Page 1

1MITSUBISHI CT-32BW 1B

General Information

W1 Chassis

Matrix

Item See Model Book

Safety Precautions (See Notes).......................................................... CT-14MS1 4

Service Adjustments

ITC Adjustment

ITC adjustments should be performed in the

following sequence after replacing either the

CRT, Deflection Yoke or Convergence and

Purity Magnet Assembly.

When not replacing parts, perform the necessary adjustment only.

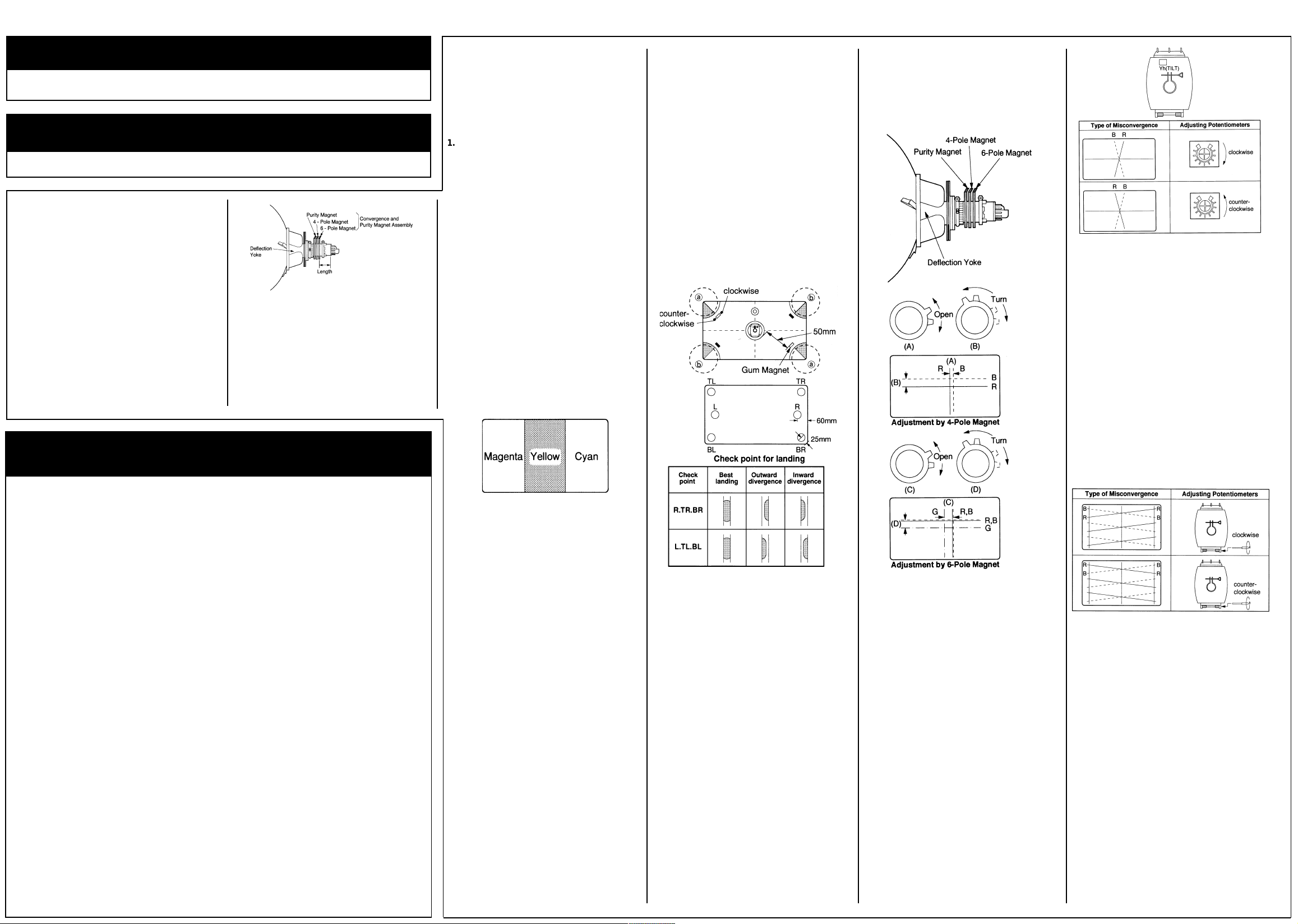

Installation

1: Put the Deflection Yoke on the neck of the

CRT, fully forward against the cone.

2: Put the Convergence and Purity Magnet

Assembly on the neck of the CRT so that the

distance between the 6-Pole Magnet and the

base of the tube is as indicated in fig. 1 and

then tighten the screw lightly.

MODEL LENGTH

CT-32BW1 45.0±1.5mm

Preliminary Adjustment

1: Position the receiver with the CRT facing

East or West.

2: Degauss not only front and rear of the CRT

but also the CRT holder, the chassis and front

and sides of the cabinet. Don’t allow the

Degaussing Coil near the Deflection Yoke.

Fig 1.

(Insufficient degaussing causes magnetisation, giving an unfavourable effect on colour

purity adjustment).

3: Run the picture tube for more than thirty

minutes with a white raster signal applied

giving normal beam current flow.

4: Make sure that all electrical adjustments have

been performed.

1. Purity

Adjustment purpose:

Insure the R, G and B beams land on their

respective phosphorus.

Symptom when incorrectly adjusted:

Colour patches appear, poor white uniformity.

Input signal:

VIDEO signal (yellow raster).

Input terminal:

VIDEO IN terminal.

1: Supply a VIDEO signal (yellow raster).

2: With the Deflection Yoke positioned fully

foreword, adjust the Purity Magnet so that the

yellow bar is at the centre of the screen with

normal vertical centring.

3: Slide the Deflection Yoke slowly backwards to

produce a uniform yellow raster.

4: Tighten the Deflection Yoke in position.

5: Supply a VIDEO signal for the red raster,

green raster and blue raster respectively to

confirm no contamination is observed in each

colour. Adjust again steps 1 to 4 if observed.

1: If beam landing divergence is to be corrected

in areas (a) shown in the figure, place the

Gum Magnet on the funnel of the CRT, on

axis with the corner, with the white side of the

magnet facing outwards.

2: If beam landing divergence is to be corrected

in areas (b) shown in the figure, then the Gum

Magnet is placed on the funnel of the CRT

with the white side facing the CRT.

Note: The Gum Magnets will distort the raster

shape and disturb corner convergence. To

minimise the effect on raster shape and corner

convergence do not place the Gum Magnets

closer than 50mm to the bobbin of the Deflection

Yoke.

3: If correction is required in the shaded area,

move the Gum Magnet counter-clockwise until

the best position is found. If correction is

required in the unshaded areas, move the

Gum Magnet in a clockwise direction until the

best position is found.

3: Adjust the angle between the tabs of the 6-

Pole Magnet and the “B” and “R” beans to the

“G” beam at the centre of the screen.

4: Make sure that purity in each colour “R”,“G”

and “B” is maintained. If necessary repeat

item 1(Purity), item 2 (Screen Corner Beam

Landing Correction) and item 3 (Static

Convergence).

Fig. 5

5. Xv Correct

Adjustment purpose:

Correct colour divergence of R, G and B

horizontal lines at the sides of the picture.

Symptom when incorrectly adjusted:

Colour edging around horizontal lines at the

sides of the picture.

Input signal: VIDEO signal (crosshatch).

Input terminal: VIDEO IN terminal.

Before adjusting, be sure to tighten the Deflection Yoke in position.

Recommended Safety Parts

Item Part No. Description

T532 334D100O04 Flyback (334P228O50 & CAP)

T901 350P589O20 Power

T9A1 350P673O10 Power 350P67301

R9001 109D021O80 Solid 1/2W 3.9M OHM-K

R9002 109D021O80 Solid 1/2W 3.9 OHM-K

R3F01, R3F02, R3G01, R3G02,

R3H01, R3H02, R3J01, R3J02 103P398O40 Fuse Metal 2W 0.56 OHM -K/J

R8002 103P392O50 Fuse1/2W 1K OHM-J

R8014 103P370O10 Fuse 1/4W 10 OHM-J

R8015 103P370O10 Fuse 10W OHM-J

R8016 103P370O20 Fuse 1/4W 12 OHM -J

R8045 103P370O10 Fuse 1/4W 10 OHM -J

R8067 103P392O50 Fuse 1K OHM-J

R931, R945 109D021O20 Composition W 6.8 OHM-K

C901, C908 189P153O40 C-M-P-AC AC250V 0.1uF-M

C934 189P094O40 C-CERAMIC-AC ACT 4K E2200pF-M

C9A7, C9001 189P153O40 C-M-P-AC AC250V 0.1uF-M

S901 432C074O60 Push switch 2-1

F9001 283D047O80 Fuse T5A

J601 449C123O20 Socket CRT

K941, K9A1 287P049O30 Relay Power DJ12D-0(M)-L

PC901, PC9A1 268P069O10 Photo Coupler ON3171R

Z801 299P200O70 Protector Fuse CCP800

Z951, Z952, Z953 299P201O70 Protector Fuse CCP4000

Z954 299P201O20 Protector Fuse CCP2000

Z9A1, Z9A2, Z9A3, Z9A4 299P201O80 Protector Fuse CCP5000

409B128O10 Degaussing Coil

930B717O01 AMP PCB ASSY

930C956O01 AV PCB ASSY

920D625O01 Control PCB ASSY

930C955O01 DBF PCB ASSY

930C667O09 DCF PCB ASSY

920D629O01 DEFL PCB ASSY

930C947O10 JUST PCB ASSY

920D626O01 LED PCB ASSY

930C952O01 MSP/DSP PCB ASSY

920D627O01 Phone PCB ASSY

930C957O01 PIP PCB ASSY

930C954O01 Power-2 PCB ASSY

930C986O01 Power-SUB PCB ASSY

930B713O01 Signal PCB ASSY

920D659O01 Y/C-SW PCB ASSY

920D661O01 OSD-SW PCB ASSY

920D662O01 SYNC PCB ASSY

930C948O01 Text PCB ASSY

930C950O01 VMCRT PCB ASSY

930C949O01 WAC PCB ASSY

930C953O01 Wide PCB ASSY

246C162O10 AC Power Cord

700C215O20 Back Cover

290P056O10 Remote Hand Unit

Fig 2.

