Page 1

0

v

n

MITSUBISHI

MOTORS

Worl<shop

Mqnuol

chossis

SUPPLEMENT

3000GiT'96

v

/----.-:

1C

- ..--:

---:

_

--+'----

.-___

=--:=-

:

\'

/z-:=-

-::--t-

:.8

Page 2

v

MITSUBISHI

(-,

i.

v

3000GiT

WORKSHOP

SUPPLEMENT

FOREWORD

This Workshop

removal,

sembly and installation,

Use the

manual as required.

TECHNICAL

WORKSHOP

All information,

tions

time

to make

or obligation.

disassembly, inspection,

following

CHASSIS

ENGINE

ELECTRICAL

PARTS

contained in

publication.

of

changes

Manual

manuals

INFORMATION

MANUAL

GROUP PWUEg119

GROUP

WIRING

CATALOGUE

illustrations

this manual

We, however,

at any time

MANUAL

contains

etc. for

in

combination with this

PYUE92O1

(Loose-leaf

PWUE9203

PWUE92O3-1

(Supplement)

PWUE92O3-2

(Supplement)

PWUE92O3-3

(Supplement)

PWEEDN!N

(Loose-leaf

PHUE92O1

(Loose-leaf

PHUE9406

PHUE94O6-1

(Supplement)

8608K40!A!

B608K454An

B608K406A!

8808K404A!

8808K454A!

BFASK4O4AD

BFA8K454A!

8808K405A!

8808K406A!

BFASK4O6AN

and

procedures

adjustment, reas-

service mechanics.

MANUAL

product

are

current as

reserye

without

edition)

(Basic)

edition)

edition)

(Basic)

descrip-

the right

prior

for

at the

notice

General

Fuel

Engine

Electrical

Body

Chassis

Electrical

G

IE

IE

JE

-E

GI

-l

Milsubishi

@

A[!,LT-,'.H-BJ-iJJI

Molors

Corporation July 1995

Page 3

WARNINGS REGARDING

(sRs)

WARNING!

(1)

lmproper

lead to

driver

(2)

lf it is

after

beforehand.

(3)

Service or

an authorized MITSUBISHI dealer.

(4)

MITSUBISHI

Supplemental Restraint

of the

NOTE

Section titles with asterisks

warnings.

EQUTPPED VEHTCLES

service or

personal

(from

possible

painting,

rendering

maintenance

dealer

or any

SRS

remove the

maintenance

injury

that the

or death to service

the SRS

SRS

personnel

System

SRS-related

components

SRS

of any

(.)

in the table of contents in each

OF SUPPLEMENTAL

of any component of the

inoperative).

components

component or

SRS

must thoroughly review this manual, and

(SRS),

component.

before beginning any service or maintenance

personnel

subjected to heat

are

(air

(from

bag module,

SRS-related

RESTRAINT

or any

SRS,

inadvertent

over 93oC

SRS diagnosis unit, front impact

component must

group

SRS-related component,

firing

of the air

(200'F)

especially

indicate

in baking

be

operations requiring

SYSTEM

bag) or to the

or

performed

its

GROUP

of any component

can

in

drying

sensors)

only at

528-

ll

ri

v

r)

Page 4

GENERAL

-

Vehicle

ldentification

00-1

VEHICLE

IDENTIFICATION

MODELS

VEHICLES

Zl6AMNGFL6

Zl6AMNGFR6

Zl6AMJGFL6

Zl6AMJGFR6

VEHICLES

Zl64MNGFL

Zl6AMNGFR

FOR

Model

FOR

Model

code

code

EUROPE

6G72

GENERAL

EXPORT

6G72

Engine

(2,972

mt

Engine

(2,972

m(

GROUP

GENERAL

model

)

model

)

Transmission

WsMG1

W6MG1

Transmission

WsMG1

OO

model

model

MPI

MPI

Fuel

Fuel

supply

supply

system

system

VEHICLES

Zl6AMNGFLW

VEHICLES

Zl64MNGFR8

FOR

Model

FOR

Model

GCC

code

AUSTRALIA

code

6G72

6G72

Engine

(2,972

m(

Engine

(2,972

me

model

)

model

)

CHASSIS

The

engine

Transmission

WsMG1

Transmission

WsG1

NUMBER

chassis

number

compartment.

model

model

is

stamped

Fuel

supply system

MPI

Fuel

supply

MPI

on

the toeboard

system

inside

the

<VEHICLES

FOR

EUROPE

AND

AUSTRALIA>

AJMBMN216

T_ITTTI-

ttttll

123456

APY

TTT

ttl

ltl

789

000001

---l---

I

I

10

A

Page 5

00-2

GENERAL - Vehicle

ldentification

1. Asia

2.

Japan

MITSUBISHI

3.

A - For

-

B

F - For Australia, right

4.

Body style

M - 2-door hatchback

Transmission

5.

6.

<VEHICLES

-

N

J - 6-speed manual transmission

Development

216- 2,972 me

Europe, right hand

For

Europe, left hand

type

S-speed

FOR

manual transmission

order

(Full

GENERAL EXPORT AND GCC>

time 4WD)

C

TTT_T-]_TT

tttlttl

tttrrtl

1234567

drive

drive

hand drive

M N 216 A P Y

7. Sort

A - Passenger

8.

9.

10.

Model

Plant

Serial

00001

--T--

year

P - 1993

R - 1994

-

1995

s

T - 1996

-

Y

Ohe Motor

number

I

I

B

ll

car

Vehicle Works

c

MITSUBISHI

1.

4.

-

For

C

D - For

drive

Body

style

M - 2-door hatchback

Transmission

-

N

S-speed

Development order

216 - 2,972 me

General

General

type

Export, right hand

Export

manual

(Full

or GCC,

transmission

4WD)

time

left hand

drive

Sort

5.

A - Passenger

Model

6.

P - 1993

R - 1994

-

s

T - 1996

Plant

7.

-

Y

Serial

number

car

year

1995

Motor Vehicle Works

Ohe

o

a

Page 6

I

V

MAJOR

SPECIFICATIONS

GENERAL - Major

Specifications

00-3

L

Items

Dimensions

Overall

Overall width

Overall

Wheelbase

Track-front

Track- rear

Ground clearance

Overhang-front

Overhang

Angle

Angle

Weight

Kerb weight

Gross

Max. axle weight

length

height

-

rear

approach

of

of departure degrees

vehicle weight

front

rear

mm

(unladen)

(unladen)

degrees 10

k9

(in.)

1

2

3

4

5

6

7

8

9

'11

(lbs.)

Zl6AMNGFL6

Zl6AMNGFR6

(179.9)

4,570

(72.4)

1,840

(50.6)

1,285

(97.2)

2,470

(61.4)

1,560

(62.2)

1,580

(5.5)

140

(40.6)

1,030

(42.1)

1,070

1'1.00

17.60

(3,792)

1,720

(4,674)

2,120

(2,535)

1,150

(2,249)

1,020

Zl6AMJGFL6

Zl6AMJGFR6

(179.9)

4,570

(72.4)

1,840

(50.6)

1,285

(97.2)

2,470

'1,560

(61.4)

(62.2)

1,580

(5.5)

140

(40.6)

1,030

(42.1)

1,070

'1

1.00

17.60

(3,858)

1,730

(4,674)

2,120

(2,535)

1,150

(2,249)

1,020

Zl6AMNGFL

Zl6AMNGFR

Zl6AMNGFLW

(179.9)

4,570

(72.4)

1,840

(50.6)

1,285

(97.2)

2,470

(61.4)

1,560

(62.2)

1,580

(5.7)

145

(40.6)

1,030

(42.1)

1,070

12.0"

17.4"

(3,737)

1,695

(4,57s)

2,075

(2,535)

1,150

(2,249)

1,020

Zl64MNGFRB

(179.9)

4,570

(72.4)

1,840

(50.6)

1,285

(97.2)

2,470

(61.4)

1560

(62.2)

1,580

(5.7)

145

(40.6)

1,030

(42.1)

1,070

12.00

17.40

(3,748)

1,700

(4,575)

2,075

(2,535)

1,150

(2,249)

1,020

Seating capacity

Engine

Model

Total

displacement m(

Transmission

Model

Type

4

6G72

2,972

WsMG1

S-speed manual

4

6G72

2,972

W6MG1

6-speed manual

4

6G72

2,972

WsMG1

5-speed manual

4

6G72

2,972

WsMG1

S-speed manual

Page 7

\/

,

v

t,

GENERAL

Outline

SPECIFICATIONS

General Specifications

TROUBLESHOOTING

Engine

(Check

Self-diagnosis

Problem Diagnosis

Check Chart

Problem

of Changes

Warning Lamp

Engine Lamp)

Classified by

Symptoms

..............

...........

Content

.............

Chart

FUEL

CONTENTS

2

2

ON.VEHICLE

coMPoNENTS

Fuel Pump

2

2

2

2

2

2

Air

Conditioner

Engine

Voltage

INSPECTION

Control

Check

........

Switch

Terminal

Unit

MPI

OF

Power Relay .......

and

13-1

4

4

8

Page 8

13-2

FUEL

-

General/Specifications/Troubleshooting

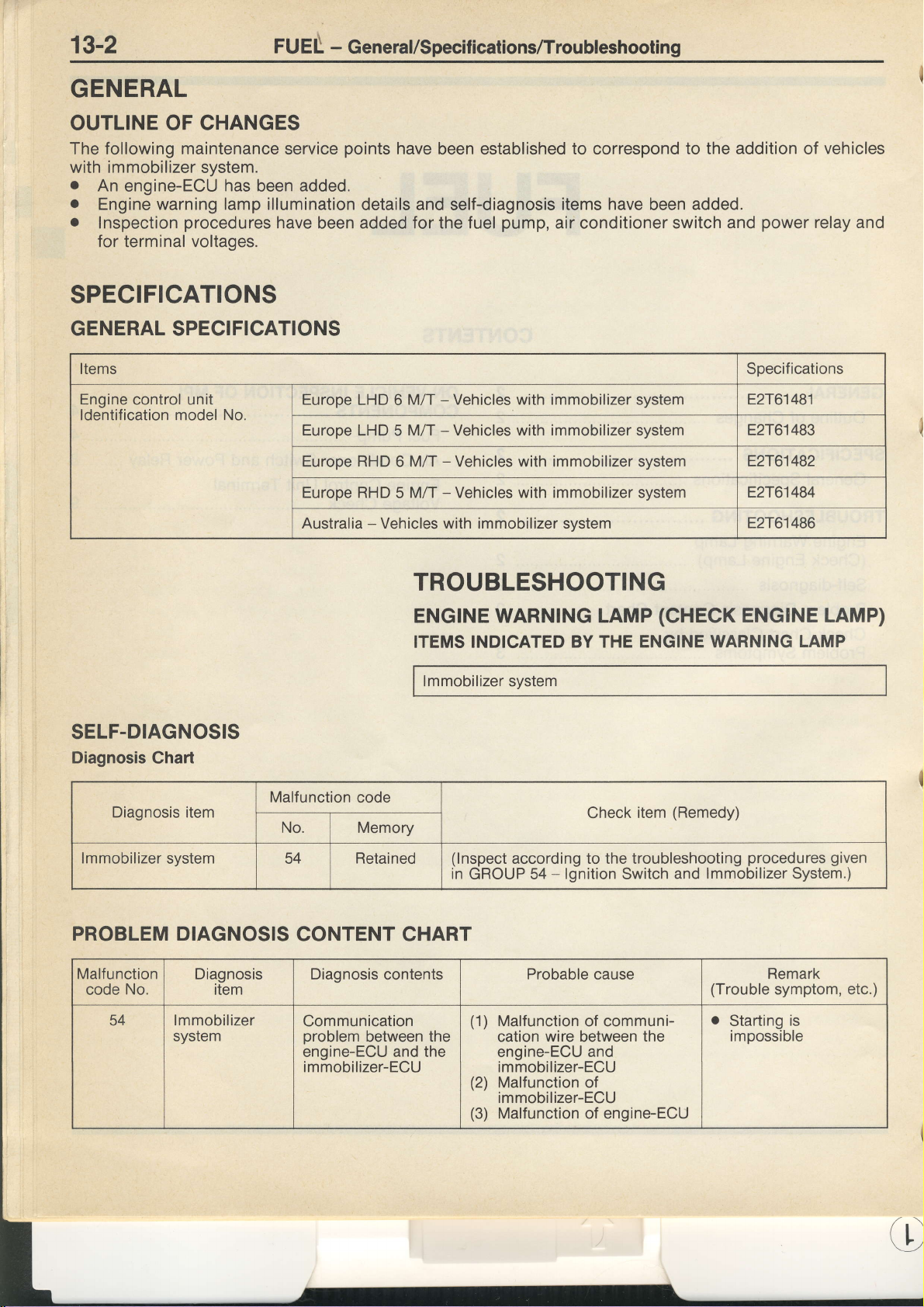

GENERAL

OUTLINE OF CHANGES

The following maintenance service

with immobilizer system.

o

An

engine-ECU

.

Engine warning lamp illumination

.

Inspection

for terminal voltages.

has

been

procedures

have been added for the fuel

points

added.

have been established to correspond to

details

and

self-diagnosis

pump,

items have

air conditioner switch

been

SPECIFICATIONS

GENERAL SPECIFICATIONS

Items Specifications

the addition

added.

power

and

vehicles

of

relay and

Engine

ldentification model No.

control unit

SELF.DIAGNOSIS

Diagnosis

Chart

Diagnosis item

Europe LHD 6 M/T - Vehicles with immobilizer system

Europe

Europe

Europe RHD 5 Mft - Vehicles with immobilizer system

Australia - Vehicles with immobilizer system

LHD 5

RHD

MlT - Vehicles with immobilizer system E2T61483

6 M/T - Vehicles with immobilizer system

TROUBLESHOOTING

ENGTNE WARNTNG LAMP

ITEMS INDICATED BY THE ENGINE WARNING

lmmobilizer system

Malfunction code

No. Memory

Check

(CHECK

(Remedy)

item

E2T61481

E2T61482

E2T61484

E2T61486

ENGINE LAMP)

LAMP

lmmobilizer

PROBLEM DIAGNOSIS

Malfunction

code

54

system 54

Diagnosis

No.

lmmobilizer

system

CONTENT CHART

item

Retained

Diagnosis contents Probable cause

Communication

problem

engine-ECU

immobilizer-ECU

between

and the

(lnspect

in

the

according to the troubleshooting

-

GROUP 54

(1)

Malfunction

cation

engine-ECU and

immobilizer-ECU

(2)

Malfunction of

immobilizer-ECU

(3)

Malfunction of engine-ECU

lgnition

of communi-

wire

between

Switch

the

procedures given

lmmobilizer System.)

and

(Trouble

Remark

symptom, etc.)

