Page 1

ENGINE

ELECTRICAL

CONTENTS

16-1

CHARGING SYSTEM 2................

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 3..............

SPECIAL TOOL 3.........................

ON-VEHICLE SERVICE 4..................

Alternator Output Line Voltage Drop Test 4....

Output Current Test 5.......................

Regulated Voltage Test 7....................

Waveform Check Using An Analyzer 9........

Alternator Relay Continuity Check 10.........

ALTERNATOR 11..........................

STARTING SYSTEM 17................

GENERAL INFORMATION 17..............

SERVICE SPECIFICATIONS 17............

IGNITION SYSTEM 25.................

GENERAL INFORMATION 25..............

SERVICE SPECIFICATIONS 26............

ON-VEHICLE SERVICE 26................

Ignition Coil (With Built-in Power Transistor)

Check 26...................................

Spark Plug Check and Cleaning 27...........

Camshaft Position Sensor Check 28.........

Crank Angle Sensor Check 28...............

Detonation Sensor Check 28.................

IGNITION COIL 29.......................

CRANK ANGLE SENSOR 29..............

CAMSHAFT POSITION SENSOR 30.......

DETONATION SENSOR 31................

STARTER MOTOR 18.....................

Page 2

16-2

ENGINE ELECTRICAL -

CHARGING SYSTEM

GENERAL INFORMATION

The charging system uses the alternator output

to keep the battery charged at a constant level

under various electrical loads.

Charging System

Voltage

OPERATION

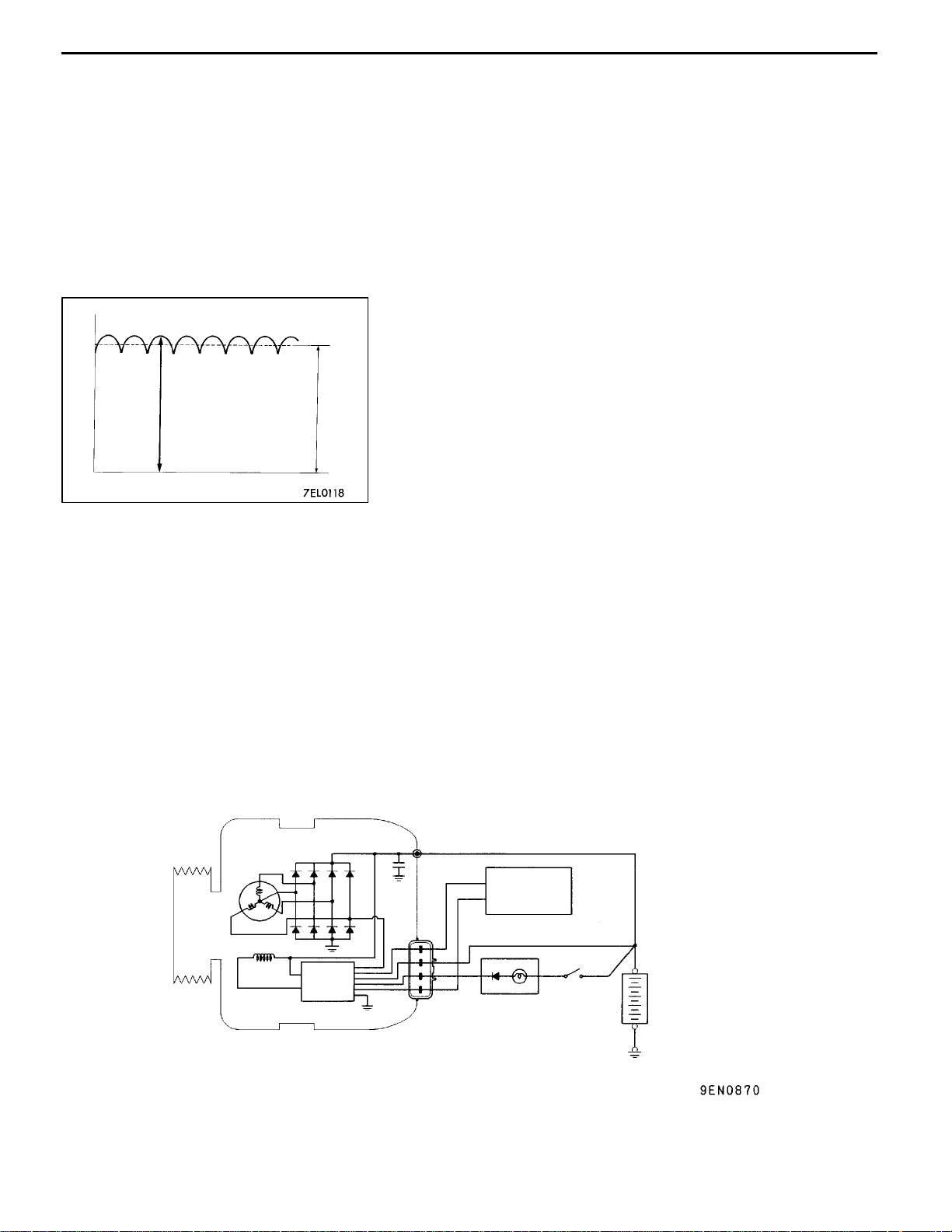

Rotation of the excited field coil generates AC voltage in

the stator.

This alternating current is rectified through diodes to DC

voltage having a waveform shown in the illustration at left.

Approx. 14.4 V

The average output voltage fluctuates slightly with the

alternator load condition.

Time

When the ignition switch is turned on, current flows

in the field coil and initial excitation of the field

coil occurs.

When the stator coil begins to generate power after

the engine is started, the field coil is excited by

the output current of the stator coil.

The alternator output voltage rises as the field

current increases and it falls as the field current

decreases. When t he battery voltage (alternator

S terminal voltage) reaches a regulated voltage

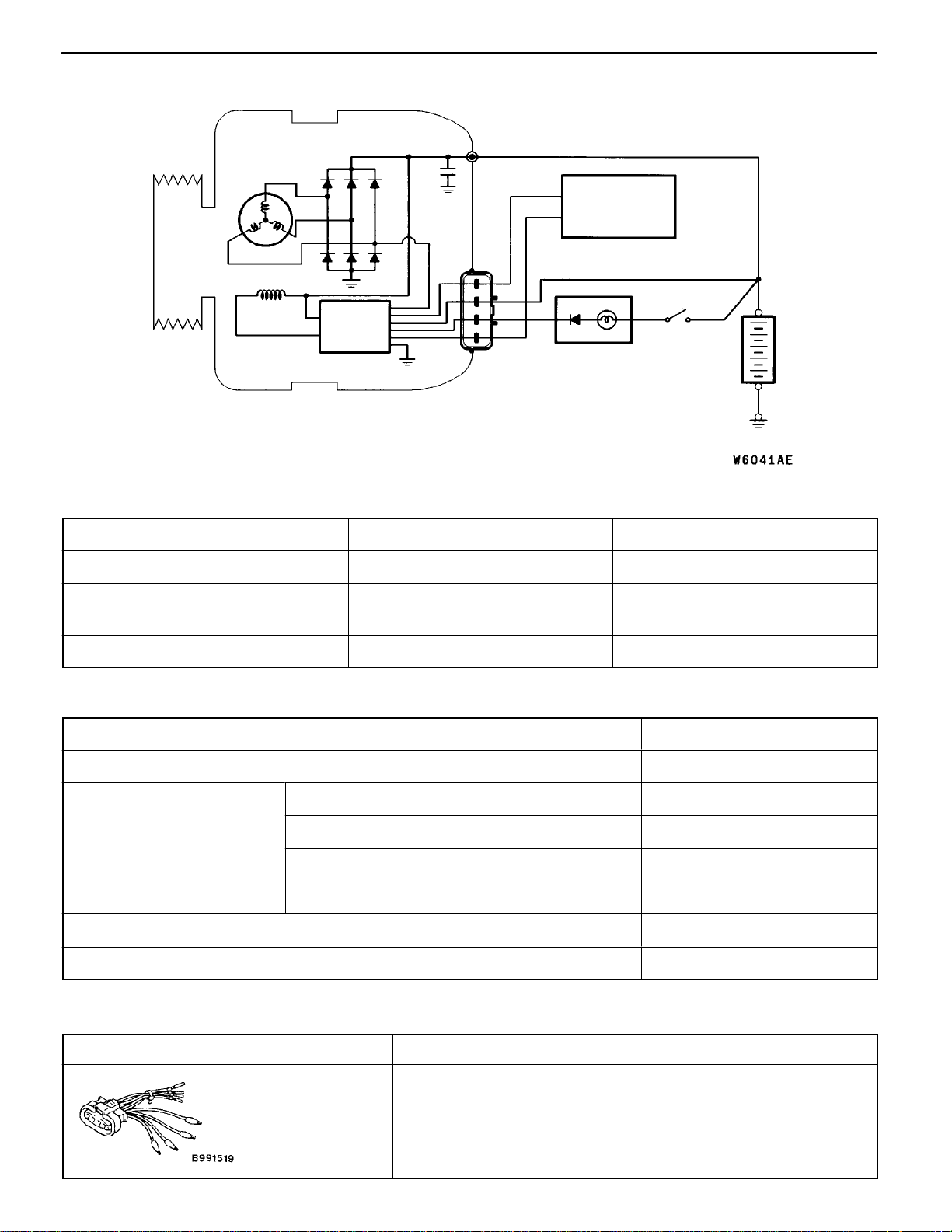

SYSTEM DIAGRAM

<4G9>

of approx. 14.4 V, the field current is cut off. When

the battery voltage drops below t he regulated

voltage, the voltage regulator regulates the output

voltage to a constant level by controlling the field

current.

