Page 1

Page 2

Introduction

This manual is a guide for using the MITSUBISHI CNC.

Supported models are as follows:

Supported model Abbreviations in this manual

M800W Series

M800S Series

M80W Series

M80 Series

E80 Series E80, M800/M80 Series, M8

C80 Series C80

Be sure to keep this manual always at hand.

Notes on Reading This Manual

(1) This manual explains general parameters as viewed from the NC.

For information about each machine tool, refer to manuals issued from the machine manufacturer.

If the descriptions relating to "restrictions" and "allowable conditions" conflict between this manual and the machine manufacturer's instruction manual, the later has priority over the former.

(2) This manual is intended to contain as much descriptions as possible even about special operations.

The operations to which no reference is made in this manual should be considered impossible.

M800 Series, M800, M8

M80 Series, M80, M8

CAUTION

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual issued by the machine tool

builder takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all the applicable functions are included. Some of them, however, may not

be available for your NC system. Refer to the specifications issued by the machine tool builder before use.

Refer to the Instruction Manual issued by each machine tool builder for details on each machine tool.

Some screens and functions may differ depending on the NC system (or its version), and some functions may not be possible. Please confirm the specifications before use.

Do not connect NC system to the Internet-connected network.

To maintain the safety of the NC system against unauthorized access from external devices via the network, take appropriate measures.

In this manual, the following abbreviations might be used.

L system: Lathe system

M system: Machining center system

MTB: Machine tool builder

Also refer to the manuals on "Manual List" as necessary.

Page 3

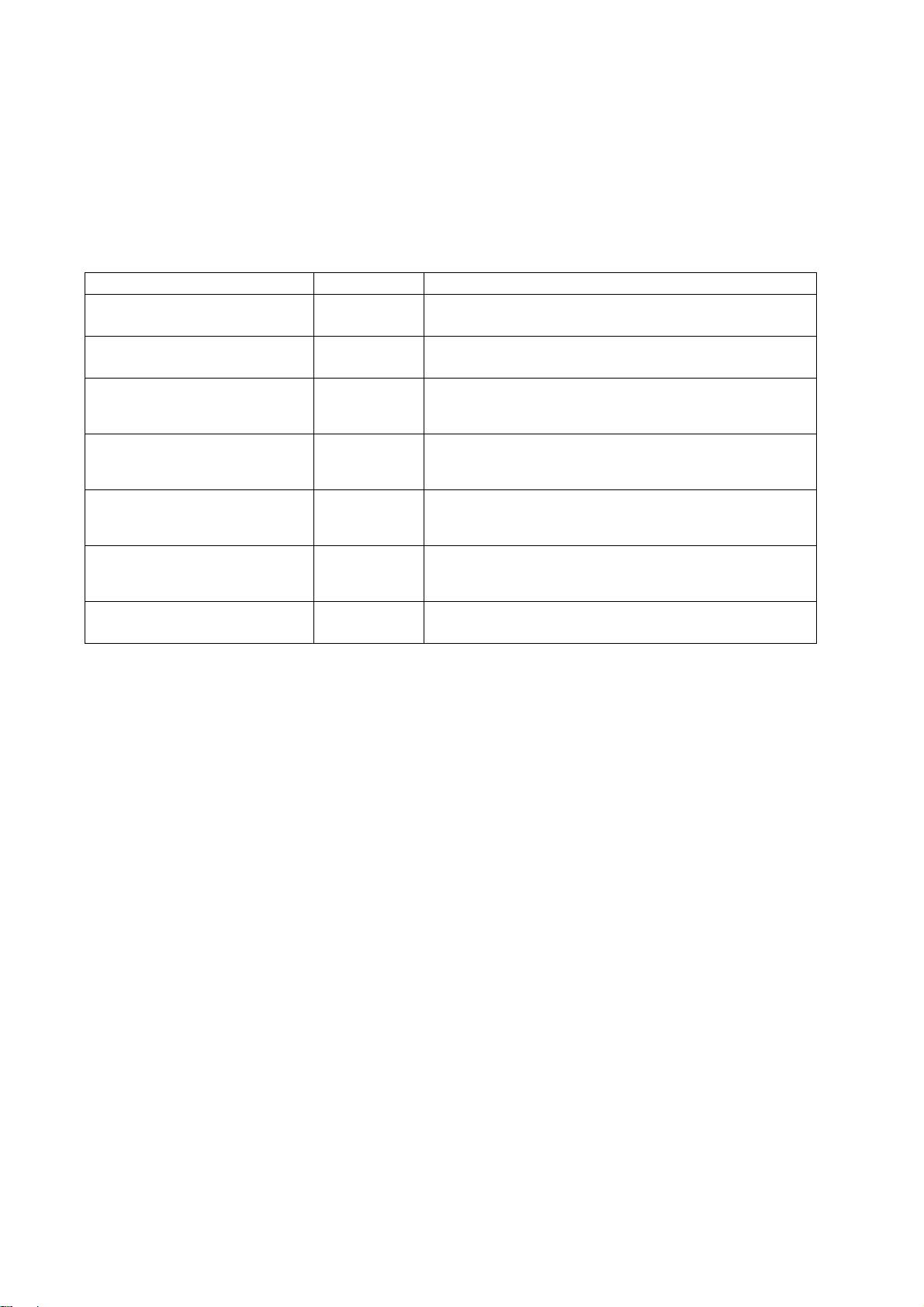

Manual List

Manuals related to M800/M80/E80/C80 Series are listed as follows.

These manuals are written on the assumption that all optional functions are added to the targeted model.

Some functions or screens may not be available depending on the machine or specifications set by MTB. (Confirm the

specifications before use.)

The manuals issued by MTB take precedence over these manuals.

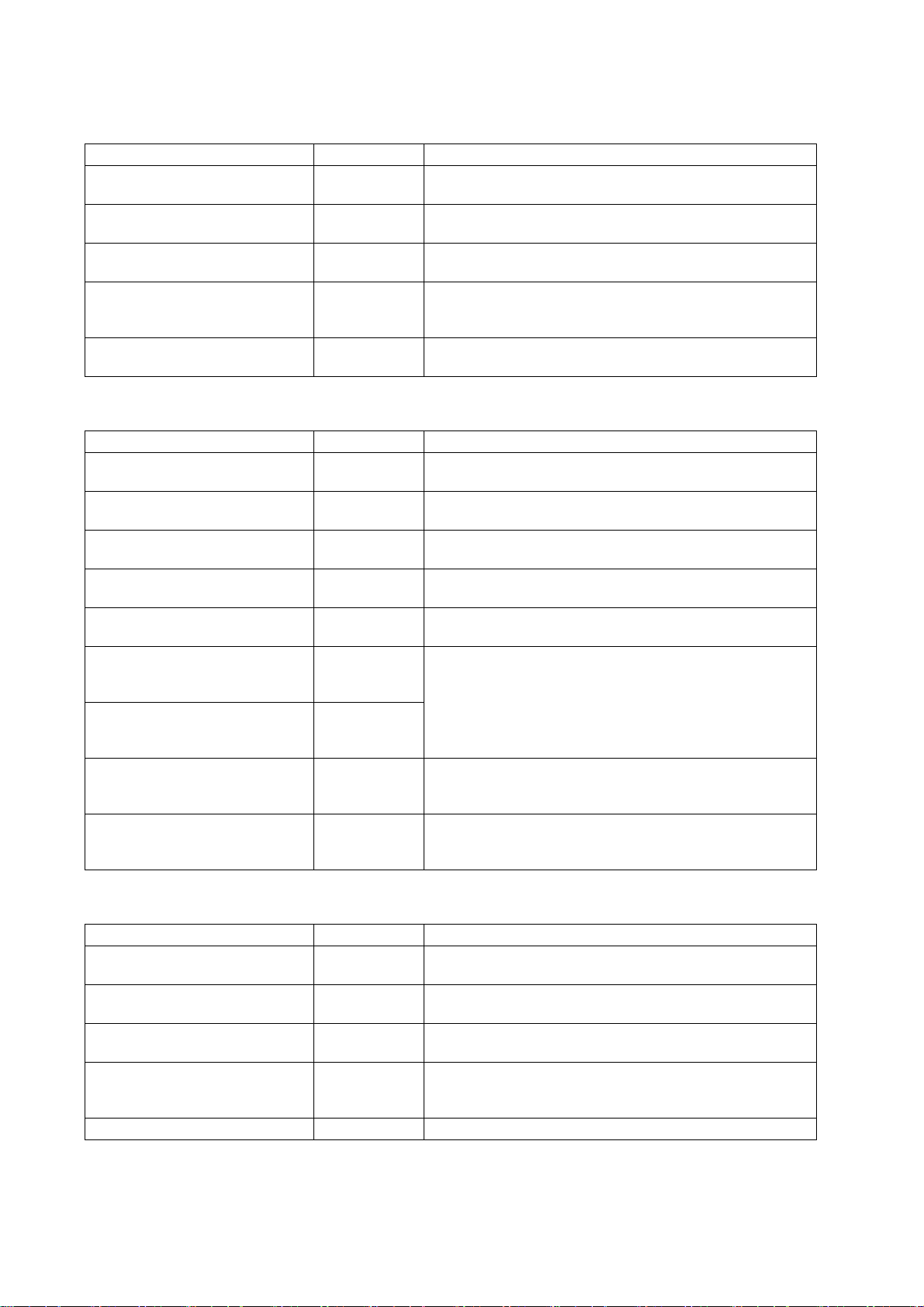

Manual IB No. Purpose and Contents

M800/M80/E80 Series

Instruction Manual

C80 Series

Instruction Manual

M800/M80/E80/C80 Series

Programming Manual

(Lathe System) (1/2)

M800/M80/E80/C80 Series

Programming Manual

(Lathe System) (2/2)

M800/M80/E80/C80 Series

Programming Manual

(Machining Center System) (1/2)

M800/M80/E80/C80 Series

Programming Manual

(Machining Center System) (2/2)

M800/M80/E80/C80 Series

Alarm/Parameter Manual

IB-1501274

IB-1501453

IB-1501275

IB-1501276

IB-1501277

IB-1501278

IB-1501279

Operation guide for NC

Explanation for screen operation, etc.

