Mitsubishi Electric Industrial Robot

BFP-A3526-A

CR800-D series controller

Network Base Card

Instruction Manual

2F-DQ535

Safety Precautions

Always read the following precautions and the separate "Safety

Manual" before starting use of the robot to learn the required

measures to be taken.

CAUTION All teaching work must be carried out by an operator who has received special

training.

(This also applies to maintenance work with the power source turned ON.)

→Enforcement of safety training

CAUTION For teaching work, prepare a work plan related to the methods and procedures

of operating the robot, and to the measures to be taken when an error occurs

or when restarting. Carry out work following this plan.

(This also applies to maintenance work with the power source turned ON.)

→Preparation of work plan

WARNING Prepare a device that allows operation to be stopped immediately during

teaching work.

(This also applies to maintenance work with the power source turned ON.)

→Setting of emergency stop switch

CAUTION During teaching work, place a sign indicating that teaching work is in progress

on the start switch, etc.

(This also applies to maintenance work with the power source turned ON.)

→Indication of teaching work in progress

DANGER Provide a fence or enclosure during operation to prevent contact of the operator

and robot.

→Installation of safety fence

CAUTION Establish a set signaling method to the related operators for starting work,

and follow this method.

→Signaling of operation start

CAUTION As a principle turn the power OFF during maintenance work. Place a sign

indicating that maintenance work is in progress on the start switch, etc.

→Indication of maintenance work in progress

CAUTION Before starting work, inspect the robot, emergency stop switch and other

related devices, etc., and confirm that there are no errors.

→Inspection before starting work

The points of the precautions given in the separate "Safety Manual" are given below.

Refer to the actual "Safety Manual" for details.

DANGER When automatic operation of the robot is performed using multiple control

devices (GOT, programmable controller, push-button switch), the interlocking

of operation rights of the devices, etc. must be designed by the customer.

CAUTION Use the robot within the environment given in the specifications. Failure to do

so could lead to faults or a drop of reliability.

(Temperature, humidity, atmosphere, noise environment, etc.)

CAUTION Transport the robot with the designated transportation posture. Transporting

the robot in a non-designated posture could lead to personal injuries or faults

from dropping.

CAUTION Always use the robot installed on a secure table. Use in an instable posture

could lead to positional deviation and vibration.

CAUTION Wire the cable as far away from noise sources as possible. If placed near a

noise source, positional deviation or malfunction could occur.

CAUTION Do not apply excessive force on the connector or excessively bend the cable.

Failure to observe this could lead to contact defects or wire breakage.

CAUTION Make sure that the workpiece weight, including the hand, does not exceed the

rated load or tolerable torque. Exceeding these values could lead to alarms or

faults.

WARNING Securely install the hand and tool, and securely grasp the workpiece. Failure to

observe this could lead to personal injuries or damage if the object comes off or

flies off during operation.

WARNING Securely ground the robot and controller. Failure to observe this could lead to

malfunctioning by noise or to electric shock accidents.

CAUTION Indicate the operation state during robot operation. Failure to indicate the state

could lead to operators approaching the robot or to incorrect operation.

WARNING When carrying out teaching work in the robot's movement range, always secure

the priority right for the robot control. Failure to observe this could lead to

personal injuries or damage if the robot is started with external commands.

CAUTION Keep the jog speed as low as possible, and always watch the robot. Failure to do

so could lead to interference with the workpiece or peripheral devices.

CAUTION After editing the program, always confirm the operation with step operation before

starting automatic operation. Failure to do so could lead to interference with

peripheral devices because of programming mistakes, etc.

CAUTION Make sure that if the safety fence entrance door is opened during automatic

operation, the door is locked or that the robot will automatically stop. Failure to do

so could lead to personal injuries.

CAUTION Never carry out modifications based on personal judgments, non-designated

maintenance parts. Failure to observe this could lead to faults or failures.

WARNING When the robot arm has to be moved by hand from an external area, do not place

hands or fingers in the openings. Failure to observe this could lead to hands or

fingers catching depending on the posture.

CAUTION Do not stop the robot or apply emergency stop by turning the robot controller's

main power OFF. If the robot controller main power is turned OFF during automatic

operation, the robot accuracy could be adversely affected. Also a dropped or

coasted robot arm could collide with peripheral devices.

CAUTION Do not turn OFF the robot controller's main power while rewriting the robot

controller's internal information, such as a program and parameter. Turning OFF

the robot controller's main power during automatic operation or program/parameter

writing could break the internal information of the robot controller.

DANGER Do not connect the Handy GOT when using the GOT direct connection function of

this product. Failure to observe this may result in property damage or bodily injury

because the Handy GOT can automatically operate the robot regardless of whether

the operation rights are enabled or not.

DANGER Do not connect the Handy GOT to a programmable controller when using an iQ

Platform compatible product with the CR800-R/CR800-Q controller. Failure to

observe this may result in property damage or bodily injury because the Handy GOT

can automatically operate the robot regardless of whether the operation rights are

enabled or not.

DANGER Do not remove the SSCNET III cable while power is supplied to the multiple CPU

system or the servo amplifier. Do not look directly at light emitted from the tip of

SSCNET III connectors or SSCNET III cables of the Motion CPU or the servo

amplifier. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

DANGER Do not remove the SSCNET III cable while power is supplied to the controller.

Do not look directly at light emitted from the tip of SSCNET III connectors or

SSCNET III cables. Eye discomfort may be felt if exposed to the light.

(Reference: SSCNET III employs a Class 1 or equivalent light source as

specified in JIS C 6802 and IEC60825-1 (domestic standards in Japan).)

