Page 1

A

MITSUBISHI

INDUSTRIAL

SEWING

MACHINE

Model

classes

Compound

Compound

Feed

Feed

Single-Needle

Double-Needle

Lockstitch

Lockstitch

INSTRUCTION

FOR

OPERATION

MANUAL

Page 2

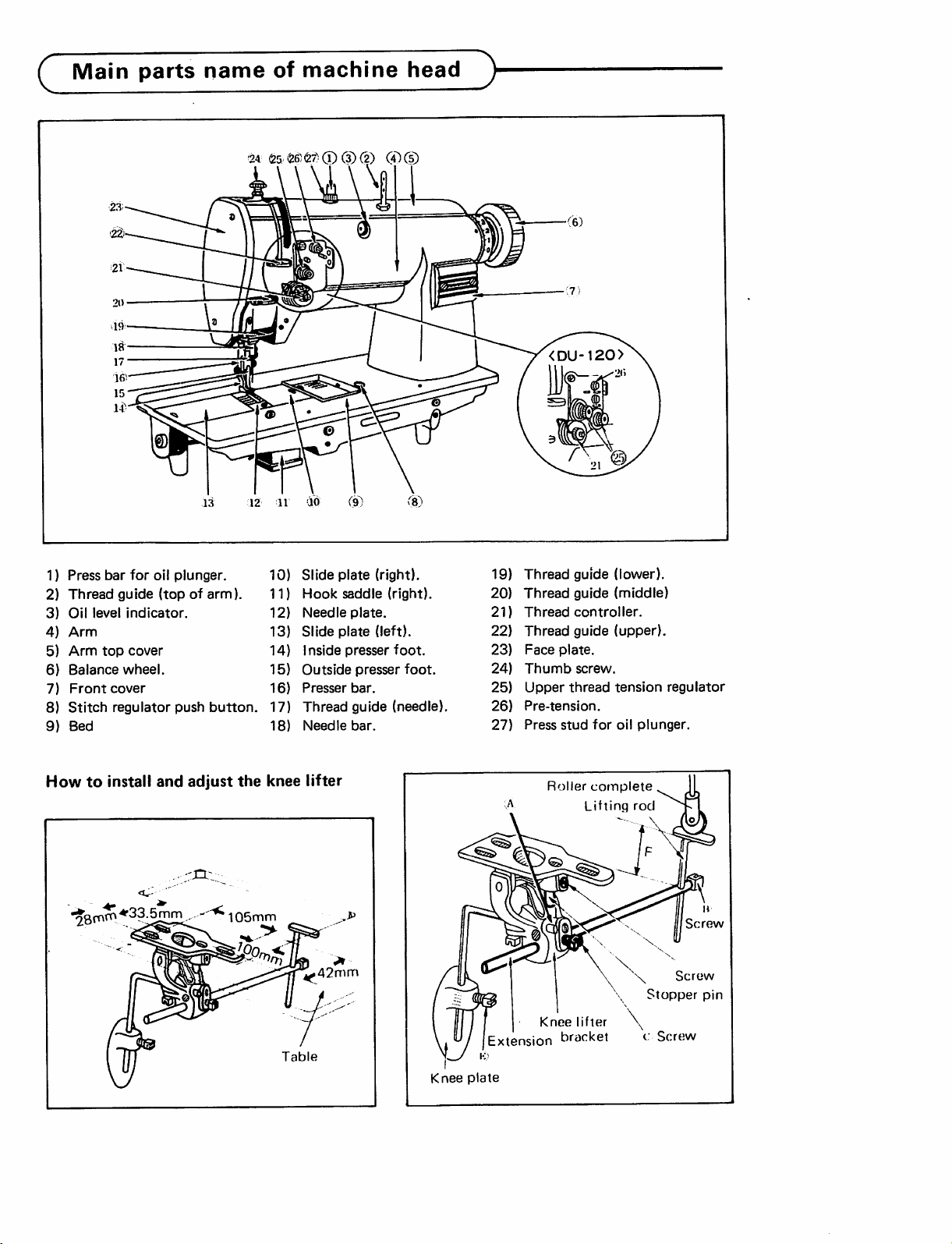

Main

parts

nameofmachine

24

(25

<26167)CD(3) (2)

-m

C^)

head

®

^

1)

Press

bar

for

2)

3)

4)

5)

6)

7)

8)

9)

Thread

Oil

Arm

Arm

Balance

Front

Stitch

Bed

level

top

cover

regulator

guide

indicator.

cover

wheel.

Howtoinstall

*2^^^

oil

plunger.

