads the data and check code written by the Write with Error

Correction function from the ID tag, inspects data reliability, and

corrects any 1-bit errors.

Section 6.2.11

Read

Read UID Reads the UID (unit identification number) of an ID tag. Section 6.2.13

Write Writes data to an ID tag. Section 6.2.2

Set Bit Sets the bit specified in the data of an ID tag to “1”. Section 6.2.3

Clear Bit Clears the bit specified in the data of an ID tag to “0”. Section 6.2.4

Write Mask Bit

Protects the data area within the ID tag data that you do not want

overwritten, and writes data.

Section 6.2.5

Write Calculation

Writes an addition or subtraction calculation result (data) to ID tag

data.

Section 6.2.6

Write

Write with Error

Correction

Writes data and check codes for inspecting data reliability to an ID

tag.

Section 6.2.12

Duplicate Copy*1 Copies data of an ID tag between channel 1 and channel 2. Section 6.2.10

Initialize Fill Data Initializes data of an ID tag with specified data. Section 6.2.7

Check Data

Checks whether or not an error occurred in data of an ID tag.

Writes data and code for checking data to an ID tag.

Section 6.2.8

Manage Number

of Writes

Writes the number of EEPROM-type ID tag writes to an ID tag, and

assesses whether or not the ID tag number of writes has been

exceeded.

Section 6.2.9

Management

Measure Noise Measures the noise environment around an antenna. Section 6.2.14

*1. Available with EQ-V680D2.

Page 25

3 - 4 3 - 4

3. SPECIFICATIONS

3.2.2 TEST mode

TEST mode is used when starting the RFID system or when performing maintenance.

To set the mode to TEST mode, either set the test switch located on the front of the

RFID interface module to “TEST,” or set the test mode execution request (Y15) to ON

in the sequence program.

Table 3.3 TEST mode functions list

Function

Description Reference

Communication test

Has the RFID interface module read ID tag data without operating the sequence

program.

Checks whether a sequence program, antenna, or ID tag caused a read error

when a data read error occurs with an ID tag.

Section 5.1.3(2)

Distance level

measurement

Checks the potential maximum communication distance of the installation distance

of the ID tag.

Use this function to adjust the installation location.

Section 5.1.3(3)

Communication

success rate

measurement

Checks the data reading potential in terms of the repeated execution success rate,

in the installation state with the ID tag in a stationary state.

Use this function to adjust the installation location.

Section 5.1.3(4)

Speed level

measurement

(read)

Checks the data reading potential in terms of the number of times read can be

repeatedly executed while moving an ID tag.

Use this function to adjust the ID tag movement speed.

Section 5.1.3(5)

Speed level

measurement

(write)

Checks the data writing potential in terms of the number of times write can be

repeatedly executed while moving an ID tag.

Use this function to adjust the ID tag movement speed.

Section 5.1.3(5)

Noise level

measurement

Checks whether noise that adversely affects communication with an ID tag is

occurring in the area surrounding the antenna installation location.

Section 5.1.3(6)

Page 26

3 - 5 3 - 5

3. SPECIFICATIONS

3.3 Programmable Controller CPU IO Signals

3.3.1 IO signal list

The following provides a list of the IO signals of the RFID interface module.

Note that the IO numbers (X/Y) shown hereafter indicate the number when the first IO

number of the RFID interface module is set to 0.

Table 3.4 IO signal list

Signal Direction: CPU Module <- RFID Interface Module Signal Direction: CPU Module -> RFID Interface Module

Device No. (Input) Signal Name Device No. (Output) Signal Name

X0 Module READY Y0

X1 Use prohibited Y1

X2 ID communication complete Y2

X3 ID-BUSY Y3

X4 ID command complete Y4

X5

CH1

Error detection Y5

X6 Y6

X7 Y7

X8 Y8

X9

Use prohibited

Y9

XA ID communication complete YA

XB ID-BUSY YB

XC ID command complete YC

XD

CH2*

1

Error detection YD

XE YE

XF YF

X10 Y10

X11 Y11

X12 Y12

X13 Y13

Use prohibited

X14 Y14 CH1 ID command execution request

X15 Y15 TEST mode execution request*2

X16 Y16 CH1 Result reception

X17 Y17

X18 Y18

X19 Y19

X1A Y1A

X1B Y1B

Use prohibited

X1C Y1C CH2*1ID command execution request

X1D Y1D Use prohibited

X1E Y1E CH2*

1

Result reception

X1F

Use prohibited

Y1F Use prohibited

*1. Effective only with EQ-V680D2 use.

