Mitsubishi Electric City Multi PUMY-P36NHMU, City Multi PUMY-P36NHMU-BS Datasheet

Model: PUMY-P36NHMU (-BS)

Job Name:

Drawing Reference: Schedule No.

System No.:

OUTDOOR VRF

SYSTEM FEATURES

tinu roodtuo esahp-elgniS •

with variable refrigerant

ow (VRF)

technology

• Inverter-driven (variable

speed) compressor

• Total refrigerant piping

length of 394' (120 m)

• Uses CITY MULTI indoor

units and Controls Network

OUTDOOR VRF SYSTEM

SPECIFICATIONS

Capacity

Cooling……………………………………………..36,000 Btu/h

Heating……………………………………………..40,000 Btu/h

Power

Power Source……………….........208 / 230V, 1-phase, 60Hz

Power Input

Cooling………………………………………………3.22 kW

Heating………………………………………………2.93 kW

Current

Cooling (208 / 230)........................................14.2 / 15.7 A

Heating (208 / 230) ...................................…12.9 / 14.2 A

Minimum Circuit Ampacity (MCA) (208 / 230)….……..…26 A

Breaker Size for Wiring ........................................….......30 A

External Finish………Pre-coated Galvanized-steel Sheets

Munsell No. 3Y 7.8 / 1.1

External Dimensions

Inches………………..53-3/16 h x 37-7/16 w x 13 (+1-3/16) d

mm……………………………..1,350 h x 950 w x 330 (+30) d

Net Weight………………………………….287 lbs. / 130 kg

Fan

Type x Quantity...………..............................Propeller Fan x 2

Airflow Rate……………………………………...……3,530 cfm

Motor Output……...…..………………………0.086 + 0.086 kW

Compressor

Type………………...................………….Inverter-driven Scroll

Motor Output………..…………………………………….2.2 kW

Lubricant………………..…...………………………….FV50S

Refrigerant……………..…...…………………………..R410A

Protection Devices

High Pressure Protection………………High Pressure Switch

Compressor…………Discharge Thermo / Overcurrent Detection

Fan…...…………………………..Overheat / Voltage Protection

Piping Diameter

Liquid (High Pressure)………..……………3/8" / 9.52 mm Flare

Gas (Low Pressure)………………………5/8" / 15.88 mm Flare

Indoor Unit

Total Capacity…..…….50% –130% of Outdoor Unit Capacity

Model / Quantity…………………..…………..….P06-P36 / 1 ~ 6

Sound Level (Cooling / Heating)………….49 / 51 dB(A)

Operating Temperature Range

Cooling (Outdoor)……………….23°F ~ 115°F (-5° ~ +46°C) DB*

Heating (Outdoor)…………….0°F ~ +60°F (-18° ~ +15°C) WB

Anti-corrosion Protection

Blue Fin Treatment applied to condenser coil protects coil

from airborne contaminants.

Seacoast Protection

External Panel Base: Steel sheets with aluminum-zinc-

•

magnesium coating on external and internal surfaces

•

External Panel (Top, Front, Back): Galvanized steel sheets

with acrylic- and polyester-resin coating on external and

internal surfaces

•

Fan Motor Support: Galvanized-steel sheets with epoxy resin coating applied to external surface

•

Separator and Valve Bed: Galvanized-steel sheets with

epoxy-resin coating

Options

□ Branch Joint (T-Branch)…………………..…....CMY-Y62-G-E

□ Header - Four-Branch…………………………….CMY-Y64-G-E

□ Header - Eight-Branch……………………………..CMY-Y68-G-E

□ Drain Pan………………………………….….….PAC-SG64DP-E

□ Drain Socket………………………………….….PAC-SG61DS-E

Notes:

