Page 1

Side

Sensor

Connector dedicated

to CC-Link/LT

(sold separately)

Switches

X0 input operation

indicator LED

Y0 output operation

indicator LED

0

0

Crimp-style connection device with

insulator or closed end connection

device

Sensor,

switch, etc.

Crimp-style connection device with

insulator or closed end connection

device

Lamp,

solenoid, etc.

Input

equipment

Connector dedicated to CC-Link/LT

Output

equipment

Wire diameter: AWG18 (34/0.18)

30mm(1.19") 30mm(1.19")

B

Side

A

JAPANESE ENGLISH

Side

B

CL1XY2-DTE1D5S

CC-Link/LT Remote I/O Module

Please read this manual thoroughly before star ting to use the product and

handle the product properly.

User’s Manual

MODEL CL1XY2-DTE1D5S

MANUAL Number JY997D06301A

Date NOVEMBER 2002

SAFETY PRECAUTIONS

●●●●

Please read this m anual carefully a nd pay special atten tion to safely in order

to handle this produc t properly. Also pay careful attention t o safely and handle

the module properly.

These precautions apply onl y to Mitsubishi equipment. Refer to th e user’s

manual of the CPU mo dule to use for a descr iption of the PLC system safety

precautions.

These ●SAFETY PRECAUTIONS● classify the safety precautions into two

categories: "DANGER" and "CAUTION".

DANGER

CAUTION

Depending on c ircumstances, procedures ind icated by

may also be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

[DESIGN PRECAUTIO NS]

• Configur e an interlock circuit in a sequence program so that the system

operates on the safety side usi ng the communication status information

in the event the data link falls into a communi cation problem.

Otherwise, erroneous outp ut and malfunction may result i n accidents.

• Remote input and output can not be switched ON or OFF when a

problem occurs in the remote I/O modules. Therefore build an exter nal

monitoring circuit that will monitor any input signa ls that could cause a

serious accident.

(Read these precautions before using )

Procedures which may lead to a dangerous c ondition

and cause death or serious injur y if not carried out

properly.

Procedures which may lead to a dangerous c ondition

and cause superficial to medium injur y, or physical

damage only, if not carried out properly.

DANGER

CAUTION

• Do not have control cables and communication ca bles bundled with or

placed near by the main c ircuit and/or power cables. Wire thos e cables

at least 100mm(3.94 inc h) away from the main circuit and/or p ower

cables. It may cause malfunction du e to noise interference.

• Use the m odule in the status in which any force is not applied on the

module, flat cables dedicated to CC-Link/LT and flat cables for I/O.

If a force is applied, wire break age or failure may be caused.

[INSTALLATION PRECAUTIONS]

CAUTION

• Use t he module in an environment that meets the general specifications

contained in this manual . Using this module in an environment outside

the range of the general specifications could result in electric shock, fire,

erroneous operation, and damage to or deterio ration of the product.

• Do not directly touch the module 's conductive parts.Doing so could

cause malfunction or trouble in the module.

[WIRING PRE CAUTIONS]

• Perform installation an d wiring after disconne cting the power supply at

all phases externally. If the power is not disconnect ed at all phases an

electric shock or produ ct damage may result.

DANGER

●●●●

CAUTION

• Perform correct wiring for the modul e according to the product’s rated voltage

and terminal arrangement. Connecting to a power supply different from rating

or miss-wiring may cause f ire, product failure or malfunctio n.

• Make sure foreign objects do not get inside the module, such as dir t and wire

chips. It may cause fire, product failure or ma lfunction.

• Attach a warning label (hazar d symbol 417-IEC-5036) concerning the ele ctric

shock to the location.

[STARTING AND MAINTENANCE PRECAUTIONS]

• Do no t touch the terminals when the power is ON. It may cause a n electric

shock or malfunction.

• Perform cleaning th e module after tur ning OFF the all external power supply

for sure. Failure to do so may cause failure or malfunction of the modules.

DANGER

CAUTION

CAUTION

• Do no t disassemble or modify the module. Doing so may cause failure,

malfunction, injur y, or fire.

• The module case is made of resi n; do not drop it or subject it to strong shock.

A module damage may result.

• Make sure t o switch all phases of the exter nal power supply OFF before

installing or removing the mod ule to/from the pane l. Failure to do so may

cause failure or malfunction of th e modules.

[DISPOSAL PR ECAUTIONS]

• When d isposing of this produ ct, treat it as industri al waste.

DANGER

[TRANSPORTATION AND MAINTENANCE PRECAUTIONS]

CAUTION

• Dur ing transportation avoid any impact as the module is a precision

instrument. Doing so could cause trouble in the module.

• If is n ecessary to check the ope ration of module after t ransportation, in case

of any impact damage.

Notification of CE marking

This notification does not guarantee that an entire mechanical modul e produced

in accordance with the contents of the notification comply with the following

standards. C ompliance to EMC stand ards of the ent ire mechani cal module

should be checked by the user / ma nufacturer.

Standards with which this product complies

Type : Programmable Controller (Open Type Equipment) Remote I/O module

Models : Products manufactured from November 1st, 2002.

Electromagnetic Compat ibility Standards

EN61000-6-4:2001

Electromagnetic compatibilit y

-Generic standards - Emiss ion standard for

Industrial environment

EN61131-2:1994 Programmable controllers

/A11: 1996 -Equipment re quirements and

tests

/A12: 2000

For more details please conta ct the local Mitsubishi Ele ctric sales site.

- Notes For compliance to EMC re gulation.

It is necessary to install th e CL1 series module in a shielded metal control panel.

●●●●

(EMC)

●●●●

Remark

Compliance with all relevant

aspects of the standard. (Radiate d

Emissions and Mains Terminal

Voltage Emissions)

Compliance with all relevant

aspects of the standard. (RF

Immunity, Fast transients, ESD and

Damped oscillatory wave)

1. Outline of Product

This product is a cable typ e composite I/O module con nected to CC-Link/LT.