*2. Available for use only when both the “test mode enable” bit and “Y contact test

request enable” bit are set to “0” (enable) on switch 2 of the intelligent function

module switch. (Refer to Section 4.7)

Point

Use-prohibited IO signals are used by the system and cannot be used by users. In

the unlikely event that a use-prohibited IO signal is turned ON/OFF by a sequence

program, the functions of the RFID interface module cannot be guaranteed.

Page 27

3 - 6 3 - 6

3. SPECIFICATIONS

3.3.2 IO signal details

The following describes in detail the input/output signals of the RFID interface module.

(1) Input signals

Device

No.

Signal Name Description

X0 Module READY

(1) Turns ON when the RFID interface module is ready after programmable controller

CPU power ON or reset.

(2) Turns OFF when an RFID interface module hardware error occurs.

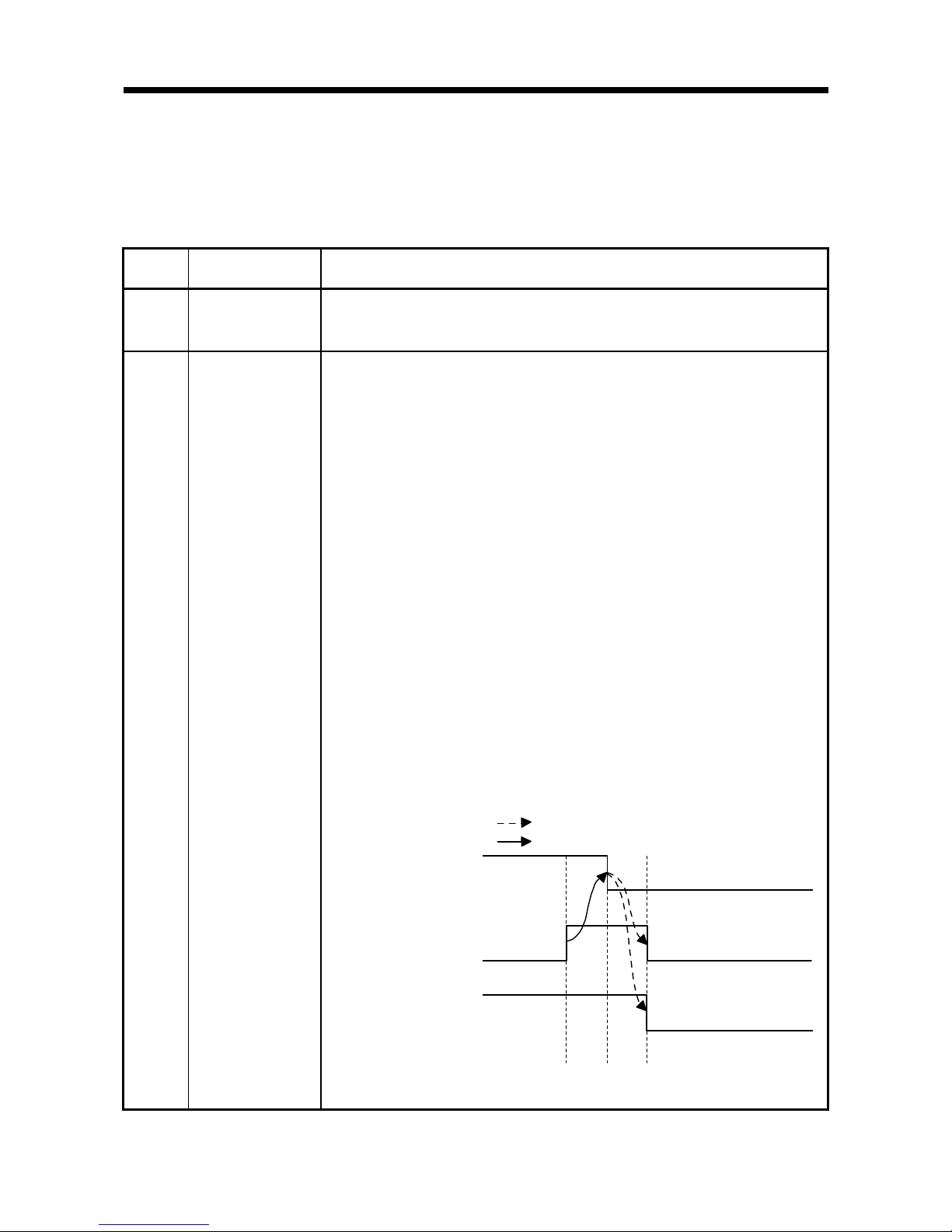

X2, XA

ID communication

complete

(1) Turns ON when the communication processing with all ID tags is completed when

the communication specification is multi-trigger.

