Page 1

Volume 2

Electrical

: ~*.. $c :

._-.

~.~~

~l.1

-.-~-

&?&a-&&

-

Page 2

Page 3

GROUP / SECTION INDEX

MOOAAA- -B

1

L.J

BackupService

3OOOG-r

1991: Volume

FOREWORD

This Service Manual has been prepared

latest service information available at the time of

publication. It is subdivided into various group

categories

disassembly,

along

with

references. Use of this manual

performing

i

restore

designed

and each section contains diagnosis,

repair, and installation procedures

complete specifications and tightening

any servicing necessary to maintain or

the

high levels of performance

into these outstanding vehicles.

Manual

with

will

aid in properly

and

reliability

2

the

General

Fusible Link and Fuse Location

Inspection Terminal Location

Grounding

Diode Location

Junction

Centralized Junction

Inspection of Harness Connector

How to Diagnose

Configuration Diagram

Circuit Diagrams

Engine Electrical

. . . . . . . . . . . . . . . . . . . . .

Location

Block

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

.._................_...____.._.._._.......

. . . . . . . . . . . . . . . . . .

............................................

....................................

................................................

..................................

.._......._..._..__.._.......

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

.._....

.._....

..__._...

II

.._...................

................

m

q

a

Chassis Electrical

WE SUPPORT

VOLUNTARY

CERTIFICATION

AUKi~V~~VE

EXCELLENCE

Mitsubishi

design or

imposing any obligations upon itself

previously

c

@ 1990 Mitsubishi Motors Corporation

Motors

to

Corporation reserves

make additions

manufactured.

TECHNiClAN

THROUGH

National ln*titutefor

the

right

to or improvements in

to

install

to make

them on

its products

its products

Rap&ted

changes in

without

in USA

..................................

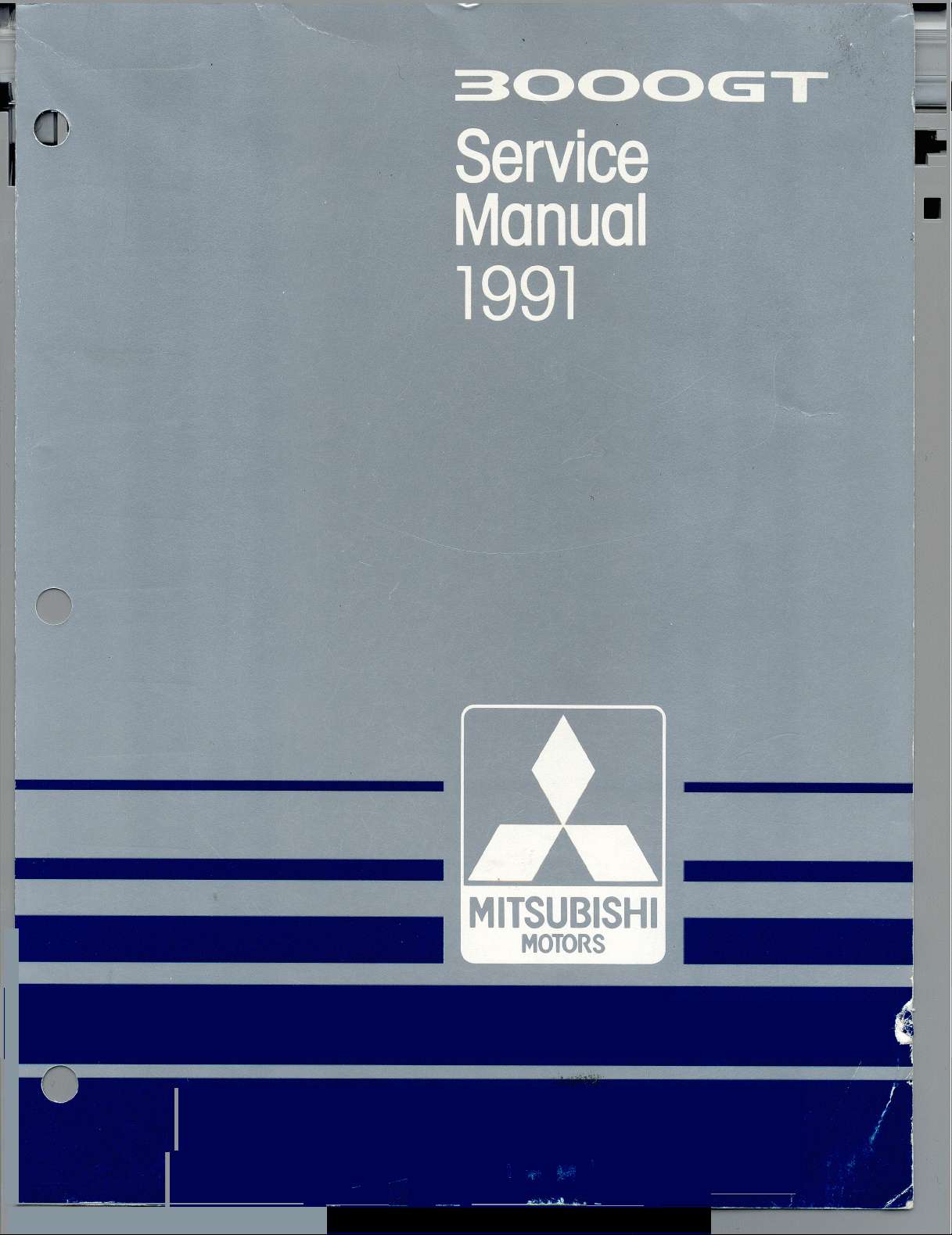

Page 4

2

GENERAL - Fusible Link and Fuse Location

FUSIBLE LINK AND FUSE LOCATION

Symbol

Name

Symbo

M16BA-

/

-

B

C

E

NOTE

The “Name” column is arranged in alphabetical order.

<Engine compartment>

16FO257

Fusible link

Multi-purpose fuse

A

D

-

<Interior>

\ / fl

\\ 16FO266

19FO134

16FO260

TSB Revision

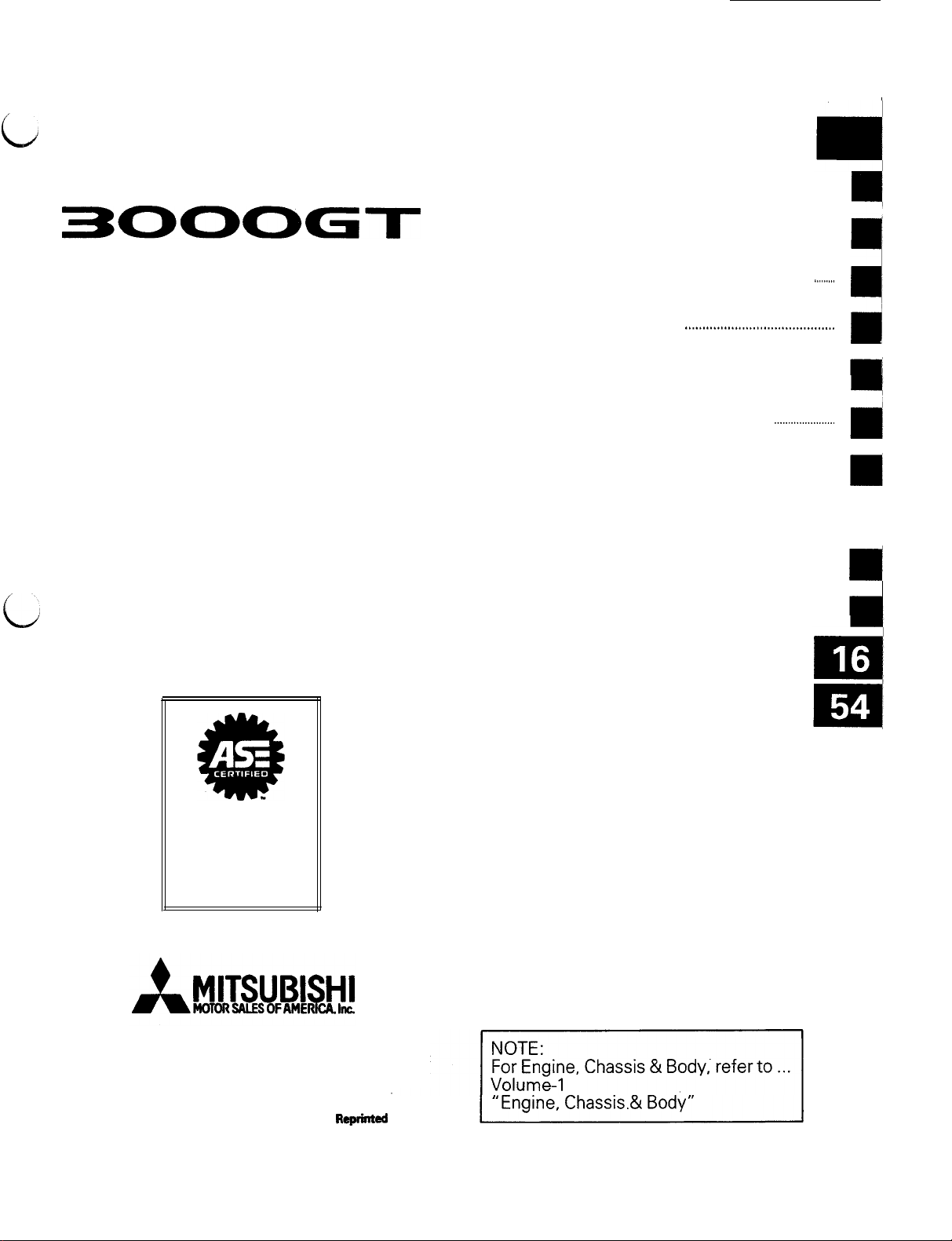

Page 5

GENERAL -

lrispection

INSPECTION TERMINAL LOCATION

Terminal Location

3

c

Engine speed detection connector

Fuel pump check connector

NOTE

The “Name” column is arranged in alphabetical order.

