Page 1

MITSUBISHI CT 29BV1 BD

1

Load Dressing

1.4.2 Lead dressing

Leads must be dressed as shown in table 1 .4B

and the diagram (fig. 1.4C) below. The leads are

routed or clamped so that they do not come

close to any heat generating or high-tension

parts. The anode lead wire is routed such that

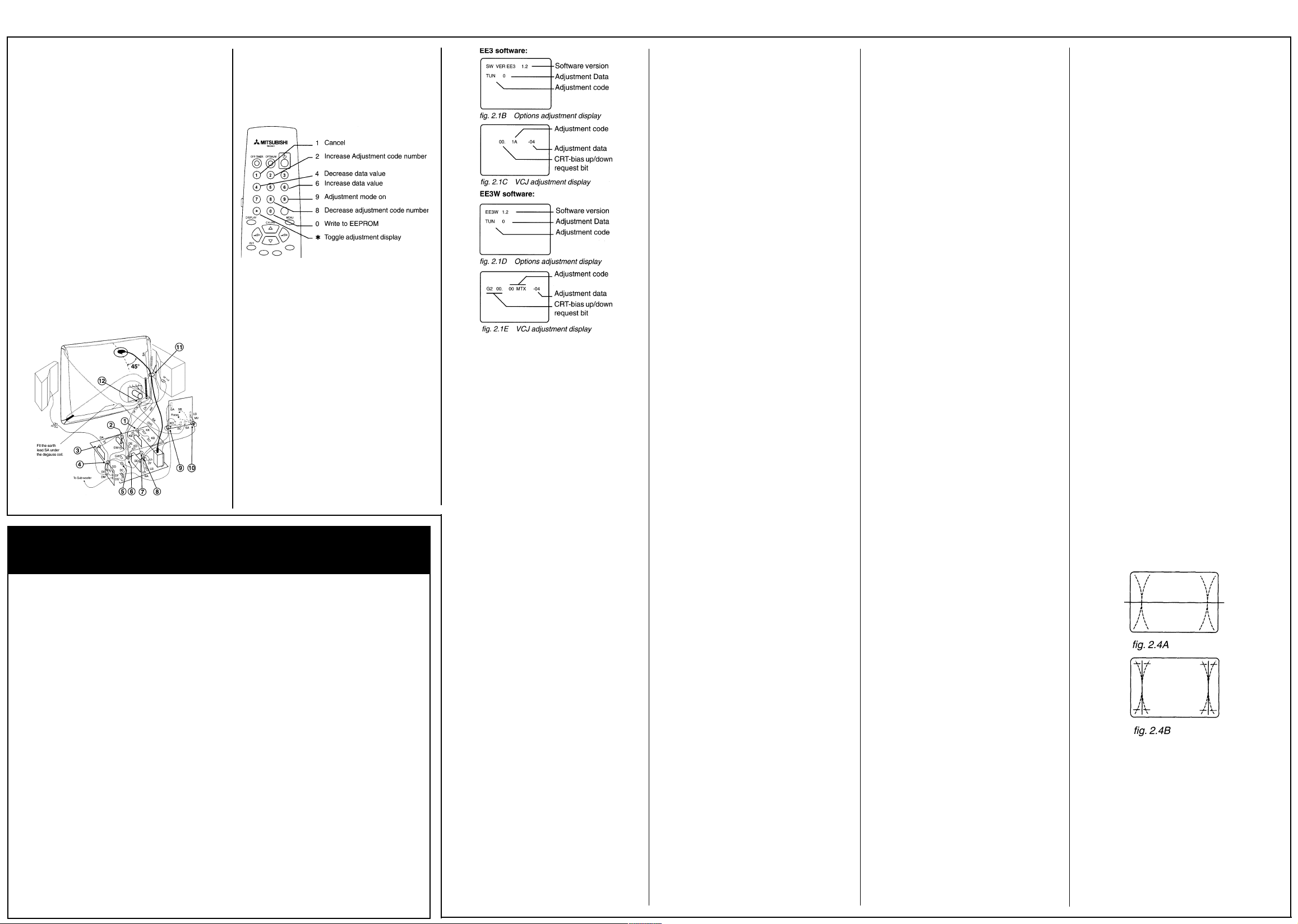

2.1 introduction

Most service adjustments to these models are

made using the remote control (figure 2.1A) with

the TV in service mode. The adjustment data is

stored in an EEPROM.