In addition, when the field current is constant, the

alternator output voltage rises as the engine speed

increases.

Stator coil

Field coil

Voltage

regulator

B

Engine-ECU

G

S

L

FR

Charging

warning lamp

Ignition

switch

+

Battery

-

Page 3

<4G6>

ENGINE ELECTRICAL -

Stator coil

Field coil

Voltage

regulator

Charging System

B

Engine-ECU

G

S

L

FR

Charging

warning lamp

Ignition

switch

16-3

+

Battery

-

ALTERNATOR SPECIFICATIONS

Items 4G9 4G6

Type Battery voltage sensing Battery voltage sensing

Rated output V/A 12/85 <Except cold climate zone>

12/100 <Cold climate zone>

Voltage regulator Electronic built-in type Electronic built-in type

12/100

SERVICE SPECIFICATIONS

Items Standard value Limit

Alternator output line voltage drop (at 30A) V - max. 0.3

Regulated voltage ambient -20_C 14.2- 15.4 temp. at voltage regulator V

20_C 13.9- 14.9 -

60_C 13.4- 14.6 -

80_C 13.1- 14.5 -

Output current - 70% of normal output current

Rotor coil resistance

W

Approx. 2 - 5 -

SPECIAL TOOL

Tool Number Name Use

MB991519 Alternator test

harness

Checking the alternator (S terminal voltage)

Page 4

16-4

ENGINE ELECTRICAL -

Charging System

ON-VEHICLE SERVICE

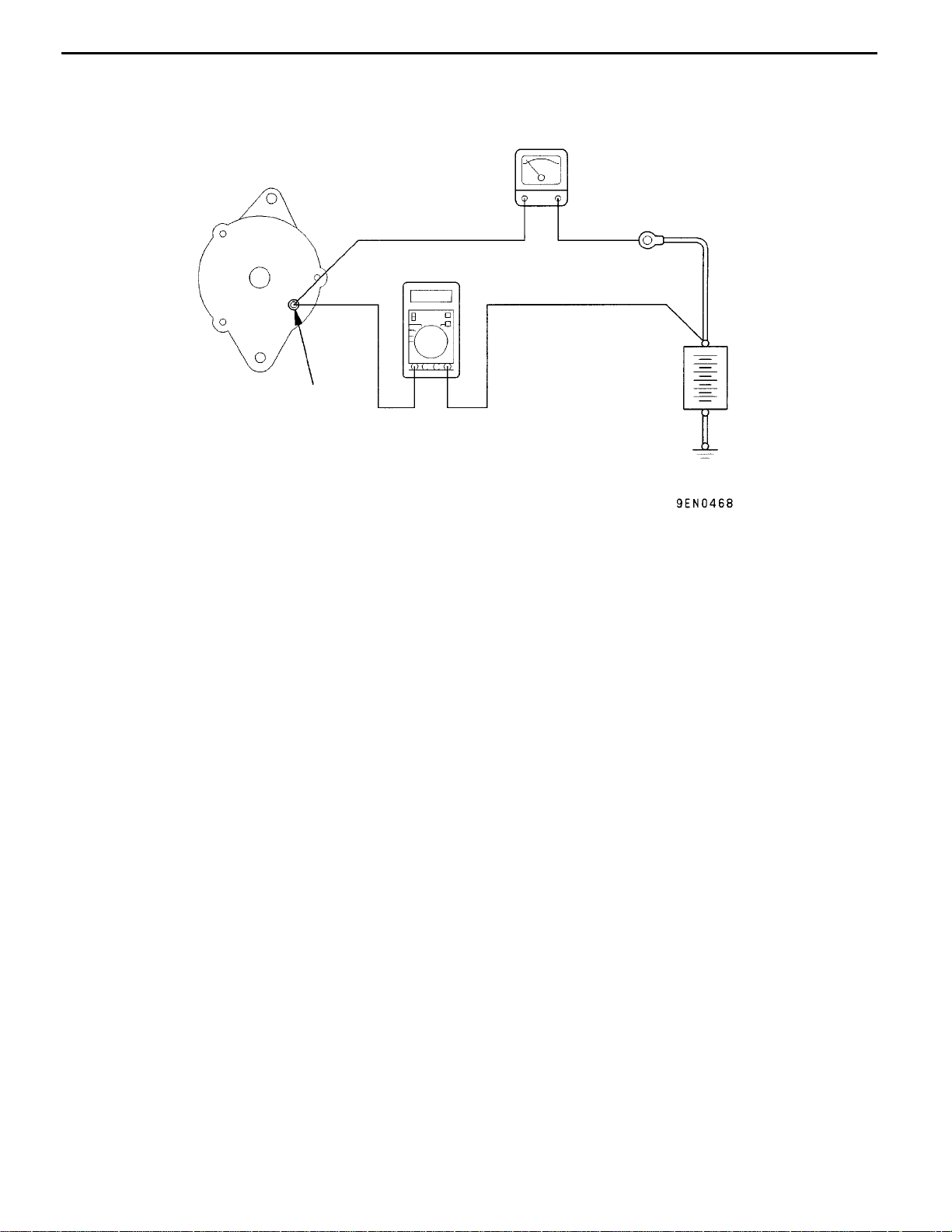

ALTERNATOR OUTPUT LINE VOLTAGE DROP TEST

+-

Alternator

Voltmeter

Terminal B

This test determines whether the wiring from the

alternator “B” terminal to the battery (+) terminal

(including the fusible line) is in a good condition

or not.

1. Always be sure to check the following before

the test.

D

Alternator installation

D

Alternator drive belt tension

D

Fusible link

D

Abnormal noise from the alternator while

the engine is running

2. Turn the ignition switch off.

3. Disconnect the negative battery cable.

4. Disconnect the alternator output wire from the

alternator “B” terminal and connect a DC test

ammeter with a range of 0 - 100 A in series

between the “B” terminal and the disconnected

+-

Ammeter

Battery

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal, and then connect

the (- ) lead of the ammeter to the disconnected

output wire.)

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended. Using this equipment will

lessen the possibility of a voltage drop caused

by a loose “B” terminal connection.

5. Connect a digital-type voltmeter between the

alternator “B” terminal and the battery (+)

terminal. (Connect the (+) lead of the voltmeter

to the “B” terminal and the connect the ( - ) lead

of the voltmeter to the battery (+) cable.)

Page 5

ENGINE ELECTRICAL -

Charging System

16-5

6. Reconnect the negative battery cable.

7. Connect a tachometer or the MUT-II.

8. Leave the hood open.

9. Start the engine.

10. With the engine running at 2,500 r/min, turn

the headlamps and other lamps on a n d off

to adjust the alternator load so that the value

displayed on the ammeter is slightly above 30

A.

Adjust the engine speed by gradually

decreasing it until the value displayed on th e

ammeter is 30 A. Take a reading of the value

displayed on the voltmeter at this time.

Limit: max. 0.3 V

NOTE

When the alternator output is high and the value

displayed on the ammeter does not decrease

until 30 A, set the value to 40 A. Read the

value displayed on the voltmeter at this time.

When the value range is 40 A, the limit is max.

0.4 V.

OUTPUT CURRENT TEST

11. If the value displayed on the voltmeter is above

the limit value, there is probably a malfunction

in the alternator output wire, so check the wiring

between the alternator “B” terminal and the

battery (+) terminal (including fusible link).