DANGER Attach the cap to the SSCNET III connector after disconnecting the SSCNET III cable.

If the cap is not attached, dirt or dust may adhere to the connector pins, resulting in

deterioration connector properties, and leading to malfunction.

CAUTION Make sure there are no mistakes in the wiring. Connecting differently to the way

specified in the manual can result in errors, such as the emergency stop not

being released. In order to prevent errors occurring, please be sure to check

that all functions (such as the teaching box emergency stop, customer

emergency stop, and door switch) are working properly after the wiring setup

is completed.

CAUTION Use the network equipments (personal computer, USB hub, LAN hub, etc)

confirmed by manufacturer. The thing unsuitable for the FA environment

(related with conformity, temperature or noise) exists in the equipments connected

to USB. When using network equipment, measures against the noise, such as

measures against EMI and the addition of the ferrite core, may be necessary.

Please fully confirm the operation by customer. Guarantee and maintenance

of the equipment on the market (usual office automation equipment) cannot

be performed.

CAUTION To maintain the safety of the robot system against unauthorized access from external

devices via the network, take appropriate measures. To maintain the safety against

unauthorized access via the Internet, take measures such as installing a firewall.

Print date

Instruction manual No.

Revision content

2017-05-31

BFP-A3526

First print

2018-02-01

BFP-A3526-A

Safety Precautions was revised. (The CR800-Q controller

was added.)

■ Revision History

・

Precaution indicating cases where there is a risk of operator fatality or

safely use the robot.

Precaution indicating cases where the operator could be subject to fatalities

safely use the robot.

Precaution indicating cases where operator could be subject to injury or

precautions to safely use the robot.

Introduction

Thank you for purchasing Mitsubishi Electric industrial robot.

This instruction manual explains network base card (2F-DQ535) option.

The network base card is an option which realizes various communication interfaces

when the HMS Anybus-CompactCom module is mounted on the card.

The mountable modules are listed in Chapter 3.2 for reference.

Always read this manual thoroughly and understand the contents before starting use of

the network base card (2F-DQ535).

The information contained in this document has been written to be accurate as much as

possible. Please interpret that items not described in this document "cannot be

performed."

Note that this instruction manual has been prepared for use by operators who

understand the basic operations and functions of the Mitsubishi industrial robot.

Refer to the separate "Instruction Manual, Detailed Explanation of Functions and

Operations" for details on basic operations.

*Symbols in instruction manual

DANGER

WARNING

CAUTION

serious injury if handling is mistaken. Always observe these precautions to

or serious injuries if handling is mistaken. Always observe these precautions to

physical damage could occur if handling is mistaken. Always observe these

・ No part of this document may be reproduced without express permission of

Mitsubishi Electric Corporation.

・ Please note that the information in this manual is subject to change without notice in

the future.

・ The specification values in this manual are obtained with the Mitsubishi standard test

method.

・ Although this manual has been prepared to contain accurate information, please

contact us if you find any errors or have questions.

・ The product names used in this manual are trademarks or registered trademarks of

respective owners.

・ In the body text of this manual, ® and TM marks are omitted.

Copyright© 2017-2018 MITSUBISHI ELECTRIC CORPORATION ALL RIGHTS RESERVED

CONTENTS

1. BEFORE USE ................................................................................................................ 1-1

1.1. Terminology .............................................................................................................. 1-1

1.2. How to Use the Instruction Manual ........................................................................... 1-2

2. FLOW OF OPERATIONS............................................................................................... 2-3

2.1. Work Procedures ...................................................................................................... 2-3

3. FEATURES OF NETWORK BASE CARD (2F-DQ535) ................................................. 3-4

3.1. What is a Network Base Card? ................................................................................. 3-4

3.2. Mountable Modules................................................................................................... 3-4

3.3. Features when Module is Mounted ........................................................................... 3-5

3.3.1. Features when CC-Link IE Field module is mounted .......................................... 3-5

3.4. Hardware of the 2F-DQ535 Card .............................................................................. 3-6

3.4.1. Card overview ..................................................................................................... 3-6

3.4.2. LED ..................................................................................................................... 3-6

3.5. Software configuration .............................................................................................. 3-8

3.5.1. For the CC-Link IE Field module ......................................................................... 3-8

4. CC-LINK IE FIELD MODULE AND 2F-DQ535 CARD SPECIFICATIONS .................... 4-9

4.1. Specifications list ...................................................................................................... 4-9

4.2. List of robot parameters .......................................................................................... 4-10

4.3. Robot controller I/O signals ..................................................................................... 4-11

4.3.1. I/O signal number map (CC-Link IE Field) ...................................................... 4-12

4.3.2. I/O register number map (CC-Link IE Field) ................................................... 4-13

4.3.3. Flow of I/O signal .............................................................................................. 4-14

4.3.4. Deducated Input/Output .................................................................................... 4-14

4.3.5. Output signal Reset pattern .............................................................................. 4-15

4.3.6. Specifications related to Robot language .......................................................... 4-16

5. ITEMS TO BE CHECKED BEFORE USING THIS PRODUCT .................................... 5-18

5.1. Checking the Product .............................................................................................. 5-18

5.2. Devices to be Prepared by the Customer ............................................................... 5-19

5.2.1. For the CC-Link IE Field module ....................................................................... 5-19

6. HARDWARE SETTINGS ............................................................................................. 6-20

6.1. Module Mounting Procedures ................................................................................. 6-20

6.2. Setting the 2F-DQ535 Card Hardware .................................................................... 6-22

7. CONNECTIONS AND WIRING .................................................................................... 7-23

7.1. Mounting 2F-DQ535 Card onto Robot Controller .................................................... 7-23

7.1.1. CR800-D controller ........................................................................................... 7-23