Adjustments

no tension is applied to the anode cap. If the

mounting angle of the anode cap and the route

of the anode lead wires are changed, return

them to the initial angle and route.

CLAMP No WIRES CLAMPED

1 KB, KK

2 DA, DM

3DM

4 DA, DD, DE, DF (3+4)

5DD

6 DA (looped), KD

7 DY (Loop the lead twice)

8 LB, BA (Loop the lead twice)

9 KD, SC, GA (Loop the lead)

10 LB (Loop the lead twice), SB, Focus

11 Anode lead

12 BA, DF(1+2)

table 1.4B Lead-dressing table.

NOTE: The software in the microcontroller

IC701 may be either of 2 versions -EE3 or

EE3W. EE3 software is used in IC701 part no.

274P755010, EE3W software is used in IC701

part no. 274P755040.

The actual software in use is shown on the

Options adjustment display - see the next

section.

2.1.1 Basic adjustment procedure

1.Turn the power on and enter service mode either (EE3) press the Service switch (S701,

next to the aerial socket) and then button

within 5 seconds (EE3W) press the MENU

button to display the MAIN MENU then

immediately key-in 2-3-5-7.

2. Press the “*” button to toggle between the

VCJ or OPTION adjustment display (figs. 2.1

B, C, D and E).

table 1.4C Lead-dressing diagram.

