Mitsubishi Electric City Multi PURY-EP-YJM-A, City Multi PURY-EP-YJM-A-BS, City Multi PURY-P-YJM-A, City Multi PURY-P-YJM-A-BS Installation Manual

GBPO HG SV CZ TR RU GR P NL I E F DSLRO BG HR SW

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

MANUAL DE INSTALAÇÃO

Para segurança e utilização correctas, leia atentamente este manual de instalação antes de instalar a unidade de ar condicionado.

ΕΓΧΕΙΡΙΔΙΟ ΟΔΗΓΙΩΝ ΕΓΚΑΤΑΣΤΑΣΗΣ

Για ασφάλεια και σωστή χρήση, παρακαλείστε διαβάσετε προσεχτικά αυτό το εγχειρίδιο εγκατάστασης πριν αρχίσετε την εγκατάσταση της μονάδας

κλιματισμού.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по установке до

выполнения установки кондиционера.

MONTAJ ELKİTABI

Emniyetli ve doğru biçimde nasıl kullanılacağını öğrenmek için lütfen klima cihazını monte etmeden önce bu elkitabını dikkatle okuyunuz.

安装手册

为了安全和正确地使用本空调器,请在安装前仔细阅读本安装手册。

PŘÍRUČKA K INSTALACI

V zájmu bezpečného a správného používání si před instalací klimatizační jednotky důkladně pročtěte tuto příručku k instalaci.

NÁVOD NA INŠTALÁCIU

Pre bezpečné a správne použitie si pred inštalovaním klimatizačnej jednotky, prosím, starostlivo prečítajte tento návod na inštaláciu.

TELEPÍTÉSI KÉZIKÖNYV

A biztonságos és helyes használathoz, kérjük, olvassa el alaposan ezt a telepítési kézikönyvet, mielőtt telepítené a légkondicionáló egységet.

PODRĘCZNIK INSTALACJI

W celu bezpiecznego i poprawnego korzystania należy przed zainstalowaniem klimatyzatora dokładnie zapoznać się z niniejszym podręcznikiem

instalacji.

PRIROČNIK ZA NAMESTITEV

Za varno in pravilno uporabo pred namestitvijo klimatske naprave skrbno preberite priročnik za namestitev.

INSTALLATIONSHANDBOK

Läs den här installationshandboken noga innan luftkonditioneringsenheten installeras, för säker och korrekt användning.

PRIRUČNIK ZA UGRADNJU

Radi sigurne i ispravne uporabe, temeljito pročitajte ovaj priručnik prije ugradnje klimatizacijskog uređaja.

РЪКОВОДСТВО ЗА МОНТАЖ

За безопасна и правилна употреба, моля, прочетете внимателно това ръководство преди монтажа на климатизатора.

MANUAL CU INSTRUCŢIUNI DE INSTALARE

Pentru o utilizare corectă şi sigură, vă rugăm să citiţi cu atenţie acest manual înainte de a instala unitatea de aer condiţionat.

Air-Conditioners For Building Application

OUTDOOR UNIT

PURY-P-YJM-A (-BS)

PURY-EP-YJM-A (-BS)

For use with R410A

2

6

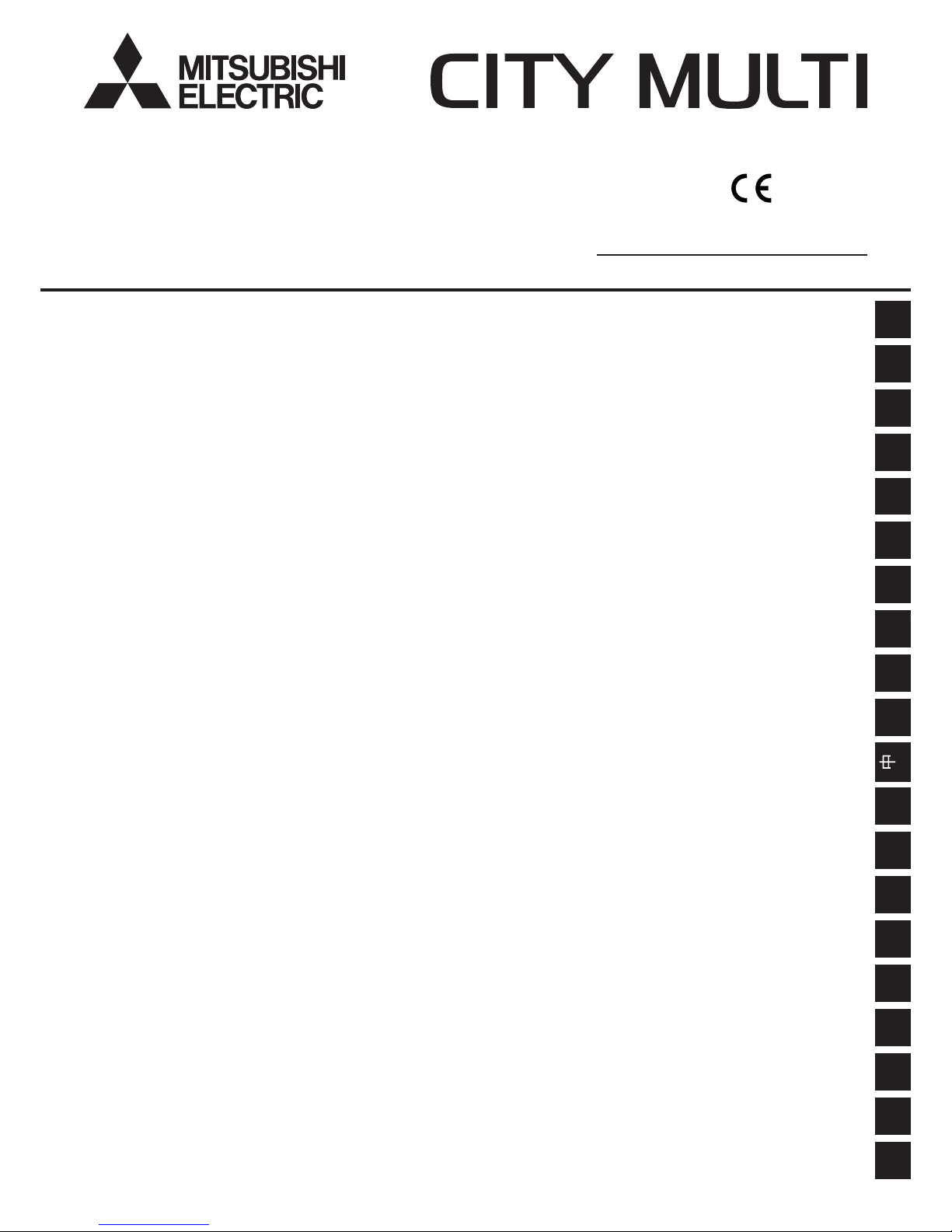

[Fig. 6.0.1]

(1)

15

*

15

*

450

*

300

*

<A>

A

(2)

100

*

450

*

50

*

50

*

<A>

A

(3)

A

B

<B>

500

H

h

h

H

(4)

240

45°

A

D

C

50

<C>

1000

(mm)

[Fig. 6.0.2]

30

450

*

300

*

C

BB

C

A

100

450

*

100

*

BB

C

C

A

450

*

100*

CC

B

A

A

A

B

450 450

15

*

C

AAA

450 450

900

300

*

300

*

BB

C

C

A

1000

*

900 300

*

B

B

C

A

(mm)

<A> Top view

<B> Side view

<C> When there is little space up to an obstruction

A:

Front

B:

Unit height

C:

Back

D:

Air outlet guide (Procured at the site)

A:

Front

B:

Must be open

C:

Wall height (H)

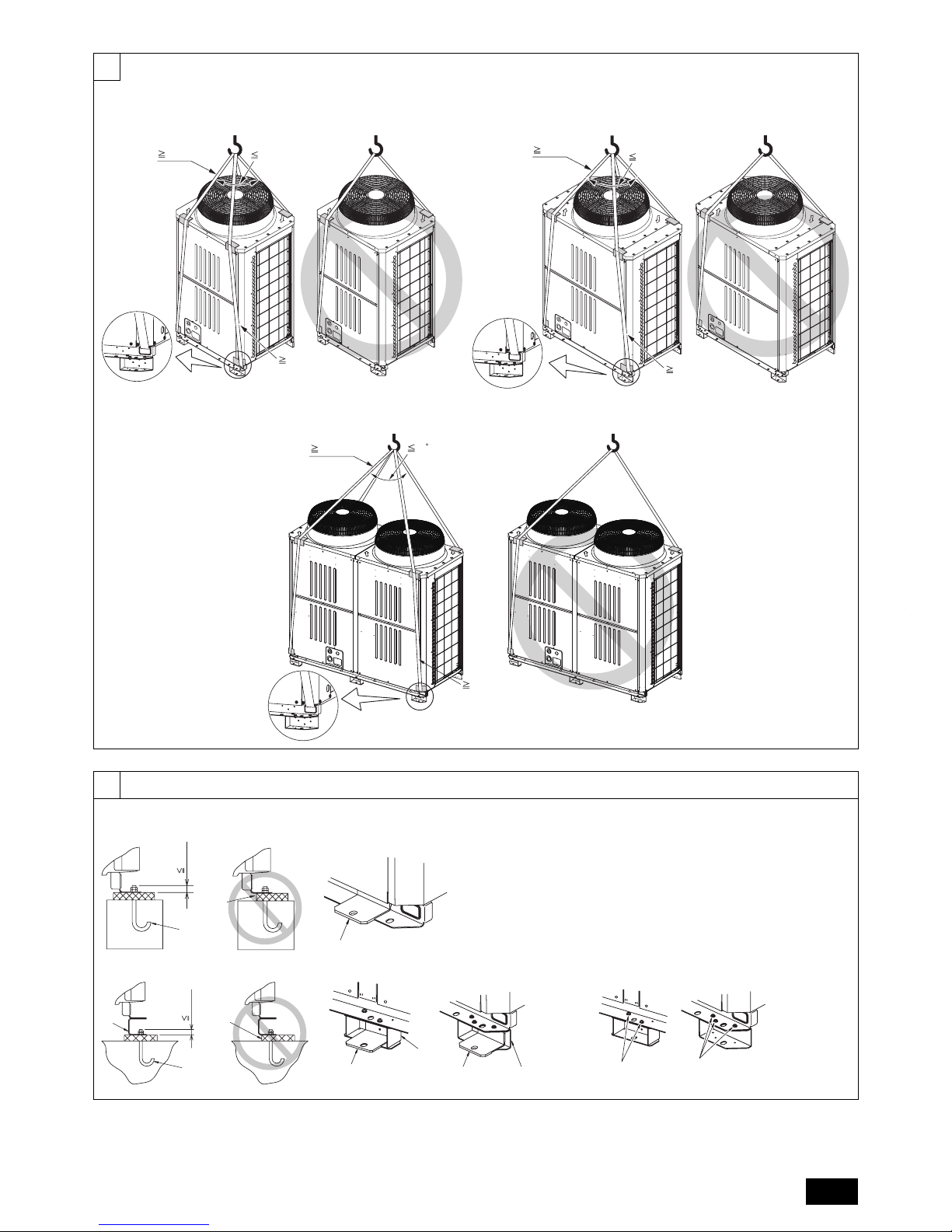

3

8

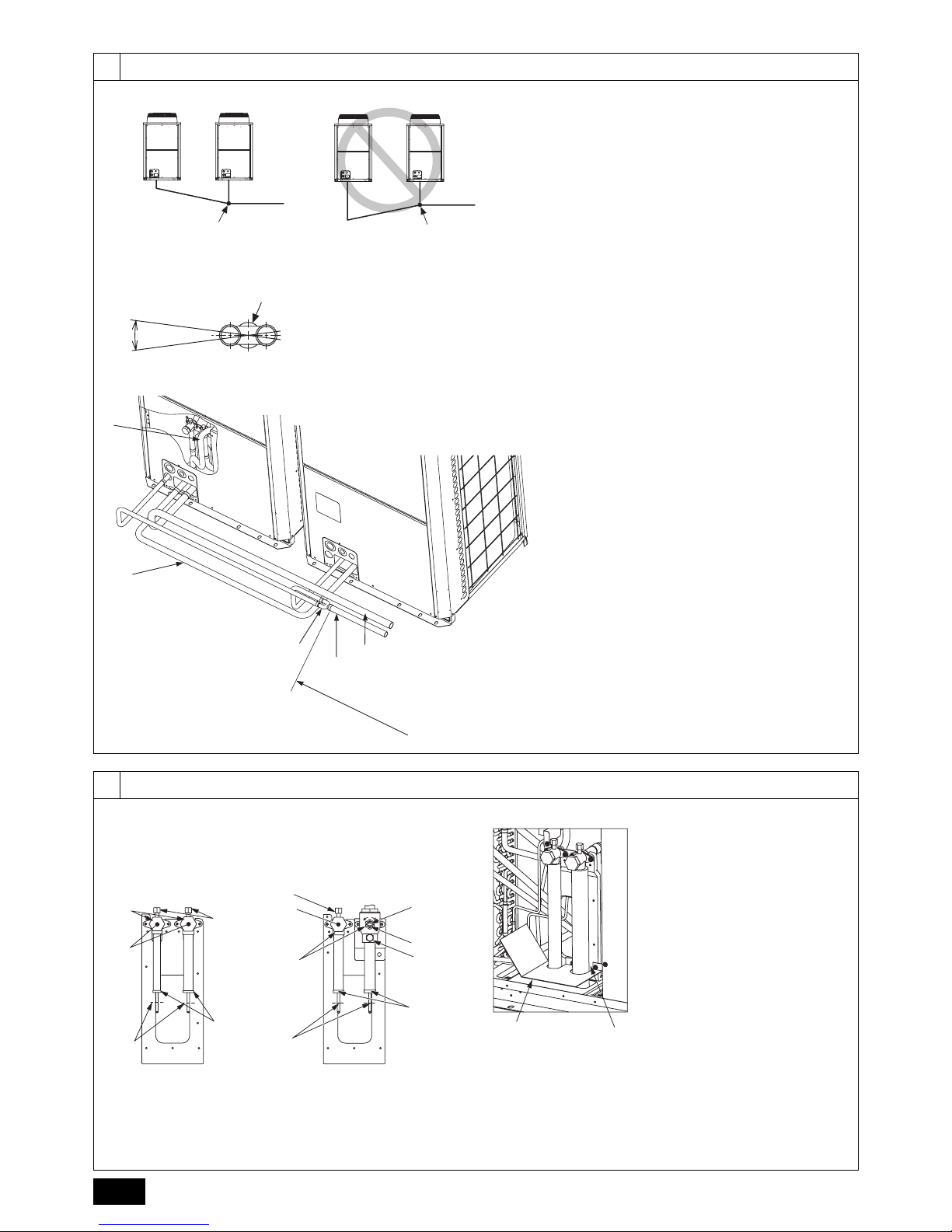

8.1

[Fig. 8.1.1]

<A> Without detachable leg

30mm

A

B

C

<B> With detachable leg [Fig. 8.1.2]

30mm

A

D

B

CD

D

C

A

A

A:

M10 anchor bolt procured at the site.

B:

Corner is not seated.

C:

Fixing bracket for hole-in anchor bolt (3 locations to fi x with screws).

D:

Detachable leg

A:

Screws

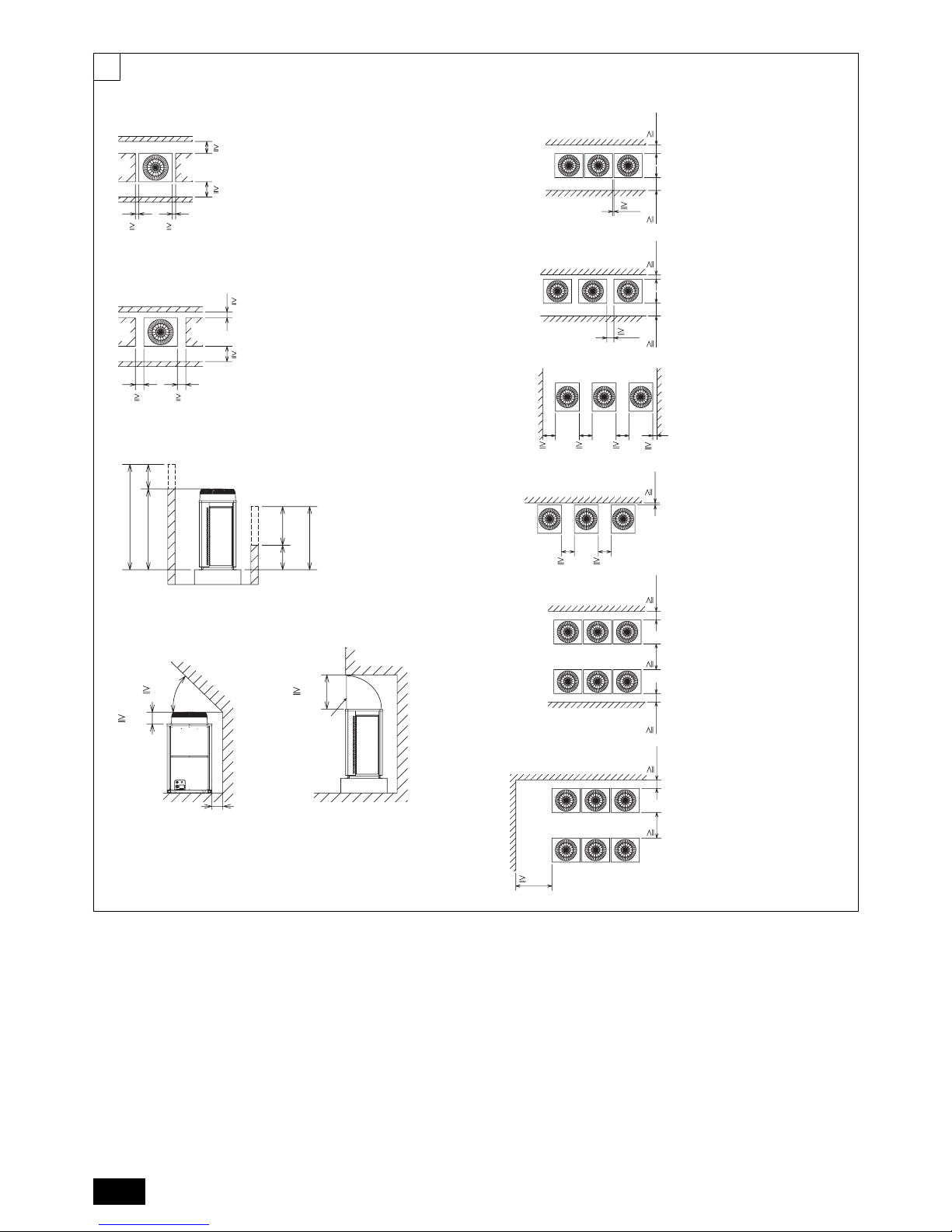

7

8m

8m

40°

[Fig. 7.0.1]

1 P200 ~ P300

EP200

8m

40°

8m

2 P350 ~ P400

EP250 ~ EP300

8m

8m

40

3 P450

EP350

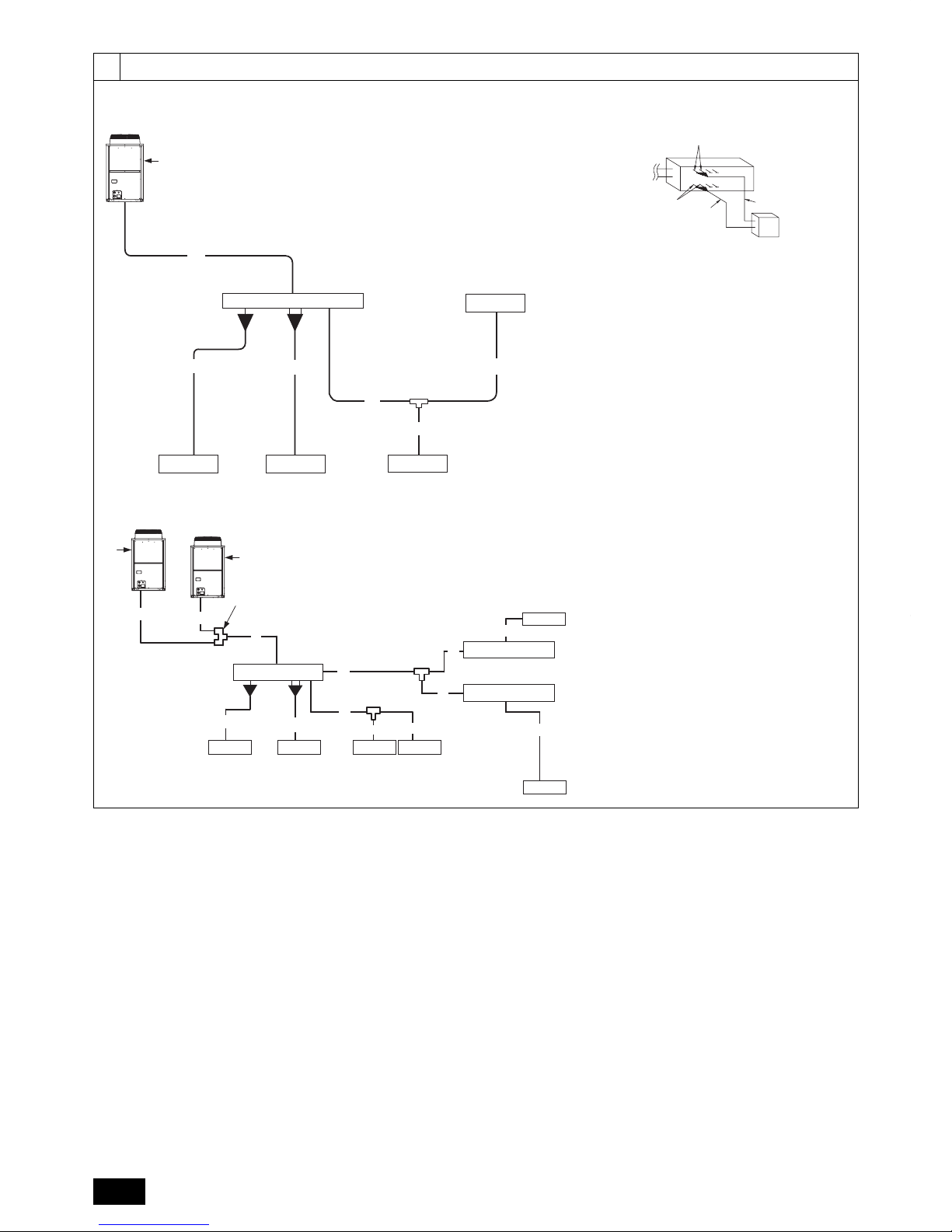

4

9

9.2

[Fig. 9.2.1]

