Page 1

MITSUBISHI

INDUSTRIAL

DN-260

A

SEWING

MACHINE

Model

classes

INSTRUCTION

FOR

OPERATION

MANUAL

Page 2

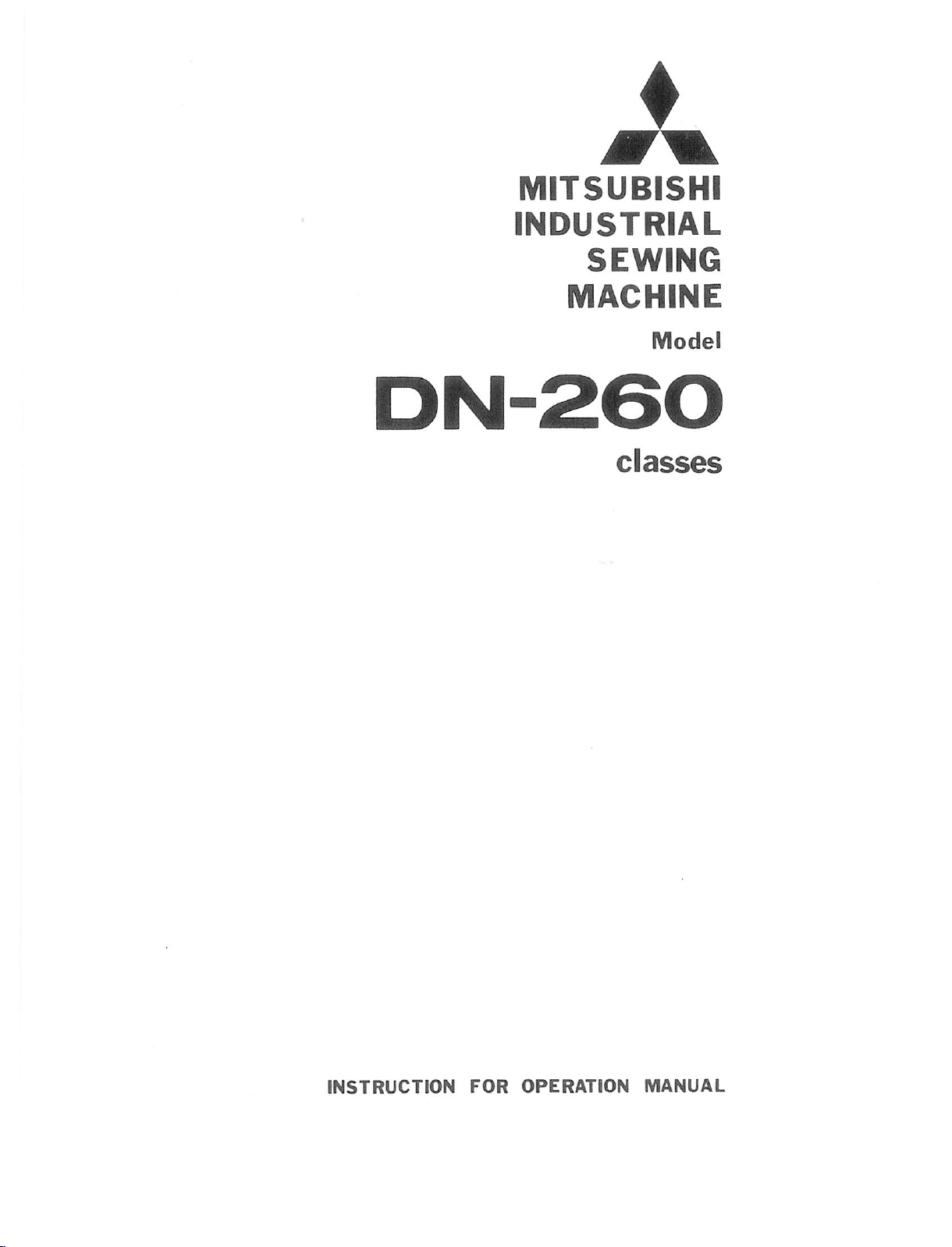

Main

parts

name

of

machine

head

1) Press

2) Press

3)

4)

5)

6)

7)

8)

9)

10)

Oil

level

Thread

Arm

Balance

Front

Arm

Upper

Thread

stud

bar

guide

top

cover.

thread

Howtoinstall

•28mm*33.5mm

for

oil plunger.

for oil plunger.

indicator.