7.2. Wiring ...................................................................................................................... 7-24

7.2.1. For the CC-Link IE Field module ....................................................................... 7-24

8. PROCEDURES FOR STARTING OPERATION .......................................................... 8-26

8.1. Setting the Parameters ........................................................................................... 8-27

8.1.1. For the CC-Link IE Field module ....................................................................... 8-27

8.2. Checking the I/O Signals ........................................................................................ 8-33

8.2.1. For the CC-Link IE Field module ....................................................................... 8-33

8.3. Execution of robot program ..................................................................................... 8-36

8.3.1. Setting the dedicated input/output ..................................................................... 8-36

8.3.2. General-purpose input/output............................................................................ 8-36

8.3.3. Example of robot program creation (using general-purpose input/output) ........ 8-37

8.3.4. Sample program for input/output confirmation .................................................. 8-38

9. TROUBLESHOOTING ................................................................................................. 9-39

9.1. List of Errors ........................................................................................................... 9-39

10. APPENDIX ................................................................................................................. 10-41

10.1. Displaying the Option Card Information .......................................................... 10-41

10.1.1. For the EtherNet/IP module ........................................................................... 10-42

10.2. Pseudo-input Function .................................................................................... 10-43

1 Before Use

Term

Explanation

CC-Link IE Field

CC-Link IE Field Network is an all-around field network based on Gigabit

(as of April 2016).

1. Before Use

This chapter describes items to be checked and precautions to be taken before start using the network

base card (2F-DQ535).

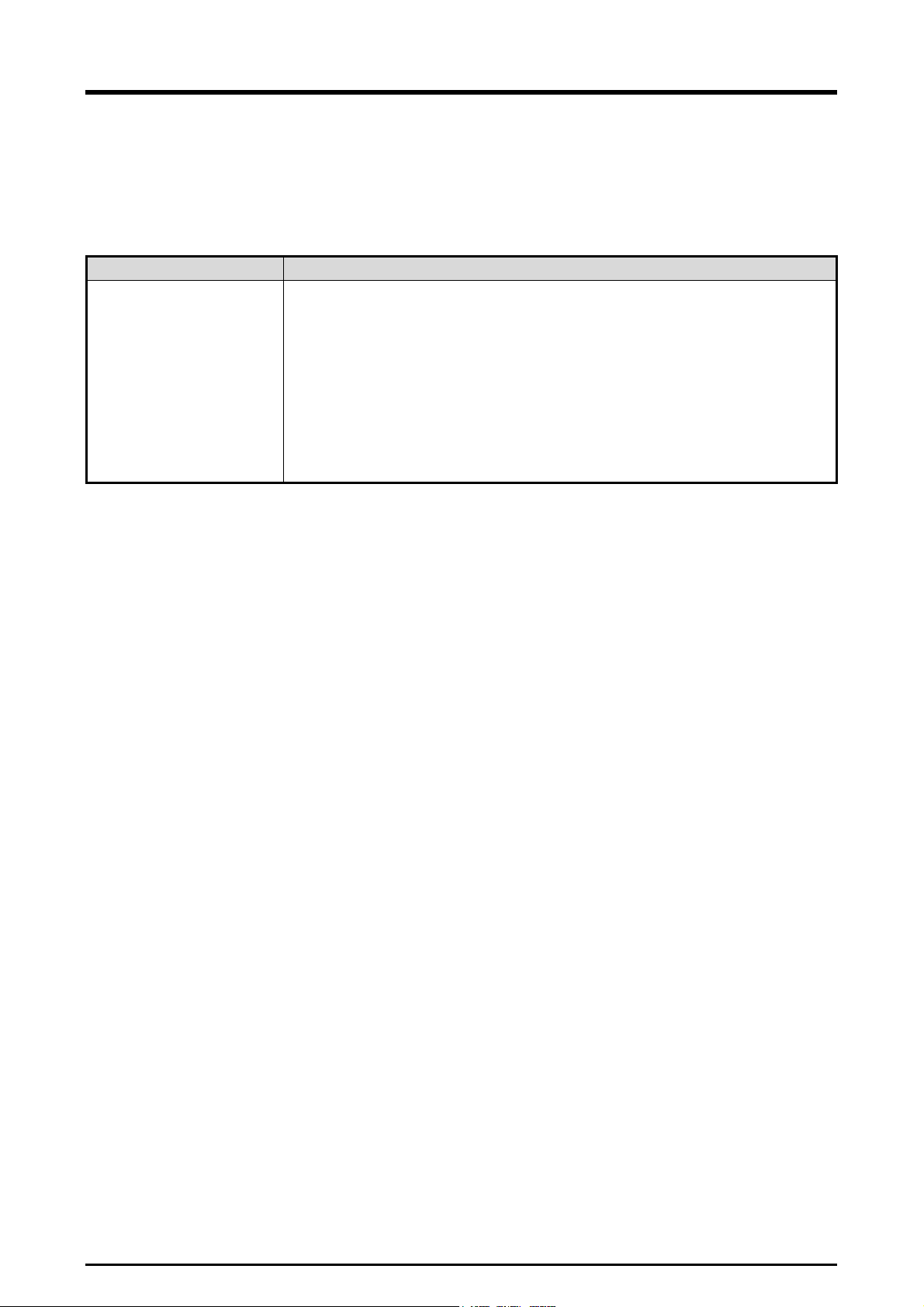

1.1. Terminology

Table 1-1 Terminology

Ethernet that integrates the controller-distributed control, I/O control, safety

control, and motion control. It enables flexible wiring with the topology such as

star, line, or ring depending on the production line or the layout of equipment

or devices.

