Page 1

INSTRUCTIONS.,

'•'vlv>;Sv

FOR

>

y-ii:/-'/

'f/9^

/>.

.

i.

\ •:.

MITSUBISHI

INDUSTRIAL

SEWING

MACHINE

TWO

LOCKSTITCH

SPLIT

•

rmMiTSUBiSHi

WEEDLE

NEEDLE

MODEL

HIGH

NEEDLE

BAR

: ON-275

MACHINE

: DN-275-20

ADVANCEDANDr.VERADVANCING

ELECTRIC

SPEED

FEED

Page 2

Thank

you

for

your

purchaseof"Mitsubishi"

DN-275. Kindly read

DN-275

tion

case of

machine.

for

manual

your

your

with

ready

you

troubles

this

Instruction

reference.

for

your

caused during

INDEX

And

ready

Manual

keep

this

information

operation

machine

for

instruc

in

of

Specifications

1. Specifications 2

2.

Name

and

numberofthe

accessories 2

3. Name of main

Preparation

of

parts)

1.

Place

2.

for

Howtomount

3. Howtomount

4.

Howtoconnect

foot

pedal

5.

Howtomount

parts

for

operation

installationofmachine

the

the

the

the

(installation

machine

motor

motor

bobbin

assembly 4

6.

Howtomount

the

accessories

table 5

Head

holder,

knee

lifter

Pedal

system

presser

bar

assembly

lifter

assembly 5

Oil

pan.

Vibration

preventing

rubber

3.

Lubrication

before

startingtosew

1. Oiltobe used 8

2. Oilingto oil reservoir g

3. Oiling to main parts 3

4.

Howtoadjust

5.

Adjustmentoflubrication

hook

6. Precaution before

Howtooperate

1. How to select

2. Howtoattach

3.

Howtothread

the

lubrication...9

operation

the

machine

the

th read 1q

the

needle

the

upper

thread

4.

Howtowind

on

the

bobbin

the

lower

thread

head

lever

winder

on

for

. . .9

.4

and

10

10

11

5.

Howtoadjust

assembly

the

bobbin

winder

11

6. How to place the bobbin into the

rotating

7.

hook

2

Howtolead

8. Sewing

9.

Stoppingofthe

the

lower

start

and over 13

needle

thread..-12

bars

11

(left

and right) 14

10.

Angleofthe

stitch

11.

4

4

Adjustmentofstitch

reverse

5.

Stitch

adjustment

1.

Adjustmentoflower

tension

2.

Adjustmentofupper

tension

3.

Adjustmentofthe

length

stitching

corner

and

stitching

length

Proper

thread

thread

height

and

14

and

15

timing

15

ig

of feed

dog and pressure of presser foot -i 7

4.

Howtoremove

-7

9

5.

6.

7.

8.

9.

10.

rotating

Proper

hook

and

Up-down

needle

Proper

hook

and

Proper

hook

and

Proper

Proper

timing

timing

timing

positionoffeed

and

and

needle

between

between

take-up

between

case

between

place

hook

needle

adjustmentofthe

thread

bobbin

timing

the

the

rotating

the

rotating

lever..20

the

rotating

opener...

regulator

the

needle

18

19

20

20

21

and feed dog 22

6.

Maintenance,

Trouble

and

Repairing

1. Maintenance 23

2.

Oiling

3.

Howtofind

the

trouble

and

23

how

to repair 24

Page 3

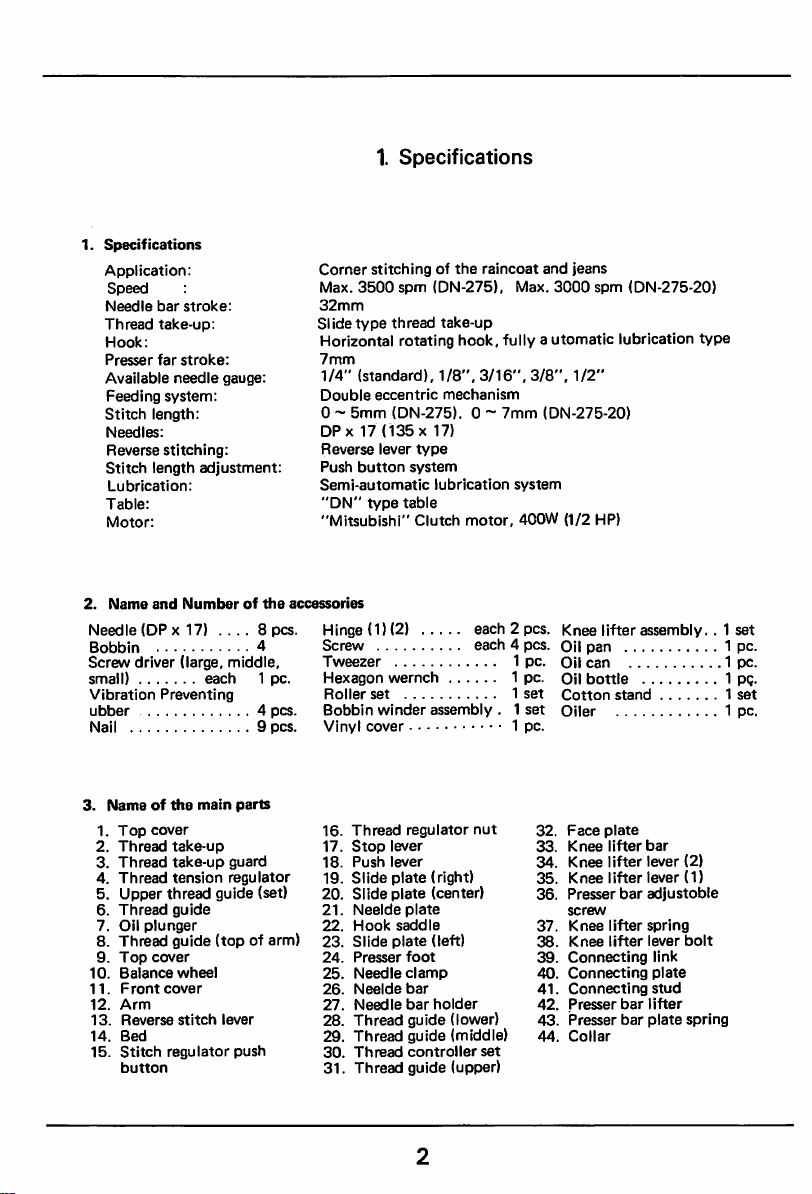

1.

Specifications

Application:

Speed

Needle

bar

Thread

Hook:

Presser

Available

Feeding

Stitch

Needles:

Reverse

Stitch

Lubrication:

Table:

Motor:

2.

Name

Needle

Bobbin

Screw driver (large, middle,

small)

Vibration

ubber

stroke:

take-up:

far

stroke:

needle

system:

length:

stitching:

length

and

Numberofthe

(DP x 17)

Preventing

gauge:

adjustment:

....

each

Nail 9

8 pcs.

4

1 pc.

4

pcs.

pcs.

1.

Specifications

Corner

Max.

32mm

Slide

stitchingofthe

3500

spm

type

thread

raincoat

(DN-275),

take-up

Max.

and

3000

jeans

spm

(DN-275-20)

Horizontal rotating hook, fully a utomatic lubrication type

7

mm

1/4"

Double

0 ~

DPx17(135

Reverse

Push

Semi-automatic

"DN"

"Mitsubishi"

accessories

Hinged)(2)

Screw

Tweezer

Hexagon

Roller

Bobbin

Vinyl

(standard),

eccentric

5mm

button

type

set

cover

(DN-275).

lever

system

table

wernch

winder

1/8",

mechanism

X 17)

type

lubrication

Clutch

assembly

3/16",

0 ~

7mm

system

motor,

400W (1/2 HP)

each

2pcs.

each4pcs.

1

1 pc.

1

. 1

1 pc.

3/8",

(DN-275-20)

Knee

Oil

pc.

Oil

Oil

set

Cotton

set

Oiler

1/2"

lifter

pan

can

bottle

stand

assembly..1set

1 pc.

1

pc.

1 pg.

1

set

1

pc.