(2) Turns ON when RFID interface module communication is suspended due to the

elapse of the auto command wait time when the communication specification is

repeat auto, FIFO repeat, or multi-repeat.

Turns ON when communication is suspended due to antenna disconnection when

the communication specification is repeat auto, FIFO repeat, multi-trigger, or

multi-repeat.

(3) Turns OFF when the ID command execution request (Y14, Y1C) is turned OFF.

(4) The timing chart is as follows:

1) ID communication complete (X2, XA) turns ON when the communication

specification is Multi-trigger and the last communication is completed.

Turns ON when communication is suspended due to the elapse of the auto

command wait time when the communication specification is repeat auto, FIFO

repeat, or multi-repeat.

Turns ON when communication is suspended due to antenna disconnection

when the communication specification is repeat auto, FIFO repeat, multi-trigger,

or multi-repeat.

2) The ID command execution request (Y14, Y1C) turns OFF when ID

communication complete (X2, XA) turns ON.

3) ID communication complete (X2, XA) and ID-BUSY (X3, XB) turn OFF

when the ID command execution request (Y14, Y1C) turns OFF.

ID communication complete

(X2, XA)

ID-BUSY(X3,XB)

Implemented by RFID interface module

Implemented by sequence program

1) 3)2)

ID command execution

request (Y14, Y1C)

Page 28

3 - 7 3 - 7

3. SPECIFICATIONS

Device

No.

Signal Name Description

X3, XB ID-BUSY

(1) Turns ON when the ID command execution request (Y14, Y1C) is turned ON and

received by the RFID interface module.

(2) Turns OFF when the ID command execution request (Y14, Y1C) is turned OFF and

received by the RFID interface module.

(3) Always ON in TEST mode.

(4)

For the timing chart, refer to ID command complete (X4, XC).

