Page 1

A975GOT-TBA/TBD(-B

)

)

A970GOT-TBA/TBD(-B

A970GOT-SBA/SBD

A970GOT-LBA/LBD

A960GOT-EBA/EBD

User’s Manual

(Hardware)

Thank you for buying the MELSEC-GOT Series.

Prior to use, please read both this manual and detailed manual

thoroughly and familiarize yourself with the product.

MODEL A900GOT-U-JE

MODEL

1DM100

CODE

IB(NA)-80032-H(0512)MEE

Mitsubishi Graphic Operation Terminal

Page 2

A

z SAFETY PRECAUTIONS z

(Read these precautions before using.)

When using this equipment, thoroughly read this manual. Also pay careful

attention to safety and handle the module properly.

These precautions apply only to this equipment.

Refer to the user’s manual of the CPU module to use for a description of the

PLC system safety precautions.

These "Safety Precautions" classify the safety precautions into two categories:

"DANGER" and "CAUTION".

Procedures which may lead to a dangerous condition and

DANGER

CAUTION

cause death or serious injury, if not carried out properly.

Procedures which may lead to a dangerous condition and

cause superficial to medium injury, or physical damage

only, if not carried out properly.

Depending on circumstances, procedures indicated by

be linked to serious results.

In any case, it is important to follow the directions for usage.

Store this manual in a safe place so that you can take it out and read it

whenever necessary. Always forward it to the end user.

CAUTION

may also

[DESIGN PRECAUTIONS]

DANGER

z Some failures of the GOT main unit, communication module,

communication board or cable may keep the outputs on or off.

An external monitoring circuit should be provided to check for output

signals which may lead to a serious accident.

Not doing so can cause an accident due to false output or malfunction.

z If a communication fault (including cable disconnection) occurs during

monitoring on the GOT, communication between the GOT and PLC CPU is

suspended and the GOT becomes inoperative.

For bus connection: The CPU becomes faulty and the GOT inoperative.

For other than bus connection: The GOT becomes inoperative.

A system where the GOT is used should be configured to perform any

significant operation to the system by using the switches of a device other

than the GOT on the assumption that a GOT communication fault will

occur.

Not doing so can cause an accident due to false output or malfunction.

-1

Page 3

A

[DESIGN PRECAUTIONS]

DANGER

z Do not use the GOT as the warning device that may cause a serious

accident.

An independent and redundant hardware or mechanical interlock is required

to configure the device that displays and outputs serious warning.

Failure to observe this instruction may result in an accident due to incorrect

output or malfunction.

z Incorrect operation of the touch switch(s) may lead to a serious accident if

the GOT backlight is gone out.

When the GOT backlight goes out, the display section turns black and

causes the monitor screen to appear blank, while the input of the touch

switch(s) still remains active.

This may confuse an operator in thinking that the GOT is in “screensaver”

mode, who then tries to release the GOT from this mode by touching the

display section, which may cause a touch switch to operate.

Note that the following occurs on the GOT when the backlight goes out.

• The monitor screen disappears even when the screensaver is not set.

• The monitor screen will not come back on by touching the display section,

even if the screensaver is set.

CAUTION

z Do not bundle the control and communication cables with main-circuit,

power or other wiring.

Run the above cables separately from such wiring and keep them a

minimum of 100mm apart.

Not doing so noise can cause a malfunction.

[MOUNTING PRECAUTIONS]

DANGER

z Before installing or removing the GOT main unit to or from an enclosure,

always switch off the GOT power externally in all phases.

Not doing so can cause a module failure or malfunction.

z Before loading or unloading the communication board, communication

module, External I/O module or memory board to or from the GOT, always

switch off the GOT power externally in all phases.

Not doing so can cause a module failure or malfunction.

-2

Page 4

A

[MOUNTING PRECAUTIONS]

CAUTION

z The GOT should be used in the environment given in the general

specifications of this user's manual.

Not doing so can cause an electric shock, fire, malfunction or product

damage or deterioration.

z When mounting the GOT main unit to an enclosure, tighten the mounting

screws in the specified torque range.

Undertightening can cause a drop, short circuit or malfunction.

Overtightening can cause a drop, short circuit or malfunction due to the

damage of the screws or module.

z When loading the communication board, communication module or

External I/O module to the GOT main unit, fit it to the connection interface

of the GOT and tighten the mounting screws in the specified torque range.

Undertightening can cause a drop, failure or malfunction.

Overtightening can cause a drop, failure or malfunction due to the damage

of the screws or module.

z When loading the memory board into the GOT main unit, load it into its

corresponding GOT slot and tighten the mounting screws in the specified

torque range.

Undertightening can cause a malfunction due to a contact fault.

Overtightening can cause a malfunction due to the damage of the screws

or module.

z When loading the PC card into the GOT main unit, insert and push it into

its corresponding GOT slot until the PC card eject button comes up.

Not doing so can cause a malfunction due to a contact fault.

z Before loading or unloading the PC card to or from the GOT, set the

memory card access switch to the OFF position.

Not doing so can cause the PC card data to be corrupted.

z Be sure to support the PC card with your hand when removing it.

Otherwise, the PC card may drop, resulting in a failure or damage.

[WIRING PRECAUTIONS]

z Before starting wiring, always switch off the GOT power externally in all

phases.

Not doing so may cause an electric shock, product damage or malfunction.

DANGER

-3

Page 5

A

[WIRING PRECAUTIONS]

CAUTION

z Please make sure to ground FG terminal, LG terminal, and protective

ground terminal of the GOT power supply unit by applying Class D

Grounding (Class 3 Grounding Method) or higher which is used exclusively

for the GOT.

Not doing so may cause an electric shock or malfunction.

z Correctly wire the power supply module on the GOT after confirming the

rated voltage and terminal arrangement of the product.

Not doing so can cause a fire or failure.

z Tighten the terminal screws of the GOT power supply section in the

specified torque range.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage

of the screws or module.

z Exercise care to avoid foreign matter such as chips and wire offcuts

entering the module.

Not doing so can cause a fire, failure or malfunction.

z Plug the bus connection cable by inserting it into the connector of the

connected module until it "clicks".

After plugging, check that it has been inserted snugly.

Not doing so can cause a malfunction due to a contact fault.

z Plug the communication cable into the connector of the connected module

and tighten the mounting and terminal screws in the specified torque

range.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage

of the screws or module.

[TEST OPERATION PRECAUTIONS]

DANGER

z Before performing test operation (bit device on/off, word device's present

value changing, timer/counter's set value and present value changing,

buffer memory's present value changing) for a user-created monitor

screen, system monitoring, special module monitoring or ladder monitoring,

read the manual carefully to fully understand how to operate the

equipment.