Name

<Engine compartment>

ca

Symbol

A

A

Name

Ignition timing adjustment connector

Self-diagnosis check connector

/f co?nector

----,

;e;ooso

II

Symbol

A

B

‘J

c

<Interior>

19FO134

1

TSB Revision

Page 6

4

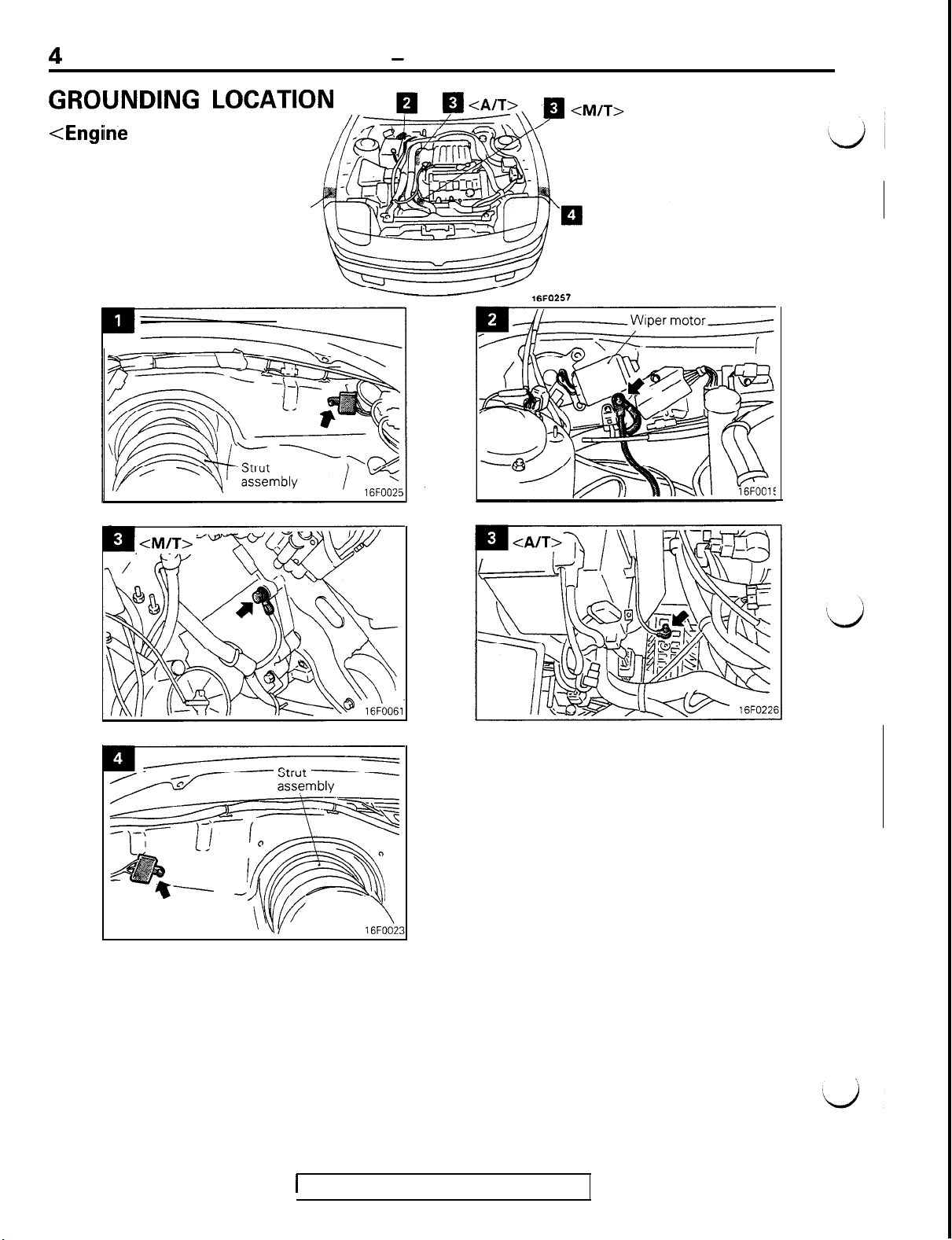

GENERAL - Groundina Location

GROUNDING LOCATION

<Engiine

compartment>

a

1

TSB Revision

Page 7

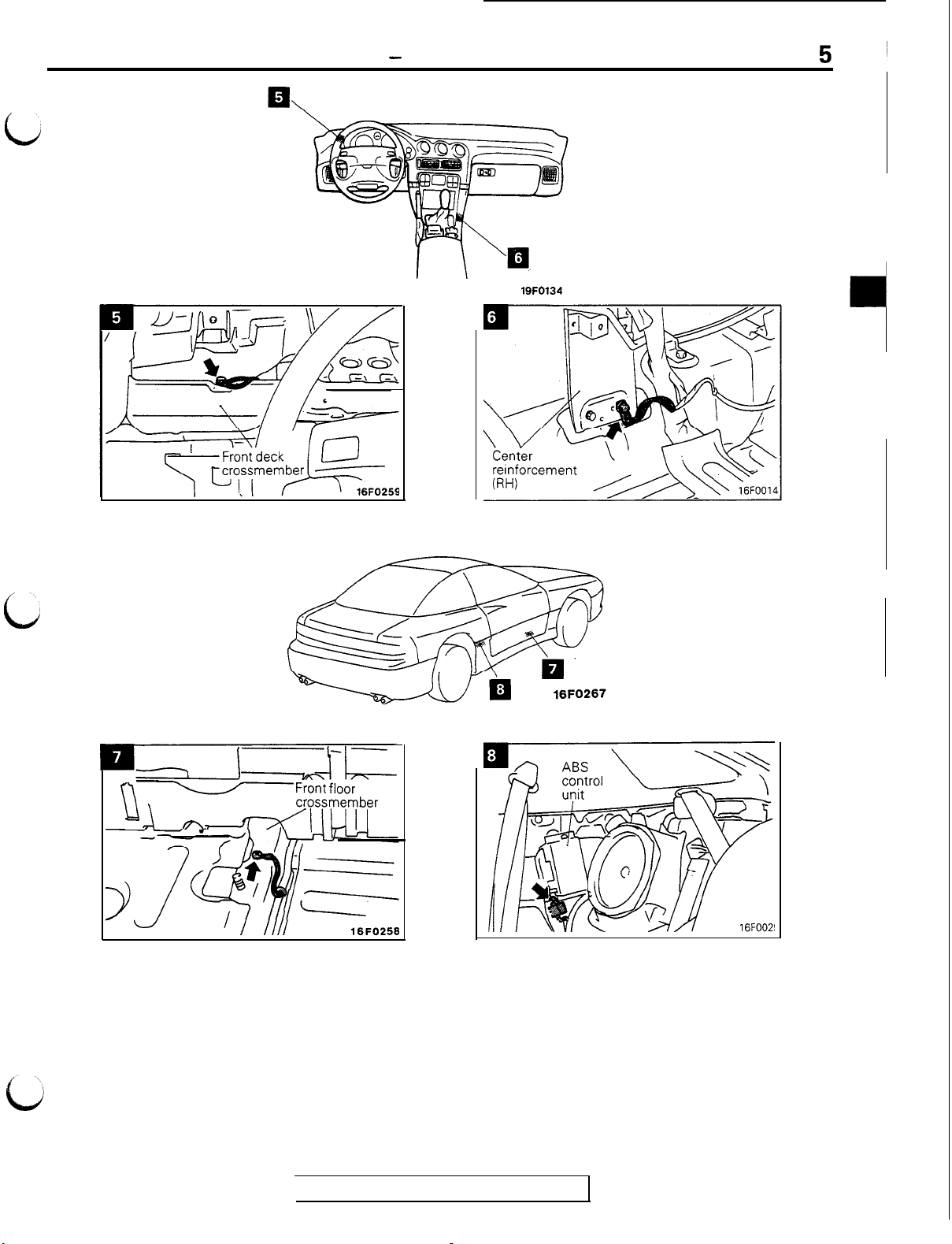

c

GENERAL - Grounding Location

<Interior>

19FO134

c

RZLJI-L

r‘\v

\\ \

“d n> dIIuII

r

d

Front

floor

crossmember

16FO256

TSB Revision

Page 8

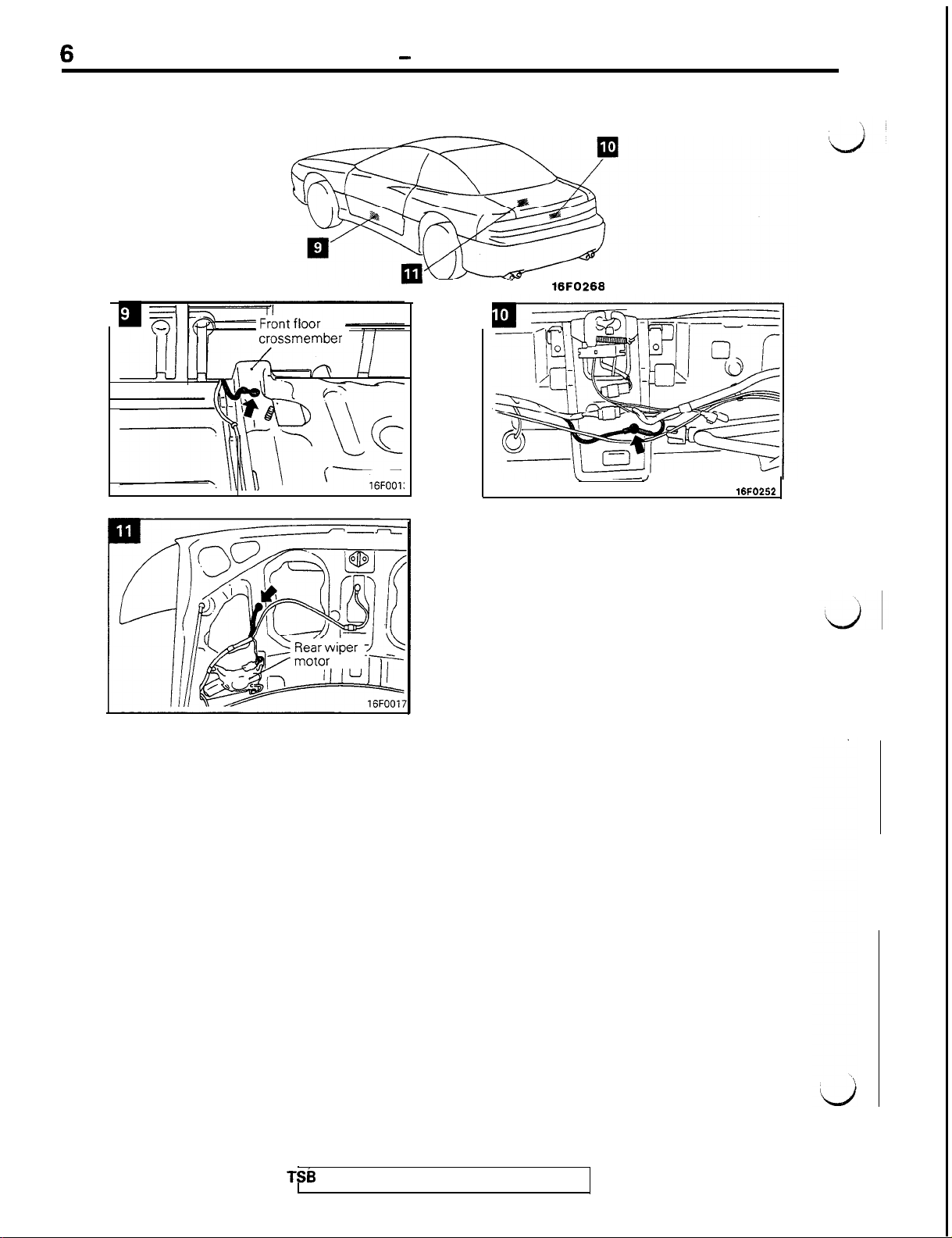

6

GENERAL - Grounding Location

16FO268

crossmember

,

16FO252

TSb

Revision

Page 9

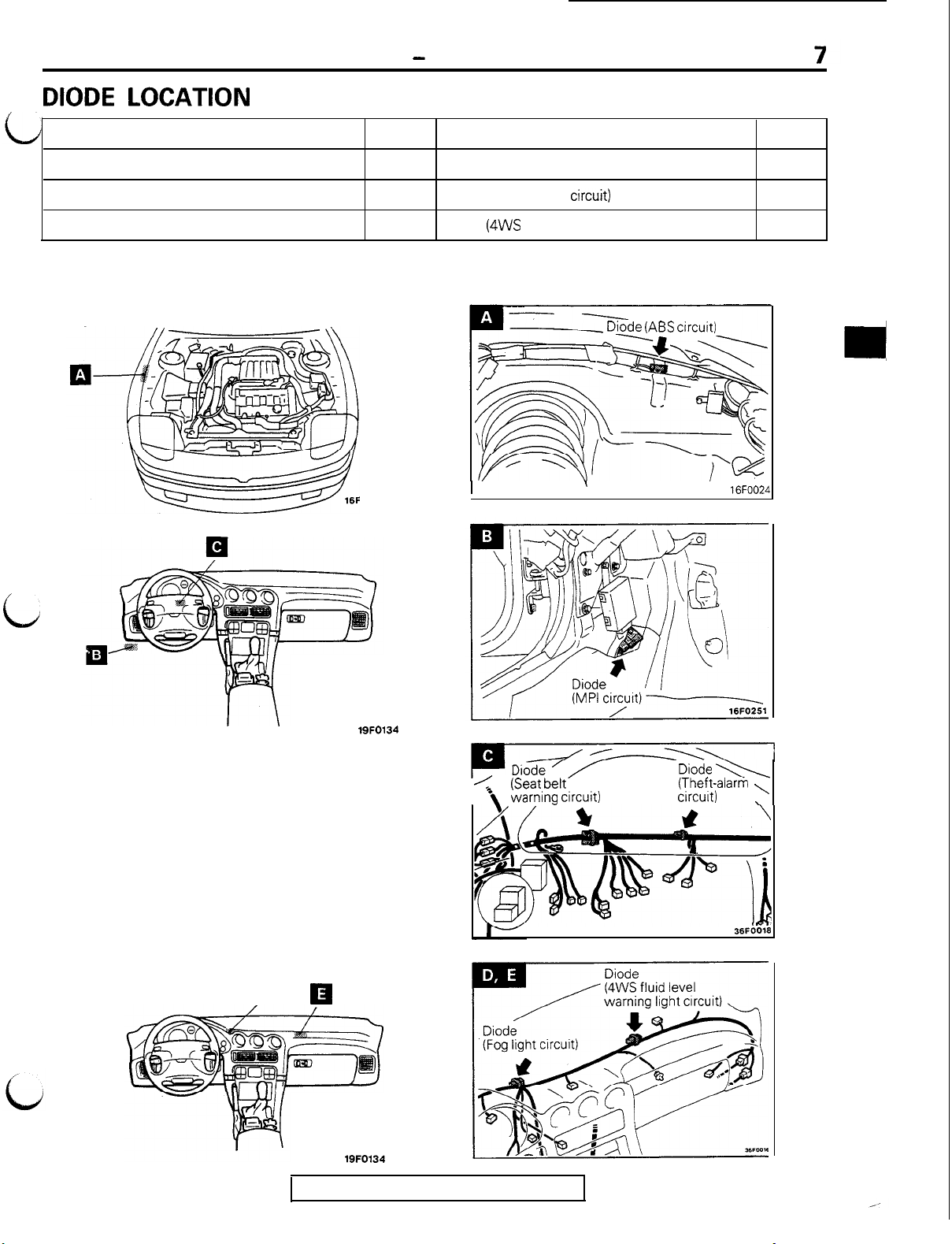

DIODE LOCATION

GENERAL

-

Diode Location

Name

Diode (ABS circuit)

Diode (Fog light circuit)

Diode (MPI circuit)

<Engine compartment>

<Dash panel>

Symbol

0257

Name

A

D

B

Diode (Seat belt warning circuit)

Diode (Theft-alarm

Diode

(4WS

fluid level warning light circuit)

I

circuit)

-

Diode (ABS circuit)

Symbol

C

C

E

16FOO2L

c

<Instrument panel>

q

R

19FO134

<

(Seat belt

\

warning circuit)

)ioZ ’

Diode \\

(Theft-alarm ,

circuit)

36FOO18

,

,-.

19FO134

TSB Revision

Page 10

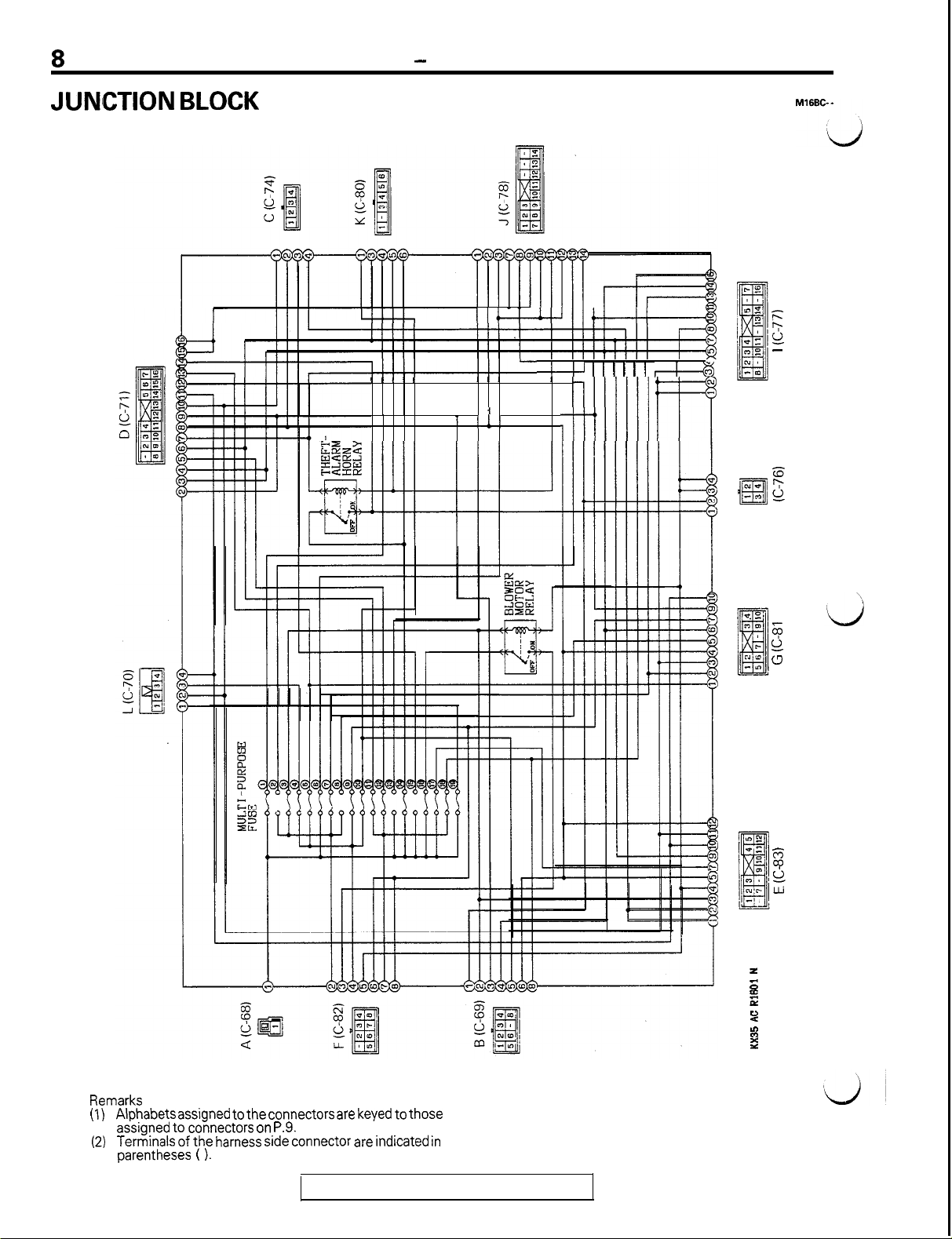

8

JUNlCTION BLOCK

GENERAL - Junction Block

I I , I I

I I I I I

lI+-4--wlI-

I I I

I 1 I

I I!1

4-l-J I I I I I I 4r-43

’ iIII/IlI

I I

dIllIll

m

cu

E!

NV

-0

E

k

-

E

ii

I

6

0

u

Remarks

(1)

Alphabets

assigned to connectors on P.9.

(2)

Terminals of the harness side connector are indicated in

parentheses ( ).

assigned to

the connectors

TSB Revision

are keyed

to those

E

ii

Lu

z

6

E

P

B

::

Page 11

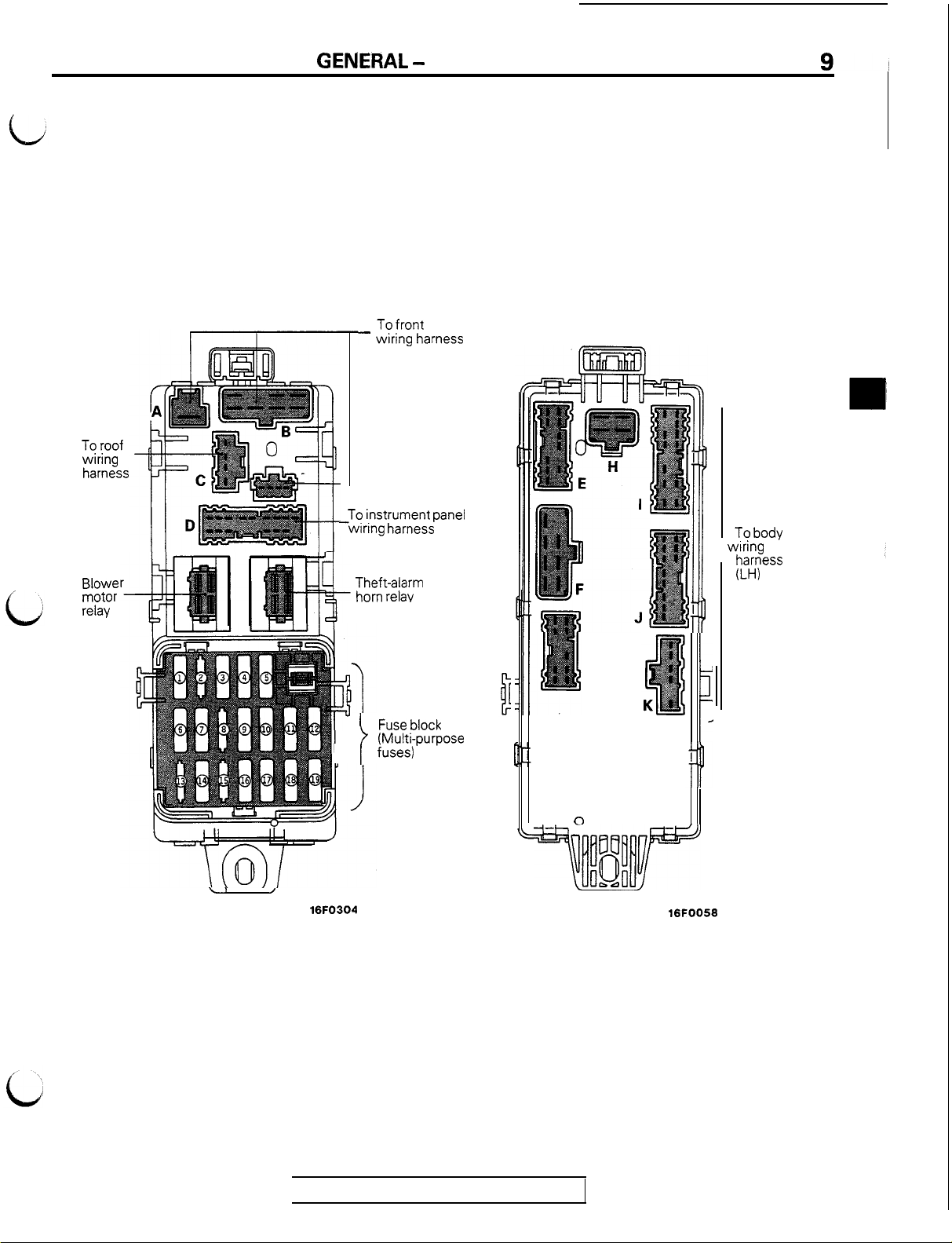

GENERAL

- Junction Block

To roof

wiring

harness

Blowe

motor

relay

Front

To front

- wiring harness

To instrument panel

-wiring harness

Theft-alarm

horn relay

Back

To body

wiring

harness

(LH)

G

Fuse block

(Multi-purpose

fuses)

i

h

0

uu

\1

/

16FO304

~tfb#J”

oe.Jl

d

i

LYJ

16FOO56

TSB Revision

Page 12

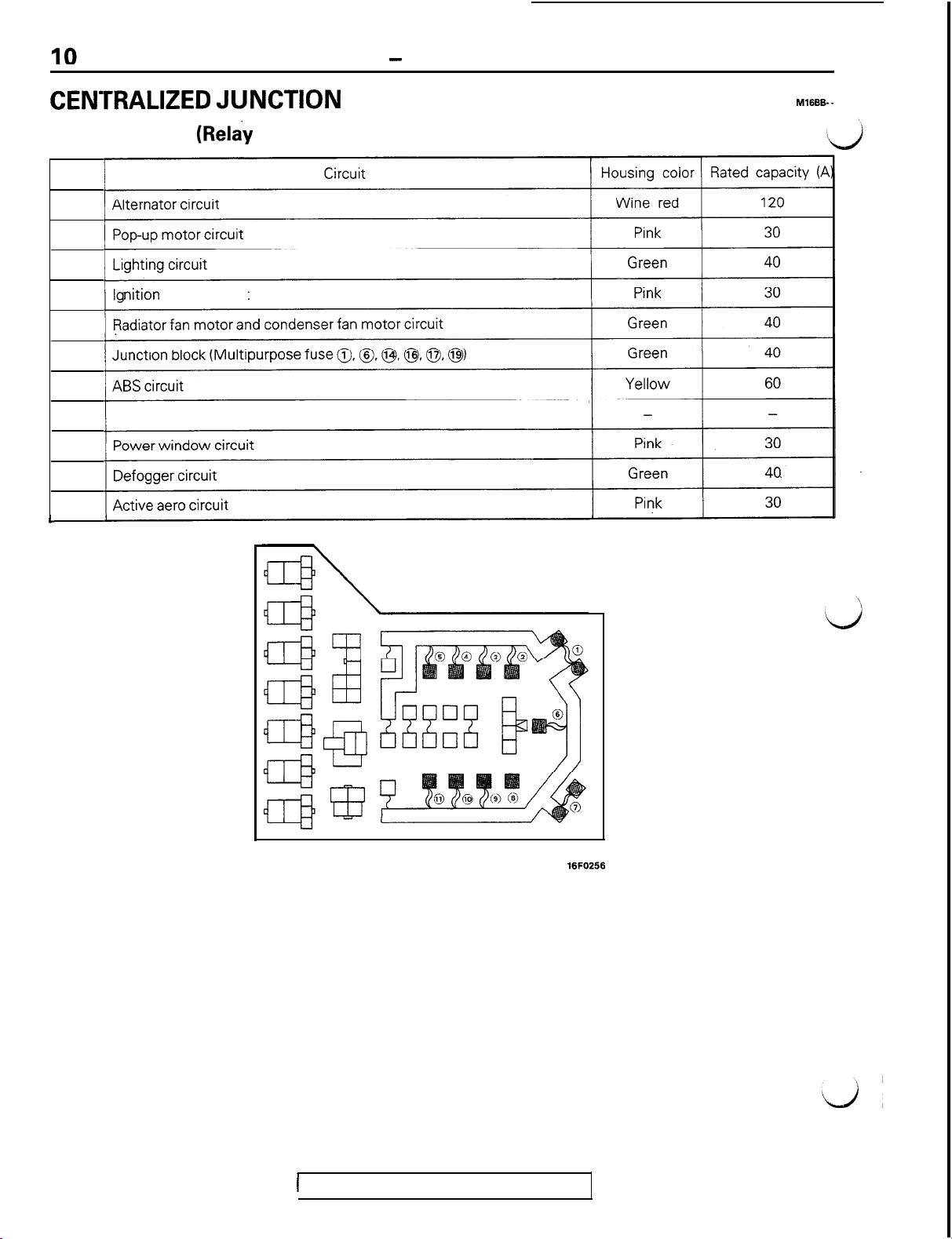

GENERAL - Centralized Junction

CENTRALIZED JUNCTION

FUSIBLE LINK (Relay box in engine compartment)

No.