[P200 ~ P450YJM]

[EP200 ~ EP350YJM]

B

A

a

b

c

d

A

BC

EF E

E

(*Note1)

g

i

j

h

BCD

E

[P400 ~ P900YSJM]

[EP400 ~ EP700YSJM]

a

C

b

B

c d

f

D

E

A

e

A1

unit1

unit2

A2

A

G

C

EEE

D

E

D

E

F

A

*

NOTE1

A:

Outdoor unit

B:

BC controller (standard)

C:

BC controller (main)

D:

BC controller (sub)

E:

Indoor unit (15 ~ 80)

F:

Indoor unit (100 ~ 250)

G:

Outdoor twinning kit

5

9

9.2

A [Standard]

Outdoor model

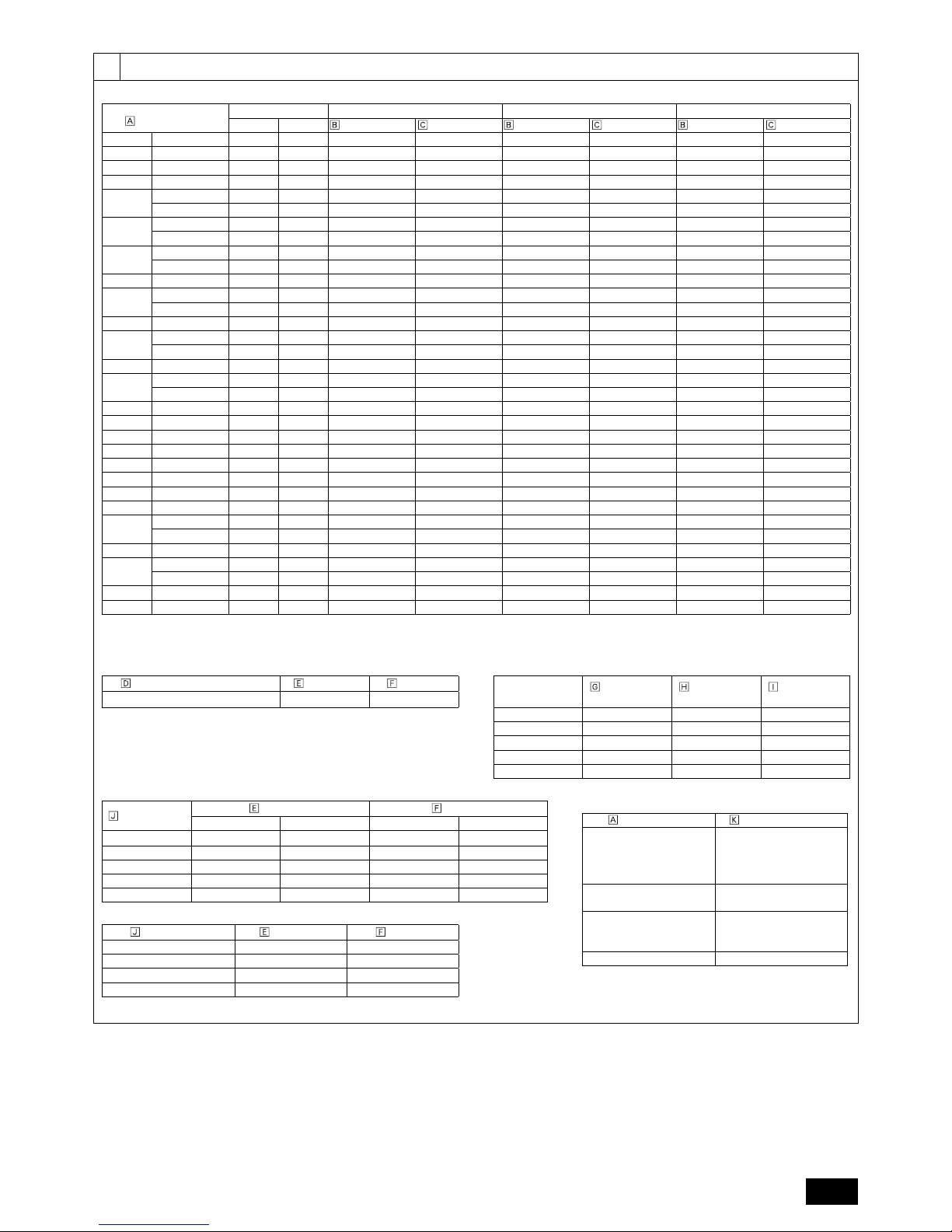

Unit combination A A1 *1 A2 *1

Unit 1 Unit 2

High-pressure side Low-pressure side High-pressure side Low-pressure side High-pressure side Low-pressure side

P200 YJM-A - - ø15.88 ø19.05 - - - P250 YJM-A - - ø19.05 ø22.2 - - - P300 YJM-A - - ø19.05 ø22.2 - - - P350 YJM-A - - ø19.05 ø28.58 - - - P400 YJM-A - - ø22.2 ø28.58 - - - -

YSJM-A1 P200 P200 ø22.2 ø28.58 ø15.88 ø19.05 ø15.88 ø19.05

P450 YJM-A - - ø22.2 ø28.58 - - - -

YSJM-A1 P250 P200 ø22.2 ø28.58 ø19.05 ø22.2 ø15.88 ø19.05

P500 YSJM-A P250 P250 ø22.2 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

YSJM-A1 P300 P200 ø22.2 ø28.58 ø19.05 ø22.2 ø15.88 ø19.05

P550 YSJM-A P300 P250 ø28.58 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

P600 YSJM-A P300 P300 ø28.58 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

YSJM-A1 P350 P250 ø28.58 ø28.58 ø19.05 ø28.58 ø19.05 ø22.2

P650 YSJM-A P350 P300 ø28.58 ø28.58 ø19.05 ø28.58 ø19.05 ø22.2

P700 YSJM-A P400 P300 ø28.58 ø34.93 ø22.2 ø28.58 ø19.05 ø22.2

YSJM-A1 P350 P350 ø28.58 ø34.93 ø19.05 ø28.58 ø19.05 ø28.58

P750 YSJM-A P400 P350 ø28.58 ø34.93 ø22.2 ø28.58 ø19.05 ø28.58

P800 YSJM-A P400 P400 ø28.58 ø34.93 ø22.2 ø28.58 ø22.2 ø28.58

YSJM-A1 P450 P350 ø28.58 ø34.93 ø22.2 ø28.58 ø19.05 ø28.58

P850 YSJM-A P450 P400 ø28.58 ø41.28 ø22.2 ø28.58 ø22.2 ø28.58

P900 YSJM-A P450 P450 ø28.58 ø41.28 ø22.2 ø28.58 ø22.2 ø28.58

EP200 YJM-A - - ø15.88 ø19.05 - - - EP250 YJM-A - - ø19.05 ø22.2 - - - EP300 YJM-A - - ø19.05 ø22.2 - - - EP350 YJM-A - - ø19.05 ø28.58 - - - EP400 YSJM-A EP200 EP200 ø22.2 ø28.58 ø15.88 ø19.05 ø15.88 ø19.05

EP450 YSJM-A EP250 EP200 ø22.2 ø28.58 ø19.05 ø22.2 ø15.88 ø19.05

EP500 YSJM-A EP300 EP200 ø22.2 ø28.58 ø19.05 ø22.2 ø15.88 ø19.05

YSJM-A1 EP250 EP250 ø22.2 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

EP550 YSJM-A EP300 EP250 ø28.58 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

EP600 YSJM-A EP300 EP300 ø28.58 ø28.58 ø19.05 ø22.2 ø19.05 ø22.2

YSJM-A1 EP350 EP250 ø28.58 ø28.58 ø19.05 ø28.58 ø19.05 ø22.2

EP650 YSJM-A EP350 EP300 ø28.58 ø28.58 ø19.05 ø28.58 ø19.05 ø22.2

EP700 YSJM-A EP350 EP350 ø28.58 ø34.93 ø19.05 ø28.58 ø19.05 ø28.58

*1 The pipe sizes listed in columns A1 to A2 in this table correspond to the sizes for the models listed in the unit 1 and 2 columns. When the order of unit 1 and 2 is

changed, make sure to use the appropriate pipe size for the model.

B (mm) C, D, E (mm)

Total capacity of indoor units

Liquid pipe Gas pipe

Downstream unit

model total

High-pressure

gas pipe

Low-pressure

gas pipe

Liquid pipe

~ 80

ø9.52 ø15.88

~ 200 ø15.88 ø19.05 ø9.52

201 ~ 300 ø19.05 ø22.2 ø9.52

301 ~ 350 ø19.05 ø28.58 ø12.7

351 ~ 400 ø22.2 ø28.58 ø12.7

401 ~ 450 ø22.2 ø28.58 ø15.88

g, h, i, j (mm)

Model number

Liquid pipe Gas pipe

gh i j

100 ø9.52 ø9.52 ø15.88 ø15.88

125 ø9.52 ø9.52 ø15.88 ø15.88

140 ø9.52 ø9.52 ø15.88 ø15.88

200 ø9.52 ø9.52 ø19.05 ø15.88

250 ø9.52 ø9.52 ø22.2 ø15.88

a, b, c, d, e, f (mm)

Model number

Liquid pipe Gas pipe

15, 20, 25, 32, 40, 50 ø6.35 ø12.7

63, 71, 80, 100, 125, 140 ø9.52 ø15.88

200 ø9.52 ø19.05

250 ø9.52 ø22.2

Outdoor model

Outdoor twinning kit

P500 ~ P650YSJM-A

P400 ~ P600YSJM-A1

EP400 ~ EP600YSJM-A

EP500YSJM-A1

CMY-R100VBK

P700 ~ P800YSJM-A

P700YSJM-A1

CMY-R200VBK

P800YSJM-A1

EP650, EP700YSJM-A

EP600YSJM-A1

CMY-R100XLVBK

P850, P900YSJM-A CMY-R200XLVBK

6

9

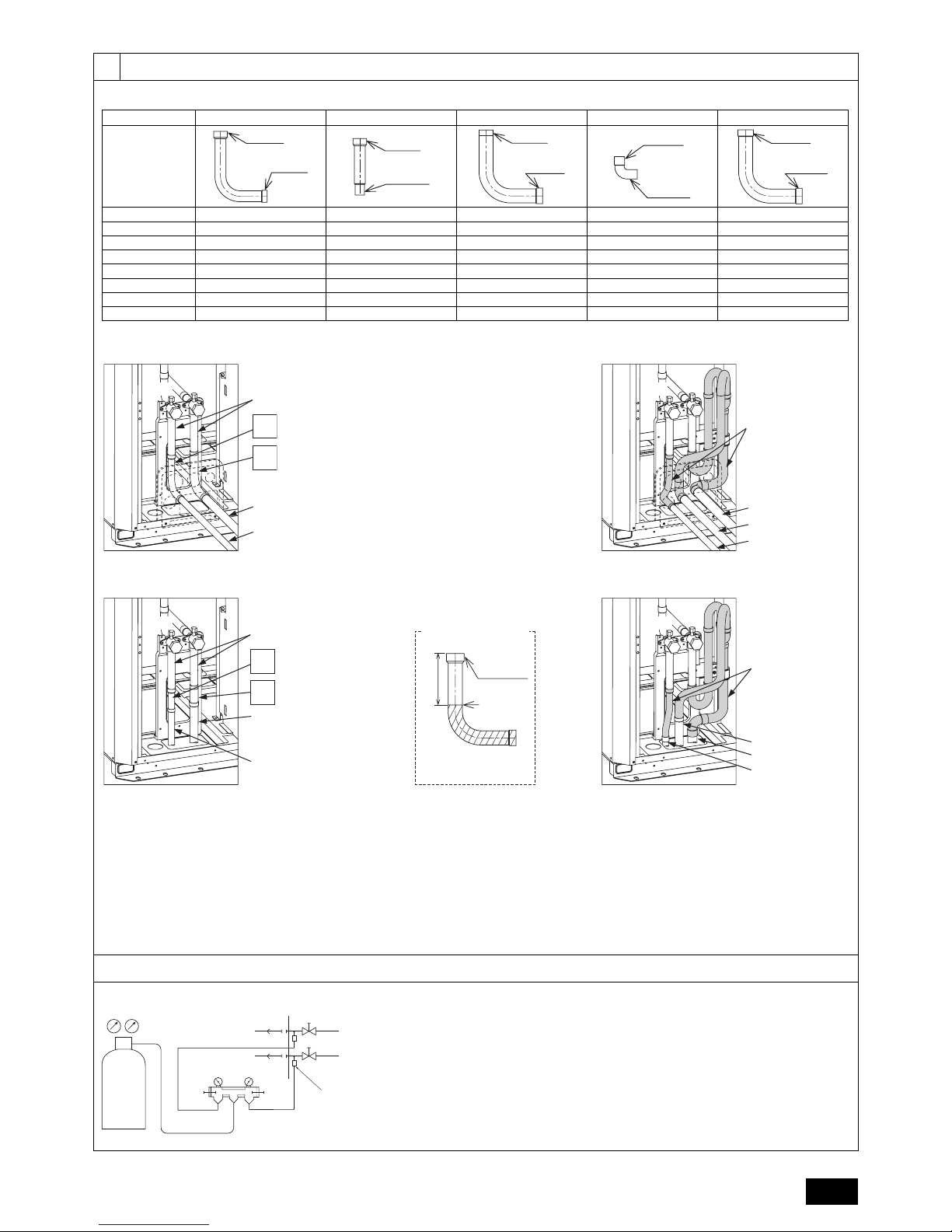

9.2

[Fig. 9.2.2]

A

C

D

B

C

D

<A> The piping from the outdoor units to twinning pipe must be made to slope downwards the twinning pipe. (high-pressure side only)

<B> Slope of twinning pipe (high pressure side only)

±15°

D

E

<C> Pipe connection example

F

H

G

J

K

I

A:

Downward slope

B:

Upward slope

C:

BC controller (standard or main)

D:

Twinning pipe

E:

Slope of the twinning pipe is at an angle within ±15° to the ground

F:

Twinning pipe (low-pressure side)

G:

Twinning pipe (high-pressure side)

H:

On-site piping (low-pressure connecting pipe: between outdoor units)

I:

On-site piping (low-pressure main pipe: to BC controller)

J:

On-site piping (high-pressure main pipe: to BC controller)

K:

Straight run of pipe that is 500 mm or more

10

10.2

[Fig. 10.2.1]

<A> Refrigerant service valve (High-pressure side/brazed type)

<B> Refrigerant service valve (Low-pressure side/brazed type)

A

E

D

G

F

<A>

<B>

S

O

F

G

E

A

<A>

<B>

D

C

D

B

P200~P400

EP200

~EP300

P450

EP350

A:

Shaft

B:

Shaft

C:

Stopper pin

D:

Service port

E:

Cap

F:

Pinched connecting pipe severing portion

G:

Pinched connecting pipe brazing portion

[Fig. 10.2.3]

A

B

A:

Example of closure materials (fi eld supply)

B:

Fill the gap at the site

* When not attaching a low-pressure twinning pipe.

7

10

10.2

[Fig. 10.2.2]

No.

12345

A Shape

ø22.2

ID ø25.4

ID ø22.2

OD ø19.05

ø22.2

ID ø25.4

ID ø28.58

ø28.58

ID ø25.4

ID ø19.05

OD ø19.05

OD ø28.58

ø28.58

ID ø28.58

P250YJM 1 <C> Low-pressure side - - - P300YJM 1 <C> Low-pressure side - - - P350YJM - 1 <D> High-pressure side 1 <C> Low-pressure side 1 <D> High-pressure side P400YJM 1 <D> High-pressure side - 1 <C> Low-pressure side - -

P450YJM 1 <D> High-pressure side - - - 1 <C> Low-pressure side

EP250YJM 1 <C> Low-pressure side 1 <D> High-pressure side - 1 <D> High-pressure side EP300YJM 1 <C> Low-pressure side 1 <D> High-pressure side - 1 <D> High-pressure side EP350YJM - 1 <D> High-pressure side - 1 <D> High-pressure side 1 <C> Low-pressure side

<A> Front pipe routing

B When not attaching a low-pressure twinning pipe

F

E

<C>

<D>

D

A

B

C When attaching a low-pressure twinning pipe *1,*2

G

H

I

F

<C>

<D>

<B> Bottom pipe routing

B When not attaching a low-pressure twinning pipe

D

E

F

<C>

<D>

C

D

*3

K

L

J

<E> Severing portion

referral fi gure

C When attaching a low-pressure twinning pipe *1,*2

F

H

I

G

<C>

<D>

<A> Front pipe routing <B> Bottom pipe routing <C> Low-pressure side

<D> High-pressure side <E> Severing portion referral fi gure

A:

Shape

B:

When not attaching a low-pressure twinning pipe

C:

When attaching a low-pressure twinning pipe

D:

Refrigerant service valve piping

E:

On-site piping (low-pressure connecting pipe)

F:

On-site piping (high-pressure connecting pipe)

G:

Twinning kit (sold separately)

H:

On-site piping (low-pressure connecting pipe: to BC controller)

I:

On-site piping (low-pressure connecting pipe: to outdoor unit)

J:

75 mm (reference measurement)

K:

ID ø25.4 side

L:

Severing portion

*1 For the attachment of the Twinning pipe (sold separately), refer to the instructions included in the kit.

*2 Connection pipe is not used when the Twinning kit is attached.

*3 Use a pipe cutter to sever.

