Mitsubishi Electric CITY MULTI PFD-P250-A, CITY MULTI PFD-500VM-A Installation Manual

Air-Conditioners For Building Application

INDOOR UNIT

PFD-P250·500VM-A

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

INSTALLATIONSHANDBUCH

Zum sicheren und ordnungsgemäßen Gebrauch der Klimageräte das Installationshandbuch gründlich durchlesen.

MANUEL D’INSTALLATION

Veuillez lire le manuel d’installation en entier avant d’installer ce climatiseur pour éviter tout accident et vous assurer d’une utilisation correcte.

MANUAL DE INSTALACIÓN

Para un uso seguro y correcto, lea detalladamente este manual de instalación antes de montar la unidad de aire acondicionado.

MANUALE DI INSTALLAZIONE

Per un uso sicuro e corretto, leggere attentamente questo manuale di installazione prima di installare il condizionatore d’aria.

INSTALLATIEHANDLEIDING

Voor een veilig en juist gebruik moet u deze installatiehandleiding grondig doorlezen voordat u de airconditioner installeert.

РУКОВОДСТВО ПО УСТАНОВКЕ

Для осторожного и правильного использования прибора необходимо тщательно ознакомиться с данным руководством по

установке до выполнения установки кондиционера.

GB

D

F

I

NL

E

RU

GR

RU

TR

2

5

[Fig. 5.1.1]