Operation guide for NC

Explanation for screen operation, etc.

G code programming for lathe system

Basic functions, etc.

G code programming for lathe system

Functions for multi-part system, high-accuracy function, etc.

G code programming for machining center system

Basic functions, etc.

G code programming for machining center system

Functions for multi-part system, high-accuracy function, etc.

Alarms

Parameters

Page 4

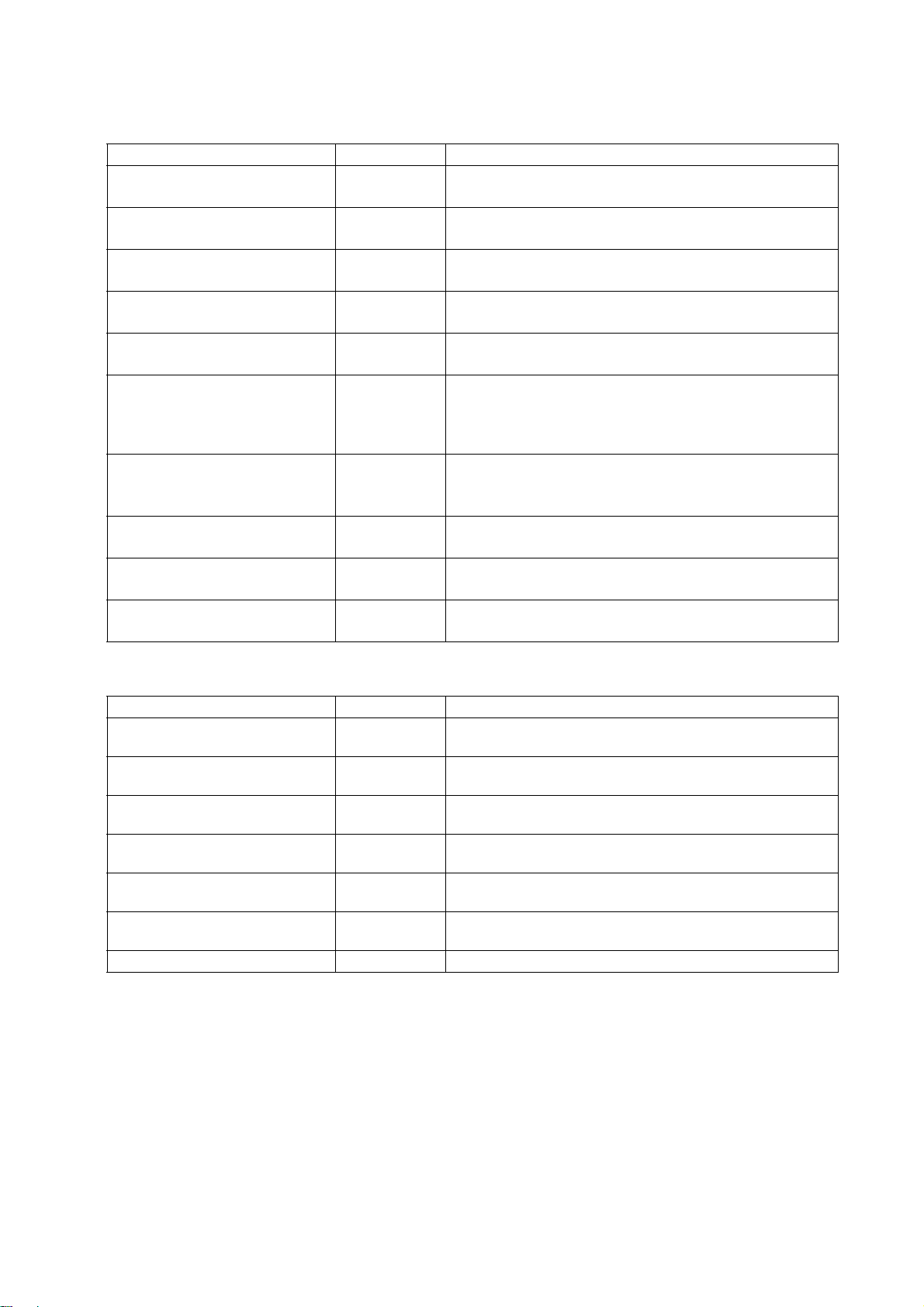

Manuals for MTBs (NC)

Manual IB No. Purpose and Contents

M800/M80/E80/C80 Series

Specifications Manual (Function)

M800/M80/E80/C80 Series

Specifications Manual (Hardware)

M800W/M80W Series

Connection and Setup Manual

M800S/M80/E80 Series

Connection and Setup Manual

C80 Series

Connection and Setup Manual

M800/M80/E80 Series

PLC Development Manual

M800/M80/E80 Series

PLC Programming Manual

M800/M80/E80/C80 Series

PLC Interface Manual

M800/M80/E80 Series

Maintenance Manual

C80 Series

Maintenance Manual

IB-1501505

IB-1501506

IB-1501268

IB-1501269

IB-1501452

IB-1501270

IB-1501271

IB-1501272

IB-1501273

IB-1501454

Model selection

Outline of various functions

Model selection

Specifications of hardware unit

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Detailed specifications of hardware unit

Installation, connection, wiring, setup (startup/adjustment)

Electrical design

I/O relation (assignment, setting, connection), field network

Development environment (PLC on-board, peripheral

development environment), etc.

Electrical design

Sequence programming

PLC support functions, etc.

Electrical design

Interface signals between NC and PLC

Cleaning and replacement for each unit

Other items related to maintenance

Cleaning and replacement for each unit

Other items related to maintenance

Manuals for MTBs (drive section)

Manual IB No. Contents

MDS-E/EH Series

Specifications Manual

MDS-E/EH Series

Instruction Manual

MDS-EJ/EJH Series

Specifications Manual

MDS-EJ/EJH Series

Instruction Manual

MDS-EM/EMH Series

Specifications Manual

MDS-EM/EMH Series

Instruction Manual

DATA BOOK IB-1501252 Specifications of servo drive unit, spindle drive unit, motor, etc.