If a terminal is not sufficiently tight or if the

harness has become discolored due to

overheating, repair and then test again.

12. After the test, run the engine at idle.

13. Turn off all lamps and the ignition switch.

14. Remove the tachometer or the MUT-II.

15. Disconnect the negative battery cable.

16. Disconnect the ammeter an d voltmeter.

17. Connect the alternator output wire to the

alternator “B” terminal.

18. Connect the negative battery cable.

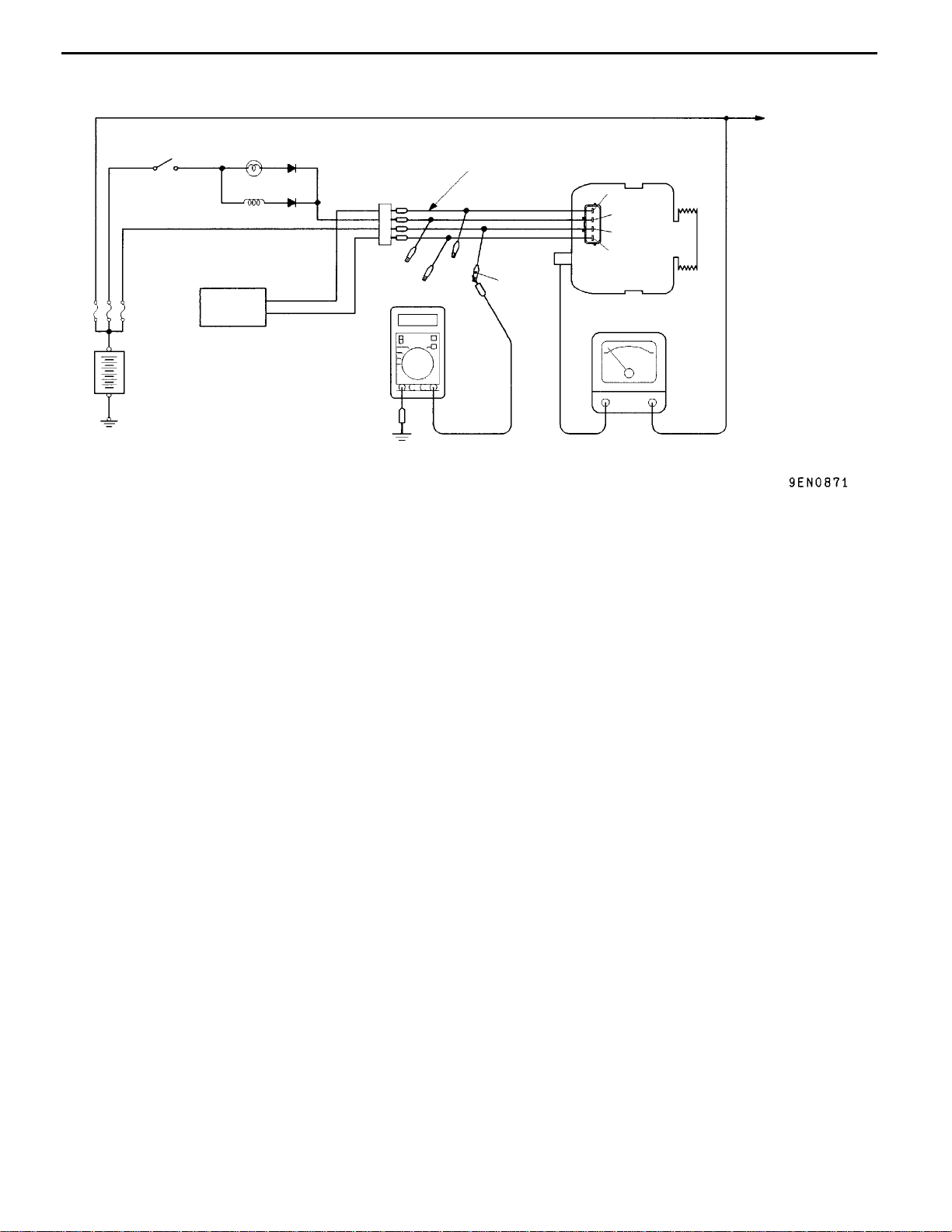

Ignition switch

Battery

Charging warning lamp

Alternator relay

Voltmeter

Ammeter

+-+-

Engine

-ECU

Load

B

FR

L

S

G

Alternator

Page 6

16-6

ENGINE ELECTRICAL -

Charging System

This test determines whether the alternator output

current is normal.

1. Before the test, always be sure to check the

following.

D Alternator installation

D Battery

NOTE

The battery should be slightly discharged.

The load needed by a fully-charged battery

is insufficient for an accurate test.

D Alternator drive belt tension

D Fusible link

D Abnormal noise from the alternator while

the engine is running.

2. Turn the ignition switch off.

3. Disconnect the negative battery cable.

4. Disconnect the alternator output wire from the

alternator “B” terminal. Connect a DC test

ammeter with a range of 0 - 100 A in series

between the “B” terminal and the disconnected

output wire. (Connect the (+) lead of the

ammeter to the “B” terminal. Connect the ( - )

lead of the ammeter to the disconnected output

wire.)

Caution

Never use clips but tighten bolts and nuts

to connect the line. Otherwise loose

connections (e.g. using clips) will lead to

a serious accident because of high current.

NOTE

An inductive-type ammeter which enables

measurements to be taken without

disconnecting the alternator output wire should

be recommended.

5. Connect a voltmeter with a range of 0- 20 V

between the alternator “B” terminal and the

earth. (Connect the (+) lead of the voltmeter

to the “B” terminal, and then connect the (- )

lead of the voltmeter to the earth.)

6. Connect the negative battery cable.

7. Connect a tachometer or the MUT-II.

8. Leave the hood open.

9. Check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “B” terminal and the battery (+)

terminal.

10. Turn the light switch on to turn on headlamps

and then start the engine.

11. Immediately after setting the headlamps to high

beam and turning the heater blower switch to

the high revolution position, increase the engine

speed to 2,500 r/min and read the maximum

current output value displayed on the ammeter.

Limit: 70% of normal current output

NOTE

D For the nominal current output, refer to the

Alternator Specifications.

D Because the current from the battery will

soon drop after the engine is started, the

above step should be carried out as quickly

as possible in order to obtain the maximum

current output value.

D The current output value will depend on

the electrical load and the temperature of

the alternator body.

D If the electrical load is small while testing,

the specified level of current may not be

output even though the alternator is normal.

In such cases, increase the electrical load

by leaving the headlamps turned on for

some time to discharge the battery or by

using the lighting system in another vehicle,

and then test again.

D The specified level of current also may not

be output if the temperature of the alternator

body or the ambient temperature is too

high. In such cases, cool the alternator and

then test again.

12. The reading on the ammeter should be above

the limit value. If the reading is below t he limit

value and the alternator output wire is normal,

remove the alternator from the engine and

check the alternator.

13. Run the engine at idle after the test.

14. Turn the ignition switch off.

15. Remove the tachometer or the MUT-II.

16. Disconnect the negative battery cable.

17. Disconnect the ammeter an d voltmeter.

18. Connect the alternator output wire to the

alternator “B” terminal.

