Page 1

MITSUBISHI

INDUSTRIAL

SEWING

MACHINE

Model

Thank

you

you

for

your

will

read

through

A

MITSUBISHI

purchaseof"Mitsubishi"

this

manual

book

for

ELECTRIC

machineatthis

your

long

periods

time.

using

CORPORATION

We

efficiently.

hope

Page 2

(

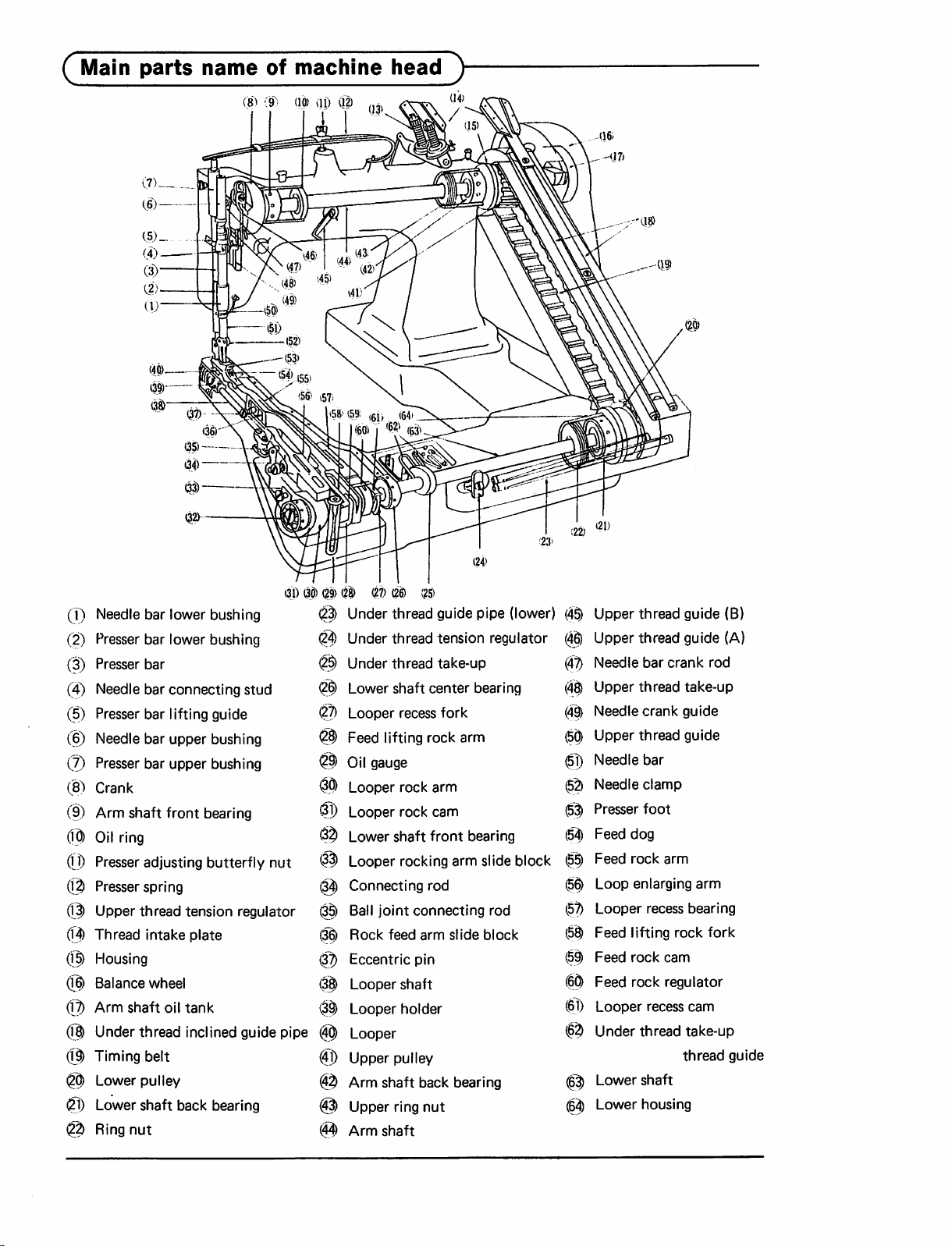

Main

parts

nameofmachine

(8)