IB-1501226 Specifications for power supply regeneration type

IB-1501229 Instruction for power supply regeneration type

IB-1501232 Specifications for regenerative resistor type

1235 Instruction for regenerative resistor type

IB-150

IB-1501238

IB-1501241 Instruction for multi-hybrid, power supply regeneration type

Specifications for multi-hybrid, power supply regeneration

type

Page 5

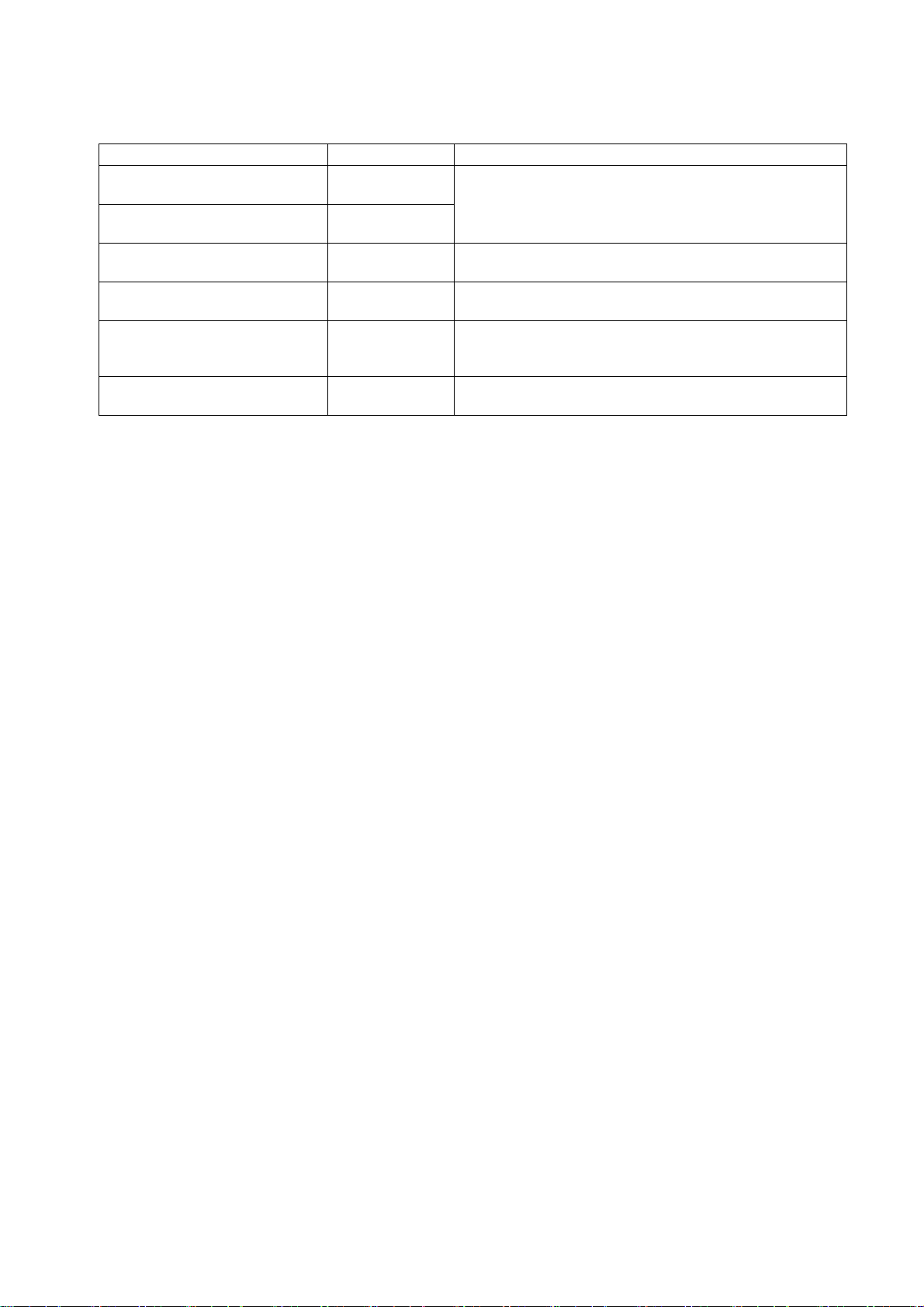

Manuals for MTBs (Others)

Manual No. Purpose and Contents

GOT2000 Series User’s Manual

(Hardware)

GOT2000 Series User’s Manual

(Utility)

GOT2000 Series User’s Manual

(Monitor)

GOT2000 Series Connection

Manual (Mitsubishi Electric

Products)

GT Designer3 (GOT2000) Screen

Design Manual

■ For M800/M80/E80 Series

Manual No. Purpose and Contents

GOT2000/GOT1000 Series CC-Link

Communication Unit User's Manual

GX Developer Version 8 Operating

Manual (Startup)

GX Developer Version 8 Operating

Manual

GX Converter Version 1 Operating

Manual

MELSEC-Q CC-Link System Master/

Local Module User’s Manual

GOT2000 Series Connection

Manual (Non-Mitsubishi Electric

Products 1)

GOT2000 Series Connection

Manual (Non-Mitsubishi Electric

Products 2)

GOT2000 Series Connection

Manual (Microcomputers, MODBUS/

Fieldbus Products, Peripherals)

GT SoftGOT2000 Version1

Operating Manual

SH-081194

SH-081195

SH-081196 Outline of each monitor function of GOTs

SH-081197

SH-081220

IB-0800351

SH-080372E

SH-080373E

IB-0800004E

SH-080394E

SH-081198ENG

SH-081199ENG

SH-081200ENG

SH-081201ENG

Outline of hardware such as part names, external dimensions,

installation, wiring, maintenance, etc. of GOTs

Outline of utilities such as screen display setting, operation

method, etc. of GOTs

Outline of connection types and connection method between

GOT and Mitsubishi Electric connection devices

Outline of screen design method using screen creation

software GT Designer3

Explanation for handling CC-Link communication unit (for

GOT2000 series/GOT1000 series)

Explanation for system configuration, installation, etc. of PLC

development tool GX Developer

Explanation for operations using PLC development tool GX

Developer

Explanation for operations using data conversion tool GX

Converter

Explanation for system configuration, installation, wiring, etc.

of master/local modules for CC-Link system

Explanation for connection types and connection method

between GOT and other company's devices

Explanation for connection types and connection method

between GOT and microcomputers, MODBUS/fieldbus

products, peripherals

Explanation for system configuration,

and operation method of monitoring software GT

SoftGOT2000

screen configuration

■ For C80 Series

Manual No. Purpose and Contents

MELSEC iQ-R Module Configuration

Manual

MELSEC iQ-R CPU Module User’s

Manual (Startup)

MELSEC iQ-R CPU Module User’s

Manual (Application)

QCPU User’s Manual (Hardware

Design, Maintenance and

Inspection)

GX Works3 Operating Manual SH-081215 Outline of functions, programming, etc.

SH-081262

SH-081263

SH-081264

SH-080483

Outline of system configuration, specifications, installation,

wiring, maintenance, etc.

Outline of specifications, procedures before operation,

troubleshooting, etc. for CPU module

Outline of memory, functions, devices, parameters, etc. for

CPU module

Outline of specifications, necessary knowledge to configure

the system and maintenance-related descriptions for Q series

CPU module, etc.

Page 6

Reference Manual for MTBs

Manual No. Purpose and Contents

M800/M80 Series Smart safety

observation Specification manual

C80 Series Smart safety observation

Specification manual

M800/M80 Series CC-Link (Master/

Local) Specification manual

M800/M80 Series PROFIBUS-DP

Specification manual

M800/M80 Series Interactive cycle

insertion (Customization)

Specification manual

M800/M80 Series EtherNet/IP

Specifications manual

BNP-C3072-022

Explanation for smart safety observation function

BNP-C3077-022

BNP-C3072-089 Explanation for CC-Link

BNP-C3072-118 Explanation for PROFIBUS-DP communication function

BNP-C3072-121-

0003

BNP-C3072-263 Explanation for EtherNet/IP

Explanation for interactive cycle insertion

Page 7

Page 8

Precautions for Safety

Always read the specifications issued by the machine tool builder, this manual, related manuals and attached documents before installation, operation, programming, maintenance or inspection to ensure correct use.

Understand this numerical controller, safety items and cautions before using the unit.

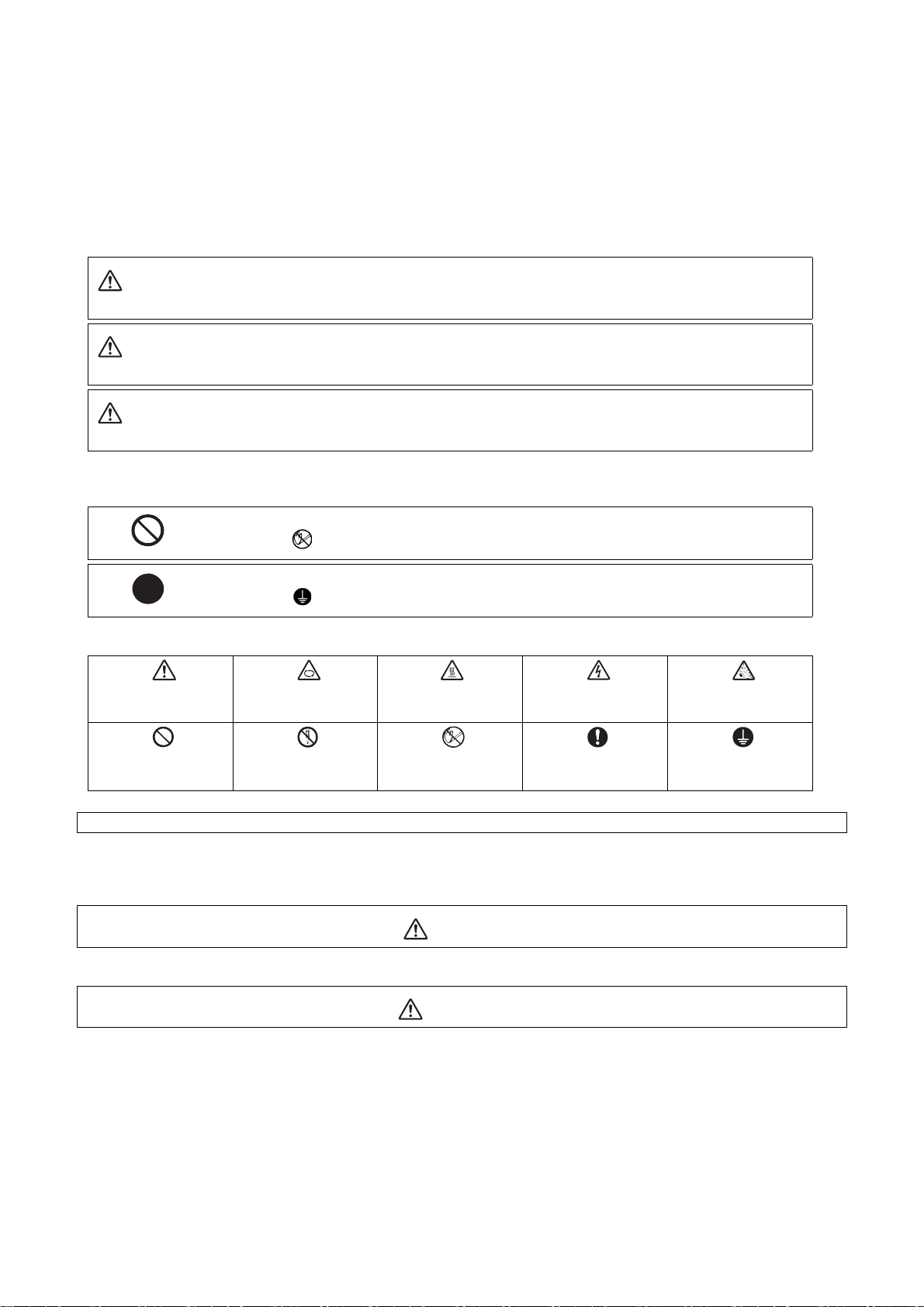

This manual ranks the safety precautions into "DANGER", "WARNING" and "CAUTION".