Starting

impossible

is

O

Page 9

FUEL

-

Troubleshooting

13-3

CHECK

(Vehicles

Check items

Power

supply

Engine

control unit

pump

Fuel

Air flow

sensor

Intake

air temperature

Barometric

Engine

coolant

position

Throttle

position

ldle

position

Cam

Crank angle

lgnition

switch-ST

Vehicle

speed sensor

Power

steering fluid

Air

conditioner

Detonation

Electrical

Fan

Oxygen

Mixture

Injectors

ldle

lgnition

Purge

EGR

Fuel

Waste gate

Anti-lock

Fuel

:

o

:

n

sensor

load

motor relay

sensor

adjusting

speed

control

coil and

control

control

pressure

control

braking

pressure

Warm

engine

Cold engine

CHART

CLASSIFIED

with immobilizer

Problem

and ignition

pressure

temperature

sensor

switch

sensor

sensor

switch and

switch

(radiator

screw

power

solenoid valve

solenoid

control valve

signat

(number

(number

power

sensor

sensor

pressure

fan,

(variable

(stepper

servo

transistor

valve

solenoid

insrde

switch-lG

earth

sensor

switch

power

condenser

resistor)

motor

valve

inside

indicates

indicates

relay

system)

symptoms

fan)

type)

check order)

check order)

BY PROBLEM

Starting

E

o

-=^

o

r

6

c

=

3C

o

E-

o

.g

E

a

SYMPTOMS

ldling

stability

o

-o

o@

:9'

otr

@a

@tr

otr

o

o

@E

otr

otr

@a

@E @e

G'LqI

@tr

@E @ts

r2)

@

@

@

@

@

@E

@a OE

@trotr

OE

@

@tr

@

o

@E

Refer

Refer to

Refer

OE @a

to 3000GT'93

3000GT'95 Workshop

to 3000GT

o

.g

p

!>

Y'=

*7

otr

OE

@m

@E

@E @tr

@tr

@E OE

@tr

@E

@E

otr

@

@@

@tr

@a

@E

@E

@

o@

OE

Workshop

Workshop

6

f

F

6

=

o

r

L6

otr

@B

@a

@a

os

@ts

@E

@tr@a

Manual

E

F

6

O

@E

@E

@tr

on

@@

Manual

Manual

Driving

o

c

E

o

l

E

U)

6

@E

@ts

@a

otr

\9

@@

otr

o

(Pub.

No. PWUE9203)

(Pub.

No. PWUE920S-3)

(Pub.

No. PWUE9119-D)

o

g

l

a

@E

otr

@E

@E

-E

o

c

:<

@E

@e

@E

on

@E

e

PE

co

cc3

c

e

-1

P.1

.3P.1

-1

P.1

-3P.1

r

'T

-3P

.1

P.1

-3P.13-62

-1P.13-72

.3P.1

.1P.13-74

-3P.13-72

'1P.13-77

-3P.1

-

1

P.1

.3P.13-78

,1P

-rP

*3P

*3P

-r

P.1

-3P.13-90

P.13-00

-1

P.1

.3P.'13-92

.rP.13-96

-3P.13-94

.1

P.1

-3P.1

.2P

.3P

-1

P.1

.3P.1

.rP.13-1

.3P.13-108

-1

P.1

.3P.1

-1P.13-127

.3P.13-1

.1

P.13-1

.3P.1

.1P.1

.3P.1

-1P.13-'134

-3P.13-126

'3P

-3P

O

6

o

o

I

c

E

o

3-54

3-52

3-57

3-55

3-00

3-58

3-56

3-64

J-OZ

3-69

3-70

3-75

3-80

3-82

3-80

3-86

3-84

3-89

3-87

1

3-90

1 3-88

3-92

3,94

3-98

3-96

J-J

3-1 00-1

3-1

00

3-98

3-1

06

3-109

3- 1 01

16

21

3-1

3-1 1 3

19

29

3- 1 21

3-1 31

23

3-1

3-138

3-1 30

3-1 39

J-IJI

Page 10

13-4

ON-VEHICLE

INSPECTION

FUEL

-

On-vehicle

OF

Inspection

MPI

of MPI

COMPONENTS

Gomponents

,l

,

v

FUEL

PUMP

(Vehicles

with immobilizer

-1

,/o

,r'n

w

system)

u>Z/

pump

Fuel

check terminal

\:::-=-====<=

(:

\_----'==

----r-

;;G,

Fuel

pump

connector

lJ

tL

tg

Page 11

FUEL

-

On-vehicle

Inspection

of MPI

Components

13-5

Equipment

@

connector

side

lgnition

switch

flGl

Control

reray

(for

fuel

@

pu

mp)

r..;.€---r

ll1l2l3l I

lr-#l

| 4 | 5 ll

Equipment

connector

@

Equipment

)

side

connector

Harness

@

connector

side

CIrrrcl

(61

L4f5

Fuel

pump

side

\9

Engine

control

unit

Engine

control

[ffi,]:ipump)lrcra-sl

unit

connector

Equipment

connector

side

"t"l

"t"l

;F[

'l'l'

,l

+

"t.

't-

:t:

9FU0lol

EF

pump

Fuel

check

1a

termina

7FU1352

Page 12

13-6

FUEL

-

On-vehicle Inspection

of MPI

Gomponents

HARNESS

INSPECTION

Check the fuel

o

Apply

battery voltage

checking terminal

pump.

the

Check

pump.

o

the

earth

pump

Fuel

Disconnected

pump.

to the

and operate

circuit of the fuel

connector:

@

OK

@

0(

Repair

harness.

the

(@tr-

Earth)

l4

a

Harness

@

conneclor

side

@

r

@

F

I

7FUOg5

7FU0960

Engine

control

unit harness

side

connector

Check for

fuel

terminal.

o

Check for

checking terminal

relay

the resistor

r

Control relay

connector: Disconnected

o

Resistor

con nector: Discon

r

Fuel

Disconnected

Check

short-circuit

control relay

engine

o

Control

connector: Disconnected

.

Engine

Disconnected

continuity

pump

and

the

connector:

(for

pump

for

control unit.

Disconnected

continuity

pump),

fuel

(for

fuel

(for

fuel

connector:

an

open-circuit,

to

earth,

(for

relay

control

checking

and the

pump).

(for

fuel

(for

unit connector:

between the

between the

control

and between

pump)

fuel

pump)

nected

a

or

between the

pump)

fuel

and

pump)

OK)

@

OK

the

Z \

\_-/

Repair

harness.

the

(@tr-oa)

Repair

narness.

(otr-@)

(@tr-@)

Repair

harness.

(@tr-E)

the

the

tu

v)

Page 13

FUEL

-

On-vehicle

Inspection

of Mpl

Components

13-7

6

o=

Harness

connector

side

Harness

@

connector

side

Check for

control

resistor (for

Measure

the

control

r

Control relay

Disconnected

lgnition

Check

short-circuit to

control relay and

unit.

o

Control

Disconnected

o

Engine

Disconnected

continuity

(for

relay

fuel

Control relay

connector:

Resistor (for

connector:

OFF

ON

for

Disconnected

Disconnected

power

the

relay.

switch

an open-circuit,

earth

relay

control

between

pump)

fuel

pump).

(for

fuel

pump)

fuel

supply voltage

connector:

Voltage (V)

between the

the engine

connector:

unit connector:

and

pump)

0-1

SV

or a

control

the

the

@

0(

of

'9K)

OK

@

Repair

harness.

the

(@E-@tr)

Repair

harness.

(lgnition

switch-@fl)

or check

the ignition

switch.

Repair

harness.

(@tr-tr

the

the

)

r^'-l

t-\

l/\---\

tnl

t

f-\---l

l-)i-l

t _,:z__J

Check for

control relay

./

___,

fuel

.

o

continuity

and the

pump).

Control relay

Disconnected

Control relay

connector: Disconnected

between

control relay

connector:

(for

fuel

pump)

the

(for

Repair

harness.

the

(@n-@tr)

(@tr-@tr)

Check for

short-circuit

control relay

fuel

o

Control

connector: Disconnected

o

Fuel

Disconnected

pump.

pump

an

open-circuit,

to earth,

(for

fuel

(for

relay

connector:

or a

between

pump)

fuel

and the

pump)

the

Repair

narness.

the

(@tr-oE)

Page 14

13-8

AIR

CONDITIONER SWITCH

(Vehicles

with immobilizer system)

FUEL

-

On-vehicle

Inspection of

AND POWER RELAY

MPI

Components

Battery

'uu

1i-#\

^l

Air conditioner

compressor

//

l\ A-,\

) | /\ -\l

Air conditioner

control

relay

Engine

control

unit

Enoine control unit connector

unit

tq

-t-

"t'

"t"

"t'

4

,l:

HARNESS

INSPECTION

power

Measure

the air conditioner

e

o

o

o

the

circuit.

Air conditioner

Engine control

Disconnected

lgnition

Dual

switch:

air conditioner

Voltage

SV

supply

switch:

connector:

unit

ON

switch: ON

(V)

voltage

ON

of

OK

o(

a

Check the

air

conditioner

circuit.

l,)

Page 15

FUEL - On-vehicle

Inspection of

MPI Components

13-9

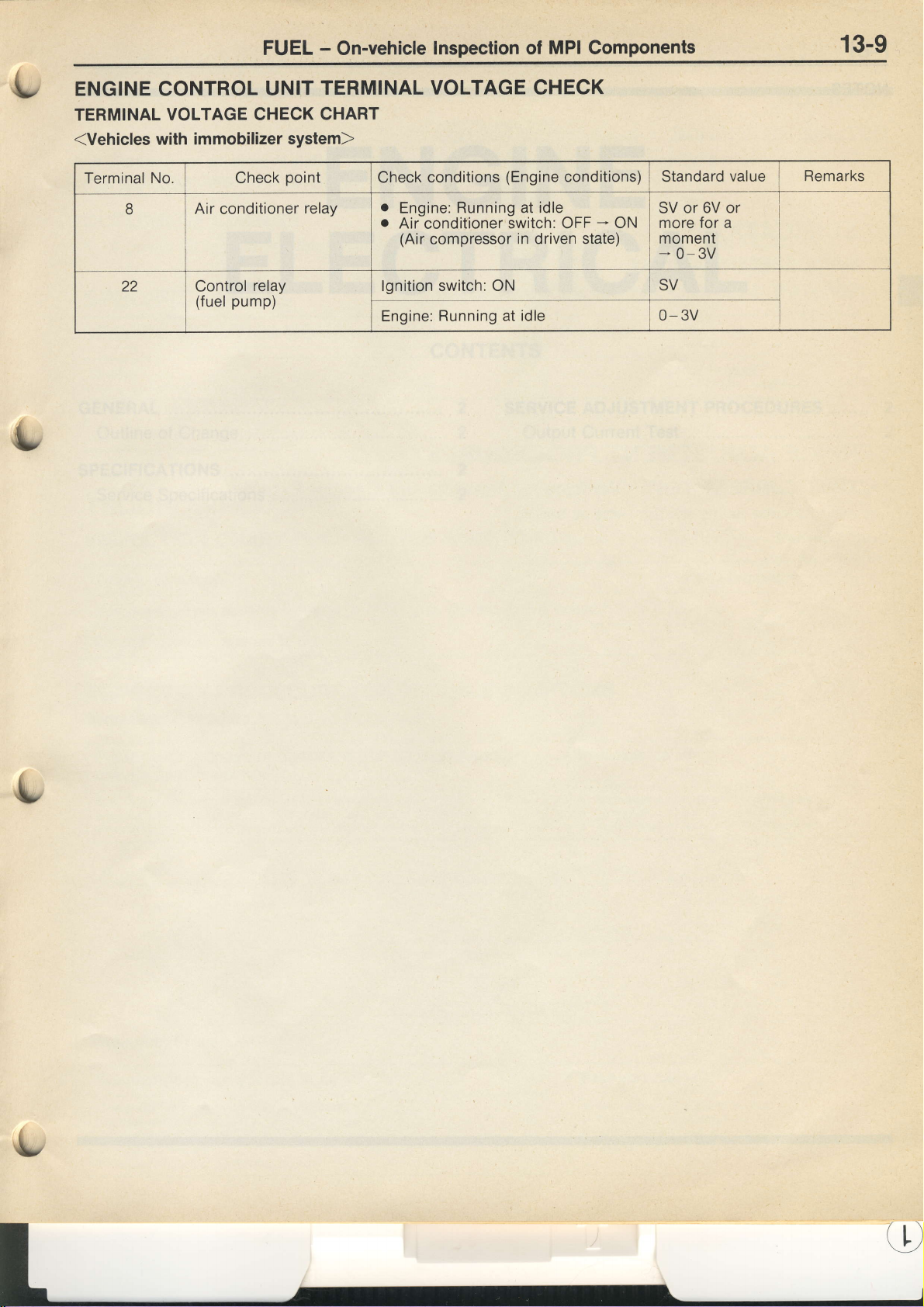

ENGINE CONTROL

TERMINAL

(Vehicles

Terminal

VOLTAGE CHECK

with immobilizer

No. Check

B

22 Control

Air

(fuel

UNIT

conditioner

relay

pump)

TERMINAL VOLTAGE CHECK

CHART

system)

point

relay

Check

conditions

.