This product has one input point (24V DC) and one output point (transistor

output).

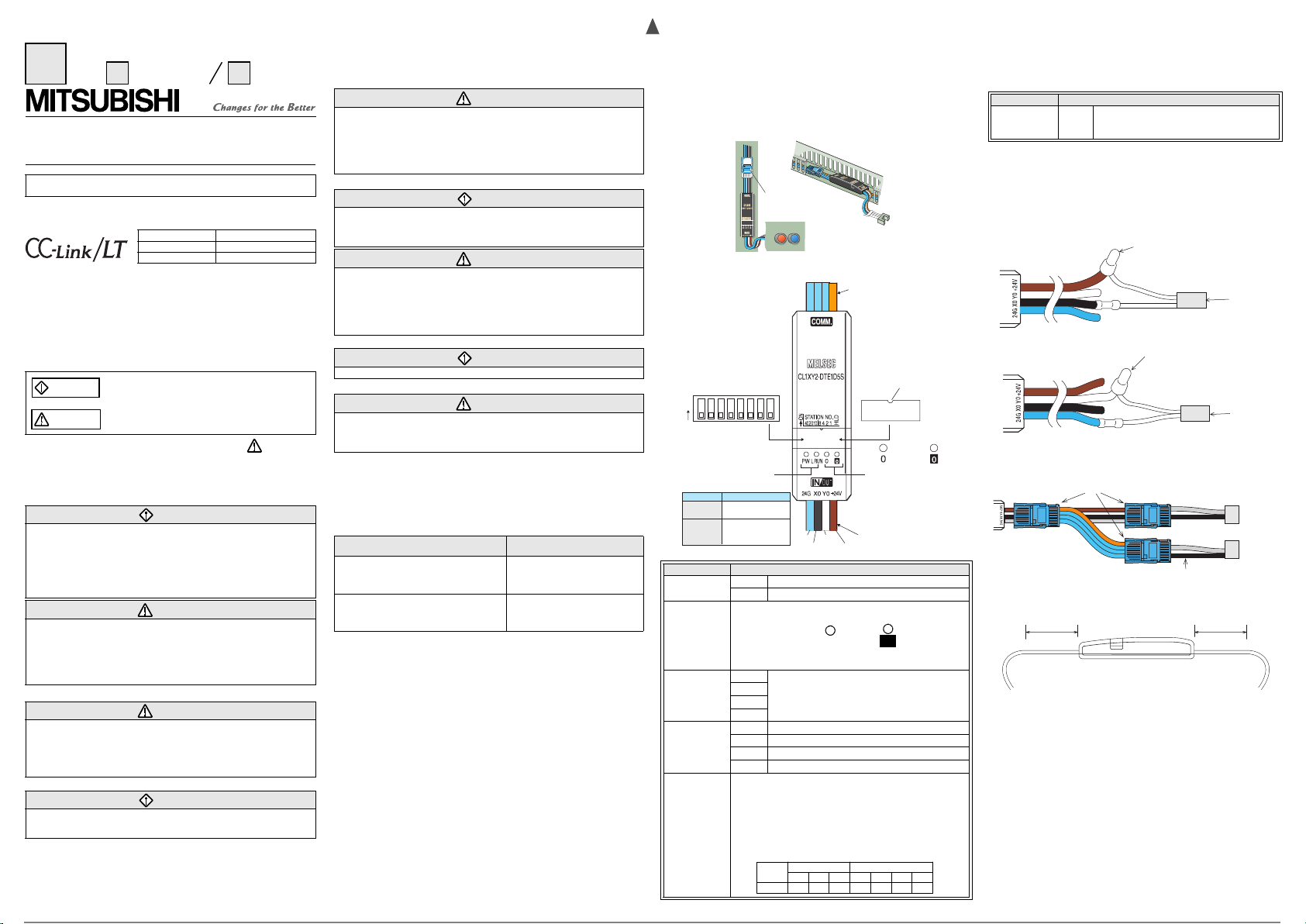

2. Name and Setting of Each Part

Flat cable dedicated

to CC-Link/LT

DIP switch

(Remove the switch cover

when setting the DIP switch.)

DIP switch assignment

40 20 10

ON

Status indicator LEDs

LED name

PW

L RUN

Name Description

Status indicator

LED

I/O operation

indicator LED

Flat cable

dedicated to CCLink/LT

Flat cable for I/O

DIP switch

HLD

8

4 2 1

Operation

Lit while the

power is supplied.

Lit while normal

operation is

executed.

PW ON while the power is supplied.

L RUN ON while nor mal operation is executed.

ON while the input or output is ON.

Extinguished while the input or out put is OFF.

24G

DB

DA

+24V

Blue 24G

Black X0

White Y0

Brown +24V

Set the 10's digit of the station No. using "STATION NO. 10",

"STATION NO. 20" and "STATION NO. 40". Set the 1's digit of

the station No. using "STATION NO. 1", "STATION NO. 2",

"STATION NO. 4" and "STATION NO. 8".

Factory default = All bits are OFF.

Make sure to set the station No. in the range from 1 to 64.

Example: When setting the station No. to "32", set the

DIP switch as follows.

Blue

White

Black

Connector for CC-Link/LT communication line/

module power supply

10's digit 1's digit

Station

No.

40 20 10 8 4 2 1

32 ONOFFONOFF ON OFF OFF

Switch cover

(Make sure to attach the

switch cover after setting

the DIP switch.)

Attach it with

this area facing

upward.

Input

operation

indicator

LED

Input/output is ON: Lit

Input/output is OFF: Extinguished

Flat cable for I/O

Brown

Output

operation

indicator

LED

Name Description

DIP switch HLD

Holds the output (w hen an error has occurred).