1

2

3

nition

4

5

6

7

8

9

IO

11

L

switch circuit

1

TSB Revision

Page 13

DEDICATED FUSE

GENERAL

-

Centralized Junction

<Relay box in engine compartment>

<Air conditioner relay box

in engine compartment>

16FOOO2

TSB Revision

16FOE.6

<Interior relay box>

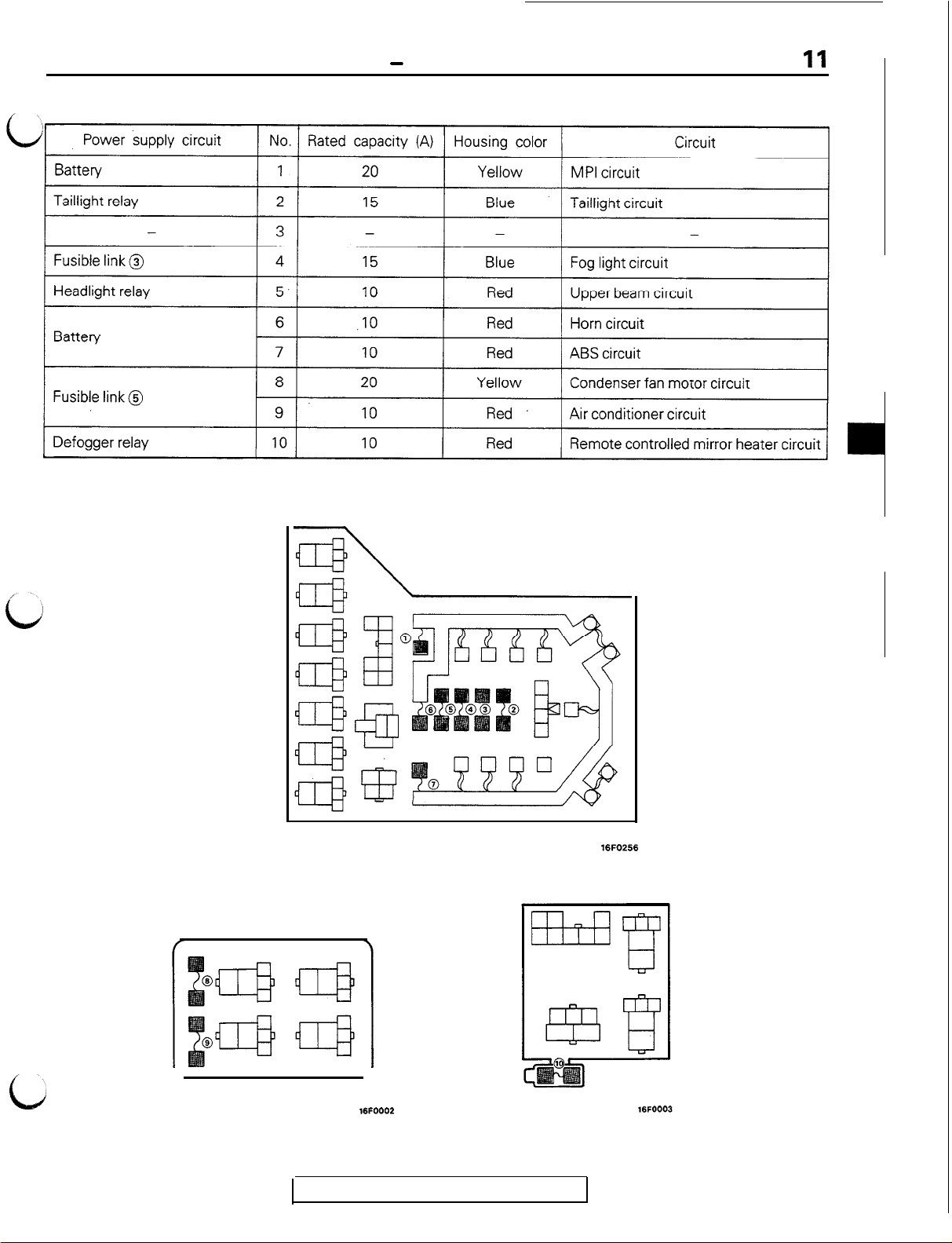

Page 14

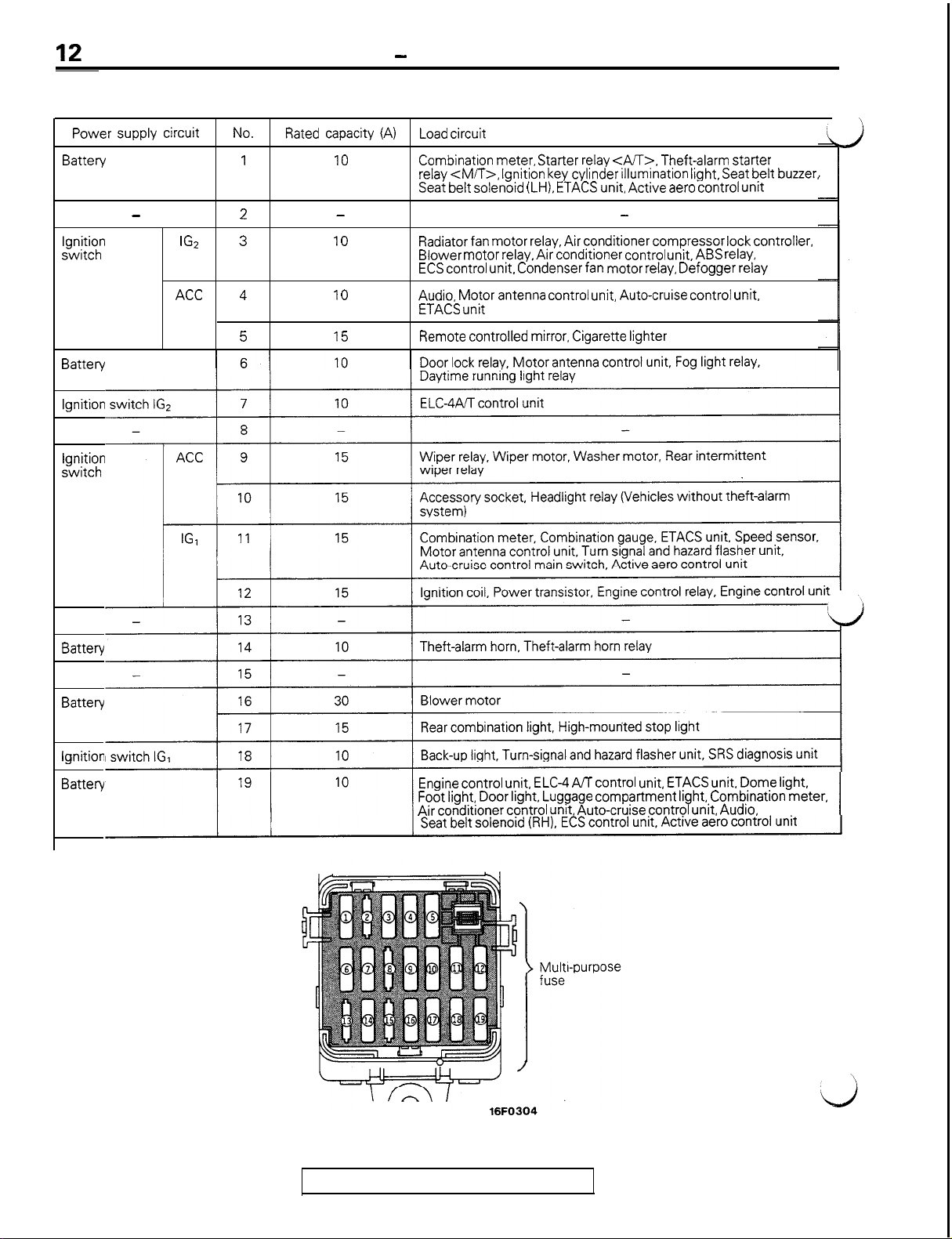

12

GENERAL - Centralized Junction

MULTI-PURPOSE FUSE (In junction block)

Power supply circuit

Battery

-

Ignition

switch

Battery

Ignition

Ignition

switch

1%

ACC

No.

1

2

3

4

5 15

Rated capacity (A)

IO

-

10

10

Load circuit

Combination meter, Starter relay <AA>. Theft-alarm starter

relay <M/T>, Ignition key cylinder illumination light, Seat belt buzzer,

Seat belt solenoid (LH), ETACS unit, Active aero control unit

-

Radiator fan motor relay, Air conditioner compressor lock controller,

Blower motor relay, Air conditioner control unit, ABS relay,

ECS control unit, Condenser fan motor relay, Defogger relay

Audio, Motor antenna control unit, Auto-cruise control unit,

ETACS unit

Remote controlled mirror, Cigarette lighter

Battery

Battery

ignition

Battery

Engine control unit, ELC-4 A/T control unit, ETACS unit. Dome light,

Foot light, Door light, Luggage compartment light, Combination meter,

Air conditioner control unit, Auto-cruise control unit, Audio,

TSB Revision

Page 15

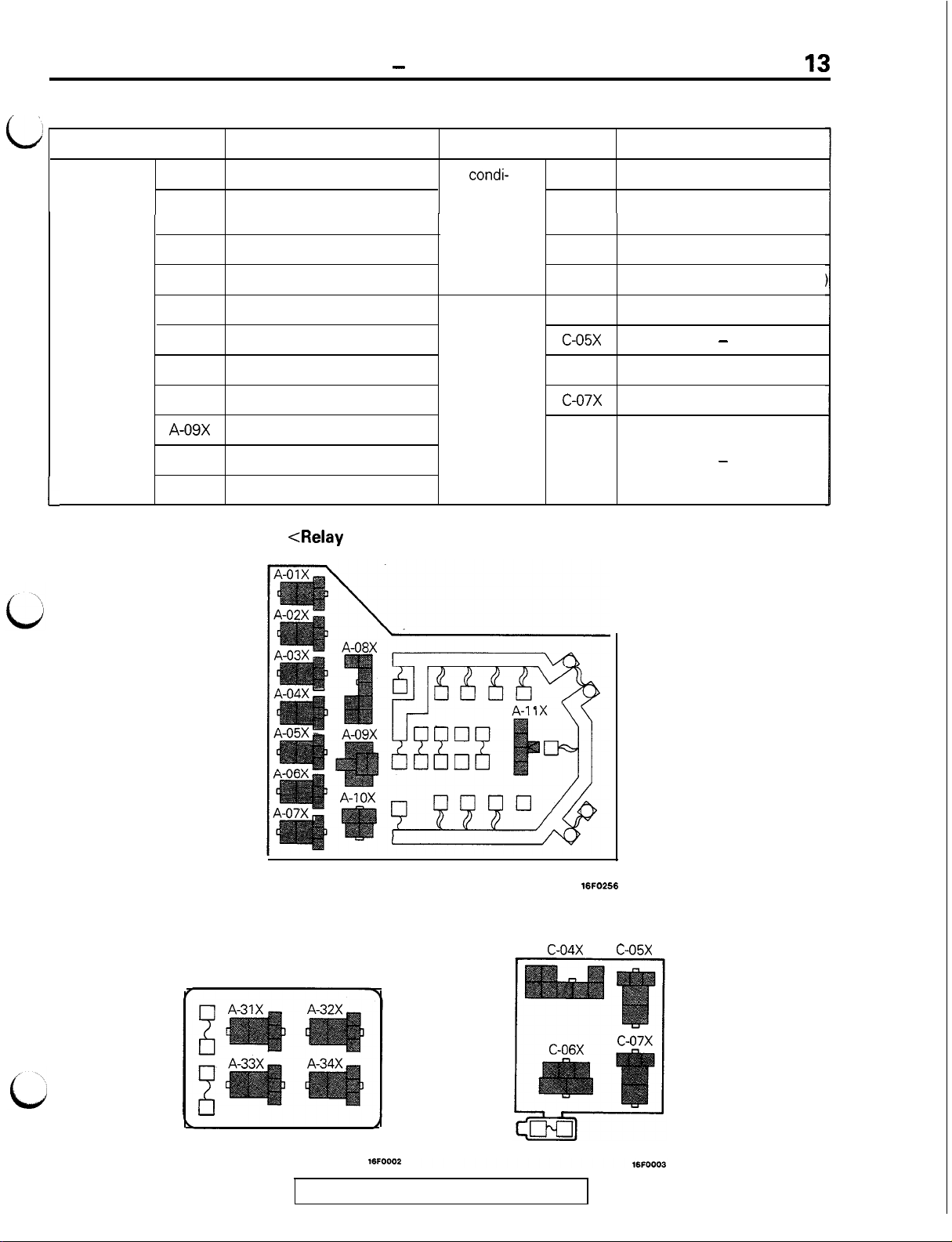

CENTRALIZED RELAY

GENERAL

-

Centralized Junction

13

Classification Name

Relay box

in engine

compartment

L

,A-01X

A-02X

A-03X Fog light relay

A-04X

A-05X Taillight relay

A-06X Horn relay

A-07X

A-08X

A-09X

A-l OX

A-l 1 X

Headlight relay

ABS power relay

Radiator fan motor relay (LO)

Radiator fan motor relay (HI)

Pop-up motor relay

Starter relay

Alternator relay

Jumper connector

Classification

Air

condi-

tioner relay

box in engine

compartment

Interior

relay box

A-31X

A-32X

A-33X

A-34X

C-04X

c-05x

C-06X

c-07x

<Relay box in engine compartment>

Name

Condenser fan motor relay (HI)

Radiator fan motor control

relay

Magnetic clutch relay

Condenser fan motor relay (LO

Door lock relay

-

Defogger relay

Power window relay

-

<Air conditioner relay box

in engine compartment>

TSB Revision

16FO266

<Interior relay box>

c-04x c-05x

Page 16

GENERAL

- lnwection

of Harness Connector

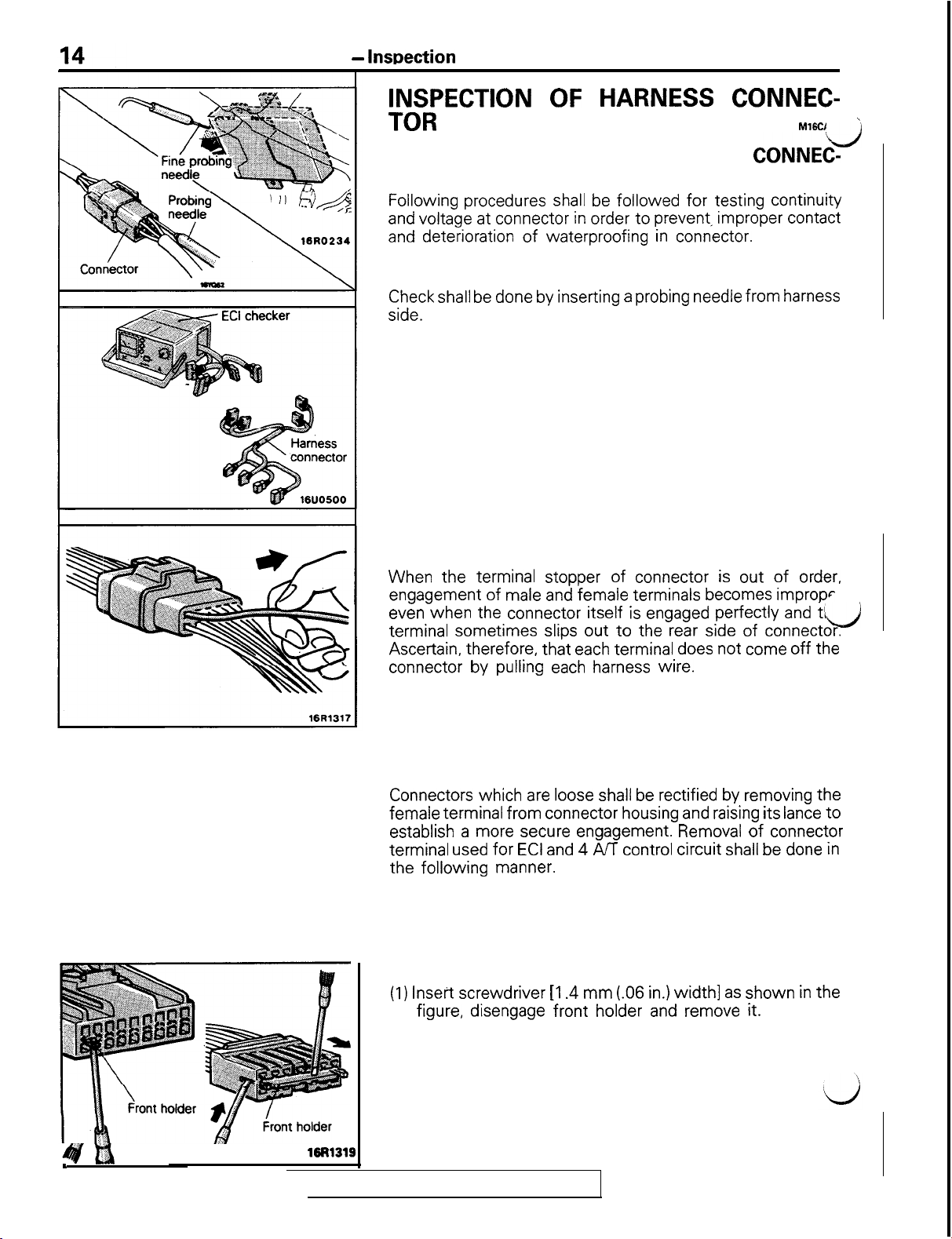

INSPECTION OF HARNESS CONNEC-

TOR

CONTINUITY AND VOLTAGE TEST FOR CONNEC-

TOR

Following procedures shall be followed

and voltage at connector in order to prevent, improper contact

and deterioration of waterproofing in connector.

CONVENTIONAL (NON-WATERPROOF) CONNECTOR

Check shall be done by inserting a probing needle from harness

side.

WATER PROOF CONNECTOR

Caution

Do not insert probing needle from harness side as it will

deteriorate waterproofing and cause rusting. To inspect

the energized circuit, use the ECI checker.

for

testing continuity

M16CI

d

’

CHECK FOR IMPROPER ENGAGEMENT OF TER-

MINAL

When the terminal stopper of connector is out of order,

engagement of male and female terminals becomes impropr

even when the connector itself is engaged perfectly and tl&

terminal sometimes slips out to the rear side of connector.

Ascertain, therefore, that each terminal does not come off the

connector by pulling each harness wire.

ENGAGING AND DISENGAGING OF CONNECTOR

TERMINAL’

Connectors which are loose shall be rectified by removing the

female terminal from connector housing and raising its lance to

establish a more secure engagement. Removal of connector

terminal used for ECI and 4 A/T control circuit shall be done in

the following manner.

COMPUTER CONNECTOR

(1) Insert screwdriver

figure, disengage front holder and remove it.

[I .4 mm

(.06 in.) width] as shown in the

14fti

19R1319

TSB

Revision

Page 17

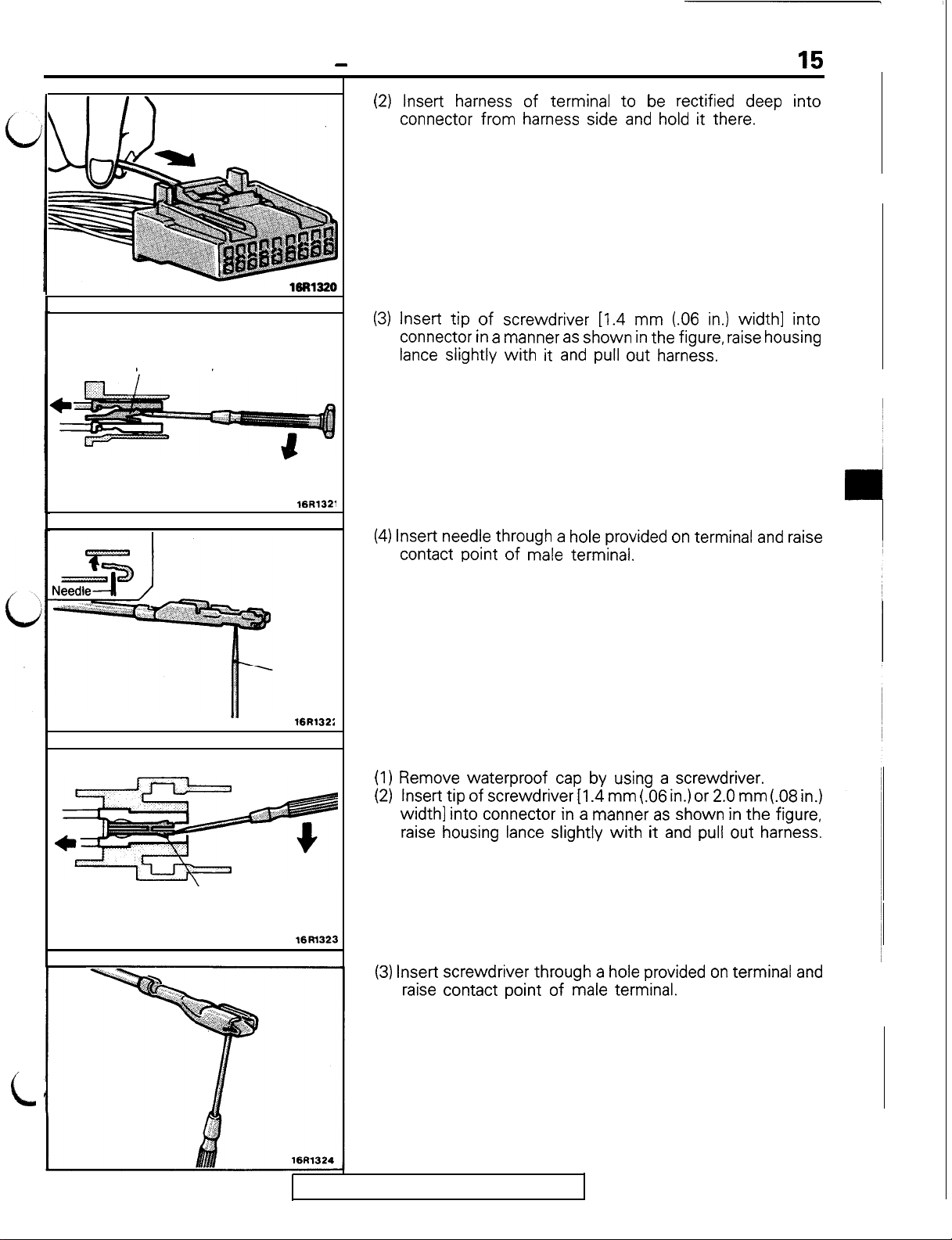

Housing lance

GENERAL

16R1321

-

Inspection of Harness Connector

(2) Insert harness of terminal to be rectified deep into

connector from harness side and hold it there.

