Mitsubishi Electric DPro930SB-BK, DPro930SB-BKAB, DPro930SB-BKA, Diamond Pro 930SB, DPro930SB-BKB Service Manual

PART NO. 599910624

COLOR MONITOR Diamond Pro 930SB

MODELS DPro930SB -BK(A)/(B)/-BK(B)

200307

08M530A3

08M540B3

08M530B3

SERVICE MANUAL

NEC-MITSUBISHI ELECTRIC VISUAL SYSTEMS CORPORATION

OCTOBER 2002

WARNING

The SERVICE PERSONNEL should have the appropriate technical training, knowledge and

experience necessary to:

• Be familiar with specialized test equipment, and

• Be careful to follow all safety procedures associated with high voltage CRT circuit designs to

minimize danger to themselves and their coworkers.

To avoid electrical shocks, this equipment should be used with an appropriate power code and be

connected only to a properly grounded AC outlet.

This equipment utilized a micro-gap power switch. Turn off the set by first pushing the front panel

power switch. Next, remove the power cord from the AC outlet.

To prevent fire or shock hazards, do not expose this unit to rain or moisture.

This symbol warns the personnel that un-insulated voltage within the unit may have

sufficient magnitude to cause electric shock.

This symbol alerts the personnel that important literature concerning the operation and

maintenance of this unit has been included.

Therefore, it should be read carefully in order to avoid any problems.

PRODUCT SAFETY CAUTION

1. When parts replacement is required for servicing, always use the manufacturer's specified replacement.

2. Comply with all caution and safety-related notes on the product display chassis and picture tube.

3. When replacing the component, always be certain that all the components are put back in the place.

4. When servicing display monitor unit, it is required that the provided lead dress is used in the high voltage

circuit area.

5. It is also recommended that shatter proof goggles are worn, when removing installing and handling the

picture tube. People not equipped with the proper precautionary measures mentioned should keep the

picture tube away from body while handling.

6. As for a connector, pick and extract housing with fingers properly since a disconnection and improper

contacts may occur, when wires of the connector are led.

7. Use a proper screwdriver. If you use screwdriver that does not fit, you may damage the screws.

8. X-radiation precaution

This product contains critical electrical and mechanical parts essential for X-ray protection.

Normal anode voltage is 26.0 kV at zero beam picture tube current under AC 100-120V/220-240V input,

and anode voltage must not exceed the voltages shown below under any operation condition.

To measure anode voltage set brightness for very dim picture, and use a high impedance volt meter

between chassis and anode lead and measure high voltage.

If high voltage exceeds the specifications on the chassis schematic diagram, take the necessary

corrective action.

Table MAXIMUM ANODE VOLTAGE

beam current at 0 mA at 0.6 mA at 1.2 mA

A/B Ver. 31.0 kV 30.5 kV 30.5 kV

9. When you degauss the set with an external degaussing coil, you must keep strictly item “ * Notes about

degaussing method “ of ADJUSTMENT Procedures.

CONTENTS

Page No.

USER'S MANUAL ------------------------------------------------------------------------------- 1-1

SERIAL NUMBER INFORMATION ---------------------------------------------------------- 2-1

DISASSEMBLY ----------------------------------------------------------------------------------- 3-1

ADJUSTMENT PROCEDURES -------------------------------------------------------------- 4-1

INSPECTION -------------------------------------------------------------------------------------- 5-1

TROUBLE SHOOTING ------------------------------------------------------------------------- 6-1

CIRCUIT DESCRIPTION ----------------------------------------------------------------------- 7-1

REPLACEMENT PARTS LIST --------------------------------------------------------------- 8-1

BLOCK DIAGRAMS ---------------------------------------------------------------------------- 9-1

SCHEMATIC DIAGRAMS --------------------------------------------------------------------- 10-1

PACKING SPECIFICATION ------------------------------------------------------------------- 11-1

1-1

User's Manual

1. A Version

www.mitsubishidisplay.com

1

9

"

Diamond Pro 930

SB

18" Viewable Image Size

USER’S MANUAL

1-2

Index

Warning.......................................................................................1

Contents ......................................................................................2

Quick Start...................................................................................3

Controls.......................................................................................5

Recommended Use...................................................................... 8

Specifications ............................................................................10

Features ....................................................................................11

Troubleshooting.........................................................................13

References ................................................................................15

Limited Warranty........................................................................16

TCO’95 ...................................................................................... 17

Avertissement............................................................................20

Contenu.....................................................................................21

Mise en marche rapide .............................................................. 22

Commandes ..............................................................................24

Usage recommandé...................................................................28

Fiche technique ......................................................................... 30

Fonctions...................................................................................31

Dépannage ................................................................................ 33

Références ................................................................................35

Garantie limitée .........................................................................36

TCO’95 ...................................................................................... 37

Sicherheitsvorkehrungen ...........................................................39

1-3

1

TO PREVENT FIRE OR SHOCK HAZARDS, DO NOT EXPOSE THIS UNIT TO RAIN OR MOISTURE. ALSO, DO NOT USE

THIS UNIT'S POLARIZED PLUG WITH AN EXTENSION CORD RECEPTACLE OR OTHER OUTLETS UNLESS THE PRONGS

CAN BE FULLY INSERTED.

REFRAIN FROM OPENING THE CABINET AS THERE ARE HIGH VOLTAGE COMPONENTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

WARNING

Canadian Department of Communications Compliance Statement

DOC: This Class B digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

C-UL: Bears the C-UL Mark and is in compliance with Canadian Safety Regulations

according to C.S.A. C22.2 No. 950.

FCC Information

1.

Use the attached specified cables with the

Diamond Pro 930SB-BK

color monitor so as not to

interfere with radio and television reception.

(1)

Please use the supplied power cord or equivalent to ensure FCC compliance.

(2) Shielded captive type signal cable.

Use of other cables and adapters may cause intereference with radio and

television reception.

2.

This equipment has been tested and found to comply with the limits for a Class B digital

device, pursuant to part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference in a residential installation. This

equipment generates, uses, and can radiate radio frequency energy, and, if not installed

and used in accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or

television reception, which can be determined by turning the equipment off and on, the user

is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver

is connected.

• Consult your dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

If necessary, the user should contact the dealer or an experienced radio/television

technician for additional suggestions. The user may find the following booklet, prepared

by the Federal Communications Commission, helpful: ”How to Identify and Resolve

Radio-TV Interference Problems.“ This booklet is available from the U.S. Government

Printing Office, Washington, D.C., 20402, Stock No. 004-000-00345-4.

CAUTION

RISK OF ELECTRIC SHOCK • DO NOT OPEN

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR BACK). NO USER

SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

This

symbol warns user that uninsulated voltage within the unit may have sufficient magnitude to cause

electric shock. Therefore, it is dangerous to make any kind of contact with any part inside this unit.

This symbol alerts the user that important literature concerning the operation and maintenance of this

unit has been included. Therefore, it should be read carefully in order to avoid any problems.

