Page 1

RESIDENTIAL AIR-CONDITIONING

TECHNICAL MANUAL & PARTS LIST

INVERTER WALL MOUNTED TYPE

RESIDENTIAL AIR-CONDITIONER

(Split system, air to air heat pump type)

DXK09ZJ-S

DXK12ZJ-S

DXK18ZJ-S

Manual No.'11•SRK-T-118

Page 2

Page 3

TECHNICAL MANUAL

Page 4

-

1

-

'11 • SRK-T-118

CONTENTS

1. SPECIFICATIONS

........................................................................................ 3

(2) Outdoor units ....................................................................................... 7

....................................................... 18

(3) Remote controller

................................................................................ 9

......................................................................... 6

(1) Indoor units .......................................................................................... 6

2. EXTERIOR DIMENSIONS

3. ELECTRICAL WIRING .............................................................................. 11

(1) Indoor units .......................................................................................... 11

4. NOISE LEVEL ............................................................................................ 14

(2) Outdoor units ....................................................................................... 12

6. RANGE OF USAGE & LIMITATIONS

................................................................................... 20

7. CAPACITY TABLES

5. PIPING SYSTEM ...................................................................................... 17

.................................................................................. 21

8. APPLICATION DATA

(1) Installation of indoor unit ..................................................................... 21

(2) Installation of outdoor unit .................................................................... 25

9. OUTLINE OF OPERATION CONTROL BY MICROCOMPUTER ............... 39

(6) 3D auto operation ............................................................................. 42

(7) Timer operation

.................................................................................. 43

....................................................... 40

(1) Operation control function by remote controller

(5) Flap and louver control ...................................................................... 41

(4) Custom cord switching procedure

......................................................................... 40(3) Auto restart function

(2) Unit ON/OFF button

........................................................................... 40

.................................. 39

(8) Installation location setting ................................................................. 43

(9) Outline of heating operation ................................................................ 44

(11) Outline of automatic operation ........................................................... 45

(10) Outline of cooling operation ............................................................... 45

(12) Protective control function

................................................................... 46

............................................................................... 53

10. MAINTENANCE DATA

..................... 54

(4) Troubleshooting procedure (If the air conditioner runs)

(3) Troubleshooting procedure

(If the air conditioner does not run at all)

........ 53

(1) Cautions

............................................................................................. 53

(2) Items to check before troubleshooting ................................................. 53

(5) Self-diagnosis table ............................................................................. 55

(6) Service mode (Trouble mode access function) ................................... 56

Page 5

-

2

-

'11 • SRK-T-118

(10) How to make sure of wireless remote controller .................................. 70

(11) Outdoor unit inspection points .............................................................. 71

(8)

Phenomenon observed after shortcircuit, wire breakage on sensor

......... 68

(7) Inspection procedures corresponding to detail of trouble .................... 64

(9) Checking the indoor electrical equipment

........................................... 69

11.1 Instullation of wired remote controller (RC-E4) ............................... 74

11. OPTION PARTS ....................................................................................... 74

11.2 Interface kit (SC-BIKN-E) .................................................................... 80

11.3 Super link E board (SC-ADNA-E) ...................................................... 84

■How to read the model name

Example: DXK 09 Z

Series code

Inveter type

Product capacity

Model name DXK : Wall mounted type

DXC : Outdoor unit

J-S

Page 6

-

3

-

'11 • SRK-T-118

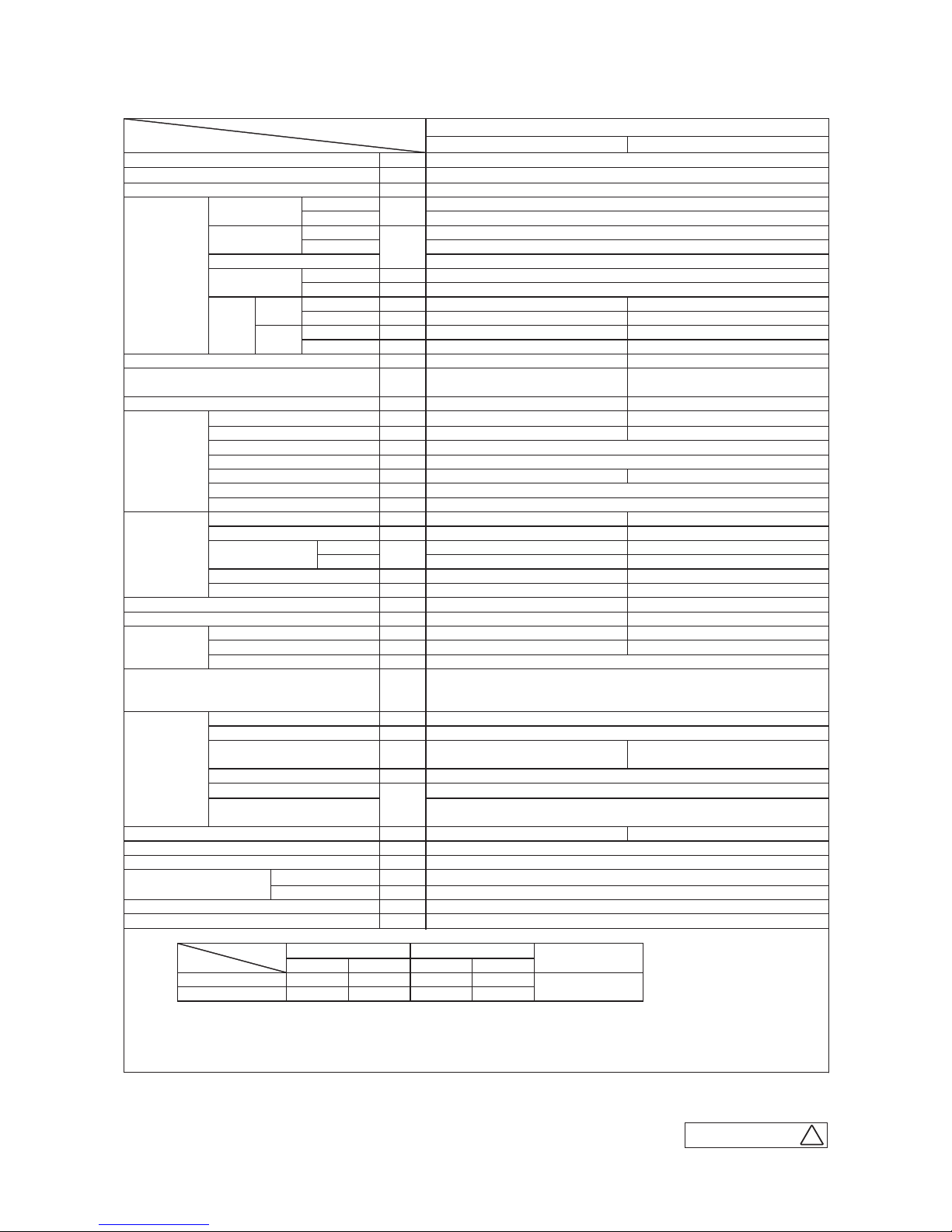

1. SPECIFICATIONS

D

RWA000Z225

GDWD

&23

1RLVH

+HDWLQJ

OHYHO

([WHULRUDSSHDUDQF

HTXLSPHQ

W

HTXLSPHQ

W

FRQWURO

GDW

D

$WWDFKHGOHQJWKRISLSLQJ

&RQQHFWLRQZLULQJ

1RWH

3XUJLQJLVQRWUHTXLUHGHYHQIRUWKHVKRUWSLSLQJ

+HDWLQJFDSDFLW\ : 0LQᨺ0D[

3RZHUVXSSO

\

N:

3KDVHᨺ9+]

2SHUDWLRQ

3RZHU &RROLQJ ᨺ

FRQVXPSWLRQ +HDWLQJ

$

ᨺ

5XQQLQJ &RROLQJ

9

FXUUHQW +HDWLQJ 9

,QUXVKFXUUHQW 9

&RROLQJ

+HDWLQJ

G%

G%

G%$

G%$

6RXQGOHYH

O +L0H/R

3RZHUOHYHO

6RXQGOHYH

O +L0H/R

3RZHUOHYHO

([WHULRUGLPHQVLRQV+HLJKW[:LGWK['HSWK

PP [[ ;;

H )LQHVQRZ 6WXFFRZKLWH

0XQVHOOFRORU

<QHDUHTXLYDOHQW <QHDUHTXLYDOHQW

1HWZHLJK

W NJ

5HIULJHUDQ

W

&RPSUHVVRUW\SH4W\ ዙ 50%0'(5RWDU\W\SH[

0RWRU6WDUWLQJPHWKRG N: ዙ /LQHVWDUWLQJ

5HIULJHUDQWRLO ',$021')5((=(0$

5HIULJHUDQW NJ 5$3UH&KDUJHGXSWRWKHSLSLQJOHQJWKRIP

+HDWH[FKDQJH

U /RXYHUILQVLQQHUJURRYHGWXELQJ 0ILQVLQQHUJURRYHGWXELQJ

5HIULJHUDQWFRQWURO &DSLOODU\WXEHV(OHFWURQLFH[SDQVLRQYDOYH

'HLFHFRQWURO 0LFURFRPSXWHUFRQWURO

$LUKDQGOLQJ

)DQW\SH4W\ 7DQJHQWLDOIDQ[ 3URSHOOHUIDQ[

0RWRU

$LUIORZ

:

&00

&RROLQJ +L0H/R

+HDWLQJ +L0H/R

)UHVKDLULQWDN

H 1RWSRVVLEOH ዙ

$LUILOWHU4XDOLW\4XDQWLW\ 3RO\SURS\OHQHQHWZDVKDEOH[ ዙ

6KRFNYLEUDWLRQDEVRUEH

U ዙ

&XVKLRQUXEEHUIRUFRPSUHVVRU

(OHFWULFKHDWHU ዙ ዙ

2SHUDWLRQ

2SHUDWLRQVZLWFK

:LUHOHVV5HPRWHFRQWUR

O ዙ

5RRPWHPSHUDWXUHFRQWURO

0LFURFRPSXWHUWKHUPRVWD

W ዙ

2SHUDWLRQ'LVSOD

\ 581*UHHQ7,0(5<HOORZ+,32:(5*UHHQ'$872*UHHQ

6DIHW\GHYLFHV

&RPSUHVVRURYHUKHDWSURWHFWLRQ2YHUFXUUHQWSURWHFWLRQ

)URVWSURWHFWLRQ6HULDOVLJQDOHUURUSURWHFWLRQ,QGRRUIDQPRWRUHUURUSURWHFWLRQ

+HDWLQJRYHUORDGSURWHFWLRQ+LJKSUHVVXUHFRQWURO&RROLQJRYHUORDGSURWHFWLRQ

,QVWDOODWLRQ

5HIULJHUDQWSLSLQJVL]H2' PP /LTXLGOLQHǾ*DVOLQHǾ

FRQQHFWLQJPHWKRG

P

)ODUHFR

QQHFWLQJ

ዙ

/LTXLGOLQH

*DV/LQH

,QVXODWLRQIRUSLSLQ

J

P

1HFHVVDU\%RWKVLGHVLQGHSHQGHQW

5HIULJHUDQWOLQHRQHZD\OHQJWK 0D[

9HUWLFDOKHLJKWGLIIHUHQFHEHWZHHQ 0D[2XWGRRUXQLWLVKLJKHU

RXWGRRUXQLWDQGLQGRRUXQLW 0D[2XWGRRUXQLWLVORZHU

'UDLQKRVH &RQQHFWDEOH93 ዙ

3RZHUFDEOH ዙ

5HFRPPHQGHGEUHDNHUVL]H $

6L]H[&RUHQXPEHU PP [FRUHV,QFOXGLQJHDUWKFDEOH

&RQQHFWLQJPHWKR

G 7HUPLQDOEORFN6FUHZIL[LQJW\SH

$FFHVVRULHVLQFOXGHG 0RXQWLQJNLW&OHDQILOWHU$OOHUJHQFOHDUILOWHU[3KRWRFDWDO\WLFZDVKDEOHGHRGRUL]LQJILOWHU[

2SWLRQDOSDUW

V ,QWHUIDFHNLW6&%,.1(

7KHGDWDDUHPHDVXUHG

,WHP

DWWKHIROORZLQJFRQGLWLRQV 7KHSLSHOHQJWKLVP

,QGRRUDLUWHPSHUDWXUH 2XWGRRUDLUWHPSHUDWXUH

6WDQGDUGV

2SHUDWLRQ

'% :% '% :%

&RROLQJ

ഒ ഒ ഒ

ഒ

+HDWLQJ

ഒ ഒ

7KLVDLUFRQGLWLRQHULVPDQXIDFWXUHGDQGWHVWHGLQFRQIRUPLW\ZLWKWKH,6

2

7KHRSHUDWLRQGDWDDUHDSSOLHGWRWKH9GLVWULFWVUHVSHFWLYHO\

7KHUHIULJHUDQWTXDQWLW\WREHFKDUJHGLQFOXGHVWKHUHIULJHUDQWLQPFRQQHFWLQJSLSLQJ

&RROLQJFDSDFLW\ : 0LQᨺ0D[

$GDSWHGWRRoHS GLUHFWLYH

DXK09ZJ-S

Indoor unit DXK09ZJ-S Outdoor unit DXC09ZJ-S

,627-,6&

&RROLQJ

ഒዙ

Model

Item

Page 7

-

4

-

'11 • SRK-T-118

D

RWA000Z225

GDWD

&23

+HDWLQJ

([WHULRUDSSHDUDQF

HTXLSPHQ

W

HTXLSPHQW

FRQWURO

GDW

D

$WWDFKHGOHQJWKRISLSLQJ

&RQQHFWLRQZLULQJ

1RWH

3XUJLQJLVQRWUHTXLUHGHYHQIRUWKHVKRUWSLSLQJ

3RZHUVXSSO\

N:

