Page 1

MITSUBISHI CT-32CW1BD

General Information

Also Covers

CT-32CW1CD

Recommended Safety Parts

Item Part No. Description

255P813O10 ASSY-ITC W76EGX023X122

T 552 334P247O10 TRANS-FLYBACK

T 901 350P684O10 TRANS-POWER

4098139O10 COIL-DEGAUSSING

4098143O10 COIL-CANCEL

R 545 103P390O70 R-FUSE 1/2W 33-J

R 557 103P442O20 R-FUSE-METAL 1W 560 -K/J

R 558 103P397O90 R-FUSE 1/2W 0.82-J

R 560 103P397O90 R-FUSE 1/2W 0.82-J

R 562 103P398O20 R-FUSE 1/2W 15-J

R 582 103P398O20 R-FUSE 1/2W 1.5-J

R 583 103P397O90 R-FUSE 1/2W 0.82-J

R 609 103P370O10 R-FUSE 1/4W 10-J

R 612 103P392O50 R-FUSE 1/2W 1K-J

R 614 103P370O10 R-FUSE 1/4W 10-J

R 615 103P370O10 R-FUSE 1/4W 10-J

R 647 103P392O50 R-FUSE 1/2W 1K-J

R 662 103P370O10 R-FUSE 1/4W 10-J

R 671 103P438O10 R-FUSE-METAL 2W 1.2-K/J

R 930 1090021O20 R-COMPOSITION 1/2W 6.8M-K

R 931 1090021O20 R-COMPOSITION 1/2W 6.8M-K

R 3530 103P398O80 R-FUSE 1/2W 4.7-J

R 3531 103P398O80 R-FUSE 1/2W 4.7-J

R 3540 103P398O80 R-FUSE 1/2W 4.7-J

R 3541 103P398O80 R-FUSE 1/2W 4.7-J

R 3550 103P398O80 R-FUSE 1/2W 4.7-J

R 3551 103P398O80 R-FUSE 1/2W 4.7-J

R 3560 103P398O80 R-FUSE 1/2W 4.7-J

R 3561 103P398O80 R-FUSE 1/2W 4.7-J

R 5352 103P398O80 R-FUSE 1/2W 4.7-J

R 5355 103P392O50 R-FUSE 1/2W 1K-J

R 5356 103P392O20 R-FUSE 1/2W 560J

C 918 189P094O20 C-C-AC ACT4K E3300pF-M

C 990 189P117O30 C-M-P-AC AC250V 0.22uF-M

C 991 189P117O30 C-M-P-AC AC250V 0.22uF-M

C 992 189P117O30 C-M-P-AC AC250V 0.22uF-M

C 993 189P117O20 C-M-P-AC AC275V 0.luF-M

J 651 449C113O10 SOCKET-CRT

S 991 432C074O40 SW-PUSH

F 991 2830047O40 FUSE T2A BD

F 991 2830091O60 FUSET 3.15AH 250V CD

K 901 287P049O30 RELAY-POWER

K 902 287P049O50 RELAY-POWER

PC951 268P068O10 PHOTO-COUPLER TCDT1124G

RP901 265P047O60 POSISTOR PTH451A102BF140M270A

Z 550 299P192O70 PROTECTOR 1000

Z 551 299P193O70 PROTECTOR 5000

Z 552 299P193O40 PROTECTOR 3150

Z 950 299P193O70 PROTECTOR 5000

Z 951 299P193O70 PROTECTOR 5000

Z 952 299P193O70 PROTECTOR 5000

Z 953 299P193O70 PROTECTOR 5000

Z 954 299P200O50 PROTECTOR 630

Z 9X1 299P193O70 PROTECTOR 5000

Z 9X2 299P193O70 PROTECTOR 5000

Z 9X3 299P193O70 PROTECTOR 5000

Z 9X4 299P193O70 PROTECTOR 5000

921C126O01 ASSY-PCB-AV

921C127O01 ASSY-PCB-PIP

921C128O01 ASSY-PCB-MGV

921C130O01 ASSY-PCB-MSP/DSP

921C131O01 ASSY-PCB-TEXT

921C132O01 ASSY-PCB-VIF

921C134O01 ASSY-PCB-DBF

921C136O01 ASSY-PCB-SVM

921C137O01 ASSY-PCB-CRT

921C138O01 ASSY-PCB-CONTROL

921C140O01 ASSY-PCB-AMP

