This page intentionally left blank.

©

f

M ITSU BISH I

3000GT

TECHNICAL

INFORMATION

MANUAL

FOREWORD

This manual has been prepared as an introduction to the

specifications, features, construction, functions, etc. of

the newly developed 3000GT. Please read this manual

carefully so that it will be of assistance for your service

and sales activities. Please note that the following service

manuals are also available and should be used in

conjunction with this manual.

WORKSHOP MANUAL

ENGINE GROUP

CHASSIS GROUP

ELECTRICAL WIRING

PARTS CATALOGUE

All information, illustrations and product descriptions

contained in this manual are current as at the time o

publication. We, however, reserve the right to make

changes at any time without prior notice or obligation.

PWEE

(Looseleaf edition)

PWUE9119 (Vehicles

for Europe)

PWUE9203

(Vehicles for

General Export

and Australia)

PHUE9201

(Vehicles for Europe)

PHUE9203 (Vehicles

for General Export

and Australia)

B608K402AD

(Vehicles for Europe)

B808K402AD

(Vehicles for General

Export) BFA8K402A1

(Vehicles for

Australia)

GROUP INDEX

GENERAL ...... ………………………. .

ENGINE .............................................

POWER- TRANSMISSION

COMPONENTS

DRIVE-CONTROL

COMPONENTS ................................ .

BODY ................................................ .

EXTERIOR ........................................ .

INTERIOR ......................................... .

EQUIPMENT ..................................... .

……......

Mitsubishi Motors Corporation May 1992

MODEL INDICATIONS

The following abbreviations are used in this manual for classification of model types.

M/T

:

Indicates the manual transmission, or models equipped with the manual transmission.

MPI: Indicates the multi-point injection, or engines equipped with the multi-point injection.

4WD: Indicates the 4 wheel-drive vehicles.

DOHC: Indicates an engine with the double overhead camshaft, or a model equipped with such an engine.

INDICATION OF DESTINATION -

Europe, General Export, Australia, New Zealand and GCC used for convenience to indicate destination.

NOTE

1. "General Export" means territories other than Europe, Australia, New Zealand, GCC, the U.S.A. and

Canada.

2. "GCC" means member of the Gulf Cooperation Council nation.

3. In some instances, vehicles with other specifications may be shipped to some countries.

GENERAL - How to Use This

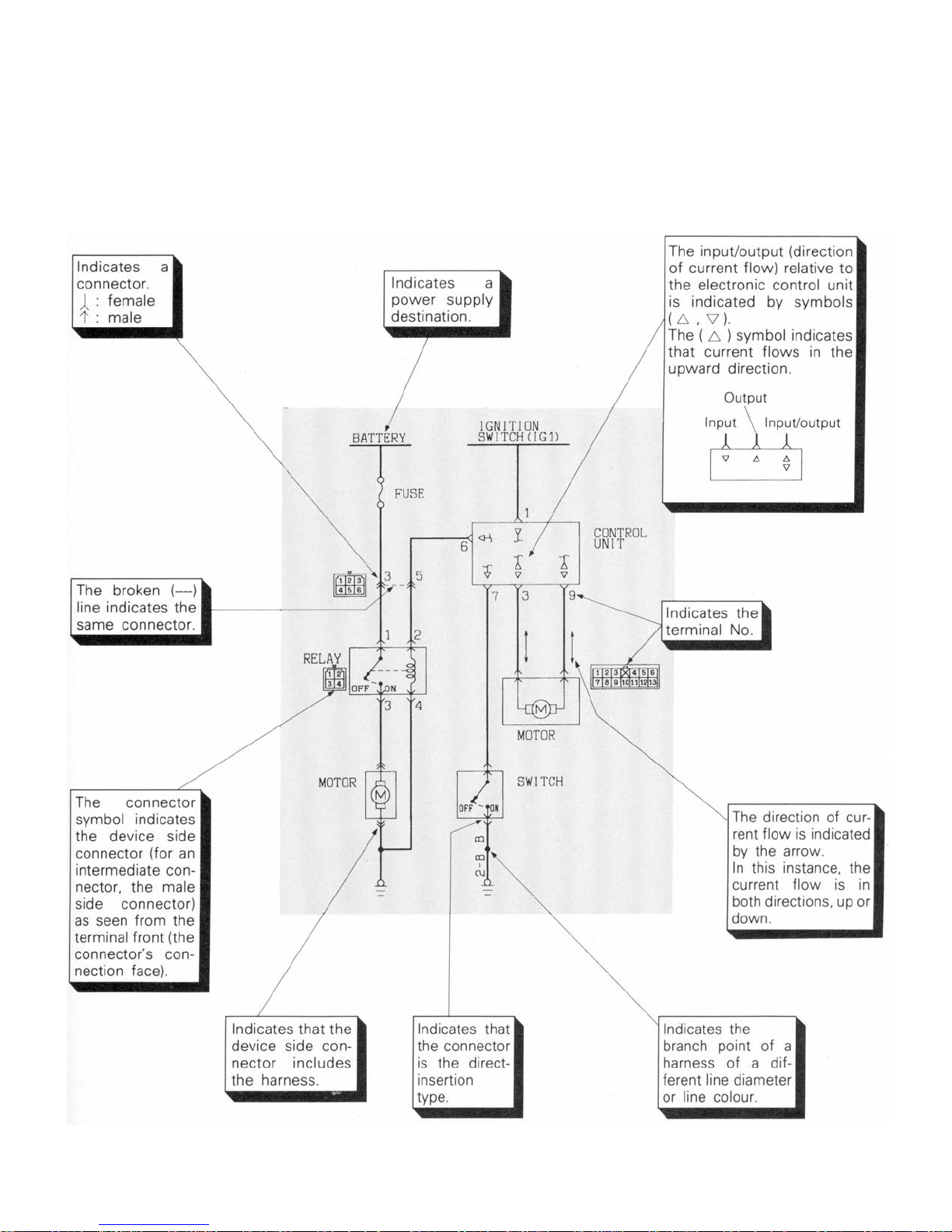

EXPLANATION OF CIRCUIT DIAGRAMS

The symbols used in circuit diagrams are used as

described below.

Manual

NOTE

For detailed information concerning the reading of circuit

diagrams, refer to the separate manual of

WIRING".

"ELECTRICAL

NOTES

This electronic document was created from material published and copyrighted in 1992 by Mitsubishi Motor

Corporation (MMC). All rights to the original material are reserved by them.

This electronic document may be distributed freely, without financial charge. Note that this document is not an exact

replica of the original manual. Because of this, copies of this document are easily identified.

MMC cannot be held liable for any changes that have occurred. Typographical and factual errors may have been

introduced, and some may have been corrected, while others may have been preserved. MMC and I disclaim all

liability for direct, indirect, incidental, or consequential damages or personal injury that may result from any use of the

information in this manual. MMC and I make no warranty, claim, or representation, expressed or implied, concerning

the accuracy of the material here, or the suitability of the information or instructions for any purpose.

Please note that this manual does not cover vehicles destined to the USA and Canada. The vehicles covered include the

turbocharged model destined for Europe, Australia, New Zealand, the Gulf Coast Council (GCC) nations, and General

Export (those territories other than Europe, Australia, New Zealand, GCC, USA, and Canada). In some cases,

information here may be identical to that for USA and Canada vehicles. In other case, the information does not apply

to USA and Canada vehicles.

I used an Epson Perfection 2450 scanner and Readiris Pro 9.04 to scan a single sheet (page) and recognize images,

text, and tables. I placed a sheet of black paper behind the sheet to be scanned to reduce bleed-through of images and

text from the back of the sheet or from other sheets. Scanner options in Readiris were set to grayscale, 400 dpi, letter

format, and contrast and brightness set to 299 to reduce the yellowing caused by the age of the manuscript. Readiris

allows the identification and selection or elimination of areas of the scanned image that are text, graphics, or table

format. This did not allow the embedding of graphics into text areas or vice versa. These two areas may overlap but

this created visual confusion. Pages were deskewed as necessary. The formatted, scanned page was saved in MS Word

document format.

I used MS Word 2002 to make spelling corrections, format the page size (8.5” x 11”), and set margins, generally 0.5”

all around. Re-arranging of objects occurred on some pages. From Word, I “printed” the page to Adobe Distiller 7.0.0,

creating a PDF file for each page. Distiller was set to not compress images. This increases the size of the final

document, but improves resolution and clarity of the images. In Adobe Acrobat 7.0.0, I concatenated the individual

PDF files into a single document, adding bookmarks and thumbnails.

I tested the final document with Acrobat and Acrobat Reader versions 5, 6, and 7. No problems were encountered with

versions 6 and 7. However, with Acrobat version 5 errors were encountered. These were avoided by having the

Bookmarks panel on the left “open”. I recommend using version 6 or 7 of Acrobat or Acrobat Reader to view this

document.

I thank the dedication and generosity of Jan Borgelin for getting an original printed version of this publication to me.

Jeff Lucius, February 2005

0-1

GENERAL

CONTENTS

DESIGN STRATEGIES FOR

DEVELOPMENT ...........................................................

Basic Themes for Development ................................2

COMMODITY FEATURES ............................................

TECHNICAL FEATURES .............................................

Exterior ......................................................................4

Interior ........................................................................5

Engine ........................................................................6

Transaxle ...................................................................9

Clutch Booster ........................................................ 10

2

3

4

Chassis ...................................................................11

Supplemental Restraint System (SRS) .................. 13

Small Amount Refrigerant System

(Air Conditioner) ...................................................... 14

Theft-alarm System ................................................ 15

Serviceability ........................................................... 16

VEHICLES IDENTIFICATION .................................... 17

Model ...................................................................... 17

Model Code ............................................................. 17

MAJOR SPECIFICATIONS ........................................18

0-2

A

GENERAL - Design Strategies for Development

DESIGN STRATEGIES FOR DEVELOPMENT

BASIC THEMES FOR DEVELOPMENT

New 4WD Sports Car

4WD system that accurately transmits the power of

the engine to the road surface, thus eliminating the

danger that normally accompanies speed, has been

adopted in a sports car so that anyone can comfortably

Exhilarating driving and safety

Faithful and speedy responsiveness to the intentions of

the driver and direct response. Also, safety equipment

has been adopted in order to maintain safety.

drive in a sporty manner.

The DOHC twin-turbochargers and twin-intercoolers

coupled with the 4WD maintain overwhelming

performance

In pursuit of sports car styling

Stylish design that abolishes design compromises.

•

•

•

•

GENERAL - Commodity Features 0-3

COMMODITY FEATURES

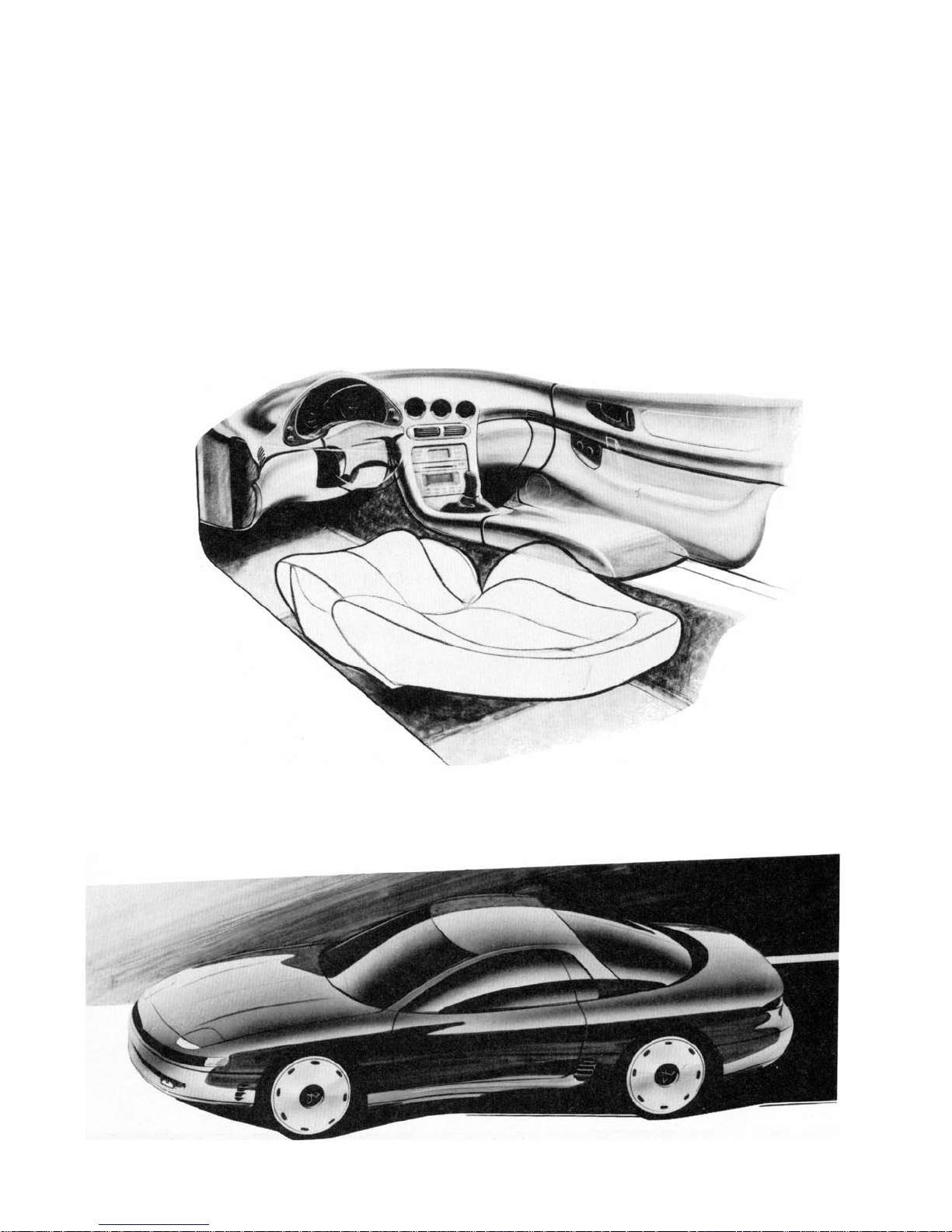

Dynamic real sports styling

Interior with an abundantly

sporty feel

Excellent driving performance

Excellent steering stability

Low and wide proportions

• Capsule image due to glass with complex curves

• Large-diameter wide tyres that symbolize super 4WD

Sports cockpit centered around the driver

• Simple interior qesign

• Front seat which stresses driving performance

• Excellent acceleration performance from a standing start due to

a high-performance engine and 4WD

• Extra-wide tread and wide tyres together provide a high limit for

cornering performance

• High-performance brakes due to the combination of 4-piston

aluminum caliper brakes and 4-wheel ABS

• Optimization of torque distribution to front and rear wheels

High-tech components

Safety features

Full-time 4WD and 5-speed

• Combination of 4WD, 41S, 4ABS and 4WS

• 4-piston aluminum caliper brakes

• Active aero system

• SRS air bag

4WD

• 4ABS

• SRS air bag

• Rear seat 3-point seat belts

• High-mounted stop lamp

• Side door beam

• Fire-resistant materials used inside the passenger compartment

MfT

manufactured by GETRAG

0-4 GENERAL - Technical Features

TECHNICAL FEATURES

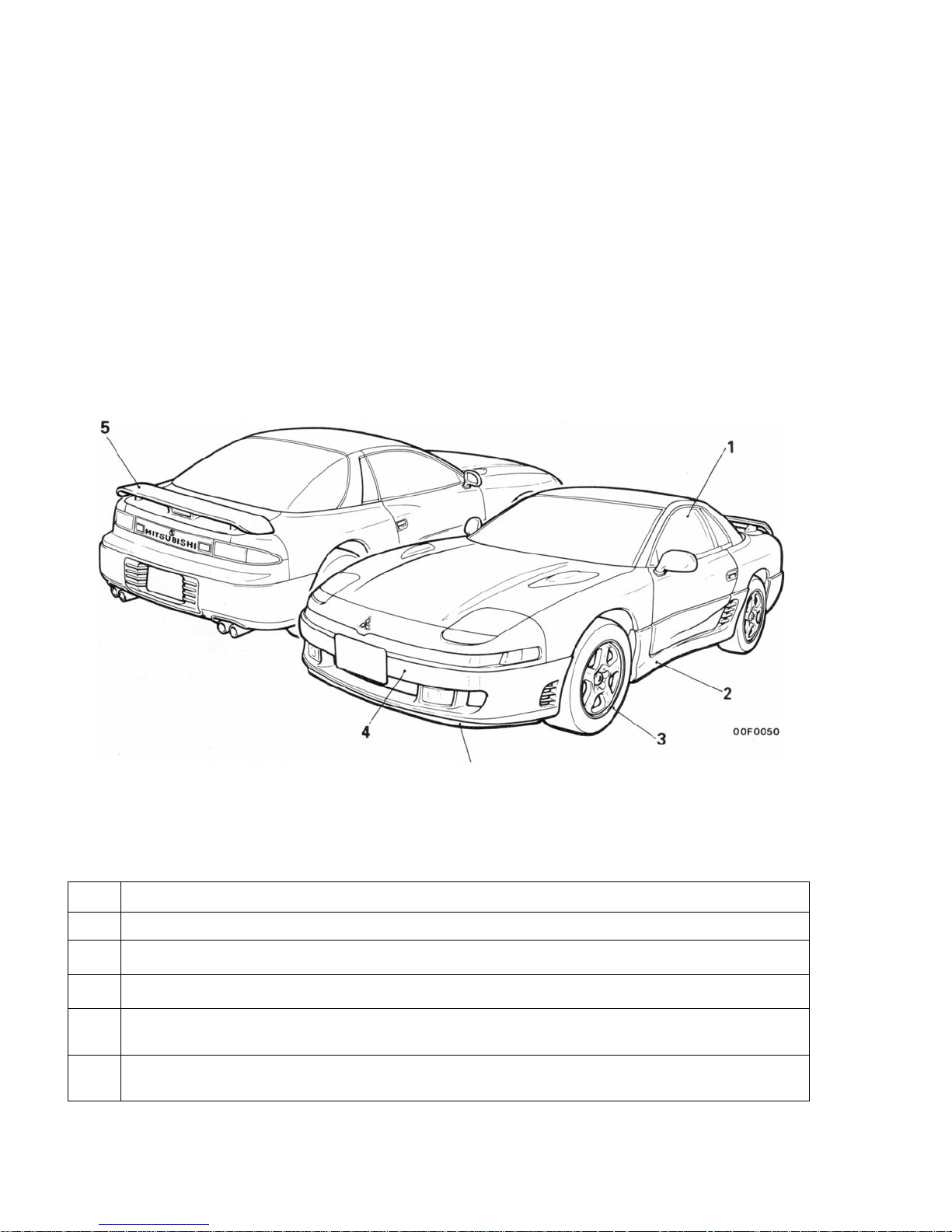

EXTERIOR

Dynamic sports car proportions with wide tread and

tight interior.