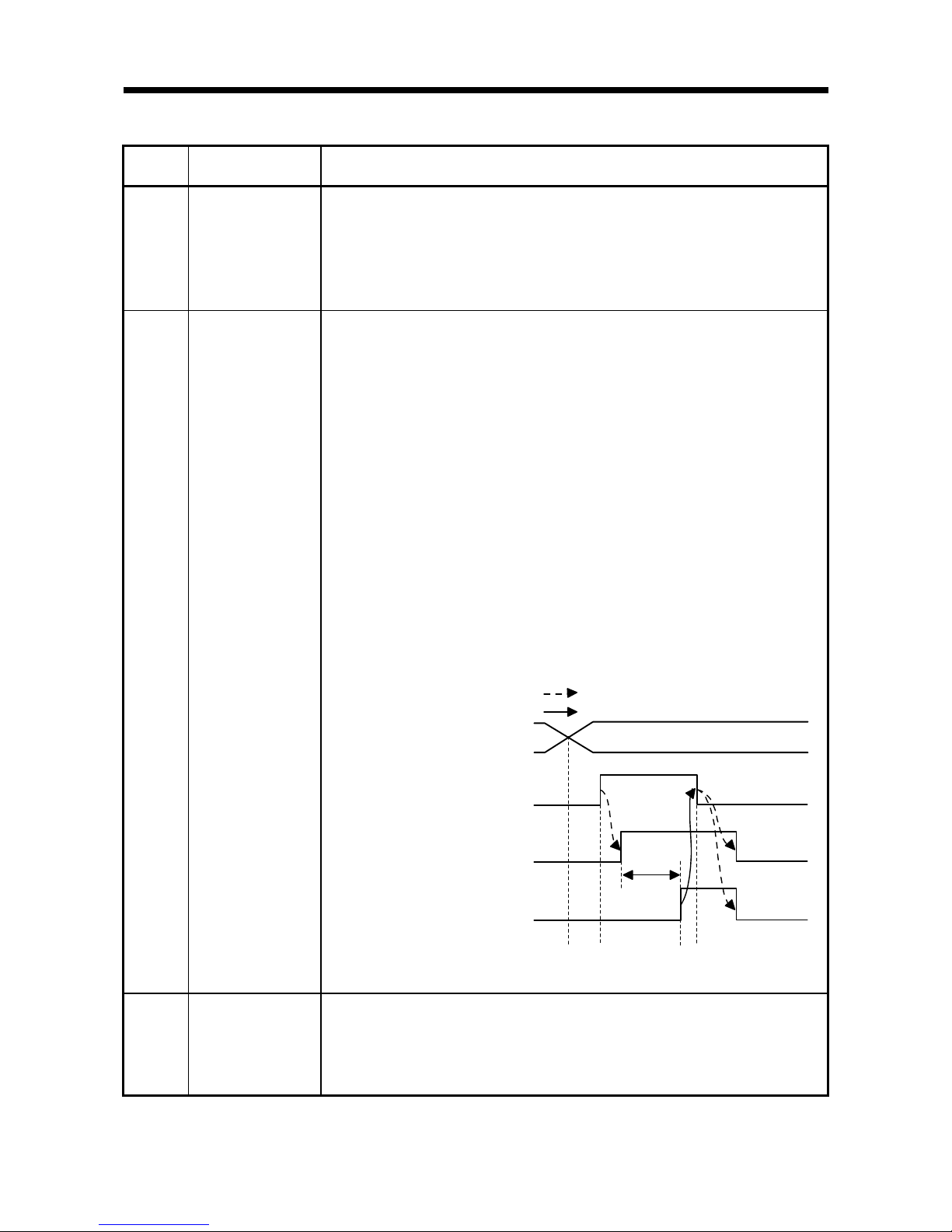

X4, XC

ID command

complete

(1) Turns ON when the ID command execution request (Y14, Y1C) is turned ON and

the status is normal upon ID command execution completion. Error detection (X5,

XD) turns ON when the status is abnormal upon ID command execution

completion.

(2) Turns OFF when the ID command execution request (Y14, Y1C) is turned OFF and

received by the RFID interface module.

(3) The timing chart is as follows:

1) The ID command execution contents are set in the buffer memory (Un\G0 to

Un\G5, Un\G10 to Un\G11/Un\G4000 to Un\G4005, Un\G4010 to Un\G4011).

2) ID-BUSY (X3, XB) turns ON when the ID command execution request (Y14,

Y1C) turns ON, and the ID command is executed in accordance with the setting

contents of Step 1 above.

3) ID command complete (X4, XC) turns ON when the status is normal upon ID

command execution completion. Error detection (X5, XD) turns ON when the

status is abnormal upon ID command execution completion.

4) ID-BUSY (X3, XB), ID command complete (X4, XC), and error detection (X5,

XD) turn OFF when the ID command execution request (Y14, Y1C) turns OFF.

3)

ID command complete (X4, XC)

/ Error detection (X5, XD)

ID-BUSY (X3, XB)

ID command execution

request (Y14, Y1C)

2)1) 4)

Implemented by RFID interface module

Implemented by sequence program

Execution contents

Buffer memory

(Un\G0 to Un\G5, Un\G10 to Un\G11

/Un\G4000 to Un\G4005,

Un\G4010 to Un\G4011).

ID command

execution

X5, XD Error detection

(1) Turns ON when the ID command execution request (Y14, Y1C) is turned ON and

the ID command ends abnormally.

(2) Turns OFF when the ID command execution request (Y14, Y1C) is turned OFF and

received by the RFID interface module.

(3) For the timing chart, refer to ID command complete (X4, XC).

Page 29

3 - 8 3 - 8

3. SPECIFICATIONS

(2) Output signals

Device

No.

Signal Name Description

Y14, Y1C

ID command

execution request

(1) Executes the ID command of the contents set in the buffer memory (Un\G0 to

Un\G5, Un\G10 to Un\G11/Un\G4000 to Un\G4005, Un\G4010 to Un\G4011).

when the sequence program turns ON.

(2) Processing is executed from channel 1 first when the ID command execution

request (Y14, Y1C) turns ON simultaneously on channel 1 and channel 2. The read

of channel 2 is ignored when channel 1 is copy and channel 2 is read. A channel 2

copy command error occurs when channel 1 is read and channel 2 is copy.

The ID command error (bit 0) of the error details storage area (Un\G4041) turns

ON, and error detection (XD) turns ON.

(3) For the timing chart, refer to ID command complete (X4, XC).

Y15

TEST mode

execution request

(1) Executed when turned ON by the sequence program.

(2) Available for use only when both the “test mode enable” bit and “Y contact test

request enable” bit are set to “0” (enable) on switch 2 of the intelligent function

module switch.