This robot controller can communicate with the master station as a slave

station (intelligent device station) in CC-Link IE Field Network using I/O signals

(bit device) or periodic communication (cyclic transmission) of I/O registers

(word device).

* Non-periodic communication (transient transmission) is not supported

Terminology 1-1

1 Before Use

Chapter

Title

Description

1

Before Use

Chapter 1 describes how to use this manual (Network Base Card

use the 2F-DQ535 card.

2

Flow of Operations

Chapter 2 describes the operations required to configure a network

system. Make sure to perform all of the required operations.

3

Features of Network Base

Card (2F-DQ535)

Chapter 3 describes the features of the DQ535 card and for

mounting the module.

4

2F-DQ535 Card and

Specifications

Chapter 4 describes the specifications of the DQ535 card.

5

Items to Be Checked Before

Using This Product

Before purchasing the DQ535 card, check the required devices

and the version of the robot controller.

6

Hardware Settings

This product has no hardware settings.

7

Connections and Wiring

Chapter 7 describes how to connect the DQ535 card and the

master station using cables.

8

Procedures for Starting

Operation

Chapter 8 describes the procedures up to operating the network

system with the module mounted.

9

Troubleshooting

Chapter 9 describes how to resolve problems that may occur when

refer to this chapter as needed.

10

Appendix

Chapter 10 describes the methods of displaying the DQ535 card

information with RT ToolBox3.

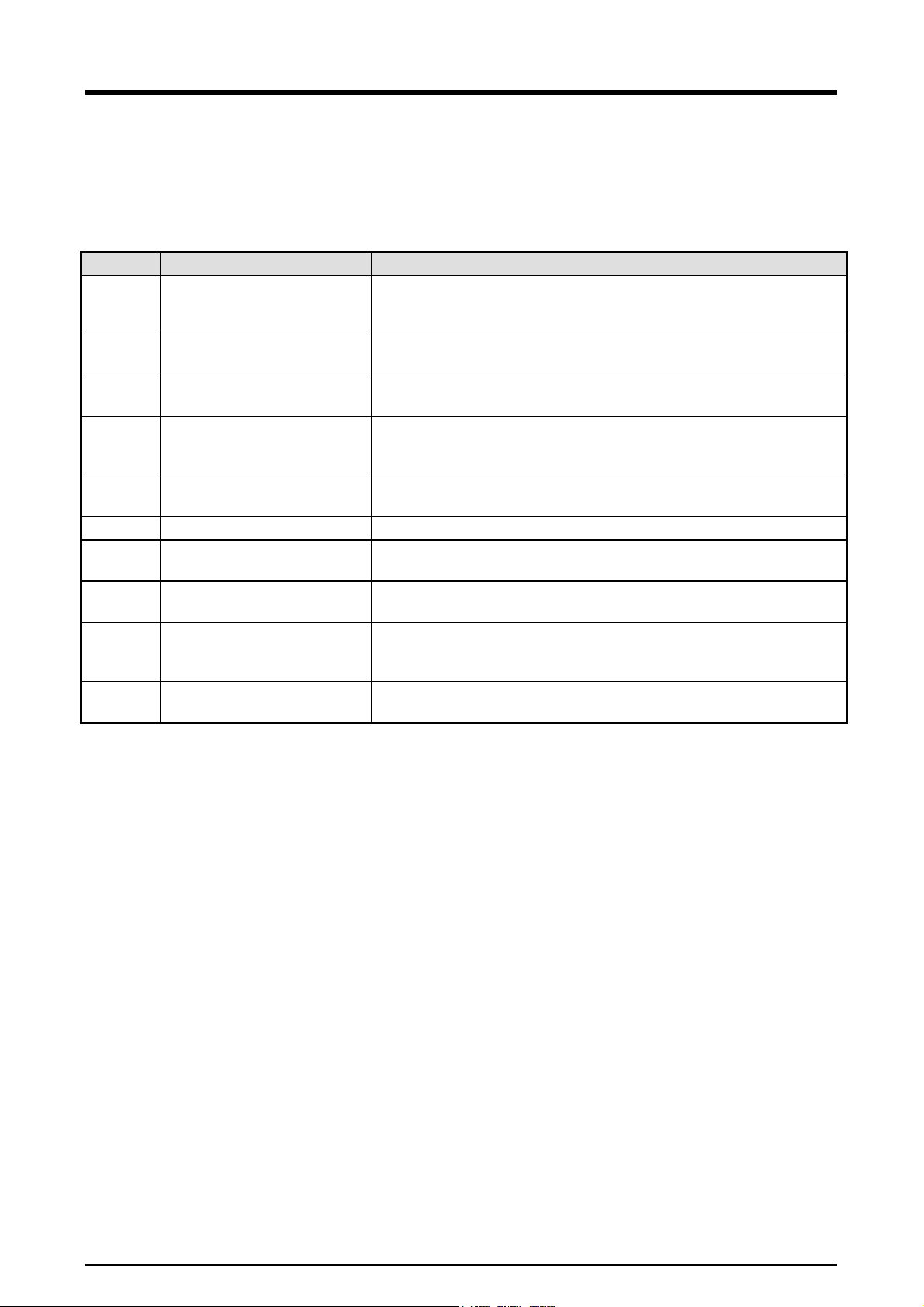

1.2. How to Use the Instruction Manual

This manual is organized as follows and describes functions of the 2F-DQ535 card. For information about

the functions provided for standard robot controllers and how to operate them, refer to the instruction

manual that comes with the robot controller.

