Mitsubishi Electric City Multi PFD-P250·500VM-E Installation Manual

Air-Conditioners For Building Application

INDOOR UNIT

PFD-P250·500VM-E

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALA CIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

MANUAL DE INSTALAÇÃO

Para um uso seguro e correcto, é favor ler o manual de instruções por completo antes de utilizar a unidade de ar condicionado.

KURULUM KILAVUZU

Do¤ru ve güvenli kullan›m için, klima ünitesini kullanmadan önce lütfen bu kullanma k›lavuzunu bafltan sona okuyun.

GB

D

F

I

P E

TR

HG

RU

TR

2

5

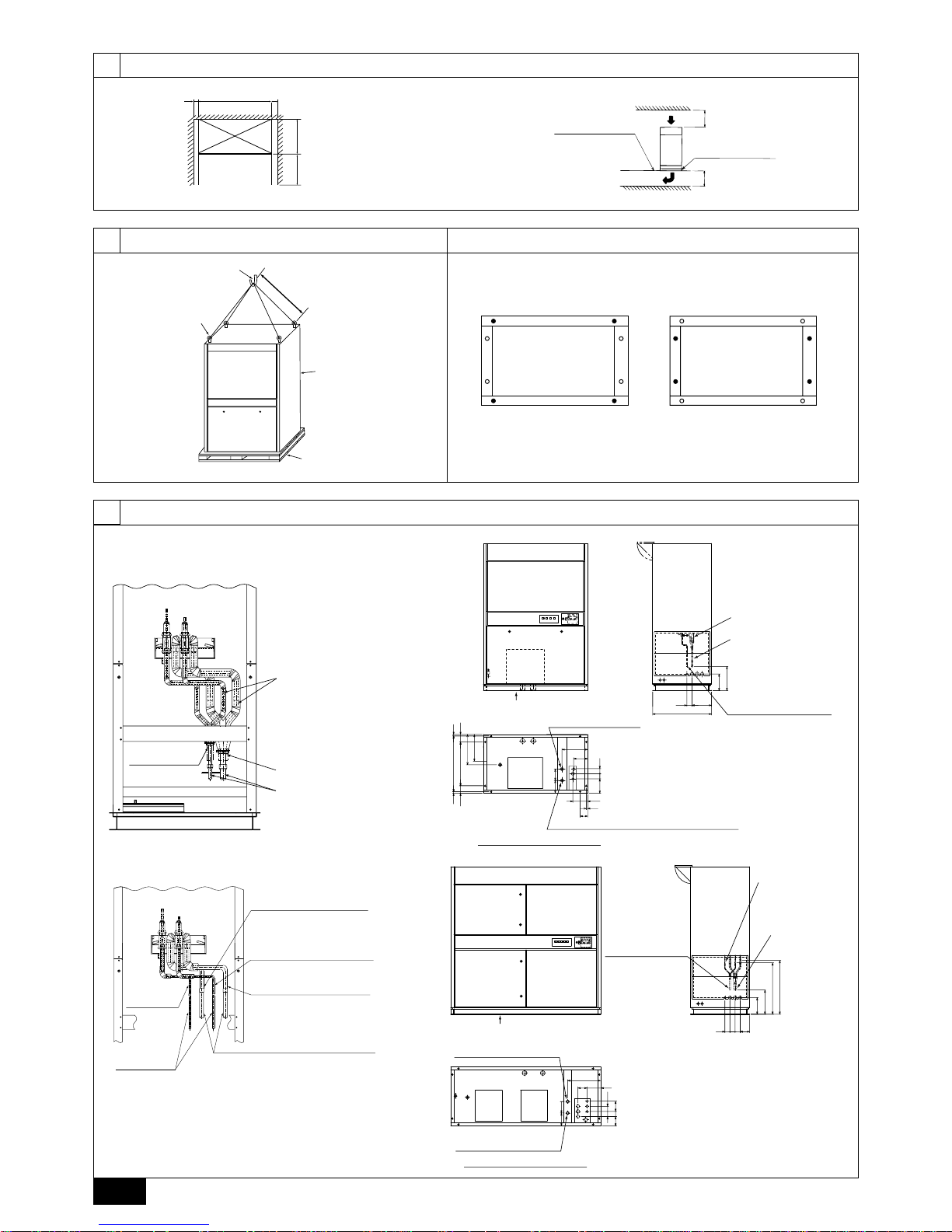

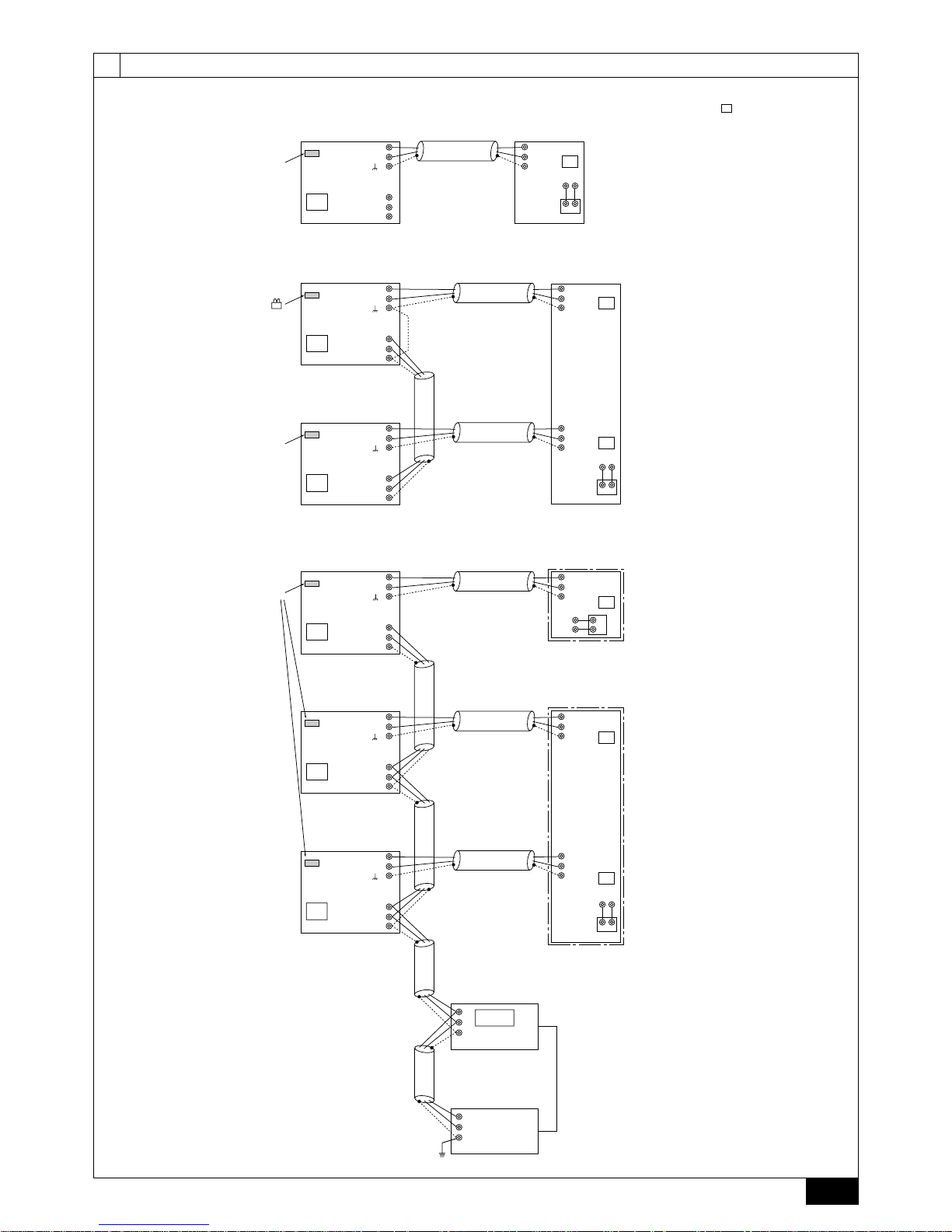

[Fig. 5.1.1]

<A> Single refrigerant circuit

5.1

3

3.1

[Fig. 3.1.1]

[Fig. 4.1.1] [Fig. 4.2.1]

C “•” indicates foundation bolt holes used.