During test operation, never change the data of the devices which are used

to perform significant operation for the system.

False output or malfunction can cause an accident.

-4

Page 6

A

[STARTUP/MAINTENANCE PRECAUTIONS]

DANGER

z When power is on, do not touch the terminals.

Doing so can cause an electric shock or malfunction.

z Before starting cleaning or terminal screw retightening, always switch off

the power externally in all phases.

Not switching the power off in all phases can cause a module failure or

malfunction.

Undertightening can cause a short circuit or malfunction.

Overtightening can cause a short circuit or malfunction due to the damage

of the screws or module.

CAUTION

z Do not disassemble or modify the module.

Doing so can cause a failure, malfunction, injury or fire.

z Do not touch the conductive and electronic parts of the module

directly.

Doing so can cause a module malfunction or failure.

z The cables connected to the module must be run in ducts or clamped.

Not doing so can cause the module or cable to be damaged due to the

dangling, motion or accidental pulling of the cables or can cause a

malfunction due to a cable connection fault.

z When unplugging the cable connected to the module, do not hold and pull

the cable portion.

Doing so can cause the module or cable to be damaged or can cause a

malfunction due to a cable connection fault.

-5

Page 7

A

[BACKLIGHT CHANGING PRECAUTIONS]

DANGER

z Before changing the backlight, always switch off the GOT power externally

in all phases (when the GOT is connected to the bus, the PLC CPU power

must also be switched off externally in all phases) and remove the GOT

main unit from the enclosure.

Not switching the power off in all phases may cause an electric shock.

Not removing the unit from the enclosure can cause injury due to a drop.

CAUTION

z While changing the backlight, do not touch the circuit boards and electronic

parts of the GOT.

Doing so can cause a failure or malfunction.

z When changing the backlight, always note the following.

(1) Wear gloves or fingerstalls before starting the replacement of the

backlight.

Not doing so can cause injury.

(2) Start changing the backlight more than 5 minutes after switching the

GOT power off.

Not doing so can cause a burn due to the heat of the backlight.

[DISPOSAL PRECAUTIONS]

DANGER

z When disposing of the product, handle it as industrial waste.

-6

Page 8

A

Revisions

*The manual number is given on the bottom right of the top cover.

Print Date *Manual Number Revision

Jan., 1999 IB(NA)-80032-A First edition

Jun., 1999 IB(NA)-80032-B

Jun., 2001 IB(NA)-80032-C

Feb., 2002 IB(NA)-80032-D

Jan., 2004 IB(NA)-80032-E

Mar., 2004 IB(NA)-80032-F

Aug., 2004 IB(NA)-80032-G

Dec., 2005 IB(NA)-80032-H

Partial correction

Section 5.1

Partial addition

Section 3.2, Section 3.3, Section 5.2

Addition

A970GOT-LBA/LBD

Partial correction

Chapter 2, Section 5.1, Section 5.2, Section 5.3

Addition

Appendix 2

Partial correction

SAFETY PRECAUTIONS

Partial correction

Chapter 1, Section 3.2

Addition

Section 5.4

Partial correction

Section 5.4

MODEL CODE change

Changed from 13JN45 to 1DM100.

Addition

Section 5.4, 5.5, 5.6

Partial correction

Section 5.7 corresponds to the former Section 5.4.

About Manuals, Section 3.3, Appendix 1

Partial correction

Section 3.2

This manual does not warrant or license any industrial property rights and other rights.

Under no circumstances will Mitsubishi Electric be liable or responsible for any

consequential problems involving the industrial property rights which may arise as a

result of the use of this equipment described in this manual.

© 1999 MITSUBISHI ELECTRIC CORPORATION

-7

Page 9

A

CONTENTS

1. Overview .......................................................................................................1

1.1 Packing List ..............................................................................................1

2. System Configuration ....................................................................................2

3. Specifications ................................................................................................3

3.1 General Specifications..............................................................................3

3.2 Performance specifications.......................................................................4

3.3 Power supply specifications......................................................................6

4. Name of the Parts ..........................................................................................7

5. Handling .......................................................................................................8

5.1 Handling instructions ................................................................................8

5.2 Installation method ...................................................................................8

5.3 Wiring diagram .......................................................................................11

5.4 The precautions on the wiring.................................................................12

5.5 Connecting to the GOT Power Section...................................................15

5.6 Connection Cable Wiring........................................................................16

5.7 Precautions for back light replacement...................................................17

Appendices ....................................................................................................18

Appendix 1 Outline dimension drawing.........................................................18

Appendix 2 Depth dimension for when mounting each type of module.........19

About Manuals

The following manuals are related to this product.

Referring to this list, please order the necessary manuals.

Detailed Manual

Manual No.

Manual name

(Model code)

A985GOT/A975GOT/A970GOT/A960GOT

SH-4005

User’s Manual

(1DM099)

(Available as an Option)

Relevant Manuals

For relevant manuals, refer to the PDF manual stored within the drawing

software.

-8

Page 10

1. Overview

e

This user's manual describes the system configuration, specifications, part

names, handling and outline dimensions of the A975GOT/A970GOT/A960GOT

Graphic operation terminal (Referred to as GOT, hereafter).

The following GOT types are available.