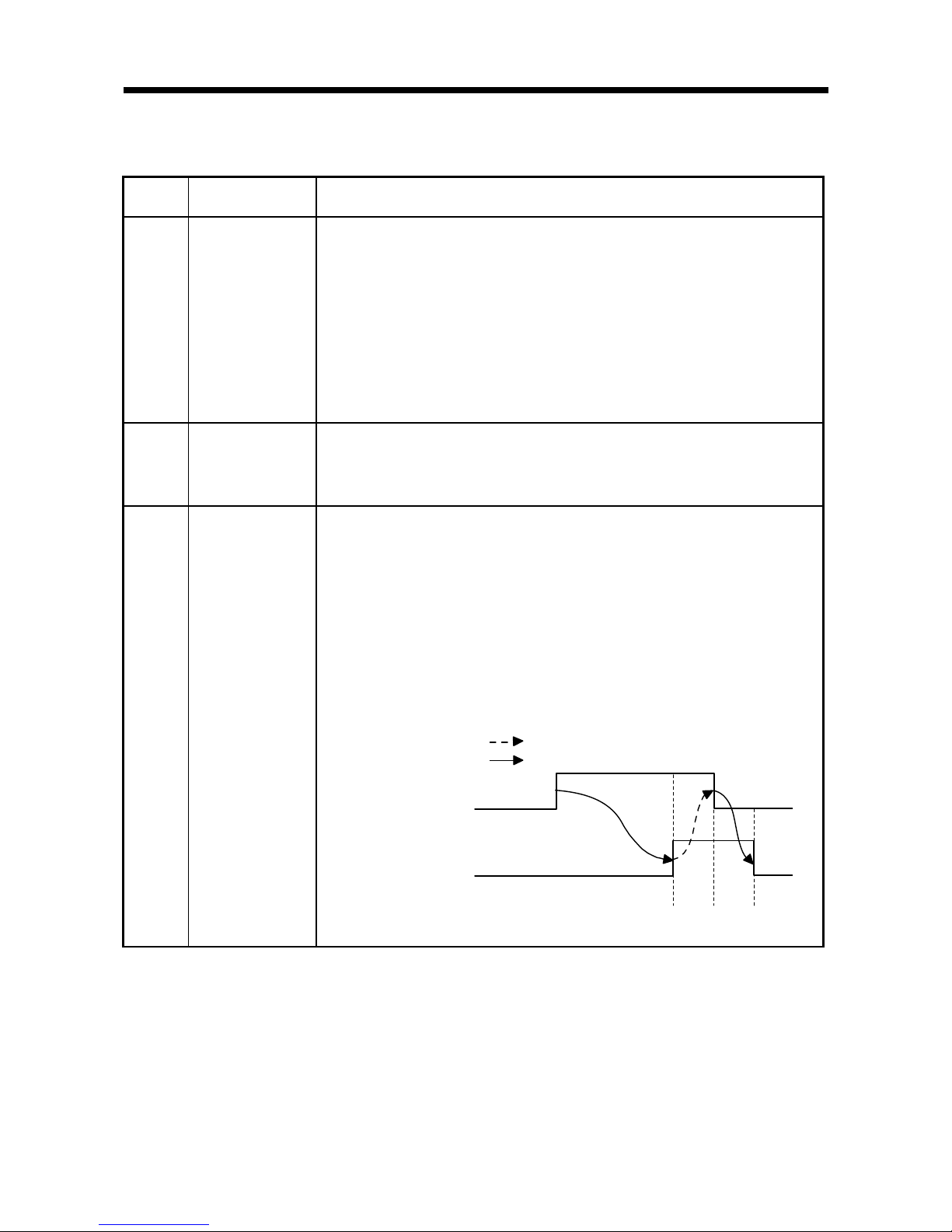

Y16, Y1E Result reception

(1) Used as a timing signal for communication with the next ID tag when the

communication specification is repeat auto, FIFO repeat, multi-trigger, or

multi-repeat.

(2) The timing chart is as follows:

1) The result information is acquired and result reception (Y16, Y1E) is turned ON

when ID command complete (X4, XC) turns ON.

2) ID command complete (X4, XC) turns OFF when result reception (Y16, Y1E) is

turned ON.

3) Result reception (Y16, Y1E) is turned OFF when ID command complete (X4,

XC) turns OFF.

ID command complete

(X4, XC)

Result reception

(Y16, Y1E)

1) 3)2)

Implemented by the RFID interface module

Implemented by the sequence program

Page 30

3 - 9 3 - 9

3. SPECIFICATIONS

3.4 Buffer Memory

Buffer memory refers to an area that stores read/write data and control information for

exchanging data between ID tags and the programmable controller CPU.

The buffer memory can be accessed by the MOV command from the sequence program.

Note that the contents of buffer memory return to default values at power OFF and

programmable controller CPU reset.

3.4.1 Buffer memory list

The following table lists the buffer memory of the RFID interface module.