(3) Insert tip of screwdriver L1.4 mm (.06 in.) width] into

connector in a manner as shown in the figure, raise housing

lance slightly

Caution

Tool No. 753787-l supplied by AMP can be used instead

of screwdriver.

with it

and pull out harness.

15

Housing lance

Needle

16R132:

16Rl323

(4) Insert needle through a hole provided on terminal and raise

contact point of male terminal.

ROUND WATERPROOF CONNECTOR

(1) Remove waterproof cap by using a screwdriver.

(2)

Insert tip of screwdriver

width] into connector in a manner as shown in the figure,

raise housing lance slightly

(3) Insert screwdriver through a hole provided on terminal and

raise contact point of male terminal.

[I .4 mm

with it

(.06 in.) or 2.0 mm (.08 in.)

and pull out harness.

c

TSB

Revision

Page 18

16

GENERAL

- lnwection

RECTANGULAR WATERPROOF CONNECTOR

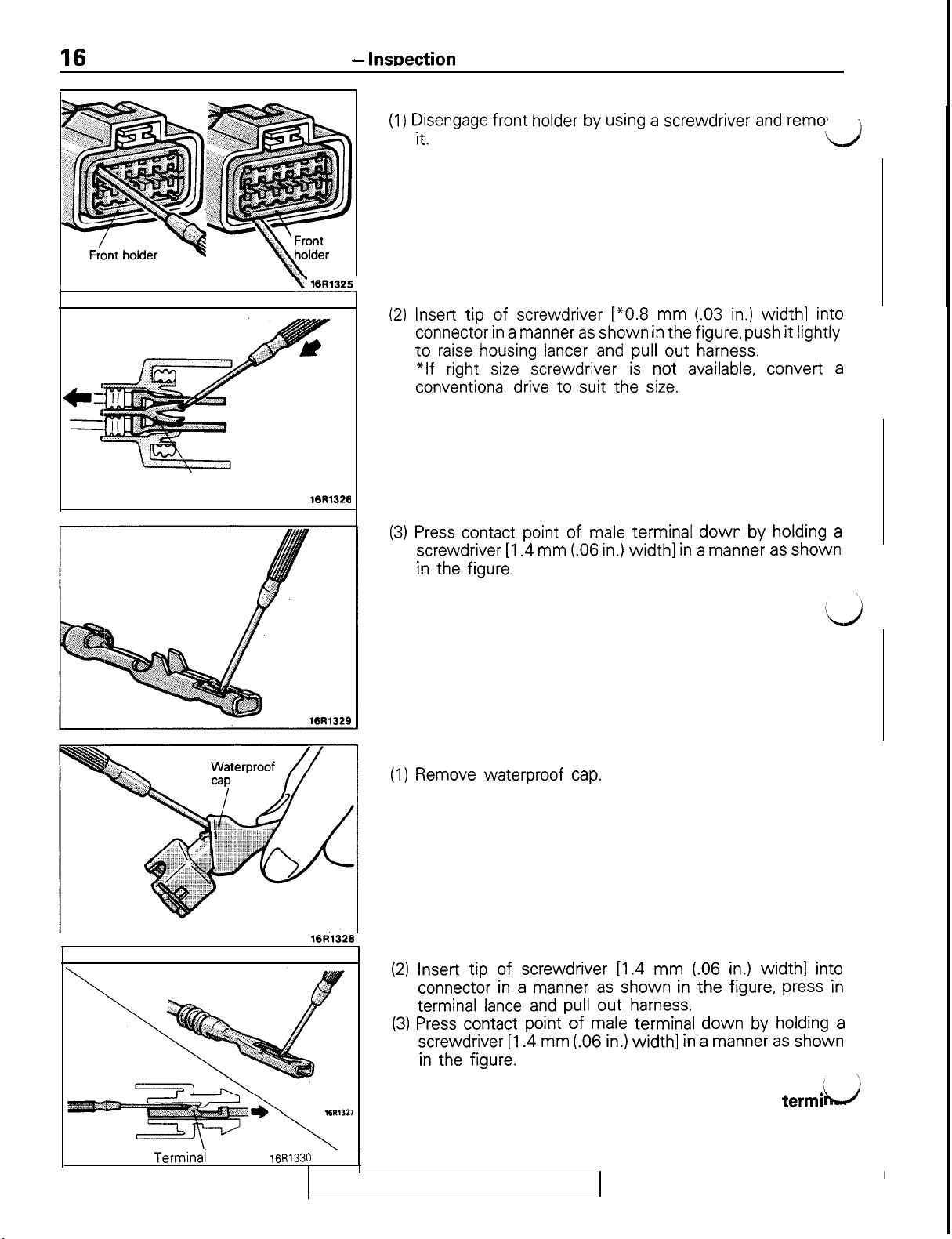

1) Disengage front holder by using a screwdriver and remo’

of Harness Connector

it.

\,

LJ

I

Housing lance

yl(6R1325]

16R1326

(2) Insert tip of screwdriver [*0.8 mm (.03 in.) width] into

connector in a manner as shown in the figure, push it lightly

to raise housing lancer and pull out harness.

*If

right size screwdriver is not available, convert a

conventional drive to suit the size.

(3) Press contact point of male terminal down by holding a

screwdriver [I .4 mm (06 in.)

in the figure.

width] in a

manner as shown

INJECTOR CONNECTOR

(1) Remove waterproof cap.

I

Terminal

lance

16R1326

16R1330

\

TSB Revision

(2) Insert tip of screwdriver [1.4 mm (.06 in.)

connector in a manner as shown in the figure, press in

terminal lance and pull out harness.

(3) Press contact point of male terminal down by holding a

screwdriver [I .4 mm (.06 in.)

in the figure.

Caution

Correct lancer to be in proper condition before termi

is inserted into connector.

width] in a

width]

manner as shown

into

Page 19

GENERAL

-

How to Diaanose

17

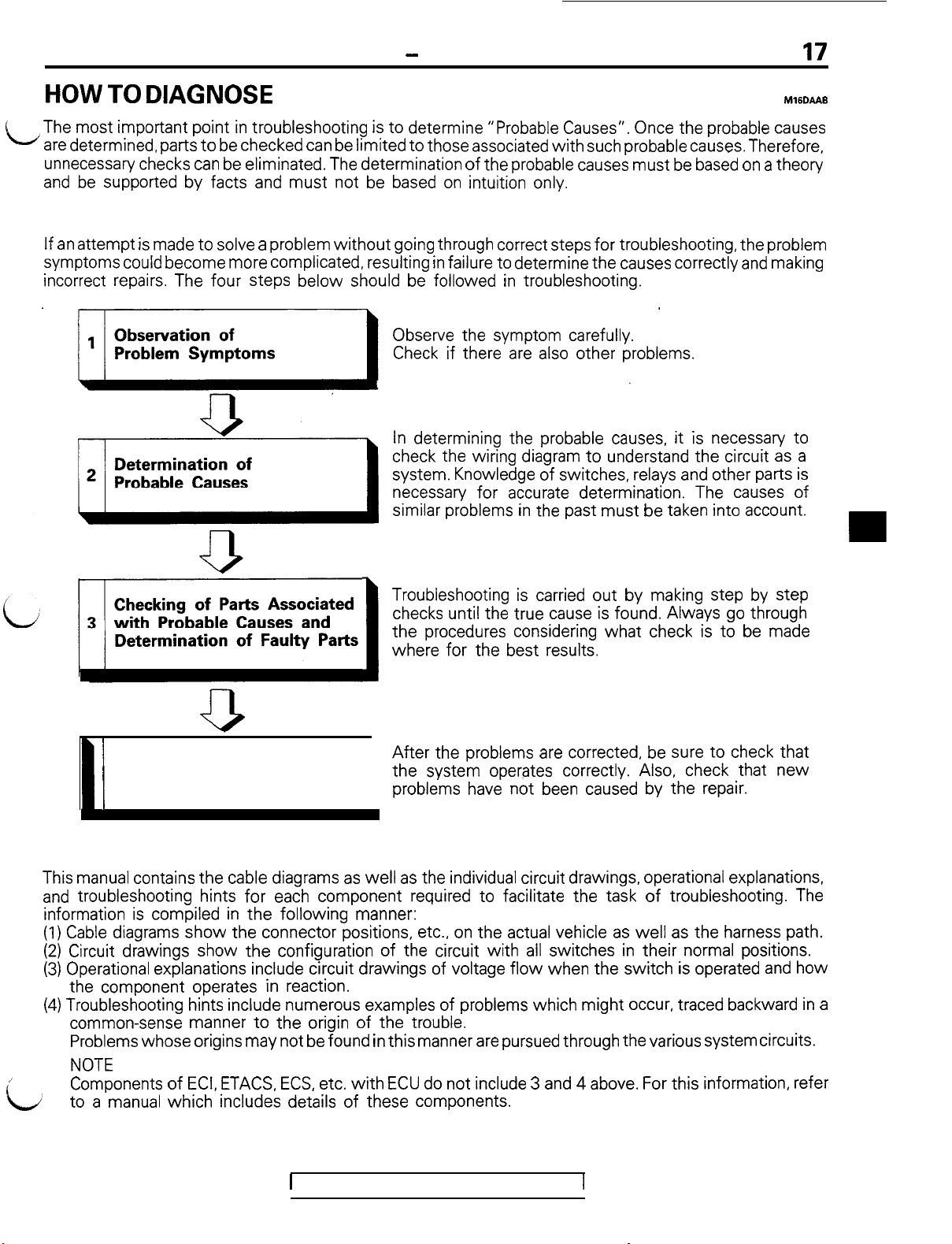

HOW TO DIAGNOSE

The most important point in troubleshooting is to determine “Probable Causes”. Once the probable causes

L

are determined, parts to be checked can be limited to those associated with such probable causes. Therefore,

unnecessary checks can be eliminated. The determination of the probable causes must be based on a theory

and be supported by facts and must not be based on intuition only.

TROUBLESHOOTING STEPS

If an attempt is made to solve a problem

symptoms could become more complicated, resulting in failure to determine the causes correctly and making

incorrect repairs. The four steps below should be followed in troubleshooting.

without

going through correct steps

Observe the symptom carefully.

Check if there are also other problems.

In determining the probable causes, it is necessary to

check the wiring diagram to understand the circuit as a

system. Knowledge of switches, relays and other parts is

necessary for accurate determination. The causes of

similar problems in the past must be taken into account.

for

troubleshooting, the problem

M16DAA6

Troubleshooting is carried out by making step by step

checks until the true cause is found. Always go through

the procedures considering what check is to be made

where for the best results.

I

After

the problems are corrected, be sure to check that

14 1

Repair and Confirmation

INFORMATION FOR DIAGNOSIS

This manual contains the cable diagrams as well as the individual circuit drawings, operational explanations,

and troubleshooting hints

information is compiled in the following manner:

(1) Cable diagrams show the connector positions, etc., on the actual vehicle as well as the harness path.

(2) Circuit drawings show the configuration of the circuit with all switches in their normal positions.

(3) Operational explanations include circuit drawings of voltage

the component operates in reaction.

(4) Troubleshooting hints include numerous examples of problems which might occur, traced backward in a

common-sense manner to the origin of the trouble.

Lj

Problems

I

NOTE

Components of ECI, ETACS, ECS, etc.

to a manual which includes details of these components.

whose

origins

for

each component required to facilitate the task of troubleshooting. The

may

not be found in this manner are pursued through

the system operates correctly. Also, check that new

problems have not been caused by the repair.

flow

when the switch is operated and how

the

various system circuits.

with

ECU do not include 3 and 4 above. For this information, refer

1

TSB Revision

Page 20

18

GENERAL

1680222

-

How to Diagnose

INSPECTION

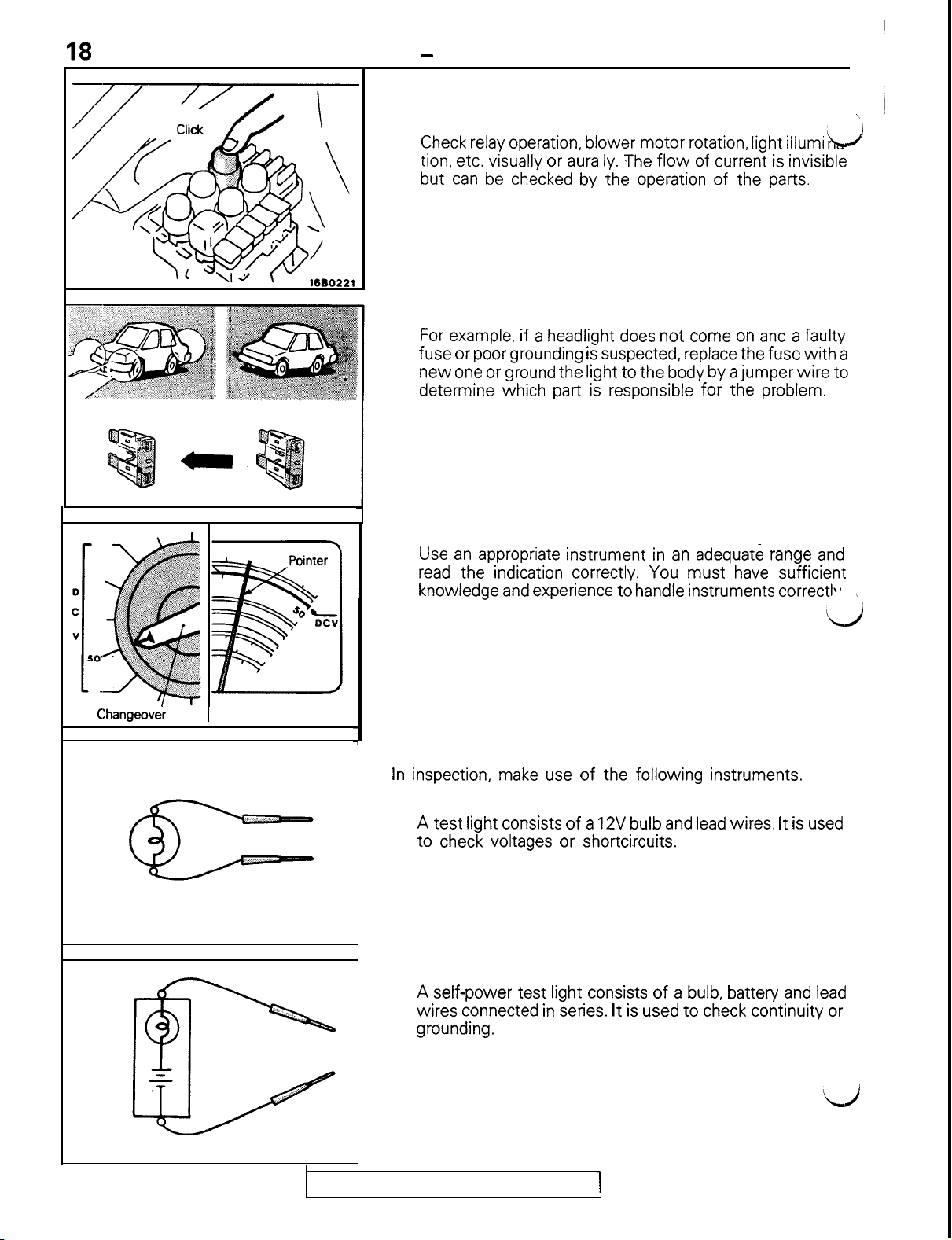

1. Visual and aural checks

Check relay operation, blower motor rotation, light illumi

tion, etc. visually or aurally. The

but can be checked by the operation of the parts.

2. Simple checks

For example, if a headlight does not come on and a faulty

fuse or poor grounding is suspected, replace the fuse

new one or ground the light to the body by a jumper wire to

determine which part is responsible for the problem.

flow of

current is invisible

ht!J

with

\

a

CIhangeovei knob

3. Checking with instruments

Use an appropriate instrument in an adequate range and

read the indication correctly. You must have sufficient

knowledge and experience to handle instruments correctI\*

\

!L)

1

1680224

INSPECTION INSTRUMENTS

In inspection, make use of the following instruments.

1. Test lights

A test light consists of a 12V bulb and lead wires. It is used

to check voltages or shortcircuits.

1660226

2. Self-power test light

A self-power test light consists of a bulb, battery and lead

wires connected in series. It is used to check continuity or

grounding.

1660226

TSB Revision

ij

Page 21

c

GENERAL

1680227

-

How to Diagnose

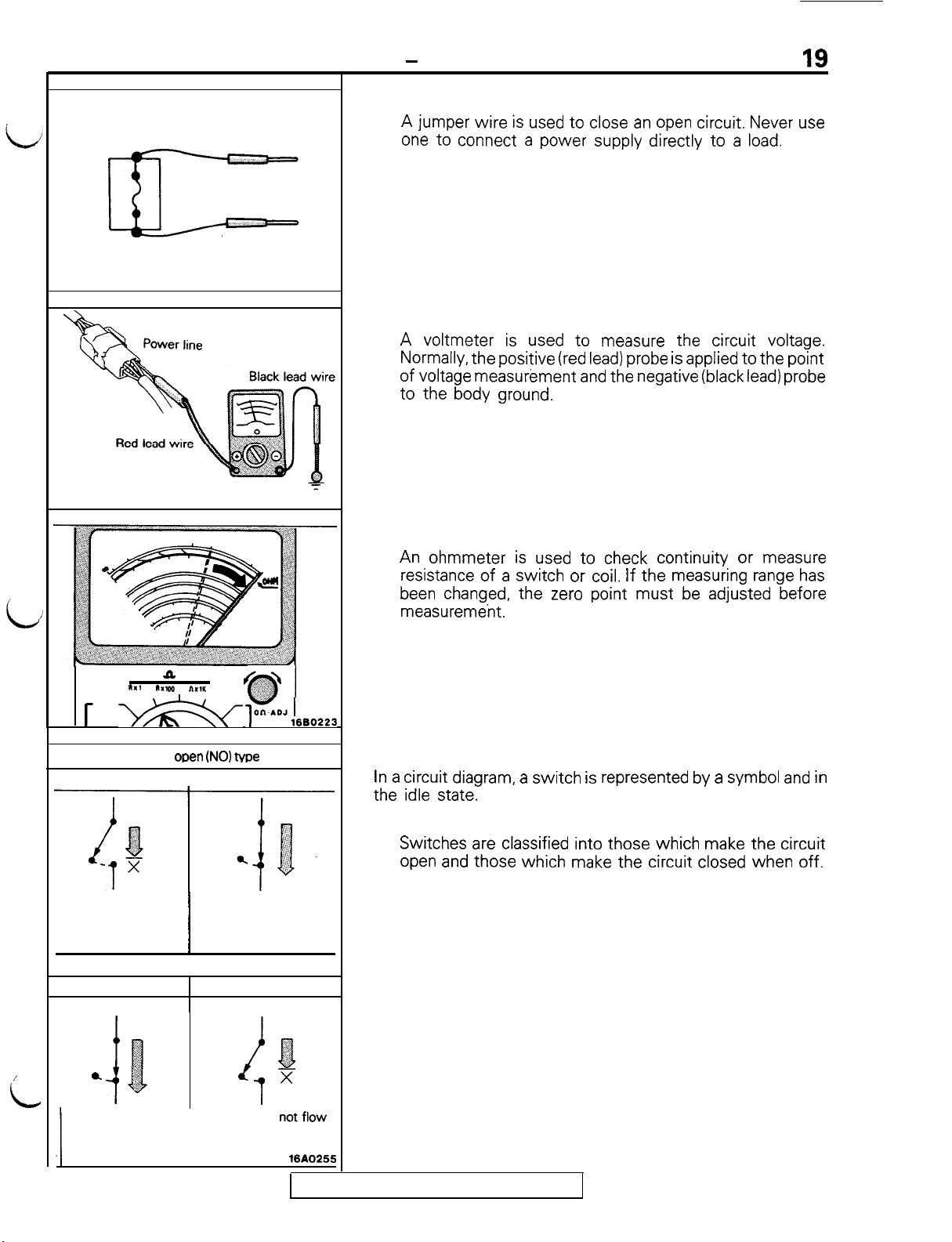

3. Jumper wire

A jumper wire is used to close an open circuit. Never use

one to connect a power supply directly to a load.