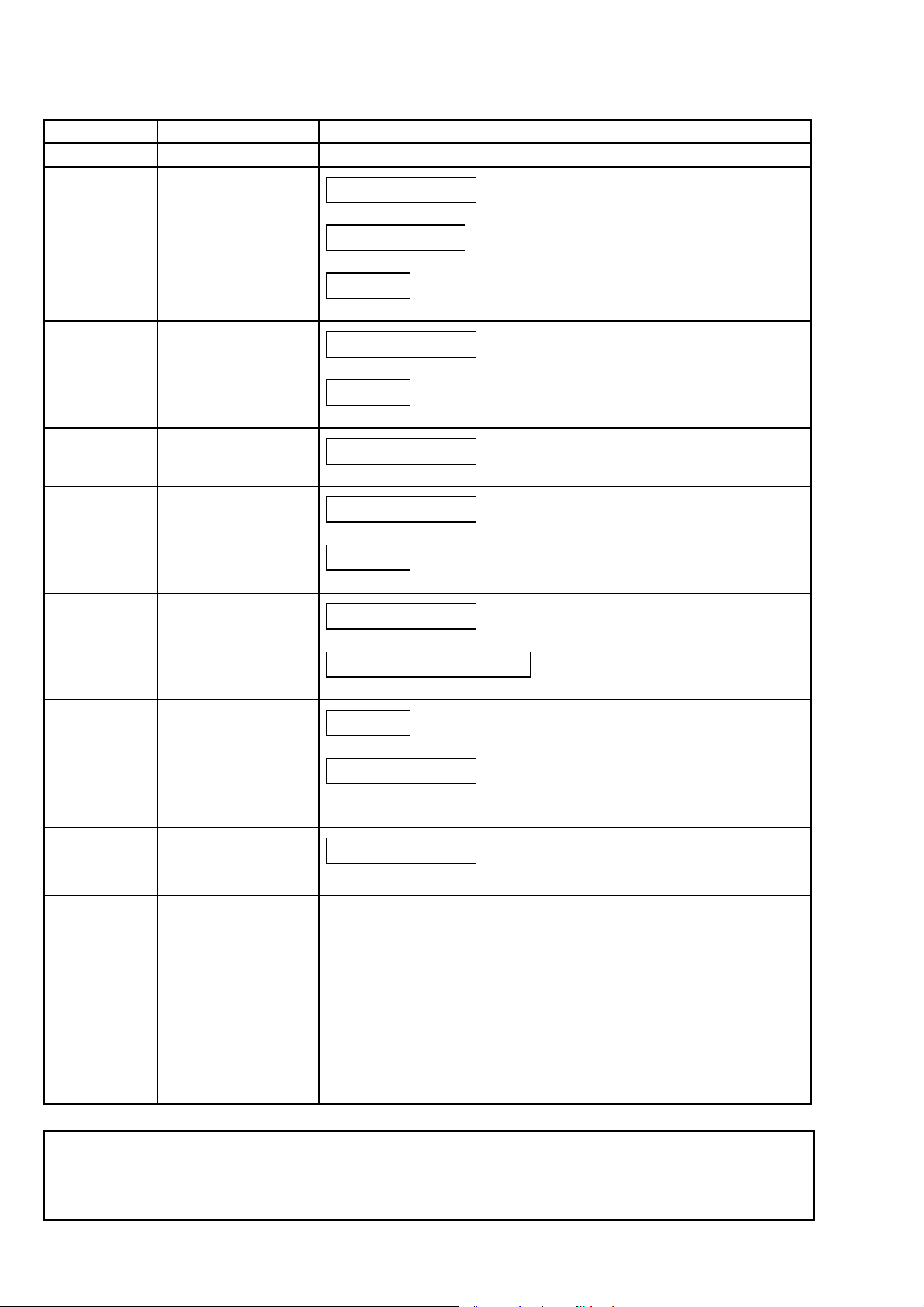

Item Type Display section

A975GOT

A975GOT-TBA,A975GOT-TBD TFT color liquid crystal

A975GOT-TBA-B,A975GOT-TBD-B TFT color liquid crystal *1

A970GOT-TBA,A970GOT-TBD TFT color liquid crystal

A970GOT-TBA-B,A970GOT-TBD-B TFT color liquid crystal *1

A970GOT

A970GOT-SBA,A970GOT-SBD D-STN color liquid crystal

STN monochrome liquid

A970GOT-LBA,A970GOT-LBD

crystal

A960GOT A960GOT-EBA,A960GOT-EBD EL

*1:This manual explains the GOT of function version B.

For specifications of GOTs of other function version, refer to A985GOT/

A975GOT/A970GOT/A960GOT User’s Manual.

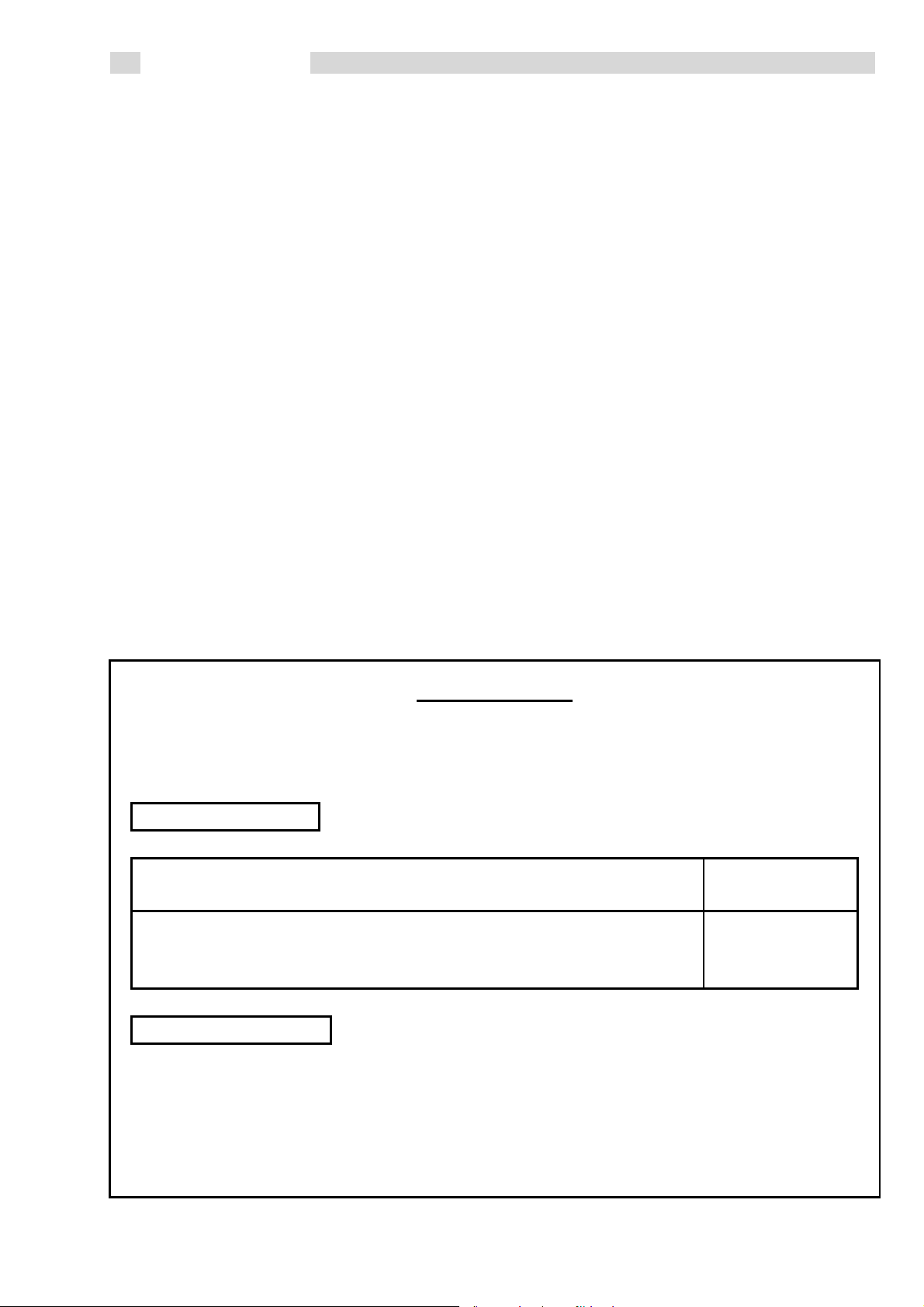

1.1 Packing List

After unpacking, confirm that you have received the following products.

