Page 1

ENGINE AND

EMISSION

CONTROL

CONTENTS

17-1

ENGINE CONTROL SYSTEM 2........

GENERAL INFORMATION 2................

SERVICE SPECIFICATIONS 2..............

ON-VEHICLE SERVICE 2..................

Accelerator Cable Check and Adjustment 2....

Accelerator Pedal Position Sensor Check 3....

ACCELERATOR CABLE AND PEDAL 4....

ACCELERATOR PEDAL POSITION

SENSOR <4G6> 5.........................

EMISSION CONTROL SYSTEM 6......

GENERAL INFORMATION 6................

Emission Control Device Reference

Table 6.....................................

SERVICE SPECIFICATION 7...............

SPECIAL TOOL 7.........................

VACUUM HOSE 7.........................

Vacuum Hose Piping Diagram 7..............

V acuum Circuit Diagram 9...................

V acuum Hose Check 9......................

V acuum Hose Installation 9..................

CRANKCASE EMISSION CONTROL

SYSTEM 10..............................

General Information 10......................

System Diagram 10.........................

Component Location 10......................

Positive Crankcase Ventilation System

Check 11...................................

PCV Valve Check 11........................

EVAPORATIVE EMISSION CONTROL

SYSTEM 12..............................

General Information 12......................

System Diagram 12.........................

Component Location 12......................

Purge Control System Check 13..............

Purge Port Vacuum Check 13................

Purge Control Solenoid Valve Check 14.......

EXHAUST GAS RECIRCULATION (EGR)

SYSTEM 15..............................

General Information 15......................

Operation 15................................

System Diagram 15.........................

Component Location 15......................

Exhaust Gas Recirculation (EGR) Control

System Check 16...........................

EGR Valve (Stepper Motor)

Check 16...................................

CATALYTIC CONVERTER 17..............

Page 2

17-2

ENGINE AND EMISSION CONTROL -

Engine Control System

ENGINE CONTROL SYSTEM 17100010102

GENERAL INFORMATION

A cable-type accelerator mechanism and a

suspended-type pedal have been adopted.

Accelerator pedal position sensor is used for

vehicles with 4G6 engine which is equipped with

the electronically-controlled fuel injection system.

SERVICE SPECIFICATION

Items Standard value

Accelerator cable play mm 1-2

ON-VEHICLE SERVICE

ACCELERATOR CABLE CHECK AND

ADJUSTMENT

1. Turn A/C and lamps OFF.

Inspect and adjust at no load.

2. Warm engine until stabilized at idle.

3. Confirm idle speed is at prescribed value. (Refer to

GROUP 11 - On-vehicle Service.)

