Page 1

Thank you for purchasing the Mitsubishi general-purpose

programmable controller MELSEC-A series.

Prior to use, please read this manual thoroughly and

familiarize yourself with the product.

z

zz

z SAFETY PRECAUTIONS z

zz

z

(Please read these precautions prior to use.)

When using Mitsubishi equipment, thoroughly read this manual and

the associated manuals introduced in this manual. Also, pay careful

attention to safety and handle the module properly.

These precautions apply only to Mitsubishi equipment. Refer to the

CPU module user's manual for a description of the PC system safety

precautions.

These zSAFETY PRECAUTIONSz classify the safety precautions

into two categories: "DANGER" and "CAUTION".

Procedures which may lead to a dangerous

condition and cause death or serious injury if not

carried out properly.

Procedures which may lead to a dangerous

condition and cause superficial to medium injury,

or physical damage only, if not carried out

properly.

Depending on circumstances, procedures indicated by

CAUTION

may also be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read

it whenever necessary. Always forward it to the end user.

[Design precautions]

DANGER

z Configure a safety circuit external to the PC, so that the entire system

operates safety even if there is an external power error or if the PC is

malfunctioning.

[Design precautions]

CAUTION

z Do not bundle, or near the control cables and communication cables with

the main circuit and power cables. Keep them at least 100mm

(3.94inch) away from such cables. Noise may cause e rroneous

operation.

[Installation precautions]

CAUTION

z Use the PC in the environment given in the general specifications of the

this manual. Using the PC outside the range of the general

specifications may result in electri c shock, fire or malfunctioni n g, or may

damage or degrade the module.

z Insert the tabs at the bottom of the module into the mounting hole s in the

base module before installing the module, and after tightening the

module fixing screws with specified torque. If the conne c tor is not

property installed and tightened, it may result in malfunctioning, failure or

cause the module to fall out.

Tightening the screws too far may cause damage to the screw and/or the

module, resulting in fall out, short circuit or malfunctions.

z Do not directly touch the module’s conductive parts or electronic

compone nts. Doing so could caus e m alfuncti on or failure in the module.

z Insert the wire breakage detection connector installation screw into the

mounting holes in the module, and after tightening the connector

installation screw with specified toque. If the connector is not property

installed and tightened, it may result in malfunction, failure, or fall out.

[Wiring precautions]

CAUTION

z Be sure to ground the shield wire with a special PC ground of Type III or

above. Not doing so could result in malfunction.

z When wiring in the PC, be sure that it is done correctly by che c king the

product's rated voltage and the terminal layout. Connecting a power

supply that is different from the rating or incorrectly wiring the product

could result in fire or failure.

z Tighten the terminal screws with specified torque. Loose terminal screws

may cause a sh ort circuit, fi r e, or malfun ction.

Tightening the terminal screws too fa r may cause damage to the screw

and/or the module, resulting in short circuit , or malfunctions.

z Be sure that cuttings, wire chips, or other foreign matter do not enter the

module. Foreign matter may start a fire or cause failure or malfunctions.

z Be sure to fix communication cables and power cables leading from the

module by placing them in the duct or clamping them. Cables not placed

in the duct or without clamping may hang or shift, allowing them to be

accidentally pulled, which may result in a module malfunction and cable

damage.

z When detaching the communication cable fro m the module , do not pull

the cable portion. For cables with connectors, hold the connector at the

junction to the module, then detach it. For cables without connectors,

first loosen the screw at the junction, then detach the cable. Pulling the

cable portion while it is connected to the module may caus e a

malfunction or damage to the module and cable.

[Starting and maintenance precautions]

CAUTION

z Do not touch the terminal while the power is on.

It may cause malfunction.

z Make sure to switch all pha ses of the exter n a l power supply off before

cleaning or re-tightening the terminal screws. If you do not switch off the

external power supply, it will cause failure or malfunction of the module.

z Never disassemble or modify the module. This may cause failure,

malfunctioning, injury and/or fire.

z Make sure to switch all pha ses of the exter n a l power supply off before

mounting or removing the module. If you do not switch off the external

power supply, it will cause failure or malfunction of the module.

[Disposal precaution]

CAUTION

z When disposing of this product, handle it as an industrial waste.

About the Manuals

The following product manuals are available. Please use this table as

a reference to request the appropriate manual as necessary.

Detailed manual

Manual name

Manual No.