19. Connect the negative battery cable.

Page 7

ENGINE ELECTRICAL -

ENGINE ELECTRICAL -

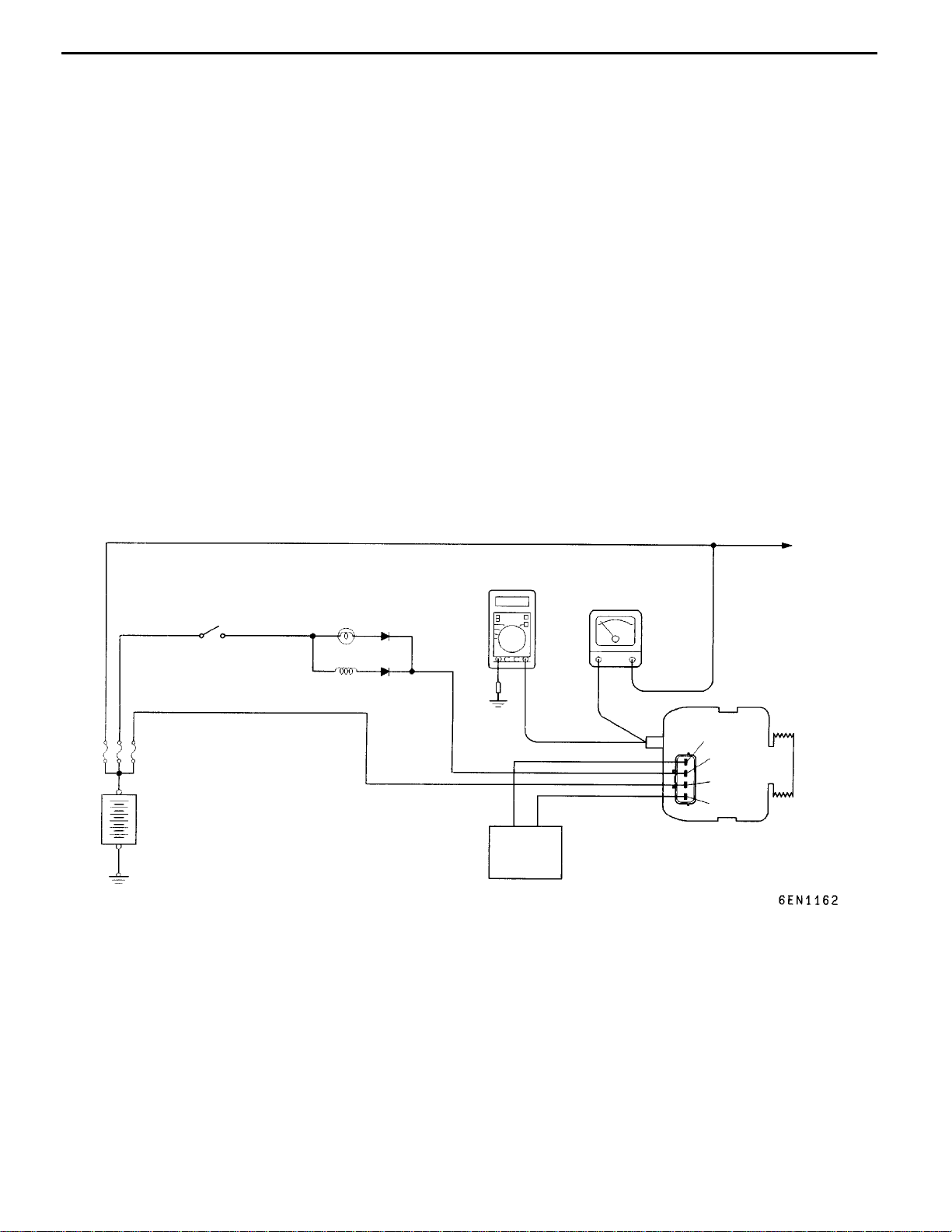

REGULATED VOLTAGE TEST

Ignition

switch

Charging warning

lamp

Alternator relay

EngineECU

MB991519

Charging System

Charging System

Alternator

FR

L

S

B

Yellow

G

Ammeter

16-7

Load

Battery

Voltmeter

-

This test determines whether the voltage regulator

is correctly controlling the alternator output voltage.

1. Always be sure to check the following before

the test.

D

Alternator installation

D

Check that the battery installed in the

vehicle is fully charged.

D

Alternator drive belt tension

D

Fusible link

D

Abnormal noise from the alternator while

the engine is running

2. Turn the ignition switch off.

3. Disconnect the negative battery cable.

4. Use the special tool (Alternator test harness:

MB991519) to connect a digital voltmeter

between the alternator S terminal and earth.

(Connect the (+) lead of the voltmeter to the

”S” terminal, and then connect the (-) lead of

the voltmeter to a secure earth or to the battery

(-) terminal.)

5. Disconnect the alternator output wire from the

alternator “B” terminal.

+

+

-

6. Connect a DC test ammeter with a range of

0 - 100 A in series between the “B” terminal

and the disconnected output wire. (Connect

the (+) lead of the ammeter to the “B” terminal.

Connect the ( - ) lead of the ammeter to the

disconnected output wire.)

7. Reconnect the negative battery cable.

8. Connect a tachometer or the MUT-II.

9. Turn the ignition switch to the ON position a nd

check that the reading on the voltmeter is equal

to the battery voltage.

NOTE

If the voltage is 0 V, the cause is probably

an open circuit in the wire or fusible link between

the alternator “S” terminal and the battery (+)

terminal.

10. Turn all lamps and accessories off.

11. Start the engine.

12. Increase the engine speed to 2,500 r/min.

13. Read the value displayed on the voltmeter when

the alternator output current alternator

becomes 10 A or less.

Page 8

16-8

ENGINE ELECTRICAL -

Charging System

14. If the voltage reading conforms to th e value

in the voltage regulation, then the voltage

regulator is operating normally.

If the voltage is not within the standard value,

there is a malfunction of the voltage regulator

or of the alternator.

15. After the test, lower the engine speed to the

idle speed.

16. Turn the ignition switch off.

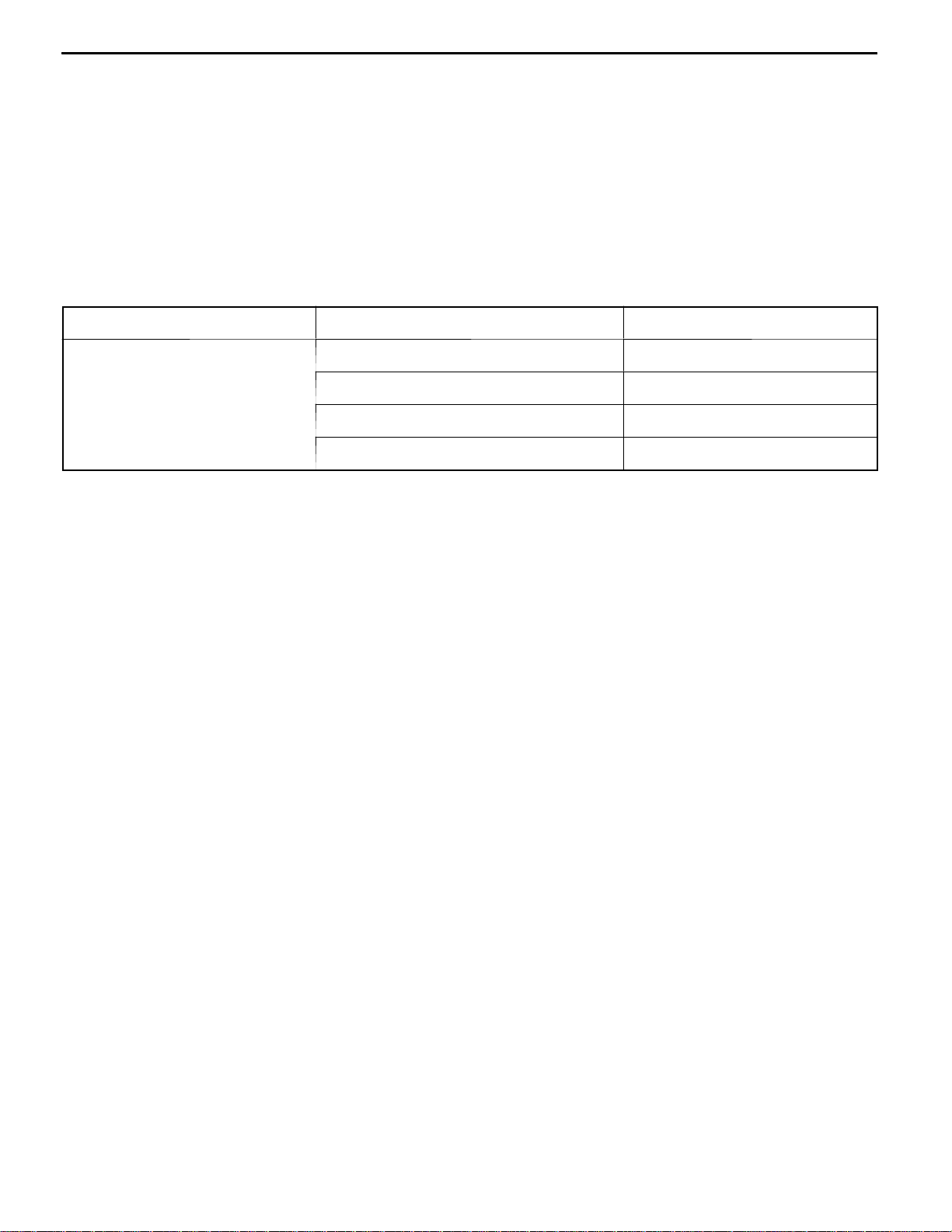

Voltage Regulation Table

Standard value:

Inspection terminal Voltage regulator ambient temperature_C Voltage V

Terminal “S” -20 14.2- 15.4

20 13.9- 14.9

60 13.4- 14.6

80 13.1- 14.5

17. Remove the tachometer or the MUT-II.

18. Disconnect the negative battery cable.

19. Disconnect the ammeter an d voltmeter.

20. Connect the alternator output wire to the

alternator “B” terminal.