3KDVHᨺ9+]

2SHUDWLRQ

3RZHU &RROLQJ ᨺ

FRQVXPSWLRQ +HDWLQJ

$

ᨺ

5XQQLQJ &RROLQJ

9

FXUUHQW +HDWLQJ 9

,QUXVKFXUUHQW 9

&RROLQJ

+HDWLQJ

6RXQGOHYH

O +L0H/R

3RZHUOHYHO

6RXQGOHYH

O +L0H/R

3RZHUOHYHO

([WHULRUGLPHQVLRQV+HLJKW[:LGWK['HSWK PP [[ ;;

H )LQHVQRZ 6WXFFRZKLWH

0XQVHOOFRORU <QHDUHTXLYDOHQW <QHDUHTXLYDOHQW

1HWZHLJKW NJ

5HIULJHUDQW

&RPSUHVVRUW\SH4W\ ዙ 50%0'(5RWDU\W\SH[

0RWRU6WDUWLQJPHWKRG N: ዙ /LQHVWDUWLQJ

5HIULJHUDQWRLO ഢ ',$021')5((=(0$

5HIULJHUDQW NJ 5$3UH&KDUJHGXSWRWKHSLSLQJOHQJWKRIP

+HDWH[FKDQJHU /RXYHUILQVLQQHUJURRYHGWXELQJ 0ILQVLQQHUJURRYHGWXELQJ

5HIULJHUDQWFRQWURO &DSLOODU\WXEHV(OHFWURQLFH[SDQVLRQYDOYH

'HLFHFRQWURO 0LFURFRPSXWHUFRQWURO

$LUKDQGOLQJ

)DQW\SH4W\ 7DQJHQWLDOIDQ[ 3URSHOOHUIDQ[

0RWRU

$LUIORZ

:

&00

&RROLQJ +L0H/R

+HDWLQJ +L0H/R

)UHVKDLULQWDN

H 1RWSRVVLEOH ዙ

$LUILOWHU4XDOLW\4XDQWLW\ 3RO\SURS\OHQHQHWZDVKDEOH[ ዙ

6KRFNYLEUDWLRQDEVRUEH

U ዙ &XVKLRQUXEEHUIRUFRPSUHVVRU

(OHFWULFKHDWHU ዙ ዙ

2SHUDWLRQ

2SHUDWLRQVZLWFK

:LUHOHVV5HPRWHFRQWURO ዙ

5RRPWHPSHUDWXUHFRQWURO

0LFURFRPSXWHUWKHUPRVWDW ዙ

2SHUDWLRQ'LVSOD\ 581*UHHQ7,0(5<HOORZ+,32:(5*UHHQ'$872*UHHQ

6DIHW\GHYLFHV

&RPSUHVVRURYHUKHDWSURWHFWLRQ2YHUFXUUHQWSURWHFWLRQ

)URVWSURWHFWLRQ6HULDOVLJQDOHUURUSURWHFWLRQ,QGRRUIDQPRWRUHUURUSURWHFWLRQ

+HDWLQJRYHUORDGSURWHFWLRQ+LJKSUHVVXUHFRQWURO&RROLQJRYHUORDGSURWHFWLRQ

,QVWDOODWLRQ

5HIULJHUDQWSLSLQJVL]H2' PP

/LTXLGOLQHǾ*DVOLQHǾ

FRQQHFWLQJPHWKRG

P

)ODUHFR

QQHFWLQJ

ዙ

/LTXLGOLQH

*DV/LQH

,QVXODWLRQIRUSLSLQ

J

P

1HFHVVDU\%RWKVLGHVLQGHSHQGHQW

5HIULJHUDQWOLQHRQHZD\OHQJWK 0D[

9HUWLFDOKHLJKWGLIIHUHQFHEHWZHHQ 0D[2XWGRRUXQLWLVKLJKHU

RXWGRRUXQLWDQGLQGRRUXQLW 0D[2XWGRRUXQLWLVORZHU

'UDLQKRVH &RQQHFWDEOH93 ዙ

3RZHUFDEOH ዙ

5HFRPPHQGHGEUHDNHUVL]H $

6L]H[&RUHQXPEHU PP

[FRUHV,QFOXGLQJHDUWKFDEOH

&RQQHFWLQJPHWKRG 7HUPLQDOEORFN6FUHZIL[LQJW\SH

$FFHVVRULHVLQFOXGHG 0RXQWLQJNLW&OHDQILOWHU$OOHUJHQFOHDUILOWHU[3KRWRFDWDO\WLFZDVKDEOHGHRGRUL]LQJILOWHU[

2SWLRQDOSDUW

V ,QWHUIDFHNLW6&%,.1(

7KHGDWDDUHPHDVXUHG

,WHP

DWWKHIROORZLQJFRQGLWLRQV 7KHSLSHOHQJWKLVP

,QGRRUDLUWHPSHUDWXUH 2XWGRRUDLUWHPSHUDWXUH

6WDQGDUGV

2SHUDWLRQ

'% :% '% :%

&RROLQJ

ഒ ഒ ഒ

ഒ

+HDWLQJ

ഒ ഒ

7KLVDLUFRQGLWLRQHULVPDQXIDFWXUHGDQGWHVWHGLQFRQIRUPLW\ZLWKWKH,6

2

7KHRSHUDWLRQGDWDDUHDSSOLHGWRWKH9GLVWULFWVUHVSHFWLYHO\

7KHUHIULJHUDQWTXDQWLW\WREHFKDUJHGLQFOXGHVWKHUHIULJHUDQWLQPFRQQHFWLQJSLSLQJ

G%

G%

G%$

G%$

&RROLQJFDSDFLW\

+HDWLQJFDSDFLW\

:

:

0LQᨺ0D[

0LQᨺ0D[

$GDSWHGWRRoHS GLUHFWLYH

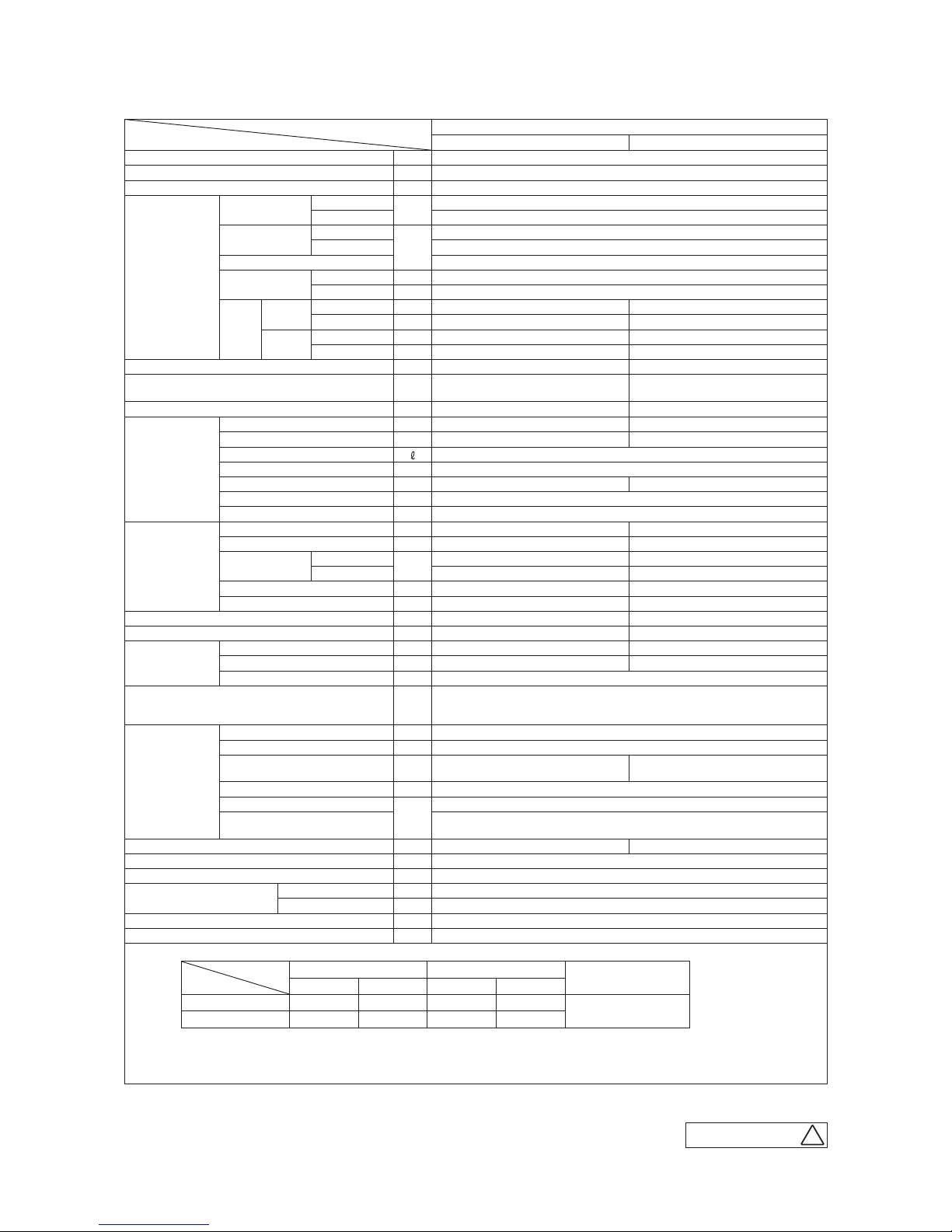

DXK12ZJ-S

Indoor unit DXK12ZJ-S Outdoor unit DXC12ZJ-S

&RROLQJ

,627-,6&

1RLVH

OHYHO

ഒዙ

Model

Item

Page 8

-

5

-

'11 • SRK-T-118

B

RWA000Z225

Model

Item

DXK18ZJ-S

Indoor unit DXK18ZJ-S Outdoor unit DXC18ZJ-S

Cooling capacity (1) W 5000 (1600 (Min.)~5500 (Max.))

Heating capacity (1) W 5800 (1600 (Min.)~6600 (Max.))

Power supply 1 Phase, 220~240 V, 50Hz

Operation

data (1)

Power

consumption

Cooling

kW

1.55 (0.40~2.20)

Heating 1.59 (0.42~2.10)

Running

current

Cooling

A

7.1 / 6.8 / 6.5 (220/ 230/ 240 V)

Heating 7.3 / 7.0 / 6.7 (220/ 230/ 240 V)

Inrush current 7.3 / 7.0 / 6.7 (220/ 230/ 240 V)

COP

Cooling 3.23

Heating 3.65

Noise

level

Cooling

Sound level dB(A) Hi : 46 Me : 37 Lo : 26 51

Power level dB 61 61

Heating

Sound level dB(A) Hi : 45 Me : 37 Lo : 31 53

Power level dB 61 63

Exterior dimensions (Height x Width x Depth) mm 294 x 798 x 229 640 x 800 (+71) x 290

Exterior appearance

(Munsell color)

Fine snow

( 8.0Y 9.3/0.1 ) near equivalent

Stucco white

( 4.2Y 7.5/1.1 ) near equivalent

Net weight kg 9.5 42

Refrigerant

equipment

Compressor type & Q'ty — 5RS132XAB21 (Rotary type) x 1

Motor (Starting method) kW — 0.90 (Line starting)

Refrigerant oil 0.37 (FV50S)

Refrigerant (4) kg R410A 1.35 (Pre-Charged up to the piping length of 15m)

Heat exchanger Louver fins & inner grooved tubing M fins & inner grooved tubing

Refrigerant control Capillary tubes + Electronic expansion valve

Deice control Microcomputer control

Air handling

equipment

Fan type & Q'ty Tangential fan x 1 Propeller fan x 1

Motor W 38 34

Air flow

Cooling

CMM

Hi : 11.3 Me : 7.8 Lo : 5.3 36.0

Heating Hi : 13.5 Me : 10.2 Lo : 7.5 36.0

Fresh air intake Not possible —

Air filter, Quality / Quantity Polypropylene net (washable) x 2 —

Shock & vibration absorber — Cushion rubber (for compressor)

Electric heater — —

Operation

control

Operation switch Wireless-Remote control —

Room temperature control Microcomputer thermostat —

Operation Display RUN : Green, TIMER : Yellow, HI POWER : Green, 3D AUTO : Green

Safety devices

Compressor overheat protection, Overcurrent protection,

Frost protection, Serial signal error protection, Indoor fan motor error protection,

Heating overload protection (High pressure control), Cooling overload protection

Installation

data

Refrigerant piping size (O.D) mm Liquid line :φ6.35 (1/4") Gas line :φ12.7 (1/2")

Connecting method Flare connecting

Attached length of piping m

Liquid line : 0.53

Gas line : 0.40

—

Insulation for piping Necessary (Both sides), independent

Refrigerant line (one way) length

m

Max. 25

Vertical height difference between

outdoor unit and indoor unit

Max. 15 (Outdoor unit is higher)

Max. 15 (Outdoor unit is lower)

Drain hose Connectable (VP16) —

Power cable —

Recommended breaker size A 16

Connection wiring

Size x Core number 1.5mm2 x 4 cores (Including earth cable)

Connecting method Terminal block (Screw fixing type)

Accessories (included)

Mounting kit, Clean filter (Allergen clear filter x 1, Photocatalytic washable deodorizing filter x 1)

Optional parts Interface kit (SC-BIKN-E)

Note (1) The data are measured at the following conditions.

