Mitsubishi CR750-Q, CRnQ-700, CR751-Q, CRnD-700, CR750-D Instruction Manual

...

Mitsubishi Industrial Robot

CR750/CR751 series controller

CRn-700 series controller

Tracking Function INSTRUCTION MANUAL

BFP-A8664-H

Safety Precautions

Always read the following precautions and separate

carefully before using robots, and take appropriate action when

required.

Caution

Caution

Caution

Caution

Caution

Caution

Warning

Warning

"Safety Manual"

Teaching work should only be performed by those individuals who have undergone special

training.

(The same applies to maintenance work with the robot power ON.)

→ Conduct safety education.

Prepare work regulations indicating robot operation methods and procedures, and

measures to be taken when errors occur or when rebooting robots, and observe these

rules at all times.

(The same applies to maintenance work with the robot power ON.)

→ Prepare work regulations.

Only perform teaching work after first equipping the controller with a device capable of

stopping operation immediately.

(The same applies to maintenance work with the robot power ON.)

→ Equip with an EMERGENCY STOP button.

Notify others when teaching work is being performed by affixing a sign to the START

switch, etc.

(The same applies to maintenance work with the robot power ON.)

→ Indicate that teaching work is being performed.

Install fences or enclosures around robots to prevent contact between robots and workers

during operation.

→ Install safety fences.

Stipulate a specific signaling method to be used among related workers when starting

operation.

→ Operation start signal

As a rule, maintenance work should be performed only after turning OFF the power, and

other workers should be notified that maintenance is being performed by affixing a sign to

the START switch, etc.

→ Indicate that maintenance work is being performed.

Before starting operation, conduct an inspection of robots, EMERGENCY STOP buttons,

and any other related devices to ensure that there are no abnormalities.

→ Inspection before starting operation

The following precautions are taken from the separate "Safety Manual".

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Caution

Refer to the "Safety Manual" for further details.

Use robots in an environment stipulated in the specifications.

Failure to observe this may result in decreased reliability or breakdown.

(Temperature, humidity, atmosphere, noise environment, etc.)

Only transport robots in the manner stipulated.

Failure to observe this may result in bodily injury or breakdown if the robot is dropped.

Install and use the robot on a secure and stable platform.

Positional displacement or vibrations may occur if the robot is unstable.

Ensure that cables are kept as far apart from noise sources as possible.

Positional displacement or malfunction may occur if in close contact with one another.

Do not apply too much force to connectors, or bend cables too much.

Failure to observe this may result in contact defects or wire damage.

Ensure that the weight of the workpiece, including the hand, does not exceed the rated

load or allowable torque.

Failure to observe this may result in alarms or breakdown.

Attach hands and tools, and grip workpieces securely.

Warning

Failure to observe this may result in bodily injury or property damage if objects are sent

flying or released during operation.

Warning

Ground the robot and controller properly.

Failure to observe this may result in malfunction due to noise, or even electric shock.

Always indicate the robot operating status during movement.

If there is no indication, operators may approach the robot, potentially leading to

incorrect operation.

Warning

If performing teaching work inside the robot movement range, always ensure complete

control over the robot beforehand. Failure to observe this may result in bodily injury or

property damage if able to start the robot with external commands.

Jog the robot with the speed set as low as possible, and never take your eyes off the

robot. Failure to observe this may result in collision with workpieces or surrounding

equipment.

Always check robot movement in step operation before commencing auto operation

following program editing. Failure to observe this may result in collision with

surrounding equipment due to programming mistakes, etc.

If attempting to open the safety fence door during auto operation, ensure that the door

is locked, or that the robot stops automatically. Failure to observe this may result in

bodily injury.

Caution

Caution

Warning

Caution

Caution

Warning

Caution

Do not perform unauthorized modifications or use maintenance parts other than those

stipulated. Failure to observe this may result in breakdown or malfunction.

If moving the robot arm by hand from outside the enclosure, never insert hands or

fingers in openings. Depending on the robot posture, hands or fingers may become

jammed.

Do not stop the robot or engage the emergency stop by turning OFF the robot controller

main power.

Robot accuracy may be adversely affected if the robot controller main power is turned

OFF during auto operation. Furthermore, the robot arm may collide with surrounding

equipment if it falls or moves under its own inertia.

When rewriting internal robot controller information such as programs or parameters, do

not turn OFF the robot controller main power.

If the robot controller main power is turned OFF while rewriting programs or parameters

during auto operation, the internal robot controller information may be destroyed.

Horizontal

The hand may drop

pressed, and therefore due care should be taken. Failure to observe this may result in

collision between the hand and surrounding equipment, or hands or fingers becoming

jammed if the hand falls.

Attach the cap to the SSCNET III connector after disconnecting the SSCNET III cable. If

the cap is not attached, dirt or dust may adhere to the connector pins, resulting in

deterioration connector properties, leading to malfunction.

Do not look directly at light emitted from the tip of SSCNET III connectors or SSCNET III

cables. Eye discomfort may be felt if exposed to the light. (SSCNET III employs a Class

1 or equivalent light source as specified in JISC6802 and IEC60825-1.)

multi-joint robots

under its own weight while the robot brake release switch is

Date of print

Specifications No.

Details of revisions

2009-02-10

BFP-A8664-*

First print

2009-10-23

BFP-A8664-A

The EC Declaration of Conformity was changed.

(Correspond to the EMC directive; 2006/42/EC)

2010-04-30

BFP-A8664-B

The tracking function is realized to SQ series.

2010-10-18

BFP-A8664-C

The notes were added about physical encoder number (List 1-1)

and No.9 (List 1-2).

2012-03-01

BFP-A8664-D

CR750/CR751 series controller were added.

The note was added to Trk command.

2012-10-19

BFP-A8664-E

The explanation of vision was changed from MELFA-Vision to

"Troubleshooting" is enhanced.

2013-01-22

BFP-A8664-F

The statement about trademark registration was added.

2013-05-27

BFP-A8664-G

“Table 21-3 Connectors: CNENC/CNUSR Pin Assignment” was

corrected.

2014-02-13

BFP-A8664-H

The explanations about Encoder distribution unit (option) were

added.

Revision history

In-Sight Explorer for EasyBuilder.

Sample program for RH-3S*HR was added.

The explanation of parameter "TRPACL" and "TRPDCL" was

added.

No part of this manual may be reproduced by any means or in any form, without prior consent from

Copyright(C) 2009-2014 MITSUBISHI ELECTRIC CORPORATION

Preface

Thank you very much for purchasing Mitsubishi Electric Industrial Robot.

The tracking function allows robots to follow workpieces on a conveyer or transport, line up and process the

workpieces without having to stop the conveyer. The conveyor tracking function is the standard function in

the controller. It can use only by having the parameter "TRMODE" changed into "1."

Please be sure to read this manual carefully and understand the contents thoroughly before starting to use

the equipment in order to make full use of the tracking function.

Within this manual, we have tried to describe all ways in which the equipment can be handled, including

non-standard operations, to the greatest extent possible. Please avoid handling the equipment in any way

not described in this manual.

Tracking function is installed as standard for the controller, and the function can be used only by changing

parameter "TRMODE" from “0" to “1". However, there are different parts in the system configuration and the

way of programming in the CR750-Q/CR751-Q, CRnQ-700 series and the CR750-D/CR751-D, CRnD-700

series. Please give the attention that this manual explains these differences between CR750-Q/CR751-Q,

CRnQ-700 series and CR750-D/CR751-D, CRnD-700SD series.

Note that this manual is written for the following software version.

CR750-Q/CR751-Q series : Ver. R3 or later

CR750-D/CR751-D series : Ver. S3 or later

CRnQ-700 series : Ver. R1 or later

CRnD-700 series : Ver. P1a or later

・

Mitsubishi.

・The contents of this manual are subject to change without notice.

・An effort has been made to make full descriptions in this manual. However, if any discrepancies or

unclear points are found, please contact your service provider.

・The information contained in this document has been written to be accurate as much as possible.

Please interpret that items not described in this document "cannot be performed." or "alarm may

occur".

Please contact your service provider if you find any doubtful, wrong or skipped point.

・This specifications is original.

・The ETHERNET is a registered trademark of the Xerox Corp.

・All other company names and production names in this document are the trademarks or registered

trademarks of their respective owners.

[Contents]

[Part 1] Overview .................................................................................................................1-1

1. Overview ................................................................................................................................................... 1-1

1.1. What is the Tracking Function? ........................................................................................................ 1-1

1.2. Applications ...................................................................................................................................... 1-2

1.3. Contents of this manual .................................................................................................................... 1-3

1.4. The generic name and abbreviation ................................................................................................. 1-4

1.5. System that can achieve ................................................................................................................... 1-5

[Part 2] System Configuration and Setting (CR750-Q/CR751-Q series, CRnQ-700 series)

..............................................................................................................................................1-6

2. System Configuration ............................................................................................................................... 2-6

2.1. Components ..................................................................................................................................... 2-6

2.1.1. Robot controller enclosure products ......................................................................................... 2-6

2.1.2. Devices Provided by Customers ............................................................................................... 2-6

2.2. Example of System Configuration .................................................................................................... 2-9

2.2.1. Configuration Example of Conveyer Tracking Systems ........................................................... 2-9

2.2.2. Configuration Example of Vision Tracking Systems ............................................................... 2-10

3. Specification ........................................................................................................................................... 3-11

3.1. Tracking Specifications and Restriction matter .............................................................................. 3-11

4. Operation Procedure .............................................................................................................................. 4-12

5. Connection of Equipment ....................................................................................................................... 5-13

5.1. Preparation of Equipment ............................................................................................................... 5-13

5.1.1. Q173DPX(manual pilser input) unit specification ................................................................ 5-14

5.2. Connection of Equipment ............................................................................................................... 5-20

5.2.1. Connection of Unit ................................................................................................................... 5-20

5.2.2. Connection with encoder for conveyer and encoder cable ..................................................... 5-21

5.2.3. Connection of Photoelectronic Sensor ................................................................................... 5-23

6. Parameter Setting .................................................................................................................................. 6-25

6.1. Dedicated Input/Output Parameters ............................................................................................... 6-25

6.2. Operation Parameters .................................................................................................................... 6-25

6.3. Tracking Parameter Setting ............................................................................................................ 6-26

6.3.1. Robot Parameter Setting ......................................................................................................... 6-26

6.3.2. Sequencer CPU Parameter Setting ........................................................................................ 6-28

[Part 3] System Configuration and Setting (CR750-D/CR751-D series, CRnD-700 series)

............................................................................................................................................ 6-31

7. System Configuration ............................................................................................................................. 7-31

7.1. Components ................................................................................................................................... 7-31

7.1.1. Robot controller enclosure products ....................................................................................... 7-31

7.1.2. Devices Provided by Customers ............................................................................................. 7-31

7.2. Example of System Configuration .................................................................................................. 7-34

7.2.1. Configuration Example of Conveyer Tracking Systems ......................................................... 7-34

7.2.2. Configuration Example of Vision Tracking Systems ............................................................... 7-35

8. Specification ........................................................................................................................................... 8-36

8.1. Tracking Specifications and Restriction matter .............................................................................. 8-36

9. Operation Procedure .............................................................................................................................. 9-37

10. Connection of Equipment ................................................................................................................. 10-38

10.1. Preparation of Equipment ......................................................................................................... 10-38

10.2. Connection of Equipment.......................................................................................................... 10-38

10.2.1. Connection of Conveyer Encoder ......................................................................................... 10-38

10.2.2. Installation of encoder cable ................................................................................................. 10-41

10.2.3. Connection of Photoelectronic Sensor ................................................................................. 10-45

11. Parameter Setting ............................................................................................................................. 11-46

11.1. Dedicated Input/Output Parameters ......................................................................................... 11-46

11.2. Operation Parameters ............................................................................................................... 11-46

11.3. Tracking Parameter Setting ...................................................................................................... 11-47

[Part 4] Tracking Control (common function between series) .................................... 11-48

12. Sample Robot Programs .................................................................................................................. 12-48

13. Calibration of Conveyer and Robot Coordinate Systems (“A1” program)........................................ 13-49

13.1. Operation procedure ................................................................................................................. 13-49

13.2. Tasks ........................................................................................................................................ 13-51

13.3. Confirmation after operation ..................................................................................................... 13-53

13.4. When multiple conveyers are used .......................................................................................... 13-53

14. Calibration of Vision Coordinate and Robot Coordinate Systems (“B1” program) .......................... 14-54

14.1. Operation procedure ................................................................................................................. 14-54

14.2. (2) Tasks ................................................................................................................................... 14-57

14.3. (3) Confirmation after operation ................................................................................................ 14-62

15. Workpiece Recognition and Teaching (“C1” program) .................................................................... 15-63

15.1. Program for Conveyer Tracking ............................................................................................... 15-63

15.2. Program for Vision Tracking ..................................................................................................... 15-67

16. Teaching and Setting of Adjustment Variables (“1” Program) ......................................................... 16-77

16.1. Teaching ................................................................................................................................... 16-77

16.2. Setting of adjustment variables in the program ........................................................................ 16-78

17. Sensor Monitoring Program (“CM1” Program) ................................................................................. 17-84

17.1. Program for Conveyer Tracking ............................................................................................... 17-84

17.2. Program for Vision Tracking ..................................................................................................... 17-84