Engine:

o

Air

conditioner

(Air

compressor

lgnition

Engine:

Running at idle

switch: ON

Running at idle

(Engine

switch: OFF

in driven state)

conditions) Standard

6V or

ON

SV or

for

more

moment

*

0-3v

SV

a

-*

0- 3v

value

Remarks

Page 16

16-1

{"

ENGINE

ELECTRICAL

CONTENTS

GENERAL

Outline

SPECIFICATIONS

Service

of

Change

Specifications

.............

2

SERVICE

2

2

2

Output

ADJUSTMENT

Current

Test

PROCEDURES

.......

2

2

Page 17

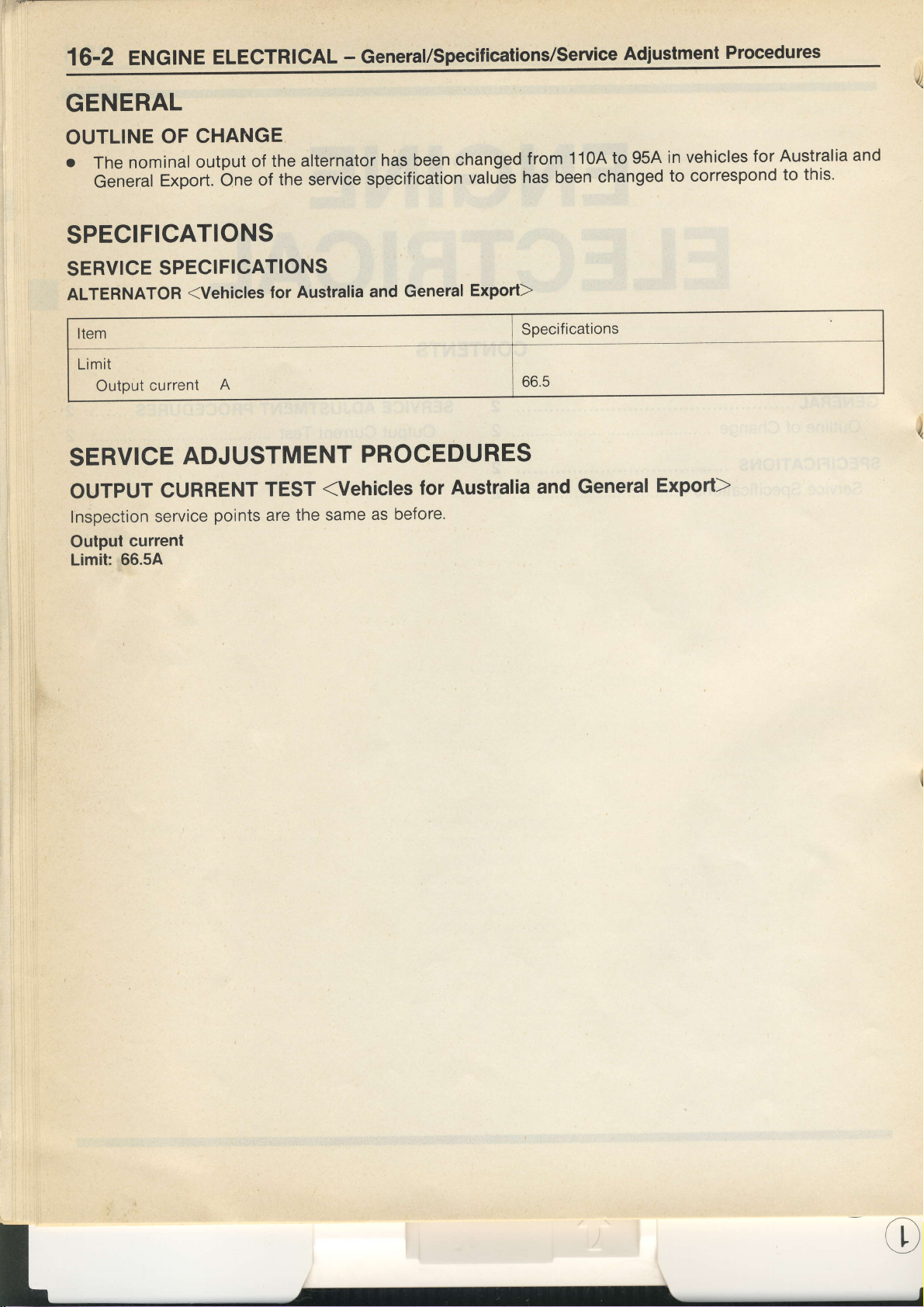

16-2

ENGINE

GENERAL

ELECTRICAL

-

General/Specifications/Service

Adiustment

Procedures

OUTLINE

o

The

General

OF CHANGE

nominal

output

Export.

bne

the alternator

of

the service

of

SPECIFICATIONS

SERVICE

ALTERNATOR

Item

Limit

Output

SERVICE

OUTPUT

Inspection

Output

Limit: 66.5A

SPECIFICATIONS

(Vehicles

current

A

for Australia

ADJUSTMENT

CURRENT

service

current

points

TEST

are

the same

has been

specification

and General

changed

valuies

Export)

PROCEDURES

(Vehicles

as before'

Australia

for

to 95A

1 1OA

from

has been

Specifications

66.5

and

changed

General

in vehicles

to correspond

for Australia

Export)

to

and

this.

Page 18

BODY

-

General/Specifications/Troubleshooting

42-1

GENERAL

OUTLINE

o

power

A

OF

CHANGE

tilt

and

outer

sliding

sunroof

SPECIFICATIONS

SERVICE

Items

Roof

Sunroof

SPECIFICATIONS

lid

sliding resistance

motor

clutch slippage

N

force

N

TROUBLESHOOTING

INSPECTION

CHART

FOR

TROUBLE

GROUP

BODY

has

provided

been

SYMPTOMS

42

as an

option

Standard

147

39- 49

in vehicles

or

for Europe.

value

more

I

I

Trouble

sunroof

Sunroof

INSPECTION

Inspection

Front

drive/s

After

turned

impossible,

Inspection

symptom

does not

does

Procedure

sunroof

door is

the driver's

off, the sunroof

door is opened

the

driver's door

Procedure

operate

not

operate at

PROCEDURE

does not

opened.

can still

within

30

all.

1

operate within

within

30 seconds

be operated

switch

or

the

sunroof

2

seconds

FOR

TROUBLE

30

after

for a further

control

Check

c-63, E-16,

Check the harness

roof

switch.

Replace

after

driver's

seconds

the ignition

30

seconds. lf

unit mav

control

be defective.

the following

E-39, E-40,

unit

the

sunroof

door is

openeo.

SYMPTOMS

after

switch is

it is

connectors.

between

and the

control

F-35

driver's

Probable

.

o

.

the

sun-

door

unit.

Inspection

1

2

cause

Malfunction

Malfunction

Malfunction

procedure

of

door switch

of sunroof control

of wiring harness

Repair

Repair

(driver's

side)

unit

or connector

Sunroof

One of the following

Sunroof

Sunroof motor

Sunroof

Power

does not

switch

control

supply

unit

circuit

operate

items

may

(including

at all.

be defective

theYuse)

Probable

.

Malfunction

.

Malfunction

r

Malfunction

.

Malfunction

cause

of sunroof

of sunroof

of

sunroof

wiring

of

switch

motor

control unit

harness

or connector

Page 19

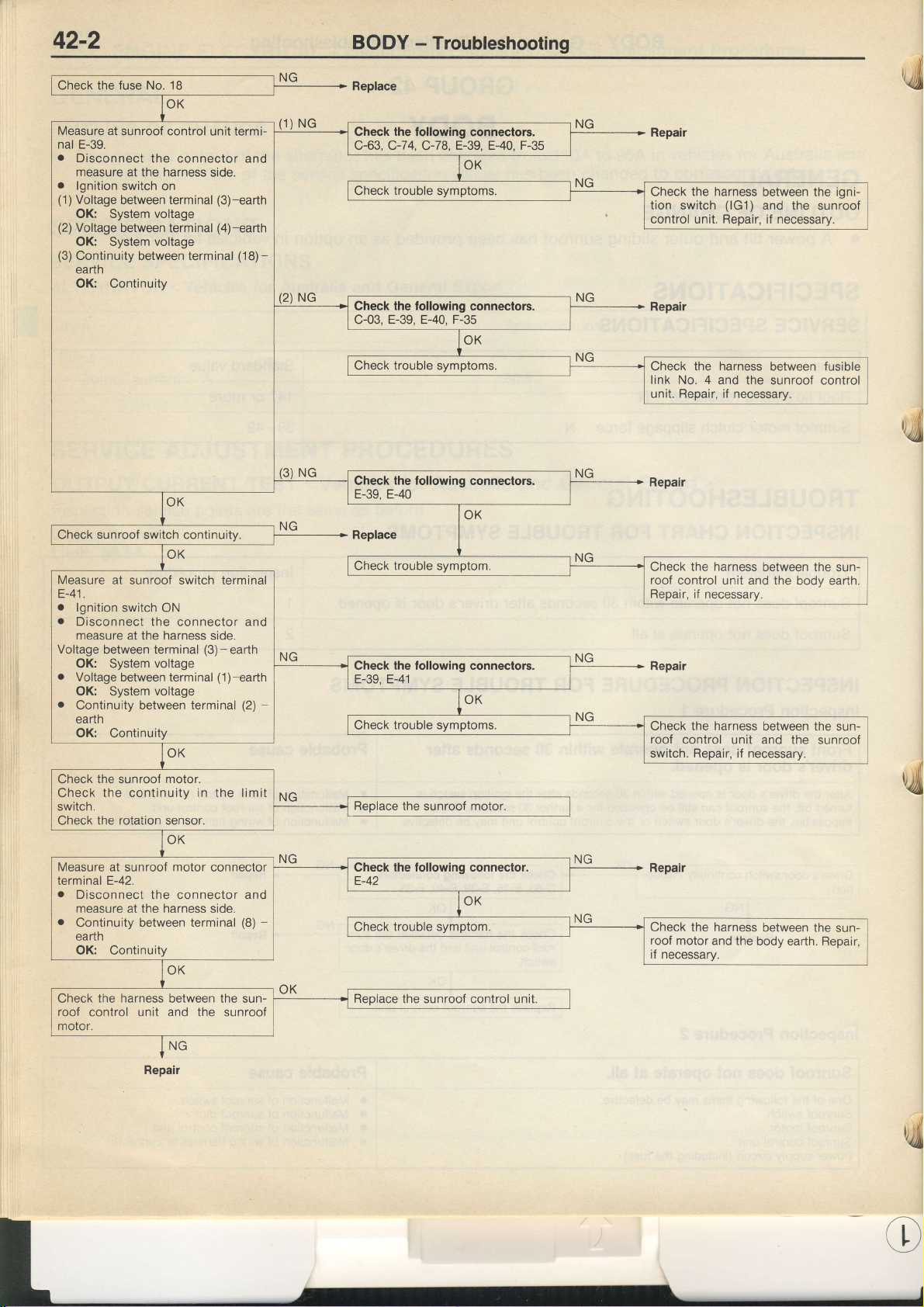

42-2

BODY - Troubleshooting

Check the fuse No. 18

Measure at

nal E-39.

.

o

(1

)

(2)

(3)

sunroof control unit termi-

Disconnect

measure

lgnition

Voltage between terminal

OK: System voltage

Voltage between terminal

OK: System

Continuity between terminal

earth

OK:

the connector and

at the harness side.

switch

on

voltage

Continuity

(3)-eadh

(4)-eadh

(18)-

(1)

(2)

NG

NG

Replace

the following

Check

c-63, C-74,

Check the following

c-03,

Check trouble symptoms.

Check

E-39, E-40

C-78,

E-39, E-40, F-35

the following

connectors.

E-39, E-40, F-35

connectors.

connectors.

Repair

Check the harness

tion switch

control unit. Repair, if necessary.

Repair

the harness

Check

link

No. 4 and

unit. Repair, if

Repair

between the

(lG1)

and the

between fusible

the sunroof control

necessary.

sunrooi

t'l)

igni-

,ll

sunroof

Check

Measure

tr-4t.

o

lgnition

.

Disconnect the connector and

measure at the harness

Voltage

OK: System voltage

.

Voltage between terminal

OK:

o

Continuity between terminal

earth

OK: Continuity

the sunroof motor.

Check

Check the continuity in the limit

switch.

Check the rotation sensor.

Measure at

terminal E-42.

.

Disconnect the

measure at the harness side.

.

Continuity

earth

OK: Continuity

switch continuitv

at sunroof switch terminal

switch ON

side.

between terminal

voltage

System

sunroof

between terminal

(3)-earth

(1)-earth

(2)

motor

connector

connector and

(8)

Replace

the harness

Check

roof

control unit and the

Repair,

if necessary.

Ctect fre tottowingcon'1ectqrs.

tr-:lq tr-41

-

OK

l-\q

+

Repair

Check the harness

roof control

switch. Repair, if necessary.

between the sun-

body earth.

between the sun-

unit and the sunroof

,,Jd

Reolace

-

the sunroof motor

the

Check

roof

motor and the

if

necessarv.

harness

between the

body earth. Repair,

sun-

Check

roof

control unit

molor.

the harness

Repair

between the sun-

and the

sunroof

Reolace

the sunroof control unit.

,c

Page 20

BODY

-

Service

Adjustment

procedures

42-3

=s

im

\ lL----Jl

l-

z-:-[=

Approx.