No. Features

1 The forward passenger compartment looks like a capsule, using glass with complex curves.

2

Side air dam that provides improved aerodynamic characteristics for the side of the vehicle.

3

17" aluminum wheel and wide tread tyre to create the image of a highyerformance sports car.

4 Large soft-face bumper (with built-in bumper absorber) that gives the feeling ot being one unit with the

body.

Active aero system improves aerodynamic characteristics when driving at high speed. (movable front

5

venturi skirt and rear spoiler)

5

GENERAL - Technical Features 0-5

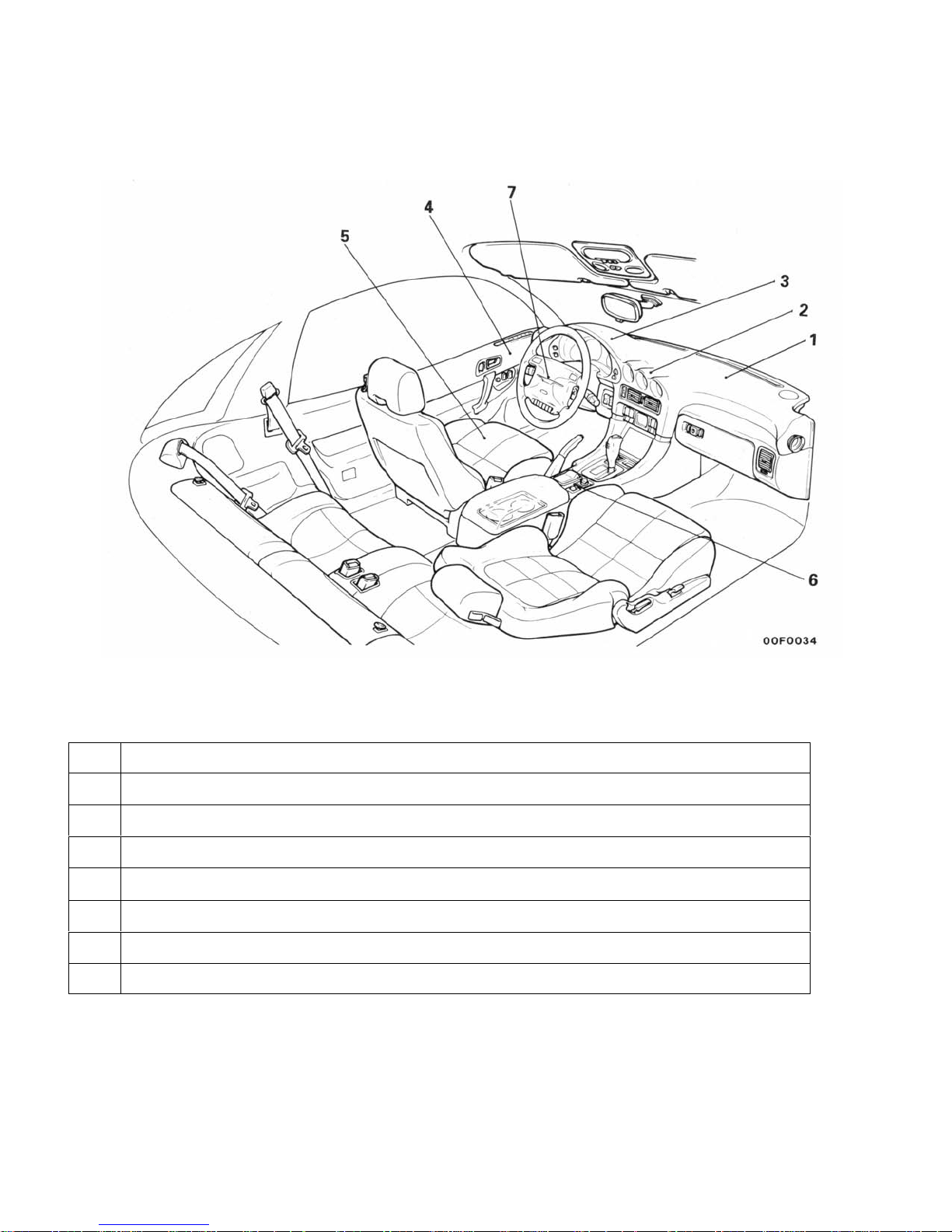

INTERIOR

Interior that creates a real feeling of a cockpit

centering around the driver.

No. Features

An instrument panel that emphasizes a feeling of closeness.

1

Round 3-meter arrangement with sporty imag.e.

2

3 Easy-to-see goggle type meter cluster.

4 Full round door trim that appears to be one with the instrument panel.

Superior sports type front seat that gives support.

5

6

High, wide and large floor console.

Sports steering wheel with built-in air bag (SRS).

7

0-6

GENERAL -

Technical Features

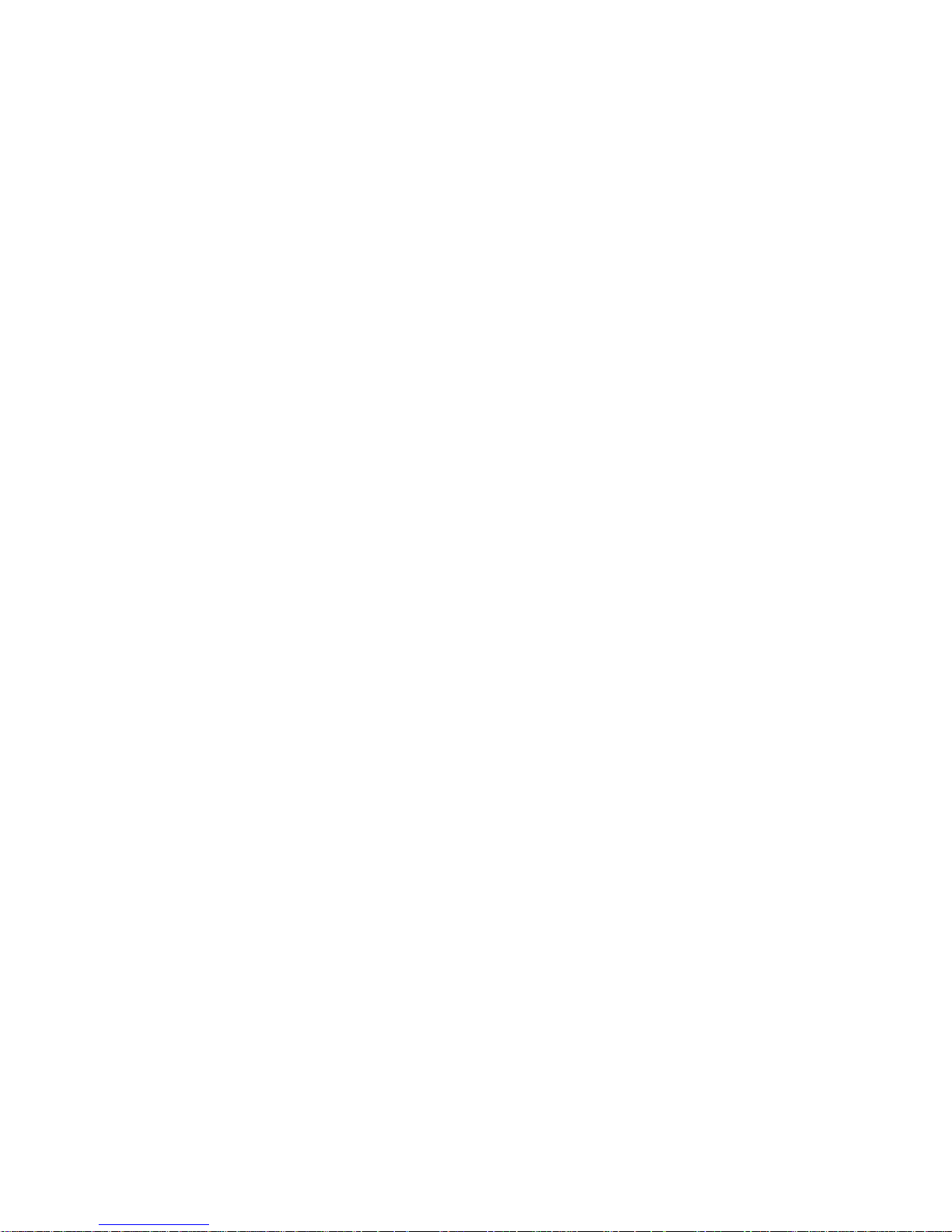

ENGINE

A 3.0L DOHC engine with twin-turbochargers and twin-intercoolers have been developed to provide even higher

output and higher performance.

SPECIFICATIONS

Items

Displacement

3

(cu. in.)

cm

Maximum output

kW (PS)/rpm

Maximum torque

kgm (Nm)/rpm

Specifications

2972 (181.4)

210 (285) / 6,000

41.5 (407) /3,000

FEATURES

High performance and low fuel consumption

• The roller rocker arm reduces the valve-actuation torque as well as fuel consumption.

• Improved response and fuel consumption have been achieved by electronic control multi-point fuel injection.

• Electronic control of fuel pump fuel discharge for high response and low fuel consumption.

• Overwhelming acceleration due to combination of the twin-turbochargers and twin-intercoolers.

• A lightweight sodium-filled vacuum valve has been developed for use as the exhaust valve to improve valve follow in high-

speed ranges. <Vehicles for Europe>

GENERAL - Technical Features

Quiet operation

• Noise and vibration have been decreased by the adoption of roller rocker arms.

• Noise generated by the valve mechanism has been decreased by the hydraulic auto lash adjusters.

• Both powerful exhaust sound fitting a high performance vehicle and quietness due to the active exhaust system.

• Reduction in noise and vibration by improving the rigidity of the cylinder block.

• Vibrations have been decreased by the adoption of bearing caps with beams which increase the rigidity of the crank-

shaft support points.

• Reduction in vibration due to the use of a crankshaft pulley with torsion damper and, because of that, improvement in

the durability of the belts.

Serviceability

• Complete self-diagnosis functions.

• Enhanced reliability through the adoption of gold-plated connector terminals.

• Use of an auto tensioner achieves maintenance-free, automatic adjustment of timing belt tension.

• Use of the auto-lash adjusters achieves maintenance-free, automatic adjustment of valve clearance.

• The 3-coil distributorless ignition system supplies sufficient ignition energy even during high speed operation.

0-7

0-8

GENERAL - Technical Features

GENERAL - Technical Features 0-9

TRANSAXLE

W5MG1 TYPE MANUAL TRANSAXLE

The W5MG1 type manual transaxle is a full-time 4WD

manual transaxle made by GETRAG

* and newly

developed to match the high output and high torque of

the 6G72-DOHC (Turbo) engine.

1. Sportier driving is possible by using a centre

differential method with viscous coupling for

distributing (front 45: rear 55) front and rear torque

unevenly.

2. A double-cone synchronizer for 1st and 2nd speeds

and a reverse synchronizer are used and, in

addition to sure shifting performance, the shift

feeling is also improved.

3. Low vibration and low noise are realized by the use

of high precision gears and high rigidity shaft.

*

GETRAG is a German manufacturer who develops

and manufactures high performance transaxles

especially in Europe.

0-10 GENERAL - Technical Features

CLUTCH BOOSTER

A 4" single type clutch booster is used to reduce the

force needed to depress the clutch pedal.

Air intake plenum

Release cylinder

Clutch booster

Vacuum tank

Clutch pedal

GENERAL - Technical Features

CHASSIS

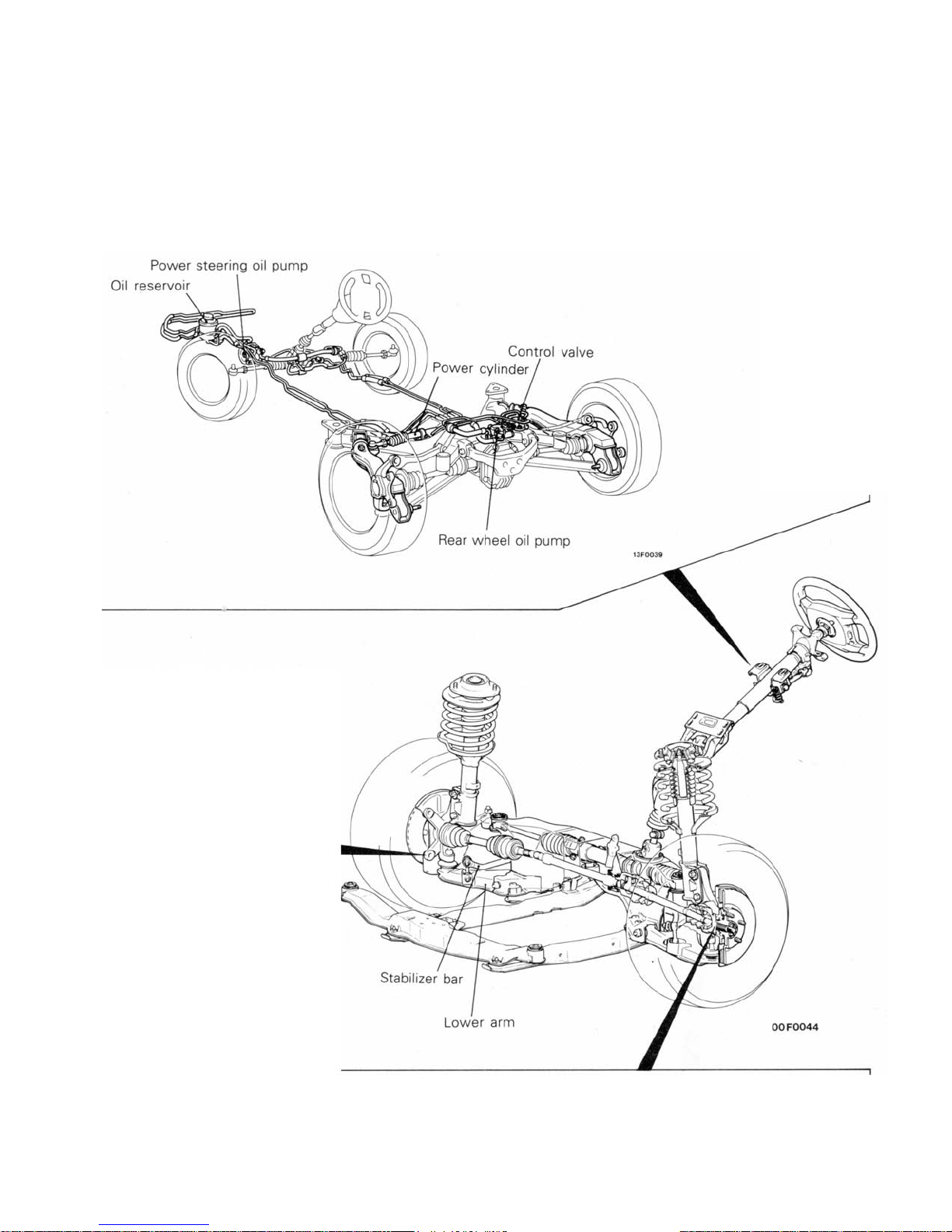

Steering

• A compact lightweight integral type rack and pinion type power steering for outstanding steering response.

• Tilt steering construction for ideal steering position.

• SRS built into the steering wheel to protect the driver.

• 4-wheel steering system (4WS) for improved stability in the medium and high speed range.

0-11

Front Suspension

• Very lightweight and rigid McPherson

strut type independent suspension.

• Offset coil spring for comfortable ride.

• Anti-diving geometry for outstanding

stability.

• Negative offset geometry for superior

stability when braking.

• Electronic control suspension (ECS) for

both driving stability and riding comfort.

• Liquid filled bushing to reduce noise.

Front Axle

• BJ-TJ type constant velocity joint with high transmission efficiency and minimum vibration and noise.

