Mitsubishi Electric City Multi PEFY-WP20, City Multi PEFY-WP40, City Multi PEFY-WP25, City Multi PEFY-WP32, City Multi PEFY-WP50VMA-E Installation Manual

Air-Conditioners

INDOOR UNIT

PEFY-WP20, 25, 32, 40, 50VMA-E

GB

INSTALLATION MANUAL

For safe and correct use, please read this installation manual thoroughly before installing the air-conditioner unit.

2

33.2

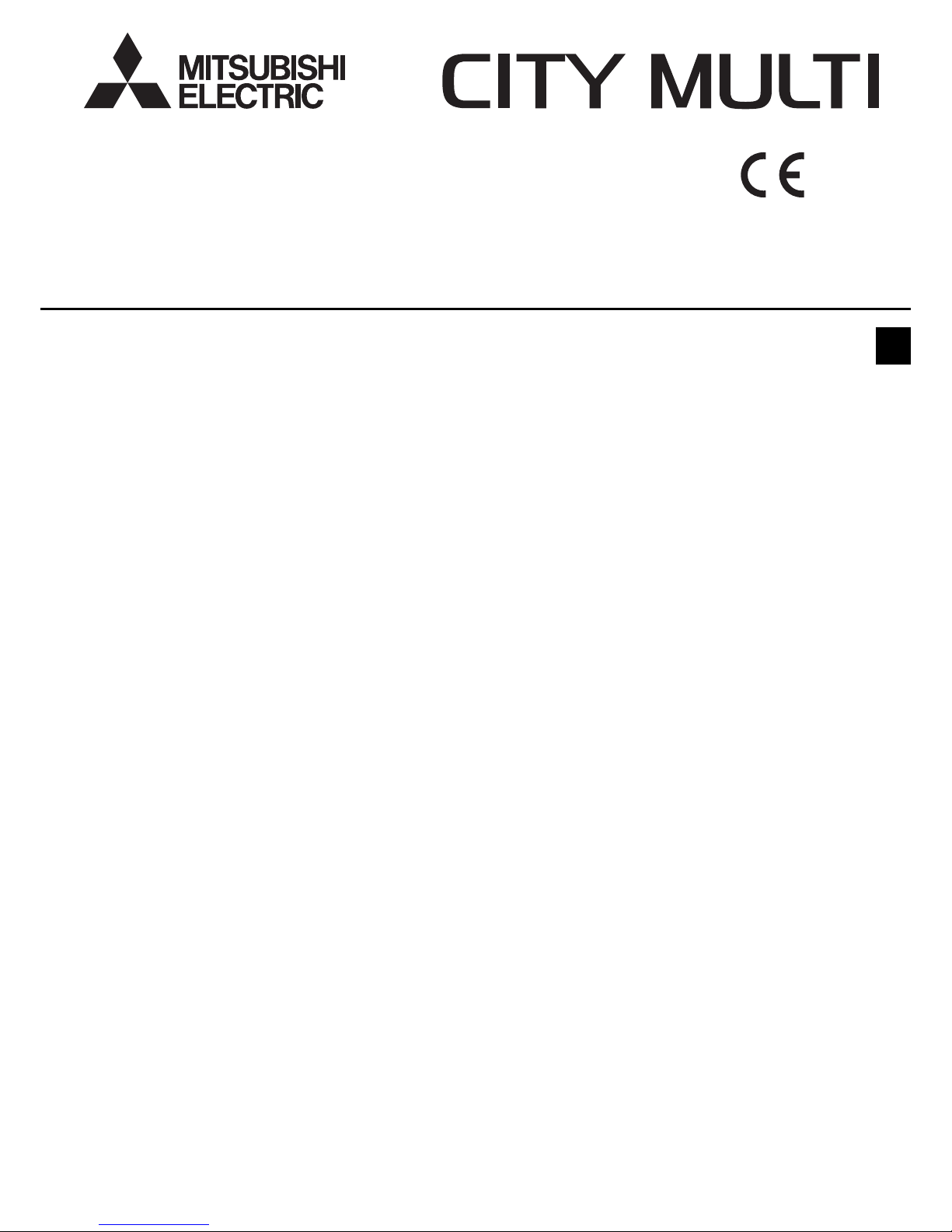

[Fig. 3.2.1]