-<=

a\\\

r8AO216

18XO545

30

cm

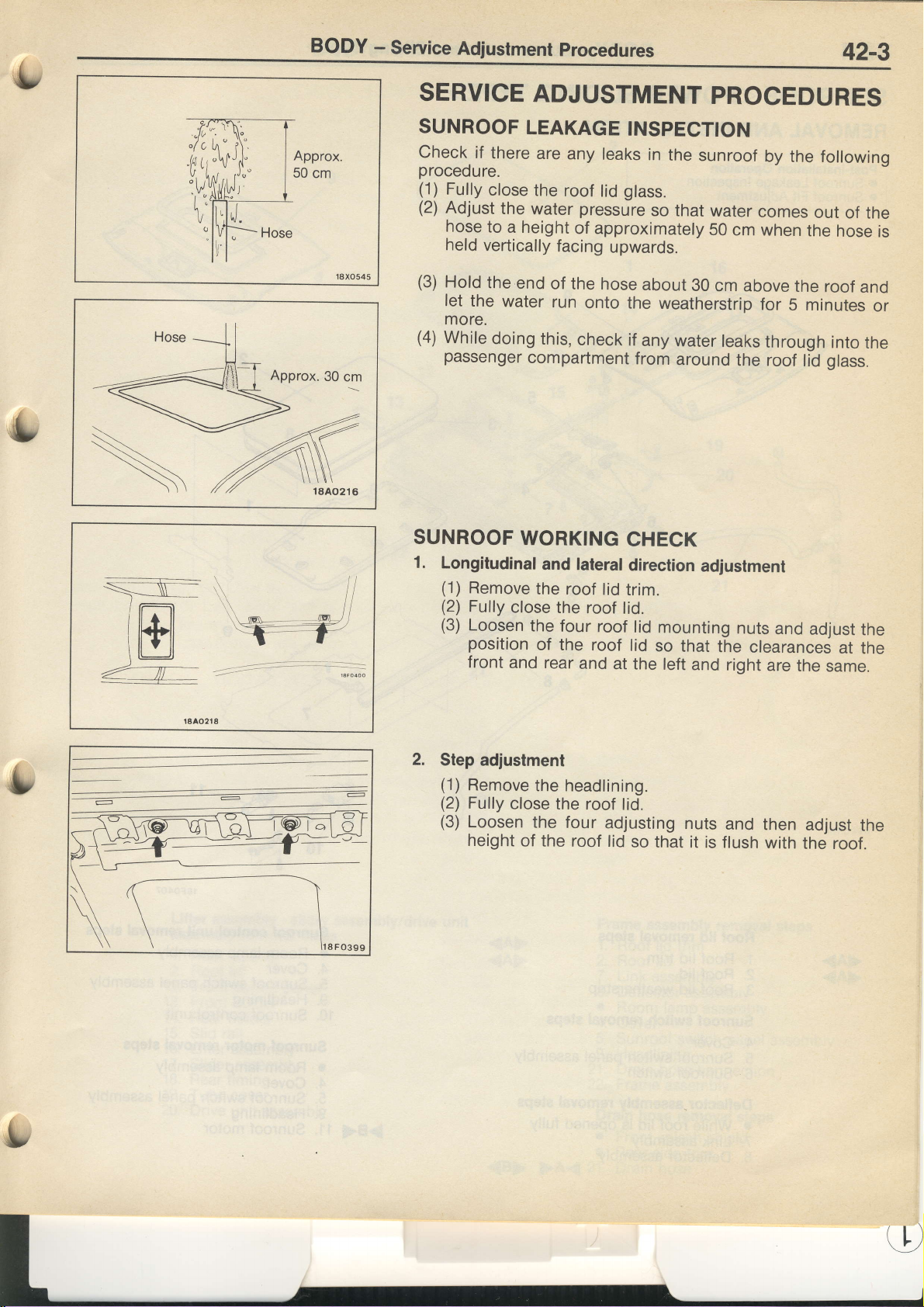

SERVICE

SUNROOF

check

procedure.

(1)

(2)

(3)

if

Fully

Adjust

hose

held

vertically

Hold

let

the

ADJUSTMENT

LEAKAGE

there

close

the

the

water

to

a height

the

end

water

more.

(4)

While

passenger

SUNROOF

1.

Longitudinal

(1)

(2)

(3)

doing

compartment

WORKING

Remove

Fully

close

Loosen

position

front

the

and

the roof

INSPECTION

are

any

leaks

roof

of approximately

facing

of

the hose

run

this,

check

glass.

lid

pressure

upwards.

onto the

if

from

CHECK

and lateral

the roof

four

of the roof

rear

and

direction

lid

trim.

tid.

roof

lid

at the

lid

PROCEDURES

in

the

sunroof

so

that

water

50

cm when

about

any

30

cm above

weatherstrip

water

leaks

around

adjustment

mounting

so

that

the

left

and right

by

the following

comes

the

the

for

5 minutes

through

the roof

nuts

clearances

and

are

lid

adjust

the

out

hose

roof

into

glass.

at

same.

of the

is

and

or

the

the

the

2.

Step

adjustment

(1)

Remove

(2)

Fully

(3)

Loosen

height

\

the headlining.

close

the roof

the four

of the roof

lid.

adjusting

lid

so that it

nuts

is flush

and

then

with

adjust

the roof.

the

Page 21

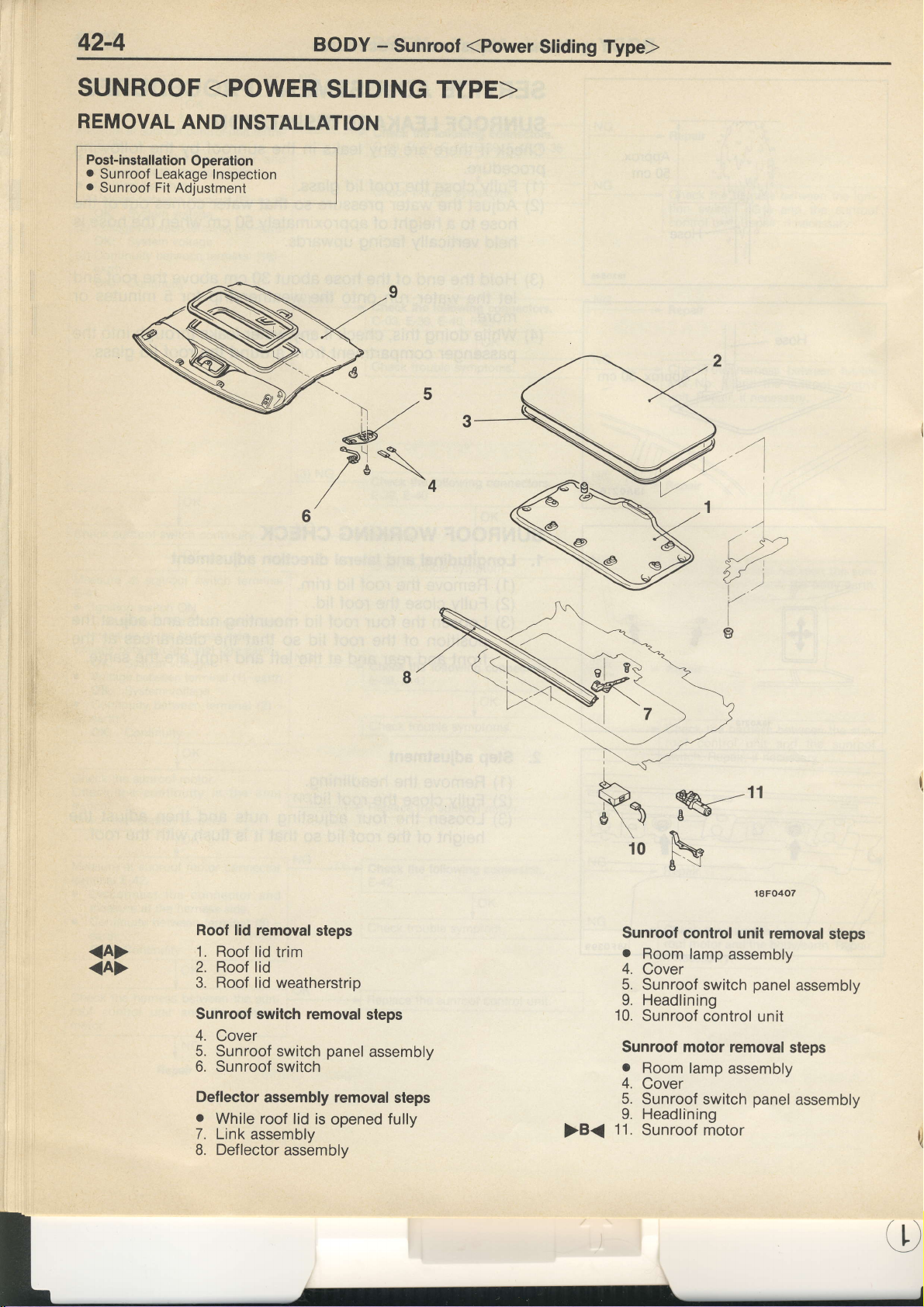

42-4

BODY

-

Sunroof

(Power

Sliding

Type)

SUNROOF

REMOVAL

Post-installation

o

Sunroof Leakage

o

Sunroof Fit Adjustment

<POWER

AND INSTALLATION

Operation

Inspection

SLIDING TYPE>

<A>

<A>

Roof lid

1.

2. Roof

3. Roof lid

Sunroof switch

4.

5. Sunroof

6. Sunroof

Deflector

o

7.

B.

removal

Roof lid

Cover

While roof

Link assembly

Deflector

trim

lid

weatherstrip

switch

switch

assembly removal

lid is

assembly

steps

removal

panel

opened

steps

assembly

steps

fully

>B<

M

N

Sunroof

.

4.

5.

9. Headlining

10.

Sunroof motor

o

4.

5.

9. Headlininq

'11.

control

Room

Cover

Sunroof switch

Sunroof

Room

Cover

Sunroof switch

Sunroof

lamp

c-ontrol

lamp

riotor

11

18F0407

unit removal

assembly

panel

assembly

unit

removal

assembly

steps

panel

assembly

steps

Page 22

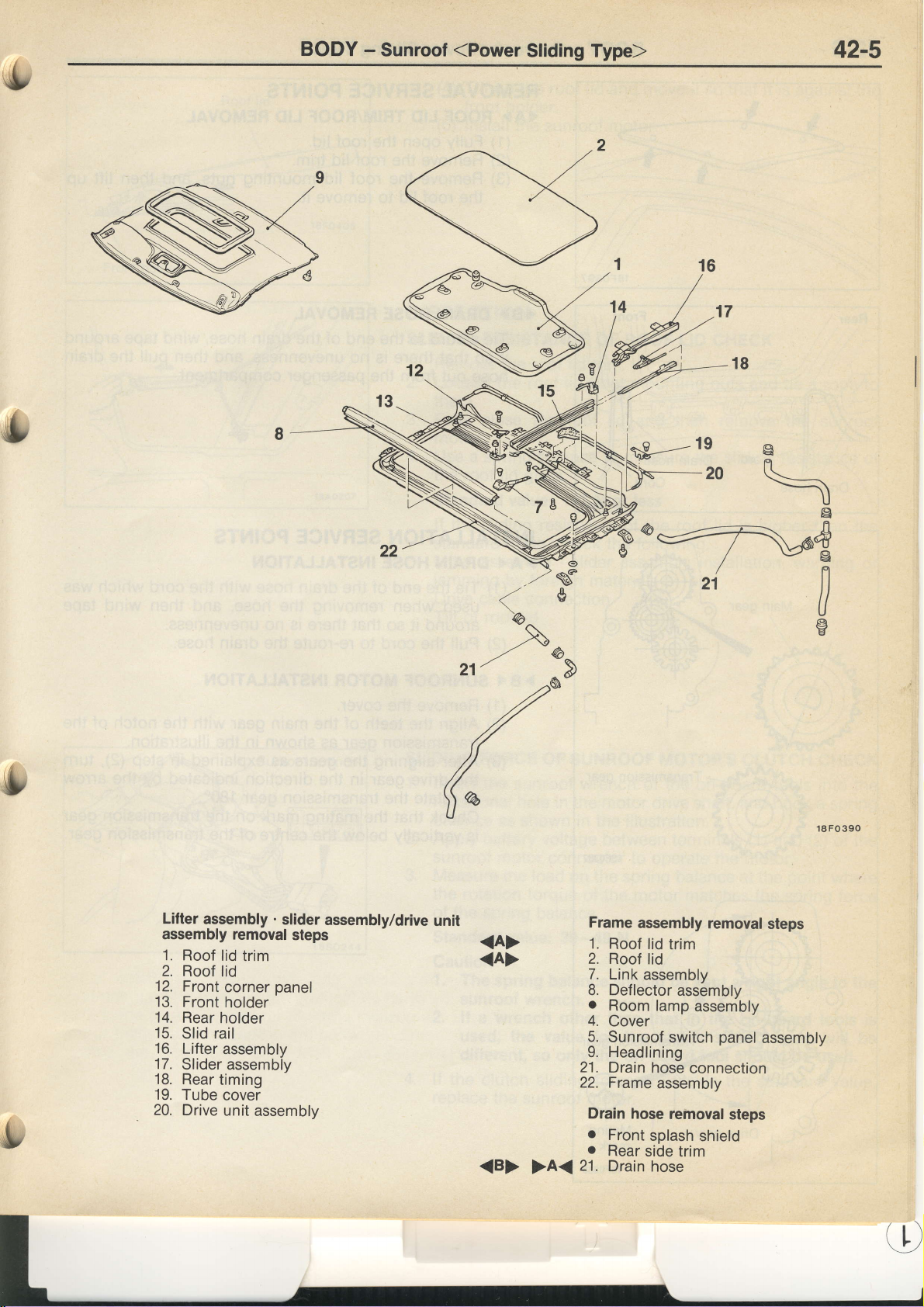

BODY

-

Sunroof

(Power

Sliding Type)

42-5

ip

v,.,

N--20

o#

/

,n

21

R

\

u

Lilter

assembly

assembly removal

'1.

Roof

lid

2. Roof lid

12. Front

13. Front

14.