(9":

(10)

(If) (1^

head

y

Nee(Jle

0

Presser

(2)

Presser

(3)

Needle

(4)

Presser

0

Needle

Presser

@

Crank

(8)

Arm

(9)

Oil

0

Presser

©

Presser

Upper

®

0

Thread intakeplate (||)

bar lower

bar

lower

bushing

bushing

bar @

bar

bar

bar

bar

shaft

connecting

lifting

upper

upper

front

stud

guide

bushing

bushing

bearing

ring

adjusting

spring

thread

butterfly

tension

nut

regulator

Housing

Balance

wheel

Armshaft oil tank

Under

thread

@

@)

Timing

Lower

inclined

belt (g)

pulley

guide

Lowershaft back bearing @

Ring

nut 0

(31)

pipe

# (|

0)

(27)

(26)

(25)

Under thread guide pipe (lower) (4^

(i|)

Under

thread

0

Under thread take-up

Lowershaft center bearing

®

Looper

®

Feed lifting rock arm l5^

®

Oil

@

®

*|J)

®

®

(0

@

(3^

(3^

gauge

Looperrockarm

Looper

Lower

Looper

Connecting rod (|^

Ball

joint connecting rod 0

Rock feed arm slide block (5$

Eccentric

Looper

Looper

tension

recess

fork

rock

cam

shaft front

rocking

bearing

arm slideblock 0

pin 0

shaft 0

holder

Looper

Upper

pulley

Arm shaft back bearing

Upper ring nut

Arm

shaft

regulator

Upper

thread

Upper thread guide (A)

@

(aT)

(4i^

(4^

(0

(0

(5|)

0

0

0

(0

(0

Needle

Upper

Needle

Upper

Needle

Needle

Presser

Feed

Feed

Loop

Looper

Feed

Feed

Feed

Looper

Under

Lower

Lower

bar

crank

thread

crank

thread

bar

clamp

foot

dog

rock

arm

enlarging

recess

lifting

rock

cam

rock

regulator

recess

thread

shaft

housing

guide

take-up

guide

guide

arm

bearing

rock

cam

take-up

thread

(B)