Table 3.5 Buffer memory list

Address

Intelligent Function Module Device

CH.1 CH.2

Buffer Memory Address Name

Initial

Value

R/W*

1

Reference

Un\G0 Un\G4000 Command code specification area 0 R/W Section 3.4.2 (1)

Un\G1 Un\G4001 Communication specification area 0 R/W Section 3.4.2(2)

Un\G2 Un\G4002 Processing specification area 0 R/W Section 3.4.2(3)

Un\G3 Un\G4003 Head address specification area 0 R/W Section 3.4.2(4)

Un\G4 Un\G4004 No. of processing points specification area 0 R/W Section 3.4.2(5)

Un\G5 Un\G4005 Command option specification area 0 R/W Section 3.4.2(6)

Un\G6 to Un\G9 Un\G4006 to Un\G4009 Use prohibited ─ ─ ──

Un\G10 Un\G4010 Auto command wait time setting area 0 R/W Section 3.4.2(7)

Un\G11 Un\G4011 Processing result monitor switch setting area 0 R/W Section 3.4.2(8)

Un\G12 to Un\G39 Un\G4012 to Un\G4039 Use prohibited ─ ─ ──

Un\G40 Un\G4040 Module status storage area 0 R Section 3.4.2(9)

Un\G41 Un\G4041 Error details storage area 0 R Section 3.4.2(10)

Un\G42 Un\G4042 Processing result monitor storage area 0 R Section 3.4.2(11)

Un\G43 to Un\G89 Un\G4043 to Un\G4089 Use prohibited ─ ─ ──

Un\G90 to Un\G93 Un\G4090 to Un\G4093 ID tag UID storage area (8 bytes)*2 0 R Section 3.4.2(12)

Un\G94 to Un\G99 Un\G4094 to Un\G4099 Use prohibited ─ ─ ──

Un\G100 to Un\G1123 Un\G4100 to Un\G5123 Data storage area (2,048 bytes) 0 R/W Section 3.4.2(13)

Un\G8000 Test operation mode specification area 0 R/W Section 3.4.2(14)

Un\G8001 Test operation antenna specification area 0 R/W Section 3.4.2(15)

Un\G8002

No. of processing points during testing

specification area

0 R/W Section 3.4.2(16)

*1. Read and write are enabled/disabled from the sequence program. R: Read enabled,

W: Write enabled.

*2. Does not change according to the setting contents of the data storage order of the

processing specification area (Un\G2, Un\G4002).

Point

Use-prohibited buffer memory is used by the system and cannot be used by users.

If you execute read or write with this buffer memory in the sequence program,

normal operation cannot be guaranteed.

3.4.2 Buffer memory details

(1) Command code specification area (Un\G0, Un\G4000)

This area is used to specify the processing contents for ID tags using command codes.

For command code details, refer to Section 6.2, “Command Specification List.”

Page 31

3 - 10 3 - 10

3. SPECIFICATIONS

(2) Communication specification area (Un\G1, Un\G4001)

The communication specification method is selected according to the ID tag status

(stationary, moving, number of ID tags in antenna communication area, etc.).

For details of the control method for each communication specification, refer to

Section 6.3, “Control Method by Communication Specification”.

Table 3.6 Communication specification list

Name

Specification

Details

Description

Trigger

0000

H

(1) Communicates with a static ID tag located within the antenna communication area

when the ID command execution request (Y14, Y1C) turns ON.

(2) Be sure that there is only one ID tag in the antenna communication area.

Auto

0001

H

(1) Waits for detection of an ID tag moving within the antenna communication area after the ID

command execution request (Y14, Y1C) turns ON, and then executes communication.

(2) Be sure that there is only one ID tag in the antenna communication area.

Repeat

auto

0002

H

(1) Waits for detection of an ID tag moving within the antenna communication area after the ID

command execution request (Y14, Y1C) turns ON, and then executes communication.

(2) Does not execute communication with ID tags that stay in the communication area.

(3) Waits again for the approach of a moving ID tag after response transmission is

completed, continually executes communication with subsequent ID tags, and stops

communication when the ID command execution request (Y14, Y1C) turns OFF.

(4) Be sure that there is only one ID tag in the antenna communication area.

FIFO

trigger *

1

0003

H

(1) Communicates with an operable ID tag within the antenna communication area after

the ID command execution request (Y14, Y1C) turns ON.

(2) Sets the ID tag to an operation disabled state after communication completion.

(3) Does not communicate with an ID tag with which communication was once already

performed when that same ID tag is within the communication range.

(4) Be sure that only one operable ID tag is within the antenna communication area during

ID tag communication.

FIFO

repeat*

1

0004

H

(1) Waits for detection of an operable ID tag within the antenna communication area after the

ID command execution request (Y14, Y1C) turns ON, and then performs communication.

(2) Sets the ID tag to an operation disabled state after communication completion.

(3) Does not communicate with the same ID tag again when an ID tag with which

communication was once already performed is within the communication range.

(4) Be sure that only one operable ID tag is within the antenna communication area during

ID tag communication.

