Page 1

ENGINE

11A-1

CONTENTS

ENGINE <4G6> 11A............................................

ENGINE <4G9> 11B............................................

11109000276

Page 2

11A-2

ENGINE

<4G6>

CONTENTS

GENERAL INFORMATION 3..................

SERVICE SPECIFICATIONS 3.................

SEALANTS 4................................

SPECIAL TOOLS 5..........................

ON-VEHICLE SERVICE 6.....................

Drive Belt Tension Check and Adjustment 6......

Ignition Timing Check 10.......................

Idle Speed Check 11...........................

Idle Mixture Check 12..........................

Compression Pressure Check 13................

Manifold Vacuum Check 14.....................

Lash Adjuster Check 14........................

CRANKSHAFT PULLEY 17..................

CAMSHAFT AND CAMSHAFT OIL SEAL 18..

OIL PAN 22.................................

CRANKSHAFT OIL SEAL 24.................

CYLINDER HEAD GASKET 27...............

TIMING BELT AND TIMING BELT B 30......

ENGINE ASSEMBLY 37.....................

Page 3

ENGINE <4G6> -

General Information/Service Specifications

GENERAL INFORMATION

Items 4G64-GDI

Total displacement mL 2,350

Bore ´ Stroke mm 86.5 ´ 100.0

Compression ratio 11.5

Combustion chamber Pentroof + ball-in-piston

Camshaft arrangement DOHC

11A-3

Number of valve

V alve timing Intake

Fuel system Electronically controlled multipoint fuel injection

Rocker arm Roller type

Auto-lash adjuster Equipped

Intake 8

Exhaust 8

Opening BTDC 16_

Closing ABDC 60_

Exhaust

Opening BBDC 56_

Closing ATDC 16_

SERVICE SPECIFICATIONS

Items Standard value Limit

Alternator drive Vibration

belt tension frequency Hz

Tension N

When checked 189 - 232 -

When a used belt is installed 201 - 222 -

When a new belt is installed 241 - 276 -

When checked 392 - 588 -

Deflection

(Reference

value) mm

When a used belt is installed 441 - 539 -

When a new belt is installed 637 - 833 -

When checked 6.7 - 9.0 -

When a used belt is installed 7.2 - 8.4 -

When a new belt is installed 5.0 - 6.4 -

Page 4

11A-4

Items LimitStandard value

ENGINE <4G6> -

Service Specifications/Sealants

Power steering Vibration

oil pump and

A/C compressor

drive belt tension

Basic ignition timing 5_ BTDC ± 3_ -

Ignition timing Approx. 20_BTDC*

Idle speed r/min M/T 600 ± 100*

CO contents % 0.5 or less -

HC contents ppm 100 or less -

Compression pressure kPa - r/min 1,570 - 300 1,210 - 300

frequency Hz

Tension N

Deflection

(Reference

value) mm

A/T 650 ± 100 -

When checked 108 - 132 -

When a used belt is installed 114 - 126 -

When a new belt is installed 137 - 157 -

When checked 392 - 588 -

When a used belt is installed 441 - 539 -

When a new belt is installed 637 - 834 -

When checked 11.7 - 15.3 -

When a used belt is installed 12.5 - 14.3 -

When a new belt is installed 8.8 - 11.0 -

1

2

2

-

-

Compression pressure difference of all cylinder kPa - Max. 100

Intake manifold vacuum kPa - Min. 56*

Cylinder head bolt shank length mm - 99.4

Auto-tensioner push rod movement mm Within 1 -

Timing belt tension torque Nm (Reference value) 2.5 -

Auto-tensioner rod protrusion amount mm 3.8 - 4.5 -

NOTE

*1: Indicates the value measured within 4 minutes since the engine was started.

2

*

: Varies depending on the transmission oil temperature. For details, refer to P.11A-11.

3

*

: Indicates the value when more than 4 minutes have passed since the engine was started.

SEALANTS

Items Specified sealants Remarks

Beam camshaft cap

Cylinder head

Cam position sensor support

Oil pan

3M ATD Part No.8660 or equivalent -

MITSUBISHI GENUINE PART

MD970389 or equivalent

Semi-drying sealant

3

Flywheel or drive plate bolt 3M Stud Locking 4170 or equivalent -

Page 5

ENGINE <4G6> -

Special Tools

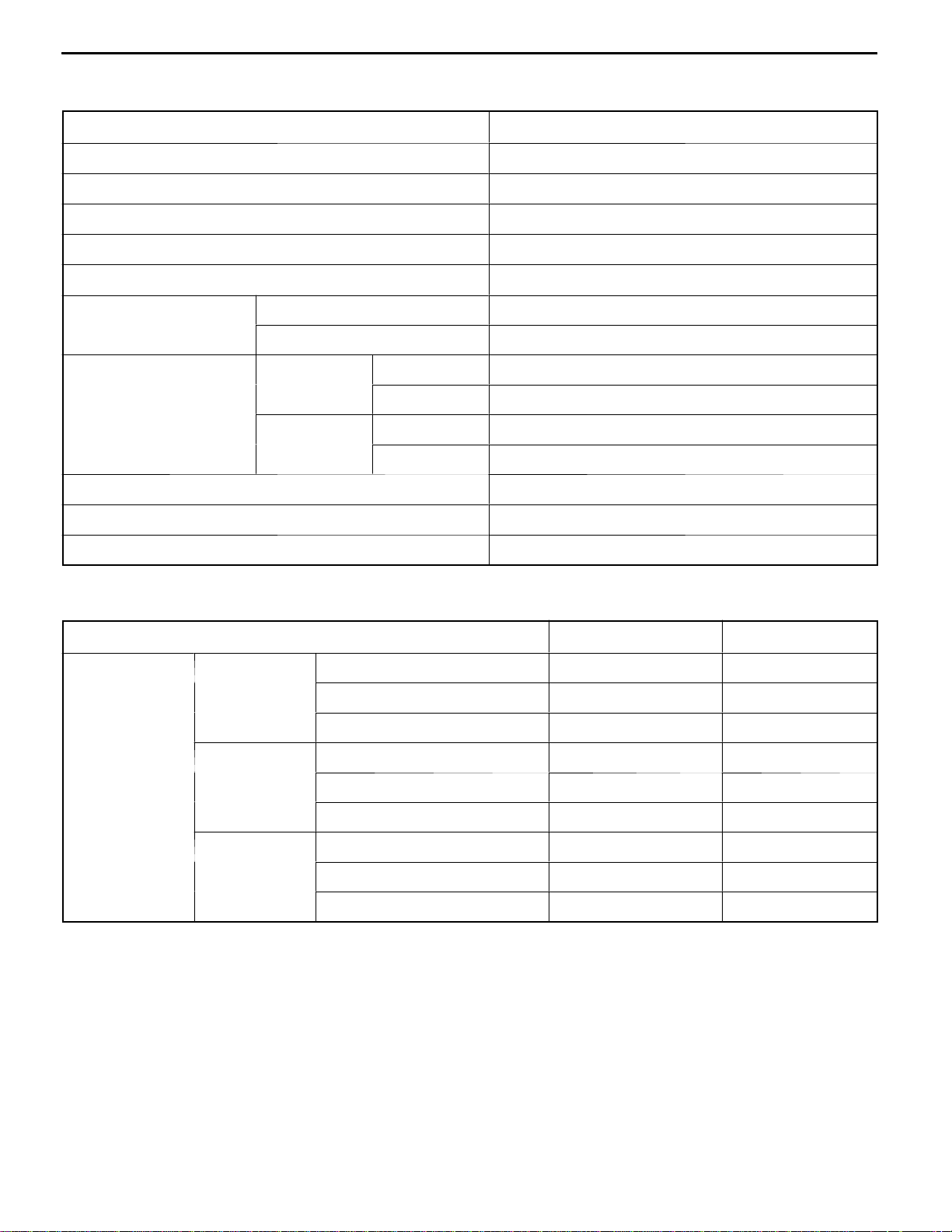

SPECIAL TOOLS

Tool Number Name Use

11A-5

MB991502 MUT-II sub

assembly

MB991668 Belt tension meter

set

MB990767 End yoke holder D Holding the camshaft sprocket

MD998719 or

MD998754

Crankshaft pulley

holder pin

D Measuring the drive belt tension

D Checking the ignition timing

D Checking the idle speed

D Erasing diagnosis code

Measuring the drive belt tension

(used together with the MUT-II)

D Holding the crankshaft sprocket

D Holding the camshaft sprocket

D Holding the crankshaft sprocket

MD998713 Camshaft oil seal

installer

MD998727 Oil pan remover Removal of oil pan

MD998781 Flywheel stopper Securing the flywheel

MD998776 Crankshaft rear oil

seal installer

Press-in of the camshaft oil seal

Press-in of the crankshaft rear oil seal

MB990938 Handle Press-in of the crankshaft rear oil seal

Page 6

11A-6

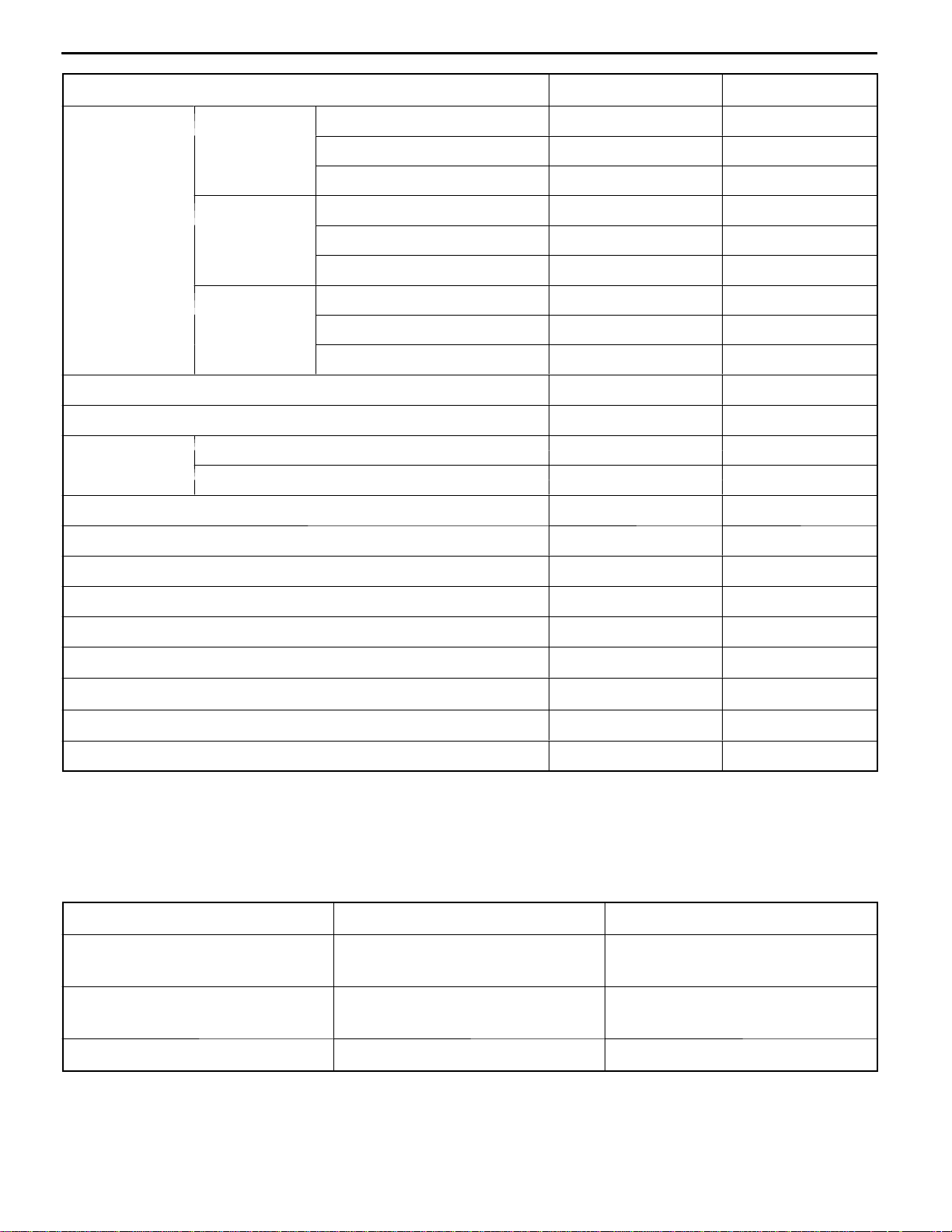

Tool UseNameNumber

ENGINE <4G6> -

Special Tools/On-vehicle Service

MD998382 Crankshaft front oil

seal installer

MD998285 Crankshaft front oil

seal guide

MD998767 Tension pulley

socket wrench

GENERAL

SERVICE

TOOL

MZ203827

Engine lifter Supporting the engine assembly during

Installation of crankshaft front oil seal

Timing belt tension adjustment

removal and installation of the transmission

MB991453 Engine hanger

assembly

ON-VEHICLE SERVICE

DRIVE BELT TENSION CHECK AND

ADJUSTMENT

ALTERNATOR DRIVE BELT TENSION CHECK

Check the drive belt tension in the following procedure.

Standard value:

Vibration frequency Hz 189 - 232

Tension N 392 - 588

Deflection (Reference value) mm 6.7 - 9.0

Page 7

ENGINE <4G6> -

On-vehicle Service

11A-7

MB991668

(Microphone)