(Model Code)

A1S64TCTT-S1 Temperature Control Module

A1S64TCTTBW-S1 Temperature Control Module with

Disconnection Detection Function

User's Manual (Detaile d edit io n)

IB-66747

(13J891)

Please read A1S64TCTT-S1 Temperature Control Module A1S64TCTTBWS1 Temperature Control Module with Disconnection Detection Function

User's Manual (Detailed edition) when using this unit.

DANGER

A1S64TCTT-S1 Temperature Control Module

A1S64T C T T B W-S1 Te mp eratur e C o nt rol

Module with Disconnection

Detection Function

Mitsubishi General-Purpose Programmable Controller

User’s Manual

(Hardware)

C 1996 MITSUBISHI ELECTRIC CORPORATION

Type A1S64TCS1-U-E-H/W

Type

Code

13J890

IB(NA)-66746-D(0210)MEE

CAUTION

Page 2

1. General Description

This user's manual describes the specification, name of each part,

wiring, etc. of the A1S64TCTT-S1 Temperature Control Module

(Hereafter abbreviated as A1S64TCTT-S1) A1S64TCTTBW-S1

Temperature Control Module with Disconnection Detection Function

(Hereafter abbreviated as A1S64TCTTBW-S1).

A1S64TCTT-S1 and A1S64TCTTBW-S1 abbreviated as A1S64TC.

After unpacking, confirm that there is the following products.