5.1

3

3.1

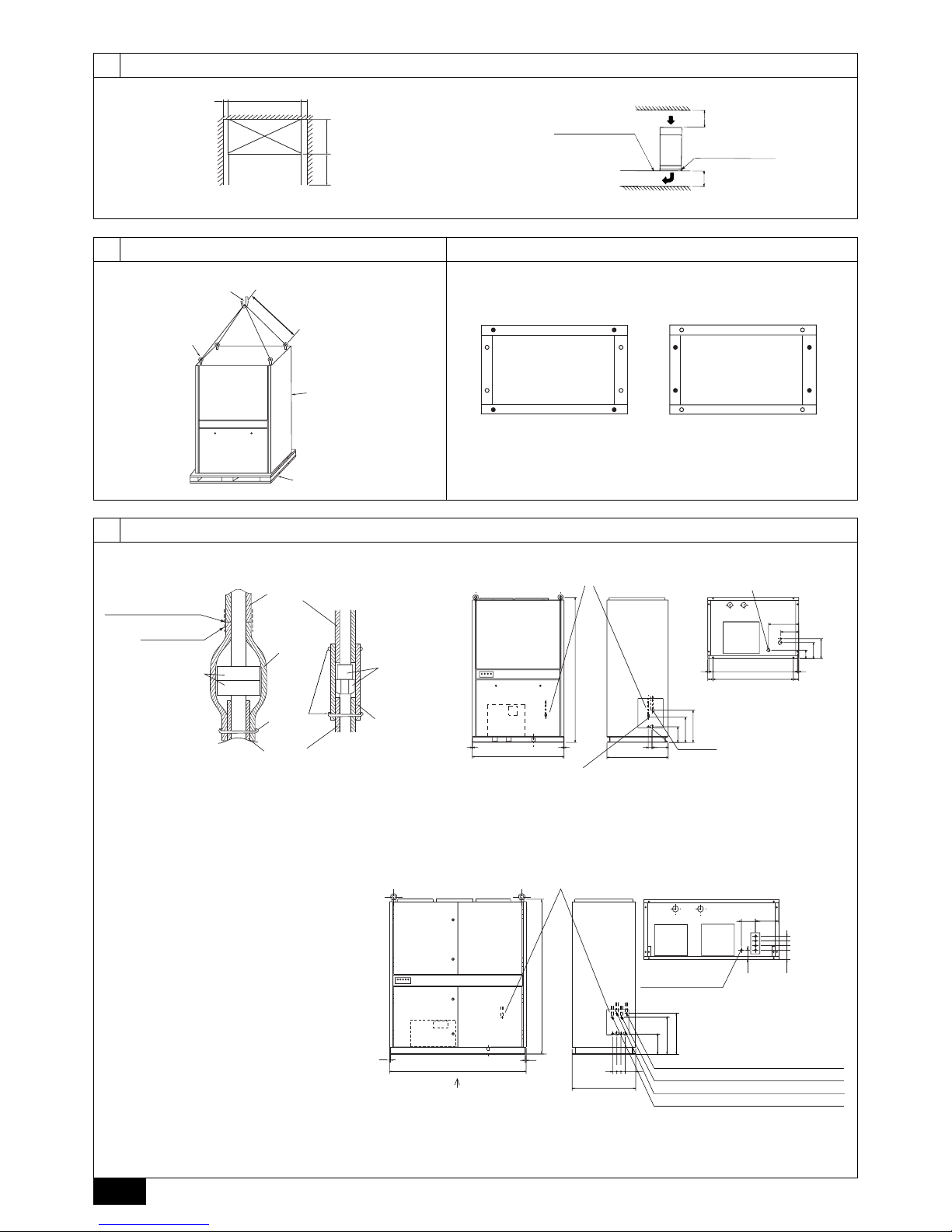

[Fig. 3.1.1]

[Fig. 4.1.1] [Fig. 4.2.1]

C “•” indicates foundation bolt holes used.

4

4.24.1

[Fig. 3.1.2]

1200 mm

unit

800 mm

>

=

800 mm

AA

*

300 mm

B Free access floor

C Anti-vibration pad

>

=

300 mm

>

=

A: 200 mm or more (as seen from top face of unit)

* At least 500 mm when piping is taken from the right side.

1300 mm

>

=

A Lifting hook

C Unit

D Base

B Eyebolt (supplied)

A Example 1 - Use holes at front and rear. B Example 2 - Use holes at sides.