Product Quantity

GOT main unit 1

Mounting fixture 4

Communication module securing fixture 3

Caution plate (seal) 1

*1: Affix a caution plate in a conspicuous position such as memory card

interface part. (Affix a caution plate on a communication module during its

use)

When affixing a coution plate on the

memory card interface

Caution plate

When affixing a coution plate on th

communication module

Caution plate

*2: If the protective sheet needs to be replaced, please obtain the one that is to

be purchased separately.

1

Page 11

2. System Configuration

The overall configuration of the GOT is shown below.

GOT

Drawing software

Communication module, Communication board *1

Option

Memory board

Flash PC card *1

External I/O interface module *1

Backlight

Protective sheet

Debug stand

Others

Audio output device (Commercially available)

Printer (Commercially available) *1

Barcode reader (Commercially available) *1

*1: For details of the system configuration, refer to the GOT-A900 Series User’s

Manual (Connection System Manual).

2

Page 12

3. Specifications

3.1 General specifications

Item Specifications

Operating

ambient

temperature

Storage ambient

temperature

Operating

ambient humidity

Storage ambient

humidity

Conforms

Vibration

resistance

Shock resistance

Operating

atmosphere

Operating

altitude*4

Installation site Inside control box

Overvoltage

category *2

Contamination

level *3

to JIS

B3502

and IEC

61131-2.

Display section

Other than display section

10 to 90%RH, non-condensing

10 to 90%RH, non-condensing

Frequency Acceleration Amplitude Sweep Count

In case of

intermittent

vibration

In case of

continuous

vibration

(147m/s2, 3 times in each of X, Y and Z directions)

10 to 57Hz

57 to

150Hz

10 to 57Hz

57 to

150Hz

Conforms to JIS B3502 and IEC 61131-2

No corrosive gas

-20 to 60°C

⎯

9.8m/s

⎯

4.9m/s

2000m max.

II or less

2 or less

2

2

0 to 40°C *1

0 to 55°C

0.075mm

⎯

0.035mm

⎯

10 times in

each of X, Y

and Z

directions

(for 80

minutes)

*1: For A975GOT-TBA/TBD (-B) and A970GOT-TBA/TBD (-B), it becomes 0 to

55°C.

*2: Indicates the element in the distribution system between the public

electricity grid and the mechanical equipment inside the premises that the

relevant device is assumed to be connected to.

Category II applies to devices such as those that draw their power supply

from fixed installations.

The surge voltage withstand capability of devices with ratings up to 300V is

2,500V.

*3: This index gives a measure of the incidence of conductive materials in the

environment in which the device is used.

A contamination level of 2 indicates an environment in which there is only

contamination by non-conducting materials, but due to occasional

condensation, conductivity may occur.

*4: Please do not use or store GOT in an environment with atmospheric

pressure greater than the atmospheric pressure at sea level (0m).

There is a possibility errors may occur if this point is not observed.

3

Page 13

3.2 Performance specifications

×

Specifications

A975GOT-

Item

Type TFT color liquid crystal

Resolution 640 × 480 dots 640 × 400 dots

Display

size

Display

section

Backlight

Life*1

Environmental

protective

structure*5

Outline dimensions

Panel cutting

dimensions

Weight 1.8 (3.96) kg (lb) 1.9 (4.18) kg (lb) 1.6 (3.52) kg (lb)

Compatible

software package*4

Display

color

Intensity

Display

angle

Display

section*2*3

Backlight

Touch key 1 million times or more (operating force 100g max.)

Built-in

memory

TBA(-B)

A975GOT-

TBD(-B)

256 color 16 color 8 color

TBA/TBD:250 cd/m

TBA/TBD-B:380 cd/m

(LCD only)

TBA/TBD:80 degrees

TBA/TBD-B:85 degrees

(right, left, up and down)

(Backlight OFF/screen saving time setting allowed)

TBA/TBD:41,000h

TBA/TBD-B:43,000h

(Operating ambient

temperature: 25)

TBA/TBD:40,000h

TBA/TBD-B:43,000h

(Time when display luminance reaches 50% at the

297 (11.7) (W) × 208 (8.2) (H) × 46 (1.81) (D)

SW0D5C-GTWORKS-E

Version A or later,

SW1D5C-GOTRE-PACK

Version A or later

(The 8-step brightness

adjustment of the high

luminance model is

complied to with Version

C and above.)

*1: When parts must be changed, consult your sales representative.

*2: The screen save and back light OFF functions of the GOT and operator detect sensor

function are used to prevent the display of the screen from being printed and prolong the

service life of the back light.

*3: Bright dots (always lit) and dark dots (unlit) may appear on a liquid crystal display panel. It

is impossible to completely avoid this symptom, as the liquid crystal display comprises of

a great number of display elements.

Please note that these dots appear due to its characteristic and are not caused by

product detect.

A970GOT-

TBA(-B)

A970GOT-

TBD(-B)

211 (8.31) × 158 (6.23) mm (inch)

Cold cathode fluorescent tube backlight

operating ambient temperature of 25°C)

Number of write times: 100,000 times

Front section: Equivalent to IP67/NEMA4

Panel inside: IP2X

289 (11.38) (W) × 200 (7.88) (H)

A970GOT-

A970GOT-

D-STN color

liquid crystal

2

2

50 degrees(right and left),

mm (inch)

mm (inch)

SW0D5C-

GTWORKS-E

Version A or

SW1D5C-

GOTRE-

Version A or

SBA

SBD

45 degrees(up),

40 degrees(down)

(Operating ambient

temperature: 25)

later,

PACK

later

A970GOT-LBA

A970GOT-LBD

monochrome

liquid crystal

2 color

(monochrome)

250 cd/m

(LCD only)

50,000h

40,000h

SW0D5C-

GTWORKS-E

Version A or

SW1D5C-

GOTRE-

Version J or

STN

2

later,

PACK

later

A960GOT-EBA

A960GOT-EBD

EL

192 (7.57)

(yellow orange, black)

(Initial luminance

268 (10.56) (W) ×

192 (7.56) (H) ×

49 (1.93) (D)

258 (10.17) (W) ×

183 (7.21) (H)

GTWORKS-E

Version A or

Version A or

120 (4.73)

mm (inch)

2 color

⎯

⎯

⎯

30,000h

70%,25°C)

⎯

mm (inch)

mm (inch)

SW0D5C-

later,

SW1D5C-

GOTRE-

PACK

later

4

Page 14

*4: GT Works2 and GT Designer2, are supported from the first version (Version1.00A).