Item

A1S64TCTT-S1

Main body

A1S64TCTTBW-S1

Main body

A1S64TCTT-S1 1 -

A1S64TCTTBW-S1 - 1

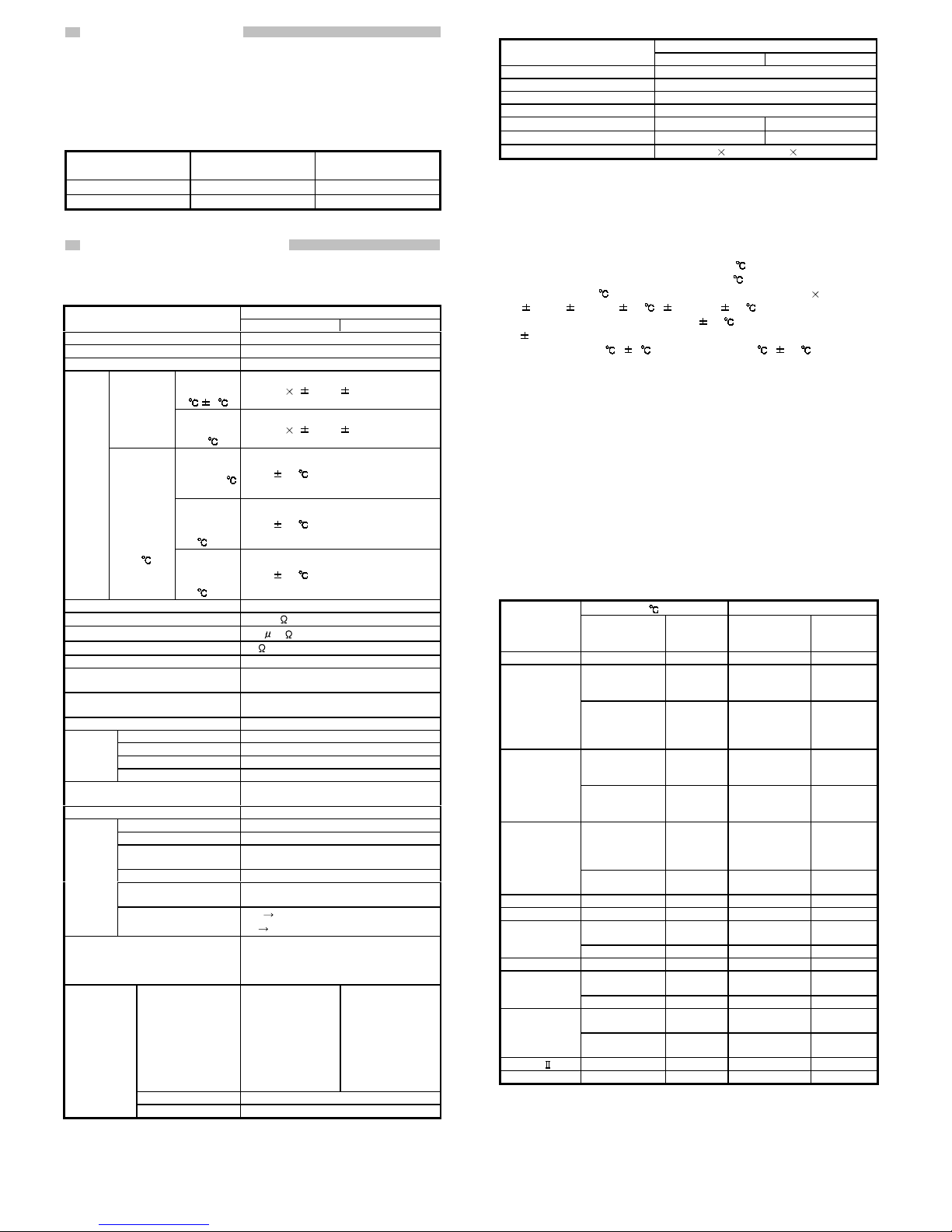

2. Performance Specification

The A1S64TC performance specification is indicated in Table 2.1.

Table 2.1 A1S64TC performance specification

Specification

Item

A1S64TCTT-S1 A1S64TCTTBW-S1

Control output va lu e Transistor ou tput

Temperature input points 4-channel/module

Supported thermocouple Refer to Table 2.2

Ambient

temperature:

23

5

Full scale ( 0.3%) 1 digit*2

Specification

accuracy

Ambient

temperature:

0 to 55

Full scale ( 0.7%) 1 digit*2

Temperature

measurement

value: -100

or higher

Within

1.0

Temperature

measurement

value: -150 to

-100

Within 2.0

Accuracy

*1

Cold-junction

compensation

temperature

accuracy

(ambient

temperature:

0 to 55

)

Temperature

measurement

value: -200 to

-150

Within 3.0

Sampling cycle 0.5s/4-channe l

Control output cyc le

1 to 100

Effects of the external resistance

0.35

V/

Input impedan ce

1M

or more

Input filter 1 to 100S (0: input filter off)

Sensor compensation value setting

Software version A -5.00 to 5.00%

Software version B or later -50.00 to 50.00%

Operation when there is an input

disconnection

Upscale processing

Temperature control method PID ON/OFF pulse or 2-position control

PID constant setting Auto-tuning setting is possible

Proportional region (P) 0.0 to 1000.0% (0.0: 2-position control)

Integral time (I) 1 to 3600s

PID

constant

range

Derivative time (D) 1 to 3600s (Set 0 for PI control)

Set value range

Within the temperature range set with the

thermocoupl e to be us ed .

Blind sector se tt in g ra nge 0.1 to 10.0%

Output signal ON/OFF Pulse

Rated load volt ag e 10.2 to 30VDC

Maximum load curren t

0.1A/point

0.4A/common

Maximum inrush curr en t 0.4A 10ms

Maximum voltage drop

when ON

0.1VDC (TYP) 0.1A

2.5VDC (MAX) 0.1A

Transistor

output

Response time

OFF

ON: Less than 2 ms

ON

OFF: Less than 2ms (resistor load)

Insulation method

Between the thermocouple input and

grounding: Transformer insulation

Between the thermocouple input and

channel: Transformer insulation

Current sensor -

URD manufactured

current sensor*3

CTL-12-S36-8

(0.0 to 100.0A)

CTL-6-P-H

(0.00 to 20.00A)

(Former model, CTL6-P is also

applicable.)

Input method Multiplexor me thod A/ D con ve rsi on

Heater

disconnection

specification

Alert delay count 3 to 255

Table 2.1 A1S64TC performance specification (continued)

Specification

Item

A1S64TCTT-S1 A1S64TCTTBW-S1

I/O occupied points 32 points

Connection terminal 20 poin ts term i n al block

Supported cable size 0.75 to 1.5mm

Supported solderless term in al R1.25-3,1.25-YS3,RAV1.25- 3,V1.25-YS3A

Internal consumed current (mA)

330 420

Weight (kg) [lb]

0.27[0.59] 0.3[0.66]

External dimensions (mm) [inch]

130[5.12](H)

34.5[1.36](w) 93.6[3.69](D)

For the noise resistance, dielectric withstand voltage, and insulation

resistance for the PC system which uses this module, refer to the power

module specification found in the CPU Module User's Manual.

