Page 1

ENGINE

LUBRICATION

CONTENTS

12-1

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 3.................

SEALANT 3..................................

LUBRICANTS 3..............................

SPECIAL TOOLS 3..........................

ON-VEHICLE SERVICE 4.....................

Engine Oil Check 4............................

Engine Oil Replacement 4.......................

Oil Filter Replacement 5........................

Oil Level Warning System Check 6..............

Oil Pressure Check 7..........................

Page 2

12-2

ENGINE LUBRICATION -

GENERAL INFORMATION

General Information

The lubrication method is a fully force-fed, full-flow

filtration type. The oil pump for 4G9 engines is

a trochoid type which is directly mounted to the

crankshaft, and the one for 4G6 engines is a gear

type which is driven by the crankshaft via the timing

ENGINE OILS

Health Warning

Prolonged and repeated contact with mineral oil

will result in the removal of natural fats from the

skin, leading to dryness, irritation and dermatitis.

In addition, used engine oil contains potentially

Recommended Precautions

The most effective precaution is to adapt working

practices which prevent, as far as practicable, the

risk of skin contact with mineral oils, for example

by using enclosed systems for handling used engine

oil and by decreasing components, where

practicable, before handling them.

Other precautions:

D Avoid prolonged and repeated contact with oils,

particularly used engine oils.

D Wear protective clothing, including impervious

gloves where practicable.

D Avoid contaminating clothes, particularly

underpants, with oil.

D Do not put oily rags in pockets, the use of

overalls without pockets will avoid this.

D Do not wear heavily soiled clothing and

oil-impregnated foot-wear. Overalls must be

cleaned regularly and kept separate from

personal clothing.

belt.

Furthermore, the oil level sensor is located in the

oil pan, and a system is equipped whereby an

indicator gives a warning when the oil level drops.

harmful contaminants which may cause skin cancer.

Adequate means of skin protection and washing

facilities must be provided.

D Where there is a risk of eye contact, eye

protection should be worn, for example,

chemical goggles or face shields; in addition

an eye wash facility should be provided.

D Obtain First Aid treatment immediately for open

cuts and wounds.

D Wash regularly with soap and water to ensure

all oil is removed, especially before meals (skin

cleansers and nail brushes will help). After

cleaning, the application of preparations

containing lanolin to replace the natural skin

oils is advised.

D Do not use petrol, kerosine, diesel fuel, gas

oil, thinners or solvents for cleaning skin.

D Use barrier creams, applying them before each

work period, to help the removal of oil from

the skin after work.

D If skin disorders develop, obtain medical advice

without delay.