18. Automatic Operation ......................................................................................................................... 18-85

18.1. Preparation ............................................................................................................................... 18-85

18.2. Execution .................................................................................................................................. 18-86

18.3. At error occurrence ................................................................................................................... 18-86

18.4. Ending ....................................................................................................................................... 18-86

18.5. Adjusting method ...................................................................................................................... 18-86

19. Maintenance of robot program ......................................................................................................... 19-87

19.1. MELFA-BASIC V Instructions ................................................................................................... 19-87

19.1.1. List of Instructions ................................................................................................................. 19-87

19.1.2. List of Robot Status Variables ............................................................................................... 19-87

19.1.3. List of Functions .................................................................................................................... 19-88

19.1.4. Explanation of Tracking Operation Instructions .................................................................... 19-88

19.2. Timing Diagram of Dedicated Input/Output Signals ................................................................. 19-97

19.2.1. Robot Program Start Processing .......................................................................................... 19-97

20. Troubleshooting ................................................................................................................................ 20-98

20.1. Occurrence of Error Numbers in the Range from 9000 to 9999 .............................................. 20-98

20.2. Occurrence of Other Errors .................................................................................................... 20-100

20.3. In such a case (improvement example) .................................................................................. 20-102

20.3.1. The adsorption position shifts. ............................................................................................ 20-102

20.3.2. Make adsorption and release of the work speedy .............................................................. 20-105

20.3.3. Make movement of the robot speedy. ................................................................................ 20-105

20.3.4. The robot is too speedy and drops the work. ..................................................................... 20-105

20.3.5. Restore backup data to another controller ......................................................................... 20-106

20.3.6. Circle movement in tracking. ............................................................................................... 20-106

20.3.7. Draw the square while doing the tracking. .......................................................................... 20-107

21. Appendix ......................................................................................................................................... 21-108

21.1. List of Parameters Related to Tracking .................................................................................. 21-108

21.2. Shine of changing parameter.................................................................................................. 21-110

21.3. Expansion serial interface Connector Pin Assignment ........................................................... 21-113

21.4. Chart of sample program ........................................................................................................ 21-115

21.4.1. Conveyer tracking ............................................................................................................... 21-115

21.4.2. Vision Tracking ................................................................................................................... 21-121

21.5. Sample Programs ................................................................................................................... 21-125

21.5.1. Conveyer Tracking .............................................................................................................. 21-125

21.5.2. Vision Tracking ................................................................................................................... 21-134

21.5.3. For RH-3S*HR .................................................................................................................... 21-139

1 Overview

[Part 1] Overview

1. Overview

1.1. What is the Tracking Function?

The tracking function allows a robot to follow workpieces moving on a conveyer. With this function, it

becomes possible to transport, line up and process workpieces without having to stop the conveyer. It also

eliminates the need for mechanical fixtures and so forth required to fix workpiece positions.

The features of this function are described below.

1) It is possible to follow lined-up workpieces moving on a conveyer while working on them (conveyer

tracking making use of photo electronic sensors).

2) It is possible to follow workpieces that are not in a line moving on a conveyer while working on them,

even in the case of different types of workpieces (vision tracking combined with vision sensors).

3) It is possible to follow changes of movement speed due to automatic calculation of conveyer

movement speed.

4) Tracking function can be easily achieved by using Mitsubishi’s robot command MELFA-BASIC V.

5) System construction is made easy by use of sample programs.

What is the Tracking Function? 1-1

1 Overview

1.2. Applications

Tracking is primarily intended for applications such as the following.

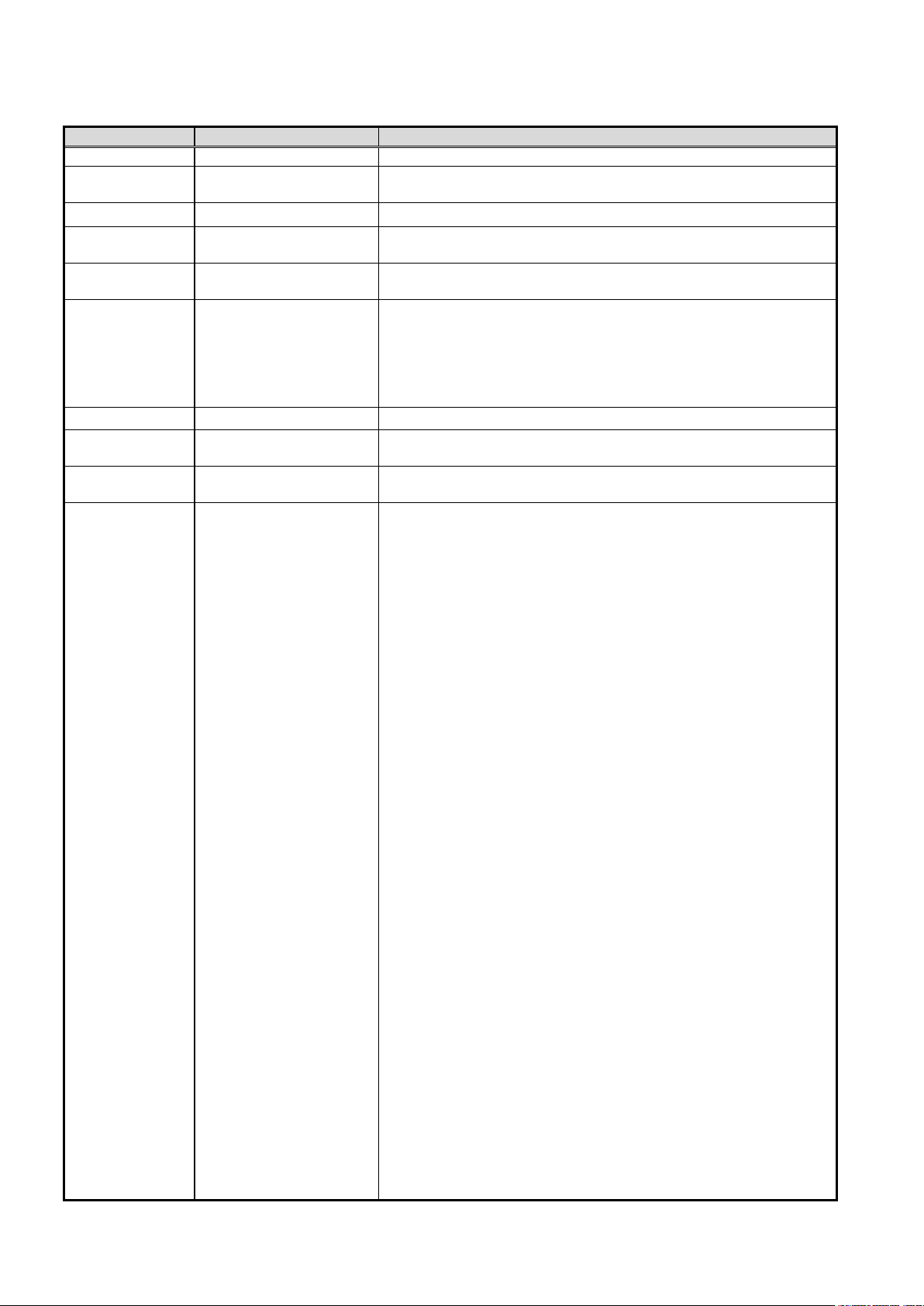

(1) Transfer of processed food pallets

Figure 1

−1 Example of Processed Food Pallet Transfer

(2) Lining up parts

Figure 1

(3) Assembly of small electrical products

−2 Example of Parts Lineup

1-2 Applications

Figure 1

−3 Example of Small Electrical Products Assembly

1 Overview

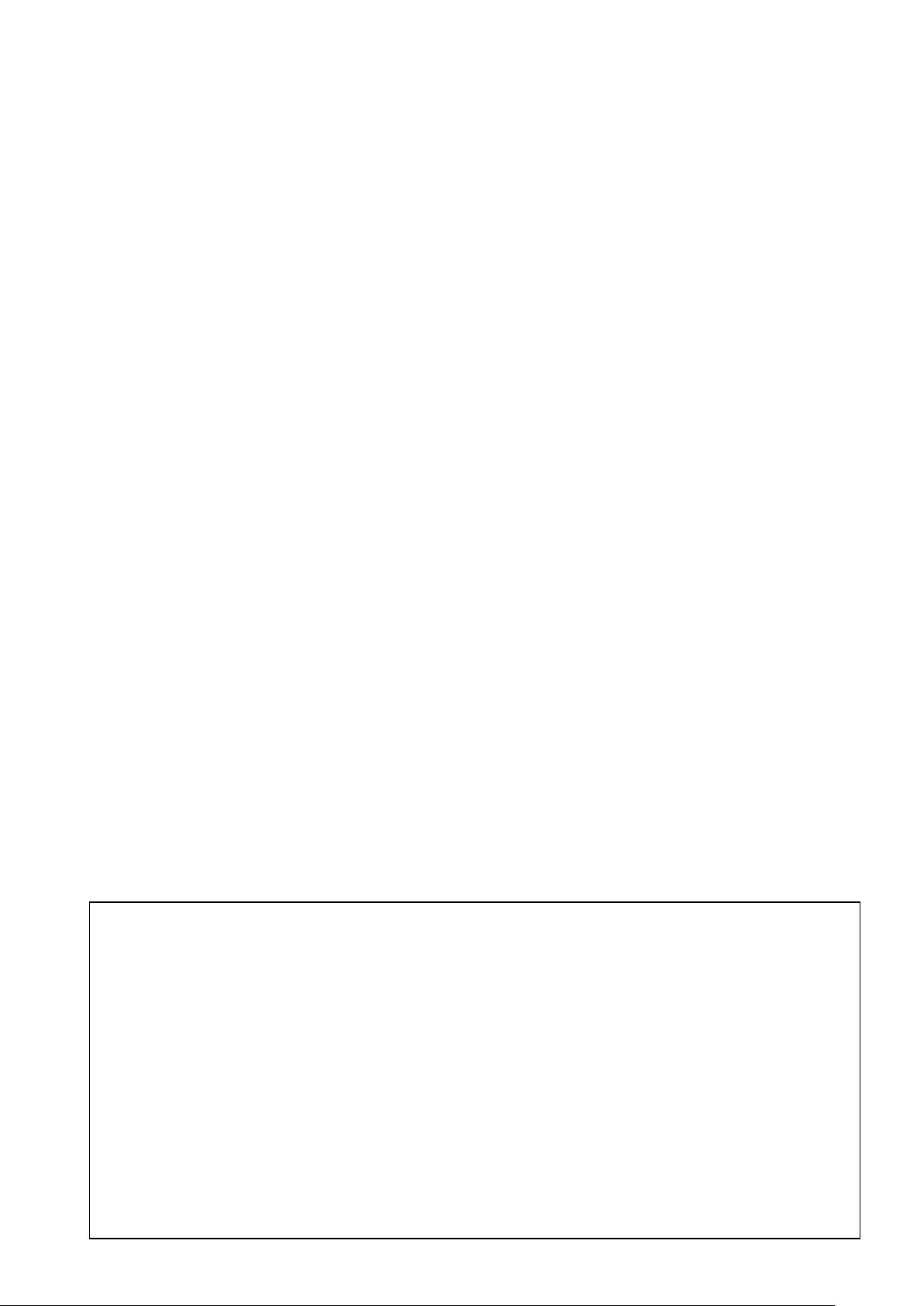

Part.4 Tracking Control(12~21)

Part.2 System Configuration CR750-Q/CR751-Q/CRnQ-700 series(2~6)

Part.4 Tracking Control(12~21)

Part.3 System Configuration CR750-D/CR751-D/CRnD-700 series(7~11)

CR750-D/CR751-D/CRnD-700Series

CR750-Q/CR751-Q/CRnQ-700 series

1.3. Contents of this manual

This manual explains the operation procedure when the customer use conveyer tracking system and vision

tracking system using Mitsubishi robot. The robot model are CR750-Q/CR751-Q/CRnQ-700 series and

CR750-D/CR751-D/CRnD-700 series, however there are H/W differences. Please read as following.