*1: Calculate the accuracy as follows:

(Accuracy) = (specification accuracy) + (cold-junction temperature

compensation accuracy)

Example: When measuring the temperature 300

with the input range setting

“38 (the thermocouple K, -200.0 to 400.0, in 0.1

unit)” at ambient

temperature of 35

, the accuracy is: (400.0-(-200.0))[full scale]

( 0.007)[ 0.7%] + ( 0.1 )[ 1 digit] + ( 1.0 )[cold-junction

temperature compensation accuracy] =

5.3

*2: “ 1 digit” error depends on the input range.

For setting unit of 1

, 1 For setting unit of 0.1 , 0.1

*3: Only the URD International, Ltd. current sensor can be used.

Sales channels for current sensors manufactures by URD International Ltd. are

listed as follows:

U.S.A. Julia Industries Inc.

Tel:949-831-0111

BRAZIL Ananda Industial Ltda.

Tel:011-5584-0959

UNITED

KINGDOM Omni Components

Tel:024-7622-5757

GERMANY Allied Electronics GmbH

Tel:0221-497-3084

FRANCE Diltronic S.A.

Tel:01-34-51-33-00

ITALY ELNET s.n.c.

Tel:041-50-19-939

KOREA Joyang Trading Co.

Tel:02-521-2294

Sewon Tech Co.,Ltd.

Tel:02-868-9355/9356

Keum Ho Corporation

Tel:51-319-4155/4156

HONG-KONG Weltronics Components Ltd.

Tel:2410-0623

TAIWAN Tope Co.,Ltd.

Tel:886-2-8228-0658

INDIA AmtechElectronics PVT.Ltd.

Tel:02712-25324

Table 2.2 The types of supported thermocouples and the measured

temperature range

°F

Thermocouple

Measured

temperature

range

Data

resolution

Measured

temperature

range

Data

resolution

R 0 to 1700 1 0 to 3000 1

0 to 500

0 to 800

0 to 1300

1

0 to 1000

0 to 2400

1

K

-200.0 to 400.0

0.0 to 400.0

0.0 to 500.0

0.0 to 800.0

0.1 0.0 to 1000.0 0.1

0 to 500

0 to 800

0 to 1200

1

0 to 1000

0 to 1600

0 to 2100

1

J

0.0 to 400.0

0.0 to 500.0

0.0 to 800.0

0.1 0.0 to 1000.0 0.1

-200 to 400

-200 to 200

0 to 200

0 to 400

1

0 to 700

-300 to 400

1

T

-200.0 to 400.0

0.0 to 400.0

0.1 0.0 to 700.0 0.1

S 0 to 1700 1 0 to 3000 1

B 0 to 1800 1 0 to 3000 1

0 to 400

0 to 1000

1 0 to 1800 1

E

0.0 to 700.0 0.1 - -

N 0 to 1300 1 0 to 2300 1

0 to 400

-200 to 200

1

0 to 700

-300 to 400

1

U

0.0 to 600.0 0.1 - 0 to 400

0 to 900

1

0 to 800

0 to 1600

1

L

0.0 to 400.0

0.0 to 900.0

0.1 - -

PL 0 to 1200 1 0 to 2300 1

W5Re/W26Re 0 to 2300 1 0 to 3000 1

For the general specifications, refer to the User’s Manual for the PC CPU used.