4. Stop engine (ignition switch OFF).

5. Confirm there are no sharp bends in accelerator cable.

6. Check inner cable for correct slack.

Standard value: 1 - 2 mm

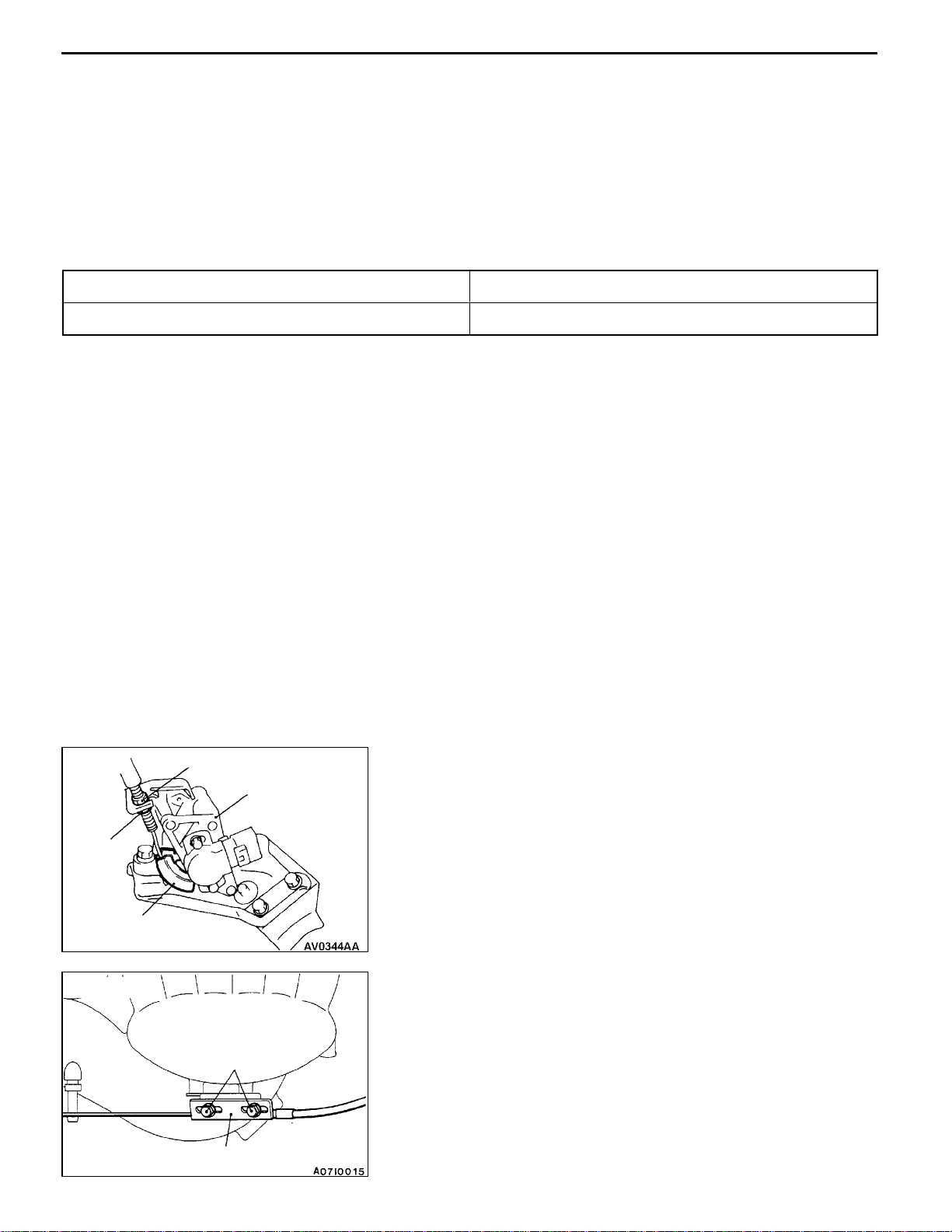

17100030139

17100090243

<4G6>

Lock nut

<4G9>

Lever

Adjusting nut

Accelerator pedal

position sensor

Adjusting bolt or

adjusting nut

Plate

7. If there is too much slack or no slack, adjust play by the

following procedures.

<4G6>

(1) Loosen the adjusting nut, and then move the lever

to throttle fully-closed position.

(2) Tighten the adjusting nut until the lever start to move,

turn back one turn, and then tighten the lock nut

to the specified torque.

<4G9>

(1) Loosen the adjusting bolt or adjusting nut to release

the cable.

(2) Move the plate until the inner cable play is at the

standard value, and then tighten the adjusting bolt

or adjusting nut.

(3) After adjusting, check that the throttle lever is touching

the stopper.

Page 3

ENGINE AND EMISSION CONTROL -

ACCELERATOR PEDAL POSITION SENSOR

CHECK

Refer to GROUP 13A - On-vehicle Service.