System Configuration/ systemup/ Setting option parts/

Connection to encoder/ Parameter setting

Sample program/ Teaching/ Automatic operation/ Trouble shooting

System Configuration/ systemup/ Setting option parts/

Connection to encoder/ Parameter setting

Sample program/ Teaching/ Automatic operation/ Trouble shooting

Contents of this manual 1-3

1 Overview

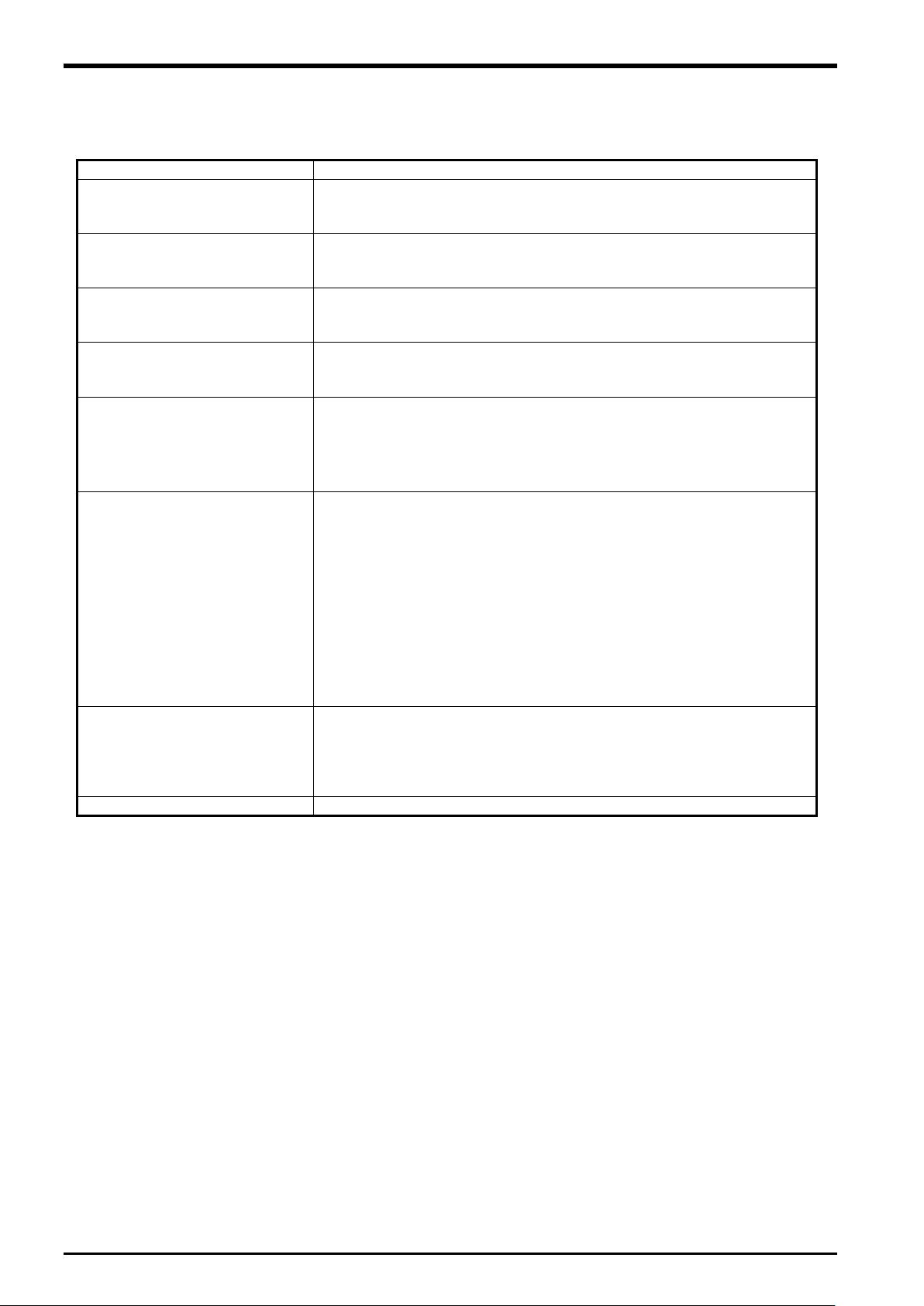

Generic name and abbreviation

Contents

Tracking function

The tracking function allows a robot to follow workpieces moving on a

and process workpieces without having to stop the conveyer.

Conveyer tracking

The conveyer tracking allows a robot to follow workpieces lining up on

a conveyer. With this function, it becomes possible to transport,

process workpieces.

Vision tracking

The vision tracking allows a robot to follow workpieces not lining up on

and process workpieces.

Network vision sensor

The network vision sensor is an option which makes it possible to

inspect or find the workpieces by using with robot controller and

processing the image.

Q173DPX unit

Q173DRX unit is manual pulser input unit for motion controller. At Q

ncoder figure can be got by connection with 1 pc the manual

pulser machine

MR-HDP01) or 3pcs the incremental encoder.

Physical encoder number

Physical encoder numbers a number of the encoder physically

Note) The 3rd set of Q173DPX units can use only the two channels.

Logical encoder number

The physical encoder number change to the logical encoder number

number by the parameter for the encoder physically arranged. This

the instruction and the state

variable of the robot program.

TREN signal

tracking enable signal

1.4. The generic name and abbreviation

List 1-1

conveyer. With this function, it becomes possible to transport line up

a conveyer. With this function, it becomes possible to transport line up

series CPU, it is used as intelligent function unit ( occupation 32

points

Each e

generic name and abbreviation

)

(

allocated according to a certain rule.

In the CR750-Q/CR751-Q/CRnQ-700 series, the number is allocated

by arranging the encoder connected with Q173DPX unit.

The encoder which connected with CH1 of the Q173DPX unit

specified for parameter “ENC UNIT1” is the first, the encoder which

connected with CH2 is the second and with CH3 is the third.

It becomes from 4 to 6 for the Q173DPX unit specified for

parameter”ENCUNIT2”.

It becomes from 7 to 8 for the Q173DPX unit specified for

parameter”ENCUNIT3”.

by parameter “EXTENC”. The purpose of this is to change freely

logical encoder number is used with

1-4 The generic name and abbreviation

1 Overview

CR750-Q

CRnQ-700

CR750-D

CRnD-700

When a robot picks the workpieces moving on a conveyer, it is tracking.

transportation)

When a robot places workpieces which taken out from the pallet to a

workpieces on S character hook that moves the above of the robot.

A robot decorates (processing) the workpieces moving on a conveyer

while tracking.

A robot attaches the parts (assembling) with the workpieces moving on a

conveyer while tracking.

A robot has the vision sensor (hand eye) and it checks the workpieces

while tracking, not the vision sensor.

When a robot picks the workpieces moving on a conveyer A, the tracking

conveyer B.

The tracking is done with an encoder of line driver (differential motion)

output type.

The tracking is done with an encoder of voltage output/open collector

type.

In case of multi CPU system, it makes possible to add max 9 pcs

two channels can be used at the 3rd set of Q173DPX units.

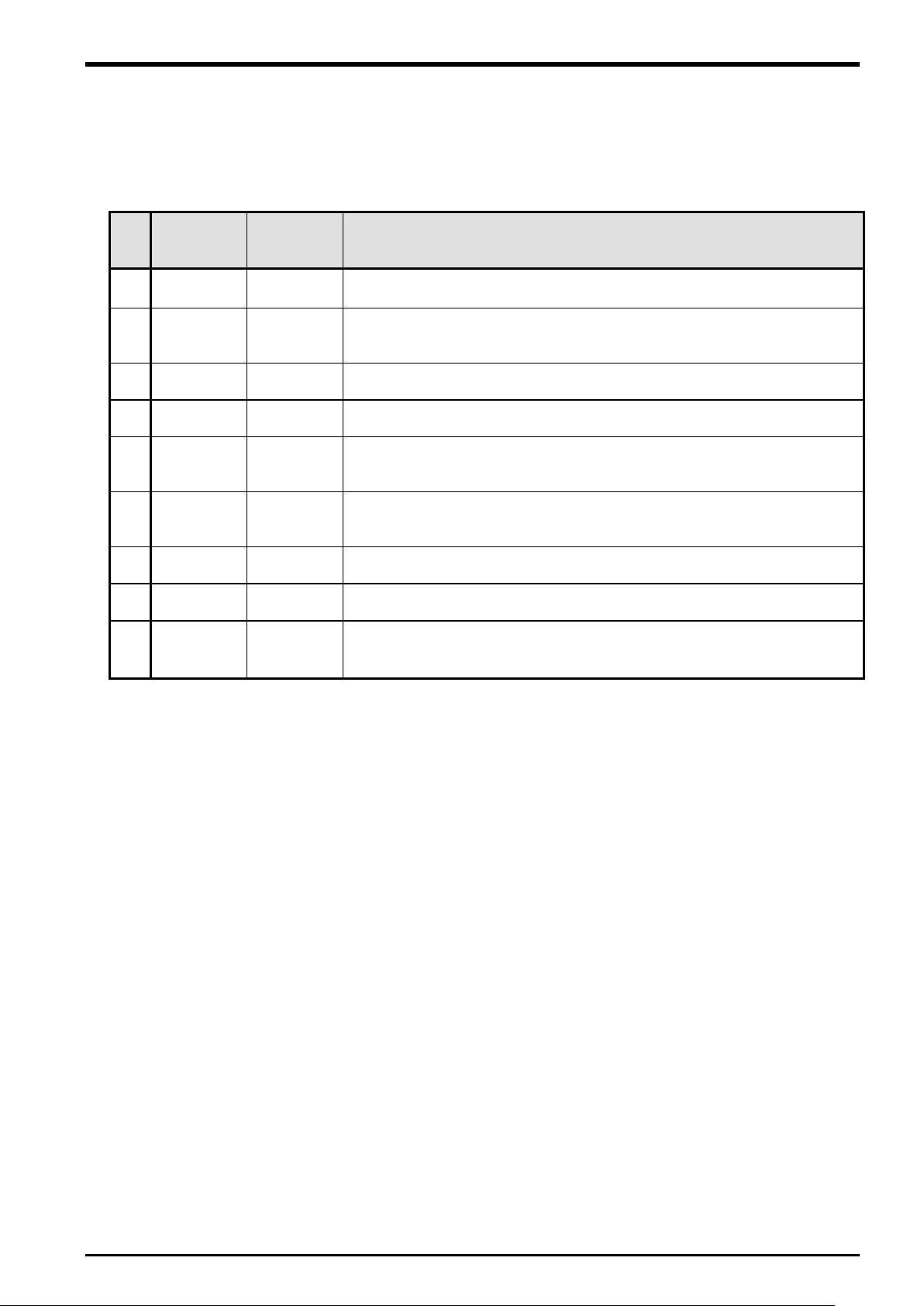

1.5. System that can achieve

With the tracking function of CR750-Q/CR751-Q/CRnQ-700 series, CR750-D/CR751-D/CRnD-700 series, the

example of the system that can be achieved is shown as following.

List 1-2

Example of system that can be achieved by the tracking function

No.

CR751-Q

CR751-D

1 ● ●

2 ● ●

Example of the system

(

conveyer, it is tracking (transportation). It is also possible to hang

3 ● ●

4 ● ●

5 ● ●

6 ● ●

moving on a conveyer. (inspection) It also can check and push the button

is done and a robot places the workpieces while tracking to marking on a

7 ● ●

8 ● (●)

9 ● -

Note1)

Q173DPX units (3 units per 1 CPU). However, in each CPU, only the

Note1) This system requires the Encoder distribution unit. Please refer to the Encoder Distribution Unit

Manual (BFP-A3300) for details.

System that can achieve 1-5

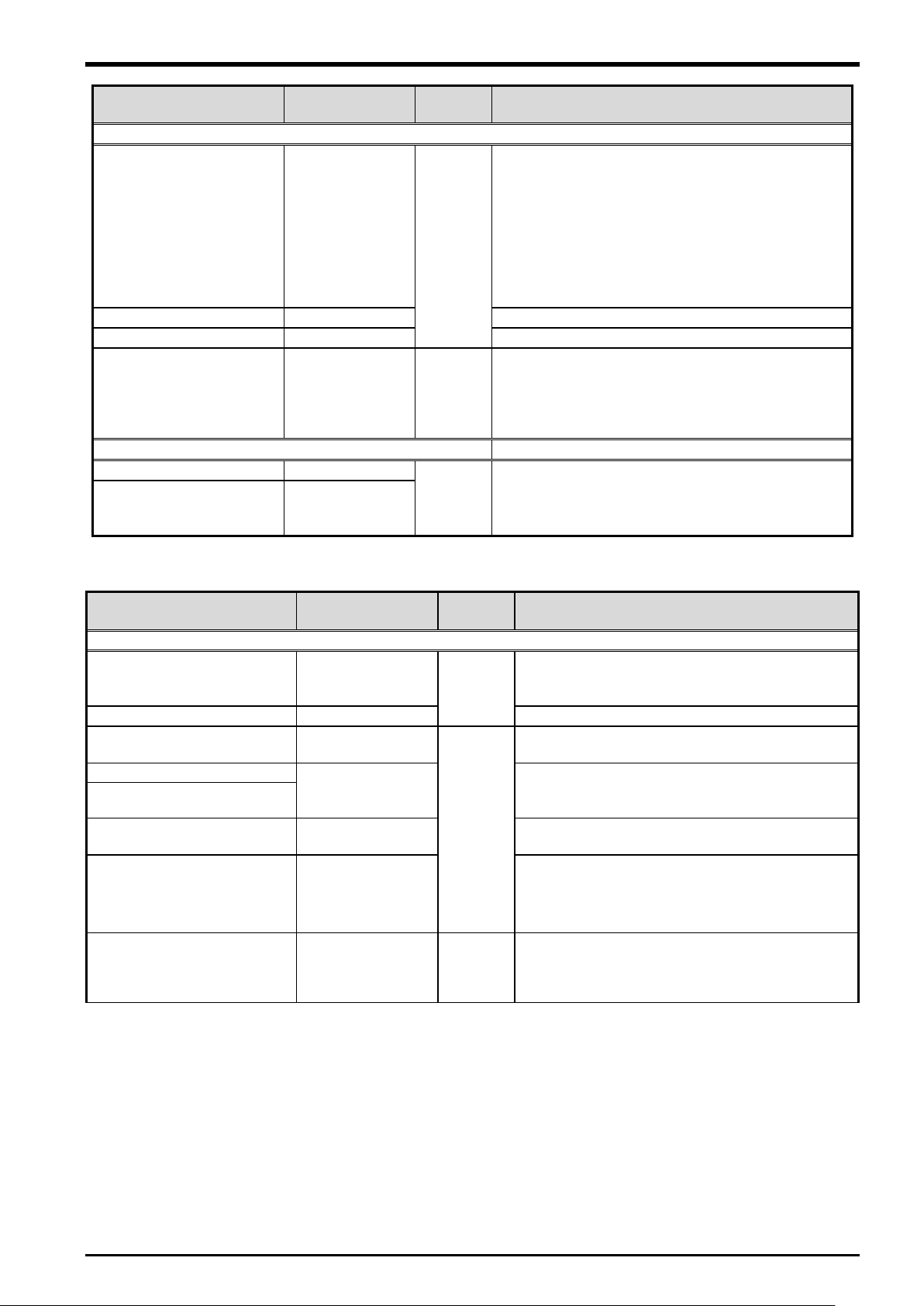

2 System Configuration

Product name

Model name

Remark

Tracking Function

INSTRUCTION MANUAL

BFP-A8664

This manual is included in instruction-manual CD-ROM

attached to the product.