Page 3

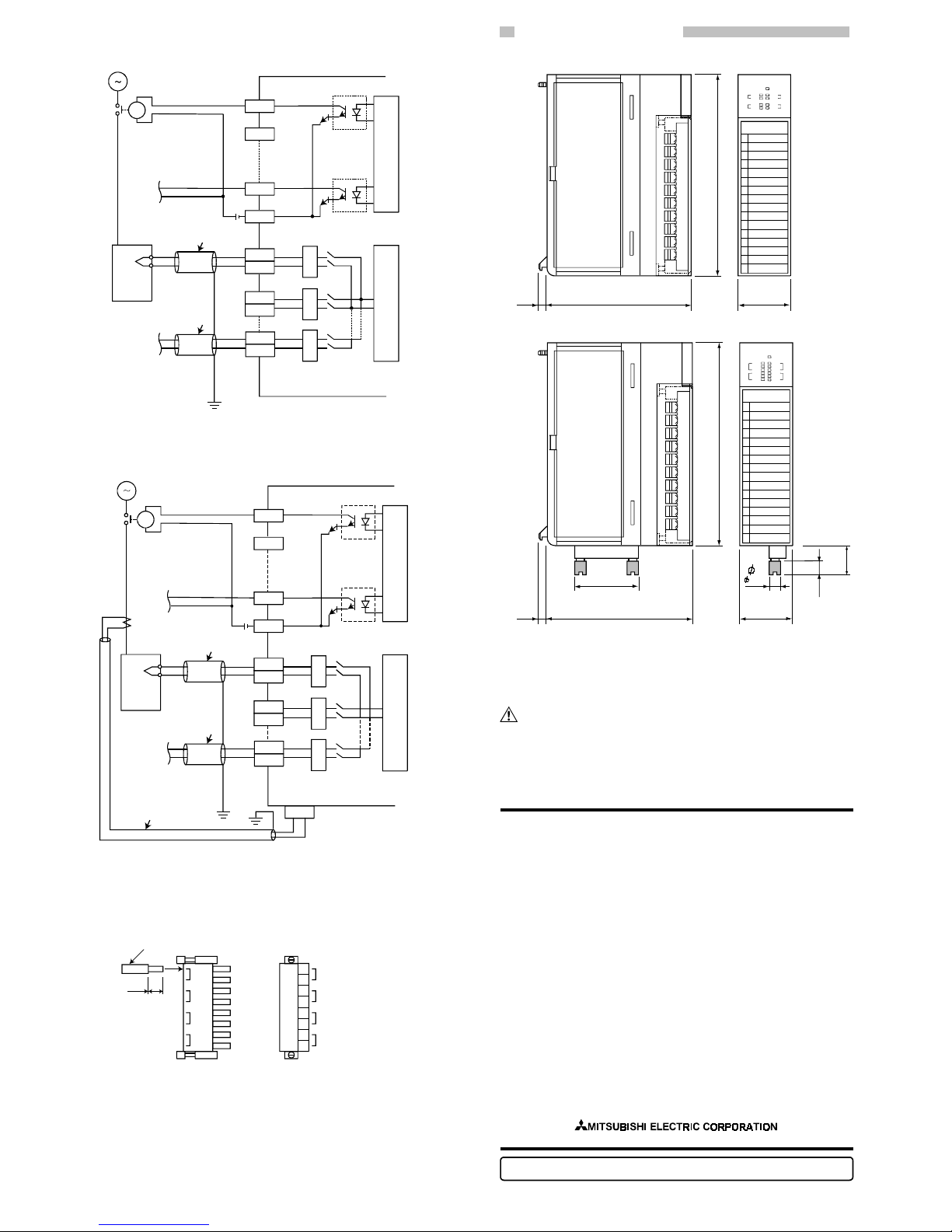

3. Name of Each Part

A

1S64TCTT-S1

RUN

OUT

ALM

OUT

ALM

OUT

ALM

OUT

ALM

CH3

CH4

CH1

CH2

L4

+

+

+

C

H

1

C

H

3

C

H

2

C

J

C

H

4

-

-

+

-

-

+

-

NC

NC

NC

L3

L2

L1

A

1S64TCTTBW-S1

RUN

OUT

ALM

BR.W

OUT

ALM

BR.W

OUT

ALM

BR.W

OUT

ALM

BR.W

CH3

CH4

CH1

CH2

L4

+

+

+

C

H

1

C

H

3

C

H

2

C

J

C

H

4

-

-

+

| -

-

{

-

NC

NC

NC

L3

L2

L1

1)

2)

1)

2)

3)

2

4

6

8

10

12

14

16

18

20

1

3

5

7

9

11

13

15

17

19

2

4

6

8

10

12

14

16

18

20

1

3

5

7

9

11

13

15

17

19

A1S64TCTT-S1 LED A1S64TCTTBW-S1 LED

A

1S64TCTT-S1

RUN

OUT

ALM

OUT

ALM

OUT

ALM

OUT

ALM

CH3

CH4

CH1

CH2

A

1S64TCTTBW-S1

RUN

OUT

ALM

BR.W

OUT

ALM

BR.W

OUT

ALM

BR.W

OUT

ALM

BR.W

CH3

CH4

CH1

CH2

Number

Name Description

RUN A1S64T C ope ra tion status display

ON: Normal operation

Flashing (2 sec. ON, 2 sec. OFF)

: When write data error occurs

Flashing (1 sec. ON, 1 sec. OFF): Hardware error

OFF: 5V power OFF

OUT Transistor output status display

ON: Transistor output ON

OFF: Transistor output OFF

ALM Alert alarm status display

ON : The alert alarm is turned ON.