Engine Control System

17-3

17100190011

Page 4

17-4

ENGINE AND EMISSION CONTROL -

Engine Control System

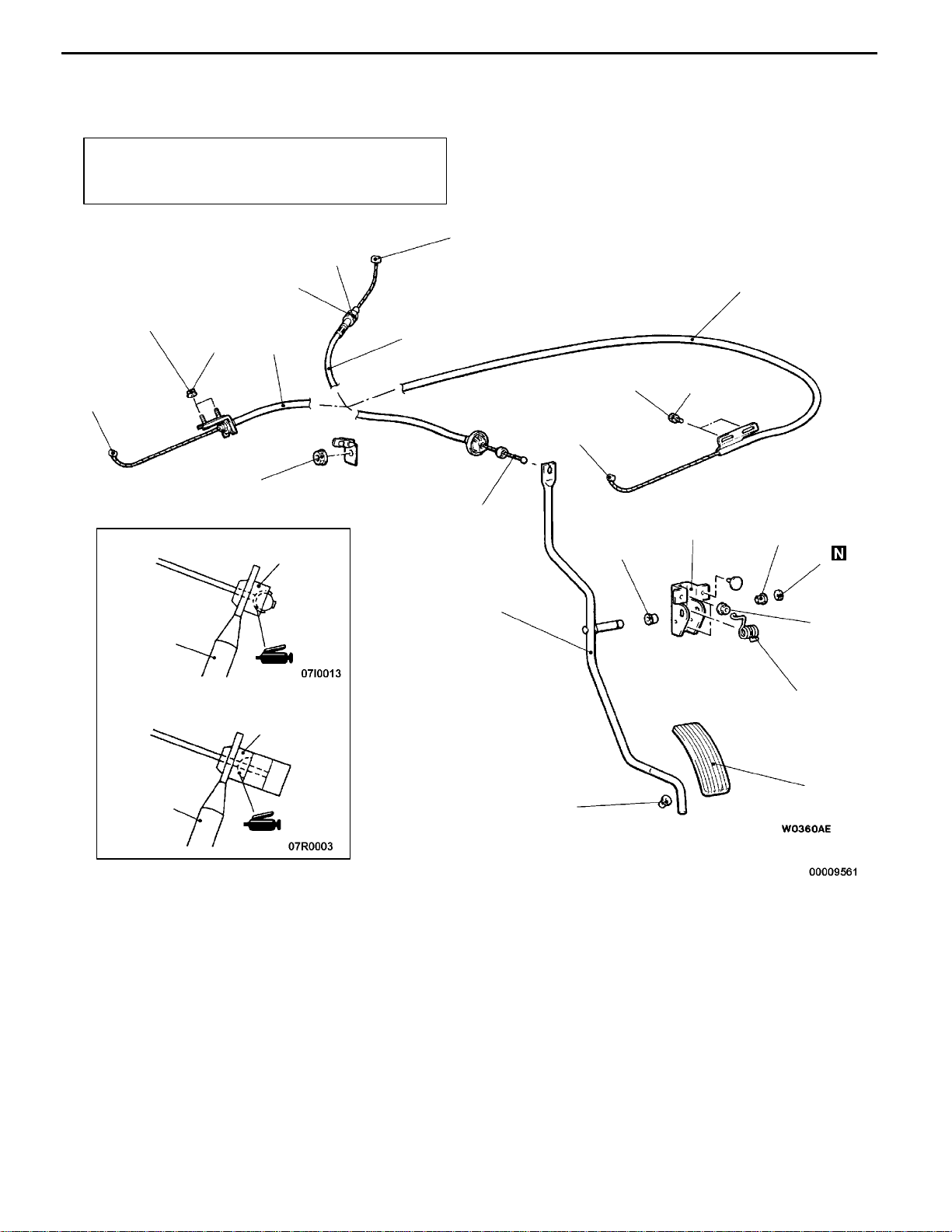

ACCELERATOR CABLE AND PEDAL

REMOVAL AND INSTALLATION

Post-installation Operation

Adjusting the Accelerator Cable (Refer to

P.17-2

plink=17100090052.)

<4G9 - R.H. drive vehicles>

10 Nm

5Nm

1

4

2

12 Nm

<4G6>

3

<4G6>

1

4

2

3

<4G9 - L.H. drive vehicles>

5Nm

1

2

9

10

17100120256

4

10

5

<4G9>

6

3

6

Removal steps

1. Adjusting bolt or adjusting nut

2. Inner cable connection (Engine

side)