(topofarm).

cover.

wheel,

tension

controller,

and

adjust

^

regulator.

the

knee lifter

11)

12)

13)

14)

15)

16)

17)

18)

Bed.

Stitch

Slide

Needle

Slide

Hook

Throat

Hook

regulator

plate

clamp

plate

saddle,

plate.

saddle,

(right).

(front).

(right)

(left)

push

button.

21)

22)

23)

24)

25)

26)

27)

28)

19) Slide plate, (left) 29)

20)

Presser

foot.

Needle

Presser

Thread

Thread

Face

Thread

Pre-tension.

Feed

Thread

Roller

bar.

bar.

guide

guide

plate.

guide

reverse

take-up

complete.

Lifting

(lower).

(middle)

(upper).

lever

lever

rod

Knee

I j

'Extension

plate

Knee

bracket

lifter

\

c

Screw

Page 3

How

to

use

the

machine

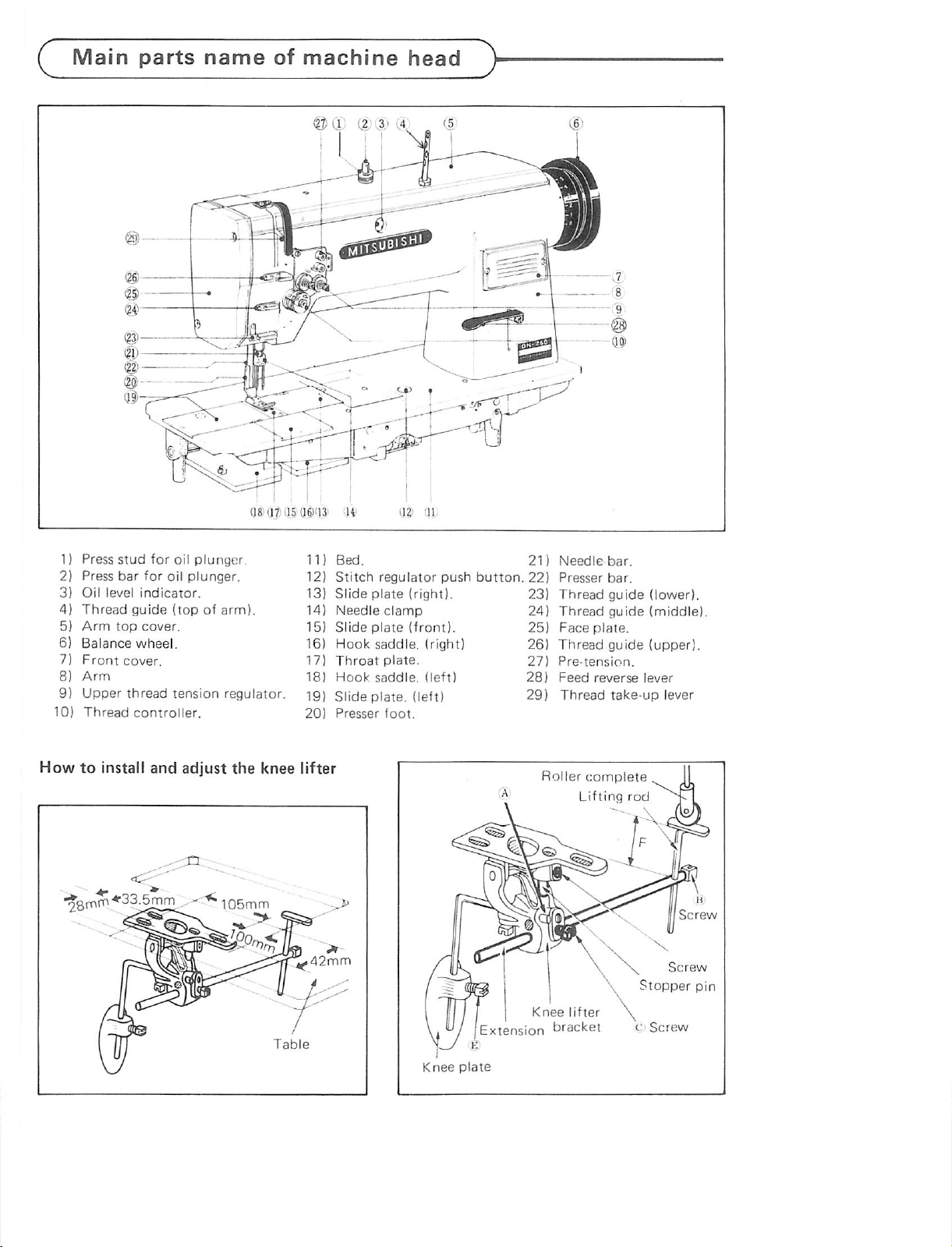

1.

Insert

of

screw

screw

of

How

needle

to

the

needle

keeoina

keeping

attach

needle

clamp

toward

needle

opto

the

and tighten the

the

lona

long

the

afoove

groove

face

the

bottom

side

side

to

face.

Note:

Insufficient

insertion

Before

switch

making

off

the

the

power

Needle

following

source

distorted

adjustment,

by

all

means.

2.

How

to

on

the

Adjustinent:

wind

the

lower

bobbin

**

Strength

It is

thread

of winding: Particularly in case of

desirable

that

Note:

In

case

ing,

the

bobbiniswound

keep

of

rotate

the

** Uneven winding: In case of uneven winding,

guide slightly toward

even

** Winding

cessive loosen