Page 3

ENGINE LUBRICATION -

Service Specifications/Sealant/Lubricants/Special Tools

SERVICE SPECIFICATIONS

Item Standard value Limit

Oil pressure kPa at idle 29 or more -

at 3,500 r/min 294 - 686 -

SEALANT

Item Specified sealant Remark

Oil pressure switch 3M ATD Part No. 8660 or equivalent -

LUBRICANTS

Items Specifications

Engine oil (API classification) SG or higher

Engine oil quantity L Oil filter 0.3

12-3

Total 3.8

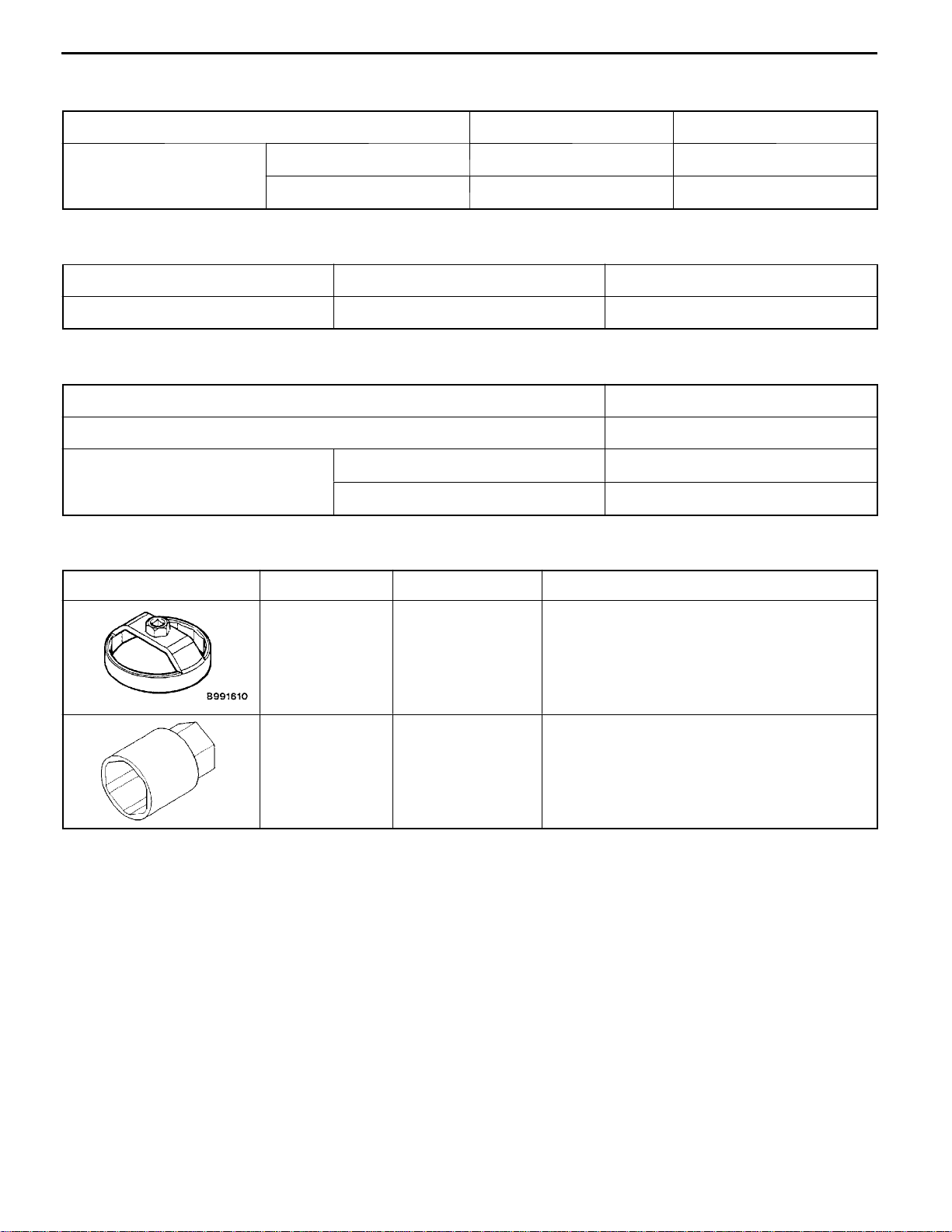

SPECIAL TOOLS

Tool Number Name Use

MB991610 Oil filter wrench Removal and installation of engine oil filter

MD998054 Oil pressure switch

wrench

(When using the oil filter of MD136466 and

MD356000)

Removal and installation of oil pressure switch

Page 4

12-4

ENGINE LUBRICATION -

ON-VEHICLE SERVICE

ENGINE OIL CHECK

1. Pull out the level gauge slowly and check that the oil

level is in the illustrated range.

2. Check that the oil is not excessively dirty, that there is

no coolant or gasoline mixed in, and that it has sufficient

viscosity.

ENGINE OIL REPLACEMENT

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80_Cto90_C.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

Caution

Use care as oil could be hot.

On-vehicle Service

Drain plug gasket

39 Nm

Barometric temperature

Oil

pan

side

4. Install a new drain plug gasket so that it faces in the

direction shown in the illustration, and then tighten the

drain plug to the specified torque.

NOTE

Install the drain plug gasket so it faces in the direction

shown in the illustration.

5. Refill with specified quantity of oil.

Specified Engine Oil (API classification):

SG or higher

Total quantity (Includes volume inside oil filter and

oil cooler): 3.8 L

6. Install the engine oil filler cap.

7. Check oil level.

Page 5

ENGINE LUBRICATION -

OIL FILTER REPLACEMENT

MB991610 or

commerciallyavailable tool

1. Start the engine and allow it to warm up until the

temperature of the coolant reaches 80_Cto90_C.