ON: Holds the outp ut.

OFF: Clears the output.

3. Cautions on Handling

3.1 Handling of flat cable for I/O

The cable length from the module to a sensor shall be within 3m(9'10").

Measure the cable outside the mod ule, and confirm that the dr iving voltage

for the used sensor is assur ed.

• Inp ut

• Outpu t

If the diameter of the I/O equipment connection cable is equivalent to the

diameter of the flat cable for I/O of this module, connectors dedicated to

CC-Link/LT can be used for connection.

3.2 Handling of cable

Do not bend the cable within 3 0mm(1.19") from the module.

Use a crimp-style terminal in a status in which no force is applied on the

cable.

Page 2

Sensor

Connector dedicated

to CC-Link/LT

(sold separately)

Switches

X0 input operation

indicator LED

Y0 output operation

indicator LED

0

0

Crimp-style connection device with

insulator or closed end connection

device

Sensor,

switch, etc.

Crimp-style connection device with

insulator or closed end connection

device

Lamp,

solenoid, etc.

Input

equipment

Connector dedicated to CC-Link/LT

Output

equipment

Wire diameter: AWG18 (34/0.18)

30mm(1.19") 30mm(1.19")

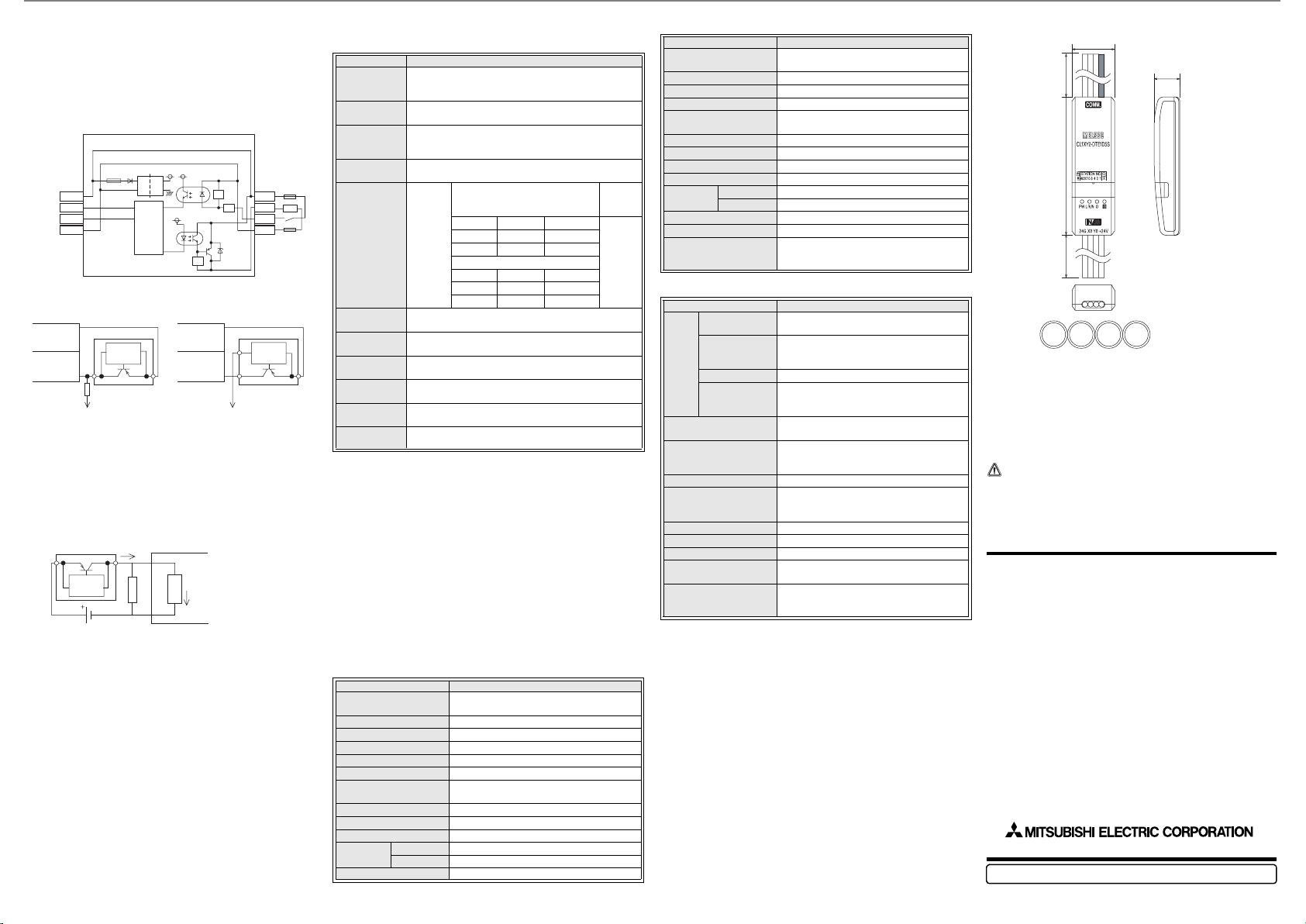

4. Connection to External Equipment

4.1 External wiring

The input and output terminals of the CL1XY2-DTE1D5S operate while

using the power supplied from the interface.

When connecting a sensor to the input terminal, use a sensor of the PNP

open collector transistor t ype.

The output wiring is fixed to the sink output.

I/O wiring

CL1XY2-DTE1D5S

Flat cable

dedicated

to CC-Link/LT

+24V

DA

DB

24G

4.2 Connection to s ensor

• When using a two-wire type sensor!When using a three-wire type sensor

+24

X *

Bleeder

resistor *1

Replace * in the figure with the used input No.

Notes:

*1 Bleeder resistor

When connecting a two-wire type sensor or input equipment containing a

parallel resistor, select a sensor or equipment whose leakage current is

1.7mA or less.