10.3

[Fig. 10.3.1]

D

C

C

B

B

E

F

G

H

I

J

A

LOW

HI

A:

Nitrogen gas

B:

To indoor unit

C:

System analyzer

D:

Low knob

E:

Hi knob

F:

Val ve

G:

Low-pressure pipe

H:

High-pressure pipe

I:

Outdoor unit

J:

Service port

8

10

10.3

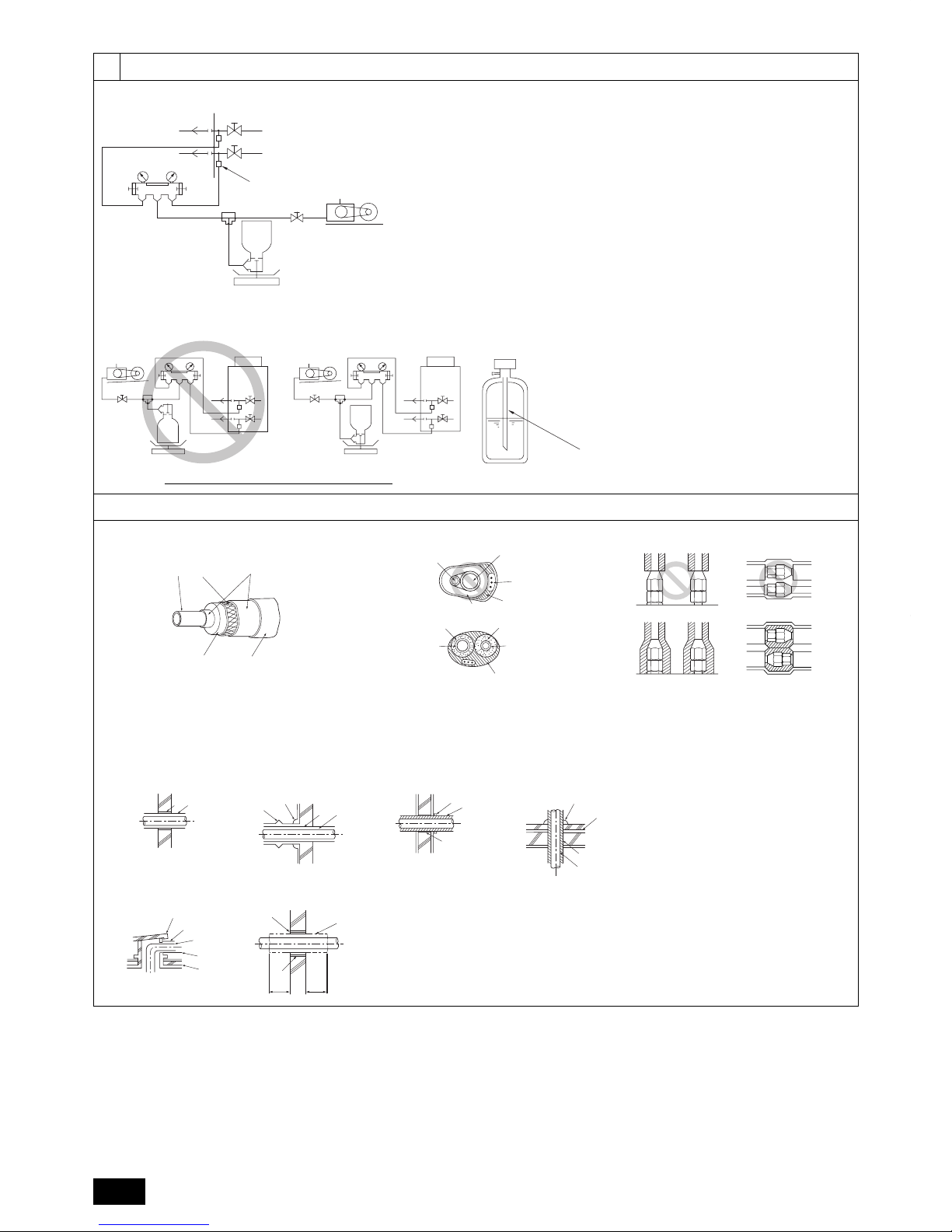

[Fig. 10.3.2]

LOW

HI

B

A

K

J

L

H

M

C

D

EN

N

O

F

G

I

A:

System analyzer

B:

Low knob

C:

Hi knob

D:

Val ve

E:

Low-pressure pipe

F:

High-pressure pipe

G:

Service port

H:

Three-way joint

I:

Val ve

J:

Val ve

K:

R410A cylinder

L:

Scale

M:

Vacuum pump

N:

To indoor unit

O:

Outdoor unit

[Fig. 10.3.3]

A

B:

In case of the R410A cylinder having no syphon pipe.

A:

Syphon pipe

10.4

[Fig. 10.4.1] [Fig. 10.4.2] [Fig. 10.4.3]

C

A

B

D

E

B

A

D

C

E

E

E

D

A

B

A:

Steel wire

A:

High-pressure pipe

B:

Piping

B:

Low-pressure pipe

C:

Asphaltic oily mastic or asphalt

C:

Electric wire

D:

Heat insulation material A

D:

Finishing tape

E:

Outer covering B

E:

Insulator

[Fig. 10.4.4]

<A> Inner wall (concealed) <B> Outer wall <C> Outer wall (exposed) <D> Floor (waterproofi ng)

A B

A B

D

C

E

A

B

D

F

G

B

<E> Roof pipe shaft <F> Penetrating portion on fi re

limit and boundary wall

A:

Sleeve

B:

Heat insulating material

C:

Lagging

D:

Caulking material

E:

Band

F:

Waterproofi ng layer

G:

Sleeve with edge

H:

Lagging material

I:

Mortar or other incombustible caulking

J:

Incombustible heat insulation material

F

H

D

B

G

I

A

J

1m1m

9

11

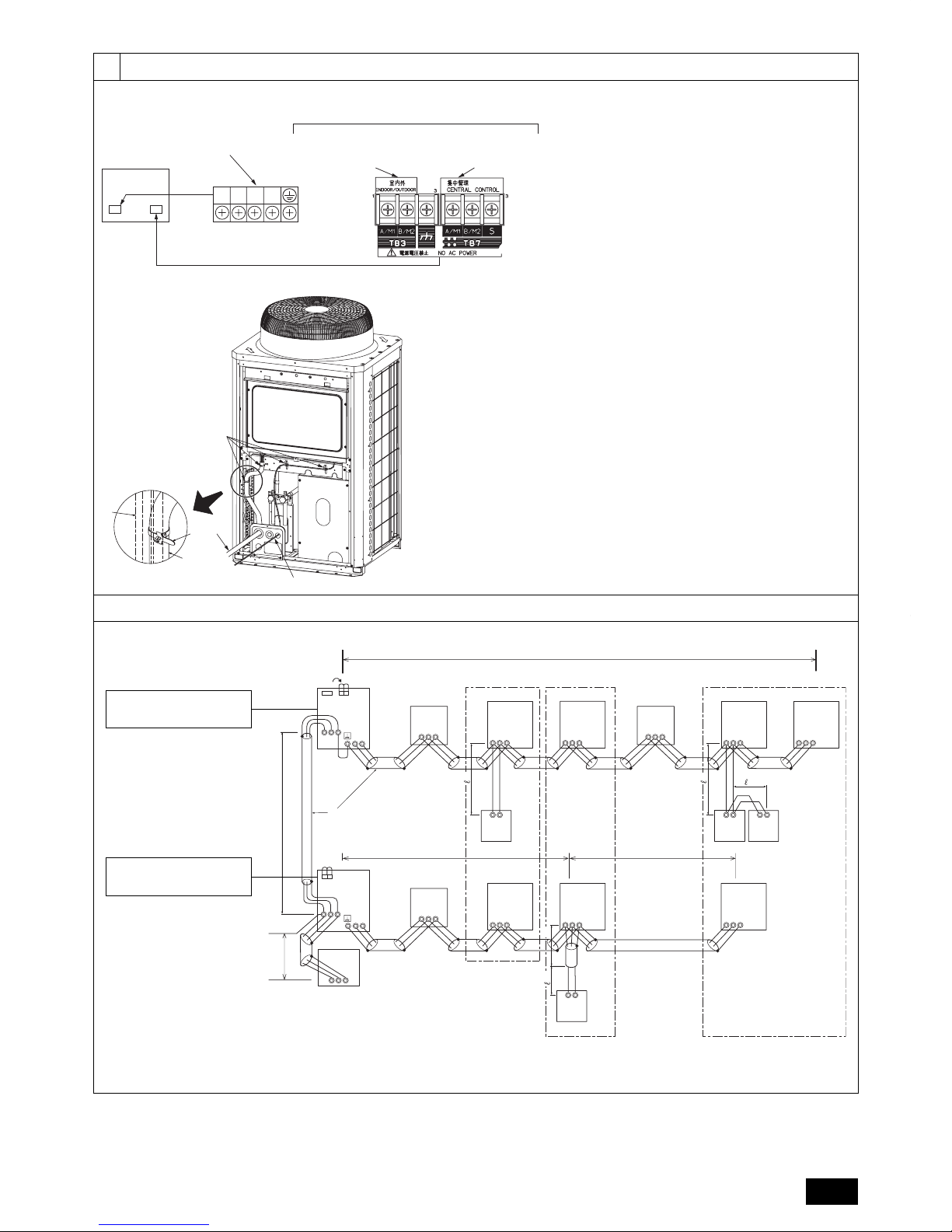

11.2

[Fig. 11.2.1]

A:

Power source

B:

Transmission line

C:

Earth screw

C

L1 L2 L3 N

Terminal block for indoor –

outdoor transmission line

(TB3)

Terminal block for

centralized control

(TB7)

Power supply terminal block

(TB1)

Control box

A

B

[Fig. 11.2.2]

A:

Cable strap

B:

Power source cable

C:

Transmission cable

D:

Pillar

A

B

C

D

A

B

11.3

[Fig. 11.3.1]

A B C

E

D

M1M2

M1M2

S

TB7

TB3

IC

(51)

M1 M2 S

TB5

RC

(01)

IC

M1 M2 S

TB5

(02)

IC

M1 M2 S

TB5

(04)

IC

M1 M2 S

TB5

(03)

IC

M1 M2 S

TB5

(05)

IC

M1 M2 S

TB5

(07)

IC

M1 M2 S

TB5

(06)

L2

L1

(101)

RC

(105)

RC

(103)

RC

(155)

M1M2

M1M2

S

TB7

TB3

CN41

(53)

OC

3

ABS

System

controller

L3

L6

L4

L5

2

4

1

AB AB AB

AB

BC

M1 M2 S

(52)

BS

M1 M2 S

(55)

BC

M1 M2 S

(54)

TB02

TB02

TB02

OC

CN41

CN41

CN40

<A> Change the jumper connector

from CN41 to CN40 *1

<B> SW2-1:ON *2

( ) Address

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

*1 When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply connector (CN41) from ONE outdoor unit in the system and

connect it to CN40.

*2 If a system controller is used, set SW2-1 on all of the outdoor units to ON.

10

11

11.3

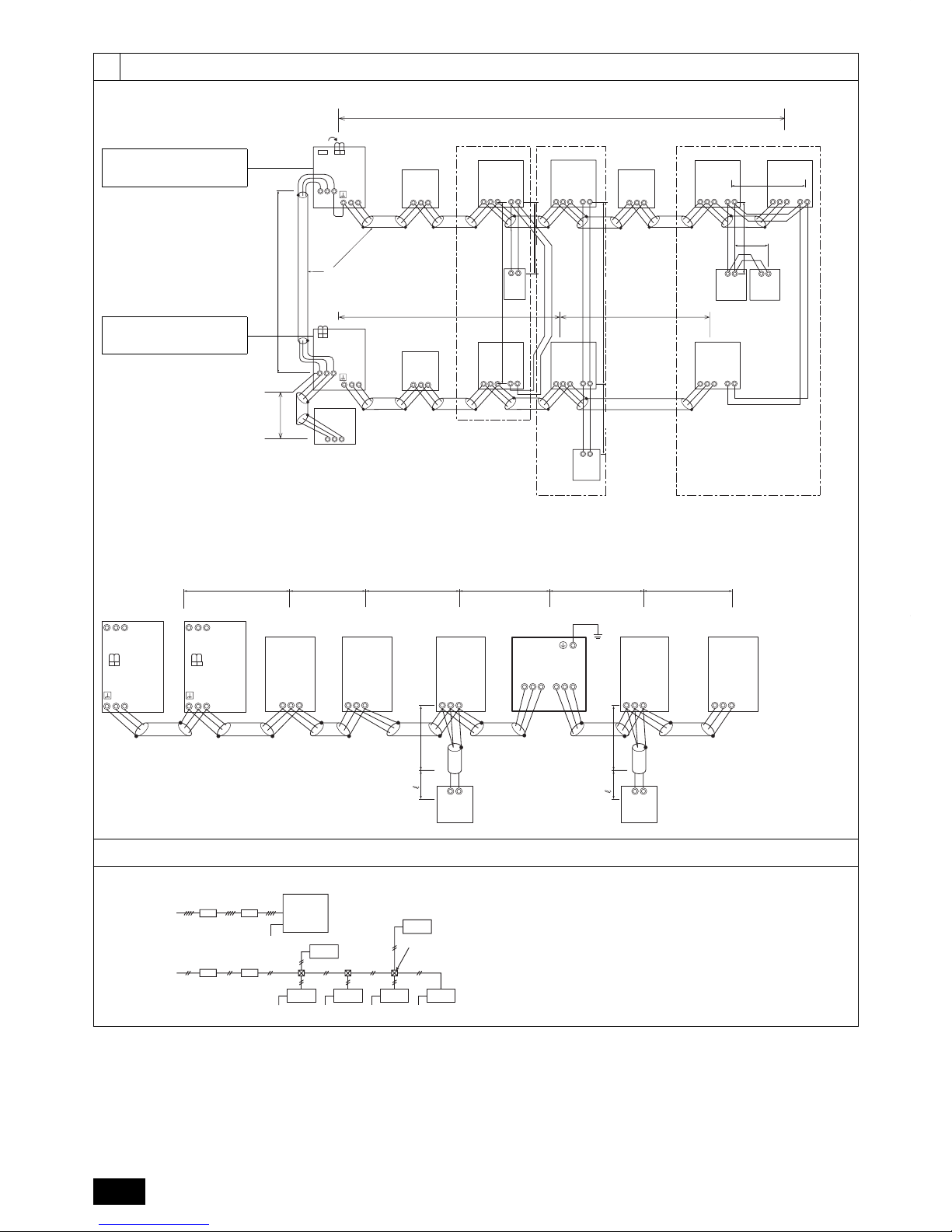

[Fig. 11.3.2]

A B C

E

D

M1M2

M1M2

M1M2

S

TB7

TB3

IC

(51)

M1 M2 12S

TB5 TB15

12

TB15

12

TB15

12

TB15

12

TB15

12

TB15

MA

(01)

IC

M1 M2 S

TB5

(02)

IC

M1 M2 S

TB5

(04)

IC

M1 M2 S

TB5

(03)

IC

M1 M2 S

TB5

(05)

IC

M1 M2 S

TB5

(07)

IC

M1 M2 S

TB5

(06)

L2

L1

MAMAMA

M1M2

S

TB7

TB3

(53)

m1

m4

m3

S

System

controller

L3

L6

L4

m2

ABABAB

AB

AB

m2

m1

m1

m2

BC

M1 M2 S

(52)

BS

M1 M2 S

(55)

BC

M1 M2 S

(54)

TB02

TB02

TB02

CN41

CN40

OC

OC

CN41

<A> Change the jumper connector

from CN41 to CN40 *1

<B> SW2-1:ON *2

<C> Keep the jumper connector

on CN41

<B> SW2-1:ON *2

A:

Group 1

B:

Group 3

C:

Group 5

D:

Shielded wire

E:

Sub remote controller

( ): Address

*1 When the power supply unit is not connected to the transmission line for centralized control, disconnect the male power supply connector (CN41) from ONE outdoor unit in the system and

connect it to CN40.

*2 If a system controller is used, set SW2-1 on all of the outdoor units to ON.

[Fig. 11.3.3]

RC

ICBC

M1M2 S

TB5

IC

M1M2 S

TB5

RP

Ground

AB

ABAB

S

TB2

ABS

TB3

L15 1

1

L18

RC

IC

M1M2 S

TB5

IC

M1M2 S

TB5

L17L16L14L13

M1M2 S

M1M2

TB3

M1M2

TB3

M1M2 S

TB7

M1M2 S

TB7

OC

(51)

L11 L12

OS

(52)

CN41 CN41

TB02

• ( ) Address

• Daisy-chain terminals (TB3) on outdoor units in the same refrigerant

system together.

• Leave the power jumper connector on CN41 as it is. When connecting

a system controller to the transmission line (TB7) for centralized control,

refer to [Fig. 11.3.1], [Fig. 11.3.2], or DATA BOOK.

11.4

[Fig. 11.4.1]

BA

C

3N~380 - 415V

L

1, L2, L3, N

BA

~220 - 240V

L, N

Earth

Earth

EarthEEarth Earth

E

F

F’

D

EE

A:

Switch (Breakers for wiring and current leakage)

B:

Breakers for current leakage

C:

Outdoor unit

D:

Pull box

E:

Indoor unit

F:

BC controller (standard or main)

F':

BC controller (sub)

11

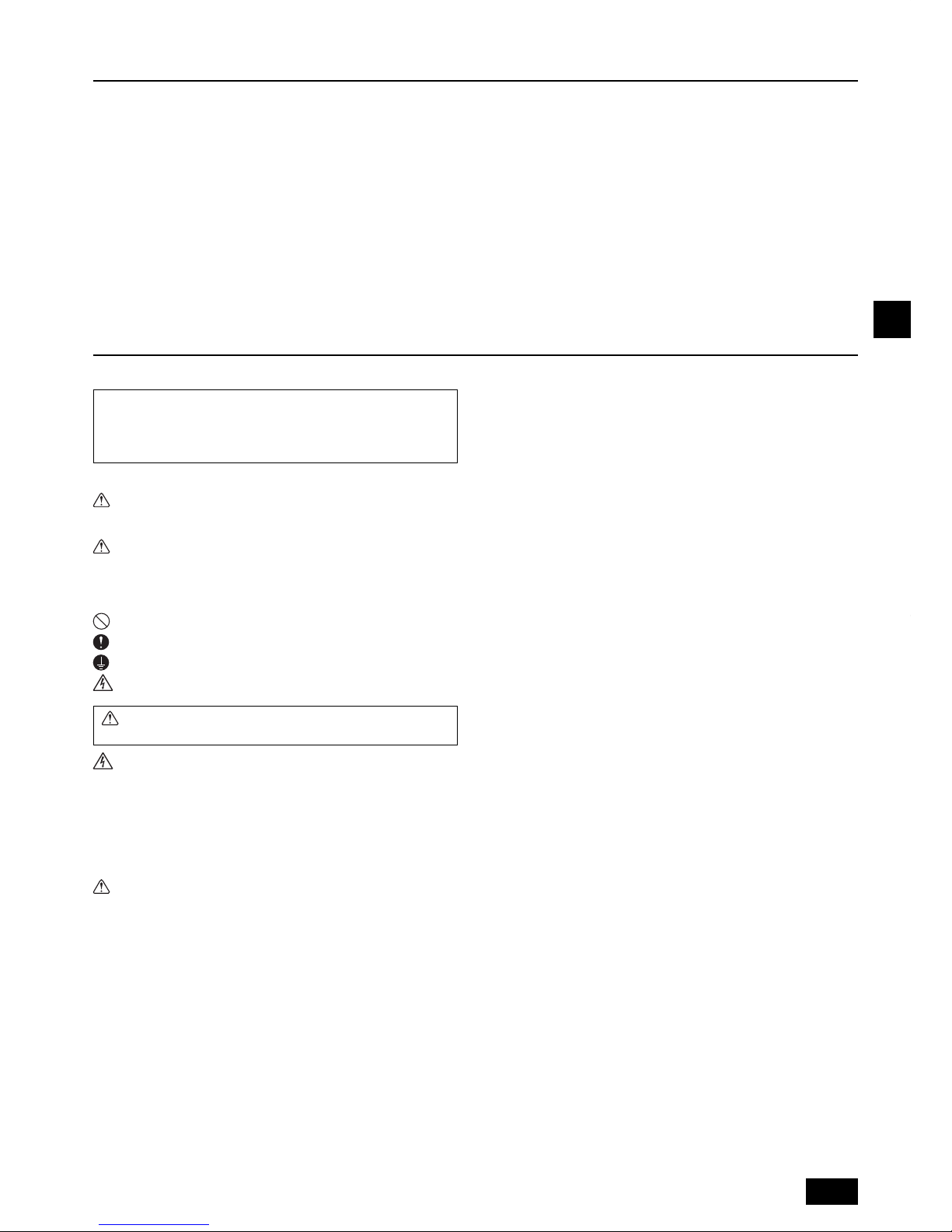

GB

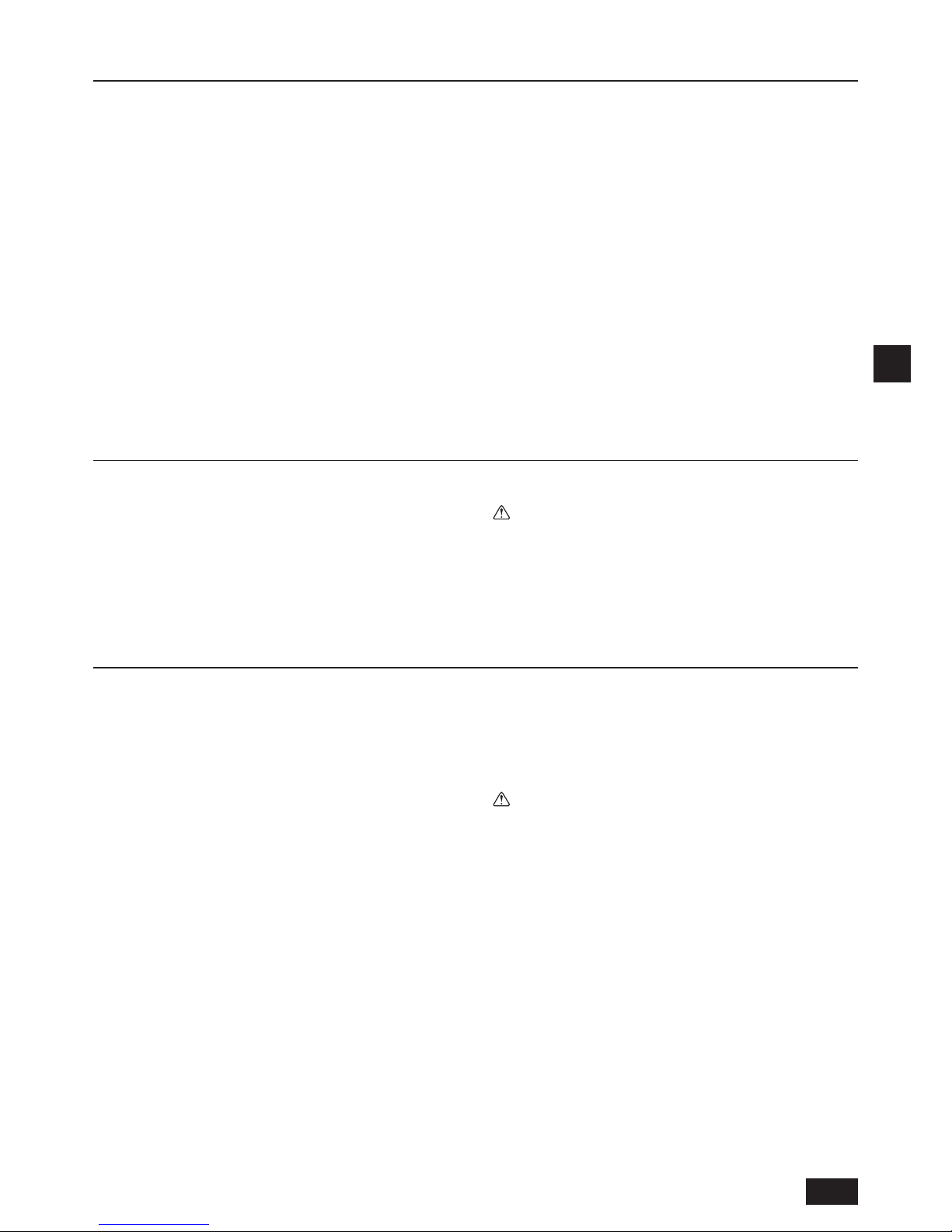

1.1. Before installation and electric work

X Before installing the unit, make sure you read all the

“Safety precautions”.