1-4

2

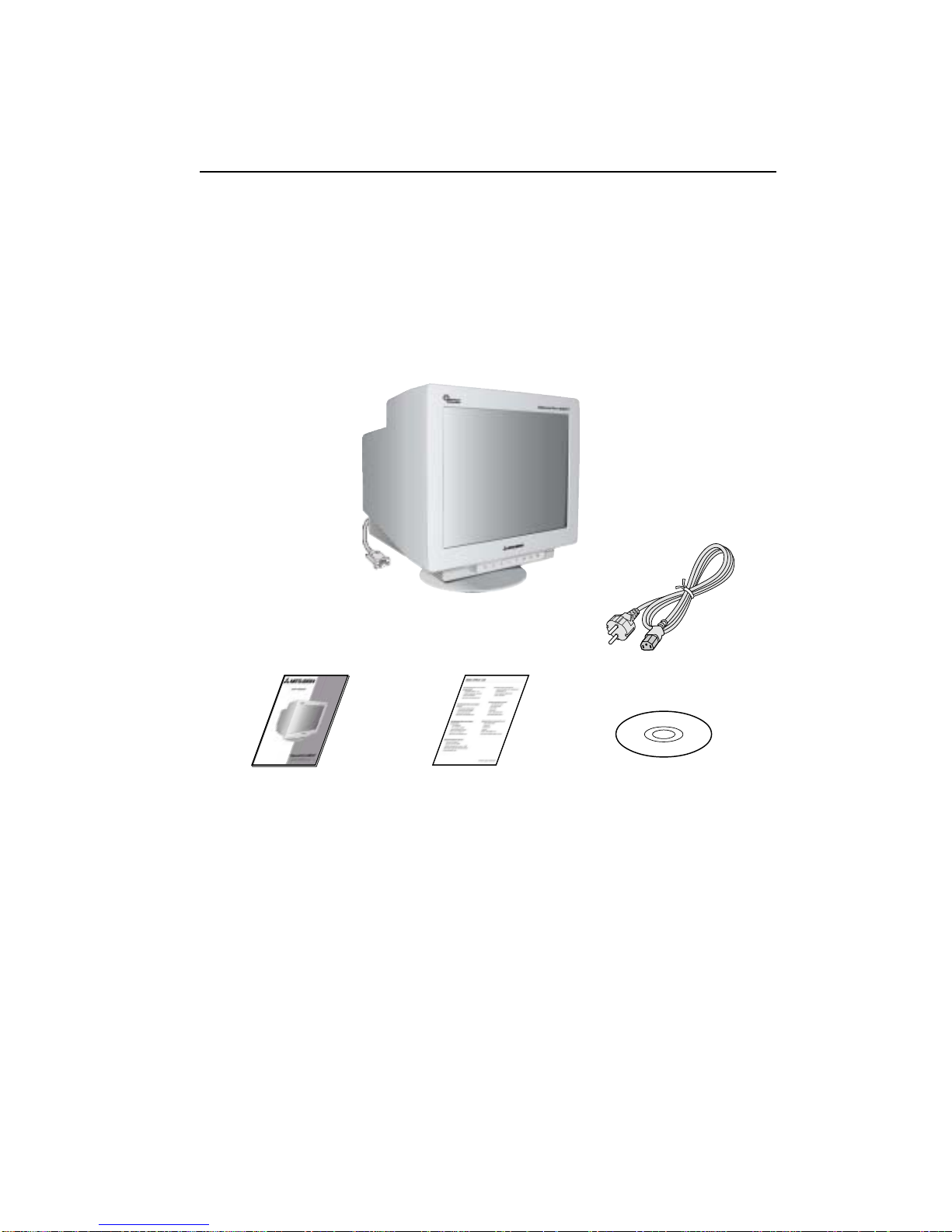

Your new Diamond Pro 930SB monitor box* should contain the

following:

• Diamond Pro 930SBMonitor with tilt/swivel base

• Power Cord

• Captive Signal Cable

• User’s Manual

Contents

Power Cord

User’s Manual

* Remember to save your original box and packing material to transport or ship the monitor.

Captive Signal Cable

1-5

3

Quick Start

Figure A.1

To attach the Diamond Pro monitor to your system, follow these

instructions:

1. Turn off the power to your computer.

2. If necessary, install the display card into your system. For more information,

refer to the display card manual.

3. For the PC: Connect the 15-pin mini D-SUB of the captive signal cable to the

connector of the display card in your system (Figure A.1). Tighten all screws.

For the Mac: Connect the Diamond Pro Macintosh cable adapter (not included) to the monitor connector on the Macintosh (Figure B.1). Attach the

15-pin mini D-SUB end of the captive signal cable to the Diamond Pro

Macintosh cable adapter on the computer (Figure B.1). Tighten all screws.

NOTE: To obtain the Diamond Pro Macintosh cable adapter, call

NEC-Mitsubishi Electronics Display of America, Inc. at (800) 632-4662.

4. For download information on the Windows

®

95/98/Me/2000/XP INF file

for your Diamond Pro monitor, refer to the References section of this User’s

Manual.

5. Connect one end of the power cord to the Dimond Pro monitor and the other

end to the power outlet (Figure C.1).

6. Turn on the monitor (Figure D.1) and the computer.

NOTE: If you have any problems, please refer to the Troubleshooting section of

this User’s Manual.

Figure B.1

Captive Signal Cable

Captive Signal Cable

15-pin

mini

D-SUB

Mac Adapter

(Not Included)

1-6

4

Quick Start –continued

Figure D.1

Power

Cord

Figure C.1

Power Button

Power Indicator

1-7

5

Controls

OSD™ (On-Screen Display) control buttons on the front of the monitor function

as follows:

Main Menu Sub-Menu

EXIT Exits the OSD menu. Exits to the OSD controls

main menu.

NOTE:

Deactivates the OSD menu and activates the OSD menu when the OSD is turned off.

CONTROL Moves the highlighted Moves the highlighted area

area left/right to select left/right to select one of the

one of the sub-menu. controls.

NOTE:

When the OSD menu is off, CONTROL acts as a Hot key for Brightness.

CONTROL Has no function Moves the bar in the – or +

-/+ direction to decrease or

increase the adjustment.

NOTE:

CONTROL button will act as a “Hot Key” for Contrast when the OSM is off and Hot Key is on.

SELECT/ While in OSD, this will enter the Has no function.

SBMODE sub-menu. If OSD is off, this button

will turn on the SuperBright function.

NOTE: When the OSD is off, it will act as the SuperBright (SB) function key.

User can select between SB MODE OFF, SB MODE1, and SB MODE2. The first

time this key is pressed, the current SB Mode is indicated. Within a 3 second

window, if this key is selected again, the SB MODE will change to the next SB

MODE. For example, the current mode is SB MODE OFF, the key is pressed

twice within a 3 second time frame, the SB MODE will change to SB MODE1

and so on. The color temperature at each SB Mode is adjusted by appropriate

color control except for the sRGB mode whose color setting cannot be adjusted.

When the unit is turned off, it will reset to SB off mode.

RESET Resets all the controls within the high- Resets the highlighted control to

lighted menu to the factory setting. the factory setting.

NOTE: When RESET is pressed in the main and sub-menu, a warning window

will appear allowing you to select the reset function.

Brightness/Contrast Controls

Brightness: Adjusts the overall image and background screen brightness.

Contrast: Adjusts the image brightness in relation to the background.

Degauss: Eliminates the buildup of stray magnetic fields which alter the correct scan of the

electron beams and affect the purity of the screen colors, focus and convergence. When

activated, your screen image will jump and waver a bit as the screen is demagnetized.

NOTE:

Please allow a minimum of 20 minutes to elapse between uses of the Degauss Control.

Size and Position Controls

Left/Right: Moves the image horizontally (left or right).

Down/Up: Moves the image vertically (up or down).

Narrow/Wide: Decreases or increases the horizontal size of the image.

Short/Tall: Decreases or increases the vertical size of the image.

1-8

6

Controls –continued

Color Control/AccuColor®Control System

Color presets 1 through 5 selects the desired color setting. The bar is replaced by the

color setting choice from 1, 2, 3, sRGB, 5. Each color setting is adjusted at the factory to

the stated Kelvin degrees. If a setting is adjusted, the name of the setting will change from

Kelvin to Custom. NOTE: sRGB does not allow you to adjust each color.

Red, Green, Blue: AccuColor Control System decreases or increases the monitor’s red,

green or blue color guns depending upon which is selected. The change in color will

appear on screen and the direction (decrease or increase) will be shown by the bars.

sRGB mode: sRGB mode provides the suitable color managed picture image. You

can not change Red, Green and Blue colors, brightness and contrast individually.

Color Temperature Adjustment: Adjusts the color temperature of the screen image.

Geometry Controls

Geometry Controls Menu

The Geometry controls allow you to adjust the curvature or angle of the sides of your display.

In/Out (pincushion): Decreases or increases the curvature of the sides either inward or

outward.

Left/Right (pincushion balance): Decreases or increases the curvature of the sides either to

the left or right.

Tilt (parallelogram): Decreases or increases the tilt of the sides either to the left or right.

Align (trapezoidal): Decreases or increases the bottom of the screen to be the same as the top

.

Rotat

e (raster rotation): Rotates the entire display clockwise or counterclockwise.

Corner Correction: Allows you to adjust the geometry of the corners of your display

—

Top or Bottom.

Tools 1

Moiré Canceler: Moiré is a wavy pattern which can sometimes appear on the screen. The

pattern is repetitive and superimposed as rippled images. When running certain applications,

the wavy pattern is more evident than in others. To reduce moiré, adjust the level by using the

–/+ CONTROL buttons.

Linearity: This selection allows you to adjust the spacing of the area on the screen. The

purpose of this control is to ensure that a one-inch circle is a true one-inch circle wherever

it is on the screen. The best way to determine the vertical linearity is as follows:

• Draw equally spaced horizontal lines using a drawing application that has a ruler.

• Use the Vertical Balance control to adjust the lines near the top and bottom of your screen.

• Use the LINEARITY (VER.) control to adjust the spacing between the lines near the center and

top of your screen.