If the leakage current is more than 1.7mA, connect a bleeder resistor

obtained in the following calculation formula.

Circuit image

R(kΩ) < 1.7(mA) / Leakage current(mA) - 1.7( mA) x 5.6(kΩ)

The power capacity W of the bleeder resistor R is as follows:

W = (Input voltage)

• Make sure that both the ON and OFF time of the input s ignal are 1.5ms or

more.

Sensor (PNP) Sensor (PNP)

Connected to 24G cable Connected to 24G cable

Sensor(PNP)

Detection

circuit

24V DC

Isolation

DC DC

Internal

circuit

Detection

circuit

Leakage

Unit

current

R

2

/R

R

R

R

+24

X *

Input impedance

5.6 kΩ

1.7 mA or less

R: Bleeder resistor

Flat cable

for I/O

+24V

Detection

circuit

Y0

X0

24G

0.5A

0.5A

5. Specifications

5.1 General specifications

Item Specification

Ambient

workin g

temperature

Ambient storage

temperature

Ambient

operating

humidity

Ambient storage

humidity

L

Vibration

resistance

Impact

resistance

Operating

atmosphere

Operating

altitude

Installation

place

Over-voltage

category

Degree of

contamination

Notes:

*1 The ambient operating/storage temperature satisfies the requirements beyond

the specification in the JIS B3502 and the IEC61131-2.

*2 The module cannot be used in an environment pressurized above the

atmospheric pressur e which can be generated arou nd the altitude of 0 m. If the

module is used in such an environmen t, it may fail.

*3 The module can be used in any enviro nment even outside the control panel as

far as the requir ements of the ambient op erating temp erature, the a mbient

operating humidity, etc. are satisfied.

*4 This indicates the section of the power supply to which the equipment is

assumed to be connected between the public electrical power distribution

network and the machinery within premises. Category II applies to equipment

for which electrical power is supplied from fixed facilities.

The surge voltage withstand level for up to the rated voltage of 300V is 2500V.

*5 This index indicates th e degree of conductive generating subst ances in the

environment in which the module is used. The degree of contamination 2

indicates that contamination is caused by generation of only non-conductive

substances.

In this degree, however, temporary conduction may be caused by accidental

condensation.

5.2 Input specifications

Input method

Number of input

Isolation method

Rated inpu t voltage

Rated inpu t curren t

Operating voltage range

Max. simultaneous ON

input points

ON voltage/ON current

OFF voltage/OFF current

Input resistance

Response

time

Common wiring method

0 to 55°C (32 to 131°F) (*1)

-25 to 75°C (-13 to 167°F) (*1)

Conforming to JIS B3502 and IEC61 131-2, Level RH-2

(5 to 95%RH: Dew condensation shall not be considered.)

Conforming to JIS B3502 and IEC61 131-2, Level RH-2

(5 to 95%RH: Dew condensation shall not be considered.)

When intermittent vib ration is present

Frequency

Conforming

to JIS

B3502 and

IEC61131-2

Conforming to JIS B3502 and IEC61 131-2

2

, 3 times in each of X, Y and Z directions)

(147 m/s

Acceleration Half amplitude

10 to 57Hz

57 to 150Hz

9.8m/s

−

2

When continuous vibration is present

Acceleration Half amplitude

Frequency

10 to 57Hz

57 to 150Hz

4.9m/s

−

2

Corrosive gas shall not be present.

Conforming to JIS B3502 and IEC61 131-2

(2,000m(6561'8") or less)(*2)

Inside control panel (*3)

Conforming to JIS B3502 and IEC61 131-2

(Category ΙΙ or less)(*4)

Conforming to JIS B 3502 and IEC61131- 2, Degree of

contamination 2 or less (*5)

Item Specification

DC input (using module power supply in comm on)

EN61131-2, Section3.3.1.2-Type1

1 point

Isolation with photocoupler

24V DC

Approx. 4 mA

Same as module power supply

100% (at 24V DC)

19 V or more/3 mA or more

11 V or less/1.7 mA or less

5.6 k

Ω

OFF

ON

1.5 ms or less ( at 24V DC)

ON

→→→→

1.5 ms or less ( at 24V DC)

OFF

→→→→

1 point/1 common (Mutually exclusive output)

0.075mm

0.035mm

5.3 Ou tput specifications

Item Specification

Output method

Number of output

Isolation method

Rate d load voltage

Operating load voltage

range

Max. load current

Max. inrush current

Leakage current a t OFF

Number of

times of

sweep

10 times

in each of

−

X, Y and Z

directions

(for 80

min)

−

Max. voltage drop at ON

Response

time

OFF

ON

Surge suppression

Common wiring method

Internal protection for

outputs

5.4 Performance specifications

Item Specification

Vol ta ge

Module

power

supply

Number of stations

occupied

Current

consumption

Initial current

Max. allowable

momentary power

failure period

Noise dur ability

Withstand voltage

Isolation resistance

Protection class

I/O part connection method

Module installation method

Flat cable for I/O (wire

diameter)

Mass (weight)

Transistor output

(using module power supply in common) (source)

1 point

Isolation with photocoupler

24V DC

Same as module power supply

0.1A/point 0.2 A/1 common

0.4A/10 ms

0.1mA or less/30V DC

1V or less (max.)/0.1A

1.0ms or less

ON

→→→→

1.0ms or less

OFF

→→→→

Zener diode

1 point/1 common (Mutually exclusive output)

Internal protecti on circuit none

Please connect the fuse in the conn ected load

outside.

20.4 to 28.8V DC (24V DC -15% to +20%)

Ripple ratio: Within 5%

40mA (when all p oints are ON)

(Current consumption contains neither t he input

current nor the load current.)