21. Remove the special tool, and return the

connector to the original condition.

22. Connect the negative battery cable.

Page 9

ENGINE ELECTRICAL -

Charging System

16-9

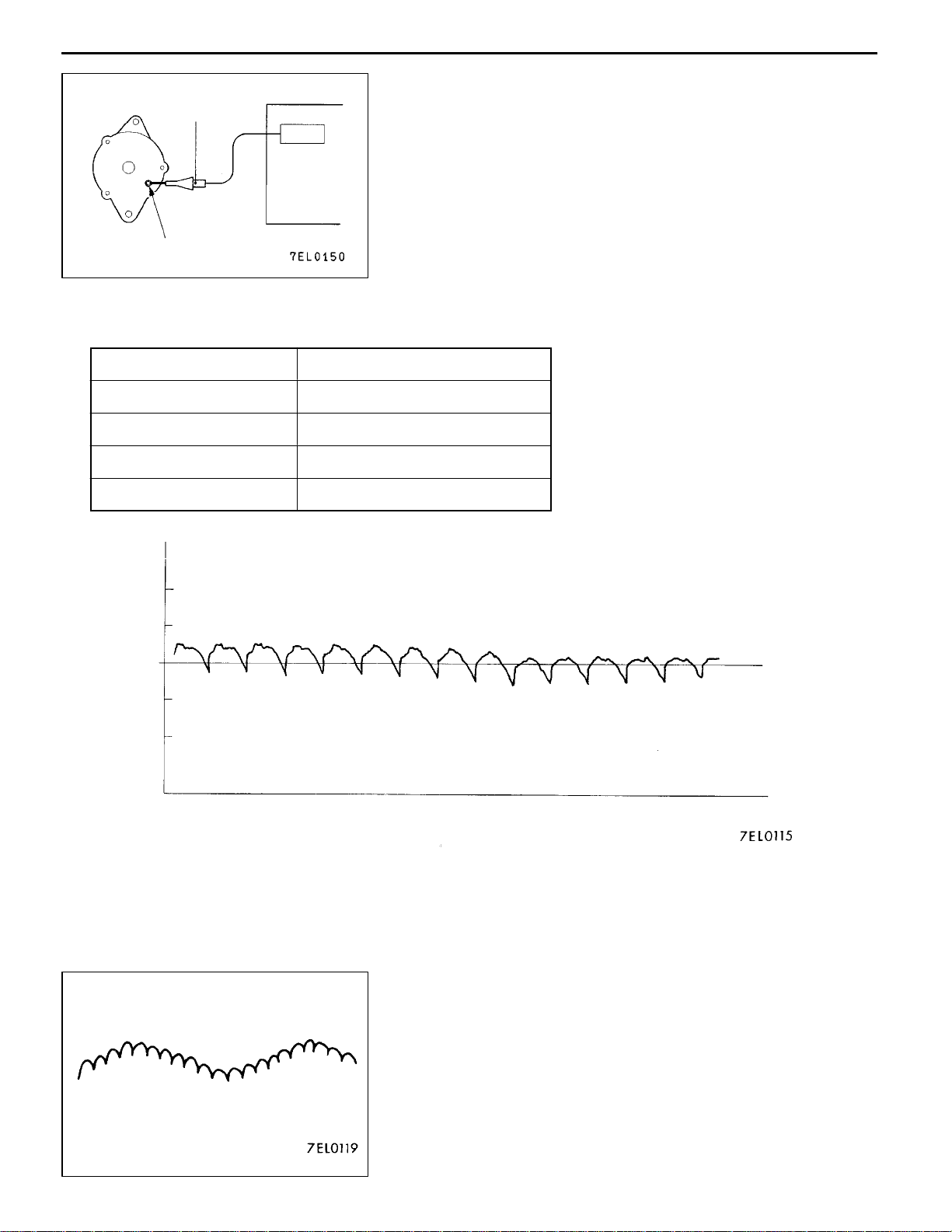

WAVEFORM CHECK USING AN ANALYZER

MEASUREMENT METHOD

Alternator

Special

patterns

pickup

Analyzer

Connect the analyzer special patterns pick-up to th e alternator

B terminal.

B terminal

STANDARD WAVEFORM

Observation Conditions

FUNCTION SPECIAL PATTERNS

PATTERN HEIGHT VARIABLE

VARIABLE knob Adjust while viewing the waveform.

PATTERN SELECTOR RASTER

Engine speed Curb idle speed

Voltage at

alternator

B terminal

0.4

0.2

0

- 0.2

- 0.4

Time

NOTE

The voltage waveform of the alternator B terminal can undulate

as shown at left. This waveform is produced when the regulator

operates according to fluctuations in the alternator load

(current), and is normal for the alternator.

In addition, when the voltage waveform reaches an

excessively high value (approx. 2 V or higher at idle), it often

indicates an open circuit due to a brown fuse between

alternator B terminal and battery, but not a defective alternator.

Page 10

16-10

ENGINE ELECTRICAL -

Charging System

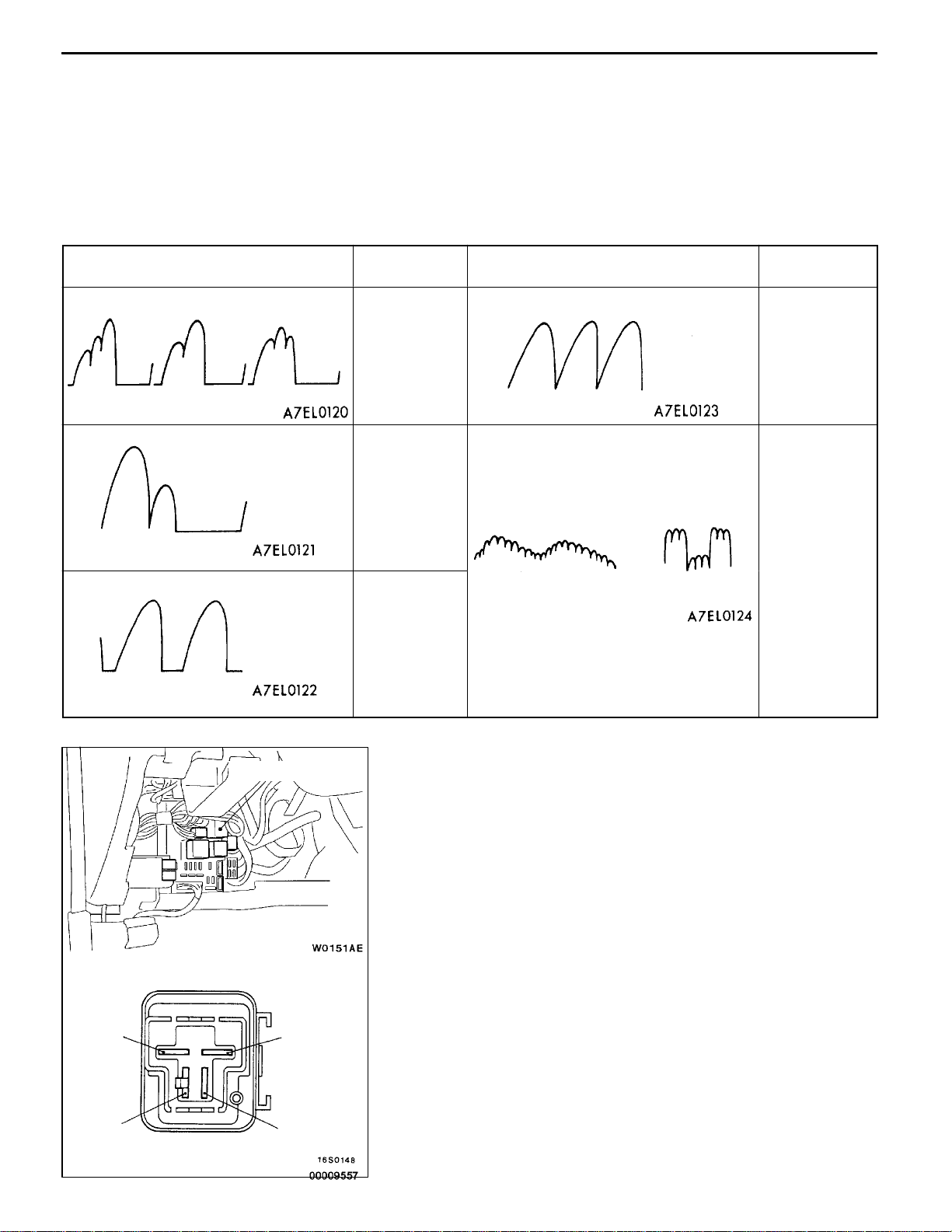

EXAMPLES OF ABNORMAL WAVEFORMS

NOTE

1. The size of the waveform patterns differs largely, depending on the adjustment of the variable knob

on the analyzer.