Item

Operation

Indoor air temperature Outdoor air temperature

Standards

DB WB DB WB

Cooling 27˚C 19˚C 35˚C 24˚C

ISO -T 1, JI S C 961 2

Heating 20˚C — 7˚C 6 ˚C

(2) This air-conditioner is manufactured and tested in conformity with the ISO.

(3) The operation data are applied to the 220/230/240V districts respectively.

(4) The refrigerant quantity to be charged includes the refrigerant in 15m connecting piping.

(Purging is not required even for the short piping.)

The pipe length is 7.5m.

Adapted to RoHS directive

Page 9

-

6

-

'11 • SRK-T-118

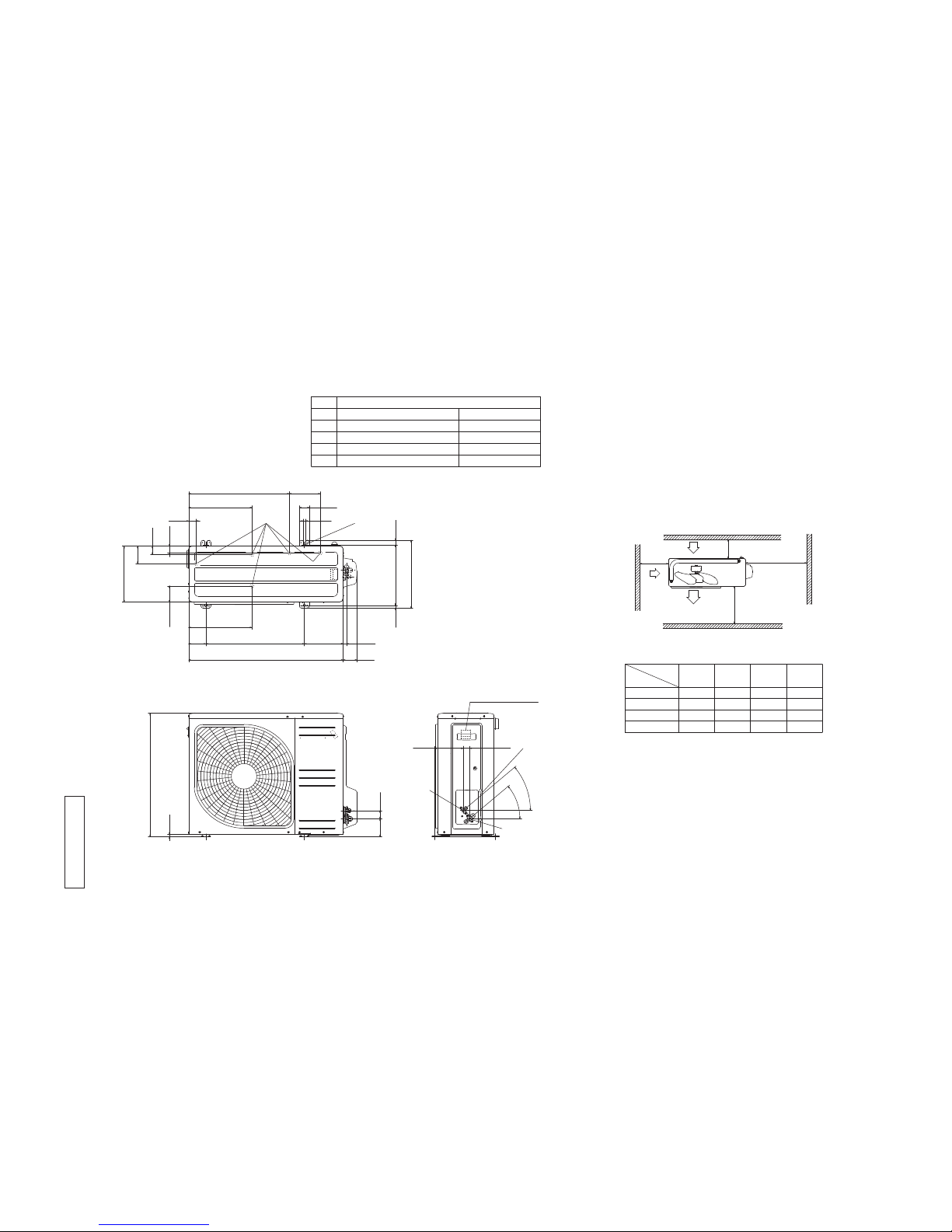

2. EXTERIOR DIMENSIONS

(1) Indoor units

Models DXK09ZJ-S, 12ZJ-S, 18ZJ-S

Space for installation and service when viewing from the front

Wired - remote controller

㧔Option㧕

Notes㧔1㧕The model name label is attached

ޓޓ ޓ on the underside of the panel.

Wireless remote controller

ޓ 㧔2㧕It takes the interface kit 㧔SC-BIKN-E㧕

ޓޓ ޓ to connect the wired remote controller.

Outlet for down piping

㧔Refer to the above view㧕

Hole on wall for right rear piping

Hole on wall for left rear piping

Gas piping

Outlet for wiring

Drain hose

Liquid piping

F

E

C

D

B

Symbol

A

㧔Ǿ65㧕

VP16

Ǿ6.35㧔1㧛4"㧕㧔Flare㧕

Content

㧔Ǿ65㧕

09, 12 Ǿ9.52㧔3㧛8"㧕㧔Flare㧕

Outlet for piping㧔on both side㧕

G

18 Ǿ12.7㧔1㧛2"㧕㧔Flare㧕

Model

Unit:mm

غ120

19

60

150

17.3

G

790

6014.5

45

3160

45

798

294

229 3

45

609

100106.5585106.5

50

48.9

55

47

47

55

403.6

471.6

531.8

F

139 450 209

Unit

D

C

A

E

B

65

15

7.7279.17.2

㧔Service space㧕

㧔Service space㧕

㧔Service space㧕

㧔Service space㧕

Installation plate

a

RL A 000Z 051

Page 10

-

7

-

'11 • SRK-T-118

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service

space

( )

L4

L2

L3

L4

L1

100

100

250

Open

Ⅰ Ⅱ

Open

250

80

280

Ⅲ

280

Open

80

75

Examples of

Dimensions

installation

Ⅳ

180

Open

80

Open

Content

C Pipe/ cable draw-out hole

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(igas side

)

M10×4places

Unit:mm

φ

20×2places

Service valve connection(iliquid side

)

D

φ9.52(3/8")(Flare)

φ6.35(1/4")(Flare)

Notes

(1)It must not be surrounded by walls on the four sides.

(2)The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more than 15mm.

(3)Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4)Leave 1m or more space above the unit.

(5)A wall in front of the blower outlet must not exceed the units height.

(6)The model name label is attached on the lower right corner of the front panel.

40°

40°

138.4 33.5

Terminal block

C

B

A

97.7

42.5

15.8

595

63.4

390.6

390.6

69.4

111.6

510 158.4

780 61.9

17.9

14.8 312.5 24.3

351.6

50.6

12

290

E

D

(2) Outdoor units

Models DXC09ZJ-S, 12ZJ-S

RC V 000Z 012

Page 11

-

8

-

'11 • SRK-T-118

Model DXC18ZJ-S

RC T 000Z 005

L2

Intake

Outlet

Intake

L3

L1

Minimum installation space

Service

space

( )

L4

L2

L3

L4

L1

100

100

250

Open

I II

Open

250

80

280

III

280

Open

80

75

Examples of

Dimensions

installation

IV

180

Open

80

Open

φ12.7(1/2")(Flare)

Content

C Pipe/cable draw-out hole

D

E Anchor bolt hole

Drain discharge hole

Symbol

B

A Service valve connection(gas side)

M10 × 4places

φ20 × 5places

Service valve connection(liquid side)

φ6.35(1/4")(Flare)

Notes

(1) It must not be surrounded by walls on the four sides.

(2) The unit must be fixed with anchor bolts. An anchor bolt must not

protrude more the 15mm.

(3) Where the unit is subject to strong winds, lay it in such

a direction that the blower outlet faces perpendicularly

to the dominant wind direction.

(4) Leave 1m or more space above the unit.

(5) A wall in front of the blower outlet must not exceed the units height.

(6) The model name label is attached on the right side of the unit.

A

C

Terminal block

B

93 42.5

640

800

89 510 201

327.3

83.5

290

43.5

327.3 50.6

12

24.3312.514.8

71.2

17.9

40°

40°

33.5148.4

12.4

351.6

38.6

90.6

520.6 161

35.6

D

E

Unit:mm

Page 12

-

9

-

'11 • SRK-T-118

(3) Remote controller

(a) Wireless remote controller

Unit: mm

60

17.3

150

Page 13

-

10

-

'11 • SRK-T-118

(b) Wired remote controller (option parts)

PJZ000Z274

TEMP ON/OFF

48

غ120

L C D

Wall surface

Wiring

Electrical box

䋨Not included䋩

19

Wiring specifications

Exposed mounting

23

46

11.5 11

Remote

control

outline

120

45

83.5

42

120

Remote control installation dimensions

Wiring oulet

Installation hole

12×7 Slot hole

9.5×5 Slot hole 䋨4places䋩

䋨1䋩 Installation screw for remote control

M4 Screw (2 pieces)

44

(1) If the prolongation is over 100m, change to the size below.

But, wiring in the remote controller case should be under 0.5mm2. Change the wire size outside of

the case according to wire connecting. Waterproof treatment is necessary at the wire connecting

section. Be careful about contact failure.

Length Wiring thickness

100 to 200m

0.5mm2×2 cores

0.75mm2×2 cores

1.25mm2×2 cores

2.0mm2×2 cores

Under 300m

Under 400m

Under 600m

Upper part

Lower part

Lower case

Sheath

Upper cace

Board

Wiring

Upper

Lower

X Y

Sheath

Upper cace

Board

Wiring

Upper

Lower

YX

Tighten the screws after

cutting off the thin part of

screw mounting part.

Embedded mounting

The peeling-off length of sheath

The peeling-off length

of sheath

In case of pulling out from

upper left

In case of pulling out

from upper left

In case of pulling out

from upper left

X wiring : 170mm

Y wiring : 190mm

Pulling out from center

X wiring : 215mm

Y wiring : 195mm

Pulling out from upper left

In case of pulling out from center

In case of pulling out

from center

In case of pulling out

from center

Wiring outlet

Cut off the upper thin part of remote control lower case with a nipper or knife,

and grind burrs with a file etc.

0.3mm2×2 cores.