70mA

PS1:1ms

4-, 8- or 16-point mode: 1 station

500Vp-p

Noise width: 1µs Cycle: 25 to 60 Hz

(by noise simulator)

500V AC for 1 min

10 MΩ or more between primar y area (external

DC terminal) and second ary area (internal circuit)

by 500V DC megger

IP2X

Connection with cable

Can be installed in six directions

AWG18 (34/0.18)

0.07 kg (0.15 lbs )

(including 500mm (19.69") f lat cable dedicated to

CC-Link/LT and 500mm (19.69") flat cable for I/O)

6. Outside Dimensions

20(0.79")

12(0.48")

500(19.69")

65(2.56")500(19.69")

Unit: mm(inches)

24G X0 Y0

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be the

cause of Mitsubishi; machine damage or lost profits caused by faults in the Mitsubishi

products; damage, secondary damage, accident compensation caused by special

factors unpredict able by Mitsubishi ; damages to pro ducts other th an Mitsubishi

products; and to other duties.

For safe use

• This product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in a

device or system used in purposes related to human life.

• Before using the product for special purposes such as nuclear power, electric power,

aerospace, medicine or passenger movement vehicles, consult with Mitsubishi.

• This product has been manufactured under strict quality control. However when

installing the product where major accidents or losses could occur if the product

fails, install appropriate backup or failsafe functions in the system.

Country/Region Sates office/Tel

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessor ia

Tecnica Ltda.

Av. Rio Branco, 123-15 ,and S/1507,

Rio de Janeiro, RJ CEP 20040-005,

Brazil

Tel : +55-21-221-8343

Germa ny Mitsubis hi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Her ts., AL10

8XB, UK

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo - Ingr.2

Via Paracelso 12, 20041 Agrate B.,

Milano, Italy

Tel:+39-039-60531

Spain M itsubishi Electric Europe B.V. Spanish

BranchCarretera de Rubi 76-80

08190 - Sant Cugat del Valles,

Barcelona, Spain

Tel:+34-935-653135

South Africa

Circuit Breaker Industries LTD.

Private Bag 2016, Isando 1600,

Johannesburg, South Africa

Tel : +27-11-928-2000

Hong Kong Ryoden Automation Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, HongKong

Tel : +852-2887-8870

HEAD OFFICE : MITSUBISHI DENKI BLDG MARUNOUTI TOKYO 100-8310 TELEX:J24532 CABLE MELCO TOKYO

HIMEJI WORKS : 840, CH IYODA CHO, HIMEJI, JAPAN

When exported from Japan, this manual does not require application to the Ministry of Economy,

Trade and Industry for service transaction permission.

+24V

Country/Region Sates office/Tel

China Ryoden International Shanghai Ltd.

3F Block5 Building Automation

Instrumentatio n Plaza 103 Cao Bao Rd.

Shanghai 200233 China

Tel : +86-21-6475-3228

Taiwan Setsuyo Enterprise Co., Ltd.

6F., No.105 Wu-Kung 3rd.RD, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea HAN NEUNG TECHNO CO.,LTD.

1F Dong Seo Game Channel Bldg.,

660-11, Deungchon-dong Kangsec-ku,

Seoul, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 ALEXANDRA ROAD #05-01/02,

MITSUBISHI ELECTRIC BUILDING

SINGAPORE159943

Tel : +65-473-2480

Thailand F. A. Tech Co.,Ltd.

898/28,29,30 S.V.City Building,Office

Tower 2,Floor 17-18 Rama 3 Road,

Bangkpongpang, Yannawa,

Bangkok 10120

Tel : +66-2-682-6522

Indonesia P.T. Autoteknindo SUMBER MAKMUR

Jl. Muara Karang Selatan BlockA Utara

No.1 Kav. No.11 KawasanIndustri/

PergudanganJakarta - Utara 14440

Tel : +62-21-663-0833

India Messung Systems Put,Ltd.

Electronic Sadan NO:111 Unit No15,

M.I.D.C BHOSARI,PUNE-411026

Tel : +91-20-7128927

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, PostalBag, No 2,

Rydalmere, N.S.W 2116, Australia

Tel : +61-2-9684-7777

Specifications are subject to change without notice

Page 3

Side

Sensor

Connector dedicated

to CC-Link/LT

(sold separately)

Switches

X0 input operation

indicator LED

Y0 output operation

indicator LED

0

0

Crimp-style connection device with

insulator or closed end connection

device

Sensor,

switch, etc.

Crimp-style connection device with

insulator or closed end connection

device

Lamp,

solenoid, etc.

Input

equipment

Connector dedicated to CC-Link/LT

Output

equipment

Wire diameter: AWG18 (34/0.18)

30mm(1.19") 30mm(1.19")

B

Side

A

JAPANESE ENGLISH

Side

B

CL1XY2-DTE1D5S

CC-Link/LT Remote I/O Module

Please read this manual thoroughly before star ting to use the product and

handle the product properly.

User’s Manual

MODEL CL1XY2-DTE1D5S

MANUAL Number JY997D06301A

Date NOVEMBER 2002

SAFETY PRECAUTIONS

●●●●

Please read this m anual carefully a nd pay special atten tion to safely in order

to handle this produc t properly. Also pay careful attention t o safely and handle

the module properly.

These precautions apply onl y to Mitsubishi equipment. Refer to th e user’s

manual of the CPU mo dule to use for a descr iption of the PLC system safety

precautions.

These ●SAFETY PRECAUTIONS● classify the safety precautions into two

categories: "DANGER" and "CAUTION".

DANGER

CAUTION

Depending on c ircumstances, procedures ind icated by

may also be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

[DESIGN PRECAUTIO NS]

• Configur e an interlock circuit in a sequence program so that the system

operates on the safety side usi ng the communication status information

in the event the data link falls into a communi cation problem.

Otherwise, erroneous outp ut and malfunction may result i n accidents.