*5: The specifications differ depending on the version of GOT (hardware version, function

version).

(1) Specification differences by the version of GOT

The specifications of the GOT-A900 series differ depending on the version (hardware

version, function version).

The following shows specification differences of the GOT-A900 series by version.

(a) Environmental protective structure

The environmental protective structure (IP rating) differs depending on the

hardware version of GOT.

Specification

Environmental

protective

structure

Item

Front section:

Equivalent to

IP65

Panel inside:

IP2X

Front section:

Equivalent to

IP67/NEMA4

Panel inside:

IP2X

A975GOT-TBA(-B)

A975GOT-TBD(-B)

A970GOT-TBA(-B)

A970GOT-TBD(-B)

Hardware version A or later

Hardware version N (Dec., 2001) or

A970GOT-SBA

A970GOT-SBD

A970GOT-LBA

A970GOT-LBD

later

A960GOT-EBA

A960GOT-EBD

Hardware

version K (Dec.,

2001) or later

5

Page 15

3.3 Power supply specifications

Specifications

A975GOT-TBA(-B)

Item

Input power supply

voltage

Input frequency [Hz]

Using 100VAC

Communication board loaded:

Communication module loaded:

Input max. apparent

power

Input max. power - 40W

Inrush current

Permissible

instantaneous power

failure time

Noise immunity

Dielectric withstand

voltage

Insulation resistance

Applicable wire size 0.75 to 2mm

Applicable solderless

terminal

Applicable tightening

torque (Terminal block

terminal screw)

External output Refer to *2

Using 200VAC

Communication board loaded:

Communication module loaded:

By noise simulator of 1,500Vp-p

noise voltage, 1μs noise width and

1500VAC for 1 minute across AC

A970GOT-TBA(-B)

A970GOT-SBA

A970GOT-LBA

A960GOT-EBA

100AC to 240V (+10%,-15%) 24VDC(+25%,-20%)

50/60 ± 3

50VA or less

60VA or less *1

63VA or less

75VA or less *1

40Ap max.

(264VAC, max. load)

20ms (100VAC or more) 1ms (19.2VDC or more)

25 to 60Hz noise frequency

external terminals and earth

10MΩ or larger by insulation resistance tester

RAV1.25–3, V2–S3.3, V2-N3A, FV2-N3A

59 to 88Nycm

A975GOT-TBD(-B)

A970GOT-TBD(-B)

A970GOT-SBD

A970GOT-LBD

A960GOT-EBD

61Ap max.

(30VDC, max. load)

By noise simulator of

500Vp-p noise voltage,

1μs noise width and 25 to

60Hz noise frequency

500VAC for 1 minute

across DC external

terminals and earth

2

-

-

*1: When the communication module for bus connection (A9GT-BUSSU/A9GT-

BUS2SU/A9GT-QBUS2SU) is loaded, this value is equivalent to the input

max. apparent power value when the communication board is loaded.

*2: For external outputs please refer to the A985GOT/A975GOT/A970GOT/

A960GOT User’s Manual that is to be purchased separately.

Remarks

Note that the power is reset if an instantaneous power failure occurs.

However, if the instantaneous power failure is within 20ms when using 100

to 240VAC, or within 1ms when using 24VDC, the operation will be normal.

6

Page 16

4. Name of the Parts

)

1) 2) 3) 4) 5) 6) 7)

15)

When 9) is removed

17) 17)

18)

13) 12)11) 10)

9) 8)

17) 17)

14) 16)

No. Name Description

1)Display section Shows the screen

2)Reset button Used to reset the hardware of the GOT

Used to set the condition of access to the PC card

when it is loaded during power-on (Factory-set to

3)memory card access switch

OFF)

OFF: Access from GOT to PC card inhibited

ON : Access from GOT to PC card enabled

Indicates whether the PC card may be

loaded/unloaded or not

4)memory card LED

Off: PC card may be loaded/unloaded

(When switch 3 is OFF)

On: PC card must not be loaded/unloaded

(When switch 3 is ON)

5)Communication module interface Interface for loading the communication module

6)memory card interface Interface for loading the PC card

7)memory card ejection button Button used to withdraw the PC card

8)Speech output terminal For external speaker connection

9)Slot cover Fixture to cover the slot

10)Printer interface For printer connection

11)RS-232C interface

For connection of personal computer

For connecting the bar code reader

12)Option module interface For option module loading (for future extension)

13)Terminal block For power input and external output

14)Communication board slot Slot for communication board loading

15)Memory board slot Slot for memory board loading

Screw hole for attaching memory

16

board

Screw hole used to attach the memory board

17)Mounting fixture fitting portion For mounting fixture fitting

18)Rating plate ⎯⎯⎯⎯

7

Page 17

5. Handling

5.1 Handling instructions

When mounting the main unit to a control box or the like, set the display section

as shown below.

When the temperature inside the enclosure is 40 to 55°C or less, the mounting

angle should be in the range 60 to 105 degrees.

GOT

Display

section

Enclosure, etc.

105°

60°

The GOT will be deteriorated earlier if it is used at the mounting angle other

than the above. Therefore, the temperature inside the enclosure should be

within 40°C.

Tighten the screws in the following specified range.

Screw Location Tightening Torque Range

Terminal block terminal screw (M3 screw) 59 to 88Nycm

Mounting Fixture screw (M4 screw)

Communication module mounting screw (M3 screw)

Communication board mounting screw (M3 screw)

36 to 48Nycm

Option module mounting screw (M3 screw)

Case fixing screw (M3 screw)

Memory board mounting screw (M2.6 screw) 25 to 35Nycm

RS-232C connector mounting screw

20 to 28Nycm

(#4-40 UNC (inch screw))

5.2 Installation method

(1) Mounting panel cutting dimensions

When mounting the GOT on a control box door, user-made mounting

base or the like, the door or mounting base must be cut as indicated

below.

