Mitsubishi A1S64AD User Manual

A/D Converter module

t

y

pe A1S64AD

User's Manual

(Hardware)

Thank you for buying the Mitsubishi general-purpose programmable

logic controller MELSEC-A Series

Prior to use, please read both this manual and detailed manual

thoroughly and familiarize yourself with the product.

MODEL A1S64AD(H/W)-U-E

MODEL

CODE

13JE46

IB(NA)-66485-D(0609)MEE

©1994 MITSUBISHI ELECTRIC CORPORATION

DANGER

CAUTION

z SAFETY PRECAUTIONS z

(Read these precautions before using.)

When using Mitsubishi equipment, thoroughly read this manual and the

associated manuals introduced in this manual. Also pay careful attention to

safety and handle the module properly.

These precautions apply only to Mitsubishi equipment. Refer to the CPU

module user's manual for a description of the PLC system safety precautions.

These zSAFETY PRECAUTIONSz classify the safety precautions into two

categories: "DANGER" and "CAUTION".

Procedures which may lead to a dangerous condition

and cause death or serious injury if not carried out

properly.

Procedures which may lead to a dangerous condition

and cause superficial to medium injury, or physical

damage only, if not carried out properly.

Depending on circumstances, procedures indicated by

CAUTION may also

be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

[PRECAUTIONS FOR DESIGN]

CAUTION

z Do not bunch the control wires or communication cables with the main

circuit or power wires, or install them close to each other.

They should be installed 100mm (3.9inch) or more from each other.

Not doing so could result in noise that may cause malfunction.

[INSTALLATION PRECAUTIONS]

CAUTION

z Use the PC in an environment that meets the general specificaitons

contained in this manual. Using this PC in an environment outside the

range of the general specifications could result in electric shock, fire,

erroneous operation, and damage to or deterioration of the product.

z Install so that the pegs on the bottom of the module fit securely into the

base unit peg holes.

The module fixing screws must be tighten by the specified torque.

Not installing the module correctly or tightening the screws to the terminal

base could result in erroneous operation, damage, or pieces of the product

falling.

[WIRING PRECAUTIONS]

CAUTION

z If there are high levels of noise, ground the AG terminal and FG terminal with

Class D grounding (Class 3 grounding) or higher dedicated for the PLC.

Failure to observe this could lead to malfunctioning.

z When wiring in the PLC, be sure that it is done correctly by checking the product's

rated voltage and the terminal layout. Connecting a power supply that is different

from the rating or incorrectly wiring the product could result in fire or damage.

z Tighten terminal screws to the specified torque.

If a terminal screw is not tightened to the specified torque, it the module may fall

out, short circuit, or malfunction.

If a terminal screw is tightened excessively, exceeding the specified torque, the

module may fall out, short circuit, or malfunction due to breakage of the screw or

the module.

z Be careful not to let foreign matters such as sawdust or wire chips get inside the

module. These may cause fires, failure or malfunction.

[STARTUP/MAINTENANCE PRECAUTIONS]

DANGER

z When power is on, do not touch the terminals.

Doing so can cause an electric shock or malfunction.

z Before starting cleaning or terminal screw retightening, always switch off the

power externally in all phases.

Not switching the power off in all phases can cause a module failure or

malfunction.

CAUTION

z Never disassemble or modify the module.

Failure to observe this could lead to trouble, malfunctioning, injuries or fires.

z Always turn the power OFF before installing or removing the module. Failure to

observe this could lead to module faults or malfunctioning.

z Do not install/remove the terminal block more than 50 times after the first use of

the product. (IEC 61131-2 compliant)

[PRECAUTIONS FOR DISPOSAL]

CAUTION

z Dispose of this product as industrial waste.

About the Manuals

The following manuals are related to this product.

Refer to the following table, and procure these manuals as necessary.

Detailed Manual

Manual name

Manual No.

(Model code)

A/D converter module type A1S64AD User’s Manual

IB-66336

1. Outline

This manual explains the specifications and names of each part of the A1S64AD type

analog/digital converter (hereinafter, A1S64AD) used in combination with the

MELSEC-A Series PLC CPU module (hereinafter PLC CPU).