• Remote input and output can not be switched ON or OFF when a

problem occurs in the remote I/O modules. Therefore build an exter nal

monitoring circuit that will monitor any input signa ls that could cause a

serious accident.

(Read these precautions before using )

Procedures which may lead to a dangerous c ondition

and cause death or serious injur y if not carried out

properly.

Procedures which may lead to a dangerous c ondition

and cause superficial to medium injur y, or physical

damage only, if not carried out properly.

DANGER

CAUTION

• Do not have control cables and communication ca bles bundled with or

placed near by the main c ircuit and/or power cables. Wire thos e cables

at least 100mm(3.94 inc h) away from the main circuit and/or p ower

cables. It may cause malfunction du e to noise interference.

• Use the m odule in the status in which any force is not applied on the

module, flat cables dedicated to CC-Link/LT and flat cables for I/O.

If a force is applied, wire break age or failure may be caused.

[INSTALLATION PRECAUTIONS]

CAUTION

• Use t he module in an environment that meets the general specifications

contained in this manual . Using this module in an environment outside

the range of the general specifications could result in electric shock, fire,

erroneous operation, and damage to or deterio ration of the product.

• Do not directly touch the module 's conductive parts.Doing so could

cause malfunction or trouble in the module.

[WIRING PRE CAUTIONS]

• Perform installation an d wiring after disconne cting the power supply at

all phases externally. If the power is not disconnect ed at all phases an

electric shock or produ ct damage may result.

DANGER

●●●●

CAUTION

• Perform correct wiring for the modul e according to the product’s rated voltage

and terminal arrangement. Connecting to a power supply different from rating

or miss-wiring may cause f ire, product failure or malfunctio n.

• Make sure foreign objects do not get inside the module, such as dir t and wire

chips. It may cause fire, product failure or ma lfunction.

• Attach a warning label (hazar d symbol 417-IEC-5036) concerning the ele ctric

shock to the location.

[STARTING AND MAINTENANCE PRECAUTIONS]

• Do no t touch the terminals when the power is ON. It may cause a n electric

shock or malfunction.

• Perform cleaning th e module after tur ning OFF the all external power supply

for sure. Failure to do so may cause failure or malfunction of the modules.

DANGER

CAUTION

CAUTION

• Do no t disassemble or modify the module. Doing so may cause failure,

malfunction, injur y, or fire.

• The module case is made of resi n; do not drop it or subject it to strong shock.

A module damage may result.

• Make sure t o switch all phases of the exter nal power supply OFF before

installing or removing the mod ule to/from the pane l. Failure to do so may

cause failure or malfunction of th e modules.

[DISPOSAL PR ECAUTIONS]

• When d isposing of this produ ct, treat it as industri al waste.

DANGER

[TRANSPORTATION AND MAINTENANCE PRECAUTIONS]

CAUTION

• Dur ing transportation avoid any impact as the module is a precision

instrument. Doing so could cause trouble in the module.

• If is n ecessary to check the ope ration of module after t ransportation, in case

of any impact damage.

Notification of CE marking

This notification does not guarantee that an entire mechanical modul e produced

in accordance with the contents of the notification comply with the following

standards. C ompliance to EMC stand ards of the ent ire mechani cal module

should be checked by the user / ma nufacturer.

Standards with which this product complies

Type : Programmable Controller (Open Type Equipment) Remote I/O module

Models : Products manufactured from November 1st, 2002.

Electromagnetic Compat ibility Standards

EN61000-6-4:2001

Electromagnetic compatibilit y

-Generic standards - Emiss ion standard for

Industrial environment

EN61131-2:1994 Programmable controllers

/A11: 1996 -Equipment re quirements and

tests

/A12: 2000

For more details please conta ct the local Mitsubishi Ele ctric sales site.

- Notes For compliance to EMC re gulation.

It is necessary to install th e CL1 series module in a shielded metal control panel.

●●●●

(EMC)

●●●●

Remark

Compliance with all relevant

aspects of the standard. (Radiate d

Emissions and Mains Terminal

Voltage Emissions)

Compliance with all relevant

aspects of the standard. (RF

Immunity, Fast transients, ESD and

Damped oscillatory wave)

1. Outline of Product

This product is a cable typ e composite I/O module con nected to CC-Link/LT.

This product has one input point (24V DC) and one output point (transistor

output).

2. Name and Setting of Each Part

Flat cable dedicated

to CC-Link/LT

DIP switch

(Remove the switch cover

when setting the DIP switch.)

DIP switch assignment

40 20 10

ON

Status indicator LEDs

LED name

PW

L RUN

HLD

8

4 2 1

Operation

Lit while the

power is supplied.

Lit while normal

operation is

executed.

Blue

Black

White

Name Description

Status indicator

LED

I/O operation

indicator LED

Flat cable

dedicated to CCLink/LT

PW ON while the power is supplied.

L RUN ON while nor mal operation is executed.

ON while the input or output is ON.

Extinguished while the input or out put is OFF.

24G

DB

Connector for CC-Link/LT communication line/

module power supply

DA

+24V

Blue 24G

Flat cable for I/O

Black X0

White Y0

Brown +24V

Set the 10's digit of the station No. using "STATION NO. 10",

"STATION NO. 20" and "STATION NO. 40". Set the 1's digit of

the station No. using "STATION NO. 1", "STATION NO. 2",

"STATION NO. 4" and "STATION NO. 8".

Factory default = All bits are OFF.

DIP switch

Make sure to set the station No. in the range from 1 to 64.

Example: When setting the station No. to "32", set the

DIP switch as follows.

10's digit 1's digit

Station

No.

40 20 10 8 4 2 1

32 ONOFFONOFF ON OFF OFF

Switch cover

(Make sure to attach the

switch cover after setting

the DIP switch.)

Attach it with

this area facing

upward.