X The “Safety precautions” provide very important points

regarding safety. Make sure you follow them.

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury

or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the

unit.

Symbols used in the illustrations

: Indicates an action that must be avoided.

: Indicates that important instructions must be followed.

: Indicates a part which must be grounded.

: Beware of electric shock. (This symbol is displayed on the main unit

label.) <Color: yellow>

Warning:

Carefully read the labels affi xed to the main unit.

HIGH VOLTAGE WARNING:

Control box houses high-voltage parts.

When opening or closing the front panel of the control box, do not let it

come into contact with any of the internal components.

Before inspecting the inside of the control box, turn off the power,

keep the unit off for at least 10 minutes, and confi rm that the voltage

between FT-P and FT-N on INV Board has dropped to DC20V or less.

(It takes about 10 minutes to discharge electricity after the power

supply is turned off.)

Warning:

Ask the dealer or an authorized technician to install the air conditioner.

- Improper installation by the user may result in water leakage, electric

shock, or fi re.

This appliance is not intended for use by persons (including children)

with reduced physical, sensory or mental capabilities, or lack of

experience and knowledge, unless they have been given supervision

or instruction concerning use of the appliance by a person responsible

for their safety.

Install the unit at a place that can withstand its weight.

- Failure to do so may cause the unit to fall down, resulting in injuries and

damage to the unit.

Use the specifi ed cables for wiring. Make the connections securely so

that the outside force of the cable is not applied to the terminals.

- Inadequate connection and fastening may generate heat and cause a fi re.

Prepare for strong winds and earthquakes and install the unit at the

specifi ed place.

- Improper installation may cause the unit to topple and result in injury and

damage to the unit.

Always use fi lters and other accessories specifi ed by Mitsubishi Electric.

- Ask an authorized technician to install the accessories. Improper

installation by the user may result in water leakage, electric shock, or fi re.

•

•

•

•

•

•

•

•

•

Never repair the unit. If the air conditioner must be repaired, consult

the dealer.

- If the unit is repaired improperly, water leakage, electric shock, or fi re may

result.

If the supply cord is damaged, it must be replaced by the manufacturer,

its service agent or similarly qualifi ed persons in order to avoid a

hazard.

Do not touch the heat exchanger fi ns.

- Improper handling may result in injury.

If refrigerant gas leaks during installation work, ventilate the room.

- If the refrigerant gas comes into contact with a fl ame, poisonous gases will

be released.

Install the air conditioner according to this Installation Manual.

- If the unit is installed improperly, water leakage, electric shock, or fi re may

result.

Have all electric work done by a licensed electrician according

to “Electric Facility Engineering Standard” and “Interior Wire

Regulations” and the instructions given in this manual and always use

a dedicated power supply.

- If the power source capacity is inadequate or electric work is performed

improperly, electric shock and fi re may result.

Securely install the outdoor unit terminal cover (panel).

- If the terminal cover (panel) is not installed properly, dust or water may

enter the outdoor unit and fi re or electric shock may result.

When installing and moving the air conditioner to another site, do not

charge it with a refrigerant different from the refrigerant specifi ed on

the unit.

- If a different refrigerant or air is mixed with the original refrigerant, the

refrigerant cycle may malfunction and the unit may be damaged.

If the air conditioner is installed in a small room, measures must be

taken to prevent the refrigerant concentration from exceeding the

safety limit if the refrigerant should leak.

- Consult the dealer regarding the appropriate measures to prevent the

safety limit from being exceeded. Should the refrigerant leak and cause

the safety limit to be exceeded, hazards due to lack of oxygen in the room

could result.

When moving and reinstalling the air conditioner, consult the dealer or

an authorized technician.

- If the air conditioner is installed improperly, water leakage, electric shock,

or fi re may result.

After completing installation work, make sure that refrigerant gas is not

leaking.

- If the refrigerant gas leaks and is exposed to a fan heater, stove, oven, or

other heat source, it may generate noxious gases.

Do not reconstruct or change the settings of the protection devices.

- If the pressure switch, thermal switch, or other protection device is shorted

or operated forcibly, or parts other than those specifi ed by Mitsubishi

Electric are used, fi re or explosion may result.

To dispose of this product, consult your dealer.

The installer and system specialist shall secure safety against leakage

according to local regulation or standards.

- Choose the appropriate wire size and the switch capacities for the main

power supply described in this manual if local regulations are not available.

Pay special attention to the place of installation, such as a basement,

etc. where refrigeration gas can accumulate, since refrigerant is

heavier than the air.

For outdoor units that allow fresh air intake to the indoor unit, the

installation site must be carefully chosen to ensure only clean air can

enter the room.

- Direct exposure to outdoor air may have harmful effects on people or food.

Children should be supervised to ensure that they do not play with the

appliance.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1. Safety precautions

Contents

1. Safety precautions ......................................................................................11

1.1. Before installation and electric work ...........................................11

1.2. Precautions for devices that use R410A refrigerant .................. 12

1.3. Before installation ...................................................................... 12

1.4. Before installation (relocation) - electrical work ......................... 12

1.5. Before starting the test run ........................................................ 12

2. About the product ....................................................................................... 13

3. Combination of outdoor units ..................................................................... 13

4. Specifi cations ............................................................................................. 13

5. Confi rmation of parts attached ................................................................... 14

6. Space required around unit ........................................................................ 14

7. Lifting method ............................................................................................ 15

8. Installation of unit ....................................................................................... 15

8.1. Installation ................................................................................. 15

9. Refrigerant piping installation ..................................................................... 15

9.1. Caution ...................................................................................... 15

9.2. Refrigerant piping system ........................................................ 16

10. Additional refrigerant charge ...................................................................... 17

10.1. Calculation of additional refrigerant charge ............................... 17

10.2. Precautions concerning piping connection and valve operation 18

10.3. Airtight test, evacuation, and refrigerant charging ..................... 19

10.4. Thermal insulation of refrigerant piping ..................................... 20

11. Wiring (For details, refer to the installation manual of each unit and

controller.) .................................................................................................. 20

11.1. Caution ...................................................................................... 20

11.2. Control box and connecting position of wiring ........................... 20

11.3. Wiring transmission cables ....................................................... 21

11.4. Wiring of main power supply and equipment capacity .............. 22

12. Test run ...................................................................................................... 23

12.1. The following phenomena do not represent faults. ................... 23

13. Information on rating plate ......................................................................... 24

12

GB

1.4. Before installation (relocation) -

electrical work

Caution:

Ground the unit.

- Do not connect the ground wire to gas or water pipes, lightning rods, or

telephone ground lines. Improper grounding may result in electric shock.

Never connect in reverse phases.

Never connect the Power Line L1, L2, and L3 to Terminal N.

- If the unit is miss wired, when power is supplied, some electrical parts will

be damaged.

Install the power cable so that tension is not applied to the cable.

- Tension may cause the cable to break and generate heat and cause a fi re.

Install a leak circuit breaker, as required.

- If a leak circuit breaker is not installed, electric shock may result.

Use power line cables of suffi cient current carrying capacity and rating.

- Cables that are too small may leak, generate heat, and cause a fi re.

Use only a circuit breaker and fuse of the specifi ed capacity.

- A fuse or circuit breaker of a larger capacity, or the use of a substitute

simple steel or copper wire may result in a general unit failure or fi re.

Do not wash the air conditioner units.

- Washing them may cause an electric shock.

Be careful that the installation base is not damaged by long use.

- If the damage is left uncorrected, the unit may fall and cause personal

injury or property damage.

Install the drain piping according to this Installation Manual to ensure

proper drainage. Wrap thermal insulation around the pipes to prevent

condensation.

- Improper drain piping may cause water leakage and damage to furniture

and other possessions.

Be very careful about transporting the product.

- One person should not carry the product. Its weight is in excess of 20kg.

- Some products use PP bands for packaging. Do not use any PP bands as

a means of transportation. It is dangerous.

- Do not touch the heat exchanger fi ns. Doing so may cut your fi ngers.

- When transporting the outdoor unit, support it at the specifi ed positions on

the unit base. Also support the outdoor unit at four points so that it cannot

slip sideways.

Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may

cause stabs or other injuries.

- Tear apart and throw away plastic packaging bags so that children will not

play with them. If children play with a plastic bag which has not been torn

apart, they face the risk of suffocation.

1.5. Before starting the test run

Caution:

Turn on the power at least 12 hours before starting operation.

- Starting operation immediately after turning on the main power switch

can result in irreversible damage to internal parts. Keep the power switch

turned on during the operational season. Make sure of the phase order of

power supply and voltage between each phase.

Do not touch the switches with wet fi ngers.

- Touching a switch with wet fi ngers can result in an electric shock.

Do not touch the refrigerant pipes during and immediately after

operation.

- During and immediately after operation, the refrigerant pipes may be hot

or cold, depending on the condition of the refrigerant fl owing through the

refrigerant piping, compressor, and other refrigerant cycle parts. Your

hands may suffer burns or frostbite if you touch the refrigerant pipes.

Do not operate the air conditioner with the panels and guards removed.

- Rotating, hot, or high-voltage parts can cause injuries.

Do not turn off the power immediately after stopping operation.

- Always wait at least 5 minutes before turning off the power. Otherwise,

drainage water leakage or mechanical failure of sensitive parts may occur.

Do not touch the surface of the compressor during servicing.

- If unit is connected to a supply and not running, the crank case heater

located at the base of the compressor may still be operating.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

1.2. Precautions for devices that use

R410A refrigerant

Caution:

Do not use existing refrigerant piping.

- The old refrigerant and refrigerant oil in the existing piping contains a large

amount of chlorine which may cause the refrigerant oil of the new unit to

deteriorate.

- R410A is a high-pressure refrigerant and can cause the existing piping to

burst.

Use refrigerant piping made of phosphorus deoxidized copper and

copper alloy seamless pipes and tubes. In addition, be sure that the

inner and outer surfaces of the pipes are clean and free of hazardous

sulphur, oxides, dust/dirt, shaving particles, oils, moisture, or any other

contaminant.

- Contaminants on the inside of the refrigerant piping may cause the

refrigerant oil to deteriorate.

Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing. (Store elbows and

other joints in a plastic bag.)

- If dust, dirt, or water enters the refrigerant cycle, deterioration of the oil and

compressor failure may result.

Apply a small amount of ester oil, ether oil, or alkyl benzene to fl ares.

(for indoor unit)

- Infi ltration of a large amount of mineral oil may cause the refrigerant oil to

deteriorate.

Use liquid refrigerant to fi ll the system.

- If gas refrigerant is used to fi ll the system, the composition of the

refrigerant in the cylinder will change and performance may drop.

Do not use a refrigerant other than R410A.

- If another refrigerant (R22, etc.) is mixed with R410A, the chlorine in the

refrigerant may cause the refrigerant oil to deteriorate.

Use a vacuum pump with a reverse fl ow check valve.

- The vacuum pump oil may fl ow back into the refrigerant cycle and cause

the refrigerant oil to deteriorate.

Do not use the following tools that are used with conventional

refrigerants.

(Gauge manifold, charge hose, gas leak detector, reverse fl ow check

valve, refrigerant charge base, refrigerant recovery equipment)

- If the conventional refrigerant and refrigerant oil are mixed in the R410A,

the refrigerant may deteriorate.

- If water is mixed in the R410A, the refrigerant oil may deteriorate.

- Since R410A does not contain any chlorine, gas leak detectors for

conventional refrigerants will not react to it.

Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

Be especially careful when managing the tools.

- If dust, dirt, or water gets into the refrigerant cycle, the refrigerant may

deteriorate.

1.3. Before installation

Caution:

Do not install the unit where combustible gas may leak.

- If the gas leaks and accumulates around the unit, an explosion may result.

Do not use the air conditioner where food, pets, plants, precision

instruments, or artwork are kept.

- The quality of the food, etc. may deteriorate.

Do not use the air conditioner in special environments.

- Oil, steam, sulfuric smoke, etc. can signifi cantly reduce the performance of

the air conditioner or damage its parts.

When installing the unit in a hospital, communication station, or similar

place, provide suffi cient protection against noise.

- Inverter equipment, private power generator, high-frequency medical

equipment, or radio communication equipment may cause the air

conditioner to operate erroneously, or fail to operate. On the other hand,

the air conditioner may affect such equipment by creating noise that

disturbs medical treatment or image broadcasting.

Do not install the unit on or over things that are subject to water

damage.

- When the room humidity exceeds 80% or when the drain pipe is clogged,

condensation may drip from the indoor unit. Perform collective drainage

work together with the outdoor unit, as required.