rod

fork

guide

Page 3

(

Howtouse

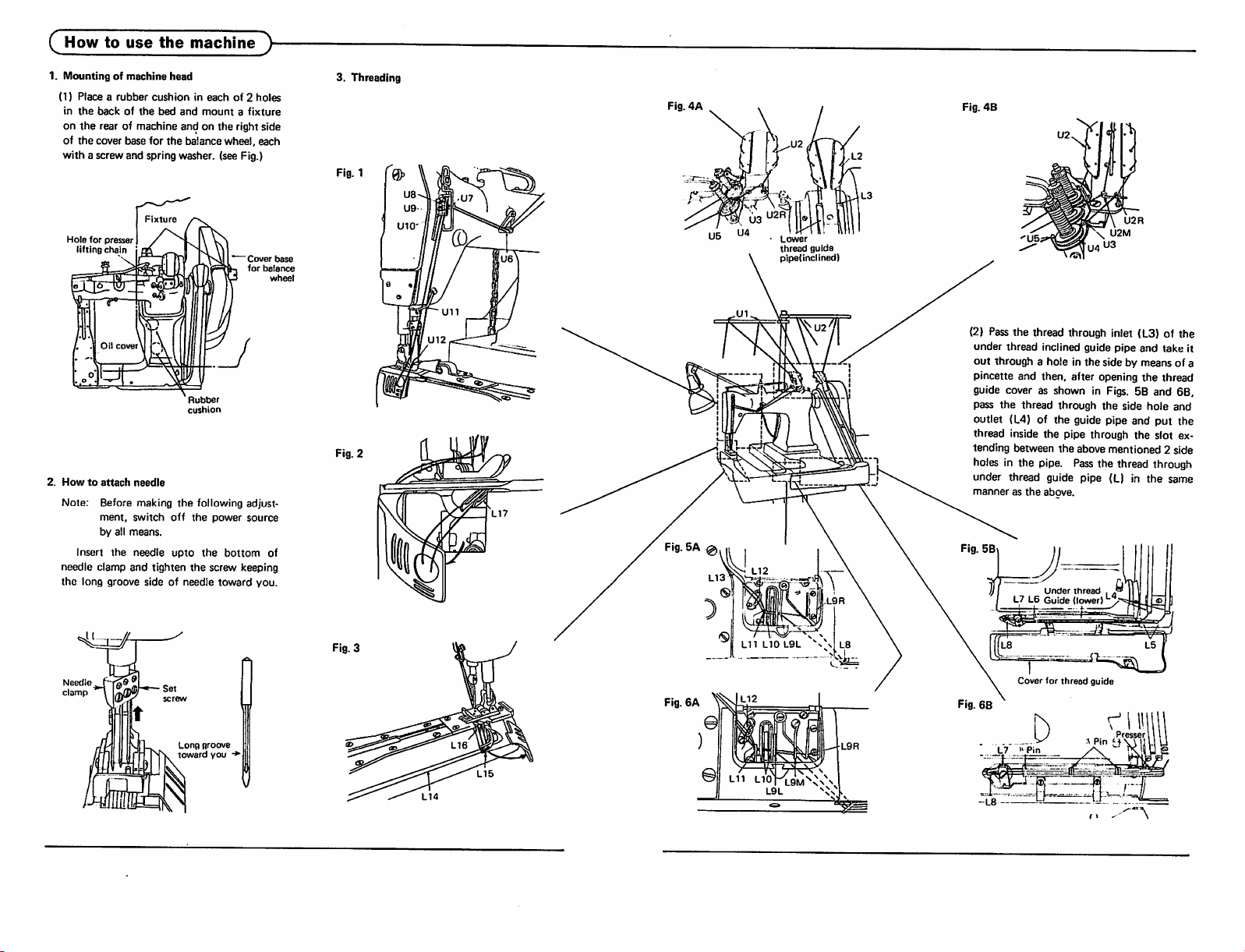

1.

Mountingofmachine

(1)

Placearubber

in

the

backofthe

on

the

rear of machine and on the right side

of

the

cover base for

the

machine

head

cushionineachof2

bed

and

mountafixture

the

balance wheel, each

with a screw and spring washer, (see Fig.)

}-

holes

3.

Threading

Fig. 1

Fig.

4A

Fig. 4B

Hole

for

presser

lifting

chain

Oil

cover

2.

Howtoattach

needle

Note: Before making

ment.

switch

by all

means.

insert

the

needle

needle clamp and tighten

the

long

groove

sideofneedle

Fixture

Rubber

cushion

the

following adjust

off

the

upto

the

the

screw keeping

power

bottom

toward

Cover

for

balance

source

you.

of

whee

base

Fig. 2

Fig. 3

Lower

thread

guide

plpe(inclmed)

\ U2M

(2) Passthe thread through inlet (L3) of the

under thread inclined guide pipe and take it

out

through a hole in the side by means of a

pincette and then, after opening the thread

guide cover as shown in Figs. 5B and 6B,

pass

the

thread

through

the

side

hole

outlet (L4) of the guide pipe and put the

thread inside the pipe through the slot ex

tending between the above mentioned 2 side

holes in the pipe.

Pass

the thread through

under thread guide pipe (L) in the same

mannerasthe

Fig. 5B

L7 L6

above.

Under

Guide

thread

, .

(lower) ^

and

Need

clamp

e

Set

screw

Long

toward

groove

you

Fig.6A

Cover

for

thread

guide

^

LIT

L10

Fig.

6B

h

\J

L7

"Pin

_

^'

PresserUll

"11

Page 4

(^Howtouse

4.

Adjustmentofthread

O

Well

In

caseofupper

too

is

too

6.

Upper

thread

tension

**

Upper

threadisadjusted

lower

thread

tension.

**

Upper

thread

sion

regulating

Strengthen

Weaken

the

machine

tension

balanced

weakorlower

strong

stitch

thread

is

thread

accordingtothe

tensionisadjustedbyten

thumb

Thumb

nut.

nut

^

5.