Input

operation

indicator

LED

Input/output is ON: Lit

Input/output is OFF: Extinguished

Flat cable for I/O

Brown

Output

operation

indicator

LED

Name Description

DIP switch HLD

Holds the output (w hen an error has occurred).

ON: Holds the outp ut.

OFF: Clears the output.

3. Cautions on Handling

3.1 Handling of flat cable for I/O

The cable length from the module to a sensor shall be within 3m(9'10").

Measure the cable outside the mod ule, and confirm that the dr iving voltage

for the used sensor is assur ed.

• Inp ut

• Outpu t

If the diameter of the I/O equipment connection cable is equivalent to the

diameter of the flat cable for I/O of this module, connectors dedicated to

CC-Link/LT can be used for connection.

3.2 Handling of cable

Do not bend the cable within 3 0mm(1.19") from the module.

Use a crimp-style terminal in a status in which no force is applied on the

cable.

4. Connection to External Equipment

4.1 External wiring

The input and output terminals of the CL1XY2-DTE1D5S operate while

using the power supplied from the interface.

When connecting a sensor to the input terminal, use a sensor of the PNP

open collector transistor t ype.

The output wiring is fixed to the sink output.

I/O wiring

CL1XY2-DTE1D5S

Flat cable

dedicated

to CC-Link/LT

+24V

DA

DB

24G

4.2 Connection to s ensor

• When using a two-wire type sensor!When using a three-wire type sensor

+24

X *

Bleeder

resistor *1

Replace * in the figure with the used input No.

Notes:

*1 Bleeder resistor

When connecting a two-wire type sensor or input equipment containing a

parallel resistor, select a sensor or equipment whose leakage current is

1.7mA or less.

If the leakage current is more than 1.7mA, connect a bleeder resistor

obtained in the following calculation formula.

Circuit image

R(kΩ) < 1.7(mA) / Leakage current(mA) - 1.7( mA) x 5.6(kΩ)

The power capacity W of the bleeder resistor R is as follows:

W = (Input voltage)

• Make sure that both the ON and OFF time of the input s ignal are 1.5ms or

more.

Sensor (PNP) Sensor (PNP)

Connected to 24G cable Connected to 24G cable

Sensor(PNP)

Detection

circuit

24V DC

Isolation

DC DC

Internal

circuit

Detection

circuit

Leakage

Unit

current

R

2

/R

R

R

R

+24

X *

Input impedance

5.6 kΩ

1.7 mA or less

R: Bleeder resistor

Flat cable

for I/O

+24V

Detection

circuit

Y0

X0

24G

0.5A

0.5A

5. Specifications

5.1 General specifications

Item Specification

Ambient

workin g

temperature

Ambient storage

temperature

Ambient

operating

humidity

Ambient storage

humidity

L

Vibration

resistance

Impact

resistance

Operating

atmosphere

Operating

altitude

Installation

place

Over-voltage

category

Degree of

contamination

Notes:

*1 The ambient operating/storage temperature satisfies the requirements beyond

the specification in the JIS B3502 and the IEC61131-2.

*2 The module cannot be used in an environment pressurized above the

atmospheric pressur e which can be generated arou nd the altitude of 0 m. If the

module is used in such an environmen t, it may fail.

*3 The module can be used in any enviro nment even outside the control panel as

far as the requir ements of the ambient op erating temp erature, the a mbient

operating humidity, etc. are satisfied.

*4 This indicates the section of the power supply to which the equipment is

assumed to be connected between the public electrical power distribution

network and the machinery within premises. Category II applies to equipment

for which electrical power is supplied from fixed facilities.

The surge voltage withstand level for up to the rated voltage of 300V is 2500V.

*5 This index indicates th e degree of conductive generating subst ances in the

environment in which the module is used. The degree of contamination 2

indicates that contamination is caused by generation of only non-conductive

substances.

In this degree, however, temporary conduction may be caused by accidental

condensation.

5.2 Input specifications

Input method

Number of input

Isolation method

Rated inpu t voltage

Rated inpu t curren t

Operating voltage range

Max. simultaneous ON

input points

ON voltage/ON current

OFF voltage/OFF current

Input resistance

Response

time

Common wiring method

0 to 55°C (32 to 131°F) (*1)

-25 to 75°C (-13 to 167°F) (*1)

Conforming to JIS B3502 and IEC61 131-2, Level RH-2

(5 to 95%RH: Dew condensation shall not be considered.)

Conforming to JIS B3502 and IEC61 131-2, Level RH-2

(5 to 95%RH: Dew condensation shall not be considered.)

When intermittent vib ration is present

Frequency

Conforming

to JIS

B3502 and

IEC61131-2

Conforming to JIS B3502 and IEC61 131-2

2

, 3 times in each of X, Y and Z directions)

(147 m/s

Acceleration Half amplitude

10 to 57Hz

57 to 150Hz

9.8m/s

−

2

When continuous vibration is present

Acceleration Half amplitude

Frequency

10 to 57Hz

57 to 150Hz

4.9m/s

−

2

Corrosive gas shall not be present.