Alternator

pulley

15

15

_

_

10 - 20 mm

Water pump

pulley

Crankshaft

pulley

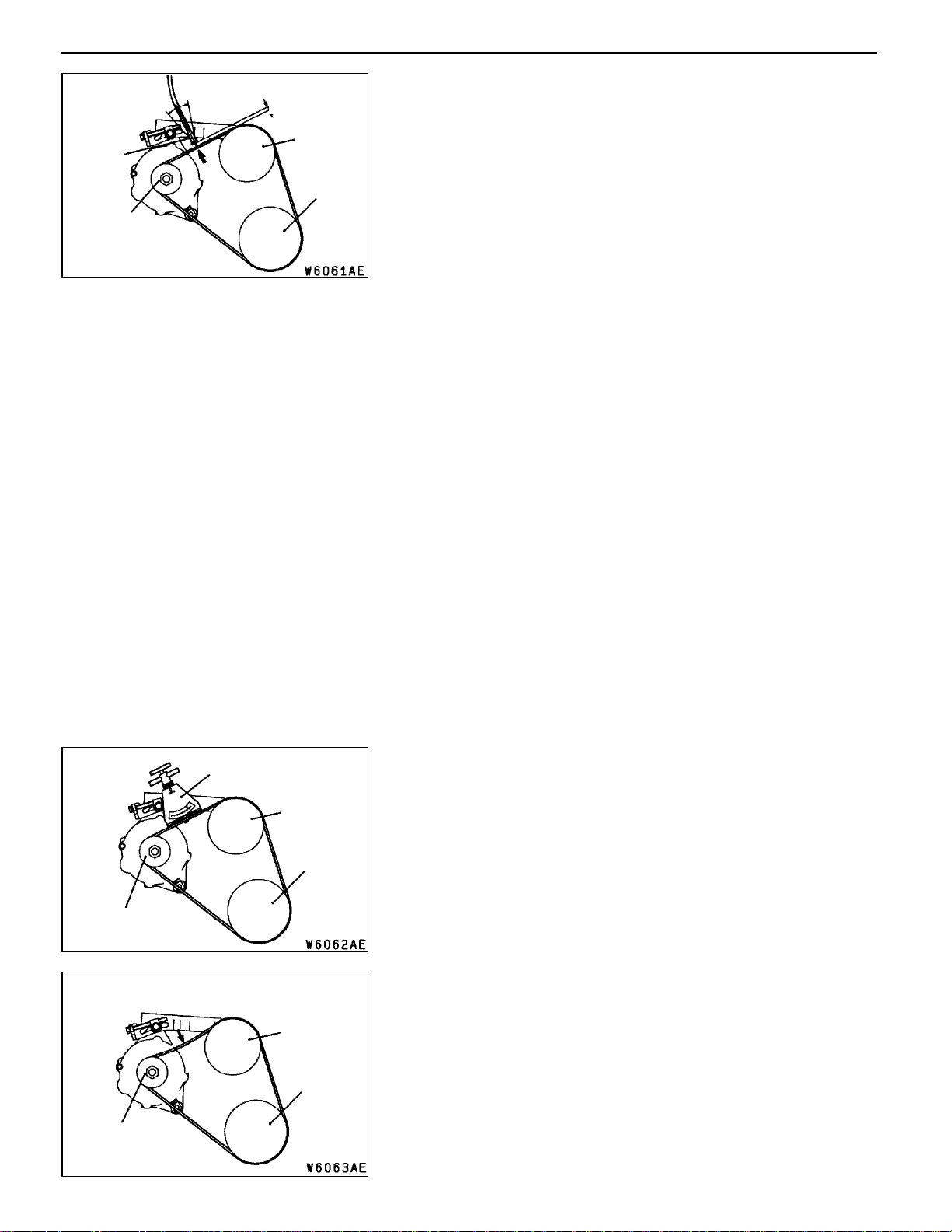

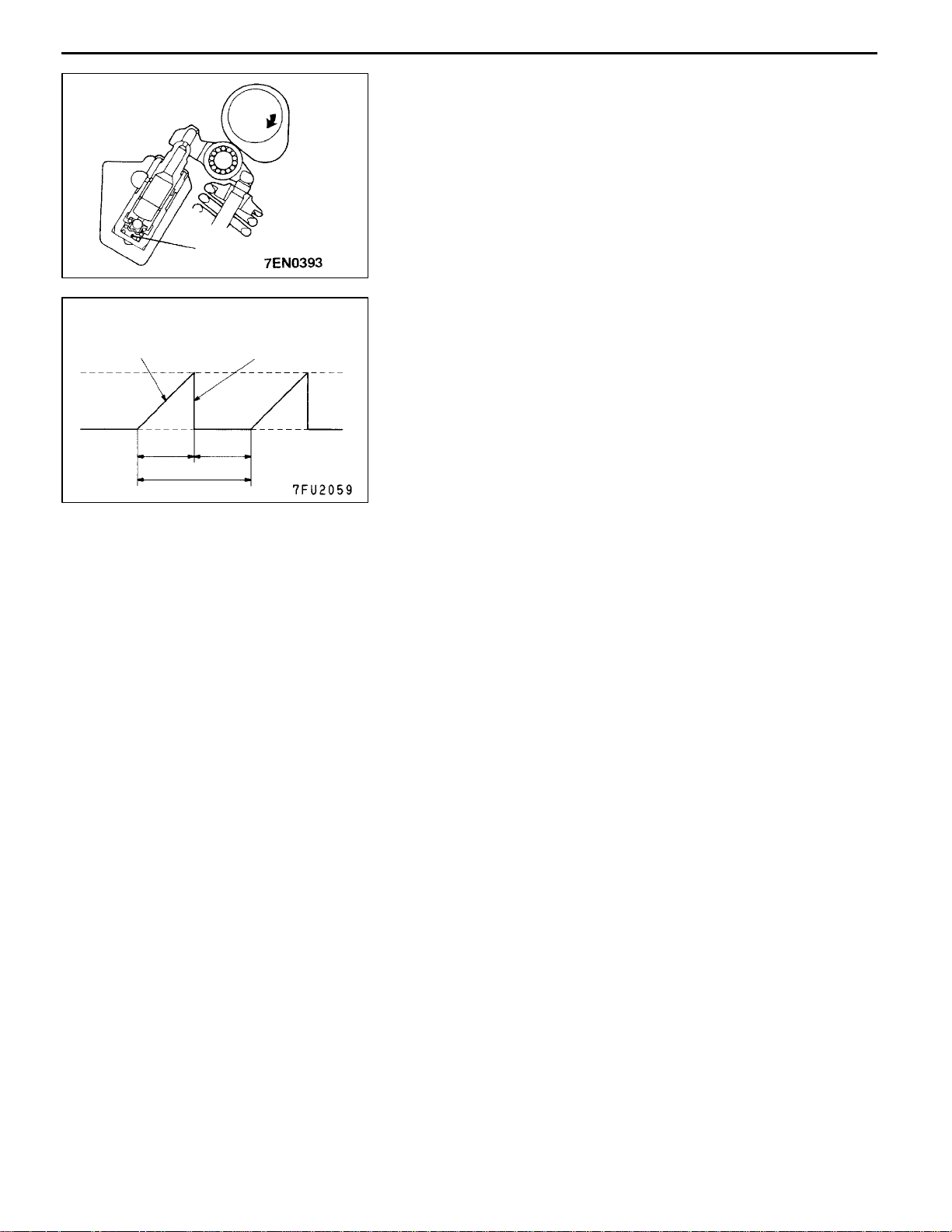

1. Connect the special tool (belt tension meter set) to the

MUT-II.

2. Connect the MUT-II to the diagnosis connector.

3. Turn the ignition switch to ON and select “Belt Tension

Measurement” from the menu screen.

4. Hold the microphone to the middle of the drive belt

between the pulleys (at the place indicated by the arrow),

about 10 - 20 mm away from the rear surface of the

belt and so that it is perpendicular to the belt (within

an angle of ± 15_).

5. Gently tap the middle of the belt between the pulleys

(the place indicated by the arrow) with your finger as

shown in the illustration, and check that the vibration

frequency of the belt is within the standard value.

Caution

(1) The temperature of the surface of the belt should

be as close as possible to normal temperature.

(2) Do not let any contaminants such as water or

oil get onto the microphone.

(3) If strong gusts of wind blow against the

microphone or if there are any loud sources of

noise nearby, the values measured by the

microphone may not correspond to actual values.

(4) If the microphone is touching the belt while the

measurementis being made, the values measured

by the microphone may not correspond to actual

values.

(5) Do not take the measurement while the vehicle’s

engine is running.

<When using the MUT-II>

Alternator

pulley

Alternator

pulley

Belt tension gauge

98 N

Water pump

pulley

Crankshaft

pulley

Water pump

pulley

Crankshaft

pulley

<When using a tension gauge>

Use a belt tension gauge to check that the belt tension is

within the standard value.

<Belt deflection check>

Apply 98 N of force to the middle of the drive belt between

the pulleys (at the place indicated by the arrow) and check

that the amount of deflection is within the standard value.

Page 8

11A-8

Adjusting bolt

Lock bolt

ENGINE <4G6> -

ALTERNATOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen the nut of the alternator pivot bolt.

2. Loosen the lock bolt.

3. Use the adjusting bolt to adjust the belt tension and belt

deflection to the standard values.

Standard value:

4. Tighten the nut of the alternator pivot bolt.

Tightening torque: 49 Nm

5. Tighten the lock bolt.

Tightening torque: 22 Nm

6. Tighten the adjusting bolt.

On-vehicle Service

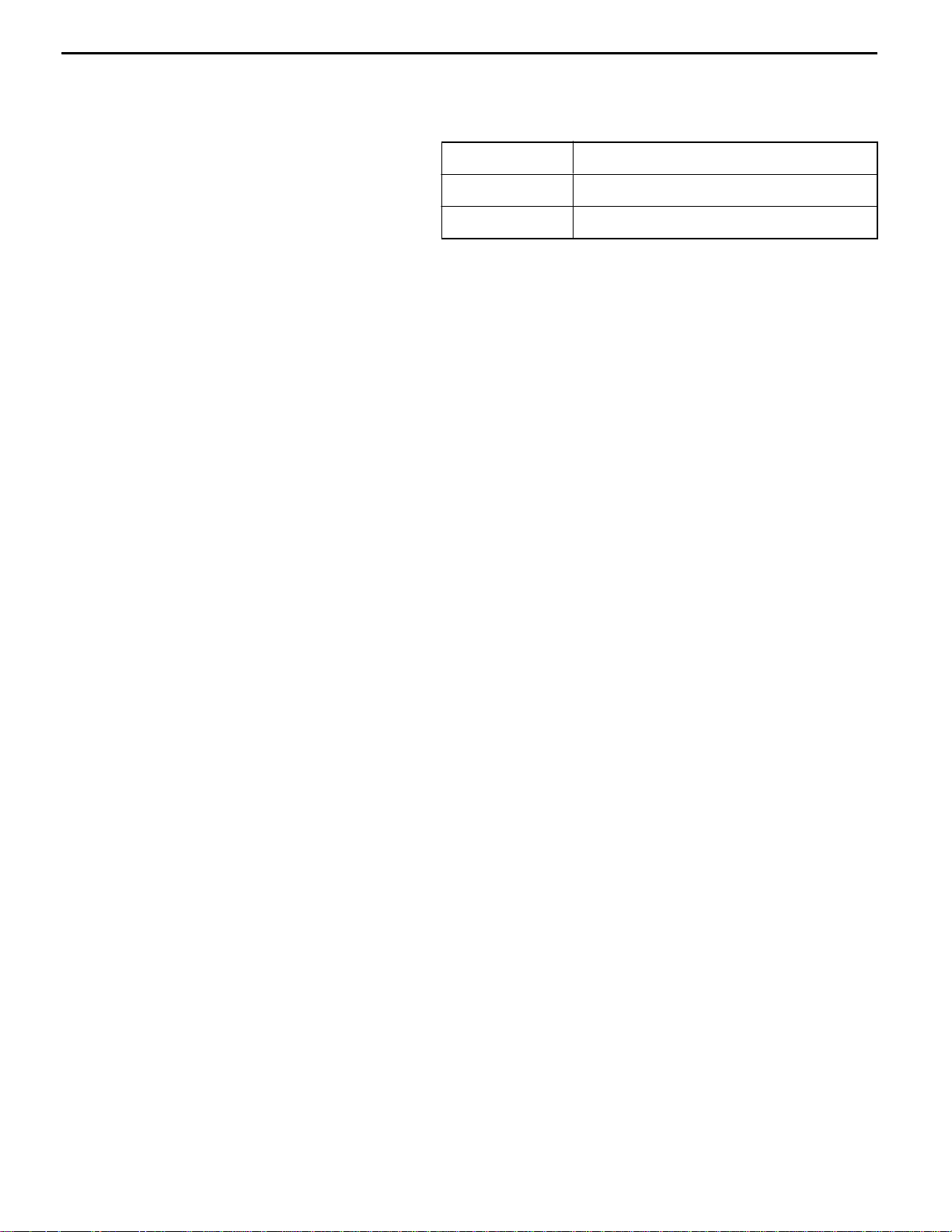

Items When a used

belt is installed

Vibration frequency Hz 201 - 222 241 - 276

Tension N 441 - 539 637 - 833

Deflection

(Reference value) mm

7.2 - 8.4 5.0 - 6.4

When a new

belt is installed

Tightening torque: 5 Nm

Page 9

ENGINE <4G6> -

On-vehicle Service

11A-9

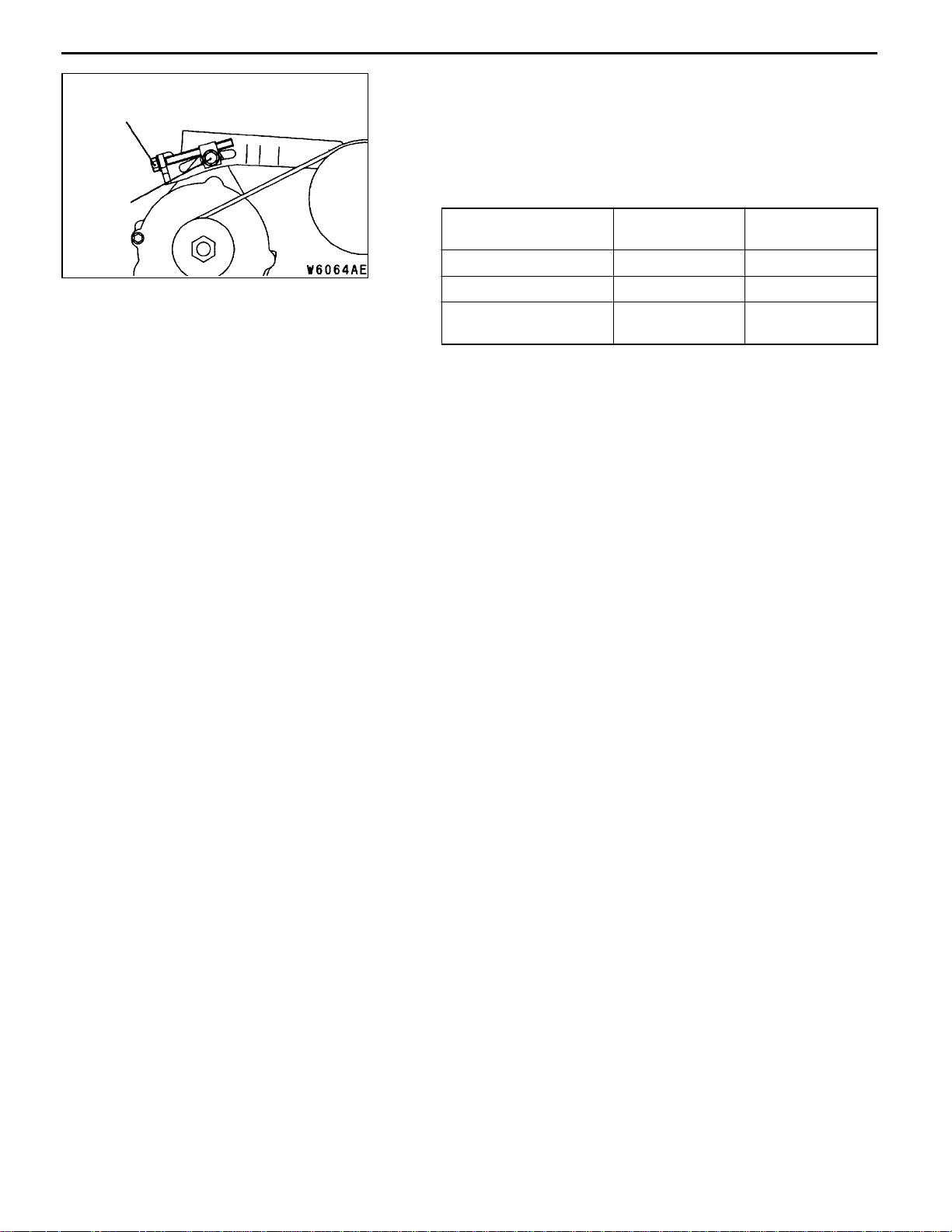

<VehicleswithoutA/C>

Oil pump pulley

98 N

A

Crankshaft

pulley

<Vehicleswith A/C>

Oil pump pulley

98 N

Crankshaft

pulley

A

B

Tensioner pulley

Tensioner

pulley

B

A/C

compressor

pulley

POWER STEERING OIL PUMP AND AIR CONDITIONER

COMPRESSOR DRIVE BELT TENSION CHECK AND

ADJUSTMENT

11100130127

1. Check if the belt tension is within the standard value

using one of the methods below.

Standard value:

Items When

checked

Vibration

frequency

Hz

Tension N 392 - 588 441 - 539 637 - 834

Deflection

(Reference

value) mm

108 - 132 114 - 126 137 - 157

11.7 - 15.3 12.5 - 14.3 8.8 - 11.0

When a

used belt is

installed

When a new

belt is

installed

<When measuring the vibration frequency>

With your finger tip lightly tap the centre of the belt between

the pulleys in t he location shown by the arrow in the

illustration and then measure the belt vibration frequency.

NOTE

Refer to P.11A-7 for information regarding the vibration

frequency measurement method using MUT-II.

<When measuring the tension>

Use a belt tension gauge to measure the belt tension.

<When measuring the deflection>

Apply 98 N of pressure against the location between

the pulleys shown by the arrow in the illustration and

then measure the deflection.

2. If the tension or deflection is outside the standard value,

adjust by the following procedure.

(1) Loosen tensioner pulley fixing nut A.

(2) Adjust the amount of belt deflection using adjusting

bolt B.

(3) Tighten fixing nut A.

Tightening torque: 25 Nm

(4) Check the belt deflection amount and tension, and

readjust if necessary.

Caution

Check after turning the crankshaft once or more

clockwise (right turn).