DANGER

When the user may be subject to imminent fatalities or major injuries if handling is mistaken.

WARNING

When the user may be subject to fatalities or major injuries if handling is mistaken.

CAUTION

When the user may be subject to injuries or when physical damage may occur if handling is mistaken.

Note that even items ranked as " CAUTION", may lead to major results depending on the situation. In any case, important in-

formation that must always be observed is described.

The following sings indicate prohibition and compulsory.

This sign indicates prohibited behavior (must not do).

For example, indicates "Keep fire away".

This sign indicated a thing that is pompously (must do).

For example, indicates "it must be grounded".

The meaning of each pictorial sing is as follows.

CAUTION

Prohibited

Mitsubishi CNC is designed and manufactured solely for applications to machine tools to be used for industrial purposes.

Do not use this product in any applications other than those specified above, especially those which are substantially influential

on the public interest or which are expected to have significant influence on human lives or properties.

CAUTION

rotated object

Disassembly is

prohibited

CAUTION HOT

KEEP FIRE AWAY

For Safe Use

Danger

Electric shock risk

General instruction

Danger

explosive

Earth ground

DANGER

Not applicable in this manual.

WARNING

Not applicable in this manual.

Page 9

CAUTION

(1) Product and manual

For items described as "Restrictions" or "Usable State" in this manual, the instruction manual issued by the machine tool

builder takes precedence over this manual.

Items not described in this manual must be interpreted as "not possible".

This manual is written on the assumption that all the applicable functions are included. Some of them, however, may not

be available for your NC system. Refer to the specifications issued by the machine tool builder before use.

Refer to the Instruction Manual issued by each machine tool builder for details on each machine tool.

Some screens and functions may differ depending on the NC system (or its version), and some functions may not be pos-

sible. Please confirm the specifications before use.

Do not connect NC system to the Internet-connected network.

To maintain the safety of the NC system against unauthorized access from external devices via the network, take appro-

priate measures.

(2) Adjustments

Do not adjust or change the parameter settings greatly as operation could become unstable.

In the explanation on bits, set all bits not used, including blank bits, to "0".

(3) Troubleshooting

If the battery low warning is issued in the controller side, save the machining programs, tool data and parameters in an

input/output device, and then replace the battery. When the battery alarm is issued, the machining programs, tool data and

parameters may have been destroyed. Replace the battery and then reload the data.

If the battery low warning is issued in the drive unit side, immediately replace the battery. Replace the batteries while applying the drive unit's control power.

(4) Maintenance, inspection and part replacement

Do not short-circuit, charge, heat, incinerate or disassemble the battery.

Dispose of the spent battery according to local laws.

Page 10

Disposal

(Note) This symbol mark is for EU countries only.

This symbol mark is according to the directive 2006/66/EC Article 20 Information for endusers and Annex II.

Your MITSUBISHI ELECTRIC product is designed and manufactured with high quality materials and

components which can be recycled and/or reused.

This symbol means that batteries and accumulators, at their end-of-life, should be disposed of

separately from your household waste.

If a chemical symbol is printed beneath the symbol shown above, this chemical symbol means that the

battery or accumulator contains a heavy metal at a certain concentration. This will be indicated as

follows:

Hg: mercury (0,0005%), Cd: cadmium (0,002%), Pb: lead (0,004%)

In the European Union there are separate collection systems for used batteries and accumulators.

Please, dispose of batteries and accumulators correctly at your local community waste collection/

recycling centre.

Please, help us to conserve the environment we live in!

Page 11

Page 12

Trademarks

MELDAS, MELSEC, EZSocket, EZMotion, iQ Platform, MELSEC iQ-R, MELSOFT, GOT, CC-Link, CC-Link/LT,

CC-Link IE, CC-Link IE/field, EcoMonitorLight and SLMP are either trademarks or registered trademarks of

Mitsubishi Electric Corporation in Japan and/or other countries.

Ethernet is a registered trademark of Xerox Corporation in the United States and/or other countries.

Microsoft®, Windows®, SQL Server® and Access® are either trademarks or registered trademarks of Microsoft

Corporation in the United States and/or other countries.

SD logo and SDHC logo are either registered trademarks or trademarks of LLC.

UNIX is a registered trademark of The Open Group in the United States and/or other countries.

Intel® and Pentium® are either trademarks or registered trademarks of Intel Corporation in the United States and/or

other countries.

MODBUS® is either a trademark or a registered trademark of Schneider Electric USA, Inc. or the affiliated

companies in Japan and/or other countries.

EtherNet/IP is a trademark of Open DeviceNet Vendor Association,Inc.

PROFIBUS-DP and PROFINET are either trademarks of Profibus International.

Oracle® is a registered trademark of Oracle Corporation, the subsidiaries, or the affiliated companies in the United

States and /or other countries.

VNC is a registered trademark of RealVNC Ltd. in the United States and other countries.

Other company and product names that appear in this manual are trademarks or registered trademarks of the

respective companies.

Page 13

Page 14

本製品の取扱いについて

( 日本語 /Japanese)

本製品は工業用 ( クラス A) 電磁環境適合機器です。販売者あるいは使用者はこの点に注意し、住商業環境以外で

の使用をお願いいたします。

Handling of our product

(English)

This is a class A product. In a domestic environment this product may cause radio interference in which case the

user may be required to take adequate measures.

본 제품의 취급에 대해서

( 한국어 /Korean)

이 기기는 업무용 (A 급 ) 전자파적합기기로서 판매자 또는 사용자는 이 점을 주의하시기 바라며 가정외의 지역에

서 사용하는 것을 목적으로 합니다 .

Page 15

Page 16

Contents

Alarm

1 Operation Errors (M).................................................................................................................................... 3

2 Stop Codes (T)............................................................................................................................................ 37

3 Servo/Spindle Alarms (S) .......................................................................................................................... 45

3.1 Servo Errors (S01/S03/S04) ................................................................................................................................... 46

3.2 Initial Parameter Errors (S02) ................................................................................................................................. 56

3.3 Safety Function Errors (S05) .................................................................................................................................. 58

3.4 Parameter Errors (S51) .......................................................................................................................................... 59

3.5 Servo Warnings (S52) ............................................................................................................................................ 60

3.6 Safety Function Warnings (S53)............................................................................................................................. 63

4 MCP Alarms (Y) .......................................................................................................................................... 65

5 System Alarms (Z)...................................................................................................................................... 81

6 Absolute Position Detection System Alarms (Z7*) ................................................................................. 95

7 Distance-coded Reference Scale Errors (Z8*)....................................................................................... 101

8 Emergency Stop Alarms (EMG).............................................................................................................. 103

9 Computer Link Errors (L) ........................................................................................................................ 107

10 User PLC Alarms (U).............................................................................................................................. 109

11 Network Service Errors (N) ................................................................................................................... 119

12 Program Errors (P)................................................................................................................................. 123

13 Smart Safety Observation Alarm (V) .................................................................................................... 161

13.1 Smart Safety Observation Error (V01/V02/V03/V04/V05/V06/V07) ................................................................... 162

13.2 Smart Safety Observation Warning (V50/V51/V52/V53/V54)............................................................................. 172

14 Multi CPU Errors (A) [C80] .................................................................................................................... 175

Parameter

15 User Parameters..................................................................................................................................... 201

15.1 Machining Parameters........................................................................................................................................ 202

15.2 Fixed Cycle Parameters ..................................................................................................................................... 218

15.3 Control Parameters 1.......................................................................................................................................... 220

15.4 Control Parameters 2.......................................................................................................................................... 227

15.5 I/O Parameters [M8] ........................................................................................................................................... 229

15.6 Axis Parameters ................................................................................................................................................. 251

15.7 Ethernet Parameters........................................................................................................................................... 255

15.8 Computer Link Parameters [M8]......................................................................................................................... 270

15.9 Subprogram Storage Location Parameters [M8] ................................................................................................ 274

15.10 Barrier Data (for L system only)........................................................................................................................ 277

15.11 High-accuracy Control Parameters................................................................................................................... 280

15.12 High-accuracy Control Axis Parameters........................................................................................................... 289

15.13 Operation Parameters ...................................................................................................................................... 291

15.14 Machining Condition Selection Parameters ...................................................................................................... 316

15.15 Menu Selection Parameters ............................................................................................................................. 331

15.16 Tolerance Parameters[M8] ............................................................................................................................... 340

Page 17

16 Machine Parameters .............................................................................................................................. 343

16.1 Base System Parameters ................................................................................................................................... 344

16.2 Base Axis Specification Parameters................................................................................................................... 374

16.3 Base Common Parameters ................................................................................................................................ 379

16.4 Axis Specifications Parameters .......................................................................................................................... 468

16.5 Zero Point Return Parameters............................................................................................................................ 505

16.6 Absolute Position Detection Parameters ............................................................................................................ 511

16.7 Servo Parameters............................................................................................................................................... 513

16.8 Spindle Specification Parameters....................................................................................................................... 545

16.9 Spindle Parameters ............................................................................................................................................ 586

16.10 Spindle-type Servo Parameters........................................................................................................................ 617

16.11 Rotary Axis Configuration Parameters ............................................................................................................. 618

16.12 PLC Timer......................................................................................................................................................... 627

16.13 PLC Integrated Timer ....................................................................................................................................... 628

16.14 PLC Counter ..................................................................................................................................................... 629

16.15 PLC Constants.................................................................................................................................................. 630