• Isometric drive shaft for reduced vibration, noise and torque steer.

• A unit ball bearing consisting of the hub and bearing for good serviceability and little rolling

resistance.

0-12 GENERAL - Technical Features

g

Brake

X-arrangement of lines that

maintains balanced braking in

front and rear even if the

hydraulic system is lost.

4-wheel anti-lock braking

system (4ABS) using 4sensor, 2-channel lock

method.

Dual proportioning valve

for control of rear wheel brakin

8+9 inch tandem brake

booster to reduce the

force needed to depress

the brake pedal.

.

Rear drum-in-ventilated disc

brake with built-in parking

brake and featuring good

braking stability.

Face-to-face and different diameter 4piston front ventilated disc brake with

stable braking force and good braking

feeling.

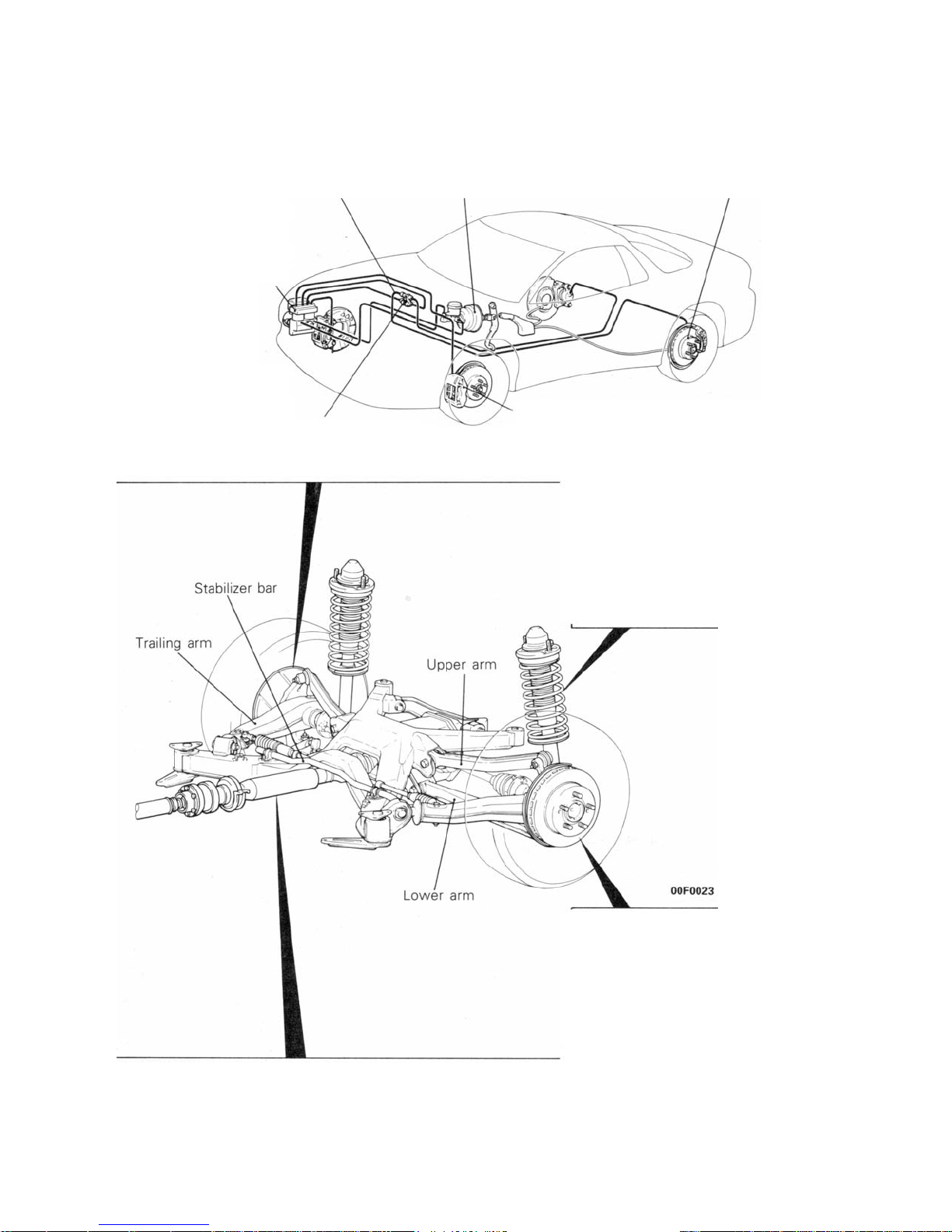

Rear Suspension

• Double wishbone type independent suspension for

outstanding riding comfort.

• Electronic control suspension (ECS) for both stable

handling and riding comfort.

Propeller Shaft

• 3-section 4-joint type propeller shaft with two center bearings.

• Robro joint to absorb lengthwise and angular change and prevent transmission of vibrations.

• Anti-vibration type propeller shaft (rear propeller shaft) to reduce vibration and noise from the drive train.

Rear Axle

• BJ-TJ type constant velocity joint with high transmission

efficiency and minimum vibration and noise.

• Viscous coupling type limited-slip differential.

GENERAL - Technical Features

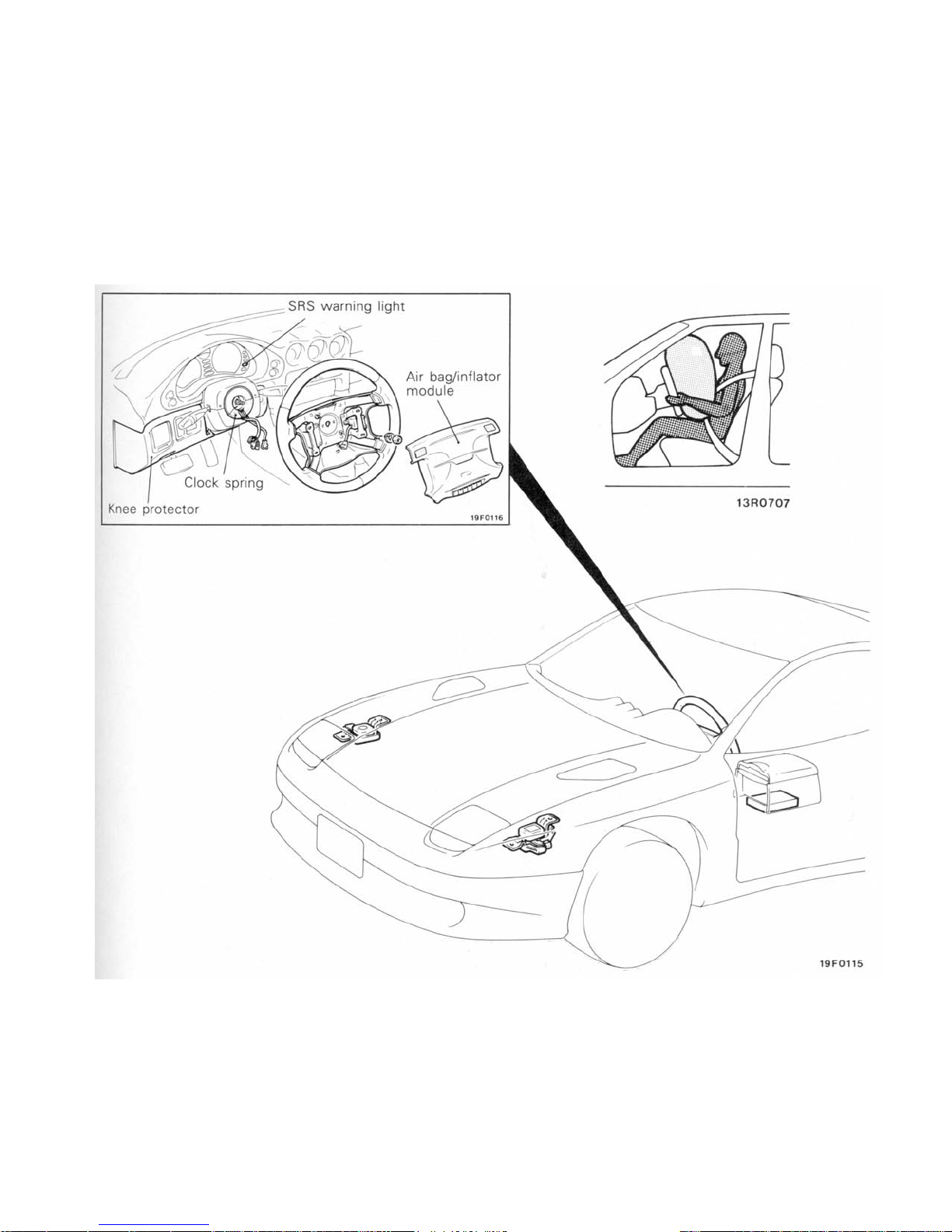

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

SRS is a system that works with the seat belt and is

designed as auxiliary equipment to the seat belt.

It only functions to protect the upper body of the driver

0-13

when a shock that is over the design value (deceleration

G) is added to the entire vehicle from the front.

0-14

GENERAL - Technical Features

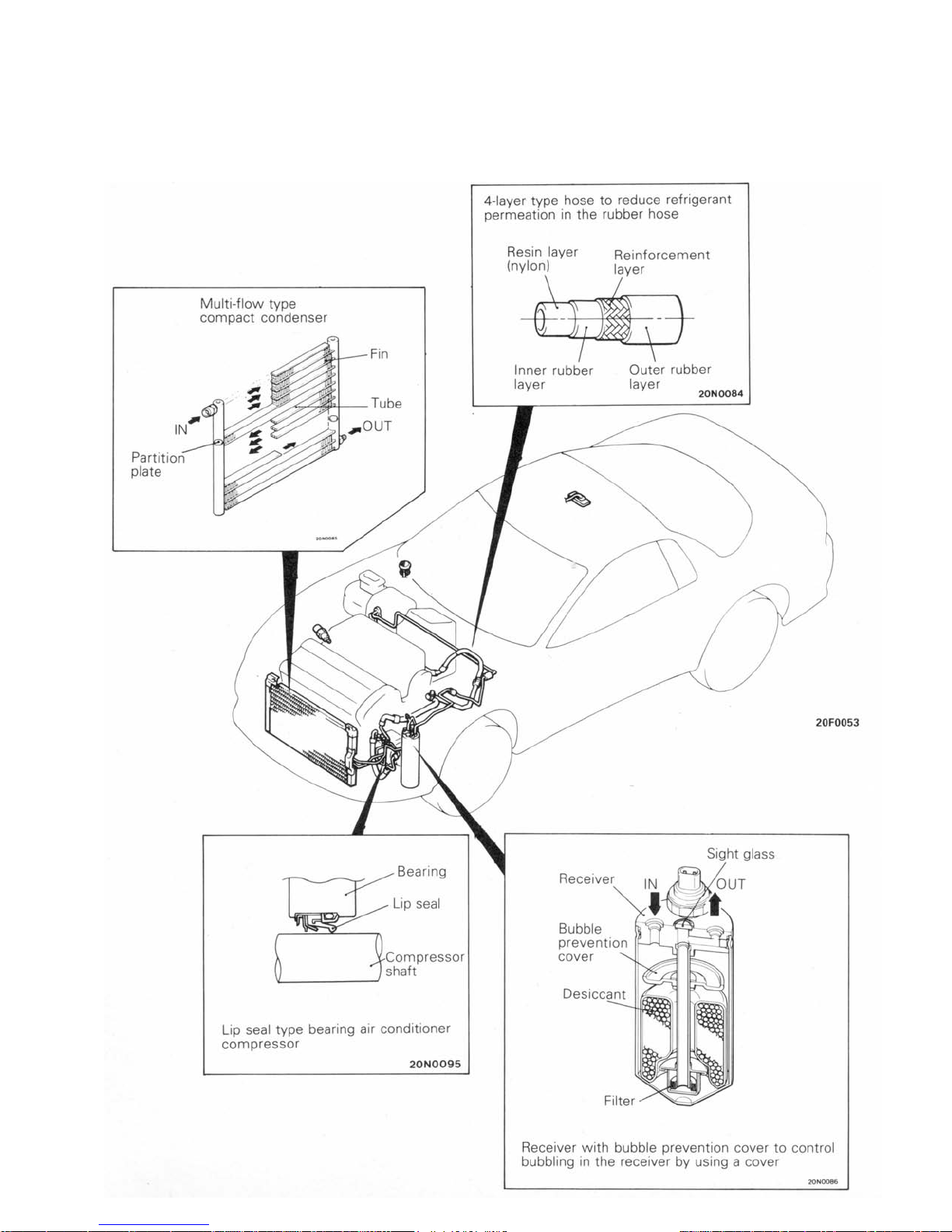

SMALL AMOUNT REFRIGERANT SYSTEM (AIR CONDITIONER)

In order to protect the ozone layer, the small amount

refrigerant system was developed by improving the

structural parts of the air conditioner, making it more

compact, etc. in order to reduce as much as possible

the amount of chloro-fluoro carbon used as the

refrigerant in automobile air conditioners.

A

GENERAL - Technical Features

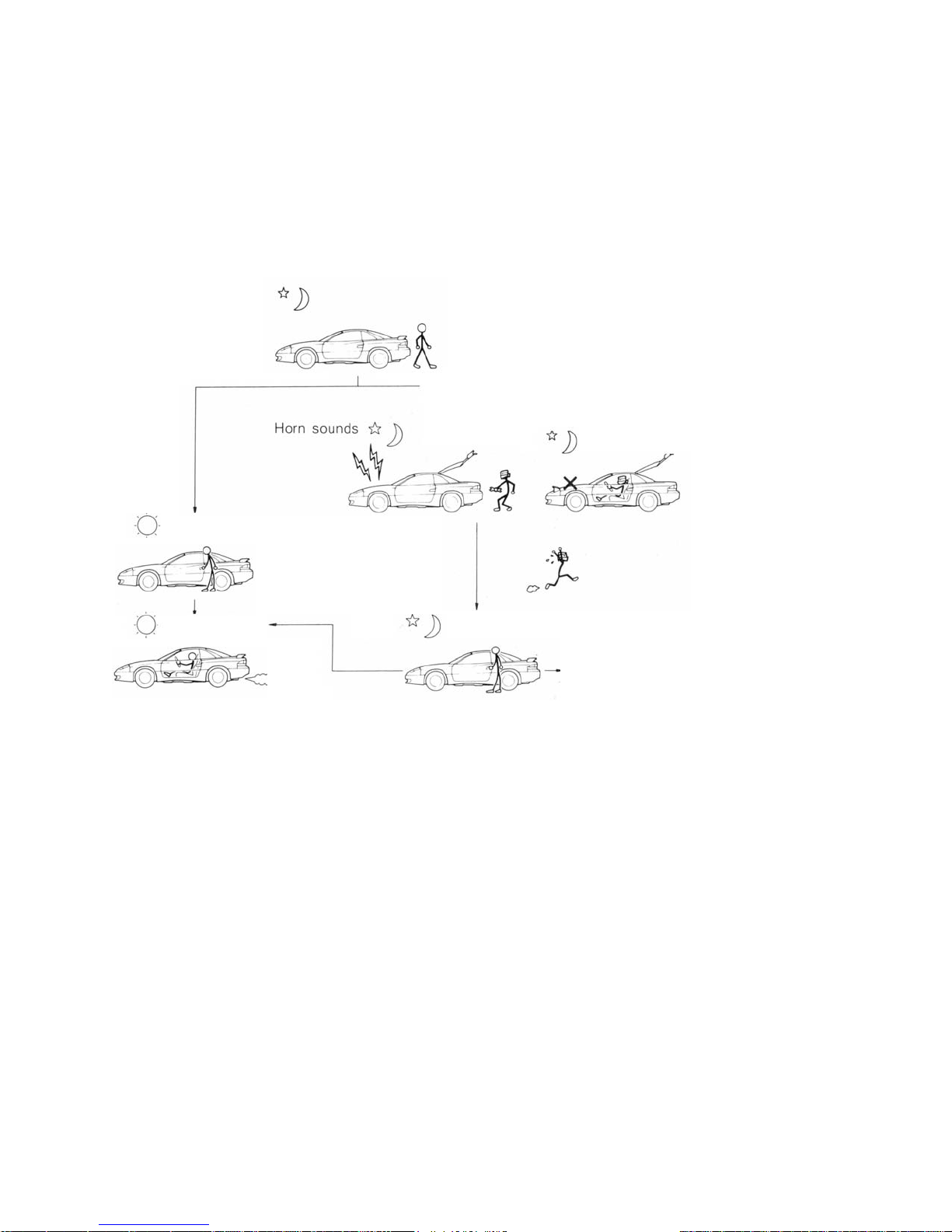

THEFT-ALARM SYSTEM

To make the vehicle theftproof, this system is designed to operate the horn intermittently for 30 seconds when the locked door, hood or tailgate has

been forced open without using a key. Furthermore,

the starter circuit is interrupted so that the engine

may not be operated.

About 20 seconds after all doors are closed and

locked, the tailgate is closed, and the hood is

closed

Æ

SYSTEM ARMED

0-15

Authorized

Driver opens door with the key

SYSTEM DISARMED

Normal starting

Unauthorized

A door, tailgate or hood is broken to

open

Æ

ALARM ACTIVATED

Driver unlocks a door or tailgate with the key.