4

4.24.1

[Fig. 3.1.2]

unit

1000

*

mm

>

=

780 mm

ACB

*

300 mm

D Free access floor

E Anti-vibration pad

>

=

300 mm

>

=

A: 200 mm or more

(as seen from top face of unit)

B: 500 mm or more

* It is necessary for the removal of the

panel beyond 600 mm

C: PFD-P250VM-E: 1380 mm

PFD-P500VM-E: 1980 mm

1300 mm

>

=

A Lifting hook

C Unit

D Base

B Eyebolt (supplied)

A Example 1 - Use holes at front and rear. B Example 2 - Use holes at sides.

E Unit weight

PFD-P250VM-E: 380 kg

PFD-P500VM-E: 520 kg

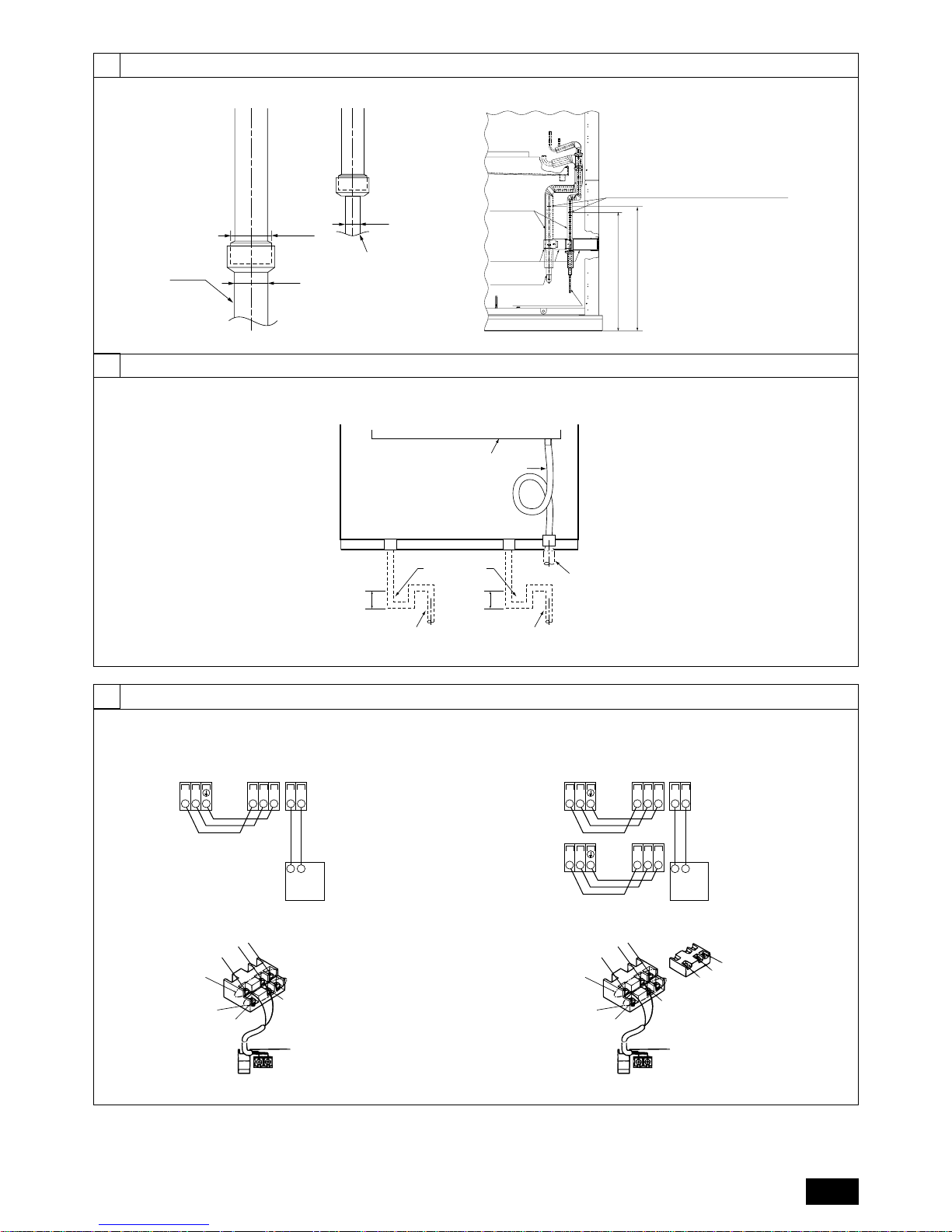

<C> Model 250

<D> Model 500

B

Refrigerant piping

(liquid)

A Thermal insulation

C Refrigerant piping

(gas)

D Piping for close

68 260

320

220

780

186

196

68

68

192

100 580 100

20 740 20

401

365

100

20

150171

340

K Location of

refrigerant piping

L Refrigerant piping

(ø22.2 Brazed) (gas)

M Refrigerant piping

(ø9.52 Brazed) (liquid)

A

N Main drain piping

joint outlet (Rp1-1/4)

W

Air outlet

O Emergency drain piping joint outlet (Rp1-1/4)

P As seen from bottom face A

220

68

68 68

124

320

710

680

135

68

124

120

171 150

440

185

135

<Rp1-1/4>

A

Q Location of

refrigerant piping

R Refrigerant piping

(ø28.58 Brazed)

(gas)

S Refrigerant piping

(ø15.88 Brazed)

(liquid)

W

Air outletWAir outlet

V As seen from bottom face A

U Emergency drain piping

joint outlet (Rp1-1/4)

T Main drain piping joint outlet

(Rp1-1/4)

<B> Two refrigerant circuits

E

No. 1 gas pipe on the unit side

Outer diameter

Model P500:

ø

22.2

H

No. 2 gas pipe on the unit side

Outer diameter

Model 500:

ø

22.2

G

No. 2 liquid pipe on the unit side

Outer diameter:

ø

9.52

F

No. 1 liquid

pipe on the

unit side

J

Field-installed gas pipe

Outer diameter <Expansion work required>

Model 500:

ø

22.2

To be connected to the gas pipe

on the unit pipe by brazing.

* Use non-oxidized brazing material.

I

Field-installed

liquid pipe

Outer diameter:

ø

9.52

<Expansion work required>

To be connected to the liquid pipe

on the unit pipe by brazing.

* Use non-oxidized brazing material.

Outer diameter:

ø

9.52

3

6

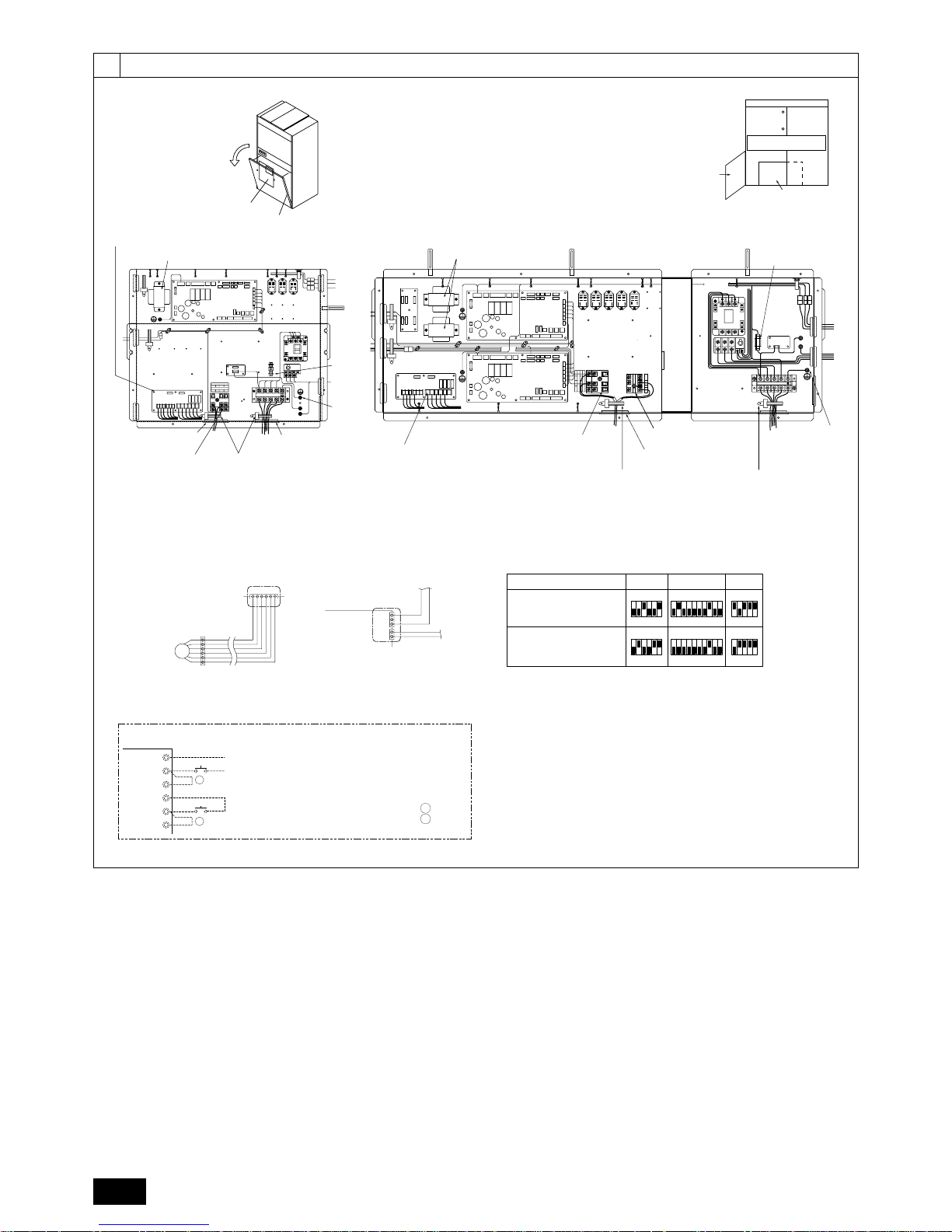

6.1

[Fig. 6.1.1]

[Fig. 6.2.1]

[Fig. 7.2.1]

6.2

7

7.2

ø

22.2

(ø28.58) OD

ø

22.2

(ø28.58)

ø9.52

(ø15.88)

A Piping on site

Expand the end of the

pipe and braze it to the

connecting pipe

(non-oxidizing brazing).

B Piping on site

Expand the end of the pipe

and braze it to the connecting

pipe (non-oxidizing brazing).