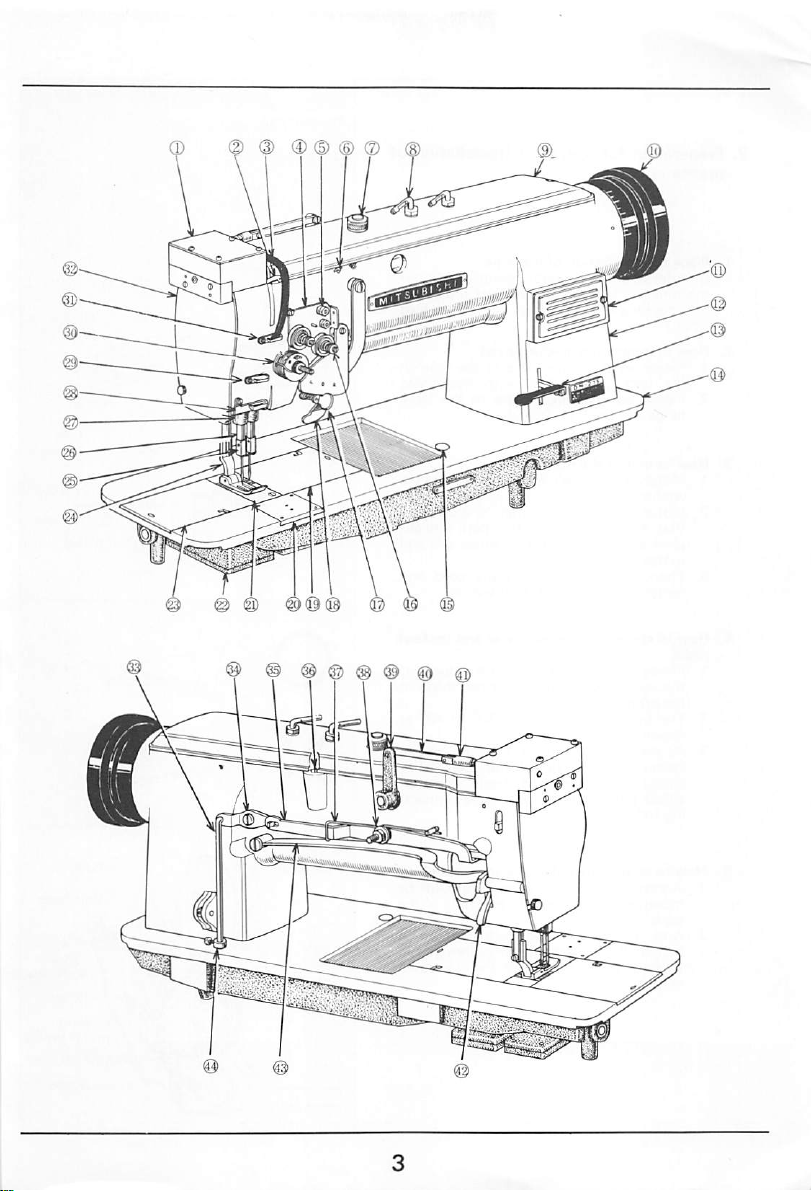

3.

Nameofthe

Top

1.

2.

Thread

Thread

3.

Thread

4.

5.

Upper thread guide (set)

Thread

6.

7.

Oil

Thread guide

8.

9.

Top

Balance

10.

Front

11.

Arm

12.

13.

Reverse

14.

Bed

15.

Stitch

button

cover

take-up

take-up

tension

guide

plunger

cover

cover

regulator

main

wheel

stitch

parts

guard

regulator

(top

lever

push

of arm)

Thread

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

regulator

Stop

lever

Push

lever

Slide

plate

Slide

plate

Neelde

plate

Hook

s^dle

Slide

plate

Presser

foot

Needle

clamp

Neelde

bar

Needle

bar

Thread guide (lower)

Thread guide (middle)

Thread

controller

Thread guide (upper)

(right)

(center)

(left)

holder

nut

Face

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

set

plate

Knee

lifter

Knee

iifter

Knee

lifter

Presser

bar

screw

Knee

lifter

Knee

lifter

Connecting

Connecting

Connecting

Presser

bar

Presser

bar

Collar

bar

lever

(2)

lever

(1)

adjustoble

spring

lever

bolt

link

plate

stud

lifter

plate

spring

Page 4

Page 5

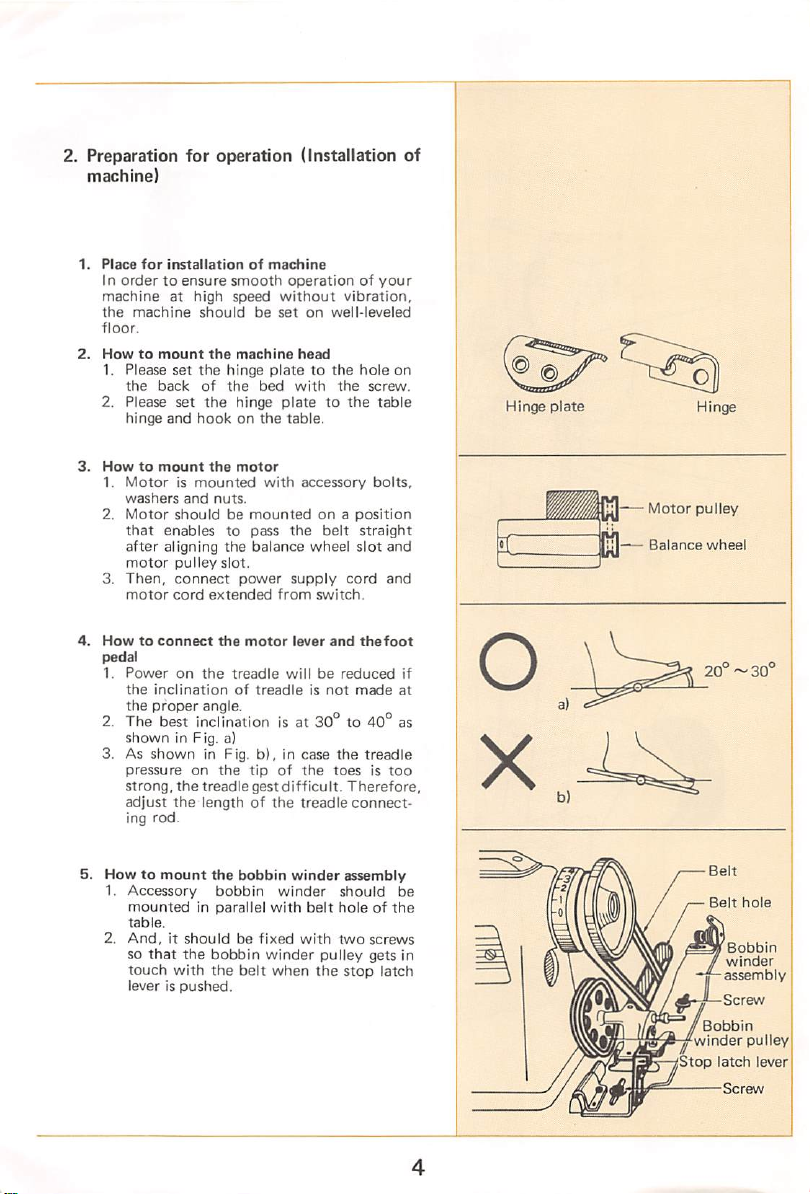

2. Preparation for operation (Installation of

machine)

1.

Place

for

In

ordertoensure

machineathigh

the

machine

floor.

2.

Howtomount

1. Please

the

2. Please

hinge

3.

Howtomount

1,

Motorismounted

washers

2,

Motor

that

after

motor

3,

Then,

motor

4.

Howtoconnect

pedal

1.

Power

the

inclination

the

proper

2.

The

shown

3. As

shown

pressure

strong,

adjust

ing

rod.

installation

set

back

set

and

and

shouldbemountedona

enables

aligning

pulley

connect

cord

on

best

in Fig. a)

the

the

of

smooth

speed

should

the

machine

the

hinge

of

the

the

hinge

hookonthe

the

motor

nuts.

to

the

slot.

power

extended

the

motor

the

treadle

of

angle.

inclination

in Fig.

on

the

tipofthe

treadle

length of

machine

operationofyour

without

be

setonwell-leveled

head

platetothe

bed

with

platetothe

table.

with

accessory

pass

the

balance

treadleisnot

belt

wheel

supply

from

switch.

lever

willbereduced

is at

30to40°

b).incase

gest

difficult.

the

treadle

vibration,

hole

the

screw.

table

bolts,

position

straight

slot

cord

and

thefoot

made

the

treadle

toesistoo

Therefore,

connect

on

and

and

if

at

as

Hinge

plate

Motor

Balance

pulley

wheel

20°~30°

5.

Howtomount

1.

Accessory

mountedInparallel

table.

2.