Sample program

−

Please refer to "12 Sample Robot Programs" for the

sample robot program.

Name of devices to be

provided by customers

Robot part

Teaching pendant

R32TB/R33TB

R56TB/R57TB

Hand

−

Hand sensor

Used to confirm that workpieces are gripped

correctly. Provide as necessary.

Solenoid valve set

Different models are used depending on the robot

necessary.

Hand input cable

Air hand interface

2A-RZ365 or

2A-RZ375

(CRnQ-700/CRnD-700 series controller)

Provide as necessary.

Calibration jig

This is a jig with a sharp tip that is attached to the

calibration tasks. It is recommended to use the jig if

high precision is required.

Encoder pulse unit

Manual pulser input unit for motion controller

robot CPU

[Part 2] System Configuration and Setting (CR750-Q/CR751-Q series,

CRnQ-700 series)

2. System Configuration

2.1. Components

2.1.1. Robot controller enclosure products

The product structure of the tracking functional relation enclosed by the robot controller is shown in the

Table 2−1.

Table 2

2.1.2. Devices Provided by Customers

When configuring the system, the customers must have certain other devices in addition to this product. The

table below shows the minimum list of required devices. Note that different devices are required depending

on whether conveyer tracking or vision tracking is used. Please refer to “Table 2−2 List of Devices Provided

by Customers (Conveyer Tracking)” and “Table 2−3 List of Devices Provided by Customers (Vision

Tracking)” for further details.

−1 List of Configuration in the tracking functional-related product

Table 2

−2 List of Devices Provided by Customers (Conveyer Tracking)

Model Quantity Remark

or

−

See the Remark

column

−

Q173DPX

1

(1)

More than

1

used. Check the robot version and provide as

mechanical interface of the robot arm and used for

[*]This unit cannot be connected with two or more

robot CPU. Please prepare for unit necessary in each

2-6 Components

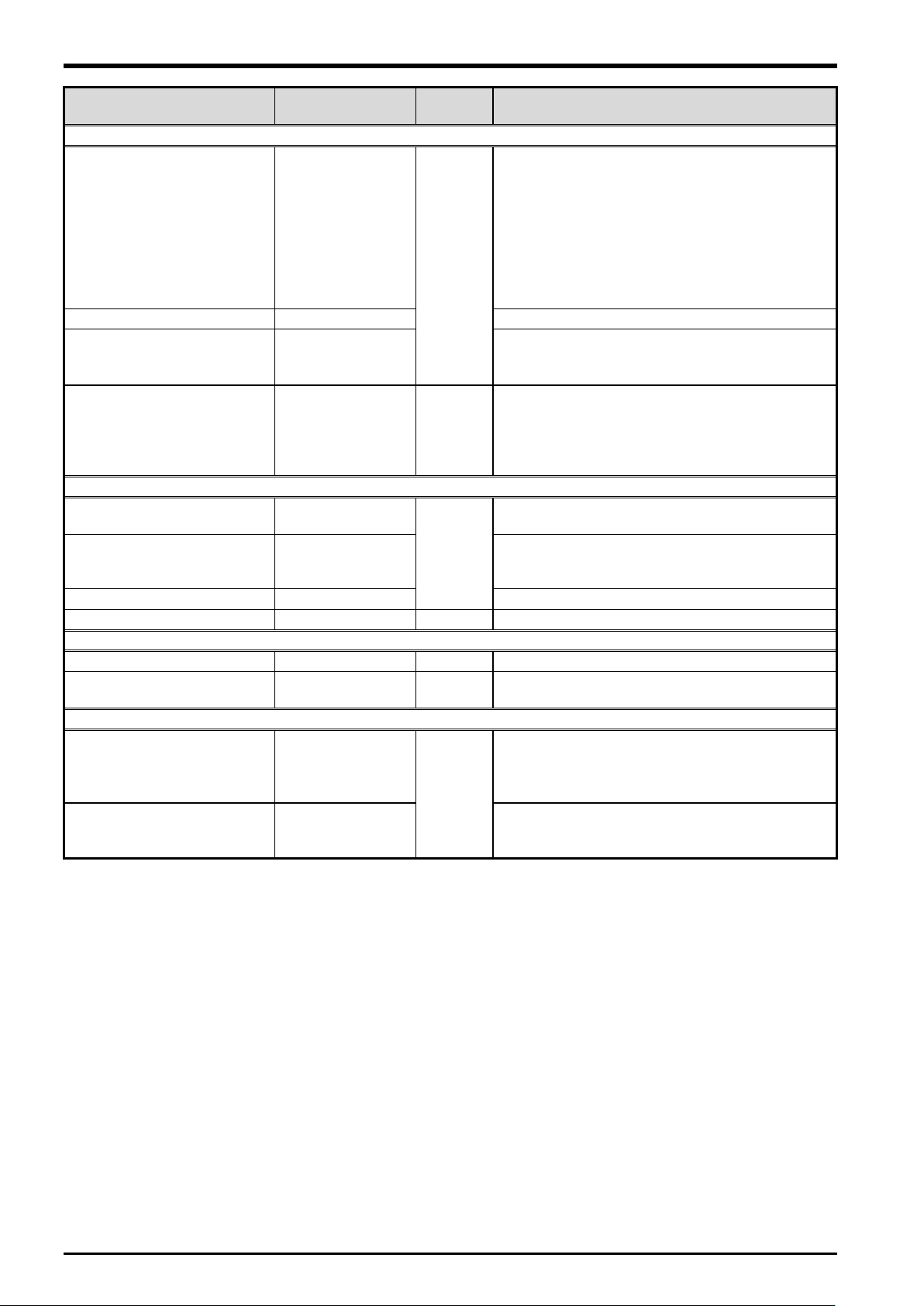

2 System Configuration

Name of devices to be

provided by customers

Conveyer part

Conveyer

Encoder:

to the encoder.

Photo electronic sensor

−

Used to synchronize tracking

24V power supply

−

+24 VDC (±10%) : For the Photo electronic sensor

Encoder distribution unit

The Encoder distribution unit is required when two

(BFP-A3300) for details.

Personal computer part

Personal computer

−

Please refer to the instruction manual of RT

RT ToolBox2

support software)

Name of devices to be

provided by customers

Robot part

Teaching pendant

R32TB/R33TB

R56TB/R57TB

Hand

−

Hand sensor

Used to confirm that workpieces are gripped

correctly. Provide as necessary.

Solenoid valve set

Different models are used depending on the

as necessary.

Hand input cable

Air hand interface

2A-RZ365 or

2A-RZ375

(CRnQ-700/CRnD-700 series controller)

Provide as necessary.

Calibration jig

This is a jig with a sharp tip that is attached to the

Encoder pulse unit

More than

manual pulser input unit for motion controller

【*】

ith two or more

robot CPU. Please prepare for unit necessary in

each robot CPU.

Model Quantity Remark

(with encoder)

(Personal computer

Voltage output/open collector type

Line driver output

[Confirmed operation product]

−

1

Omron encoder (E6B2-CWZ1X-1000 or -2000)

Encoder cable (Recommended product):

2D-CBL05/2D-CBL15

[*]The Q173DPX unit supplies 5V power supply

or more manual pulser input units are connected to

2F-YZ581 (1)

the one encoder. Provide this unit as necessary.

Refer to the Encoder Distribution Unit Manual

ToolBox2 for the details of the personal computer

3D-11C-WINE

3D-12C-WINE

1

specifications.

Table 2−3 List of Devices Provided by Customers (Vision Tracking)

Model Quantity Remark

or

−

See the Remark

column

−

Q173DPX

1

robot used. Check the robot version and provide

(1)

mechanical interface of the robot arm and used

for calibration tasks. It is recommended to use

the jig if high precision is required.

1

This unit cannot be connected w

Components 2-7

2 System Configuration

Name of devices to be

provided by customers

Conveyer part

Conveyer

Encoder:

supply to the encoder.

Photo electronic sensor

−

Used to synchronize tracking

24V power supply

+24 VDC (±10%) :

sensor

Encoder distribution unit

The Encoder distribution unit is required when

Unit Manual (BFP-A3300) for details.

Vision sensor part

Basic network vision sensor

set

See the instruction manual of the network vision

sensor for details

In-Sight 5000 series

In-Sight EZ

COGNEX Vision sensor

Lens

−

C-mount lens

Lighting installation

−

(1)

Provide as necessary.

Connection part

Hub

−

1

Ethernet cable (straight)

Between Robot controller and Hub

Between Personal computer and Hub

Personal computer part

Personal computer

Please refer to the instruction manual of RT

specifications.

RT ToolBox2

(Personal computer support

software)

Please refer to the instruction manual of RT

ils of the personal computer

specifications.

Model Quantity Remark

(with encoder)

In-Sight Micro

−

−

2F-YZ581 (1)

4D-2CG5xxxx-PKG

−

1

1

Voltage output/open collector type

Line driver output

[Confirmed operation product]

Omron encoder (E6B2-CWZ1X-1000 or -2000)

Encoder cable (Recommended product):

2D-CBL05/2D-CBL15

[*]The Q173DPX unit supplies 5V power

For the Photo electronic sensor and Vision

two or more manual pulser input units are

connected to the one encoder. Provide this unit

as necessary. Refer to the Encoder Distribution

−

−

2

ToolBox2 or the instruction of the network vision

sensor for details of the personal computer

1

3D-11C-WINE

3D-12C-WINE

ToolBox2 for the deta

2-8 Components

2 System Configuration

Robot movement range

Workpieces

DU

R

Encoder

(Detected the speed

of the convetor)

(Detected the inflow

of the work)

Photoelectric sensor

Robot

Controler

Q173DPX

Robot CPU

Workpieces

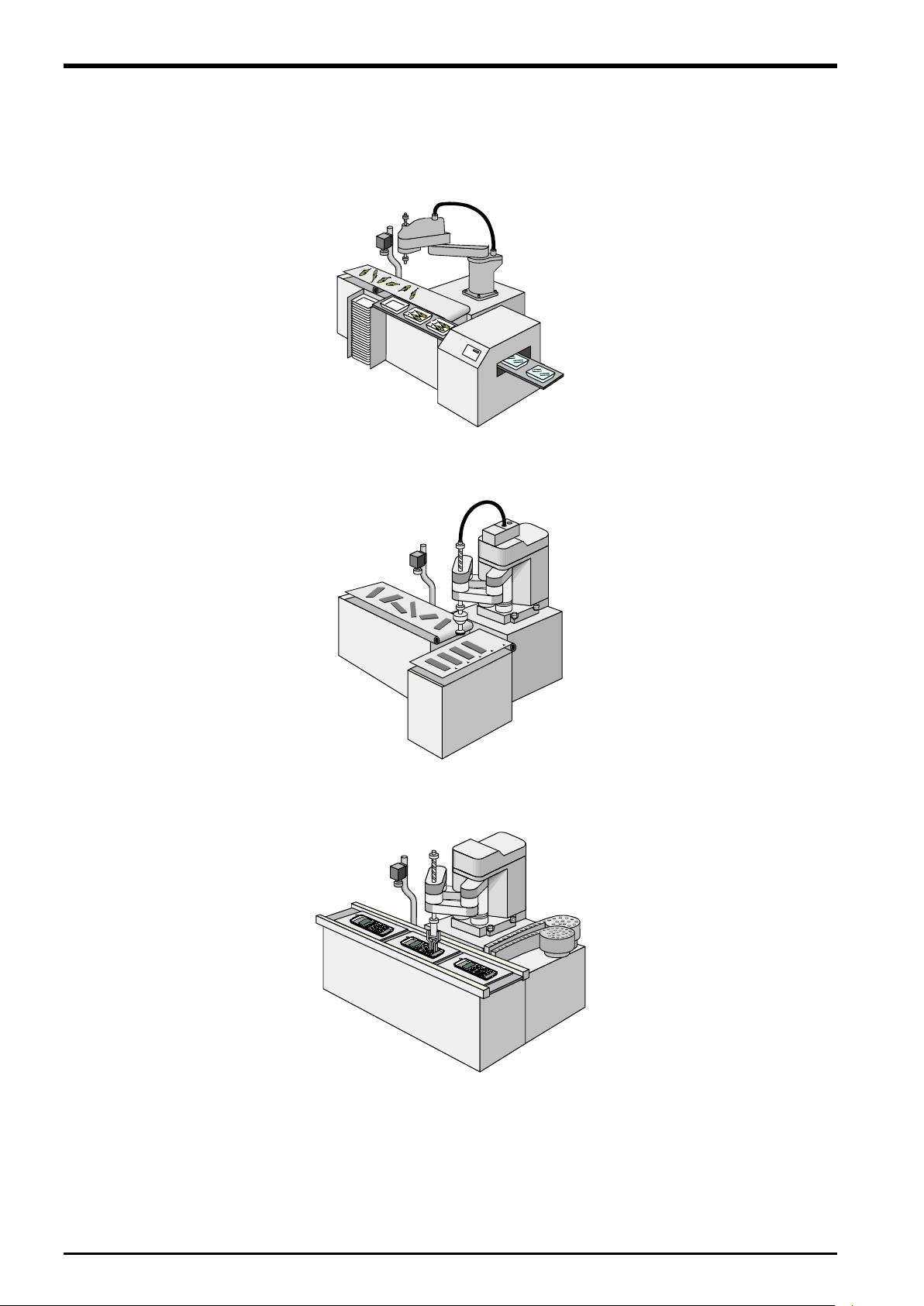

2.2. Example of System Configuration

The following figure shows examples of conveyer tracking systems and vision tracking systems.