4. Voltmeter

A voltmeter is used to measure the circuit voltage.

Normally, the positive (red lead) probe is applied to the point

of voltage measurement and the negative (black lead) probe

to the body ground.

19

L

i

1x1

r b&&q

Normal open

OFF

Current flowsCurrent does not flow

a

RX100

nx,r

I

/

(NO) Me

$g

01

l”~~AoJ16B0223

ON

Ground

1680226

y

5. Ohmmeter

An ohmmeter is used to check continuity or measure

resistance of a switch or coil. If the measuring range has

been changed, the zero point must be adjusted before

measurement.

CHECKING SWITCHES

In a circuit diagram, a switch is represented by a symbol and in

the idle state.

1. Normal open or normal close switch

Switches are classified into those which make the circuit

open and those which make the circuit closed when off.

/

id

Normal close (NC) type

OFF

ON

i

0.

,,,!

-2

D

i

Current flows

1

Current does

i

1

3

‘,:

0

x

nI;I;.v,

TSB Revision

Page 22

20

r-t

GENERAL

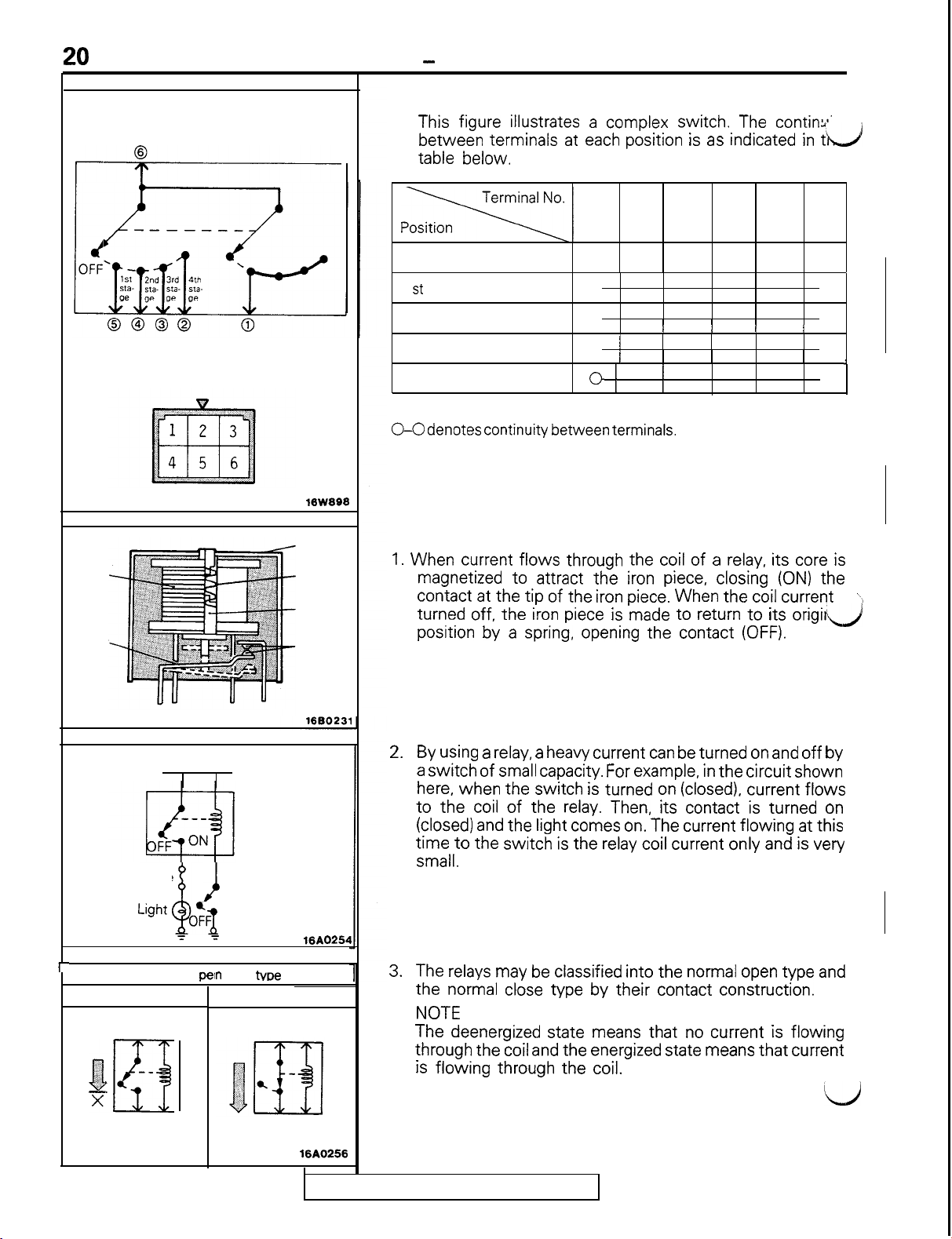

2. SWITCH CONNECTION

-

How to Diagnose

This figure illustrates a complex switch. The continu’

between terminals at each position is as indicated in t’il/l

table below.

Coil

Iron

piece

1640253

lBW898

Cover

Spring

Iron

core

Contact

1

2 3

OFF

1 st stage

2nd stage

3rd stage

4th stage

NOTE

O-O denotes continuity between terminals.

0 n 0

0

I I

I

0

j

0 1

0

1

n

I

n

4

5 6

I I

0

0

0

CHECKING RELAYS

1. When current flows through the coil of a relay, its core is

magnetized to attract the iron piece, closing (ON) the

contact at the tip of the iron piece. When the coil current

turned off, the iron piece is made to return to its origiljl/i

position by a spring, opening the contact (OFF).

4

\,

Power supply

Fuse

Light

r

Deenergized state

:.‘

-.

X

olzi

Current does not flow

,

Normal o

--

OF{

i

1 T

Relay

i

Switch

ON

n

(NO)

Energized state

Current flows

me

16A0254

16AO256

TSB Revision

2.By

3.

using a relay, a heavy current can be turned on and off by

a switch of small capacity. For example, in the circuit shown

here, when the switch is turned on (closed), current flows

to the coil of the relay. Then, its contact is turned on

(closed) and the light comes on. The current

time to the switch is the relay coil current only and is very

small.

The relays may be classified into the normal open type and

the normal cl,ose type by their contact construction.

NOTE

The deenergized state means that no current is flowing

through the coil and the energized state means that current

is

flowing

through the coil.

flowing at

this

LJ

Page 23

GENERAL - How to Diagnose

21

Deenergized state

i

Current flows

7

State of fuse blown due to overcurrent

L

Normal close (NC) type

/

Fuse

L ,

block

Energized state

Current does not flow

16A0257

16BO235

1680237

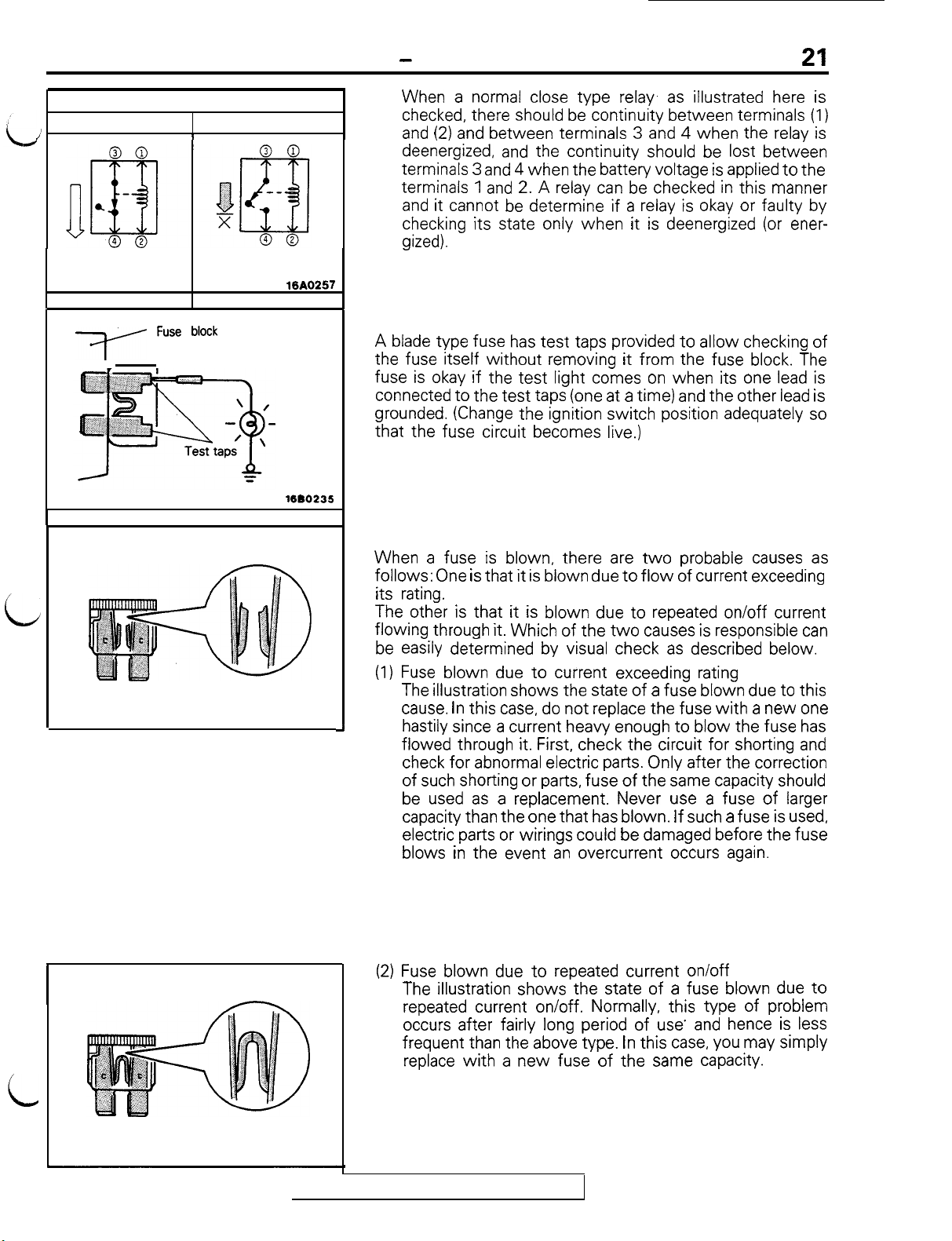

When a normal close type relay. as illustrated here is

checked, there should be continuity between terminals (1)

and (2) and between terminals 3 and 4 when the relay is

deenergized, and the continuity should be lost between

terminals 3 and 4 when the battery voltage is applied to the

terminals 1 and 2. A relay can be checked in this manner

and it cannot be determine if a relay is okay or faulty by

checking its state only when it is deenergized (or ener-

gized).

CHECKING FUSES

A blade type fuse has test taps provided to allow checking of

the fuse itself

fuse is okay if the test light comes on when its one lead is

connected to the test taps (one at a time) and the other lead is

grounded. (Change the ignition switch position adequately so

that the fuse circuit becomes live.)

CAUTIONS IN EVENT OF BLOWN FUSE

When a fuse is blown, there are

follows: One is that it is blown due to

its rating.

The other is that it is blown due to repeated on/off current

flowing through it. Which of the

be easily determined by visual check as described below.

(1) Fuse blown due to current exceeding rating

The illustration shows the state of a fuse blown due to this

cause. In this case, do not replace the fuse

J

hastily since a current heavy enough to blow the fuse has

flowed through it. First, check the circuit for shorting and

check for abnormal electric parts. Only after the correction

of such shorting or parts, fuse of the same capacity should

be used as a replacement. Never use a fuse of larger

capacity than the one that has blown. If such a fuse is used,

electric parts or wirings could be damaged before the fuse

blows in the event an overcurrent occurs again.

without

removing it from the fuse block. The

two

two

probable causes as

flow of

causes is responsible can

current exceeding

with a

new one

State of fuse blown due to thermal fatigue

1660236

TSB Revision

(2) Fuse blown due to repeated current on/off

The illustration shows the state of a fuse blown due to

repeated current on/off. Normally, this type of problem

occurs after fairly long period of use- and hence is less

frequent than the above type. In this case, you may simply

replace

with a

new fuse of the same capacity.

Page 24

GENERAL

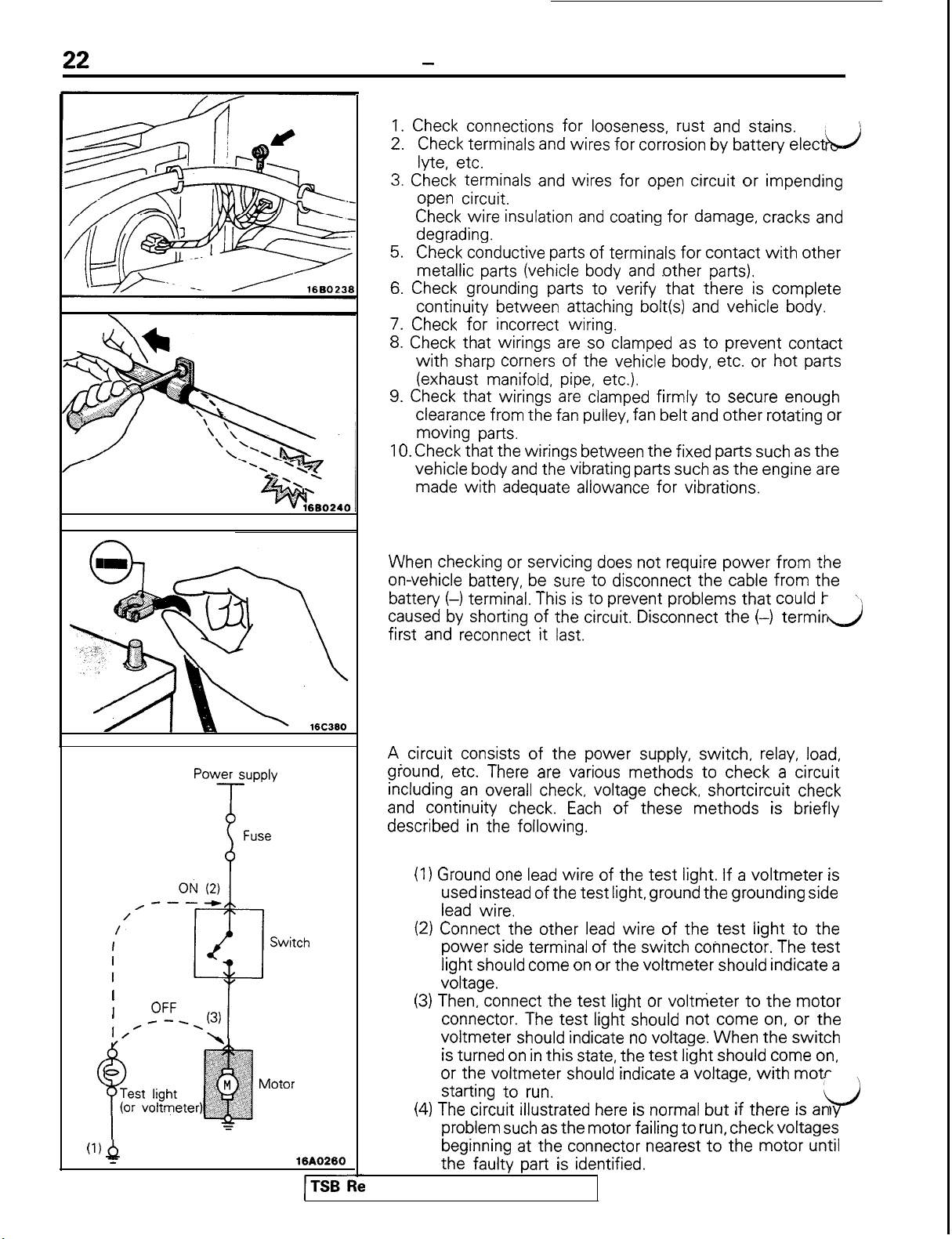

CHECKING CABLES AND WIRES

1. Check connections for looseness, rust and stains.

2.

3. Check terminals and wires for open circuit or impending

4.

5.

6. Check grounding parts to verify that there is complete

7. Check for incorrect wiring.

8. Check that wirings are so clamped as to prevent contact

9. Check that wirings are clamped

10. Check that the wirings between the fixed parts such as the

-

How to Diagnose

Check terminals and wires for corrosion by battery elect

AJ

lyte, etc.

open circuit.

Check wire insulation and coating for damage, cracks and

degrading.

Check conductive parts of terminals for contact

with

other

metallic parts (vehicle body and other parts).

continuity between attaching bolt(s) and vehicle body.

with

sharp corners of the vehicle body, etc. or hot parts

(exhaust manifold, pipe, etc.).

firmly to

secure enough

clearance from the fan pulley, fan belt and other rotating or

moving parts.

vehicle body and the vibrating parts such as the engine are

made with adequate allowance

for

vibrations.

(1) 4

HANDLING ON-VEHICLE BATTERY

When checking or servicing does not require

on-vehicle battery, be sure to disconnect the cable from the

battery (-1 terminal. This is to prevent problems that could t

caused by shorting of the circuit. Disconnect the (-)

first and reconnect it last.

power

from the

term?

d

\

TROUBLESHOOTING

A circuit consists of the power supply, switch, relay, load,

Power

supply

I

OFF

I

/---.

I/

Motor

=

16AO260

TSB

I-

ground, etc. There are various methods to check a circuit

including an overall check, voltage check, shortcircuit check

and continuity check. Each of these methods is briefly

described in the following.

1. VOLTAGE CHECK

(I)

Ground one lead wire of the

test

light. If a

voltmeter

used instead of the test light, ground the grounding side

lead wire.

(2) Connect the other lead wire of the

test

light to the

power side terminal of the switch connector. The

light should come on or the voltmeter should indicate a

voltage.

(3) Then, connect the test light or voltmeter to the motor

connector. The test light should not come on, or the

voltmeter should indicate no voltage. When the switch

is turned on in this state, the

or the voltmeter should indicate a voltage,

test

light should come on,

with motr

starting to run.

(4) The circuit illustrated here is normal but if there is an

problem such as the motor failing to run, check voltages

beginning at the connector nearest to the motor until

the faulty part is identified.