And,itshouldbefixed

so

that

touch

with

leverispushed.

the

the

bobbin

bobbin

bobbin

the

belt

winder

winder

with

winder

when

belt

with

the

assembly

should

holeofthe

two

pulley

stop

screws

gets

latch

be

in

Stop

Belt

Bobbin

winder

latch

hole

Bobbin

winder

assembly

pulley

lever

Screw

Page 6

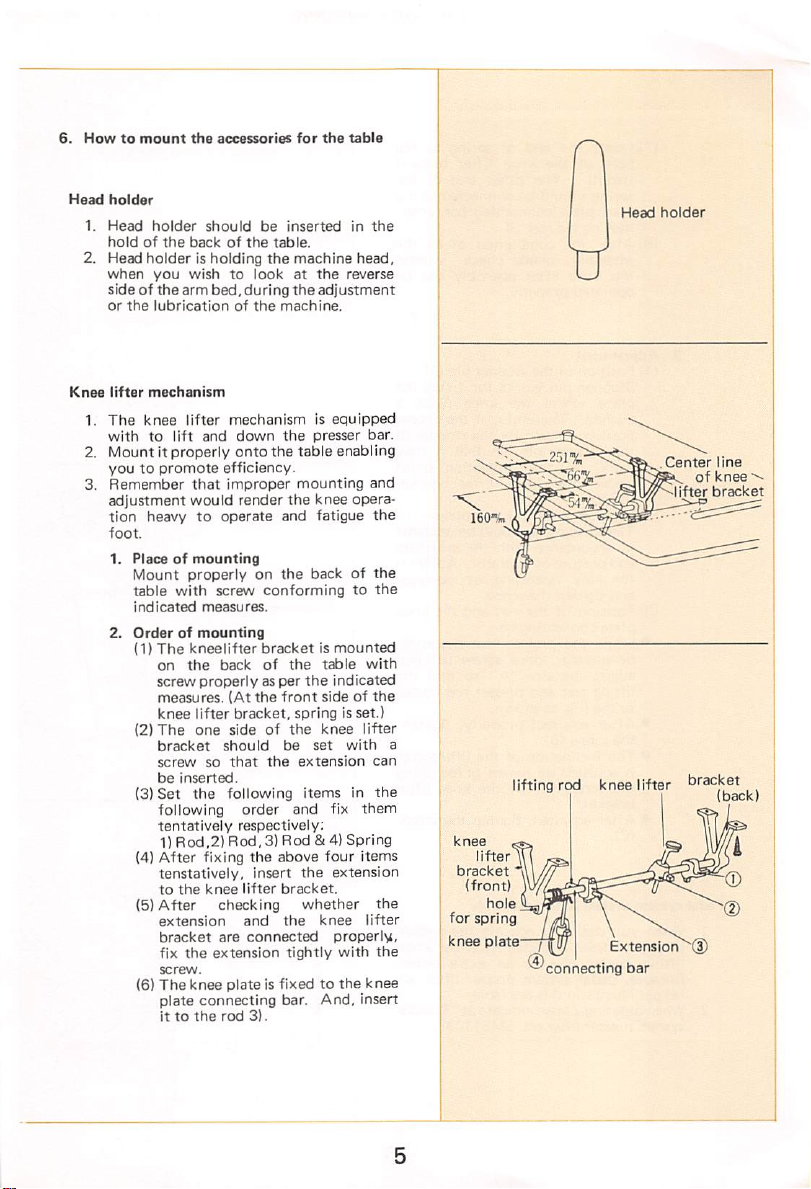

6.

Howtomount

Head

holder

1.

Head

holder

holdofthe

2. Head

Knee

1.

2. Mount it properly

holder

when

you

sideofthe

or

the

lubrication

lifter

mechanism

The

knee

withtolift

youtopromote

Remember

3.

adjustment

tion

heavy to

foot.

1.

Placeofmounting

Mount

table

indicated

2.

Orderofmounting

(1)

The

on

screw

measures.

knee

(2)

The

bracket

screw

be

(3)

Set

following

tentatively

1)

(4)

After

tenstatively.

to

(5)

After

extension

bracket

fix

screw.

(6)

The

plate connecting bar. And, insert

ittothe

the

accessories

should

be

backofthe

is holding

wishtolookatthe

arm

bed,

lifter

and

inserted

table.

the

during

the

of

the

machine.

mechanismisequipped

down

the

onto

the

efficiency.

that

improper

would

render

operate

the

and

properlyonthe

with

screw

conformingtothe

measures.

kneelifter

the

properlyasper

lifter

one

inserted.

the

Rod,2)

the

the

knee

bracketismounted

back

of

the

(At

the

front

bracket,

sideofthe

should

so

fixing

knee

checking

are

extension

that

the

following

order

respectively;

Rod,3)

the

above

Insert

lifter

bracket.

and

connected

be

and

Rod &4) Spring

the

tightly

plateisfixedtothe

rod

3).

for

the

table

in

machine

mounting

adjustment

presser

table

knee

head,

reverse

bar.

enabling

opera

fatigue

backofthe

table

indicated

sideofthe

knee

set

with

fix

four

extension

knee

properly,

with

with

lifter

them

items

lifter

the

spring is set.)

extension

itemsinthe

the

whether

knee

the

and

the

can

the

the

Head

holder

U

Center

line

of

knee

bracket

a

lifting

knee

lifter

bracket

(front)

hole

for

spring

knee plate—j

®

rod

knee

connecting

Extension

bar

lifter

bracket

(back)

Page 7

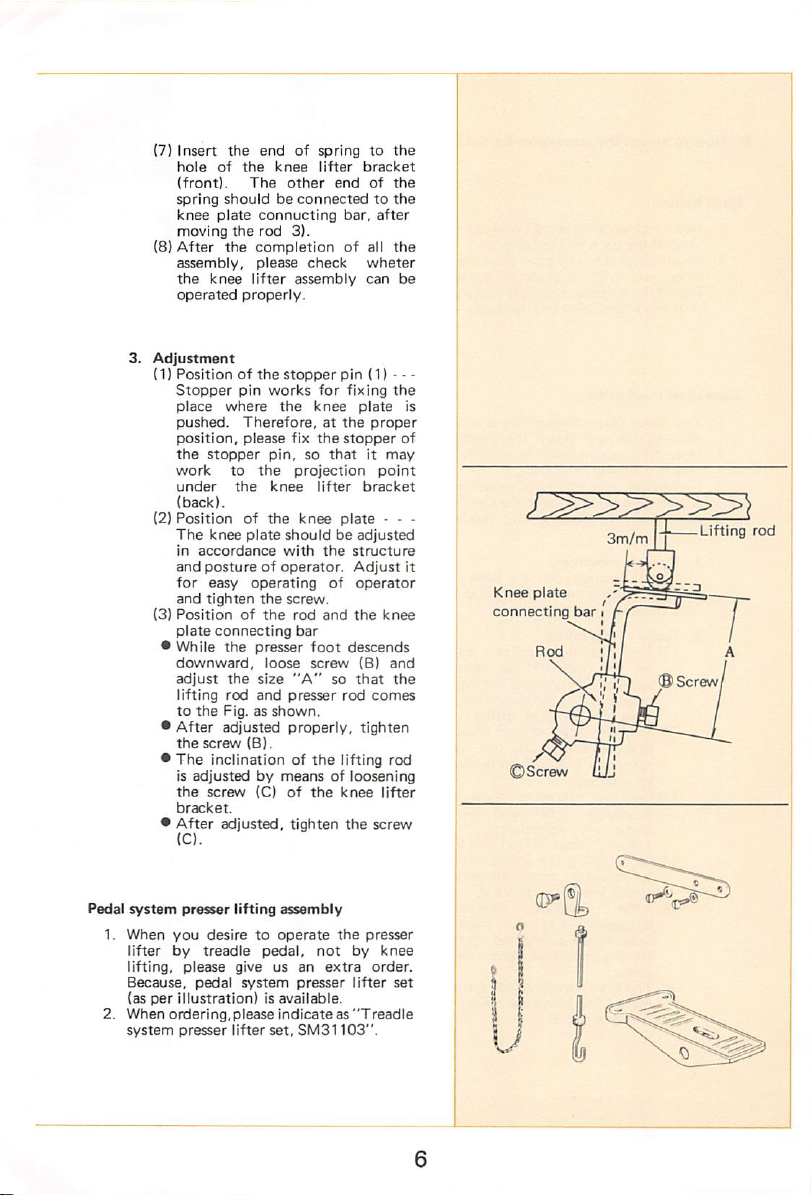

(7)

spring

(8)

After

3.

Adjustment

(1)

Stopper

place

pushed.

position,

the

work

under

(2)

Positionofthe

The

in

and

for

and

(3)

Positionofthe

plate

•

While

downward,

adjust

to

•

After

the

•

The

the

bracket.

•

After

Insert

the

hole

(front).

knee

moving

assembly,

the

operated

Positionofthe

(back).

accordance

lifting

the

is

adjustedbymeansofloosening

(C).

endofspringtothe

of

the

knee

The

shouldbeconnectedtothe

plate

connucting

the

the

completionofall

please

knee

lifter

properly.

pin

where

Therefore,atthe

please

stopper

to

the

the

knee

plate

postureofoperator.

easy

operating

tighten

connecting

the

presser

the

size

rod

and

Fig, as

adjusted

screw

(B).

inclination of

screw

(C)ofthe

adjusted,

lifter

other

endofthe

bar,

rod

3).

check

assembly

stopper

works

the

pin,sothatitmay

knee

the

loose

shown.

pin (1) —

for

fixing

knee

fix

the

stopper

projection

lifter

knee

plate

shouldbeadjusted

with

the

structure

Adjust

of

screw.

rod

and

the

bar

foot

descends

screw

"A"sothat

presser

rod

properly,

the

lifting rod

knee

tighten

the

bracket

wheter

can

plate

bracket

operator

(B)

tighten

after

the

the

proper

point

- - •

knee

and

the

comes

lifter

screw

be

is

of

3m/ml-^

it

Knee

plate

connecting

bar

Lifting

rod

©Screw

Pedal

1.