2. Screen Corner Beam Landing Correction

Adjustment purpose:

Correct divergence in the corners of the screen.

Symptom when incorrectly adjusted:

Poor corner white uniformity or low light output.

Input signal:

VIDEO signal (white raster).

Input terminal:

VIDEO IN terminal.

The adjustments described below are for

correction of poor corner beam landing which is

normally seen as low light output from the

effected corner. A microscope is used to judge

the beam landing condition and divergence

direction.

1: Supply a VIDEO signal (white raster).

2: Using a microscope check the beam landing

in the four corners, where beam landing

divergence is found correction should be

made with the application of Gum Magnets to

the funnel of the CRT. Up to 3 Gum Magnets,

Part Number: 461D033O20, can be placed in

one position if necessary to correct the

divergence.

Magnet Adjustment Procedure

The examples given here are for correction of

inward beam landing divergence, reverse the

Gum Magnet for correction of outwards divergence.

Fig. 3

4: After correction, degauss not only front and

rear of CRT but also the CRT holder, the

chassis and front and sides of the cabinet and

visually check that the corners of the picture

do not appear dim or discoloured. If further

correction is required, finely adjust the

position of the Gum Magnet for that corner.

5: Once good beam landing is achieved in all

four corners, place a piece of glass tape over

the Gum Magnets to ensure that they remain

bonded in place.

3. Static Convergence

Adjustment purpose:

Correct any colour misconvergence that occurs

in the centre of the screen.

Symptom when incorrectly adjusted:

Colour edging of objects in the main picture

area.

Input signal: VIDEO signal (crosshatch).

Input terminal: VIDEO IN terminal.

1: Supply a VIDEO signal (crosshatch).

2: Adjust the angle between the tabs of the 4-

Pole Magnet and the angular position to

converge the “B” and “R” beams on the

screen.

Fig. 4

Note: With both 4-Pole and 6-Pole Magnets,

converge the vertical line opening the tabs and

the horizontal line by turning the tabs.

4. Yh Correct

Adjustment purpose:

Correct the colour divergence of R,G and B

vertical lines at the top and bottom of the picture.

Symptom when incorrectly adjusted:

Colour edging of vertical lines at the top and

bottom of the picture.

Input signal: VIDEO signal (crosshatch).

Input terminal: VIDEO IN terminal.

Before adjusting, be sure to tighten the Deflection

Yoke in position.

1: Supply a VIDEO signal (crosshatch).

2: When the Red (R) and Blue (B) beams do not

converge on the upper and lower portions of

the Y axis, adjust the Th (TILT volume on the

Deflection Yoke until the beams converge. By

turning the volume clockwise, Red (R) beam

shifts left and Blue (B) beam shifts right on

the upper portion of the screen. The beam

shifts in the opposite direction on the lower

portion.

1: Supply a VIDEO signal (crosshatch).

2: When beam lines do not converge at left and

right portion of the screen, adjust vertical

cross (Xv) with the horizontal Differential Coil

as shown in Fig. 6.

Fig. 6

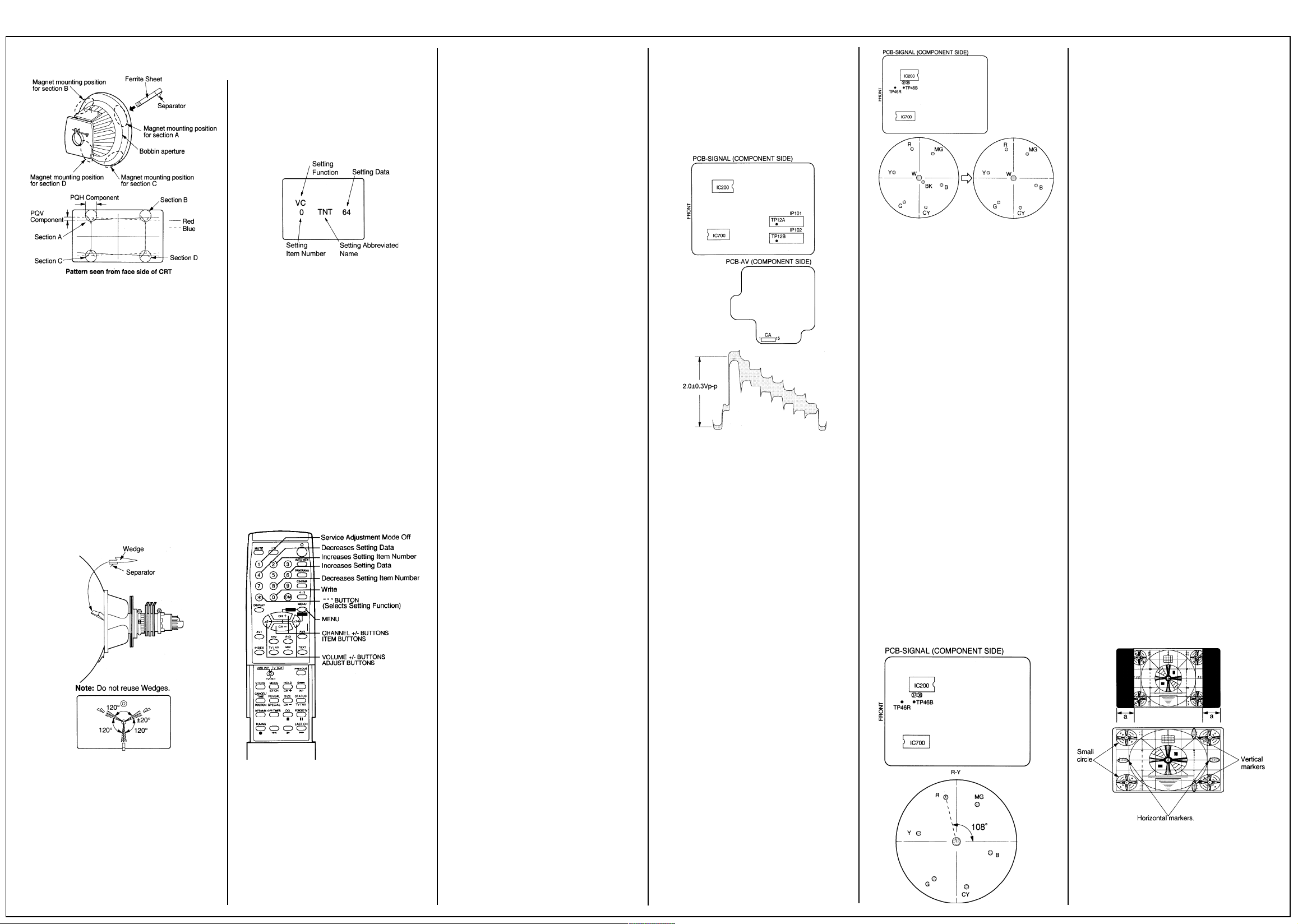

6. Convergence of Screen Corner

Adjustment purpose:

Correct convergence at the corner of the picture.

Symptom when incorrectly adjusted:

Colour edging in the corners.

Input signal: VIDEO signal (crosshatch).

Input terminal: VIDEO IN terminal.

1: Supply a VIDEO signal (crosshatch).

2: If convergence is poor at corners, insert the

Ferrite Sheet (at the magnetic side) into the

gap between the CRT and the Deflection

Yoke. Magnet mounting position is respectively corresponding with each corner as

shown below (part no. 479D002O10).

3: Peel the separator on the cohesive part to

stick the Ferrite Sheet so that the PQH and

PQV components are minimised.

Page 2

MITSUBISHI CT-32BW 1B

2

Service Adjustments Cont’d.

Fig. 7

7. Wedges Position

Adjustment purpose:

Fix the Deflection Yoke to the funnel of the CRT.

Symptom when incorrectly adjusted:

Poor peripheral convergence and beam landing.

Input signal: Input terminal: -

1: Insert three wedges at approx. right angels

vertically and horizontally allowing no

movement of the Yoke.

2: After the position of the wedges has been

determined, gently turn up the end of the

wedge and strip the tape from the rear of the

end to expose the adhesive material, then

adhere to the funnel of the CRT.