Engine is disabled and will not start

LARM DEACTIVATED

(SYSTEM DISARMED)

16F0295

0-16

GENERAL - Technical Features

SERVICEABILITY

A series of investigations from a variety of angles are

carried out starting from the planning and design stages,

to produce a vehicle with complete diagnosis functions

Items of improved serviceability

• Adoption of hydraulic-type lash adjusters which make valve clearance adjustment unnecessary

• Adoption of an auto tensioner which makes timing belt tension adjustment unnecessary

• Adoption of a distributorless 3 coil ignition system

• Adoption of a camber adjustment mechanism in the front suspension

• Adoption of an alignment adjustment mechanism in the rear suspension

• Adoption of an outer disc method which makes brake disc removal and installation simple

• Adoption of audible pad wear indicators in the brakes

• Adoption of a drum in parking disc type brake to improve workability for the rear brakes

• Adjustment of gap between wheel speed sensors and rotors in 4ABS

• Colour-coding of service connectors (for ignition timing adjustment, fuel pump inspection and engine speed

inspection) to distinguish then from other connectors and make them easier to find

• Expansion and full realization of the self-diagnosis system

• Improvement in reliability due to harness junction connectors

• Centralization of relays

• Receiver piping connection has been made into a flange fitting and the end of the piping section has been flared to

prevent falling off of O-rings

and a reduced need for maintenance, with

improvements in reliability and durability.

GENERAL -

V

V

V

V

ehicle Identification

0-17

VEHICLE IDENTIFICATION

MODEL

VEHICLES FOR EUROPE

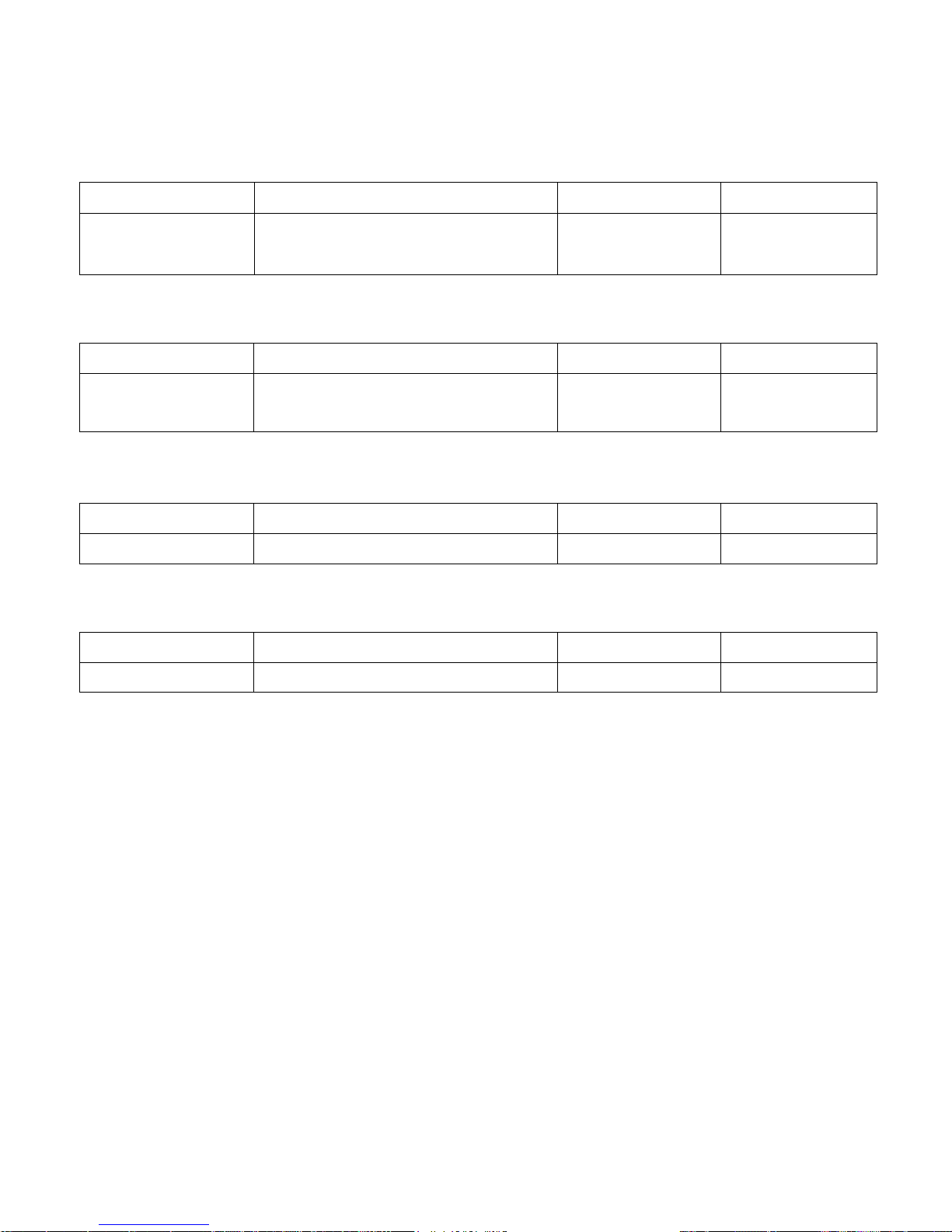

Model code Engine model Transmission model Fuel supply system

Z16AMNGFL6

Z16AMNGFR6

EHICLES FOR GENERAL EXPORT

Model code Engine model Transmission model Fuel supply system

Z16AMNGFL

Z16AMNGFR

EHICLES FOR GCC

6G72 [2,972 cm3 (181.4 cu. in.)] W5MG1 MPI

6G72 [2,972 cm3 (181.4 cu. in.)] W5MG1 MPI

Model code Engine model Transmission model Fuel supply system

Z16AMNGFLW 6G72 [2,972 cm3 (181.4 cu. in.)] W5MG1 MPI

EHICLES FOR AUSTRALIA

Model code Engine model Transmission model Fuel supply system

Z16AMNGFR8 6G72 [2,972 cm3 (181.4 cu. in.)] W5MG1 MPI

MODEL CODE

Z1 6 A M N G F L 6

1

1. Development order

Z1 - MITSUBISHI 3000GT

(Full time 4WD)

2. Engine type

6 - 2,972 cc (181.4 cu. in.), petrol

3. Sort

A - Passenger car

4. Body style

M - 2-door hatchback

5. Transmission type

N - 5-speed manual transmission

6. Trim code

(&

Drive train)

2 3

4

5

6

7

8

9

7. Specified engine feature

F - Turbocharger (with intercooler)

8. Steering wheel location

L - Left hand

R - Right hand

9. Destination

6 - For Europe

8 - For Australia

W - For GCC

None - For General Export

0-18

OO

GENERAL - Major Specifications

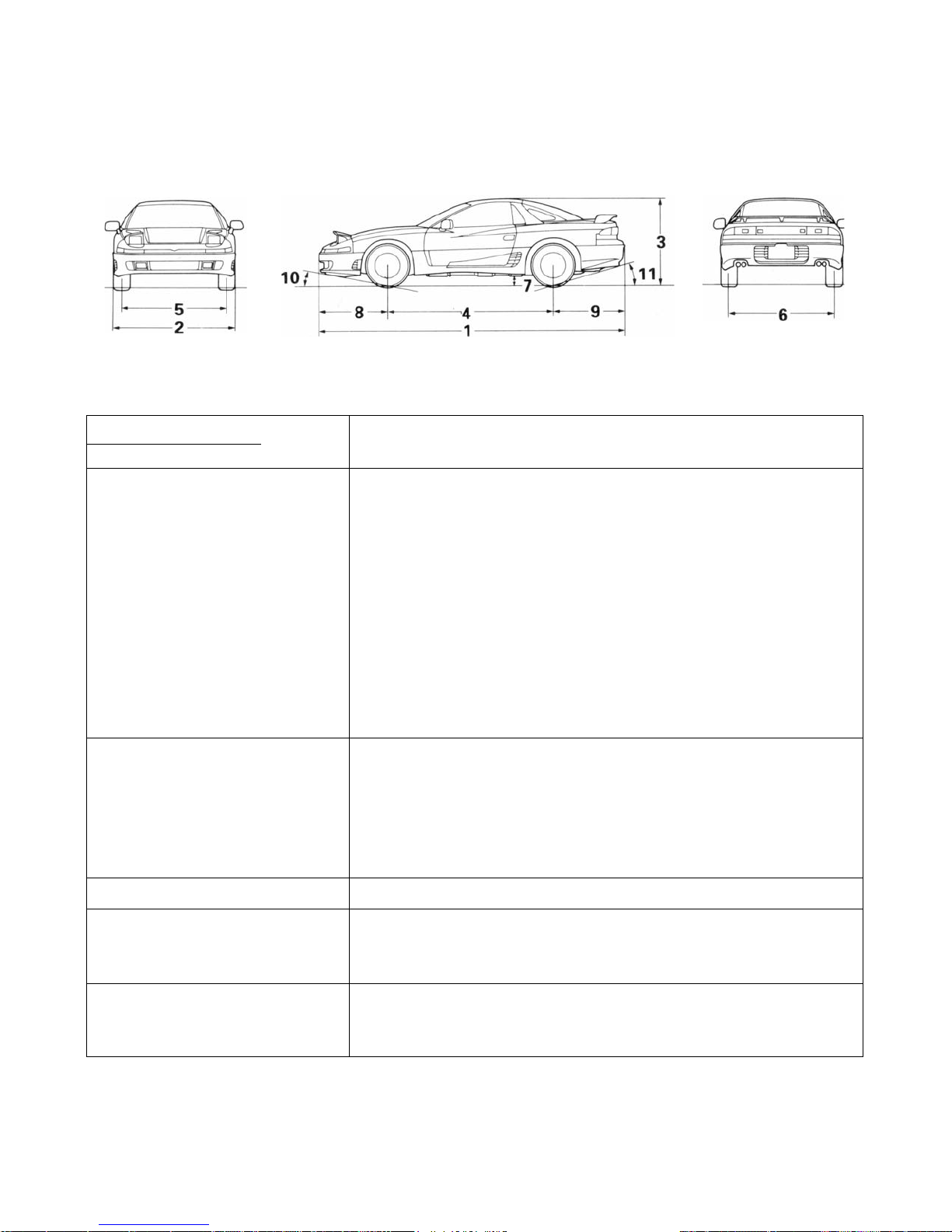

MAJOR SPECIFICATIONS

Items Z16AMNGFL6 Z16AMNGFL Z16AMNGFLW

Dimensions mm(in.)

Overall length 1 4,560 (179.5)

Overall width 2 1,840 (72.4)

Overall height (unladen) 3 1,285 (50.6)

Wheelbase 4 2,470 (97.2)

Track-Front 5 1,560 (61.4)

Track-Rear 6 1,580 (62.2)

Ground clearance (unladen) 7 145 (5.7)

Overhang-Front 8 1,030 (40.6)

Overhang-Rear 9 1,060 (41.7)

Angle of approach degrees 10 11.2°

Angle of departure degrees 11 17.3°

, Z16AMNGFR6 Z16AMNGFR Z16AMNGFR8

F0015

Weight kg (Ibs.)

Kerb weight 1,740 (3,836)

Gross vehicle weight 2,120 (4,674)

Max. axle weight

Front 1,150 (2,535)

Rear 1,020 (2,249)

Seating capacity 4

Engine

Model 6G72

Total displacement cm3 (cu.in) 2,972 (181.4)

Transmission

Model W5MG1

Type 5-speed manual

/

1-1

CONTENTS

ENGINE

-

GENERAL INFORMATION .........................................2

Specifications ......... ............................................... 2

Engine Sectional View ............................................ 2

BASE ENGINE ..............................................................

Oil Jet .........................................................................4

Main Bearing Cap ......................................................4

Crank Angle Sensor and

Cam Position Sensor .................................................5

Crank shaft ................................................................5

Exhaust Valve ...........................................................5

MOUNTING ..................................................................

LUBRICATION SYSTEM ............................................. 7

COOLING SYSTEM .....................................................

Specifications ............................................................8

INTAKE/EXHAUST SYSTEM .................................... 10

Twin-turbochargers and Twin-intercoolers ………. 10

Turbo Pressure Control ...........................................10

Exhaust Pipe .......................................................... 11

FUEL SYSTEM ...........................................................12

Fuel-pressure Control Valve .................................. 12

Fuel Tank ............................................................... 12

4

6

8

CONTROL SYSTEM …………………………………....14

System Block Diagram ……………………………….15

Sensors ……………………………………………….. 16

Actuators ……………………………………………….18

Fuel Injection Control …………………………………19

Idle Speed Control (ISC) …………………………… 20

Mechanical Dashpot ………………………...............21

Ignition Timing and

On Time Control ......................................................22

Power Supply and

Fuel Pump Control ..................................................23

Fuel Pump Discharge

Volume Control ………............................................ 24

Turbo Meter Control ... ............................................ 24

Turbo Pressure /Control .......................................... 25

Fuel Pressure Control ............................................. 26

Air Flow Sensor (AFS)

Filter Reset Control ................................................. 26

Self Diagnosis System ............................................ 27

EMISSION CONTROL SYSTEM ................................30

CRUISE CONTROL SYSTEM ....................................32

1-2

ENGINE -

General Information

GENERAL INFORMATION

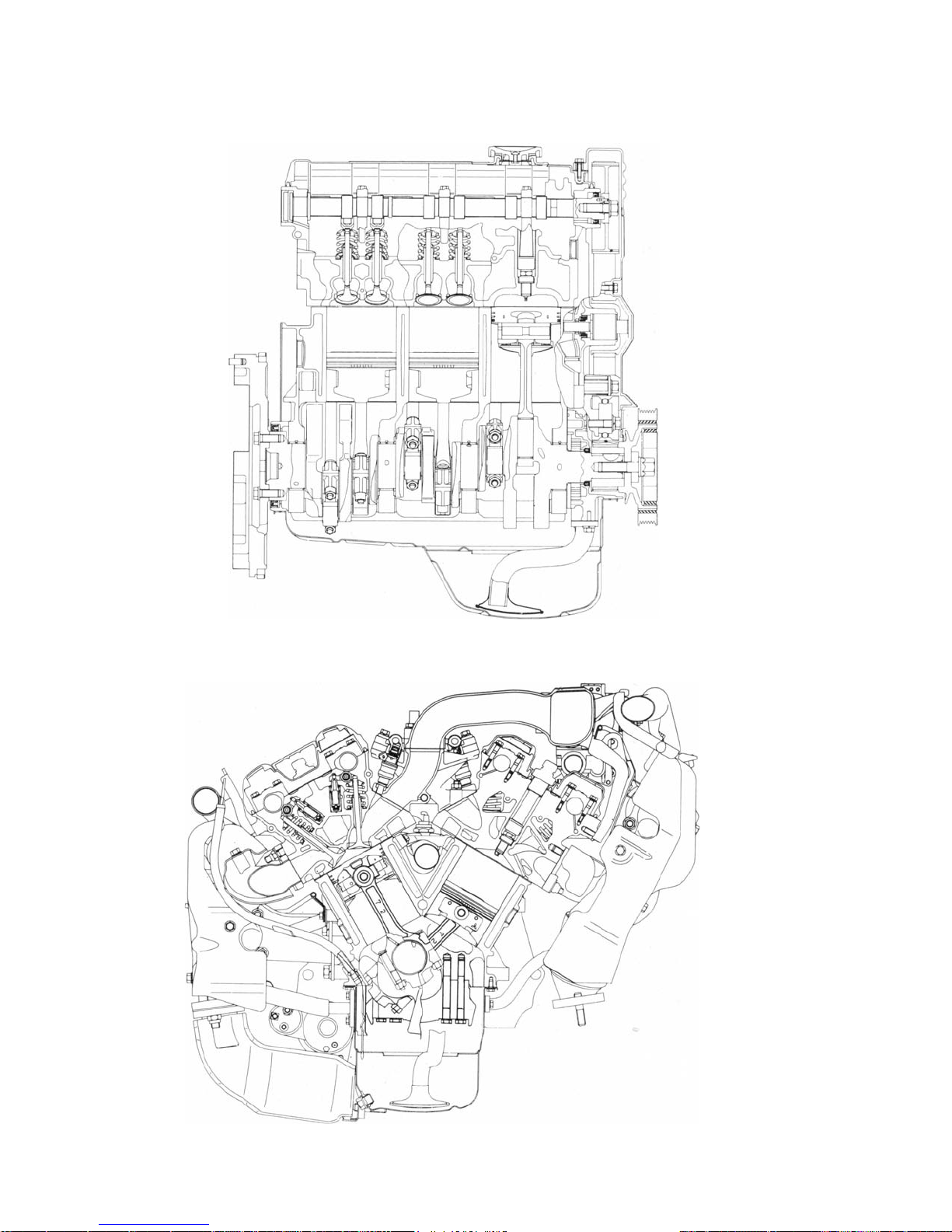

The engine is a V-type 6-cylinder (bank angle 60°) 2,972

3

(181.4 cu.in.) DOHC 24 valve design and is

cm

basically the same as the engine equipped in the

SIGMA. However, twin turbochargers and twin intercoolers have been installed to provide even higher

output and higher performance.

SPECIFICATIONS

Items Specifications

Total displacement cm3 (cu. in.) 2,972 (181.4)

Arrangement and number of cylinders V type, 6 cylinders

Combustion chamber type Pentroof type

Number of intake and exhaust valve (per cylinder) 2 each

Valve mechanism OHV, DOHC (per bank)

NOTE

For details of the basic engine structure, refer to the

previously-issued '91 SIGMA Technical Information

Manual. (Pub. No. PYGE9008).