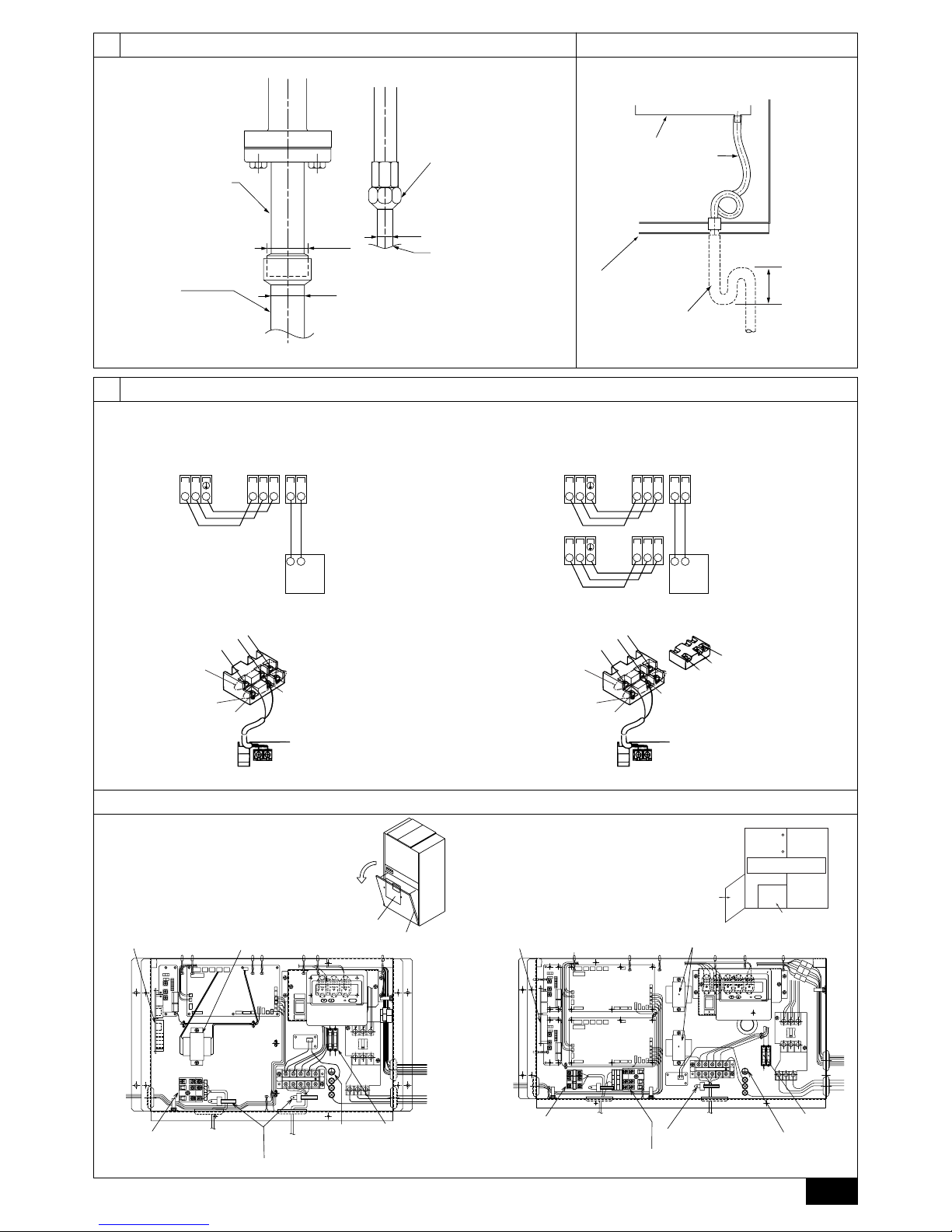

B Sealing tape

C Flange

H Flare

A Joint (Ensure that there

is no gap in the joint.)

E Flange cover

(supplied)

D Thermal insulating

material inside unit

I Thermal insulating

material (procured

on-site)

G Site thermal

insulating material

F Bind with

band or tape

235

210

260

340

420

205

210

50

395

110

15 151160

70

1050

70

1895

800

5

5

1200

1A

K

Refrigerant piping flange (gas)

O

Air outlet

M

Drain piping joint outlet (Rp1)

N

As seen from bottom face A.

L

Refrigerant piping flare (ø12.7) (liquid)

J

Location of refrigerant piping

<A> Gas <B> Liquid

E Unit weight

PFD-P250VM-A: 350 kg

PFD-P500VM-A: 500 kg

<C> Model 250

1800

1895

5

5

250

150

110

A

50

50

50

100

110

50

50

205

340

420

800

O

Air outletOAir outlet

N

As seen from bottom face A.

K

Refrigerant piping flange (gas)

L

Refrigerant piping flare (ø12.7) (liquid)

K

Refrigerant piping flange (gas) No. 2

No. 2

No. 1

No. 1

L

Refrigerant piping flare (ø12.7) (liquid)

J

Location of refrigerant piping

50

M

Drain piping joint

outlet (Rp1)

<D> Model 500

3

6

6.1

[Fig. 6.1.1] [Fig. 6.2.1]

[Fig. 7.2.1]

6.2

7

7.2

ø28.58 OD

ø28.58

ø12.7

A Connecting pipe (supplied)

Fit packing (supplied) firmly

(50 N·m torque) to the

flange to prevent a gas leak.

Apply refrigerator oil (ester

oil, ether oil, or a small

amount of alkyl benzene) to

both sides of the packing.

B Piping on site

Expand the end of the

pipe and braze it to the

connecting pipe (nonoxidizing brazing).

C Flared nut

Tighten to 55 N·m torque.

Open and close with a double

spanner.

Apply refrigerator oil (ester oil,

ether oil, or a small amount of

alkyl benzene) to the contact

surfaces of the flare.

D Piping on site

Expand the end of the pipe

and connect it. Do not use the

supplied piping.