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

13

GB

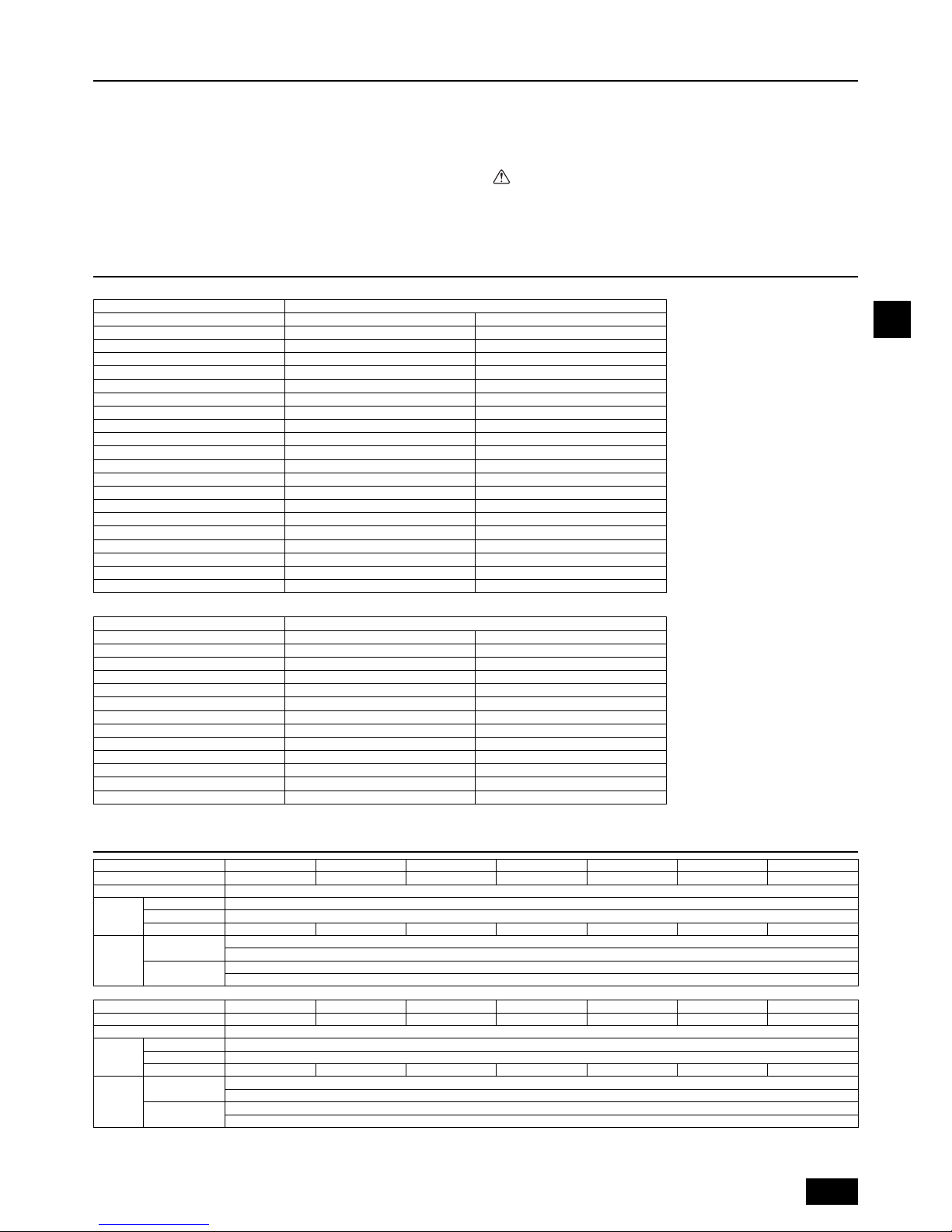

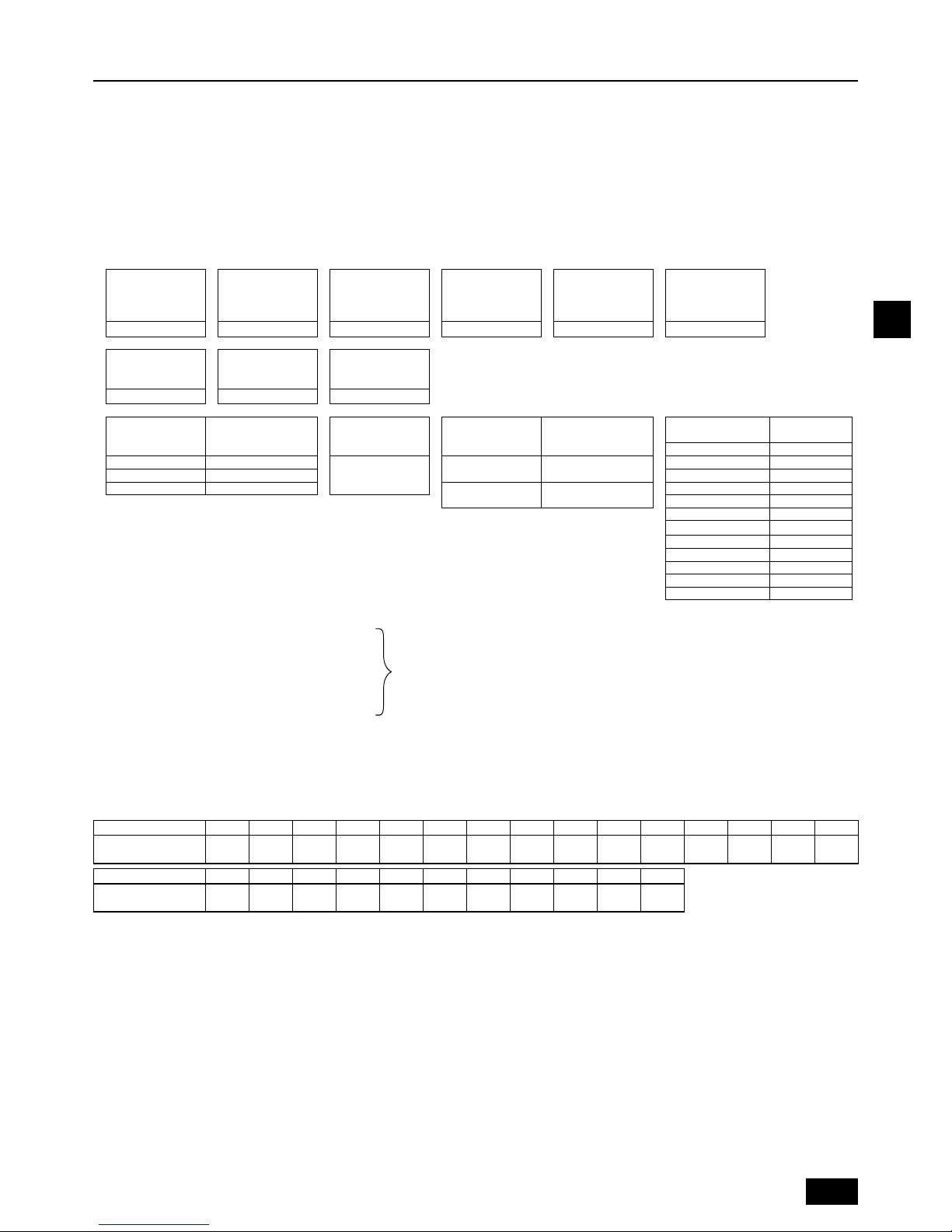

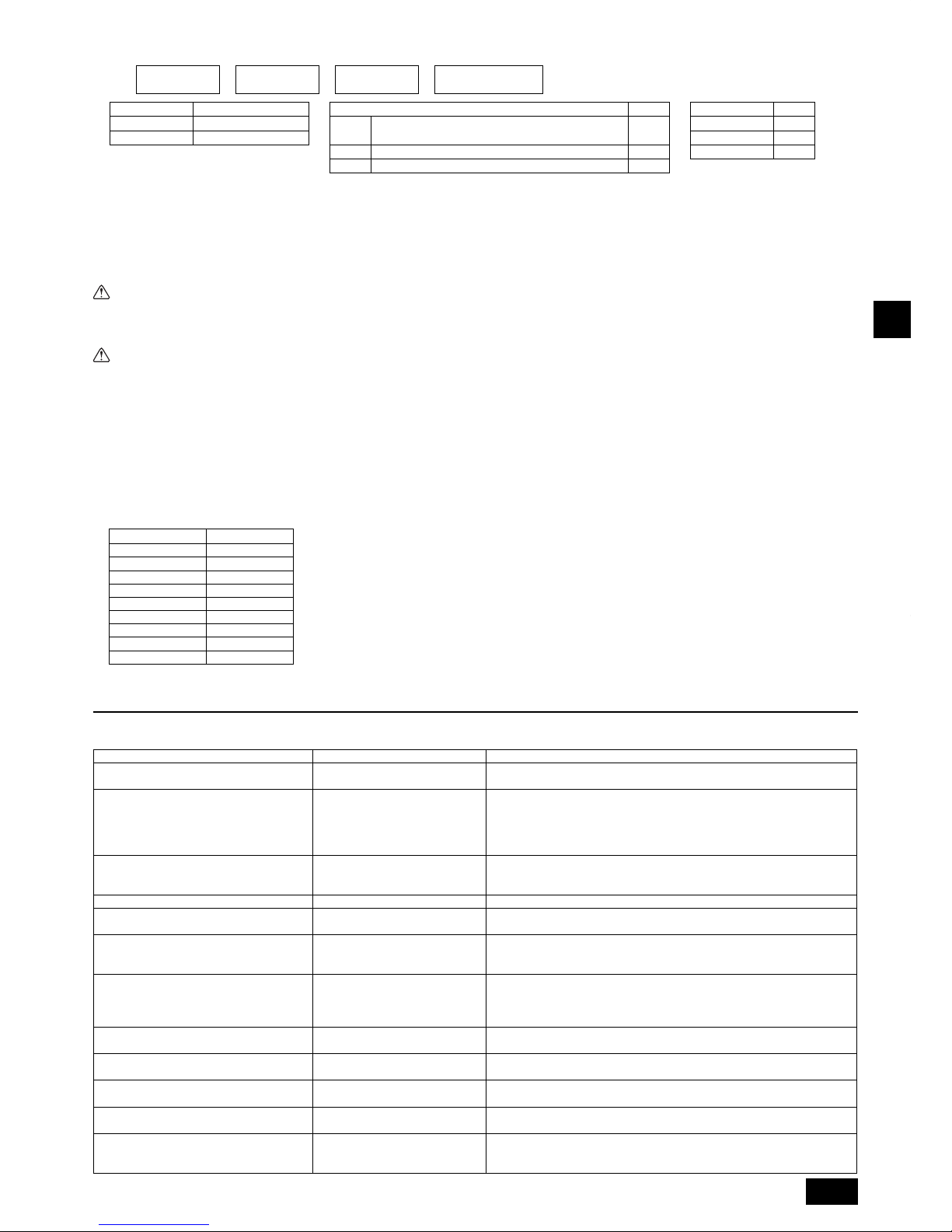

3. Combination of outdoor units

Component units of PURY-P400 to P900YSJM are listed below.

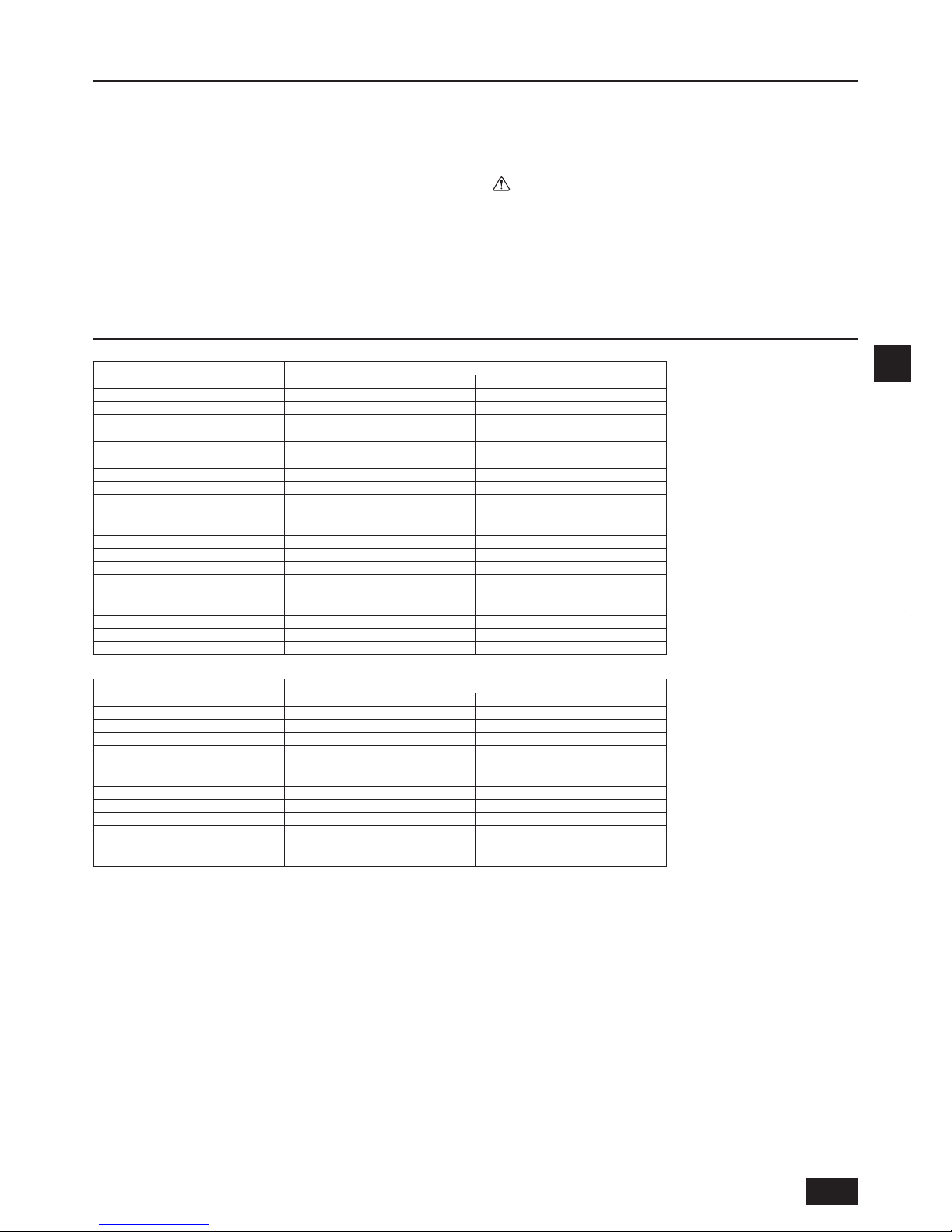

Outdoor unit model Component unit model

PURY-P200YJM-A(-BS) - PURY-P250YJM-A(-BS) - PURY-P300YJM-A(-BS) - PURY-P350YJM-A(-BS) - PURY-P400YJM-A(-BS) - PURY-P400YSJM-A1(-BS) PURY-P200YJM-A(-BS) PURY-P200YJM-A(-BS)

PURY-P450YJM-A(-BS) - PURY-P450YSJM-A1(-BS) PURY-P250YJM-A(-BS) PURY-P200YJM-A(-BS)

PURY-P500YSJM-A(-BS) PURY-P250YJM-A(-BS) PURY-P250YJM-A(-BS)

PURY-P500YSJM-A1(-BS) PURY-P300YJM-A(-BS) PURY-P200YJM-A(-BS)

PURY-P550YSJM-A(-BS) PURY-P300YJM-A(-BS) PURY-P250YJM-A(-BS)

PURY-P600YSJM-A(-BS) PURY-P300YJM-A(-BS) PURY-P300YJM-A(-BS)

PURY-P600YSJM-A1(-BS) PURY-P350YJM-A(-BS) PURY-P250YJM-A(-BS)

PURY-P650YSJM-A(-BS) PURY-P350YJM-A(-BS) PURY-P300YJM-A(-BS)

PURY-P700YSJM-A(-BS) PURY-P400YJM-A(-BS) PURY-P300YJM-A(-BS)

PURY-P700YSJM-A1(-BS) PURY-P350YJM-A(-BS) PURY-P350YJM-A(-BS)

PURY-P750YSJM-A(-BS) PURY-P400YJM-A(-BS) PURY-P350YJM-A(-BS)

PURY-P800YSJM-A(-BS) PURY-P400YJM-A(-BS) PURY-P400YJM-A(-BS)

PURY-P800YSJM-A1(-BS) PURY-P450YJM-A(-BS) PURY-P350YJM-A(-BS)

PURY-P850YSJM-A(-BS) PURY-P450YJM-A(-BS) PURY-P400YJM-A(-BS)

PURY-P900YSJM-A(-BS) PURY-P450YJM-A(-BS) PURY-P450YJM-A(-BS)

Component units of PURY-EP400 to EP700YSJM are listed below.

Outdoor unit model Component unit model

PURY-EP200YJM-A(-BS) - PURY-EP250YJM-A(-BS) - PURY-EP300YJM-A(-BS) - PURY-EP350YJM-A(-BS) - PURY-EP400YSJM-A(-BS) PURY-EP200YJM-A(-BS) PURY-EP200YJM-A(-BS)

PURY-EP450YSJM-A(-BS) PURY-EP250YJM-A(-BS) PURY-EP200YJM-A(-BS)

PURY-EP500YSJM-A(-BS) PURY-EP300YJM-A(-BS) PURY-EP200YJM-A(-BS)

PURY-EP500YSJM-A1(-BS) PURY-EP250YJM-A(-BS) PURY-EP250YJM-A(-BS)

PURY-EP550YSJM-A(-BS) PURY-EP300YJM-A(-BS) PURY-EP250YJM-A(-BS)

PURY-EP600YSJM-A(-BS) PURY-EP300YJM-A(-BS) PURY-EP300YJM-A(-BS)

PURY-EP600YSJM-A1(-BS) PURY-EP350YJM-A(-BS) PURY-EP250YJM-A(-BS)

PURY-EP650YSJM-A(-BS) PURY-EP350YJM-A(-BS) PURY-EP300YJM-A(-BS)

PURY-EP700YSJM-A(-BS) PURY-EP350YJM-A(-BS) PURY-EP350YJM-A(-BS)

4. Specifi cations

Model

PURY-P200YJM-A PURY-P250YJM-A PURY-P300YJM-A PURY-P350YJM-A PURY-P400YJM-A

PURY-P400YSJM-A1

PURY-P450YJM-A

Noise level (50/60Hz)

56dB <A> 57dB <A> 59dB <A> 60dB <A> 61dB <A> 59dB <A> 62dB <A>

External static pressure

0 Pa *2

Indoor units

Total capacity

50~150% *1

Model

15~250

Quantity

1~20 1~25 1~30 1~35 1~40 1~40 1~45

Operation

temperature

Standard type

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Fresh air intake type

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

Model

PURY-P450YSJM-A1

PURY-P500YSJM-A

PURY-P500YSJM-A1

PURY-P550YSJM-A PURY-P600YSJM-A

PURY-P600YSJM-A1

PURY-P650YSJM-A

Noise level (50/60Hz)

59.5dB <A> 60dB <A> 61dB <A> 61dB <A> 62dB <A> 62dB <A> 62.5dB <A>

External static pressure

0 Pa *2

Indoor units

Total capacity

50~150% *1

Model

15~250

Quantity

1~45* 1~50* 1~50* 2~50* 2~50* 2~50* 2~50*

Operation

temperature

Standard type

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Fresh air intake type

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

2. About the product

This unit uses R410A-type refrigerant.

Piping for systems using R410A may be different from that for systems using

conventional refrigerant because the design pressure in systems using

R410A is higher. Refer to the Data Book for more information.

Some of the tools and equipment used for installation with systems that use

other types of refrigerant cannot be used with the systems using R410A.

Refer to the Data Book for more information.

•

•

•

Do not use the existing piping, as it contains chlorine, which is found in

conventional refrigerating machine oil and refrigerant. This chlorine will

deteriorate the refrigerant machine oil in the new equipment. The existing

piping must not be used as the design pressure in systems using R410A

is higher than that in the systems using other types of refrigerant and the

existing pipes may burst.

Caution:

Do not vent R410A into the atmosphere.

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol

with a Global Warming Potential (GWP) = 1975.

•

•

•

14

GB

Model

PURY-P700YSJM-A

PURY-P700YSJM-A1

PURY-P750YSJM-A PURY-P800YSJM-A

PURY-P800YSJM-A1

PURY-P850YSJM-A

PURY-P900YSJM-A

Noise level (50/60Hz)

63dB <A> 63dB <A> 63.5dB <A> 64dB <A> 64dB <A> 64.5dB <A> 65dB <A>

External static pressure

0 Pa *2

Indoor units

Total capacity

50~150% *1

Model

15~250

Quantity

2~50* 2~50* 2~50* 2~50* 2~50* 2~50* 2~50*

Operation

temperature

Standard type

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Fresh air intake type

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

Model

PURY-EP200YJM-A PURY-EP250YJM-A PURY-EP300YJM-A PURY-EP350YJM-A

PURY-EP400YSJM-A PURY-EP450YSJM-A PURY-EP500YSJM-A

Noise level (50/60Hz)

57dB <A> 60dB <A> 60dB <A> 61dB <A> 60dB <A> 62dB <A> 62dB <A>

External static pressure

0 Pa *2

Indoor units

Total capacity

50~150% *1

Model

15~250

Quantity

1~20 1~25 1~30 1~35 1~40 1~45 1~50*

Operation

temperature

Standard type

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Fresh air intake type

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

Model

PURY-EP500YSJM-A1

PURY-EP550YSJM-A

PURY-EP600YSJM-A

PURY-EP600YSJM-A1

PURY-EP650YSJM-A PURY-EP700YSJM-A

Noise level (50/60Hz)

63dB <A> 63dB <A> 63dB <A> 63.5dB <A> 63.5dB <A> 64dB <A>

External static pressure

0 Pa *2

Indoor units

Total capacity

50~150% *1

Model

15~250

Quantity

1~50* 2~50* 2~50* 2~50* 2~50* 2~50*

Operation

temperature

Standard type

Cooling mode: – 5°CDB ~ 46°CDB

Heating mode: – 20°CWB ~ 15.5°CWB

Fresh air intake type

Cooling mode: 21°CDB ~ 43°CDB

Heating mode: – 12.5°CWB ~ 20°CWB

* Connectable branch pipe number is max.48.

*1: The total indoor capacity of units run simultaneously is 150% or less.

*2: To enable high static pressure with (E)P200, (E)P250, (E)P300, (E)P350, P400, and P450, set the DipSW on the main panel as follows.

SW3-9: ON, SW3-10 60Pa compatible: OFF, 30Pa compatible: ON

5. Confi rmation of parts attached

This unit includes the following parts. Please check.

For usage methods, refer to item 10.2.

1 Connecting pipe

ID ø25.4, ID ø22.2

<Low-pressure side>

<High-pressure side>

2 Connecting pipe

ID ø25.4, OD ø19.05

<High-pressure side>

3 Connecting pipe

ID ø25.4, ID ø28.58

<Low-pressure side>

4 Connecting elbow

ID ø19.05, OD ø19.05

<High-pressure side>

5 Connecting elbow

ID ø28.58, OD ø28.58

<Low-pressure side>

Model P250YJM 1 pc. – – – –

P300YJM 1 pc. – – – –

P350YJM – 1 pc. 1 pc. 1 pc. –

P400YJM 1 pc. – 1 pc. – –

P450YJM 1 pc. – – – 1 pc.

EP250YJM 1 pc. 1 pc. – 1 pc. –

EP300YJM 1 pc. 1 pc. – 1 pc. –

EP350YJM – 1 pc. – 1 pc. 1 pc.