2. Remove the engine oil filler cap.

3. Remove the drain plug to drain oil.

Caution

Use care as oil could be hot.

4. Remove the under cover.

5. Use the respective tool in the following table to remove

the engine oil filter.

6. Clean the filter bracket side mounting surface.

On-vehicle Service

12-5

7. Apply a small amount of engine oil to the O-ring of the

new oil filter.

8. Once the O-ring of the oil filter is touching the flange,

use the respective tool in the following table to tighten

to the specified torque.

9. Install the drain plug and refill engine oil. (Refer to Engine

Oil Replacement on P.12-3.)

10. Race the engine 2 - 3 times, and check to be sure that

O-ring

Number Tool Tightening torque

MD136466 MB991610 or equivalent tool Approx. 3/4 turn (17 Nm)

MD322508 Commercially-available tool Approx. 3/4 turns (17 Nm)

MD356000 MB991610 or equivalent tool Approx. 3/4 turn (14 Nm)

no engine oil leaks from installation section of the oil

filter.

Page 6

12-6

ENGINE LUBRICATION -

Engine oil level relay

On-vehicle Service

OIL LEVEL WARNING SYSTEM

CHECK <4G6>

1. Check that the proper amount of oil has been filled.

2. When the ignition switch is turned to ON (do not start

the engine), check that the oil level warning lamp

illuminates.

NOTE

If the oil level warning lamp does not illuminate, the cause

is probably a blown lamp, or a malfunction in the relay.

Engine oil level sensor

connector (Harness side)

Engine oil level sensor

connector (Equipment side)

3. When the engine is started, check that the oil level warning

lamp turns off.

If the oil level warning lamp will not go out, disconnect

the connector of the oil level relay and measure the voltage

of the No.1 terminal on the harness side of the connector

while idling the engine in order to confirm that it is the

same as the battery voltage.

NOTE

(1) If the voltage at the connector is the same as t he

battery voltage, the problem is probably a malfunction

of either the oil level relay or the oil level sensor.

(2) If the voltage at the connector is lower than the battery

voltage, t he problem is probably a malfunction of either

the alternator or the wiring harness.

4. Disconnect the oil level sensor connector. Check that

the oil level warning lamp illuminates after approximately

40 seconds.

If the oil level warning lamp does not illuminate, replace

the oil level relay.

5. Check the continuity between the oil level sensor

terminals.

Engine oil temperature

Oil level Continuity

Engine oil level sensor

9Nm

At 50_C or lower Normal

(proper volume)

Low (drained) Continuity

At 60_C or higher Normal

(proper volume)

Low (drained) No continuity

Continuity

Continuity

6. If there is a defect, replace the oil level sensor.

Page 7

ENGINE LUBRICATION -

On-vehicle Service

12-7

<4G6>

<4G9>

Oil pressure switch

Oil pressure

switch

MD998054

OIL PRESSURE CHECK

1. Check engine oil quantity.

2. Remove the oil pressure switch terminal.

3. Use the special tool (oil pressure switch wrench) to remove

the oil pressure switch.

Caution

Since sealant is applied to the thread of oil pressure

switch,take care nottodamage theoil pressureswitch

when removing it.

4. Install the oil pressure gauge.

NOTE

Use a adapter of PT 1/8 thread.

5. Run the engine to warm it.

6. After the engine has been warmed up, check that oil

pressure is within the standard value.

Standard value:

At idle: 29 kPa or more

At 3,500 r/min: 294 - 686 kPa

7. Remove the oil pressure gauge.

8. Apply the specified sealant to the thread of oil pressure

switch.

Specified sealant: 3M ATD Part No. 8660 or equivalent

Page 8

12-8

ENGINE LUBRICATION -

On-vehicle Service

MD998054

9. Use the special tool to tighten the oil pressure switch

to the specified torque.

Tightening torque: 19 Nm

Caution

Do not start the engine within one hour after the oil

pressure switch has been installed.

10. Install the oil pressure switch terminal.

Loading...

Loading...