16.16 PLC Bit Selection.............................................................................................................................................. 631

16.17 Machine Error Compensation Parameters ....................................................................................................... 634

16.18 Macro List ......................................................................................................................................................... 636

16.19 Position Switches.............................................................................................................................................. 643

16.20 RIO Device Allocation Parameters [M8] ........................................................................................................... 645

16.21 Open Parameters ............................................................................................................................................. 657

16.22 Device Open Parameters ................................................................................................................................. 658

16.23 SRAM Open Parameters .................................................................................................................................. 659

16.24 CC-Link Parameters [M8] ................................................................................................................................. 660

16.25 PLC Axis Indexing Parameters......................................................................................................................... 674

16.26 Machine Type Parameters [M8]........................................................................................................................ 685

16.27 Machining Time Parameters[M8]...................................................................................................................... 689

16.28 Safety Common Parameters ............................................................................................................................ 692

16.29 Safety Axis Parameters .................................................................................................................................... 694

16.30 Safety Spindle Parameters ............................................................................................................................... 700

16.31 Safety I/O Assignment Parameters .................................................................................................................. 703

16.32 EtherNet/IP Parameters [M8]............................................................................................................................ 707

16.32.1 EtherNet/IP Parameters Scanner 1.......................................................................................................... 707

16.32.2 EtherNet/IP Parameters Scanner 2.......................................................................................................... 709

16.32.3 EtherNet/IP Parameters Adapter 1 .......................................................................................................... 710

16.32.4 EtherNet/IP Parameters Adapter 2 .......................................................................................................... 712

16.33 CC Link IE Field Parameters [M8] .................................................................................................................... 714

1 CC Link IE Field Network 1...................................................................................................................... 714

16.33.

16.33.2 CC Link IE Field Network 2...................................................................................................................... 718

16.33.3 CC Link IE Field Master Parameters........................................................................................................ 722

16.34 PROFIBUS-DP Parameters[M8]....................................................................................................................... 723

16.35 Multi CPU Parameters [C80] ............................................................................................................................ 724

Page 18

1

IB-1501279-H

Alarm

Page 19

M800/M80/E80/C80 Series Alarm/Parameter Manual

IB-1501279-H

2

Page 20

1

3

IB-1501279-H

Operation Errors (M)

Page 21

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

1Operation Errors (M)

M00 Aux ax dog overrun 0001

Details

When executing dog-type reference position, the zero point return speed is too fast or the dog length is too

short.

Remedy

Lower the zero point return speed or increase the dog length.

M00 Aux ax R-pnt direction illegal 0003

Details

When executing reference position return, the axis was moved in the opposite of the designated direction.

Remedy

Move the axis in the correct direction.

M00 Aux ax external interlock 0004

Details

The axis interlock function is valid.

Remedy

Cancel the interlock signal.

M00 Aux ax internal interlock 0005

Details

An interlock was established by the servo OFF function.

Remedy

Cancel the servo OFF.

M00 Aux ax soft limit 0007

Details

The stored stroke limit was reached.

Remedy

Check the stored stroke limit setting and machine position.

M00 Aux ax R ret invld at abs alm 0024

Details

Reference position return was executed during an absolute position alarm.

Remedy

Initialize the absolute position reference point and then fix the absolute position coordinates.

M00 Aux ax R ret invld at ini 0025

Details

Reference position return was executed during absolute position initial setting.

Remedy

Initialize the absolute position reference point and then fix the absolute position coordinates.

M01 Dog overrun 0001

Details

When returning to the reference position, the near-point detection limit switch did not stop over the dog, but

overran the dog.

Remedy

Increase the length of the near-point dog.

Reduce the reference position return speed.

IB-1501279-H

4

Page 22

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Some ax does not pass Z phase 0002

Details

One of the axes did not pass the Z-phase during the initial reference position return after the power was turned

ON.

Remedy

Move the detector one rotation or more in the opposite direction of the reference position, and repeat reference position return.

M01 R-pnt direction illegal 0003

Details

When manually returning to the reference position, the return direction differs from the axis movement direction

selected with the AXIS SELECTION key.

Remedy

The selection of the AXIS SELECTION key's +/- direction is incorrect. The error is canceled by feeding the

axis in the correct direction.

M01 External interlock axis exists 0004

Details

The external interlock function has activated (the input signal is "OFF") and one of the axes has entered the

interlock state.

Remedy

As the interlock function has activated, release it before resuming operation.

Correct the sequence on the machine side.

Check for any broken wires in the "interlock" signal line.

M01 Internal interlock axis exists 0005

Details

The internal interlock state has been entered.

The absolute position detector axis has been removed.

A command for the manual/automatic simultaneous valid axis was issued from the automatic mode.

The manual speed command was issued while the "tool length measurement 1" signal is ON.

A travel command has been issued to an inclined axis whose base axis is in control axis synchronization across

part systems.

Selected an axis other than the 1st axis when the manual speed command was issued.

A travel command has been issued to an axis stopped by the collision detection function.

Positioning or interpolation command was issued during the spindle-mode rotary axis control mode.

Remedy

The servo OFF function is valid, so release it first.

An axis that can be removed has been issued, so perform the correct operations.

The command is issued in the same direction as the direction where manual skip turned ON, so perform

the correct operations.

During the manual/automatic simultaneous mode, the axis commanded in the automatic mode became

the manual operation axis. Turn OFF the "manual/automatic valid" signal for the commanded axis.

Turn ON the power again, and perform absolute position initialization.

Turn OFF the "tool length measurement 1" signal to start the program by the manual speed command.

Cancel the control axis synchronization across part systems, then issue a travel command to the inclined

axis.

Select the 1st axis of each part system when issuing the manual speed command.

Cancel the collision detection alarm.

Check the program after cancelling the error by reset.

M01 H/W stroke end axis exists 0006

Details

The stroke end function has activated (the input signal is "OFF") and one of the axes is in the stroke end status.

Remedy

Move the machine manually.

Check for any broken wires in the "stroke end" signal line.

Check for any limit switch failure.

5

IB-1501279-H

Page 23

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 S/W stroke end axis exists 0007

Details

The stored stroke limit I, II, IIB or IB function has activated.

Remedy

Move the machine manually.

Correct any setting error of the parameters for the stored stroke limit.

M01 Chuck/tailstock stroke end ax 0008

Details

The chuck/tail-stock barrier function turned ON, and an axis entered the stroke end state.

Remedy

Reset the alarm with reset, and move the machine in the reverse direction.

M01 Ref point return No. invalid 0009

Details

2nd reference position return was performed before 1st reference position return has been completed.

Remedy

Execute 1st reference position return.

M01 Illegal op in mid pt sg block 0013

Details

The operation mode was changed to MDI during single block stop at the middle point of G28/G29/G30.

Remedy

Change the operation mode.

Reset to clear the alarm.

M01 Sensor signal illegal ON 0019

Details

The sensor signal was already ON when the tool measurement mode (TLM) signal was validated.

The sensor signal turned ON when there was no axis movement after the tool measurement mode (TLM) signal

was validated.

The sensor signal turned ON at a position within 100 μm from the final entry start position.

Remedy

Turn the tool measurement mode signal input OFF, and move the axis in a safe direction.

Disabling the sensor signal also clears the operation alarm.

(Note) When the "tool length measurement 1" signal is disabled, the axis can be moved in either direction. Pay

attention to the movement direction.

M01 Ref point retract invalid 0020

Details

Reference position retract was performed while the coordinates had not been established.

Remedy

Execute reference position return.

M01 Tool ofs invld after R-pnt 0021

Details

Reference position return had been performed during the tool retract and return, which invalidated the tool compensation amount after the reference position return.

Remedy

The error is cleared if the operation mode is changed to other than reference position return before the

axis performs reference position return.

The error is cleared when the tool return is completed.

The error is cleared if reset 1 is input or the emergency stop button is pushed.

IB-1501279-H

6

Page 24

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 R-pnt ret invld at abs pos alm 0024

Details

A reference position return signal was enabled during an absolute position detection alarm.

Remedy

Reset the absolute position detection alarm, and then perform the reference position return.

M01 R-pnt ret invld at zero pt ini 0025

Details

A reference position return signal was input during zero point initialization of the absolute position detection

system.

Remedy

Complete the zero point initialization, and then perform reference position return.

M01 High-accuracy skip disabled 0028

Details

The drive unit's hardware or software does not conform to the high-accuracy skip.

Remedy

The software or hardware does not conform to the function. Contact service center.

M01 Hi-ac skip coord retrieval err 0029

Details

Failed to retrieve the skip coordinate value from the drive unit.

Remedy

Check the wiring.

Check the parameters.

M01 Now skip on 0030

Details

The "skip input" signal remains enabled when the operation has shifted from skip retract to measurement.

Remedy

Increase the skip retract amount.

M01 No skip 0031

Details

Even though the 1st skip was to the correct position, the 2nd skip could not be found.

Remedy

Check whether the measurement target has moved.

M01 Rtn dir err in manual measure 0033

Details

Return direction in manual measurement is the opposite of the parameter setting.

Remedy

Check the setting of the parameter "#2169 Rtn dir err in manual measure" (Return direction in manual

measurement).

Move the axis manually in the direction to a safe position, then reset.

M01 No specifications 0036

Details

The specification is not supported.

Remedy

Check the specifications.

7

IB-1501279-H

Page 25

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Chopping axis R-pnt incomplete 0050

Details

Chopping mode has been entered while the chopping axis has not completed reference position return.