Recommended Safety Parts

Item Part No. Description

T551 MAIN 334P243030 TRANS-FLYBACK

T901 MAIN 350P663020 TRANS-POWER

R352 MAIN 103P378060 R-FUSE 1/4W 3.3-J

R353 MAIN 103P378060 R-FUSE 1/4W 3.3-J

R3A11 AUDIO-PWR 103P378060 R-FUSE 1/4W 3.3-J

R3A12 AUDIO-PWR 103P378060 R-FUSE 1/4W 3.3-J

R3B01 AUDIO-PWR 103P378060 R-FUSE 1/4W 3.3-J

R3B02 AUDIO-PWR 103P378060 R-FUSE 1/4W 3.3-J

R512 MAIN 103P442020 R-FUSE-METAL 1W 560-K/J

R513 MAIN 103P398040 R-FUSE 1/2W 2.2-J

R514 MAIN 103P397090 R-FUSE 1/2W 0.82-J

R516 MAIN 103P397090 R-FUSE 1/2W 0.82-J

R5M1 MAIN 109P913050 R-COMPOSITION 1/2W 68M-J

R671 VM/CRT 103P448050 R-FUSE-METAL 1W 27-K/J

R6B1 VM/CRT 103P370010 R-FUSE 1/4W 10-J

R6B4 VM/CRT 103P392050 R-FUSE 1/2W 10K-J

R6B6 VM/CRT 103P370050 R-FUSE 1/4W 22-J

R6B7 VM/CRT 103P370010 R-FUSE 1/4W 10-J

R6B8 VM/CRT 103P392050 R-FUSE 1/2W 10K-J

R981 MAIN 109P913050 R-COMPOSITION 1/2W 6.8M-J

R982 MAIN 109P913050 R-COMPOSITION 1/2W 6.8M-J

R992 POWER-SUB 109P91 1090 R-COMPOSITION 1/2W 470K-J

RP991 POWER-SUB 265P071 050 POSISTOR PTH451 041 BG180N

J601 VM/CRT 4490126010 CRT SOCKET

F991 POWER-SUB 283D047040 FUSE T2A

P0951 MAIN 268P068010 PHOTOCOUPLER TCDT1124G

Z552 MAIN 299P193010 PROTECTOR 2000

Z951 MAIN 299P193030 PROTECTOR 3150

Z952 MAIN 299P193070 PROTECTOR 5000

Z953 MAIN 299P193000 PROTECTOR 1600

255P941040 CRT A68EDG038X301

409P564070 ADG-COIL

920A427002* ASSY-PWB-MAIN Later models *

H92A002001* ASSY-PWB-MAIN Early models *

9300899011 ASSY-PWB-VM/CRT

9300900005 ASSY-PWB-POWER-SUB

9300901003 ASSY-PWB-LED

9300904004 ASSY-PWB-AUDIO-PWR

9300909001 ASSY-PWB-TEXT

9300911017 ASSY-PWB-DOLBY

2460162010 AC-POWERCORD/U K-PLUG

7000609080 ASSY BACK COVER

3. Press buttons “2” or “8” to increase or

decrease the adjustment code number.

4. Press buttons “6” or “4” to increase or

decrease the data value.

5. After making adjustments, press button “0’, to

write the adjustment data to the EEPROM. To

“9”

cancel a change, press button “1’, and all

data adjusted since the last EEPROM write

will be reset.

2.2 INITIALISING THE EEPROM

If you have replaced the EEPROM (IC702) or if

for any reason the adjustment data has become

corrupted it will be necessary to initialise the

EEPROM.

2.2.1 Initialising the EEPROM

1. If necessary, switch off by the Main switch.

2. (EE3) Hold in the service switch (S701, next

to the aerial socket) or (EE3W) connect pin

55 of IC701 to ground via a 1000 resistor

while switching on by the Main switch.

3. (EE3) Release the service switch after 3

seconds or (EE3W) remove the shorting

resistor.

4. Switch off by the Main switch. The EEPROM

data values have now all been reset to their

initial default values.

5. Switch on by the Main switch. (EE3) Press

the Service switch and then button 9 on the

remote control within 5 seconds to enter

service mode (EE3W) press MENU then key

in 2-3-5-7.

6. Press the “*” button to select the OPTIONS

adjustment display.

7. Press buttons 2 or 8 to select the adjustment

code.

8. Adjust the data value for each code as shown

in table 2.2A below using buttons 2 or 4:

(other codes may be displayed but are not

used) EE3 software:

CODE: SETTING:

TUN 1

SAT 0

AUD 0

ATS 1

STD 1

SYS 2

AVI 2

SPK 0

ABG 12

Al 08

AL 06

CODE: SETTING:

ADK 08

MNP 70

FFT 1

VOL 74

HYP 1

SCP 20

FMP 23

EE3W software:

CODE: SETTING:

TUN 1

SAT 0

AUD 0

ATS STD 1

SYS 2

AVI 2

AUD SPK 1

MNP 70

FFT VOL 74

HYP 1

SCP 20

FMP 23

DBY 1

WID 0

table 2.2A Data values for the OPTIONS

adjustments.

9. Press the 0 button to write the changes to the

EEPROM.

10.Press the * button to select the VCJ adjustment display.

11.Press buttons 2 or 8 to select the adjustment

code.

12.Adjust the data value of each code using

buttons 2 or 4 according to table 2.2B below:

EE3 software

CODE: 11 19 1B

VALUE: 001 -1 -13

EE3W software

CODE: SHA HPT HPX

VALUE: 001 -1 -13

table 2.2B Data values for the VCJ adjustments.

13.Press the “0,” button to write the changes to

the EEPROM.