Convergence: Aligns all three colors (R,G,B) to form a single color (white). The purpose of

this control is to ensure that a white line drawn on the screen is as crisp and clear as

possible

.

•

Use the CONVERGENCE (HOR.) control to adjust the alignment of the white lines in the

left/right

direction.

• Use the CONVERGENCE (VER.) control to adjust the alignment of the white lines in the

up/down

direction.

1-9

7

Controls –continued

GlobalSync® Control: Eliminates picture impurities that may result from the

earth’s magnetic field. While in the sub-menus (TL: Top Left, TR: Top Right, BL:

Bottom Left, or BR: Bottom Right) use the –/+ control buttons to fine tune the

GlobalSync corrections.

NOTE: Mitsubishi recommends that you perform GlobalSync correction while

running a typical application such as a spreadsheet or text document.

Tools 2

Language: OSD controls menus are available in six languages.

OSD Position: You can choose where you would like the OSD controls menu to

appear on your screen. Selecting OSD Position allows you to manually adjust the

OSD controls menu left, right, up or down.

OSD Turn Off: The OSD controls menu will stay on as long as it is in use. In the

OSD Turn Off sub-menu, you can select how long the monitor waits after the last

touch of a button for the OSD controls menu to disappear. The preset choice is in

5 seconds step between 5–120 seconds.

O

SD Lock Out: This control completely locks out access to all OSD controls func-

tions except Brightness and Contrast. When attempting to activate OSD controls

while in the lock out mode, a screen will appear indicating that OSD controls are

locked out. To activate the OSD Lock Out function, press SELECT, then press + and

hold down simultaneously. To deactivate the OSD Lock Out, press SELECT, then

press + and hold down simultaneously.

IPM™ System Off Mode:

Enable: The IPM System works normally and all

stages of energy savings are utilized.

Disable: The Off Mode reset

NOTE:

For standard systems and graphics boards, keep the factory setting at ENABLE.

NOTE:

Don’t keep the Diamond Pro monitor on when ‘No Signal’ is applied. This could cause

image burn in on the screen due to the ‘No Signal’ message being displayed.

EdgeLock™ Control: Operating your monitor at a nonstandard timing may cause

images to appear darker than normal or have color distortion. Use of the

EdgeLock control will adjust images to their normal state.

Hot Key: This selection allows you to use as brightness control and –/+

as contrast control.

Factory Preset: Selecting Factory Preset allows you a reset most OSD

™

control

settings back to the factory settings. A warning statement will appear to confirm

that you do want to reset ALL settings. Individual settings can be reset by highlighting the control to be reset and pressing the RESET button.

Information

Display Mode: Indicates the current mode and frequency setting of the monitor.

Monitor Info: Indicates the model and serial numbers of your monitor.

Refresh Notifier: A message will advise you if the refresh rate of the signal being

applied to the monitor by the computer is too low. For further information, please

refer to your display card or system manual.

1-10

8

Safety Precautions and Maintenance

FOR OPTIMUM PERFORMANCE, PLEASE NOTE THE

FOLLOWING WHEN SETTING UP AND USING

THE DIAMOND PRO COLOR MONITOR:

• DO NOT OPEN THE MONITOR. There are no user serviceable parts inside and opening or

removing covers may expose you to dangerous shock hazards or other risks. Refer all servicing to

qualified service personnel.

• Do not spill any liquids into the cabinet or use your monitor near water.

• Do not insert objects of any kind into the cabinet slots, as they may touch dangerous voltage

points, which can be harmful or fatal or may cause electric shock, fire or equipment failure.

• Do not place any heavy objects on the power cord. Damage to the cord may cause shock or fire.

• Do not place this product on a sloping or unstable cart, stand or table, as the monitor may fall,

causing serious damage to the monitor.

•

Keep the monitor away from high capacity transformers, electric motors and other devices such as

external speakers or fans, which may create strong magnetic fields.

• If possible, position the monitor so that it is facing the east to minimize the effects of the earth’s

magnetic field.

• Changing the direction of the monitor while it is powered on may cause image discoloration. To

correct this, turn the monitor off for 20 minutes before powering it back on.

• When operating the Diamond Pro 930

SB

with its AC 100-240V worldwide power supply, use a

power supply cord that matches the power supply voltage of the AC power outlet being used. The

power supply cord you use must have been approved by and comply with the safety standards of

your country.

• In UK, use a BS-approved power cord with molded plug having a black (5A) fuse installed for use with

this monitor. If a power cord is not supplied with this monitor, please contact your supplier.

Cleaning Your Monitor

A special coating is provided on the glass (CRT) surface of this monitor to reduce a reflection and

static electricity on the glass surface. Due to the delicate coating on the glass surface, use a lint-free,

non-abrasive cloth (cotton or equivalent) and a non-alcohol, neutral, non-abrasive cleaning solution

to minimize dust. If the screen requires more than a light cleaning, apply a soft neutral detergent and

water directly to a soft cloth and use it upon wringing water, to clean the glass surface. Clean your

monitor regularly.

CAUTION:

The following agents will cause damage to the CRT when cleaning the glass surface:

Benzene, thinner, acid/alkaline detergent, alcohol detergent, detergent with abrasive powder,

detergent with anti-static agent, detergent for cleaning.

Immediately unplug your monitor from the wall outlet and refer servicing to qualified service personnel

under the following conditions:

• When the power supply cord or plug is damaged.

• If liquid has been spilled, or objects have fallen into the monitor.

• If the monitor has been exposed to rain or water.

• If the monitor has been dropped or the cabinet damaged.

• If the monitor does not operate normally by following operating instructions.

• Allow adequate ventilation around the monitor so that heat can properly

dissipate. Do not block ventilated openings or place the monitor near a

radiator or other heat sources. Do not put anything on top of monitor.

• The power cable connector is the primary means of detaching the system

from the power supply. The monitor should be installed close to a power

outlet which is easily accessible.

• Handle with care when transporting. Save packaging for transporting.

Recommended Use

CAUTION

1-11

9

CORRECT PLACEMENT AND ADJUSTMENT OF THE MONITOR

CAN REDUCE EYE, SHOULDER AND NECK FATIGUE. CHECK THE

FOLLOWING WHEN YOU POSITION THE MONITOR:

Recommended Use –continued

• Adjust the monitor height so that the top of

the screen is at or slightly below eye level.

Your eyes should look slightly downward

when viewing the middle of the screen.

• Position your monitor no closer than 16 inches

and no further away than 24 inches from your

eyes. The optimal distance is 20 inches.

• Rest your eyes periodically by focusing on

an object at least 20 feet away. Blink often.

• Position the monitor at a 90° angle to

windows and other light sources to minimize

glare and reflections. Adjust the monitor tilt so that ceiling lights do not reflect

on your screen.

• If reflected light makes it hard for you to see your screen, use an anti-glare filter.

• Adjust the monitor’s brightness and contrast controls to enhance readability.

• Use a document holder placed close to the screen.

• Position whatever you are looking at most of the time (the screen or

reference material) directly in front of you to minimize turning your head

while you are typing.

• Get regular eye checkups.

Ergonomics

To realize the maximum ergonomics benefits, we recommend the following:

• Adjust the Brightness until the background raster disappears

• Do not position the Contrast control to its maximum setting

• Use the preset Size and Position controls with standard signals

• Use the preset Color Setting and Sides Left/Right controls

• Use non-interlaced signals with a vertical refresh rate between 75-160Hz

• Do not use primary color blue on a dark background, as it is difficult to see

and may produce eye fatigue due to insufficient contrast

For more detailed information on setting up a healthy work environment, write the

American National Standard for Human Factors Engineering of Visual Display Terminal

Workstations – ANSI-HFS Standard No. 100-1988 – The Human Factors Society, Inc.

P.O. Box 1369, Santa Monica, California 90406.

1-12

10

Monitor Diamond Pro 930SBNotes

Specifications Monitor

Picture Tube Diagonal: 19 inch 90° deflection, 0.24 mm grille pitch,

Viewable Image Size: 18 inch medium short persistence phosphor,

Radius: 50,000 mm aperture grille CRT, multi-layered,

anti-static screen coating, dark-tint screen

and OptiClear® screen.

Input Signal Video: ANALOG 0.7 Vp-p/75 Ohms

Sync: Separate sync. TTL Level

Horizontal sync. Positive/Negative

Vertical sync. Positive/Negative

Composite sync. (Positive/Negative) (TTL Level)

Display Colors Analog input: Unlimited number of Colors Depends on display card used.