X, Y Terminal block

Attach M3 screw

with washer

Unit:mm

Page 14

-

11

-

'11 • SRK-T-118

250V 3.15A

PRINTED

CNF CNE

CNX

CNG

4

CNU

1 3 65

12,18

CNY

M M M

5 5

U

2 8

2

t

o

CNS

CNM

M

5

TO OUTDOOR

S/N

J

L

G

1

CIRCUIT

BOARD

INTERFACE KIT

RDBKWHYBL

WIRELESS

DISPLAY

BACK-UP SW

UNIT

BKWHRD

Y/G

HEAT

EXCHANGER

2/N

3

Y/G

HD

ONLY

t

o

2

t

o

R-AMP

2

HEAT

EXCHANGER

5

FM

I

SM

I

LM

1

LM

2

F

Va

Th

I

Th

2

Th

3

T

DS

㨪

㨪

Blue

BlackBK

Red

BL

RD

WhiteWH

Yellow㧛GreenY㧛G

ColorMark

Heat exch. sensor

Fan motor

Room temp. sensor

Flap motor

Diode stackDS

FuseF

Connector

CNE-CNY

FM

I

Terminal blockT

Description

Item

VaristorVa

LM

1,2

SM

I

Louver motor

Th

I

Th

2,3

YellowY

Humidity sensor

HD

Power Source

1 Phase

220㧛230㧛240V 50Hz

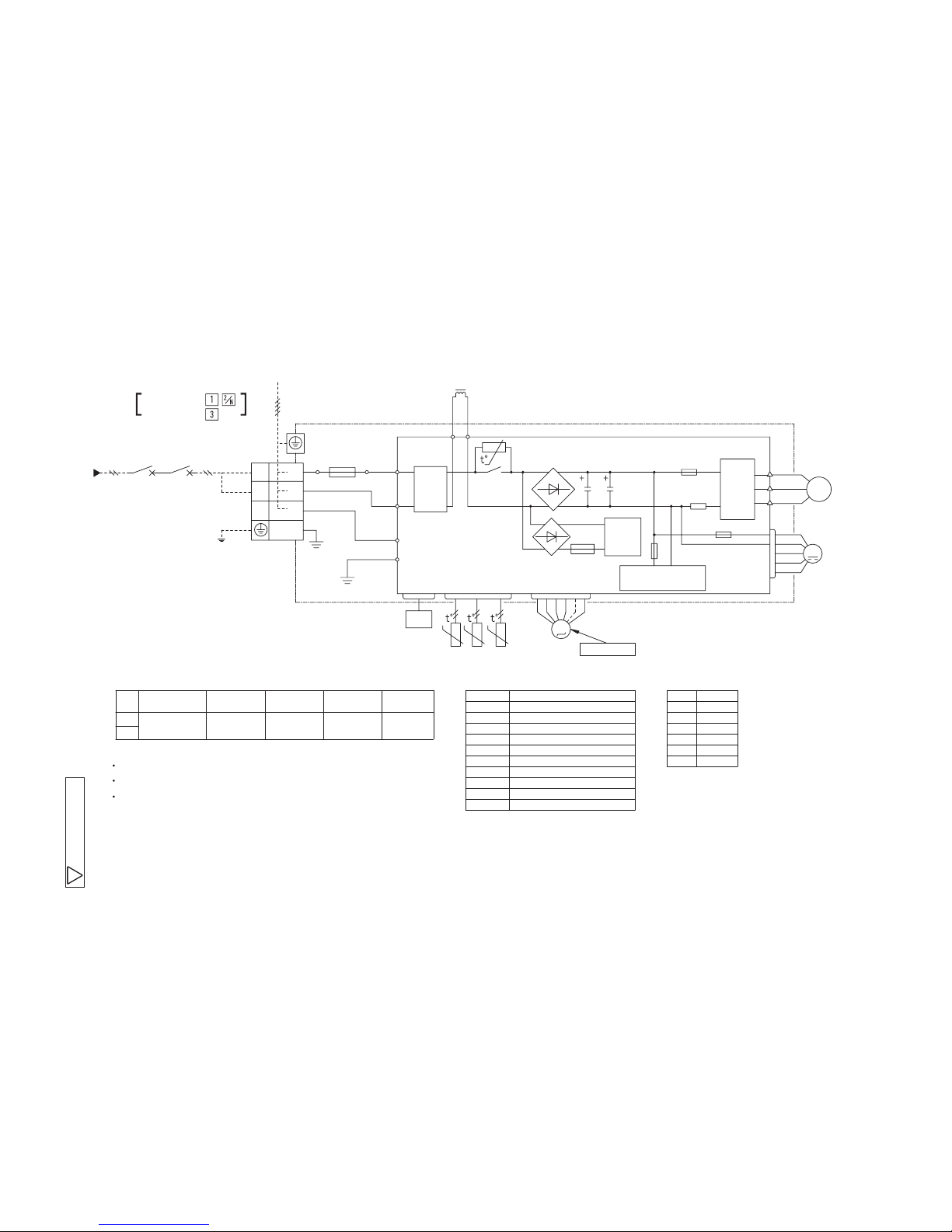

3. ELECTRICAL WIRING

(1) Indoor units

Models DXK09ZJ-S, 12ZJ-S, 18ZJ-S

a

RWA000Z226

Page 15

-

12

-

'11 • SRK-T-118

Color

RD

Mark

OrangeOR

Yellow㧛GreenY㧛G

BlackBK

YellowY

WhiteWH

Red

L

T

DescriptionItem

Connector

CNEEV㨪20S

Electric expansion valve㧔coil㧕

EEV

Fan motor

FMo

Reactor

Terminal block

Compressor motor

CM

Solenoid valve for 4 way valve

20S

Heat exchanger sensor㧔outdoor unit㧕

TH1

Outdoor air temp.sensor

TH2

TH3

Discharge pipe temp.sensor

Model

Power cable, indoor-outdoor connecting wires

The specifications shown in the above table are for units without heaters. For units with heaters, refer

to the installation instructions or the construction instructions of the indoor unit.

Switchgear of Circuit breaker capacity which is calculated from MAX. over current should be chosen

along the regulations in each country.

The cable specifications are based on the assumption that a metal or plastic conduit is used with no

more than three cables contained in a conduit and a voltage drop is 2%. For an installation falling

outside of these conditions, please follow the internal cabling regulations. Adapt it to the regulation

in effect in each country.

9

2.0

32

1.5mm2 x 3 1.5mm

2

12

09

MAX running current

Power cable size

㧔mm 㧕

2

㧔A㧕

Power cable length

㧔m㧕

indoor-outdoor

wire size x number

Earth wire size

㧔BK㧕

㧔WH㧕

㧔RD㧕

PWB ASSY

TRANSISTOR

POWER

250V 20A

F2

W

W

V

V

U

U

P

N

M

M

CIRCUIT

SWITCHING POWER

250V 2A

250V 10A

CNEEV

PAM

CIRCUIT

F1

F4

F3 250V 1A

CNFAN

FMo

CNTH

20S

CN20S

G1

C-2

NOISE

FILTER

T2

L

L

N

T

TERMINAL

BLOCK

T1

R. IN

S. IN

TH1

TH2

TH3

EEV

5 or 6 wires

㧔OR㧕

㧔Y㧕

㧔BK㧕

㧔WH㧕

㧔RD㧕

㧔Y/G㧕

㧔Y/G㧕

250V 15A

TO INDOOR UNIT

POWER WIRES

SIGNAL WIRE

POWER SOURCE

1㨪220㨺240V 50Hz1㨪220V 60Hz

M

CM

3㨪

(2) Outdoor units

Models DXC09ZJ-S, 12ZJ-S

a

RWC000Z238

Page 16

-

13

-

'11 • SRK-T-118

b

RWC000Z228

Color

RD

Mark

OrangeOR

Yellow/GreenY/G

BlackBK

BrownBR

YellowY

WhiteWH

Red

DescriptionItem

Connector

CNEEV~CN20S

Electric expansion valve(coil)

EEV

Fan motor

FMo

Reactor

L

Terminal block

T1,2

Compressor motor

CM

Solenoid valve for 4 way valve

20S

Heat exchanger sensor(outdoor unit)

TH1

Outdoor air temp.sensor

TH2

TH3

Discharge pipe temp.sensor

POWER SOURCE 1~220ー240V 50Hz/1~220V 60Hz

Model

Power cable, indoor-outdoor connecting wires

The specifications shown in the above table are for units without heaters. For units with heaters, refer

to the installation instructions or the construction instructions of the indoor unit.

Switchgear of Circuit breaker capacity which is calculated from MAX. over current should be chosen

along the regulations in each country.

The cable specifications are based on the assumption that a metal or plastic conduit is used with no

more than three cables contained in a conduit and a voltage drop is 2%. For an installation falling

outside of these conditions, please follow the internal cabling regulations. Adapt it to the regulation

in effect in each country.

14

2.0

18

1.5mm2 x 3 1.5mm

2

3

1

2

[ ]

N

18

M

T2

T1

S

(BK)

(WH)

(RD)

V

W

U

PWB ASSY (MAIN)

M

M

+ + +

R

TRANSISTOR

POWER

CIRCUIT

SWITCHING POWER

250V 2A

F1

250V 20A

F2

F3 250V 1A

W

V

U

P

NU

NV

NW

CNTH

CNEEV

CNFAN

t゜

3~

ACTIVE

FILTER

UNIT

250V 20A

F8

(OR)

(Y)

S-2

t゜ t゜

(BK)

(WH)

(WH)

(BK)

PWB ASSY (SUB)

S-1

CNSUB

CNMAIN

250V 10A

F10

S

R

R

(BK)

(WH)

G1

(Y/G)

(BR)

IN

IN

OUT

S

R

O

O

N

L

250V 20A

FUSE

2

1

N

3

(Y/G)

(Y/G)

CN20S

C-2

(RD)

20S

(RD)

T1

T2

TERMINAL

BLOCK

TH1 TH2 TH3

EEV

FMo

CM

BLOCK

TERMINAL

(WH)

TO INDOOR UNIT

POWER WIRES

SIGNAL WIRE

L

5 or 6 wires

MAX running current

Power cable size

(mm )

2

(A)

Power cable length

(m)

indoor-outdoor

wire size x number

Earth wire size

Model DXC18ZJ-S

Page 17

-

14

-

'11 • SRK-T-118

Model DXK09ZJ-S

10

20

30

40

50

60

70

10

20

30

40

50

60

70

10

20

30

40

50

60

70

10

20

30

40

50

60

70

1000 2000 4000 800063 125 250 500

Sound Pressure Level (dB)

(standard 2×10

-5

Pa)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa)

Mid Octave Band frequency (Hz)

1000 2000 4000 8000

63 125 250

500

Mid Octave Band frequency (Hz)

(Indoor Unit)

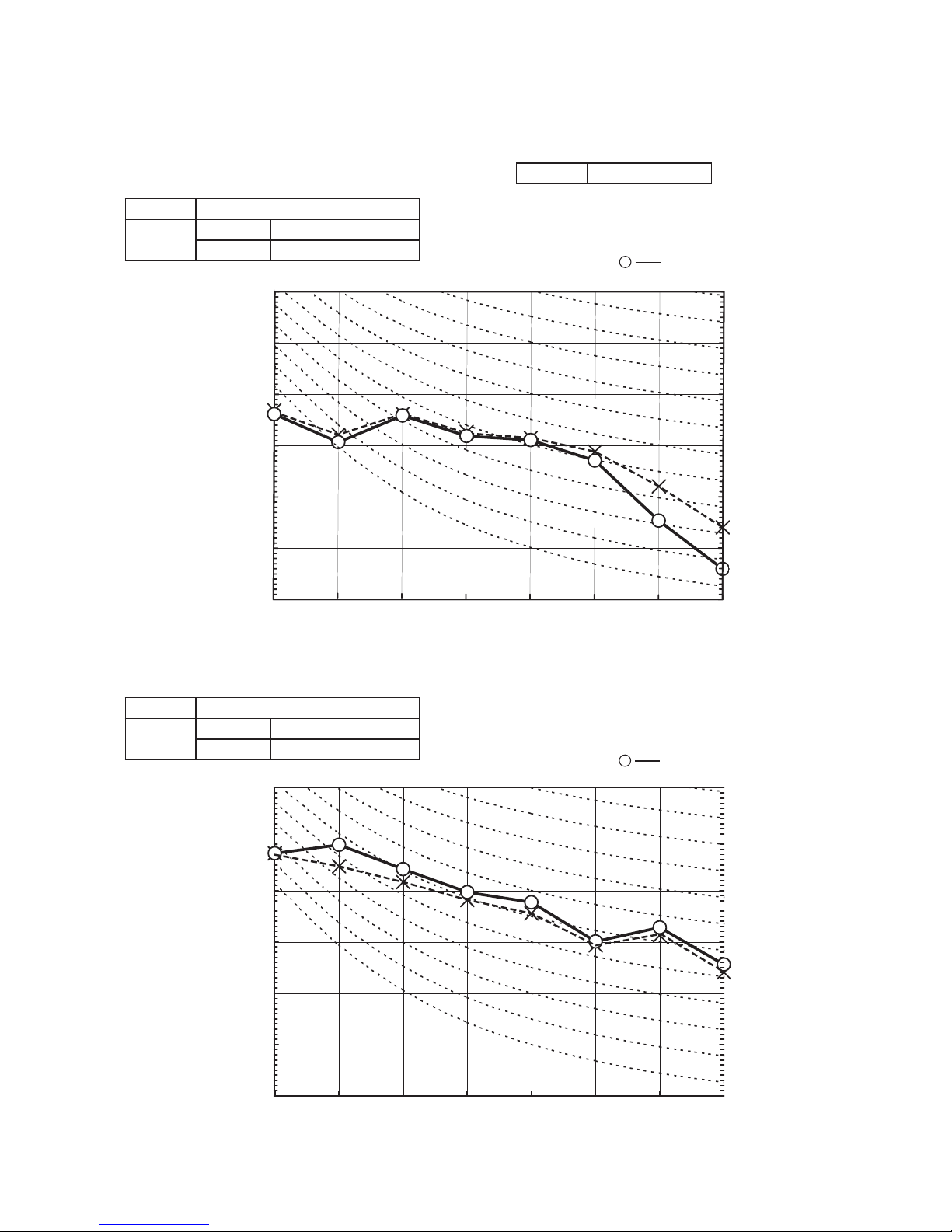

Model DXK09ZJ-S

Noise

Level

Cooling 34 dB(A)

Heating 39 dB(A)

×

......

Cooling

Heating

Condition ISO-T1, JIS C9612

N70

N60

N50

N40

N30

N20

N70

N60

N50

N40

N30

N20

(Outdoor Unit)

Model DXC09ZJ-S

Noise

Level

Cooling 48 dB(A)

Heating 47 dB(A)

×

......

Cooling

Heating

ISC10016

4. NOISE LEVEL

Page 18

-

15

-

'11 • SRK-T-118

Model DXK12ZJ-S

10

20

30

40

50

60

70

10

20

30

40

50

60

70

10

20

30

40

50

60

70

10

20

30

40

50

60

70

1000 2000 4000 800063 125 250 500

Sound Pressure Level (dB)

(standard 2×10

-5

Pa)

Sound Pressure Level (dB)

(standard 2×10

-5

Pa)

Mid Octave Band frequency (Hz)

1000 2000 4000 8000

63 125 250

500

Mid Octave Band frequency (Hz)

(Indoor Unit)

Model DXK12ZJ-S

Noise

Level

Cooling 45 dB(A)

Heating 42 dB(A)

×

......

Cooling

Heating

Condition ISO-T1, JIS C9612

N70

N60

N50

N40

N30

N20

(Outdoor Unit)

Model DXC12ZJ-S

Noise

Level

Cooling 50 dB(A)

Heating 50 dB(A)

×

......

Cooling

Heating

N70

N60

N50

N40

N30

N20

ISC10016

Page 19

-

16

-

'11 • SRK-T-118

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(standard 2×10

-5

Pa)

Mid Octave Band frequency (Hz)

10

20

30

40

50

60

70

10

20

30

40

50

60

70

63 125 250 500 1000 2000 4000 8000

N50

N30

N40

N60

N70

N20

Sound Pressure Level (dB)

(standard 2×10

-

5

P

a

)

Mid Octave Band frequency (Hz)

10

20

30

40

50

60

70

10

20

30

40

50

60

70

63 125

250

500

1000

2000

4000

8000

(Indoor Unit)

Model DXK18ZJ-S

Noise

Level

Cooling 46 dB(A)

Heating 45 dB(A)

×

......

Cooling Heating

Model DXK18ZJ-S

(Outdoor Unit)

Model DXC18ZJ-S

Noise

Level

Cooling 51 dB(A)

Heating 53 dB(A)

×

......