(5) Waits again for the approach of a moving ID tag after response transmission

completion, continuously executes communication with subsequent ID tags, and stops

communication when the ID command execution request (Y14, Y1C) turns OFF.

Multi-trigger

*

1, *2

0005

H

(1) Communicates with all static ID tags within the antenna communication area after the

ID command execution request (Y14, Y1C) turns ON.

(2) Sets the ID tag to an operation disabled state after communication completion.

(3) Turns ON ID communication complete (X2, XA) upon completion of communication

with all ID tags within the antenna communication area.

(4) Sends a tag not present error when there is no ID tag within the antenna communication area.

Multi-repeat

*

1, *2

0006

H

(1) Waits for detection of an ID tag moving within the antenna communication area after

the ID command execution request (Y14, Y1C) turns ON, and then communicates with

all ID tags within the antenna communication area.

(2) Sets the ID tag to an operation disabled state after communication completion.

(3) Waits again for the approach of a moving ID tag after response transmission

completion, continuously executes communication with subsequent ID tags, and stops

communication when the ID command execution request (Y14, Y1C) turns OFF.

*1. Cannot be used with communication with V680-D1KP.

*2. It may not be possible to execute read/write with all ID tags due to the ID tag

installation location and surrounding environment. Be sure to identify the

quantity of ID tags to be subject to reading and writing prior to use.

Page 32

3 - 11 3 - 11

3. SPECIFICATIONS

(3) Processing specification area (Un\G2, Un\G4002)

This area is used to select the processing specification contents according to the

commands used.

Table 3.7 Processing specification list

Name

Specification

Contents

Processing

Contents

Applicable Commands

0000H

Upper ->

Lower

Data storage

order

0001

H

Lower ->

Upper

Read, Write, Set Bit, Clear Bit, Write Mask Bit, Fill Data,

Read with Error Correction, Write with Error Correction,

Read System

0000H

Addition

Calculation

method

0001

H

Subtraction

Write Calculation, Control No. of Writes

0000H

Calculation

Calculation/Verifi

cation

0001

H

Verification

Check Data

(a) Data storage order setting example

Within ID tag memory, data are processed in units of bytes (8 bytes). Since data

are processed in units of words in the RFID interface module, one of the

following two data storage orders is selected and specified.

1. Upper -> Lower

Buffer memory

4241

H

4241

H

4443

H

42

H

41

H

44

H

43

H

4443

H

Buffer memoryID tag

2. Lower -> Upper

4241

H

4241

H

4443

H

41

H

42

H

43

H

44

H

4443

H

Buffer memory Buffer memoryID tag

Page 33

3 - 12 3 - 12

3. SPECIFICATIONS

(4) Head address specification area (Un\G3, Un\G4003)

This area is used to specify the ID tag head address when ID tag reading and

writing are to be executed.

(5) No. of processing points specification area (Un\G4, Un\G4004)

This area is used to specify the number of processed bytes when ID tag reading

and writing are to be executed.

(6) Command option specification area (Un\G5, Un\G4005)

This area is used to specify the details of the command processing method when

Write Calculation, Control Number of Writes, and Copy commands are executed.

(Refer to Section 6.2.6, 6.2.9, 6.2.10)

(7) Auto command wait time setting area (Un\G10, Un\G4010)

This area is used to set the wait time in BCD for an ID tag response after the ID

command execution request (Y14, Y1C) is turned ON by an auto command (Auto,

Auto Repeat, FIFO Repeat, Multi-repeat).

Table 3.8 Auto command wait time setting list

Setting Value Description

0000, value other than BCD

Continually executes the ID command until there is a response from the ID tag.

0001 to 9999

Stops the ID command with a tag not present error when an ID tag is not detected within a

period of the set value[BCD] x 0.1 seconds, causing error detection to turn ON.

(8) Processing result monitor switch setting area (Un\G11, Un\G4011)

This area is used to set the contents to be stored in the processing result monitor

storage area (Un\G42, Un\G4042).

Table 3.9 Processing result monitor switch setting list

Setting Value Description

0001

Stores the noise level in the processing result monitor storage area (Un\G42, Un\G4042).

Other than 0001

Stores the communication time in the processing result monitor storage area

(Un\G42, Un\G4042).

(9) Module status storage area (Un\G40, Un\G4040)

This area stores the operation status of the RFID interface module.

Table 3.10 Module status list

Bit Name Description

0 Antenna error*1

0: Normal or antenna not connected

1: An antenna other than the set antenna is connected.

1 24VDC power supply error

0: 24VDC power is normally supplied.

1: 24VDC power is not normally supplied.