winding.

amount

Winding

adjusting

Winding

adjusting

of thread: When

the

tension

screw

\

the

less

adjusting screw

Thread

guide

amount

screw

wound

the

and

part of bobbin so

winding

tighten

the

machine

presser

foot

nylonortetoron

enough

loose.

amountofthread

when

without

raised.

adjust

the

thattoobtain

insufficient.

Even

winding

with

amount

4/5offull

capacity

sew

thread.

thread

is ex

of

Page 4

How

to

c

3.

Threading

machine

Note:

guide (A) should

be

above

spool.

4.

Adjustment

Stitching

the

bed

1)

2)

Caution:

while

To change

tacking,

lowest

pleted.

The

positioned

the

stitch

and

the

Pushing

turn

the

ward

you.

So

that

further

ning.

At

this

the

dial

the

marking

release

Fig.

the

position

use

the

machine

the

thread

just

thread

/gff

of

stitch

length

length

regulator

and

the

NEVER

machineisrunning.

the

depress

can

be

adjusted

push

button

balance

the

balance

the

time

on

push

push

the

set

the

on

push

wheel.

button

wheel

button

balance

the

Balance

the

button

arm

graduation of

depress

direction of feed for back

feed

reverse lever

until

back

]

with

on

the

down

slowly

goes

wheel

Wheel

the

tackiscom

down

and

shown

button

Mark

and

to

run

with

then

in

to

Raise

the

position

following

(R7)

r

Right

to

left

Howtoplace

into

the

Note:

thread

and

order.