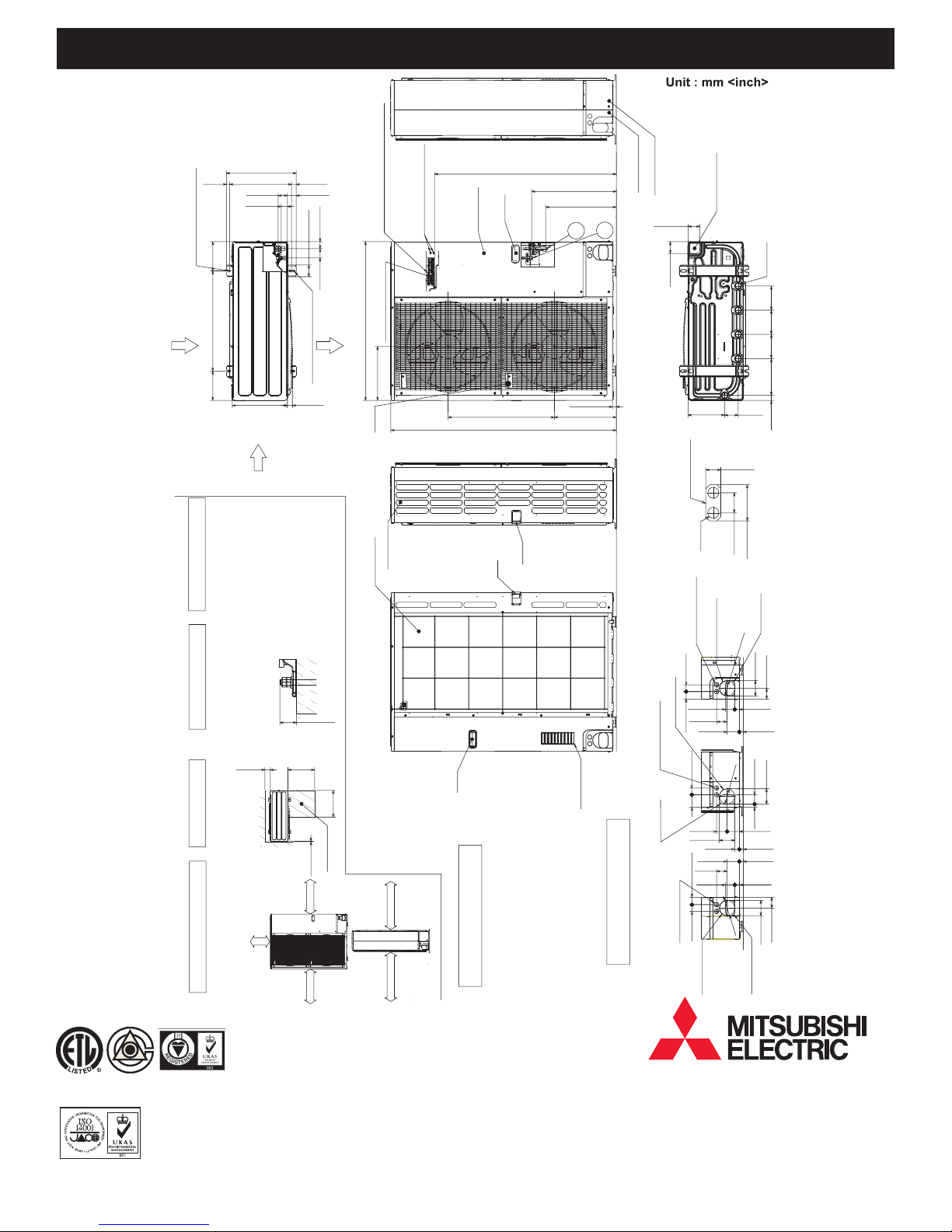

Model: PUMY-P36NHMU (-BS) – DIMENSIONS

19<3/4>

2-U Shaped notched hole

(Foundation Bolt M10<W3/8>)

175

<6-7/8>

Rear Air Intake

600<23-5/8>

175

<6-7/8>

417<16-13/32>

56<2-7/32>

37<1-15/32>

330<13>

Side Air Intake

4 PIPING-WIRING DIRECTIONS

Piping and wiring connections

can be made using one of four

locations on the unit: front, right,

back, and bottom.