Cooling Heating

Condition ISO-T1,JIS C9612

Page 20

-

17

-

'11 • SRK-T-118

5. PIPING SYSTEM

Indoor unit

Outdoor unit

Flare

connection

Flare connection

Liquid

pipe

(φ6.35)

Gas pipie

(φ12.7)

Service valve

Heat

exchanger

Heat

exchanger

sensor

Electronic

expansion valve

(Liquid)

Strainer

Receiver

Muffler

Capillary tube

Outdoor air

temp. sensor

Muffler

Muffler

Compressor

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Check joint

4way valve

Service valve

Heat

exchanger

sensor

(Th3)

(TH3)

Room temp.

sensor

(Th1)

(Th2)

(

Gas

)

(TH2)

Heat

exchanger

sensor

(TH1)

(EEV)

Capillary tube

Heat

exchanger

Humidity

sensor

(HD)

Model DXK18ZJ-S

Models DXK09ZJ-S, 12ZJ-S

Indoor unit

Outdoor unit

Flare

connection

Flare connection

Liquid

pipe

(φ 6.35)

Gas pipie

(φ 9.52)

Service valve

Heat

exchanger

Heat

exchanger

sensor

Electronic

expansion valve

(Liquid)

Strainer Muffler

Capillary tube

Outdoor air

temp. sensor

Muffler

Muffler

Compressor

Accumlator

Discharge pipe

temp. sensor

Cooling cycle

Heating cycle

Check joint

4way valve

Service valve

Heat

exchanger

sensor

(Th3)

(TH3)

Room temp.

sensor

(Th1)

(Th2)

(

Gas

)

(TH2)

Heat

exchanger

sensor

(TH1)

(EEV)

Capillary tube

Heat

exchanger

Humidity

sensor

(HD)

(35 only)

Page 21

-

18

-

'11 • SRK-T-118

'09•SRK-DB-087D

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

(3) Correction relative to frosting on outdoor heat exchanger during heating

How to obtain the cooling and heating capacity

=

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

Air inlet temperature of

DXK12ZJ-S

outdoor unit in °C WB

Adjustment coefficient

-15

0.95 0.95 0.94 0.93 0.91 0.88 0.86 0.87 0.92 1.00

-10 -9 -7 -5 -3 -1 1 3

5 or more

DXK12ZJ-S

3300 3217

RANGE OF USAGE & LIMITATIONS

Indoor return air temperature

(Upper, lower limits)

Refrigerant line (one way) length

Power source voltage Rating ±10%

Voltage at starting Min. 85% of rating

Frequency of ON-OFF cycle

Max. 4 times/h

(Inching prevention 10 minutes)

Max. 7 times/h

(Inching prevention 5 minutes)

ON and OFF interval Min. 3 minutes

Outdoor air temperature

(Upper, lower limits)

Vertical height difference between

outdoor unit and indoor unit

Max. 15m Max. 25m

Max. 10m

(Outdoor unit is higher)

Max. 10m

(Outdoor unit is lower)

Max. 15m

(Outdoor unit is higher)

Max. 15m

(Outdoor unit is lower)

Item

Models

DXK09, 12ZJ-S DXK18ZJ-S

Cooling operation : Approximately 18 to 32℃ D.B.

Heating operation : Approximately 10 to 27℃ D.B.

(Refer to the selection chart)

Cooling operation : Approximately -15 to 46℃ D.B.

Heating operation : Approximately -15 to 24℃ D.B.

(Refer to the selection chart)

Selection chart

Correct the cooling and heating capacity in accordance with the conditions as follows. The net cooling and heating capacity can be

obtained in the following way.

Net capacity = Capacity shown on specication × Correction factors as follows.

(1) Coefcient of cooling and heating capacity in relation to temperatures

0.6

0.7

0.8

0.9

1.0

1.2

1.1

1.3

0

-5

-10

-15

24

26

20

25

30

35

40

46

10

15

20

25

27

Outdoor air W.B. temperature °C W.B.

-15 -10 -5 0 5 10 15

.

Cooling operation

Outdoor air D.B.

temperature

°C D. B.

Coefficient of cooling

&

Heating capacity in

relation to temperature

Heating operation

Indoor air D.B.

temperature

°C D. B.

ISO-T1 Standard Condition

Depends on installed situation

ISO-T1 Standard Condition

2220181614

Indoor air W.B. temperature °C W.B

Applicable range

Cooling

Heating

6. RANGE OF USAGE & LIMITATIONS

Page 22

-

19

-

'11 • SRK-T-118

'09•SRK-DB-087D

(2) Correction of cooling and heating capacity in relation to one way length of refrigerant piping

(3) Correction relative to frosting on outdoor heat exchanger during heating

How to obtain the cooling and heating capacity

=

Piping length [m]

Cooling

Heating

7

1.0

1.0

10

0.99

1.0

15

0.975

1.0

20

0.965

1.0

25

0.95

1.0

Air inlet temperature of

DXK12ZJ-S

outdoor unit in °C WB

Adjustment coefficient

-15

0.95 0.95 0.94 0.93 0.91 0.88 0.86 0.87 0.92 1.00

-10 -9 -7 -5 -3 -1 1 3

5 or more

DXK12ZJ-S

3300 3217

Page 23

-

20

-

'11 • SRK-T-118

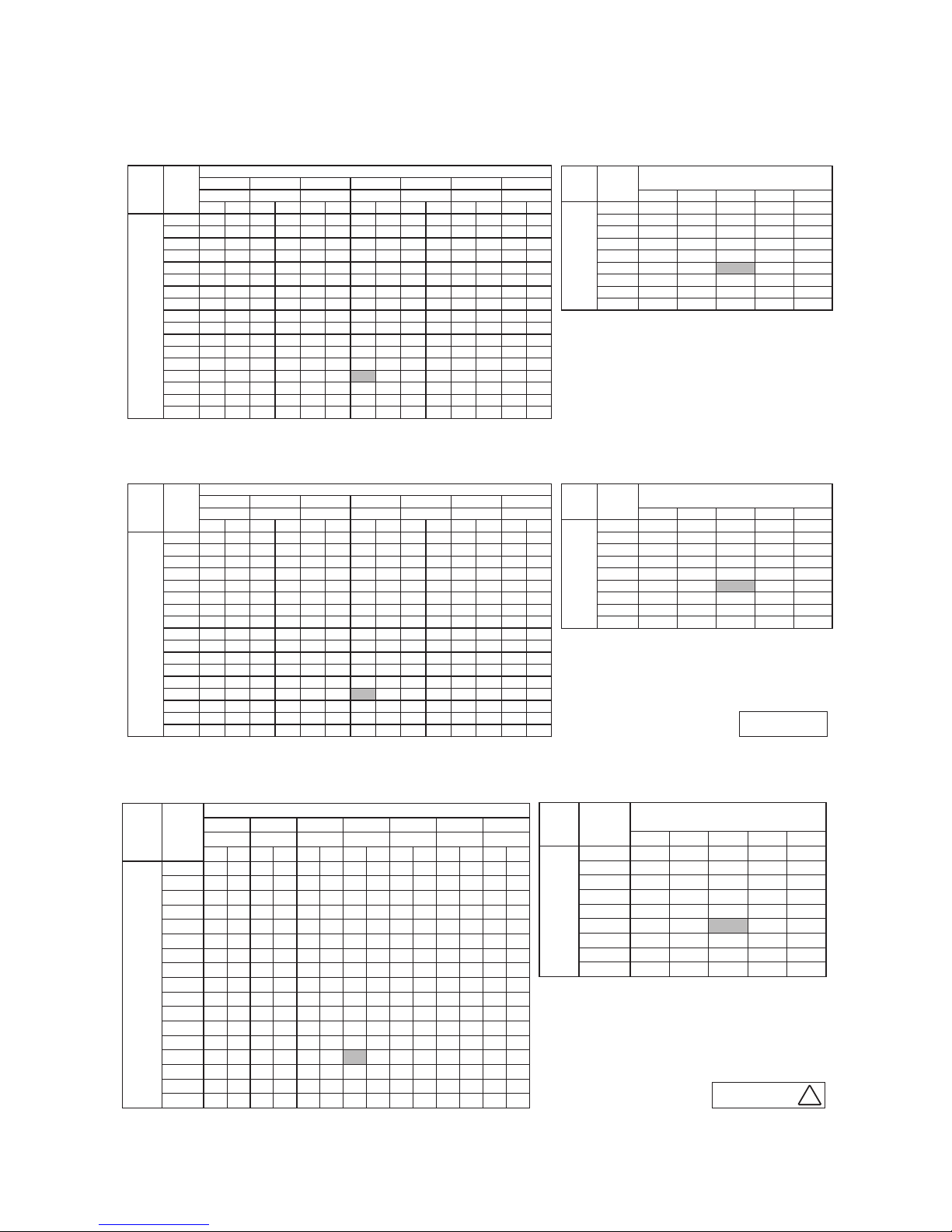

7. CAPACITY TABLES

2.70

Heat Mode

Indoor air temp

Air flow Outdoor 21 ℃DB 23 ℃DB 26 ℃DB 27 ℃DB 28 ℃DB 31 ℃DB 33 ℃DB

Outdoor

air temp. 14 ℃WB 16 ℃WB 18 ℃WB 19 ℃WB 20 ℃WB 22 ℃WB 24 ℃WB

Air flow air temp. Indoor air temp

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

16℃ DB 18℃ DB 20℃ DB 22℃ DB 24℃ DB

10 2.82 2.22 2.95 2.19 3.06 2.27 3.11 2.24 3.16 2.21 3.26 2.28 3.34 2.21

-15℃WB 1.97 1.93 1.88 1.84 1.80

12 2.77 2.20 2.90 2.16 3.01 2.25 3.07 2.22 3.12 2.20 3.22 2.27 3.31 2.20

-10℃WB 2.23 2.19 2.16 2.10 2.06

14 2.71 2.17 2.85 2.14 2.97 2.23 3.03 2.20 3.08 2.17 3.18 2.25 3.28 2.19

-5℃WB 2.41 2.38 2.33 2.30 2.27

16 2.66 2.14 2.80 2.12 2.92 2.20 2.98 2.18 3.04 2.15 3.15

2.24 3.24 2.18

Hi 0℃WB 2.53 2.49 2.45 2.42 2.38

18 2.60 2.12 2.74 2.09 2.88 2.18 2.94 2.16 2.99 2.14 3.11 2.22 3.20 2.16

11.0 5℃WB 3.22 3.19 3.17 3.10 3.06

20 2.55 2.09 2.68 2.06 2.83 2.17 2.89 2.15 2.95 2.12 3.07 2.21 3.17 2.15

(

m

3

/

min

)

6℃WB 3.27 3.24 3.20 3.16 3.12

Hi 22 2.49 2.06 2.63 2.04 2.78 2.15 2.84 2.13 2.90 2.11 3.02 2.19 3.13 2.14

10℃WB 3.48 3.45 3.42 3.38 3.34

7.9 24 2.43 2.03 2.57 2.01 2.72 2.13 2.80 2.11 2.85 2.09 2.98 2.18 3.08 2.12

15℃WB 3.79 3.75 3.73 3.69 3.65

(

m3/min

)

26 2.37 2.00 2.51 1.98 2.67 2.10 2.74 2.09 2.80 2.07 2.93 2.16 3.04 2.11

20℃WB 4.07 4.04 4.02 3.97 3.94

28 2.31 1.97 2.44 1.95 2.61 2.08 2.69 2.07 2.75 2.05 2.89 2.14 3.00 2.09

30 2.24 1.94 2.38 1.92 2.56 2.05 2.64 2.04 2.70 2.03 2.84 2.12 2.95 2.08

32 2.18 1.91 2.31 1.90 2.50 2.03 2.58 2.02 2.64 2.01 2.79 2.11 2.90 2.07

34 2.11 1.88 2.25 1.86 2.44 2.00 2.53 2.00 2.59 1.98 2.74 2.09 2.85 2.05

35 2.08 1.86 2.21 1.85 2.41 1.99 2.50 1.99 2.56 1.97 2.71 2.08 2.83 2.04

36 2.04 1.85 2.18 1.84 2.38 1.98 2.47 1.98 2.53 1.96 2.69 2.07 2.80 2.03

38 1.97 1.81 2.11 1.80 2.32 1.95 2.41 1.95 2.47 1.94 2.63 2.05 2.75 2.02

39 1.94 1.80 2.07 1.79 2.28 1.94 2.38 1.94 2.44 1.93 2.61 2.05 2.72 2.00

Heat Mode

Indoor air temp

Air flow Outdoor 21 ℃DB 23 ℃DB 26 ℃DB 27 ℃DB 28 ℃DB 31 ℃DB 33 ℃DB

Outdoor

air temp. 14 ℃WB 16 ℃WB 18 ℃WB 19 ℃WB 20 ℃WB 22 ℃WB 24 ℃WB

Air flow air temp. Indoor air temp

TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC TC SHC

16℃ DB 18℃ DB 20℃ DB 22℃ DB 24℃ DB

10 3.72 3.01 3.89 2.96 4.04 3.09 4.10 3.04 4.17 3.01 4.30 3.11 4.41 3.01

-15℃WB 2.46 2.41 2.35 2.30 2.25

12 3.65 2.98 3.83 2.93 3.98 3.06 4.05 3.02 4.12 2.99 4.25 3.08 4.37 3.00

-10℃WB 2.79 2.74 2.70 2.63 2.58

14 3.58 2.95 3.76 2.90 3.92 3.04 3.99 3.00 4.07 2.96 4.20 3.06 4.33 2.98

-5℃WB 3.02 2.97 2.91 2.88 2.83

16 3.51 2.90 3.69 2.86 3.86 3.01 3.94 2.98 4.01 2.94 4.15 3.05 4.28 2.97

Hi 0℃WB 3.16 3.12 3.06 3.02 2.98

18 3.44 2.87 3.62 2.83 3.80 2.98 3.88 2.95 3.95 2.92 4.10 3.03 4.23 2.96

12.8 5℃WB 4.03 3.98 3.96 3.88 3.83

20 3.36 2.84 3.54 2.80 3.73 2.95 3.82 2.93 3.89 2.90 4.05 3.01 4.18 2.94

(

m

3

/

min

)