Page 10

11A-10

ENGINE <4G6> -

On-vehicle Service

Idle speed r/min

900

800

700

600

-10 20 50

Transmission oil temperature_C

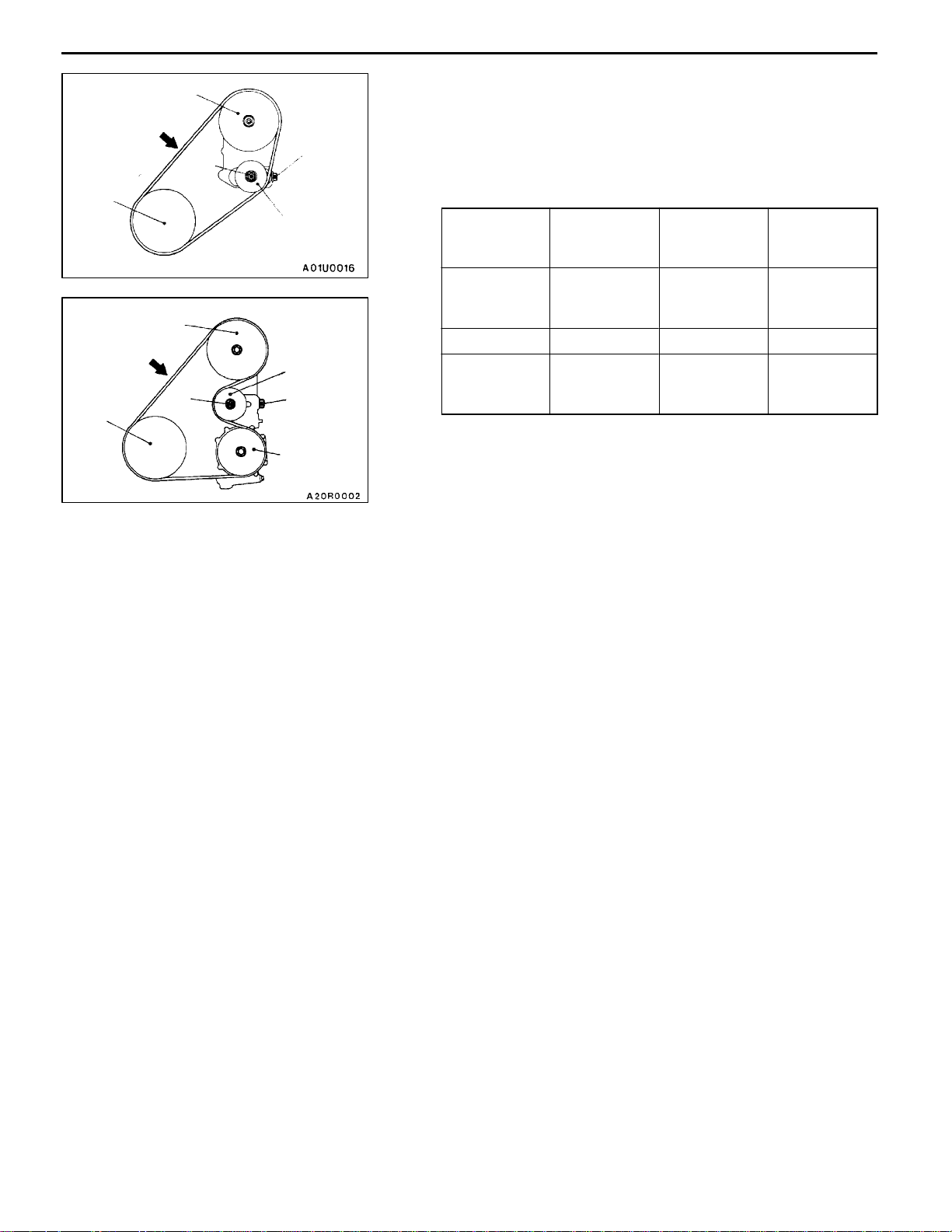

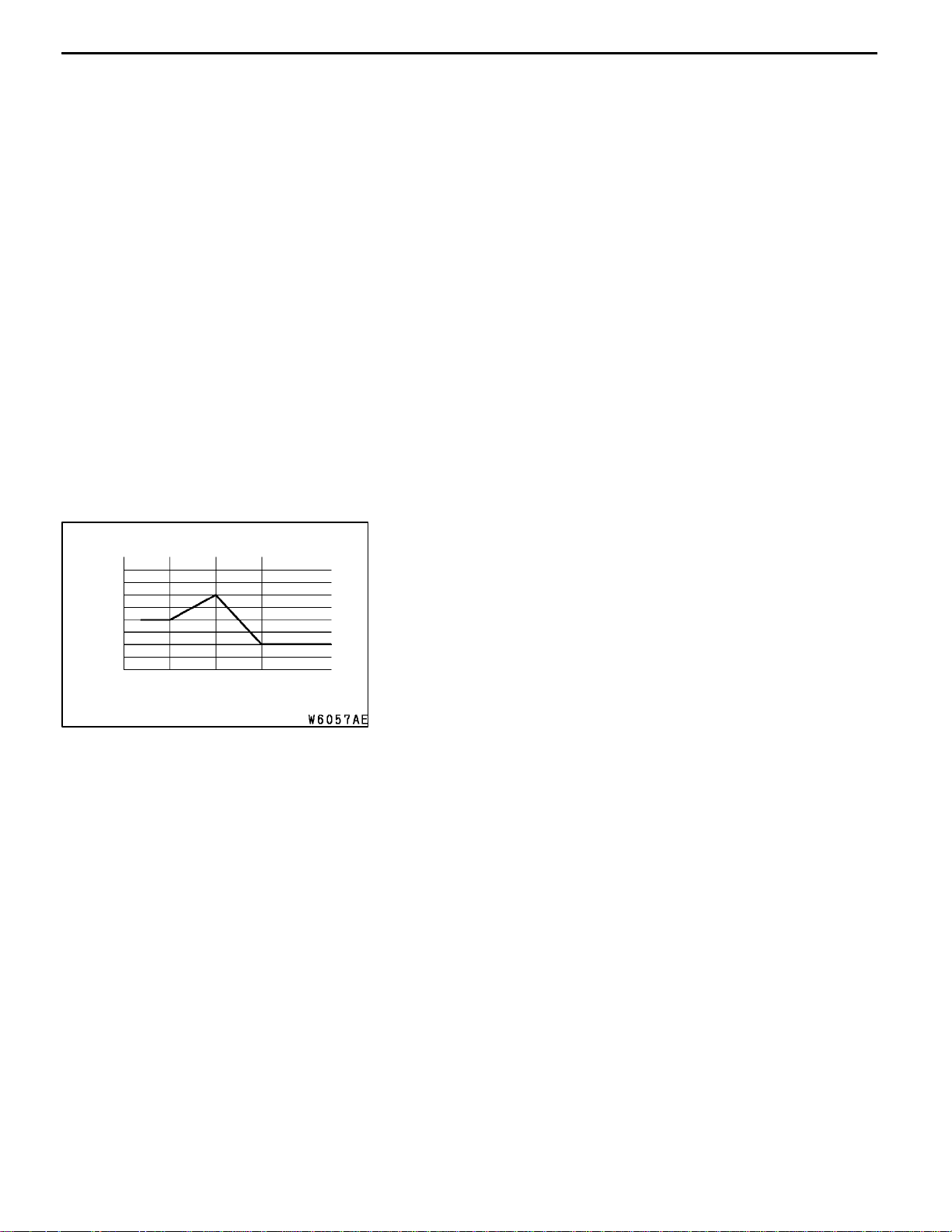

IGNITION TIMING CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

For vehicles with manual transmission, drive the vehicle

for 15 minutes or more to warm the engine, and then

carry out the checking while the transmission oil

temperature is more than 50°C.

NOTE

The idle speed in vehicles with manual transmission varies

as shown in the illustration in accordance with the

transmission oil temperature.

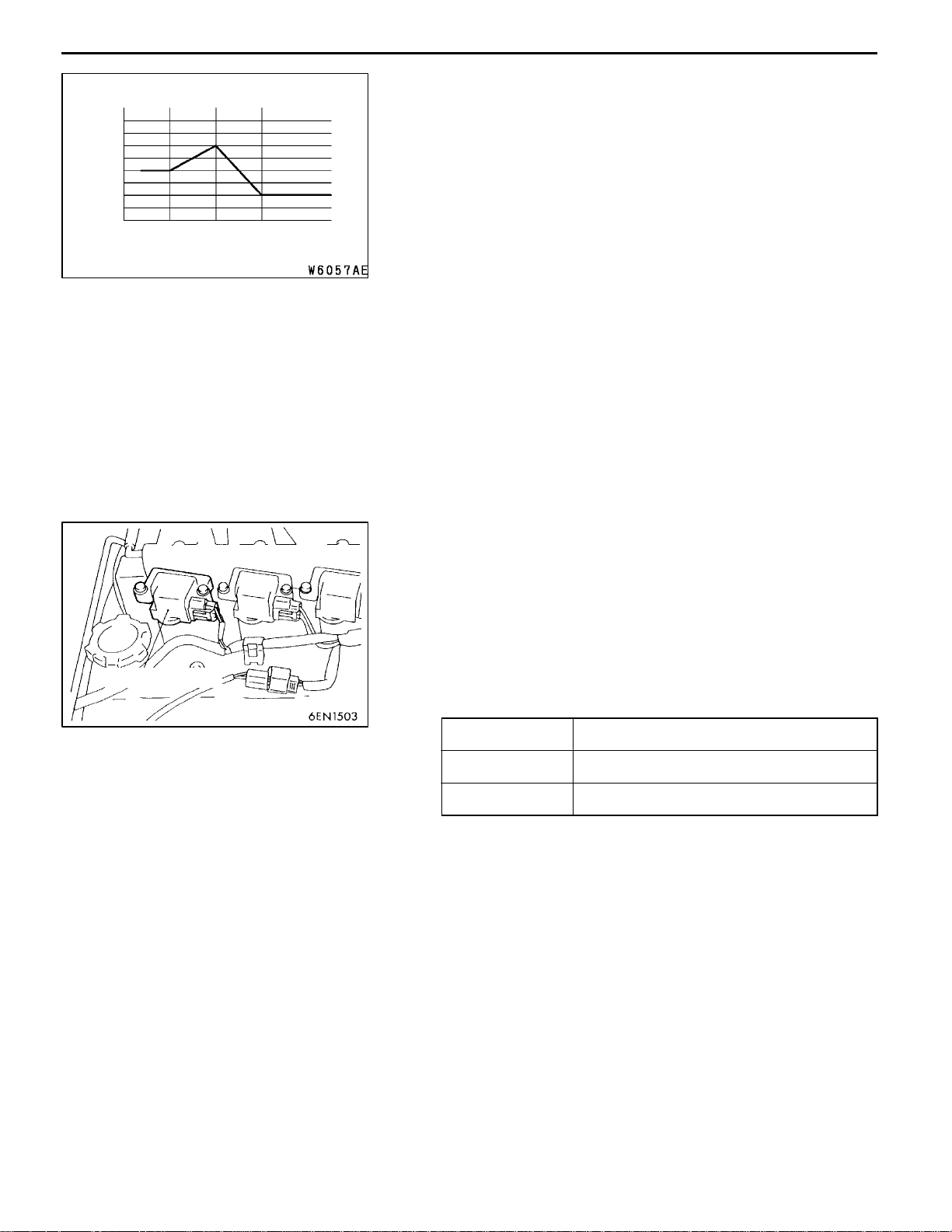

2. Turn off the ignition switch and then connect the MUT-II

to the diagnosis connector.

3. Set the timing light to the power supply line (terminal

No.1) of the ignition coil No.1.

No.1 ignition coil

NOTE

The power supply line is looped and also longer than

the other ones.

4. Start the engine a nd let it run at idle.

5. Use the MUT-II to measure engine idle speed and check

that it is within the standard value.

Standard value:

Items Idle speed r/min

M/T 600±100 (700±100)*

A/T 650±100 (700±100)*

NOTE

*: Indicates the values when more than 4 minutes have

passed since the idling condition was started.

6. Select No.17 of the MUT-II Actuator test.

NOTE

At this time, the engine speed will become approximately

700 r/min.

7. Check that basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3

_

8. If the basic ignition timing is outside the standard value,

inspect the GDI system while referring to GROUP 13A Troubleshooting.

Page 11

ENGINE <4G6> -

9. Press the MUT-II clear key (Select a forced driving cancel

mode) to release the Actuator test.

Caution

If the test is not cancelled, a forced driving will

continue for 27 minutes. Driving under this condition

may damage the engine.

10. Check that ignition timing is at the standard value.

Standard value: approx. 20_BTDC

NOTE

(1) The ignition timing will become approximately 5_BTDC

(2) The ignition timing may fluctuate within ±7_BTDC.

(3) In higher altitude, the ignition timing is more advanced

11. Remove the timing light.

12. Turn off the ignition switch and then remove the MUT-II.

On-vehicle Service

11A-11

after more than 4 minutes have passed since the

basic ignition timing set mode was released.

This is normal.

than the standard value by approximately 5 degree.

Idle speed r/min

900

800

700

600

-10 20 50

Transmission oil temperature_C

IDLE SPEED CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

For vehicles with manual transmission, drive the vehicle

for 15 minutes or more to warm the engine, and then

carry out the checking while the transmission oil

temperature is more than 50°C.

NOTE

The idle speed in vehicles with manual transmission varies

as shown in the illustration in accordance with the

transmission oil temperature.

2. Turn off the ignition switch and then connect the MUT-II

to the diagnosis connector.

3. Check the basic ignition timing.

NOTE

Refer to P.11A-10 concerning the check procedure of

the basic ignition timing.

Standard value: 5_BTDC±3

4. Run the engine at idle for 2 minutes.

_

Page 12

11A-12

ENGINE <4G6> -

5. Check the idle speed. Select item No. 22 and take a

reading of the idle speed.

Standard value:

NOTE

(1) *: Indicates the values when more than 4 minutes

(2) The idle speed is controlled automatically by the idle

6. If the idle speed is outside the standard value, inspect the

GDI components by referring to GROUP 13A Troubleshooting.

IDLE MIXTURE CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Connect the MUT-II to the diagnosis connector.

3. Check that the basic ignition timing is within the standard

value.

NOTE

Refer to P.11A-10 concerning the check procedure of

the basic ignition timing.

Standard value: 5_BTDC ± 3

4. Run the engine at 2,500 r/min for 2 minutes.

5. Set t he CO, HC tester.

6. Check the CO contents and the HC contents at idle.

NOTE

This measurement should be performed in less than

approximately 4 minutes since the engine speed become

the idle speed.

Standard value

7. If there is a deviation from the standard value, check t he

following items:

D Diagnosis output

D Fuel pressure

D Injector

D Ignition coil, spark plug

D EGR control system

D Evaporative emission control system

D Compression pressure

NOTE

Replace the three way catalyst when the CO and HC

contents are not within the standard value, even though

the result of the inspection is normal on all items.

On-vehicle Service

Items Idle speed r/min

M/T 600±100 (700±100)*

A/T 650±100 (700±100)*

have passed since the idling condition was started.

speed control system.

_

CO contents: 0.5% or less

HC contents: 100 ppm or less

Page 13

Crank angle sensor

connector

ENGINE <4G6> -

ENGINE <4G6> -

COMPRESSION PRESSURE CHECK

1. Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

2. Remove all of t he ignition coils and spark plugs.

3. Disconnect the crank angle sensor connector.

NOTE

Doing this will prevent the engine-ECU from carrying out

ignition and fuel injection.

4. Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

Caution

(1) Keep away from the spark plug hole when

(2) If compression is measured with water, oil, fuel,

On-vehicle Service

On-vehicle Service

cranking.

etc.,that has comefrom cracks inside the cylinder,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

11A-13

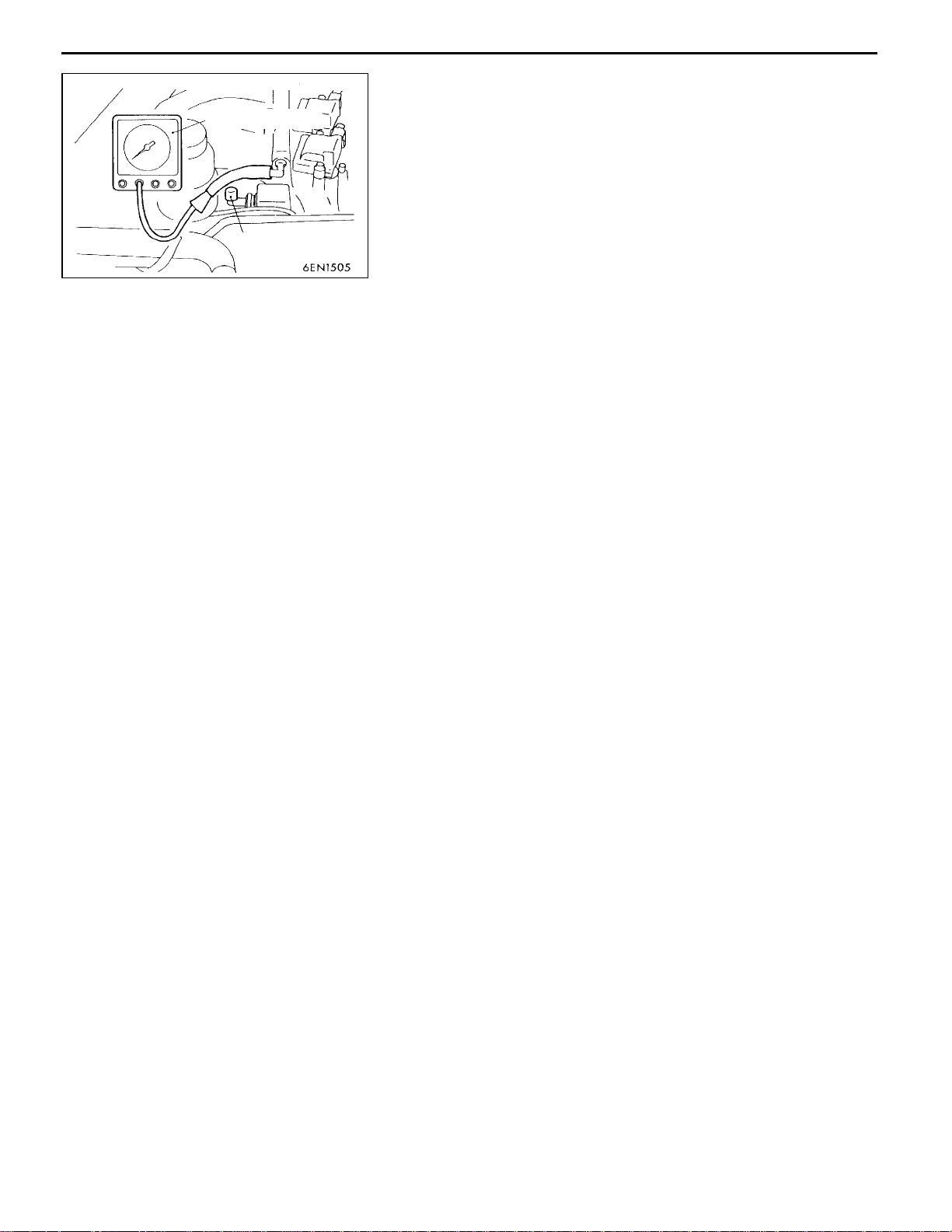

Compression gauge

5. Set compression gauge to one of the spark plug holes.

6. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value (at engine speed of 300 r/min):

1,570 kPa

Limit (at engine speed of 300 r/min):

Min. 1,210 kPa

7. Measure the compression pressure for all the cylinders,

and check that the pressure differences of the cylinders are

below the limit.