2.2.2 OPTION and VCJ code descriptions.

VCJ

CODE FUNCTION CODE

(EE3) (EE3W)

00 V-AMP-50 0 VH5

01 V-B-CORRECTION 1 VBC

02 P-AMP-50 2 PA5

03 P-TILT 3 PT5

04 V-LIN 4 LIN

05 C-CORRECTION-50 5 CC5

06 H-AMP 6 HW5

07 16x9-SW.RGB-MATRIX 0 MTX

08 V-SHIFT- 50 7 VS5

09 H-PHASE-5O 13 HP5

0A BLUE DRIVE 1 BDR

0B GREEN DRIVE 2 GDR

0C RED DRIVE 3 RDR

0D CONTRAST 4 CON

0E BRIGHT 5 BRI

0F COLOUR SATURATION 6 COL

10 NTSC TINT 8 TNT

11 SHARPNESS 7 SH

12 PAL-LUMA-DELAY 12 PCD

13 SECAM-LUMA-DELAY 11 SCD

14 V-AMP-60 8 VH6

15 P-AMP-60 9 PA6

16 H-AMP-60 12 HW6

17 V-SHIFT-60 13 VS6

18 H-PHASE-60 14 HP6

19 H-PHASE-TEXT 15 HPT

1A H-PHASE-SECAM 16 HPS

1B H-PHASE-RGB 17 HPX

1C P-AMP-16: 9 18 PA9

1D 358 NTSC-LUMA-DELAY 1E 443 NTSC-LUMA-DELAY -

- NTSC (358 & 443) CHROMA DELAY 10 NTD

- BG CHROMA DELAY OFFSET 9 BGD

- P-AMP-60 9 PA6

- P-TILT-60 10 PT6

- C-CORRECTION-60 11 CC6

- TOP-BLANKING-50 14 TB5

- BOTTOM-BLANKING-50 15 BB5

- H-BLANKING-WIDTH-50 16 BW5

- H-BLANKING-PHASE-50 17 BP5

- TOP-BLANKING-60 18 TB6

- BOTTOM-BLANKING-60 19 BB6

- H-BLANKING-WIDTH-60 20 BW6

- H-BLANKING-PHASE-60 21 BP6

OPTIONS

CODE FUNCTION CODE

(EE3) (EE3W)

TUN TUNER TYPE TUN

SAT SATELLITE ENABLE SAT

AUD AUDIO SYSTEM AUD

ATS AUTOTUNING SORT ATS

STD RECEPTION STANDARD STD

SYS COLOUR SYSTEM SYS

AVI NO. OF AV INPUTS AVI

AVD AV DUBBING AVD

EEX CHASSIS TYPE SPK SPEAKER SW ENABLED SPK

EEP EEPROM SIZE ABG AGC GAIN – BG Al AGC GAIN-I AL AGC GAIN-L ADK AGC GAIN-DK MNP NICAM PRESCALE MNP

TXT TELETEXT TYPE FFT FAST/TOP TEXT FFT

VOL VOLUME PRESCALE VOL

HYP HYPERSOUND HYP

SCP SCART PRESCALE SCP

FMP FM PRESCALE FMP

- DOLBY DBY

- WIDE SCREEN WID

2.3 VIF CIRCUITS

2.3.1RF AGC

VR101 (adjacent to the tuner)

1. Connect an RE signal such as an off-air

broadcast.

2. Check the AFT is on for the current channel.

3. Adjust VR101 so that the picture and sound

exhibit no noise, beat or intermodulation

distortion.

2.3.2 SIF OFFSET

VR 102 (near IC101)

1. Connect an RE Crosshatch pattern signal

with NO sound modulation

2. Set the Volume control to about 3/4 of

maximum.

3. Adjust VR102 to obtain minimum noise.

2.4 DEFLECTION CIRCUITS

2.4.1Important notes

Before making any adjustments, if you have

changed the CRT, FLYBACK TRANSFORMER

or made any changes in the deflection circuits;

adjust the CRT bias as described in 2.6.1 steps

1 ~ 4.

Check the VERTICAL BREATHING CORRECTION as follows:

1. Select the VCJ adjustment display.

2. Set the adjustment code to 01 (1 VBC) with

buttons “2” or “8” on the remote control.

3. If necessary, adjust the data value to “-31”

using buttons “4’ or “6’ on the remote control.

2.4.2 Horizontal centre

Code: 09 (13 HP5) [H-PHASE-50]

1. Connect a VCR and play a PAL-Monoscope

alignment tape.