921C141O01 ASSY-PCB-POWER-SUB CD

921C141O02 ASSY-PCB-POWER-SUB BD

9306746O01 ASSY-PCB-SIGNAL

9308747O01 ASSY-PCB-POWER

246C022O70 AC-POWER-CORD CD

246C162O10 AC-POWER-CORD BD

Adjustments

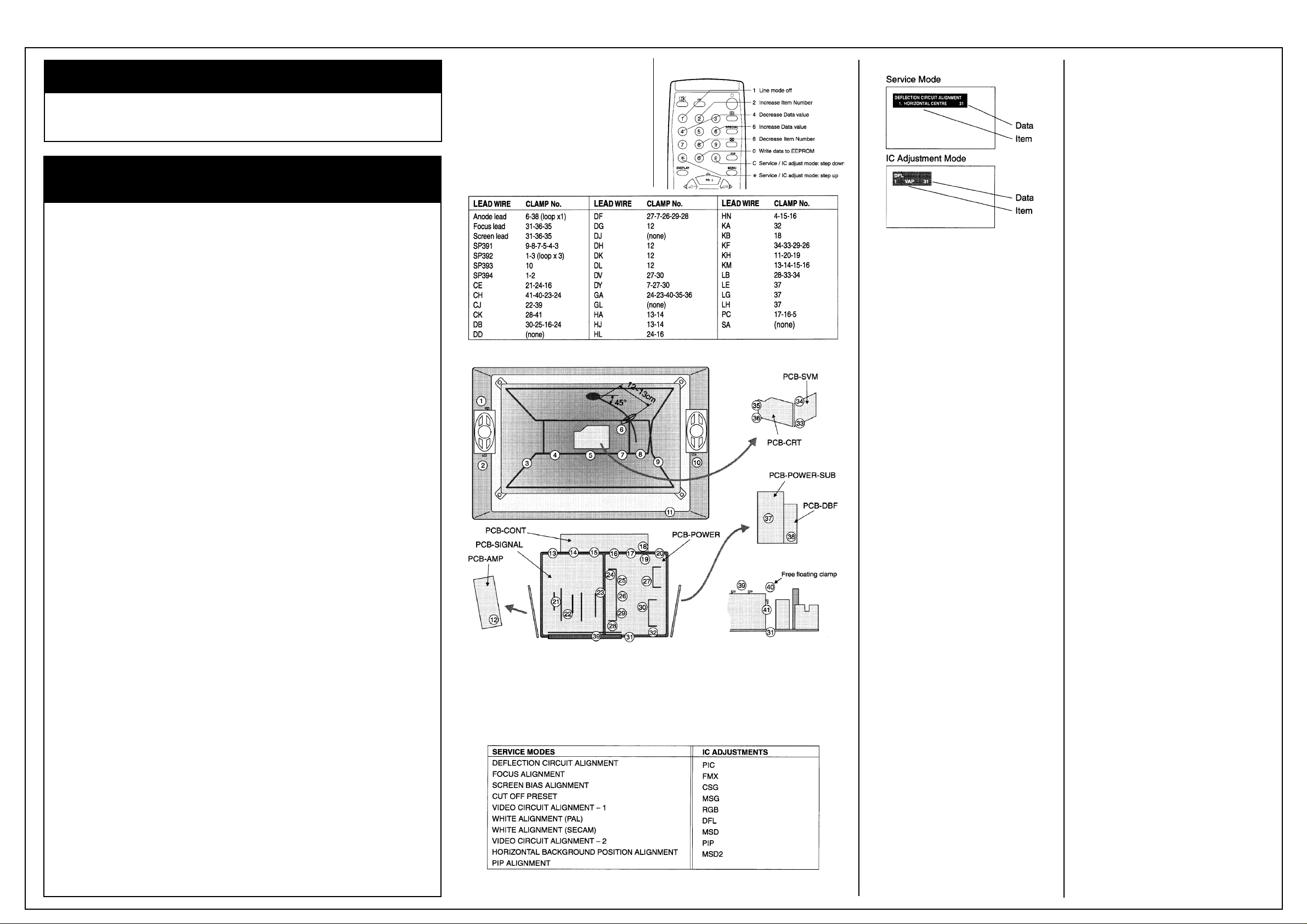

1.6.2 Lead dressing

• Leads must be dressed as shown in table 1

.4B and the diagram (fig. 1 .4C).

• The leads are routed or clamped so that they

do not come close to any heat generating or

high-tension parts.

• The anode lead wire is routed such that no

tension is applied to the anode cap. If the angle

and the route of the anode lead wire is changed,

return it to the initial angle and route.

table 1.4B

fig 1.4C

2 SERVICE ADJUSTMENT PROCEDURES

2.1 INTRODUCTION

Most service adjustments are made using the

remote control unit (fig 2.1A) with the TV in “Line

Mode”. Line mode consists of a series of

Service modes and IC adjustments:

Fig 2.1A The remote control buttons used in

Line Mode:

Fig 2. 1B Line Mode on-screen displays:

2.2 BASIC ADJUSTMENT PROCEDURE

2.2.1 Activating Line Mode

Press the MENU button on a remote control

then press buttons 2, 3, 5 and 7 in that order

within 4 seconds. (The screen will change to the

Line Mode display.)

2.2.2 Selecting a Service Mode or IC Adjustment

Press the * or C button on the remote control to

step through the various service modes or IC

adjustments.

2.2.3 Selecting and adjusting a Service or IC

Adjustment Item

1. Press the 2 or 8 button to select a specific

adjustment item: 2 = step up, 8 = step down.

2. Press the 4 or 6 button to change data value:

4 = decrease adjustment data, 6 = increase

adjustment data.

3. Press the 0 button to save the data to the

EEPROM memory. The display of characters

goes red for approximately three seconds in

this step.

Note: If the line mode is terminated without

pressing the 0, changes in data are not saved.

2.2.4 Terminating Line Mode

Press the 1 button on the remote control to

terminate line mode. Line mode can also be

terminated by turning the power off.

2.3 REPLACING THE EEPROM (IC702)

The EEPROM (IC702) stores the data specified

in Line Mode. When the EEPROM is replaced

all the data is initialized. After replacement

check the data is as shown in the Line Mode

Data Table.

Data in brackets ( ) are default values. The data

should be adjusted according to the adjustments specified in procedures 2.4 to 2.8. Other

data values need not be changed.