3: Apply Silicone adhesive (part no.

859D106O20) between the Wedges and the

Funnel of the CRT.

4: Bond the Yoke to the Wedges using contact

cement.

1. Activating the Service Adjustment Mode

1: Press the MENU button on a remote hand

unit (the MAIN MENU display will appear).

2: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode). If not changed repeat

steps 1 and 2 again within four seconds.

Fig. 9 (a)

2. Selecting of Setting Functions and Setting

Items

To select a setting item in the service adjustment mode, select first the setting function, that

includes the specific setting item to be selected,

next select the setting item.

Refer to the following pages for the listing of

setting functions and setting items.

1: Press the “*“ button on a remote hand unit to

select a setting function. Each time the button

is pressed the setting function changes in the

following sequence:

Note: “*“ designates the button used to

select a setting function hereafter. (Refer to

the right figure of a remote hand unit).

-->VC -->V DRIVE-->PIP-->IF-->JUST-->OPTION-->

2: Press the “2” or “8” button to select a specific

setting item. If “2” button is pressed, the

setting item number increases. If “8” button is

pressed, the setting item number decreases.

terminated without pressing the “0” changes in

setting data are not saved.

5. Terminating the Service Adjustment Mode

Press the “1” button on the remote hand unit to

terminate the service adjustment mode.

Note: The service adjustment mode can also be

terminated by turning the power off.

1. RF AGC (VIF Circuit)

Adjustment purpose:

The best receiving condition of RF signal.

Symptom when incorrectly adjusted:

Poor S/N ratio or cross modulation.

Input signal: RF signal (programme).

Input terminal: RF IN terminal.

1: Supply an RF signal (programme).

2: Press the MENU button on a remote hand

unit.

3: Turn on AFT.

Set the MAIN MENU to “SET UP 1”.

Select the SIGNAL BOOSTER “ON”.

Press the TUNING button.

Select the system “BG”.

Turn on AFT.

Press the TUNING button and cancel the

tuning mode. Press the MuNU button.

4: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

5: Select the setting function “IF” ( “ * “ button).

6: Select the setting item “1 RF0” (main picture)

and “3 RF1” (sub picture), (“2” or “8” button).

7: Adjust the setting data so that the picture and

sound have no beat, noise and inter-modula-

tion distortion.

8: Write the setting data into memory (“0” button).

9: Terminate the service adjustment mode, (“1”

button).

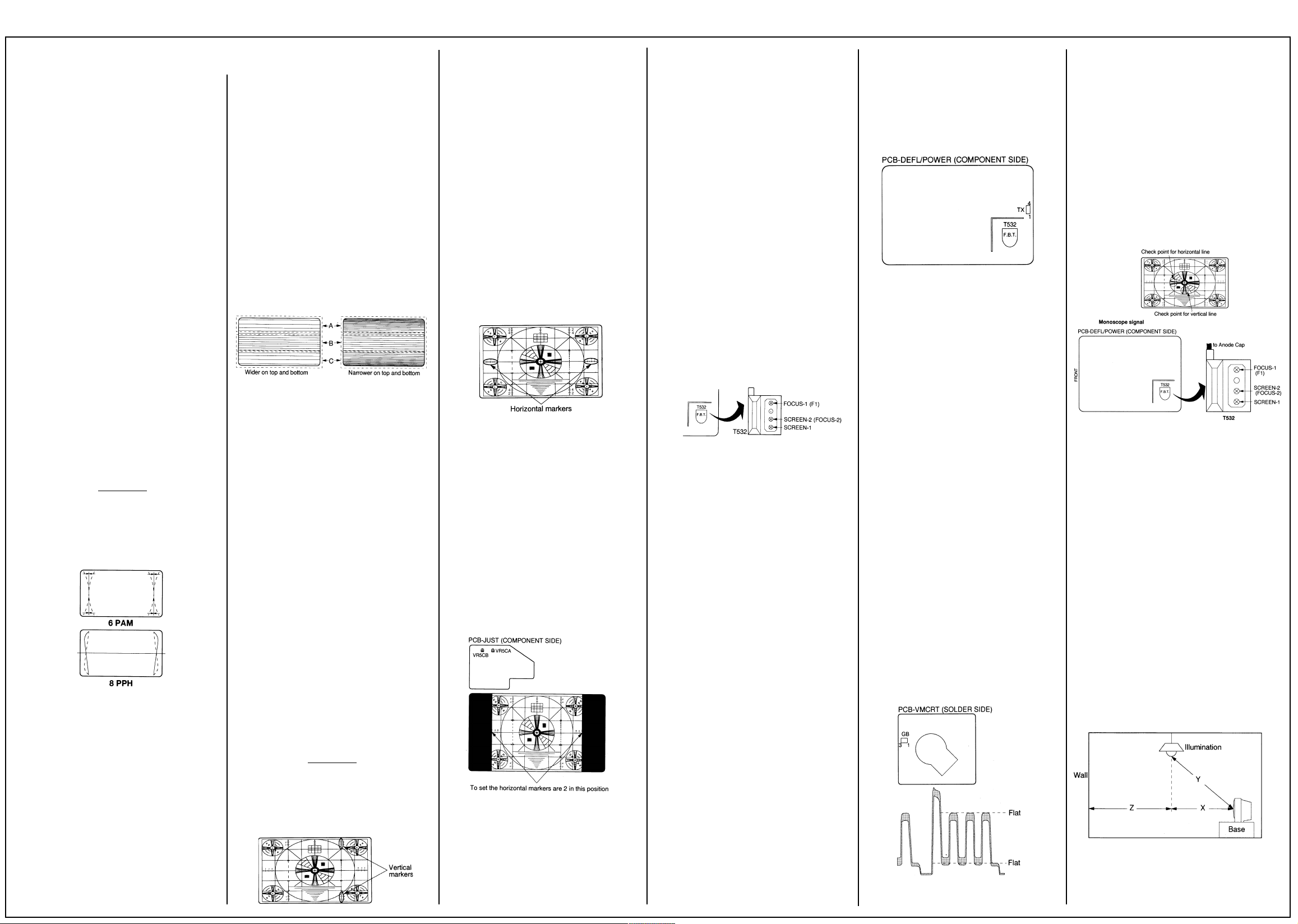

2. L-SYSTEM Video Output (VIF Circuit)

Adjustment purpose:

To set the level of video detection output (CCIRL SYSTEM) correctly.

Symptom when incorrectly adjusted:

Too bright or too dark picture, or disturbed

picture (if not set correctly).

Measuring instrument: Oscilloscope.

Test point:

TP 12A (pin (13) of connector CA).

TP 12B (pin (15) of connector CA).

(“ * ”button).

6:Select the setting item “0 LV0” (main picture)

and “2 LV1” (sub picture). (“2” or “8” button).

7:Adjust the setting data so that the amplitude

of waveform is 2.0±0.3Vp-p, (“4” or “6”

button).

8:Write the setting data into memory, (“0”

button).

9:Terminate the service adjustment mode, (“1”

button). See Fig 10.

Fig 10

SECAM Demodulator (Chroma Circuit)

Adjustment purpose:

Setting the colour to give best results when

receiving an NTSC signal.

Symptom when incorrectly adjusted:

Incorrect colour in sub picture when receiving a

SECAM signal.

Measuring instrument: Oscilloscope.

Test point: CH-1: TP46B., CH-2: TP46R.

Measurement range:

DIV 10mV.

TIM X-Y mode.

Input signal: VIDEO signal (NTSC colour bar).

Input terminal: VIDEO IN terminal.

Fig. 11

4. Tint (Chroma Circuit)

Adjustment Purpose:

Setting the colour to its best result when

receiving a SECAM signal.

Symptom when incorrectly adjusted:

Incorrect colour in sub picture when receiving a

SECAM signal.

Measuring instrument: Oscilloscope

Test Point: CH-1: TP46B, CH-2: TP46R

Measurement range:

DIV 10mV

TIM X-Y mode

Input signal: VIDEO signal (SECAM colour bar)

Input terminal: VIDEO in terminal

1: Supply a VIDEO signal (SECAM colour bar)

2: Set the oscilloscope to X-Y mode.

3: Observe the waveform at TP46B (pin 38 of

IC200) and TP46R (pin 37 of IC200). (CH-1

to TP46B)

4: Press the MENU button on a remote hand unit.

5: Press the MENU buttons “2”, “3”, “5” and “7”

in that order. (The screen will change to the

service adjustment mode.)

6: Select the setting function “VC”.

7: Select the setting item “0 TNT”.

8: Adjust the setting data so that the red point in

the vector waveform is at 108m degrees. (“4”

or “6” button)

9: Write the setting data into memory. (“0”

button)

10:Terminate the service adjustment mode. (“1”

button) See fig 12.

5. Horizontal Width, Vertical Linearity and

Height (Deflection Circuit)

Adjustment purpose:

Horizontal and vertical balance of picture.

Symptom when incorrectly adjusted:

Horizontally or vertically compressed or

expanded picture.

Input signal: VIDEO signal (monoscope).

Input terminal: VIDEO IN terminal.

This adjustment item should be performed for

each of the 7 picture sizes shown in the table

below.