6℃WB 4.09 4.04 4.00 3.95 3.90

Hi 22 3.29 2.80 3.47 2.77 3.66 2.92 3.75 2.90 3.83 2.87 3.99 3.00 4.13 2.93

10℃WB 4.35 4.31 4.28 4.22 4.18

10.1 24 3.21 2.76 3.39 2.73 3.59 2.90 3.69 2.87 3.77 2.85 3.93 2.98 4.07 2.91

15℃WB 4.73 4.69 4.66 4.61 4.56

(

m3/min

)

26 3.13 2.72 3.31 2.70 3.52 2.86 3.62 2.85 3.70 2.82 3.87 2.96 4.02 2.89

20℃WB 5.09 5.05 5.02 4.96 4.92

28 3.04 2.69 3.23 2.66 3.45 2.84 3.55 2.82 3.63 2.79 3.81 2.93 3.96 2.87

30 2.96 2.64 3.14 2.62 3.38 2.80 3.48 2.80 3.56 2.77 3.75 2.91 3.90 2.85

32 2.87 2.60 3.05 2.58 3.30 2.77 3.41 2.76 3.49 2.74 3.68 2.89 3.83 2.83

34 2.79 2.56 2.96 2.54 3.22 2.74 3.34 2.74 3.42 2.71 3.62 2.87 3.77 2.81

35 2.74 2.54 2.92 2.52 3.18 2.71 3.30 2.72 3.38 2.68 3.58 2.85 3.73 2.80

36 2.69 2.52 2.87 2.51 3.14 3.26 2.69 3.34 2.67 3.55 2.84 3.70 2.78

38 2.60 2.48 2.78 2.46 3.06 2.67 3.18 2.66 3.26 2.64 3.48 2.81 3.63 2.77

39 2.56 2.45 2.73 2.45 3.01 2.65 3.14

2.65 3.22 2.63 3.44 2.80 3.60 2.76

Model DXK09ZJ-S

Cool Mode

Model DXK12ZJ-S

Cool Mode

ISC09165

Air flow

outdoor

air temp.

indoor air temp

16˚CDB 18˚CDB 20˚CDB 22˚CDB 24˚CDB

Hi

13.5

(m3/min)

-15˚CWB 3.57 3.49 3.41 3.34 3.26

-10˚CWB 4.04 3.97 3.91 3.81 3.73

-5˚CWB 4.37 4.31 4.22 4.18 4.11

0˚CWB 4.59 4.52 4.44 4.39 4.32

5˚CWB 5.84 5.77 5.74 5.63 5.55

6˚CWB 5.94 5.87 5.80 5.73 5.66

10˚CWB

6.31 6.25 6.21 6.12 6.06

15˚CWB 6.86 6.80 6.76 6.68 6.62

20˚CWB

7.38 7.32 7.28 7.20 7.14

Heat Mode

Model DXK18ZJ-S

Cool Mode

Air flow

Outdoor

air temp.

Indoor air temp

21˚CDB 23˚CDB 26˚CDB 27˚CDB 28˚CDB 31˚CDB 33˚CDB

14˚CWB 16˚CWB 18˚CWB 19˚CWB 20˚CWB 22˚CWB 24˚CWB

TC SHC TC

SHC TC SHC

TC SHC TC SHC

TC SHC TC

SHC

Hi

11.3

(m3/min)

10 5.63 4.09 5.90 4.02 6.11 4.12 6.22 4.05 6.32 3.99 6.51 4.05 6.69 3.92

12 5.53 4.03 5.80 3.97 6.03 4.07 6.14 4.01 6.25 3.96 6.44 4.02 6.62 3.89

14 5.43 3.98 5.70 3.91 5.94 4.03 6.05 3.98 6.16 3.92 6.37 4.00 6.55 3.86

16 5.32 3.92 5.59 3.86 5.85 3.98 5.96 3.93 6.08 3.88 6.29 3.96 6.48 3.84

18 5.21 3.85 5.48 3.80 5.75 3.94 5.88 3.90 5.99 3.84 6.21 3.93 6.41 3.81

20 5.10 3.79 5.37 3.74 5.65 3.89 5.78 3.85 5.90 3.80 6.13 3.90 6.33 3.78

22 4.98 3.73 5.25 3.68 5.55 3.84 5.69 3.81 5.80 3.76 6.05 3.86 6.25 3.75

24 4.86 3.67 5.14 3.62 5.45 3.79 5.59 3.76 5.71 3.72 5.96 3.83 6.17 3.72

26 4.74 3.60 5.01 3.56 5.34 3.74 5.49 3.71 5.61 3.67 5.87 3.79 6.08 3.69

28 4.61 3.54 4.89 3.50 5.23 3.69 5.39 3.67 5.50 3.63 5.78 3.76 5.99 3.66

30 4.49 3.46 4.76 3.43 5.11 3.64 5.28 3.62 5.40 3.58 5.68 3.72 5.90 3.62

32 4.35 3.40 4.63 3.37 5.00 3.58 5.17 3.57 5.29 3.54 5.58 3.68 5.81 3.59

34 4.22 3.33 4.49 3.31 4.88 3.52 5.06 3.52 5.18 3.49 5.48 3.64 5.71 3.55

35 4.15 3.29 4.42 3.27 4.82 3.49 5.00 3.49 5.12 3.45 5.43 3.62 5.66 3.53

36 4.08 3.26 4.35 3.24 4.76 3.47 4.94 3.46 5.06 3.43 5.37 3.60 5.61 3.50

38 3.94 3.19 4.21 3.18 4.63 3.42 4.82 3.42 4.94 3.39 5.27 3.54 5.50 3.47

39 3.87 3.15 4.14 3.14 4.57 3.39 4.76 3.39 4.88 3.36 5.21 3.52 5.45 3.45

a

ISC09106

Page 24

-

21

-

'11 • SRK-T-118

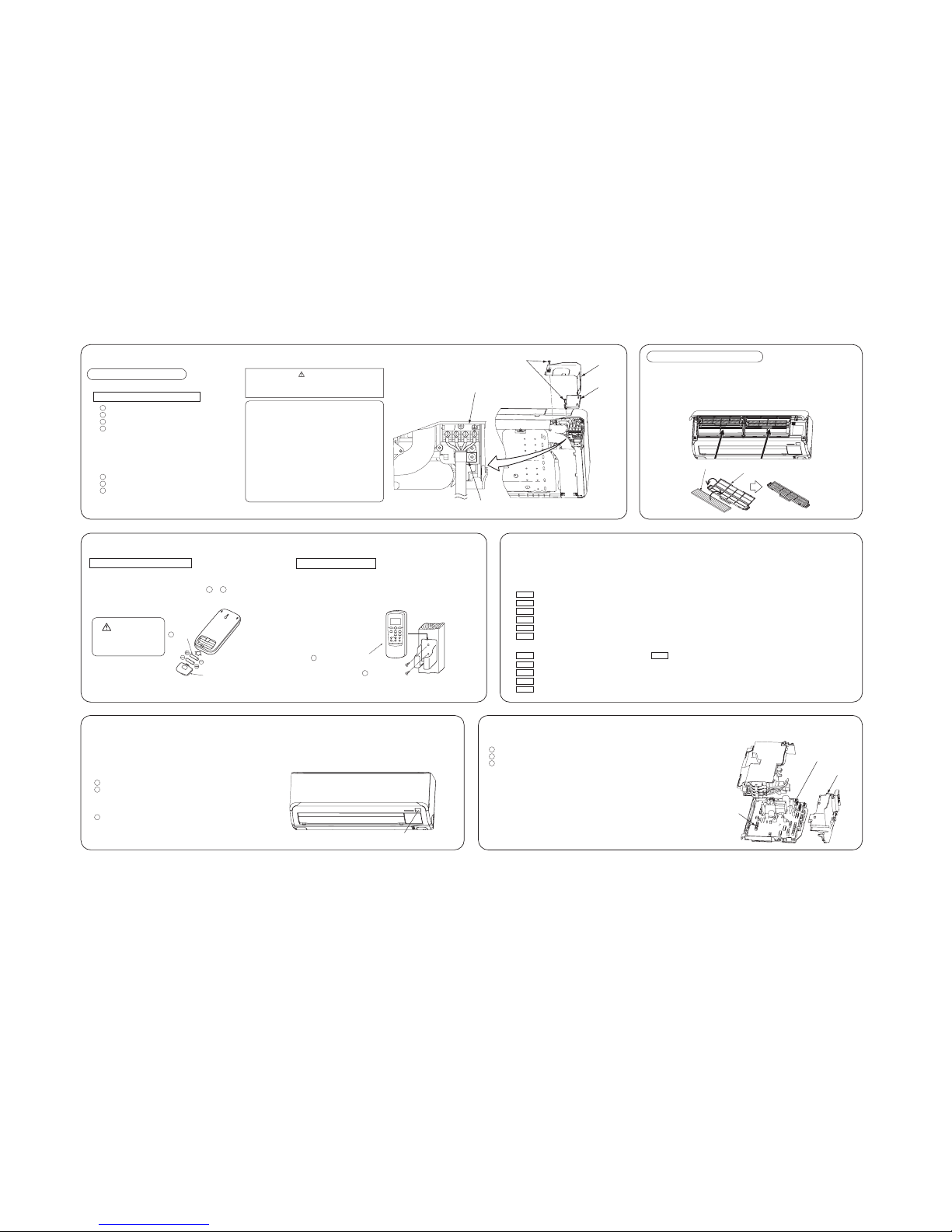

R410A REFRIGERANT USED

WALL TYPE AIR CONDITIONER

INSTALLATION MANUAL FOR INDOOR UNIT

RLA012A012B

WARNING

• Installation must be carried out by the qualified installer.

If you install the system by yourself, it may cause serious trouble such as

water leaks, electric shocks, fire and personal injury, as a result of a system

malfunction. Do not carry out the installation and maintenance work except

the by qualified installer.

• Install the system in full accordance with the installation manual.

Incorrect installation may cause bursts, personal injury, water leaks, electric

shocks and fire.

• Be sure to use only for household and residence.

If this appliance is installed in inferior environment such as machine shop

and etc., it can cause malfunction.

• Use the original accessories and the specified components for

installation.

If parts other than those prescribed by us are used, It may cause water

leaks, electric shocks, fire and personal injury.

• Install the unit in a location with good support.

Unsuitable installation locations can cause the unit to fall and cause

material damage and personal injury.

• Ventilate the working area well in the event of refrigerant leakage

during installation.

If the refrigerant comes into contact with naked flames, poisonous gas is

produced.

• When installing in small rooms, take prevention measures not to

exceed the density limit of refrigerant in the event of leakage,

referred by the formula (accordance with ISO5149).

If the density of refrigerant exceeds the limit, please consult the dealer and

install the ventilation system, otherwise lack of oxygen can occur, which

can cause serious accident.

• After completed installation, check that no refrigerant leaks from

the system.

If refrigerant leaks into the room and comes into contact with an oven or

other hot surface, poisonous gas is produced.

• Use the prescribed pipes, flare nuts and tools for R410A.

Using existing parts (for R22 or R407C) can cause the unit failure and

serious accidents due to burst of the refrigerant circuit.

• Tighten the flare nut by torque wrench with specified method.

If the flare nut were tightened with excess torque, this may cause burst and

refrigerant leakage after a long period.

• The electrical installation must be carried out by the qualified

electrician in accordance with “the norm for electrical work” and

“national wiring regulation”, and the system must be connected to

the dedicated circuit.

Power supply with insufficient capacity and incorrect function done by

improper work can cause electric shocks and fire.

• Be sure to shut off the power before starting electrical work.

Failure to shut off the power can cause electric shocks, unit failure or

incorrect function of equipment.

• Be sure to use the cables conformed to safety standard and cable

ampacity for power distribution work.

Unconformable cables can cause electric leak, anomalous heat production

or fire.

• This appliance must be connected to main power supply by means

of a circuit breaker or switch (fuse:16A) with a contact separation of

at least 3mm.

• When plugging this appliance, a plug conforming to the norm

IEC60884-1 must be used.

• Use the prescribed cables for electrical connection, tighten the

cables securely in terminal block and relieve the cables correctly to

prevent overloading the terminal blocks.

Loose connections or cable mountings can cause anomalous heat

production or fire.

• Arrange the wiring in the control box so that it cannot be pushed up

further into the box. Install the service panel correctly.

Incorrect installation may result in overheating and fire.

• Be sure to switch off the power supply in the event of installation,

inspection or servicing.

If the power supply is not shut off, there is a risk of electric shocks, unit

failure or personal injury due to the unexpected start of fan.

• Be sure to wear protective goggles and gloves while at work.

• Earth leakage breaker must be installed.

If the earth leakage breaker is not installed, it can cause electric shocks.

CAUTION

• Use the circuit breaker of correct capacity. Circuit breaker should

be the one that disconnect all poles under over current.

Using the incorrect one could cause the system failure and fire.

• Install isolator or disconnect switch on the power supply wiring in

accordance with the local codes and regulations.

The isolator should be locked in OFF state in accordance with EN60204-1.