Table 1-2

Ethernet/IP Module

Contents of the instruction manual

Instruction Manual). Please read here before actually starting to

using the DQ535 card, such as malfunctions and errors. Please

1-2 How to Use the Instruction Manual

2 Flow of operations

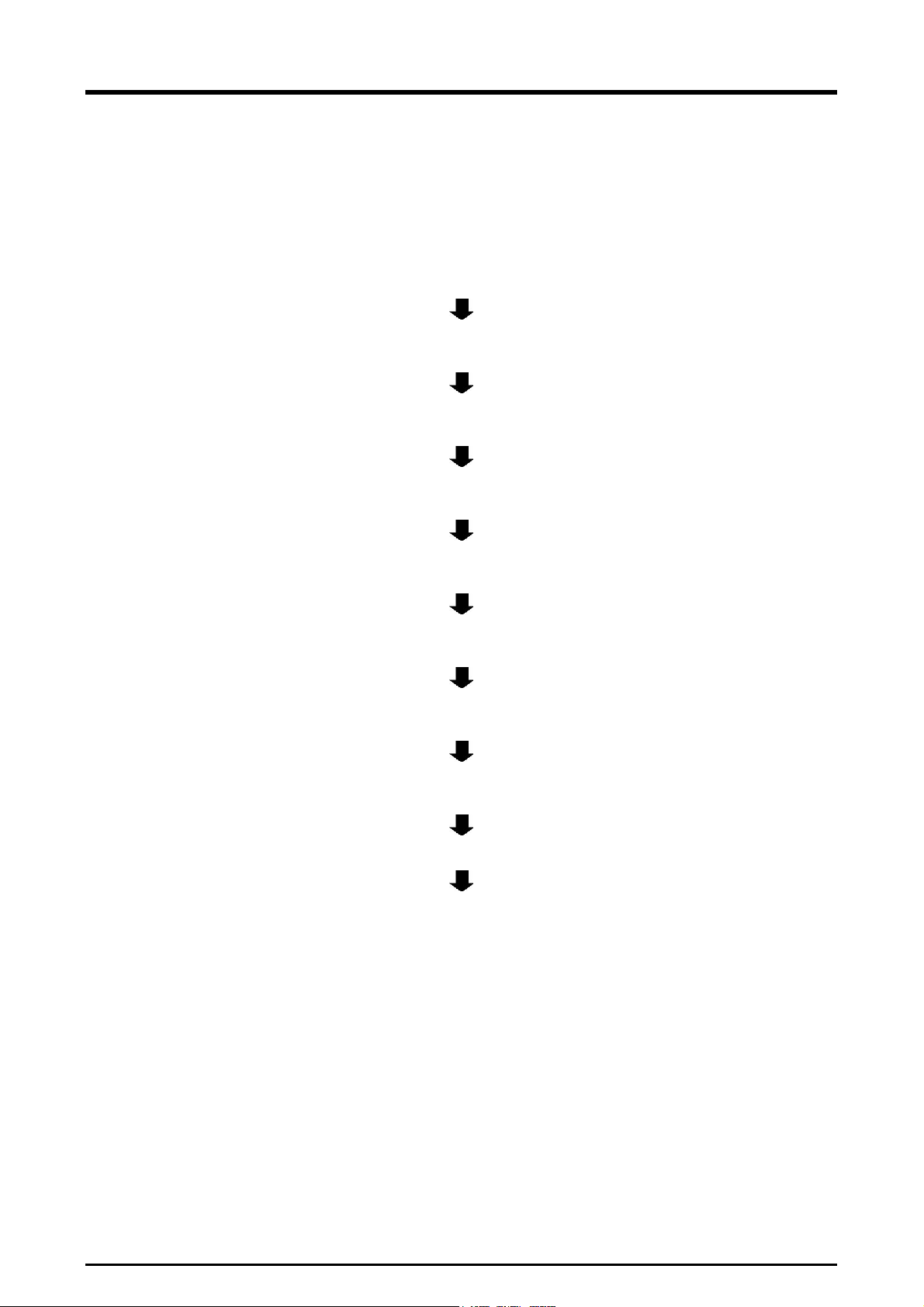

2. Flow of operations

The flowchart below shows the flow of operations necessary for configuring a network base card system.

Use it as a reference to perform the required operations without any excess or deficiency.

2.1. Work Procedures

1 Determining the Network Specifications ......................................... See Chapters 3 and 4 of this manual.

With an understanding of the network base card and communication module specifications, determine the

interface related to the system signals using the communication module. (For example, assignment of

dedicated I/O signals, specification of general-purpose I/O signals).

2 Checking Products ........................................................................... See Chapter 5 of this manual.

Check the product you have purchased and prepare other products as needed.

3 Mounting Module onto Network Base Card ............................. See Section 6.1 of this manual.

Mount the communication module onto 2F-DQ535.

4 Setting Hardware and Mounting onto Robot Controller ........... See Section 6.2 of this manual.

The 2F-DQ535 hardware has no settings, so mount the 2F-DQ535 onto the robot controller as it is.

5 Wiring and Connections ................................................................... See Chapter 7 of this manual.

Wire the 2F-DQ535 card mounted on the robot controller to the master station using an Ethernet cable.

6 Setting Master Station Parameters .................................................. See Chapter 8 of this manual.

Set the IP address with the master station.

7 Setting Robot Controller Parameters ............................................... See Chapter 8 of this manual.

Set the IP address on the robot controller side.

8 Creating Robot Programs ................................................................ See Section 8.3 of this manual.

Create a robot program, and run it with automatic operation.

9 Troubleshooting ............................................................................... See Chapter 9 of this manual.