•

•

6. Space required around unit

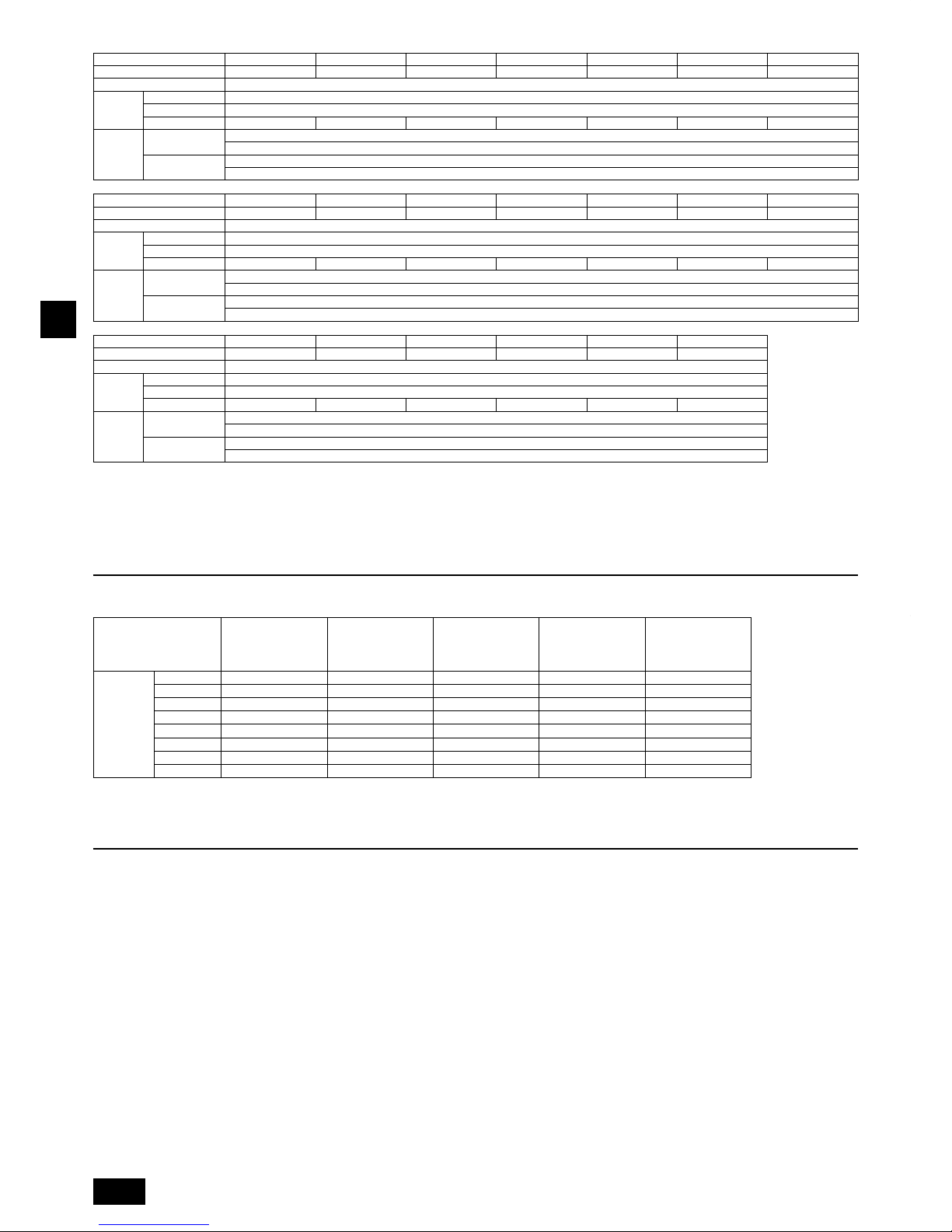

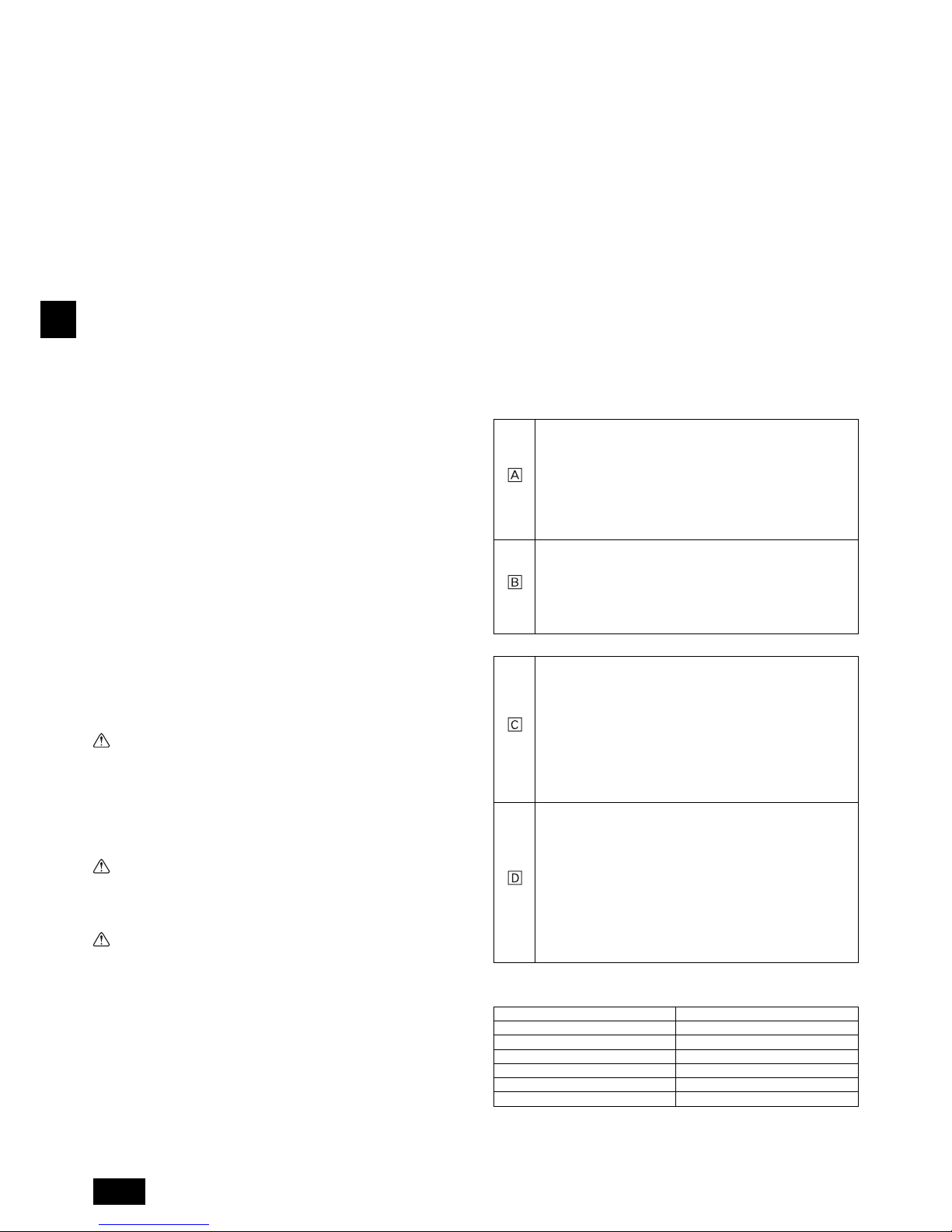

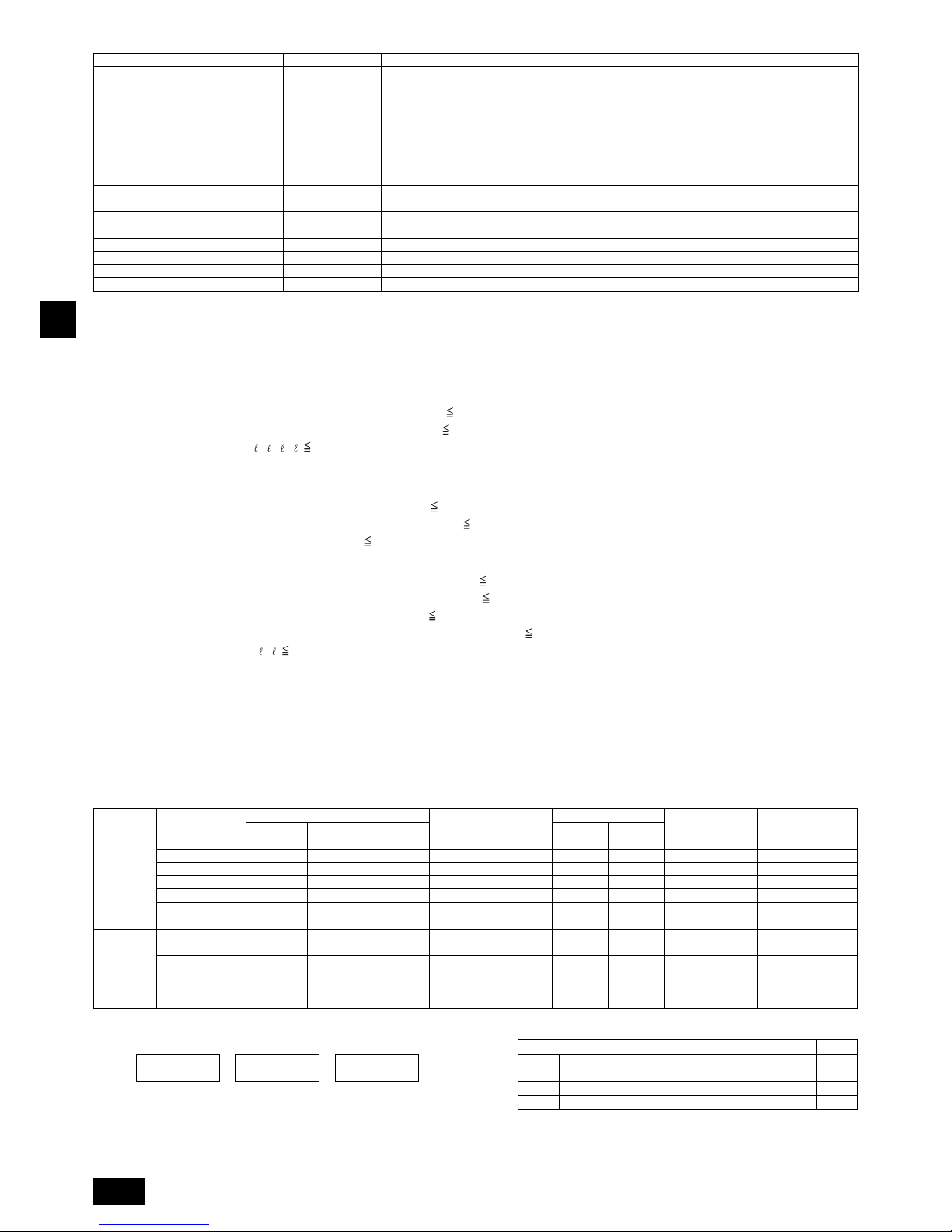

1 In case of single installation

Secure enough space around the unit as shown in the fi gure on page 2.

[Fig. 6.0.1] (P.2)

<A> Top view <B> Side view

<C> When there is little space up to an obstruction

A

Front

B

Unit height

C

Back

D

Air outlet guide (Procured at the site)

(1) If the distance is 300 mm or more between the rear side and the wall

(2) If the distance is 100 mm or more between the rear side and the wall

(3) If the wall height (H) of the front, rear or side exceeds the wall height

restriction

When the height of the walls on the front, back or on the sides <H> exceeds

the wall height limit as defi ned here, add the height that exceeds the height

limit <h> to the fi gures that are marked with an asterisk.

If the unit cannot be kept clear of the wall, please change the direction of the

air outlet of the unit to blow against the wall to avoid air short cycle.

<Wall height limit> Front: Up to the unit height

Back: Up to 500 mm from the unit bottom

Side: Up to the unit height

•

•

•

(4) If there are obstacles at the upper part of the unit

2 In case of collective installation

[Fig. 6.0.2] (P.2)

A

Front

B

Must be open

C

Wall height (H)

When multiple units are installed adjacent to each other, secure enough

space to allow for air circulation and walkway between groups of units as

shown in the fi gures on page 2.

At least two sides must be left open.

As with the single installation, add the height that exceeds the height limit

<h> to the fi gures that are marked with an asterisk.

If there is a wall at both the front and the rear of the unit. Install up to six

units (three units: P450, EP350) consecutively in the side direction and

provide a space of 1000 mm or more as inlet space/passage space for each

six units (three units: P450, EP350).

•

•

•

•

15

GB

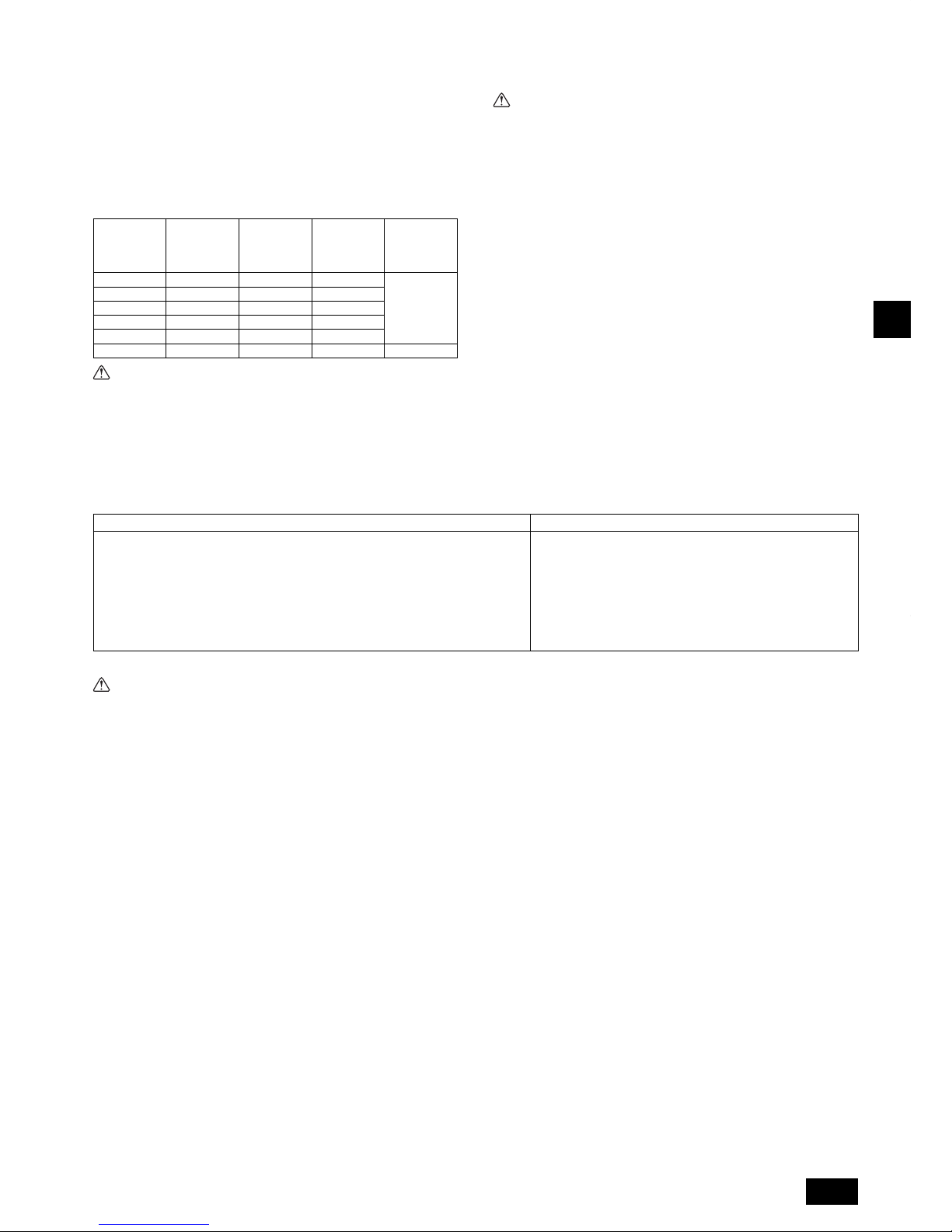

[Fig. 7.0.1] (P.3)

Use suspension ropes that will withstand the weight of the unit.

When moving the unit, use a 4-point suspension, and avoid giving impacts

to the unit (Do not use 2-point suspension).

Place protective pads on the unit where it comes in contact with the ropes to

protect the unit from being scratched.

Set the angle of roping at 40° or less.

Use 2 ropes that are each longer than 8 meters.

•

•

•

•

•

Place protective padding at the corners of the product to protect the product

from scratches or dents that might be caused by the rope.

Caution:

Be very careful when carrying/moving the product.

- When installing the outdoor unit, suspend the unit at the specifi ed location of

the unit base. Stabilize as necessary so that it does not move to the side and

support it at 4 points. If the unit is installed or suspended with 3-point support,

the unit may become unstable and fall.

•

7. Lifting method

8.1. Installation

[Fig. 8.1.1] (P.3)

<A> Without detachable leg <B> With detachable leg

A

M10 anchor bolt procured at the site.BCorner is not seated.

C

Fixing bracket for the hole-in anchor

bolt (3 locations to fi x with screws).

D

Detachable leg

Fix unit tightly with bolts so that unit will not fall down due to earthquakes or

strong winds.

Use concrete or an angle bracket for the foundation of unit.

Vibration may be transmitted to the installation section and noise and

vibration may be generated from the fl oor and walls, depending on the

installation conditions. Therefore, provide ample vibrationproofi ng (cushion

pads, cushion frame, etc.).

Be sure that the corners are fi rmly seated. If the corners are not fi rmly

seated, the installation feet may be bent.

When using cushion pads, be sure that the full width of the unit is covered.

The projecting length of the anchor bolt should be less than 30 mm.

Hole-in anchor bolts are not compatible with this product. However, if fi xing

brackets are mounted on the 4 locations (6 locations: P450, EP350) of the

unit attachment part, hole-in anchor bolts can be used.

[Fig. 8.1.2]

A

Screws

•

•

•

•

•

•

•

The detachable leg can be removed at the site.

Detaching the detachable leg

Loosen the three screws to detach the detachable leg (Two (three: P450,

EP350) each in the front and back).

If the base leg fi nish is damaged when detaching, be sure to repair at the

site.

Warning:

Be sure to install unit in a place strong enough to withstand its weight.

Any lack of strength may cause unit to fall down, resulting in a

personal injury.

Have installation work in order to protect against strong winds and

earthquakes.

Any installation defi ciency may cause unit to fall down, resulting in a

personal injury.

When building the foundation, give full attention to the fl oor strength, drain water

disposal <during operation, drain water fl ows out of the unit>, and piping and

wiring routes.

Precautions when routing the pipes and wires below the unit (Without

detachable leg)

When routing the pipes and wires below the unit, be sure that the foundation and

base work do not block the base through-holes. Also make sure the foundation

is at least 100 mm high so that the piping can pass under the unit.

•

•

•

•

8. Installation of unit

9. Refrigerant piping installation

The pipe is connected via a terminal-branch type connection in which refrigerant

piping from the outdoor unit is branched at the terminal and is connected to each

of the indoor units.

The method of pipe connection is as follows: fl are connection for the indoor

units, low-pressure pipes and high-pressure pipes for outdoor units, brazed

connection. Note that the branched sections are brazed.

Warning:

Always use extreme care to prevent the refrigerant gas from leaking while

using fi re or fl ame. If the refrigerant gas comes in to contact with a fl ame

from any source, such as a gas stove, it breaks down and generates

a poisonous gas which can cause gas poisoning. Never weld in an

unventilated room. Always conduct an inspection for gas leakage after

installation of the refrigerant piping has been completed.

Caution:

Do not vent R410A into the atmosphere.

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto Protocol

with a Global Warming Potential (GWP) = 1975.

9.1. Caution

This unit uses refrigerant R410A. Follow the local regulations on materials and

pipe thickness when selecting pipes. (Refer to the table below.)

1 Use the following materials for refrigeration piping.

Material: Use copper alloy seamless pipes made of phosphorus

deoxidized copper. Ensure the inner and outer surfaces of the pipes

are clean and free from hazardous sulfur, oxide, dusts, shaving

particles, oils, and moisture (contamination).

Size: Refer to item 9.2. for detailed information on refrigerant piping

system.

2 Commercially available piping often contains dust and other materials.

Always blow it clean with a dry inert gas.

3 Use care to prevent dust, water or other contaminants from entering the

piping during installation.

•

•

•

•

4 Reduce the number of bending portions as much as possible, and make

bending radii as big as possible.

5 For indoor and outdoor branching and merging section, be sure to use the

following twinning pipe sets and merge pipe sets (sold separately).

Indoor twinning pipe kit

model

Indoor junction pipe kit

model

Line branch

Total indoor model

P100 ~ P250

Lower stream unit model

Less than 80 in total

CMY-Y102S-G2 CMY-R160-J1

Outdoor twinning kit model

Total outdoor model

P500 ~ P650YSJM-A

P400 ~ P600YSJM-A1

EP400 ~ EP600YSJM-A

EP500YSJM-A1

Total outdoor model

P700 ~ P800YSJM-A

P700YSJM-A1

Total outdoor model

P800YSJM-A1

EP650, EP700YSJM-A

EP600YSJM-A1

Total outdoor model

P850, P900YSJM-A

CMY-R100VBK CMY-R200VBK

CMY-R100XLVBK CMY-R200XLVBK

Copper pipe size and radial thickness for R410A CITY MULTI.

Size (mm) Size (inch) Radial thickness (mm) Pipe type

ø6.35 ø1/4" 0.8 Type-O

ø9.52 ø3/8" 0.8 Type-O

ø12.7 ø1/2" 0.8 Type-O

ø15.88 ø5/8" 1.0 Type-O

*ø19.05 ø3/4" 1.2 Type-O

*ø19.05 ø3/4" 1.0 Type-1/2H or H

ø22.2 ø7/8" 1.0 Type-1/2H or H

ø25.4 ø1" 1.0 Type-1/2H or H

ø28.58 ø1-1/8" 1.0 Type-1/2H or H

ø31.75 ø1-1/4" 1.1 Type-1/2H or H

ø34.93 ø1-3/8" 1.2 Type-1/2H or H

ø41.28 ø1-5/8" 1.4 Type-1/2H or H

* Both pipe types can be used for pipe size ø19.05 (3/4 inch) for R410A air

conditioner.

16

GB

6 Use a fi tting if a specifi ed refrigerant pipe has a different diameter from that

of a branching pipe.

7 Always observe the restrictions on the refrigerant piping (such as rated

length, height difference, and piping diameter) to prevent equipment failure

or a decline in heating/cooling performance.

8 Either a lack or an excess of refrigerant causes the unit to make an

emergency stop. Charge the system with an appropriate amount of

refrigerant. When servicing, always check the notes concerning pipe

length and amount of additional refrigerant at both locations, the refrigerant

volume calculation table on the back of the service panel and the additional

refrigerant section on the labels for the combined number of indoor units

(Refer to item 9.2. for detailed information on refrigerant piping system).

9 Be sure to charge the system using liquid refrigerant.

0 Never use refrigerant to perform an air purge. Always evacuate using a

vacuum pump.

a Always insulate the piping properly. Insuffi cient insulation will result in a

decline in heating/cooling performance, water drops from condensation and

other such problems (Refer to item 10.4 for thermal insulation of refrigerant

piping).

b When connecting the refrigerant piping, make sure the valve of the outdoor

unit is completely closed (the factory setting) and do not operate it until

the refrigerant piping for the outdoor, indoor units and BC controller has

been connected, a refrigerant leakage test has been performed and the

evacuation process has been completed.

c Braze only with non-oxide brazing material for piping. Failure to do so

may damage the compressor. Be sure to perform the non-oxidation

brazing with a nitrogen purge.

Do not use any commercially available anti-oxidizing agent since it may

cause pipe corrosion and degrading of the refrigerant oil.

Please contact Mitsubishi Electric for more details.

(Refer to item 10.2. for details of the piping connection and valve operation)

d Never perform outdoor unit piping connection work when it is raining.

Warning:

When installing and moving the unit, do not charge the system with any

other refrigerant other than the refrigerant specifi ed on the unit.

- Mixing of a different refrigerant, air, etc. may cause the refrigerant cycle to

malfunction and may result in severe damage.

Caution:

Use a vacuum pump with a reverse fl ow check valve.

- If the vacuum pump does not have a reverse fl ow check valve, the vacuum

pump oil may fl ow back into the refrigerant cycle and cause deterioration of

the refrigerant oil.