(topofarm).

push

button.

and

adjust

the

105mm

10)

11)

12)

13)

14)

15)

16)

17)

18)

knee

Table

Slide

Hook

Needle

Slide

1

nside

Outside

Presser

Thread

Needle

lifter

42mm

plate

saddle

plate.

plate

presser

presser

bar.

guide

bar.

(right).

(right).

(left).

foot.

foot.

(needle).

Knee

Thread

19)

20)

Thread

21)

Thread

22)

Thread

23)

Face

plate.

24)

Thumb

25)

Upper

Pre-tension.

26)

27)

Press

stud

Roller

Knee

'Extension bracket

plate

guide (lower).

guide (middle)

controller.

guide

(upper).

screw.

thread

tension

for

oil

plunger.

complete

Lifting

lifter

rod

\

c:

regulator

Screw

Stopper

Screw

Screw

pin

Page 3

How

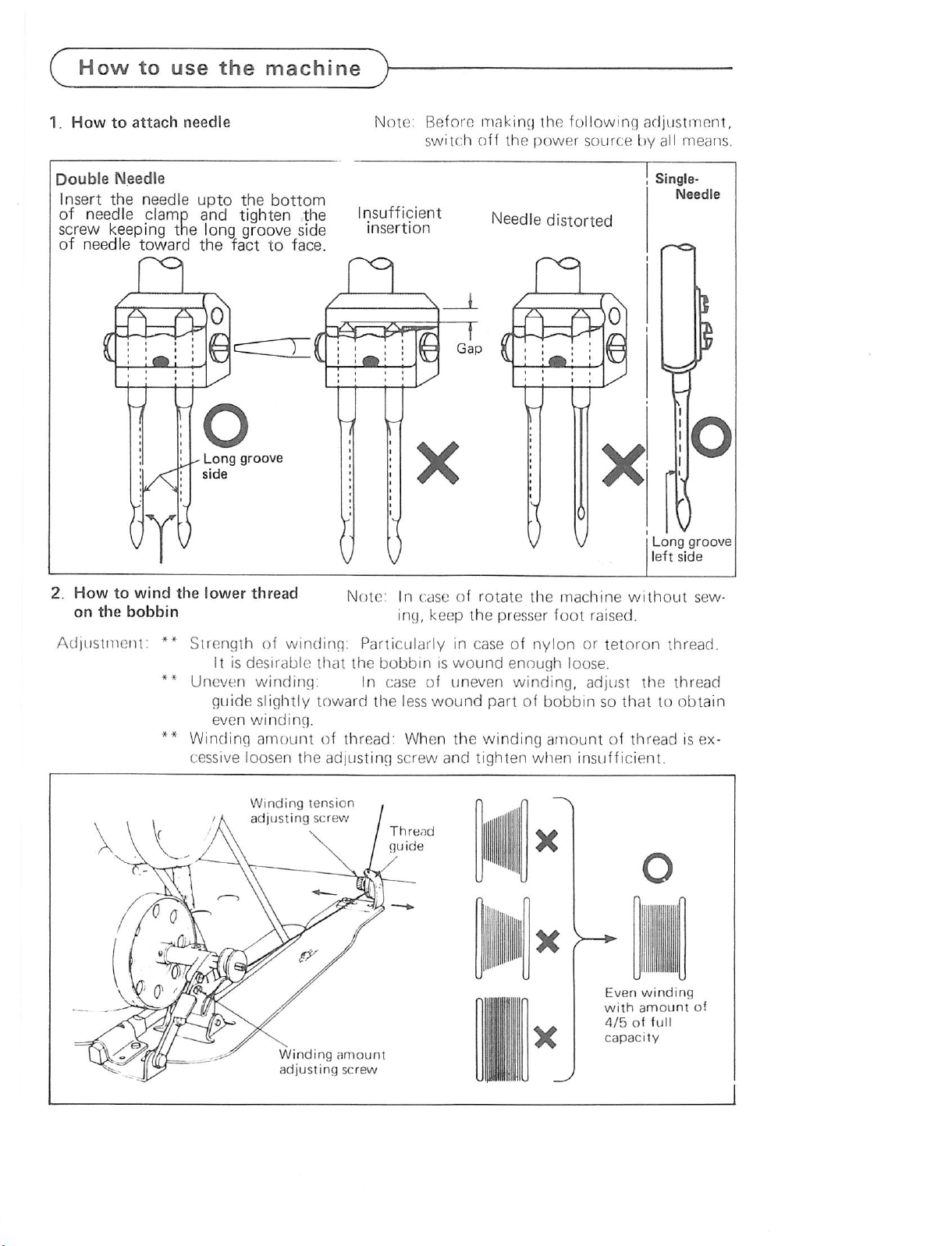

1.