28<1-3/32> 370<14-9/16>

53<2-3/32>

Left …… For the power supply

70<2-3/4>

2-12 o36 Oval hole

Terminal block

56<2-7/32> 42<1-21/32>

Air Discharge

950<37-13/32>

(Foundation Bolt M10<W3/8>)

30<1-3/16>

Center … For the transmission line

Right…… For concentration control

( )

Ground for the transmission line

Ground for concentration control

Ground for the power supply

("GR"marking position)

322<12-11/16>

Handle

Side Air Intake

Rear Air Intake

Handle

Service panel

635<25>371<14-19/32>

1350<53-5/32>

Handle

Handle

1088<42-27/32>

1

w1 507<19-31/32>

w1 423<16-21/32>

2

23<29/32>

Front piping cover

Rear piping cover

71<2-13/16>

When installing the conduit,

set the attachment to the

Bottom piping hole

(Knockout)

71<2-13/16>

1/2 Conduit attachment

inside of each panel.

2-ø22<7/8>

Conduit hole

(2-n27<1-1/16>Knockout)

Rear trunking hole

(Knockout)

219<8-5/8>

40<1-9/16>

n92

<3-5/8>

Drain hole

5-n33<1-5/16>

145

145

145

220

81<3-3/16>

31<1-7/32>

74<2-19/32>

Back piping hole

(Knockout)

<5-23/32>

<5-23/32>

<5-23/32>

<8-21/32>

30<1-3/16>

mm<inch>

Certicate Number FM33568

Certicate Number EC97J1227

FOUNDATION

Please rmly secure the unit

using 4 foundation (M10<W3/8>)

2 SERVICE SPACE 3 FOUNDATION BOLTS

Space needed for service

access is shown in the

1 CLEARANCE SPACE

The diagram below shows a

basic example.

Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired environmental

management system standard ISO 14001 certication.

The ISO 14000 series is a set of standards applying to environmental protection set by the

International Standard Organization (ISO).

<Foundation bolt height>

bolts.(Bolts and washers must

be purchased separately.)

<5-29/32>

Min.150mm

diagram below.

FREE

See the installation manuals for details.

Mitsubishi Electric Air Conditioning & Refrigeration Systems Works acquired ISO

9001 certication under Series 9000 of the International Standard Organization (ISO)

based on a review of quality warranties for the production of refrigeration and air

conditioning equipment.

ISO Authorization System

The ISO 9000 series is a plant authorization system relating to quality warranties as

stipulated by the ISO. ISO 9001 certies quality warranties based on the "design,

development, production, installation and auxiliary services" for products built at

an authorized plant.

<19-11/16>

Min.500mm

Min.500mm

Service space

Min.10mm<3/8>

Min.10mm<3/8>

Min.10mm<3/8>

30mm<1-3/16>

Max.

<19-11/16>

Min.150mm<5-29/32>

Min.1000mm<39-3/8>

Handle

Ø

Ø

Example of Notes

1 ……Refrigerant GAS pipe connction (FLARE) 15.88 (5/8 inch)

2 ……Refrigerant LIQUID pipe connection (FLARE) 9.52 (3/8 inch)

w1…..Indication of STOP VALVE connection location.

92<3-5/8>

65<2-9/16>

Right trunking hole

(Knockout)

45<1-25/32> 40<1-9/16>

Conduit hole

(2-n27<1-1/16>Knockout)

40<1-9/16>

63<2-1/2>

n92

27<1-1/16> 55<2-3/16>

23<29/32> 73<2-7/8>

/8>

<3-5

92<3-5/8>

Air intake

75

Right piping hole

(Knockout)

Conduit hole

<2-31/32>

45<1-25/32>40<1-9/16>

(2-n27<1-1/16>Knockout)

92<3-5/8>

73<2-7/8>

<2-1/2>

63

55<2-3/16>

19<3/4> 55<2-3/16>

73<2-7/8> 63<2-1/2>

23<29/32> 27<1-1/16>

23<29/32>

27<1-1/16>

/8>

<3-5

n92

65<2-9/16>

92<3-5/8>

Piping Knockout Hole Details

Front piping hole

Front trunking hole

(Knockout)

(Knockout)

Mitsubishi Electric Sales Canada Inc.

www.MitsubishiElectric.ca

Specifications are subject to change without notice.

PUMY-P36NHMU(-BS)_200802b © MITSUBISHI ELECTRIC

Loading...

Loading...