Do not use the tools shown below used with conventional refrigerant.

(Gauge manifold, charge hose, gas leak detector, check valve,

refrigerant charge base, vacuum gauge, refrigerant recovery

equipment)

- Mixing of conventional refrigerant and refrigerant oil may cause the

refrigerant oil to deteriorate.

- Mixing of water will cause the refrigerant oil to deteriorate.

- R410A refrigerant does not contain any chlorine. Therefore, gas leak

detectors for conventional refrigerants will not react to it.

Manage the tools used for R410A more carefully than normal.

- If dust, dirt, or water gets in the refrigerant cycle, the refrigerant oil will

deteriorate.

Never use existing refrigerant piping.

- The large amount of chlorine in conventional refrigerant and refrigerant oil

in the existing piping will cause the new refrigerant to deteriorate.

Store the piping to be used during installation indoors and keep both

ends of the piping sealed until just before brazing.

- If dust, dirt, or water gets into the refrigerant cycle, the oil will deteriorate

and the compressor may fail.

Do not use a charging cylinder.

- Using a charging cylinder may cause the refrigerant to deteriorate.

Do not use special detergents for washing piping.

•

•

•

•

•

•

•

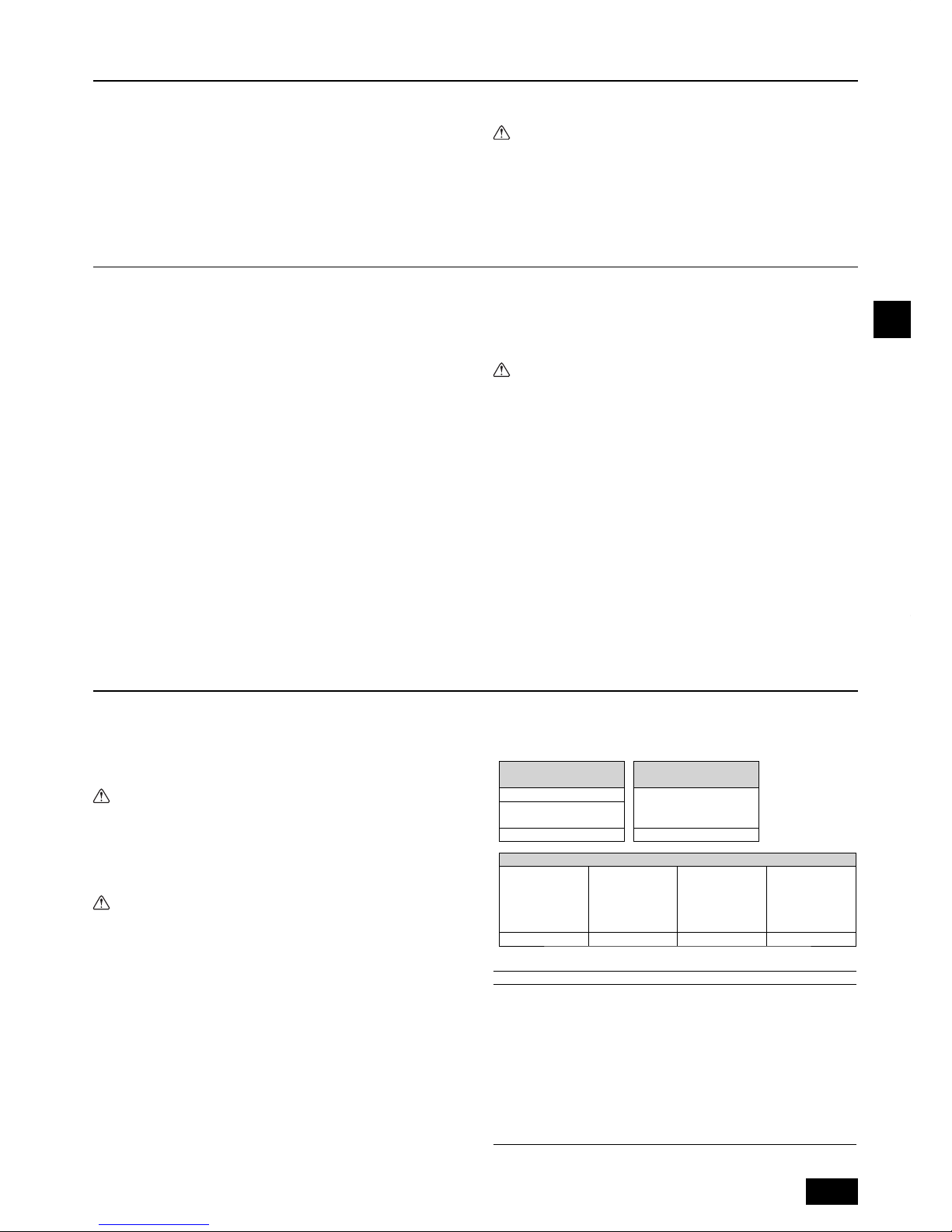

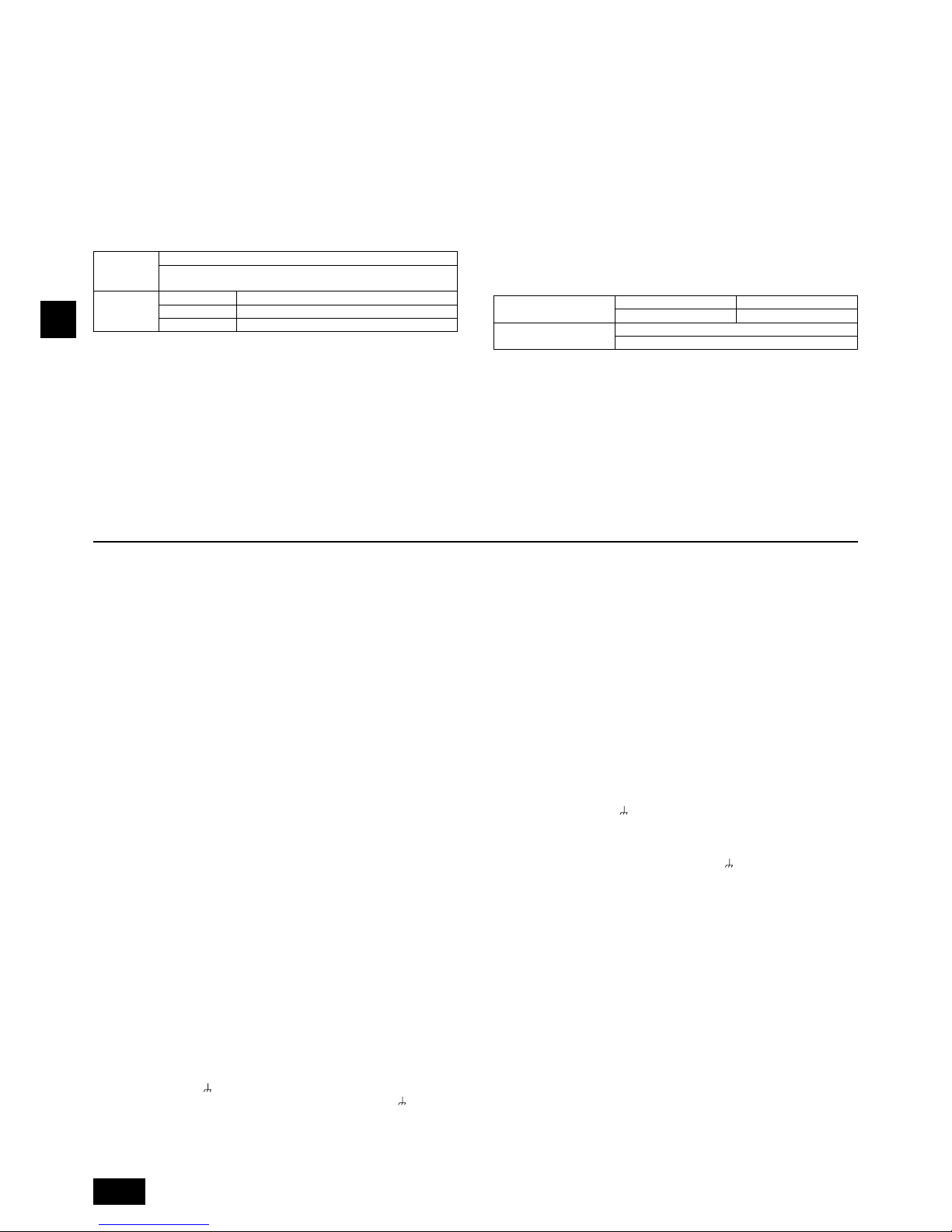

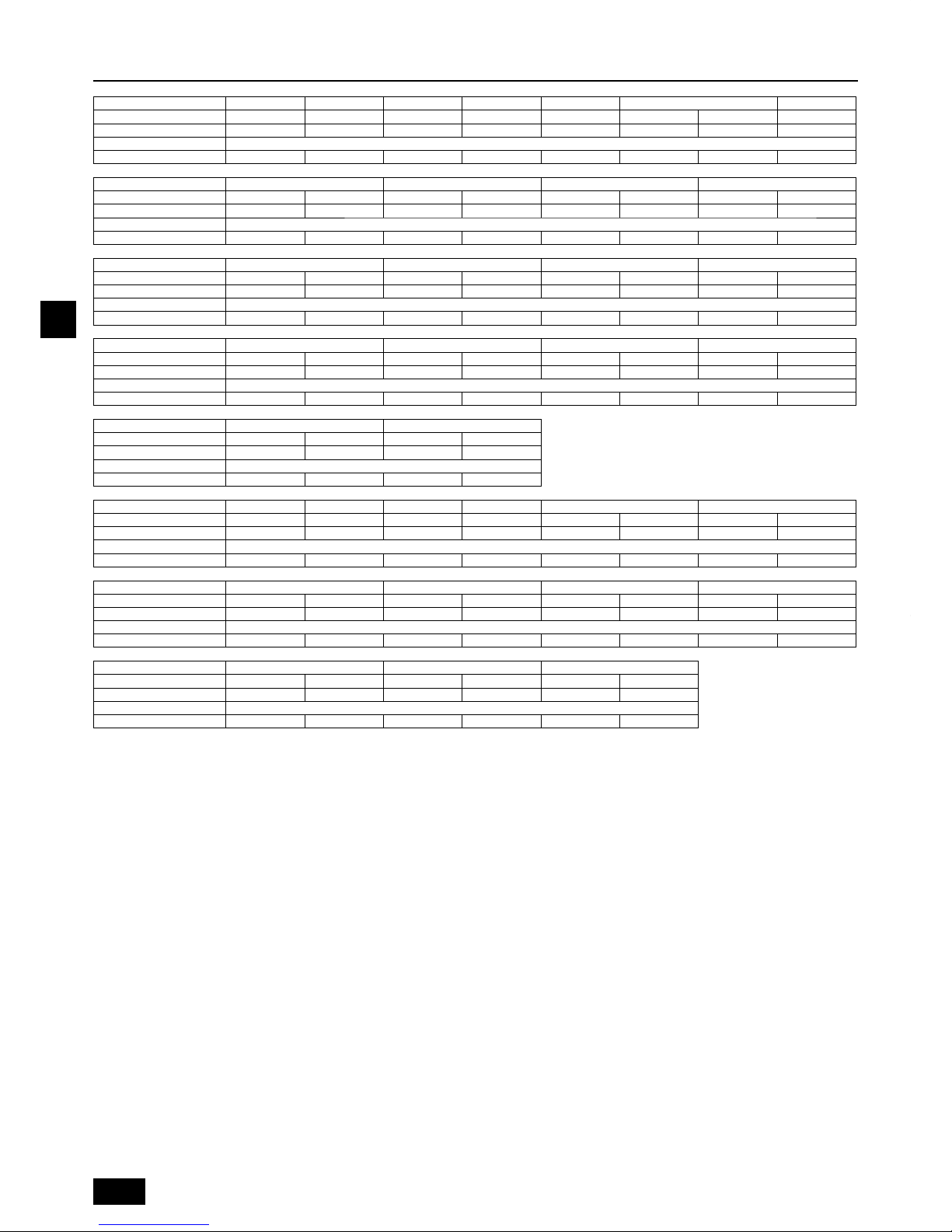

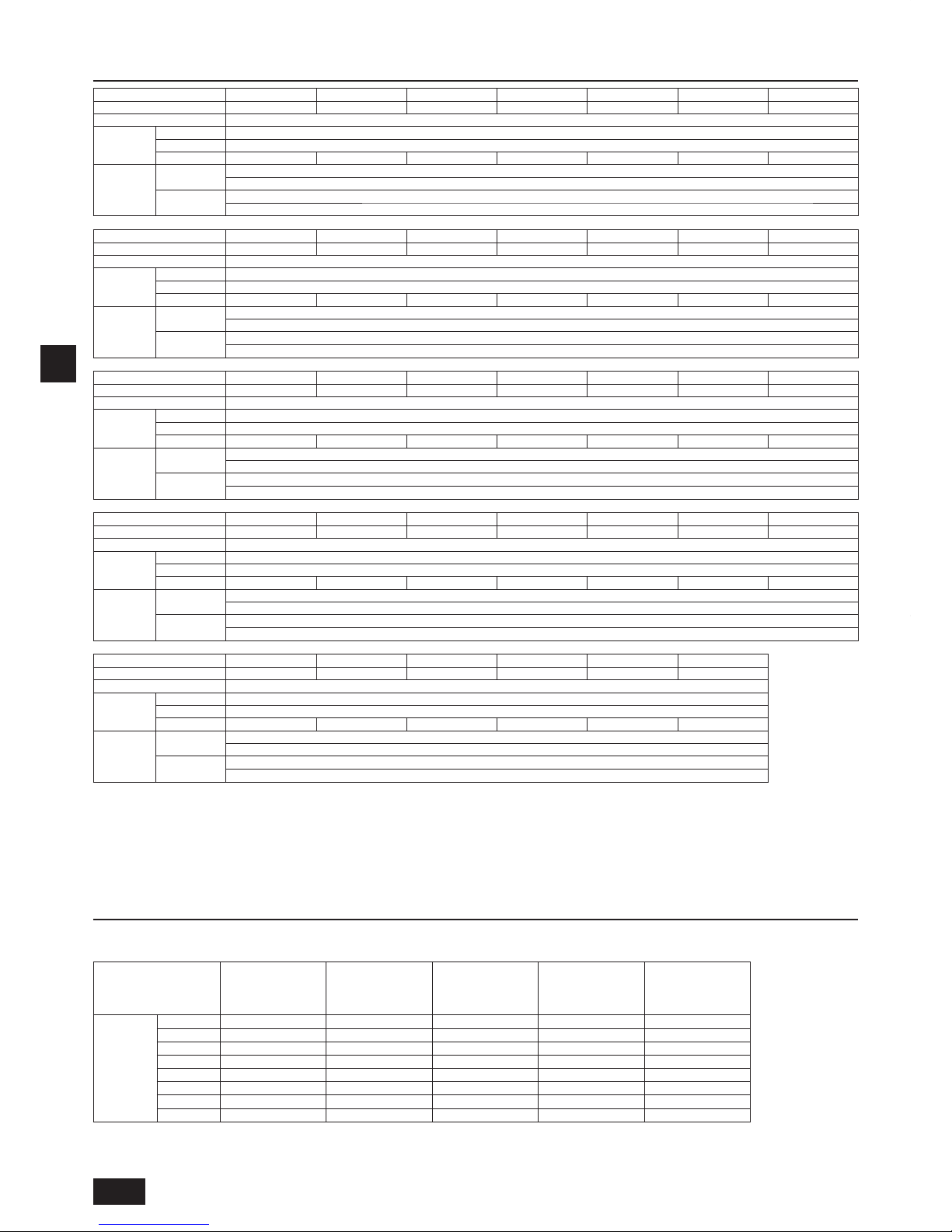

9.2. Refrigerant piping system

Connection example

[Fig. 9.2.1] (P.4)

Outdoor model High-pressure side

Low-pressure side Total capacity of indoor units

Liquid pipe Gas pipe

High-pressure gas pipe Low-pressure gas pipe

Liquid pipe

Model number

Outdoor twinning kit

A

Outdoor unit

B

BC controller (standard)

C

BC controller (main)

D

BC controller (sub)

E

Indoor unit (15 ~ 80)

F

Indoor unit (100 ~ 250)

G

Outdoor twinning kit

*1 The pipe sizes listed in columns A1 to A2 in this table correspond to the sizes

for the models listed in the unit 1 and 2 columns. When the order of unit 1 and

2 is changed, make sure to use the appropriate pipe size for the model.

Precautions for outdoor unit combinations

Refer to [Fig. 9.2.2] for the positioning of twinning pipes.

[Fig. 9.2.2] (P.6)

<A> The piping from the outdoor units to twinning pipe must be made to slope

downwards the twinning pipe. (high-pressure side only)

<B> Slope of twinning pipes (high-pressure side only)

Make sure the slope of the twinning pipes are at an angle within ±15° to the

ground.

If the slope exceeds the specifi ed angle, the unit may be damaged.

<C> Pipe connection example

The distributor on the low-pressure side must be placed in the outdoor

unit that has a larger capacity index of the two, regardless of the relative

positions of the outdoor units or their addresses.

(If outdoor units that have the same capacity are used in combination, the

distributor can be placed in either outdoor unit.)

If the distributor is placed in the outdoor unit that has a smaller capacity,

refrigerant will not be properly distributed and compressor failure may result.

A

Downward slope

B

Upward slope

C

BC controller

D

Twinning pipe

E

Slope of the twinning pipe is at an angle within ±15° to the ground

F

Twinning pipe (low-pressure side)GTwinning pipe (high-pressure side)

H

On-site piping (low-pressure connecting pipe: between outdoor units)

I

On-site piping (low-pressure main pipe: to BC controller)

J

On-site piping (high-pressure main pipe: to BC controller)

K

Straight run of pipe that is 500 mm or more

Caution:

Do not install traps other than the ones between outdoor units

described on a separate sheet to prevent oil backfl ow and compressor

start-up failure.

Do not install solenoid valves to prevent oil backfl ow and compressor

start-up failure.

Do not install a sight glass because it may show improper refrigerant

fl ow.

If a sight glass is installed, inexperienced technicians that use the

glass may overcharge the refrigerant.

•

•

•

17

GB

10. Additional refrigerant charge

At the time of shipping, the outdoor unit is charged with refrigerant.

This charge does not include the amount needed for extended piping and

additional charging of each refrigerant line will be required on site. In order that

future servicing may be properly provided, always keep a record of the size and

length of each refrigerant line and the amount of additional charge by writing it in

the space provided on the outdoor unit.

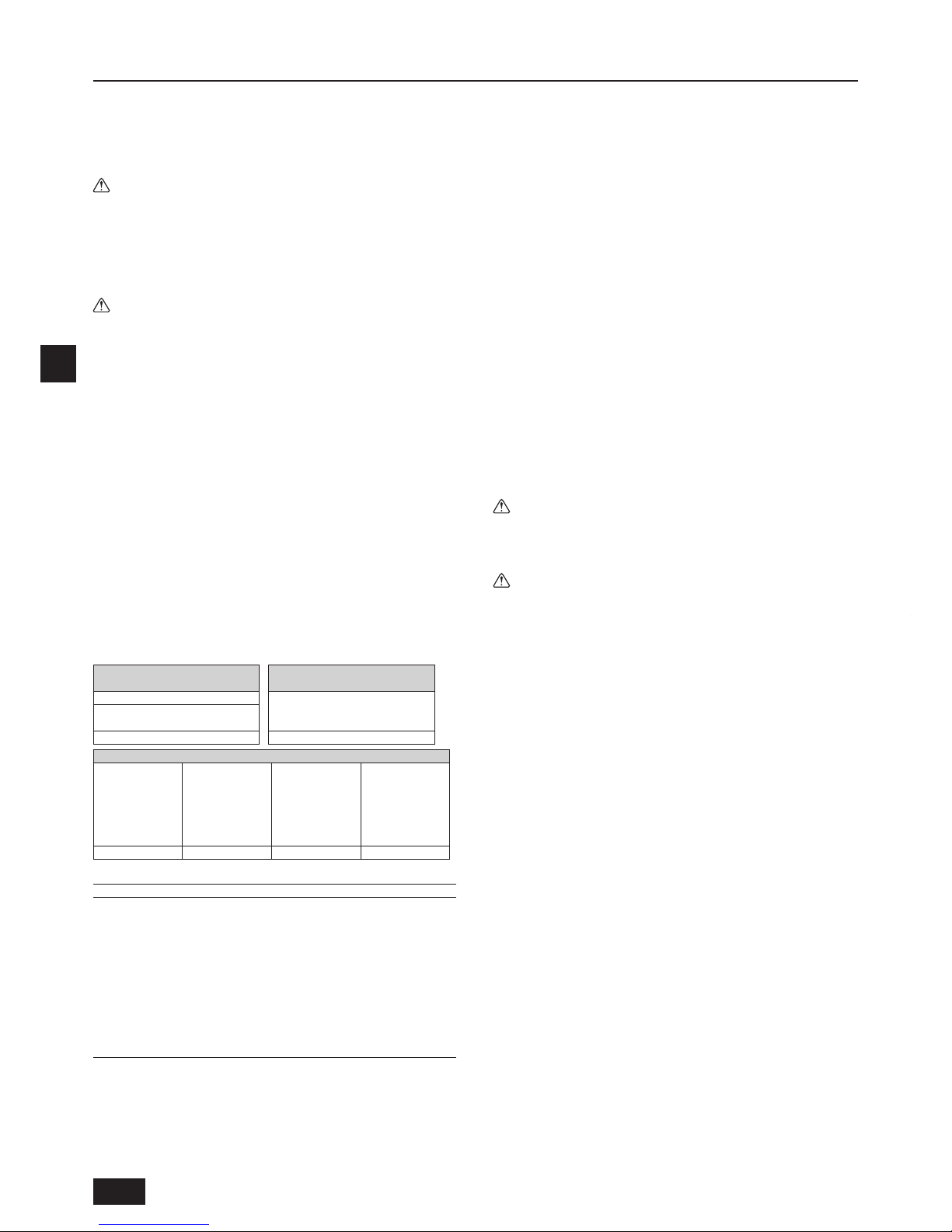

10.1. Calculation of additional refrigerant

charge

Calculate the amount of additional charge based on the length of the piping

extension and the size of the refrigerant line.