Conforming to JIS B3502 and IEC61 131-2

(2,000m(6561'8") or less)(*2)

Inside control panel (*3)

Conforming to JIS B3502 and IEC61 131-2

(Category ΙΙ or less)(*4)

Conforming to JIS B 3502 and IEC61131- 2, Degree of

contamination 2 or less (*5)

Item Specification

DC input (using module power supply in comm on)

EN61131-2, Section3.3.1.2-Type1

1 point

Isolation with photocoupler

24V DC

Approx. 4 mA

Same as module power supply

100% (at 24V DC)

19 V or more/3 mA or more

11 V or less/1.7 mA or less

5.6 k

Ω

OFF

ON

1.5 ms or less ( at 24V DC)

ON

→→→→

1.5 ms or less ( at 24V DC)

OFF

→→→→

1 point/1 common (Mutually exclusive output)

0.075mm

0.035mm

5.3 Ou tput specifications

Item Specification

Output method

Number of output

Isolation method

Rate d load voltage

Operating load voltage

range

Max. load current

Max. inrush current

Leakage current a t OFF

Number of

times of

sweep

10 times

in each of

−

X, Y and Z

directions

(for 80

min)

−

Max. voltage drop at ON

Response

time

OFF

ON

Surge suppression

Common wiring method

Internal protection for

outputs

5.4 Performance specifications

Item Specification

Vol ta ge

Module

power

supply

Number of stations

occupied

Current

consumption

Initial current

Max. allowable

momentary power

failure period

Noise dur ability

Withstand voltage

Isolation resistance

Protection class

I/O part connection method

Module installation method

Flat cable for I/O (wire

diameter)

Mass (weight)

Transistor output

(using module power supply in common) (source)

1 point

Isolation with photocoupler

24V DC

Same as module power supply

0.1A/point 0.2 A/1 common

0.4A/10 ms

0.1mA or less/30V DC

1V or less (max.)/0.1A

1.0ms or less

ON

→→→→

1.0ms or less

OFF

→→→→

Zener diode

1 point/1 common (Mutually exclusive output)

Internal protecti on circuit none

Please connect the fuse in the conn ected load

outside.

20.4 to 28.8V DC (24V DC -15% to +20%)

Ripple ratio: Within 5%

40mA (when all p oints are ON)

(Current consumption contains neither t he input

current nor the load current.)

70mA

PS1:1ms

4-, 8- or 16-point mode: 1 station

500Vp-p

Noise width: 1µs Cycle: 25 to 60 Hz

(by noise simulator)

500V AC for 1 min

10 MΩ or more between primar y area (external

DC terminal) and second ary area (internal circuit)

by 500V DC megger

IP2X

Connection with cable

Can be installed in six directions

AWG18 (34/0.18)

0.07 kg (0.15 lbs )

(including 500mm (19.69") f lat cable dedicated to

CC-Link/LT and 500mm (19.69") flat cable for I/O)

6. Outside Dimensions

20(0.79")

12(0.48")

500(19.69")

65(2.56")500(19.69")

Unit: mm(inches)

24G X0 Y0

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be the

cause of Mitsubishi; machine damage or lost profits caused by faults in the Mitsubishi

products; damage, secondary damage, accident compensation caused by special

factors unpredict able by Mitsubishi ; damages to pro ducts other th an Mitsubishi

products; and to other duties.

For safe use

• This product has been manufactured as a general-purpose part for general

industries, and has not been designed or manufactured to be incorporated in a

device or system used in purposes related to human life.

• Before using the product for special purposes such as nuclear power, electric power,

aerospace, medicine or passenger movement vehicles, consult with Mitsubishi.

• This product has been manufactured under strict quality control. However when

installing the product where major accidents or losses could occur if the product

fails, install appropriate backup or failsafe functions in the system.

Country/Region Sates office/Tel

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessor ia

Tecnica Ltda.

Av. Rio Branco, 123-15 ,and S/1507,

Rio de Janeiro, RJ CEP 20040-005,

Brazil

Tel : +55-21-221-8343

Germa ny Mitsubis hi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Her ts., AL10

8XB, UK

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo - Ingr.2

Via Paracelso 12, 20041 Agrate B.,

Milano, Italy

Tel:+39-039-60531

Spain M itsubishi Electric Europe B.V. Spanish

BranchCarretera de Rubi 76-80

08190 - Sant Cugat del Valles,

Barcelona, Spain

Tel:+34-935-653135

South Africa

Circuit Breaker Industries LTD.

Private Bag 2016, Isando 1600,

Johannesburg, South Africa

Tel : +27-11-928-2000

Hong Kong Ryoden Automation Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, HongKong

Tel : +852-2887-8870

HEAD OFFICE : MITSUBISHI DENKI BLDG MARUNOUTI TOKYO 100-8310 TELEX:J24532 CABLE MELCO TOKYO

HIMEJI WORKS : 840, CH IYODA CHO, HIMEJI, JAPAN

When exported from Japan, this manual does not require application to the Ministry of Economy,

Trade and Industry for service transaction permission.

+24V

Country/Region Sates office/Tel

China Ryoden International Shanghai Ltd.

3F Block5 Building Automation

Instrumentatio n Plaza 103 Cao Bao Rd.

Shanghai 200233 China

Tel : +86-21-6475-3228

Taiwan Setsuyo Enterprise Co., Ltd.

6F., No.105 Wu-Kung 3rd.RD, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea HAN NEUNG TECHNO CO.,LTD.

1F Dong Seo Game Channel Bldg.,

660-11, Deungchon-dong Kangsec-ku,

Seoul, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 ALEXANDRA ROAD #05-01/02,

MITSUBISHI ELECTRIC BUILDING

SINGAPORE159943

Tel : +65-473-2480

Thailand F. A. Tech Co.,Ltd.

898/28,29,30 S.V.City Building,Office

Tower 2,Floor 17-18 Rama 3 Road,

Bangkpongpang, Yannawa,

Bangkok 10120

Tel : +66-2-682-6522

Indonesia P.T. Autoteknindo SUMBER MAKMUR

Jl. Muara Karang Selatan BlockA Utara

No.1 Kav. No.11 KawasanIndustri/

PergudanganJakarta - Utara 14440

Tel : +62-21-663-0833

India Messung Systems Put,Ltd.

Electronic Sadan NO:111 Unit No15,

M.I.D.C BHOSARI,PUNE-411026

Tel : +91-20-7128927

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, PostalBag, No 2,

Rydalmere, N.S.W 2116, Australia

Tel : +61-2-9684-7777

Specifications are subject to change without notice

Loading...

Loading...