LAB error occurred.

Flashing: The measured temperature range is

exceeded.

The thermocouple is not connected.

The thermocouple cable is not connected.

OFF : The alert alarm is OFF.

1) LED

BR.W Heater disconnecti on detection status display

ON: The heater disconnection is detected.

OFF: The heater disconnection has not been

detected.

2) Cool contact

temperature

compensation

resistor

Shipped pre-installed to the te rm i nal bl ock .

3) Disconnection

detection

connector

Connector to the current sensor

BW1(For CH1)

Wire breakage detection connector

installation screw

BW2(For CH2)

BW3(For CH3)

BW4(For CH4)

Cable fixing screws

4. Loading and Installation

Precautions when handling the A1S64TC and installation enviroment

are explained.

For details of implementing and setting up this unit, please refer to the

User’s Manual for the PC CPU used.

4.1 Handling Instructions

1) The module case is made of plastic. Be sure not to drop it or

subject it to strong vibration.

2) Do not remove the module printed circuit boards from the case.

It may cause trouble.

3) When connecting the wiring, do not allow wire cuttings or other

foreign matter to enter from the top of the module. Remove any

foreign matter from the module.

4) Tighten the module installation screws within the following

tightening torque range.

Screw position Tightening torque range

Module installation screw (M4 screw)

78 to 118N•cm

Terminal block terminal screw (M3.5 screw)

59 to 88N•cm

Terminal block installation scr e w

(M4 screw)

78 to 118N•cm

Wire breakage detection connector installation

screw *(M2.6 screws)

15 to 30N•cm

Cable fixing screw *(M2 screws)

11 to 14N•cm

*: Use only for A1S64TCTTBW-S1.

4.2 Installations Enviroment

Never install the AnS series PC in the following environments:

1) Locations where the ambient temperature is outside the range of 0

to 55

.

2) Locations where the ambient humidity is outside the range of 10 to

90%RH.

3) Locations where dew condensation takes place due to sudden

temperature changes.

4) Locations where there are corrosive and/or combustible gasses.

5) Locations where there is a high level of conductive power (such as

dust and iron filings, oil mist, salt, and organic solvents).

6) Locations exposed to the direct rays of the sun.

7) Locations where strong power and magnetic fields are generated.

8) Locations where vibration and shock are directly transmitted to the

main module.

5. Wiring

The precaution when wiring and the module connection example are

shown below.

5.1 Precaution when wiring

In order to have the best result from the A1S64TC functions and to

make the system highly reliable, an external cabling with low noise

effects are necessary.

The external wiring precautions are shown below:

1) Use separate cables for the alternating current and A1S64TC

external input signals to avoid A/C surges and induction effects.

2) Do not bunch the cables with the main circuit, high-voltage cable or

load cables from other than PC, or install them close to each other.

Install the cables far apart from high-frequency circuits, such as the

high-voltage cable and inverter load main circuit, as much as

possible.

This increases the noises, surges, and induction.

3) Perform a one-point grounding for the shielded line and shields of

the seal and cable at the PC. However, there may be cases when

grounding should be performed externally depending on the noise

condition.

Page 4

5.2 Module wiring example

1) A1S64TCTT-S1

R

A1S64TCTT-S1

L1

L2

L4

24VDC

*

*

Control

object

COM-

CH1+

CH1-

CH2+

CH2-

CH4+

CH4-

Internal circuit Internal circuit

Filter Filter Filter

*: Always use the shielded compensating conductor for the cable.

2) A1S64TCTTBW-S1

R

A1S64TCTTBW-S1

L1

L2

L4

24VDC

*1

*3

*2

*1

Control

object

COM-

CH1+

CH1-

CH2+

CH2-

CH4+

CH4-

Internal circuit Internal circuit

(CT)

Current

censor

Filter

BW1

Filter Filter

*1: Always use the shielded compensating conductor for the cable.

*2: Refer to the following for the connection of the disconnection

detector connector.

*3: Please use the cable with shield.