TB5 TB15

SA1 B1

TB3

M1M2 21

A Terminal block for

indoor transmission

cable

B Terminal block for

outdoor transmission

cable

C MA Remote

controller

TB5-1 TB15

SA1 B1

TB3

M1M2 21

TB5-2

SA2 B2

TB3

M1M2

A Terminal block for

indoor transmission

cable

B Terminal block for

outdoor transmission

cable

C MA Remote

controller

DC10~13V

AB

12

A2

1

2

A Non-polarized

D MA Remote Controller

Upper level

(TB5-1)

C Lower level

(TB15)

B2

S

S

A1

B1

(TB5-2)

DC10~13V

AB

12

A1

1

2

A Non-polarized

D MA Remote Controller

Upper level

(TB5)

C Lower level

(TB15)

B1

S

B B

[Fig. 7.2.2]

<A> Model 250

<A> Model 250

<B> Model 500

<B> Model 500

100mm

or more

100mm

or more

A Drain pan

B Drain hose

C As seen from

front of unit

D Main drain piping

on site

E Emergency drain piping

on site

G Drain piping on site

(for humid filter)

F Trap (on-site

piping work)

A

Pipe cover

B

Pipe

mounting

plate

C

Refrigerant

piping (gas)

D

Refrigerant

piping (liquid)

680 (Cut the liquid pipe here)

710 (Cut the gas pipe here)

When the unit is connected to a 2-refrigerant circuit,

cut off these pipes approximately 20 mm above

the point where expanded pipes are connected.

<Preparation of the pipes in a 2-refrigerant-circuit>

• Remove the pipe mounting plate.

• Peel off the pipe cover.

• Cut off both pipes at the specified location.

[Fig. 6.1.2]

6

4

7

7.3

[Fig. 7.3.1]

A Transformer

A Transformer

E Connect trasmission

line to outdoor unit

D Fix in place after

connecting writing.

F To power supply

B External I/O board

H Fuse

G Earth

D No.2 Transmission line

terminal block

(Note: Connect to top

terminal block)

C No.1 Transmission line

terminal block

E Connect trasmission line

to outdoor unit

F Fix in place after connecting writing.

G Earth

B External I/O board

C Transmission line

terminal block

H Fuse

I Control box

J Bottom panel

I Control Box

J Bottom panel

<A> Model 250 <B> Model 500

[Fig. 7.3.2]

Connection changes to be made when connected to a 2-refrigerant circuit

When connected to

a 2-refrigerant circuit

When connected to

a 2-refrigerant circuit

Remove the LEV2B connector

from the adapter board, and

connect it to CN60 on No. 2 board.

CN60

6 5 4 3 2 1

6

5

4

3

2

1

CN3A

CN2M

1

2

2

1

3

No. 2 board

Connect the connectors to

CN3A and CN2M on No. 2 board.

When connected to a

single-refrigerant circuit

(factory setting)

When connected to t a

2-refrigerant circuit

Model 500 SW2 SW3 SW4

ON

123456 12345123456789

10

123456 12345123456789

10

ON ON

ON ON ON

LEV2

Switch setting changes to be made when connected to a 2-refrigerant circuit.

External input-output

board (IFB)

AC

A1

A2

BC

B1

B2

The case of with-voltage input

...

A

The case of no-voltage input

....

B

A

B

TB23

TB21

When using the external input function on the

indoor unit that is connected to a two-refrigerant

circuit, connect the short-circuit plate that is

supplied with the unit to the appropriate terminals

on the external input-output board.

5

7.4

[Fig. 7.4.1]

[Fig. 7.4.2]

[Fig. 7.4.3]

• When there is a single Model 250 unit

• When there is a single Model 500 unit (Two refrigerant circuits)

• When connected to G50

TB3

TB7

M1

M2

M1

M2

S

M1

TB5

TB15

MA

12

M2

AB

S

51

<PUHY-P250YGM-A>

G-50

000

D Power supply unit

IC

CN41

01

TB3

TB7

M1

M2

M1

M2

S

M1

TB5-1

TB5-2

M2

S

51

OC <PUHY-P250YGM-A> IC

01

TB3

TB7

M1

M2

M1

M2

S

M1

TB15

MA

12

M2

AB

S

52

OC <PUHY-P250YGM-A>

02

TB15

MA

12

AB

TB3

TB7

M1

M2

M1

M2

S

M1

TB5

TB5-1

TB5-2

M2

S

51

OC

IC

(model 250)

IC (model 500)

01

TB3

TB7

M1

M2

M1

M2

S

M1

TB15

MA

1

2

M2

A

B

S

53

OC

03

04

M1

M2

S

TB3

TB7

M1

M2

M1

M2

S

54

OC

OC

A

B

S

A

B

S

TB2

*2 The Model 250 indoor unit

contains one indoor controller board.