2.

system

presser

When

you

lifter

lifting,

Because,

(as

When

system

desiretooperate

by

treadle

please

pedal

per

illustration)isavailable.

ordering,please

presser

lifting

assembly

pedal,

give us an

system

presser

indicateas"Treadle

lifter

set,

SM31103".

not

the

extra

presser

by

lifter

knee

order.

set

Page 8

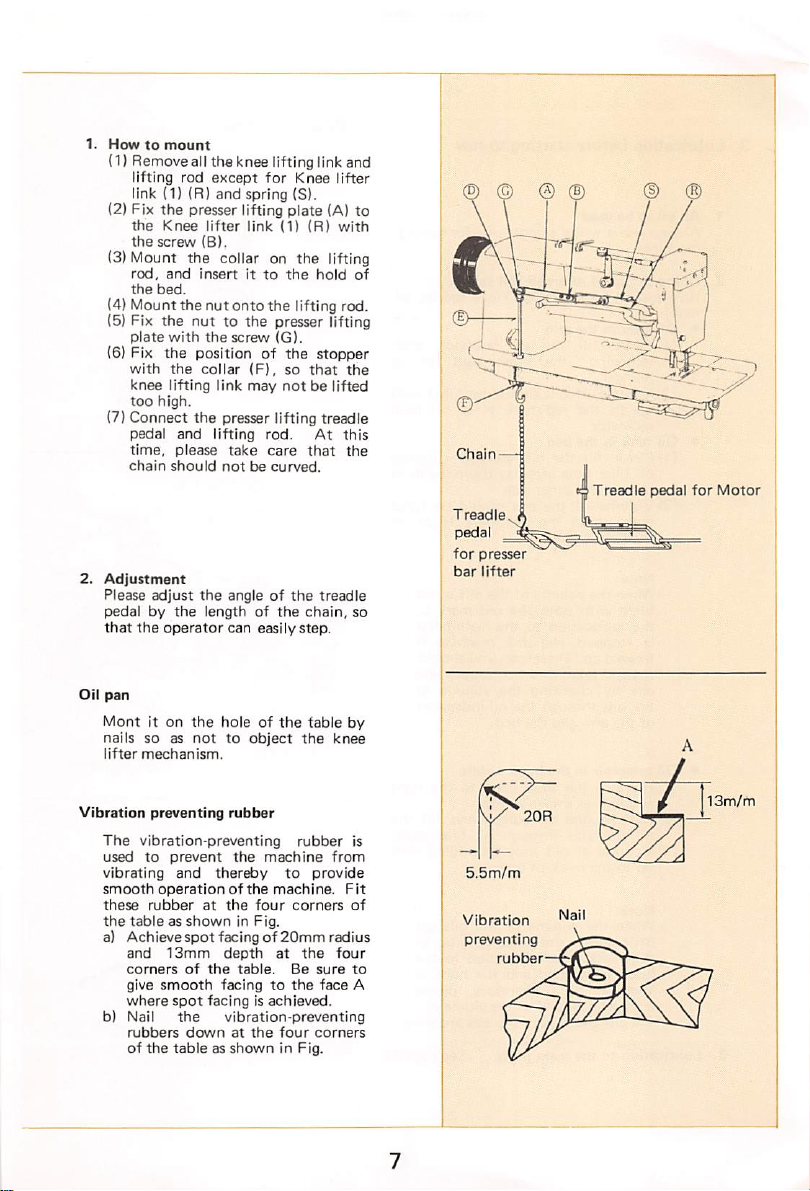

1.

Howtomount

(1) Removeall the knee lifting link and

lifting

rod

except

for

link (1) (R) and spring (S).

(2) Fix the presser lifting plate (A) to

the

Knee

screw

and

bed.

the

with

the

lifting link

high.

and

please

should

adjust

operator

it on

lifter

(B).

insertitto

nuttothe

the

screw

collar

the

presser lifting treadle

lifting

take

notbecurved.

the

angleofthe

lengthofthe

can

the

holeofthe

nottoobject

the

(3)Mount the collar on the lifting

rod,

the

(4) Mountthe nut onto the lifting rod.

(5) Fix

plate

(6) Fix the position of the stopper

with

knee

too

(7) Connect

pedal

time,

chain

2.

Adjustment

Please

pedalbythe

that

the

Oil

pan

Mont

nails

so as

lifter

mechanism.

Knee

link

(11

the

presser lifting

(Gl.

(F),sothat

may

not

rod.

care

easilystep.

(R)

hold

be lifted

At

that

treadle

chain,

fable

the

lifter

with

the

this

the

by

knee

of

Cham—

Treadle

pedal

for

Motor

Treadle

pedal

for

presser

bar

lifter

so

Vibration

preventing

The

vibration-preventing

usedtoprevent

vibrating

smooth

operatlonofthe

these

rubber

the

tableasshowninFig.

a)

Achievespot

and

corners

give

smooth

where

b) Nail

rubbers

of

the

rubber

the

thereby

the

machine

machine.

four

to

corners

and

at

facingof20mm

13mm

depth

of

the

spot

facingisachieved.

the

downatthe

tableasshowninFig.

at

table.

facingtothe

vibration-preventing

Be

four

rubber

provide

the

sure

face

corners

is

from

Fit

of

radius

four

to

A

V/

5.5m/m

Vibration

preventing

rubber

20R

13m/m

Page 9

3.

Lubrication

before

startingtosew

Oil

plunger

darner

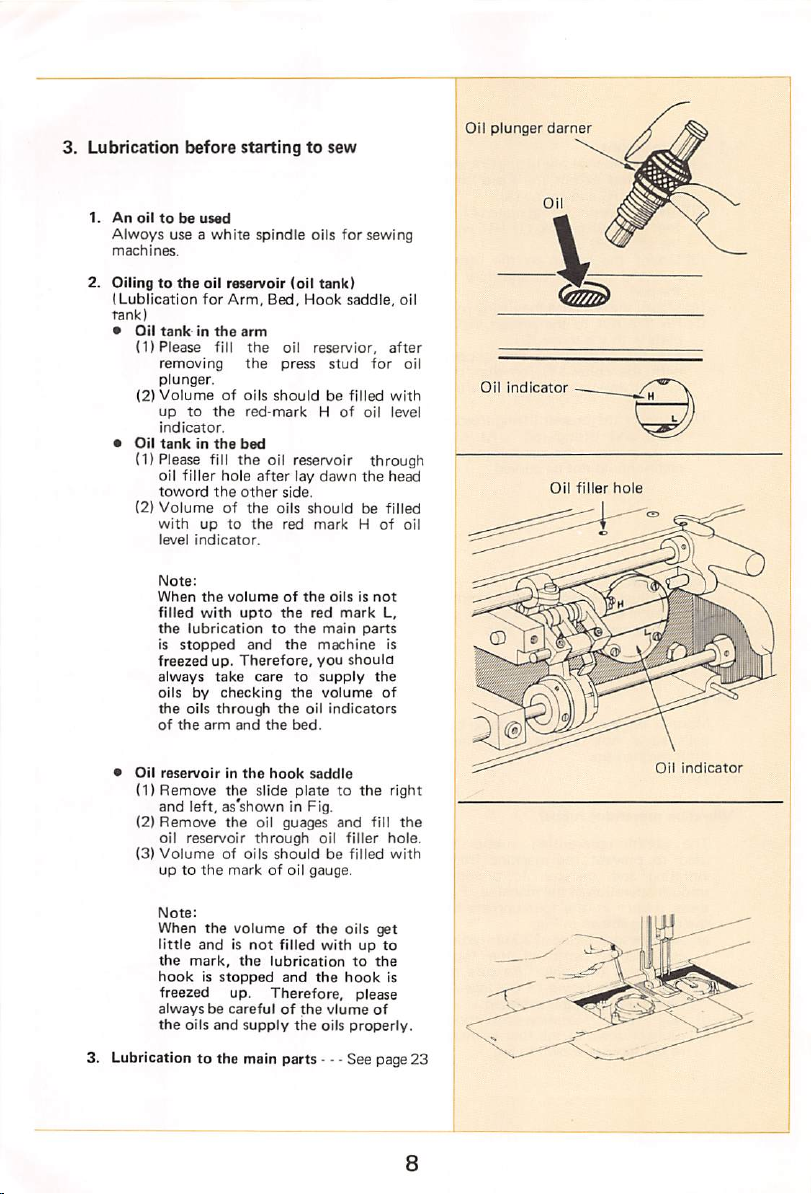

1.Anoiltobe

Alwoys

use a

machines.

2.

Oilingtothe

ILublication

tank)

*

Oil

tankinthe

(1)

Please

removing

plunger.

(2)

Volumeofoils

uptothe

indicator.

•

Oil

tankinthe

(1) Please fill

oil

toword

(2)

Volumeofthe

with

level

Note:

When

filled

the

is

freezed

always

oilsbychecking

the

of

•

Oil

reservoirinthe

(1)

Remove

and left, as'shown in Fig.

(2)

Remove

oil

(3)

Volumeofoils

uptothe

used

white

spindle

oil

reservoir

for

Arm,

Bed,

arm

fill

the

the

shouldbefilled

red-markHof

bed

the

filler

uptothe

indicator.

the

with

lubricationtothe

stopped

oils

the

arm

reservoir

oil reservoir

hole

after

the

other

volumeofthe

upto

and

up.