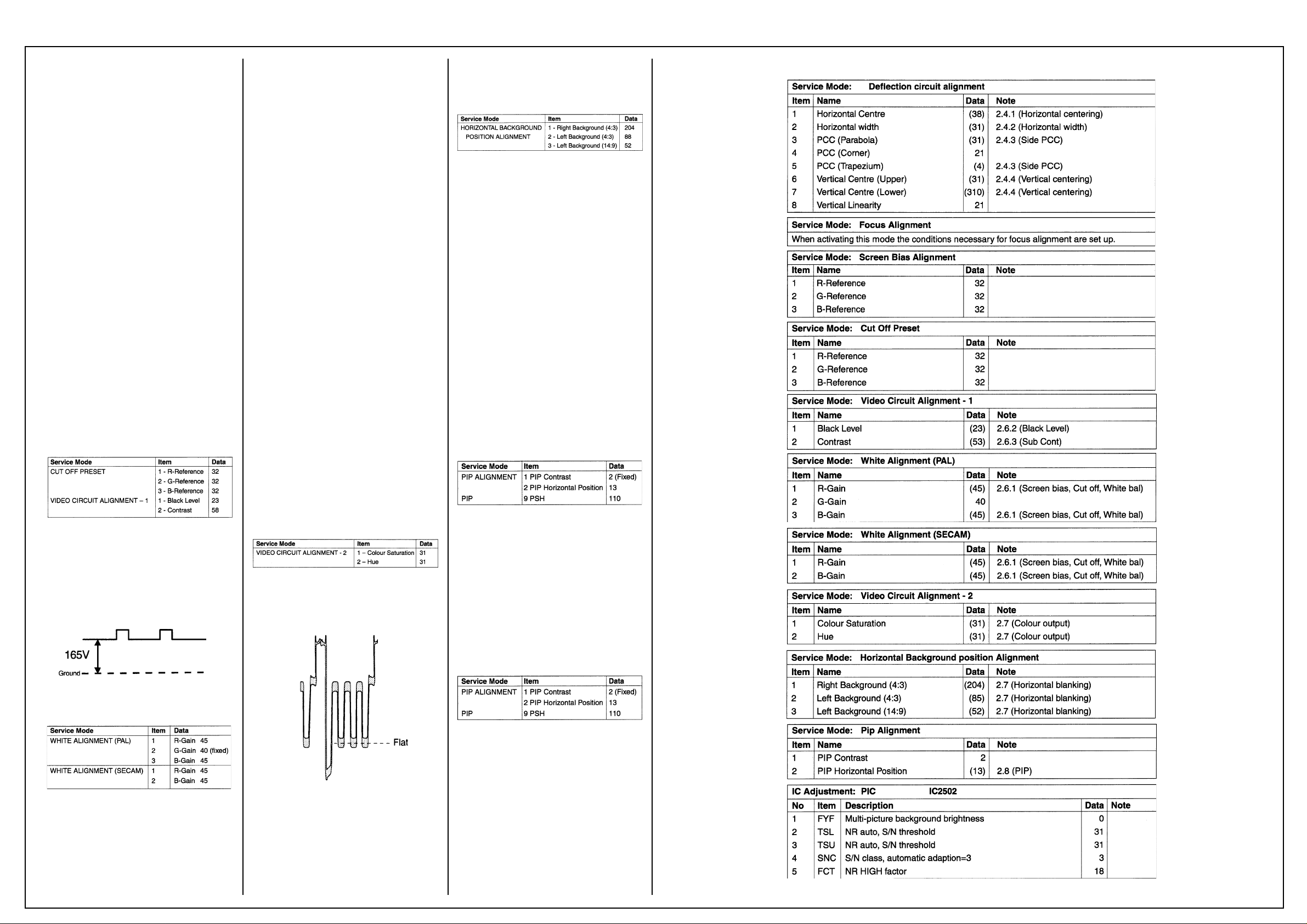

LINE MODE DATA TABLES - SERVICE

MODES: See Next Page.

2.4 VIF CIRCUIT

2.4.1 RFAGC

Conduct this adjustment for all the channels to

be received (field strength ≥75dBu at 75Ohms

load).

The adjustment is necessary both for the main

picture and the sub-picture in this model.

1. Supply an RF signal (off-air program).

2. Set the BOOSTER condition to ON in the

MANUAL PRESET menu.

3. Turn on AFT.

4. Observe the main picture.

5. Adjust VR101 so that the picture and the

sound have no beat, noise or intermodualtion

distortion.

6. Activate PIP and display the program on sub

picture screen.

7. Observe the sub picture

8. Adjust VR7101 so that the picture has no

beat, noise or intermodulation distortion.

2.5 DEFLECTION CIRCUITS - STAGE 1

2.5.1 Horizontal Centring

1. Supply a VIDEO signal (monoscope).

2. Set the picture format to 16:9.

3. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

4. Select the DEFLECTION CIRCUIT ALIGNMENT (* or C button).

5. Select item 1 — Horizontal Centre (2 or 8

button).

6. Adjust the data so that the positions of the left

and right markers are the same. (4 or 6

button).

7. Write the data into memory (0 button).

8. Terminate line mode (1 button).

Note: this adjustment is made with the picture

format set to 16:9. Adjustment in other picture

formats is not necessary.

2.5.2 Horizontal Width

1. Supply a VIDEO signal (monoscope).

2. Set the picture format to 16:9

3. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

4. Select the DEFLECTION CIRCUIT ALIGNMENT (* or C button).

5. Select item 2 — Horizontal Width (2 or 8

button).

6. Adjust the data so that the sum of the

markers is 2.8±0.2 (equivalent to 8±1%

overscan).

7. Write the data into the memory (0 button).

8. Terminate line mode (1 button).

Note: the adjustment is made with the picture

format set to 16:9 Adjustment in any other

picture format is not necessary.

2.5.3 Side PCC

1. Supply a VIDEO signal (crosshatch).

2. Set the picture format to 16:9.

3. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

4. Select the DEFLECTION CIRCUIT ALIGNMENT (* or C button).

5. Select item 3— PCC (PARABOLA) (2 or 8

button).

6. Adjust the data so that both the vertical lines

are straight (4 or 6 button).