3. Inner cable connection (Pedal side)

4. Accelerator cable

5. Snap ring

6

12 Nm

7

8

11

6. Accelerator arm assembly

7. Spring

8. Pedal pad

9. Accelerator pedal bracket

10. Bushing

11. Accelerator pedal stopper

sub=

Page 5

ENGINE AND EMISSION CONTROL -

Engine Control System

17-5

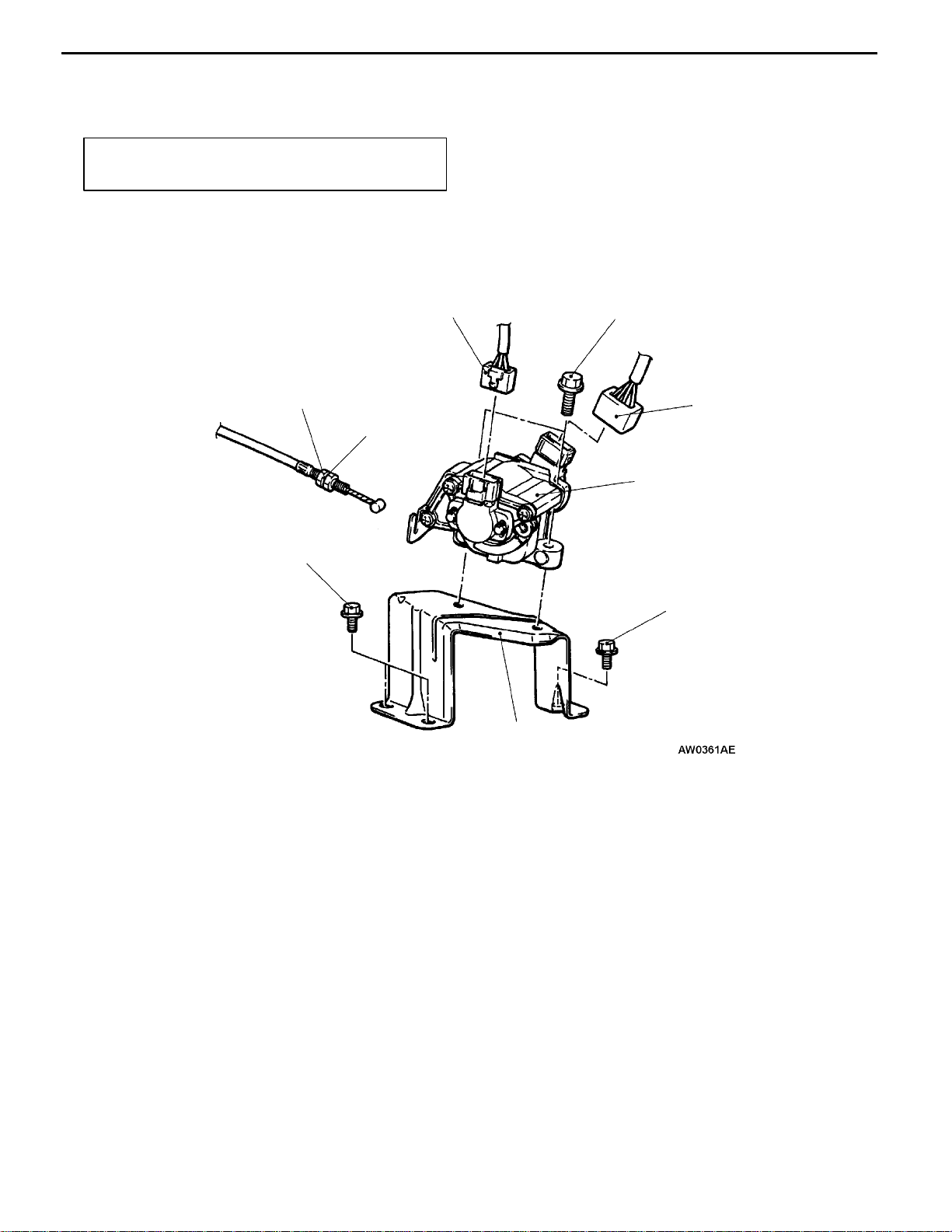

ACCELERATOR PEDAL POSITION SENSOR <4G6>

REMOVAL AND INSTALLATION

Post-installation Operation

Adjusting the Accelerator Cable (Refer to P.17-2.)