1: Supply a VIDEO signal (monoscope).

2: Press the MENU button on a remote hand unit.

3: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

4: Select the setting function “V-DRIVE”, (“ * “

button).

5: Set the setting data of the setting item “9

HCM” and “4 VCM” to the data shown in the

list below, (“4” or “6” and “2” or “8” button).

MODE 9 HCM 4 VCM

CT-32BW1 10 10

6: Select the setting item “1 VLR”, (“2” or “8”

button).

7: Adjust the setting data for symmetry of vertical

linearity, (“4” or “6” button).

8: Adjust the sum of markers of the setting items

“5 HWD” (horizontal width) and “0 VHT”

(vertical height) to the data shown in the list

below, (“4” or “6” button).

Picture Size 5 HWD 0 VHT

(horizontal) (vertical)

16:9 5.8 5.8

14:9 4.0 3.5

(a=35+/-5mm)

4:3 4.0 3.8

(a=65+/-5mm)

PANORAMA 1 5.5 6.0

PANORAMA 2 5.5 6.0

CINEMA 6.0 the centre of small circle

CAPTION 6.0 upper:

the centre of

small circle

bottom: 3.0

9: Write the setting data into memory , (“0” button).

10:Terminate the service adjustment mode, (“1”

button).

Fig. 8

Service Adjustment Mode

On this model the following setting items may

only be performed using the remote hand unit:

Item 1(RF AGC - Item 9 (Horizontal Position).

Item 11 (CRT Cut Off, White and Black Level) ~

13 (Colour Output). Item 16 (PIP).

To perform these adjustments, use the following

procedure to activate the service adjustment

mode.

Fig. 9 (b)

3. Changing Data

After selecting a setting item, use the “4” or “6”

button to change setting data.

If “4” button is pressed, the setting data

decreases.

If “6” button is pressed, the setting data

increases.

4. Saving of Setting Data

Press the “0” to save the setting data in

memory. The display of characters goes red for

approx. three seconds in this step.

Note: If the service adjustment mode is

Measurement range: DIV 50mV, TIM 10ms.

Input signal: RF signal (L-SYSTEM).

Input terminal: RF IN terminal.

Make this adjustment only in the areas an L SYSTEM signal is received. In areas not

receiving the L-SYSTEM signal, confirm that the

setting data in List of Setting Item “IF” is set to

the final data.

This adjustment must follow item (RF AGC).

1: Supply an RF signal (L-SYSTEM signal 95%

MOD) to main and sub pictures.

2: Connect the oscilloscope to TP12A (pin (13)

of connector CA) and TP12B (pin (15) of

connector CA).

3: Press the MENU button on the remote hand

unit.

4: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

5:Select the setting function “IF”,

1: Supply a VIDEO signal (NTSC colour bar).

2: Set the oscilloscope to X-Y mode.

3: Observe the waveform at TP46B (pin (38) of

IC200) and TP46R (pin (37) of IC200), (CH-1

to TP46B).

4: Press the MENU button on a remote hand

unit.

5: Press the MENU buttons “2”,“3”,“5” and “7” in

that order, (the screen will change to the

service adjustment mode).

6: Select the setting function “VC”.

7: Select the setting item “0 TNT”.

8: Adjust the setting data so that the red point in

the vector waveform is at 108 degrees, (“4” or

“6” button).

9: Write the setting data into memory , (“0” button).

10:Terminate the service adjustment mode, (“1”

button).

Fig 12

Fig 13

6. Side PCC

Adjustment purpose:

Minimise side pincushion distortion.

Symptom when incorrectly adjusted:

Horizontal distortion in the picture.

Page 3

3MITSUBISHI CT-32BW 1B

Service Adjustments Cont’d.

Input signal: VIDEO signal (crosshatch).

Input terminal: VIDEO IN terminal.

This adjustment item should be performed for

each of the 7 picture sizes shown in the table

below.

This adjustment must follow item 5 (Horizontal

Width, Vertical Linearity and Height).

1: Supply a VIDEO signal (Crosshatch).

2: Press the MENU button on a remote hand

unit.

3: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

4: Select the setting function “V-DRIVE”,

(“*“ button).

5: Select the setting item “6 PAM”

(“2” or “8” button).

6: Note the second vertical lines from both right

and left sides. Adjust the setting data so that

the second line is almost straight, (“4” or “6”

button).

7: Select the setting item “8 PPH”,

(“2” or “8” button).

8: Note the second line from both right and left

of crosshatch. Adjust the setting data so that

the distortion is symmetrical at the top and

bottom of vertical lines, (“4” or “6” button).

9: Alternately repeat steps 5 to 8 to minimise

side raster distortion.

10:Write the setting data into memory,

(“0” button).

11:Terminate the service adjustment mode,

(“1” button).

Note: If the side raster is significantly distorted

in the middle, set the setting data of items “7

PCN” and “6 PAM” for minimum distortion.

Picture Size

16:9

14:9

4:3

PANORAMA 1

PANORAMA 2

CINEMA

CAPTION

Fig 14

7. Vertical S Correction (Deflection circuit)

Adjustment purpose:

Set the vertical compression/expansion at the

top and bottom.

Symptom when incorrectly adjusted:

Vertically compressed or expanded at the top

and bottom of the picture.

Input signal: VIDEO signal (crosshatch).

Input terminal: VIDEO IN terminal.

This adjustment item should be performed for

each of the 7 picture sizes shown in the table.

1: Supply a VIDEO signal, (crosshatch).

2: Press the MENU button on a remote control.

3: Press the buttons “2”,“3”,“5” and “7” in that

order, (the screen will change to the service

adjustment mode).

4: Select the setting function “V-DRIVE”,

(“*“ button).

5: Select the setting item “2 VSC” and “10 VSS”

(“2” or “8” button).

6: Set the adjustment data so that the ratio of

the height of the squares on the top (A) and

the bottom (C) of the pattern to those on the

middle (B) is adjusted to that specified in the

table below, (“4” or “6” button).

7: Write the setting data into memory,

(“0” button).

8: Terminate the service adjustment mode,

(“1” button).

Picture Size Ratio (A:B:C)

16:9 1:1:1

14:9 1:1:1

4:3 1:1:1

PANORAMA 1 1:1:1

PANORAMA 2 0.8:1:0.8

CINEMA 1:1:1

CAPTION 1:1:1

Fig 15

8. Vertical Centre Position (Deflection circuit)

Adjustment purpose:

To set the vertical position of the picture.

Symptom when incorrectly adjusted:

The picture will be too high or too low on the

screen.

Input signal: VIDEO signal (monoscope).

Input terminal: VIDEO IN terminal.

This adjustment item should be performed for

each of the 7 picture sizes shown in the table

below.

1: Supply a VIDEO signal, (monoscope).

2: Press the MENU button on a remote control.

3: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

4: Select the setting function “V-DRIVE “,

(“*“ button).

5: Select the setting item “11 VP0”, (“2” or “8”

button).

6: Adjust the setting data so the upper and lower

markers are the same, (“4” or “6” button).

Note: confirm the data of “3 VFS” is “4”.

7: Write the setting data into memory,

(“0” button).

8: Terminate service adjustment mode,

(“1” button).

Picture Size

16:9

14:9

4:3

PANORAMA 1

PANORAMA 2

CINEMA

CAPTION

Fig 16

9. Horizontal Position (Deflection circuit)

Adjustment purpose:

Horizontal position of picture on screen.

Symptom when incorrectly adjusted:

Picture shifted from the left or right.

Input signal: VIDEO signal (monoscope).

Input terminal: VIDEO IN terminal.

1: Supply a VIDEO signal, (monoscope).

2: Press the MENU button on a remote control.

3: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

4: Select the setting function “V-DRIVE 60”,

(“4:3” button).

5: Select the setting item “0 HPH” (“2” or “8”

button).

6: Adjust the setting data so the left and right

markers are the same, (“4” or “6” button).

7: Write the setting data into memory,

(“0” button).

8: Terminate the service adjustment mode,

(“1” button).

Fig 17

10. Horizontal Blanking (Deflection circuit)

Adjustment purpose:

To set the horizontal size of 4:3 picture on

screen.

Symptom when incorrectly adjusted:

Picture shifted to the left or right.

Input signal: VIDEO signal (monoscope).

Input terminal: VIDEO IN terminal.

This adjustment must follow item 9 (Horizontal

Position).

1: Supply a VIDEO signal, (monoscope).

2: Select the picture size “4:3”.

3: Adjust VR5CA so that the reading of the left

marker is “2”.

4: Adjust VR5CB so that the reading of the right

marker is “2”.

Fig 18

11. CRT Bias, Cut Off, White and Black Level

(VIDEO circuit)

Adjustment purpose:

Setting the cut off level of the three electron

beams.

Symptom when incorrectly adjusted:

Monochrome has a colour tint.

Input terminal: VIDEO IN terminal.

1: Set the no signal condition in AV mode.

2: Press the MENU button on a remote control

unit.

3: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

4: Select the setting function “VC “ and set the

setting items shown in the table to the setting

data value.

5: Set the data of item “4 MUT” to “3” (“6”

button). The screen will change to display a

single horizontal line.