10 Completion of Operations

Work Procedures 2-3

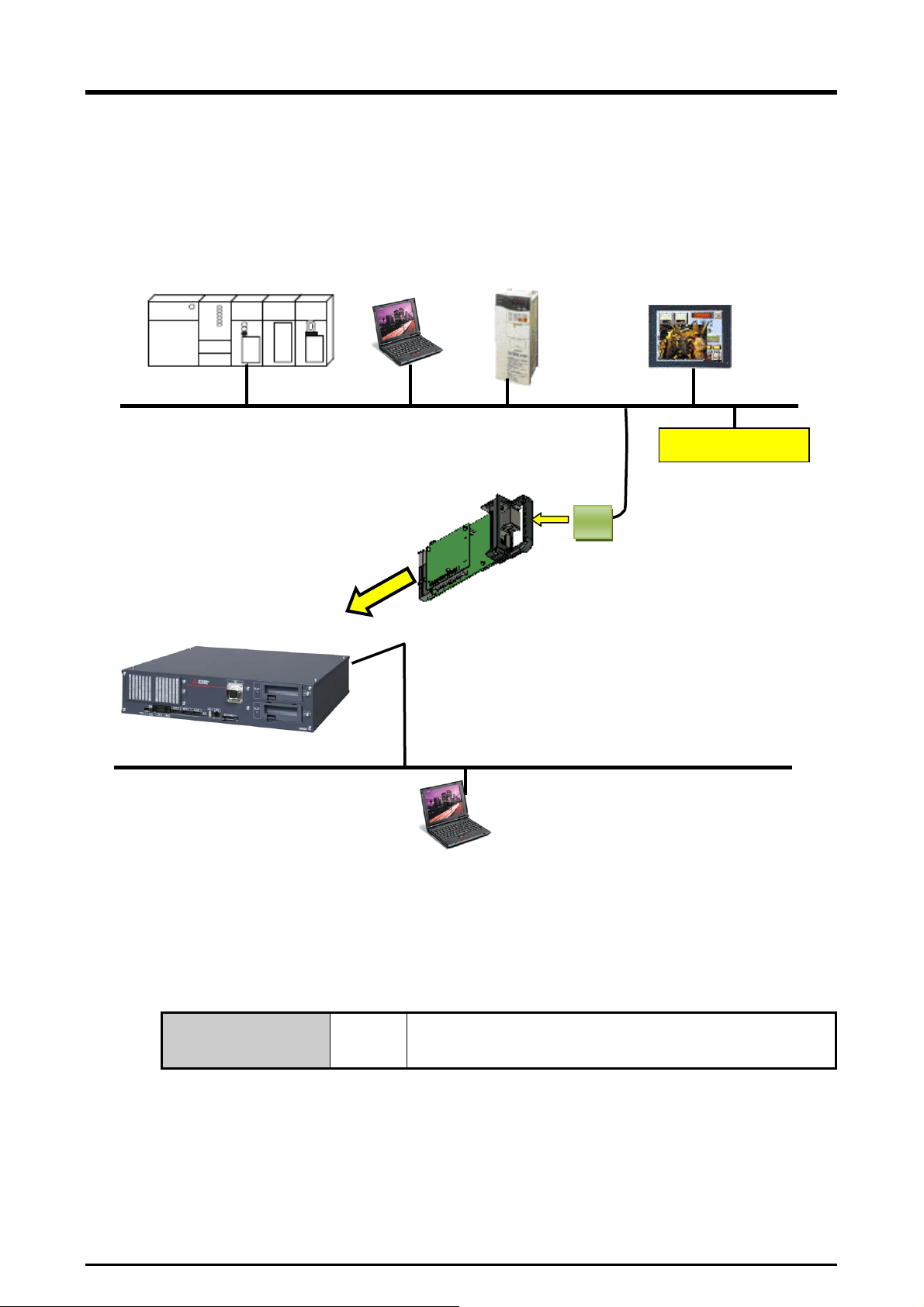

3 Features of Network Base Card (2F-DQ535)

PLC

Inverter

Equipment by partner

manufacturer

Personal

computer

Network base card

Touch panel

Various communication lines

Ethernet

Personal

(RT ToolBox

Anybus-ComPactCom

CR800-D series

3. Features of Network Base Card (2F-DQ535)

3.1. What is a Network Base Card?

The network base card is an optional card for the robot controller.

By mounting a HMS's Anybus-CompactCom module on the card, various communication interfaces can

be realized.

controller

(Prepared by user)

module

(2F-DQ535)

Mountable to the

option slot 2

(Up to one card)

computer

3, etc.)

Figure 3-1 Example of configuring CC-Link IE Field with network base card

3.2. Mountable Modules

The modules which can be mounted on the network base card (2F-DQ535) are shown below.

Mountable module

3-4 What is a Network Base Card?

CC-Link IE Field module (AB6709)

3 Features of Network Base Card (2F-DQ535)

CC-Link IE

module

Standard

interface

Handling of data using I/O signals and

above.

Communication

with RT3

Communication with RT ToolBox3 by

Ethernet

Communication with other devices, such

as a network vision sensor, by Ethernet

Real-time

external control

Robot control from a personal computer,

etc.

Only cyclic transmission is supported. Transient transmission is not

CAUTION

3.3. Features when Module is Mounted

CC-Link IE Field

3.3.1. Features when CC-Link IE Field module is mounted

The following features are enabled when the CC-Link IE Field module is mounted on the 2F-DQ535 card.

(1) Connection

Connection to CC-Link IE Field Network is enabled.

CC-Link IE Field Network is an all-around field network based on Gigabit Ethernet that integrates the

controller-distributed control, I/O control, safety control, and motion control.