7. Select item 5 — PCC (TRAPEZIUM) (2 or 8

button).

8. Adjust the data so that both the vertical lines

are straight (4 or 6 button).

9. Write the data into the memory (0 button).

10. Terminate line mode. (1 button).

Note: this adjustment is made with the picture

format set to 16:9. Adjustment in any other

picture format is not necessary.

2.5.4 Vertical Centring

1. Supply a VIDEO signal (monoscope).

2. Set the picture format to 16:9.

3. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

4. Select the DEFLECTION CIRCUIT ALIGNMENT (* or C button).

5. Select item 6— VERTICAL CENTRE (UPPER) (2 or 8 button).

6. Adjust the data so that the upper marker is 2

(4 or 6 button).

7. Select item 7— VERTICAL CENTRE

(LOWER) (2 or 8 button).

8. Adjust the data so that the lower marker is 2

(4 or 6 button).

Page 2

MITSUBISHI CT-32CW1BD

Adjustments Cont’d

9. Write the data into the memory (0 button).

10. Terminate line mode (1 button).

Note: this adjustment is made with the picture

format set to 16:9. Adjustment in any other

picture format is not necessary.

2.6 CRT CIRCUIT

2.6.1 Focus

1. Supply a VIDEO signal (monoscope).

2. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

3. Select the FOCUS ALIGNMENT (* or C

button).

4. Observe the vertical lines and adjust FOCUSV control on the Flyback Transformer (T552)

for the best focus.

5. Observe the horizontal lines and adjust

FOCUS-H control on the Flyback Transformer

(T552) for the best focus.

6. Repeat steps 5 and 6 two or more times until

no further improvement is seen.

7. Terminate line mode (1 button).

2.7 VIDEO CIRCUIT

2.7.1 Screen Bias, Cut Off, White balance

Allow the set to warm up for twenty minutes or

more.

1. Supply a PAL VIDEO signal (white raster).

2. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

3. Make adjustments as shown in table 2.7A:

Table 2.7A

4. Select the SCREEN BIAS ALIGNMENT (* or

C button). The screen will change to display a

black picture.

5. Connect an oscilloscope to the cathode of

R684 and observe the waveform.

6. Adjust the SCREEN control on the flyback

transformer (T552) so that the waveform is as

shown in fig 2.7B:

2.7.2 Black Level

Note: this adjustment must follow adjustment

2.6.1 (Screen Bias, Cut Off, White balance).

1. Supply an RF signal (G-card).

2. Set the picture format to 16:9.

3. Select the VIDEO CIRCUIT ALIGNMENT - 1

(* or C button). Colour will be minimised

automatically.

4. Select item 1 BLACK LEVEL (2 or 8 button).

5. Adjust the data so that a difference in

brightness is just visible between the blue

area and the black area (4 or 6 button).

6. Write the data into memory (0 button).

Note: adjustment 2.6.3 (Sub Contrast) must be

performed immediately after this adjustment.

2.7.3 Sub Contrast

Note: this adjustment must follow adjustment

2.6.2 (Black Level).

1. Supply an RF signal (Colour-bar, 80%

Modulation).

2. Set the picture format to 16:9.

3. Select the VIDEO CIRCUIT ALIGNMENT - 1

(* or C button). Colour will be minimised

automatically.

4. Connect a DC milliammeter between pin 1

and 4 of connector LA on PCB-CRT (+ lead to

pin 1).

5. Select item 2 CONTRAST (2 or 8 button).

6. Adjust the data so that the DC milliameter

indicates 11 00±50uA (4 or 6 button).

7. Write the data into memory (0 button).

8. Terminate line mode (1 button).

2.8 CHROMA CIRCUIT

Note: perform this adjustment after the Cut Off,

White balance and Video circuit adjustments.

1. Supply a VIDEO signal (PAL Colour bar).

2. Connect an oscilloscope between TP6B on

PCB-CRT and ground.

3. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

4. Select the VIDEO CIRCUIT ALIGNMENT -2 (*

or C button).

5. Make adjustments as shown in table 2.8A:

Table 2.8A

6. Select item 1 COLOUR SATURATION (2 or 8

button).

7. Adjust the data so that the waveform is as

shown in figure 2.7B (4 or 6 button):

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

3. Make adjustments as shown in table 2.9:

Table 2.9

4. Select item 1 RIGHT BACKGROUND (4:3)

(2 or 8 button).

5. Adjust the data so that the reading of the right

marker is 2 (4 or 6 button).

6. Select item 2 LEFT BACKGROUND (4:3)

(2 or 8 button).

7. Adjust the data so that the reading of the left

marker is 2 (4 or 6 button).

8. Select item 3 LEFT BACKGROUND (14:9)

(2 or 8 button).

9. Adjust the data so that the reading of the left

marker is 2 (4 or 6 button).

10. Write the data into the memory (0 button).

11. Terminate line mode (1 button).

2.10 PIP CIRCUIT

1. Supply a VIDEO signal (monoscope).

2. Press the MENU button, select the PIP menu

and set the PIP style to 1. Press the DISPLAY

button and set the receiver to PIP mode.

3. Display a monoscope signal on the subpicture.

4. Press the MENU button on the remote control

(the MENU display will appear.) then press

buttons 2, 3, 5 and 7 in that order within 4

seconds. (The MENU display will change to

the Line Mode display.)

5. Make adjustments as shown in table 2.10A:

Table 2.10A

6. Select item 2 PIP HORIZONTAL POSITION

(2 or 8 button).

7. Adjust the data so that the readings of the left

and right markers are the same on the subpicture (4 or 6 button).