44.1

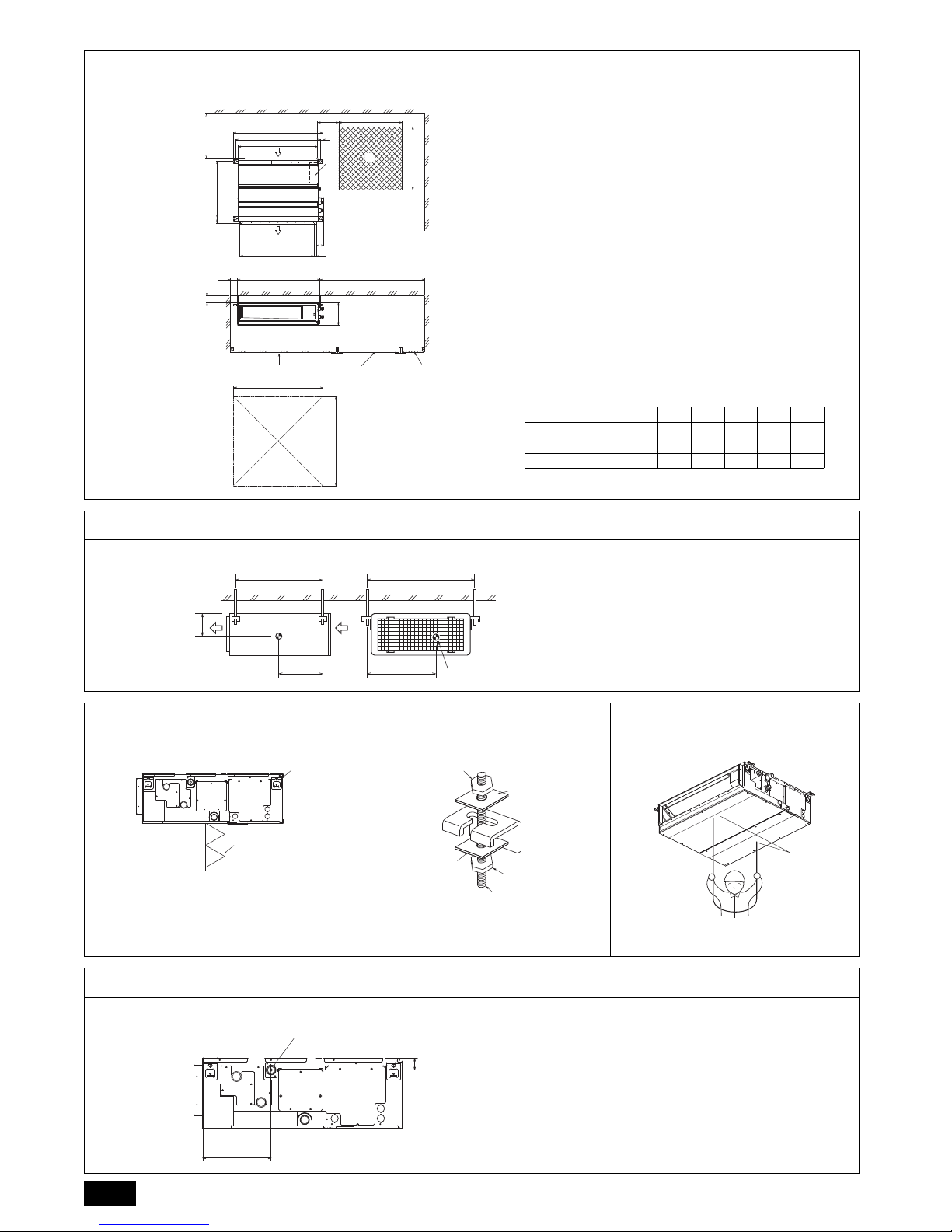

[Fig. 4.1.1]

55.1 5.2

[Fig. 5.1.1] [Fig. 5.1.2] [Fig. 5.2.1]

66.2

[Fig. 6.2.1]

B

C

D

A

F

G

3

4

E

A

50~150 450

450

49

643

777

20

64

23

C

B

A

D

B

E

250

1

2

A Access door

B Electrical parts box 1 600 mm or more

C Air inlet 2 100 mm or more

D Air outlet 3 20 mm or more

E Ceiling surface 4 300 mm or more

F Service space (viewed from the side)