It enables flexible wiring with the topology such as star, line, or ring depending on the production line

or the layout of equipment or devices.

(2) Transmission style

IEE 802.3ab (1000BASE-T) Ethernet standard compatible, shielded twisted pair cable (Category 5e),

RJ-45 connector

(3) Data

Maximum 256-byte data communication using the real-time I/O signals (bit devices) and maximum

512-byte data communication using I/O registers (word devices) are available. The allocation can be

set with parameters described later.

Example 1) 128 bits (16 bytes) for input signals, 64 words (128 bytes) for input registers, 144 bytes in

total

128 bits (16 bytes) for output signals, 64 words (128 bytes) for output registers, 144 bytes

in total

Example 2) 2048 bits (256 bytes) for input signals, 0 words (0 bytes) for input registers, 256 bytes in

total

2048 bits (256 bytes) for output signals, 0 words (0 bytes) for output registers, 256 bytes

in total

(4) The table below shows differences of the functions available when the CC-link IE Field module is used

and those available with the standard Ethernet interface of the robot controller.

No. Function name Explanation

1 General-purpose I/O signal

2

TCP/IP

3 Data link

communication

4

I/O registers by Ethernet.

*For details of the data, refer to (3)

supported.

Although two types of transmission, cyclic transmission (periodic) and transient

transmission (non-periodic), are possible, this controller does not support the transient

transmission (as of April 2017).

Field

−

−

−

Ethernet

−

Features when Module is Mounted 3-5

3 Features of Network Base Card (2F-DQ535)

(Prepared by user)

(Red)

(Green)

Status

(Red) (Green)

Status

(Green)

Activity

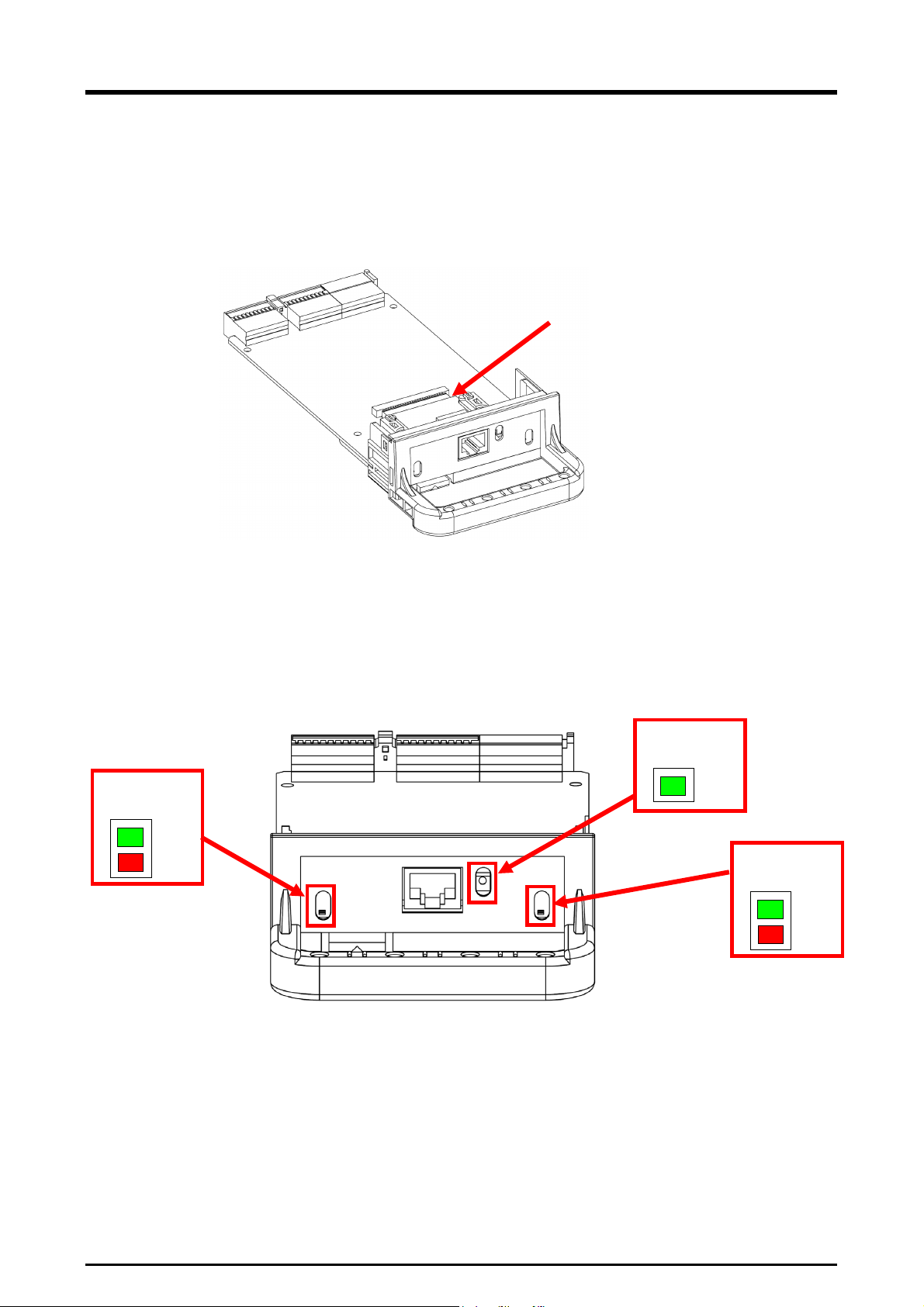

3.4. Hardware of the 2F-DQ535 Card

The 2F-DQ535 card hardware is explained in this section. An Anybus-CC module is mounted on the

network base card.