2

1

10 Nm

10 - 13 Nm

3

17100180018

2

10 - 13 Nm

Removal steps

1. Inner cable connection

2. Accelerator pedal position sensor

connector

3. Accelerator pedal position sensor

assembly

10 - 13 Nm

4

4. Accelerator pedal position sensor

bracket

Page 6

17-6

ENGINE AND EMISSION CONTROL -

Emission Control System

EMISSION CONTROL SYSTEM

GENERAL INFORMATION

The emission control system consists of the following subsystems:

D Crankcase emission control system

D Evaporative emission control system

D Exhaust emission control system

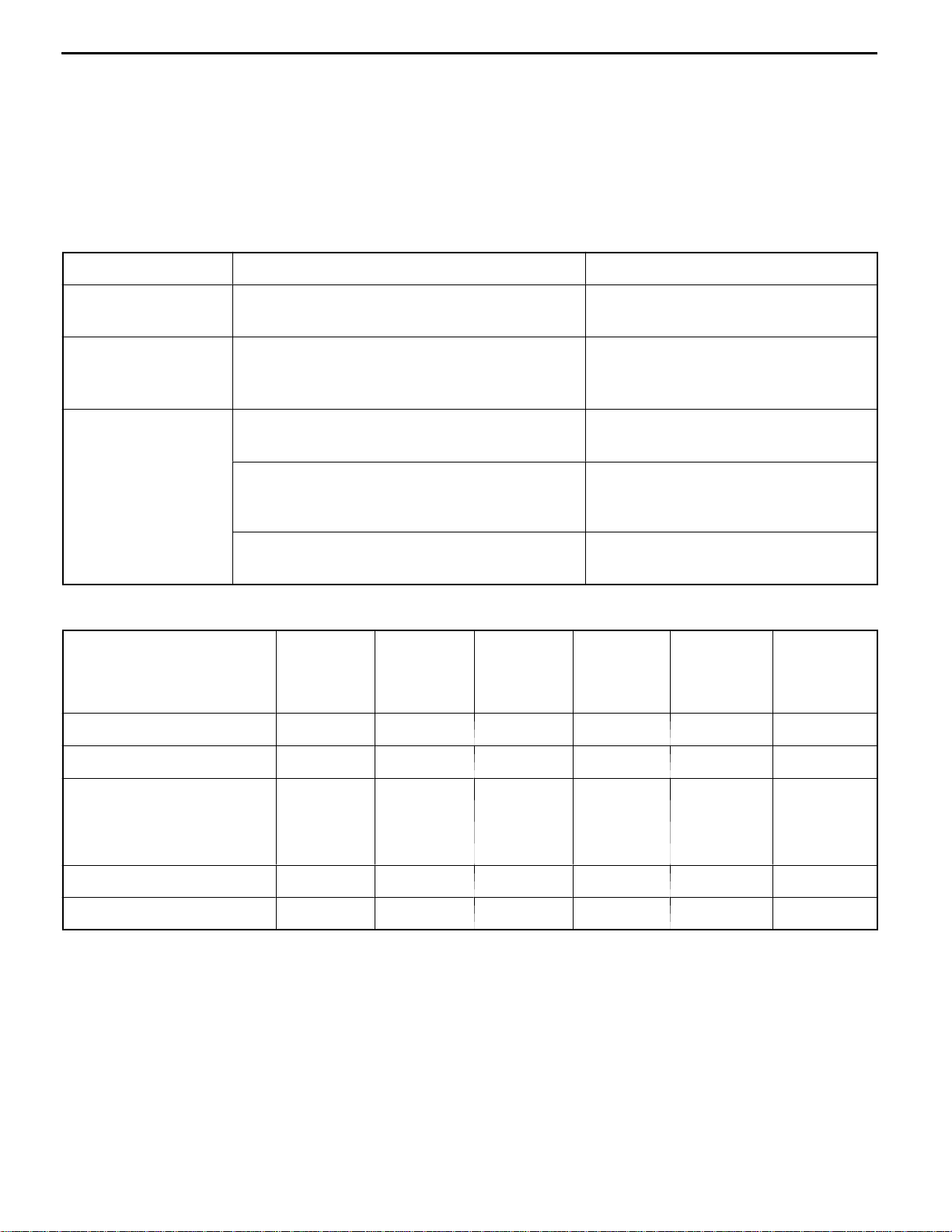

Items Name Specification

Crankcase emission

control system

Evaporative emission

control system

Exhaust emission

control system

Positive crankcase ventilation (PCV) valve Variable flow type

Canister

Purge control solenoid valve

Air-fuel ratio control device- GDI system Oxygen sensor feedback type

Exhaust gas recirculation system

D

EGR valve

Catalytic converter Monolith type

EMISSION CONTROL DEVICE REFERENCE TABLE

Related parts Crankcase

emission

control

system

PCV valve

´

Evaporative

emission

control

system

Air/fuel

ratio

control

system

(Purpose: HC reduction)

Equipped

Duty cycle type solenoid valve

(Purpose: HC reduction)

(Purpose: CO, HC, NOx reduction)

Equipped

Stepper motor type

(Purpose: NOx reduction)

(Purpose: CO, HC, NOx reduction)

Catalytic

converter

Exhaust

gas

recirculation

system

Reference

page

17-11

Purge control solenoid valve

GDI system component

Catalytic converter

EGR valve

´

´ ´

17-14

GROUP

13A <4G6>

GROUP

13B <4G9>

´

´

17-17

17-16

Page 7

ENGINE AND EMISSION CONTROL -

SERVICE SPECIFICATIONS

Items Standard value

Purge control solenoid valve coil resistance (at 20_C) W 36 - 44

EGR valve coil resistance (at 20_C) W 10 - 20

SPECIAL TOOL

Tool Number Name Use

MB991658 Test harness set Inspection of EGR valve

VACUUM HOSE

VACUUM HOSE PIPING DIAGRAM

<4G9>

Emission Control System

17-7

From fuel pump (low-pressure)

To fuel tank

Fuel pressure

regulator (highpressure)