Bore x stroke mm (in.) 91.1 x 76.0 (3.59 x 2.99)

Compression ratio 8.0

Maximum output PS/rpm 285/6,000

Maximum torque kgm/rpm 41.5/3000

Valve timing Intake Opened 16° BTDC

Exhaust Opened 50° BBDC

Fuel supply system Electronic controlled multi-point fuel injection

Ignition system Power distribution method Electronic controlled 3-coil type

Ignition timing control method Electronic controlled type

Closed 55° ABDC

Closed 17° ATDC

ENGINE -

1-3

General Information

ENGINE SECTIONAL VIEW

7EN0477

7EN0478

1-4

BASE ENGINE

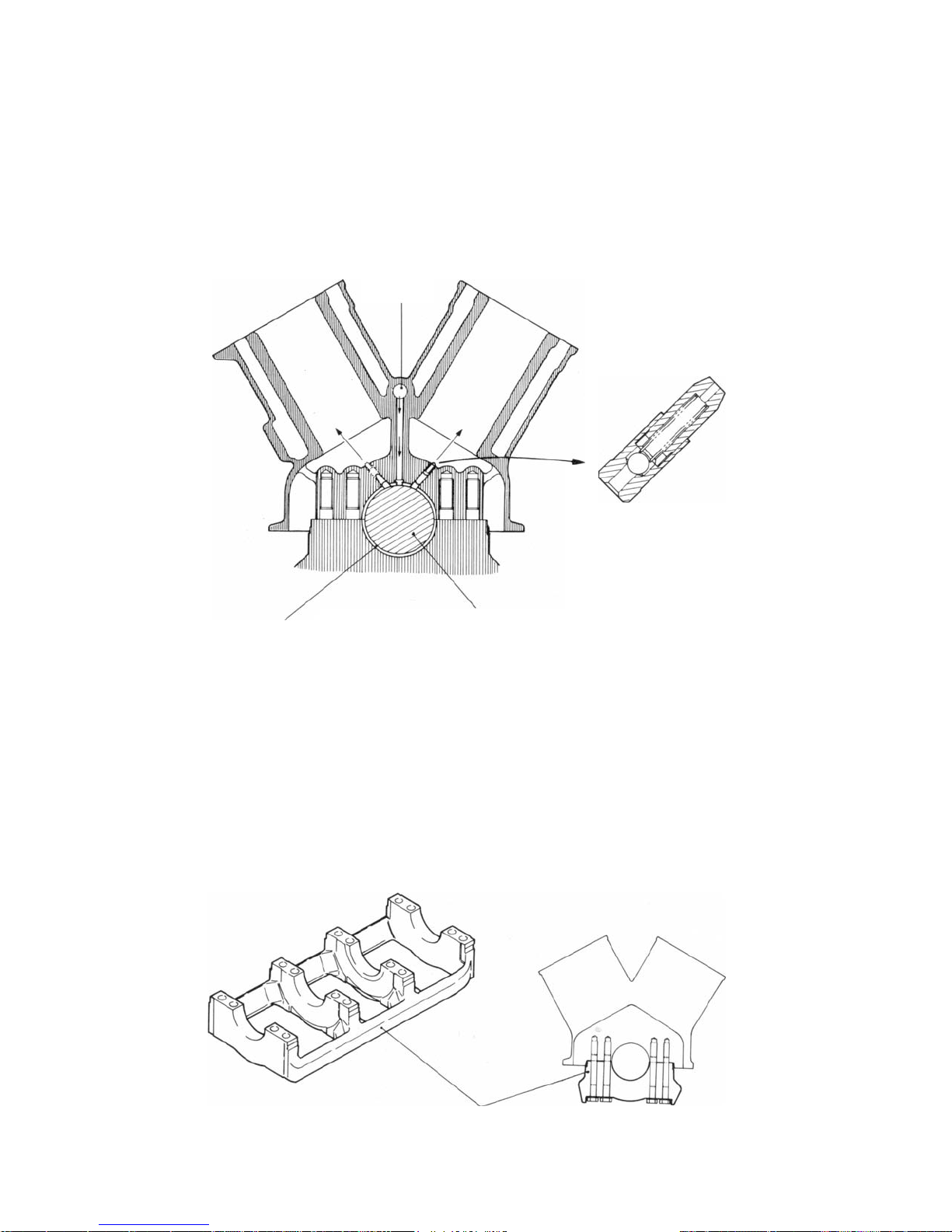

OIL JET

There is an oil jet for cooling the pistons.

ENGINE - Base Engine

Main gallery

Main bearing

Crankshaft

MAIN BEARING CAP

The main bearing caps are of a conventional integrated

type with beam. By tightening each of the bearing

sections with 4 bolts, rigidity has been improved and

Oil jet

[opens valve at

2

2 kg/cm

(28 psi) or more]

7EN0479

vibration from the main drive section has been

reduced.

Main bearing cap

7EN0480

ENGINE - Base Engine 1-5

N

A

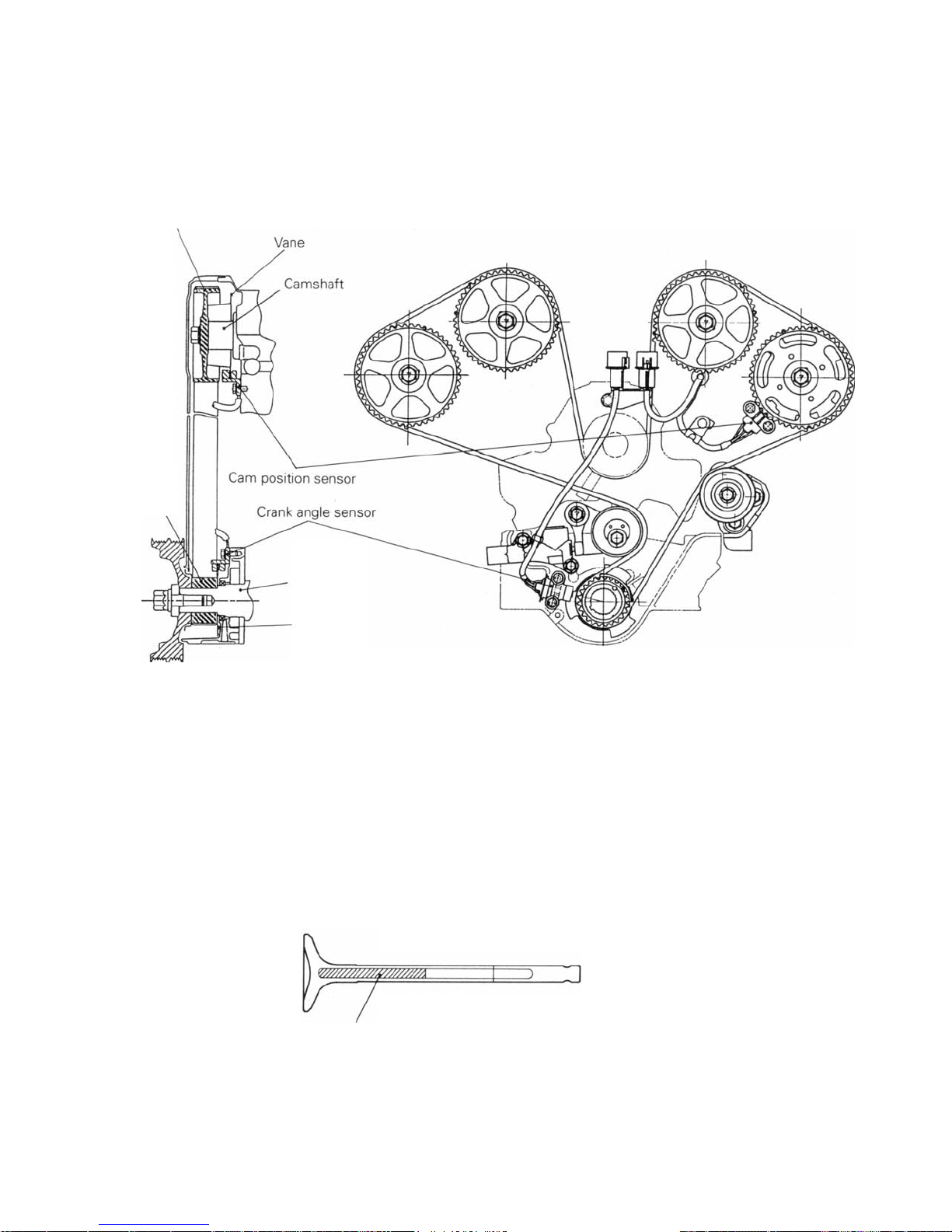

CRANK ANGLE SENSOR AND CAM POSITION SENSOR

An ultra-small crank angle sensor and cam position a large space saving and to provide improved

sensor have been positioned inside the crankshaft crank angle detection precision.

sprocket and camshaft sprocket respectively to realize

Cam sprocket

Crank sprocket

Crankshaft

Vane

7EN0481

CRANKSHAFT

steel crankshaft has been adopted in order to cope

with the increased engine output and to provide

reduced noise and reduced vibration.

EXHAUST VALVE (VEHICLES FOR EUROPE ONLY)

Lightweight sodium-filled vacuum valves have been been improved, and improvements have been real-

developed for use as the exhaust valve to improve ized in anti-knock characteristics and fuel consump-

valve follow in high-speed ranges. At the same time, tion efficiency at high speeds.

the cooling performance of the exhaust valve has

Caution on handling the metallic sodium-filled exhaust valve.

Because metallic sodium reacts violently when it For specific details, refer to the Engine Workshop

comes into contact with water or moisture to gener- Manual.)

ate hydrogen gas, there is a danger that explosion or

fire may occur, so it should be treated with caution.

a

7EN0482

01R0639

01F001

01N0101

1-6

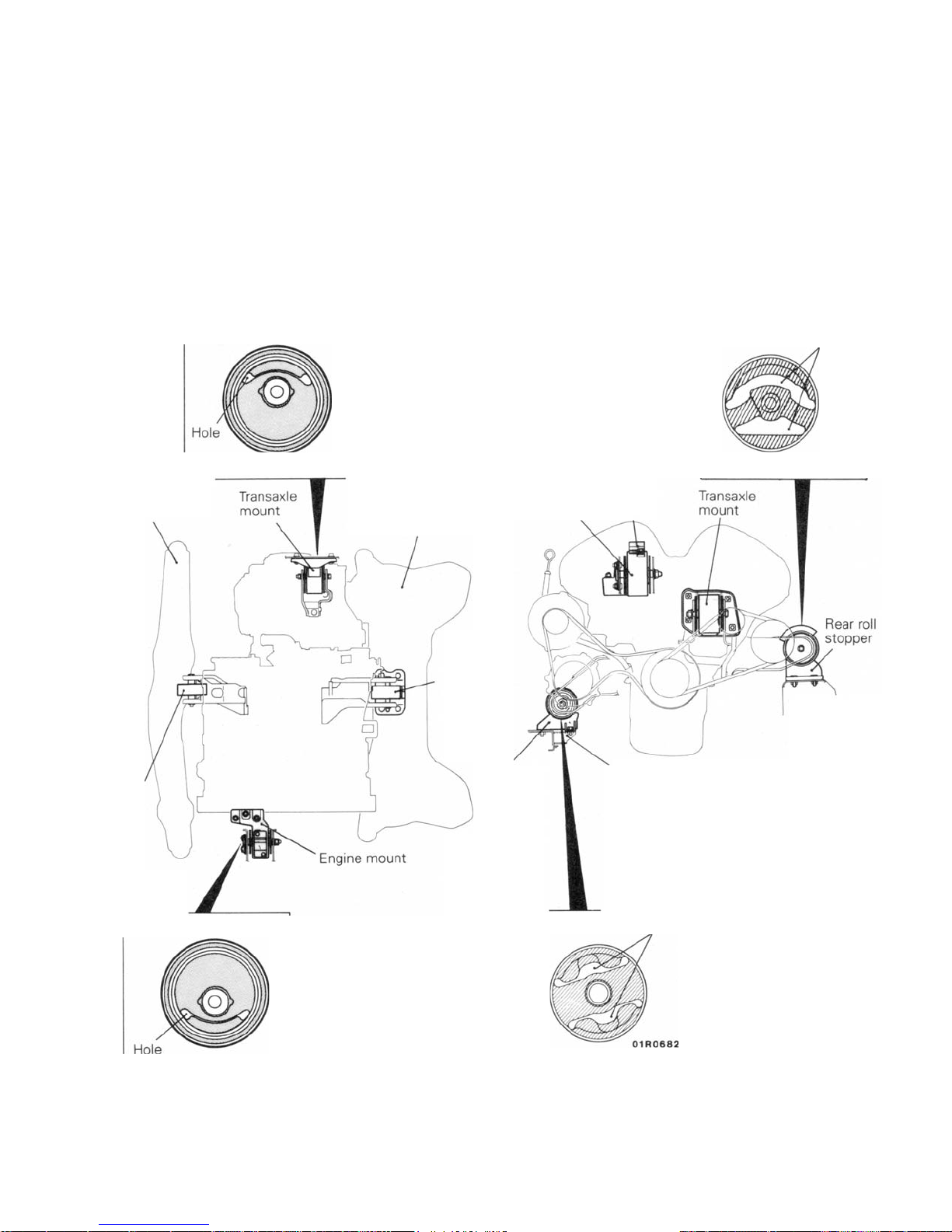

MOUNTING

ENGINE -

Mounting

The engine mounts use a principal axis inertia support

system.

This support method on the principal axis inertia is a

structure that supports the top of the engine and top of

the transmission to effectively control engine vibration.

A dynamic damper is provided on top of the engine

mount to cut out high-frequency noise.

Insulator

01N0101

No. 1 crossmember

No.2 crossmember

Roll stoppers (front and rear) are installed on the

crossmember that is elastically supported on the body to

reduce transmission of engine vibration to the body.

The various mounts have the following features

• Each insulator has a hole to effectively absorb small

and large vibrations.

Engine

mount

Dynamic

damper

Insulator

Hole

Front

~

Front roll

stopper

Insulator

Front

~

Rear

roll

stopper

Front roll

stopper

7

Insulator

No.1

crossmember

Hole

No. 2

crossmember

01 F0014

A

LUBRICATION SYSTEM

ENGINE - Lubrication System

1-7

n oil pressure gauge unit has been installed in all

models. In addition, an oil level sensor has been

Rocker arm

Lash

adjuster

Orifice

equipped in the oil pan (Vehicles for Europe).

Oil filter

Oil pressure

gauge unit

Oil cooler

To oil level relay •

Oil pressure

switch,

Relief

valve

Lash

adjuster

To

turbocharger

t,

I

Oil pan

Oil level sensor

7EN0483

1-8

•

COOLING SYSTEM

ENGINE - Cooling System

The cooling system uses a water cooling pressure

control circulation system and it has the following

features.

• The cooling (radiator) fan uses a motor driven system. The fan is driven by the motor only when

needed to efficiently control the cooling water

temperature and reduce engine output loss .

• The cooling fan is a full shroud type for improved

cooling performance.

The two step control system is used for the motor

driven cooling fan and condenser fan for less fan

noise, reduced vehicle vibration and improved

cooling when the engine is idling. (Refer to GROUP

7 - Condenser Fan and Radiator Fan Control for fan

speed operation mode.)

SPECIFICATIONS

Items Specifications

Cooling fan

Type Motor driven system

Water pump

Type Centrifugal type impeller

Drive method Timing belt

Thermostat

Type Wax type

Open valve temperature °C (ºF) 76.5 (170)

Radiator

Coolant capacity (including that in

condenser tank) dm3 (U.S. qts., Imp. qts.) 8.0 (8.5, 7.0)

Condenser tank capacity dm3 (U.S. qts., Imp. qts.)

Full 0.65 (0.69, 0.57)

Low 0.25 (0.25, 0.22)

Type Corrugated type

0

ENGINE - Cooling System

Items Specifications

Radiator fan motor

Maker Nippon Denso

Type Direct flow ferrite type

Rated load torque Nm (kgm, ft.lbs.) 53 (5.3, 39)

Speed rpm 2,080 ± 250

Current

Thermo sensor for radiator fan

Operating temperature °C (ºF)

OFF --+ ON 81-89 (178-192)

ON --+ OFF 77 (171) or more

Thermo sensor for condenser fan

Operating temperature

OFF --+ ON 91-99 (196-210)

ON --+ OFF 87 (189) or more

-

°C (ºF)

·A

13.6 ± 1

1-9

4 FOOO3

1-10

ENGINE -

Intake/Exhaust System

INTAKE/EXHAUST SYSTEM

TWIN TURBOCHARGERS AND TWIN INTERCOOLERS

Compact, lightweight, turbochargers with outstanding

response are used in each bank, front and rear, for the

best turbo feeling at all speeds, from low to high. The

turbocharger is a water-cooled TD04 type with waste

gate valve. The intercoolers are very efficient and each

Intake

one is arranged on the front and rear banks just like the

turbocharger. With the combined action of the

turbocharger and intercooler, powerful acceleration is

possible from any speed.