Therefore,

take

caretosupply

through

and

the

hook

the

slide

the

oil guages

through

markofoil

oils

the

shouldbefilled

oils

for sewing

(oil

tank)

Hook

saddle,

oil

resen/ior,

press

stud

lay

dawn

side.

shouldbefilled

red

markHof

oilsisnot

the

red

mark

main

the

machine

you

shoula

the

volume

oil

indicators

bed.

saddle

piatetothe

and

oil

filler

gauge.

oil

after

for

with

oil level

through

the

head

L,

parts

is

the

of

right

fill

the

hole.

with

oil

Oil

indicator

Oil

filler

hole

oil

Oil

indicator

Note:

When

the

andisnot

mark,

oils

and

volumeofthe

the

supply

little

the

hookisstopped

freezed up.

alwaysbecarefulofthe

the

3. Lubricationtothe main

oils

filled

lubricationtothe

and

the

Therefore,

the

parts

get

withupto

hook

please

vlume

of

oils

properly.

- - - See page 23

is

8

Page 10

4.

Howtoadjust

1.

Oil

plunger

When

startingtooperate

please

push

oil

penetrates

necessary

2.

When

the

please

push

that

the

back

and

Note:

Keep

putting

(a rest)

shown

cose of

outofoperotion.

be

careful

5.

Adjustmentofhook

(1) Lay

down

other

(2)

(3) A red line mark is

(4)

side.

Loosen

the

saddle.

ing screw,

volumeoflubrication.

screw

clockwise

markisto

turn

counterclockwise

After

adjusted,

the

lubrication

device

the

the

press

bar

partsinthe

stop

throughly

machineisoutofoperation,

the

press

oils

arm.

press

stud

bar

put

to lubricate

the

press

in Fig. by all

happentoflow

machine,

downsothat

into

downward

automatically

automatically.

bar

back

means

Otheriwse,

out.

lubrication

the

machine

nutonthe

which

increase,

tighten

head

toward

sideofthe

indicatedinthe

shows

the

Turn

the

the

istoreduce.

the

nut.

adjust^le

basing

andonthe

adjust

standard

red

contrary,

as

in

hook

the

the

line

Press

bar

for

oil

plung

an

When

operate

so

Press

bar

for

oil

plunger

Oil

plunger

knob

When

not

operate

6.

Precaution

When

timeorwhen

long

(1) It is

necessary

(2)

Fill

each

(3)

Please

downward.

(4)

Operate

penetrated

before

the

machineisoperated

interval:

operating

necessarytofill

parts.

oilsatthe

oil

reservoirs.

push

the

the

machine

throughly

startingtosew

the

oils

throughly

levelofred

press

bar

for

slowly

Into

necessary

for

the

machine

markedHof

oil

plunger

until

oils are

first

after

into

parts.

Adjusting

screw

increose

0)

Special

nut

Page 11

4.

Howtooperate

1.

Selection

(1)

Always

thread.

{2) in

twistedorleft-twisted,

shown

with

2.

Howtoattacf

Use

1)

Turn

to

position.

2)

Then,

3) Hold

groove

insert

needle

4)

Then,

the

of

thread

use

left-twisted

ordertocheck

in Fig.

your

right

the

raise

the

loosen

side

it as

clamping

tighten

the

{135X17)

balance

the

needlesothat

deeply

DP X 17

machine

and

hand.

needle

needle

the

faces

the

wheel

hole.

thread

if a

thread

hold

the

twistittoward

needle.

toward

bartoits

needle

clamping

its side

each

two

as it will go

neelde

clamping

for

is right-

thread

you

with

needle,

into

upper

you

so as

highest

screw.

long

and

the

screw.

Needle

clamp

Needle

as

groove

Thread

Thread

take-up

groove

side

Thread

guide

clamping

guide

y.

screw

side

Q

3.

Howtothread

The

following:

1)

Turn

that

upto

2)

Thread

side

respectively:

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

upper

Thread

Thread

Upper

Thread

Thread

Thread

Thread

Thread

Needle

Needle

the

its

the

spool

the

upper-thread

threadispassed

balance wheel by

thread

highest

the

take

position.

two

threads

in

guide

(top

guide

thread

regulator

guide (arm)

take-up

guide

(arm)

guide

(arm)

guide

(arm)

clamp

the

accordingtothe

your

up

leverisraised

from

following

cover)

the

hand so

left

order

10

Thread

guide

Page 12

4.

Howtowind

(1)1

nsert

shaft,

(2) As shown in Fig., pass

wind

times

machine.

(3) When

thread,

free

the

the

on

the

from

the

lower

bobbin

edgeofthe

the

bobbin

the

pulley

the

belt

into

bobbin,

and

is fully

will

(4) This operation can be

S.

Howtoadjust

(1) It is

evenly

(2) In case of uneven winding

If it is

screw (Al shown in Fig, and move

thread

right

thread.

the

(3)

Strengthofthe

Thereisthe

maybedamagedifthe

too

the

the

led

(4)

Best

woundupto

thread.

poor

the

bobbin,

to

andtothe

the

with

bobbin

that

thread,

the

desirable

inclinedtoleftorright.loosen

guide

rest

so astoobtain

After

screw

tightly

pressureofthe

nut

(B), so

slightly

resultisobtained

Excessive

draw-outofthe

amount

turn

the

left

adjusting,

(A).

winding

possiblity

with

that

outofthe

4/5

of

the

when

right

when

slightlytothe

thread.

the

of its full

winding

thread

screw

the

threadonthe

the

the

thread

and

automatically

stopped.

done

winder

bobbiniswound

uniform

that

bobbiniswound

regulator

thread

regulator

when

thread.

wound

(C)

windingisexcessive,

insufficient.

bobbin

bobbin

winder

thread and

about

5 to 6

operate

wound

while sewing.

assembly

left

winding

please

tighten

the

bobbin

Please

adjust

plate

can be pul

plate,

the

bobbin

capacity

will

result-in

To

adjust

on

shown

in Fig.

with

with

with

the

the

the

the

be

Bobbin

case

thread

guide

To

adjust

the

the

or

of

is

thread

windingofthe

guide

to,

leftorright.

threadbymoving

6.

Howtoplace

hook

(1)Turn

(2)

(3)

(4)

tfie

the

that

the

the

the

the

flap

balance

the

needle

position.

slide

hookasshown

bobbin

hook

down

so

highest

Open

(A) of

Hold

threadbyabout

into

Then

bobbin

plate

5cm,

center

the

wheel

pulling

into

the

rotating

with

pull up

in Fig.

out

fit

your

the

the

barisraised

and

and

pin.

latch lever(A},

upto

the

end

bobbin

hand,

latch

Thread

its

of

Slide

hook

plate(g)

center

slide

plate

®

hook

center

11

Page 13

7.

Howtolead

(1) Lead

(2)

the

the

hook

After

hook

(2)

and

ontothe

the

lower

thread

(1)

opener

thread

(1)

shown

through

(3),pull

endofthreadtothe

center

led

the

center

the

bed.

from

in Fig.

the

the

the

groove

groove

hook

thread

beak

out

Thread

of

of

Thread

Bobbin

case

opener

(3) Holding

left

hand

slowlybyright

thread

shown

of

the

(Then,

the

lower

hook.)

(4)Atthis

toward

as

shown

(5) Pull

the

the

directionasshown

(6)

Please

opened

the

end of

the

turn

hand.

the

through

regulating

bobbin

the

upper

Then

lower

the

and

are

led

out

in Fig.)

feed

dog.

the

thread accerdingly lead to

thread

time,

the

the

counterclockwise

in Fig.

lower

thread

and

close

when

the

the

slide

bobbin

in Fig.

plate

was

thread by

balance

wheel

the

upper

thread

needle

hold

springofthe

should

turn

direction

leadittoward

which

was

inserted.

(as

12

Page 14

8.

Sawing

start

and

ouer

Howtooperate

*

Sewing

(1) Lift the presser foot and

cloth

(2)

Turn

your

Note:

When

upper

in

lengthsoas

*

Sewing

(1) When sewing over,

shouldbeliftatits

(2) Lift

cloth

(3)

Trim

the

machine

start

to

start

and

pulled

presser

diagonally

sewing

needle

nottobe

foot

upper

the balance wheel

hand

startingtosew,

thread

over

the

toward

bothofthe

put

under

toward

stitches

please

outbyapprox.

foil

out.

the

thread

highest

position.

and

pull

other

side.

and

lower

the

the

your

the

leave

10cm

take-up

out

the

thread.

part

needle.

side by

cloth.

the

lever

sewn

of

13

Page 15

9.

Stopofneedle

0

Set

Note:

the

machineisworking,

operating

stop

take-up

sition.

(1)

Stoppingofthe

When

stop

Fig-

(2)

Stoppingofthe

When

stop

Fig,

(3)

Operationofthe

When

bars

please

opposit

turned

and

10.