Rear

15.

Slid rail

16. Lifter

17.

Slider

18. Rear

19. Tube

20.

Drive

trim

corner

holder

holder

assembly

assembly

timing

cover

unit

assembly

.

slider

steps

panel

assembly/drive

unit

<A>

<A>

<B>

>A<

Frame

1

I.

Roof

Roof

2.

Link

7.

Deflector

8.

a

Room

4.

Cover

Sunroof

9.

Headlining

21.

Drain hose

Frame

22.

Drain

o

Front

.

Rear

21.

Drain

assembly

lid

lid

assembly

lamp

assembly

hose removal

splash

side

removal

trim

assembly

assembly

switch

connection

shield

trim

hose

panel

steps

steps

assembly

Page 23

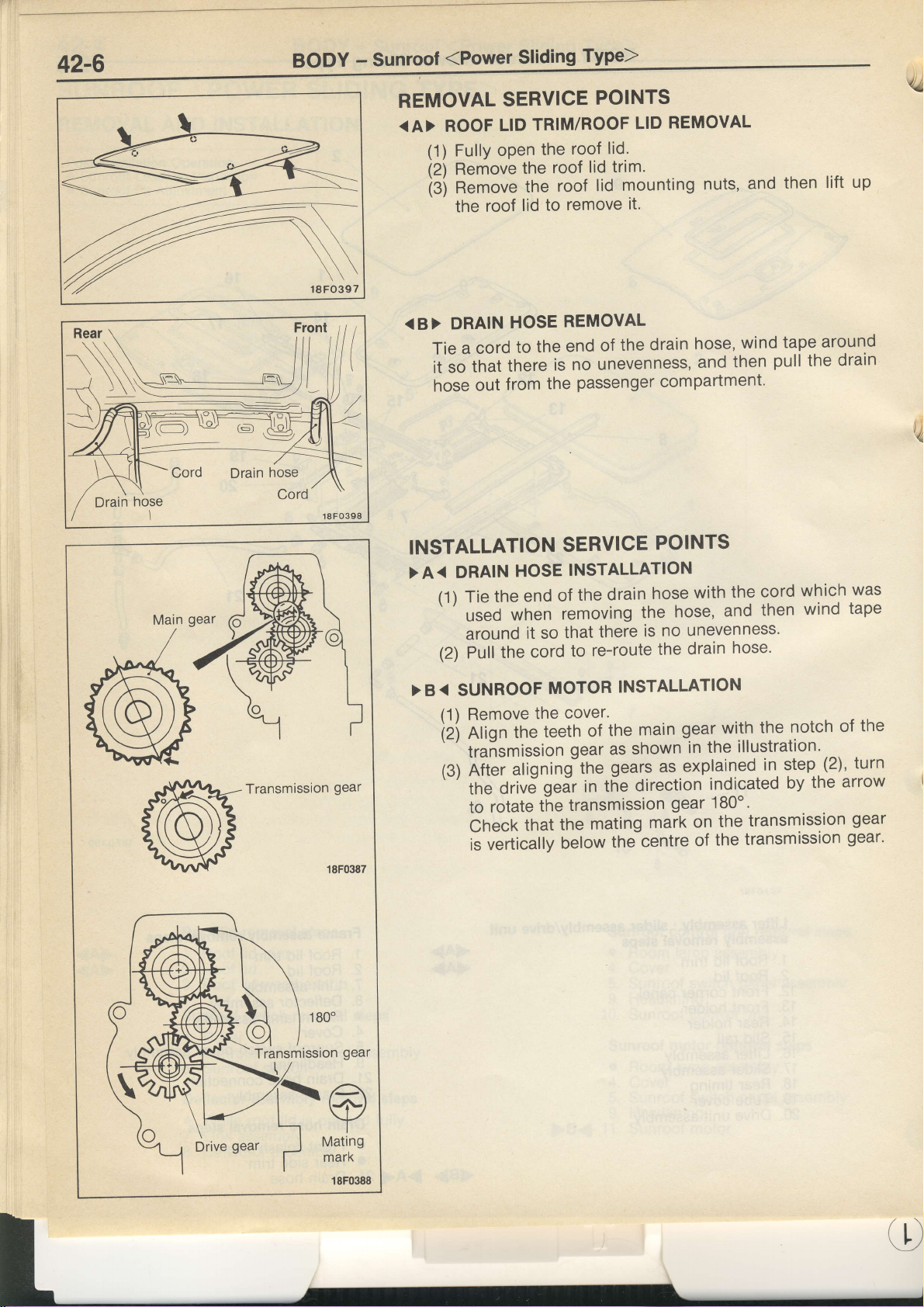

BODY

-

Sunroof

REMOVAL

<A>

(Power

ROOF

(1)

Fully

(2',)

Remove

(3)

Remove

the

Sliding

SERVICE

TRIM/ROOF

LID

the

open

roof

the

roof

the

remove

to

lid

roof

Type)

POINTS

lid.

roof

trim.

lid

mounting

lid

REMOVAL

LID

it.

nuts,

and

then

lift

4,1,

up

Main

gear

Transmission

gear

REMOVAL

passenger compartment'

the

SERVICE

INSTALLATION

removing

there

that

so

it

re-route

to

cord

MOTOR

cover.

the

teeth

INSTALLATION

the

of

gear as

gears as.explained

geir

the

the

in

transmission

POINTS

hose,

the

no unevenness'

is

the

main

shown

direction

and

hose'

drain

gear with

the

in

indicated

gear 180o'

wind

then

notch

the

illustration'

(2)' turn

step

in

the

by

tape

the

of

arrow

out

HOSE

from

DRAIN

<B>

Tieacordtotheendofthedrainhose,windtapearound

itsothatthereisnounevenness,andthenpullthedrain

hose

INSTALLATION

>A<

DRAIN

(1)Tietheendofthedrainhosewiththecordwhichwas

'

used

HOSE

when

around

> B

(2)

<

(1)

iZi

'

the

Pull

SUNROOF

Remove

the

nf ign

'

traismission

(g)

aligningithe

Aiier

drivJ

the

rotate

to

Checkthatthematingmarkonthetransmissiongear

isvertical|ybe|owthecentreofthetransmissiongear.

q

Drive

gear

,4.

w

Mating

marK

18F0388

Page 24

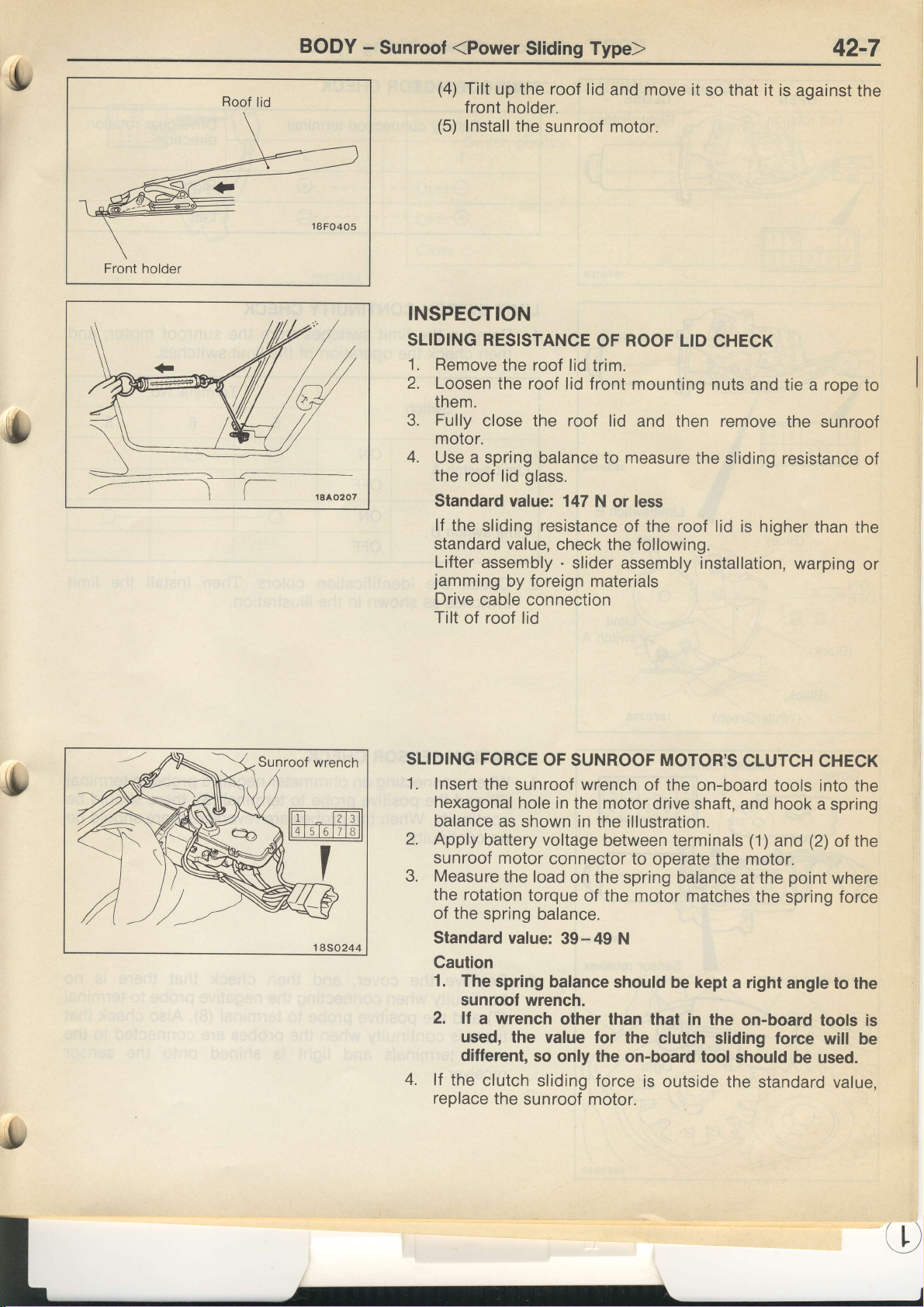

Front holder

Roof

lid

BODY

-

Sunroof

(Power

(4)

Tilt

front

(5)

lnstall

up the roof

holder.

INSPECTION

SLIDING RESISTANCE

1. Remove

2.

Loosen

them.

3. Fully

motor.

4.

Use a

the roof lid

Standard value: 147

lf

the sliding

standard

Lifter

jamming

Drive

Tilt

the roof lid

the roof

close the roof lid

spring

value,

assembly

by foreign

cable connection

of roof lid

Sliding Type)

lid

and move it

the

sunroof motor.

ROOF

OF

trim.

lid front mounting

balance to

glass.

resistance

check the following.

.

slider

measure

N

or

of the roof lid is

assembly installation,

materials

so that it is

LID CHECK

nuts

and

and then remove

the

sliding resistance

less

higher

42-7

against

tie a rope

the

warping

the

sunroof

than the

io

of

or

SLIDING FORCE

1.

Insert

hexagonal

balance

2.

Apply

sunroof

3. Measure

the rotation

of the

Standard

Gaution

1.

2.

4.

lf

replace

the

sunroof wrench

hole

as

shown in

battery voltage

motor

the load

torque

spring

value:

The

spring

sunroof

lf

used, the

different,

the

wrench.

a wrench

clutch

the

sunroof motor.

balance.

so

sliding force

OF SUNROOF MOTOR'S

of the on-board

in the motor

the illustration.

between terminals

connector to

on the spring

the

of

39-49

balance

other

value

for the

only the

drive

shaft, and hook

operate the motor.

balance

motor matches

N

should

than that

be kept

in the

clutch

on-board

is

outside the

CLUTCH

at the

a right

on-board

sliding force

tool

should be

CHECK

tools into

(1)

and

point

the spring force

angle to

standard

the

a spring

(2)

the

of

where

the

tools is

will

be

used.

value,

Page 25

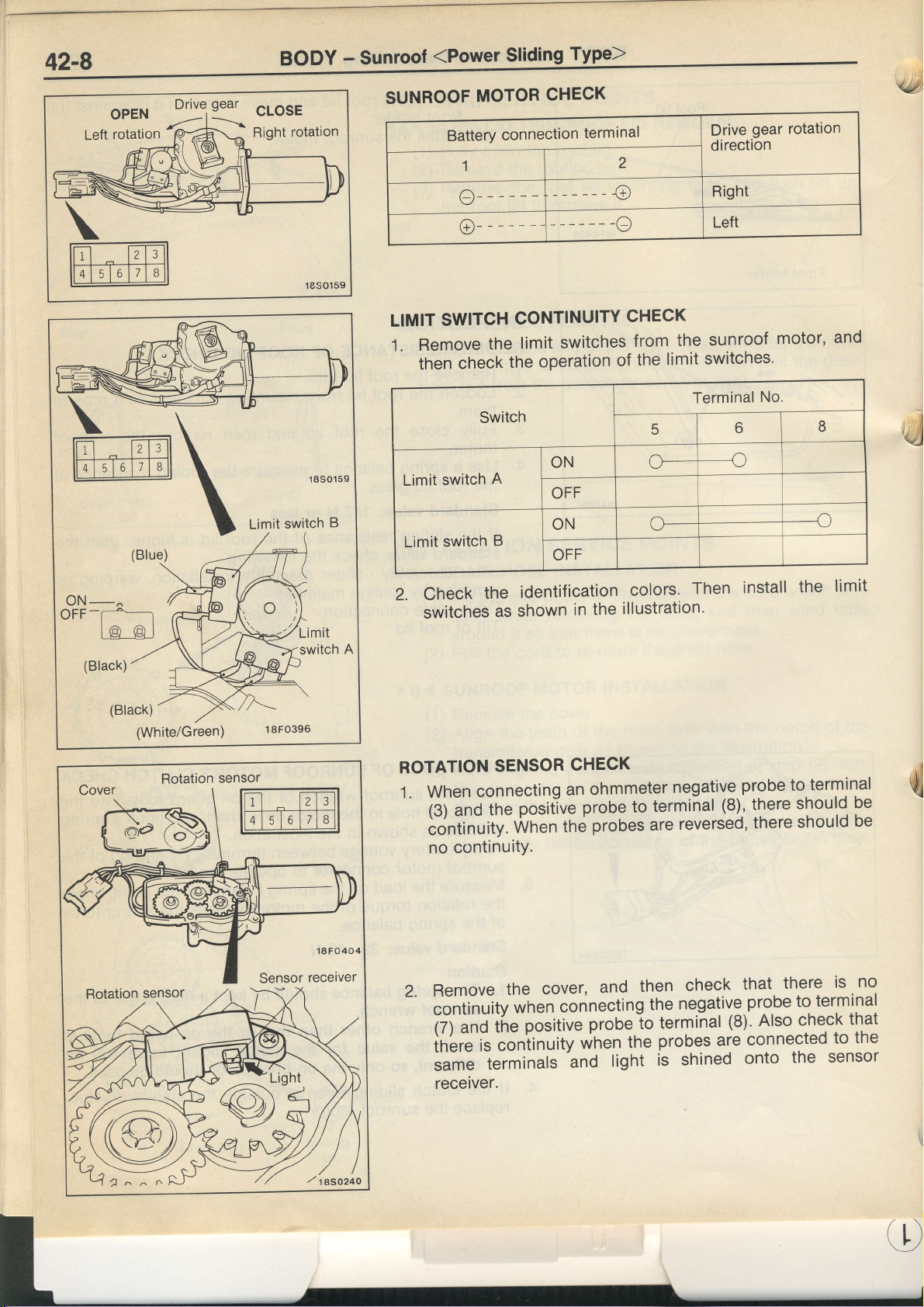

42-8

BODY

-

Sunroof

(Power

Sliding

Type)