Synchronization Horizontal: 30.0 kHz to 110.0 kHz Automatically

Range Vertical: 50 Hz to 160 Hz Automatically

Resolutions Supported 640 x 480 @ 60 to 160 Hz

Some systems may not support

Resolution based on

horizontal and

800 x 600 @ 50 to 160 Hz

all modes listed.

vertical frequencies only

832 x 624 @ 50 to 160 Hz

1024 x 768 @ 50 to 132 Hz

NEC-Mitsubishi Electronics Display cites

1152 x 870 @ 50 to 118 Hz

recommended resolution at 85 Hz for

1280 x 1024 @ 50 to 101 Hz ...................

optimal display performance.

1600 x 1200 @ 50 to 87 Hz

1792 x 1344 @ 50

to

78 Hz

1800 x 1440 @ 50

to

73 Hz

1856 x 1392 @ 50

to

75 Hz

1920 x 1440 @ 50 to 73 Hz

Active Display Area Horizontal:

356 mm/14.0 inches Dependent upon signal timing used,

(Factory Setting) Vertical:

266 mm/10.5 inches and does not include border area.

Active Display Area

366 mm/14.4 inches Dependent upon signal timing used,

(Full Scan)

266 mm/10.5 inches and does not include border area.

Power Supply

AC 100 – 240 V, 50-60 Hz

Current Rating 2.2A @ 100-240 V

Dimensions

442 mm (W) x 443 mm (H) x 447.5 mm (D)

17.4 inches (W) x 17.4 inches (H) x 17.6 inches (D)

Weight 23.8 kg

52.5 lbs

Environmental Considerations

Operating Temperature: +5°C to +35°C / +50°F to +90°F

Humidity: 10% to 90%

Feet: 0 to 10,000 Feet

Storage Temperature: -20°C to +60°C / -4°F to +140°F

Humidity: 10% to 90%

Feet: 0 to 50,000 Feet

NOTE: Technical specifications are subject to change without notice.

Specifications

1-13

11

Features

SuperBrightTM Diamondtron® CRT: This patented flat aperture grille CRT delivers

an exceptional viewing experience with unprecedented brightness and contrast

and a virtually flat image that reduces distortion and glare so that what you see

on-screen is what you get on your printed output. The state-of-the-art Mitsubishi

U-NX

TM

electron gun and tight 0.24mm grille pitch delivers precise focus for

crisp, clear text and images.

SuperBright

TM

Mode: With the simple touch of a button, you can achieve up to

two times the normal brightness level. This function enhances the crispness of

images for clarity-conscious applications such as graphics, animation and video.

Super Bright Mode OFF: for text based images (normal use)

Super Bright Mode-1 ON: for images

Super bright Mode-2 ON: for moving image such as DVD movies

OptiClear® Screen Surface: Further reduces reflection and glare and increases

contrast without sacrificing focus level, clarity or brightness.

Dual Dynamic Beam Focus: Provides precise, continuous focus adjustments of the

electron beams and optimum image quality, even to the far edges of the screen.

AccuColor

®

Control System: Allows you to change between five color settings on

your display to match your personal preference. The sRGB-enabled color matching setting found within AccuColor helps achieve a consistent color environment

with other sRGB-enabled hardware and software applications.

On-Screen Diaplay Controls (OSD) : Allows you to quickly and easily adjust all

elements of your screen image via simple to use on-screen menus.

ErgoDesign

®

Features: Enhances human ergonomics to improve the working

environment, protect the health of the user and save money. Examples include

OSD controls for quick and easy image adjustments, tilt/swivel base for preferred angle of vision, space-conscious cabinet design and compliance with

MPRII guidelines for lower emissions.

Plug and Play: The Microsoft

®

solution with the Windows® 95/98/Me/2000/XP

operating system facilitates setup and installation by allowing the monitor to send

its capabilities (such as screen size and resolutions supported) directly to your

computer, automatically optimizing display performance.

Intelligent Power Manager (IPM™) System: Provides innovative power-saving

methods that allow the monitor to shift to a lower power consumption level when

on but not in use, saving two-thirds of your monitor energy costs, reducing

emissions and lowering the air conditioning costs of the workplace.

Reduced Magnetic Field™ Technology: Reduces magnetic and alternating

electric field emissions and static electricity, addressing ergonomic concerns

regarding potential risks from extended computer monitor use.

1-14

12

Multiple Frequency Technology: Automatically adjusts monitor to the display

card’s scanning frequency, thus displaying the resolution required.

FullScan™ Capability: Allows you to use the entire screen area in most

resolutions, significantly expanding image size.

GlobalSync®/Corner Purity Control: Allows you to easily adjust impurities in the

four corners of your monitor.

Convergence Control: Allows you to adjust the horizontal and vertical convergence of the top and bottom area to ensure that a white line drawn on the screen

is as crisp and clear as possible.

Copyright 2002 by NEC-Mitsubishi Electronics Display of America, Inc.

Features –continued

1-15

13

Troubleshooting

No picture

• Display card should be completely seated in its slot.

• Power Button and computer power switch should be in the ON position.

• Signal cable should be completely connected to display card/computer.

• Check connector for bent or pushed-in pins.

Image is scrolling or unstable

• Signal cable should be completely attached to the computer.

• Check pin assignments and signal timings of the monitor and your display card with

respect to recommended timings and pin assignments.

•

If the Macintosh cable adapter is used, check for proper connection or make sure the

display card is Macintosh compatible and that the card is properly seated in the computer

.

LED on monitor is not lit

(no green, orange color can be seen)

• Power Switch should be in the ON position and power cord should be connected.

LED on monitor is flashing and/or dissapears

• Contact Customer Service at (800) 632-4662.

Picture is fuzzy or color looks blotchy

• If the picture is fuzzy, adjust the Moiré Canceler control. If the color looks

blotchy, adjust the Brightness, Contrast or GlobalSync

®

controls, or use the

EdgeLock

™

control to change modes.

• Access the Degauss Control through OSD™ controls. Activate the Degauss Control.

CAUTION: A minimum interval of 20 minutes should elapse before the Deguass

Control is used a second time when not switching between modes.

Picture bounces or a wavy pattern is present in the picture

•

Move electrical devices that may be causing electrical interference away from the monitor.

• See inside cover of User’s Manual for FCC information.

Edges of the display image are not square

• Use the OSD Geometry Controls to straighten the edges.

• If possible, position the front of the monitor facing east.

Display image is not centered, too small, or too large

• Use the OSD Size and Position Controls to adjust the image.

Thin lines appear on your screen

• Thin lines are normal for an aperture grille CRT and are not a malfunction.

These are shadows from the damper wires used to stabilize the aperture grille and

are most noticeable when the screen’s background is light (usually white).

Black vertical lines are visible on the screen

• Thin vertical black lines on one or both sides of the screen. This minor condition is

caused by grille element overlap which can occur during shipping.

• Position an open white window over the affected area of the screen and maximize

the brightness and contrast controls. This will cause localized heating of the overlap

which will clear in a few minutes. Be sure to readjust the brightness and contrast

controls back to the normal viewing level after this procedure.

1-16

14

Attention message displayed

• Check the inputted signal.

NOTE:The attention message may display when power on

the Diamond Pro monitor. In case that the attention

message disappear after in a little while, there is no

problem at the inputted signal.

Self check function

• Press any control button on the front of monitor when

you see a problem on the screen.

- In case that all R, G and B colors are seen in the

diagnosis message, the Diamond Pro monitor has no

problem. In case that some color is lack in the

message, the Diamond Pro monitor has a problem.

Contact Customer Service.

- In case that no diagnosis message displayed with LED

lit in green, power off the computer.

• Check the signal cable and computer in case that the diagnosis message

displayed.

• Contact Customer Service in case that the diagnosis message still does not

display.

- In case that no diagnosis message displayed with LED lit in orange.

• Check the signal cable and computer.

• Move the mouse or press any key on the keyboard.

- In case that no diagnosis message displayed with LED lit in green and

orange.

• Contact Customer Service.