G Service space (viewed from the direction of arrow)

(mm)

Model A B C D E

PEFY-WP20VMA-E 700 754 800 660 800

PEFY-WP25, 32VMA-E 900 954 1000 860 1000

PEFY-WP40, 50VMA-E 1100 1154 1200 1060 1200

YX

LW

A

Z

A Center of gravity

B

A

A Unit body

B Lifting machine

C

D

C

E

D

C Nuts (field supply)

D Washers (field supply)

E M10 hanging bolt (field supply)

A

A Indoor unit’s bottom surface

A

239

41

A Drain pipe (O.D. ø32)

3

6.3

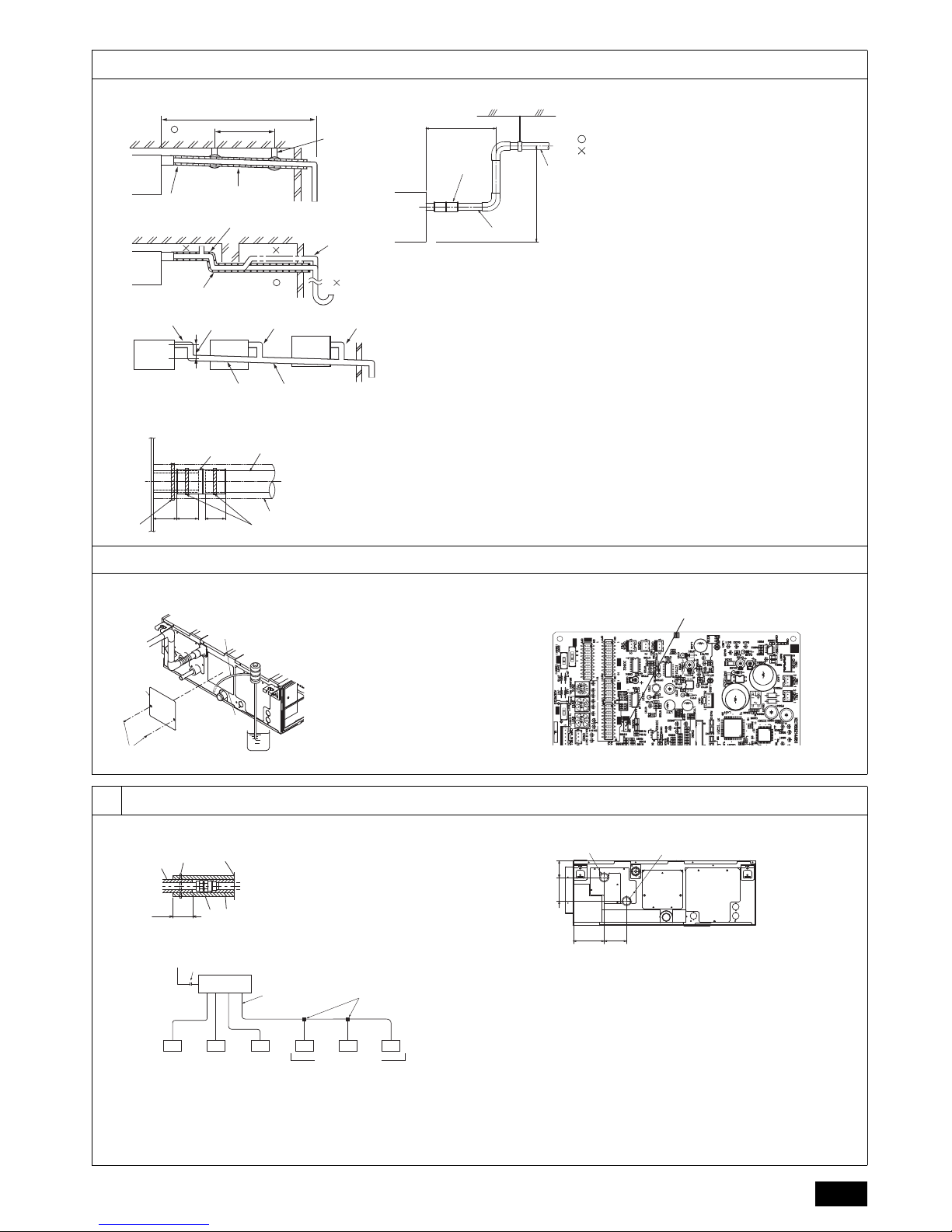

[Fig. 6.3.1]