Thread

1.

Lower

regularly

of

required

ease.

The

be

2.

Upper

en

3. Irregular

in its

Checkupthe

7.

Lower

Weaken

tension

thread:

through

in case of

When

threadispulled,

to

be

pulled

thread

weak.

gradually

thread:

tension

Start

watching

stitching;

mounting

side.

wrong

thread

'W

Under

tension

thread

tension

Strengthen

Adjusting

startingtosew

threadingismade

looper

eye

the

lower

out

smoothly

is

recommendable

weakly

the

and

trial

Check up

threading.

device

•

screw

and

thread

strength

stitches.

the

|i(

-

the

needle

end

is

in

to

8.

Adjustmentofstitch

(1)

For

adjusting

the

large screw on the oil cover,

length

stitch

length, first remove

bring screw 0 (white) on the feed cam into

the

sight

through

balance

Loosen

wheel

under

(2)

increases

wheel.

the screw 0 and then turn the

further

the

hole,

Counter-clockwise

the

the

hole by

until screw

(see Fig.)

rotationofscrew

lengthofstitch

(B)

and

turning

(red)

vice versa.

After the adjustment, tighten screw 0 .

(see Fig.)

9.

Adjustmentofpressureonpresser

Pressure on

justedinaccordance

sewn.

the

presser

with

Butterfly nut Thumb

foot

footisto

materials

nut^

and

the

comes

(B)

be ad

to be

10.

o

Cutting

At

thread

the

material

to

that

Feed

cam

( I

Large

screw

of

thread

the

tipofthe

cutterisprovided,

downward

point,

the

thread

(A.

bedofthe

and

when

canbecut.

(White)

machine

by

it is

(Red)

pulling

sewn

a

up

Presser

spring

Page 5

Adjustment

1.

Mounting

guide

positionofthe

(top of

arm)

y

upper

0

(Make proper loop with needle thread.)

When

the

position,

heightofthe

upper

2.

Mounting

thread

set

thread

angleofthe

take-up lever is at its lowest

the

threadtobe looped by

diameterofthe

wire

guide (arm) (D is

upper

thread

guide (g)

(Adjust

When

position,

thread

and

level.

3.

Mounting

take-up

When

lower

of 4 —5 mm

contact

Thread

operation

Thread

slow

tensionofthe

the

thread

it is

recommendable

between

the

upper

positionofthe

lever

the

looperisat

thread

take-up

from

with

the

take-upisimprovedincaseofquick

take-up

the

upper

thread

the

lower

thread

take-up.)

lever is at its lowest

thread

guide

become

lower

its

extreme

lever is

setatthe

mounting

thread.

(high).

take-upisnot

operation

(low).

improvedincase

thread

which

made

of.

to

make

guide (arm)

almost

thread

left,

plate

making

the

the

the

the

place

of

Upper

Needle

at

lowest

position

/Upper

thread

take-up

\i')

' y '

bar

thread

V"

Upper

horizontally.

i

guide

^

,7

threadispositioned

\

Upper

extreme

position

""'pp''

Thread

thread

Lower

thread

take-up

Looperatits

\

right

guide

4—5

""'P®

@

mm

4.

Relationofneedle

(1) When

tion,

position

center

shouldbe3.5

be

looper

(2)

adjusted

the

of needle

adjusted

tightening

The

height of

the

looper will be at its extreme right

where

that

and

needle bar is at its lowest posi

the

and

mm

(9/64").

by

resetting

screw.

the

when

from its lowest position,

meets

with

the

eyeinthe

its

advance

5.

Positionofneedle

The

guard

it

canbeadjusted

which

tubular

motion,atthe

guard

clearance

shouldbeapproximately

can

part.

be

between

after

reached

looper

distance

the

needle

the

between

tip of

The

distance

the

looperatthe

bar

should

needle is going up

the

looper

same

level.

the

0.1

loosening

from

the

the

the

looper

can

be so

needle eye

which is in

needle

mm

the

bottom

and

and

screw

1

0

3.5

mm

Looper

eye

and

Needle

eye

Forward

Needle

Needle

guide

of

Backward

\

r

Approx.