Drive

-ffi

gear

CLOSE

Right

switch

Limit

rotation

B

SUNROOF

LIMIT

MOTOR

Battery

SWITCH

CHECK

connection

termi

CONTINUITY

nal

CHECK

gear rotation

Drive

direction

l.Removethelimitswitchesfromthesunroofmotor'and

switches'

limit

the

then

Limit

check

switch

the

A

operation

of

Terminal

No.

,d

oN-^

OrF-[+__1

t@

(Black)

(Black)

@l

(White/Green)

Rotation

sensor

1

8FO396

2'ChecktheidentificationcoIors.Theninsta||theIimit

shown

switches

ROTATION

as

SENSOR

in the

CHECK

l.Whenconnectinganohmmeternegativeprobetotermina|

posiiive

and

the

when

the

(3)

iontinuity.

illustration'

probe

terminal

to

probes are

(8), there

reversed,

there

should

should

be

be

ui

no cclntinuitY.

no

terminal

to

sensor

the

is

to

the

there

Remove

2.

continuity

cover,

the

when

then

and

connecting

the

check

ne.gative

that

probe

(7)andthepositiveprobe-totermina|(8).A|socheckthat

inbre

same

is coniinuity

terminals

when

and

the

light

probes are

shined

is

connected

onto

receiver.

Page 26

'(,

BODY

-

Sunroof

SUNROOF

(Power

SWITCH

Sliding

CONTINUITY

Type)

42-9

CHECK

Open

OFF

Close

Switch

position

1

o_

Terminal

2

--{

G-

No.

3

----c

v

Page 27

54-1

cHASSls ELECTRIGAL

-

General/speciat

root/Troubleshooting

,4g,)

GENERAL

OUTLINE

o

An immobilizer

equipment in vehicles

IGNITION

OF CHANGE

system has

SWITCH AND

SPECIAL TOOL

Tool

GROUP

54

CHASSIS ELECTRICAL

been

for Australia.

Number

M8991502

provided

IMMOBILIZER

Name

MUT-II

assembly

as

sub

an

option in vehicles

SYSTEM

Use

for

Checking the

(diagnosis

Registering

sysrem

display using

lD

Europe,

immobilizer

codes for the immobilizer

and

as

standard

system

the MUT-II)

lra

TROUBLESHOOTING

STANDARD FLOW

Gathering information

Check diagnosis

(Refer

No diagnosis

can't

communicate

code or

OF DIAGNOSTIC

from

customer

to P.54-2.1

code

TROUBLESHOOTING

Verify

complaint

Diagnosis

displayed

Recheck

(Reler

Check trouble

(Refer

diagnosis

to

P.54-2.)

to P.54-2.)

code

code(s) then

codes

Diaonosis

Does not

Check diagnosis

(Refer

to P.54-2.)

erase

code

reoccur

code

No

diagnosis

code

,rl)

Inspection

(Refer

to P.54-2.)

chart for trouble

symptoms

Inspection

(Refer

to P.54-2.)

chart for

diagnosis

codes

t/l

Page 28

CHASSIS

ELECTRICAL

-

Troubteshooring

54-2

INSPECTION

Diagnosis

NOTE

*

:

Diagnosis

CHART

code No.

'11

12*

21

31

32

code

No.

FOR

DIAGNOSIS

Transponder

lD

codes

are

Communication

EEPROM

12

is not

lgnition

switch

recorded.

DIAGNOSIS

DIAGNOSIS

Connect

the lower

codes.

ERASING

Connect

erase

Caution

The

the

TROUBLE

communication

not

the

same

system

abnormality

lG

inside

signal

FUNCTION

CODES

the

MUT-II

of the

DIAGNOSIS

the MUT-II

the

diagnosis

diagnosis

battery

CODES

Inspection

system

or

are not

between

immobilizer-ECU

circuit

trouble

cables

items

registered

MUT-II

system

CHECK

to

the

instrument

under

CODES

to

the

diagnosis

codes.

codes

cannot

and

be

engine-ECU

diagnosis

connector (16-pin)

cover,

connector (16-pin)

which

result

erased.

then

check

from

Reference

at

diagnosis

then

disconnecting

page

54-3

54-3

54-4

54-4

54-5

Page 29

54-3

CHASSIS

ELECTRICAL

-

lgnition Switch

lmmobilizer

and

System

INSPECTION

Gode

The lD code of

after

Does

ignition

code

lgnition

check

No.

the ignition

the engine start

key which

registered?

key ring

(Refer

PROCEDURE

11 Transponder

the transponder

switch

has had the

NG

Code

antenna continuity

P.54-10.)

to

is

using

No.

is not

turned

the spare

generated

11

FOR DIAGNOSIS

communication

immobilizer-ECU

to the

sent

code

NG

position.

12

No.

generated

To inspection

code

Check

bilizer-ECU

antenna.

to the ON

lD

TROUBLE GODES

system

immediately

procedure

(Refer

No. 12

the harness between

and the

for

P.54-3.)

to

ignition key

Probable

o

.

.

o

diagnosis

immo-

the

ring

cause

Malfunction of

Mallunction

Malfunction

Malfunction of

of

of

transponder

key ring

ignition

harness or

immobilizer-ECU

Re-register

(Reler

to

antenna

connector

the lD code.

P.54-11.)

ud)

No. 12

Code

registered

The lD code

is registered

which

Re-register

(Refer

the

to P.54-1

lD codes

is

which

lD code.

1.)

from the

sent

in the immobilizer-ECU.

Reolace the

not

are

the same

transponder is not the same

or are

immobilizer-ECU.

not

lD

as the

code

Probable

o

The lD code

properly

been

.

Malfunction of

cause

in the ignition

registered"

immobilizer-ECU

key being used

has not

ui

Page 30

cHAssls

ELECTRIGAL

-

tgnition

switch

and rmmobitizer

system

54-4

c

Code No.21

engine-EGU

After

the ignition

received

received.

ls

erated

Check the

c-21.

from

diagnosis

by the

following

C-44. C-90

the

code

engine-ECUt

Communication

switch

is turned

engine-ECU within

No.

54

connectors.

being

to the

the

gen-

system

position,

ON

allowable

between

the confirmation

time, or an

Engine-ECU

circuit

Check the harness

ECU

MUT-II

code is nol

abnormal

power

(Refer

check

and the immobilizer-ECU.

between the engine

and

is

code

circuit and

to

GROUP 13-

Probable

o

Malfunction

a

Malfunction

a

Malf

unction

earth

cause

of harness

of engine-ECL

of immobilizer-ECU

or connector

s

Code No.31

No

data

has been written

CtrecX trouble

l

EEPROM

symptoms.

abnormality inside

to the EEPROM

inside

immobilizer-EGu

the immobilizer-EOU. o

Probable

Malfunction

cause

of immobilizer-EOU

b

Page 31

54-5

Code

ignition

The

No.32

switch

GHASSIS

lgnition

signal

switch

not being

is

ELECTRICAL

lG signal

input

circuit

the immobilizer-EOU'

to

-

lgnition

system

Switch

Probable

a

a

a

lmmobili4lty$g.

and

cause

Malfunction

Malfunction

Malf unction

of

of

of

connector

harness

ignition

immobilizer-ECU

or

switch

@

switch

conneclors.

between

fuses

and

(lG1) and the

im-

switch

lgnition

Measure

tor C-90.

o

Disconnect

measure

.

Voltage

OK:

immobilizer-ECU

at

earth

body

(lgnition switch:

System

lG signal

the connector

harness

at the

between

terminal

ON

voltage

input check

connec-

and

side.

(2)

Position)

and

Check

c-76.

Check

the

mobilizer-ECU.

c-78,

harness

the

ignition

C-90

following

the

Irr!)

TROUBLE

INSPECTION

Communication

Diagnosis

lD code

l

l

Engine

lmmobilizer-ECU

CHART

code

cannot

not start

does

with

No. 54

be

FOR

Trouble

MUT-II

the

been

has

registered

(turns

power

circuit

symptom

is

generated

using

but

over

and

SYMPTOMS

possible

not

by

MUT-II

the

not

does

circuit

earth

engine-ECU

the

ignite)

check

Inspection

procedure No.

I

I

2

e

4

5

Reference

54-6

54-7

54-7

54-8

54-9

page

@l

q

Page 32

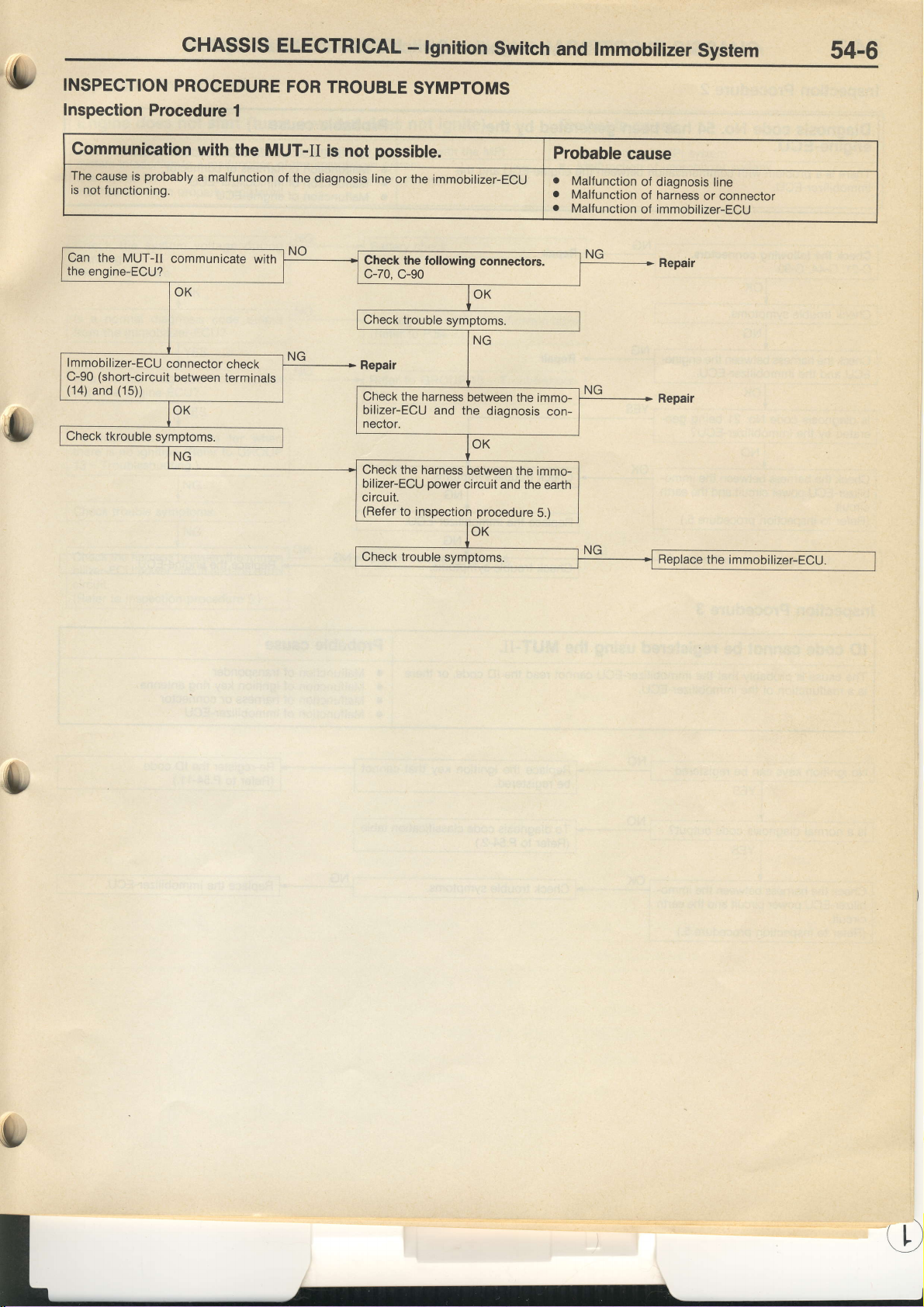

,s

cHAsSls

INSPECTION

Inspection

PROCEDURE

Procedure

ELECTRIGAL

FOR

TROUBLE

1

-

tgnition

switch

SYMPTOMS

and tmmobitizer

system

54-6

Communication

The

cause is

is not

Can

the

engine-ECU?

lmmobilizer-ECU

C-90

(14)

and

probably

functioning.

the MUT-II

(short-circuit

(15))

connector

communicate

between

with

the MUT-II

a malfunction

with

check

terminals

is not

of

the diagnosis

possible.

line

or the immobilizer-ECU

Check the following

c-70,

c-90

Check the harness

bilizer-ECU

nector.