8. Using the * or C button select the IC Adjustment display PIP.

9. Select item 9 PSH (2 or 8 button).

10. Adjust the data so that the sub-picture

horizontal positions are adjusted as shown in

fig. 2.10B. Press the PIP POSITION button on

the remote control to select the PIP position

11. Write the data into memory (0 button).

12. Terminate line mode (1 button).

LINE MODE DATA TABLES - SERVICE MODES:

Fig. 2.7B

7. Make adjustments as shown in table 2.7C:

Table 2.7C

8. With a PAL signal supplied, adjust 1 R-GAIN

and 3 B-GAIN for PAL to obtain the best

white.

9. Supply a SECAM white raster signal.

10. Adjust 1 R-GAIN and 2 B-GAIN for SECAM

to obtain the best white.

Note: adjustment 2.6.2 (Black Level) must be

performed immediately after this adjustment.

Fig. 2.7B

8. Supply a VIDEO signal (NTSC colour bar).

9. Select item 2 HUE (2 or 8 button).

10.Adjust the data so that the waveform is also

as shown in figure 2.7B (4 or 6 button).

11.Write the data into memory (0 button).

12.Terminate line mode (1 button).

2.9 DEFLECTION CIRCUITS — STAGE 2

1. Supply a VIDEO signal (monoscope).

2. Press the MENU button on the remote control

Fig 2.10B

Continues next page.

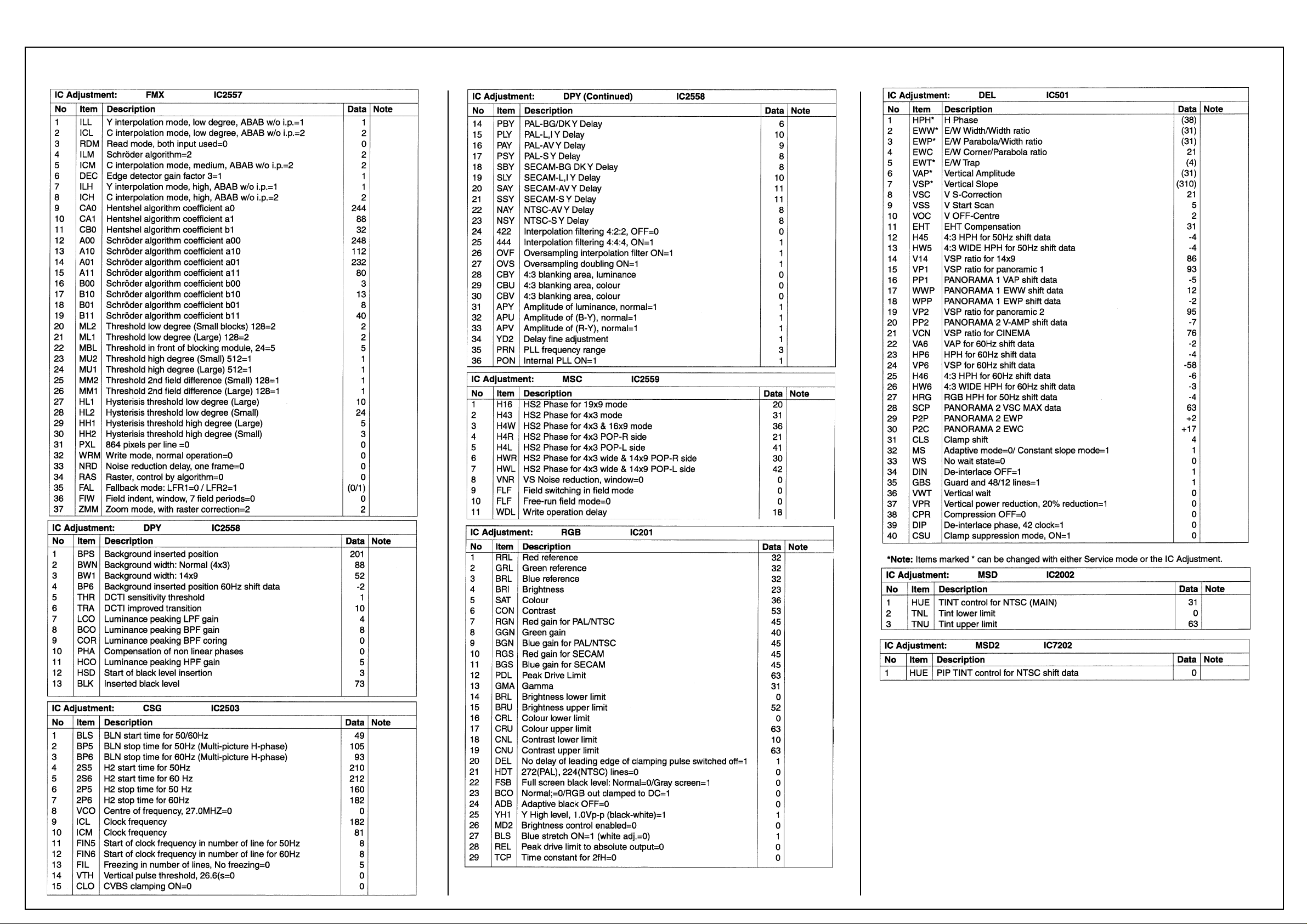

Page 3

MITSUBISHI CT-32CW1BD

Adjustments Cont’d

Continues next page.