2 TEST mode

0: RUN mode in operation

1: TEST mode in operation

3 to 15 Not used

0: Fixed

*1. The antenna error bit is changed to 0 or 1 when 24V DC current is not normally

supplied.

Page 34

3 - 13 3 - 13

3. SPECIFICATIONS

(10) Error details storage area (Un\G41, Un\G4041)

When an error occurs, the bit corresponding to the error contents turns ON.

The bit in the error details storage area (Un\G41, Un\G4041) either turns OFF the

ID command execution request (Y14, Y1C) or clears when result reception (Y16,

Y1E) turns ON/OFF.

Table 3.11 Error details list

Bit Name Description

0 ID command error

Turns ON when there is an error in the specified ID command.

1 Not used

--

2 Not used

--

3 Data correction flag

Turns ON when data become normal by data correction as a result of read with

error correction.

4 Status flag*1

Turns ON under in the following cases:

When the number of rewrites is exceeded by the Control Number of Writes

command.

When the verification results indicate an error as a result of a memory data

check (verification).

When a data error occurs as a result of Read with Error Correction.

When overflow occurs as a result of an addition operation of Write

Calculation.

When underflow occurs as a result of a subtraction operation of Write

Calculation.

When an error occurs as a result of data writing after reading during the

Copy command.

*

1

5 Not used

--

6 Not used

--

7 ID system error 3

ID system error

8 ID system error 2

ID system error

9 ID system error 1

ID system error

10 Tag not present error

Turns ON when there is no communicable ID tag in the antenna communication

area.

11 Protect error

Turns ON when data are written in an area set as write protected.

12 Tag communication error

Turns ON when communication with an ID tag does not end normally.

13 Address error

Turns ON when the ID tag address range has been exceeded and an attempt is

made to read or write data.

14 Verify error

Turns ON when data writing cannot be performed normally with an ID tag.

15 Antenna error

Turns ON when failure occurs possibly because the antenna is not connected.

*1. When a Copy command error occurs causing an error on the copy destination

side, the bit on the copy source side also turns ON.

(11) Processing result monitor storage area (Un\G42, Un\G4042)

This area stores the processing result of each test.

For processing result details, refer to Section 5.1.3.

Page 35

3 - 14 3 - 14

3. SPECIFICATIONS

(12) ID tag UID storage area (Un\G90 to Un\G93, Un\G4090 to Un\G4093)

This area stores the UID (individual identification number) of the ID tag with which

communication was performed.

(13) Data storage area (Un\G100 to Un\G1123, Un\G4100 to Un\G5123)

This area stores read data when reading is performed.

The area stores write data when writing is performed.

(14) Test operation mode specification area (Un\G8000)

This area sets the test contents to be executed.

Table 3.12 Test operation mode specification list

Setting Value Description

0000H, value other below

Communication test

00A0H

Distance level

00B0H

Speed level (read)

00B1H

Speed level (write)

00C0H

Noise level

00C1H

Communication success rate

00C2

H

*

1

Use prohibited

*1. Use prohibited. Do not set this value. Normal operation cannot be guaranteed if

the value is set.

(15) Test operation antenna specification area (Un\G8001)

This area is used to specify an antenna when tests other than the communication

test are executed.

Table 3.13 Test operation antenna specification list

Setting Value Description

0001H

Specifies antenna 1.

0002H

Specifies antenna 2.

Value other than the above*1

Executes the communication test.

*1. The communication test is executed when the setting value is not properly

specified.

(16) No. of processing points during testing specification area (Un\G8002)

This area is used to specify the number of bytes to be executed during testing other

than the noise level test.

Table 3.14 No. of processing points during testing specification list

Setting Value Description

0001H to 0800H

Specifies the number of bytes to be executed.

Value other than the above*1

Executes the communication test.

*1. The communication test is executed when the setting value is not properly

specified.

Page 36

4 - 1 4 - 1

4. SETUP AND PROCEDURES PRIOR TO OPERATION

Chapter 4 SETUP AND PROCEDURES PRIOR TO OPERATION

The following describes the setup and procedures to be executed prior to operation,

names of parts, wiring, and the like for a system that uses the RFID interface module.

Point

(1) When using the RFID interface module, be sure to review the Safety

Precautions provided in the beginning of this manual.

(2) The mounting and installation of the RFID interface module are the same as

those for the CPU module.

(3) For module mounting and installation, refer to the user’s manual of the CPU

module used.

4.1 Usage Precautions

The following describes the usage precautions for the RFID interface module unit.

(1) The module case is made of plastic. Do not drop the case or expose the case to

strong impact.

(2) Before touching the module, be sure to touch grounded metal or the like to release