Limit: Max. 100 kPa

8. If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 6 and 7.

(1) If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

9. Connect the crank angle sensor connector.

10. Install the spark plugs and ignition coils.

11. Use the MUT-II to erase the diagnosis codes.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

Page 14

11A-14

ENGINE <4G6> -

Vacuum gauge

Plug

On-vehicle Service

MANIFOLD VACUUM CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Disconnect the ventilation hose from the positive

crankcase ventilation (PCV) valve, and then connect a

vacuum gauge to the ventilation hose.

3. Check the intake manifold vacuum while the engine is

idling.

Limit: Min. 56 kPa

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, and will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not th e lash adjusters.

(2) If there is a problem with the lash adjusters, the noise

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused by

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

3. While the engine is idling, check that the noise level does

not change when the engine load is varied (for example,

by shifting from N ® D).

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

Page 15

ENGINE <4G6> -

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If t he noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters. (Refer to P.11A-15.)

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters. (Refer to the Engine

Workshop Manual.)

<LASH ADJUSTER AIR BLEEDING>

NOTE

(1) If the vehicle is parked on a slope for a long period

(2) After parking the vehicle for long periods, the oil drains

(3) If either of the above situations occur, the abnormal

On-vehicle Service

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

out of the oil passage, and it takes time for the oil

to be supplied to the lash adjuster, so air can get

into the high pressure chamber.

noise can be eliminated by bleeding the air from inside

the lash adjusters.

11A-15

Good

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft an d a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

Page 16

11A-16

ENGINE <4G6> -

High-pressure chamber

On-vehicle Service

(4) If the air which has been mixed in with the oil due

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

Drive pattern for air bleeding

Gradually open the

throttle valve.

Approx.

3,000 r/min

Idle speed

15

seconds

Once

Close the throttle

valve.

15

seconds

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Page 17

ENGINE <4G6> -

Crankshaft Pulley

11A-17

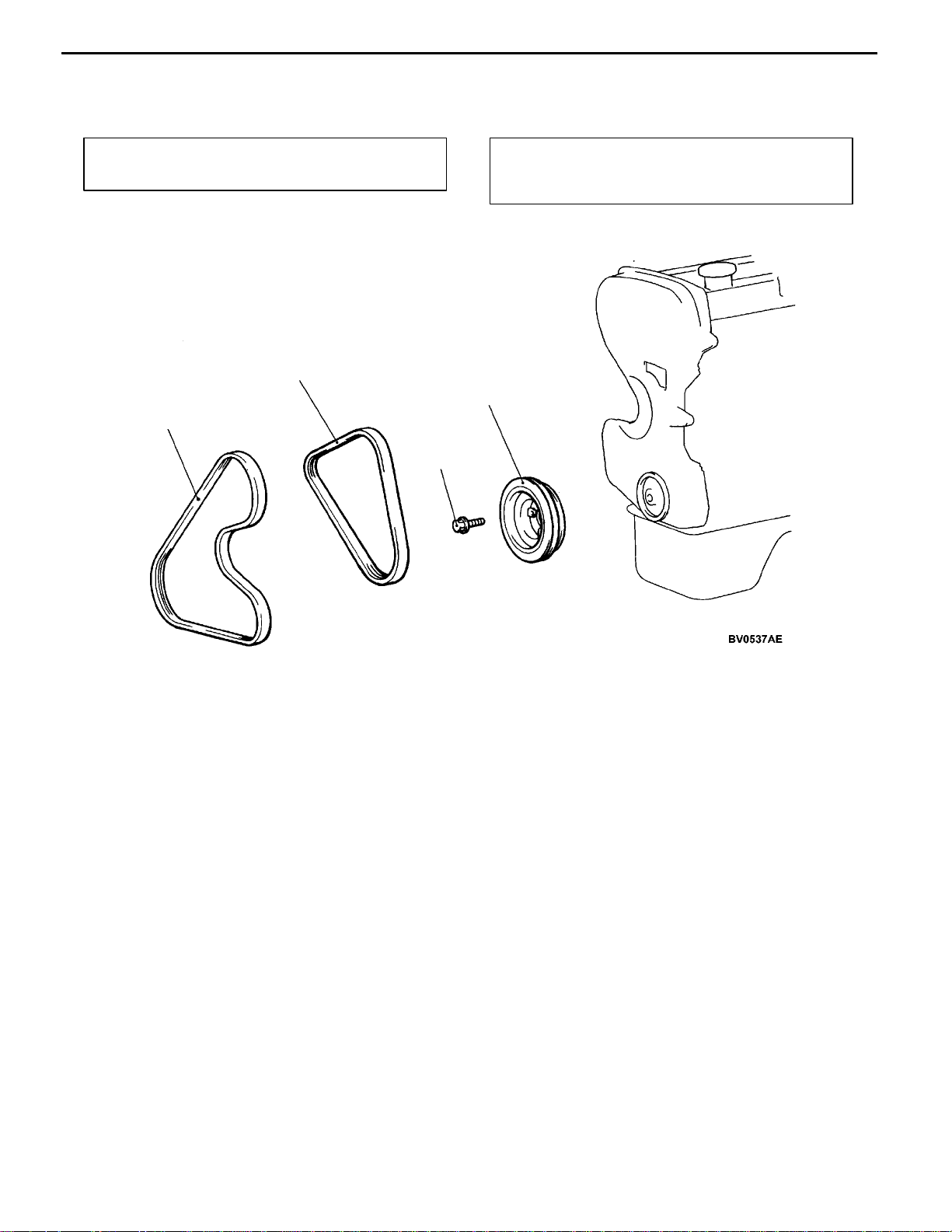

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

Pre-removal Operation

Under Cover Removal

2

1

11200160303

Post-installation Operation

D Drive Belt Tension Adjustment (Refer to P.11A-6.)

D Under Cover Installation

e

3

25 Nm

Removal steps

1. Drive belt (Power steering and

A/C)

2. Drive belt (Alternator)

3. Crankshaft pulley

Page 18

11A-18

ENGINE <4G6> -

Camshaft and Camshaft Oil Seal

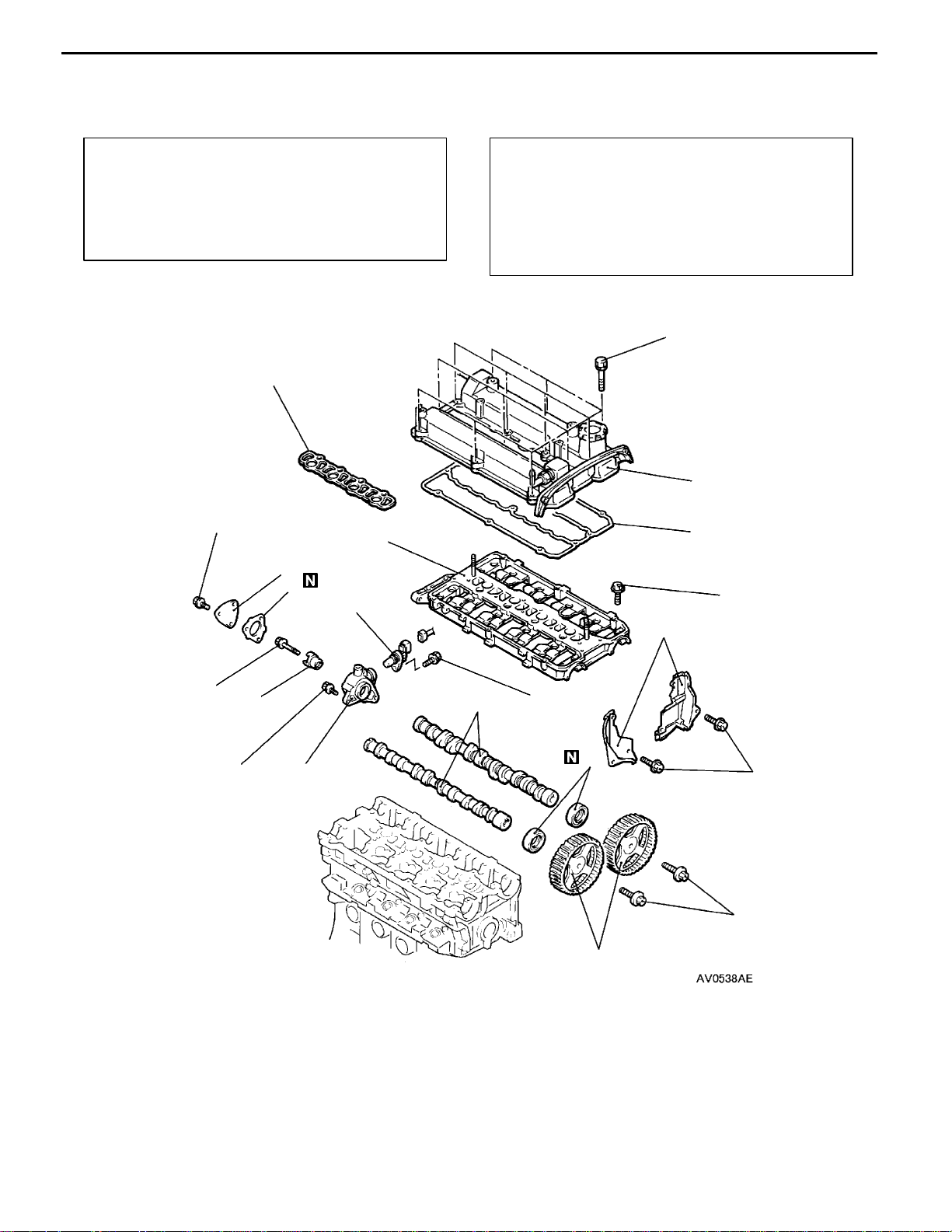

CAMSHAFT AND CAMSHAFT OIL SEAL

REMOVAL AND INSTALLATION

Pre-removal Operation

D Air Intake Hose Assembly Removal

D Timing Belt Removal (Refer to P.11A-30.)

D Engine Coolant Draining

D Intake Manifold Removal (Refer to GROUP 15.)

D Fuel Pump (High Pressure) Removal (Refer to

GROUP 13A.)

12

10 Nm

11

Post-installation Operation

D Fuel Pump (High Pressure) Installation (Refer to

GROUP 13A.)

D Intake Manifold Installation (Refer to GROUP 15.)

D Timing Belt Installation (Refer to P.11A-30.)

D Air Intake Hose Assembly Installation

D Engine Coolant Supplying

D Drive Belt Tension Adjustment (Refer to P.11A-6.)

11200190418

3.4 Nm

8

9

22 Nm

4

12 - 15 Nm

2

3

19 - 21 Nm

1

7

13

9Nm

10

5

10 - 12 Nm

88 Nm

6

"EA

AA""DA

Removal steps

1. Cam position sensor

2. Cover

3. Gasket

4. Camshaft position sensing cylinder

5. Camshaft position sensor support

6. Camshaft sprocket

7. Timing belt rear cover

"CA

"BA

"AA

8. Rocker cover

9. Rocker cover gasket

10. Camshaft oil seal

11. Beam camshaft cap

12. Beam camshaft cap gasket

13. Camshaft

Page 19

ENGINE <4G6> -

Lubrication points

<Seen from underneath

beam camshaft cap>

Sealant: 3M ATD Part No.8660 or equivalent

Camshaft and Camshaft Oil Seal

f3mm

11A-19

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

<Seen from above cylinder head>

Lip section

Engine oil

Sealant: 3M ATD Part No.8660 or equivalent

Page 20

11A-20

MB990767

MD998715 or

MD998719

ENGINE <4G6> -

Camshaft and Camshaft Oil Seal

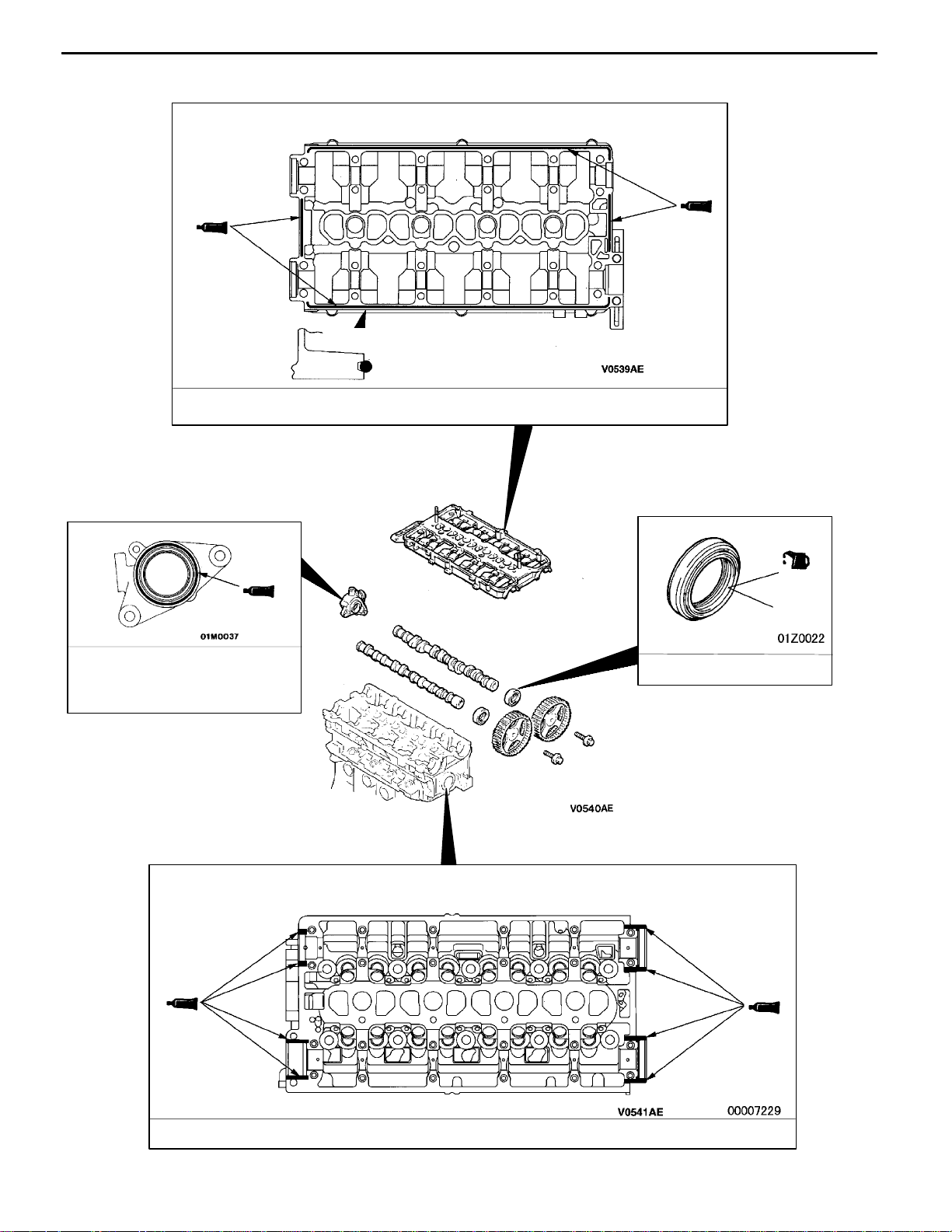

REMOVAL SERVICE POINTS

AA"