2. Select the VCJ adjustment display.

3. Set the adjustment code to 09 (13 HP5) with

buttons “2” or “8” on the remote control.

4. Adjust the horizontal position with buttons “4’

or “6” on the remote control.

2.4.3 Horizontal width

Code: 06 (6 HW5) [H-AMP]

1. Connect a VCR and play a PAL-Monoscope

alignment tape.

2. Select the VCJ adjustment display.

3. Set the adjustment code to 06 (6 HW5) with

buttons “2” or “8” on the remote control.

4. Adjust horizontal width with the buttons “4” or

“6” on the remote control.

2.4.4 East-West PCC

Code: 05 (5 CC5) [CORNER CORRECTION-50]

Code: 03 (3 PT5) [PARABOLA TILT]

Code: 02 (2 PA5) [PARABOLA AMP-50]

1. Connect an RF PAL Crosshatch signal.

2. Select the VCJ adjustment display.

3. Set the adjustment code to 05 (5 CC5) with

buttons “2” or “8” on the remote control.

4. Adjust the data value to “-25” with buttons “4”

or “6” on the remote control.

5. Set the adjustment code to 03 (3 PT5) with

buttons “2” or “8” on the remote control.

6. Watching the second vertical line in from both

sides of the screen (figure 2.4A), make any

upper and lower distortion symmetrical using

buttons “4” or “6” on the remote control.

7. Set the adjustment code to 02 (2 PA5) with

buttons “2”or “8” on the remote control.

8. Adjust the straightness of both vertical lines

(figure 2.4B) using buttons “4” or “6” on the

remote control.

9. Repeat steps 1 to 8 above if necessary.

10.Connect a VCR and play a PAL-Monoscope

alignment tape.

11.Make sure the horizontal width and horizontal centre are correct. If necessary readjust

Horizontal Centre 09 (13 HP5) and Horizontal

Width 06 (6 HW5) again.

Page 2

MITSUBISHI CT 29BV1 BD

2

Adjustments Cont’d

2.4.5 Height and linearity

Code: 00 (0 VH5) [V-AMP]

Code: 04 (4 LIN) [V-LIN]

1. Connect a VCR and play a PAL-Monoscope

alignment tape.

2. Select the VCJ adjustment display.

3. Set the adjustment code to 00 (0 VH5) with

buttons “2” or “8” on the remote control.

4. Adjust the circle to a true circle with buttons

“4” or “6” on the remote control.

5. Set the adjustment code to 04 (4 LIN) with

buttons “2” or “8” on the remote control.

6. Adjust the linearity to be the same for the top

and bottom halves of the circle using buttons

“4” or “6” on the remote control.

7. Set the adjustment code to 00 (0 VH5) with

buttons “2” or “8” on the remote control.

8. Readjust V-AMP with buttons “4” or “6”.

9. Repeat the steps above, if necessary.

2.4.6 Vertical centre

Code: 08 (7 VS5) [V-SHIFT-50]

1. Connect a VCR and play a PAL-Monoscope

alignment tape.

2. Select the VCJ adjustment display.

3. Set the adjustment code to 08 (7 V55) with

buttons “2” or “8’ on the remote control.

4. Adjust the centre line of picture to be within +/

- 3mm from the vertical centre on the screen

using buttons “4” or “6” on the remote control.

2.4.7 60Hz Deflection circuit offsets

Code: 14 (8 VH6) [V-AMP-60]

Code: 15 (9 PA6) [P-AMP 60]

Code: 16 (12 HW6) [H-AMP 60]

Code: 17 (13 VS6) [V-SHIFT 60]

Code: 18 (14 HP6) [H-PHASE 60]

1. Connect an RE 60Hz Crosshatch signal.

2. Select the VCJ adjustment display.

3. Select each adjustment code in turn with

buttons “2” or “8” on the remote control and

adjust each item to the figures shown in table

2.4C below using buttons “4” or “6” on the

remote control.