‘vision

is

test

y’

Page 25

GENERAL

-

How to Diagnose

23

Power supply

A- Short-circuit

\

,\

Switch

lllumrnation

light

7

Power supply

-T-

location

16A0502

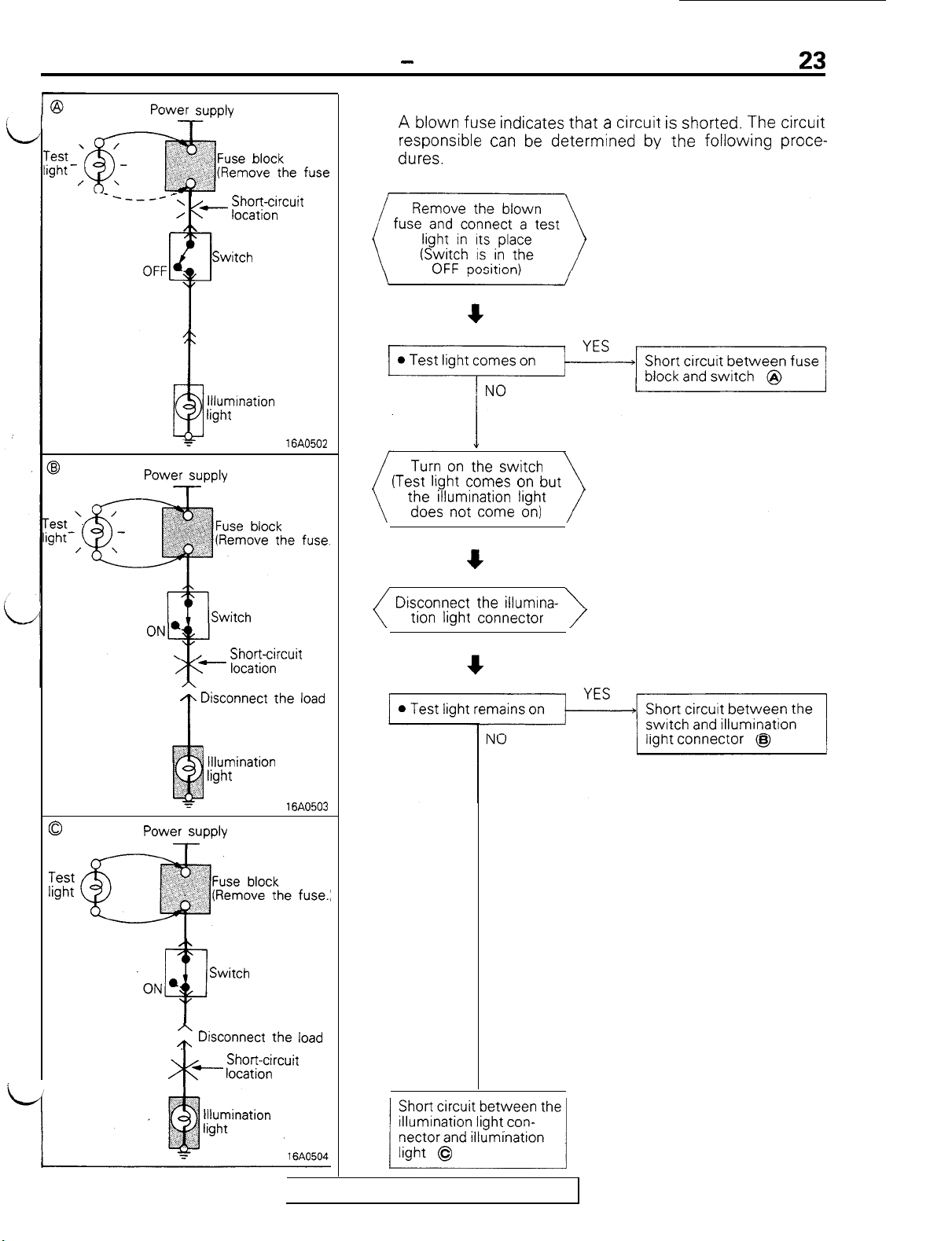

2. CHECKING SHORT CIRCUITS

A blown fuse indicates that a circuit is shorted. The circuit

responsible can be determined by the following proce-

dures.

Turn

on the

(Test light comes on but

the illumination light

does not come

switch

on)

0

Test

light

Disconnect the load

T

llluminatron

light

Power supply

-

Switch

c

Disconnect the illumina-

tion light connector

Short-circuit

16A0503

fuse.:

A

/t\ Disconnect

Short-circuit

+- location

*

the

load

TSB Revision

12s&$%z;;eI

Page 26

24

Self power

(or

ohmmeter)

c@++

1

.

_,;

test

,I

%

j :; ii,,’

‘, ‘:

light

1

+--pi

:

GENERAL

B

-0

Iii

40

P

-

How to Diaanose

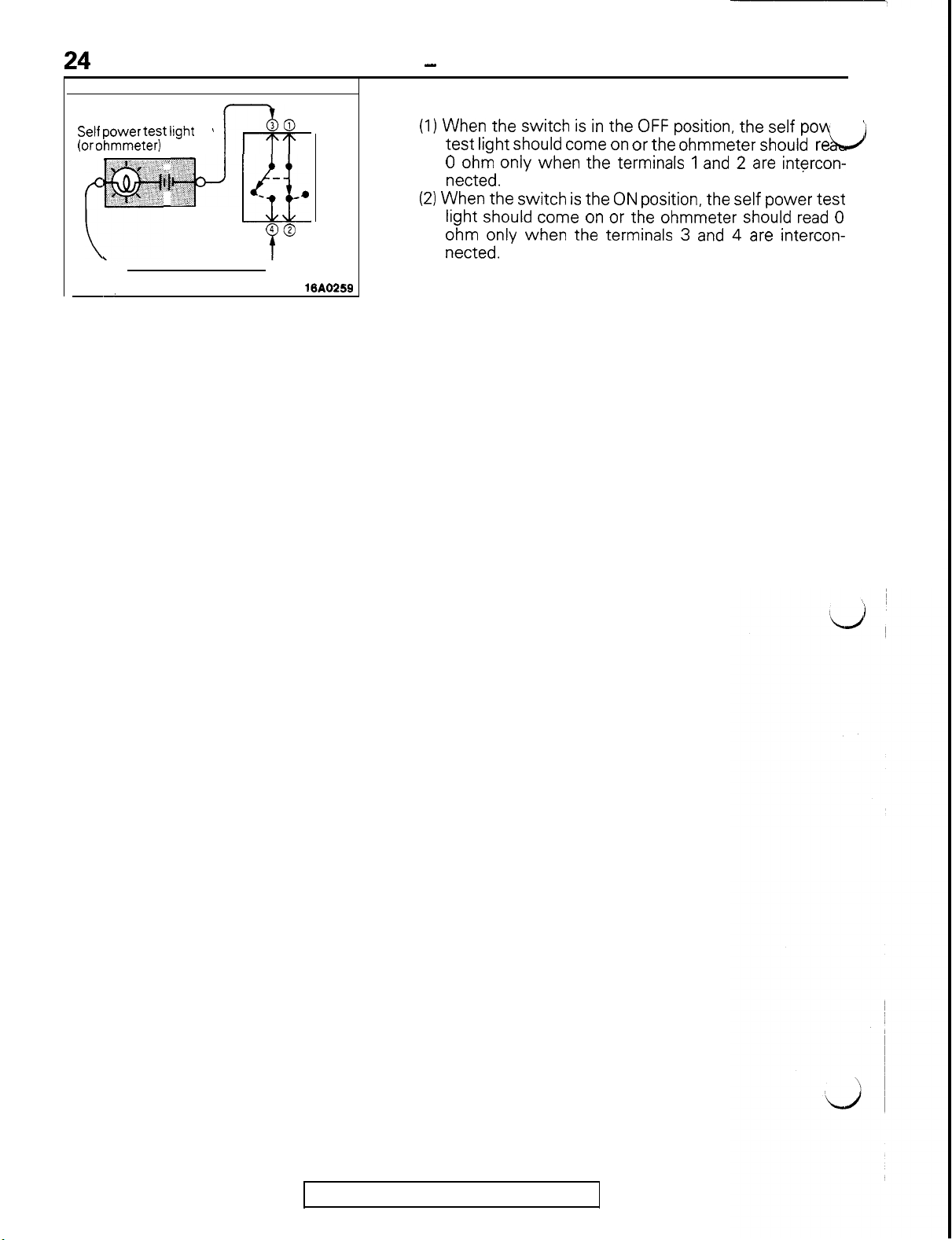

3. CHECKING CONTINUITY

(I)

When the switch is in the OFF position, the self pow

test

light should come on or the ohmmeter should

0 ohm only when the terminals 1 and 2 are intercon-

nected.

(2) When the switch is the ON position, the self power

light should come on or the ohmmeter should read 0

ohm only when the terminals 3 and 4 are interconnected.

re

&J

test

’

-.

16A0259

TSB Revision

Page 27

L

25

CONFIGURATION

DIAGRAM

Dash Panel

Engine and Transaxle

Engine and Transaxle <M/T>

Engine Compartment

How to Read Configuration Diagrams

............................................................

<A/T>

............................................

................................

............................

CONTENTS

................

34

32

30

28

27

Instrument Panel and Floor Console

Interior

Luggage Compartment

Overall Configuration Diagram

..............................................................

..................................

......................

..............

.

. . . .

. .

. . . .

M16VA- _

. .

36

.

38

. .

40

. .

26

Page 28

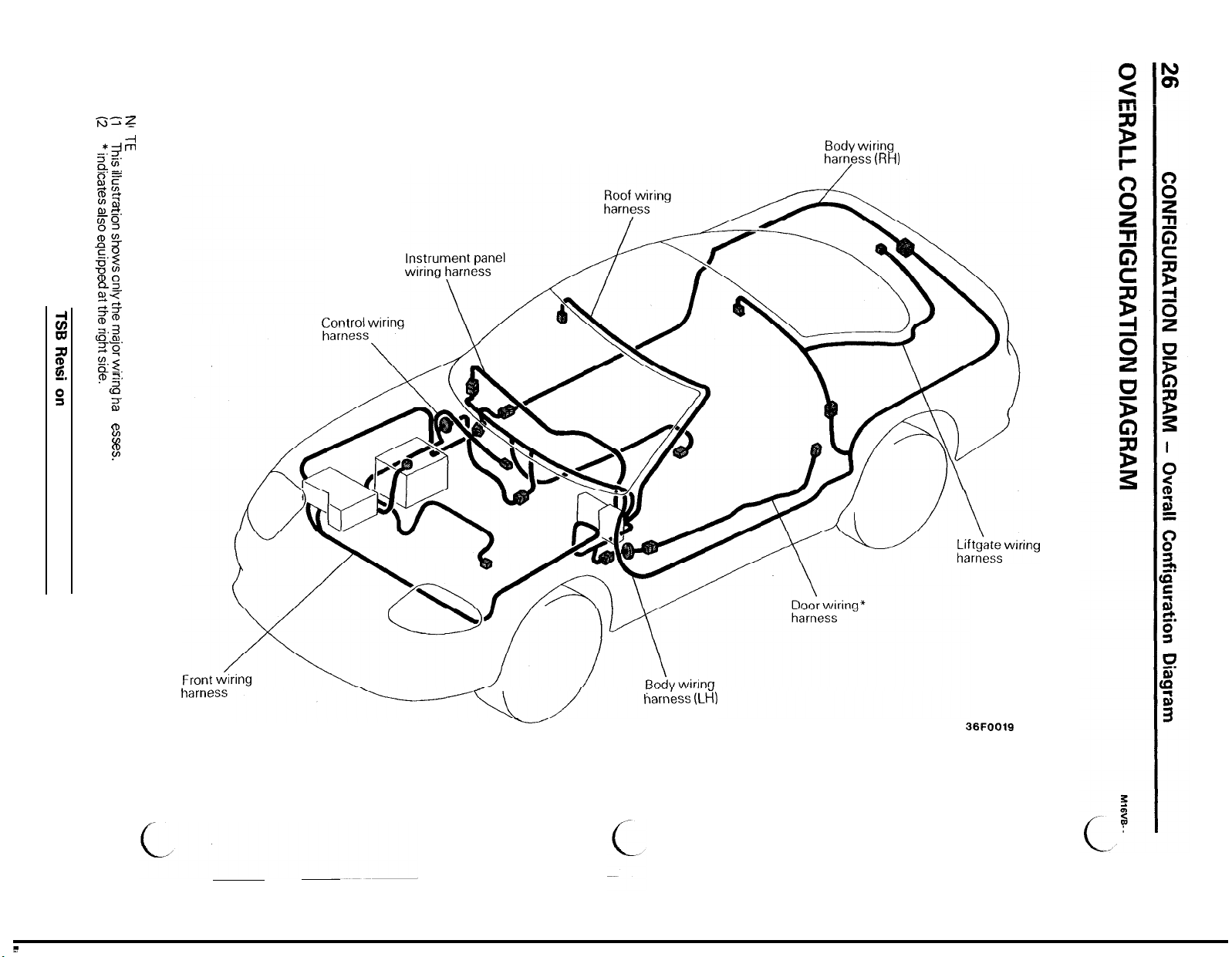

g

T

-a

2

s

Gj-32

--0

*-id

25,

gg

sg

nl

5.

GiO

03

2%

5.2

COO

a3

z<

55

:;

&‘a,

2%’

gg.

? 2.

a

z

3

(D

z

F

Control

Body wiring

harness (RH)

wiring

harness

harness (LH)

36FOO19

Page 29

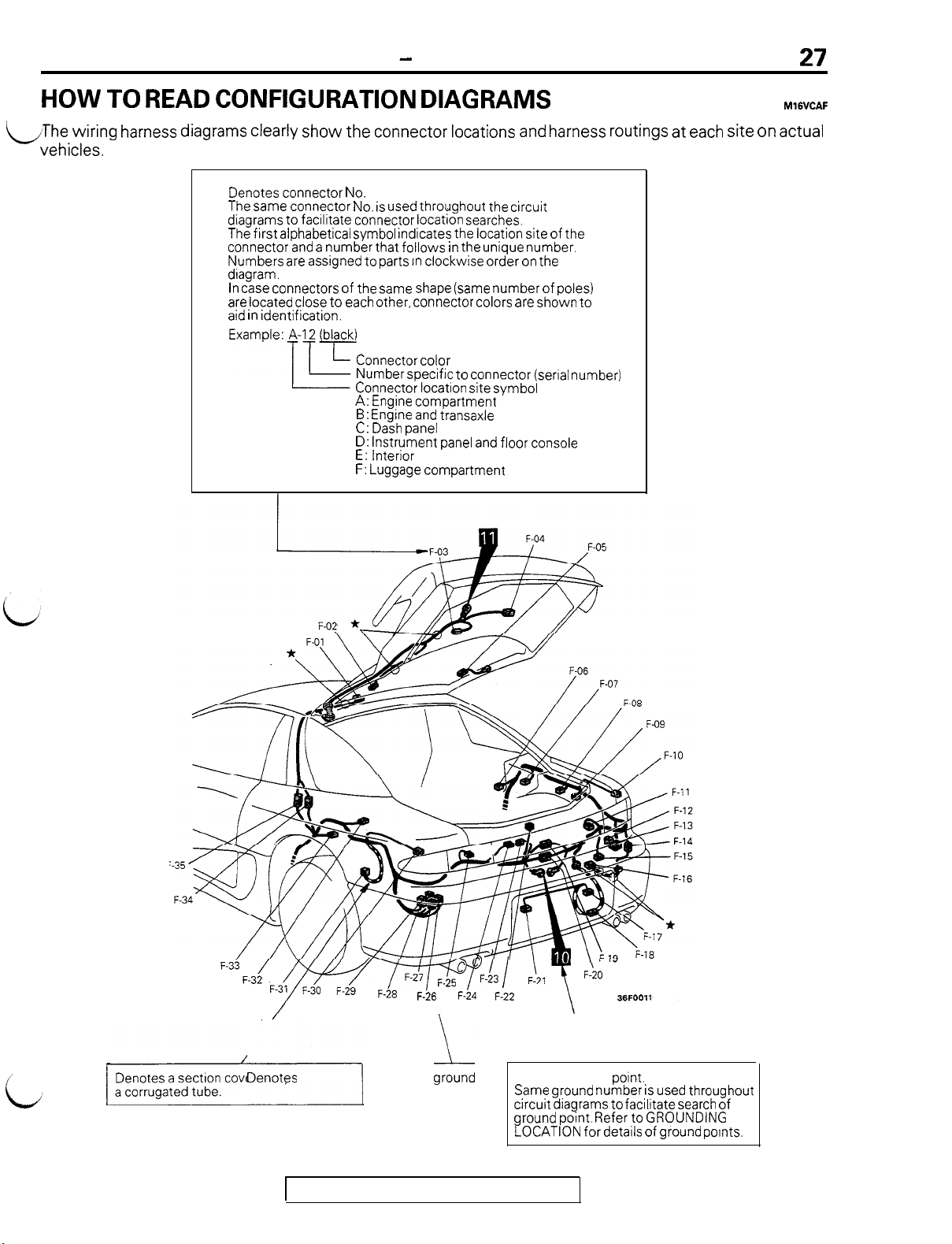

CONFIGURATION DIAGRAM

-

How to Read Configuration Diagrams

27

HOW TO READ CONFIGURATION DIAGRAMS

M16VCAF

LThe wiring harness diagrams clearly show the connector locations and harness routings at each site on actual

- vehicles.

Denotes connector No.

The same connector No. is used throughout the circuit

dragrams to facrlitate connector location searches.

The

first

connector and a number that

Numbers are assigned to parts rn clockwise order on the

diagram.

In case connectors of the same shape (same number of poles)

are located close to each other, connector colors are shown to

aid in identification.

alphabetical symbol indicates the location site of the

follows in

the unique number.

Connector color

Number specific to connector (serral number)

Connector location site symbol

A: Engine compartment

B: Engine and transaxle

C: Dash panel

D: Instrument panel and floor console

E: Interior

F: Luggage compartment

i

/I-

F-33 /

F-32

Denotes

77$=$5?-!3

F-28

TSB Revision

F-26

/

F-24

F-22

g!und

Same ground number is used throughout

circuit diagrams to facilitate search of

ground point. Refer to GROUNDING

LOCATION for detarls of ground pornts.

36FOOll

point.

Page 30

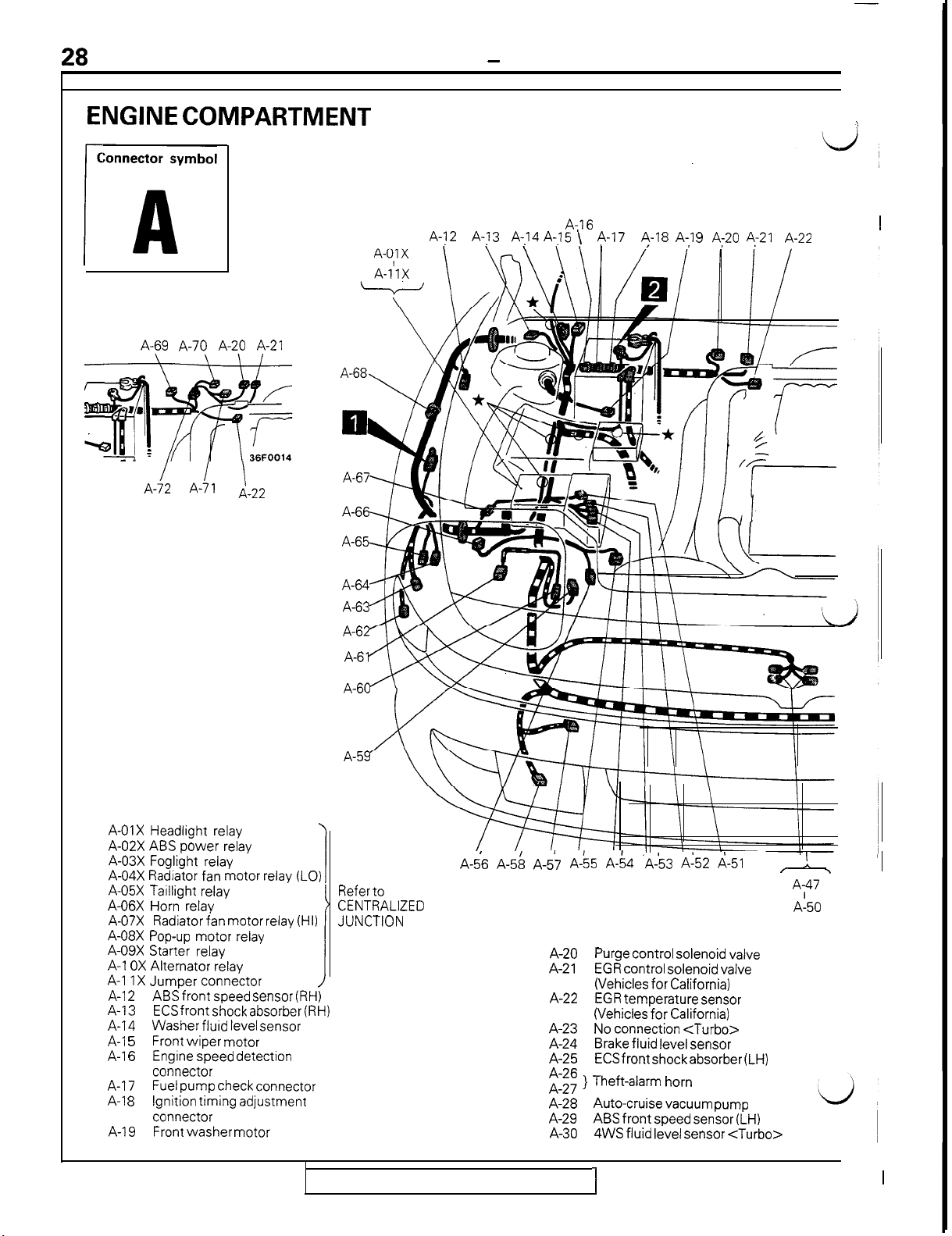

28

CONFIGURATION DIAGRAM

-

Engine Compartment

ENGINE COMPARTMENT

<Turbo>

r

ml

-

-r

A-69 A-70 A-20 A-21

A-67

A-66

A-65

A-j

\

2

A-?