[ Connect to ]

BW1 (For CH1)

6.5mm

Cable with shield

BW1

BW2

BW3

BW4

(

0.26inch

)

BW2 (For CH2)

BW3 (For CH3)

BW4 (For CH4)

6. External Dimensions

1) A1S64TCTT-S1

A

1S64TCTT-S1

130

(5.12)

34.5

(1.36)

93.6

(3.69)

6.5

(0.26)

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

RUN

OUT

ALM

OUT

ALM

OUT

ALM

OUT

ALM

CH3

CH4

CH1

CH2

2) A1S64TCTTBW-S1

130

(5.12)

34.5

(1.36)

18

(0.71)

8

(0.31)

42

(1.65)

93.6

(3.69)

6.5

(0.26)

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

A

1S64TCTTBW-S1

RUN

OUT

ALM

BR.W

OUT

ALM

BR.W

OUT

ALM

BR.W

OUT

ALM

BR.W

CH3

CH4

CH1

CH2

6

( 0.24)

Unit : mm(inch)

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be the cause

of Mitsubishi; machine damage or lost profits caused by faults in the Mitsubishi products;

damage, secondary damage, accident compensation caused by special factors

unpredictable by Mitsubishi; damages to products other than Mitsubishi products; and to

other duties.

For safe use

y This product has been manufactured as a general-purpose part for general industries,

and has not been designed or manufactured to be incorporated in a device or system

used in purposes related to human life.

y Before using the product for special purposes such as nuclear power, electric power,

aerospace, medicine or passenger movement vehicles, consult with Mitsubishi.

y This product has been manufactured under strict quality control. However, when

installing the product where major accidents or losses could occur if the product fails,

install appropriate backup or failsafe functions in the system.

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessoria

Tecnica Ltda.

Av. Rio Branco, 123-15 ,and S/1507,

Rio de Janeiro, RJ CEP 20040-005,

Brazil

Tel : +55-21-221-8343

Germany Mitsubishi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Herts., AL10

8XB,UK

Tel : +44-1707-276100

Italy Mitsubishi Electric Eur ope B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo - Ingr.2

Via Paracelso 12, 20041 Agrate B.,

Milano, Italy

Tel:+39-039-60531

Spain Mitsubishi Electric Europe B.V. Spanish

Branch Carretera de Rubi 76-80

08190 - Sant Cugat del Valles,

Barcelona, Spain

Tel:+34-935-653135

South Africa Circuit Breaker Ind ustries LTD.

Private Bag 2016, Isando 1600,

Johannesburg, South Africa

Tel : +27-11-928-2000

Hong Kong Ryoden Automation Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, HongKong

Tel : +852-2887-8870

China Ryoden International Shanghai Ltd.

3F Block5 Building Automation

Instrumentation Plaza 103 Cao Bao Rd.

Shanghai 200233 China

Tel : +86-21-6475-3228

Taiwan Setsuy o E n te r pr is e Co ., Ltd .

6F., No.105 Wu-Kung 3rd.RD, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea HAN NEUNG TECHNO CO.,LTD.

1F Dong Seo Game Channel Bldg.,

660-11, Deungchon-dong Kangsec-ku,

Seoul, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 ALEXANDRA ROAD #05-01/02,

MITSUBISHI ELECTRIC BUILDING

SINGAPORE 159943

Tel : +65-473-2480

Thailand F. A. Tech Co.,Ltd.

898/28,29,30 S.V.City Building,Office

Tower 2,Floor 17-18 Rama 3 Road,

Bangkpongpang, Yannawa,

Bangkok 10120

Tel : +66-2-682-6522

Indonesia P.T. Autoteknindo SUMBER MAKMUR

Jl. Muara Karang Selatan Block A Utara

No.1 Kav. No.11 Kawasan Industri/

Pergudangan Jakarta - Utara 14440

Tel : +62-21-663-0833

India Messung Systems Put,Ltd.

Electronic Sadan NO:111 Unit No15,

M.I.D.C BHOSARI,PUNE-411026

Tel : +91-20-7128927

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, PostalBag, No 2,

Rydalmere, N.S.W 2116, Australia

Tel : +61-2-9684-7777

Country/Region Sales office/Tel Country/Region Sales office/Tel

When exported from Japan, this m anual does not require application to the Ministry

of Economy, Trade and Industry for service transaction permi ssion.

Specifications subject to change without notice.

Printed in Japan on recycled paper.

HEAD OFFICE : 1-8-12 , OFFICE TOWER Z 14F HA RUMI CHUO-KU 104-6212, JAPAN

NAGOYA WORKS : 1-14, YADA-MINAMI5, HIG ASHI-KU, NAGOYA, JAPAN

Loading...

Loading...