6: Set the SCREEN-1 VR on Flyback Trans-

former (T532) to the point where a red, green

or blue line just becomes visible.

7: Select the data of item “4 MUT” to “0” (“4”

button).

8: Refer to adjustment items “5 COR”, “6 COG”

and “7 COB”, adjust the data of the items for

the two colours not visible in the step 6. Adjust

the data so that the horizontal line is white (“4”

or “6” button).

9: Supply a VIDEO signal (G card).

10:Set the data item “1 COL” to “0” (“4” button).

11:Select the setting item “2 BRI” (“2” or “8”

button).

12:Adjust the setting data so that the difference

in tone is just visible between the blue area

and the black area (“4” or “6” button).

13:Write the setting data into memory (“0” button).

14:Terminate the service adjustment mode

(“1” button).

Fig 19

No. Setting Item Setting Data

2 BRT 128

3 CNT 67

5 COR 230

6 COG 230

7 COB 230

8 DRR 134

9 DRB 96

12. Contrast (Video circuit)

Adjustment purpose:

The best value for beam current

Symptom when incorrectly adjusted:

The picture will be too bright or too dark.

Measuring instrument: DC milliammeter.

Test point:

+ lead: pin (4) of connector TX.

- lead: pin (1) of connector TX.

Measurement range: 3mA

Input signal: VIDEO signal (G card).

Input terminal: VIDEO IN terminal.

This adjustment must follow item CRT Bias Cut

Off, White and Black Level.

Preheat the set for two minutes or more.

1: Supply a VIDEO signal (G card).

2: Select the picture size to “16:9”.

3: Press the MENU button on a remote hand set.

4: Press the buttons “2”,“3”,“5” and “7” in that

order, (the screen will change to the service

adjustment mode).

5: Select the setting function “VC “.

6: Select the setting item “1 COL” (“2” or “8”

button).

7: Set the setting data of item “1 COL” to “0” (“4”

or “6” button).

8: Observe the beam current values at pins (1)

and (4) of connector TX, (plus lead to pin (4)

of connector TX).

9: Select the setting data “3 CNT” (“2” or “8”

button).

10:Adjust the setting data so that the beam

current is 1200 ± 70µA (“2 or “6” button).

11:Write the setting data into memory

(“0”button).

12:Terminate the service adjustment mode

(“1” button).

Fig 20

13. Colour Output (Video circuit)

Adjustment purpose:

Colour output of video signal.

Symptom when incorrectly adjusted:

The colour level will be too high or too low.

Measuring Instrument: Oscilloscope.

Test point: Pin (2) of connector GB.

Measurement range:

DIV 2V.

TIM 10ms.

Input signal: VIDEO signal (colour bar).

Input terminal: VIDEO IN terminal.

This adjustment must follow item Contrast.

1: Supply a video signal (colour bar).

2: Observe the waveform at pin (2) of connector

GB, (use the pin (3) of connector GB for

GND.

3: Press the MENU button on a remote hand

unit.

4: Press the buttons “2”, “3”, “5”, and “7” in that

order, (the screen will change to the service

adjustment mode).

5: Select the setting function “VC”.

6: Select the setting item “1 COL” (“2” or “8”

button).

7: Adjust the setting data of item “1 COL” so that

the waveform as shown below (“4” or “6”

button).

8: Write the setting data into memory

(“0” button).

9: Terminate the service adjustment mode

(“1” button).

Fig 21

14. Focus (CRT circuit)

Adjustment purpose: Sharpness of picture.

Symptom when incorrectly adjusted:

Poor sharpness of picture.

Input signal: VIDEO signal (monoscope).

Input terminal: VIDEO IN terminal.

1: Supply a VIDEO signal (monoscope).

2: Observe the vertical lines and adjust

SCREEN-2 VR (FOCUS-2) on the Flyback

Transformer (T532).

3: Observe the horizontal lines and adjust

FOCUS-1 VR on the Flyback Transformer

(T532).

4: Repeat steps 2 and 3, two or more times until

no further improvement is seen.

Fig 22

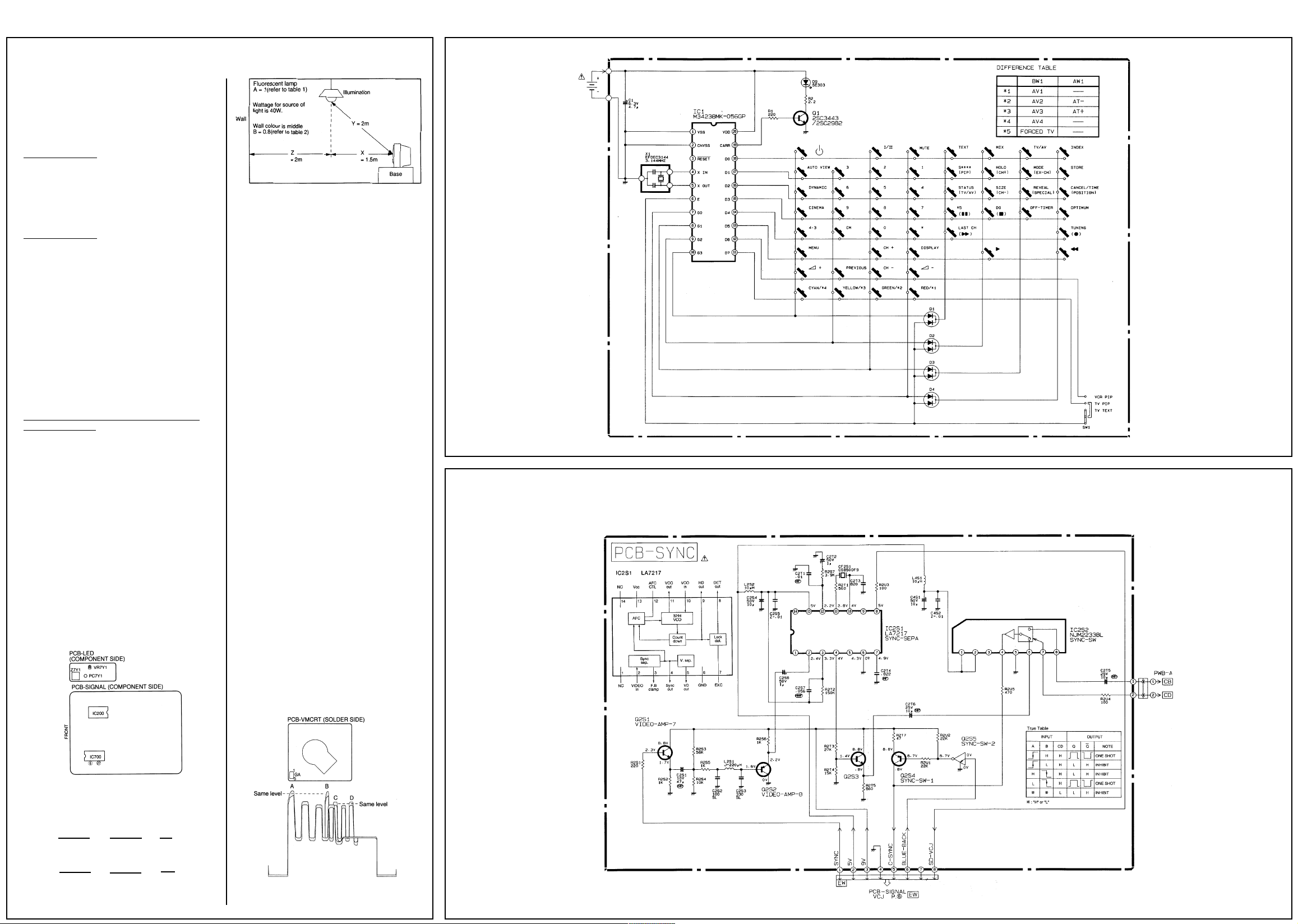

15. Sensor Level (AI circuit)

Adjustment purpose:

Set the operating conditions for the AI light

sensor.

Symptoms when incorrectly adjusted:

Too dark a picture in a bright room or too bright

a picture in a dark room, when AI is selected.

Measuring instrument: DC Voltmeter.

Test point:

+lead: pin (27) of IC700.

- lead: pin (6) of IC700.

When replacing PC7Y1 or VR7Y1 perform this

adjustment.

1: Shut the shutter or curtain in the room and

intercept the outside light.

2: Turn off the light except the ceiling light. If

there are plural ceiling lights in the room, turn

on the light located at the centre of the room

only.

3: Place the set as shown in fig. 23. At this time

ensure the source of light is not hidden by the

set’s side.

4: Measure X, Y and Z shown in fig. 23 at the

adjustment room. Calculate the amount of

brightness at the front of the set (L) by the

following method:

Page 4

MITSUBISHI CT-32BW 1B

4

Service Adjustments Cont’d.

L1 = 11A.X.W/Y

L2 = A.B.W/Z

L = L1 + L”

Note: find the coefficient A or B refer to Table 1

and 2. “W” is wattage for the source of light.