[Fig. 6.3.2]

6.4

[Fig. 6.4.1] [Fig. 6.4.2]

77.2

C

B

A

L

D

D

D

E

K

M

B

H

I

Max. 20m

1.5-2m

G

F

FF

B

J

O

N

F

Max. 300mm

Grouped piping

Correct piping

Wrong piping

A Insulation (9 mm or more)

B Downward slope (1/100 or more)

C Support metal

K Air bleeder

L Raised

M Odor trap

D O. D. ø32 PVC TUBE

E Make it as large as possible. About 10 cm.

F Indoor unit

G Make the piping size large for grouped piping.

H Downward slope (1/100 or more)

I O. D. ø38 PVC TUBE for grouped piping.

(9 mm or more insulation)

J Up to 550 mm

N Drain hose (accessory)

O Horizontal or slightly upgradient

B

CD D

G

F

E

H

A

3235 25

A Indoor unit

B Tie band (accessory)

C Visible part

D Insertion margin

E Drain hose (accessory)

F Drain pipe (O.D. ø32 PVC TUBE, field supply)

G Insulating material (field supply)

H Tie band (accessory)

A

B

F

C

D

E

A Insert pump’s end 2 to 4 cm.

B Remove the water supply port.

C About 2500 cc

D Water

E Filling port

F Screw

SWE

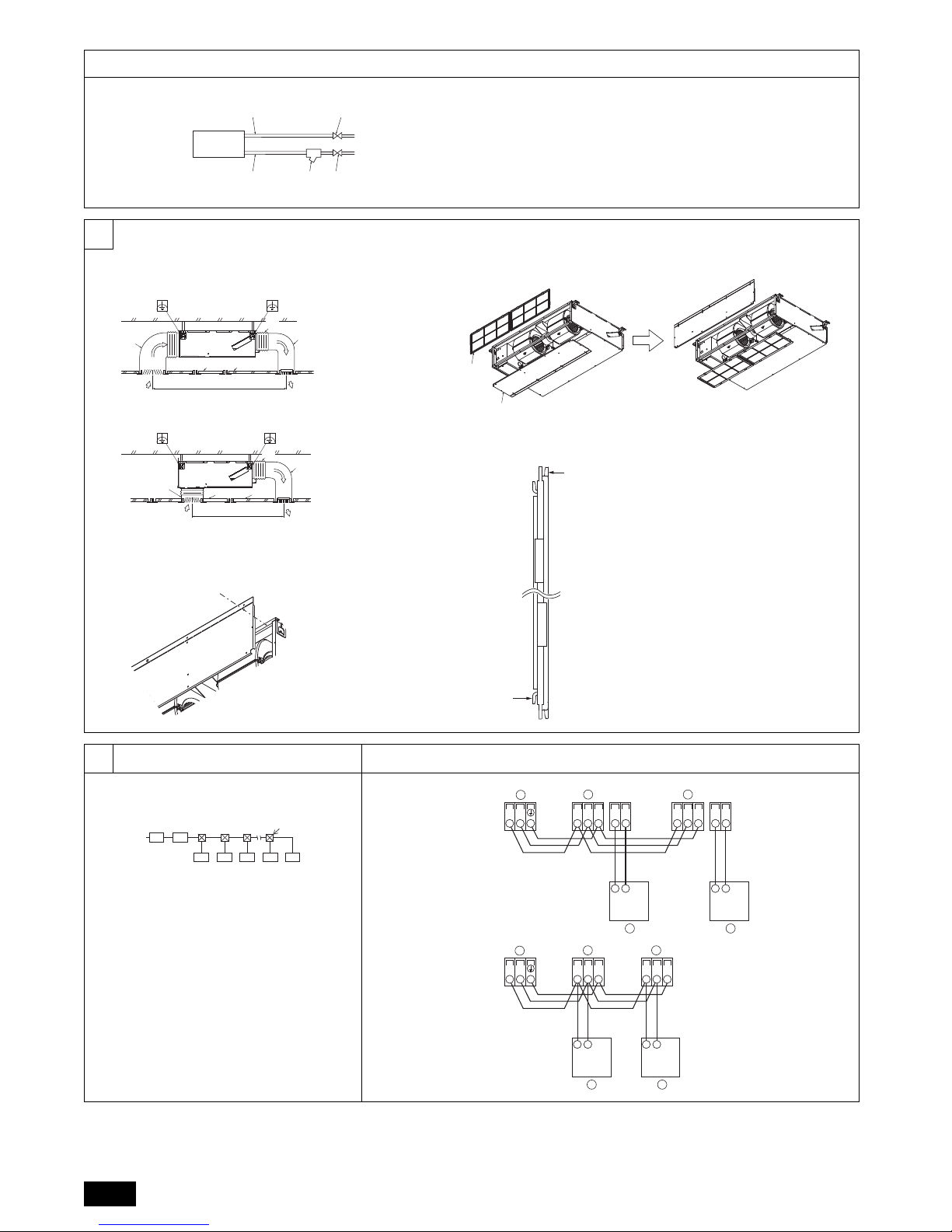

<Indoor controller board>

F

E

D

C

B

A

D

DD

DDFD

A

B

E

*1

C

A

B

117 87

64

91

A Locally procured insulating material

for pipes

B Bind here using band or tape.

C Do not leave any opening.

D Lap margin: more than 40 mm

E Insulating material (field supply)

F Unit side insulating material

A To outdoor unit

B End connection (brazing)

C HBC controller

D Indoor unit

E Twinning pipe (field supply)

F Up to three units for 1 branch hole ; total capacity: below 80 (but in same mode,

cooling/heating)

Water pipework is screw

connections

Note:

*1. Connection of multiple indoor units with one connection (or joint pipe)

• Total capacity of connectable indoor units: Less than 80

• Number of connectable indoor units: Maximum 3 Sets

• Selection of water piping

Select the size according to the total capacity of indoor units to be installed

downstream.

• Please group units that operate on 1 branch.

[Fig. 7.2.3]

[Fig. 7.2.1] [Fig. 7.2.2]

A Water pipe: To HBC unit

B Water pipe: From HBC unit

4

7.2

[Fig. 7.2.4]