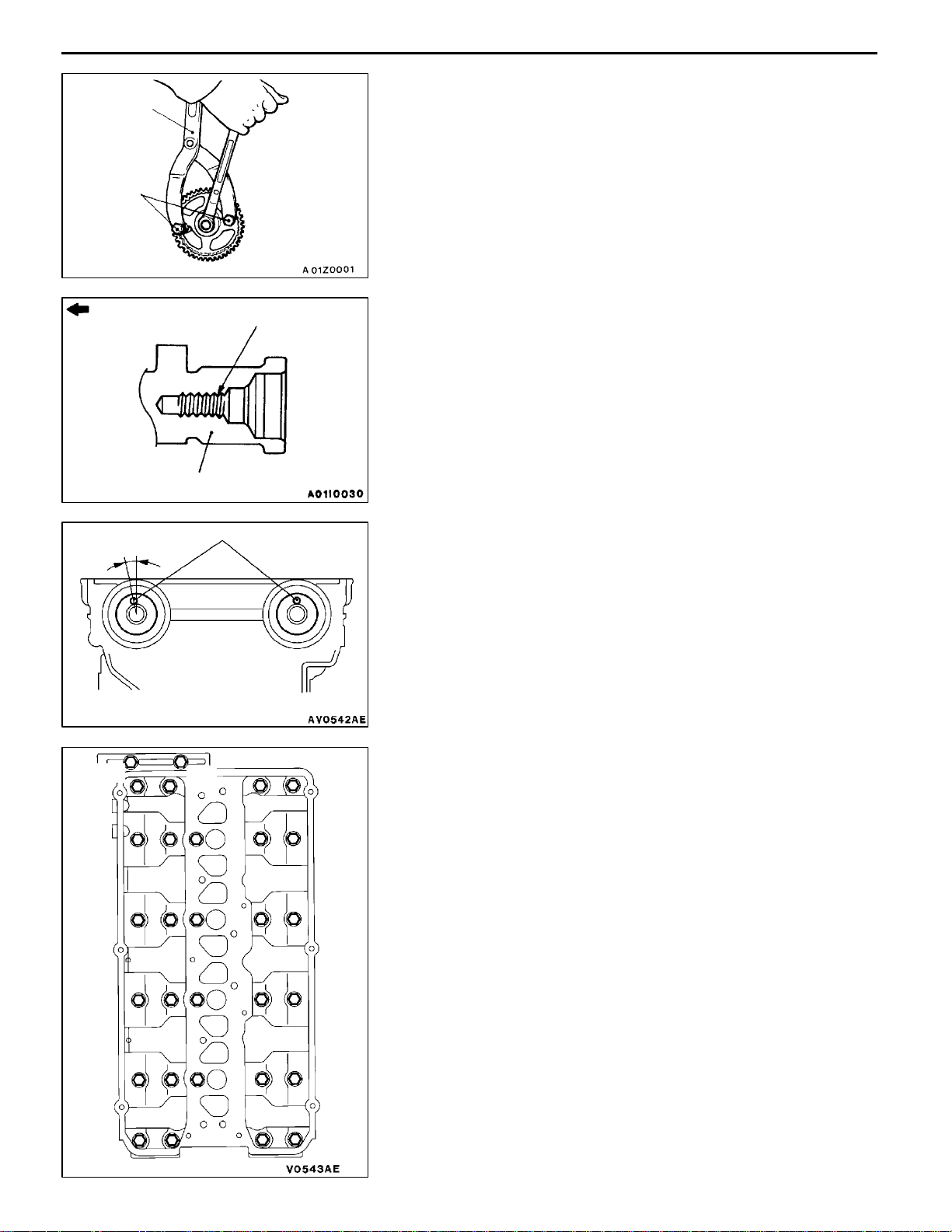

CAMSHAFT SPROCKET REMOVAL

Camshaft sprocket side

Exhaust camshaft

Approx. 12

Intake side

28

20

Dowel pin

_

27

19 23

Screw hole

Exhaust side

24

INSTALLATION SERVICE POINTS

"AA

1. Apply engine oil to journals and cams of the camshafts.

2. Install the camshafts on the cylinder head.

"BA

1. Place the camshaft dowel pin as shown in the illustration.

2. Tighten the beam camshaft cap mounting bolts to the

CAMSHAFT INSTALLATION

Caution

Be careful not to confuse the intake camshaft with

the exhaust one. There is a screw hole for the cam

position sensing cylinder mounting bolt on the

exhaust-side camshaft.

BEAM CAMSHAFT CAP INSTALLATION

specified torque in the order shown in the illustration.

Tightening torque: 19 - 21 Nm

11

12

87

14

22

30

3

13

2

21 17

4

29

15 16

5

61

910

18

25

26

Page 21

ENGINE <4G6> -

Camshaft and Camshaft Oil Seal

11A-21

MD998713

90

"CA

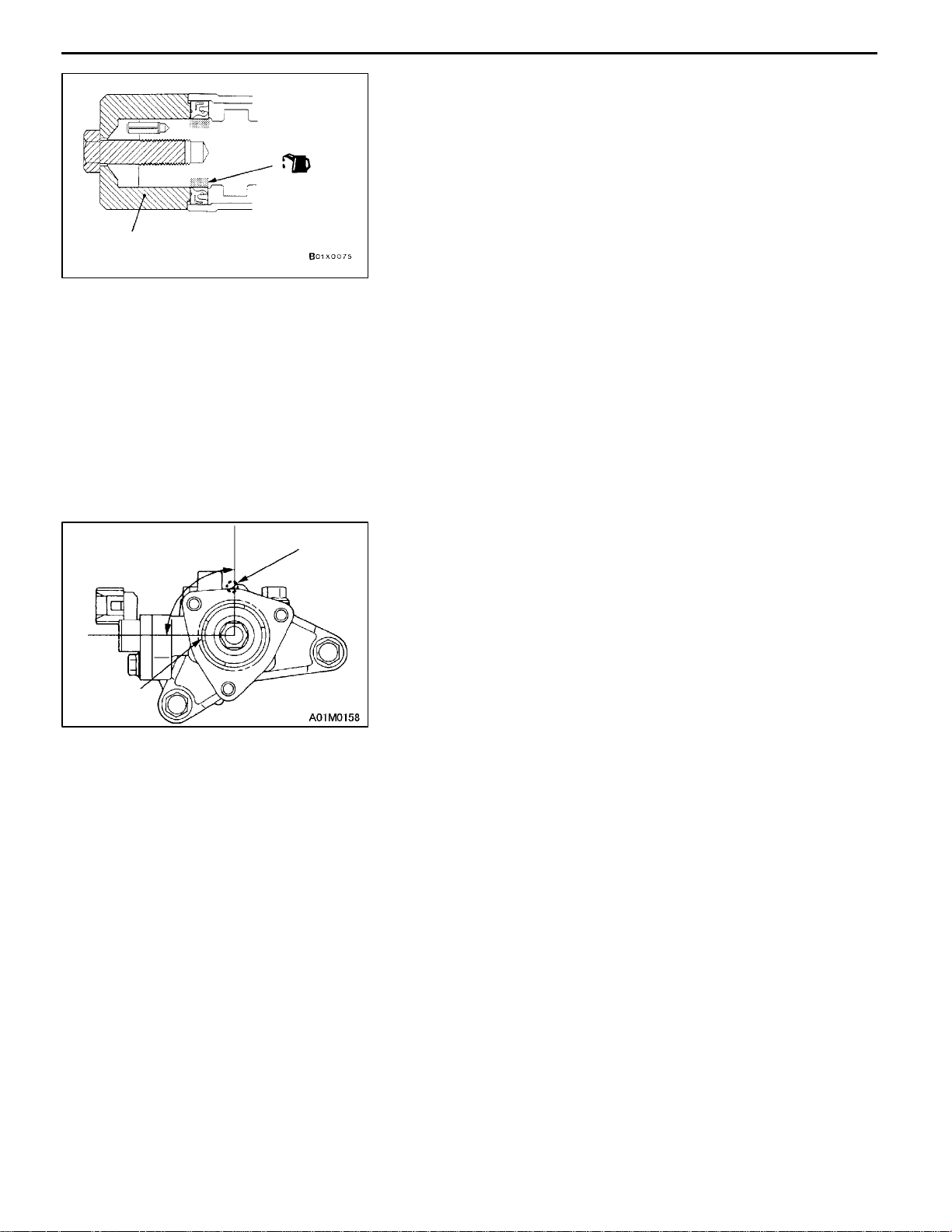

CAMSHAFT OIL SEAL INSTALLATION

1. Apply engine oil to the entire circumference of the oil

seal lip.

2. Press-fit the oil seal as shown in the illustration.

"DA

CAMSHAFT SPROCKET INSTALLATION

Use the special tool to secure the camshaft sprocket in the

same way as during removal, and then tighten the bolt to

the specified torque.

Tightening torque: 88 Nm

Dowel pin

_

"EA

Position the identification paint of cam position sensing

CAM POSITION SENSING CYLINDER

INSTALLATION

cylinder as shown in the illustration.

Identification

paint

Page 22

11A-22

ENGINE <4G6> -

Oil Pan

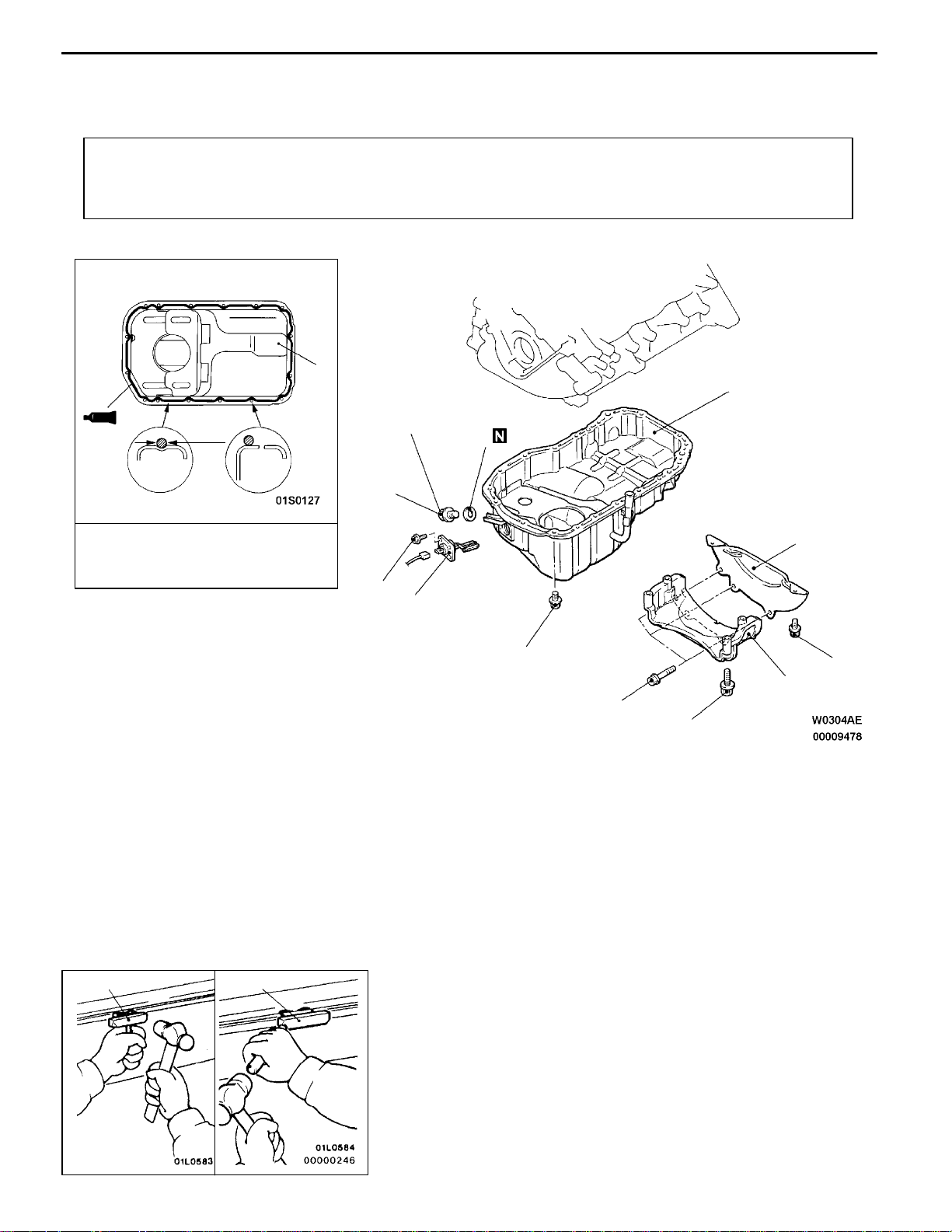

OIL PAN

REMOVAL AND INSTALLATION

Pre-removal a nd Post-installation Operation

D Under Cover Removal and Installation

D Engine Oil Draining and Supplying (Refer to GROUP

12 - On-vehicle Service.)

6

f 4 ± 1mm

Groove

Sealant:

MITSUBISHI GENUINE PART

MD970389 or equivalent

Bolt

hole

9Nm

11200280207

D Oil Level Gauge Removal and Installation

D Front Exhaust Pipe Removal and Installation (Refer

to GROUP 15.)

6

39 Nm

2

1

4

5

"AA

MD998727

Removal steps

1. Drain plug

2. Drain plug gasket

3. Transmission stay

MD998727

9Nm

9Nm

3

44 Nm

22 Nm

4. Bell housing cover

AA"

5. Oil level sensor

6. Oil pan

REMOVAL SERVICE POINT

AA"

After removing the oil pan mounting bolts, remove the oil

pan with the special tool and a brass bar.

Caution

Perform this slowly to avoid deformation of the oil pan

flange.

OIL PAN REMOVAL

Page 23

Drain plug

gasket

Oil pan side

ENGINE <4G6> -

INSTALLATION SERVICE POINT

"AA

Install the drain plug gasket in the direction so that it faces

as shown in the illustration.

DRAIN PLUG GASKET INSTALLATION

Oil Pan

11A-23

Page 24

11A-24

ENGINE <4G6> -

Crankshaft Oil Seal

CRANKSHAFT OIL SEAL

REMOVAL AND INSTALLATION

3

2

1

9

<M/T>

<A/T>

11200310135

5

4

127-137 Nm

7

127-137 Nm

9

4

6

8

Lip section

Engine oil

"CA

3

Lip section

Crankshaft front oil seal removal

steps

D

Timing belt (Refer to P.11A-30.)

1. Crankshaft sprocket B

2. Key

3. Crankshaft front oil seal

9

<A/T>

Crankshaft

(Engine oil:

bolt washer surface)

<M/T>

Crankshaft

6

Sealant: 3M Stud locking 4170 or equivalent

Crankshaft rear oil seal removal

steps

AA"D

AB""BA

AB""BA

AB""BA

AB""BA

"AA

Transmission assembly

D

Clutch cover and disc <M/T>

4. Adapter plate

5. Flywheel <M/T>

6. Drive plate <A/T>

7. Adapter plate <M/T>

8 Crankshaft bushing <A/T>

9. Crankshaft rear oil seal

(Engine oil:

bolt washer

surface)

5

Page 25

ENGINE <4G6> -

Crankshaft Oil Seal

11A-25

<M/T>

Flywheel

Crankshaft

rear oil seal

MD990938

MD998781

Bolt

Crankshaft

REMOVAL SERVICE POINTS

AA"

<M/T>:

Refer to GROUP 22.

Caution

Do not remove the flywheel mounting bolt shown by the

arrow. If this bolt Is removed, the flywheel will become

out of balance and damaged.

<A/T>:

Refer to GROUP 23.

AB"

Use the special tool to secure the flywheel or drive plate,

and remove the bolts.

TRANSMISSION ASSEMBLY REMOVAL

ADAPTER PLATE/FLYWHEEL <M/T>/DRIVE

PLATE <A/T> REMOVAL

INSTALLATION SERVICE POINTS

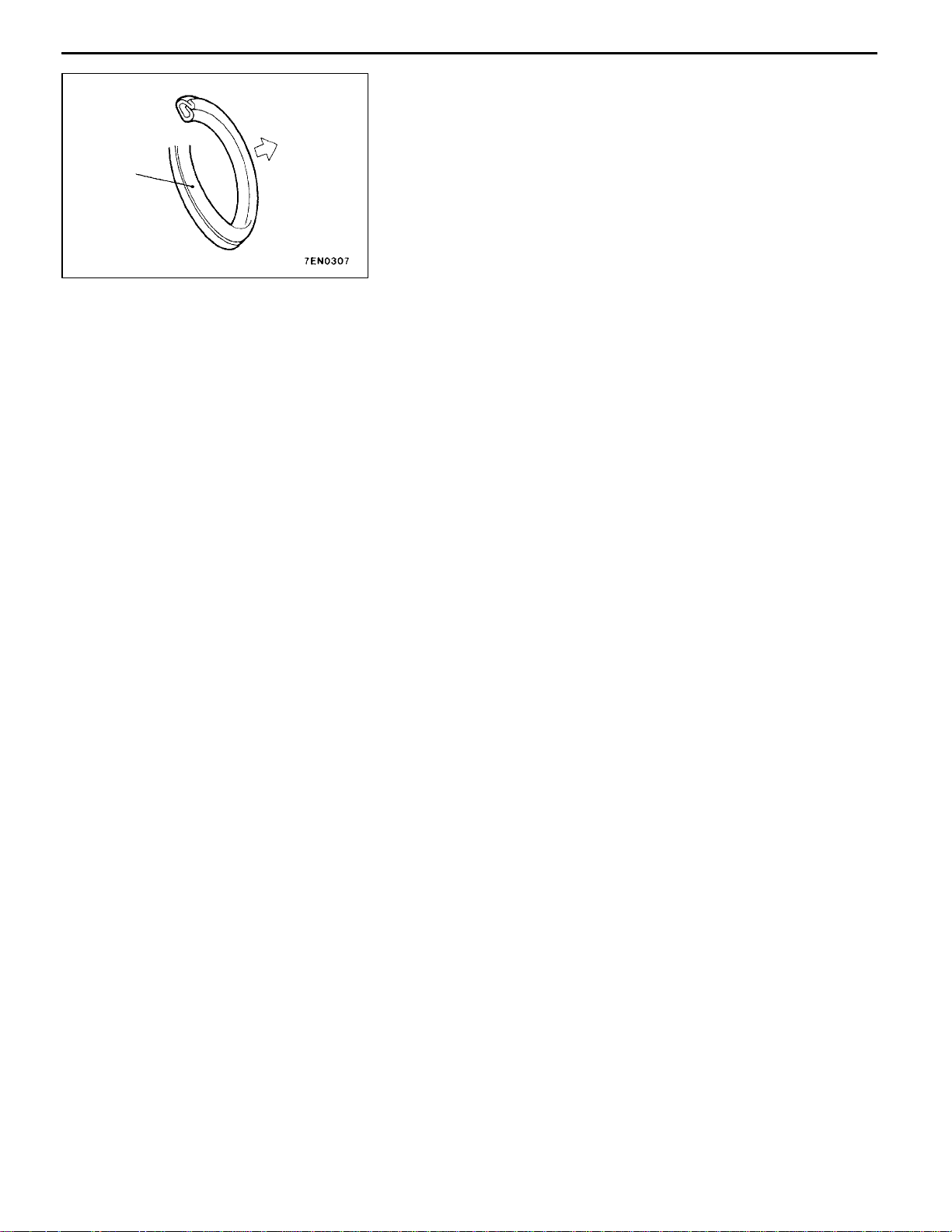

"AA

1. Apply a small mount of engine oil to the entire

2. Install the oil seal by tapping it as far as the chamfered

CRANKSHAFT REAR OIL SEAL INSTALLATION

circumference of the oil seal lip.

position of the oil seal case as shown in the illustration.