(L7)

take-up

thread

the

(L5){L3')(L2'ML1)

1(L6)

R12)

Left

to

right

the

shuttle

In caseofplacing

the

shuttle

by

thread

in Fig.

hook

making

in

bobbin

hook,

correct

levertoits

upper

»(Detail)

Thread

the

place

winding

direction

highest

threadinthe

bobbin

the

toward

into

bobbin

the

shown

Stitch

o

regulating

button

^

Balance

wheel

Feed reverse lever

Winding

Slide

towardofthread

plate

(b;

Hook

shaft

Slide

plate

(K)

Hook

Shaft

Page 5

c

How

to

use

the

machine

>

Lower

threading

1) Lead the end of thread to the groove

of the shuttle hook 0 shown In F

and

2)

through

thread

Holding

by

left

wheel

thread

from

foot.

out.

slowly.

the

Thread

Bobbin

the

hand

and

holditon

underneath

the

end

and

horn

case

of

Pull

opener

the

turn

out

the

of

(2) . pull

upper

the

the

the

other

ig.

the

Thread

thread

balance

lower

side

presser

7.

Adjustment

Upper

**

**

For

thread,

tained

erating

The

is

lower

cx

The

threadistoo

of

thread

Upper

to

the

Upper

tension

special

by

of

thread

tensionofthe

too

loose,orthe

threadistight.

tensionofthe

the

lower

tension

thread

lower

thread

thread

regulating

fabric

the

desired tension can be ob

adjusting

range

of

tension

Proper

tight,orthe

threadistoo

is

adjusted

Stitch

upper

tensionofthe

upper

tension.

tensionisadjusted

thumb

sewing

the

tnread

with

strength

take-up

thread

tension

loose.

according

nut.

special

and

spring.

by

op

9.

Lower

Thread

thread

tension

screw

I

tension

Thread

tension

nut

Strenathen

Weaken

(0^

10.

Adjustment

on

presser

Pressure

on

of

foot

the

pressure

presser

footistobead

justed in accordance with materials to

be

sewn.

Pressure

Strong

regulating

Weak

screw

Page 6

^

Trouble&Repair

^

Skip

Irregular

stitch

Trouble

stitching

1)

*

*

2)

*

'

•

1}

2)

3)

1)

2)

•

•

•

Causes

Needle

Bent

Not

suited

thread

Wrong

needle

Insertion

enough

Needle

Attached

opposite

Upper

tension

Thread

spring

Lower

tension

Poor

Needle

Needle

Wrong

needle

Thread

for

the

size

attached

not

distorted

side

thread

too

take-up

too

thread

too

thread

bent

attached

too

needle

with

with

weak

weak

weak

big

Repairing

Change

Replace

of

Insert

Attach

the

what,

its

Correct

groove

right.

Turn

the

Turn

Turn

strengthen.

Change

Change

See

Either

needle.

the

needle

with

thread.

proper

properlyasper

the

needle

nylonortetoron

after

checkingofloop

the

attaching

side

toward

the

upper

righttostrengthen.

the

the

the

the

No.2of

change

thread

tension

bobbin

thread

needle

skip

with

with

new

one

accordingtothe

instruction

as its

hole

thread,

side,

the

left,

tension

studtothe

case

tension

with

better

with

new

stitching.

proper

one.

manual.

faces

side

distance

ways.

the

finish.)

attach

the

and

needle

concave

regulator

righttostrengthen.

screwtothe

quality

one.

one.

size

threadorwith

thickness

needle

keeping

side

thumb

right

(But,

hole

toward

nut

to

proper

using

some

its

the

to

Thread

Puckering

cuts

3)

Upper

thread

tension

*

Dust

deposit

between

discs.