3.4.1. Card overview

Anybus-CC module

Figure 3-2 Overall view of 2F-DQ535 card

3.4.2. LED

There are three LEDs on the 2F-DQ535 card, and the operating state of the interface card can be

confirmed by each on/off.

* The shape and specifications of the Anybus-CC module vary depending on its type. (The following

figure shows an example of a CC-Link IE Field module.)

Network

LINK/

Module

3-6 Hardware of the 2F-DQ535 Card

Figure 3-3 Layout of LEDs

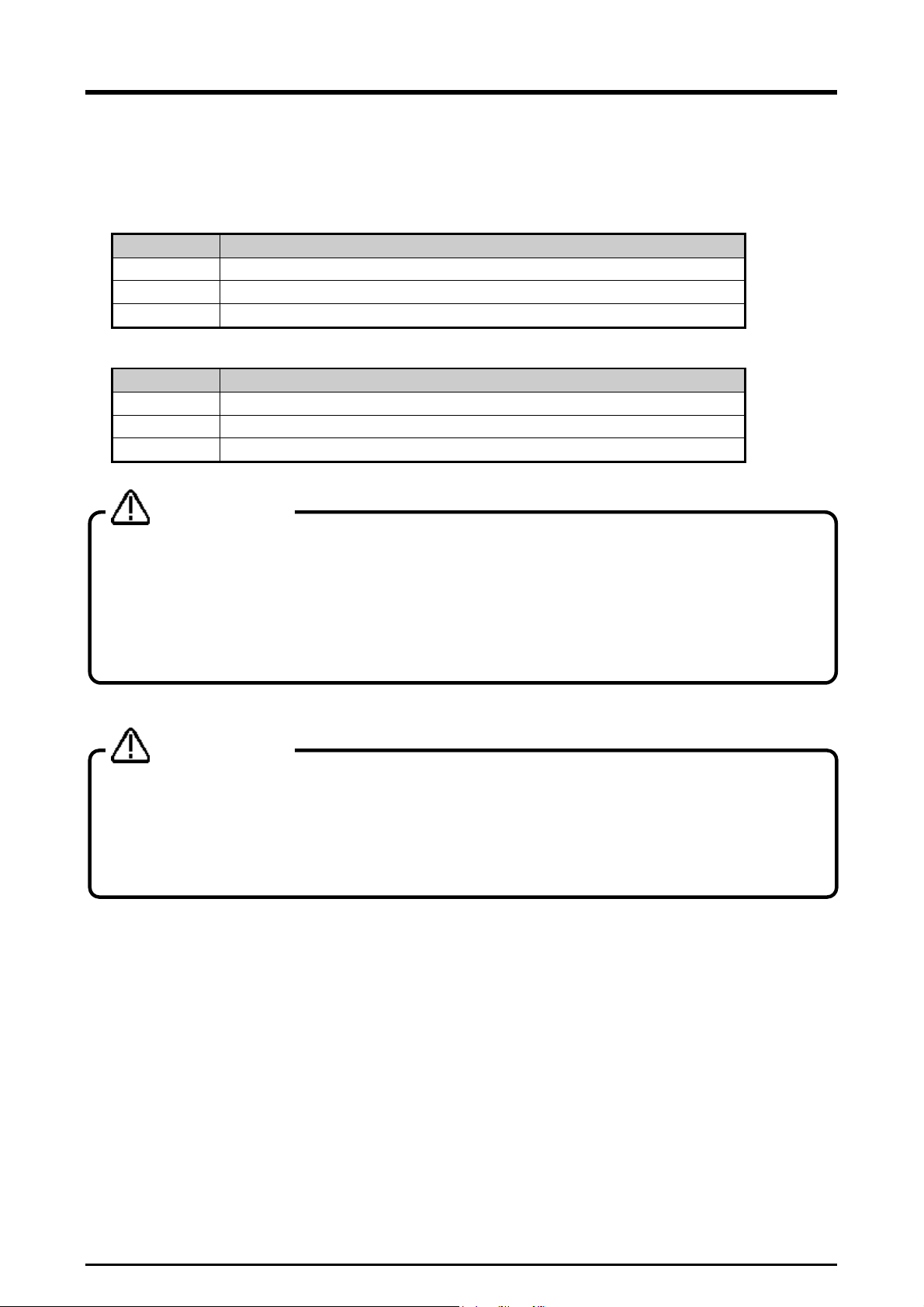

LED status

Details

Off

Power is not ON, or there is no IP address.

Green (on)

Online with one or more connection established (CIP Class 1 or 3).

Red (on)

IP address duplicate, FATAL error.

LED status

Details

Off

Power is not ON.

Green (on)

Controlling with RUN state scanner.

Red (on)

Serious error (EXCEPTION state, FATAL error, etc.).

It takes some time for the communication line to be established after the cable is

CAUTION

It takes some time for the communication line to be established after the robot

CAUTION

The meaning of each LED on, flash and off state is shown below.

Please confirm specifications of the HMS Co. about details.

Table 3-1

Details of Network Status LED

Details of Module Status LED

Description of LED

3 Features of Network Base Card (2F-DQ535)

controller power is turned ON.

It takes about one minute for the communication line to be established (for the Network Status LED to

turn on) after the robot controller power is turned ON. If automatic operation is started immediately

after turning the power ON, L6130 (network communication error) will occur. Wait for a short time

before starting automatic operation.

connected.

It takes about one minute for the communication line to be established (for the Network Status LED to

turn on) after the cable is connected to the Anybus-CC module on the DQ535 card.

Hardware of the 2F-DQ535 Card 3-7

Loading...

Loading...