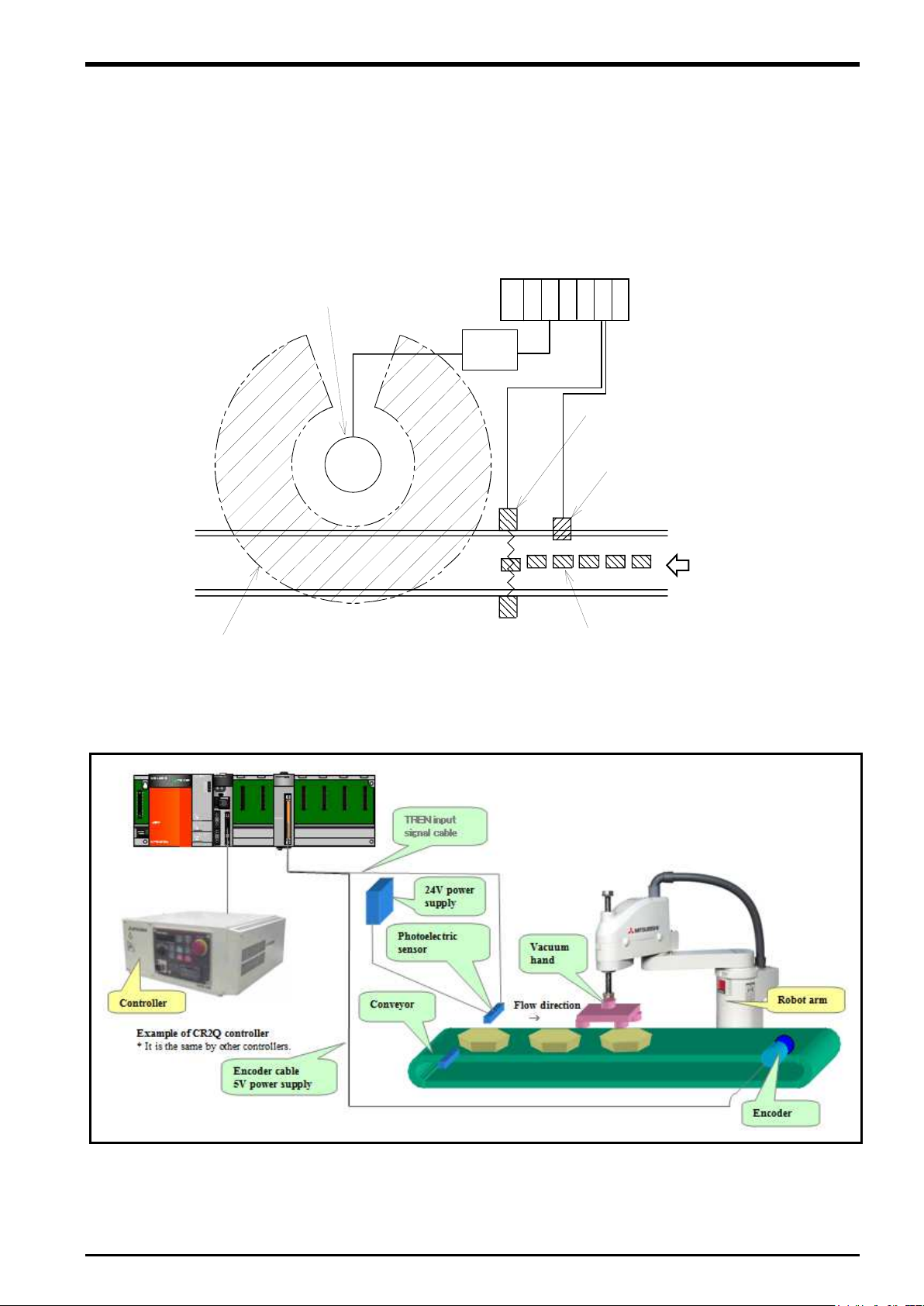

2.2.1. Configuration Example of Conveyer Tracking Systems

The following figure shows a configuration example of a system that recognizes lined-up workpieces on a

conveyer passing a photo electronic sensor and follows the workpieces.

flow direction

Figure 2

−1 Configuration Example of Conveyer Tracking (Top View)

Figure 2

−2 Configuration Example of Conveyer Tracking

Example of System Configuration 2-9

2 System Configuration

Robot movement range

Workpieces

DU

R

Encoder

(Detected the speed

(Recognized the work

Robot

Controler

Q173DPX

Robot CPU

Camera for vision sensors

Workpieces

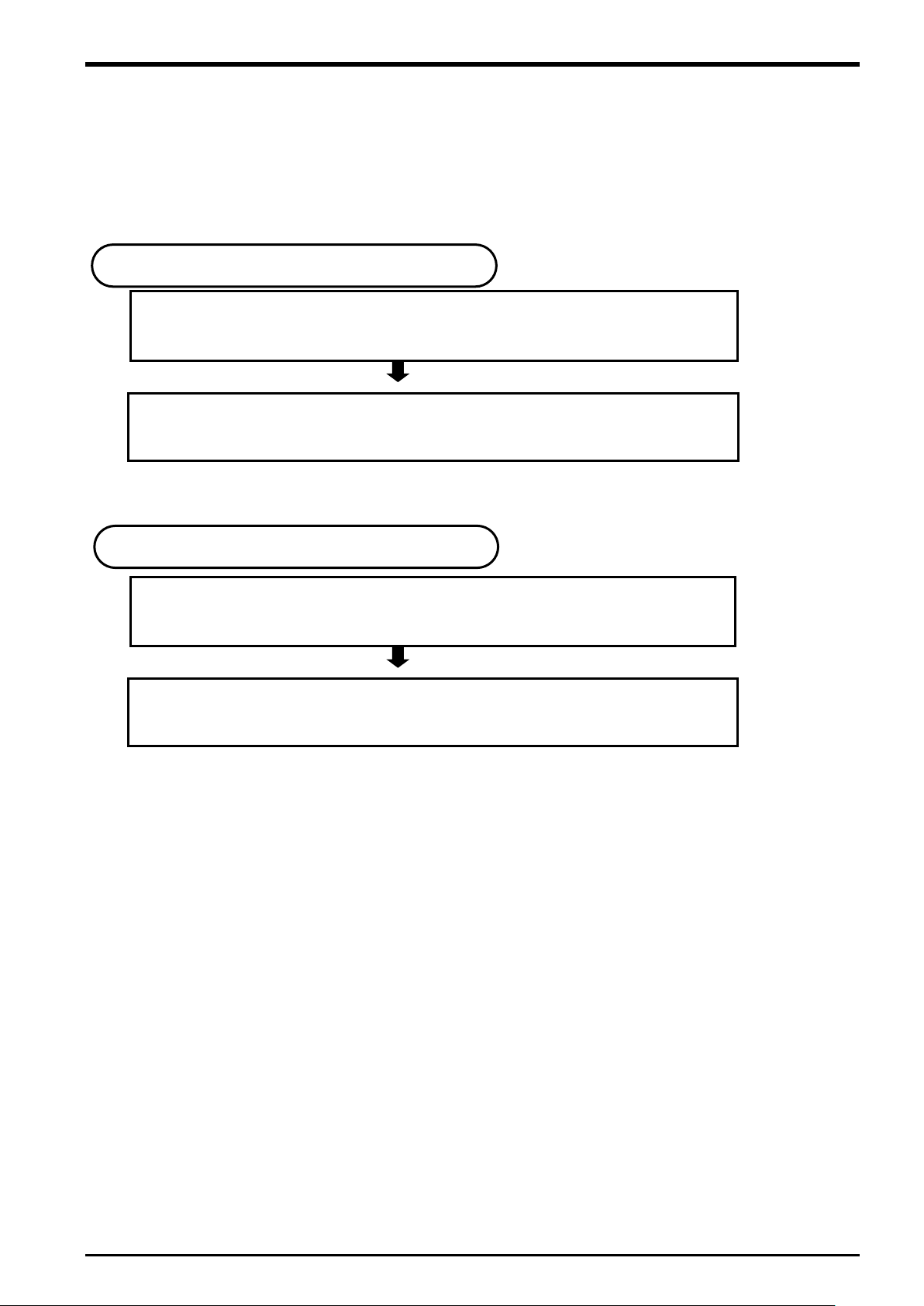

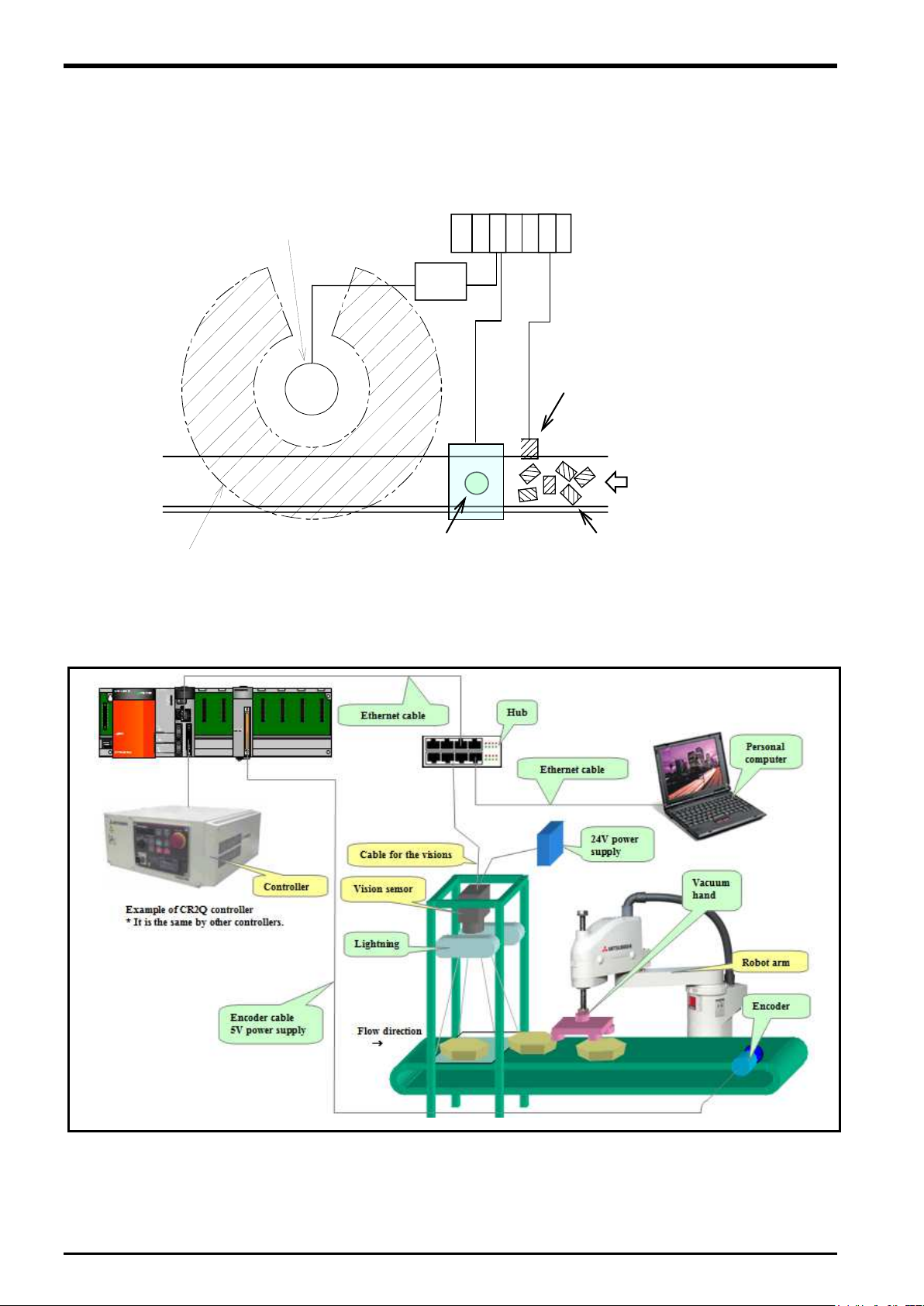

2.2.2. Configuration Example of Vision Tracking Systems

The following figure shows a configuration example of a system that recognizes positions of workpieces that

are not lined up on a conveyer with a vision sensor and follows the workpieces.