Turbocharger

Intercooler

Turbocharger

Intercooler

TURBO PRESSURE CONTROL

The waste gate operating pressure is controlled to

make possible flat turbo pressure characteristics

Intercooler

Air from

air cleaner

71N0107

over the entire rpm range and to provide a linear ac:celeration feeling.

¢

Air into engine

Exhaust

from engine

Waste gate

solenoid valve

Exhaust to

exhaust pipe

Waste gate actuator

71N0108

f

ENGINE -

Intake/Exhaust System

EXHAUST PIPE

The exhaust pipe is divided into three sections, front

pipe, centre pipe and main muffler. It is installed on the

body via a rubber hanger to reduce transmission o

vibrations from the exhaust system to the body. A dual

Oxygen sensor <Vehicles for Australia>

Heat protector <Vehicles

for Australia>

Flexible pipe

pipe is used for the front pipe to improve exhaust

efficiency, and a dual tail pipe with muffler cutter is used

as the main muffler.

1-11

Catalytic converter

(Right) <Vehicles for

Europe> or exhaust

pipe (Right) <Vehicles

for General Export, GCC and Australia>

05F0061

Pre-muffler

Catalytic converter

<Vehicles for Europe and Australia>

or pre-muffler <Vehicles

for General Export and GCC>

1-12

j

r

ENGINE - Fuel System

FUEL SYSTEM

The fuel system consists of electromagnetic fuel in-

ectors, delivery valves, a fuel pressure regulator for

regulating fuel pressure, and an electromagnetic fuel

pump which operates at high pressure. It is basically

the same as the fuel system in the conventional 6G7

engine, but the fuel pressure is controlled to 3.0 kg/

2

cm

. In addition, in order to verify the idling stability

immediately after re-starting the engine at high

temperatures, a fuel pressure control solenoid valve

which is the same as the one fitted in the convention-

al 4G63 engine.

The fuel tank is located under the luggage compartment floor and the fuel filters are in the fuel tank and

in the engine compartment to filter the fuel. For bette

serviceability, there is a terminal for the fuel pump

drive in the engine compartment and a service hole in

the luggage compartment; the pump and gauge

assembly can be removed without removing the fuel

tank.

Fuel pump drive

terminal

Fuel filter

Fuel pressure

regulator

PCV

Canister

~

Fuel injector

Delivery pipe

FUEL-PRESSURE CONTROL VALVE

Two-way valve

Protector

Fuel pump and

gauge assembly

Fuel tank

In-tank filter

03 FOO09

1-13

A

ENGINE - Fuel System

Normally, the negative pressure in the intake manifold

acts upon the fuel pressure regulator to maintain the

fuel pressure at a constant level with regard to the

pressure inside the intake manifold, causing the amount

of fuel injected to be controlled in proportion to the

injector drive time. However, if the engine is started

while the engine coolant temperature and the intake air

temperature are high, the engine control unit makes

FUEL TANK

The electric fuel pump, in-tank filter and fuel gauge unit

are built into the fuel tank.

The fuel tank has the following features.

• Baffle plates are placed inside the fuel tank to

prevent abnormal noise due to fuel movement.

• There is a reseve cup inside the fuel tank for

Thermistor

(for fuel warning light)

current flow to the fuel pressure control valve to activate

the fuel pressure regulator by means of atmospheric

pressure.

Because of this, the generation of fuel vapour due to

the high fuel pressure and high temperature is

avoided, and the idling stability immediately after restarting the engine at high temperatures is maintained.

smooth supply of fuel even when there is little fuel

remaining.

pump and gauge assembly that combines the

•

gauge unit and fuel pump in one unit is adopted.

• A drain plug is standard-equipped on all models.

Pump and gauge assembly

In-tank filter

Drain plug

Fuel tank

03F0008

1-14

CONTROL SYSTEM

ENGINE - Control System

The control system used is basically the same as that in

the conventional 6G72 engine in the SIGMA. However,

Main items changed or added Notes

Control relay and fuel pump power circuit have

been changed.

Crank angle sensor mounting position has been

changed. (Crank angle previously detected from Improvement in ignition timing control precision

the camshaft is now detected directly from the

crankshaft.)

Adoption of fuel pump relay No.2 and fuel pump Improvement in fuel pump reliability

resistor

Fuel pressure control has been added.

(Refer to P.1-26.)

Turbo pressure control has been added. Control additions to correspond to adoption of a turbocharger

Turbo meter control has been added.

Adoption of a twin oxygen sensor system Reduction in exhaust gas levels

<Vehicles for Europe, Hong Kong and Singapore>

·

·

·

some parts differ as shown below.

Simplified power circuit

Basically the same as the 4G9-DOHC engine

Improvement in crank angle sensor precision

SYSTEM BLOCK DIAGRAM

ENGINE - Control System

1-15

Remarks

The changed or added items with respect to the conventional engine are shown in bold letters.

1-16

SENSORS

Carn position sensor and crank angle sensor

ENGINE - Control System

6AF0009

Carn position sensor

The cam position sensor consists of a flux screening

plate fixed to the crankshaft sprocket on the rear bank

exhaust side and a sensor unit fixed to the cylinder

head. The crank angle sensor consists of a flux

screening plate fixed to the crankshaft sprocket and a

sensor unit fixed to the engine oil pump case. The cam

position sensor and crank angle sensor convert the

rotation of the camshaft and crankshaft into pulse sig-

NO.1 cylinder TOC signal

No. 2 cylinder No.3 cylinder No. 4 cylinder No.5 cylinder No.6 cylinder

TOC signal TOC signal TOC signal TOC signal TOC signal

J

Cam position

sensor signal

Crank angle

sensor signal

.. 5V

No. 1 cylinder

TOC signal

OV

5V

OV

6AF0002

Crank angle sensor

nals as shown in the illustration below, and input these

pulse signals to the engine control unit. Furthermore,

these waveforms are the same as those for the

conventional 6G7-DOHC engine, but the mounting

precision of the crank angle sensor has been improved,

making basic ignition timing adjustment unnecessary.

Two rev. of engine

7FU0729

1-1

ENGINE - Control System

7

Flux screening plate for Carn

position sensor

Flux screening plate for

crank angle sensor

Vane

6AF0010

Vane

6AF0003

The shapes of the flux screening plates used in the cam position

sensor and crank angle sensor are as shown in the illustration at left.

Detection of the cam position and crank angle is the same as for the

conventional 4G93-S0HC engine, where the magnetic flux passing

through the Hall element inside the sensor unit is alternately

screened and allowed through by the vanes on the flux screening

plate.

TWIN OXYGEN SENSOR <Europe, Hong Kong and

Singapore>

There are sub catalysts in both the front and rear banks in the engine.

In order to maintain the proper air/fuel ratio in both banks, there is an

oxygen sensor for each one before the catalyst of both banks to

enable feedback control of the air/fuel ratio for each bank separately.

Each oxygen sensor is the same as the conventional oxygen sensor

with heater.

1-18 ENGINE - Control System

ACTUATORS

FUEL PUMP RELAY NO.2

Fuel pump relay No.2 is the relay that changes the supply voltage to

the fuel pump in 2 steps, High/Low.

The engine control unit controls the amount of fuel discharged from

the fuel pump by changing the supply voltage.

FUEL PUMP RESISTOR

The fuel pump resistor lowers the supply voltage to the fuel pump.

ENGINE -

Control System

FUEL INJECTION CONTROL

The fuel injection control method is basically the same

as that used in the conventional 6G72 engine.

SYSTEM CONFIGURATION DIAGRAM

1-19

1-20

ENGINE -

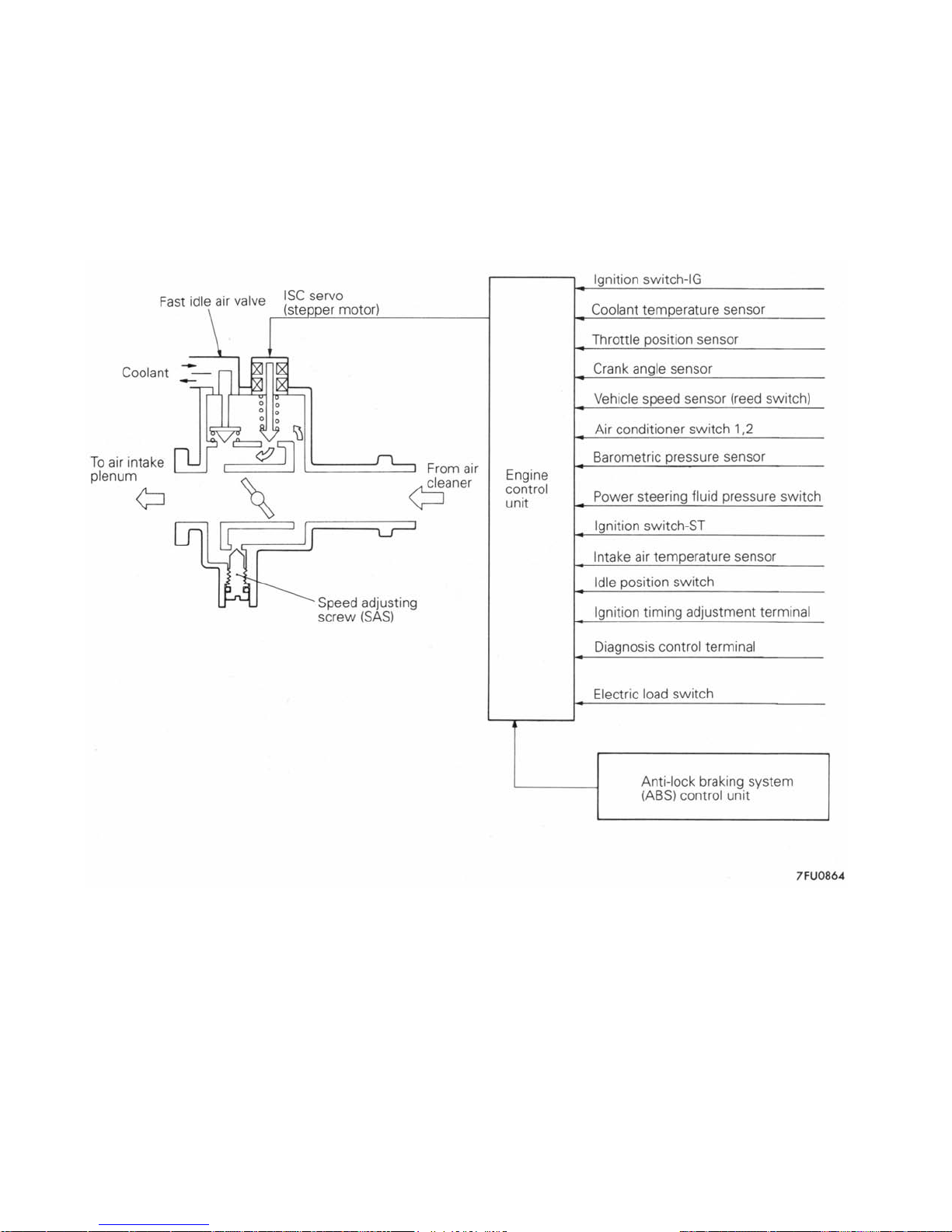

IDLE SPEED CONTROL (ISC)

Control System

(1) Stepper motor (STM) position control with the anti-

lock braking system (ABS) function was added.

SYSTEM CONFIGURATION DIAGRAM

(2) Other controls are basically the same control system

as in the conventional 6G72 engine.

ENGINE - Control System

1-21

MECHANICAL DASHPOT

There is a mechanical dashpot which gradually closes the throttle

valve from a set opening during deceleration to improve deceleration

feeling.

1-22

ENGINE -

Control System

IGNITION TIMING AND ON TIME CONTROL

The ignition timing and on time control methods are

basically the same as those used before.

SYSTEM CONFIGURATION DIAGRAM

ENGINE - Control System

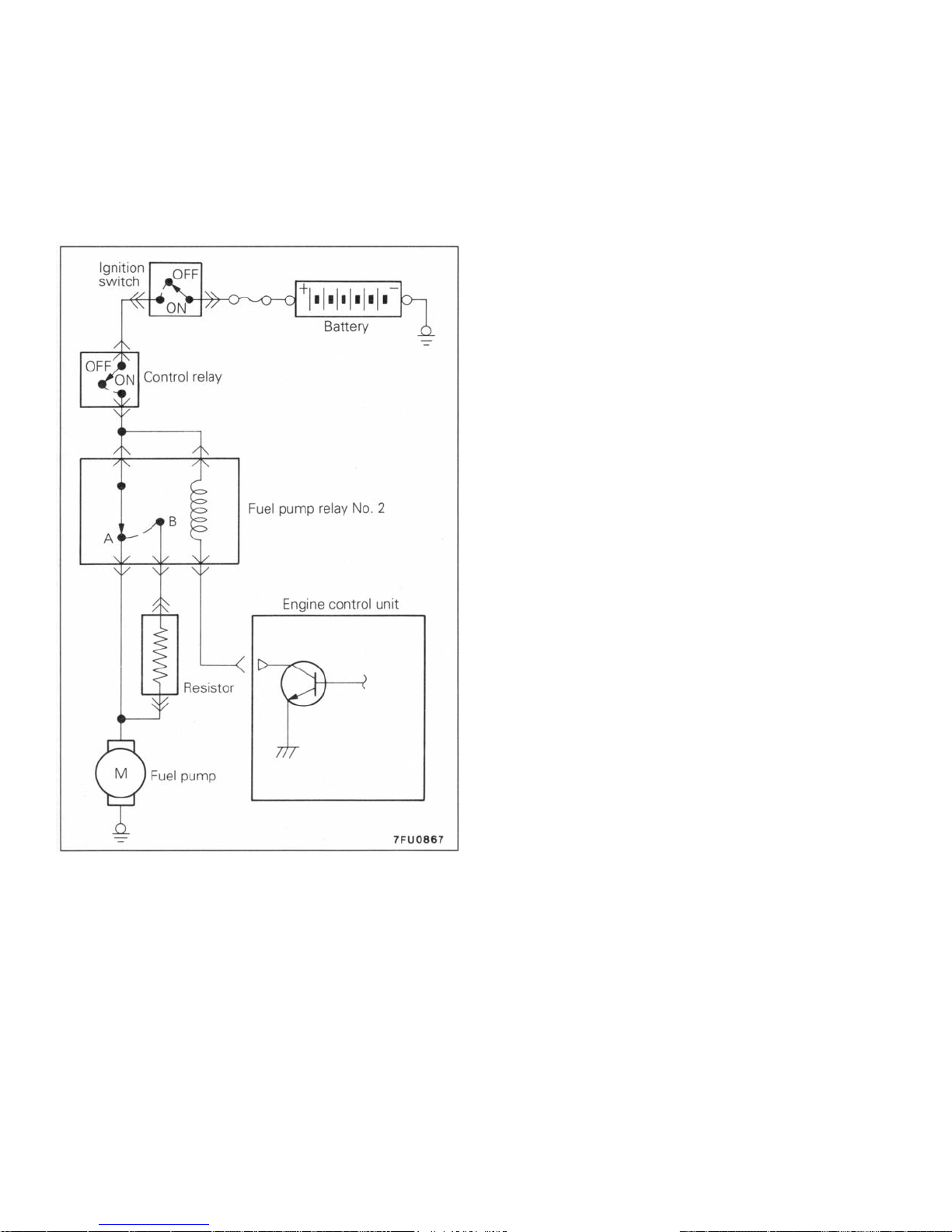

POWER SUPPLY AND FUEL PUMP CONTROL

1-23

Power supply control to the injector, air flow sensor, ISC

servo, etc. is the same as in the conventional 6G72

engine.

Fuel pump control for controlling power supply to the

fuel pump is also the same as in the conventional 6G72

engine.

FUEL PUMP DISCHARGE

VOLUME CONTROL

Fuel pump discharge volume is controlled in two steps

according to the amount of intake air (engine load) in 1

cylinder in 1 cycle for improved reliability of the fuel

pump. When the amount of intake air in this 1 cylinder 1

cycle is small (engine load is low), the engine control

unit turns on the power transistor so current flows in the

coil of fuel pump relay

changes form A to B (refer to the figure on the left.), and

current flows via the resistor to the fuel pump motor. The

supply voltage to the fuel pump is reduced since the

voltage is lowered by the resistor, pump speed falls and

the amount of fuel discharged from the fuel pump is

reduced.

When the amount of intake air in this 1 cylinder 1 cycle

is large (engine load is high), the engine control unit

turns off the power transistor and changes the relay

switch from B to A (refer to the figure on the left.). As a

result, voltage drop due to the resistor increases, pump

speed rises and the amount of fuel discharged from the

fuel pump increases.

No.2. As a result, the relay switch

1-24

TURBO METER CONTROL

FUEL - Control System

The turbo meter is a current type meter. The engine

control unit receives the intake air volume signal from

the air flow sensor and the rpm signal from the crank

angle sensor and calculates the engine load.

Duty Ratio

The duty ratio is defined as ON time ratio

When the duty ratio increases, average current that flows to the

turbo meter also increases so that the turbo meter indicates higher

value.

When the duty ratio is decreased, the turbo meter indicates smaller

value.

Then, the unit determines the duty ratio according to the

load and drives the turbo meter.

Duty ratio ~=

Load ~=

T2/T1

of a 33.3 Hz pulse.