All axes interlock has been applied.

Remedy

Reset the NC or disable the "chopping" signal, and then carry out the reference position return.

M01 Synchronous error excessive 0051

Details

The synchronization error of the master and slave axes exceeded the allowable value under synchronous control.

A deviation exceeding the synchronization error limit value was found with the synchronization deviation detection.

Remedy

Select the correction mode and move one of the axes in the direction in which the errors are reduced.

Check the parameter "#2024 synerr".

Increase the allowable value or reset it to "0" (check disabled).

When using simple C-axis synchronous control, set the contents of the R2589 register to "0".

M01 No spindle select signal 0053

Details

Synchronous tapping command was issued when the spindle select signals (SWS) for all spindles were OFF

in the multiple-spindle control II.

Remedy

Turn ON the spindle select signal (SWS) responding to the tapping spindle before performing the synchronous tapping command.

M01 No spindle serial connection 0054

Details

Synchronous tapping command was issued when the spindle that the spindle select signal (SWS) was ON was

not serially connected in the multiple-spindle control II.

Remedy

Make sure the spindle select signal (SWS) for the responding spindle is ON.

Consider the machine construction when issuing the command.

M01 Spindle fwd/rvs run para err 0055

Details

Asynchronous tapping command was issued when M code of the spindle forward/reverse run command, set

by the parameter "#3028 sprcmm", was one of the followings in the multiple-spindle control II.

M0, M1, M2, M30, M98, M99, or M198

M code No. that commands to enable/disable the "macro interrupt" signal

Remedy

Correct the parameter "#3028 sprcmm" (Tap cycle spindle forward run/reverse run M command) setting.

M01 Tap pitch/thread number error 0056

Details

The command for the pitch or the number of threads is not correct in the synchronous tapping command of the

multiple-spindle control II.

The pitch is too small for the spindle rotation speed.

Thread number is too large for the spindle rotation speed.

Remedy

Correct the pitch, number of threads or rotation speed of the tapping spindle.

IB-1501279-H

8

Page 26

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Wait for tap retract 0057

Details

The axis travel command is interlocked as the tap retract is being enabled.

Remedy

If tapping is necessary, perform tapping retract in advance. However, tapping retract is not allowed during

cycle start operation. Carry out tapping retract after resetting.

If tapping is not necessary, cancel the tap retract enabled condition by the tap retract enabled cancel signal.

M01 Handle ratio too large 0060

Details

The handle ratio is too large for the handle feed clamp speed.

(The handle feed clamp speed changes according to the rapid traverse rate, external feedrate, maximum

speed outside the soft limit range and etc. (or external deceleration speed when external deceleration is valid))

Too large handle ratio means the ratio with which the machine is unable to move the distance of [iunit * handle

ratio] within 0.1ms at the clamp speed.

Example)

When iunit=B (0.001mm) and clamp speed cs (mm/min)

The operation error (M01 0060) will occur if

ratio M>cs/60(s)*0.1(ms)/0.001(mm)=cs*10/6.

Remedy

Change the settings of the handle feed clamp speed or the handle ratio.

M01 R-pos offset value illegal 0065

Details

At the start of reference position initial setting, the parameter "#2034 rfpofs" (Distance-coded reference position

detection offset) is not set to "0".

Remedy

Set the parameter "#2034 rfpofs" to "0", then turn the power ON again to perform the reference position

initial setting.

M01 R-pos scan distance exceeded 0066

Details

Reference position could not be established within the maximum scan distance.

Remedy

Check the scale to see if it has dirt or damage.

Check if the servo drive unit supports this function.

M01 Illegal op in wk instl err cmp 0070

Details

One of the following operations was attempted during workpiece installation error compensation.

Manual interruption

Automatic operation handle interruption

MDI interruption

PLC interruption

Remedy

Return the operation mode to the original mode to remove the cause. During workpiece installation error

compensation, manual interruption, automatic operation handle interruption, MDI interruption, PLC interruption, etc. is not allowed.

9

IB-1501279-H

Page 27

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Illegal op in dia/rad select 0095

Details

An axis used in the following functions is also used as an axis to perform diameter/radius designation selection.

Chopping

Synchronization control

Or diameter/radius designation selection (G10.9) was issued to the axis in the above mode.

Remedy

Check the program.

Do not carry out the following functions using an axis to perform diameter/radius designation selection.

- Chopping

- Synchronization control

M01 No operation mode 0101

Details

[No operation mode]

No operation mode

[Aux ax no operation mode]

The operation mode is not designated, or the operation mode was changed during axis movement.

Remedy

[No operation mode]

Check for any broken wires in the input mode signal wire.

Check for any failure of the MODE SELECT switch.

Correct the sequence program.

[Aux ax no operation mode]

Correctly designate the operation mode.

M01 Cutting override zero 0102

Details

The "cutting feed override" switch on the machine operation panel is set to"0".

The override was set to "0" during a single block stop.

Remedy

Set the "cutting feed override" switch to a value other than "0" to clear the error.

If the "cutting feed override" switch has been set to a value other than "0", check for any short circuit in the

signal line.

Correct the sequence program.

M01 External feed rate zero 0103

Details

[External feed rate zero]

MANUAL FEEDRATE switch on the machine operation panel is set to "0" when the machine is in the JOG or

automatic dry run mode.

"Manual feedrate B" is set to "0" during the JOG mode when manual feedrate B is valid.

"Each axis manual feedrate B" is set to "0" during the JOG mode when each axis manual feedrate B is valid.

[Aux ax feedrate 0]

The operation parameter's feedrate setting is zero.The operation parameter feedrate setting is zero. Or, the

override is valid, and the override value is zero.

Remedy

[External feed rate zero]

Set the MANUAL FEEDRATE switch to a value other than "0" to release the error.

If the MANUAL FEEDRATE switch has been set to a value other than "0" check for any short circuit in the

signal line.

Correct the sequence program.

[Aux ax feedrate 0]

Set a value other than zero in the feedrate setting or override value.

IB-1501279-H

10

Page 28

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 F 1-digit feed rate zero 0104

Details

The F1-digit feedrate has been set to "0" when the F1-digit feed command was executed.

Remedy

Set the F1-digit feedrate (the parameter "#1185 spd_F1" (F1 digit feedrate F1) to "#1189 spd_F5" (F1 digit

feedrate F5)).

M01 Spindle stop 0105

Details

The spindle stopped during the synchronous feed/thread cutting command.

Remedy

Rotate the spindle.

If the workpiece is not being cut, start dry run.

Check for any broken wire in the spindle encoder cable.

Check the connections for the spindle encoder connectors.

Check the spindle encoder pulse.

Correct the program. (commands and addresses)

M01 Handle feed ax No. illegal 0106

Details

The axis, designated at handle feed, is out of specifications.

No axis has been selected for handle feed.

Multiple axes in a part system are allocated to a handle.

Remedy

Check for any broken wires in the handle feed axis selection signal line.

Correct the sequence program.

Check the number of axes in the specifications.

Check the axis allocation to the handle.

M01 Spindle rotation speed over 0107

Details

Spindle rotation speed exceeded the axis clamp speed during the thread cutting command.

Remedy

Lower the commanded rotation speed.

M01 Fixed pnt mode feed ax illegal 0108

Details

The axis, designated in the manual arbitrary feed, is out of specifications.

The feedrate in manual arbitrary feed mode is illegal.

Remedy

Check for any broken wires in the axis selection signal line or the feedrate line for the manual arbitrary feed

mode.

Check the specifications for the manual arbitrary feed mode.

M01 Block start interlock 0109

Details

An interlock signal has been input to lock the block start.

Remedy

Correct the sequence program.

M01 Cutting block start interlock 0110

Details

An interlock signal has been input to lock the cutting block start.

Remedy

Correct the sequence program.

11

IB-1501279-H

Page 29

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Restart switch ON 0111

Details

Restart switch has been turned ON and manual mode has been selected before the restart search is completed.

Remedy

Search the block to restart.

Turn the restart switch OFF.

M01 Program check mode 0112

Details

The cycle start button was pressed during program check or in program check mode.

Remedy

Press the reset button to cancel the program check mode.

M01 Cycle st. in buffer correct 0113

Details

The cycle start button was pressed during buffer correction.

Remedy

Press the cycle start button after the buffer correction is completed.

M01 In reset process 0115

Details

The cycle start button was pressed during resetting or tape rewinding.

Remedy

When rewinding the tape, wait for the winding to end, or press the reset button to stop the winding, and

then press the cycle start button.

During resetting, wait for the resetting to end, and then press the automatic start button.

M01 Playback not possible 0117

Details

The playback switch was turned ON during editing.

Remedy

Cancel the editing by pressing the input or previous screen key before turning ON the playback switch.

M01 Turn stop in normal line cntrl 0118

Details

The turning angle at the block joint exceeded the limit during normal line control.

In normal line control type I:

The parameter "#1523 C_feed" (Normal line control axis turning speed) has not been set.

In normal line control type II:

When turning in the inside of the arc, the set value for the parameter "#8041 C-rot. R" is larger than the arc

radius.

Remedy

Correct the program.

Correct the parameter "#1523 C_feed" (Normal line control axis turning speed) setting.

Correct the parameter "#8041 C-rot. R" setting.

M01 Reverse run impossible 0119

Details

Any of the following conditions are occurring.

a) There is no block to run backward

b) Eight blocks without a travel command continued

Remedy

Execute forward run to clear the alarm.