Relationship

er

sewing

(DThe

according

showninthe

the

(2) When

the

stitches

obtained

(3)

For

stitch

stitch

diagram.

bar

(rightorleft)

the

stop

Stop

the

after

the

proper

needle

curving

example.

leverto"L"or"R"

lever

maybeoperated

the

stop

machine

lever has

stop

lever

stop

lever

resume

push

automatfcallytothe

and

decide

*fch1

length

numberissix

foratime

come

needle

the

toward

needle

the

toward

the

the

operation

the

side.

two

needle

between

stitch

corner

to

the

following

gaugeof1/4")

the

angle,

for

the

COCO

from

the

In case of

by

but

it is

lever in

about

bar

left

needle

the

mark (L) as

bar

right

needle

the

mark

two

needle

operationOftwo

pushing

Then,

operation

Curving

length

sewing

proper

stitch

the

outside

diagram.

2.9mm,

stitihesasshowninthe

desirable

the

bestoforder

when

its

heighest

(left)

bar,

(right)

bar,

(R) as

bars

with

one

lever

toward

the

stop

neutral

canbedone.

angleofthe

canbeobtained

stitch

diagram

length

according

proper

needle,

40®

curving

the

most

even

the

turn

shown

turn

shown

needle

lever

position,

length

(In

case

number

can

though

thread

the

needle

bar,

the

com

and

proper

the

po

to

be

for

in

In.

as

of

of

to

Stop

lever

is

Pushing

lever

Curving

angie

(40")

Proper

gauge

\

S.N

C./\

30®

40®

50®

60®

70®

80®

90®

100®

no®

120®

130®

140®

stitch

1/4")

2 3

5.5

3.2

2,7

2.2

1.8

1.5

1.1

length&stitch

4 5

4.8

4.4

3.5

4.6

3 4

2.8

2.3

1.9

1.6

1.3

27

2.2

1.8

1.5

1.3

3.7

3.0

2.5

2.1

1 ft

1.5

1.2

number

6

4.0

2.9

7 3

1.9

1.5

1.3

(needle

7 8

3.7

2.5

2.0

1.6

3.0

2.2

1.7

14

Page 16

11.

Adjustmentofstitch

*

Adjustmentofstitch

(1) Pushing

the

balance

(2)

Then,

the

and

the

(3)

Push

the

so

that

this

time

dialonthe

ing on

push

button

the

push

balance

push

the

set

the

push

wheel

button

button

balance

the

balance

arm

shown

length

and

length

button

slowly

goes

wheel

down

wheel

graduation

wheel

and

then

in Fig.

revers

down

toward

down

stops

additionally

rotates.

(0~5)

with

release

stitch

and

you.

further

rotating.

ofthe

the

mark

turn

At

the

Markingofthe

Balance

arm

wheel

5.

Note:

Please

push

operationofthe

*

Reverse

(1)

Reverse

reverse

Stiteh

adjustment

*

Adjustmentofthread

Thread

that

link

fabrictoprouide

A.

In

caseofFig. B,

threadIstoo

lower

In

case

threadistoo

upper

1.

Tension

(DThe

tensionisno

except

thread,

(2)

Turn

hook

sirengther

counterclockwise,

*

Thread

(1)

Thread

the

However,

machine

part

remember

button

stitch

sewing

lever

the

togetherinthe

being

tension

upper

thatdonot

by

all

machine.

canbedone

pushed

and

proper

should

and

perfectasshown

threadistoo

of Fig. C,

threadistoo

of

adjustment

the

center

adjustment

and

tight

the

tightorthe

the

lower

thread

of

need

the

special

some

adjustment

thread

tension

to

tight,

to

tension

screw

tension

screwIsslitted,sothat

can

if It

looses

operation,

tightenitaccordingly.

push

means

down.

timing

tension

be

adjusted

lower

middleofthe

the

tensionofupper

or

the

loose.

tensionofthe

loose.

the

lower

necessary

sewing

fabricorthe

willbenecessary.

screwofthe

the

clockwise

and

turn

weoken.

be

made

often

please

open

while

during

thread

tension

tension

ulrtually

to

while

the

the

the

will

sewing

In Fig,

lower

thread

Is

the

easily.

the

slitted

Push

button

;The

•is

too

so

of

lower

:The

'threadistoo

tensionofthe

is

too

Leverse

Proper

tensionofthe

loose,orthe

threadistight.

tensionofthe

loose.

ever

Stitch

uppor

tensionofthe

upper

tight,orthe

lower

thread

thread

tension

of

to

Thread

tension

screw

Loose

15

Page 17

2.

Tensionofupper

(1)

Adjustmentofthe

canbeachievedbychanging

of

the

thread

thread

tension

strength

thread

*

Pressureofthread

{1)To

nuttothe

(2)T0weaken,

and

takeupspring.

strengthen, turn

right.

thread

upper

tension

regulator,

operating

tension

turntothe

discs of

discs

the

thread

left.

thread

tension

the

pressure

the

as well as

range

of

tension

upper

the

the

iThread

•

tension

nut

,

iOk'Strong

* Strengthofthe

Adjust

ing .to

(1) In case of standard fabrics. Approx. 25g.

(21

{31

(4) How to adjust the strength of the spring

the

In case of light fabrics, weaken the spring

In case of heavy fabrics, strengthen

spring

1)

Loosen

shown

2)

Next,

of

the

the

andtothe

3)

Tighten

adjustmentisdone

* Operating range of the thread take up spr

ing

(Din

caseofstandard

Adjust

the

the

positionofthe

when

the

positionofthe

when

the

highest

{2) In

case

Decrease

case

(3) In

Increase

* Howtoadjust

(D

Loosen

the

thread

(2)To increase the operating range, turn

the

stopper

turntoleft,

(3)

After

adjustment, please tighten

screw.

thread

the

strengthofthe

materialstobe

the

screw

in Fig,

fitascrew

thread

studtothe

driver

controller

lefttosterngthen

righttoweaken

the

screw

fabric

interval by

up lever

thread

take

up

tensioned

operating

operating

the

operating range

screw

whichismounted

to

right

thread

take

and

of light fabrics

the

of heavy fabrics

the

the

controller

take

up spring

spring

sewn.

Approx.

Approx.

(A)

on

the

into

the

stud

and

it.

lA)

after

shown

8mm

approx.

take

downtothe

take

up spring

lifts

upper

up spring

thread.

comes

lever

the

range.

range

disc.

andtodecrease,

accord

20g.

the

30g.

arm

groove

turn

in Fig.

from

up

the

the

Thread

tension

stud

Thread

takeupspring

(.$

Screw

it,

its

on

weak

Thread controller disc \ Stopper

strong^,.-'^

weak

strong

Screw

16

Page 18

3.

Adjustmentoffeed

of

the

presser

The

heightofthe

pressure

properly

tobesewn.

(Din

(2) In case of heavy fabrics:

(3)

*

(1) Lay

(2)

(3)

(4)

(5)

When

feed

*

on

adjusted

case of light fabrics:

If

the

feed

the

pressure

sewn

is

willbeobtained.

If

the

feed

or

the

pressureonthe

sewnistoo

will

become

become

unevenorstitch

obtained.

The

height of feed dog is measured

the

feed

from

the

wheelbyhand.

Light

fabrics

the

needle

Standard

the

needle

Heavy

fabrics

the

needle

Adjustmentoffeed

down

other

side.

Turn

the

stop

turnning

be

raisedtoits

the

needle

Loosen

the

Adjust

the

height

moving

as

showninFig.

Tighten

adjusted

Adjustmentofpressureofpresser

Adjustment

foot

arm

a)

the

deliver

dogisadjustedat1.0mm.

can

presser

regulating

shown

Turn

then.

b)

Turn

dog

foot

feed

the

sewn

accordingtothe

dogisraised

on

too

strong,

dogisnot

weak,

poor,

dog

raisedatits

needle

plate

plate

surface

fabrics

. .

plate

surface

....

plate

surface

the

machine

balance

when

plate.

screwofthe

feed dog

the

screwofthe

heightofthe

the

machine,

of

pressureofthe

be

done

in Fig.

the

screwtothe

the

screwtothe

height

and

dog

as well as

material

excessively

the

materials

shrinked

raisedsufficienctly

materialstobe

the

feeding of material

and

stitches

skipping

highest

turning

the

Approx.

Approx.

Approx.

dog

wheel by

highest

feed

screwatthe

height

head

the

feed

position

feed

to

barupand

feed

feed

the

by

means

O.Smmfrom

1.0mm

1.2mm

toward

dog

bar.

the

dog.

heightofthe

righttostreng

lefttoweaken.

pressure

the

must

materials

to

sewing

will

may

when

position

balance

from

from

the

hand

and

would

from

desired

down,

baratthe

foot

presser

of

the

center

O.Smm

be

or

be

mmmmimmMzmTiz

mm,

LOmn

1.2mm

be

Feed

bar

Feed

bar

screw

Pressur regulating

strong

of

weak

screw

17

Page 19

4.

Howtoplace

*

Howtoplace

Place

belowInthe

entangledinthe

is

or

•

Howtoremove

11)

Turn

itwhenthe

position.