Check the harness

bilizer-ECU

circuit.

(Refer

and

the

power

to inspection

connectors.

between

diagnosis

between

circuit and

procedure

Probable

o

.

.

the immo-

con-

the immo-

the

earth

5.)

cause

Malfunction

Malfunction

Malfunction

of diagnosis

of harness

of immobilizer-ECU

Replace

line

or connector

the

immobilizer-EOU.

Page 33

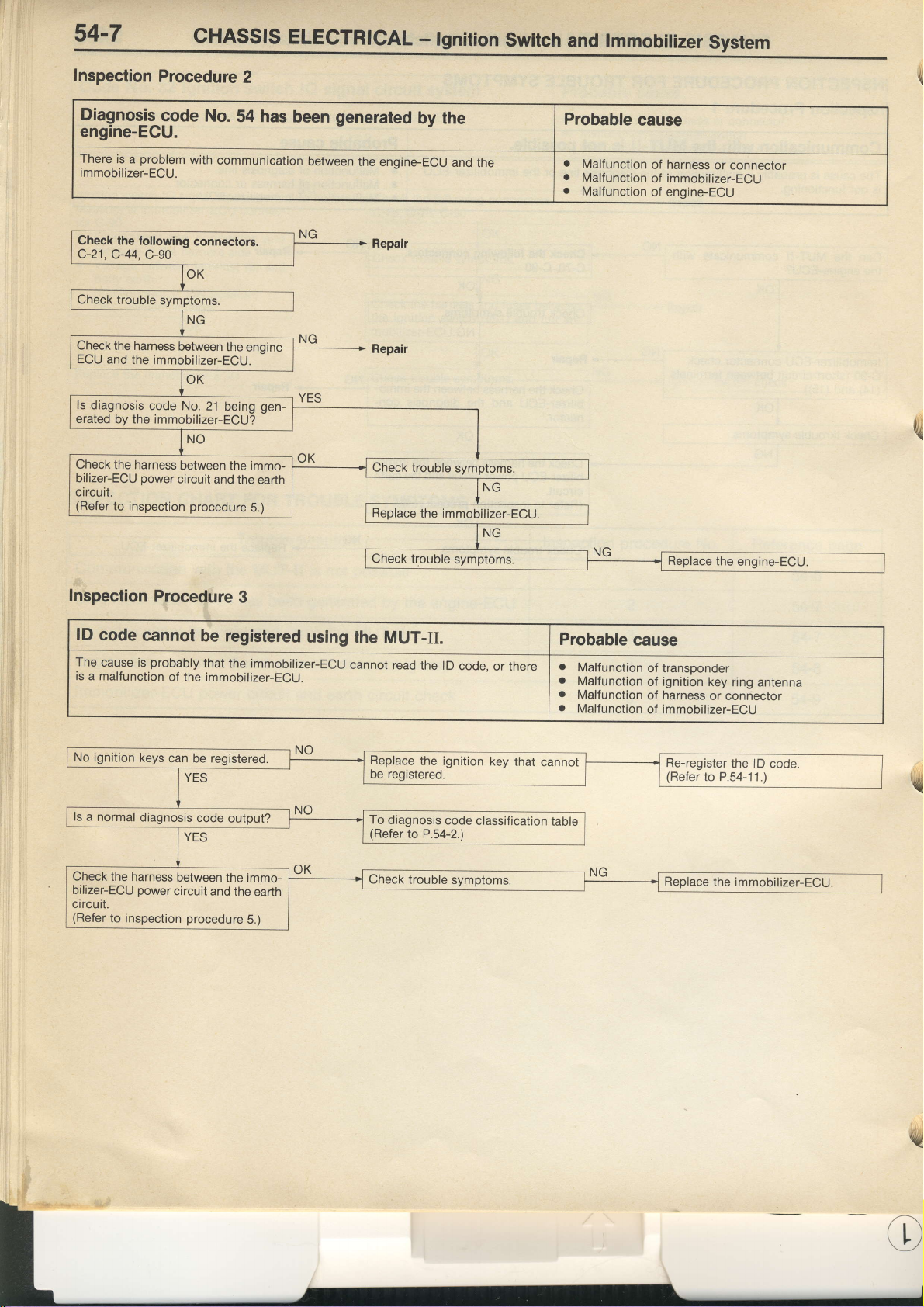

54-7

cHAssls

ELECTRIGAL

-

tgnition

switch

and tmmobitizer

system

Inspection

Diagnosis

Procedure

code

engine-ECU.

There

immobilizer-ECU.

Check

c-21.

Check

ECU

ls

diagnosis

erated

Check

bilizer-EOU

circuit.

(Refer

problem

is a

the following

C-44.

C-90

the harness

and

the immobilizer-ECU.

code No.

by the immobilizer-ECU?

the harness

power

to inspection

No.

with

communication

connectors.

between

21

between

circuit

and

procedure

2

54 has

the

enoine.

gen-

being

the immo-

the

earth

5.)

been

between

generated

the engine-ECU

by the

Replace

and

the

the immobilizer-ECU.

Probable

a

Malfunction

a

Malf

unction

a

Malfunction

cause

of harness

of immobilizer-ECU

of engine-ECU

or connector

u,

Inspection

lD

code

The

cause

is a malfunction

No ignition

ls

a normal

Check

bilizer-ECU

circuit.

(Refer

Procedure

cannot

probably

is

keys

diagnosis

the harness

power

to inspection

3

be registered

that the immobilizer-ECu

of

the immobilizer-ECU.

can

be registered.

code output?

between

circuit

the immo-

and the

procedure

earth

5.)

using

cannot

the

MUT-II

read

Replace

be registered.

To

diagnosis

(Refer

to

the lD

code,

the ignition

code

P.54-2.)

classification

or there

key

that

Probable

.

Malfunction

.

Malfunction

.

Malfunction

.

Malfunction

cannot

table

Replace

cause

of transponder

of ignition key

harness

of

immobilizer-ECU

of

Re-register

(Refer

the

engine-ECU.

ring

or connector

to P.54-11.)

antenna

the lD

code.

't{

w

Page 34

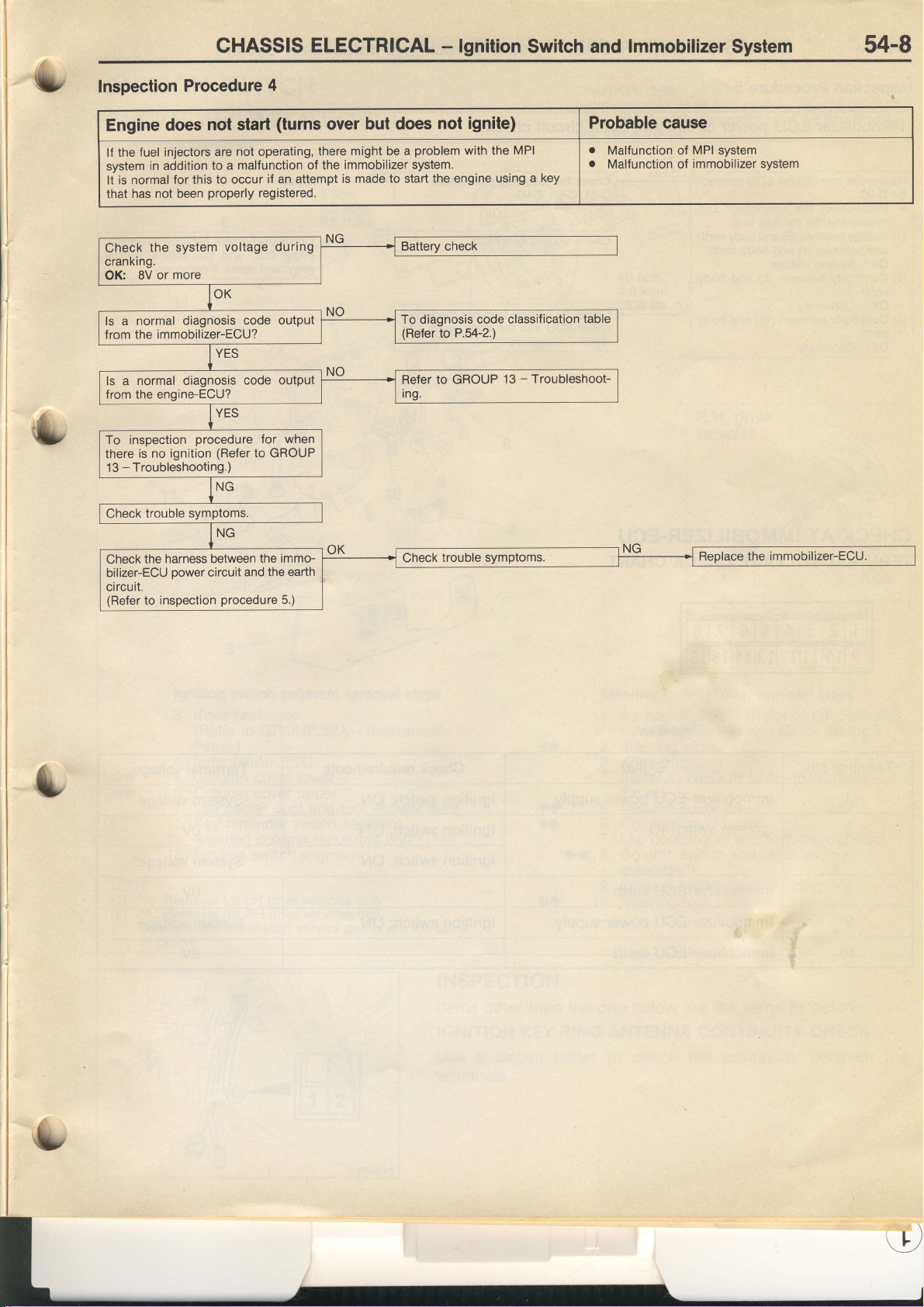

CHASSIS

ELECTRICAL - lgnition

Switch

and lmmobilizer

System 54-8

o,

Inspection

Procedure

Engine does

fuel injectors

lf the

in addition

system

is normal

It

that

Check

cranking.

OK:

a normal diagnosis

ls

f rom the

ls a normal

from

To inspection

there

-

13

for this

has not been

the system

more

8V or

immobilizer-ECU?

the engine-ECU?

Troubleshooting.)

diagnosis

is no ignition

4

not start

are not operating,

to a malfunction

to

properly

procedure

(Refer

if an attempt

occur

registered.

voltage during

code

code output

for

to GROUP

(turns

there

of the

output

when

but does

over

might be a

immobilizer system.

is made to start the engine

not ignite)

problem

To

diagnosis

(Refer

to

Reter

Ing.

to P.54-2.)

GROUP

with the

MPI

key

using a

code classification

13 - Troubleshoot-

Probable

o

Malfunction of

.

Malfunction of

table

cause

MPI system

immobilizer system

harness between

the

Check

bilizer-ECU oower

circuit.

(Refer

to inspection

and the earth

circuit

procedure

the immo-

5.)

Page 35

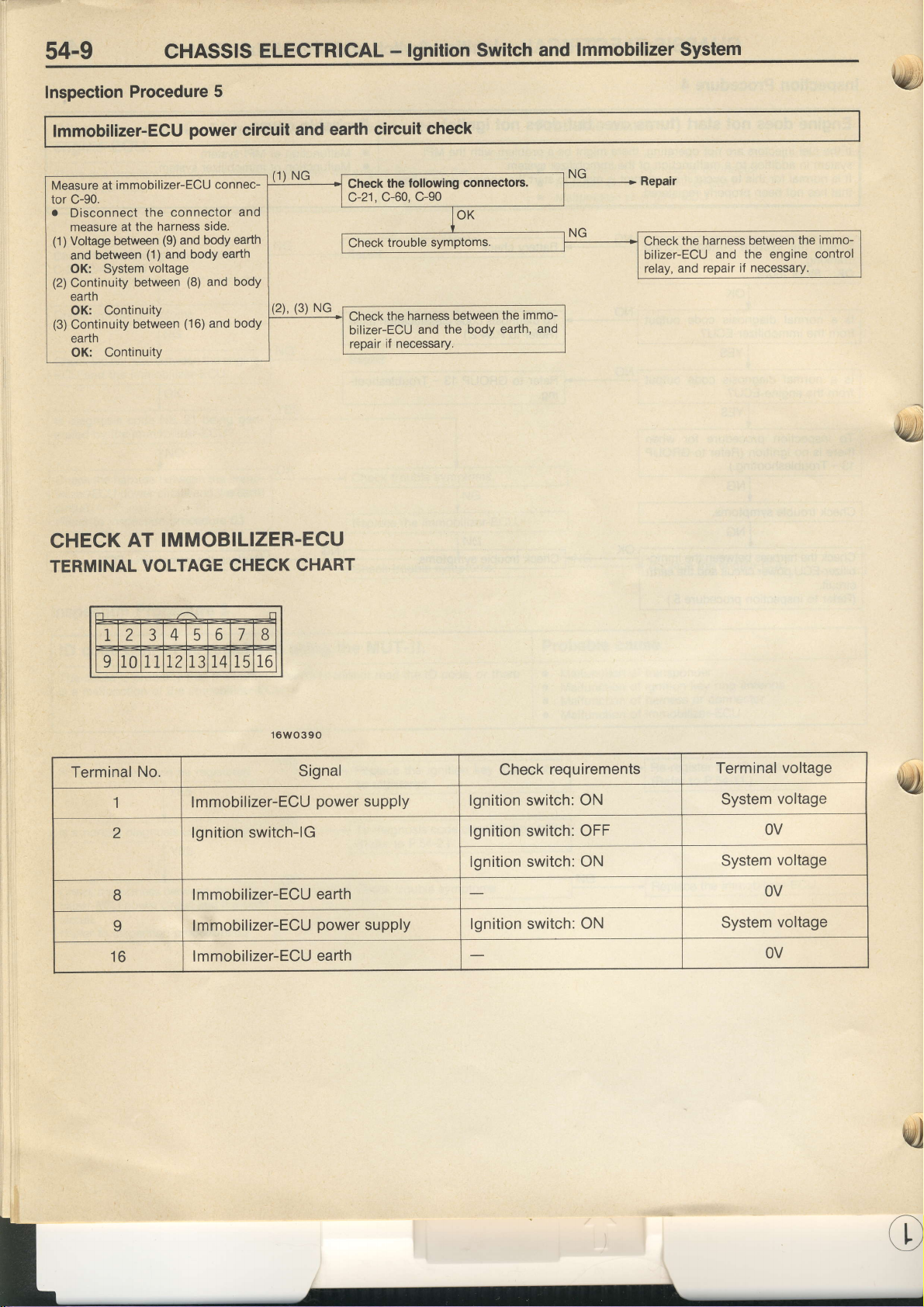

54-9

CHASSIS

ELECTRICAL

-

lgnition

Switch

lmmobilizer

and

Inspection

Procedure

lmmobilizer-EGU

Measure at

tor C-90.

o

(1)

(2)

(3)

CHECK

TERMINAL

immobilizer-ECU

Disconnect

measure at

Voltage between

and between

OK:

Continuity

earth

OK:

Continuity

earth

OK:

the

the harness

(1)

voltage

System

between

Continuity

between

Continuity

AT

VOLTAGE

connector

(9)

and body

and

IMMOBILIZER.ECU

5

power

connec-

side.

earth

bodY

(8)

and body

(16)

and body

circuit

and

earth

CHECK

and earth

Check

c-21.