A

Item A [mm](inch) B [mm](inch)

A975GOT

A970GOT

Panel opening

B

A960GOT

289 (11.39)

[+1.0(0.04), −0(0)]

258 (10.17)

[+1.0(0.04), −0(0)]

8

200 (7.88)

[+1.0(0.04), −0(0)]

183 (7.21)

[+1.0(0.04), −0(0)]

Page 18

(2) Mounting position

When mounting the GOT, the following clearances must be left from the

other device.

(80mm (3.15 inch) or more)

C

D

(100mm

(3.94 inch)

or more)

Plate thickness

within 2mm to 4mm (0.08inch to 0.16inch)

Other

device

BB

A

(50mm

(1.97inch)

or more)

(50mm

(1.97inch)

or more)

Part A size: As the GOT connection cable is led out downward, the

following clearance must be provided in consideration of the

bending radius.

Item A [mm] (inch)

A97*GOT + Communication board 130 (5.12) or more

A960GOT + Communication board 140 (5.51) or more

A97*GOT + A9GT-BUSSU/BUS2SU 15 (0.59) or more

A960GOT + A9GT-BUSSU/BUS2SU 30 (1.18) or more

When using a cable prepared by user, please consider the

connector cover to be used and the bending radius of the

cable.

When using a bar code reader, please consider the

dimensions of the connector to be used and the bending

radius of the cable.

Part B size: When using a PC card or an audio output device (for a

connected cable connector and a wire), a clearance of 100

mm (3.94 inch) or more is required. When removing a PC card

by opening a cover of the memory card interface part, a

clearance of 50 mm (1.97 inch) is required. (A clearance of 50

mm (1.97 inch) or more is required when an audio output

device or a memory card is not used.)

(A clearance of 50mm (1.97 inch) or more is required when

these are not used.)

Part C size: Please allow a gap 80mm (3.15inch) or more from the

structure and other equipment in the upper part of the unit to

often allow good ventilation.

Part D size: When installing a device that generates radiation noise

(contactor, etc.) or a device generating high levels of heat near

the GOT, provide a clearance of 100mm (3.94 inch) behind

the module to avoid the effect of the noise and heat.

9

Page 19

(3) Mounting method

(a) Put the GOT main unit into the panel opening, with its front face first.

(b) Mount the GOT in the following four locations at its top and bottom.

(Top) (Bottom)

Mounting Position Mounting position

(c) How to mount and fix the mounting fixture is given below.

1) Insert the mounting fixture into the fixture

fitting portion of the GOT main unit.

2) Tighten and fix the mounting screw in the

specified torque range.

10

Page 20

5.3 Wiring diagram

(1) 100AC to 240V

(2) DC24V

INPUT

100-240VAC

INPUT

24VDC

(LG) (FG)

+-

OUTPUT

RUN

L L

LL

+-

DC12/24V

12/24VDC 0.1A

+

-

INPUT

24VDC

-

+

(LG) (FG)

RUN

L L

OUTPUT

12/24VDC 0.1A

+

-

LL

-

+

DC12/24V

* For application of external outputs of RUN OUTPUT, please refer to

the[A985GOT/A975GOT/A970GOT/A960GOT User’s Manual]

11

Page 21

5.4 The Precautions on the Wiring

DANGER

z Completely turn off the externally supplied power used in the system when

installing or placing wiring. Not completely turning off all power could result

in electric shock, damage to the product.

CAUTION

z Be sure to ground the FG terminal and LG terminal of the GOT power

supply section to the protective ground conductor. Not doing so could

result in electric shock or erroneous operation.

z When wiring in the GOT power section, be sure that it is done correctly by

checking the product's rated voltage and the terminal layout. Connecting a

power supply that is different from the rating or incorrectly wiring the

product could result in fire or erroneous operation.

z Tighten the terminal screws of the GOT power supply section within the

specified torque range.

If the terminal screws are loose, it could result in short circuits, erroneous

operation or erroneous operation.

Tightening the terminal screws too far may cause damages to the screws

and/or the module, resulting in fallout, short circuits, or erroneous

operation.

z Be sure there are no foreign substances such as sawdust or wiring debris

inside the modle GOT main unit.

y General view of noise countermeasures

There are two types of noise: radiated noise, which is transmitted through

the air, and conducted noise, which is transmitted through a connection

wire. In noise countermeasures, the both two types of noise should be taken

into account. As the noise countermeasures, there are the following three

methods.

(1) Block noise

(a) Keep signal wires away from a possible noise source as power wires

or high-power driving circuits.

(b) Shield signal wires.

(2) Reduce generated noise

(a) Reduce the noise generated from high-power motor drive circuits.

(3) Ground noise without fail

(a) Earth the grounding wire to the ground without fail.

(b) Use a grounding wire as thick and short as possible to ensure low

grounding impedance.

(c) Separate the grounding between power and control systems.

12

Page 22

(1) Power supply wiring

y Separate the GOT's power supply line from the lines for I/O devices and

power devices as shown below.

When there is much noise, connect an insulation transformer.

Power supply wiring diagram

Insulation

Transformer

GOT

T1

I/O equipment

Main circuit equipment

200VAC

Main power

supply

GOT power

supply

I/O power supply

Main circuit equipment

y 100VAC, 200VAC and 24VDC wires should be twisted as dense as

possible.

Connect the modules with the shortest distance.

Also, to reduce the voltage drop to the minimum, use the thickest wires

possible (0.75 to 2mm

2

).

Use a solderless terminal for M3 screw. Also, be sure to tighten the M3

screw within tightening torque 0.55 to 0.88 Nym in order not to cause

trouble.

y Do not bundle the 100VAC, 200VAC and 24VDC wires with, or run them

close to, the main circuit (high voltage, large current) and I/O signal

lines. Reserve a distance of at least 100 mm from adjacent wires.

y As a countermeasure to power surge due to lightening, connect a surge

absorber for lightening as shown below.

Lightening surge absorber connection diagram

AC

E1

Surge absorber for lightening

GOT

E2

POINT

(1) Separate the ground of the surge absorber for lightening (E1) from

that of the GOT (E2).

(2) Select a surge absorber for lightening whose power supply voltage

does no exceed the maximum allowable circuit voltage even at the

time of maximum power supply voltage elevation.

13

Page 23

(2) Grounding

y For grounding, perform the following:

Use a dedicated grounding wire as far as possible. (Grounding

resistance of 100

or less.)

y When a dedicated grounding cannot be performed, use (2) Common

Grounding shown below.