A CN41 as it is

A

Replace CN41

with CN40

B Group 1

C Group 2

A CN41 as it is

B CN41 as it is

*1 The numbers shown

in the square ( )are addresses.

* The Model 500 indoor unit

contains two indoor controller boards.

E DC Power supply (DC 12V)

7

6

7.5

B External power supply

C Start/Stop

E Common

F Start/Stop

H Display power supply

A With-voltage input

K External I/O board

D No-voltage input

G Relay contact output

I Operation status

J Fault

L Terminal block connection

M Connector connection

N Wiring distance 100 m or less.

L1

L2

SW12

SW11

CN53

1

2

3

4

5

1

2

3

4

5

TB21

TB22

TB23

XA

XB

XB

XA

COM

1

2

BC

B1

B2

AC

A1

A2

3

4

5

CN54

[Fig. 7.5.1]

[Fig. 7.5.2]

Display

power supply

L1, L3

L2, L4

XA ~ XE

DC30 V 1 A or less

AC220 - 240 V 1 A

Operation status

Fault status

Relay (allowable current 10mA - 1 A)

G Relay contact output

<A> Model 250

<B> Model 500

B External power supply

C Start/Stop

A With-voltage input

E Common

F Start/Stop

H Display power supply

D No-voltage input

G Relay contact output

I Operation status (No.1)

J Fault (No.1)

I Operation status (No.2)

J Fault (No.2)

L Terminal block connection

M Connector connection

N Wiring distance 100 m or less.

SW12

K External I/O board

L1

L2

L3

L4

(*1)

Short circuit plate

(*1)