Check

bilizer-ECU

repair

CHART

circuit

check

following

the

c-90

c-60,

harness between

the

and the body

if necessary.

connectors.

the immo-

earth,

and

the harness between

Check

bilizer-ECU

relay, and

and

repair if necessary.

the engine

the

immo-

control

r 'i

tryU

Terminal

No.

I lmmobilizer-ECU

2

B

9

16

lgnition switch-lG

lmmobilizer-ECU

lmmobilizer-ECU

lmmobilizer-ECU

16WO390

Signal

power

earth

power

earth

supply

supply

Check

requirements

lgnition switch: ON

lgnition

switch: OFF

lonition switch: ON

lgnition switch:

ON

Terminal

System

voltage

OV

System

voltage

OV

System

voltage

OV

voltage

rcj

Page 36

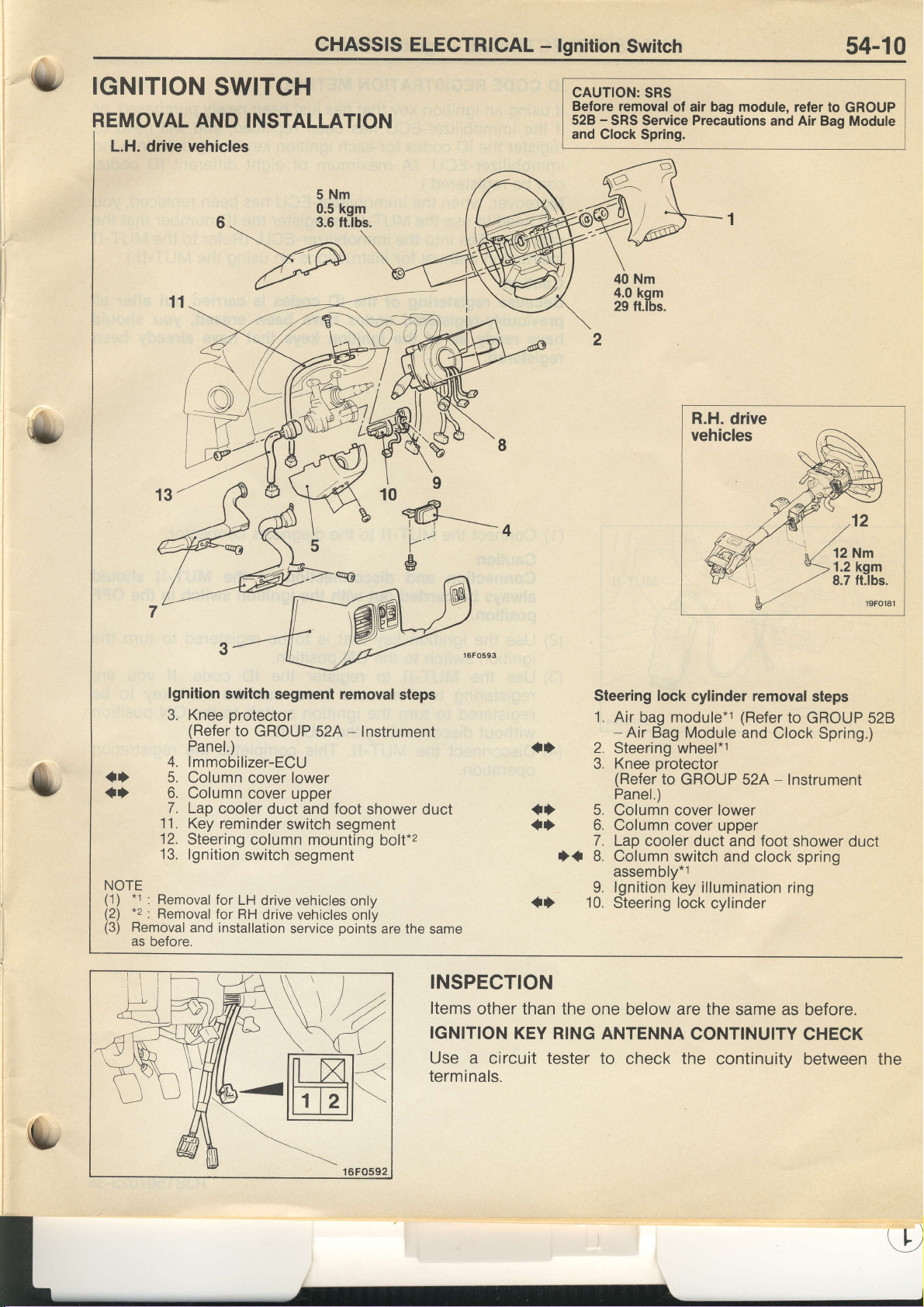

CHASSIS ELECTRICAL

-

lgnition

Switch

54-10

IGNITION

REMOVAL

L.H.

drive

SWITCH

AND INSTALLATION

vehicles

CAUTION:

Before

528

and

SRS

removal

-

SRS Service Precautions

Clock Spring.

of air bag module, refer

to

and Air Bag Module

GROUP

tf

{)

NOTE

-t

(1)

(?)

lr:

(3)

Removal

as before.

lgnition

3. Knee

switch

protector

(Refer

to

Panel.)

4.

lmmobilizer-ECU

5. Column

6. Column

7.

Lap

1].

12.

13.

: Removal

Removal

cooler

Key

reminder

Steering

lgnition

for

LH

for RH

and installation

segment removal

GROUP

52A - lnstrument

cover lower

cover

upper

duct and foot

switch

column

segment

mounting

switch segment

drive vehicles

drive vehicles

service

only

only

point5

steps

shower duct

bolt.z

are the same

INSPECTION

Items

IGNITION

Use a circuit

terminals.

Steering

1. Air

-

2.

Steering

Knee

3.

(Refer

Panel.)

{} 5.

{f

f{

Colunin

Column

6.

Lap

7.

Column switch

8.

assembly*1

lgnition

9.

10.

{}

other than

the one

Steering lock

KEY RING ANTENNA

tester to

lock

cylinder removal

bag module*1

Air Bag

Module and

wheel*1

protector

to

GROUP 52A - Instrument

cover

(Refer

lower

cover upper

cooler duct and foot

and clock

key illumination ring

cylinder

below

are the

same as

CONTINUITY

check

the

continuity

steps

to

GROUP

Clock

Spring.)

shower

spring

before.

CHECK

between the

528

duct

(.'

Page 37

54-11

CHASSIS ELECTRICAL

-

lgnition

Switch

ID

CODE

lf

using

if

the

register

immobilizer-ECU.

can

Moreover, when the

will need to use the

user

instruction manual

Caution

Because registering of

previously-registered

have ready all of the

registered.

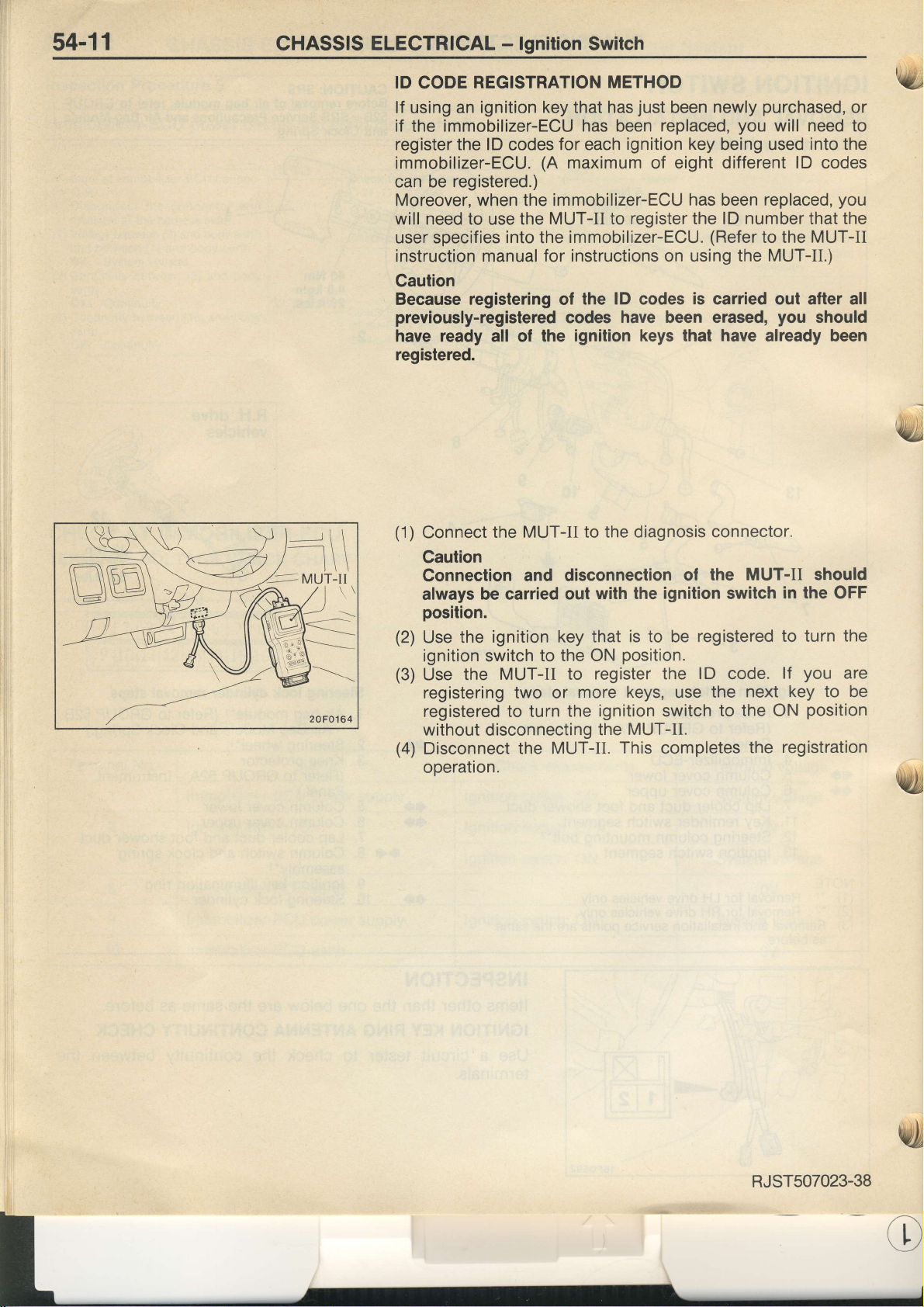

(1)

Connect

Caution

Connection and disconnection

always be carried

position.

(2)

Use

ignition switch

(3)

Use the

registering two or

registered to turn

without disconnecting

(4)

Disconnect

operation.

REGISTRATION

an ignition key that has

immobilizer-ECU has been

lD

the

registered.)

be

specifies into the

the ignition

codes

the

MUT-II to

for each

(A

immobilizer-ECU has

MUT-II

for instructions on using the MUT-II.)

MUT-II to the diagnosis connector.

key that is to be

to the ON

the MUT-II.

METHOD

ignition key

maximum

register the lD number that the

to

immobilizer-ECU.

the lD codes

codes

ignition keys that

out

the ignition switch

have been

with the

position.

register the

more

keys,

MUT-IL

the

This completes

just

replaced,

of eight different

ignition

newly

been

(Refer

is

carried out after all

erased,

the

of

registered to turn

lD

the

use

purchased,

you

being used

replaced,

been

to the

have

already been

MUT-II should

switch

code.

next

to the

the

or

will need to

into

the

lD

codes

you

MUT-II

you

should

in the

lf

ON

registration

OFF

you

key

to be

position

the

are

'!&t

RJ5T507023-38

Page 38

Pub. No.

ENGLISH

EUROPE

PWUE9I l9-E

Pub, No.

AND EXPORT

PWUE9203-4

tdl

A ursuBrsHr MoToRs

coRPoRATroN

July

1995 Printcd in Japan

1)

Loading...

Loading...