Use the table below as a guide for calculating the amount of additional

charging and then charge the system accordingly.

If the calculation results in a fraction of less than 0.1 kg, round up to the next

0.1 kg. For example, if the result of the calculation was 30.73 kg, round the

result up to 30.8 kg.

•

•

•

<Additional charge>

Additional refrigerant

charge

=

High-pressure

pipe size

Total length of ø28.58

×0.36

+

High-pressure

pipe size

Total length of ø22.2

×0.23

+

High-pressure

pipe size

Total length of ø19.05

×0.16

+

High-pressure

pipe size

Total length of ø15.88

×0.11

+

Liquid Piping Size

Total length of ø15.88

×0.2

(kg) (m)×0.36(kg/m) (m)×0.23(kg/m) (m)×0.16(kg/m) (m)×0.11(kg/m) (m)×0.2(kg/m)

+

Liquid Piping Size

Total length of ø12.7

×0.12

+

Liquid Piping Size

Total length of ø9.52

×0.06

+

Liquid Piping Size

Total length of ø6.35

×0.024

(m)×0.12(kg/m) (m)×0.06(kg/m) (m)×0.024(kg/m)

+

Total Outdoor Unit

Model Name

BC controller

(Standard/Main)

Per Unit

+

BC controller

(Main) HA-type

+

BC controller

(Sub) Total Units

BC controller

(Sub) Per Unit

+

Total Capacity of

Connected Indoor Units

Per Indoor

Unit

~80

2.0kg

(E)P200 2.0kg

2.0 kg

1 1.0 kg

81~160 2.5kg

(E)P250~(E)P500 3.0kg 161~330 3.0kg

(E)P550~(E)P900 5.0kg

2 2.0 kg

331~390 3.5kg

391~480 4.5kg

481~630 5.0kg

631~710 6.0kg

711~800 8.0kg

801~890 9.0kg

891~1070 10.0kg

1071~1250 12.0kg

1251~

14.0kg

<Example>

Indoor 1: 80 A: ø28.58 40 m a: ø9.52 10 m

At the

conditions

below:

2: 250 B: ø9.52 10 m b: ø9.52 5 m

3: 32 C: ø9.52 20 m c: ø6.35 5 m

4: 40 D: ø9.52 5 m d: ø6.35 10 m

5: 32 E: ø9.52 5 m e: ø6.35 5 m

6: 63 F: ø22.2 3 m f: ø9.52 5 m

G: ø19.05 1 m

Outdoor P550

The total length of each liquid line is as follows:

ø28.58: A = 40 m

ø22.2: F = 3 m

ø19.05: G = 1 m

ø9.52: C + D + E + a + b + f = 50 m

ø6.35: c + d + e = 20 m

Therefore,

<Calculation example>

Additional refrigerant charge

= 40 × 0.36 + 3 × 0.23 + 1 × 0.16 + 50 × 0.06 + 20 × 0.024 + 5 + 2 + 5

= 30.8 kg

Limitation of the amount of refrigerant to be charged

The above calculation result of the amount of refrigerant to be charged must become below the value in the table below.

Outdoor unit model P200 P250 P300 P350 P400 P450 P500 P550 P600 P650 P700 P750 P800 P850 P900

Maximum amount of

refrigerant *1 kg

24.8kg 33.8kg 34.8kg 39.7kg 46.7kg 53.7kg 60.2kg 69.2kg 72.9kg 74.6kg 90.3kg 91.5kg 91.5kg 91.5kg 91.5kg

Outdoor unit model

EP200 EP250 EP300 EP350 EP400 EP450 EP500 EP550 EP600 EP650 EP700

Maximum amount of

refrigerant *1 kg

27.3kg 34.0kg 35.0kg 39.7kg 47.5kg 49.2kg 62.9kg 69.6kg 73.3kg 74.8kg 74.8kg

*1 Amount of additional refrigerant to be charged on site

•

18

GB

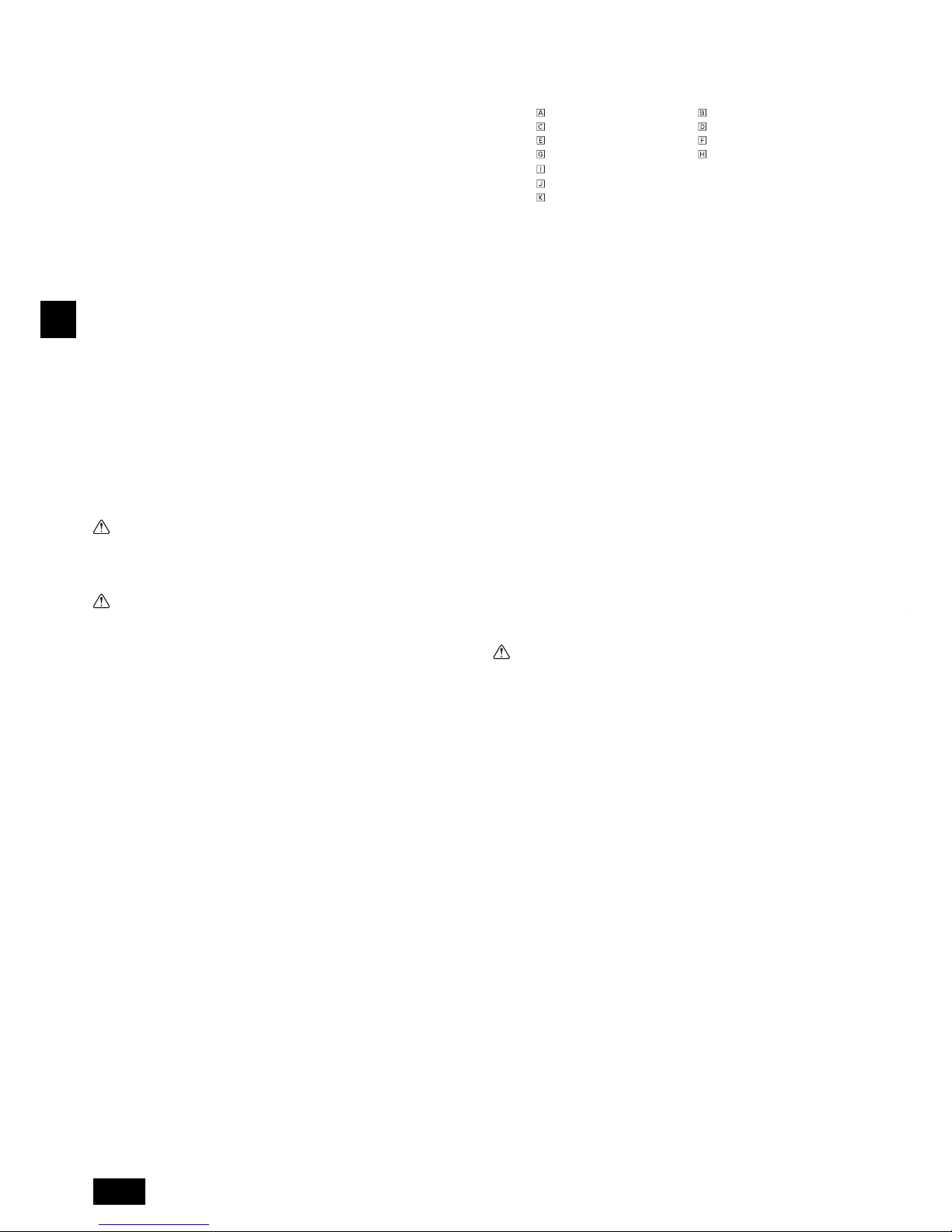

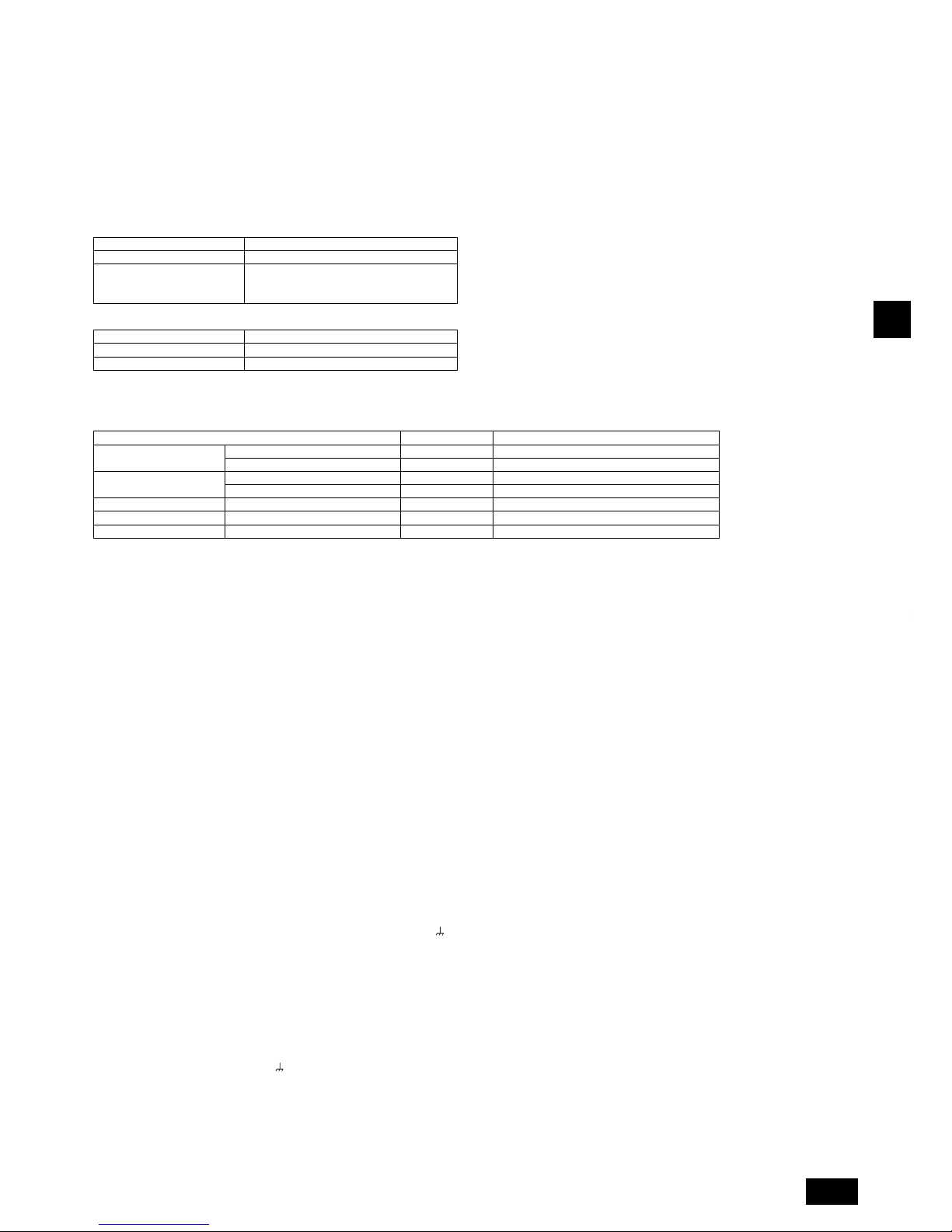

<Refrigerant piping connection examples>

[Fig.10.2.2] (P.7)

1

Connecting pipe (ID ø25.4, ID ø22.2) <Included with outdoor unit>

2

Connecting pipe (ID ø25.4, OD ø19.05) <Included with outdoor unit>

3

Connecting pipe (ID ø25.4, ID ø28.58) <Included with outdoor unit>

4

Connecting elbow (ID ø19.05, OD ø19.05) <Included with outdoor unit>

5

Connecting elbow (ID ø28.58, OD ø28.58) <Included with outdoor unit>

<A> Front pipe routing <B> Bottom pipe routing

<C> Low-pressure side <D> High-pressure side

<E> Severing portion referral fi gure

A

Shape

B

When not attaching a low-pressure twinning pipe

C

When attaching a low-pressure twinning pipe

D

Refrigerant service valve piping

E

On-site piping (low-pressure connecting pipe)

F

On-site piping (high-pressure connecting pipe)

G

Twinning kit (sold separately)

H

On-site piping (low-pressure connecting pipe: to BC controller)

I

On-site piping (low-pressure connecting pipe: to outdoor unit)

J

75 mm (reference measurement)

K

ID ø25.4 side

L

Severing portion

*1 For the attachment of the Twinning pipe (sold separately), refer to

the instructions included in the kit.

*2 Connection pipe is not used when the Twinning Kit is attached.

*3 Use a pipe cutter to sever.

Front pipe routing

P200, EP200

P250, P300

EP250, EP300,

P350, EP350

P400, P450

: Expand the high-pressure side on-site piping

(IDø15.88) and connect to the refrigerant service

valve piping.

: Expand the high-pressure side on-site piping

(IDø19.05) and connect to the refrigerant service

valve piping.

: Use the included connecting pipe 2 and elbow

4 to connect.

: Use the included connecting pipe 1 to connect.

P200, EP200

P250, P300,

EP250, EP300

P350, P400

EP350, P450

: Expand the low-pressure side on-site piping

(IDø19.05) and connect to the refrigerant service

valve piping.

: Use the included connecting pipe 1 to connect.

: Use the included connecting pipe 3 to connect.

: Use the included connecting elbow 5 to connect.

Bottom pipe routing

P200, EP200

P250, P300

EP250, EP300,

P350, EP350

P400, P450

: Expand the high-pressure side on-site piping

(IDø15.88) and connect to the refrigerant service

valve piping.

: Expand the high-pressure side on-site piping

(IDø19.05) and connect to the refrigerant service

valve piping.

: Use the included connecting pipe 2. Expand the

on-site piping to connect to ID ø 19.05.

: Sever the included connecting pipe 1 as shown

in the fi gure with a pipe cutter to use. Expand the

on-site piping to connect to ID ø 22.2.

P200, EP200

P250, P300,

EP250, EP300

P350, P400

EP350, P450

: Expand the low-pressure side on-site piping

(IDø19.05) and connect to the refrigerant service

valve piping.

: Sever the included connecting pipe 1 as shown

in the fi gure with a pipe cutter to use. Expand the

on-site piping to connect to IDø22.2.

: Sever the included connecting pipe 3 as shown

in the fi gure with a pipe cutter to use. Expand the

on-site piping to connect to IDø28.58.

: Expand the low-pressure side on-site piping

(IDø28.58) and connect to the refrigerant service

valve piping.

Satisfy the minimum insertion depth in the table below when expanding on-site

piping

Pipe diameter (mm) Minimum insertion depth (mm)

5 or more less than 8 6

8 or more less than 12 7

12 or more less than 16 8

16 or more less than 25 10

25 or more less than 35 12

35 or more less than 45 14

•

•

10.2. Precautions concerning piping

connection and valve operation

Conduct piping connection and valve operation accurately and carefully.

Removing the pinched connecting pipe

When shipped, a pinched connecting pipe is attached to the on site highpressure and low-pressure valves to prevent gas leakage.

Take the following steps 1 through 4 to remove the pinched connecting

pipe before connecting refrigerant pipes to the outdoor unit.

1 Check that the refrigerant service valve is fully closed (turned clockwise

all the way).

2 Connect a charging hose to the service port on the low-pressure/

high-pressure refrigerant service valve, and extract the gas in the

pipe section between the refrigerant service valve and the pinched

connecting pipe.

3 After vacuuming gas from the pinched connecting pipe, sever the

pinched connecting pipe at the location shown in [Fig.10.2.1] and drain

the refrigerant.

4 After completing 2 and 3 heat the brazed section to remove the

pinched connecting pipe.

[Fig. 10.2.1] (P.6)

<A> Refrigerant service valve (high-pressure side/brazed type)

<B> Refrigerant service valve (low-pressure side/brazed type)

A

Shaft

Fully closed at the factory, when connecting the piping, and when

vacuuming. Open fully after these operations are completed.

<When opening>

• Turn the shaft counterclockwise with a hexagonal wrench.

• Turn around the shaft until it stops.

<When closing>

• Turn the shaft clockwise with a hexagonal wrench.

• Turn around the shaft until it stops.

B

Shaft

Fully closed at the factory, when connecting the piping, and when

vacuuming. Open fully after these operations are completed.

<When opening>

• Turn the shaft counterclockwise.

• Turn around the shaft until it stops.

<When closing>

• Turn the shaft clockwise.

• Turn around the shaft until it stops.

C

Stopper pin

Prevents the shaft from turning 90° or more.

D

Service port

Available for gas venting of the pinched connecting pipe, or vacuuming in the

refrigerant pipes on the site.

E

Cap

Remove the cap before operating the shaft. Be sure to return it to the original

position after completing the operation.

F

Pinched connecting pipe severing portion

G

Pinched connecting pipe brazing portion

Warning:

The sections between the refrigerant service valves and the pinched

connecting pipes are fi lled with gas and refrigerant oil. Extract the gas

and refrigerant oil in the above-mentioned pipe section before heating

the brazed section to remove the refrigerant service valve pinched

connecting pipe.

- If the brazed section is heated without fi rst extracting the gas and

refrigerant oil, the pipe may burst or the pinched connecting pipe may blow

off and ignite the refrigerant oil, causing serious injury.

Caution:

Place a wet towel on the refrigerant service valve before heating the brazed

section to keep the temperature of the valve from exceeding 120 ˚C.

Direct the fl ame away from the wiring and metal sheets inside the unit

to prevent heat damage.

Caution:

Do not vent R410A into the atmosphere.

R410A is a Fluorinated Greenhouse gas, covered by the Kyoto

Protocol, with a Global Warming Potential (GWP) = 1975.

Refrigerant pipe connection

This product includes connecting pipes for front piping and bottom postpiping. (Refer to [Fig.10.2.2])

Check the high-pressure/low-pressure piping dimensions before connecting

the refrigerant pipe.

Refer to item 9.2 Refrigerant piping system for piping dimensions.

Make sure that the refrigerant pipe is not touching other refrigerants pipes,

unit panels, or base plates.

Be sure to use non-oxidative brazing when connecting pipes.

Be careful not to burn the wiring and plate when brazing.

•

•

•

•

•

•

•

•

19

GB

After evacuation and refrigerant charging, ensure that the handle is fully

open. If operating with the valve closed, abnormal pressure will be imparted

to the high- or low-pressure side of the refrigerant circuit, giving damage to

the compressor, four-way valve, etc.

Determine the amount of additional refrigerant charge by using the formula,

and charge refrigerant additionally through the service port after completing

piping connection work.

After completing work, tighten the service port and cap securely so as not to

generate any gas leakage. (Refer to the table on the below for appropriate

tightening torque.)

Appropriate tightening torque:

Outer

diameter of

copper pipe

(mm)

Cap (N·m) Shaft (N·m)

Size of

hexagonal

wrench

(mm)

Service port

(N·m)

ø9.52 15 6 4

12

ø12.7 20 9 4

ø15.88 25 15 6

ø19.05 25 30 8

ø25.4 25 30 8

ø28.58 25 – – 16

Caution:

Keep the valve closed until refrigerant charging to the pipes to be

added on site has been completed. Opening the valve before charging

the refrigerant may cause damage to the unit.

Do not use a leak detection additive.

[Fig. 10.2.3] (P.6)

A Example of closure materials (fi eld supply)

B Fill the gap at the site

*When not attaching a low-pressure twinning pipe.

•

•

•

•

•

Make sure to seal-off the space around areas where the wires and refrigerant

pipes enter the unit to ensure that small animals, rainwater, or snow cannot

enter the unit through such openings and cause damage to the unit.

Caution: