Page 1

♦

MITSUBISHI

INDUSTRIAL

SEWING

MACHINE

Model

classes

M

Series

INSTRUCTION

FOR

OPERATION

MANUAL

Page 2

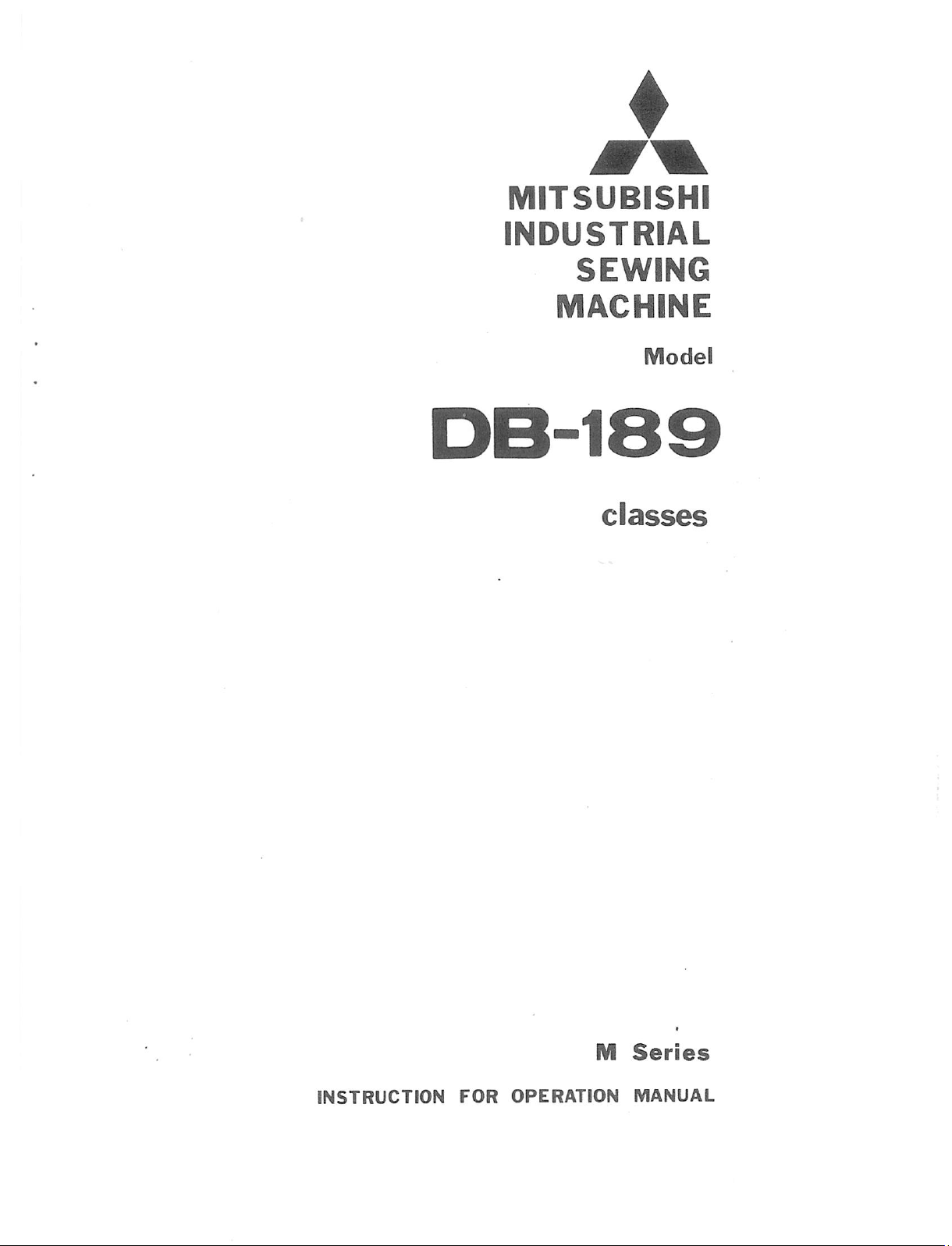

Main

parts

name

of

machine

Balance

/ /

Face

plate--.^Jll

I I

Reverse

Contrciier

switch

Limi-stop

type

clutch

Clutch

Auxiliary

\ Wiring connection between motor and Pass the two

control

When

When

safety

safety be sure to switch off or pull out Be

the

the power plug from the electric outlet.

I

To

Timing

of the

is

made by the'following.

box;

connecting

connecting

be

suretoswitch

power

stop

needle

mark©is

pedal.

the

electric

the

electric

plug

from

offorpull

the

electric

baratpre-set position

contacted

Materials

are

fully

0

plug

box-» :

^

motor

lever

y'

motor

machine

table

wire,

for

wire,

for socket respectively on

out

outlet.

sockettopreventanaccident

tric

cAdjustment

with(©and

a^usted,

stops

after

however,

through

and

insert

suretoattach

shock and damages of

synchronizer>

completing

ifthe

wheel

Synchronizer

•Safety

(2)

cords coming

the

each

plug

the

the

trimmingbykick-up

gapisabove

button

stopper

round

earth

3mm,

switch

out

hole

into

the

the

controller,

of

the

by

apparatuses.

adjustment

of the

of

the

mating

power

an elec

Preparation

(1)

Take

off

the

the

cord

the

controller.

then

the

chine

and

make

the

Adjustment

(1)

Loosen

supporting

timing

wheel

time,

the

pedal

times

lized.

marks

then

adjust

print

and

to

plug (with

coming

detector

following

platetoabout

ensure

stop

the

the

(B)

tighten

the

repeat

outofthe

(2)

Remove

cover.

itata

adjustmentsinthis

set

magnet

and

the

clearance

kick-back

that

twelve

machine

two

screws

(3)

Operate

needle-up

screw

(two

ring

by

(C)byturning

set

screws

between

0.8

mm

(2)

operations

the

stop

positionisstabi

(12) pins)

head

position,

condition.

pieces)

hand,

the

again.

the

Steponthe

from

(A)

the

while

fit

balance

At

ring

several

and

ma

and

the

this

and

of

Timing

_

mark

Magnet

^ ^

ring

nsm

print plate

*11*

0-8—

0.2mm

Page 3

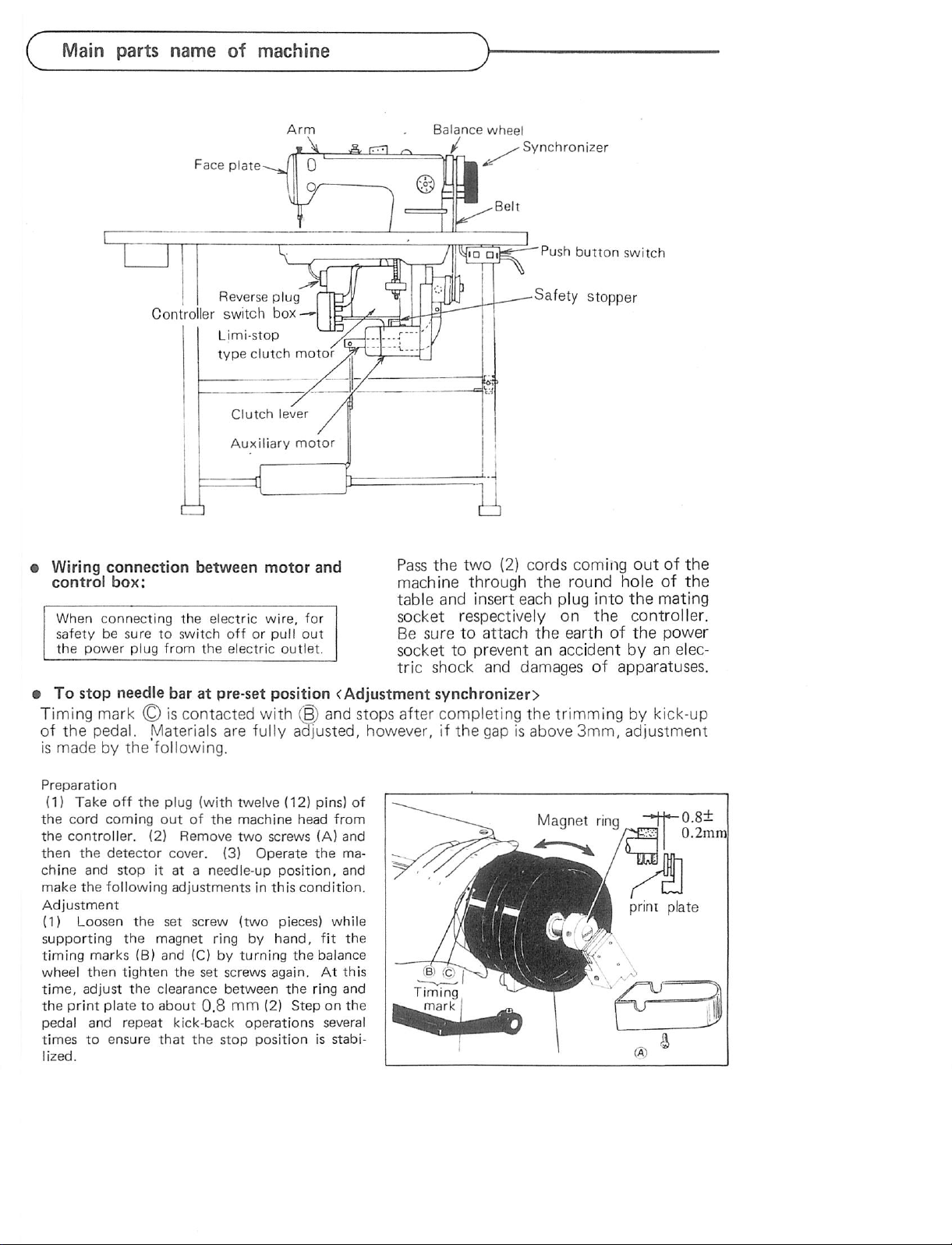

die

clamp

ing

the

toward

upto

and

long

the

the

tighten

groove

left.

bot-

ote.

Insuff

inse

sw

Be

g

direction

on

the

Adjustment;

bobbin

**

**

Strengt

Uneven

Wmdin

i

o

is

sli

i

Winding

adjusting

X

tension

screw

O

i

Winding

adjusting

amount

screw

Even

with

4/5offull

capacity

winding

amount

of

Page 4

Howtouse

3.

Threading

Raise

the

thread

est

position

in

the

following

and

the

take-up

thread

order.

machine

levertoits high

the

upper

t

thread

Thread

Thread

spring

take-up

^

Note:

5.

The

thread

istobe

Adjustmentofpressure

on

presser

Pressure on

guide (A) of

put

foot

the

presser

just

aboveofspool.

foot

justed in accordance with materials to be

sewn.

For

weight

rnaterial

(weaken)

Pressure regulating thumb screw

light

For

heavy

weight

material

istrenqthen]

cotton

is to be ad

stand

4.

Adjustmentofstitch

&

reverse

Note:

Stitch

adjusting

For

desired

reverse

by

stitch

length

Reverse

lever

lever

lever

dial

stitch

downward

length

\

Upper

guide

length

length,

adjusting

thread

and

dial.

push

adjust

the

•When

sewing is made all while

is pushed by pushing

the

touch

back

is

fixed,

the

push-button

the

push-button

reverse

lightly during sewing. When the hand is

set

free

sewing

from

turns

^ ^

the

into

push-button,

forward sewing.

reverse

^

1]

/if

j/ j

•

If^P

HI .

^Push-button

mm

Page 5

How

c

6.

Adjustment

thread

O

7.

Upper

**

Upper

the

*»

Upper

tension

For

thread,

tained

erating

Standard

ment

take-up

8.

Lower

Thread

spring--.

to

use

of

tension:

Well

balanced

stitch

thread

lower

special

the

by

range

adjust

of

thread

spring

thread

tension:

threadisadjusted

thread

thread

regulating

fabric

desired

adjusting

of

Light

weight

Medium

weight

tension

Strengthen

the

machine

y/

tension.

tensionisadjusted

thumb

sewing

tension

the

thread

tension:

Lower

canbeadjusted

screw

according

nut.

with

can

strength

take-up

Tension

strength

lOg

15-30g

Weaken

thread

A.

in

case

too

strongorlower

is

too

to

by

special

be

ob

and

op

spring.

Operating

range

6 —

7mm

6 —

8mm

tension

by

>

weak

upper

In

ff60,

sion

following.

pulled

the

the

tained.

thread

thread

case

the

can

out

bobbin

proper

is

^

of

cotton

regular

be

thread

checked

Hold

thread,

case

fall

tensionisob

the

In

case

too

weakorlower

is

too

thread

ten

as

the

end

of

and

if

slowly,

upper

strong

thread

Weaken

is

thread

Thread

tension

nut

Strengthen

Rotation

of

bobbin

9.

Adjustment

lubrication:

of

hook

oil

Adjustment ismade by means of oil lubri

cation

(0

ring (A). Regular

less

- 3

more)

amount;

1.5—2.0

Page 6

How

*10

The

(1)

stitching

speed stitching. (3)

down

up position after thread cutting.

• Speed adjustment is possible by

the amount of step-on between the above (1)

and (2). Direct kick-back

also ensures

11. Howtotreat

(1)

to

use

the

machine

Orderofpedal

(Operation

peda!

can be operatedinfour

Light

forward

(inching).

position.

startofstitching

Open

stitching

operation

of

machine)

step-on :

(2) Deep step-on :

Neutral

(4) Kick-back : Stop at

normal

thread cutting.

the

Low

: Stop at needle-

from

needle thread at

When starting to stitch

having

presser

IS

cloth

this

the

foot, the end of

stitched

together

case

start

upper thread held by

to

the

reverse

with lower thread. In

the

first

very slowly to prevent

of

the

thread

from

the

(4) steps.

speed

controlling

(2) to (4)

without

upper

sideofthe

2 - 3

stitches

the

slip

needle

High

needle-

thread

out

hole.

Upper

Upper

Lower

Upper

thread

thread

thread

thread

(2) When upper thread held under pres

ser

foot

the

mains

on

the

endofupper

surfaceofcloth.

thread

re

For

this way of stitch, it is advisable to

pull out the sewnfabric to the other

side.

12.

Adjustment

taif

for

length

of the

thread

In case the length of the upper thread

tail is changed according to the stitching

condition, adjustment can be

pretension

spring pressure.

made

by

Tighten the tension; Short thread tail

Loosen

• In case of using the cotton thread and

the

tension:

Long

thread

tail

the thick polyester thread, change the

pretension spring with the thick one.

• In case of making

the

upper thread

further lengthen, make the thread

guide

operate.

Howtooperate

Take

1.

the

presser bar lifter.

2.

Attach

off

the

thread

the

face plate and pull up

the

wire

guide

in

the

accessory

(Hook the wire in holes of the bell

crank

shown

and

in Fig.)

the

thread

guide

as

Insideofface

Bell

crank

Wire

Pretension

\

plate

'Thread

guide

Page 7

Precaution before starting to operate

1.

Lubrication—1

Before starting to operate pour oil up

to

the

operating

position

the oil volume periodically, and in

case

oil

the

the

3

While

essary

lubrication

dow.

volume

position

position

Knee

Condition

operating the machine it is nec

to

you

(A)ofoil

are

requestedtocheck

would

tank.

come

(B) replenish oil uo to

(A).

lift

pin

of

oil

lubrication

check

through

the

the

condition

oil

check

less

While

than

of

oil

win

2

Lubrication—2

When starting to sew initially and

after

kept

using it is essential to oil

idle for a long

through

the

oil

holesinthe

time

without

enough

red

color

ed rubber plug.

r Right side

Oil

check

Periodical

*

Remove

plate

dog.

window

and

cleaning

the

clean

f'

I

the

throat

feed

^Remove

and

clean

the

*Lay

head

hook.

throat

the

down

plate

feed dog.

the

and

clean

machine

the

The

filterisremoved

pulling

after

machine

the

the

laying

filter.

head.

clip

down

by

spring

the

Clean

Feed

dog

base

Page 8

Q

Specifications

MODEL

Submodel*

For

Speed (Max.)

MaX.

stitch

Needle

bar

Pressure-

foot

clearance

Needle

type

Light to

weight

4(XX)

lengtit

stroke

jw/o I

ForWiHand

! .

For W I

w/

Organ

Singer

Schmetz

Knee

h

1 j

Knee

Hand

5mm(5

33.0mm

lifterf9mm

'

7.2mm

lifteri8mm

j 6mm(15/64")

-IDBXl

14:25Nm90

DB-189-10

-WM:-WBM;-FWM:-FWBM

medium

materil

s.p.m.

s.p.i.)

(1-19/64")

j

I

.4.

;

40(X)

14 mm (6 s.p.i.)

(23/64")

(9/32")

(5/16")

#14

SY1513#14

DB-189-11

Light

weight

material

s.p.m.

30.5mm

6mm

4mm

5mm

3mm

(15/64")

(5/32")

(3/16")

(1/8")

DBXl

SY1513

14:25Nm75

(1-3/16")

#-11

#11

OB-189-12

-M:-BM

Medium to heavy : Heavy weight

material

weight

3500

s.p.m.

5 mm (5 s.p.i.)

35.0mm (1-3/8") | 35.0mm

9mm

7.2mm

DBXl

#21

SY2254

14:25

Nm

#21

130

(23/64")

(9/32")

j

DB-189-13

material,

3500

s.p.m.

5 mm (5 s.p.i.)

DBXl

#23

SY2254

14:25

#23

Nm

JEANS

160

Notes:

Cautions

J

B:

wftouch-back

2. Needle type

:

1.

Please

case

The

deformation.

be

for

exclusive

bobbins

The

device.F:w.Ifloating

(Organ

sure

for

specification

needles

to

use

the

usetothe

use shall beofgood

foot.

are

standard)

needle

automatic

may

plate,

condition

partially changed

W:wjwiper

hook

under

and

trimer.

without

device.

bobbin

any

for

improvement.

Amitsubishi

HEAD

Office

f/iTSuB'SHi

DENK

electric

BlOG

VIAPuNOuCHi

TOKVQ

corporation

100

TElEX

j?4532

CABLE

WT—00640X02

VElCO

^QKYO

printedinJapan

Loading...

Loading...