2. Identification of abnormal waveforms is easier when there is a large output current (regulator is not

operating). (Waveforms can be observed when the headlamps are illuminated.)

3. Check the conditions of the charging warning lamp (illuminated/not illuminated). Also, check the charging

system totally.

Abnormal waveforms Problem

cause

D

D

D

Open

diode

Short in

diode

Broken

wire in

stator coil

Example 1

Example 2

Example 3

Abnormal waveforms Problem

cause

D

D

Short in

stator coil

Open

supplementary

diode

Example 4

Example 5

At this time, the charging warning lamp

is illuminated.

Alternator relay

ALTERNATOR RELAY CONTINUITY CHECK

1. Remove the alternator relay from the relay box inside

the engine compartment.

2. Set the analogue-type circuit tester to the W range and

check that there is continuity when the (+) terminal of

the tester is connected to terminal 2 of the alternator

relay and the ( - ) terminal is connected to terminal 4.

3. Next, check that there is no continuity when the (+) terminal

is connected to terminal 4 and the ( - ) terminal is connected

to terminal 2.

4. If defect is found in steps 2 and 3 above, replace the

alternator relay.

1

3

2

4

Page 11

ENGINE ELECTRICAL -

Charging System

16-11

ALTERNATOR

REMOVAL AND INSTALLATION

Pre-removal Operation

Under Cover and Side Cover (R.H. side) Removal

<4G6>

20 - 25 Nm

1

2

24 Nm

16100140286

Post-installation Operation

D Drive Belt Tension Adjustment

(Refer to GROUP 11 - On-vehicle Service.)

D Under Cover and Side Cover (R.H. side) Installation

5

3

4

<4G9>

49 Nm

20 - 25 Nm

1

5

3

2

49 Nm

4

44 Nm

Removal steps

1. Drive belt (Power steering, A/C)

2. Drive belt (Alternator)

3. Alternator connector

4. Alternator

5. Alternator brace

Page 12

16-12

ENGINE ELECTRICAL -

DISASSEMBLY AND REASSEMBLY

1

Charging System

3

4

5

7

6

2

12

10

9

8

Disassembly steps

AA" 1. Front bracket assembly

AB" 2. Alternator pulley

AB" 3. Rotor

4. Rear bearing

5. Bearing retainer

6. Front bearing

7. Front bracket

14

13

11

AC" 8. Startor

9. Plate

AC""AA 10. Regulator assembly

11. Brush

12. Slinger

13. Rectifier

14. Rear bracket

Page 13

ENGINE ELECTRICAL -

DISASSEMBLY SERVICE POINTS

AA"

Insert flat tip screwdrivers or the like in the clearance between

the front bracket assembly and stator core, to pry open and

separate the stator and front bracket.

Caution

Do not insert the screwdriver too far, or the stator coil

gets damaged.

FRONT BRACKET ASSEMBLY REMOVAL

Charging System

16-13

Soldered

AB"

Face the pulley side upward, fix the rotor with a work bench

and remove the pulley.

Caution

Use care not to damage the rotor.

AC"

1. Unsolder the stator with a soldering iron (180 to 250W).

2. When removing the rectifier from the regulator assembly,

ALTERNATOR PULLEY REMOVAL

STATOR/REGULATOR ASSEMBLY REMOVAL

Complete this work within four seconds not to transfer

heat to the diode.

remove the soldered sections of the rectifier.

Caution

(1) Use careto makesure thatthe heatof thesoldering

iron is not transmitted to the diodes for a long

period.

(2) Use care that no undue force is exerted to the

lead wires of the diodes.

Page 14

16-14

ENGINE ELECTRICAL -

Wire

Rear bracket

Brush

Wire

Charging System

REASSEMBLY SERVICE POINTS

"AA

After installing the regulator assembly, insert a wire into the

hole provided on the rear bracket while pressing in the brush

to fix the brush.

NOTE

The brush is fixed when a wire is inserted, making rotor

installation easier.

REGULATOR ASSEMBLY INSTALLATION

Wire

"BA

ROTOR INSTALLATION

After installing the rotor, remove the wire used to fix the brush.

INSPECTION

16100170216

ROTOR CHECK

1. Check the continuity between the rotor coil slip rings,

and replace the rotor if the resistance value is not at

the standard value.

Standard value: 3 - 5

W

2. Check the continuity between the slip ring an d core, and

if there is continuity, replace the rotor.

Page 15

ENGINE ELECTRICAL -

STATOR CHECK

1. Check the continuity between the coil leads, and if there

is continuity, replace the stator.

2. Check the continuity between the coil and core, and if

there is continuity, replace the stator.

Charging System

16-15

RECTIFIER CHECK

1. Inspect the (+) heat sink by checking the continuity

between the (+) heat sink and stator coil lead wire

connection terminal using a tester probe.

If there is a continuity at both, the diode is short circuited,

so replace the rectifier.

2. Inspect the ( - ) heat sink by checking the continuity

between the ( - ) heat sink and stator coil lead wire

connection terminal using a tester probe.

If there is a continuity at both, the diode is short circuited,

so replace the rectifier.

3. Check the diode trio by connecting an ohmmeter to both

ends of each diode and check the continuity of the three

diodes.

If there is a continuity at both ends, or if there is no

continuity, the diode is damaged so replace the rectifier.

Page 16

16-16

Protrusion

length

ENGINE ELECTRICAL -

BRUSH CHECK

1. Measure the length of the brush protrusion shown in the

illustration, and replace the brush if th e measured value

is below the limit value.

Limit: 2 mm or less

Charging System

Soldered

2. The brush can be removed if the solder of the brush

lead wire is removed.

3. When installing a new brush, insert the brush into the

holder as shown in the illustration, and then solder the

lead wires.

Page 17

ENGINE ELECTRICAL -

STARTING SYSTEM

GENERAL INFORMATION

Starting System

16-17

If the ignition switch is turned to the ”START”

position, current flows in the pull-in and holding

coils provided inside magnetic switch, attracting

the plunger. When the plunger is attracted, the

lever connected to the plunger is actuated to

engage the starter clutch.

On the other hand, attracting the plunger will turn

on the magnetic switch, allowing the B terminal

SYSTEM DIAGRAM

Ignition

switch

Battery

Brush

and M terminal to conduct. Thus, current flows to

engage the starter motor.

When the ignition switch is returned to t he “ON”

position after starting the engine, the starter clutch

is disengaged from the ring gear.

An overrunning clutch is provided between the

pinion and the armature shaft, to prevent damage

to the starter.

Holding coil

Pull-in coil

Armature

Yoke

Plunger

Lever

Over-running

clutch

Pinion shaft

STARTER MOTOR SPECIFICATIONS

Items 4G9 4G6

Type Reduction drive with planetary gear Reduction drive with planetary gear

Rated output kW/V 1.2/12 1.4/12

No. of pinion teeth 8 8

SERVICE SPECIFICATIONS

Items Standard value Limit

Pinion gap mm 0.5 - 2.0 -

Commutator outer diameter mm 29.4 28.8

Commutator runout mm 0.05 0.1

Commutator undercut mm 0.5 0.2

Page 18

16-18

ENGINE ELECTRICAL -

Starting System

<4G9>

<4G6>

B

Battery

S

Switch

M

Wire

Switch

Wire

M

Battery

S

STARTER MOTOR

INSPECTION

PINION GAP ADJUSTMENT

1. Disconnect field coil wire from M-terminal of magnetic

switch.

2. Connect a 12V battery between S-terminal and

M-terminal.

3. Set switch to “ON”, and pinion will move out.

Caution

This test must be performed quickly (in less than

10 seconds) to prevent coil from burning.

B

4. Check pinion to stopper clearance (pinion gap) with a

thickness gauge.

Pinion

Pinion gap: 0.5 - 2.0 mm

Stopper

Pinion gap

5. If pinion gap is out of specification, adjust by adding or

removing gaskets between magnetic switch and front

bracket.