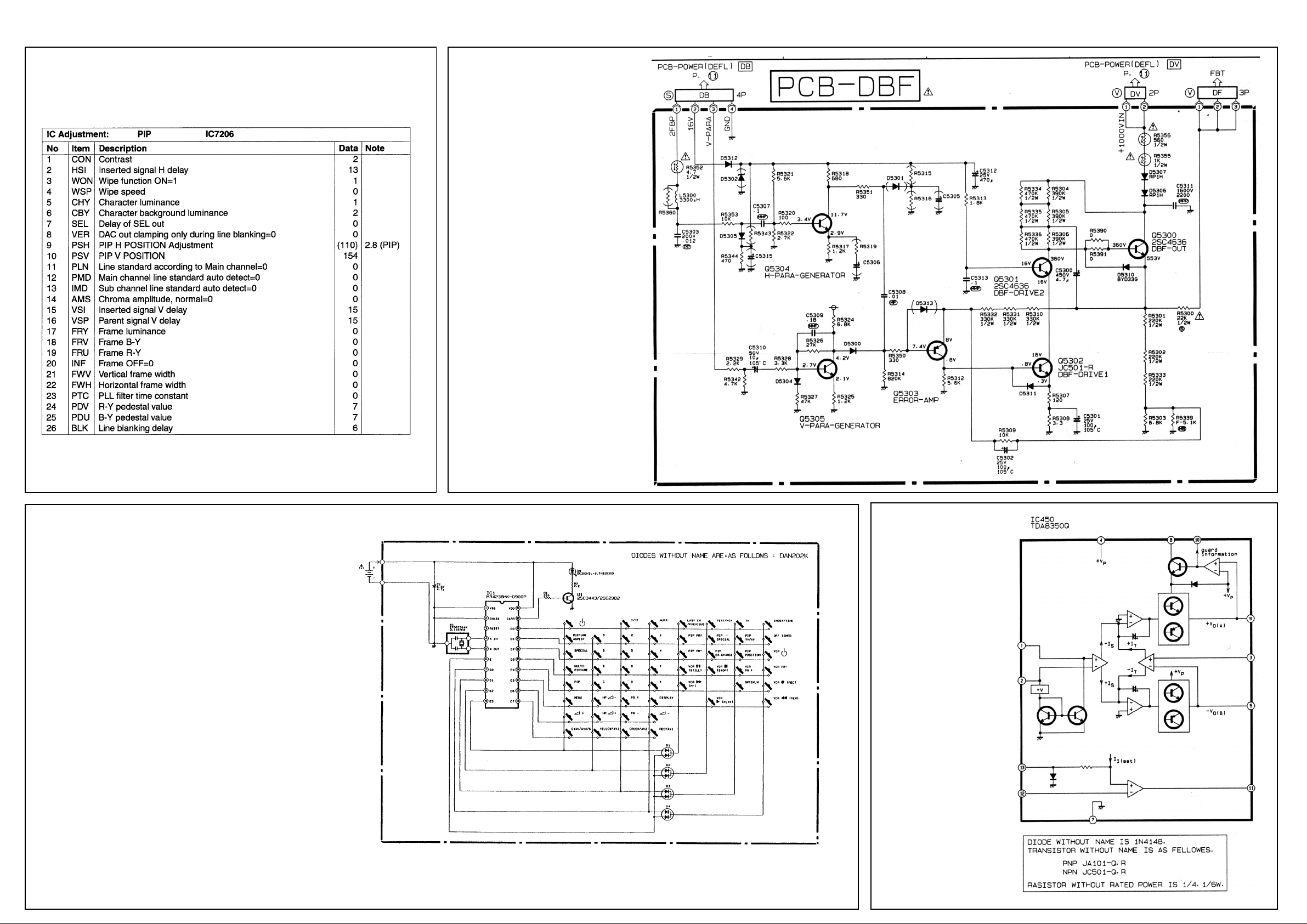

Page 4

MITSUBISHI CT-32CW1BD

Adjustments Cont’d

DBF Diagram

Remote Control Diagram

IC450

Diagram

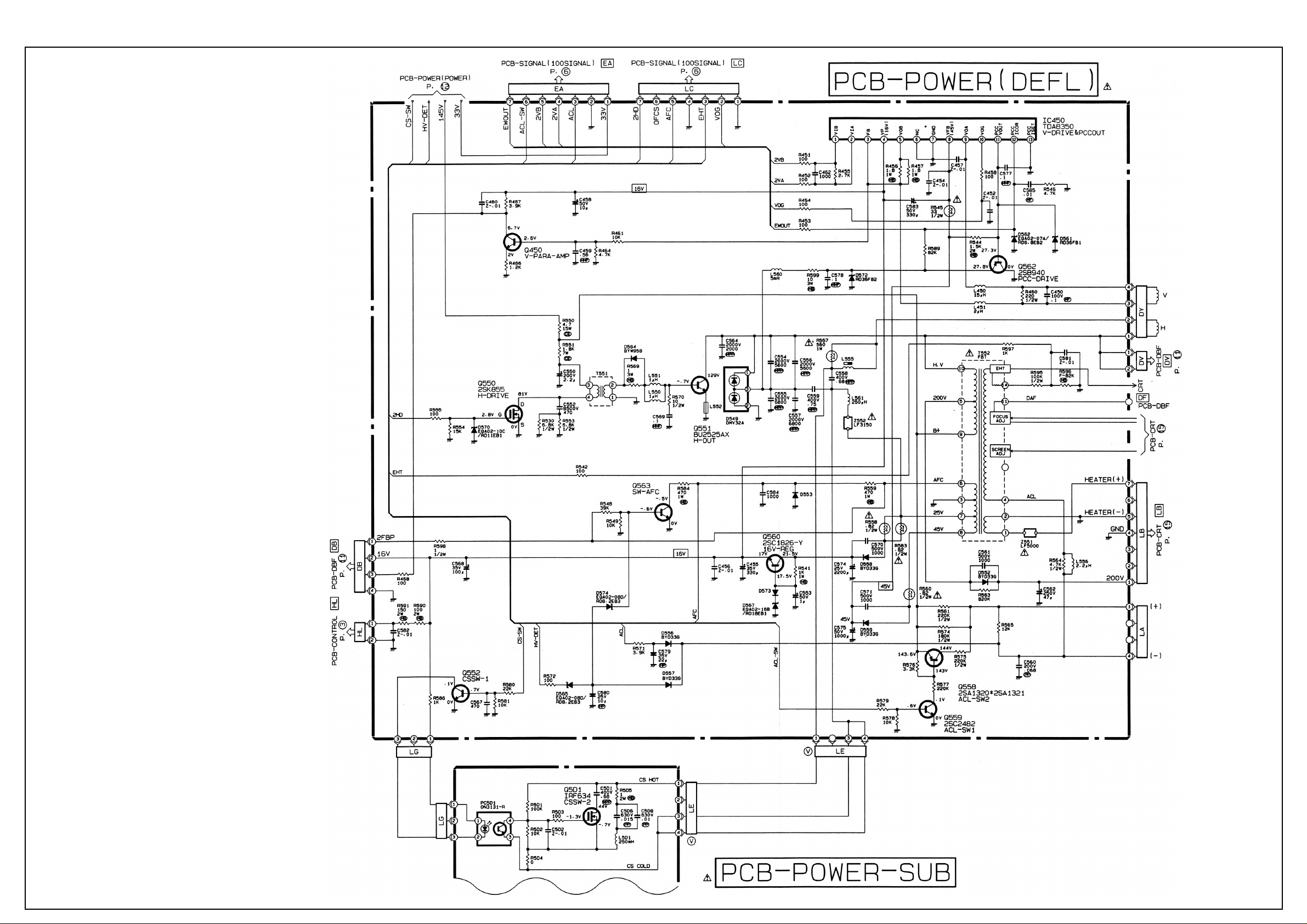

Page 5

MITSUBISHI CT-32CW1BD

Power Deflection Diagram

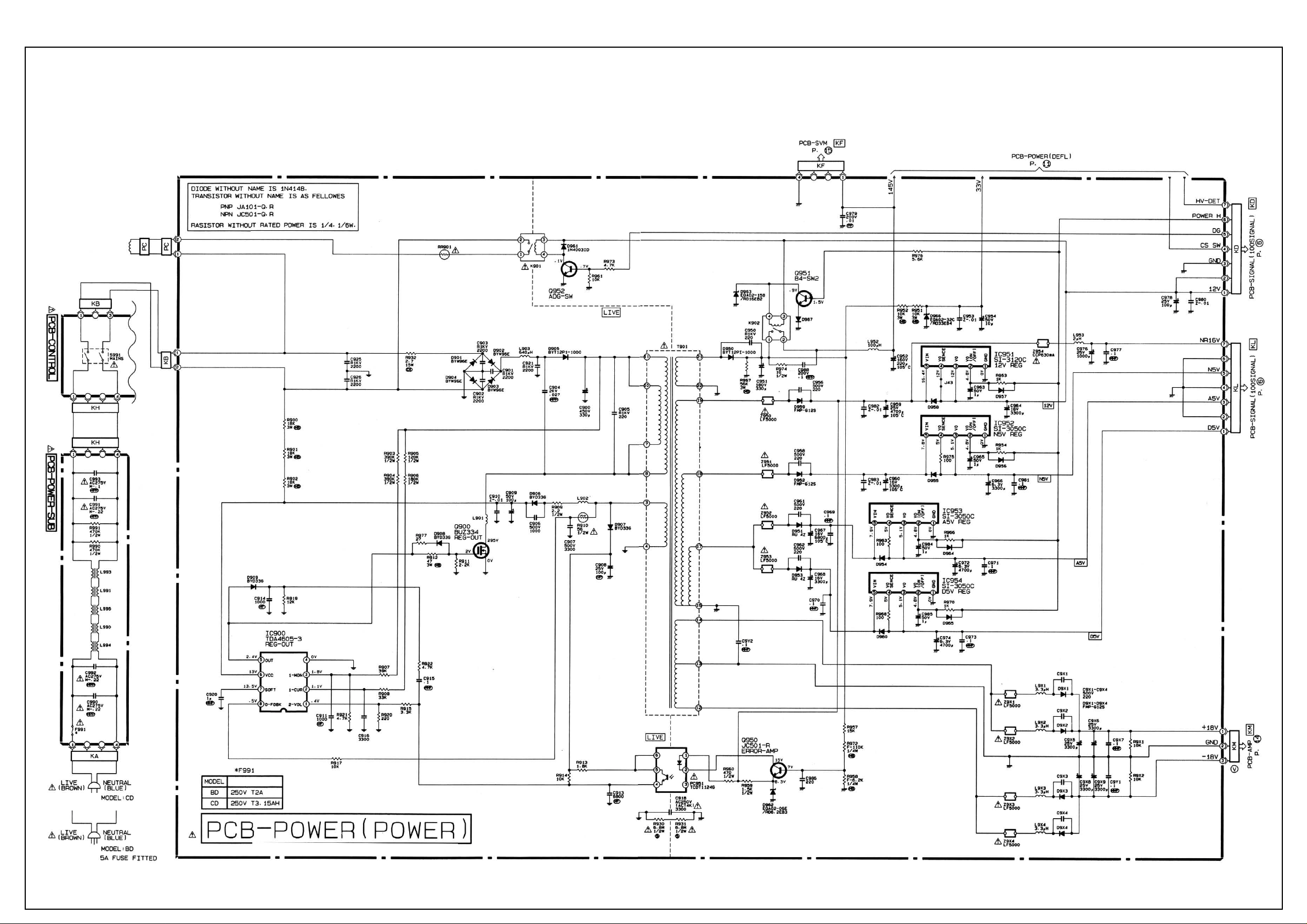

Page 6

MITSUBISHI CT-32CW1BD

Power Supply Diagram

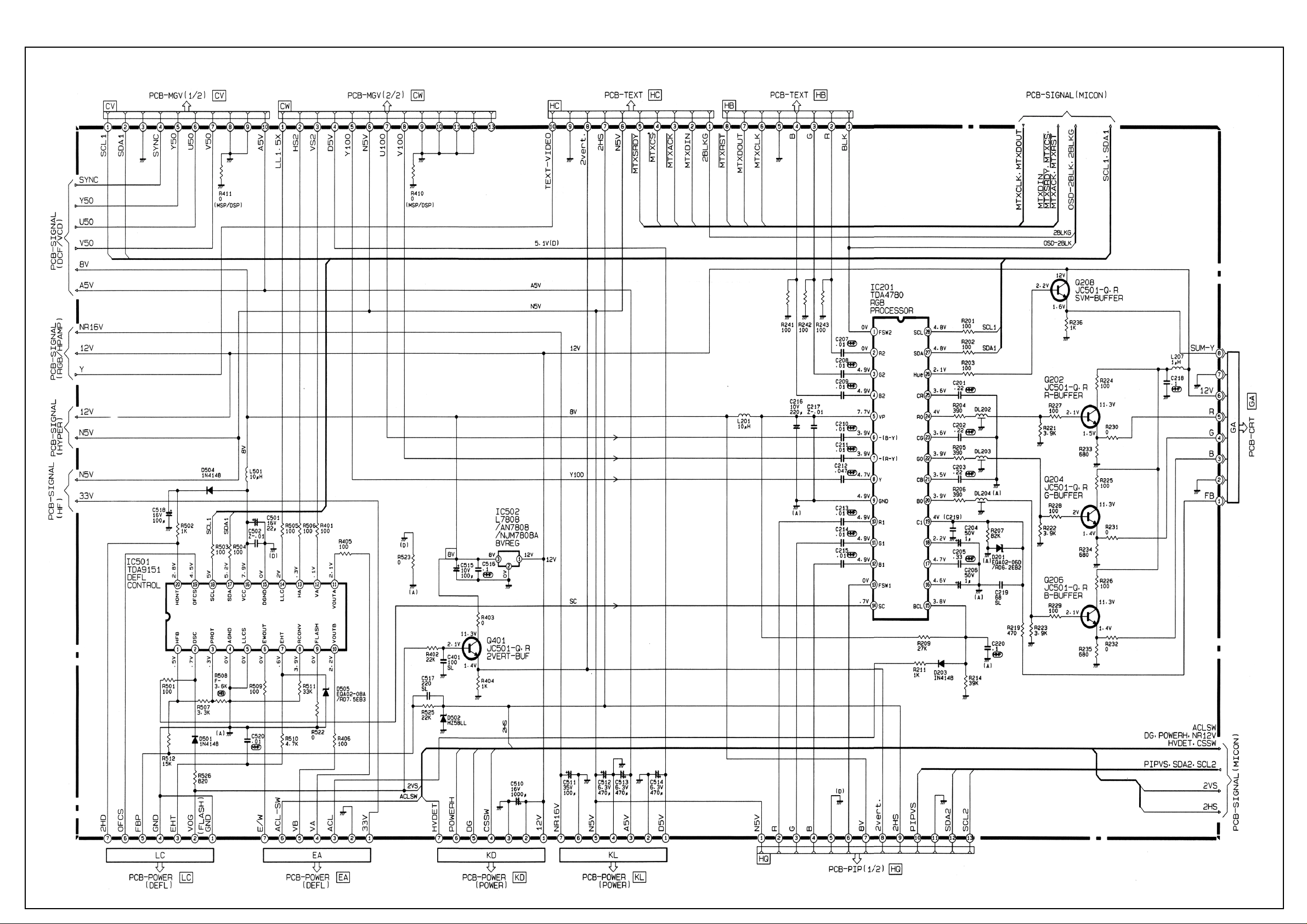

Page 7

MITSUBISHI CT-32CW1BD