Troubleshooting –continued

1-17

15

References

NEC-Mitsubishi Monitor Customer Service & Support

Customer Service and Technical Support (800) 632-4662

Fax (801) 907-3939

Parts and Accessories/Macintosh Cable Adapter:

(888) NEC-MITS

[888-632-6487]

Customer Service Policies & Processes: http://www.necmitsubishi.com/

css/ServicePolicies/ServicePolicies.htm

Online Technical Support Knowledge Base: http://www.necmitsubishi.com/

css/knowledgebase.cfm

Customer Service & Technical Support Email: http://www.necmitsubishi.com/

css/techform.htm

Sales and Product Information

Sales Information Line (888) NEC-MITS [888-632-6487]

Canadian Customers (866) 771-0266, Ext#: 4037

Government Sales (800) 284-6320

Government Sales email gov@necmitsubishi.com

Rebate Status Information

NEC Rebate Status www.rebatesHQ.com or 866-765-5696

Mitsubishi Rebate Status www.rebatesHQ.com or 877-405-4692

Electronic Channels

World Wide Web: http://www.necmitsubishi.com

Product Registration: http://www.necmitsubishi.com/productregistration

European Operations: http://www.nec-mitsubishi.com

Windows® 95/98/Me/2000/XP INF File:

http://

www.necmitsubishi.com and select

“Drivers and Downloads”

1-18

16

NEC-Mitsubishi Electronics Display of America, Inc. (hereinafter “NMD-A”) warrants this

Product to be free from defects in material and workmanship and, subject to the conditions set

forth below, agrees to repair or replace (at NMD-A’s sole option) any part of the enclosed unit

which proves defective for a period of three (3) years from the date of first consumer purchase.

Spare parts are warranted for ninety (90) days. Replacement parts or unit may be new or

refurbished and will meet specifications of the original parts or unit.

This warranty gives you specific legal rights and you may also have other rights, which vary

from state to state. This warranty is limited to the original purchaser of the Product and is not

transferable. This warranty covers only NMD-A-supplied components. Service required as a

result of third party components is not covered under this warranty. In order to be covered

under this warranty, the Product must have been purchased in the U.S.A. or Canada by the

original purchaser. This warranty only covers Product distribution in the U.S.A. or Canada by

NMD-A No warranty service is provided outside of the U.S.A. or Canada. Proof of Purchase

will be required by NMD-A to substantiate date of purchase. Such proof of purchase must be

an original bill of sale or receipt containing name and address of seller, purchaser, and the

serial number of the product.

It shall be your obligation and expense to have the Product shipped, freight prepaid, or

delivered to the authorized reseller from whom it was purchased or other facility authorized

by NMD-A to render the services provided hereunder in either the original package or a

similar package affording an equal degree of protection. All Products returned to NMD-A for

service MUST have prior approval, which may be obtained by calling 1-800-632-4662. The

Product shall not have been previously altered, repaired, or serviced by anyone other than a

service facility authorized by NMD-A to render such service, the serial number of the product

shall not have been altered or removed. In order to be covered by this warranty the Product

shall not have been subjected to displaying of fixed images for long periods of time resulting

in image persistence (afterimage effects), accident, misuse or abuse or operated contrary to

the instructions contained in the User’s Manual. Any such conditions will void this warranty.

NMD-A SHALL NOT BE LIABLE FOR DIRECT, INDIRECT, INCIDENTAL, CONSEQUENTIAL,

OR OTHER TYPES OF DAMAGES RESULTING FROM THE USE OF ANY NMD-A PRODUCT

OTHER THAN THE LIABILITY STATED ABOVE. THESE WARRANTIES ARE IN LIEU OF ALL

OTHER WARRANTIES EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED TO, THE

IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

SOME STATES DO NOT ALLOW THE EXCLUSION OF IMPLIED WARRANTIES OR THE

LIMITATION OR EXCLUSION OF LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES SO THE ABOVE EXCLUSIONS OR LIMITATIONS MAY NOT APPLY TO YOU.

This Product is warranted in accordance with the terms of this limited warranty. Consumers

are cautioned that Product performance is affected by system configuration, software, the

application, customer data, and operator control of the system, among other factors. While

NMD-A Products are considered to be compatible with many systems, specific functional

implementation by the customers of the Product may vary. Therefore, suitability of a Product

for a specific purpose or application must be determined by consumer and is not warranted

by NMD-A.

For the name of your nearest authorized NEC-Mitsubishi Electronics Display of America

service facility, contact NEC-Mitsubishi Electronics Display of America at 1-800-632-4662.

Limited Warranty

1-19

17

TCO’95

Diamond Pro 930SB Black Model

Congratulations! You have just purchased a TCO’95 approved and

labeled product! Your choice has provided you with a product developed for professional use. Your purchase has also contributed to

reducing the burden on the environment and also, to the further

development of environmentally adapted electronics products.

Why do we have environmentally labelled computers?

In many countries, environmental labelling has become an established method for encouraging the adaptation of goods and services to the environment. The main problem, as far as

computers and other electronics equipment are concerned, is that environmentally harmful

substances are used both in the products and during the manufacturing. Since it has not been

possible for the majority of electronics equipment to be recycled in a satisfactory way, most

of these potentially damaging substances sooner or later enter Nature.

There are also other characteristics of a computer, such as energy consumption levels, that are

important from the viewpoints of both the work (Internal) and natural (external) environments.

Since all methods of conventional electricity generation have a negative effect on the

environment (acidic and climate-influencing emissions, radioactive waste, etc.), it is vital to

conserve energy. Electronics equipment in offices consume an enormous amount of energy

since they are often left running continuously.

What does labelling involve?

This product meets the requirements for the TCO’95 scheme which provides for international and

environmental labelling of personal computers. The labelling scheme was developed as a joint

effort by the TCO (The Swedish Confederation of Professional Employees), Naturskyddsforeningen

(The Swedish Society for Nature Conservation) and NUTEK (The National Board for Industrial and

Technical Development in Sweden).

The requirements cover a wide range of issues: environment, ergonomics, usability, emission of

electrical and magnetic fields, energy consumption and electrical and fire safety.

The environmental demands concern restrictions on the presence and use of heavy metals,

brominated and chlorinated flame retardants, CFCs (freons) and chlorinated solvents, among other

things. The product must be prepared for recycling and the manufacturer is obliged to have an

environmental plan which must be adhered to in each country where the company implements its

operational policy. The energy requirements include a demand that the computer and/or display,

after a certain period of inactivity, shall reduce its power consumption to a lower level in one or

more stages. The length of time to reactivate the computer shall be reasonable for the user.

Labelled products must meet strict environmental demands, for example, in respect of the reduction

of electric and magnetic fields, physical and visual ergonomics and good usability.

TCO’95 is a co-operative project between TCO (The Swedish Confederation of Professional

Employees), Naturskyddsforeningen (The Swedish Society for Nature Conservation) and NUTEK

(The National Board for Industrial and Technical Development in Sweden).

Environmental Requirements

Brominated flame retardants

Brominated flame retardants are present in printed circuit boards, cables, wires, casings and

housings. In turn, they delay the spread of fire. Up to thirty percent of the plastic in a computer casing

can consist of flame retardant substances. These are related to another group of environmental

1-20

18

toxins, PCBs, which are suspected to give rise to similar harm, including reproductive damage in

fisheating birds and mammals, due to the bio-accumulative* processes. Flame retardants have

been found in human blood and researchers fear that disturbances in foetus development may

occur.

TCO’95 demand requires that plastic components weighing more than 25 grams must not contain

organically bound chlorine and bromine.

Lead**

Lead can be found in picture tubes, display screens, solders and capacitors. Lead damages the

nervous system and in higher doses, causes lead poisoning.

TCO’95 requirement permits the inclusion of lead since no replacement has yet been developed.

Cadmium**

Cadmium is present in rechargeable batteries and in the colourgenerating layers of certain

computer displays. Cadmium damages the nervous system and is toxic in high doses.

TCO’95 requirement states that batteries may not contain more than 25 ppm (parts per million) of

cadmium. The colourgenerating layers of display screens must not contain any cadmium.

Mercury**

Mercury is sometimes found in batteries, relays and switches, Mercury damages the nervous system

and is toxic in high doses.

TCO’95 requirement states that batteries may not contain more than 25 ppm (parts per million) of

mercury. It also demands that no mercury is present in any of the electrical or electronics

components concerned with the display unit. Mercury is, for the time being, permitted in the back

light system of flat panel monitors as there today is no commercially available alternative. TCO aims

on removing this exception when a mercury free alternative is available.

CFCs (freons)

CFCs (freons) are sometimes used for washing printed circuit boards and in the manufacturing of

expanded foam for packaging. CFCs break down ozone and thereby damage the ozone layer in

the stratosphere, causing increased reception on Earth of ultraviolet light with consequent increased

risks of skin cancer (malignant melanoma).

The relevant TCO’95 requirement; Neither CFCs nor HCFCs may be used during the manufacturing

of the product or its packaging.

*Bio-accumulative is defined as substances which accumulate within living organisms.