TURBO PRESSURE CONTROL

FUEL - Control System

1-25

Turbo pressure used in the waste gate actuator is

controlled by duty control of the waste gate solenoid

valve. As a result, turbo pressure corresponding to

driving conditions can be obtained.

The engine control unit turns the power transistor in the unit on and,

when normal current (duty 100%) flows in the waste gate solenoid

valve coil, the waste gate solenoid valve does not open if turbo

pressure does not rise above the set pressure of the waste gate

actuator spring since some of the turbo pressure used in the waste

gate actuator leaks out.

On the other hand, when current does not flow in the waste gate

solenoid valve coil (duty 0%), the waste gate valve opens if turbo

pressure rises to the set pressure of the waste gate actuator spring

since no pressure leaks out.

Consequently, by using duty control for the waste gate solenoid

valve, turbo pressure can be controlled in a range from 00/0 to

100% duty.

This duty control is performed in cycles of approximately 60 ms.

1-26

FUEL - Control System

FUEL PRESSURE CONTROL

FUEL SYSTEM-FUEL PRESSURE CONTROL VALVE (Refer to P. 1-12)

AIR FLOW SENSOR (AFS) FILTER RESET CONTROL, AIR CONDITIONER

RELAY CONTROL

These controls are the same as those for the conventional 6G72 engine.

ENGINE -

Control System

SELF DIAGNOSIS SYSTEM

The following items have been made more complete.

(1) Check engine lamp ON items

(2) Self diagnosis items

CHECK ENGINE LAMP CONTROL

The check engine lamp ON items are shown in the

following table.

Oxygen sensor <Except for General Export and GCC> Barometric pressure sensor

Air flow sensor (AFS) Detonation sensor

Intake air temperature sensor Ignition timing adjustment signal*

Throttle position sensor Injector

Coolant temperature sensor Ignition coil, power transistor unit

(3) Service data items to be transferred to multi-use

tester

(4) Actuator test items by multi-use tester

1-27

Crank angle sensor

Cam position sensor Engine control unit

Remarks

*:

The check engine lamp lights even when the ignition timing adjustment terminal is short-circuited to the earth during an

injection timing adjustment.

SELF DIAGNOSIS FUNCTIONS

(1) Arrangements have been made to allow changeover

of the diagnosis mode from DIAGNOSIS 1 mode to

DIAGNOSIS 2 mode by sending a diagnosis mode

changeover signal from the multiuse tester.

In the DIAGNOSIS 2 mode, note that the time from

when a fault is detected to when it is determined as a

fault is shorter than in the DIAGNOSIS 1 mode (4

Æ

seconds

Code Diagnosis item Description DIAGNOSIS

No. 2 Mode

11 Oxygen sensor (Rear bank) Malfunction of the air/fuel ratio control system

1 second).

<Except for General export and GCC> Open or short circuit in the oxygen sensor circuit

When the multi-use tester is disconnected from the

diagnosis connector, all fault codes will' be cleared

from the memory, and the DIAGNOSIS 2 mode will

be changed back to the DIAGNOSIS 1 mode.

(2) The other functions remain unchanged.

(3) The diagnosis items are as shown in the following

table.

-

12 Air flow sensor Open or short circuit in sensor and allied circuit Valid

13 Intake air temperature sensor Open or short circuit in sensor and allied circuit Valid

14 Throttle position sensor Abnormal sensor output Valid

*

1-28

Code Diagnosis item Description DIAGNOSIS

No.

21

Coolant temperature sensor

22

Crank angle sensor Abnormal sensor output Valid

23

Cam position sensor Abnormal sensor output Valid

24

Vehicle speed sensor (reed switch) Open or short circuit in sensor circuit Valid

25

Barometric pressure sensor Open or short circuit in sensor circuit Valid

31

Detonation sensor Abnormal sensor output Valid

ENGINE - Control System

Open or short circuit in sensor and allied circuit Valid

•

Increased connector contact resistance

•

2 Mode

36*

Ignition timing adjustment signal Short circuit in ignition timing adjustment signal line

39

Oxygen sensor (Front bank) Malfunction of the air/fuel ratio control system

<Europe, Hong Kong and Singapore> Open or short circuit in the oxygen sensor circuit

41

Injector (Rear bank) Open circuit in injector and allied circuit Valid

44 1-4 cylinder ignition coil, power

transistor unit generated)

52 2-5 cylinder ignition coil, power

transistor unit generated)

53 3-6 cylinder ignition coil, power

transistor unit generated)

-

Normal

: Fault code No. 36 is not memorized.

SERVICE DATA OUTPUT

The service data output items are shown in the following

table.

Item No. Service data item Unit

Abnormal ignition signal (No coil primary voltage Valid

Abnormal ignition signal (No coil primary voltage Valid

Abnormal ignition signal (No coil primary voltage Valid

-

-

-

-

11

12

13

14

16

17

18

21

22

25

26

Oxygen sensor output (Rear bank) <Except for General Export and GCC> mV

Air flow sensor output Hz

Intake air temperature sensor output °C

Throttle position sensor output mV

Battery voltage V

Mixture adjusting screw (variable resistor) <GCC, general export> ON - OFF

Cranking signal (ignition switch-ST) ON - OFF

Coolant temperature sensor output °C

Crank angle sensor output RPM

Barometric sensor output mmHg

Idle position switch ON - OFF

ENGINE - Control System

1-29

Item No. Service data item Unit

27 Power steering fluid pressure switch ON - OFF

28 Air conditioner switch ON - OFF

33 Electric load switch ON - OFF

34 Air flow sensor reset signal ON - OFF

36 Ignition timing adjustment mode ON - OFF

37 Volumetric efficiency

38 Crank angle sensor output (readable at 2,000 rpm or less) RPM

39 Oxygen sensor output (Front bank) <Europe, Hong Kong and Singapore> mV

41 Injector drive time (Rear bank) mS

44 Ignition advance angle value ºBTDC,ºATDC

45 ISC stepper motor position STEP

47 Injector drive time (Front bank) mS

49 Air conditioner relay ON - OFF

ACTUATOR TESTS

The actuator test items are shown in the following table.

NOTE

The items that have been added to the conventional

system are shown in bold letters.

I

%

Item No. Actuator test item

01 NO.1 injector: OFF

02 NO.2 injector: OFF

03 NO.3 injector: OFF

04 NO.4 injector: OFF

05 NO.5 injector: OFF

06 NO.6 injector: OFF

07 Fuel pump: ON

08 Purge control solenoid valve: ON <Europe, Hong Kong and Singapore>

09

10 EGR control solenoid valve: ON <Except for Australia>

12

13

17 Ignition timing: 5º BTDC

Fuel pump relay No.2: ON (Current flows via the resistor)

Fuel pressure control valve: ON

Waste gate solenoid valve: ON

OIL LEVEL WARNING SYSTEM

This system is the same as that of the conventional 6G72 engine.

/

1-30

ENGINE - Emission Control System

EMISSION CONTROL SYSTEM

The emission control system is basically the same as

that used in the 6G72 engine fitted to the PAJERO

MONTERO. However, the following additions have been

made to the system in vehicles for Europe, Hong Kong

and Singapore only.

(1)

Oxygen sensors and a front catalytic converter have

been added to reduce the level of exhaust gas

emissions.

(2)

The evaporative emission control system has been

improved as shown below. The fuel vapour intake

amount from the canister has been increased so

. System

Europe Singa- Australia GCC Export

Crankcase ventilation system x x x x x

Evaporative emission control Electronics controlled type

system (Europe, Hong Kong and

x x x x

Applicable destination

Hong

Kong, General

pore

Catalytic converter x x x

that the amount of vapour that escapes to the

atmosphere has been reduced.

• When driving with a low to medium load on the

engine, the fuel vapour absorbed by the,

canister is drawn into the P port of the throttle

body in the same way as in engines without

turbocharger.

• When driving with a high load on the engine, the

purge control valve opens and the fuel vapour

absorbed by the canister is drawn into the air

intake hose.

Remarks

-

Singapore)

Vacuum controlled type

(Australia and GCC)

-

-

Three way cataIyst

Air fuel ratio closed loop control x x x

Exhaust gas recirculation system x x

Emission Control System Diagram

<Europe, Hong Kong and Singapore>

-

-

x x Electronics controlled type

Oxygen sensor signal used

-

1-31

<Australia>

ENGINE - Emission Control System

<GCC and General Export>

1-32 ENGINE - Cruise Control System

CRUISE CONTROL SYSTEM

The cruise control system makes constant-speed driving

possible at a speed designated by the driver [within a

range of approx. 40 - 200km/h (25 125m ph)] without

depressing the accelerator pedal.

NOTE

The cruise control system is basically the same as the

system equipped in the SIGMA.

2-1

POWER-

TRANSMISSION

COMPONENTS

CONTENTS

CLUTCH …………………………………………………..

Specifications ………………………………................. 2

Clutch Booster ………………………………. .............. 3

MANUAL TRANSMISSION .......................................... 4

Specifications ............................................................ 4

Sectional View ........................................................... 5

W5MG1 4WD Transmission ...................................... 6

Transmission Control ............................................... 10

PROPELLER SHAFT .................................................11

Specifications ..........................................................11

2

FRONT AXLE .............................................................. 12

Specifications ..........................................................12

REAR AXLE ................................................................ 13

Specifications ..........................................................13

Axle Shaft ................................................................13

Drive Shaft ...............................................................13

Differential ...............................................................15

Differential Support ..................................................16

2-2

POWER-TRANSMISSION COMPONENTS - Clutch

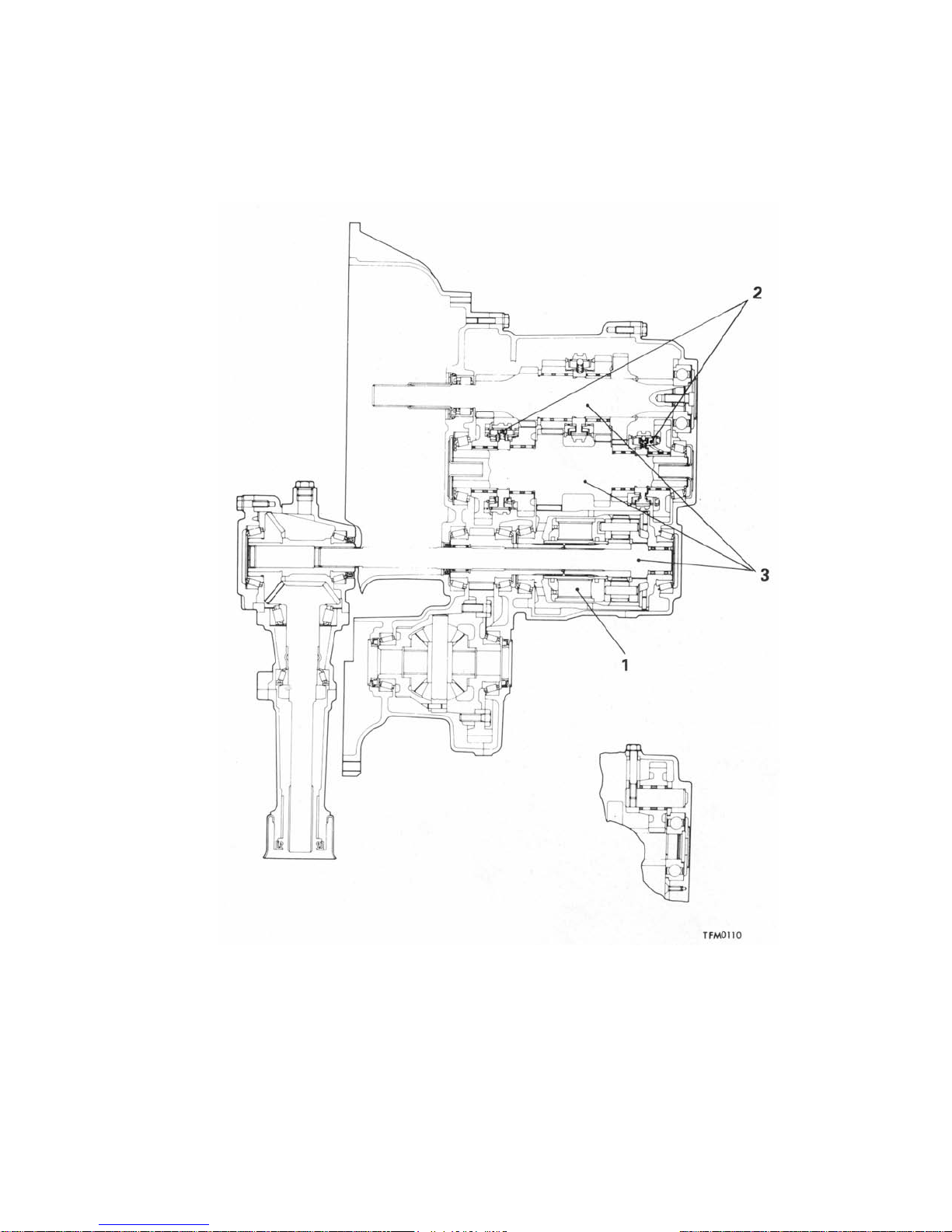

CLUTCH

The clutch is the dry single-plate diaphragm type;

A hydraulic type with clutch booster is used for the

clutch control.

Some models are equipped with a clutch damper in

the clutch tube to make changes in hydraulic pressure smoother when the clutch is engaged and to reduce the maximum value for the clutch input torque.

SPECIFICATIONS

Items Specifications

Clutch operating method Hydraulic type

Clutch disc

Type Single dry disc type

Facing diameter

0.0. x 1.0. mm (in.) 250 x 160 (9.8 x 6.3)

Clutch cover assembly

Type Diaphragm spring strap drive type

Setting load N (kg,lbs.) 9,200 (920, 2,024)

Clutch release cylinder

1.0. mm (in.) 19.05 (3/4)

Clutch master cylinder

1.0. mm (in.) 15.87 (5/8)

Clutch booster

Type Vacuum type, single

Effective dia. of power cylinder mm (in.) 101 (4.0)

Boosting ratio 1.7 [at 110 N (11 kg, 24 Ibs.)]

[Clutch pedal depressing force]

Vacuum tank

Capacity dm3 (U.S. qts., Imp. qts.) 1.2 (1.27, 1.06)

Vacuum pipe

Check valve

Vacuum hose

Clutch master cylinder

Vacuum pipe

Clutch release

cylinder

Clutch tube

clutch hose

Pedal support bracket

Clutch booster

Clutch vacuum tank

Clutch pedal

A 4" single type clutch booster is used to reduce the

force to depress the pedal. The structural operation

of the clutch booster is basically the same as with the

brake booster.

Push rod

Booster return spring

Negative pressure chamber

/

Diaphragm

Booster piston

Valve plunger

Poppet

'Reaction disc

Air chamber

Operating rod

Filter

Valve plunger stopper key

08F0007

2-4

POWER-TRANSMISSION COMPONENTS - Manual Transmission

MANUAL TRANSMISSION

The manual transmission is a W5MG1 transmission. A cable type floor shift is used for transmission control. The

W5MGI is a transmission that has been newly developed to respond to the high output and high torque of the

6G72-DOHC-Turbo engine.