of the convetor)

flow direction

of the position and inclination)

Figure 2

−3 Configuration Example of Vision Tracking (Top View)

2-10 Example of System Configuration

Figure 2

−4 Configuration Example of Vision Tracking

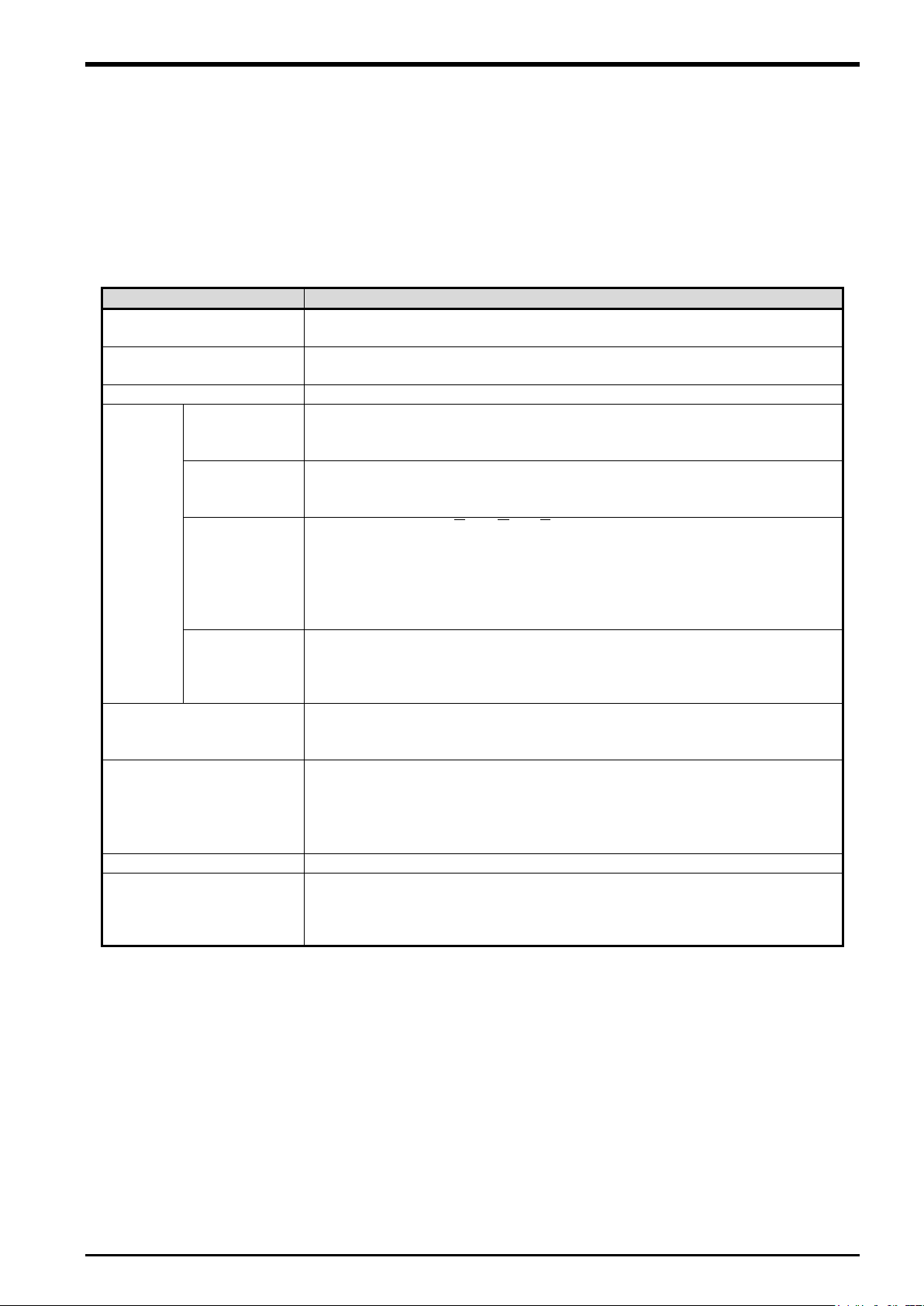

3 Specification

Item

Specification and Restriction matter

Supported robots (*8)

RH-SQH series / RV-SQ series

RH-FH-Q series / RV-F-Q series

Applicable robot controller

CR1Q / CR2Q / CR3Q controller

CR750-Q/CR751-Q series controller

Robot program language

Load commands dedicated for the tracking function

Conveyer

Number of

(*6)

Max 8pcs

in case 1pc encoder connect to 1 pc conveyer)

Q173DPX unit 3pcs / system

Movement

Possible to support up to 300mm/s (When the robot always transport the

Possible to support up to 500mm/s when the interval of workpiece is wide.

Encoder

Output aspect :

ZZBBAA 、、、、、

E6B2-CWZ1X-2000

Encoder cable

Option:

Conductor size: AWG#28

Encoder unit

Only Q173DPX unit

One Q173DPX is necessary for each robot CPU.

Photoelectronic sensor

Used to detect workpieces positions in conveyer tracking.

variable "M_EncL".

Vision sensor(*4)

Mitsubishi’s network vision sensor

Precision at handling

Approximately ±2 mm (when the conveyer speed is approximately 300

(Photoelectronic sensor recognition accuracy, vision sensor recognition

accuracy, robot repeatability accuracy and so on)

3. Specification

3.1. Tracking Specifications and Restriction matter

”Table 3−1 CR750-Q/CR751-Q Series, CRnQ-700 Series Controller Tracking Function Specifications”

shows the tracking specifications.

Please refer to “Standard Specifications Manual” for the specifications of the robot arm and controller to be

used.

Table 3−1 CR750-Q/CR751-Q Series, CRnQ-700 Series Controller Tracking Function Specifications

(

conveyer

Encoder 3 pcs / Q173DPX unit 1pc

Speed (*1)

position (*5)

(*3)

workpieces)

Output form : Voltage output/open collector type (*7)

Line driver output (*2)

Resolution(pulse/rotation)) : Up to 2000 (4000 and 8000 uncorrespond))

Confirmed operation product : Omuron E6B2-CWZ1X-1000

2D-CBL05(External I/O cable 5m)

2D-CBL15(External I/O cable 15m)

[*] Two or more robots CPU cannot share one Q173DPX.

Output signal of sensor need to be connected to TREN terminal of

Q173DPX unit. (Input signal number 810~817)

And a momentary encoder value that the input enters is preserved in state

mm/s)

(*1) The specification values in the table should only be considered guidelines. The actual values

depend on the specific operation environment, robot model, hand and other factors.

(*2) The line driver output is a data transmission circuit in accordance with RS-422A. It enables the

long-distance transmission.

(*3) Please connect the output signal of a photoelectric sensor with the terminal TREN of the Q173DPX

unit. This input can be confirmed,by the input signal 810th-817th.

(*4) In the case of vision tracking, please refer to the instruction manual of network vision sensor.

(*5) The precision with which workpieces can be grabbed is different from the repeatability at normal

transportation due to the conveyer speed, sensor sensitivity, vision sensor recognition accuracy and

other factors. The value above should only be used as a guideline.

(*6) The encoder connected with the third channel of the Q173DPX unit specified for parameter

"ENCUNIT3" cannot be used.

(*7) Voltage output/open collector type is an output circuit with two output transistors of NPN and PNP.

(*8) The sample program doesn't correspond to the RV-5 axis robot.

Tracking Specifications and Restriction matter 3-11

4 Operation Procedure

4. Sample Robot Programs ······································································ Refer to “Chapter 12.”

5. Calibration of Conveyer and Robot Coordinate Systems (“A1” program) ········ Refer to “Chapter 13.”

7. Workpiece Recognition and Teaching (“C1” program) ································ Refer to “Chapter 15.”

explains how to calculate the relationship between the position of a workpiece

9. Automatic Operation ··········································································· Refer to “Chapter 18.”

10. Maintenance ····················································································· Refer to “Chapter 19.”

11. Troubleshooting ··············································································· Refer to “Chapter 20.”

3. Parameter Setting ················································································ Refer to “Chapter 6.”

1. Start of operation

End of operation

2. Connection of Equipment ······································································· Refer to “Chapter 5.”

8. Teaching and Setting of Adjustment Variables (“1” Program) ······················· Refer to “Chapter 16.”

6.

Calibration of Vision Coordinate and Robot Coordinate Systems (“B1” program)

··· Refer to “Chapter 14.”

4. Operation Procedure

This chapter explains the operation procedure for constructing a conveyer tracking system and a vision

tracking system using Mitsubishi Electric industrial robots CR750-Q/CR751-Q series, CRnQ-700 series.

It explains Q173DPX (manual pulser input) unit preparation and the connection with the encoder.

Chapter 6 explains assignment of signals and setting of parameters related to tracking to allow an

external device to control a robot.

Chapter 12 explains functions related to supplemental sample programs.

Chapter 13 explains how to calculate the amount of robot movement per encoder pulse.

Chapter 14 explains how to display the position of a workpiece recognized by the vision sensor in

the robot coordinate system.

Chapter 15

recognized by the vision sensor and the position at which the robot grabs the workpiece.

Chapter 16 explains how to make settings such that the robot can follow workpieces moving by on a

conveyer and how to teach the robot origin and transportation destination at system start-up.

In automatic operation, the robot operates via commands from the conveyer control.

4-12 Tracking Specifications and Restriction matter

5 Connection of Equipment

5. Connection of Equipment

This section explains how to connect each of the prepared pieces of equipment.

5.1. Preparation of Equipment

Prepare equipment by referring to “Table 2−2 List of Devices Provided by Customers (Conveyer Tracking)”

to construct a conveyer tracking system and “Table 2−3 List of Devices Provided by Customers (Vision

Tracking)” to construct a vision tracking system.

Preparation of Equipment 5-13

5 Connection of Equipment

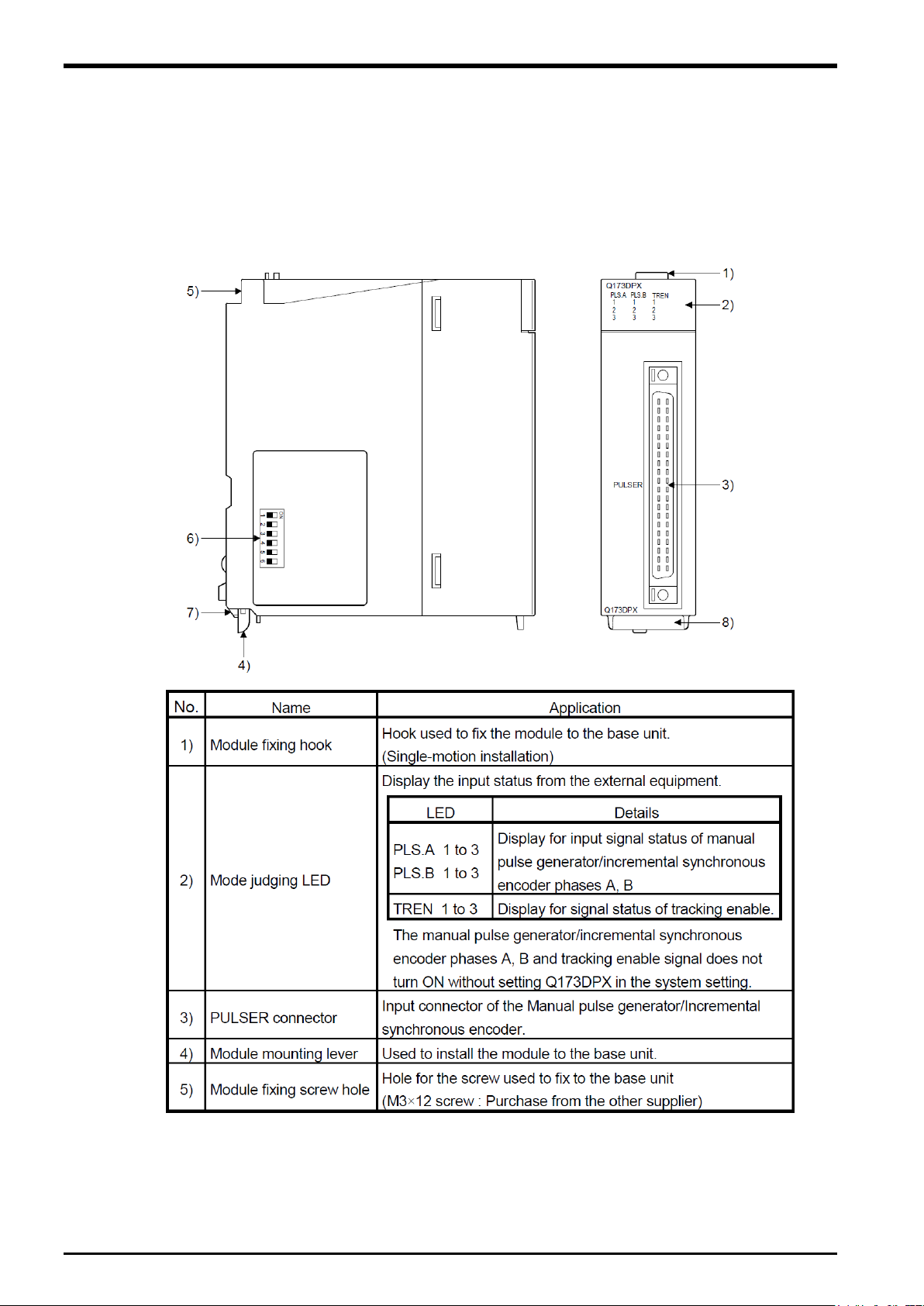

5.1.1.