Page 19

ENGINE ELECTRICAL -

Starting System

16-19

<4G9>

<4G6>

<4G9>

<4G6>

Battery

MAGNETIC SWITCH PULL-IN TEST

S

M

Battery

1. Disconnect field coil wire from M-terminal of magnetic

switch.

2. Connect a 12V battery between S-terminal and

M-terminal.

Caution

Wire

This test must be performed quickly (in less than

10 seconds) to prevent coil from burning.

3. If pinion moves out, then pull-in coil is good. If it doesn’t,

replace magnetic switch.

S

M

Wire

MAGNETIC SWITCH HOLD-IN TEST

S

1. Disconnect field coil wire from M-terminal of magnetic

switch.

Battery

2. Connect a 12V battery between S-terminal and body.

Caution

This test must be performed quickly (in less than

Wire

10 seconds) to prevent coil from burning.

3. Manually pull ou t the pinion as far as the pinion stopper

position.

4. If pinion remains out, everything is in order. If pinion moves

in, hold-in circuit is open. Replace magnetic switch.

Battery

S

Wire

Page 20

16-20

ENGINE ELECTRICAL -

Starting System

<4G9>

B

Starter

motor

<4G6>

M

Starter

motor

<4G9>

S

Carbon-pile rheostat

M

Ammeter

A

FREE RUNNING TEST

1. Place starter motor in a vise equipped with soft jaws

and connect a fully-charged 12-volt battery to starter motor

as follows:

2. Connect a test ammeter (100-ampere scale) and carbon

pile rheostat in series with battery positive post and starter

motor terminal.

3. Connect a voltmeter (15-volt scale) across starter motor.

V

Voltmeter

Battery

4. Rotate carbon pile to full-resistance position.

Carbon-pile rheostat

S

5. Connect battery cable from battery negative post to starter

motor body.

6. Adjust the rheostat until the battery voltage shown by

B

Ammeter

the voltmeter is 11 V.

7. Confirm that the maximum amperage is within the

Battery

Voltmeter

specifications and that the starter motor turns smoothly

and freely.

Current: max. 90 Amps

MAGNETIC SWITCH RETURN TEST

1. Disconnect field coil wire from M-terminal of magnetic

switch.

M

Battery

2. Connect a 12V battery between M-terminal and body.

Caution

This test must be performed quickly (in less than

Wire

10 seconds) to prevent coil from burning.

3. Pull pinion out and release. If pinion quickly returns to

its original position, everything is in order. If it doesn’t,

replace magnetic switch.

<4G6>

Battery

Caution

Be careful not to get your fingers caught when pulling

out the pinion.

M

Wire

Page 21

ENGINE ELECTRICAL -

DISASSEMBLY AND REASSEMBLY

13

14

16

Starting System

2

16-21

12

11

15

1

21

4

20

18

19

3

17

22

8

7

5

6

9

10

Disassembly steps

1. Screw

AA" 2. Magnetic switch

3. Screw

4. Through bolt

5. Rear bracket

6. Brush holder

7. Brush

8. Rear bearing

AB" 9. Armature

10. Yoke assembly

AB" 11. Ball

12. Packing A

13. Packing B

14. Plate

15. Planetary gear

16. Lever

AC""AA 17. Snap ring

AC""AA 18. Stop ring

19. Overrunning clutch

20. Internal gear

21. Planetary gear holder

22. Front bracket

Page 22

16-22

ENGINE ELECTRICAL -

Starting System

Magnetic

switch

Stop ring

S terminal

M terminal

Field coil

wire

Socket

Pinion gear

DISASSEMBLY SERVICE POINTS

AA"

AB"

AC"

1. Using an appropriate wrench socket, push the stop ring

MAGNETIC SWITCH REMOVAL

Disconnect the field coil wire from terminal M of the

magnetic switch.

ARMATURE AND BALL REMOVAL

When removing the armature, do not lose the ball placed

at the end as a bearing.

SNAP RING/STOP RING REMOVAL

toward the overrunning clutch.

Snap ring

Pinion gear

Overrunning

clutch

Overrunning

clutch

Snap ring pliers

2. Remove the snap ring with snap ring pliers and then

remove the stop ring and overrunning clutch.

STARTER MOTOR PARTS CLEANING

1. Do not immerse the parts in cleaning solvent. Immersing

the yoke and field coil assembly and/or armature will

damage insulation. Wipe these parts with a cloth only.

2. Do not immerse the drive unit in cleaning solvent. The

overrunning clutch is pre-lubricated at the factory and

solvent will wash lubrication from clutch.

3. The drive unit may be cleaned with a brush moistened

with cleaning solvent and wiped dry with a cloth.

Page 23

Stop ring

Overrunning

clutch

Snap ring

ENGINE ELECTRICAL -

REASSEMBLY SERVICE POINTS

"AA

Using an appropriate tool, pull the stop ring over the snap

ring.

Stop ring

STOP RING/SNAP RING INSTALLATION

INSPECTION

COMMUTATOR

1. Place the armature in a pair of “V” blocks and check

the runout with a dial indicator.

Standard value: 0.05 mm

Limit: 0.1 mm

Starting System

16-23

Segment

Undercut

Mica

Free

2. Measure the commutator outer diameter.

Standard value: 29.4 mm

Limit: 28.8 mm

3. Check the undercut depth between segments.

Standard value: 0.5 mm

Limit: 0.2 mm

OVERRUNNING CLUTCH

1. Check that the pinion locks when it is turned

counterclockwise and moves smoothly when it is turned

clockwise.

2. Check the pinion for wear or damage.

Lock

Page 24

16-24

ENGINE ELECTRICAL -

BRUSH

1. Check the brush for roughness of the surface that contacts

the commutator and check the brush length.

Limit: Wear limit line

2. In case the contacting surface has been corrected or

Wear limit line

the brush has been replaced, correct the contacting

surface by winding sandpaper around the commutator.

Starting System

Growler

ARMATURE COIL SHORT-CIRCUIT TEST

1. Place armature in a growler.

2. Hold a thin steel blade parallel and just above while rotating

armature slowly in growler. A shorted armature will cause

blade to vibrate and be attracted to the core. Replace

shorted armature.

Caution

Clean the armature surface thoroughly before

checking.

3. Check the insulation between each commutator segment

and armature coil core.

If there is no continuity, the insulation is in order.

ARMATURE COIL OPEN-CIRCUIT INSPECTION

Check the continuity between segments. If there is continuity,

the coil is in order.

Page 25

ENGINE ELECTRICAL -

IGNITION SYSTEM

GENERAL INFORMATION

Ignition System

16-25

This system is equipped with four ignition coils with

built-in power transistors for each of the cylinders.

Interruption of the primary current flowing in the

primary side of an ignition coil generates a high

voltage in the secondary side of the ignition coil.

The high voltage thus generated is applied to the

spark plugs to generate sparks.

The engine-ECU turns the power transistors inside

the ignition coils alternately on and off. This causes

the primary currents in the ignition coils to be

alternately interrupted and allowed to flow to fire

the cylinders in the order 1 - 3 - 4 - 2.

SYSTEM DIAGRAM

Air flow sensor

Barometric pressure sensor

Intake air temperature sensor

Engine coolant temperature

sensor

Accelerator pedal position

switch <4G6>

Camshaft position sensor

Crank angle sensor

Ignition switch-ST

Detonation sensor

Vehicle speed sensor

Inhibitor switch <A/T>

EngineECU

The engine-ECU determines which ignition coil

should be controlled by means of the signals from

the camshaft position sensor and the crank angle

sensor. It also detects th e crankshaft position, in

order to provide ignition at the most appropriate

timing in response to the engine operation

conditions.

When the engine is cold or running at high altitudes,

the ignition timing is slightly advanced to provide

optimum performance. Furthermore, if knocking

occurs, th e ignition timing is gradually retarded until

knocking ceases.

Ignition switch

Ignition coil

Battery

Spark plug

To tachometer

Cylinder No.

1

IGNITION COIL SPECIFICATION

Items Specification

Type Molded 4-coil

SPARK PLUG SPECIFICATION

Items 4G6 4G9

NGK IZFR5B IZFR6B

2

43

Page 26

16-26

ENGINE ELECTRICAL -

Ignition System

SERVICE SPECIFICATIONS

SPARK PLUG

Items Standard value Limit

Spark plug gap mm 0.5 - 0.6 0.75

Spark plug insulation resistance MW - 1

ON-VEHICLE SERVICE

1.5 V

+

-

+

-

IGNITION COIL (WITH BUILT-IN POWER

TRANSISTOR) CHECK

PRIMARY COIL AND POWER TRANSISTOR

CONTINUITY CHECK

NOTE

1. An analogue-type circuit tester should be used.

2. Connect the negative ( - ) prove of the circuit tester to

terminal 1.