• Be sure to install indoor unit properly according to the installation

manual in order to run off the drainage smoothly.

Improper installation of indoor unit can cause dropping water into the room

and damaging personal property.

• Install the drainage pipe to run off drainage securely according to

the installation manual.

Incorrect installation of the drainage pipe can cause dropping water into the

room and damaging personal property.

• Be sure to install the drainage pipe with descending slope of 1/100

or more, and not to make traps and air-bleedings.

Check if the drainage runs off securely during commissioning and ensure

the space for inspection and maintenance.

• Secure a space for installation, inspection and maintenance

specified in the manual.

Insufficient space can result in accident such as personal injury due to

falling from the installation place.

• For installation work, be careful not to get injured with the heat

exchanger, piping flare portion or screws etc.

• Be sure to insulate the refrigerant pipes so as not to condense the

ambient air moisture on them.

Insufficient insulation can cause condensation, which can lead to moisture

damage on the ceiling, floor, furniture and any other valuables.

• When perform the air conditioner operation (cooling or drying operation) in which ventilator is installed in the room. In this case, using the

air conditioner in parallel with the ventilator, there is the possibility

that drain water may backflow in accordance with the room lapse into

the negative pressure status. Therefore, set up the opening port such

as incorporate the air into the room that may appropriate to ventilation (For example; Open the door a little). In addition, just as above, so

set up the opening port if the room lapse into negative pressure status

due to register of the wind for the high rise apartment etc.

• Be sure to perform air tightness test by pressurizing with nitrogen

gas after completed refrigerant piping work.

If the density of refrigerant exceeds the limit in the event of refrigerant

leakage in the small room, lack of oxygen can occur, which can cause

serious accidents.

• Do not install the unit in the locations listed below.

• Locations where carbon fiber, metal powder or any powder is floating.

• Locations where any substances that can affect the unit such as sulphide

gas, chloride gas, acid and alkaline can occur.

• Vehicles and ships.

• Locations where cosmetic or special sprays are often used.

• Locations with direct exposure of oil mist and steam such as kitchen and

machine plant.

• Locations where any machines which generate high frequency harmonics

are used.

• Locations with salty atmospheres such as coastlines.

• Locations with heavy snow (If installed, be sure to provide base flame and

snow hood mentioned in the manual).

• Locations where the unit is exposed to chimney smoke.

• Locations at high altitude (more than 1000m high).

• Locations with ammonic atmospheres.

• Locations where heat radiation from other heat source can affect the unit.

• Locations without good air circulation.

• Locations with any obstacles which can prevent inlet and outlet air of the unit.

• Locations where short circuit of air can occur (in case of multiple units

installation).

• Locations where strong air blows against the air outlet of outdoor unit.

• Locations where something located above the unit could fall.

It can cause remarkable decrease in performance, corrosion and damage

of components, malfunction and fire.

• Do not install the indoor unit in the locations listed below (Be sure

to install the indoor unit according to the installation manual for

each model because each indoor unit has each limitation).

• Locations with any obstacles which can prevent inlet and outlet air of the

unit.

• Locations where vibration can be amplified due to insufficient strength of

structure.

• Locations where the infrared receiver is exposed to the direct sunlight or

the strong light beam (in case of the infrared specification unit).

• Locations where an equipment affected by high harmonics is placed (TV

set or radio receiver is placed within 1m).

• Locations where drainage cannot run off safely.

It can affect performance or function and etc.

• Do not install the unit near the location where leakage of

combustible gases can occur.

If leaked gases accumulate around the unit, it can cause fire.

• Do not install the unit where corrosive gas (such as sulfurous acid

gas etc.) or combustible gas (such as thinner and petroleum gases)

can accumulate or collect, or where volatile combustible

substances are handled.

Corrosive gas can cause corrosion of heat exchanger, breakage of plastic

parts and etc. And combustible gas can cause fire.

• Do not use the indoor unit at the place where water splashes may

occur such as in laundries.

Since the indoor unit is not waterproof, it can cause electric shocks and fire.

• Do not install nor use the system close to the equipment that

generates electromagnetic fields or high frequency harmonics.

Equipment such as inverters, standby generators, medical high frequency

equipments and telecommunication equipments can affect the system, and

cause malfunctions and breakdowns. The system can also affect medical

equipment and telecommunication equipment, and obstruct its function or

cause jamming.

• Do not place any variables which will be damaged by getting wet

under the indoor unit.

When the relative humidity is higher than 80% or drainage pipe is clogged,

condensation or drainage water can drop and it can cause the damage of

valuables.

• Do not install the remote control at the direct sunlight.

It can cause malfunction or deformation of the remote control.

• Do not use the unit for special purposes such as storing foods,

cooling precision instruments and preservation of animals, plants or

art.

It can cause the damage of the items.

• Do not use any materials other than a fuse with the correct rating in

the location where fuses are to be used.

Connecting the circuit with copper wire or other metal thread can cause

unit failure and fire.

• Do not touch any buttons with wet hands.

It can cause electric shocks.

• Do not touch any refrigerant pipes with your hands when the

system is in operation.

During operation the refrigerant pipes become extremely hot or extremely

cold depending the operating condition, and it can cause burn injury or

frost injury.

• Carry out the electrical work for ground lead with care.

Do not connect the ground lead to the gas line, water line, lightning conductor or telephone line’s ground lead. Incorrect grounding can cause unit faults

such as electric shocks due to short-circuiting.

• Do not put the drainage pipe directly into drainage channels where

poisonous gases such as sulphide gas can occur.

Poisonous gases will flow into the room through drainage pipe and

seriously affect the user’s health and safety. This can also cause the

corrosion of the indoor unit and a resultant unit failure or refrigerant leak.

• Ensure that no air enters in the refrigerant circuit when the unit is

installed and removed.

If air enters in the refrigerant circuit, the pressure in the refrigerant circuit

becomes too high, which can cause burst and personal injury.

• Do not processing, splice the power cord, or share a socket with

other power plugs.

This may cause fire or electric shock due to defecting contact, defecting

insulation and over-current etc.

• Do not bundling, winding or processing for the power cord. Or, do

not deforming the power plug due to tread it.

This may cause fire or heating.

• Do not vent R410A into the atmosphere : R410A is a fluorinated

greenhouse gas, covered by the Kyoto Protocol with Groval

Warming Potential (GWP)=1975.

• Do not run the unit with removed panels or protections.

Touching rotating equipments, hot surfaces or high voltage parts can cause

personal injury due to entrapment, burn or electric shocks.

• Do not perform any change of protective device itself or its setup

condition.

The forced operation by short-circuiting protective device of pressure

switch and temperature controller or the use of non specified component

can cause fire or burst.

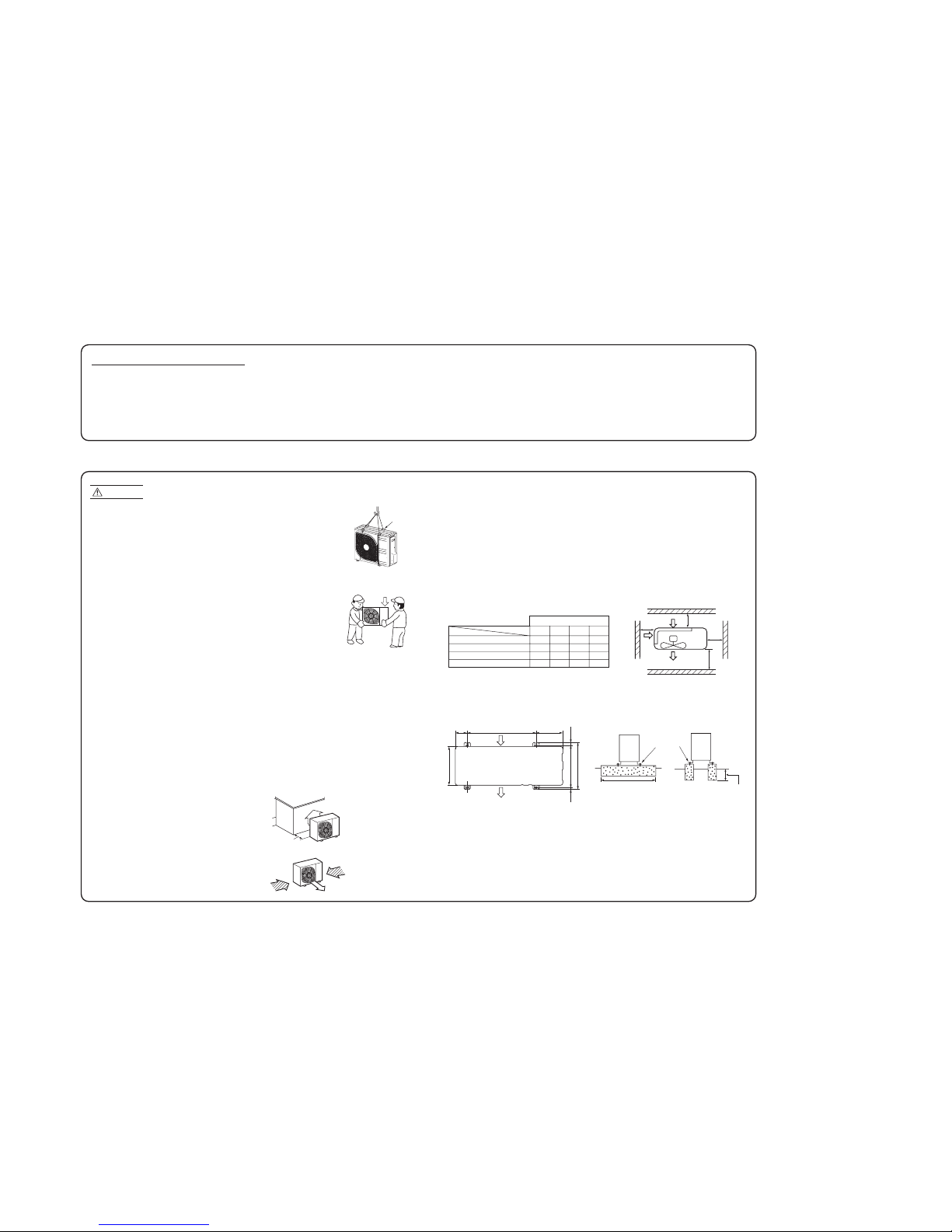

WARNING

SAFETY PRECAUTIONS

• Read the “SAFETY PRECAUTIONS” carefully first of all and strictly follow it

during the installation work in order to protect yourself.

• The precautionary items mentioned below are distinguished into two levels,

and .

: Wrong installation would cause serious consequences such

as injuries or death.

: Wrong installation might cause serious consequences

depending on circumstances.

Both mentions the important items to protect your health and safety so strictly

follow them by any means.

• Be sure to confirm no anomaly on the equipment by commissioning after completed installation and explain the operating methods as well as the maintenance

methods of this equipment to the user according to the owner’s manual.

• Keep the installation manual together with owner’s manual at a place where

any user can read at any time. Moreover if necessary, ask to hand them to a

new user.

• For installing qualified personnel, take precautions in respect to themselves by

using suitable protective clothing, groves, etc., and then perform the

installation works.

• Please pay attention not to fall down the tools, etc. when installing the unit at

the high position.

• If unusual noise can be heard during operation, consult the dealer.

• The meanings of “Marks” used here are shown as follows:

Never do it under any

circumstances.

Always do it according to the

instruction.

CAUTIONWARNING

CAUTION

WARNING

• This installation manual illustrates the method of installing an indoor

unit.

• For electrical wiring work, please see instructions set out on the

backside.

• For outdoor unit installation and refrigerant piping, please refer to the

installation manual that comes with your outdoor unit.

• A wired remote control unit is supplied separately as an optional part.