Fuel pump (highpressure)

PCV

valve

P

EGR valve

(stepper

motor)

Canister

Injector

Purge control

solenoid valve

Oxygen sensor

Catalytic converter

Page 8

17-8

ENGINE AND EMISSION CONTROL -

<4G6>

From fuel pump (low-pressure)

To fuel tank

Fuel pressure regulator

(high-pressure)

Emission Control System

P

EGR valve

(stepper

motor)

Fuel pump

(high-pressure)

PCV valve

Canister

Injector

Purge control

solenoid valve

Oxygen sensor

Catalytic converter

Page 9

ENGINE AND EMISSION CONTROL -

VACUUM CIRCUIT DIAGRAM

Emission Control System

17-9

Vacuum hose colour

B: Black

R: Red

To

combustion

chamber

Intake manifold

Throttle body

Purge control

solenoid valve

(ON: OPEN)

From air

cleaner

Canister

VACUUM HOSE CHECK

1. Using the piping diagram as a guide, check to be sure

that the vacuum hoses are correctly connected.

2. Check the connection condition of the vacuum hoses,

(removed, loose, etc.) and check to be sure that there

are no bends or damage.

VACUUM HOSE INSTALLATION

1. When connecting the vacuum hoses, they should be

securely inserted onto the nipples.

2. Connect the hoses correctly, using the vacuum hose piping

diagram as a guide.

Page 10

17-10

ENGINE AND EMISSION CONTROL -

Emission Control System

CRANKCASE EMISSION CONTROL SYSTEM

GENERAL INFORMATION

The crankcase emission control system prevents

blow-by gases from escaping inside the crankcase

into the atmosphere.

Fresh air is sent from the air cleaner into the

crankcase through the breather hose. The air

becomes mixed with the blow-by gases inside the

crankcase.

The blow-by gas inside the crankcase is drawn

into the intake manifold through the positive

crankcase ventilation (PCV) valve.

SYSTEM DIAGRAM

The PCV valve lifts the plunger according to the

intake manifold vacuum so as to regulate the flow

of blow-by gas properly. In other words, the blow-by

gas flow is regulated during low load engine

operation to maintain engine stability, while the flow

is increased during high load operation to improve

the ventilation performance.