SPECIFICATIONS

Items Specifications

Transmission model W5MG1

Type 5-speed constant-mesh cable controlled type

Gear ratio (number of gear teeth)

1 st 3.071 (43/14)

2nd 1.739 (40/23)

3rd 1.103 (32/29)

4th 0.823 (28/34)

5th 0.659 (31/47)

Reverse 3.076 (40/13)

Primary reduction ratio (number of gear teeth) 1.375 (44/32)

Front differential gear ratio (number of gear teeth) 2.888 (52/18)

Transfer gear ratio (number of gear teeth) 0.814 (22/27)

Torque split ratio Front/Rear 45/55

Speedometer gear ratio Drive/Driven 27/36

POWER-TRANSMISSION COMPONENTS -

g

p

g

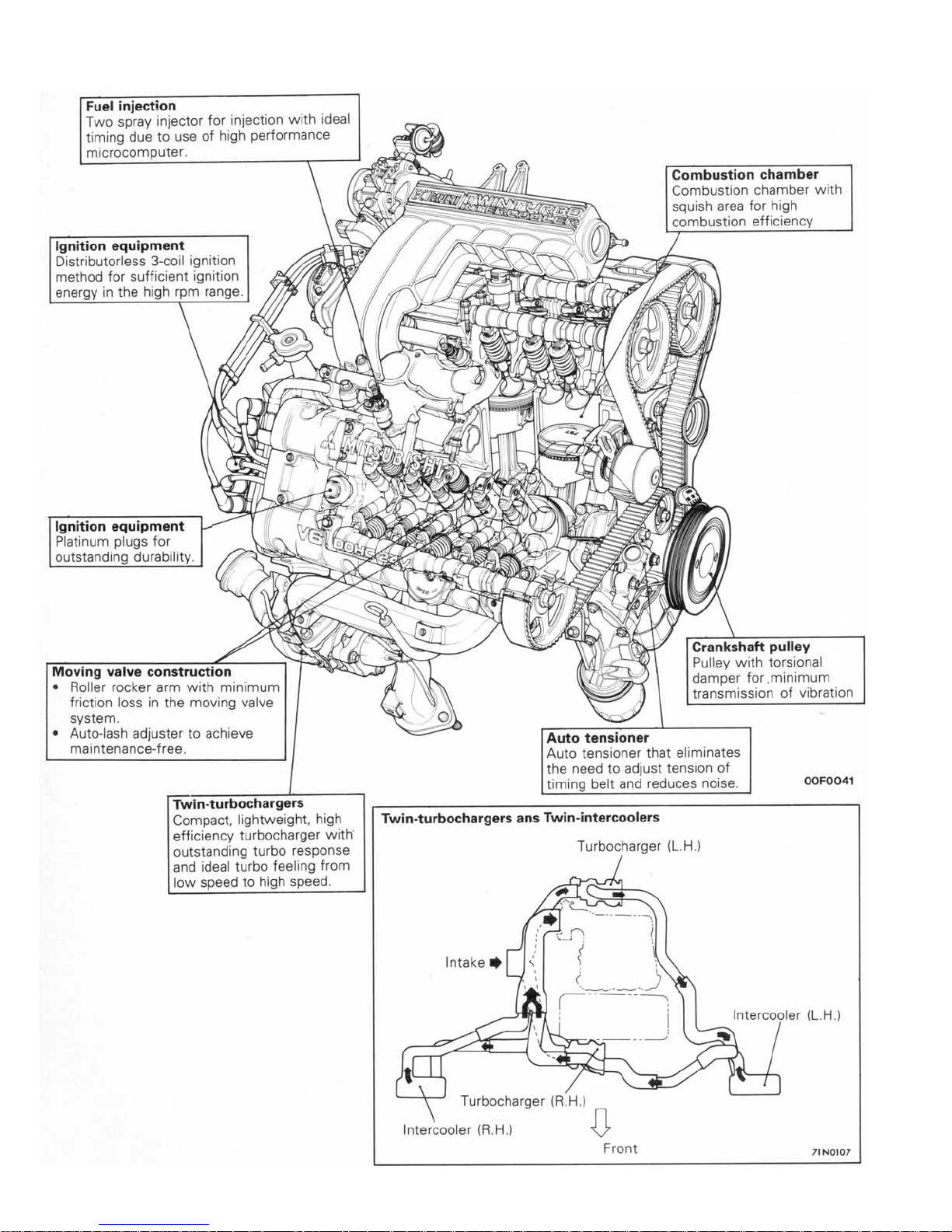

SECTIONAL VIEW

W5MG1

Manual Transmission 2-5

1. Clutch housing 14. 5th speed gear

2. 1st speed gear 15. Center shaft

3. 1st-2nd synchronizer hub 16. Viscous coupling

4. 2nd speed gear 17. Center differential

5. Transaxle case 18. Reverse idler

6. 3rd speed gear 19. Front differential

7. 3rd-4th synchronizer hub 20. Transfer driven bevel gear

8. 4th speed gear 21. Transfer drive bevel gear

9. 5th speed gear input shaft 22. Transfer case

10 5th-reverse synchronizer hub 23. Front output shaft

11 Rear cover 24. Intermediate shaft

12 In

13 Reverse

ut shaft retainer 25. Input shaft

ear

ear

A

2-6

POWER-TRANSMISSION COMPONENTS - Manual Transmission

W5MG1 4WD TRANSMISSION

The W5MG1 is a 3-shaft, full time 4WD transmission.

It is not only a planetary gear type differential with the

center differential on the NO.3 shaft used, but also a

viscous coupling acting as a differential limiter that is

built into the front and rear output shafts.

The gear meshing method is a constant-mesh method also used for reverse.

The reverse idler gear is on the rear cover.

A double-cone synchronizer is used for 1st speed and

2nd speed for improved shift feeling.

double-mesh prevention device using an interlock

plate and a reverse mis-shift prevention device using

a stopper plate are adopted in the shift control

system.

The construction and operation of the double-mesh

prevention device, and reverse mis-shift prevention

device are basically the same as on the 4WD transmission previously used.

PLANETARY GEAR TYPE CENTRE DIFFERENTIAL

Outer pinion

Viscous coupling

Front output shaft

Front output

Centre differential case (ring gear)

09F0126

The centre differential has the construction shown in the figure

above, and is made up of the differential case (integral part of

ring gear), outer pinions (3 pc.), inner pinions (3 pc.), carrier, sun

gear, front output shaft, centre shaft and viscous coupling. Drive

force input from the outside of the differential case is transmitted

to the outer pinions and inner pinions by the ring gear on the

inside of the case, from there is distributed to the sun gear and

carrier to be transmitted to the front output shaft and centre shaft.

Furthermore, since there is a viscous coupling built in this centre

differential, when a rotational speed difference arises between

the front output shaft and centre shaft, differential control torque

is redistributed according to that difference so that the ideal drive

force is always maintained.

In addition, unequal torque distribution is used in this centre

differential.

POWER-TRANSMISSION COMPONENTS - Manual Transmission 2-7

A

The distribution of the drive force to the carrier and sun gear in a

planetary gear type differential is determined by the number of teeth

on the ring gear and sun gear.

Here is the figure of the velocity diagram if the number of teeth on

the ring gear is Zr and the number of teeth on the sun gear is Zs.

The carrier is considered to be fixed, the ring gear and sun gear

revolve in the same direction, and the sun gear rotates Zr/Zs for one

rotation of the ring gear. The figure on the left shows the velocity

diagram for such a case.

ccording to the velocity diagram, the result is as follows if we

consider a state of balance with the ring gear in the center when the

ring gear and sun gear rotate at the same speed.

If

Tr: Ring gear input torque

Ts: Sun gear output torque (front output)

Tc: Carrier output torque (rear output)

Then

(1) Tr = Tc+Ts

(2) Tc x Zs = (Zr - Zs) x Ts

From (1) and (2)

Ts

= Zs/Zr

x Tr

Tc

= (Zr-Zs)/Zr

Ts:Tc = Zs: Zr - Zs = Front: Rear

With the W5MG1, Zr = 60 and Zs = 27, so Zr - Zs = 33.

Front: Rear = 27: 33 = 45 : 55.

x Tr

2-8 POWER-TRANSMISSION COMPONENTS - Manual Transmission

A

DOUBLE-CONE SYNCHRONIZER

1st speed gear

Synchronizer cone

The double-cone synchronizer used for 1st speed and

2nd speed are made up, as shown in the figure above,

of the speed gear, clutch gear (welded to the speed

gear), inner synchronizer ring, synchronizer cone, outer

synchronizer ring, synchronizer hub, synchronizer

sleeve, synchronizer key, etc.

The inner synchronizer ring touches liner of the synchronizer cone inner surface at the outer cone surface

and is coupled to the outer synchronizer ring by the

projections (3 locations) on the synchronizer hub. The

synchronizer cone touches the inner synchronizer ring

and outer synchronizer ring at the inner surface liner and

Outer synchronizer ring

Synchronizer sleeve

key 2nd speed

Synchronizer hub

Synchronizer

gear

09F0123

outer surface liner respectively, and is coupled with the

clutch gear by the projections (6 locations) on the speed

gear.

The outer synchronizer ring touches the outer surface

liner of the synchronizer cone at the inside cone surface

and is coupled to the synchronizer hub by the

projections (3 locations) on the outer circumference. In

other words, the inner synchronizer ring and outer

synchronizer ring become one

nit with the synchronizer

~

hub and rotate, and the synchronizer cone becomes one

unit with the speed gear and rotates as they touch each

other.

When the shift lever is moved toward 1st speed, the shift fork moves

the synchronizer sleeve to the left.

t this time, since the ball in the synchronizer key is pressed into the

groove of the synchronizer sleeve by the spring, the synchronizer

sleeve and key are joined and move to the left. As a result, the outer

synchronizer ring is pressed to the left, friction torque is generated

between the synchronizer cone and outer synchronizer ring and

inner synchronizer ring, and the 1st speed gear and synchronizer

hub (intermediate shaft) begin to synchronize.

Then, when the shift fork moves to the left, the synchronizer sleeve

pushes the synchronizer key spring tight, crosses over the

synchronizer key and moves to the left.

2-9

POWER-TRANSMISSION COMPONENTS - Manual Transmission

Then the chamfer of the outer synchronizer ring spline and the

chamfer of the synchronizer sleeve spline come in contact.

As a result of this contact, a major pushing force is generated in the

outer synchronizer ring, the friction torque between the synchronizer

cone and outer synchronizer ring and inner synchronizer ring

increases, and then the difference in rotational speed of the 1st

speed gear and the synchronizer hub disappears.

Under these conditions, since the synchronizer sleeve is pressed to

the left, the synchronizer sleeve spline and outer synchronizer ring

spline mesh.

Also, when the synchronizer sleeve moves to the left, the

synchronizer sleeve spline chamfer comes in contact with the clutch

gear spline chamfer of the 1st speed gear, and then the clutch gear

spline and synchronizer sleeve spine mesh to complete the shift to 1

st speed.

•

2-10

POWER-TRANSMISSION COMPONENTS - Manual Transmission

TRANSMISSION CONTROL

• There are vibration-prevention rubber pieces

mounted on the transaxle side of the shift cable

and selector cable, and on the shift lever

assembly side to prevent transmission of fine

vibrations to the body.

• The eye end on the shift lever assembly of the

shift cable has a double structure, a combination

of a resin bushing and rubber bushing, and this

not only provides smooth movement of the shift

cable but also prevents transmission of vibration

to the shift lever assembly, improving the shifting

feel.

Vibration-prevention

rubber pieces

A combination of a wave washer and thrust

washer are used in the shift lever shaft of the shift

lever assembly, and this not only reduces the

looseness in the direction of the lever shaft but

also elastically supports the shift cable on the

cable bracket of the shift lever assembly, reducing

shaking of the shift lever.

• Shaking of the shift lever caused when

accelerating and decelerating due to bent of the

shift and selector cables is reduced.

Shift cable

Selector cable

Shift lever assembly

Shift lever

09F0074

f

POWER-TRANSMISSION COMPONENTS - Propeller Shaft 2-11

PROPELLER SHAFT

The propeller shaft is a 3-section 4-joint shaft with 2

center bearings. This division into 3 sections

increases the vibration frequency characteristics o

the shaft bending, and reduces vibration and noise

when driving at high speed. The joints for connecting

each part of the propeller shaft are as follows; No.1,

No.2 and No. 4 joints are cross type universal joints

and No.3 joint is a Lobro joint (LJ) that can slide and

has small friction in the direction of the shaft. This

structure helps reducing torque fluctuation, vibration

and noise. Furthermore, the rear propeller shaft is a

vibration-control type shaft (using rubber) with an

inner tube inserted in the outer tube to reduce

vibration and noise from the drive train.

SPECIFICA TIONS

Item Specification

Propeller Length x 0.0. Front 673.5 x 65 (26.52 x 2.56)

shaft mm (in.) Center 662.5 x 65 (26.08 x 2.56)

Universal Type No.1 Cross type

joint No.2 Cross type

Type 4-joint propeller shaft

Rear 555.5 x 75 (21.87 x 2.95)

No.3 Constant velocity type (L6bro joint, LJ95)

No.4 Cross type

Lubrication Pre-packed

Size mm (in.) Cross type joint 17.996 (0.7085)

journal 0.D.

.

Constant velocity 99.73 (3.93)

joint 0.D.

NOTE

Propeller shaft length indicates the length between center points of each joint.

CONSTRUCTION DIAGRAM

Lobro joint

Front propeller shaft

Center bearing

Center propeller shaft

Center bearing

10F0007

•

2-12 POWER-TRANSMISSION COMPONENTS - Front Axle

FRONT AXLE

The drive shaft is of the Birfield joint (B.J.)-tripod joint

(T.J.) type. This type features high power transmission

efficiency and low vibration and noise. It has the

following features.

B.J.

• Large operating joint angle

• 'Compact size and decreased space req'ulrements

T.J.

• Axially slidable

• Smaller sliding friction

• The B.J. joint boot is made of highly-durable resin to

provide improved reliability

SPECIFICATIONS

Item Specifications

Hub, knuckle

Bearing type Unit ball bearing

Drive shaft

Joint type Outer B.J.

Length (between joints) x 0.D.

L.H. mm (in.) 419 x 26

R.H. mm (in.) 391 x 26

The B.J. joint boot is made of highly-durable resin to

provide improved reliability

Inner T.J.

(16.5 x 1.02)

(15.4 x 1.02)

Inner shaft

Bracket

kn,uckle

Centre bearing

T.J.

Resin boot

B.J.

Unit ball bearing

11F0048

POWER-TRANSMISSION COMPONENTS - Rear Axle 2-13

REAR AXLE

The differential carrier and axle housing have been

separated from each other, and T.J. and B.J. drive

shafts arranged in between. They drive the axle shafts.

The axle shaft is supported by ball bearings (inner and

outer) in the axle housing and are coupled with the drive

SPECIFICA TIONS

Items Specifications

Axle shaft

Type Semi-floating type

Shaft dimensions

Outer bearing portion dia. mm (in.) 35 (1.38)

Inner bearing portion dia. mm (in.) 28 (1.1 0)

Center portion dia. mm (in.) 34.5 (1.36)

Overall length mm (in.) 245.4 (9.7)

Bearing

0.D. x I.D. Outer mm (in.) 72 x 35 (2.83 x 1.38)

Drive shaft

Joint type Outer B.J.

Length (joint to joint) x diameter mm (in.) 395 x 28 (15.6 x 1.10)

Differential

Reduction gear type Hypoid gear

Reduction ratio 3.545

Differential gear type and configuration

Side gear Straight bevel gear x 2*

Pinion gear Straight bevel gear x 4

Number of teeth

Drive gear 39

Drive pinion 11

Side gear 16

Pinion Gear 10

Bearing

0.D. x I.D. Side mm (in.) 82.500 x 45.242 (3.25 x 1.78)

Final drive gear backlash adjustment method Screw type

Inner mm (in.) 58 x 28 (2.28 x 1.10)

Inner T.J.

Front mm (in.) 68.263 x 30.163 (2.69 x 1.19)

Rear mm (in.) 76.200 x 36.513 (3.00 x 1.44)

shaft with the companion flange in between.

The front of the differential carrier is supported elastically

on the rear suspension crossmember via the differential

support and the rear side via the differential support

member.

*.

Denotes the gear (L.H.) which is in a single body with the viscous coupling.

T.J.

Differential carrier

Drive shaft

B.J

Companion flange

.

Axle shaft

Trailing arm

(Axle housing)

11 N0002

A

2-14 POWER-TRANSMISSION COMPONENTS - Rear Axle

AXLE SHAFT

The axle shaft is a semi-floating type supported by

ball bearings (outer and inner) in the housing.

On models with the anti-lock braking system, there is

a wheel speed sensing rotor on the axle shaft.

Companion flange

B.J.

Trailing arm

xle shaft

DRIVE SHAFT

A B.J.-T.J. type constant velocity joint is used in the

drive shaft, featuring the same good transmission efficiency, low vibration and low noise as the front drive

shaft. On the axle shaft side there is a B.J. type joint

that can bend to a great degree to match movement

of the suspension and on the differential carrier side

there is a

amount in the shaft direction with little sliding friction.

T.J.

type joint that can slide to a large

To prevent mud that may be deposited around the

bearing (outer), a dust shield has been provided.

Dust shield

11N0009

Rotor

On the axle shaft side, they are coupled with the

companion flange in between. On the differential side,

they are spline coupled with the side gears, the right

and left drive shafts are different in length. In addition,

T.J.

the

side of the drive shaft (R.H.) is two-stage

serration coupled.

<L.H.>

<R.H.>

Two-stage

serration

11F0006

V

POWER-TRANSMISSION COMPONENTS - Rear Axle 2-15

DIFFERENTIAL

The differential uses lower friction torque bearings

and oil seals to improve power performance and fuel

consumption.

For faster differential cooling and higher reliability

during high speed operation, a differential carrier with

cooling fins has been adopted.

A speed difference responsive viscous coupling type

Cooling fins

limited slip differential which provides outstanding

performance during operation on a muddy surface

has been established.

There is a 4-wheel steering (4WS) oil pump on the

top of the differential carrier.

11 F0001

ISCOUS COUPLING TYPE LIMITED SLIP DIFFERENTIAL

While the conventional mechanical type limited slip

differential uses a cam (differential pinion shaft) and

disc equipment composed of a friction

I

plate, disc and

spring seat in limiting the differential, the viscous

Front wheel

Center differential

(viscous coupling)

Front differential

Rear wheel

Limited slip differential

assembly

Differential

Differential limiting

section

(viscous coupling)

11P0066

coupling type limited slip differential limits the

differential by use of a viscous coupling equipment

consisting of outer and inner plates and silicone oil.

2-16 POWER-TRANSMISSION COMPONENTS - Rear Axle

DIFFERENTIAL SUPPORT

The front and rear of the differential carrier are mounted

on the suspension crossmember by the differential

Differential support (R.H.)

Differential support (L.H.)

supports and differential support member. It is elastically

mounted via a bushing.

Differential

support member

11N0038

3-1

DRIVE-CONTROL

COMPONENTS

CONTENTS

SUSPENSION ............................................................... 2

Features .................................................................... 2

FRONT SUSPENSION ................................................. 3

Features .................................................................... 3

Specifications ............................................................ 3

Camber Adjustment Mechanism ............................... 4

REAR SUSPENSION ................................ .................. 5

Features ................................................. .................. 5

Specifications ......................................... .................. 5

Crossmember and Crossmember

Support Bushing ....................................................... 6

ELECTRONIC CONTROL SUSPENSION

(E CS) ..........................................................................................7