(2)

Lay

other

(3) Loosen

(small)ofthe

the

changed

when

the

down

side.

and

remove

the

and

remove

hookinthe

eventofthe

hook,

duetoshockorother

it is

replaced

the

balance

wheel by

needle

the

machine

the

three screws of

hook

the

position

when

withanew

hook

is rais^ to its

head

saddle.

hook

hand

toward

hook

described

thread

its

position

and

highest

the

gets

causes,

one.

stop

the

gear

Hook

gear (small)

Screw

Hook

saddle

(4) Raise up

move

(5)

Remove

(6)

Remove

(7)

Remove

(8)

Take

out

*

Howtoplace

(1) Place

(2)

(3)

the

howtoremove

Place

tongue

position

The

position of placing

producedinthe

the

the

slide

the

needle

the

feed

the

opener.

the

hook holding it.

the

hookinthe

the

needle

of

bobbin

slotofneedle

machine

plate.

plate.

dog.

hook

it.

plate

case

following

head as it is,

waytothe

so astofit

with

plate.

the

hook will be

ways.

contrary

the

hook

the

and

Bobbin

case

opener

Hook

positioner

TongueofBobbin

18

Page 20

5.

The

timingofthe

(1)

Please

length

dial.

(2) As shown in Fig., adjust

the hook and the

position,

2,0mm

Topofthe

lower

position

Tipofhook

the

needle

The

gap

edle

and

{3} In

ordertoadjust

hook

following

* It is

remove

feed

dog.

*

The

positionoftipofhook

As

described

soasto

needle.

(1) Lay

the

(small)

(2)

Raise

turning

stopitwhen

2.0mm

(3)

Turn

the

needle.

(4)

Adjust

saddle

screw

the

and

be

Note:

At

to

screw

leave

each

(5)

Tighteningofthe

Tighten

order:

(1) Pushing

(2)

(3)

hook

set

the

with

the

when

from

its

needle

from

between

the

tipofthe

and

needleasshown

wayisrecommendable;

easiertoadjust,ifyouatfirst

the

presser

below,

cometothe

down

the

other

side,

set

screws

the

machine

the

balance

from

the

hookbyhand

tipofhooktothe

the

by

A, B

gap

between

the

lateral

0.05mm.

this

time,

loosen

the

(C)

too

free

frome

gears

(large)

the

the

the

side

tighten

the

(C)atfirst.

Checking

needle

and

screw

(A)

Tighten

the

and

needle

amount

graduation

the

lowest

the

of

the

ne^le

at the

needleisraised

position.

hole

the

tipofthe

lateral

faceofthe

hook.0.05mm

the

positionofthe

foot,

needle

adjust

the

center

machine

then

(3 pcs.)

head

loosen

head

the

2.5ofthe

position of

following

Center

in Fig.,

plate

tipofhook

lineofthe

as it is,

wheelbyhand

the

needleisraised

the

lowest

position.

and

centerofthe

position

loosening

and

sideofthe

please

screwinthe

C (2

the

tipofthe

take

set

screw

loose,

engagement

and

screw

of

the

the

adjusting

pcs.),sothat

needle

care

of

and

not

(small).

following

gear (large) slightly to

of

the

hook

set

screwofthe

the

gap

hook,

between

tighten

the

completely.

screw (B).

stitch

1.6mm

hook.

toward

the

adjust

not

the

to

of

saddle,

screw

the

and

gear

and

and

hook

hook

.may

the

the

1.6mm

Tooofthe

needle

hole

2.0mmup^T~ri

by

of

ne

Lowest T V

position

of

the

needle

Center - ^

of

the

needle

Tipofthe

Screw

gear

Set

screw

by

A

screw

B screw C screw \

Hook

saddle

^

hook

Tipofthe

O.D5mm

A

B

screw

\

screw

hook

Hook

saddle

19

Page 21

6.

Adjustment

needle

{1i Using

box.

clamp

(2)

Remove

bar.

(3) Adjust

and

the

(4)

Insert

stopper,

(5)

After

(A)

7.

Proper

When

of it,

timing

following

(1)

Turn

it

to

(2) Lay

other

arrow (timing mark) of timing

and

holderisproperly

(3) In

not

Fig. Please adjust it by removing

timing

of

the

up-down

the

hex agon

loosen

setting.

the

the

down

needle

the

adjusting,

completely

timingofthe

removed

the

relationofhook

wouldbeadjusted

condition;

the

balance wheel by hand and

when

the

its

highest

down

side,

the

caseofthe

corresponded

belt.

wrenchinthe

the

screw

needle

clamp

clearance (C), by moving up

the

adjusting

clamp.

adjusting

and

place

tighten

with

hook

the

timing

thread

position.

the

machine

and

checkupwhether

bossofhook

corresponded.

arrow

properlyasshown

position

(A)

for

from

the

screw

screw

the

needle

the

the

hexagon

and

takeuplever

beltbyreplacing

and

takeuplever

accordingtothe

takeuplever

head

towardthe

belt

shaft

and

the

accessory

needle

needle

for

the

upto

the

clamp.

screw (B)

wrench.

stop

raised

the

pulley

bushing

boss

the

Stopper

of

Needle

bar

Needle

comeup

^

Needle

down

come

Adjusting

j

screw j

Needle

clamp

is

Mark in bed,

in

Timing

mark

Timing

belt

pulley

Timing

belt

8.

Relative

(DTurn

(2) At

(3) When

positionofthe

the

when

its

this

Fig.

the

farmost

the

opener

balance

opener

time, check up

the

gap

exceedingly,

it

to

between

shouldbeby

in

decreased

positionofthe

(B) of

hook

and

wheel by

holder

from

(A) of

hook

approx.

would

opener

holder as shown in Fig.

the

hand

and

would

the

needle

whether

and

the

0.2mmasshown

be increased

please

adjust

loosing

the

opener

stop

become

plate.

the

gap

opener

the

screw

Approx.

0.2mm

or

Opener

Opener

holder

20

Page 22

9.

Positionoffeed

(1) Pushing

buttononthe

toward

stops

stitch

the

and

lengthIszero.

the

you.

automatically

length.

balance

when

(21Atthis time, when

and

(0)ofbalance

corresponding

arm,

please

as

following:

(1) Lay

down

the

other

(2) Loosen

feed

regulator

(3) Pushing

balance

tion

(0)or(5)tothe

arm.

(4)Atthe

screws

regulator

stitch

length

bed,

turn

and

when

shows

On

wheel

the

toward

stopsitshows

the

wheel

with

the

large

cam.

push

and

the

the

machine

position,

adjust

side.

the

the

wheel

adjusted

(2 pcs.)onthe

regulator

the

balance

the

balance

the

contrary,

the

graduation (5)

would

mark

feed

regulator

head

screws

(2 pcs.)

button,

adjust

the

markonthe

tighten

cam.

other

the

turn

push

wheel

wheel

largest

turn

side,

stitch

not

on

the

cam

toward

the

gradua

the

Feed

rock

shaft

be

cam

of

Large screw

Feed

regulator

cam

21

Page 23

10.

•

Relative

positionofneedle

Adjustsothat

of

the

{1j Pushing

on

the

set

the

the

arm.

(2) Lay

down

other

(3)

Loosen

feed

shown

(4)

Raise

feed

bar

the

needle

centerofthe

(5)Atthis

machine

and

(B)ofthe

(6) As

this

whether

(right)

angle.

(7) If it Is

front

screw (C) of

then

right

(8)

After

tighten

needle

needle

holeofthe

the

stitch

bed,

graduation

side.

the

link

In Fig.

the

movingtofront

position

head,

time,asshown

the

would

not

cover

adjust

angle

adjusted

the

regulator

turn

the

(0) to

the

machine

screw

on

machine

(A)

the

back

head

would

be

needle

as it is,

and

tighten

feed

link.

rod

and

properlybeadjustedatright

at the right angle, remove

and

top

cover,

the

needle

it so astobeatthe

eack

other.

the

screws (A) (B)

respective

and

feed

dog

dropsinthe

feed

dog.

push

balance

wheel

the

mark

head

toward

and

(B)ofthe

of

the

and

adjust

and

backsothat

dropped

holesoffeed

lay

down

the

screw (Aj

in Fig.,

check

the

feed

and

loosen

bar

lifting link,

and

(C).

center

button

bed

on

dog.

proper

parts,

and

the

the

the

the

on

link

the

as

up

the

Back

of

the

Feedink(Left)

Screw

Center

\ N\ Feed shaft and pin

\\\Feed

(A)

line

of

Screw

link (right)

prin

(C)

Needle

connecting

(B)

bar

rod

22

Needle

bar

connecting

rod—f-7

Screw

f

Page 24

6. Maintenance,

trouble

1.

Cleaning

Clean

away

teethoffeed

and

thread

ununiform

2.

Lubrication

The

most

lubrication.

the

machine

and

tear.