Ventilation hose

PCV

valve

COMPONENT LOCATION

PCV valve <4G9>

Breather hose

PCV valve <4G6>

Page 11

ENGINE AND EMISSION CONTROL -

POSITIVE CRANKCASE VENTILATION SYSTEM

CHECK

1. Remove the ventilation hose from the PCV valve.

2. Remove the PCV valve from the rocker cover.

3. Reinstall the PCV valve at the ventilation hose.

4. Start the engine and run at idle.

5. Place a finger at the opening of the PCV valve and check

that vacuum of the intake manifold is felt.

NOTE

PCV valve

At this moment, the plunger in the PCV valve moves

back and forth.

6. If vacuum is not felt, clean the PCV valve or replace

it.

Emission Control System

17-11

PCV VALVE CHECK

1. Insert a thin rod into the PCV valve from the side shown

in the illustration (rocker cover installation side), a nd move

the rod back and forth to check that the plunger moves.

2. If the plunger does not move, there is clogging in the

PCV valve. In this case, clean or replace the PCV valve.

Page 12

17-12

ENGINE AND EMISSION CONTROL -

Emission Control System

EVAPORATIVE EMISSION CONTROL SYSTEM

GENERAL INFORMATION

The evaporative emission control system prevents

fuel vapours generated in the fuel tank from

escaping into the atmosphere.

Fuel vapours from the fuel tank flow through the

fuel tank pressure control valve and vapour

pipe/hose to be stored temporarily in the canister.

When driving the vehicle, fuel vapours stored in

the canister flow through the purge solenoid and

purge port and go into the intake manifold to be

SYSTEM DIAGRAM

Throttle body

sent to the combustion chamber.

When the engine coolant temperature is low or

when the intake air quantity is small (when the

engine is at idle, for example), the engine control

unit turns the purge solenoid off to shut off the

fuel vapour flow to the intake manifold.

This does not only insure the driveability when the

engine is cold or running under low load but also

stabilize the emission level.

Engine-ECU

Canister

From fuel tank

Purge control

solenoid valve

(ON: Open)

COMPONENT LOCATION

Purge control solenoid valve <4G9>

Control

relay

Air flow sensor

Engine coolant

temperature sensor

Intake air

temperature sensor

Barometric pressure

sensor

Purge control solenoid valve<4G6>

Page 13

ENGINE AND EMISSION CONTROL -

Emission Control System

17-13

<4G9>

Vacuum hose (red stripe)

Plug

<4G6>

<4G9>

Plug

Vacuum hose (red stripe)

PURGE CONTROL SYSTEM CHECK

1. Disconnect the vacuum hose (red stripe) from the throttle

body <4G9>, intake manifold <4G6>, and connect it to

a hand vacuum pump.

2. Plug the nipple from which the vacuum hose was removed.

3. When the engine is cold or hot, apply a vacuum of 53

kPa, and check the condition of the vacuum.

When engine is cold

(Engine coolant temperature: 40_C or less)

Engine condition Normal condition

At idle V acuum is maintained

3,000 r/min

When engine is hot

(Engine coolant temperature: 80_C or higher)

Engine condition Normal condition

At idle V acuum is maintained

3,000 r/min (fore

approximately 3 minutes

after the engine is started.)

V acuum will leak.

PURGE PORT VACUUM CHECK

1. Disconnect the vacuum hose (red stripe) from the throttle

body <4G9>, intake manifold <4G6> purge vacuum nipple

and connect a hand vacuum pump to the nipple.

<4G6>

Vacuum hose

(red stripe)

Vacuum hose (red stripe)

Page 14

17-14

ENGINE AND EMISSION CONTROL -

Emission Control System

Vacuum

Engine speed (r/min)

A

B

Battery

2. Start the engine and check that the vacuum remains fairly

constant after racing the engine.

NOTE

If vacuum changes, it is possible that the throttle body

purge port may be clogged and require cleaning.

PURGE CONTROL SOLENOID VALVE CHECK

NOTE

When disconnecting the vacuum hose, always make a mark

so that it can be reconnected at original position.

1. Disconnect the vacuum hose (black stripe, red stripe)

from the solenoid valve.

2. Disconnect the harness connector.

3. Connect a hand vacuum pump to nipple (A) of the solenoid

valve (refer to the illustration at left).