Also, be sure to take noise countermeasures other than grounding.

GOT

Grounding

(Class 3 grounding)

(1) Independent grounding Best

Power

equipment

GOT

Grounding

(Class 3 grounding)

(2) Common grounding Good (3) Joint grounding Not allowed

Power

equipment

y For grounding a cable, use the cable of 2 mm2 or more.

Position the ground-contact point as closely to the sequencer as

possible, and reduce the length of the grounding cable as much as

possible.

(a) An example of independent grounding

Power equipment

(Servo, etc.)

CN1A CN1B

CN2

CN3

Connection cable

FG

LG

GOT

Power

equipment

FG

FG

GOT

LG

Panel

grounding

Grounding for

Grounding

terminal

block

Grounding for

control system

Grounding terminal block

power system

* For control system grounding, apply single-point grounding for one

system.

Especially for the devices communicating each other, be sure to

earth the grounding wire at one point.

14

Page 24

(b) An example of common grounding

A

Power equipment

(Servo, etc.)

CN1A CN1B

CN2 CN3

FG

FG

LG

Connection cable

FG

GOT

LG

Panel grounding

Use a grounding wire as thick and short as possible.

Grounding terminal block

* Apply single-point grounding for one system.

5.5 Connecting to the GOT Power Section

The following diagram shows the wiring example of power lines, grounding

lines, etc. to the GOT power section.

C

100/110VAC

Fuse

AC

DC

24VDC

When using 100VAC

GOT

INPUT

100-240VAC

LG FG

When using 24VDC

GOT

INPUT

24VDC

LG FG

Grounding wire

Grounding

15

Page 25

POINT

(1) Use the thickest possible (max. 2 mm2 (14 AWG)) wires for the

100/200 VAC and 24 VDC power cables. Be sure to twist these wires

starting at the connection terminals. To prevent a short-circuit should

any screws loosen, use solderless terminals with insulation sleeves.

(2) When the LG terminals and FG terminals are connected, be sure to

ground the wires. Do not connect the LG terminals and FG terminals

to anything other than ground. If LG terminals and FG terminals are

connected without grounding the wires, the PLC may be susceptible

to noise.

In addition, since the LG terminals have potential, the operator may

receive an electric shock when touching metal parts.

5.6 Connection Cable Wiring

• Do not bind connection cables with the main circuit (high voltage, heavy

current) or I/O signal cables, or lay them close to each other.

• When using A8GT-C

(1) When using A8GT-C

PLC

FG

LG

N

L

EXSS-1 or A8GT-C BS, ground wires as below.

EXSS-1 cable

Disconnected

(A8GT-EXCNB)

6)

3)

(A8GT-C BS)

2SQ wire FG terminal,

28 cm or less

5)

OUT

FGLG

NL

4)

GOT

2)

1) Connect the LG and FG terminals of GOT unit power to the ground

through the terminal block with one wire.

2) Use FG wires of 28 cm or less for the A8GT-C

BS cable.

3) Do not connect the FG grounding wire of A8GT-EXCNB cable.

4) Connect the A8GT-C

BS cable’s FG wire to FG of the GOT unit power

terminal block.

5) Connect the A8GT-C

BS cable’s FG wire on the PLC side to FG of the

PLC power supply module.

6) Connect the LG and FG terminals of the terminal block on the PLC to

ground with one wire.

(2) When using A8GT-C

Connect the A8GT-C

BS cable

BS cable’s FG wires on the both sides to the FG

terminals on the power terminal block of the both side GOTs.

IN

1)

16

Page 26

5.7 Precautions for back light replacement

Use the following back lights for the GOT that includes this manual.

Type Model

A975GOT-TBA

(Hardware version D (JAN,1998) or later),

A975GOT-TBD

(Hardware version B (JAN,1998) or later)

A975GOT

A975GOT-TBA-B

(Function version B (JAN,2004) or later),

A975GOT-TBD-B

(Function version B (JAN,2004) or later)

A970GOT-TBA

(Hardware version D (JAN,1998) or later),

A970GOT-TBD

(Hardware version B (JAN,1998) or later)

A970GOT-TBA-B

A970GOT

(Function version B (JAN,2004) or later),

A970GOT-TBD-B

(Function version B (JAN,2004) or later)

A970GOT-SBA, A970GOT-SBD,

A970GOT-LBA, A970GOT-LBD

Replacement back

light

A9GT-70LTTB

A9GT-70LTTBW

A9GT-70LTTB

A9GT-70LTTBW

A9GT-70LTS

The GOT hardware version and function version can be checked from the

rating plate, which is situated on the backside of the GOT.

GRAPHIC OPERATION TERMINAL

MODEL

IN 100-240VAC 50/60Hz

POWER

C

MITSUBISHI ELECTRIC CORPORATION

MADE IN JAPAN

BACKLIGHT A9GT-70LTTBW

A970GOT-TBA-B

MAX 115VA 0401 AW

US LISTED

Rating plate

DATE

80M1 IND.CONT.EQ.

BD992C189H02

B

Function version

0401 AW

Hardware version

Production date

Conformed standard

Back light model

(The applicable back light model is described.)

The applicable back light differs with the GOT hardware version and function

version.

For more information, refer to A985GOT/A975GOT/A970GOT/A960GOT User’s

Manual.

17

Page 27

Appendices

A

A

A

Appendix 1 Outline dimension drawing

L

C

M

F

GG

BI

K

J

D

A

H

E

Unit: mm(inch)

Item A B C D E F G H I J K L M

975GOT,

970GOT

960GOT

297

(11.70)

268

(10.56)

208

(8.20)

192

(7.56)

235

(9.26)

204

(8.04)

229

(9.02)

198

(7.80)

288

(11.35)

257

(10.13)

199

(7.84)10(0.40)46(1.81)40(1.58)6(0.24)34(1.34)31(1.22)

182

(7.17)10(0.40)49(1.94)43(1.69)6(0.24)35(1.38)32(1.26)

15.4

(0.61)

15.4

(0.61)

18

Page 28

Appendix 2 Depth dimension for when mounting each type of module

(1) A97*GOT

Communication

board loading

B

A

Installed communication module A [mm] (inch) B [mm] (inch)

A9GT-QBUSS, A9GT-BUSS 40 (1.57) 85 (3.35)

A9GT-QBUS2S, A9GT-BUS2S 62 (2.44) 85 (3.35)

A9GT-BUSSU, A9GT-BUS2SU 74 (2.91) 15 (0.59)