Table 1 Value of A

Illumination Value of A

Fluorescent lamp

(straight tube, loop tube) 1

Incandescent lamp 0.15

Fluorescent internal lamp 0.5

Table 2 Value of B

Wall Colour Value of B

Deep black 0

Too dark 0.4

Middle 0.8

Too bright 1.2

Pure white 1.6

5: If the value of L found at step 4 is not within

50 ≥ L ≥ 150, move the set towards the

illumination or weaken the source of light so

that the value of L is within 50 ≥ L ≥ 150.

6: Find the output voltage with the value of L,

refer to Table 3. When the fraction of L is less

than 4, the fraction round off or the fraction is

over 5, it rounds up.

Table 3 Correspondence to illumination and

output voltage (V)

LV

50 1.2

60 1.5

70 1.8

80 2.1

90 2.4

100 2.7

110 3.0

120 3.3

130 3.6

140 3.9

150 4.2

7: Observe the voltage at the plus side of pin (6)

of IC700 (use the minus side of pin (27) of

IC700 for ground.

8: Turn on power source of the set.

9: Adjust VR7Y1 so that the value displayed on

digital voltmeter equals the output voltage

±0.3V found at step 6.

3

2

Fig. 25

16. PIP (PIP circuit)

Adjustment purpose:

Set the brightness and colour level between

main and sub pictures.

Set sub picture on the POP mode.

Symptom when incorrectly adjusted:

Different brightness or colour level between

main and sub pictures.

Shifted sub or main picture overflowing the

frame.

Measuring instrument: Oscilloscope.

Test point: Pin (4) of connector GA.

Measurement range:

DIV 20mV.

TIM 10ms.

Input signal: VIDEO signal (EBU colour bar).

Input terminal: VIDEO IN terminal.

This adjustment must follow the setting functions of “VC” and “V-DRIVE”.

1: Supply a VIDEO signal (EBU colour bar) for

main and sub pictures.

2: Observe the waveform at pin (4) of connector GA.

3: Press the MENU button on a remote hand

unit.

4: Press the buttons “2”, “3”, “5” and “7” in that

order, (the screen will change to the service

adjustment mode).

5: Select the setting function “PIP” (“ * “ button).

6: Select the setting item “1 CNT” (“2” or “8”

button).

7: Adjust the setting data so that the levels of A

and B are the same (“4” or “6” button).

8: Select the setting item “2 COL” (“2” or “8”

button).

9: Adjust the setting data so that the levels of C

and D are the same (“4” or “6” button).

Remote

Control

Diagram

Sync Diagram

Fig. 24

Calculation example of brightness (L)

For example, when perorming this adjustment in

the room shown in Fig 25, the method to find the

value of L is as follows.

L1 = 11•A•X•W = 11•1•1.5•40 = 660 = 82.5

Y3 23 8

L2 = A•B•W = 1•0.8•40 = 32 = 8

Z2 22 4

L = L1 + L2 = 82.5 + 8 = 90.5 = 90

Note: the adjustment of step 9, observe the

main picture to AV input with no signal for

easier adjustment.

Fig. 26

Page 5

5MITSUBISHI CT-32BW 1B

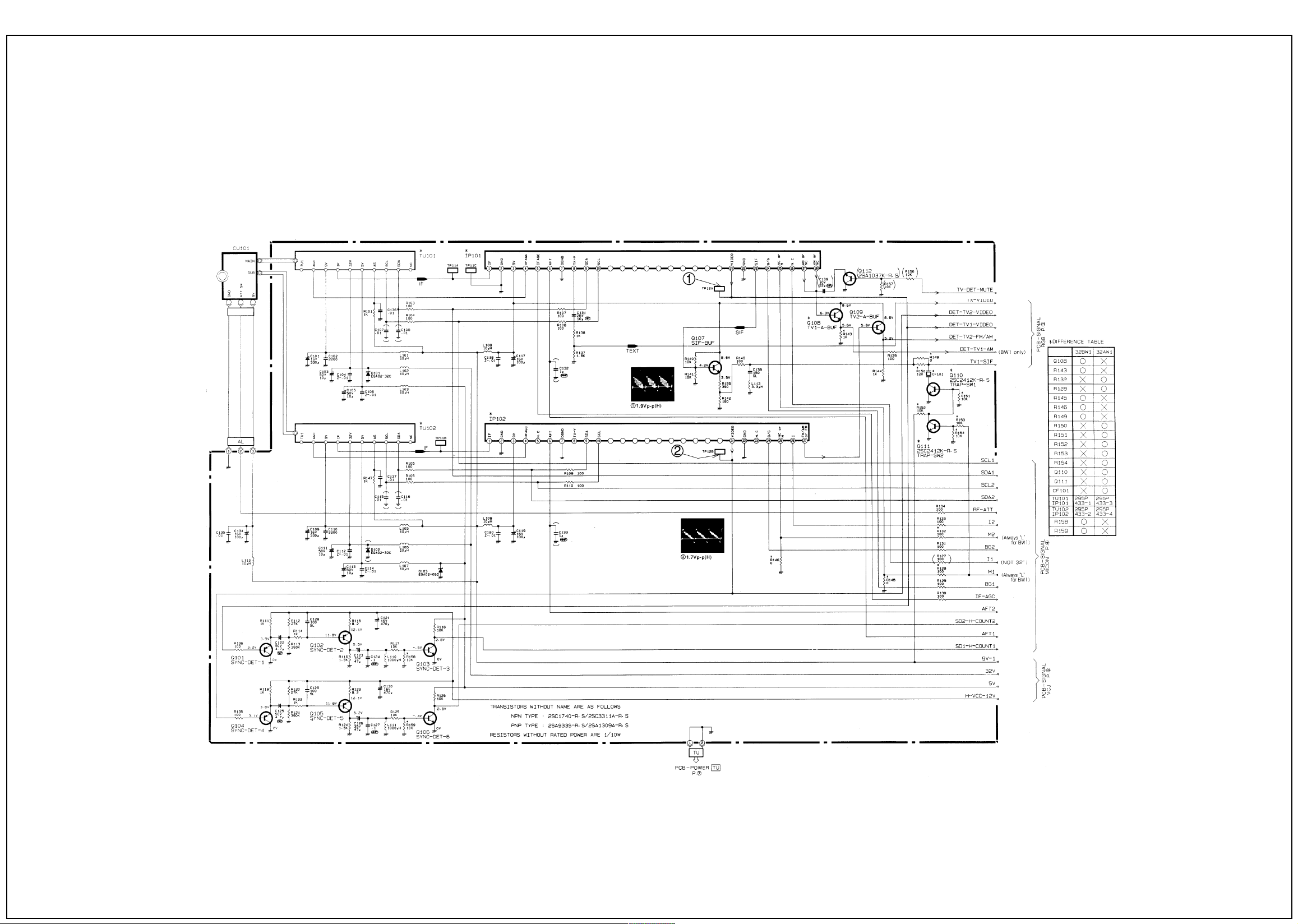

Signal HF Diagram

Page 6

MITSUBISHI CT-32BW 1B

6

Replacing EEPROM (IC702)

The EEPROM (IC702) stores the setting data

specified in the List of Setting Items. When

the EEPROM is replaced, all the setting data

is initialised. After the replacement, store the

data in the List of Setting Items.

List of Setting Items

Function Display VC IC200, IC201

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 tnt Tint Control (NTSC) 0~127 (64) Item 4 (Tint)

1 col Colour Control 0~127 (62) Item 13 (Colour Output)

2 bri Brightness Control 0~255 128

3 cnt Contrast Control 0~127 (67) Item 12 (Contrast)

4 mut Mute Mode 0~3 0

5 cor R-Cut Off Adjustment 0~1023 (230) Item 11 (CRT Bias Cut Off White & Black Level)

6 COG G-Cut Off Adjustment 0~1023 (230) Item 11 (CRT Bias Cut Off White & Black Level)

7 COB B-Cut Off Adjustment 0~1023 (230) Item 11 (CRT Bias Cut Off White & Black Level)

8 DRR R-Drive Adjustment 0~255 134

9 DRB B-Drive Adjustment 0~255 96

10 DLR R-Drive (Low) Shift Value -128 ~+127 +8

11 DLB B-Drive (Low) Shift Value -128 ~+127 -12

12 DHR R-Drive (High) Shift Value -128 ~+127 -12

13 DHB B-Drive (High) Shift Value -128 ~+127 +8

14 SRY SECAM Black level R-Y 0~15 8

15 Sby SECAM Black Level R-Y 0~15 8

16 Pna PN Amplitude 0~1 0

17 SCA SECAM Amplitude 0~3 0

18 bel BELL Filter 0~7 4

19 Wpl WPL 0~1 1

20 apc Aperture Control 0~1 0

21 png P/N GP 0~1 0

22 vmd Vertical Mode 0~3 1

23 shp Sharpness 0~63 32

24 sgp S GP 0~1 0

25 sid S ID 0~1 0

26 src Search 0~1 0

27 afc AFC 0~1 0

28 ttl Tint Lower Limit 0~63 0

29 ttu Tint Upper Limit 65~127 127

30 cll Colour Lower Limit 0~63 0

31 clu Colour Upper Limit 65~127 85

32 brl Brightness Lower Limit 0~127 110

33 bru Brightness Upper Limit 129~255 160

34 cnl Unicolour Lower Limit 0~63 35

35 cnu Unicolour Upper Limit 65~127 75

Function Display V-Drive (4:3) IC501, IC201

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 VHT Vertical Amplitude Adjustment 0~127 (77) Item 5 (Horizontal Width, Vertical Linearity & Height)