0.1

mm

Page 6

(^Precaution

Turn

the

screwonthe

fill

the

tank

When

the

line,

lubrication

Give

close

whenever

before

balance

top,

with

oil level

checkingsofthe

it is low. (see Fig. 1)

wheeltobring

remove

oiltofull.

drops

will

stop.'

the

below

startingtooperat^

plug

oil

Oil cut (g) at 3 places are to be oiled 5 cc

each

for

the

initial

and

thereafter

drops at least twice a week, (see Fig. 2)

Remove

fill

the

give

the

The

oilintank

twiceaweek

the

gauge.

the

oil gauge in Fig. 3 and

tank

with

150ccof

level uptothe

should

and

kept

mark on

be

checked

uptothe

and

oil,

the

screw,

the

center

replenish

5

which

the

gauge.

at

mark

Oil

gauge

plug

and

or

will

least

on

Fig. 1

Plug

screwv

Center

line

6

Fig. 2

(D)

Sump

Arm

shat

tank

(c

Oil

cup

/ \

I

(A)

Oil

gauge

(K

Plug

4.

Maintenance

1. As

accumulationofdustonthe

feed

affect a proper feed of the material, it should

be periodically brushed off.

2. Often

the

dust

the

looper function is impaired by

collected

on

it,

anditshould

cleaned periodically by removing its cover.

Also

at

the

same

time

clean

the

pathess.

6.

Mounting

oval

press down as far as it touches

plateasshown

of stitching on

Fit

the

slotinthe

and

adjustmentoftapper

guide plate of the lapper into the

middleofthe

oil

cover

the

in Fig. 4. Where

the

material to be lapped is

the

not properly located, adjust it after loosen

ing screw A , and when the width of lap is

not proper, adjust it by tightening screw B .

dog

be

thread

and

throat

point

5.

Drainingofwaste

1.

Excessive

sump (p) and in

at

the

jaw of the arm, and it should be peri

odically removed by means of a

oil in

oil

the

the

armiscollected

lower

partofthe

spuit

piece of waste cloth, (see Fig. 2)

2.

Waste

oil in

the

bedisdrained

the hole under the bed by removing plug

(Fig. 2)

Accumulation

lower

thread

of

take-up

oil in

and,

the

bed

therefore,

wets

thread. A special care should be taken in

periodical draining of

Fig. 4

the

waste oil.

©

in

plate

or a

through

(0.

the

the

Page 7

(^Specifications}-

Model

DV-440+suffix

Material

No.ofneedles

Max.

Max.

Needle-bar

Presser-foot

Presser-foot

MIn.

Needle

weight

speed

stitch

cylinder

type

(spm)

length

stroke

type

clearance

circumference

Weight (net/gross)

Shipping

Needle

measurement

type

(Organ

mm

In

Organ

Singer

Schmetz

mm

in

(head only)

needles

are

1-1/16

standard)

-21

Light

2

27

27:45

3.2,4.8,

1/8,

-20

Medium

2 3

4000

TVxl

m -

149x1#7-

Nm

6.4

3/16,1/4

30.2

1-3/16

70-110

-30

18

18

3.2+3.2

1/8+1/8

-22

Medium&heavy

2

4.2mm

Regular

10mm

178mm

TVx5

149x5

44:31

6.4

1/4

(Sspl)

33

1-5/16

(3/8")

jCI1 -

1/11-22

Nm

80-110

3.2+3.2

54/67kg

0.21m^

1/8

-32

(7")

-23

3

3500

22

1/8

2

TVx5

149x5

44:31

-23-U

Denim

2

36

1-27/64

Union

#14-23

#14-23

Nm

6.4

1/4

-33

3

Regular

90-160

3.2+3.2

1/8+1/8

A

MITSUBISHI

HEAD

OFFICE

MITSUBISHI

DENKI

ELECTRIC

BLDG.MARUNOUCHI.

TOKYO

CORPORATION

100.

TELEX

J24532

CABLE

MELCO

TOKYO

W'l'00532X0l

Loading...

Loading...