A,14

3

A-,I5

A-16

\

A-l

7 A-1 8 A-,I

9

A;20

A-21

A-22

1

A-01X Headlight relay

A-02X ABS

A-03X Foglight relay

A-04X Radiator fan motor relay (LO)

A-05X Taillight relay

A-06X Horn relay

A-07X

A-08X Pop-up motor relay

A-09X Starter relay

A-l OX

A-l IX

A-l

A-13

A-14

A-l

A-l

A-17

A-l 8

A-19

power

Radiator fan motor relay (HI)

Alternator relay

Jumper connector

ABS

2

ECS

Washer fluid level sensor

Front

5

Engine speed detection

6

connector

Fuel pump check connector

Ignition trming adjustment

connector

Front

relay

front

speed sensor (RH)

front

shock absorber (RH)

wiper

motor

washer

motor

A-64

A-63

A-62

A-61

A-60

A-59

Refer to

CENTRALIZED

JUNCTION

A-56 A-58 A-57 A-55 A-64 ‘A-53 A:52 A-51

Purge control solenoid valve

A-20

EGR control solenoid valve

A-21

(Vehicles

EGR temperature sensor

A-22

(Vehicles

No connection

A-23

Brake fluid level sensor

A-24

ECS

A-25

2:;; } Theft-alarm horn

Auto-cruise vacuum pump

A-28

ABS

A-29

4WS fluid level sensor

A-30

for

California)

for

California)

front

shock

front

speed sensor (LH)

<Turbo>

absorber

<Turbo>

(LH)

/ !, ,

A;47

A-50

I

TSB Revision

I

I

Page 31

CONFIGURATION DIAGRAM - Engine Compartment

ENGINE HOOD

A-73

29

A-23 A-24 A-25

=#=k==F=r

A-46 A-45 A-44

A-31X Condenser fan motor

relay (HI)

A-32X Radiator fan motor

control relay

A-33X Magnetic clutch relay

A-34X Condenser fan motor

relay (LO)

A-35

Dual pressure

A-36

A-37)

Arr conditioner relay box

A-38

SRS front impact sensor (LH)

A-39

Front combination light (LH)

A-40

Inspection ltght switch

A-43

A-26

switch

A-27

i\

//\

\

A-42

Refer to

CENTRALIZED

JUNCTION

36FQ613

/

A-41 Headlrght (LH)

A-42

A-35

A-36

A-39

‘A-40

A-64

A-65

A-66 Hood switch

A-67

A-68 Diode (for ABS circuit)

A-69 Resistor

A-70

A-71

A-72

A-73 Inspection light

Remarks

(1)

The mark * shows the standard mounting position of

wiring harness.

(2)

For details concerning the ground point (example: 0). refer

to P.4.

Front wiring harness and headlrght

wiring harness (LH) combinatton

A-43

Fog light (LH)

A-44 Pop-up motor (LH)

A-45

) Condenser fan motor

A-46

A-47

f Horn

A-50

A-51

Fuel pump resistor

A-52 A/T fluid temperature sensor

A-53

Kickdown servo switch <AA>

A-54 Pulse generator <AT>

A-55 Radiator fan motor

A-56 Engine coolant level sensor

A-57

Active aero front venturi skirt

A-58

Fog light (RH)

A-59 Pop-up motor (RH)

A-60 Front wiring harness and headlight

wiring harness (RH) combination

A-61 Headlight (RH)

A-62

Front combination light (RH)

A-63

SRS

front impact sensor

) ABS hydraulic unit

Front wiring harness and control

wiring harness combrnation

<Turbo>

Waste gate solenoid valve

Fuel pressure solenoid valve

Control wiring harness and

solenoid valve harness combrnatron

<Turbo>

16FO174

(RH)

<Turbo>

<Turbo>

1

TSB Revision

Page 32

30

CONFIGURATION DIAGRAM

ENGINE AND TRANSAXLE <M/T>

Connector symbol

r

B

B-O8

B-06

B-O I-\

B-P7 1

-

-

Front View

j,

-

Engine and Transaxle

<M/T>

B-30

-A

B-29

B-:8

B-01

Engine coolant temperature gauge unit

B-02

Engine coolant temperature sensor

B-03

Engine coolant temperature switch

(for air conditioner circuit)

B-04

Crank angle sensor and top dead

center sensor

B-05

Throttle position sensor

B-06

Control

wiring

pressure

B-07

Control

wiring harness combination

B-08

Detonation sensor

harness and oil

wiring

wiring

harness combination

harness and injector

g$J-----8-18

*

I

B-24

B-25

<Turbo>

*

B-L5

<Non-turbo>

B-0g

B-, o)

B-l 1

B-l 2Injector No. 3

B-13 Injector No. 1

B-14 Ignition co11

B-l 5 Capacitor

B-16

B-17

B-18

B-l

9

B-20 Maonetic clutch

B-21

B-22

i-23

36FOOO7

Variable induction servo motor

(with intake control valve posrtion

sensor) <Non-Turbo>

Injector No. 5

Oxvoen sensor (LH)

‘-

) Alternator

Oxygen sensor (RH)

-

) Power transistor

<Turbo>

<Turbo>

TSB Revision

Page 33

CONFIGURATION DIAGRAM

Rear View

-

Engine and Transaxle <M/T>

31

B-31

B-32

\

B-33

I

B-23

) Starter motor

B-24

B-25

Back-up light swatch

-

B-26

-

B-27

B-28

Fuel pump relay

B-29

Air flow

sensor and

B-30

Control wiring harness and battery cable

combination

B-31

Injector No. 2

B-32

/I

B-33

Injector No. 4

Injector No. 6

<Turbo>

sensor (with intake air temperature

atmosphenc

sensor)

1

TSB Revision

1

B-34

Speed sensor

B-35

Idle speed control servo (stepper motor)

B-36

Oil pressure gauge unit

B-37

Oil pressure switch

B-38

Power steering oil pressure switch

Remarks

(I)

The mark * shows the standard mounting position of

wiring harness.

(2)

[;;d;tails concerning

(3)

“gdmeans

<Turbo>

the

ground point (example: 8). refer

that the connector

I

with

code-number is

not

Page 34

32

CONFIGURATION DIAGRAM

ENGINE AND TRANSAXLE <A/T>

-

Engine

Front View

and

Transaxle <A/T>

B-30 ‘--_

B-l 0

B-07 B-08

i

B-09 \

B-l 1

I

*B-l 5

B-17

B-l

‘B-20

8

B-01

Engine coolant temperature gauge unit

EL02

Engine coolant temperature sensor

E;-03

Engine coolant temperature switch

(for air

El-04

B-05

B-06

El-07

B-08

Es09

E;-10

conditioner circuit)

Crank angle sensor and top dead center sensor

Throttle posrtion sensor

Control winng harness and oil pressure

wiring harness combination

Control wiring harness and injector

wiring harness combinatron

Detonation sensor

Variable induction servo motor

,

I

(with intake control valve position sensor)

TSB Revision

B-l 1

Injector No.

B-l 2Injector No.

B-l 3Injector No.

B-14 Ignition coil

B-l 5Capacitor

B-16

-

B-l

7

) Alternator

B-18

B-19 B-20 Maonetic clutch

B-21

-

) Power transistor

B-22

5

3

1

36FOOO6

‘d

I

Page 35

CONFIGURATION DIAGRAM

Rear View

B-32

“-Y

\ “i

-

Enaine and Transaxle <A/T>

36FOOO4

B-23

) Starter motor

B-24

B-25

Inhibitor switch

B-26

B-27

ELC-4 A/T control solenoid valve

-

B-28

B-29

Air

flow

sensor and atmospheric sensor)

B-30

Control wiring harness and battery cable

combination

B-31

Injector No. 2

B-32

i

B-33

Injector No. 4

Injector No. 6

sensor (with intake air temperature

B-34 B-35

Idle speed control servo (stepper motor)

B-36

011 pressure gauge unit

B-37

011 pressure switch

B-38

Power steering oil pressure switch

Remarks

(1)

The mark * shows the standard mounting position of

wiring harness.

(2)

(3)

:,O;d;tails

i’ldmeans

concerning the ground point (example: a),

that the connector

with

code-number is

refer

not

TSB Revision

Page 36

34

DA.SH PANEL

Connector symbol

I

c

JUNCTION BLOCK

<Front side>

CONFIGURATION DIAGRAM

-

Dash Panel

36FOOOl

<Rear side>

;;

I

C-01

Body

wiring

C-02 and front

C-033harness combination

C-04X Door lock relay

c-05x

C--06X Defogger relay

C-07X Power

CO8

c-,o9}

Diode (for seat belt warning circuit)

EIi 7 } Column switch

c-12

Diode (for theft-alarm circuit)

c-13

Accelerator pedal switch

C-l 4

Control

panel

C-l 5

Body

panel

C-l 6

} Air conditioner control panel

C-l 7

C-l 8

Air conditioner switch

c-19

Blower

c-.20

Heater control panel illumination light

c-21

Blend

harness (LH)

wiring

window

wiring

wiring

wiring

wiring

air damper control motor

harness and instrument

harness combination

harness (LH) and instrument

harness combination

switch

C-76

36FOOO3

1

Refer to

CENTRALIZED

relay

JUNCTION

i

c-77

C-78

C-80

C-65’

/

C-64

C-22

C-23

C-24 Blower

C-25 , Air conditioner control unit

C-26 ’

C-27

C-28

C-29)

C-30 ’ wiring harness combination

C-31

C-32

c-33

c-34

c-35

C-36

c-37

C-38

c-39

c-40

c-41

C-63 &

C-62

Mode selection damper control motor

Power transistor

conditioner circuit)

resistor

<Manual

Air-inlet sensor <Full-auto air conditroner>

Air selection damper control motor

Body

Body wtring harness (LH) and front wiring

harness combination

Body

I

’ harness combination

Body

harness (RH) combination

Foot light (RH)

Body

harness combination

Auto-cruise control unrt

Blower motor

Blower motor relay (HI)

Air conditioner compressor lock controller

Air-inlet sensor

air

conditioner>

wirino

harness (LH) and control

wiring

harness (RH) and front wrring

wiring

harness (LH) and body wiring

wiring

harness (RH) and control wirrng

C-60 C-59 Ci58

(for

full-auto

<Manual

air conditioner>

air

‘d

TSB Revision

Page 37

CONFIGURATION DIAGRAM

-

Dash Panel

-31

I

\-

\

C-38

36FOO18

Foot light (LH)

C-42

Air-therm0 sensor

c-43

Engine ccolant temperature sensor

c-44

Engine control relay

c-45

Over drive switch

C-46

ELC-4 A/T control unit

c-47

C-48

c-49

Arr condrtioner control unit

c-50

<Full-auto air conditioner>

c-51

C-52

c-53

Engine control unit

c-54

Oxygen sensor <Non-Trubo>

c-55

Theft-alarm starter relay

C-56

Clock spring

c-57

Key reminder switch

C-58

Ignition switch

c-59

C-60

Steering wheel angle speed sensor

i

iA

C-61

c-62 ) Stop light switch

Clutch pedal switch (for auto-cruise control circuit)

C-63

Clutch pedal swatch (for theft-alarm circuit)

C-64

C-65

c-.66 ) ETACS unit

C-67

C-68

Front wiring harness and junction block

c-6g

combination

c-70

Adapter wiring harness and junction block

C-71

combination

C-72 Theft-alarm horn relay

Blower motor relay

C-73

Roof wiring harness and junction block combination

C-74

c-75 -

Body wiring harness (LH) and

:I$

junction block combination

c-78

Self-diagnosis check connector

C-79 c-80

Body wiring harness (LH) and

C-81

junction block combination

C-82

C-83

!

nemarks

(I)

The mark + shows the standard mounting position of

wiring

(2)

harness.

The details concerning the ground point (example:

refer to P.5.

(3)

“-)1 means that the

connectorwith

code-number is not

used.

q

),

[TSB

Revision

Page 38

CONFIGURATION DIAGRAM

-

Instrument Panel and Floor Console

INSITRUMENT PANEL AND FLOOR CONSOLE

Connector symbol

D-09

D-98 \

“T \ \

D

D-0:

D-or

D-c!6

“Y

bk4-T

D-10

\

AT----7 I

D-11 D-12

\\

I

\A--

D-40

D-01

Pop-up swatch and fog light switch

D-02

Front speaker (LH)

D-03

D-04

Combination

D-05

D-06

Defogger

D-07 Diode (for fog light circuit)

D-08 Hazard

D-09 Combination gauge

D-l 0Diode (for 4WS fluid level warning

light circuit)

D-l 1

Glove box illumination

D-l 2Photo sensor

switch

switch

meter

and ECS switch

light

TSB Revision

I

/

D-13

Front speaker (RH)

D-14

Glove box illuminatton light switch

D-l

5

Instrument panel wiring harness and control

wiring harness combinatron

D-l 6

Instrument panel

wiring harness (RH) combination

Ashtray illumination light

D-l 7

D-l 8

) Cigarette lighter

D-l

9

Cigarette lighter illuminatton light

D-20

D-21

Power seat switch

Body wirtng harness (LH) and console

D-22

wiring harness combination

wiring

I

harness and body

Page 39

D-l

D-17

CONFIGURATION DIAGRAM

3

D-l

9

D-20

-

Instrument Panel and Floor Console

D-23

D-24

SRS diagnoses unrt

D-25

1

D-26

I

D-27

ABS G sensor

D-28

Parking brake swatch

D-29

Active aero switch

D-30

D-31 ) Accessory socket

D-32 Auto-cruise main switch

D-33

Seatbelt warning buzzer

D-34

D-35 Radio

D-36

3

D-37 Rear wiper and

D-38

Active exhaust switch

D-39

Remote-control mirror switch

D-40 Rheostat

D-41

D-42

Instrument panel wiring harness and

D-43?body wiring harness (LH) combination

D-44

Instrument panel‘wiring harness and adapter

wiring harness combination

D-45

Instrument panel wiring harness and

wiring harness combination

washer switch

37

front

D-16

D-23

D-24

D\-25

Remarks

The mark * shows the standard mounting position of w&g

harness.

TSB Revision

Page 40

38

INTERIOR

CONFIGURATION DIAGRAM

-

Interior

Conlnector symbol

E-32,

E-05 E-06 E-07

E-04

E-35

E-34

1

.’

\

E-08

i

I

E-3

E-01

E-02

E-03

E-04

E-05

E-06

E-07

E-08

E-09

E-l 0

E-3;

Body wiring harness (RH) and door

wiring harness (RH) combination

Vanity mirror illumination light (LH)

Door

mirror

Door speaker (RH)

Dome light

Power window

Vanity mirror illumination light (RH)

Power window motor

Door light (RH)

Door key cylinder unlock switch (RH)

(RH)

sub

I

E-29

switch

(RH)

TSB Revision

E-28

E-l 1

E-l 2

E-l 3

E-14

E-l 5

E-16

E-l 7

E-18

E-l 9

E-20

E-21

E-27 1 E-25 /

E-26

Door lock actuator (RH)

ABS control unit

ABS resistor

Front seat belt solenoid (RH)

Door

switch

ABS rear speed sensor (RH)

No connection

Rear intermittent wiper relay

ABS rear speed sensor (LH)

Front seat belt solenoid (LH)

Door switch (LH)

E-23

E-24 E-22

<AWD>

(RH)

j E-21 1

E-20

Page 41

CONFIGURATION DIAGRAM

-

Interior

39

E-09

I I

E-10

E-l 1

I

E-l

\

E-l 8

Door lock actuator (LH)

E-22

Door key cylinder unlock switch (LH)

E-23

Front seat belt switch (RH)

E-24

Door light (LH)

E-25

Front seat belt switch (LH)

E-26

Power

E-27

E-28

E-29

E-30

E-31

E-32

seat assembly

ECS G sensor

Door

speaker

Turn signal and hazard flasher unit

Diode (for MPI circuit)

Body

wiring

wiring harness (LH) combination

harness (LH) and door

E-l 7

1

TSB Revision

36F0009

E-33

Door mirror (LH)

E-34

Power

Power

harness.

window

window

E-35

Remarks

(I)

The mark * shows the standard mounting position of

wiring

(2)

;;;d;tails concerning

main switch

motor

(LH)

the

ground point

(example:

q

l,

refer

Page 42

40

CONFIGURATION DIAGRAM

LUGGAGE COMPARTMENT

-

Luggage Compartment

nnector symbol

i

F-03

//

/F-08

F-09

/

F-IO

F-l 1

F-12

F-l 3

F-l 4

F-15

F-31 F-30

F-01

Interior temperature sensor

F-02 Defogger (+)

IF-03

Rear wiper

High-mounted stop light or

IF-04

active aero rear spoiler

IE-05 Defogger (-)

Rear

IF-06

ECS rear shock absorber (RH)

IF-07

Luggage compartment light

IF-08

ABS resistor

IF-09

Rear combination light (RH)

F-IO

I--l

1

Back-up light (RH)

ECS control unit

;I;; >

Body

f’-14

wiring

Rear

F-l 5

Fuel tank

F-1 6

License plate light (RH)

F-l 7

Body

F-18

wiring

Body wiring harness (LH) and body

F-19

F-20 1

wiring harness (RH) combination

motor

speaker

wiring

washer motor

wiring

(RH)

<FWD>

harness (RH) and fuel tank

harness combination

harness (RH) and rear bumper

harness combination

F-i9

1

TSB Revision

F-L8

F-26

F-24

F-21

License plate light (LH)

F-22

Luggage compartment light switch

F-23

Liftgate cylinder lock switch

F-24 Liftgate switch

F-25

Buck-up light (LH)

F-26

Active exhaust control unit

F-27

F-28 } Active aero control unit

F-29 Active exhaust actuator assembly

F-30

Rear combination light (LH)

F-31

Motor antenna control unit

F-32

ECS rear shock absorber (LH)

F-33 Rear

F-34

Body wiring harness (LH) and

F-35 ) wiring harness combination

Remarks

(1)

The mark * shows the standard mounting position of

wiring harness.

(2)

For details concerning the ground point (example: 0 ),

refer to P.6.