Caution

This test must be performed quickly (in less than 10

seconds) to prevent coil from burning and power

transistor from breakage.

Voltage: 1.5V

When current is

flowing

When current is

not flowing

SECONDARY COIL CHECK

NOTE

It is impossible to check the secondary coil through the

continuity check as a diode is integrated in the secondary

coil circuit of this ignition coil. So, check the secondary coil

in the following procedure.

1. Disconnect the ignition coil connector.

2. Remove the ignition coil and install a new spark plug

to the ignition coil.

3. Connect the ignition coil connector.

4. Earth the side electrode of the spark plug and crank

the engine.

Terminal No.

1 2 3

Page 27

ENGINE ELECTRICAL -

5. Check that spark is produced between the electrodes of

the spark plug.

6. If no spark is produced, replace the ignition coil with a

new one and recheck.

7. If spark is produced with the new ignition coil, replace

the old one as it is faulty. If no spark is produced again,

the ignition circuit is suspected as faulty. Check theignition

circuit.

SPARK PLUG CHECK AND CLEANING

Caution

1. The spark plug gap for iridium plugs should not be

adjusted.

2. Cleaning iridium plugs may result in damage to the

iridium tip. Therefore, if cleaning is necessary

because the plug is sooty, use a plug cleaner, and

do not clean the plug for more than 20 seconds in

order to preserve the electrodes. A wire brush should

never be used.

3. The spark plugs in GDI engines are special iridium

plugs in which the electrodes can become black even

when the plugs are working normally. Carbon which

may become deposited on these plugs burns off more

readily than with conventional plugs, and so should

not cause any problems with spark plug performance.

Judgement of whether a spark plug is operating

normally or not should be made by checking the

insulation resistance.

Ignition System

16-27

1. Remove the ignition coils.

2. Remove the spark plugs.

3. Check the spark plug gap. Replace the spark plug if the

gap exceeds the limit.

Limit: 0.75 mm

Standard value: 0.5 - 0.6 mm

4. Measure the spark plug insulation resistance. Replace

the spark plug if the measured value is lower than the

limit value.

Limit: 1 M

5. Clean the spark plug holes.

6. Install the spark plugs.

7. Install the ignition coils.

W

Page 28

16-28

ENGINE ELECTRICAL -

CAMSHAFT POSITION SENSOR CHECK

Refer to GROUP 13A - Troubleshooting <4G6> or GROUP

13B - Troubleshooting <4G9>.

CRANK ANGLE SENSOR CHECK

Refer to GROUP 13A - Troubleshooting <4G6> or GROUP

13B - Troubleshooting <4G9>.

DETONATION SENSOR CHECK

Check the detonation sensor circuit if self-diagnosis code,

No. 31 is shown.

NOTE

For information concerning the self-diagnosis codes, refer

to GROUP 13A - Troubleshooting <4G6> or GROUP 13B

- Troubleshooting <4G9>.

Ignition System

Page 29

ENGINE ELECTRICAL -

Ignition System

16-29

IGNITION COIL

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Engine Cover Removal and Installation

10 Nm

3

25 Nm

16300320174

2

1

Removal steps

1. Ignition coil connector

2. Ignition coil

3. Spark plug

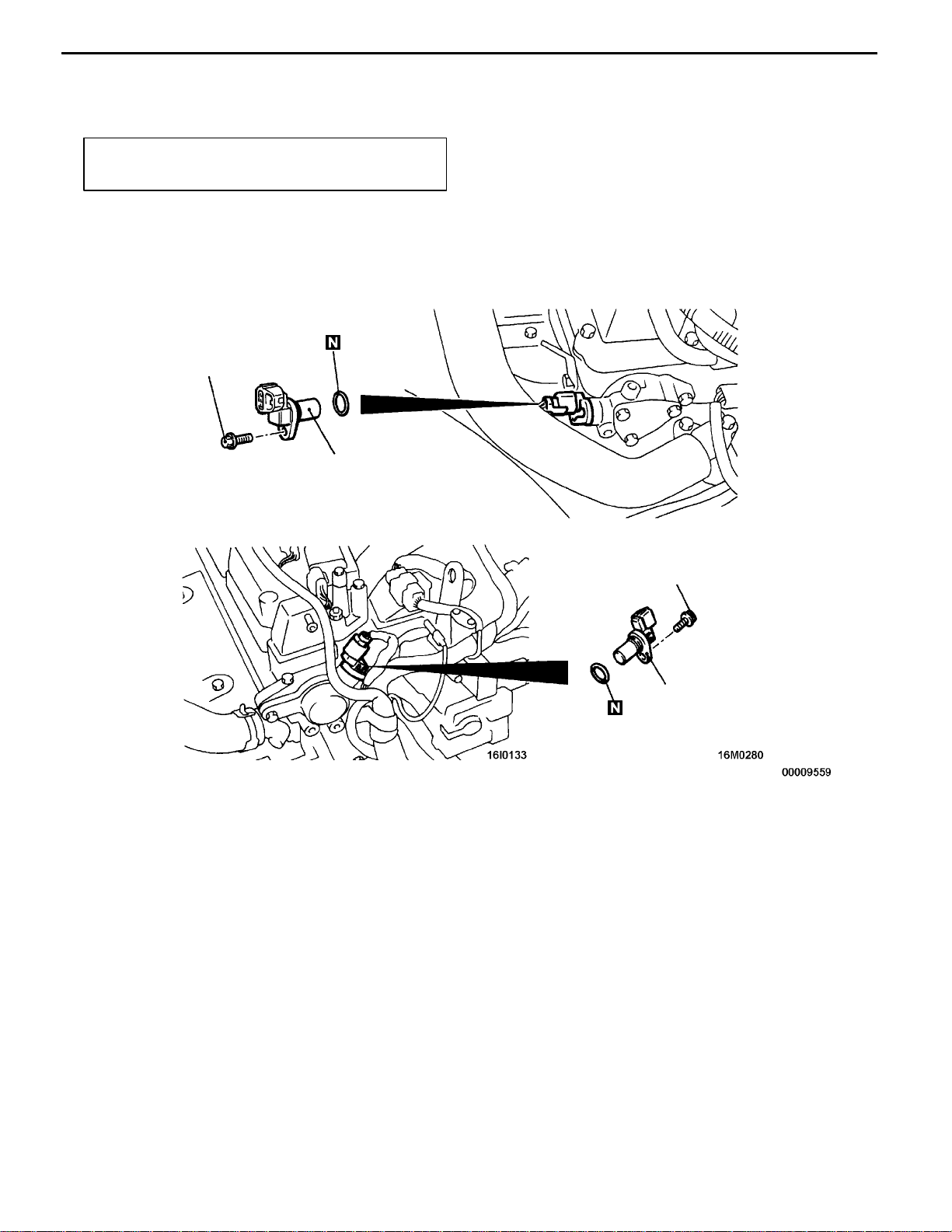

CRANK ANGLE SENSOR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

D Timing Belt Removal and Installation <4G6>

(Refer to GROUP 11A.)

<4G6> <4G9>

10 - 12 Nm

Crank angle sensor

16300350036

D Timing Belt Front Lower Cover Removal and

Installation <4G9> (Refer to GROUP 11B.)

10 - 12 Nm

Crank angle sensor

9Nm

9Nm

Page 30

16-30

ENGINE ELECTRICAL -

Ignition System

CAMSHAFT POSITION SENSOR

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Engine Cover Removal and Installation

<4G6>

9Nm

Camshaft position sensor

<4G9>

16300340026

9Nm

Camshaft position sensor

Page 31

ENGINE ELECTRICAL -

Ignition System

16-31

DETONATION SENSOR

REMOVAL AND INSTALLATION

Caution

Do not subject the detonation sensor to any shocks.

Pre-removal and Post-installation Operation

D Engine Cover Removal and Installation

D Air Cleaner Assembly Removal and Installation

<4G6>

D Intake Manifold Stay Removal and Installation

16300280144

(Refer to GROUP 15.)

1

20 - 25 Nm

<4G9>

AA""AA

1. Detonation sensor

10 - 12 Nm

REMOVAL SERVICE POINT

AA"

DETONATION SENSOR REMOVAL

1

20 - 25 Nm

MD998773

INSTALLATION SERVICE POINT

"AA

DETONATION SENSOR INSTALLATION

Page 32

NOTES

Loading...

Loading...