1 VLR Vertical Linearity Correction 0~31 (25) Item 5 (Horizontal Width, Vertical Linearity & Height)

2 VSC Vertical S Correction 0~31 (0) Item 7 (Vertical S Correction)

3 VSF Vertical Position 1 Adjustment 0~7 4

4 VCM Vertical EHT 0~63 10

5 HWD Horizontal Amplitude Adjustment 0~63 (17) Item 5 (Horizontal Width, Vertical Linearity & Height)

6PAM E-W Parabola (PCC-AMP) Correction 0~63 (17) Item 6 (Side PCC)

7 PCN PCC Corner Correction 0~15 10

8 PPH (PCC Phase)Keystone Distortion Correct 0~63 (30) Item 6 (Side PCC)

9 HCM Horizontal EHT 0~15 (0) Item 6 (Side PCC)

10 VSS Vertical Integral Correction 0~15 (15) Item 7 (Vertical Correction)

11 VP0 Vertical Position 2 Adjustment 0~255 (115) Item 8 (Vertical Centre Position)

12 V60 Vertical Position 60Hz Correction -128 ~+127 +10

Function Display V-Drive (Panorama 1) IC501, IC201

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 VHT Vertical Amplitude Adjustment 0~127 (80) Item 5 (Horizontal Width, Vertical Linearity & Height)

1 VLR Vertical Linearity Correction 0~31 (26) Item 5 (Horizontal Width, Vertical Linearity & Height)

2 VSC Vertical S Correction 0~31 (0) Item 7 (Vertical S Correction)

3 VSF Vertical Position 1 Adjustment 0~7 4

4 VCM Vertical EHT 0~63 10

5 HWD Horizontal Amplitude Adjustment 0~63 (44) Item 5 (Horizontal Width, Vertical Linearity & Height)

6PAM E-W Parabola (PCC-AMP)Correction 0~63 (10) Item 6 (Side PCC)

7 PCN PCC Corner Correction 0~15 0

8 PPH (PCC Phase)Keystone Distortion Correct 0~63 (27) Item 6 (Side PCC)

9 HCM Horizontal EHT 0~15 (10) Item 6 (Side PCC)

10 VSS Vertical Integral Correction 0~15 (15) Item 7 (Vertical Correction)

11 VP0 Vertical Position 2 Adjustment 0~255 (119) Item 8 (Vertical Centre Position)

12 V60 Vertical Position 60Hz Correction -128 ~+127 +10

The data with () is reference data. Correct

the data according to the adjustment items

specified in “Note” for optimum adjustment.

Function Display V-Drive (Panorama 2) IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 VHT Vertical Amplitude Adjustment 0~127 (92) Item 5 (Horizontal Width, Vertical Linearity & Height)

1 VLR Vertical Linearity Correction 0~31 (26) Item 5 (Horizontal Width, Vertical Linearity & Height)

2 VSC Vertical S Correction 0~31 (10) Item 7 (Vertical S Correction)

3 VSF Vertical Position 1 Adjustment 0~7 4

4 VCM Vertical EHT 0~63 10

5 HWD Horizontal Amplitude Adjustment 0~63 (35) Item 5 (Horizontal Width, Vertical Linearity & Height)

6PAM E-W Parabola (PCC-AMP) Correction 0~63 (12) Item 6 (Side PCC)

7 PCN PCC Corner Correction 0~15 3

8 PPH (PCC Phase)Keystone Distortion Correct. 0~63 (32) Item 6 (Side PCC)

9 HCM Horizontal EHT 0~15 (10) Item 6 (Side PCC)

10 VSS Vertical Integral Correction 0~15 (8) Item 7 (Vertical Correction)

11 VP0 Vertical Position 2 Adjustment 0~255 (120) Item 8 (Vertical Centre Position)

12 V60 Vertical Position 60Hz Correction -128 ~+127 +10

Function Display V-Drive (Cinema) IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 VHT Vertical Amplitude Adjustment 0~127 (110) Item 5 (Horizontal Width, Vertical Linearity & Height)

1 VLR Vertical Linearity Correction 0~31 (28) Item 5 (Horizontal Width, Vertical Linearity & Height)

2 VSC Vertical S Correction 0~31 (0) Item 7 (Vertical S Correction)

3 VSF Vertical Position 1 Adjustment 0~7 4

4 VCM Vertical EHT 0~63 10

5 HWD Horizontal Amplitude Adjustment 0~63 (36) Item 5 (Horizontal Width, Vertical Linearity & Height)

6PAM E-W Parabola (PCC-AMP) Correction 0~63 (17) Item 6 (Side PCC)

7 PCN PCC Corner Correction 0~15 0

8 PPH (PCC Phase)Keystone Distortion Correct 0~63 (34) Item 6 (Side PCC)

9 HCM Horizontal EHT 0~15 (10) Item 6 (Side PCC)

10 VSS Vertical Integral Correction 0~15 (15) Item 7 (Vertical Correction)

11 VP0 Vertical Position 2 Adjustment 0~255 (109) Item 8 (Vertical Centre Position)

12 V60 Vertical Position 60Hz Correction -128 ~+127 +10

Function Display V-Drive (Caption) IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 VHT Vertical Amplitude Adjustment 0~127 (112) Item 5 (Horizontal Width, Vertical Linearity & Height)

1 VLR Vertical Linearity Correction 0~31 (17) Item 5 (Horizontal Width, Vertical Linearity & Height)

2 VSC Vertical S Correction 0~31 (15) Item 7 (Vertical S Correction)

3 VSF Vertical Position 1 Adjustment 0~7 4

4 VCM Vertical EHT 0~63 10

5 HWD Horizontal Amplitude Adjustment 0~63 (36) Item 5 (Horizontal Width, Vertical Linearity & Height)

6PAM E-W Parabola (PCC-AMP) Correction 0~63 (18) Item 6 (Side PCC)

7 PCN PCC Corner Correction 0~15 7

8 PPH (PCC Phase)Keystone Distortion Correct 0~63 (33) Item 6 (Side PCC)

9 HCM Horizontal EHT 0~15 (10) Item 6 (Side PCC)

10 VSS Vertical Integral Correction 0~15 (0) Item 7 (Vertical Correction)

11 VP0 Vertical Position 2 Adjustment 0~255 (142) Item 8 (Vertical Centre Position)

12 V60 Vertical Position 60Hz Correction -128 ~+127 +15

Function Display V-Drive (16;9) IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 VHT Vertical Amplitude Adjustment 0~127 (77) Item 5 (Horizontal Width, Vertical Linearity & Height)

1 VLR Vertical Linearity Correction 0~31 (26) Item 5 (Horizontal Width, Vertical Linearity & Height)

2 VSC Vertical S Correction 0~31 (0) Item 7 (Vertical S Correction)

3 VSF Vertical Position 1 Adjustment 0~7 4

4 VCM Vertical EHT 0~63 10

5 HWD Horizontal Amplitude Adjustment 0~63 (36) Item 5 (Horizontal Width, Vertical Linearity & Height)

6PAM E-W Parabola (PCC-AMP) Correction 0~63 (11) Item 6 (Side PCC)

7 PCN PCC Corner Correction 0~15 10

8 PPH (PCC Phase)Keystone Distortion Correct. 0~63 (21) Item 6 (Side PCC)

9 HCM Horizontal EHT 0~15 (0) Item 6 (Side PCC)

10 VSS Vertical Integral Correction 0~15 (15) Item 7 (Vertical Correction)

11 VP0 Vertical Position 2 Adjustment 0~255 (117) Item 8 (Vertical Centre Position)

12 V60 Vertical Position 60Hz Correction -128 ~+127 +10

Function Display V-Drive (14;9) IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 VHT Vertical Amplitude Adjustment 0~127 (74) Item 5 (Horizontal Width, Vertical Linearity & Height)

1 VLR Vertical Linearity Correction 0~31 (26) Item 5 (Horizontal Width, Vertical Linearity & Height)

2 VSC Vertical S Correction 0~31 (0) Item 7 (Vertical S Correction)

3 VSF Vertical Position 1 Adjustment 0~7 4

4 VCM Vertical EHT 0~63 10

5 HWD Horizontal Amplitude Adjustment 0~63 (32) Item 5 (Horizontal Width, Vertical Linearity & Height)

6PAM E-W Parabola (PCC-AMP) Correction 0~63 (12) Item 6 (Side PCC)

7 PCN PCC Corner Correction 0~15 10

8 PPH (PCC Phase)Keystone Distortion Correct. 0~63 (34) Item 6 (Side PCC)

9 HCM Horizontal EHT 0~15 (0) Item 6 (Side PCC)

10 VSS Vertical Integral Correction 0~15 (15) Item 7 (Vertical Correction)

11 VP0 Vertical Position 2 Adjustment 0~255 (123) Item 8 (Vertical Centre Position)

12 V60 Vertical Position 60Hz Correction -128 ~+127 +10

Function Display V-Drive (HPH/60) IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 HPH Horizontal Phase (B/W) 0~31 (16) Item 9 (Horizontal Position)