CODE:

<EE3software <EE3Wsoftware VALUE:

14 8 VH6 +7

15 9 PA6 +2

16 12HW6 - 2

17 13VS6 +8

18 14HP6 -5

table 2.4C 60Hz adjustment offsets

2.5 CRT CIRCUITS

2.5.1 White balance

Code: 0A (1 BDR) [B-DRIVE]

Code: 0B (2 GDR) [G-DRIVE]

Code: 0C (3 RDR) [R-DRIVE]

1. Connect a VCR and play a PAL-Monoscope

alignment tape.

2. Select the VCJ adjustment display.

3. Set the adjustment codes to 0A (1 BDR), 0B

(2 GDR) and 0C (3 RDR) in turn and preadjust each to “+10”.

4. Adjust codes 0A (1 BDR) and OC (3 RDR) to

adjust the white balance.

2.5.2 Focus

FOCUS control on the Flyback Transformer

1. Connect an RF signal such as an off-air

broadcast.

2. Adjust the FOCUS control for the best overall

focus.

2.5 VIDEO CIRCUITS

Perform the following adjustments after

adjusting the Deflection circuits. Allow the TV to

warm up for 20 minutes before proceeding

2.6.1 Brightness and Contrast

SCREEN control on the Flyback Transformer

Code: 0F (6 COL) [COLOUR SATURATION]

Code: 0E (S BRI) [BRIGHTNESS]

Code: 0D (4 CON) [CONTRAST]

BEAM CURRENT (using connector TP adjacent

to the Flyback Transformer)

1. Connect a Black raster signal to the RE or AV

input.

2. Select the VCJ adjustment display.

3. Connect an oscilloscope to the junction of

R673 and wire link W603.

4. Adjust the SCREEN control on the Flyback

Transformer to give a voltage of 170V as

shown in fig. 2.6A.

5. Change the external signal to a G-Card.

6. Set the adjustment code to 0F (6 COL) with

buttons “2” or “8” on the remote control.

7. Adjust the data value to “-32” with buttons “4”

or “6” on the remote control.

8. Set the adjustment code to 0E (5 BRI) with

buttons “2” or “8” on the remote control.

9. Adjust using buttons “4” or “6” so that a slight

difference in brightness can be seen between

blue and black areas.

10.Connect a DC ammeter’s “+” lead to

connector TP pin 1 on the MAIN-PCB and the

“-“ lead to connector TP pin 2.

11.Adjust the beam current using buttons “4” or

“6” on the remote control to 1300±20µA.

12.Check, and if necessary, readjust the

BRIGHTNESS, code OE (5 BRI).

13.Check that the Screen Up/Down Request Bit

is “00”. If not, repeat steps 1 to 4 above.

14.Now proceed to the Colour Output adjustment.

2.6.2 Colour output

Make this adjustment only after adjusting the

White Balance, Brightness and Contrast.

Code: 0F (6 COL) [COLOUR SATURATION]

1. Connect an RE Colour-bar signal.

2. Select the VCJ adjustment display.

3. Set the adjustment code to 0F (6 COL) with

buttons “2” or “8” on the remote control.

4. Connect an oscilloscope to the junction of

R673 and IC660 Pin 9 (BLUE-OUT) on the

CRT PCB).

5. Make adjustments using buttons “4” or “6” on

the remote control until the waveform is as

shown in figure 2.6A.

2.7 POWER CIRCUIT

2.7.1 B4 Voltage

VR951 (on main PCB next to the SMT)

1. Connect a VCR and play a PAL-Monoscope

alignment tape.

2. Push the OPTIMUM button on the remote

control.

3. Connect a DC voltmeter’s “+” lead to TP91 on

the MAIN PCB and the “—“ lead to GROUND.