MD998776

Page 26

11A-26

ENGINE <4G6> -

Crankshaft Oil Seal

Crankshaft

Oil seal

"BA

DRIVE PLATE <A/T>/FLYWHEEL <M/T>/ADAPTER

PLATE INSTALLATION

1. Clean off all sealant, oil and other substances which are

adhering to the threaded bolts, crankshaft thread holes

and the flywheel or drive plate.

2. Apply oil to the bearing surface of the flywheel or drive

plate bolts.

3. Apply oil to the crankshaft thread holes.

4. Apply sealant to the threaded mounting holes.

Specified sealant: 3M Stud locking 4170 or equivalent

5. Use the special tool to hold the flywheel or drive plate

in the same manner as removal, and install the bolt.

"CA

CRANKSHAFT FRONT OIL SEAL INSTALLATION

1. Apply a small amount of engine oil to the entire

circumference of the oil seal lip.

2. Use the special tool to press-fit the oil seal unit it is flush

with the oil seal case.

MD998382

MD998285 (Apply oil to

entire circumference)

Page 27

ENGINE <4G6> -

Cylinder Head Gasket

11A-27

CYLINDER HEAD GASKET

REMOVAL AND INSTALLATION

Pre-removal a nd Post-installation Operation

D Fuel Discharge Prevention (Refer to GROUP 13A

- On-vehicle Service.) <Pre-removal only>

D Engine Coolant Draining and Supplying (Refer to

GROUP 14 - On-vehicle Service.)

D Engine Oil Draining and Supplying (Refer to GROUP

12 - On-vehicle Service.)

D Intake Manifold Removal and Installation (Refer to

GROUP 15.)

78 Nm®0Nm®20 Nm®+90

4

_ ®

3

+90

11200400542

D Fuel Pressure Regulator (High Pressure) and Fuel

Pump (High Pressure) Removal and Installation (Refer

to GROUP 13A.)

D Thermostat Case Assembly Removal and Installation

(Refer to GROUP 14 - Water Hose and Pipe.)

D Timing Belt Removal and Installation (Refer to

P.11A-30.)

7

_

8

3.4 Nm

9

5

24 Nm

Removal steps

1. Injector harness connector

2. Front exhaust pipe connection

3. Water hose connection

4. Water pipe assembly mounting bolt

5. EGR valve and stay assembly

1

AA""BA

"AA

10

6

2

44 Nm

34 Nm

6. Engine oil level gauge

7. Rocker cover

8. Cylinder head bolt

9. Cylinder head assembly

10. Cylinder head gasket

Page 28

11A-28

MB991653

Intake side Front of engine

35108 2

1796 4

Exhaust side

ENGINE <4G6> -

REMOVAL SERVICE POINT

AA"

Use the special tool to loosen the bolts in two or three steps

in the order of the numbers shown in the illustration, and

then remove the bolts.

If the washer is caught on valve spring and the bolt is not

removed, pull up the bolt slightly and remove the bolt while

tilting the washer by using a magnet, etc.

Cylinder Head Gasket

CYLINDER HEAD BOLT REMOVAL

INSTALLATION SERVICE POINTS

"AA

1. Wipe off all oil and grease from the gasket mounting

2. Install so that the shapes of the cylinder head holes match

"BA

Burred side

Head bolt

A

washer

Cylinder

head

Head bolt

(Engine

oil)

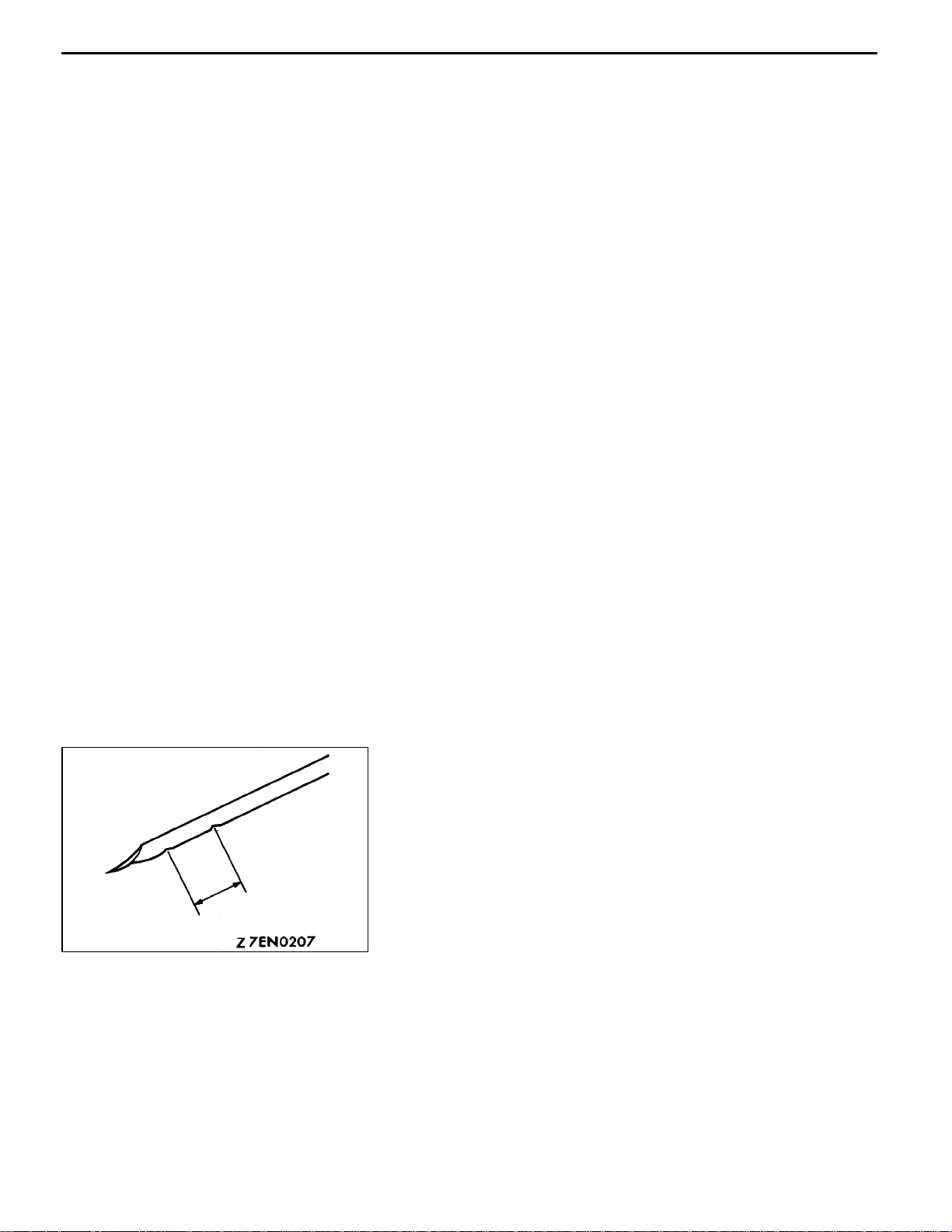

1. When installing the cylinder head bolts, the length below

2. The head bolt washer should be installed with the burred

3. Apply a small amount of engine oil to the thread section

CYLINDER HEAD GASKET INSTALLATION

surface.

the shapes of the respective cylinder head gasket holes.

CYLINDER HEAD BOLT INSTALLATION

the head of the bolts should be within the limit.

If it is outside the limit, replace the bolts.

Limit (A): 99.4 mm

side caused by tapping out facing upwards.

and the washer of the cylinder head bolt.

Page 29

ENGINE <4G6> -

4. Tighten the bolts by the following procedure.

Step Operation Remarks

Cylinder Head Gasket

1 Tighten to 78 Nm. Carry out in the order

shown in the illustration.

2 Fully loosen. Carry out in the reverse

order of that shown in the

illustration.

11A-29

MB991653

Intake side Front of engine

861 3 9

104257

Exhaust side

Step 4

90

Painted mark

_

Step 5

Painted mark

90

3 Tighten to 20 Nm. Carry out in the order

shown in the illustration.

4 Tighten 90_of a turn. In the order shown in the

illustration. Mark the head

of the cylinder head bolt

and cylinder head by paint.

5 Tighten 90_of a turn. In the order shown in the

illustration. Check that the

painted mark of the head

bolt is lined up with that of

the cylinder head.

Caution

1. Always make a tightening angle just 90_. If it is less

than 90_, the head bolt will be loosened.

2. If it is more than 90_, remove the head bolt and repeat

the procedure from step 1.

_

Page 30

11A-30

ENGINE <4G6> -

Timing Belt and Timing Belt B

TIMING BELT AND TIMING BELT B

REMOVAL AND INSTALLATION

Pre-removal a nd Post-installation Operation

D Engine Cover Removal and Installation

D Under Cover Removal and Installation

D Crankshaft Pulley Removal and Installation (Refer to

P.11A-17.)

48 Nm

4

24 Nm

2

11200430473

D Engine Mount Bracket Removal and Installation (Refer

to GROUP 32 - Engine Mounting.)

22 Nm

6

9Nm

10-12 Nm

1

10-12 Nm

9Nm

5

10

19 Nm

11

9

8

3

108-127 Nm

9Nm

7

AA""EA

"FAD

"DA

Removal steps

1. Water pump pulley

2. Timing belt front upper cover

3. Timing belt front lower cover

Timing belt tension adjustment

4. Timing belt

5. Auto tensioner

AB""CA

"BA

"AA

AC""AA

6. Tensioner pulley assembly

7. Crankshaft position sensor

8. Crankshaft sprocket

9. Crankshaft sensing blade

10. Timing belt B tensioner

11. Timing belt B

Page 31

ENGINE <4G6> -

Timing Belt and Timing Belt B

11A-31

Crankshaft

sprocket

Timing marks

MD998719 or MD998754

Centre bolt

REMOVAL SERVICE POINT

AA"

1. Turn the crankshaft clockwise (right turn) to align each

2. Loosen the tension pulley centre bolt.

3. Move the tension pulley to the water pump side, and

AB"

TIMING BELT REMOVAL

timing mark and to set the No. 1 cylinder at compression

top dead centre.

Caution

The crankshaft should always be turned only

clockwise.

then remove the timing belt.

Caution

If the timing belt is to be re-used, use chalk to mark

(on its flat side) an arrow indicating the clockwise

direction.

CRANKSHAFT SPROCKET REMOVAL

MB990767

AC"

TIMING BELT B REMOVAL

Caution

If timing belt B is to be re-used, use chalk to mark it

with an arrow on its flat side indicating the turning

direction (to the right).

Page 32

11A-32

ENGINE <4G6> -

Timing Belt B and Timing Belt B

Counterbalance shaft sprocket

Timing

marks

Crankshaft

sprocket B

Centre of

tensioner

pulley

Centre of installation

bolt

Shaft

Belt tension side

Timing marks

INSTALLATION SERVICE POINTS

"AA

1. Install timing belt B by the following procedure.

2. Adjust the tension of timing belt B by the following

TIMING BELT B/TIMING BELT B TENSIONER

INSTALLATION

(1) Ensure that crankshaft sprocket B timing mark and

the counterbalance shaft sprocket timing mark are

aligned.

(2) Fit timing belt B over crankshaft sprocket B and the

counterbalance shaft sprocket. Ensure that there is

no slack in the belt.

procedure.

(1) Temporarily fix the timing belt B tensioner such that

the centre of the tensioner pulley is to the left and

above the centre of the installation bolt, and

temporarily attach the tensioner pulley so that the

flange is toward the front of the engine.

(2) Holding the timing belt B tensioner up with your finger

in the direction of the arrow, place pressure on t he

timing belt so that the tension side of the belt is taut.

Now tighten the bolt to fix the tensioner.

Caution

Whentightening thebolt, ensure thatthe tensioner

pulley shaft does not rotate with the bolt. Allowing

it to rotate with the bolt can cause excessive

tension on the belt.

Centre of

tensioner

pulley

Centre of

installation

bolt

Crankshaft

sprocket

Crankshaft

sensing blade

A

Crankshaft

Crankshaft

sprocket B

3. To ensure that the tension is correct, depress the belt

(point A) with a finger. If not, adjust.

Standard value: 5 - 7 mm

"BA

CRANKSHAFT SENSING BLADE INSTALLATION

Confirm the installation direction of crankshaft sensing blade

and install it as shown in the illustration.

Page 33

ENGINE <4G6> -

Timing Belt and Timing Belt B

11A-33

B

A

Auto tensioner

98 - 196N

AB

Movement

Push rod

"CA

CRANKSHAFT SPROCKET INSTALLATION

1. Apply the minimum amount of engine oil to the seat surface

and thread of the crankshaft bolt.

2. Hold the crankshaft sprocket as same as for removal,

and then tighten the bolt to the specified torque.

Tightening torque: 108 - 127 Nm

"DA

AUTO TENSIONER INSTALLATION

1. Apply 98 - 196 N force to the auto tensioner by pressing

it against a metal (cylinder block, etc.), and measure the

movement of the push rod.

Standard value: Within 1 mm

A: Length when it is free (not pressed)

B: Length when it is pressed

A - B: Movement

2. If it is out of the standard value, replace the auto tensioner.

3. Use a press or vice to gently compress the auto tensioner

push rod until pin hole A of the push rod and pin hole

B of the tensioner cylinder are aligned.

Set pin

Caution

If the compression speed is too fast, the rod may

become damaged, so be sure to carry out this

operation slowly.

4. Once the holes are aligned, insert the set pin.

NOTE

When replacing the auto tensioner with a new part, the

pin will be in the auto tensioner.

5. Install the auto tensioner to the engine.

Page 34

11A-34

ENGINE <4G6> -

Timing Belt and Timing Belt B

Timing

marks

Crankshaft

sprocket

Timing marks

Plug

60 mm or

more

Counterbalance

shaft

Camshaft

sprocket

Timing

marks

Oil pump

sprocket

8mm

Screwdriver

Cylinder

block

"EA

TIMING BELT INSTALLATION

1. Align the timing marks on the camshaft sprocket,

crankshaft sprocket and oil pump sprocket.

2. After aligning the timing mark on the oil pump sprocket,

remove the cylinder block plug and insert a Phillips

screwdriver with a diameter of 8 mm, and check to be

sure that the screwdriver goes in 60 mm or more. If

the screwdriver will only go in 20 - 25 mm before striking

the counterbalance shaft, turn the sprocket once, realign

the timing mark and check that the screwdriver goes in

60 mm or more. The screwdriver should not be taken

out until the timing belt is installed.

Intake

camshaft

sprocket

Tensioner

pulley

Crankshaft

sprocket

Exhaust

camshaft

sprocket

Idler

pulley

Oil pump

sprocket

Paper clip

3. Install the timing belt by the following procedure. Take

care not to slacken the belt at the tension side.

(1) Install the timing belt to the crankshaft sprocket, oil

pump sprocket and idler pulley in that order.,

(2) Place the timing belt on the exhaust-side camshaft

sprocket, and hold it in the position shown in the

illustration with a paper clip.

Page 35

ENGINE <4G6> -

Timing Belt and Timing Belt B

11A-35

Timing marks

Paper clip

(3) Place the timing belt on the intake-side sprocket while

using two wrenches to align the timing marks.

(4) Hold the belt in the position shown in t he illustration

with another paper clip.

(5) Place the timing belt on the tensioner pulley.

(6) Remove the two paper clips.

Caution

After installing the timing belt, apply force to turn

the camshaft sprocket in the reverse direction,

and recheck to be sure that the belt is fully

tensioned and that each timing mark is in the

proper position.