1 VHT Vertical Amplitude Adjustment -64~+63 +3

2 VLR Vertical Linearity Correction -16~+15 -4

3 VSC Vertical S Correction -4~+3 0

4 VSF Vertical Position -8~+7 0

5 VCM Vertical EHT -32~+3 10

6 HWD Horizontal Amplitude -32~+3 10

7 PAM E-W Parabola (PCC-AMP) -32~+3 10

8 PCN PCC Corner -8~+7 0

9 PPH (PCC Phase) Keystone Distortion Correct. -32~+3 10

10 HCM Horizontal EHT -8~+7 0

11 VSS Vertical Integral -8~+7 0

12 HPA Horizontal Phase (PAL, NTSC) -16~+15 -8

13 HNT Horizontal Phase (60Hz) -16~+15 +2

14 HSE Horizontal Phase (SECAM) -16~+15 -3

15 HRG Horizontal Phase (RGB) -16~+15 +9

16 HTX Horizontal Phase (TEXT) -16~+15 -2

17 HP0 Horizontal Phase (PIP) -16~+15 -6

18 HP1 Horizontal Phase (POP) -16~+15 +3

19 HPS Horizontal Phase (S) -16~+15 +6

20 VPH Vertical Phase 0~7 0

Function Display PIP IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 BRI External Control D/A 0~255 2551CNT External Control D/A0~255(55)Item 16 (PIP)

2 COL External Control D/A 0~255 (210) Item 16 (PIP)

3 V-P Vertical Position (B side) 0~255 13

4 H-P Horizontal Position (B side) 160~191 177

51 VP1 VP1 50/60 V ertical Correction Data (POP) -127~127 -5

52 VP2 VP2 60/50 V ertical Correction Data (POP) -127~127 0

53 VP3 VP3 50/60 V ertical Correction Data (POP) -127~127 +5

54 HP1 HP1 50/60 Horizontal Correct. Data (POP) -127~127 +1

5 HP2 HP2 60/50 Horizontal Correct. Data (POP) -127~127 +35

6 HP3 HP3 50/60 Horizontal Correct. Data (POP) -127~127 +3

Function Display IF IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 LV0 L-Video 0~63 (40) Item 2 (L-System Video Output)

1 RF0 RF-AGC 0~63 (45) Item 1 (RF-AGC)

2 LV1 L-Video 1 0~63 (40) Item 2 (L-System Video Output)

3 RF1 RF-AGC 0~63 (45) Item 1 (Rf-AGC)

Function Display JUST IC501, IC200

Setting Setting Setting Item Name Setting Setting Note

Item Abbreviated Range Data

No. Name

0 SU50 Pulse Top Side Start Point (50Hz) 1~26 8

1 TU5 CINEMA Top Side Boundary (50Hz) 1~52 11

2 EU5 Pulse Top Side End Point (50Hz) 27~52 27

3SL5 Pulse Bottom Side Start Point (50Hz) 53~78 64

4 TL5 CINEMA Bottom Side Boundary (50Hz) 53~104 92

5EL5 Pulse Bottom Side End Point (50Hz) 79~104 95

6 CP5 Picture Centre (50Hz) 27~78 51

7 SU6 Pulse Upper Side Start Point (60Hz) 1~22 7

8 TU6 CINEMA Upper Side Boundary (60Hz) 1~44 9

9 EU6 Pulse Upper Side End Point (60Hz) 23~44 23

10 SL6 Pulse Bottom Side Start Point (60hz) 45~66 54

11 TL6 CINEMA Bottom Side Boundary (60Hz) 45~48 78

12 EL6 Pulse Bottom Side End Point (60Hz) 67~88 80

13 CP6 Picture Centre (60Hz) 23~66 44

14 43N JUST 4:3 0~15 1

15 CNN JUST CINEMA 0~15 5

Page 7

7MITSUBISHI CT-32BW 1B

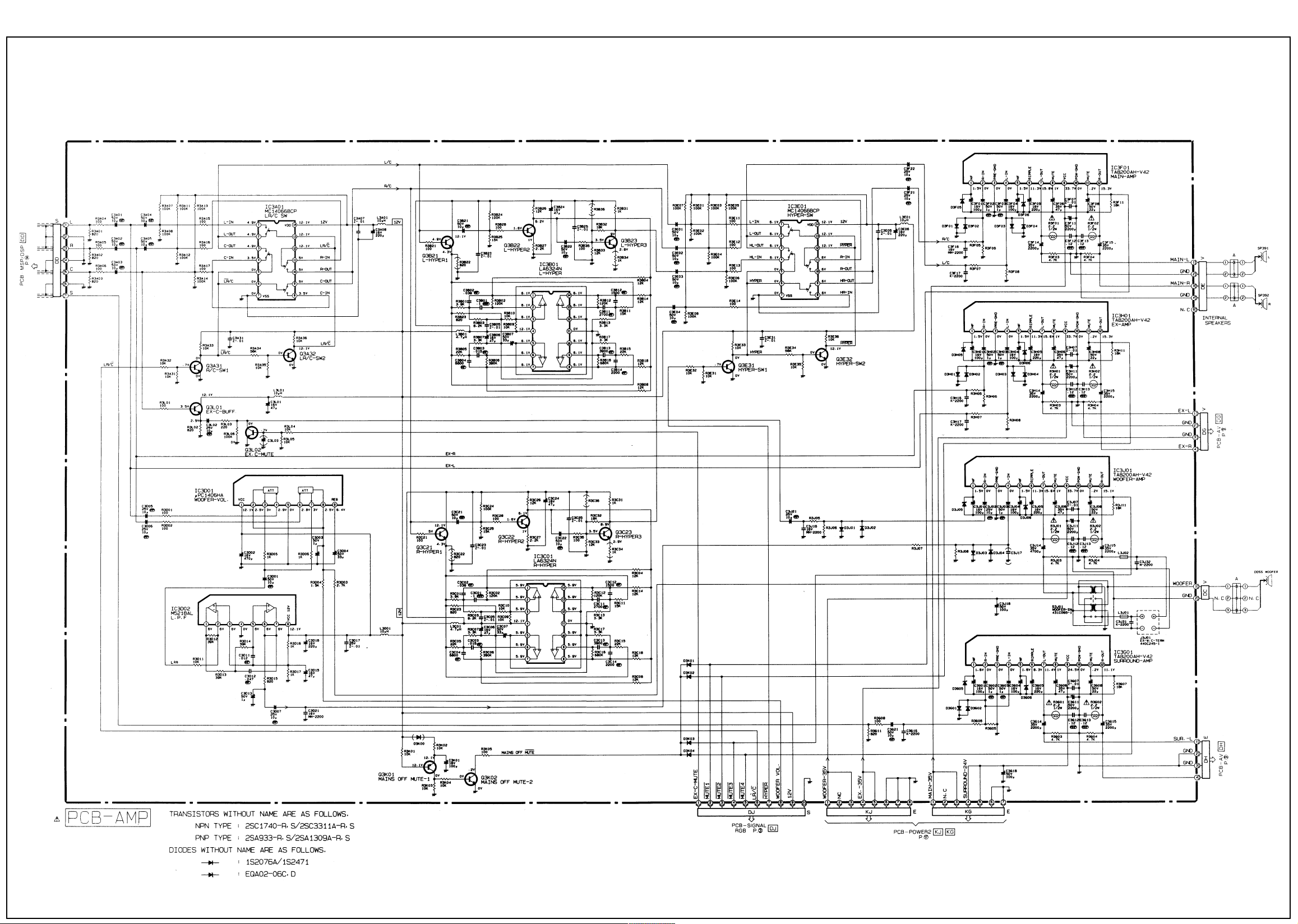

Audio Amp Diagram

Page 8

MITSUBISHI CT-32BW 1B

8

AV Diagram

Page 9

9MITSUBISHI CT-32BW 1B

Control Diagram

DCF Diagram

DBF Diagram

LED Diagram

Page 10

MITSUBISHI CT-32BW 1B

10

Deflection Diagram

Page 11

11MITSUBISHI CT-32BW 1B

JUST Diagram

Page 12

MITSUBISHI CT-32BW 1B

12

MICON (OSD) Diagram

Page 13

13MITSUBISHI CT-32BW 1B

MICON Diagram

Page 14

MITSUBISHI CT-32BW 1B

14

MSP DSP Diagram

Page 15

15MITSUBISHI CT-32BW 1B

PIP Diagram

Page 16

MITSUBISHI CT-32BW 1B

16

Power Diagram

Page 17

17MITSUBISHI CT-32BW 1B

Power 2 Diagram

Page 18

MITSUBISHI CT-32BW 1B

18

Signal RGB Diagram

Page 19

19MITSUBISHI CT-32BW 1B

Signal VCJ Diagram

Page 20

MITSUBISHI CT-32BW 1B

20

Wide Diagram

Phone Diagram

VMCRT Diagram

Page 21

21MITSUBISHI CT-32BW 1B

Text Diagram

Page 22

MITSUBISHI CT-32BW 1B

22

WAC Diagram

Page 23

23MITSUBISHI CT-32BW 1B

Y/C SW Diagram

Loading...

Loading...