F-22

speaker

36FOOll

(LH)

liftgate

’

Page 43

i;

41

CIRCUIT

Active Aero Circuit

Active Exhaust System Circuit

Anti-lock Braking System (ABS) Circuit

Audio Circuit

Auto-cruise Control Circuit

Back-up Light Circuit

Buzzer Circuit

Central Door Locking Circuit

Charging Circuit

Cigarette Lighter Circuit

Cooling Circuit

Defogger Circuit

Dome Light, Foot Light and Ignition Key

Cylinder Illumination Light Circuit

Door Light and Luggage Compartment

Light Circuit

ELC-4

AA

Electronic Control Suspension (ECS) Circuit

Fog Light Circuit

Full Auto

Glove Box Light, Vanity Mirror

Light and Inspection Light Circuit

Headlight Circuit

............................................................................

............................................................................

Circuit

Air Conditioner

.

..............................................................

.....

................................................

....................................

........................................................

............................................................

............................................................................

....................................................

....................................................................

........................................................

............................................................................

................................................................

........................................

........................................................................

........................

....................................................................

................................................

Circuit

........................................

....................................................................

DIAGRAMS

CONTENTS

54-82

54-48

54-80

54-1

54-44

54-46

5441

54-47

54-33

142

1 19

107

125

76

81

16-3

68

I

71

115

91

Heater Circuit

Horn Circuit

How to Read Circuit Diagrams

Ignition Circuit

Indicator Circurt

MPI Circuit

Manual Air Conditioner Circuit

Meter

Power Distribution

Power Seat Circuit

Power Window Circuit

5

Rear

Remote Controlled Mirror Circuit

Starting Circuit

Stop Light Circuit

Supplemental Restraint System

Taillight, Position Light and

License Plate Light Circurt

Tension-reducer Type Seat Belt Circuit

Theft-alarm System Circuit

Turn-signal Light and Hazard Light Circuit

Warning Light Circuit

Windshield Wiper

............................................................................

............................................................................

........................................................................

....................................................................

................................................................................

and Gauges Circuit

Wiper

and

Washer

........................................................................

....................................................................

and Washer Circuit

................................................

................................................

....................................................

....................................................................

....................................................................

............................................................

................................................

Circuit

............................................

(SRS)

Circuit

........................

....................................................

................................

........................................................

........................

............................................................

....................................

M16VE.

54-76

16-25

54-19

54-l

16-l

54-52

5443

54-49

54-l

84

42

52

85

48

133

78

104

106

122

135

137

101

_

3

5

5

i

Page 44

42

CIRCUIT DIAGRAMS

-

How to Read Circuit Diagrams

HOW TO READ CIRCUIT DIAGRAMS

MlGVGAE

The circuit of each system from the fuse (or fusible link) to.ground is shown. The power supply is shown atL.,)

the top (and the ground at the bottom t’o facilitate understanding of how the current flows.

If the same connector is

shown at

tions, the connector is Indicated by fi

tor symbol shown inside.

two or

with

more loca-

connec-

An

“X” at

connector No. indicates

that the connector IS connected to a centralized

junction that is shown in

the section “Centralized

Junction”.

Indicates the operating

conditions of the engine

coolant switch, etc.

Indicates that the diagram

is continued at

next page.

the end of a

on the

v

RESISTOR

m

KXS6-AC-WM-N

L-G

4.,

1.25L-G

I

TSB Revision

indicates shield wire.

I

Page 45

CIRCUIT DIAGRAMS

) Indicates terminal No.

-

How to Read Circuit Diagrams

A broken line indicates

that these connectors

b

are the same intermediate connectors.

I

la-

\

Indicates that the terminal

iS

Indicates input/output to/from

control unit (current

tion).

Indicates harness junction where

Indicates J/B (Junction Block).

Indicates vehicle body ground

point. (Same No. as that of

ground point in GROUNDING

LOCATION)

a

flow

direc-

TSB Revision

I

Page 46

CIRCUIT DIAGRAMS - How to Read Circuit Diaarams

CONNECTOR / GROUNDING INDICATIONS

\

SWITCH(IG1)

RE;

ti

4

______--------.

TOR

7c-1B

I

Ijl

1

II_

I

J

v

$

i:

I

@

GND

I

CONTRC

Q

V

/

UNIT

-@

1

TSB Revision

I

Page 47

CIRCUIT DIAGRAMS

-

How to Read Circuit Diaarams

At the connection with a device, the

connector symbol

on the device side is

,(harness

types are indicated as illustrated.

These are indicatedasillustrated.

connection type). The two

TSB Revision

Page 48

46

SYMBOLS

Devices appearing in circuit diagrams are indicated by the

CIRCUIT DIAGRAMS - H

ow to Read Circuit Diagrams

following symbols.

Battery

11111

--I

biiiiq

Fuse

Fusible

Connector

Thyristor

;link

Female side

+

tvlale

side

Body ground

Equipment

ground

ECU interior

ground

Tl7

Motor

Piezoelectric

device

-im--

Single bulb

Dual bulb

Speaker

Horn

Thermistor

1

@

Resistor

Variable resistor

x 8

Coil

Pulse generator

@

Light emitting

diode

1

Diode

1

t

Zener diode

Transistor

J

-2

I1

Buzzer

2

0

Photo diode

Capacitor

Crossing of wires

without connection

-+

Crossing of wires

with connection

1

Chime

b

0

Photo transistor

16AO252

d

TSB Revision

Page 49

CIRCUIT DIAGRAMS’

WIRE COLOR CODES

Wire colors are identified by the following color codes.

L

Code

Wire color

-

H

ow to Read Circuit Diagrams

Code

47

Wire color

B

BR

G

GR

L

LG

0

NOTE

If a cable has two colors, the first of the two color code characters indicates the basic color (color of the cable coating)

and the second indicates the marking color.

Example: <F>

1.25G -

B

Black

Brown

Green

Gray

Blue

Light green

Orange

P

R

SB

V

W White

Y

-

Pink

Red

Sky blue

Violet

Yellow

-

1660244

Basic color

<F>: Flexible wire

CT>:

Twisted wire

TSB Revision

Page 50

48

CIRCUIT DIAGRAMS

POW:ER DISTRIBUTION

BATTERY

- -

I

q n

-

Power Distribution

ALTERNATi)R

&CATED

-

a

%

mVE

CONTROL

UNIT

r

, 30A

0 0

0

30A

MULTI-PURPOSE

FUSE

0

-iii7

‘I

KSFGER

C-06X

Egs

FUSIBLE LINK

63 @

aOA

&

-1

m

4

2 c-01

vu I\

c1:

w

t-

DEFOGGER

0

30A 40A

cc:

cu

I

0 0

-POWER

K!x~ws

.

mR

.ACTIVE

ECBEE

UNIT

8

C

c

:X35-AC-ROlOl-NY

Y::s:

mm

TSB Revision

Page 51

--

CIRCUIT DIAGRAMS - Power Distribution

i

?

FUSIBLE LINK

0

40A

I,

ALTERNATOR

R8%kiP

%

a

5

.----__

I

:

I

RADIATOR

FAN MOTOR

10 A-36

m

I

%

03

d

c

m

k3

cu

s A

I

,,l

m

I

K?

cu

,,5

\

/\

>

I

6

@

10A

CONDENSER

FAN MOTOR

AIR

CONDITIONER

* pfs t2

,

9 b;TIG;hNG

0

10A

0

COMBINATION

METER(BEAM>

I

L

"

m

65

m

d

I

Co

15A

3

4

cl

3

ti

I

0

I

15A

m

>

\c

t

m

&

I

*HORN

*HORN

RELAY

i%

N

,.

’

+

ENGINE

CONTROL

UNIT

L

xl:VEHICLES

t2:VEHICLES

1

TSB Revision

WITHOUT THEF'T-ALARM SYSTEM

WITH THEFT-ALARM SYSTEM

Page 52

50

DED

FUS:

CIRCUIT DIAGRAMS - Power Distribution

G-W

+

ES;;;

COMBINATION

J/B

dyb;F'NATION

'REAR

COMBINATION

LIGHT

.LICENSE

PLATE LIGHT

.VANITY

ILLUMINATION

LIGHT

*GLOVE

BOX

ILLUMINATION

LIGHT

$I@CTION

-RHEOSTAT

.AIR

CONDITIONER

CONTROL PANEL

*AUDIO

-

3

ti

MULTI-PURPOSE

FUSE

$h$;NATION

-STARTER

RELAY(A/T>

*THEFT-ALARM

T$l&ER

*IGNITION KEY

CYLINDER

MIRROR

LIGHT

jgkZ;EiELT

*SEAT BELT

SOLENOIDlLH)

*ETACS

'@;$$LA~~T POWER RELAY

RELAY

ILLUMINATION

UNIT

*DOOR

*MOTOR ANTENNA

CONTROL UNIT

.ggfA\IGHT

*THEFT-ALARM

HORN RELAY

ppNT-ALARM

i

LOCK

-STARTER

*ENGINE

CONTROL RELAY

-ENGINE

CONTROL UNIT

*f5!5!TDIAGNOSIS

.ENGINE

CONTROL UNIT

*ELC-4A/T

v

*REAR

COMBINATION

LIGHT

CONTROL UNIT

.ETACS

:;;;; k;;;;

*#@I Flh$ED :;;i;Ak;GHT

COiPARTMENT

LIGHT

C~~f&NATION

.AIR

CONTROL UNIT

-AUTO-CRUISE

iHF?R

CONTROL UNIT

-AUDIO

-SEAT

SOLENOID

EbiLE;EENIC

SUSPENSION

CONTROL UNIT

.ACTIVE

CONTROL UNIT

MOTOR

UNIT

CONDITIONER

BELT

(RH)

AERO

KX35-AC-ROIOYA-NY

TSB Revision

Page 53

IGNITION

SWITCH

c-59

::

7

_____--_-_-____----_--------

CIRCUIT DIAGRAMS - Power Distribution

ALTERNATOR

RELAY

m

I

ti

2

------------_

51

*IGNITION COIL

*POWER

TRANSISTOR

-ENGINE

CONTROL RELAY

*ENGINE

CONTROL UNIT

t

CgCX;ANATION

.SPEED

SENSOR

*MOTOR

ANTENNA LIGHT

CONTROL UNIT

.TURN

SIGNAL

AND HAZARD

FLASHER UNIT

.;;$yREEUISE

MAIN SWITCH

.ACTIVE

AERO

CONTROL UNIT

10A

-----

*AIR

BFl;;;R

*AIR CONDITIONEI

*BLOWER

RELAY(HI1

.A.B.

POWER RELAY

.BACK

UP

*TURN

SIGNAL

AND HAZARD

FLASHER UNIT

.&~TDIAGNOSIS

I

%iF;;;NIC

SUSPENSION

CONTROL UNIT

.CONDENSOR

f%lA!oT"R

-

10A

-_-

8

CONDITIONEI

COMPRESSOR

CONTROLLER

LCCI

MOTOR

CONTROL UNIT

MOTOR

S.

&&#fi

UNIT

--.

@

10A

t

.AUDIO

*MOTOR

ANTENNA

CONTROL

*AUTO-CRUISE

CONTROL

*ETACS

UNIT

UNIT

UNIT

*REMOTE

CONTROLLED

MIRROR

'ptf$$E

*WIPER RELAY

*WIPER

MOTOR

-WASHER

-REAR

MOTOR

INTERMITTENT

WIPER RELAY

&XS~ORY

-_

Sl

15A

--

j

TSB Revision

Page 54

52

CIRCUIT DIAGRAMS

MPI CIRCUIT

(Non-Turbo>

J/B

15A

C-83 41 7

p7liRqg

G

ml

piFiR%q]

I

I f

t-.-A---

6

A

1~

1

2> 2--

,rll

0

d

FUSIBLE LINK@

DEDICATED

FUSE

10A

8

1

c-70

rt

E

2 1

1294

Ia

-

MPI Circuit <Non-Turbo>

BA

TT

ERY

-

--

1

z

u

3

r

c

201

I

-0

1

!

c

7

0

d

::

r

STARTER

RELAY

3

----- -r-A=_6_7_

r-i;+

+-

I-

L

A/T

>

w

I

\

WITH ;!JITi;"T

AEE-

IGN

SWI'

t

R

c-31

>

E

ALARM

I

ET)

I

Jy7iiEq

5

I

I

d

>

E

.G

2

-s

M/T A/T

t

$2

cc

I

t?

CL

A

:r

Iv

\r:

!OR

7

5

I

m

d:

-

A/T

%

m

6

25

-18

I

--------

&I ho8

M/T1 A/T

3

I

ENGINE

CONTROI

RELAY

c-44

;2

-

KX35-AC-R01502-NY

I-

-5

ta

TSB Revision

cl

-52

I

I

I

Page 55

L

i

D-04

r

D-03

IN

ITIt

(IGl)

TCH

3

I

??A

7

1r

--SL

\I

7:"

z

d

6

\'I

7

Liz

6

0

7

I

m

.5

77

I

CIRCUIT DIAGRAMS

C-82

J/B

D-44

p7!xsEq

COMBINATION

METER

-

MPI Circuit <Non-Turbo>

r---

53

SPEED SE

(REED SW

I

r-

j

F-14

TSB Revision

Page 56

54

CIRCUIT DIAGRAMS

AIR

FLOW

SENSOR

B-29

i-

4E

SENBOR

I \,

"7 "5

NTAKE AI

MFJERATURE

\/

"6

- MPI

-8

ATMOGPHERIC

)mISOR

Circuit <Non-Turbo>

B

\I \I \I \,

"1 "2 "4

AIR

FLOW

SENSOR

"

CRANK ANGLE

AND TOP DEAD

CENTER SENSOR

km[

B-04 d

ez

$j

3

/\

ENGINE

CONTROL

RELAY

C

m

Y

3

3

nl

d: c

I

c

.----J19

r

I

I

1

I

I

I

I

I

I

I

I

I

I

I

I

I

‘yE

I _

%

cu

s

“F

I2

cu

c

B

2

CL

m&2-

f-r

G

31 ’

1

I

5V

b

1

I

1 ’

; f

I !

; I

’ L--..

I

!

>

CL

0

- ----.-

I

I

I

I

I

3

1

6 >

E h

65

--__-__

1

V

&

5V

I f h

z- 9c:

J g

m

70

--------------------MEL&

\/

"4 "1

ix

Ll

v

- - -~~~I-~E-

\/

"2

3

.ll

V

_

_

CONTROL

UNIT

_

_

_

-

K3l

h/

KX35-AC-RO5Q2A-NY

%

m m

n

AA

= SENSOR

--

d

OXYGEN

c-55

TSB Revision

I

I

I

I

I

I

I

3,

!

J

7

it

1234

!A

I

y

7

Ei

w

7

ON

-

THROTTLE B-05

g~f&goN

~~~

m

ENGINE

COOLANT

~~~~~~ATURE

B-02

@J

d

Page 57

ENGINE

CONTROL

nl7, ,I\>

CIRCUIT DIAGRAMS

-

MPI Circuit <Non-Turbo>

55

jR

YW

I

1

1

6#

,12

1.25R

I

-q&J&g

B-11

I

:,1.252

\

I

SW

I

1

B-33

I

s b-32

I

i

-I

I I I

E2 Ic4_--~~~-~~_-~~~-------~~---

4ikbd

4 -

_.

1

a

INJECTOR

2

-----------------

58

rl

I I

I I

I I

t I

I I

TSB Revision

Page 58

56

--

CIRCUIT DIAGRAMS

J/B

(h!;!$&;RPOSE)

-

MPI Circuit <Non-Turbo>

;f;T,IL$GHT

Iu2ldI-l

I

DEFOG

ncr n\.

mxn i

;GER

f;d;;T

I C

CLUTCH

WITH

#;FiXfJISE d MJ;4XE;UiSE

I

2

,UN&-“l-Y

C-61

%

03

WITHOUT

*

STOP

C-52

.

;E;iCATED

i

11

[r:

h

9;

m

I

0

DIODE

E-31

:8

6 A-67

2?.-.------

d

47

A-36

(Lb

-r

4

-----__--~~~___---~_---

101 c-54

f

----------_

115

T

KX35-AC-I0502B-NY

--

AIR

E;/yRzlONER

UNIT

TSB Revision

POWER

3

f

J

TRANSISTOR

!z

.L

7

ENG I NE

COOLANT

#;EBATURE

(FOR AIR

CONDITIONER)

\

tLJ

--

~

Page 59

CIRCUIT DIAGRAMS

ENGINE

CONTROL

RELAY

-

MPI Circuit <Non-Turbo>

-4A/T (

NTROL

IT

I

-

57

------------------

/@

107

B-06

2

3

I

--------

? ----

I

--------------

5v

A

Q

5v

i

E

59

i

1E-----

ENGINE

CONTROL

UNIT

B-38

r

1

TSB Revision

Page 60

58.

---.

MPI CIRCUIT

(TU~ILIO)

CIRCUIT DIAGRAMS

FUSIBLE LINK@

-

MPI Circuit <Turbo>

BATTERY

I

zl

E

J/.8

m

d?

TED

0

r

4-l

3 A-67

3

::

I

:

<

4

\$

:

D-15

/2l%@lq

--

m

-

f

I

a

X35-AC-RO503-NY

i?

0

r

I

71

9

,

;

c

)

77

1

1

ENGINE

CONTROI

RELAY

c-44

OFF--ON

\/ \,

cr"4

"5

5c 12

---

1?

I

$

.G

II:

1

E

%

cu

c,

B

&l

m

&

:

5

5

c

h

z

:

Y

"8

7

Ll

208

m

\/

"E

C

\I \I

,

“7

ON*-OFF

\I

-?2

‘L

0

-5

-5

c3

El

-52

TSB Revision

Page 61

CIRCUIT DIAGRAMS

-

MPI Circuit <Turbo>

59

i

L

i

@

IGNITION

SWITCH(IG1)

5

I

E

7

C-82

J/B

of;

I

-----+d-71

P-44

3

I

t;

!

J

IT

d:

,

‘

E;uEkNATION

D-09

[ml

AL

\/

r

7

1

*9

I

SPI

SEE

-

ID

10R

-

I

ENGINE

CONTROL

RELAY

fj;%k -

RELAY

B-28

7

5

cl

!

E

@

v-

%kPUMP

CONNECTOR h

. FUEL

: RESISTOR

I

9 c-34

J

pTim$q

cu

c ,6

[--+

/ Y

; L%

I

c-d

I

-

I

1

FUEL

PUMP

I

I

f2

I cu

I .

I

’ c,,5

L--

El?

CL.

v-

,\

(I

F-14

PUMP

A-51

06

---------__--

1

______

.

.ll

..-

#

2

TSB Revision

i524

56

-a

!l

7

ENGINE

CONTROL 1

UNIT

4

-Q

q

Page 62

60

CIRCUIT DIAGRAMS

E

AIR

FLOW

SENSOR

B-29

-

MPI Circuit <Turbo>

B

AIR

FLOW

SENSOR

CRANK ANGLE

AND TOP DEAD

CENTER SENSOR m

4-1 B-04 '

3

$

I\

L

L

ENGINE

CONTROL RELAY

\I ,,

"7 "5

7:

Qi

s

\/ \/ ,L

"6 “1

;I

h.

I

B

’ L--

I

I

I

>

&

0

I

I

f

"

2 4 3

is

m

I

6 >;

.-.I

E

:I”

I

p'

---

34

72

ii? OL

cu

- L

c

---

.-----------

67 63

a

”

7

>

i

I

----------------

v

ENGINE

tETRoL

B

----_--

------

@

Xx35-AC-R0503A-NY

TSB Revision

1 1.

m

vz

&

l

CIJ

m A

,ENGINE

,

Ld

COOLANT

FE/M&ATURE

B-02

m

Page 63

0.85R

0.85R

ENGINE

CONTROL

RELAY

B

1.25R

CIRCUIT DIAGRAMS -

&

&

.MPI

Circuit <Turbo>

INJECTOR ;

I

..

&

61

RESISTOR

;

55

-------------------------

sj

i--,

.---

l&,7 -JO

-- ---

.---

1 iI

6

I

----,

Sk1

4

’

I

G3

21

OXYGEN

SE%lR(RH,

ml

I

1

I

A

I

I

8

/

592

2 2

w

I

7

m

.

>

2

m m

d d

II

.lI

-I

m

I

m