100Hz Signal Diagram

Page 8

MITSUBISHI CT-32CW1BD

Audio Amp Diagram

Page 9

MITSUBISHI CT-32CW1BD

Audio Processing Diagram

Page 10

MITSUBISHI CT-32CW1BD

AV Diagram

Page 11

MITSUBISHI CT-32CW1BD

Control & Microcontroller Diagram

Page 12

MITSUBISHI CT-32CW1BD

CRT & SVM Diagram

Page 13

MITSUBISHI CT-32CW1BD

Signal DCF/VCD

Diagram

Page 14

MITSUBISHI CT-32CW1BD

Hyper Signal Diagram

Page 15

MITSUBISHI CT-32CW1BD

MGV Diagram 1 of 2

Page 16

MITSUBISHI CT-32CW1BD

MGV Diagram 2 of 2

Page 17

MITSUBISHI CT-32CW1BD

PIP Diagram 1 of 2

Page 18

MITSUBISHI CT-32CW1BD

PIP Diagram 2 of 2

Page 19

MITSUBISHI CT-32CW1BD

RGB Switching/Headphone Amp Diagram

Page 20

MITSUBISHI CT-32CW1BD

Text Diagram

Page 21

MITSUBISHI CT-32CW1BD

Tuner IF Diagram

Page 22

MITSUBISHI CT-32CW1BD

Wiring Diagram

Loading...

Loading...