*

Excessive

uneven

of

lower

on

the

*

*

*

1)

2)

case

Wrong

bobbin

Dust

deposit

bobbin

Damaged

tension

inserted

bobbin

bobbin

Needle&thread

too

big

Thread

(upperorlower

thread)

3)

Pressure

presser

too

strong

tension

or

winding

thread

case

thread

on

bobbin

into

case

for

fabric

tension

of

foot

Turn

the

tension

Remove

the

Rewinding correctly with

of

its full

capacity.

in

Remove

Change

Replace

clockwise

the

with

the

Change with

Adjust

spring,

the

adjusting

Weaken by

tension

bobbin

new

bobbin

when

proper

thread

turning

regulator

discs

case

nuttothe

and

clean

the

winding

and

cleanbybrush.

by

one.

correctly,sothattorotate

the

threadispulled-out.

size needle

and

thread for fabric.

tension by regulators

screwonthe

the

bobbin

regulating

thumb

lefttoweaken.

brush.

amountof4/5

the

thumb

nut,

case.

screwtothe

bobbin

take-up

left.

Page 7

Precaution

1.

Lubrication—1

Before

the

position,

of

oil

tank.

Oil

indicator

high

level

(DO

NOT

OVERFILL)

starting

point

before

to

arm,

'

operate

bed

and

starting

pour

oil

hook

upto

saddle

to

operate

Lubrication—2

The

volume

of

5-6

lubrications

drops.

2)

Bed

oil

tank

Oil

filler

hole

Oil

indicator

3) Hook saddle oil tank (left to right)

Oil

gauge

Oil

filler

hole

-VOi! gauge'

m

Open

slide

oiltoall

just

under

the

slide

plate.

ptate^and

wicks

apply

r,

fWi

2. Adjustment of rotating hook oil flow regulator

l\

Decrease

Adjusting

Hook Hook

^^1

saddle saddle

.

Nut

o \oj jo I o

Adjusting

screw

Page 8

Howtomount

rubber

with

The

vibration-preventing

prevent

thereby

the

machine.

cornersofthe

•

Achieve

and

of

facingtothe

is

achieved.

• Nail

down

as

shown

^

Specifications"^

vibration-preventing

table

the

machine

to

provide

Fit

tableasshown

spot

facing

13 mm

the

depthatthe

table. Be

faceAwhere

the

vibration-preventing

at

the

four

in Fig.

these

rubber

from

vibrating

smooth

rubber

of

operation

20

suretogive

corners

is used

at

in Fig.

mm

four

spot

of

the

and

the

four

radius

corners

smooth

facing

rubbers

table

of

to

5.5m/m

Vibration

preventing

Table

ISm/in

rubber

MODEL

Number

Speed

Rotary

Max.

Needle

Presser

Spaceatright

of

Needle

Reverse

Typeoftable

Gauge

Bed

stitch

needle

dimension

of

hook

bar

stroke

foot

lever

(Standard)

(Special)

needle

length

lift

hinges

DN-260-10

two

4,000

s.p.m.

regular

5mm((5

33.4mm(1-5/16")

7.2mm(9/32")

245mm(9-11/16")

l35x7(DPx7)

DN

3.2mm(1/8").

2.4mm(3/32"),

8mm(5/16"),

16.0mm(5/8"),

and

517mmx178mm

(20-3/8"x7")

size

s.p.i.)

Type

38.9mm(1-1/2")

DN-265-10

two

3,500

regular

same

33.4mm(1-5/16")

same

same same

/5'14./5'16

same

equipped

same

4.8mm(3/16"),and

4.0mm(5%32"),

9.5mm(3/8"),

12.7mm(1/2").

25.4mm(1").

same

s.p.m.

size

6.4mm

(1/4")

5.6mm{7/32"),

28.5mm(1-1/8"),

DN-260-22

two

3,000

s.p.m.

large

size

same

35mm(1-3/8")

same

same

same

same

same

but

not

for

38.0mm(1

same

DN-265-22

two

3,000

large

same

3bmm(

same

same

same

equipped

same

same

ailable

av

-

1/2")

same

s.p.m.

size

1-3/8")

A

MITSUBISHI

HEAD OFFICE

MITSUBISHI

OEMKI BLDG MARUNOUCMI

ELECTRIC

TOKYO

CORPORATION

'00

TELEX

J24532

CABLE

MElCO

TOKYO

PrintedinJapan

Loading...

Loading...