A Drain pan

B Drain hose

C Trap

(on-site piping

work)

F 200 mm or more

D Unit base

(main drain pan)

E As seen from

front of unit.

TB5 TB15

SA1 B1

TB3

M1M2 21

A Terminal block for

indoor transmission

cable

B Terminal block for

outdoor transmission

cable

C MA Remote

controller

TB5-1 TB15

SA1 B1

TB3

M1M2 21

TB5-2

SA2 B2

TB3

M1M2

A Terminal block for

indoor transmission

cable

B Terminal block for

outdoor transmission

cable

C MA Remote

controller

DC10~13V

AB

12

A2

1

2

A Non-polarized

D MA Remote Controller

Upper level

(TB5-1)

C Lower level

(TB15)

B2

S

S

A1

B1

(TB5-2)

DC10~13V

AB

12

A1

1

2

A Non-polarized

D MA Remote Controller

Upper level

(TB5)

C Lower level

(TB15)

B1

S

B B

[Fig. 7.2.2]

7.3

[Fig. 7.3.1]

NO.2

NO.1

local

nomal

CN2M

CN29

CN21

CN20

CN3A

CN31

CN25

CN60

CN81

CN42

CN24

CN70

CNT

CND

CN3T

CN23

CNV

CN2M

CN29

CN21

CN20

CN3A

CN31

CN25

CN60

CN81

CN42

CN24

CN70

CNT

CND

CN3T

CN23

CNV

1A

5A

DOWN(Remote Controller)

UP(Transmission Line)

SB1A1

A2 B2

12

S

N

L3

L2

L1

normal

local

CNV

CN23

CN3T

CND

CNT

CN70

CN24

CN42

CN81

CN60

CN25 CN31

CN3A

CN20

CN21

CN29

CN2M

5A1A

L1

L2

L3

N

432

1

A Transformer

B External I/O board

G Earth

H Fuse

C No.1 transmission

line terminal block

C No.2 transmission line terminal block

(Note: Connect to top terminal block)

D Fix in place after

connecting wiring.

E Connect

transmission line

to outdoor unit

F To power supply

E Connect

transmission line

to outdoor unit

F To power supply

A Transformer

B External I/O board

G Earth

H Fuse

C Transmission

line terminal

block

D Fix in place after connecting wiring.

I Control box

J Bottom panel

<A> Model 250

<A> Model 250

<B> Model 500

<B> Model 500

I Control Box

J Bottom panel

<A> Model 250 <B> Model 500

4

7.4

[Fig. 7.4.1]

[Fig. 7.4.2]

[Fig. 7.4.3]