• When install the unit, be sure to check whether the selection of

installation place, power supply specifications, usage limitation (piping

length, height differences between indoor and outdoor units, power

supply voltage and etc.) and installation spaces.

a

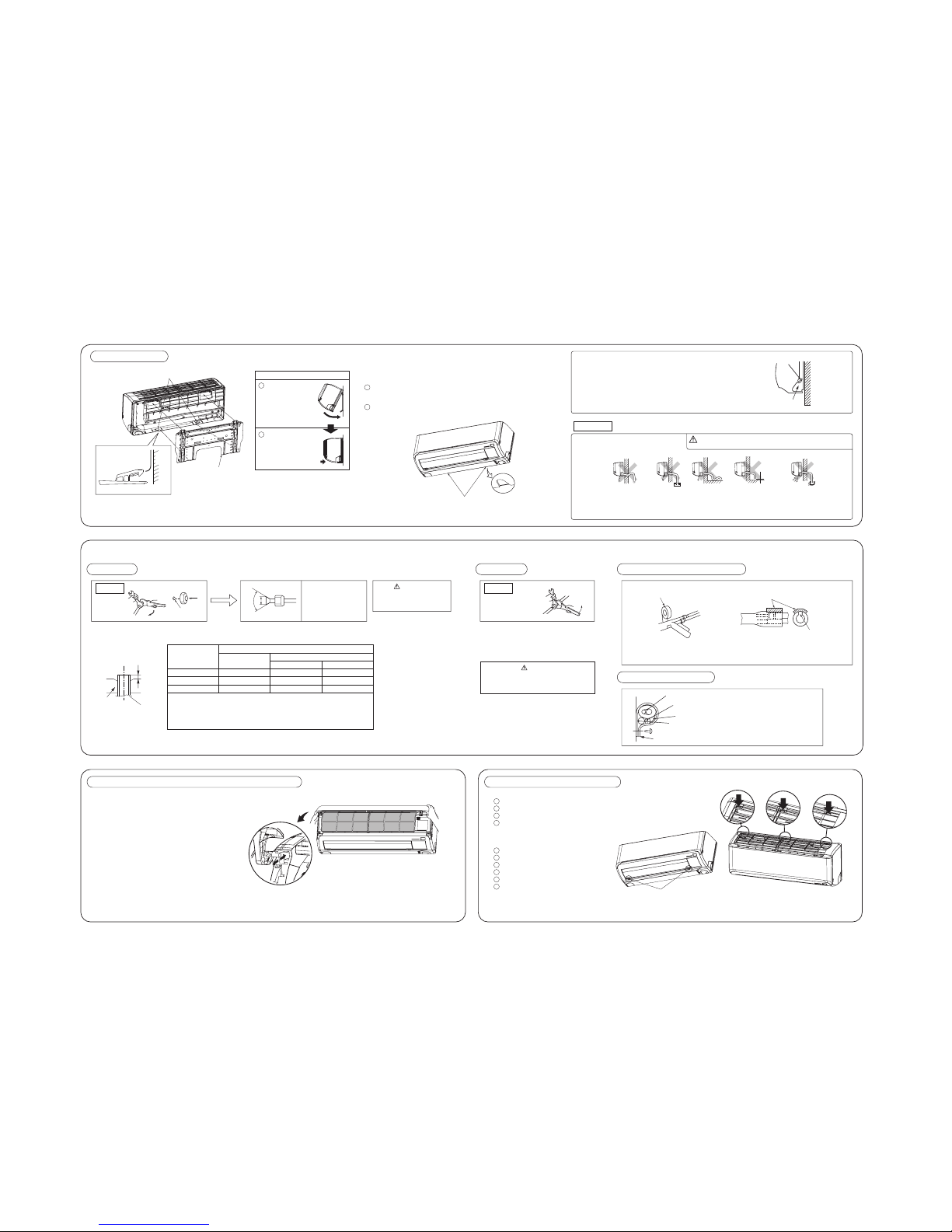

8. APPLICATION DATA

(1) Installation of indoor unit

Models DXK09ZJ-S, 12ZJ-S, 18ZJ-S

Page 25

-

22

-

'11 • SRK-T-118

Necessary tools for the installation work

1

2

3

4

5

6

7

8

9

10

11

12

13

1

1

1

1

1

1

Q’ty

Option parts

Sealing plate

Sleeve

Inclination plate

Putty

Drain hose (extension hose)

Piping cover

(for insulation of connection piping)

Plus headed driver

Knife

Saw

Tape measure

Hammer

Spanner wrench

Torque wrench

Hole core drill (65mm in diameter)

Wrench key (Hexagon) [4m/m]

Flaring tool set

Gas leak detector

Pipe bender

Gauge for projection adjustment

Used when flare is made by using

conventional flare tool

( )

( )

14.0 ~ 61.0N·m

(1.4 ~ 6.1kgf·m)

(

Designed specifically

for R410A

)

Piping in the left direction

Piping in the right rear directionPiping in the left rear direction

Piping in the right direction

INSTALLATION SPACE (INDOOR UNIT)

(FRONT VIEW)

Piping is possible in the rear, left, left rear, left downward, right or downward direction.

Right

Rear

Downward

Left

rear

Left downward

Left

Wireless remote control

Remote control holder

Wood screws

BEFORE INSTALLATION

Before installation check that the power supply matches the air conditioner.

SELECTION OF INSTALLATION LOCATION

INSTALLATION OF INDOOR UNIT

Indoor unit

Relation between setting plate and indoor unit

Installing the support of piping

(Install at location that meets the following conditions, after getting approval from the customer)

Where there is no obstructions to the air flow and where the cooled and heated air can be evenly distributed.

A solid place where the unit or the wall will not vibrate.

A place where there will be enough space for servicing. (Where space mentioned below can be secured)

Where wiring and the piping work will be easy to conduct.

The place where receiving part is not exposed to the direct rays of the sun or the strong rays of the street lighting.

A place where it can be easily drained.

A place separated at least 1m away from the television or the radio. (To prevent interference to images and sounds.)

Places where this unit is not affected by the high frequency equipment or electric equipment.

Avoid installing this unit in place where there is much oil mist.

Places where there is no electric equipment or household under the installing unit.

Wireless remote control

In case of piping in the right rear direction

A place where the air conditioner can be received the signal surely during operating the wireless remote control.

Places where there is no affected by the TV and radio etc.

Do not place where exposed to direct sunlight or near heat devices such as a stove.

Sufficient care must be taken not to damage

the panel when connecting pipes.

[Top view]

When drilling the wall that contains a metal lath, wire lath or metal plate, be sure to use pipe hole sleeve sold separately.

• Matters of special notice when piping from left or central/rear of the unit.

Left-hand-side piping Right-hand-side piping

Installation of Installation board

Drilling of holes and fixture of sleeve (Option parts)

Level position (2 locations)

Mating mark for

level surface

Fixing on concrete wall

Use of nut anchor Use of bolt anchor

Shaping of pipings Taping of the exterior

Pipings

Drain hose

Top

Nut

(M6)

Mounting

board

Mounting

board

Max.10

Thickness of the wall + 1.5cm

5

ø65

Indoor side Outdoor sideIndoor side Outdoor side Installed state

Turn to

tighten

b

b

c

a

Bolt

(M6 12)

5 cm minimum

from the wal

l

10 cm

m

inimum

from the wal

l

Installation board

Sleeve

(sold separately)

6.5 cm minimum from the ceiling

R410A REFRIGERANT USED

WALL TYPE AIR CONDITIONER

INSTALLATION MANUAL FOR INDOOR UNIT

RLA012A012B

In case of rear piping draw out, cut off the lower

and the right side portions of the sleeve collar.

Drill a hole with whole core drill.

Hold the bottom of the

piping and fix direction

before stretching it and

shaping it.

Tape only the portion

that goes through the

wall.

Always tape the wiring

with the piping.

[Drain hose changing procedures]

1. Remove the drain hose 2. Remove the drain cap.

Remove it with hand or pliers. Remove the screw and drain hose,

making it rotate.

3. Insert the drain cap. 4. Connect the drain hose.

Insert the drain cap which was removed

at procedure “2” securely using a

hexagonal wrench etc.

Note: Be careful that If it is not Inserted

securely, water leakage may occur.

Insert the drain hose securely, making

rotate. And install the screw.

Note: Be careful that If it is not Inserted

securely, water leakage may

occur.

Adjustment of the installation board in the horizontal direction is to

be conducted with four screws in a temporary tightened state.

Adjust so the board will be

level by turning the board

with the standard hole as

the center.

450

Look for the inside wall structures (Intermediats support or pillar

and firmly install the unit after level surface has been checked.)

Standard

hole

Piping for Liquid (09 to 18 type) : ø6.35

Piping for Gas (09 to 12 type) : ø9.52

(18 type) : ø12.7

CAUTION

Completely seal the hole on

the wall with putty. Otherwise,

furniture, or other, may be

wetted by leaked water or

dewing.

putty

putty

1

1

1

5

2

2

2

2

1

Q’ty

Standard accessories (Installation kit)

Accessories for indoor unit

Installation board

(Attached to the rear of the indoor unit)

Wireless remote control

Remote control holder

Battery [R03 (AAA, Micro) 1.5V]

Air-cleaning filters

Filter holders

(Attached to the front panel of indoor unit)

Insulation (#486 50 x 100 t3)

Tapping screws

(for installation board ø4 X 25mm)

Wood screws

(for remote control switch holder ø3.5 X 16mm)

1

2

3

4

5

6

7

8

9

( )

Designed specifically

for R410A

Space for service Space for service

Indoor unit

Installation board

Piping hole (ø65)

Drain hose (ø16)

Piping for Liquid

Piping for Gas

Piping hole (ø65)

Space for service

48.947

65

139 450 209

106.5 585 106.5

50 100

7.2 7.7279.1

4715 Space for service

55

531.8

471.6

403.6

55

Indoor side Outdoor side

WARNING

• Installation must be carried out by the qualified installer.

If you install the system by yourself, it may cause serious trouble such as

water leaks, electric shocks, fire and personal injury, as a result of a system

malfunction. Do not carry out the installation and maintenance work except

the by qualified installer.

• Install the system in full accordance with the installation manual.

Incorrect installation may cause bursts, personal injury, water leaks, electric

shocks and fire.

• Be sure to use only for household and residence.

If this appliance is installed in inferior environment such as machine shop

and etc., it can cause malfunction.

• Use the original accessories and the specified components for

installation.

If parts other than those prescribed by us are used, It may cause water

leaks, electric shocks, fire and personal injury.

• Install the unit in a location with good support.

Unsuitable installation locations can cause the unit to fall and cause

material damage and personal injury.

• Ventilate the working area well in the event of refrigerant leakage

during installation.

If the refrigerant comes into contact with naked flames, poisonous gas is

produced.

• When installing in small rooms, take prevention measures not to

exceed the density limit of refrigerant in the event of leakage,

referred by the formula (accordance with ISO5149).

If the density of refrigerant exceeds the limit, please consult the dealer and

install the ventilation system, otherwise lack of oxygen can occur, which

can cause serious accident.

• After completed installation, check that no refrigerant leaks from

the system.

If refrigerant leaks into the room and comes into contact with an oven or

other hot surface, poisonous gas is produced.

• Use the prescribed pipes, flare nuts and tools for R410A.

Using existing parts (for R22 or R407C) can cause the unit failure and

serious accidents due to burst of the refrigerant circuit.

• Tighten the flare nut by torque wrench with specified method.

If the flare nut were tightened with excess torque, this may cause burst and

refrigerant leakage after a long period.

• The electrical installation must be carried out by the qualified

electrician in accordance with “the norm for electrical work” and

“national wiring regulation”, and the system must be connected to

the dedicated circuit.

Power supply with insufficient capacity and incorrect function done by

improper work can cause electric shocks and fire.

• Be sure to shut off the power before starting electrical work.

Failure to shut off the power can cause electric shocks, unit failure or

incorrect function of equipment.

• Be sure to use the cables conformed to safety standard and cable

ampacity for power distribution work.

Unconformable cables can cause electric leak, anomalous heat production

or fire.

• This appliance must be connected to main power supply by means

of a circuit breaker or switch (fuse:16A) with a contact separation of

at least 3mm.

• When plugging this appliance, a plug conforming to the norm

IEC60884-1 must be used.

• Use the prescribed cables for electrical connection, tighten the

cables securely in terminal block and relieve the cables correctly to

prevent overloading the terminal blocks.

Loose connections or cable mountings can cause anomalous heat

production or fire.

• Arrange the wiring in the control box so that it cannot be pushed up

further into the box. Install the service panel correctly.

Incorrect installation may result in overheating and fire.

• Be sure to switch off the power supply in the event of installation,

inspection or servicing.

If the power supply is not shut off, there is a risk of electric shocks, unit

failure or personal injury due to the unexpected start of fan.

• Be sure to wear protective goggles and gloves while at work.

• Earth leakage breaker must be installed.

If the earth leakage breaker is not installed, it can cause electric shocks.

CAUTION

• Use the circuit breaker of correct capacity. Circuit breaker should

be the one that disconnect all poles under over current.

Using the incorrect one could cause the system failure and fire.

• Install isolator or disconnect switch on the power supply wiring in

accordance with the local codes and regulations.

The isolator should be locked in OFF state in accordance with EN60204-1.

• Be sure to install indoor unit properly according to the installation

manual in order to run off the drainage smoothly.

Improper installation of indoor unit can cause dropping water into the room

and damaging personal property.

• Install the drainage pipe to run off drainage securely according to

the installation manual.

Incorrect installation of the drainage pipe can cause dropping water into the

room and damaging personal property.

• Be sure to install the drainage pipe with descending slope of 1/100

or more, and not to make traps and air-bleedings.

Check if the drainage runs off securely during commissioning and ensure

the space for inspection and maintenance.

• Secure a space for installation, inspection and maintenance

specified in the manual.

Insufficient space can result in accident such as personal injury due to

falling from the installation place.

• For installation work, be careful not to get injured with the heat

exchanger, piping flare portion or screws etc.

• Be sure to insulate the refrigerant pipes so as not to condense the

ambient air moisture on them.

Insufficient insulation can cause condensation, which can lead to moisture

damage on the ceiling, floor, furniture and any other valuables.

• When perform the air conditioner operation (cooling or drying opera-

tion) in which ventilator is installed in the room. In this case, using the

air conditioner in parallel with the ventilator, there is the possibility

that drain water may backflow in accordance with the room lapse into

the negative pressure status. Therefore, set up the opening port such

as incorporate the air into the room that may appropriate to ventila-

tion (For example; Open the door a little). In addition, just as above, so

set up the opening port if the room lapse into negative pressure status

due to register of the wind for the high rise apartment etc.

• Be sure to perform air tightness test by pressurizing with nitrogen

gas after completed refrigerant piping work.

If the density of refrigerant exceeds the limit in the event of refrigerant

leakage in the small room, lack of oxygen can occur, which can cause

serious accidents.

• Do not install the unit in the locations listed below.

• Locations where carbon fiber, metal powder or any powder is floating.

• Locations where any substances that can affect the unit such as sulphide

gas, chloride gas, acid and alkaline can occur.

• Vehicles and ships.

• Locations where cosmetic or special sprays are often used.

• Locations with direct exposure of oil mist and steam such as kitchen and

machine plant.

• Locations where any machines which generate high frequency harmonics

are used.

• Locations with salty atmospheres such as coastlines.

• Locations with heavy snow (If installed, be sure to provide base flame and

snow hood mentioned in the manual).