Reset to clear the alarm.

IB-1501279-H

12

Page 30

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 In synchronous correction mode 0120

Details

The synchronous correction mode switch was pressed in non-handle mode.

Remedy

Select the handle or manual arbitrary feed mode.

Turn OFF the correction mode switch.

M01 No synchronous control option 0121

Details

The synchronous control operation method was set (with R2589) while no synchronous control option was provided.

Remedy

Set "0" for "synchronous control operation method".

M01 Computer link B not possible 0123

Details

Cycle start was attempted before resetting was completed.

Computer link B operation was attempted at the 2nd or further part system in a multi-part system.

Remedy

Perform the cycle start after resetting has been completed.

Set "#8109 HOST LINK" to "0" and then set to "1" before performing the cycle start.

Computer link B operation cannot be performed at the 2nd or further part system in a multi-part system.

M01 X/Z axes simultaneous prohibit 0124

Details

The basic axis corresponding to the inclined axis was started simultaneously in the manual mode while the inclined axis control was valid.

Remedy

Turn the inclined axis and basic axis start OFF for both axes. (This is also applied for manual/automatic

simultaneous start.)

Disable the basic axis compensation, or command it to axes one by one.

M01 Program restart machine lock 0126

Details

Machine lock was applied on the return axis being manually returned to the restart position.

Remedy

Cancel the machine lock and resume the operation.

M01 Rot axis parameter error 0127

Details

Orthogonal coordinate axis name does not exist.

Rotary axis name does not exist.

A duplicate name is used for the designated orthogonal coordinate axis.

The number of axes that were selected to change tool length compensation along the tool axis amount exceeds

the maximum number of axes.

The designated orthogonal coordinate axis name is the same as the rotary axis name.

Remedy

Correct the rotary axis configuration parameters.

M01 Restart pos return incomplete 0128

Details

Cycle start was performed with an axis whose return to the restart position was not complete.

Remedy

Perform restart position return manually.

Validate the parameter "#1302 AutoRP" (Automatic return by program restart), then execute cycle start.

13

IB-1501279-H

Page 31

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 PLC interruption impossible 0129

Details

After the cycle start, the "PLC interrupt" signal was turned ON during buffer correction, program restart, arbitrary reverse run, tool retract and return, high-speed high-accuracy control II, NURBS interpolation or single

block stop at the middle point of G28/G29/G30.

Remedy

By turning OFF the "PLC interrupt" signal, or by resetting the NC the error can be cancelled.

M01 Restart posn return disabled 0130

Details

Restart position return was attempted in a mode where the return is disabled.

Remedy

Correct the program restart position.

M01 Zero point return interruption 0131

Details

Compound type fixed cycle program was interrupted with manual zero point return, and cycle start was carried

out without carrying out reset.

Remedy

Cancel the program execution by reset.

M01 Excessive no. of reverse block 0133

Details

During the reverse run in arbitrary reverse run, any one of the part systems reverse-ran for 20 blocks.

Remedy

This error is cancelled by forward run.

M01 Illegal mode in prg check mode 0134

Details

Any of the following modes has been turned ON during the manual arbitrary reverse run mode.

MDI interruption mode

Manual/automatic simultaneous valid (MAE1 to 8)

Arbitrary feed mode (PTP)

Arbitrary reverse control mode (RVMD)

Manual speed command enabled

High-speed simple program check mode (SMLK)

Remedy

The error can be cancelled by turning OFF the error-causing mode.

M01 Too many active axes per sys 0135

Details

High-accuracy control has been executed in a part system which has 9 or more enabled control axes, except

for a slave or synchronous axis.

Remedy

Reduce the number of enabled control axes (except for a slave axis and synchronous axis) of the part system to 8 or less through synchronous control, control axis synchronization across part systems, or mixed

control before executing high-accuracy control.

M01 Pre-intrpl variable accel err 0136

Details

The parameter "#12060 VblAccPreInt" (Variable-acceleration pre-interpolation acceleration/deceleration

ON) is set to "1" and the parameter "#8090 SSS ON" is set to "0".

Remedy

To enable the variable acceleration pre-interpolation acceleration/deceleration, set the parameter "#8090

SSS ON" to "1".

To disable the variable acceleration pre-interpolation acceleration/deceleration, set the parameter "#12060

VblAccPreInt" to "0".

IB-1501279-H

14

Page 32

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Unable to start automatic mode 0137

Details

Although start of automatic operation is not allowed after a machine groupwise alarm stop ("#1472

mgralmrestart"=0), start of automatic operation has been attempted after the said alarm stop.

The cycle operation is started with the guide bushing spindle synchronization related spindle is not being

set.

The cycle operation is started while the "G/B spindle synchronization: temporary cancel" signal is turned

ON.

Remedy

Remove the cause of the stop by alarm.

Set the parameter "#1472 mgralmrestart" (Allowing automatic operation to start after machine groupwise

alarm stop) to "1".

Check the parameter "#3074 GBsp".

Turning OFF the "G/B spindle synchronization: temporary cancel" signal before starting the cycle opera-

tion.

M01 Tool data sorting in progress 0138

Details

Cycle start or graphic check has been attempted during sorting of tool management data.

Remedy

Execute cycle start after the tool data sorting is completed.

Execute graphic check after the tool data sorting is completed.

M01 Tolerance control invalid 0139

Details

The parameter "#12066 Tolerance ctrl ON" is set to "1", although "#8090 SSS ON" is "0".

Remedy

To enable the tolerance control, set "#8090 SSS ON" to "1".

To disable the tolerance control, set "#12066 Tolerance ctrl ON" to "0".

M01 Ill manualmode select in 3Dcnv 0145

Details

The following unselectable manual mode was selected during 3-dimensional coordinate conversion.

manual reference position return

Remedy

Cancel the 3-dimensional coordinate conversion modal.

M01 Start err in PRM rot manu feed 0146

Details

Axis start has been attempted with any of the following operations while the coordinate rotation by parameter

for manual feed is enabled.

Tool retract and return

Manual tool length measurement

Manual skip

Remedy

Turn OFF the "Coordinate rotation by parameter: Coordinate switch for manual feed" signal.

M01 Multiaxes in RRM rot manu feed 0147

Details

Two or more of the three basic axes were started at a time for the coordinate rotation by parameter for manual

feed.

Remedy

Disable the coordinate rotation by parameter for manual feed or start one axis at a time.

15

IB-1501279-H

Page 33

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Chopping override zero 0150

Details

The override became "0" in the chopping operation.

Remedy

Check the chopping override (R2503).

Check the rapid traverse override (R2502).

M01 Command axis chopping axis 0151

Details

A chopping axis movement command was issued from the program during the chopping mode. (This alarm will

not occur for the command with the movement amount "0".)

(All axes interlock state will be applied.)

Remedy

Press the reset button or turn OFF the "chopping" signal. When the "chopping" signal is turned OFF, the

axis returns to the reference position and performs the movement command in the program.

M01 Bottom dead center pos. zero 0153

Details

The bottom dead center position is set to the same position as the upper dead center position.

Remedy

Correct the bottom dead center position.

M01 Chopping disable for handle ax 0154

Details

Chopping has been attempted while the chopping axis is selected as the handle axis.

Remedy

Select an axis other than the chopping axis as the handle axis, or start chopping after changing the mode

to the other mode.

M01 Dir cmnd mode invalid 0157

Details

The drive unit's software or hardware does not conform to the direct command mode.

Inclined axis control is active.

Control axis synchronization across part system is active.

Control axis superimposition was activated during direct command mode.

Remedy

The software or hardware does not conform to the function. Contact service center.

Turn the inclined axis control valid signal OFF.

Turn the synchronous control request signal OFF.

Turn the superimposition control request signal OFF.

M01 Dir cmnd mode restart invalid 0158

Details

Cycle start was carried out without reset after the retract in direct command mode.

Remedy

Finish the machining for now by resetting the NC.

IB-1501279-H

16

Page 34

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 No speed set out of soft limit 0160

Details

[No speed set out of soft limit]

The axis, without any maximum speed outside of the soft limit range set, was returned from the outside of the

soft limit range.

[Aux ax sta No. illegal]

A station No. exceeding the No. of indexed divisions was designated.

Remedy

[No speed set out of soft limit]

Correct the parameter "#2021 out_f" (Maximum speed outside soft limit range) setting.

Correct the soft limit range (with the parameter "#2013 OT-" (Soft limit I-) and "#2014 OT+" (Soft limit I+)).

[Aux ax sta No. illegal]

Correctly designate the station No.

M01 Aux ax R-pnt ret incomplete 0161

Details

Automatic/manual operation was started before reference position return was executed with the incremental

system.

Remedy

Execute the reference position return.

M01 Aux abs position initializing 0162

Details

The start signal was input while initializing the absolute position reference point.

Remedy

Complete the absolute position reference point initialization.

M01 Aux ax abs position error 0163

Details

The start signal was input during an absolute position alarm.

Remedy

Initialize the absolute position reference point and then fix the absolute position coordinates.

M01 Aux ax arbitrary positioning 0164

Details

The manual operation mode was started during the random positioning mode.

Remedy

Turn the random positioning mode OFF before switching to the manual operation mode.

M01 Aux uneven index sta No. ilgl 0165

Details

The commanded station No. was higher than 20 or the number of indexing stations during uneven indexing.

The station No.0 was specified during uneven indexing.

Remedy

Check the commanded station No. and the parameter "#12801 aux_station" setting.