(1)

The

numberoftimesoflubrication

1. In

3

timesIna

2. In

everday

(2)

Place

(1)Dust

lubrication

cleaned

and

on

(2) You

place

in Fig.

face

(3)To

opening

to

opening

howtofind

always

dust

dog,

thread

controller

stitching.

important

Please

the

caseofusual

the

eventofcontinuous

wheretolubricate

attached

the

the

dust.

should

where

plate).

the

the

disc

careofthe

If

you

neglect

shortened

lubricateasfollows:

week

on

os

away,

requirred

for

lubrication

oil

throughlytothe

indicatedbyarrow

(bed

and

place

(A) in

the

slide

place

(B) In Fig., oil

the

slight

and

repari

covering

the

tension

which

machine

it,

withaheavy

the

working

once

everyday

the

parts

the

dust

absoads

is

not

inside

partsonthe

Fig.,

plate

(left),

plate

(front).

hook,

regulator

will

cause

life

...

at 2 or

working

where

should

sufficient

every

shown

oil

the

wear

oil

after

and

after

is

of

be

23

Page 25

3.

Trouble

and

repairing

Trouble

1.

Stitch

skipping

Cause

1)

Duetoneedle

a)

Bent

b) Damaged needle (weak)

c)

2)

Needle

a)

b)

c)

3)

Damaged

(Proper) (Improper)

needle

Needle

and

matching

thread

not

inserted

Insertionisnot

there

is a

gap

Needle

distorted

Needle

attachedonthe

opposite

side.

hook

not

size

enough

enough

Repairs

Change

the

needle

Change

the

Use

the

correct

Inserttothe

Attach

the

(But, in case using

distance

ing of

Correct

keeping its groove side

the

loop

the

hollowed side

Either

change

with

needle

with

size

bottomofthe

?

u

needle

as its

the

needle

hole

finish).

attaching

toward

side.

the

the

hookorsmoothbyoil

new

one

excellent

hole

needle

faces

one.

clamp

sideway.

nylonortetolon

somewhat,

(Attach

toward

right.)

(Refer

the

to page 10.)

after

the

left, and

thread,

check

needle

stone.

K K

4)

Gap

between

needle

too

5)

Relative

positionofhook

and

needle

a:

Hook

b:

Hook

6)

Pressureofpresser

not

sufficient

set

set

large

hook

not

correct

forwarr"

backeward

and

foot

Correct

0.05mm

When

tion,

Turn

strengthen

the

24

the

(diameterofhair)

needleisraised

set

the

tipofhookatthe

the

pressure

the

sewn

fabrics.

hook

positiontohaveagap

(Refereto

2mm

from

(Refer to page 19)

adjusting

pressure,

but

take

page

19)

its

lowest

centerofneedle.

screw

clockwise

care

nottoshrink

of

posi

to

Page 26

T

2.

Irregular

stitches

rouble

1)

2)

3)

Pressure

too

weak

Thread

weak

Working

take-up

Cause

for

tension

take-up

spring

sphereofthread

spring

too

narrow

disc

too

Turn

its

nut

Turn

the

littlebylittle.

For

heavy

Turn

the

working

the

sphere.

working

Repairs

clockwisetoincrease

(Refer

tension

stud

clockwise

fabrics,

increase

(Refertopage

tension

For

stud

clockwise,

very

sphere.

to page 16)

the

pressure.

light

the

for

to

fabrics,

pressure.

increasing,

16)

increase

increase

4)

Under

thread

weak

Unbalanced

5)

a:

Thread

b:

Poor

Dust

c:

tension

d:

Poor

on

Bobbin

springisbentorbroken

Placingofbobbin

correct

6) Relative position of

needle

7) Damaged

8)

Improper

dog

tension

thread

size

unbalanced

wound

thread

deposited

discs.

windingofthread

bobbin

case

tension

not

matching

hook

timingoffeed

too

between

not

hook

and

Tighten

little,

Use

Use

difficulttobe

Remove

burnish

of

Correct

Place

bobbin

thrad.

and

proper

the

well

the

Rewind

threadonthe

the

the

the

adjust

the

the

bobbininthe

may

(Refertoparagraph6of

Regulate

Change

Adjust

the

the

the

bobbin

case

thread

tension

the

(Refertopage 15)

grade of thread

wound

thread.

led.

tension

bobbin

bobbin.

turn

hook

into

regulator

correctly.

bobbin

clockwise,

set

position.

(Refertopage 19)

new

insideofdiscs

bending,orchange

hook

positionoffeed

tension.

Poor

nut

thread

into

when

one

regulator

screw,

little

wound

thread

and

discs,

wayonthe

Wind

about

new

one.

case,sothat

you

lead

page

11)

and

stud

4/5

by

the

the

is

25

Page 27

3.

Trouble

Thread

cuts

1)

Duetothread

a:

Poor

b:

Right

for

c;

Thread

needle

2)

Duetoneedle

a:

Bent

b:

Needle

or poor hole |

c:

Needle

correct

d:

Needle

thread

3.

Upper

strong

4)

Working

up

lever

Cause

thread

twisted

upper

needle

thread

the

too

thread

too

big

size

with

attaching

too

thin

size

tension

thread

fast

thread

poor

for

not

for

take-

used

the

groove

the

too

Use

the

thread

Changeitwith

better

cannotbeused.

Changeitwith

Changeitinto

Change it

into

Refertothe

Change

the

Turn

the

the

tension is

the

tension

upper

and

weaken

(If

tightening,

tightening

Loosen it by

regulator

counter-clockwise.

machine

left

the

new

good needle

paragraph

needle

thread

too

check

correct

turning

Repairs

thread.

twisted

thread

proper

size

one.

concerning

into

the

suitable

regulator

the

tension.

strong

duetothe

causeofthe

it.)

the

upper

conterclockwise

(Refer to page 16)

thread

thread

Irregular

the

skip-stitch

one.

insufficient

insufficient

thick

and

tension

5) Thread

6) Hook

strong

take

hurt

up spring

(damaged)

7) Damaged needle hole in

needle

plate

8) Unbalanced strength

thread

9) Relative

and

positionofhook

needle

not

matching

too

of

Turn

the

weaken

duetothe

ofitand

Grind itbyoil

the

out

not

needleisused.)

Grind

plate

the

out

needleisused.)

Refertothe

tightening.

Regulate

tension

the

insufficient tightening, check

correct

neeldeincase

during

the

placed

in a

the

needle hole, or change

into

new

needle,incase

during

the

paragraph concerning

the

stud

spring. (If

it.)

stone.

the

machine

proper

one.

(Ne^le

the

machine

hook

set

counter-clockwise,

the

spring is

(Hook

maybehurt,

sewn

materials

operationorthe

position,orthe

plate

sewn

may

materials

operation,orthe

the

position

(Refertopage

and

too

strong

the

cause

are

taken

hook

bent

the

needle

behurtby

are

taken

bent

insufficient

19.)

by

is

26

Page 28

Trouble

4.

Puckering

5.

Irregular

stitches

Cause

1)

Thread

and

thick

for

(In case of sewing up

material,

needle

The

2)

too

3)

Upper

strong

(Thread

strong)

4)

Lower

strong

5)

The

Stitch

6)

for

1)

Bent

needle

2) Pressureofthe

foot

3)

Improper

feed

material

thicker

causes

pressurebypresser

strong

thread

take-up

thread

feed

dog

length

materials

needleordamaged

point

too

weak

heightofthe

dog

needle

thread

puckering)

tension

spring

tension

too

high

too

long

presser

too

thin

too

too

and

foot

too

Repairs

Change

with

fine

thread

and

needle.

Turn

the

presser

lefttoweaken

Turn

the

tension

regulating

nuttothe

thumb

(Refertopage 16)

lefttoweaken

(Refertopage

Turn

the

tension

to

weaken (Refer to page 15)

Loosen

and

the

crank,

screwofbobbin

screwofthe

adjust

the

feed lifting rock

heightoffeed

(Refertopage 16)

Shorten

Apply

the

stitch

Changeitinto

with

oil

stone.

more

new

pressure

length

for

one,orgrind

for

heavy

thin

the

materials.

(Refertopage

Set

higher

for

thick

fabrics

(Refertopage 17.)

screwtothe

13)

casetothe

dog

materials.

needle

17.)

left

shaft

point

6.

Needle

breaks

1)

Needle

2)

Poor

3)

Needle

enough

4) Needle

hooks

5)

Feed

6)

Needle,

not

matching

bent

gradeofneedle

inserted

not

knocks

against

timing

not

correct

fabrics

and

thread

Changeitinto

Changeitinto

Refertothe

Adjust

that

clearanceofthe

needle is

not

proper.

Regulate

Use

proper

27

new

new

paragraph

the

set

not

enough,orthat

the

feed

size

one

one

concerning

positionofthe

tipofthe

(Refertopage 19.)

earn

setting

needle

the

hook.

hook

the

timingofthem

position.

skip

The

stitch

cause

and

the

is

is

Page 29

MEMO

28

Page 30

;•

' .•••-

•yT-'^/yy^r

^

\v.

•>•-'

••

•''//•-••.y

•<,

-v.xxC-

• V,\--^

'•'

^-•

\o'^\\\\^.'-"'"^ •• >

:/ly^•^•',>:

<

'/;.-•'yV-y^/.-:

;

-A-z/y/

yM//

/:yy

♦

r^lTSUBiSH!

No.

2-3

2-CHOMe

ELECTRIC

MARUNOUCHI

CORPORATION

CHIYODA-KU

TOKYO

iAPAN

Loading...

Loading...