4. Adjust VR951 so that the voltage is 145±2V.

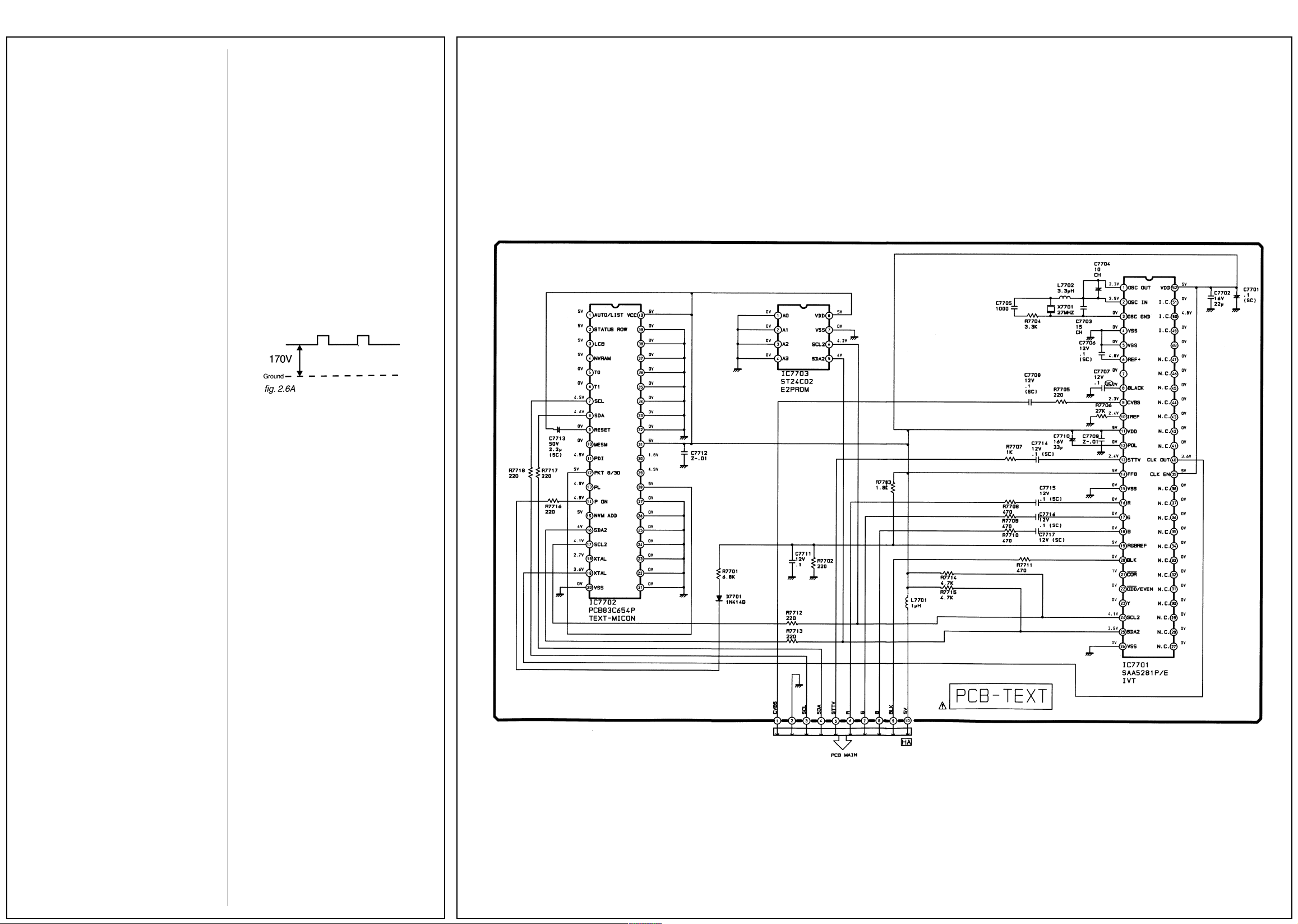

Text PCB Diagram

Page 3

MITSUBISHI CT 29BV1 BD

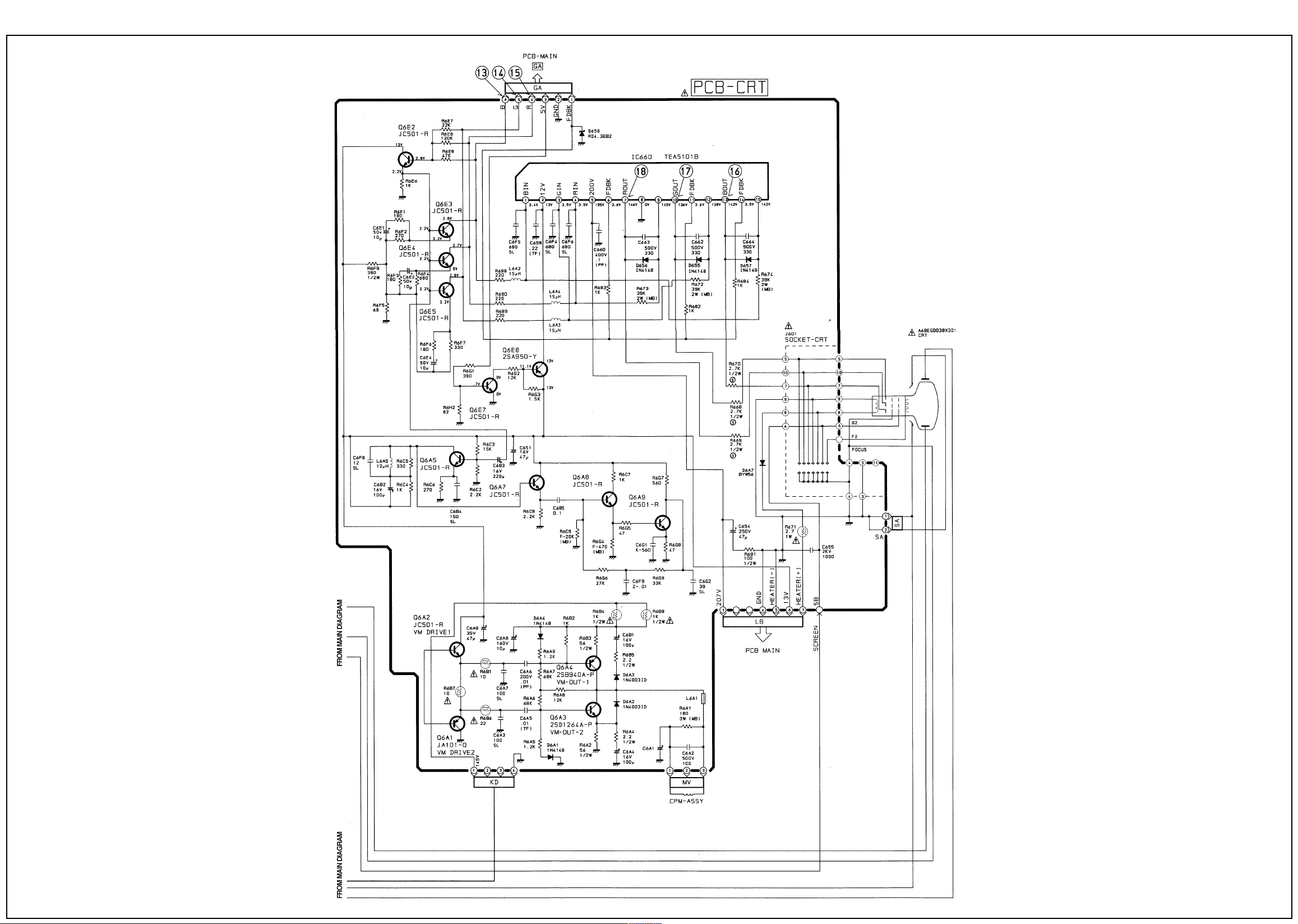

CRT Diagram

3

Page 4

MITSUBISHI CT 29BV1 BD

4

Audio Amp Diagram

Page 5

MITSUBISHI CT 29BV1 BD

Dolby PCB Diagram

5

Page 6

MITSUBISHI CT 29BV1 BD

6

Main Diagram

Page 7

MITSUBISHI CT 29BV1 BD

7

Main Diagram Cont’d

Loading...

Loading...