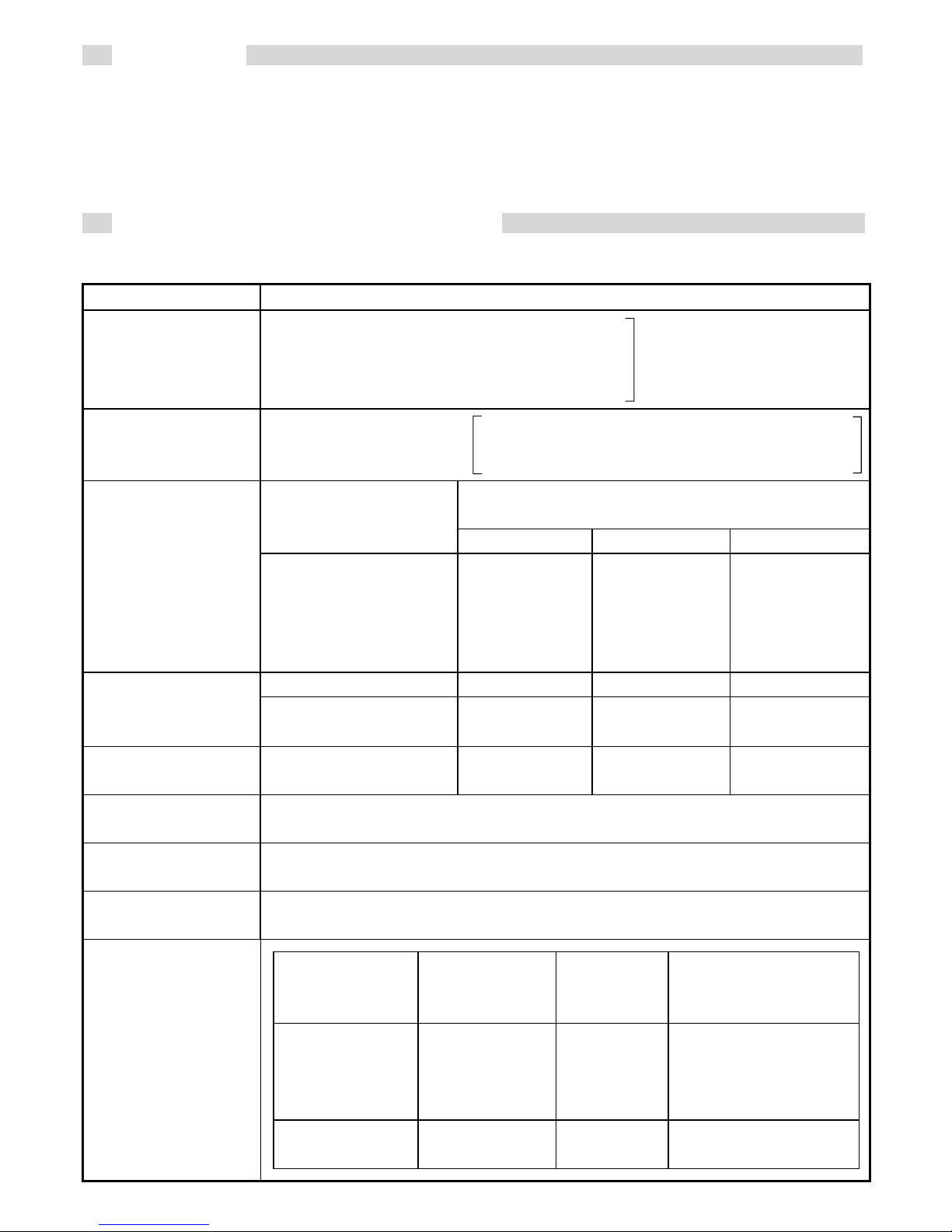

2. Performance Specifications

The performance specifications of the A1S64AD are shown below.

Item Specifications

Analog input

Voltage: -10 to 0 to +10VDC

(input resistance 1MΩ)

Current: -20 to 0 to +20mA

(input resistance 250Ω)

Select with the input

terminals.

Digital input 16-bit coded binary

-4096 to +4095 when set to 1/4000

-8192 to +8191 when set to 1/8000

-12288 to +12287 when set to 1/12000

Digital output value

(At 5V/20mA gain, 0V/90mA offset)

Analog input

1/4000 1/8000 1/12000

Input/output

characteristics *1

+10V

+5V or +20mA

0V or 0mA

-5V or -20mA

-10V

+4000

+2000

0

-2000

-4000

+8000

+4000

0

-4000

-8000

+12000

+ 6000

0

-6000

-12000

1/4000 1/8000 1/12000

Maximum

resolution

Voltage input

Current input

2.5mV

10μA

1.25mV

5μA

0.83mV

3.33μA

General accuracy

*2

Within ±1% ±40 ±80 ±120

Maximum

conversion speed

20ms/channel

Maximum

absolute input

Voltage ±15V Current ±30mA

No. of analog

input points

4 channels/module

Specific

isolated area

Isolation

method

Dielectric

withstand

voltage

Insulation

resistance

Between input

terminal and

PLC power

supply

Photocoupler

isolation

500V AC

for

1 minute

5MΩ or more

(measured with a

500V DC insulation

resistance tester)

Between

channels

Not isolated - -

Isolation

specifications

Loading...

Loading...