A9GT-RS2(T) 40 (1.57) *1

A9GT-RS4 40 (1.57) 115 (4.53)

A7GT-J71AP23, A7GT-J71LP23 74 (2.91) *2

A7GT-J71AR23, A7GT-J71BR13 74 (2.91) *3

A7GT-J71AT23B 96 (3.78) A8GT-J61BT13, A8GT-J61BT15 79 (3.11) A9GT-J71E71-T 70.2 (2.76) A9GT-70KBF 82.6 (3.25) -

Communication

module/Option

module loading

B

A

(2) A960GOT

Installed communication module A [mm] (inch) B [mm] (inch)

A9GT-QBUSS, A9GT-BUSS 43 (1.69) 100 (3.94)

A9GT-QBUS2S, A9GT-BUS2S 65 (2.56) 100 (3.94)

A9GT-BUSSU, A9GT-BUS2SU 77 (3.03) 30 (1.18)

A9GT-RS2(T) 43 (1.69) *1

A9GT-RS4 43 (1.69) 130 (5.12)

A7GT-J71AP23, A7GT-J71LP23 77 (3.03) *2

A7GT-J71AR23, A7GT-J71BR13 77 (3.03) *3

A7GT-J71AT23B 99 (3.90) A8GT-J61BT13, A8GT-J61BT15 82 (3.23) A9GT-J71E71-T 73.2 (2.88) A9GT-70KBF 85.6 (3.37) -

*1 Depends on the dimensions of the converter and cable used.

*2 This dimension is between 195mm (7.68) maximum and 80mm (3.15)

minimum depending on the optional fiber cable and connector connected.

*3 This dimension is between 80mm (3.15) maximum and 73mm (2.87)

minimum depending on the coaxial cable connected.

19

Page 29

MEMO

20

Page 30

Warranty

Mitsubishi will not be held liable for damage caused by factors found not to be the cause of

Mitsubishi; machine damage or lost profits caused by faults in the Mitsubishi products;

damage, secondary damage, accident compensation caused by special factors

unpredictable by Mitsubishi; damages to products other than Mitsubishi products; and to

other duties.

For safe use

y This product has been manufactured as a general-purpose part for general industries, and

has not been designed or manufactured to be incorporated in a device or system used in

purposes related to human life.

y Before using the product for special purposes such as nuclear power, electric power,

aerospace, medicine or passenger movement vehicles, consult with Mitsubishi.

y This product has been manufactured under strict quality control. However, when installing

the product where major accidents or losses could occur if the product fails, install

appropriate backup or failsafe functions in the system.

Country/Region Sales office/Tel

U.S.A Mitsubishi Electric Automation Inc.

500 Corporate Woods Parkway Vernon

Hills, IL 60061

Tel : +1-847-478-2100

Brazil MELCO-TEC Rep. Com.e Assessoria

Tecnica Ltda.

Rua Correia Dias, 184,

Edificio Paraiso Trade Center-8 andar

Paraiso, Sao Paulo, SP Brazil

Tel : +55-11-5908-8331

Germany Mitsubishi Electric Europe B.V. German

Branch

Gothaer Strasse 8 D-40880 Ratingen,

GERMANY

Tel : +49-2102-486-0

U.K Mitsubishi Electric Europe B.V. UK

Branch

Travellers Lane, Hatfield, Herts., AL10

8XB,UK

Tel : +44-1707-276100

Italy Mitsubishi Electric Europe B.V. Italian

Branch

Centro Dir. Colleoni, Pal. Perseo-Ingr.2

Via Paracelso 12, 20041 Agrate B.,

Milano, Italy

Tel : +39-039-6053344

Spain Mitsubishi Electric Europe B.V. Spanish

Branch

Carretera de Rubi 76-80

08190 Sant Cugat del Valles,

Barcelona, Spain

Tel : +34-93-565-3131

France Mitsubishi Electric Europe B.V. French

Branch

25 Boulevard des Bouvets, F-92741

Nanterre Cedex, France

TEL: +33-1-5568-5568

South Africa Circuit Breaker Industries LTD.

Tripswitch Drive, Elandsfontein Gauteng,

South Africa

Tel : +27-11-928-2000

Country/Region Sales office/Tel

Hong Kong Ryoden Automation Ltd.

10th Floor, Manulife Tower, 169 Electric

Road, North Point, HongKong

Tel : +852-2887-8870

China Ryoden Automation Shanghai Ltd.

3F Block5 Building Automation

Instrumentation Plaza 103 Cao Bao Rd.

Shanghai 200233 China

Tel : +86-21-6120-0808

Taiwan Setsuyo Enterprise Co., Ltd.

6F., No.105 Wu-Kung 3rd.RD, Wu-Ku

Hsiang, Taipei Hsine, Taiwan

Tel : +886-2-2299-2499

Korea HAN NEUNG TECHNO CO.,LTD.

1F Dong Seo Game Channel Bldg.,

660-11, Deungchon-dong Kangsec-ku,

Seoul, Korea

Tel : +82-2-3660-9552

Singapore Mitsubishi Electric Asia Pte, Ltd.

307 Alexandra Road #05-01/02,

Mitsubishi Electric Building

Singapore 159943

Tel : +65-6473-2308

Thailand F. A. Tech Co.,Ltd.

898/28,29,30 S.V.City Building,Office

Tower 2,Floor 17-18 Rama 3 Road,

Bangkpongpang, Yannawa,

Bangkok 10120

Tel : +66-2-682-6522

Indonesia P.T. Autoteknindo SUMBER MAKMUR

Jl. Muara Karang Selatan Block a Utara

No.1 Kav. No.11 Kawasan Industri/

Pergudangan Jakarta - Utara 14440

Tel : +62-21-663-0833

India Messung Systems Put,Ltd.

Electronic Sadan NO:111 Unit No15,

M.I.D.C BHOSARI,PUNE-411026, India

Tel : +91-20-712-2807

Australia Mitsubishi Electric Australia Pty. Ltd.

348 Victoria Road, PostalBag, No 2,

Rydalmere, N.S.W 2116, Australia

Tel : +61-2-9684-7777

HEAD OFFICE : TOKYO BUILDING, 2-7-3 MARUNOUCHI, CHIYODA-KU, TOKYO 100 -8310, JAPAN

NAGOYA WORKS : 1-14, YADA-MINAMI 5-CHOME, HIGASHI-KU, NAGOYA, JAPAN

When exported from Japan, this manual does not require application to the Ministry

of Economy, Trade and Industry for service transaction permission.

Specifications subject to change without notice.

Printed in Japan on recycled paper.

Loading...

Loading...