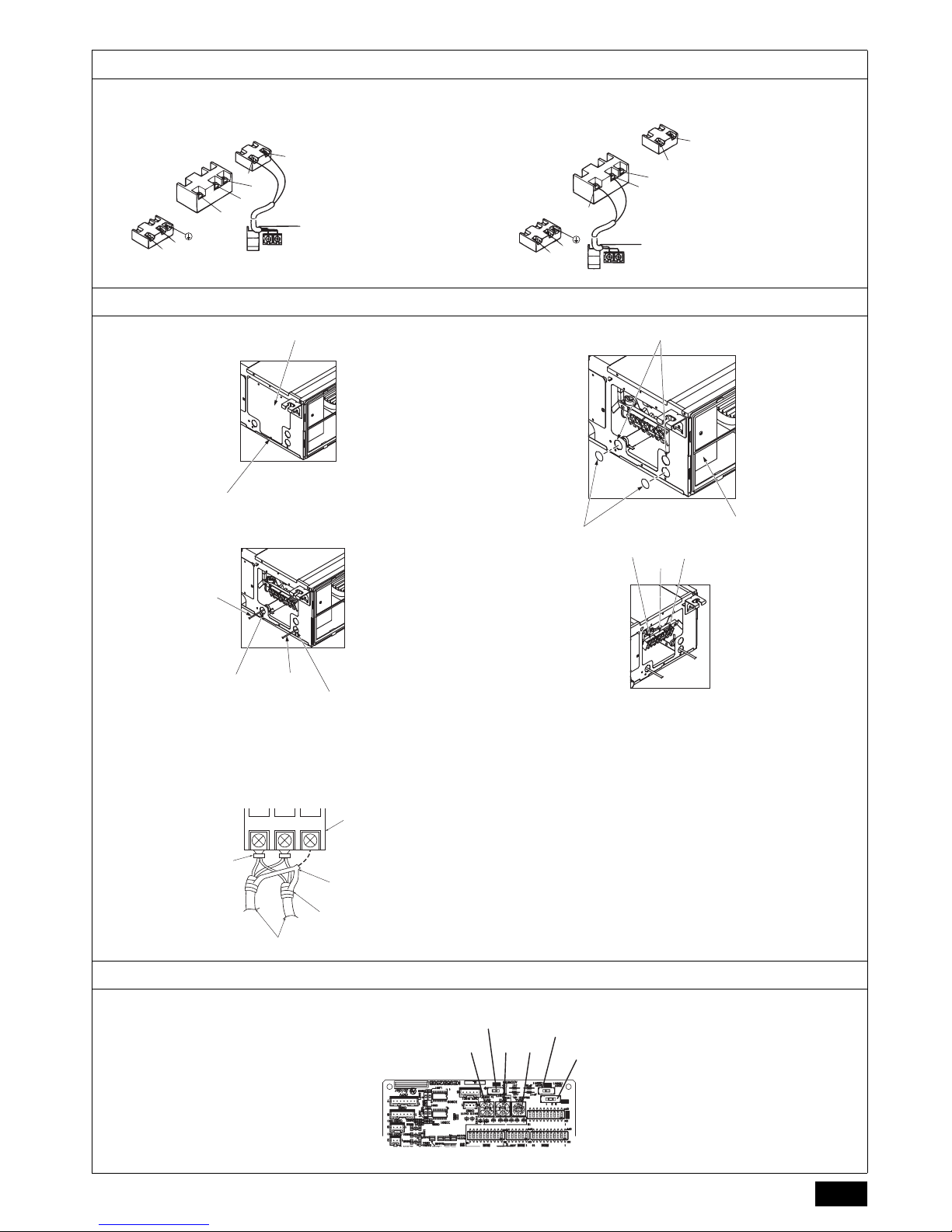

8

[Fig. 8.0.1]

[Fig. 8.0.3]

[Fig. 8.0.2]

[Fig. 8.0.4]

99.1 9.2

[Fig. 9.1.1]

C

B ED

E

A

A Indoor unit

B Water pipe: From HBC unit

C Water pipe: To HBC unit

D Strainer (40 mesh or more)

(field supply)

E Shut off valve

(field supply)

A

B

G

F

A

CE

D

A Duct

B Air inlet

C Access door

D Canvas duct

E Ceiling surface

F Air outlet

G Leave distance

enough to prevent

short cycle

<A> In case of rear inlet

A

B

G

C

E

A

F

D

<B> In case of bottom inlet

A

B

A Filter

B Bottom plate

C

D

C Nail for the bottom inlet

D Nail for the rear inlet

AB

CCCCDC

~220V

A Ground-fault interrupter

B Local switch/Wiring breaker

C Indoor unit

D Pull box

TB5 TB15 TB5 TB15

SM1M2 SM1M2

TB3

M1M2 21 21

AA

B

CC

[Fig. 9.2.1]

TB5 TB5

SM1M2 SM1M2

TB3

M1M2

AA

B

CC

[Fig. 9.2.2]

A Terminal block for indoor

transmission cable

B Terminal block for outdoor

transmission cable

C Remote controller

5

9.2

[Fig. 9.2.3] [Fig. 9.2.4]

9.3

9.5

[Fig. 9.5.1]

2

S

M2

M1

A

B

D

1

DC10~13V

AB

12

L

N

C

D

A

S

M2

M1

B

1

2

L

N

DC24~30V

(A, B)

12

C

A Non-polarized

B TB15

C Remote Controller

D TB5

A

B

A Screw holding cover (1pc)

B Cover

[Fig. 9.3.1]

H

I

F

G

F Use PG bushing to keep the weight of the cable and external force from being

applied to the power supply terminal connector. Use a cable tie to secure the

cable.

G Power source wiring

H Use ordinary bushing

I Transmission wiring

[Fig. 9.3.3]

C

D

E

C Ter mi n a l b ox

D Knockout hole

E Remove

[Fig. 9.3.2]

J

L

K

J Terminal block for power source

K Terminal block for indoor transmission

L Terminal block for remote controller

[Fig. 9.3.4]

M2 SM1

A

B

C

E

D

A Ter mi nal bl o c k

B Round terminal

C Shield wire

D The earth wire from two cables are connected together to the S terminal. (Dead-end connection)

E Insulation tape (To keep the earth wire of the shielded cable from coming in contact with the transmission

terminal)

[Fig. 9.3.5]

<Indoor controller board>

SWC

SW11 SW12 SW14

SW5

SWA

Loading...

Loading...