4. Set the tension pulley so that the pin holes of centre

bolt are at the bottom, press the tension pulley lightly

against the timing belt, and then provisionally tighten the

centre bolt.

5. Check to be sure that all timing marks are aligned.

6. Adjust the timing belt tension.

50 Nm

MD998767

Tension

direction

"FA

TIMING BELT TENSION ADJUSTMENT

1. After turning the crankshaft 1/4 of a revolution in t h e

anticlockwise direction, turn it in the clockwise direction

until the timing marks are aligned.

2. Loosen the tension pulley fixing bolt, and then use the

special tool and a torque wrench to tighten the fixing

bolt to the specified torque while applying tension to the

timing belt.

Standard value: 3.5 Nm <Timing belt tension torque>

Caution

When tightening the fixing bolt, make sure that the

tension pulley does not turn with the bolt.

Page 36

11A-36

Auto tensioner

ENGINE <4G6> -

A

Timing Belt and Timing Belt B

3. Turn the crankshaft two revolutions in the clockwise

direction so that the timing marks are aligned. After leaving

it for 15 minutes, measure the amount of protrusion of

the auto tensioner.

Standard value (A): 3.8 - 4.5 mm

4. If the amount of protrusion is outside the standard value,

repeat the operation in steps (1) to (3).

5. Check again to be sure that the timing marks of each

sprocket are aligned.

Page 37

ENGINE <4G6> -

Engine Assembly

11A-37

ENGINE ASSEMBLY

11200090015

REMOVAL AND INSTALLATION

Caution

Mounting locations marked by * should be provisionally tightened, and then fully tightened after

placing the vehicle horizontally and loading the full weight of the engine on the vehicle body.

Pre-removal a nd Post-installation Operation

D Fuel Discharge Prevention (Refer to GROUP 13A

- On-vehicle Service.) <Pre-removal only>

D Engine Cover Removal and Installation

D Under Cover Removal and Installation

D Engine Coolant Draining and Supplying (Refer to

GROUP 14 - On-vehicle Service.)

12

D Hood Removal and Installation (Refer to GROUP 42.)

D Transmission Assembly Removal and Installation

(Refer to GROUP 22 or 23.)

D Drive Belt Tension Adjustment (Refer to P.11A-6.)

<Post-installation only>

2

3

16

8

5

7

14

15

13

11

67 Nm

57 Nm

98 - 118Nm*

15

9

6

10

1

4

AA"

AB"

Removal steps

1. Drive belt (Power steering and

A/C)

2. Engine harness connector

3. Earth cable connection

4. Alternator connector

5. Power steering hose clamp

6. A/C compressor

7. Power steering oil pump

8. Vacuum hose connection

AC""CA

"BA

AD""AA

9. Brake booster vacuum hose

connection

10. Heater hose connection

11. Fuel return hose connection

12. Fuel pressure hose connection

13. Power steering oil reservoir

14. Engine mount bracket

15. Engine mount stopper

16. Engine assembly

Page 38

11A-38

ENGINE <4G6> -

REMOVAL SERVICE POINTS

AA"

Disconnect the A/C compressor connector and remove the

compressor from the compressor bracket with the hose still

attached.

NOTE

Place the removed A/C compressor where it will not be a

hindrance when removing and installing the engine assembly,

and tie it with a cord.

Engine Assembly

A/C COMPRESSOR REMOVAL

MB991453

MZ203827

AB"

Remove the power steering oil pump and bracket assembly

from the engine with the hose attached.

NOTE

Place the removed power steering oil pump in a place where

it will not be a hindrance when removing and installing the

engine assembly, an d tie it with a cord.

AC"

1. Support the engine with a garage jack.

2. Remove the special tool which was attached when the

3. Hold the engine assembly with a chain block or similar

4. Place a garage jack against the engine oil pan with a

AD"

After checking that all cables, hoses and harness connectors,

etc., are disconnected from the engine, lower the chain block

slowly to remove the engine assembly downward from the

engine compartment.

POWER STEERING OIL PUMP REMOVAL

ENGINE MOUNT BRACKET REMOVAL

transmission assembly was removed.

tool.

piece of wood in between, jack up the engine so that

the weight of the engine is no longer being applied to

the engine mount bracket, and then remove the engine

mount bracket.

ENGINE ASSEMBLY REMOVAL

Page 39

ENGINE <4G6> -

INSTALLATION SERVICE POINTS

"AA

Install the engine assembly, checking that the cables, hoses,

and harness connectors are not clamped.

Engine Assembly

ENGINE ASSEMBLY INSTALLATION

11A-39

Engine

mount

stopper

Engine mount bracket

Engine side

Arrow

"BA

ENGINE MOUNT STOPPER INSTALLATION

Clamp the engine mount stopper so that the arrow points

in the direction as shown in the diagram.

"CA

ENGINE MOUNT BRACKET INSTALLATION

1. Place a garage jack against the engine oil pan with a

piece of wood in between, and install the engine mount

bracket while adjusting the position of the engine.

2. Support the engine with the garage jack.

3. Remove the chain block and support the engine assembly

with the special tool.

Page 40

NOTES

Page 41

ENGINE

<4G9>

CONTENTS

11B-1

GENERAL INFORMATION 2..................

SERVICE SPECIFICATIONS 2.................

SEALANTS 4................................

SPECIAL TOOLS 4..........................

ON-VEHICLE SERVICE 6.....................

Drive Belt Tension Check and Adjustment 6......

Ignition Timing Check 9........................

Idle Speed Check 10...........................

Idle Mixture Check 11..........................

Compression Pressure Check 12................

Manifold Vacuum Check 13.....................

Lash Adjuster Check 13........................

CRANKSHAFT PULLEY 16..................

CAMSHAFT AND CAMSHAFT OIL SEAL 17..

OIL PAN 21.................................

CRANKSHAFT OIL SEAL 23.................

CYLINDER HEAD GASKET 25...............

TIMING BELT 28............................

ENGINE ASSEMBLY 33.....................

Page 42

11B-2

ENGINE <4G9> -

General Information/Service Specifications

GENERAL INFORMATION

Items 4G93

Total displacement mL 1,834

Bore ´ Stroke mm 81.0 ´ 89.0

Compression ratio 12.5

Combustion chamber Pentroof + ball-in-piston

Camshaft arrangement DOHC

Number of valve

V alve timing Intake

Fuel system Electronically controlled multipoint fuel injection

Rocker arm Roller type

Auto-lash adjuster Equipped

Intake 8

Exhaust 8

Opening BTDC 15_

Closing ABDC 56_

Exhaust

Opening BBDC 55_

Closing ATDC 15_

SERVICE SPECIFICATIONS

Items Standard value Limit

Alternator drive Vibration

belt tension frequency Hz

Tension N

When checked 143 - 185 -

When a used belt is installed 155 - 175 -

When a new belt is installed 203 - 234 -

When checked 294 - 490 -

Deflection

(Reference

value) mm

When a used belt is installed 343 - 441 -

When a new belt is installed 588 - 784 -

When checked 9.7 - 12.9 -

When a used belt is installed 10.5 - 12.0 -

When a new belt is installed 6.7 - 8.5 -

Page 43

ENGINE <4G9> -

Items LimitStandard value

Service Specifications

11B-3

Power steering Vibration

oil pump and

A/C compressor

drive belt tension

Basic ignition timing 5_ BTDC ± 3_ -

Ignition timing Approx. 16_BTDC

Idle speed r/min M/T 600 ± 100*

CO contents % 0.5 or less -

frequency Hz

Tension N

Deflection

(Reference

value) mm

A/T 650 ± 100 -

When checked 1 14 - 139 -

When a used belt is installed 121 - 133 -

When a new belt is installed 145 - 166 -

When checked 392 - 588 -

When a used belt is installed 441 - 539 -

When a new belt is installed 637 - 833 -

When checked 10.0 - 12.0 -

When a used belt is installed 10.0 - 11.0 -

When a new belt is installed 7.0 - 9.0 -

(Approx. 6_BTDC)*

1

(750 ± 100)*

(750 ± 100)*

2

2

2

-

-

HC contents ppm 100 or less -

Compression pressure kPa - r/min 1,790 - 300 1,400 - 300

Compression pressure difference of all cylinder kPa - Max. 100

Intake manifold vacuum kPa - Min. 37

Cylinder head bolt shank length mm - 99.4

Timing belt tension torque Nm (Reference value) 2.5 - 4.0 -

Auto-tensioner rod protrusion amount mm 3.8 - 4.5 -

NOTE

*1: Varies depending on the transmission oil temperature. For details, refer to P. 11B-10.

2

*

: Indicates the value when more than 4 minutes have passed since the engine was started.

Page 44

11B-4

ENGINE <4G9> -

Sealants/Special Tools

SEALANTS

Items Specified sealants Remarks

Beam camshaft cap

Cylinder head

Cam position sensor support

Oil pan

Flywheel or drive plate bolt 3M Stud Locking 4170 or equivalent -

3M ATD Part No.8660 or equivalent -

MITSUBISHI GENUINE PART

MD970389 or equivalent

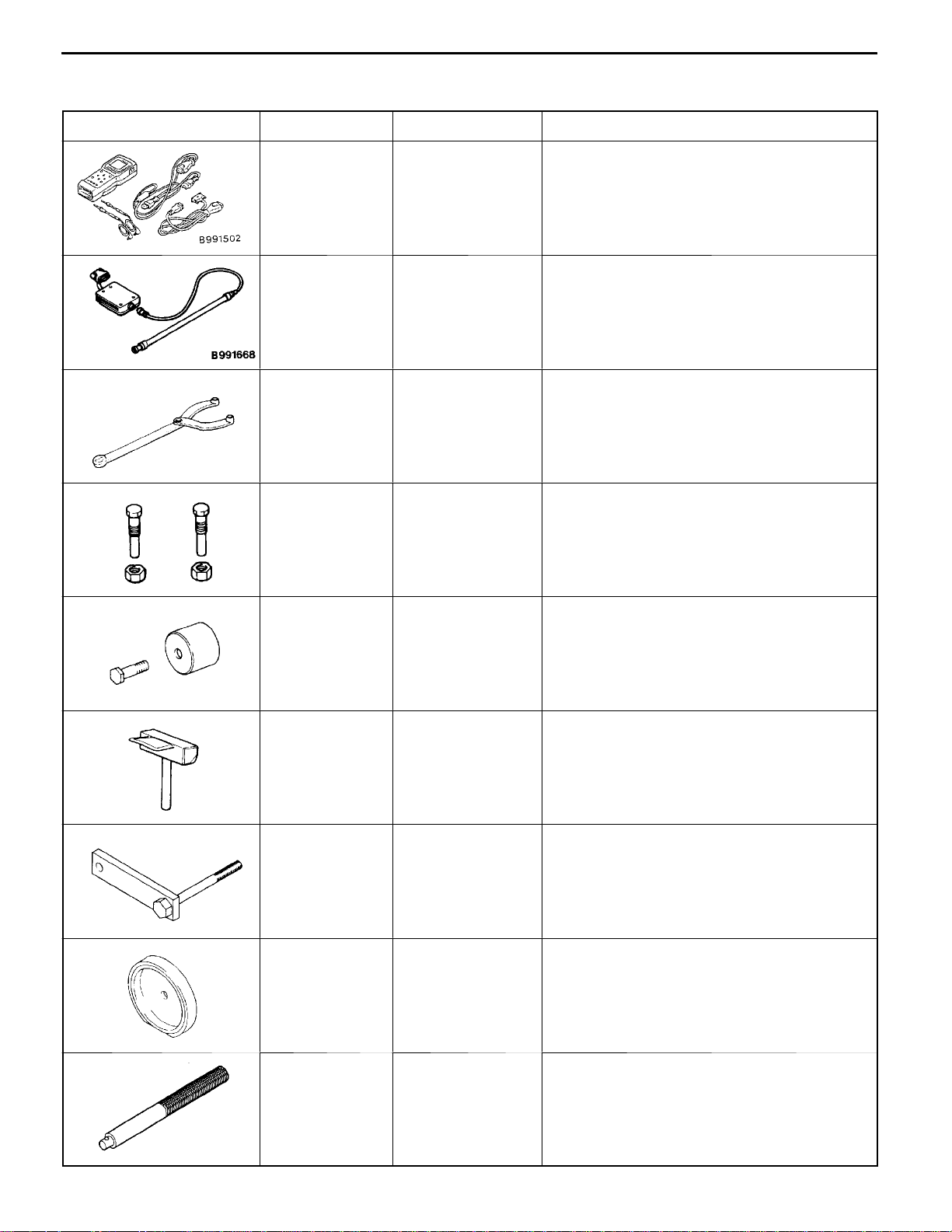

SPECIAL TOOLS

Tool Number Name Use

MB991502 MUT-II sub

assembly

MB991668 Belt tension meter

set

MB990767 End yoke holder D Holding the camshaft sprocket

D Measuring the drive belt tension

D Checking the ignition timing

D Checking the idle speed

D Erasing diagnosis code

Measuring the drive belt tension

(used together with the MUT-II)

D Holding the crankshaft sprocket

Semi-drying sealant

MD998719 or

MD998754

MD998713 Camshaft oil seal

MD998781 Flywheel stopper Securing the flywheel <M/T> or drive plate

Crankshaft pulley

holder pin

Press-in of the camshaft oil seal

installer

<A/T>

Page 45

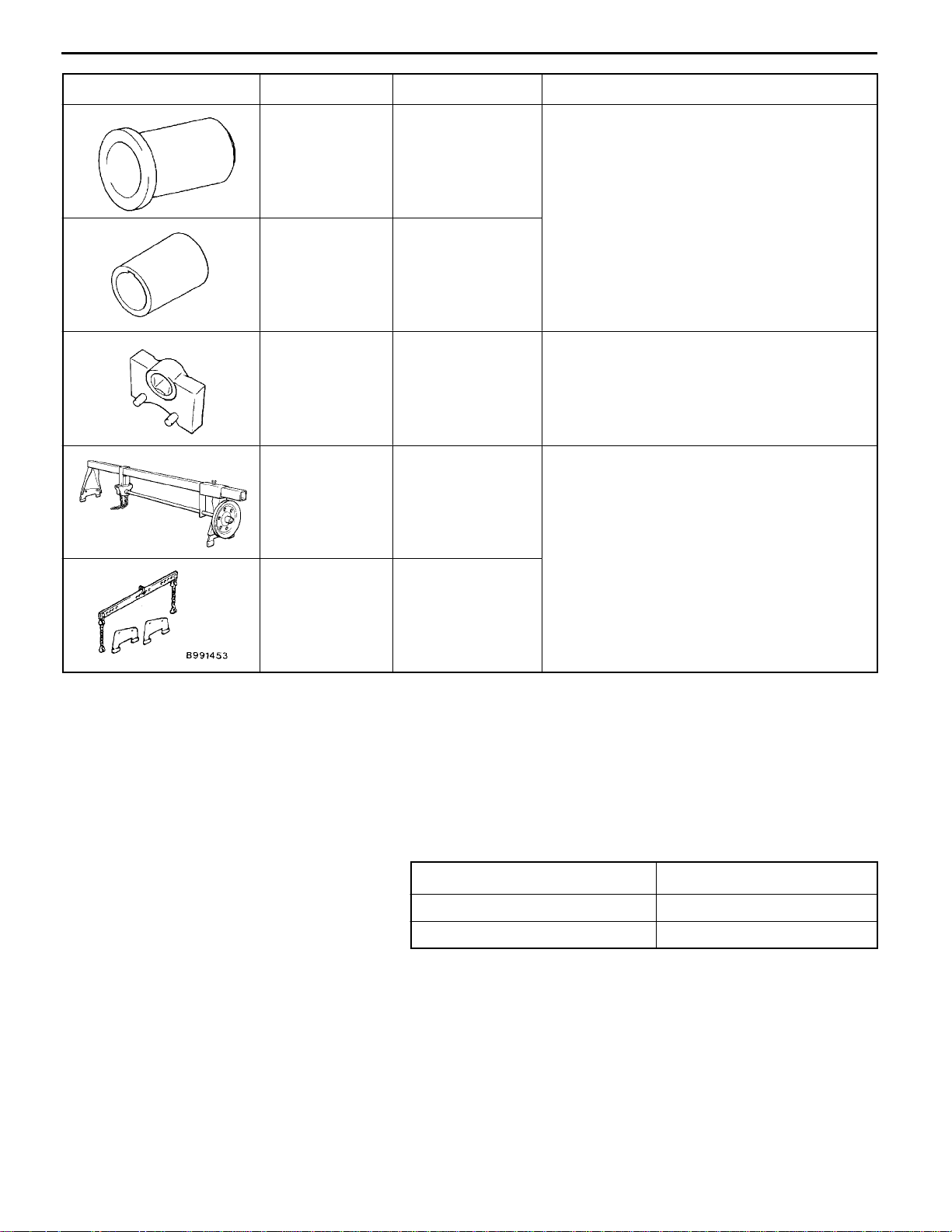

Tool UseNameNumber

ENGINE <4G9> -

Special Tools

11B-5

MD998776 Crankshaft rear oil

seal installer

MB990938 Handle

MD998717 Crankshaft front oil

seal installer

MD998767 Tension pulley

socket wrench

Press-in of the crankshaft rear oil seal

Press-in of the crankshaft front oil seal

Timing belt tension adjustment

GENERAL

SERVICE

TOOL

MZ203827

MB991453 Engine hanger

Engine lifter Supporting the engine assembly during

assembly

removal and installation of the transmission

Page 46

11B-6

ENGINE <4G9> -

ON-VEHICLE SERVICE

DRIVE BELT TENSION CHECK AND

ADJUSTMENT

ALTERNATOR DRIVE BELT TENSION CHECK

Check the drive belt tension by th e following procedure.