How

to

to

attach

use

needle

the

machine

Note:

Before

switch

making

off

the

the

power

following

source

adjustment,

by all

means.

Double

Insert

of

Needle

the

needle

needle

clamp

upto

the

bottom

and tighten the

screw keeping the long groove side

of

needle

How

on

the

to

toward

wind

bobbin

the

the

lower

fact

to

thread

face.

Insufficient

insertion

Note:

In

ing,

case

keep

Needle

of

rotate

the

presser

distorted

the

machine

foot

raised.

without

sew

Adjustment:

**

**

Strength

It is

Uneven

guide

even

of

winding;

desirable

winding:

slightly

winding.

Particularlyincaseofnylonortetoron

that

the

bobbiniswound

In

case

of

toward

the

less

wound

** Winding am{;unt of thread: When

cessive

loosen

Winding

the

tension

adjusting

screw

.

adjusting screw /

Thread

guide

—

Winding

adjusting

amount

screw

uneven

enough

winding,

loose.

adjust

partofbobbinsothattoobtain

the

and

winding

tighten

amountofthread

when

insufficient.

Even

with

4/5offull

capacity

the

winding

amount

thread.

thread

is ex

ot

Page 4

Howtouse

3.

Threading

machine

Note:

guide (A) should

be

above

spool.

4.

Adjustment

Stitching

the

bed

1) Pushing

2) So

Caution:

while

To

tacking,

lowest

pleted.

The

positioned

the

stitch

and

the

turn

the

ward

you.

that

further

ning.

At

this

the

dial

the

marking

release

Fig.

the

change

position

the

machine^)-

the

thread

just

thread

of

stitch

length

length

regulator

and

the

NEVER

balance

the

balance

the

time

on

can

push

push

the

set

the

on

push

be

push

wheel.

button

wheel

button

balance

the

Balance

the

button

depress

adjusted

button

graduation

arm

machineisrunning.

the

directionoffeed

depress

feed

until

reverse lever

back

with

on

the

down

slowly

goes

wheel

Wheel

the

tackiscom

Mark

down

and

shown

button

for

and

to

run

with

then

back

of

in

to

Raise

the

position

following

(10)

(L11

Right

to

left

Howtoplace

into

the

Note:

thread

and

order.

take-up

thread

the

levertoits

upper

m

(Detail)

.^(R12

Left

to

right

the

shuttle

In

case

the

shuttle

bobbin

hook

of placing

hook,

by making winding

thread

in Fig.

in

correct

threadinthe

Thread

&

the

bobbin

place

the

toward

direction

highest

into

bobbin

the

shown

Stitch

regulating

button

^—<5

Feed

reverse lever

Winding

Slide

Balance

wheel

towardofthread

plate

(Jk

Hook

shaft

Slide

(A;.

plate

Hook

Qi

Shaft

Page 5

How

Lower

1) I

of

and

thread

threading

eaci

the

throuc)h

to

use

the

cMulofthread

shuttle

out.

the

hook

machine

to

the

0

showninF1^.

the horn (2) , pull tlie

:

Thread

7.

Adjustment

Tlie

i<i

loo

lower

cx

The

tlirtradisto')

of

tlie

of

thread

lensiunoftlu;

loos(!,orthe

thread

is tiQlU.

tension

lower

of

tigfit.ortlie

thieadistoo

tension

Proper

ij|)|k;i

lRnsir>riofthe

the

upper

Stitch

thread

tonsion

loose.

9.

2)

Holding

by

wheel

thread

from

foot.

Lower

left

the

thread

Thread

Bobbin

the

hand

slowly.

and

underneath

end

and

hold

.1

tension

case

of

Pull

it

opener

the

turn

on

upper

out

the

of

the

the

the

other

thread

balance

lowrir

side

presser

Upper

** Upper

**

For

thread

to

the

Upper

tension

special

tension

threadisadjusted

lower

thread

thread

regulating

fabric

tension.

tensionisadjusted

thumb

sewing

according

nut.

with

thread, thr; desired tension can be ob

tained by adjusting the strength and op

erating range of thread takc^up spring.

Thread

tension

nut

Strengthen

10.

Adjustment

on

presser

Pressure

justed

be

sewn.

of

foot

on

the

in

accordance

pressure

presser

Pressure

footistobead

with

materials

regulating

by

special

to

screw

Weak

Thread

Strong

tension

screw

Page 6

How

to

use

the

machine

11.

1}

FUNCTION

1) When

2) Clean

3)

SAFETY

Safety

vent

clutch

the

CLUTCH

hook

damage in case

into

the

hook

loaded

belt

rotation

stop.

and

caught

Turn

and

shaft

place

abnormally

OF

SAFETY

the

safety clutch acts, the timing

pulley

stop

check

will

of

hook

The

arm

the

operationofmachine.

the

thread thoroughly which is

into

the

the

timing

whether

rotates

the

clutch

DEVICE;

device is installedtopre

and

timing belt from

the

when

be

shaft

thread

during

unloaded,

driving

only

is

the

machine

operation.

CLUTCH.

then

shaft

will

caught

the

will

rotates,

hook.

belt

bushing by hand,

the

hook

driving

lightly

device

and

as it

properly,

was.

is

Clutch

gear

Safety

Timing

Timing

Safety

clutch

belt

belt

0

clutch

pulley

bushing

2) HOW TO

1) While pressing

on

the

hand,

by

right

in

the

figure.

2)

The

balance

gearing

wheel

3) Release

4) As

shown

clutch

SET

THE

down

opposit

turn

the

hand

away

wheel

plate,

more

firmly.

the

push

in

the

deviceisset.

SAFETY

the

side

balance

from

will

but

turn

button.

Figure,

CLUTCH,

push

of

bed

by left

wheel

youasshown

stop

by

the

balance

the

button

slowly

the

safety

Push

button

Balance

wheel

Gear

plate

Page 7

Precaution

1.

Lubrication—1

Before

the

position, arm, bed and hook saddle

of

oil

tank.

Oil

indicaior

liigh

level

(DO

NOT

OVERFILL)

starting

w.

point

before

to

"

operate

starting

pour

oil

upto

to

operate

I

Lubrication—2

The

volume

of

5 - 6 d

lubrications

rops.

2)

Bed

oil

reservoir

Oil

filter

hole

O ®

Oil

indicator

3) Hook saddle oil tank (left to right)

Oil

gauge

Oil

filler

hole

2.

Adjustmentofrotating

Decrease

hook

oil

flow

regulator

^^ecrease

Slide plate \ \ Slide plate (right)

Adjusting

screw

o

^

Hook

saddle

—1o

« o

Hook"

saddle

Adjusting

Page 8

Howtomount

rubber

with

The

vibration-preventing

prevent

thereby

the

machine.

cornersofthe

•

Achieve

and

of

facing

is

achieved.

• Nail

down

as

shown

Q

Specifications^

vibration-preventing

table

the

machine

to

provide

Fit

tableasshown

spot

facing

13

mm

depth

the

table.

to

the

faceAwhere

the

vibration-preventing

at

the

four

in Fig.

these

Be

rubber

from

vibrating

smooth

operation

rubber

of

20

at

the

four

suretogive

corners

is used

at

the

in Fig.

mm

smooth

spot

of

the

and

of

four

radius

corners

facing

rubbers

table

to

5.5m/m

Vibration

preventing

Table

13m/m

rubber

Model

Material

Max.

Hook

Reverse

Model

Material

Max.

Hook

Reverse

Needle

^Single

speed

size

^Double

speed

size

gauges

needle>

weight

(spm)

lever

needle^

weight

(spm)

lever

mm

in

(Common Specifications]

Max.

stitch

length

Needle-bar

Walking-foot

Presser-foot

clearance

Spaceatrightofneedle

Needle

Bed

Needle

type

dimensions

stroke

stroke

Knee

Hand

Organ

Singer

Schmetz

type

(Organ needles are standard.)

lifter

DU-100-12

3500

Regular

DU-120-12

3000

Regular

No

No

6.4,

1/4,

DU-100-22

2500

Large

DU-120-22

Heavy

Large

No

9.5,

12.7,

3/8,

517X178mm

1/2,

7mm(31/2

33.4mm

2-6mm

12.7mm

9.0mm

245mm

DPx17

135x17

37:20

DU-105-12

Heavy

DU-125-12

material

16, 19,

5/8,

(1-5/16")

(5/64-

(1/2")

(23/64")

(9-5/8")

#23

#23

Nm

(20-3/8x7")

3000

Regular

2500

Regular

Yes

spi)

1/4")

160

3/4,

DU-105-22

2500

Large

Yes

DU-125-22

Large

Yes

25.4

1

A

MITSUBISHI

hE/^D OFFICE MITSUBISHI DENKI BlDG MARuMOUCHi TOKYO >00 TfuEX

ELECTRIC

CORPORATION

J2A532

CABLE

MElCOtok-Ci

Printed

in

.laonn

Loading...

Loading...