M01 Aux axis changeover error 0166

Details

One of the following attempts was made on an axis that is switchable between NC axis and auxiliary axis.

A command intended for an NC axis in manual mode was issued to an auxiliary axis.

NC axis control select signal was turned OFF while the NC axis was in motion.

NC axis control select signal was turned ON while the auxiliary axis was in motion.

Remedy

If you wish to issue a command intended for an NC axis in manual mode, turn ON the NC axis control

select signal so as to set the axis as an NC axis.

Do not change NC axis control select signal while the axis is in motion.

17

IB-1501279-H

Page 35

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Aux ax torque limit value zero 0167

Details

Torque limit value of the parameter group to use is "0".

Remedy

Check the torque limit value of the parameter group to use (#12814 aux_TL1, #12824 aux_TL2, #12834

aux_TL3, or #12844 aux_TL4).

M01 Ill. op during T tip control 0170

Details

Illegal operation was attempted during tool tip center control.

Remedy

Change the operation mode to the previous one and restart.

M01 Illegal op in spline interpol2 0180

Details

Any of the following operations was performed during spline interpolation 2.

Change to manual mode

Change to MDI mode

PLC interruption

Remedy

Return to the original operation mode, and then remove the error cause.

M01 Illegal OP in tilted face cut 0185

Details

Any of the following illegal operations was attempted during inclined surface machining mode.

Manual interrupt

Handle interrupt in automatic operation

MDI interrupt

PLC interrupt

Arbitrary reverse run

Remedy

Switch the operation mode back to the previous to remove the cause of this failure.

During inclined surface machining mode, it's impossible to perform manual interrupt, handle interrupt in

automatic operation, MDI interrupt, PLC interrupt, etc.

M01 5-axis control config. error 0186

Details

The operation you input cannot be executed under the axis configuration of the part system.

3D manual feed was attempted.

The rotation center error compensation has been turned ON.

The rotary axis is set to the spindle mode of the spindle position control.

Remedy

Check the rotary axis configuration parameters.

Correct the axis configuration of the part system.

Press the reset button to cancel this alarm.

IB-1501279-H

18

Page 36

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Rotary axis para unswitchable 0187

Details

The rotary axis configuration parameter switch request signal has turned ON for a part system where any of

the following modes is active.

Tool center point control mode

Inclined surface machining mode

Workpiece installation error compensation mode

Tool axis direction tool length compensation mode

Simple inclined surface machining mode

3D radius compensation mode

3D manual feed

Tool handle feed & interruption

R-Navi mode

Remedy

Cancel the alarm by NC reset or by turning OFF the rotary axis configuration parameter switch request

signal.

M01 Interference check invalidated 0200

Details

The 3D machine interference check is invalidated. This alarm is output to NC alarm 5.

Remedy

Validate all the interference check settings.

If there is any axis which has not completed zero point return, establish the zero point first.

M01 Machine interference 1 0201

Details

It was judged that an interference occurred in the No.1 step interference check and caused a deceleration stop.

When machine interference is detected, the interfered part is highlighted (yellow/red) and the part's name is

displayed on the 3D monitor's model display.

Remedy

Move the axis in a direction which does not cause interference.

Press RESET to cancel the alarm.

(In manual operation)

You can move the axis in the same travel direction as before the interference.

But the axis movement is done using the 2nd step interference check distance.

M01 Machine interference 2 0202

Details

It was judged that an interference occurred in the No.2 step interference check and caused a deceleration stop.

When machine interference is detected, the interfered part is highlighted (red) and the part's name is displayed

on the 3D monitor's model display.

Remedy

Move the axis in a direction which doesn't cause interference.

Press RESET to cancel the alarm.

M01 Tool interfere. check disabled 0205

Details

Tool interference check has been disabled.

This alarm is output to the NC alarm 5.

Remedy

Turn ON the [Tool check] menu of 3D monitor.

Set the tool data.

If you prevent an alarm from being output while the tool interference check is disabled, set "0" in "#11100

3D_MChk_ToolAlm".

19

IB-1501279-H

Page 37

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Too many simul. control axes 0211

Details

The given command has caused any axis other than those commanded to move. So the total number of axes

to move has exceeded the maximum number of simultaneous contour control axes.

Remedy

Check the maximum number of simultaneous contour control axes of your NC.

Check the machining program to make sure the total number of axes to move will not exceed the maximum

number of simultaneous contour control axes.

M01 Changing prg format disabled 0215

Details

The PFCHR signal has been switched (from ON to OFF or OFF to ON) during automatic operation.

Remedy

Use G188 to change the program format during automatic operation.

* The warning display is cancelled by changing PFCHR back to the previous state.

M01 Multi ax for 3D manual feed 0230

Details

More than one axis was designated in manual mode while the 3-dimensional manual feed was valid.

Remedy

Command the manual feed to each axis one by one.

M01 3D manual feed coord sys err 0231

Details

More than one of the three bits for selecting hypothetical coordinate system was turned ON.

Virtual coordinate system was selected while the 3-dimensional manual feed was invalidated by the pa-

rameter setting.

The manual tool length measurement or workpiece position measurement is being attempted.

Remedy

Check the sequence program.

Enable 3-dimensional tool radius compensation (set the parameter "#7912 NO_MANUAL" to "0").

Finish the manual tool length measurement or workpiece position measurement.

M01 Illegal op in 3D tool R comp 0232

Details

An illegal operation (such as manual interrupt) was attempted during 3-dimensional tool radius compensation

(tool vertical direction compensation).

Remedy

Operations such as manual interrupt are disabled while 3-dimensional tool radius compensation (tool vertical direction compensation) is being performed.

M01 Coord select w/o 3D man. Feed 0233

Details

Hypothetical coordinate system has been selected although 3D manual feed is not included in the specifications.

Remedy

Turn OFF all the 3D manual feed coordinate system selection signals (including MJCT).

M01 No spec: Rot center error comp 0240

Details

No option of rotation center error compensation is found.

Remedy

Check the specifications.

IB-1501279-H

20

Page 38

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 Rot center err comp excessive 0241

Details

Compensation amount calculation was excessive, so the amount was clamped by +/- 1mm.

Remedy

Review the position deviation and angular deviation values.

M01 Unable to start measuring err 0245

Details

You executed cycle start while measurement of rotation center error or workpiece installation error is invalid.

Remedy

Execute cycle start for one part system that is ready for measurement.

Activate memory mode before executing cycle start.

M01 Invalid op mode in err measure 0246

Details

You switched the operation to any mode other than memory during measurement of rotation center error or

workpiece installation error.

Remedy

Switch the operation to memory mode.

Manual interruption, automatic operation handle interruption, MDI interruption, etc. are invalid during error mea-

surement.

Execute cycle start after completion or cancel of the measurement.

M01 Machining surface operation disabled 0250

Details

Machining surface operation (selection, indexing or cancel) was attempted while the operation is disabled.

Remedy

Cancel the other modes so that the inclined surface machining command (G68.2), tool axis direction control (G53.1) and the inclined surface machining cancel command (G69) can be issued.

Wait until the axes stop completely (until the smoothing for all axes reaches zero).

Perform operation search for machining programs.

M01 Axs travel n/a in manual index 0251

Details

Moving a rotary axis was attempted during manual machining surface indexing, when a manual operation

mode other than handle mode was selected.

Remedy

Change the operation mode to a handle mode before carrying out the manual surface indexing.

M01 Tool length compensation amt 0 0252

Details

The tool length compensation amount for performing the R-Navi indexing type 2 is 0.

Remedy

Set the tool length compensation amount for performing the indexing type 2 to a value other than 0.

M01 Feat coord ill w/ multi-handle 0253

Details

Manual feed feature coordinate system was selected while two or more handles were ON.

Remedy

Manual feed on a feature coordinate system is disabled while two or more handles are enabled (*).

Press [Manual coord] and select the machine coordinate system.

Reduce the number of enabled handles (*) to one.

(*) An enabled handle means the handle for which "Nth handle valid" signal (HSnS) is ON.

21

IB-1501279-H

Page 39

M800/M80/E80/C80 Series Alarm/Parameter Manual

1 Operation Errors (M)

M01 No spec: Spatial error comp 0260

Details

The spatial error compensation option is not available.

Remedy

Check the specifications.

M01 Spatial error comp excessive 0261

Details

The compensation amount is outside the setting range.

Due to the calculation of the excessive amount, it is clamped by +/-1mm.

Remedy

Set the compensation amount within the setting range.

M01 Auto backlash adjust illegal 0270

Details

A measurement condition adjustment or backlash adjustment was attempted to an axis with which automatic backlash adjustment is impossible.

A measurement condition adjustment or backlash adjustment was attempted even though all the axes had

not reached the 1st reference position.

The operation mode is other than memory mode.

The slave axis of synchronous control is selected as adjustment axis.

An attempt has been made to start an adjustment by cycle start.

Remedy

Check the adjustment axis.

Start the adjustment after all the axes return to the 1st reference position.

Check the operation mode.

Select the master axis of synchronous control as adjustment axis when adjusting the slave axis.

Start the adjustment by automatic backlash adjustment start signal.

M01 Operating auto backlash adjust 0271

Details

An illegal operation was attempted during measurement condition adjustment or backlash adjustment.

Remedy

Continue the operation after canceling the measurement condition adjustment and backlash adjustment.

M01 APLC password mismatch 0280

Details

The APLC authentication password is inconsistent.

Remedy

Contact the machine tool builder.

M01 High-cycle sampling disabled

0290

Details