Short circuit plate

SW11

CN53

1

2

3

4

5

1

2

3

4

5

TB21

TB22

TB23

XA

XB

XC

XE

XD

XE

XD

XC

XB

XA

COM

1

2

BC

B1

B2

AC

A1

A2

3

4

5

CN54

7

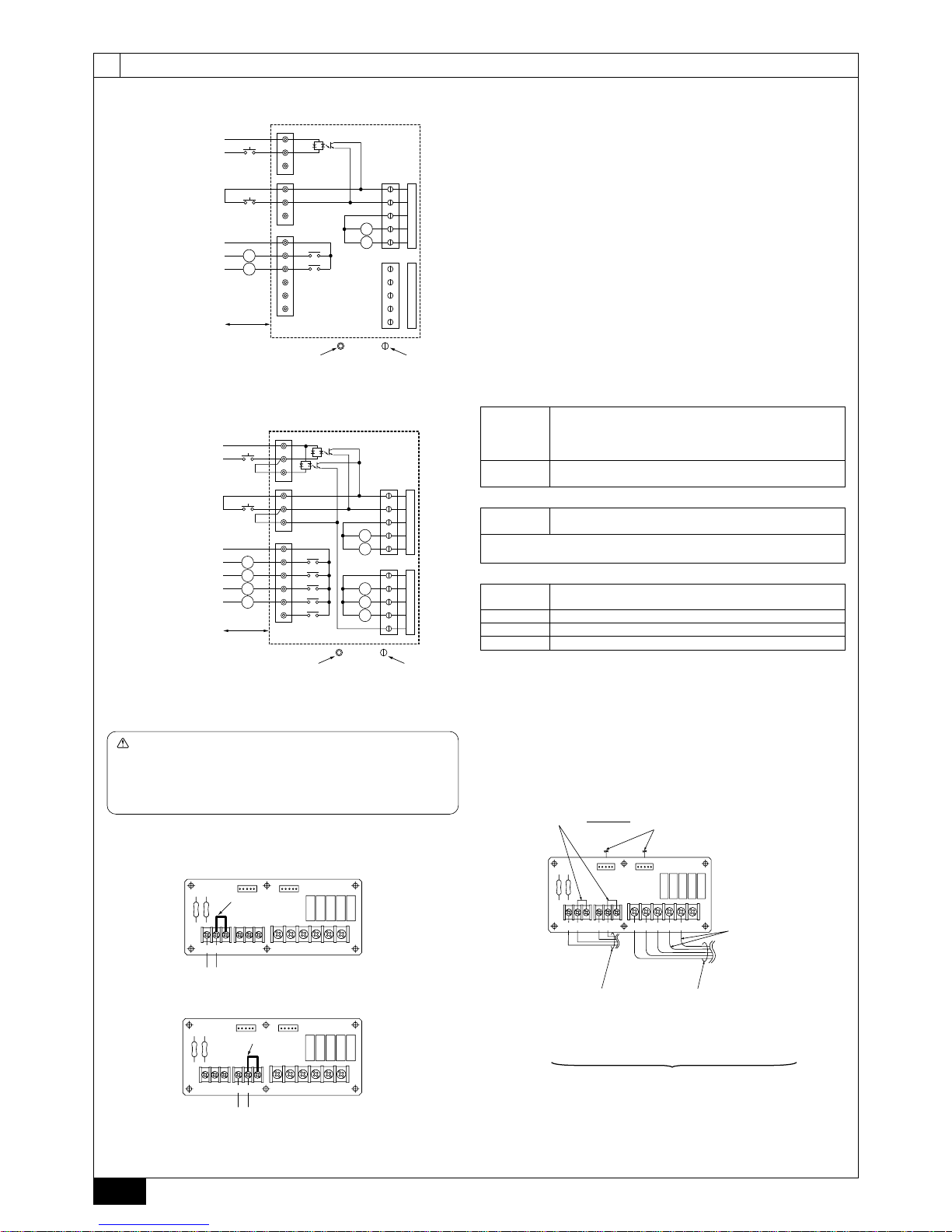

• Notes on using external functions (Model 500 only)

(*1)

For instructions on how to install the short circuit plate, refer to “Notes on using

external input function” shown below.

When using the external input function on the indoor unit that is connected to a tworefrigerant circuit, connect the short-circuit plate that is supplied with the unit to the

appropriate terminals on the external input-output board.

Without the short-circuit plate, the unit will not function properly.

Don’t connect the short-circuit plate in case of a one-refrigerant circuit.

Caution

External input-output board

<The case of with-voltage input>

· Connecting the short-circuit plate

<The case of no-voltage input>

External input-output board

Short-circuit plate

External input

54321COM

B2B1BCA2A1AC

TB23

TB21 TB22

CN53 CN54

Short-circuit plate

External input

54321COM

TB23

TB21 TB22

CN53 CN54

B2A2A1AC B1BC

A Site wiring

B Fix low-voltage system

(DC30 V or less) wiring

with clamps and pass to

unit via transmission line

wiring holes.*1

C Fix high-voltage system

(AC220 - 240 V) wiring

with clamps and pass to

unit via power supply

wiring holes.*2

D To CN51 on control board

(inner wiring)

E model 500 only

E model 500 only

For instructions on how to install

the short circuit plate, refer to

"Notes on using external input

function" shown on the left.

54321COM

B2B1BCA2A1AC

TB23

TB21 TB22

CN53 CN54

SW11

Remote Start/Stop switch

* Toggles ON/OFF each time switch is pressed (pulse input).

Contact:Minimum applicable load DC 12 V 1 mA

Contact rating DC 12 V 0.1 A and over

D No-voltage input

A With-voltage input

External

power supply

SW12

Pulse input of start or stop

DC12 - 24 V

Input current (per contact)

Approximately 10 mA (DC12 V)

Remote Start/Stop switch

* Toggles ON/OFF each time switch is pressed (pulse input).

Loading...

Loading...