**Lead, Cadmium and Mercury are heavy metals which are Bio-accumulative.

To obtain complete information on the environmental criteria document, order from:

TCO Development Unit

SE-114 94 Stockholm

SWEDEN

FAX Number: +46 8 782 92 07

E-mail (Internet): development@tco.se

You may also obtain current information on TCO’95 approved and labelled products by

visiting their website at:

http://www.tcodevelopment.com

TCO’95 –continued

1-21

PROPRIETARY NOTICE AND LIABILITY DISCLAIMER

The information disclosed in this document, including all designs and related materials, is the valuable property of

NEC-Mitsubishi Electronics Display of America and/or its licensors, as appropriate, reserve all patent, copyright and

other proprietary rights to this document, including all design, manufacturing, reproduction, use and sales rights thereto,

except to the extent said rights are expressly granted to others.

The NEC-Mitsubishi Electronics Display of America product(s) discussed in this document are warranted in accordance

with the terms of the Limited Warranty Statement accompanying each product. However, actual performance of each

such product is dependent upon factors such as system configuration, customer data and operator control. Since

implementation by customers of each product may vary, the suitability of specific product configurations and applications

must be determined by the customer and is not warranted by NEC-Mitsubishi Electronics Display of America.

To allow for design and specification improvements, the information in this document is subject to change at any time

without notice. Reproduction of this document or portions thereof without prior approval of NEC-Mitsubishi Electronics

Display of America is prohibited.

DECLARATION OF CONFORMITY

This device complies with Part 15 of FCC Rules. Operation is subject to the following two conditions. (1) This device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

U.S. Responsible Party: NEC-Mitsubishi Electronics Display of America, Inc.

Address: 1250 N. Arlington Heights Road

Itasca, Illinois 60143

Tel. No.: (630) 467-3000

Type of Product: Computer Monitor

Equipment Classification: Class B Peripheral

Models: N2901

We hereby declare that the equipment specified above

conforms to the technical standards as specified in the FCC Rules.

Windows is a registered trademark of Microsoft Corporation.

E

NERGY STAR

is a U.S. registered trademark. All other brands and product

names are trademarks or registered trademarks of their respective owners.

As an

E

NERGY STAR

®

Partner, NEC-Mitsubishi Electronics Display of America, Inc. has determined that this product meets the

E

NERGY

S

TAR

guidelines for energy efficiency. The

E

NERGY STAR

emblem does not represent EPA endorsement of any product or service.

Part No. 15501391

Printed in China

Mitsubishi Diamond Pro 930

SB

1-22

2. B Version

User’s Manual

www.nec-mitsubishi.com

Diamond Pro 930Diamond Pro 930

Diamond Pro 930Diamond Pro 930

Diamond Pro 930

SBSB

SBSB

SB

1-23

Declaration of the Manufacturer

NEC-Mitsubishi Electric Visual

Systems Corporation

686-1, Nishioi Oi-Machi

Ashigarakami-gun

Kanagawa 258-8533, Japan

We hereby certify that the

colour monitor Diamond Pro 930

SB

is in compliance with

Council Directive 73/23/EEC:

– EN 60950

Council Directive 89/336/EEC:

EN 55022

– EN 61000-3-2

– EN 61000-3-3

– EN 55024

and marked with

2 User’s Manual

ENERGYSTAR Product

As an E

NERGYSTAR

Partner, NEC-Mitsubishi Electronics Display of America, Inc. has determined that this

product meets the E

NERGYSTAR

guidelines for energy efficiency. The E

NERGYSTAR

emblem does not represent

EPA endorsement of any product or service.

IBM is registered trademark of International Business Machines Corporation.

Apple and Macintosh are registered trademarks of Apple Computer Inc.

Microsoft and Windows are registered trademarks of the Microsoft Corporation.

E

NERGYSTAR

is a U.S. registered trademark.

All other trademarks or registered trademarks are property of their respective owners.

1-24

CAUTION

CAUTION: TO REDUCE THE RISK OF ELECTRIC SHOCK, DO NOT REMOVE COVER (OR BACK). NO USER SERVICEABLE PARTS INSIDE. REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

RISK OF ELECTRIC SHOCK • DO NOT OPEN

This symbol warns user that uninsulated voltage within the unit may have sufficient magnitude to cause

electric shock. Therefore, it is dangerous to make any kind of contact with any part inside this unit.

This symbol alerts the user that important literature concerning the operation and maintenance of this unit

has been included. Therefore, it should be read carefully in order to avoid any problems.

Canadian Department of Communications Compliance Statement

DOC: This Class B digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

C-UL: Bears the C-UL Mark and is in compliance with Canadian Safety Regulations

according to C.S.A. C22.2 No. 950.

FCC Information

1. Use the attached specified cables with the Diamond Pro 930

SB

colour monitor so as not to interfere with

radio and television reception.

(1) Please use the supplied power cord or equivalent to ensure FCC compliance.

(2) Shielded captive type signal cable.

Use of other cables and adapters may cause intereference with radio and television reception.

2. This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses, and can radiate radio frequency

energy, and, if not installed and used in accordance with the instructions, may cause harmful interference

to radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult your dealer or an experienced radio/TV technician for help.

Changes or modifications not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

If necessary, the user should contact the dealer or an experienced radio/television technician for additional

suggestions. The user may find the following booklet, prepared by the Federal Communications Commission,

helpful: ”How to Identify and Resolve Radio-TV Interference Problems.“ This booklet is available from the U.S.

Government Printing Office, Washington, D.C., 20402, Stock No. 004-000-00345-4.

Diamond Pro 930

SB

3

TO PREVENT FIRE OR SHOCK HAZARDS, DO NOT EXPOSE THIS UNIT TO RAIN OR MOISTURE. ALSO, DO NOT USE

THIS UNIT'S POLARIZED PLUG WITH AN EXTENSION CORD RECEPTACLE OR OTHER OUTLETS UNLESS THE

PRONGS CAN BE FULLY INSERTED.

EFRAIN FROM OPENING THE CABINET AS THERE ARE HIGH VOLTAGE COMPONENTS INSIDE. REFER SERVICING

TO QUALIFIED SERVICE PERSONNEL.

WARNING

1-25

4 User’s Manual

Contents

* Remember to save your original box and packing material to transport or ship the monitor.

CD-ROM

Your new Diamond Pro 930

SB

monitor box* should contain the following:

• Diamond Pro 930

SB

Monitor with tilt/swivel base

• Power Cord

• Captive Signal Cable

• User’s Manual

• Sales Office List

• CD ROM with Setup Software, complete User’s Manual and other helpful files.

To see the User’s Manual, Acrobat Reader 4.0 must be installed on your PC.

Power Cord

User’s Manual

Captive Signal Cable

Sales Office List

1-26

Diamond Pro 930SB5

Quick Start

To attach the Diamond Pro 930SB monitor to your system, follow these instructions:

1. Turn off the power to your computer.

2. If necessary, install the display card into your system. For more information, refer to the display card

manual.

3. For the PC: Connect the 15-pin mini D-SUB of the captive signal cable to the connector of the display card

in your system (Figure A.1). Tighten all screws.

For the Mac: Connect the Diamond Pro 930

SB

Macintosh cable adapter (not included) to the monitor

connector on the Macintosh (Figure B.1). Attach the 15-pin mini D-SUB end of the captive signal cable to

the Diamond Pro 930

SB

Macintosh cable adapter on the computer (Figure B.1). Tighten all screws.

4. Connect one end of the power cord to the Diamond Pro 930

SB

monitor and the other end to the power

outlet (Figure C.1).

5. Turn on the monitor (Figure D.1) and the computer.

6. The Windows 95/98/2000/Me/XP INF file for your monitor can be found on the CD-ROM, delivered with the

monitor.

NOTE: If you have any problems, please refer to the Troubleshooting section of this User’s Manual.

Figure A.1

15-pin

mini

D-SUB

Captive Signal Cable

Figure B.1

Mac Adapter

(Not Included)

Captive Signal Cable

1-27

Quick Start

– continued

6 User’s Manual

Figure C.1

Power Outlet

Power

Cord

Power Button

Figure D.1

1-28

Controls

When Hot key function is set to “ON”, accessing the OSD is only possible with the “EXIT” button.

Brightness/Contrast Controls

Brightness: Adjusts the overall image and background screen brightness.

Contrast: Adjusts the image brightness in relation to the background.

Degauss: Eliminates the buildup of stray magnetic fields which alter the correct scan of the electron beams

and affect the purity of the screen colours, focus and convergence. When activated, your screen image will

jump and waver a bit as the screen is demagnetized.

Caution: Please allow a minimum of 20 minutes to elapse between uses of the Degauss Control.

Diamond Pro 930

SB

7

/

Y

Y

OSM (On-Screen Manager) control buttons on the front of the monitor function as follows:

To access OSM press any of the control buttons ( EXIT,

Y

,Y, –, +).

uneMniaMuneM-buS

TIXE .unemMSOehtstixEslortnocMSOehtotstixE

.unemniam

:ETON .ffodenrutsiMSOehtnehwunemMSOehtsetavitcadnaunemMSOehtsetavitcaeD

LORTNOC dethgilhgihehtsevoM

tcelesotthgir/tfelaera

.sunem-busehtfoeno

aeradethgilhgihehtsevoM

ehtfoenotcelesotthgir/tfel

.slortnoc

:ETON ”NO“tesyektoHhtiwssenthgirBtsujdaotdnaunemMSOehtsetavitcaeD

LORTNOC

+/–

.noitcnufonsaH+ro–ehtnirabehtsevoM

roesaercedotnoitcerid

.tnemtsujdaehtesaercni

:ETON ”NO“tesyektoHhtiwtsartnoCtsujdaotdnaunemMSOehtsetavitcaeD

/TCELES

EDOMBS

sehctiws,DSOtuohtiW

FFO/NOedoMthgirBrepuS

unembussretne,DSOhtiW

.noitcnufonsaH

:ETON tcelesnacresU.yeknoitcnuf)BS(thgirBrepuSehtsatcalliwti,ffosiMSOehtnehW

siyeksihtemittsrifehT.2EDOMBSdna,1EDOMBS,FFOEDOMBSneewteb

siyeksihtfi,wodniwdnoces3anihtiW.detacidnisiedoMBStnerruceht,desserp

eht,elpmaxeroF.EDOMBStxenehtotegnahclliwEDOMBSeht,niagadetceles

,emarfemitdnoces3anihtiweciwtdesserpsiyekeht,FFOEDOMBSsiedomtnerruc

hcaetaerutarepmetrolocehT.noosdna1EDOMBSotegnahclliwEDOMBSeht

esohwedomBGRsehtroftpecxelortnocrolocetairporppaybdetsujdasiedoMBS

.edomffoBSotteserlliwti,ffodenrutsitinuehtnehW.detsujdaebtonnacgnittesroloc

:FFOedoMthgirBrepuS )esulamron(segamidesabtxetrof

:NO1-edoMthgirBrepuS segamirof

:NO2-edoMthgirbrepuS seivomDVDsahcusegamignivomrof

TESER nihtiwslortnocehtllasteseR

unemdethgilhgiheht

.gnittesyrotcafehtot

lortnocdethgilhgihehtsteseR

.gnittesyrotcafehtot

:ETONnehW TESER raeppalliwwodniwgninrawa,unem-busdnaniamehtnidesserpsi

.noitcnufteserehtlecnacotuoygniwolla

1-29

Controls

– continued

8 User’s Manual

Size and Position Controls

Left/Right: Moves the image horizontally (left or right).

Down/Up: Moves the image vertically (up or down).

Narrow/Wide: Decreases or increases the horizontal size of the image.

Short/Tall: Decreases or increases the vertical size of the image.

Color Control System

Colour presets selects the desired colour setting. The bar is replaced by the colour setting choice. Each

colour setting is adjusted at the factory to the stated Kelvin. If a setting is adjusted, the name of the setting

will change from Kelvin to Custom except sRGB mode.

Red, Green, Blue: Color Control System decreases or increases the monitor's red, green or blue colour guns

depending upon which is selected. The change in colour will appear on screen and the direction (decrease or

increase) will be shown by the bars.

sRGB mode: sRGB mode provides the suitable colour managed picture image. You can not change Red,

Green and Blue colours, brightness and contrast individually.

Colour Temperature Adjustment: Adjusts the colour temperature of the screen image.

Geometry Controls

Geometry Controls Menu

The Geometry controls allow you to adjust the curvature or angle of the sides of your display.

Sides In/Out (pincushion): Decreases or increases the curvature of the sides either inward or outward.

Sides Left/Right (pincushion balance): Decreases or increases the curvature of the sides either to the left

or right.

Sides Tilt (parallelogram): Decreases or increases the tilt of the sides either to the left or right.

Sides Align (trapezoidal): Decreases or increases the bottom of the screen to be the same as the top.

Rotate (raster rotation): Rotates the entire display clockwise or counterclockwise.

Corner Correction: Allows you to adjust the geometry of the corners of your display – Top or Bottom.

Tools 1

Moiré Canceler: Moiré is a wavy pattern which can sometimes appear on the screen. The pattern is repetitive

and superimposed as rippled images. When running certain applications, the wavy pattern is more evident

than in others. To reduce moiré, adjust the level by using –/+ CONTROL buttons.

Linearity: This selection allows you to adjust the spacing of the area on the screen. The purpose of this

control is to ensure that a one-inch circle is a true one-inch circle wherever it is on the screen. The best way to

determine the vertical linearity is as follows:

• Draw equally spaced horizontal lines using a drawing application that has a ruler.

• Use the Vertical Balance control to adjust the lines near the top and bottom of your screen.

• Use the LINEARITY (VER.) control to adjust the spacing between the lines near the center and top of your

screen.

Convergence: Aligns all three colors (R,G,B) to form a single color (white). The purpose of this control is to

ensure that a white line drawn on the screen is as crisp and clear as possible.

• Use the CONVERGENCE (HOR.) control to adjust the alignment of the lines in the up/down direction.

• Use the CONVERGENCE (VER.) control to adjust the alignment of the lines in the left/right direction.

1-30

Diamond Pro 930SB9

Controls

– continued

GlobalSync Control: Eliminates picture impurities that may result from the earth’s magnetic field. While

in the sub-menus (GLOBALSYNC, TOP LEFT, TOP RIGHT, BOTTOM LEFT or BOTTOM RIGHT), use the

–/+ control buttons to fine tune the GlobalSync corrections.

NOTE: Mitsubishi recommends that you perform GlobalSync correction while running a typical application

such as a spreadsheet or text document.

Tools 2

Language: OSM controls menus are available in 6 languages.

OSM Position: You can choose where you would like the OSM controls menu to appear on your screen.

Selecting OSM Position allows you to manually adjust the OSM controls menu position from among Center,

Top left, Top right, Bottom left and Bottom right.

OSM Turn Off: The OSM controls menu will stay on as long as it is in use. In the OSM Turn Off sub-menu,

you can select how long the monitor waits after the last touch of a button for the OSM controls menu to

disappear. The preset choices are 5 thru 120 seconds.

OSM Lock Out: This control completely locks out access to all OSM controls functions except Brightness

and Contrast. When attempting to activate OSM controls while in the lock out mode, a screen will appear

indicating that OSM controls are locked out. To activate the OSM Lock Out function, press SELECT and

hold + down simultaneously. To deactivate the OSM Lock Out, press SELECT and hold + down simultaneously.

IPM System Off Mode: Enable: The IPM System works

normally and all stages of

energy savings are utilized.

Disable: The Off Mode of the IPM System

is not used.

NOTE: For standard systems and graphics boards, keep the factory setting at ENABLE.

NOTE: Do not keep the monitor on when ‘No Signal’ is applied. This could cause image burn-in on the screen

due to the ‘No Signal’ message being displayed.

EdgeLock Control: Operating your monitor at a nonstandard timing may cause images to appear darker than

normal or have color distortion. Use of the EdgeLock control will adjust images to their normal state.

Hot Key: This selection allows you to use

/

Y

Y

as brightness control and –/+ as contrast control. When Hot

key function is set to “ON”, accessing the OSD is only possible with the “EXIT” button.

Factory Preset: Selecting Factory Preset allows you a reset most OSM control settings back to the factory

settings. A warning statement will appear to confirm that you do want to reset ALL settings. Individual settings

can be reset by highlighting the control to be reset and pressing the RESET button.

Information

Display Mode: Indicates the current mode and frequency setting of the monitor.

Monitor Info: Indicates the model and serial numbers of your monitor.

Refresh Notifier: A message will advise you if the refresh rate of the signal being applied to the monitor by

the computer is too low. For further information, please refer to your display card or system manual.

1-31

Recommended Use

10 User’s Manual

Safety Precautions and Maintenance

• DO NOT OPEN THE MONITOR. There are no user serviceable parts inside and opening or removing covers

may expose you to dangerous shock hazards or other risks. Refer all servicing to qualified service personnel.

• Do not spill any liquids into the cabinet or use your monitor near water.

• Do not insert objects of any kind into the cabinet slots, as they may touch dangerous voltage points, which

can be harmful or fatal or may cause electric shock, fire or equipment failure.

• Do not place any heavy objects on the power cord. Damage to the cord may cause shock or fire.

• Do not place this product on a sloping or unstable cart, stand or table, as the monitor may fall, causing

serious damage to the monitor.

• Keep the monitor away from high capacity transformers, electric motors and other devices such as external

speakers or fans, which may create strong magnetic fields.

• If possible, position the monitor so that it is facing the east to minimize the effects of the earth’s magnetic

field.

• Changing the direction of the monitor while it is powered on may cause image discolouration. To correct this,

turn the monitor off for 20 minutes before powering it back on.

• When operating the Diamond Pro 930

SB

with the AC 100 - 240 V power source in EU countries except UK,

use the power cord supplied.

For all other cases, use a power cord that matches the power supply voltage of the AC power outlet and that

has been approved by and complies with the safety standards of your country.

• In UK, use a BS-approved power cord with molded plug having a black (5A) fuse installed for use with this

monitor. If a power cord is not supplied with this monitor, please contact your supplier.

Cleaning Your Monitor

A special coating is provided on the glass (CRT) surface of this monitor to reduce a reflection and static

electricity on the glass surface. Due to the delicate coating on the glass surface, use a lint-free, non-abrasive

cloth (cotton or equivalent) and a non-alcohol, neutral, non-abrasive cleaning solution to minimize dust. If the

screen requires more than a light cleaning, apply a soft neutral detergent and water directly to a soft cloth and

use it upon wringing water, to clean the glass surface. Clean your monitor regularly.

CAUTION: The following agents will cause damage to the CRT when cleaning the glass surface:

Benzene, thinner, acid/alkaline detergent, alcohol detergent, detergent with abrasive powder, detergent with

anti-static agent, detergent for cleaning.

Immediately unplug your monitor from the wall outlet and refer servicing to qualified service personnel under

the following conditions:

• When the power supply cord or plug is damaged.

• If liquid has been spilled, or objects have fallen into the monitor.

• If the monitor has been exposed to rain or water.

• If the monitor has been dropped or the cabinet damaged.

• If the monitor does not operate normally by following operating instructions.

• Allow adequate ventilation around the monitor so that heat can properly

dissipate. Do not block ventilated openings or place the monitor near a radiator

or other heat sources. Do not put anything on top of monitor.

• The power cable connector is the primary means of detaching the system from

the power supply. The monitor should be installed close to a power outlet which

is easily accessible.

• Handle with care when transporting. Save packaging for transporting.

CAUTION

FOR OPTIMUM PERFORMANCE, PLEASE NOTE

THE FOLLOWING WHEN SETTING UP AND USING THE

DIAMOND PRO 930

SB

COLOUR MONITOR:

1-32

Diamond Pro 930SB11

Recommended Use

– continued

• Adjust the monitor height so that the top of the screen is at or slightly below

eye level. Your eyes should look slightly downward when viewing the middle

of the screen.

• Position your monitor no closer than 40 cm and no further away than 60 cm

from your eyes. The optimal distance is 50 cm.

• Rest your eyes periodically by focusing on an object at least 6 meter away.

Blink often.

• Position the monitor at a 90° angle to windows and other light sources to

minimize glare and reflections. Adjust the monitor tilt so that ceiling lights do

not reflect on your screen.

• If reflected light makes it hard for you to see your screen, use an anti-glare

filter.

• Clean your monitor regularly. Use a lint-free, non-abrasive cloth and a non-alcohol, neutral, non-abrasive

cleaning solution or glass cleaner to minimize dust.

• Adjust the monitor’s brightness and contrast controls to enhance readability.

• Use a document holder placed close to the screen.

• Position whatever you are looking at most of the time (the screen or reference material) directly in front of

you to minimize turning your head while you are typing.

• Get regular eye checkups.

Ergonomics

To realize the maximum ergonomics benefits, we recommend the following:

• Adjust the Brightness until the background raster disappears

• Do not position the Contrast control to its maximum setting

• Use the preset Size and Position controls with standard signals

• Use the preset Colour Setting and Sides Left/Right controls

• Use non-interlaced signals with a vertical refresh rate between 75 - 160 Hz

• Do not use primary colour blue on a dark background, as it is difficult to see and may produce eye fatigue

due to insufficient contrast

CORRECT PLACEMENT AND ADJUSTMENT OF THE MONITOR

CAN REDUCE EYE, SHOULDER AND NECK FATIGUE. CHECK THE

FOLLOWING WHEN YOU POSITION THE MONITOR:

1-33

12 User’s Manual

Specifications

NOTE: Technical specifications are subject to change without notice.

..............

rotinoM

snoitacificepS

039orPdnomaiD

BS

rotinoM

setoN

ebuTerutciP:lanogaiDhcni91/mc05,hctipellirgmm42.0,noitcelfed°09

,rohpsohpecnetsisreptrohsmuidem

-itna,dereyal-itlum,TRCellirgerutrepa

neercstnit-krad,gnitaocneercscitats

.neercsraelCitpOdna

:eziSegamIelbaweiVhcni81/mm754

langiStupnI:oediV

:cnyS

smhO57/p-pV7.0GOLANA

leveLLTT.cnysetarapeS

evitageN/evitisoP.cnyslatnoziroH

evitageN/evitisoP.cnyslacitreV

)leveLLTT()evitageN/evitisoP(.cnysetisopmoC

neergnocnyS

sruoloCyalpsiD:tupnigolanAsruoloCforebmundetimilnU.desudracyalpsidnosdnepeD

noitazinorhcnyS:latnoziroHzHk011otzHk03yllacitamotuA

egnaR:lacitreVzH0.011otzH0.05yllacitamotuA

detroppuSsnoituloseR

dnalatnozirohnodesabnoituloseR

ylnoseicneuqerflacitrev

zH061ot06@084x046

zH641ot05@006x008

zH141ot05@426x238

zH611ot05@867x4201

zH301ot05@078x2511

zH98ot05@4201x0821

zH67ot05@0021x0061

zH86ot05@4431x2971

zH37ot05@0441x0291

llatroppustonyamsmetsysemoS

.detsilsedom

yalpsiDscinortcelEihsibustiM-CEN

tanoituloserdednemmocersetic

ecnamrofrepyalpsidlamitporofzH58

aerAyalpsiDevitcA

)gnitteSyrotcaF(

:latnoziroH

:lacitreV

sehcni0.41/mm653

sehcni5.01/mm662

,desugnimitlangisnoputnednepeD

edulcnitonseoddna

.aeraredrob

aerAyalpsiDevitcA

)nacSlluF(

sehcni4.41/mm663

sehcni5.01/mm662

,desugnimitlangisnoputnednepeD

edulcnitonseoddna

.aeraredrob

ylppuSrewoPzH06-05,V042-001CA

gnitaRtnerruCV042-001@A2.2

snoisnemiD )D(mm5.744x)H(mm344x)W(mm244

)D(sehcni6.71x)H(sehcni4.71x)W(sehcni4.71

thgieWgk8.32

sbl10.05

snoitaredisnoClatnemnorivnE

:erutarepmeTgnitarepO

:ytidimuH

:edutitlA

:erutarepmeTegarotS

:ytidimuH

:edutitlA

C°53+otC°5+

%09ot%01

m000,3ot0

C°06+otC°02-

%09ot%01

m000,51ot0

1-34

Diamond Pro 930SB13

Features

SuperBright Diamondtron CRT: This patented flat aperture grille CRT delivers an exceptional viewing experi-

ence with unprecedented brightness and contrast and a virtually flat image that reduces distortion and glare so

that what you see on-screen is what you get on your printed output. The state-of-the-art Mitsubishi U-NX-DBF

electron gun and tight 0.24 mm grille pitch delivers precise focus for crisp, clear text and images.

SuperBright Mode : With the simple touch of a button, the brightness level of the Diamondtron CRT doubles.

This function enhances the crispness of images for clarity-conscious applications such as graphics, animation

and video.

Super Bright Mode OFF: for text based images (normal use)

Super Bright Mode-1 ON: for images

Super bright Mode-2 ON: for moving image such as DVD movies

OptiClear Screen Surface: Further reduces reflection and glare and increases contrast without sacrificing focus

level, clarity or brightness.

Dual Dynamic Beam Focus: Provides precise, continuous focus adjustments of the electron beams and opti-

mum image quality, even to the far edges of the screen.

Color Control System with sRGB: Allows you to change between five colour settings on your display to match

your personal preference. The sRGB-enabled colour matching setting found within Color Control helps achieve a