Q173DPX(

manual pilser input) unit specification

Add Q173DPX unit into PLC base unit (Q3□DB ) when the customer use CR750-Q/CR751-Q series,

CRnQ-700 series tracking function. Please refer to

"Q173DCPU/Q172DCPU user's manual" about details of this unit.

(1) External and name of Q173DPX unit

Figure 5

−1 Externals of Q173DPX unit

5-14 Preparation of Equipment

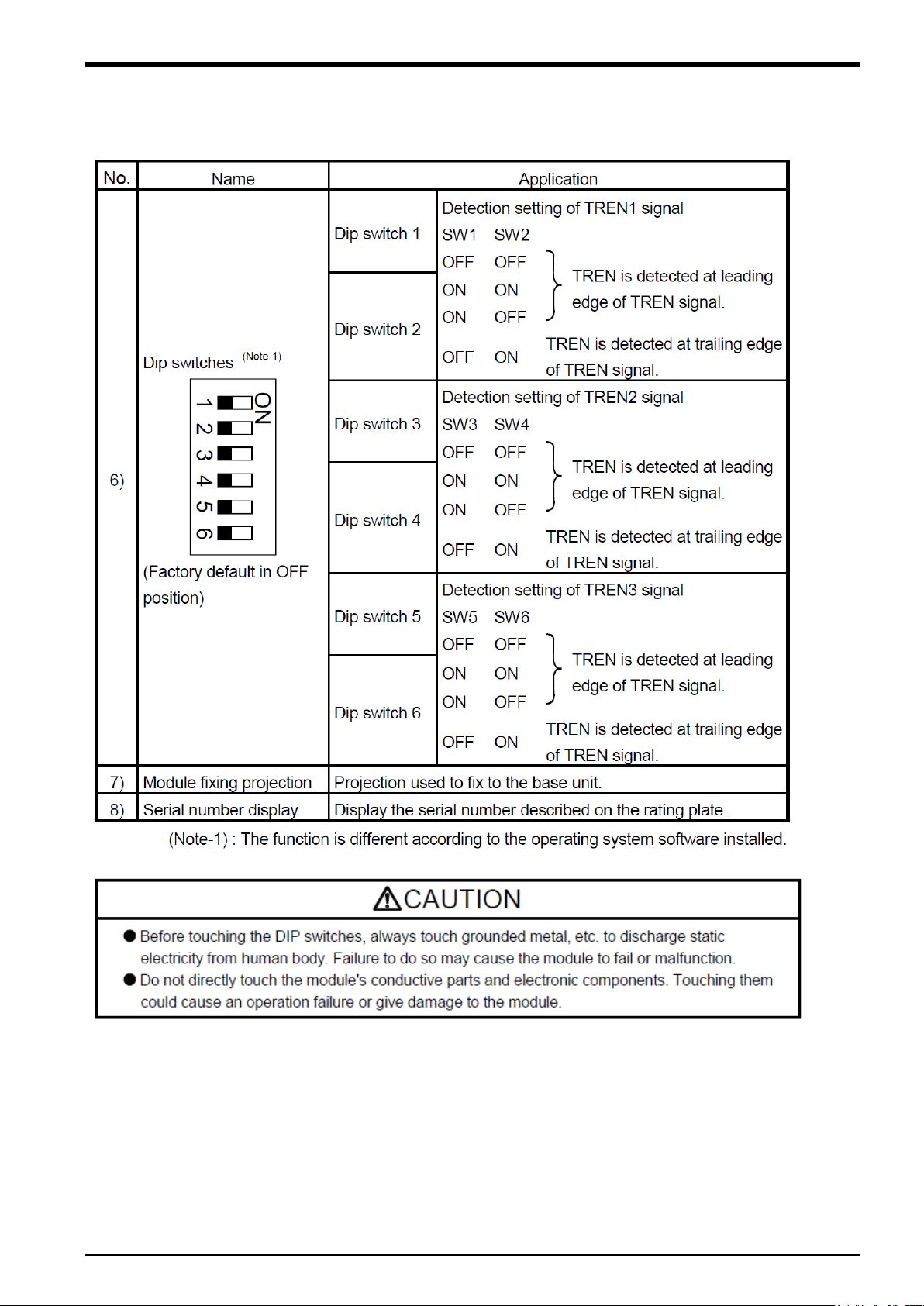

(2) Dip switch

By setting the dip switch, the condition of the tracking enable signal is decided.

List 5-1

Item of dip switch

5 Connection of Equipment

Preparation of Equipment 5-15

5 Connection of Equipment

7.1ms

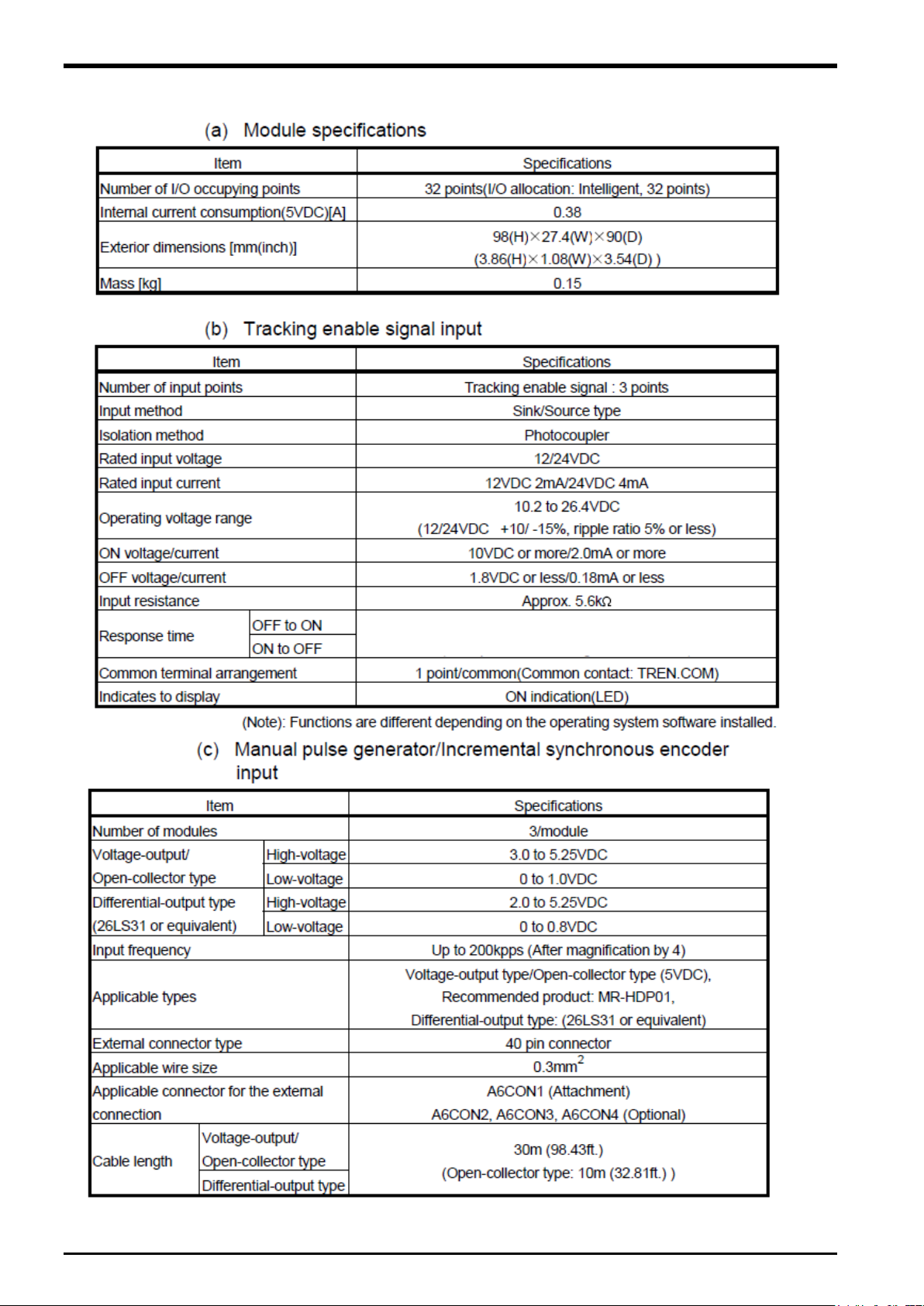

(3) Specification of hardware

5-16 Preparation of Equipment

5 Connection of Equipment

(4) Wiring

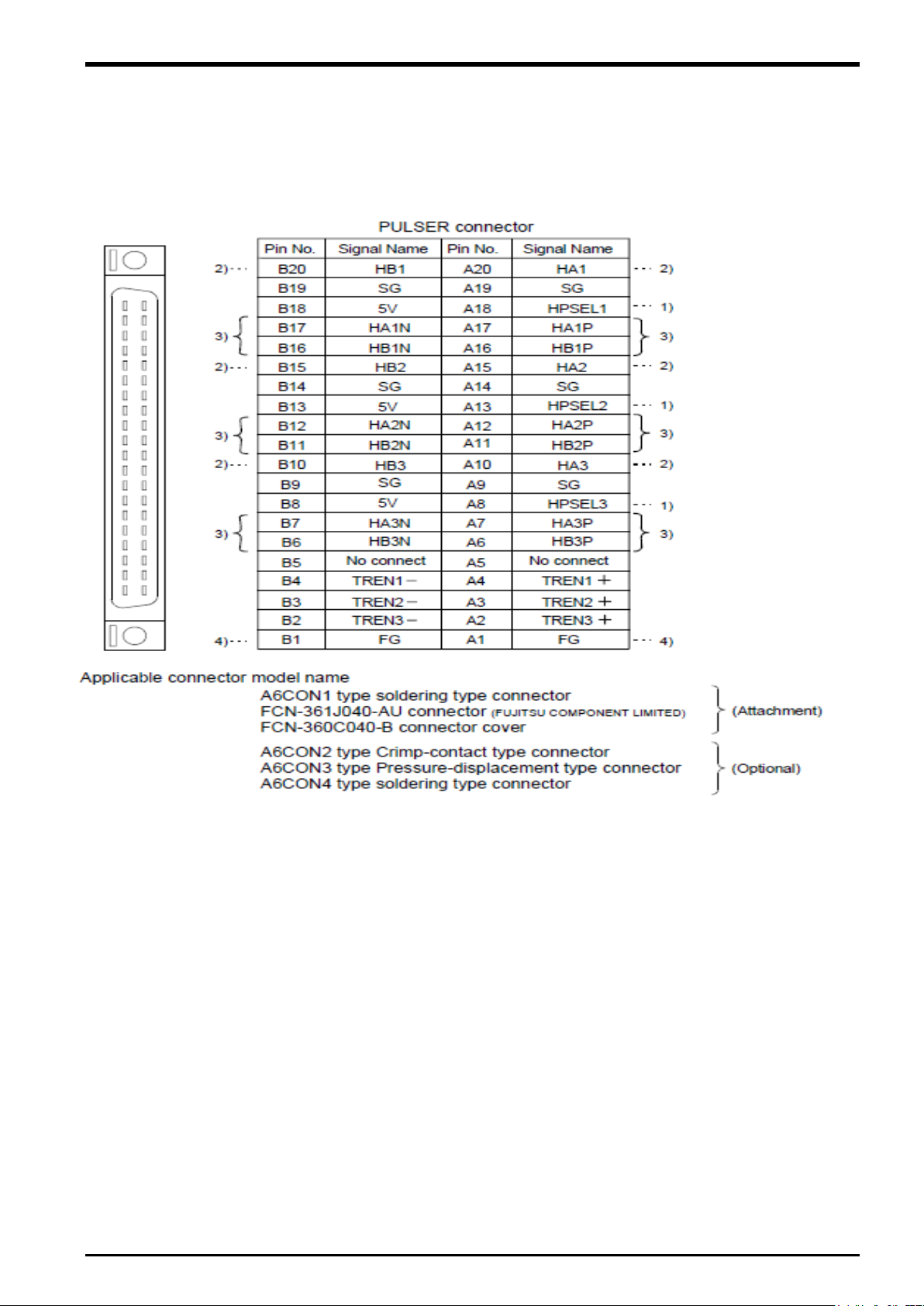

The pin layout of the Q173DPX PULSER connecter viewed from the unit is shown below.