On-vehicle Service

Alternator

pulley

15

_

15

Tap lightly with

a finger.

_

MB991668

(Microphone)

10 - 20 mm

Crankshaft

pulley

<When using the MUT-II>

1. Connect the special tool (belt tension meter kit) to the

MUT-II.

2. Connect the MUT-II to the diagnosis connector.

3. Turn the ignition switch to ON and select “Belt Tension

Measurement” from the menu screen.

4. Hold the microphone to the middle of the drive belt

between the pulleys (at the place indicated by the arrow),

about 10 - 20 mm away from the rear surface of the

belt and so that it is perpendicular to the belt (within

an angle of ± 15_).

5. Gently tap the middle of the belt between the pulleys

(the place indicated by the arrow) with your finger as

shown in the illustration, and check that the vibration

frequency of the belt is within the standard value.

Caution

(1) The temperature of the surface of the belt should

be as close as possible to normal temperature.

(2) Do not let any contaminants such as water or

oil get onto the microphone.

(3) If strong gusts of wind blow against the

microphone or if there are any loud sources of

noise nearby, the values measured by the

microphone may not correspond to actual values.

(4) If the microphone is touching the belt while the

measurementis being made, the values measured

by the microphone may not correspond to actual

values.

(5) Do not take the measurement while the vehicle’s

engine is running.

Alternator

pulley

Belt tension

gauge

Crankshaft pulley

<When using a tension gauge>

Use a belt tension gauge to check that the belt tension is

within the standard value.

Page 47

ENGINE <4G9> -

On-vehicle Service

11B-7

Deflection

Alternator

pulley

Adjusting bolt

Lock bolt

Pivot bolt

98 N

Crankshaft

pulley

<Belt deflection check>

Apply 98 N of force to the middle of the drive belt between

the pulleys (at the place indicated by the arrow) and check

that the amount of deflection is within the standard value.

Standard value:

Vibration frequency Hz 143 - 185

Tension N 294 - 490

Deflection (Reference value) mm 9.7 - 12.9

ALTERNATOR DRIVE BELT TENSION ADJUSTMENT

1. Loosen the nut of the alternator pivot bolt.

2. Loosen the lock bolt.

3. Use the adjusting bolt to adjust the belt tension and belt

deflection to the standard values.

Standard value:

Items When a used

belt is installed

Vibration frequency Hz 155 - 175 203 - 234

Tension N 343 - 441 588 - 784

Deflection

(Reference value) mm

10.5 - 12.0 6.7 - 8.5

When a new

belt is installed

NOTE

Refer to P.11B-6 concerning the measurement procedure

of the alternator drive belt tension.

4. Tighten the nut of the alternator pivot bolt.

Tightening torque: 44 Nm

5. Tighten the lock bolt.

Tightening torque: 22 Nm

6. Tighten the adjusting bolt.

Tightening torque: 5.0 Nm

Page 48

11B-8

ENGINE <4G9> -

On-vehicle Service

<VehicleswithoutA/C>

Oil pump pulley

98 N

A

Crankshaft

pulley

<Vehicleswith A/C>

Oil pump pulley

98 N

Crankshaft

pulley

A

B

Tensioner pulley

Tensioner

pulley

B

A/C

compressor

pulley

POWER STEERING OIL PUMP AND AIR CONDITIONER

COMPRESSOR DRIVE BELT TENSION CHECK AND

ADJUSTMENT

11100130127

1. Check if the belt tension is within the standard value

using one of the methods below.

Standard value:

Items When

checked

Vibration

frequency

Hz

Tension N 392 - 588 441 - 539 637 - 833

Deflection

(Reference

value) mm

1 14 - 139 121 - 133 145 - 166

10.0 - 12.0 10.0 - 11.0 7.0 - 9.0

When a

used belt is

installed

When a new

belt is

installed

<When measuring the vibration frequency>

With your finger tip lightly tap the centre of the belt between

the pulleys in t he location shown by the arrow in the

illustration and then measure the belt vibration frequency.

NOTE

Refer to P.11B-6 for information regarding the vibration

frequency measurement method using MUT-II.

<When measuring the tension>

Use a belt tension gauge to measure the belt tension.

<When measuring the deflection>

Apply 98 N of pressure against the location between

the pulleys shown by the arrow in the illustration and

then measure the deflection.

2. If the tension or deflection is outside the standard value,

adjust by the following procedure.

(1) Loosen tensioner pulley fixing nut A.

(2) Adjust the amount of belt deflection using adjusting

bolt B.

(3) Tighten fixing nut A.

Tightening torque: 25 Nm

(4) Check the belt deflection amount and tension, and

readjust if necessary.

Caution

Check after turning the crankshaft once or more

clockwise (right turn).

Page 49

ENGINE <4G9> -

On-vehicle Service

11B-9

Idle speed r/min

900

800

700

600

-10 20 50

Transmission oil temperature_C

IGNITION TIMING CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

For vehicles with manual transmission, drive the vehicle

for 15 minutes or more to warm the engine, and then

carry out the checking while the transmission oil

temperature is more than 50°C.

NOTE

The idle speed in vehicles with manual transmission varies

as shown in the illustration in accordance with the

transmission oil temperature.

2. Turn off the ignition switch and then connect the MUT-II

to the diagnosis connector.

3. Set the timing light to the power supply line (terminal

No.1) of the ignition coil No.1.

NOTE

The power supply line is looped and also longer than

the other ones.

4. Start the engine a nd let it run at idle.

5. Use the MUT-II to measure engine idle speed and check

that it is within the standard value.

Standard value:

Items Idle speed r/min

M/T 600±100 (750±100)*

A/T 650±100 (750±100)*

NOTE

*: Indicates the values when more than 4 minutes have

passed since the idling condition was started.

6. Select No.17 of the MUT-II Actuator test.

NOTE

At this time, the engine speed will become approximately

750 r/min.

7. Check that basic ignition timing is within the standard

value.

Standard value: 5_BTDC±3

_

8. If the basic ignition timing is outside the standard value,

inspect t he GDI system while referring to GROUP 13B

- Troubleshooting.

9. Press the MUT-II clear key (Select a forced driving cancel

mode) to release the Actuator test.

Caution

If the test is not cancelled, a forced driving will

continue for 27 minutes. Driving under this condition

may damage the engine.

Page 50

11B-10

ENGINE <4G9> -

10. Check that ignition timing is at the standard value.

Standard value: approx. 16_BTDC

NOTE

(1) The ignition timing will become approximately 6_BTDC

(2) The ignition timing may fluctuate within ±7_BTDC.

11. Remove the timing light.

12. Turn off the ignition switch and then remove the MUT-II.

On-vehicle Service

after more than 4 minutes have passed since the

basic ignition timing set mode was released.

This is normal.

Idle speed r/min

900

800

700

600

-10 20 50

Transmission oil temperature_C

IDLE SPEED CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

For vehicles with manual transmission, drive the vehicle

for 15 minutes or more to warm the engine, and then

carry out the checking while the transmission oil

temperature is more than 50°C.

NOTE

The idle speed in vehicles with manual transmission varies

as shown in the illustration in accordance with the

transmission oil temperature.

2. Turn off the ignition switch and then connect the MUT-II

to the diagnosis connector.

3. Check the basic ignition timing.

NOTE

Refer to P.11B-9 concerning th e check procedure of the

basic ignition timing.

Standard value: 5_BTDC±3

4. Run the engine at idle for 2 minutes.

5. Check the idle speed. Select item No. 22 and take a

reading of the idle speed.

Standard value:

_

Items Idle speed r/min

M/T 600±100 (750±100)*

A/T 650±100 (750±100)*

NOTE

(1) *: Indicates the values when more than 4 minutes

have passed since the idling condition was started.

(2) The idle speed is automatically controlled by the idle

speed control (ISC) system.

Page 51

ENGINE <4G9> -

6. If the idle speed is outside the standard value, inspect the

GDI components by referring to GROUP 13B Troubleshooting.

IDLE MIXTURE CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Connect the MUT-II to the diagnosis connector.

3. Check that the basic ignition timing is within the standard

value.

NOTE

Refer to P.11B-9 concerning th e check procedure of the

basic ignition timing.

On-vehicle Service

11B-11

Standard value: 5_BTDC±3

4. Run the engine at 2,500 r/min for 2 minutes.

5. Set t he CO, HC tester.

6. Check the CO contents and the HC contents at idle.

NOTE

This measurement should be performed in less than

approximately 4 minutes since the engine speed become

the idle speed.

Standard value

CO contents: 0.5% or less

HC contents: 100 ppm or less

7. If there is a deviation from the standard value, check t he

following items:

D Diagnosis output

D Fuel pressure

D Injector

D Ignition coil, spark plug

D EGR control system

D Evaporative emission control system

D Compression pressure

NOTE

Replace the three way catalyst when the CO and HC

contents are not within the standard value, even though

the result of the inspection is normal on all items.

_

Page 52

11B-12

ENGINE <4G9> -

ENGINE <4G9> -

On-vehicle Service

On-vehicle Service

Crank

angle

sensor

connector

Compression gauge

COMPRESSION PRESSURE CHECK

1. Before inspection, check that the engine oil, starter and

battery are normal. In addition, set the vehicle to the

pre-inspection condition.

2. Remove all of t he ignition coils and spark plugs.

3. Disconnect the crank angle sensor connector.

NOTE

Doing this will prevent the engine-ECU from carrying out

ignition and fuel injection.

4. Cover the spark plug hole with a shop towel etc., and

after the engine has been cranked, check that no foreign

material is adhering to the shop towel.

Caution

(1) Keep away from the spark plug hole when

cranking.

(2) If compression is measured with water, oil, fuel,

etc.,that has comefrom cracks inside the cylinder,

these materials will become heated and will gush

out from the spark plug hole, which is dangerous.

5. Set compression gauge to one of the spark plug holes.

6. Crank the engine with the throttle valve fully open and

measure the compression pressure.

Standard value (at engine speed of 300 r/min):

1,790 kPa

Limit (at engine speed of 300 r/min):

Min. 1,400 kPa

7. Measure the compression pressure for all the cylinders,

and check that the pressure differences of the cylinders are

below the limit.

Limit: Max. 100 kPa

8. If there is a cylinder with compression or a compression

difference that is outside the limit, pour a small amount

of engine oil through the spark plug hole, and repeat

the operations in steps 6 and 7.

(1) If the compression increases after oil is added, the

cause of the malfunction is a worn or damaged piston

ring and/or cylinder inner surface.

(2) If the compression does not rise after oil is added,

the cause is a burnt or defective valve seat, or pressure

is leaking from the gasket.

9. Connect the crank angle sensor connector.

10. Install the spark plugs and ignition coils.

11. Use the MUT-II to erase the diagnosis codes.

NOTE

This will erase the diagnosis code resulting from the crank

angle sensor connector being disconnected.

Page 53

Ventilation hose

PCV valve

ENGINE <4G9> -

Vacuum gauge

On-vehicle Service

11B-13

MANIFOLD VACUUM CHECK

1. Before inspection, set the vehicle to the pre-inspection

condition.

2. Disconnect the ventilation hose from the positive

crankcase ventilation (PCV) valve, and then connect a

vacuum gauge to the ventilation hose.

3. Check the intake manifold negative pressure while the

engine is idling.

Limit: Min. 37 kPa

LASH ADJUSTER CHECK

If an abnormal noise (knocking) that seems to be coming

from the lash adjuster is heard after starting the engine and

does not stop, carry out the following check.

NOTE

(1) The abnormal noise which is caused by a problem

with the lash adjusters is generated after the engine

is started, and will vary according to the engine speed.

However, this noise is not related to the actual engine

load.

Because of this, if the noise does not occur

immediately after the engine is started, if it does not

change in accordance with the engine speed, or if

it changes in accordance with the engine load, the

source of the noise is not th e lash adjusters.

(2) If there is a problem with the lash adjusters, the noise

will almost never disappear, even if the engine has

been run at idle to let it warm up.

The only case where the noise might disappear is

if the oil in the engine has not been looked after

properly and oil sludge has caused the lash adjusters

to stick.

1. Start the engine.

2. Check that the noise occurs immediately after the engine

is started, and that the noise changes in accordance

with changes in the engine speed.

If the noise does not occur immediately after the engine

is started, or if it does not change in accordance with

the engine speed, the problem is not being caused y

the lash adjusters, so check for some other cause of

the problem. Moreover, if the noise does not change in

accordance with the engine speed, the cause of the

problem is probably not with the engine. (In these cases,

the lash adjusters are normal.)

3. While the engine is idling, check that the noise level does

not change when the engine load is varied (for example,

by shifting from N ® D).

If the noise level changes, the cause of the noise is

probably parts striking because of worn crankshaft

bearings or connecting rod bearings. (In such cases, the

lash adjusters are normal.)

Page 54

11B-14

ENGINE <4G9> -

4. After the engine has warmed up, run it at idle and check

if any noise can be heard.

If t he noise has become smaller or disappeared, oil sludge

could make the lash adjusters stick. Clean the lash

adjusters. (Refer to the Engine Workshop Manual.) If not

improved, go to step 5.

5. Bleed air from the lash adjusters.

6. If the noise has not disappeared even after the air

bleeding, clean the lash adjusters. (Refer to the Engine

Workshop Manual.)

<LASH ADJUSTER AIR BLEEDING>

NOTE

(1) If the vehicle is parked on a slope for a long period

(2) After parking the vehicle for long periods, the oil drains

(3) If either of the above situations occur, the abnormal

On-vehicle Service

of time, the amount of oil inside the lash adjuster

will decrease, and air may get into the high pressure

chamber when starting the engine.

out of the oil passage, and it takes time for the oil

to be supplied to the lash adjuster, so air can get

into the high pressure chamber.

noise can be eliminated by bleeding the air from inside

the lash adjusters.

Good

1. Check the engine oil and replenish or replace the oil

if necessary.

NOTE

(1) If there is a only small amount of oil, air will be drawn

in through the oil screen and will get into the oil

passage.

(2) If the amount of oil is greater than normal, then the

oil will being mixed by the crankshaft an d a large

amount of air may get mixed into the oil.

(3) If the oil is degenerated, air and oil will not separate

easily in oil, and the amount of air mixed into the

oil will increase.

Page 55

ENGINE <4G9> -

High-pressure chamber

On-vehicle Service

11B-15

(4) If the air which has been mixed in with the oil due

to any of the above reasons gets into the high pressure

chamber of the lash adjuster, the air inside the high

pressure chamber will be compressed when the valve

is open and the lash adjuster will over-compress,

resulting in abnormal noise when the valve closes.

This is the same effect as if the valve clearance is

adjusted to be too large by mistake. If the air inside

the lash adjusters is then released, the operation

of the lash adjusters will return to normal.

Drive pattern for air bleeding

Gradually open the

throttle valve.

Approx.

3,000 r/min

Idle speed

15

seconds

Once

Close the throttle

valve.

15

seconds

2. Run the engine at idle for 1 - 3 minutes to let it warm

up.

3. With no load on the engine, repeat the drive pattern shown

in the illustration at left and check if the abnormal noise

disappears. (The noise should normally disappear after

10 - 30 repetitions, but if there is no change in the noise

level after 30 repetitions or more, the problem is probably

not due to air inside the lash adjusters.)

4. After the noise has disappeared, repeat the drive pattern

shown in the illustration at left a further 5 times.

5. Run the engine at idle for 1 - 3 minutes and check that

the noise has disappeared.

Page 56

11B-16

ENGINE <4G9> -

Crankshaft Pulley

CRANKSHAFT PULLEY

REMOVAL AND INSTALLATION

Pre-removal Operation

Under Cover Removal

1

2

11200160303

Post-installation Operation

D Drive Belt Tension Adjustment (Refer to P.11B-6.)

D Under Cover Installation

177 - 186 Nm

3

4

MD998719 or

MD998754

(Engine oil)

Removal steps

1. Drive belt (Power steering and

A/C)

2. Drive belt (Alternator)

MD990767

5

AA""AA

3. Crankshaft pulley bolt

4. Crankshaft pulley washer

5. Crankshaft pulley

REMOVAL SERVICE POINT

AA"

CRANKSHAFT PULLEY BOL T REMOVAL

INSTALLATION SERVICE POINT

"AA

When installing the crankshaft bolt, apply the minimum amount

of engine oil to the bearing surface and thread of the bolt.

CRANKSHAFT PULLEY BOL T INSTALLATION

Page 57