4. Check airtightness by applying a vacuum with voltage

applied directly from the battery to the purge control

solenoid valve and without applying voltage.

Battery voltage Normal condition

Applied V acuum leaks

Not applied Vacuum maintained

5. Measure the resistance between the terminals of the

solenoid valve.

Standard value: 36 - 44W(at 20_C)

Page 15

ENGINE AND EMISSION CONTROL -

ENGINE AND EMISSION CONTROL -

Emission Control System

Emission Control System

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

GENERAL INFORMATION

The exhaust gas recirculation (EGR) system lowers

the nitrogen oxide (NOx) emission level. When the

air/fuel mixture combustion temperature is high,

a large quantity of nitrogen oxides (NOx) is

generated in the combustion chamber. Therefore,

this system recirculates part of emission gas from

OPERATION

The EGR valve is being closed and dose not

recirculate exhaust gases under one of the following

conditions. Otherwise, the EGR valve is opened

and recirculate exhaust gases.

SYSTEM DIAGRAM

the exhaust port of the cylinder head to the

combustion chamber through the intake manifold

to decrease the air/fuel mixture combustion

temperature, resulting in reduction of NOx.

The EGR flow rate is controlled by the EGR valve

so as not to decrease the driveability.

D

The engine coolant temperature is low.

D

The engine is at idle.

D

The throttle valve is widely opened.

Throttle body

17-15

COMPONENT LOCATION

EGR valve <4G9>

EGR

valve

Battery

Engine

control

relay

Engine-ECU

Air flow sensor

Engine coolant

temperature sensor

Crank angle sensor

Throttle position sensor

EGR valve <4G6>

Throttle

body

Intake manifold

Page 16

17-16

ENGINE AND EMISSION CONTROL -

EXHAUST GAS RECIRCULATION (EGR)

CONTROL SYSTEM CHECK

Refer to GROUP 13 - Troubleshooting.

Emission Control System

<4G9>

EGR valve

<4G6>

Intake manifold

Throttle

body

EGR VALVE (STEPPER MOTOR) CHECK

Checking the Operation Sound

1. Check that the operation sound of the stepper motor

can be heard from the EGR valve when the ignition switch

is turned to ON (without starting the engine).

2. If the operation sound cannot be heard, check the stepper

motor drive circuit.

NOTE

If the circuit is normal, the cause is probably a malfunction

of the stepper motor or of the engine-ECU.

Checking the Coil Resistance

1. Disconnect the EGR valve connector.

2. Measure the resistance between the EGR valve-side

connector terminal No.2 an d terminal No.1 or terminal

No.3.

Standard value: 10 - 20W(at 20_C)

3. Measure the resistance between the EGR valve-side

connector terminal No.5 an d terminal No.4 or terminal

No.6.

Standard value: 10 - 20W(at 20_C)

Page 17

Battery

ENGINE AND EMISSION CONTROL -

Operation Check

1. Remove the EGR valve.

2. Connect the special tool (test harness set) to the EGR

valve-side connector.

3. Connect terminal No.2 and terminal No.5 to the positive

(+) terminal of power supply of approximately 6 V.

4. Connect each clip to the negative ( -) terminal of power

supply in th e order given below to test if any vibration

EGR valve

MB991658

occurs (as though the stepper motor is shaking slightly)

due to the operation of the stepper motor.

(1) Connect terminal No.1 and terminal No.4 to the

negative ( - ) terminal of the power supply.

(2) Connect terminal No.3 and terminal No.4 to the

negative (- ) terminal of the power supply.

(3) Connect terminal No.3 and terminal No.6 to the

negative (- ) terminal of the power supply.

(4) Connect terminal No.1 and terminal No.6 to the

negative (- ) terminal of the power supply.

(5) Connect terminal No.1 and terminal No.4 to the

negative (- ) terminal of the power supply.

(6) Repeat the test in the order from (5) to (1).

Emission Control System

17-17

CATALYTIC CONVERTER

REMOVAL AND INSTALLATION

49 Nm

5. If the results of testing show that the vibration could be

felt, the stepper motor is normal.

17500270021

Catalytic converter

49 Nm

Page 18

NOTES

Loading...

Loading...