Figure 5

−2 Pin assignment of the PULSER connector

Preparation of Equipment 5-17

5 Connection of Equipment

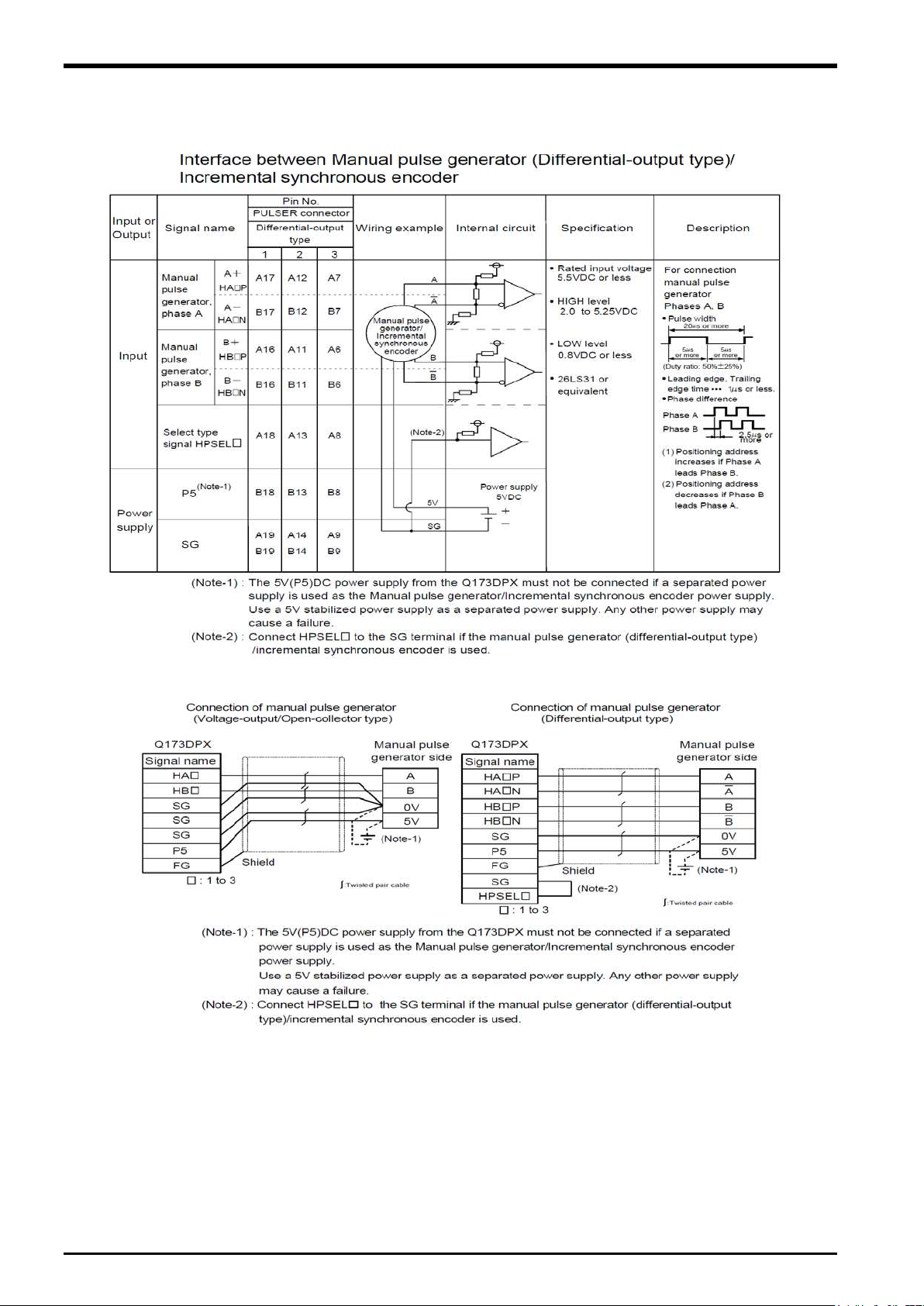

Interface between PULSER connecter and manual pulse generator (Differential-output type)/ Incremental

synchoronous encoder

Figure 5

−3 Wiring connection with rotary encoder

As above image, because DC5V voltage is output from Q173DPX unit, it makes possible to supply 5V from

Q173DPX unit to rotary encoder. When 24V encoder type of power supply is used, it makes possible to use

24V output from PLC power unit.

5-18 Preparation of Equipment

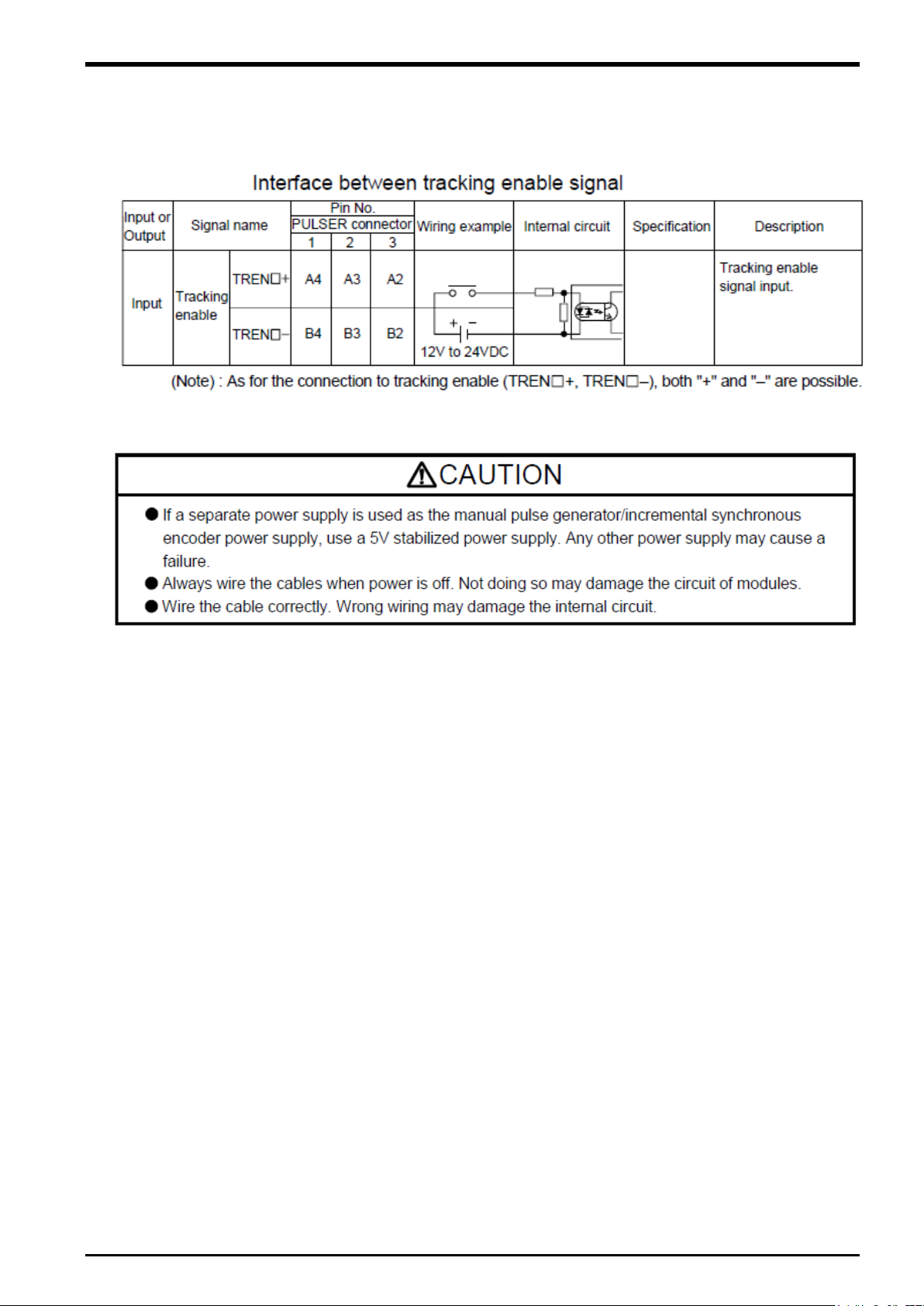

The interface between tracking enable signal is shown follow.

This signal is used for input signal when the

connect output signal of

photoelectronic sensor.

photoelectronic sensor is used to find workpieces so please

5 Connection of Equipment

Figure 5

−4 Connected composition of tracking enable signal

Preparation of Equipment 5-19

5 Connection of Equipment

Item

Spec and Remark

Encoder

Incremental synchronous encoder 3pcs

Tracking input points

3points

When the input of a photoelectric sensor is put, this input is used.

Slot that can be connected

Connection with the base unit Possible to install I/O slot since 3

Connection with additional base unit Possible to install all slots.

Robot CPU unit that can be

managed

Q173DPX unit 3pcs

Robot CPU encoder that

Max 8pcs

unit specified for parameter「ENCUNIT3」.

5.2. Connection of Equipment

The connection with each equipments is explained as follow.

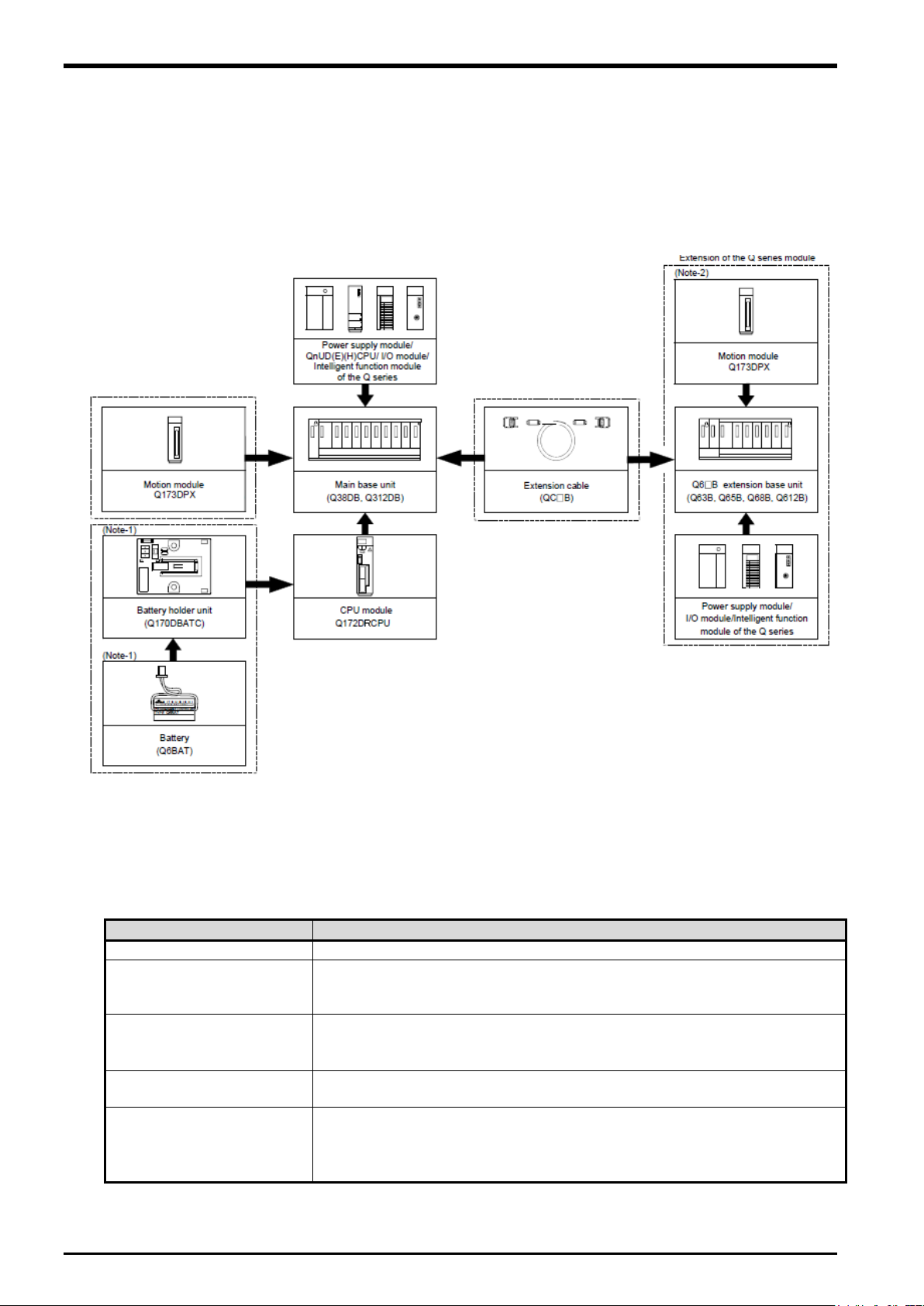

5.2.1. Connection of Unit

Q173DPX unit is connected to base unit (Q3□DB) or Q6□B increase base unit.

Figure 5

−5 Connected composition of units

The connection robot system with Q173DPX unit is shown as follow.

List 5-2 Spec list of Q173DPX in robot system

Three points can be input to ± TREN1-3 in the pin assignment of the unit.

(Impossible to install CPU slot or I/O slot 0 to 2)

can be managed

Impossible to use the third channel of the third Q173DPX unit.

And impossible to use the encoder connected with the third channel of the

5-20 Connection of Equipment

Loading...

Loading...