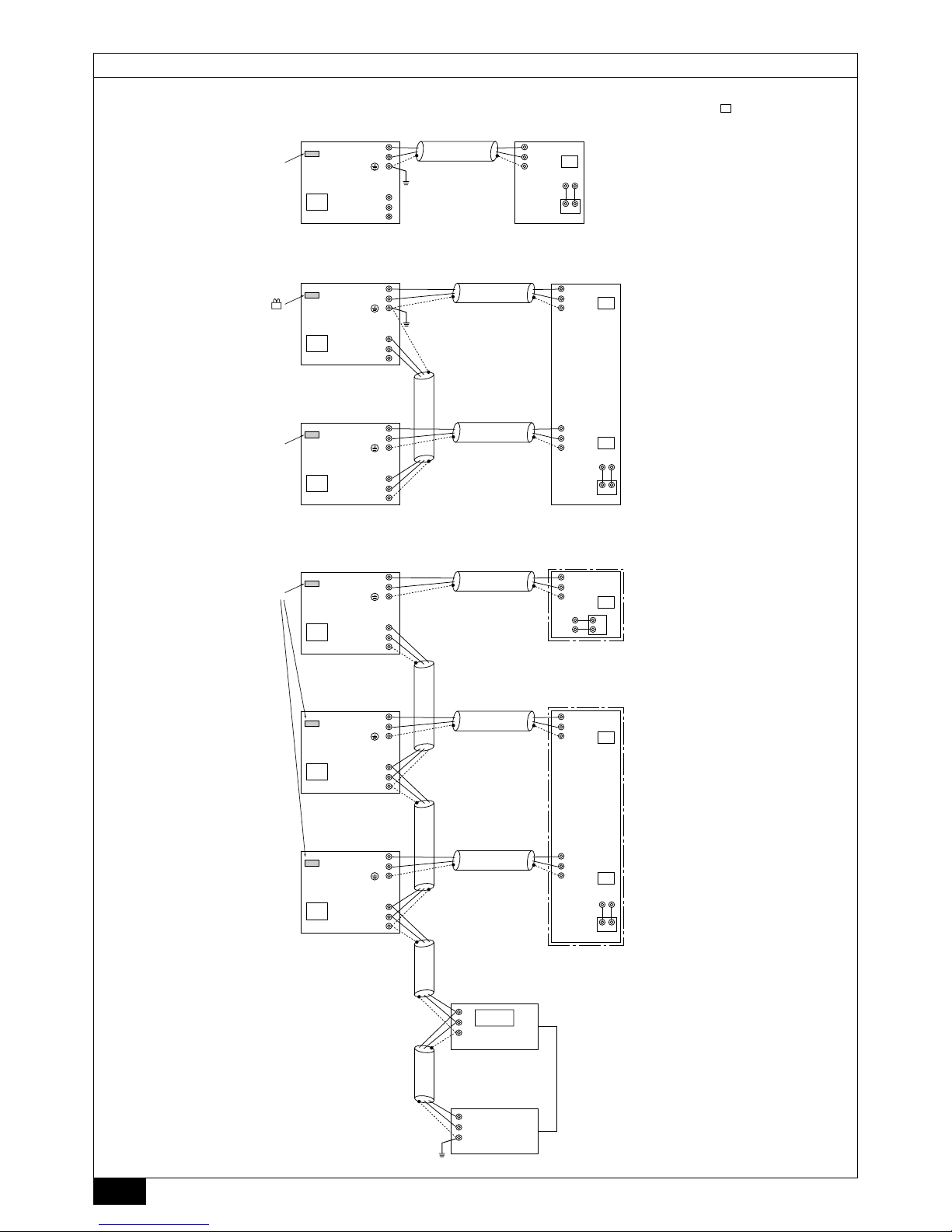

• When there is a single Model 250 unit

• When there is a single Model 500 unit

• When connected to G50

TB3

TB7

M1

M2

M1

M2

S

M1

TB5

TB15

MA

12

M2

A1 B2

S

51

<PUD-P250YMF-C>

G-50

000

D Power supply unit

IC

CN41

01

TB3

TB7

M1

M2

M1

M2

S

M1

TB5-1

TB5-2

M2

S

51

OC <PUD-P250YMF-C> IC

01

TB3

TB7

M1

M2

M1

M2

S

M1

TB15

MA

12

M2

A1 B2

S

52

OC <PUD-P250YMF-C>

02

TB15

MA

12

A1 B2

TB3

TB7

M1

M2

M1

M2

S

M1

TB5

TB5-1

TB5-2

M2

S

51

OC

IC

(model 250)

IC (model 500)

01

TB3

TB7

M1

M2

M1

M2

S

M1

TB15

MA

1

2

M2

A1

B2

S

53

OC

03

04

M1

M2

S

TB3

TB7

M1

M2

M1

M2

S

54

OC

OC

A

B

S

A

B

S

TB2

*2 The Model 250 indoor unit

contains one indoor controller board.

A CN41 as it is

A

Replace CN41

with CN40

B Group 1

C Group 2

A CN41 as it is

B CN41 as it is

*1 The numbers shown

in the square ( )are addresses.

* The Model 500 indoor unit

contains two indoor controller boards.

E DC Power supply (DC 12V)

Loading...

Loading...