SAFETY PRECAUTIONS

WARNING

CAUTION

Indicates that incorrect handling may cause hazardous conditions,

resulting in death or severe injury.

Indicates that incorrect handling may cause hazardous conditions,

resulting in minor or moderate injury or property damage.

(Read these precautions before using this product.)

Before using this product, please read this manual and the relevant manuals carefully and pay full attention

to safety to handle the product correctly.

In this manual, the safety precautions are classified into two levels: " WARNING" and " CAUTION".

Under some circumstances, failure to observe the precautions given under " CAUTION" may lead to

serious consequences.

Observe the precautions of both levels because they are important for personal and system safety.

Make sure that the end users read this manual and then keep the manual in a safe place for future

reference.

A - 1

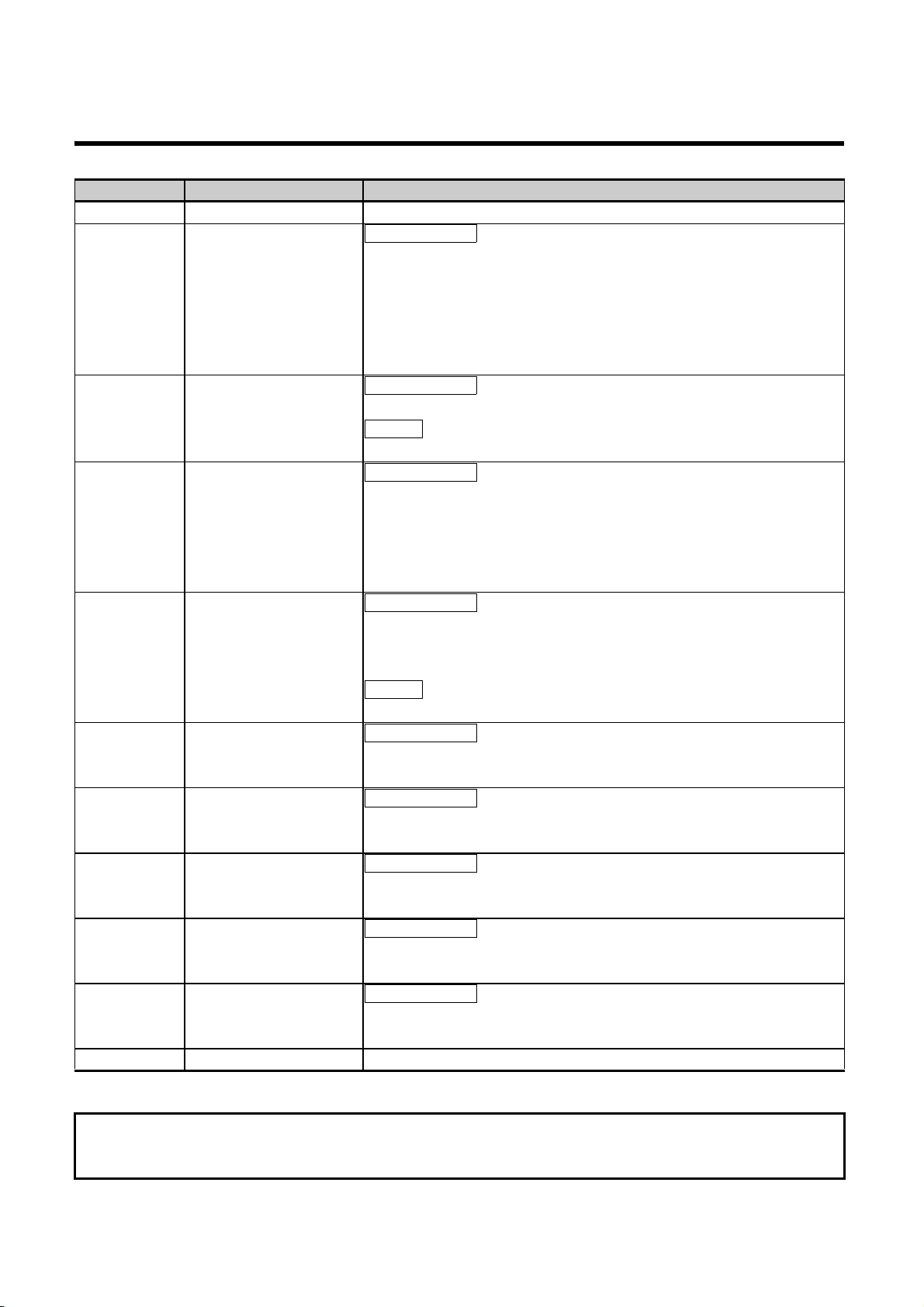

[Design Precautions]

Q series model

AnS/A series model

All outputs are turned off.

All outputs are turned off.

All outputs are held or turned

off according to the parameter

setting.

Overcurrent or overvoltage protection of the

power supply module is activated.

The CPU module detects an error such as a

watchdog timer error by the self-diagnostic

function.

All outputs are turned off.

Status

WARNING

Configure safety circuits external to the programmable controller to ensure that the entire system

operates safely even when a fault occurs in the external power supply or the programmable

controller. Failure to do so may result in an accident due to an incorrect output or malfunction.

(1) Configure external safety circuits, such as an emergency stop circuit, protection circuit, and

protective interlock circuit for forward/reverse operation or upper/lower limit positioning.

(2) The programmable controller stops its operation upon detection of the following status, and the

output status of the system will be as shown below.

All outputs may turn on when an error occurs in the part, such as I/O control part, where the CPU

module cannot detect any error. To ensure safety operation in such a case, provide a safety

mechanism or a fail-safe circuit external to the programmable controller. For a fail-safe circuit

example, refer to Appendix 8 General Safety Requirements in the QCPU User's Manual

(Hardware Design, Maintenance and Inspection).

(3) Outputs may remain on or off due to a failure of an output module relay or transistor. Configure

an external circuit for monitoring output signals that could cause a serious accident.

In an output module, when a load current exceeding the rated current or an overcurrent caused by a

load short-circuit flows for a long time, it may cause smoke and fire. To prevent this, configure an

external safety circuit, such as a fuse.

Configure a circuit so that the programmable controller is turned on first and then the external power

supply.

If the external power supply is turned on first, an accident may occur due to an incorrect output or

malfunction.

For the operating status of each station after a communication failure, refer to relevant manuals for

the network.

Incorrect output or malfunction due to a communication failure may result in an accident.

A - 2

[Design Precautions]

WARNING

When changing data of the running programmable controller from a peripheral connected to the

CPU module or from a personal computer connected to an intelligent function module, configure an

interlock circuit in the sequence program to ensure that the entire system will always operate safely.

For program modification and operating status change, read relevant manuals carefully and ensure

the safety before operation.

Especially, in the case of a control from an external device to a remote programmable controller,

immediate action cannot be taken for a problem on the programmable controller due to a

communication failure.

To prevent this, configure an interlock circuit in the sequence program, and determine corrective

actions to be taken between the external device and CPU module in case of a communication

failure.

[Design Precautions]

CAUTION

Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Keep a distance of 100mm (3.94 inches) or more between them.

Failure to do so may result in malfunction due to noise.

When a device such as a lamp, heater, or solenoid valve is controlled through an output module, a

large current (approximately ten times greater than normal) may flow when the output is turned from

off to on.

Take measures such as replacing the module with one having a sufficient current rating.

After the CPU module is powered on or is reset, the time taken to enter the RUN status varies

depending on the system configuration, parameter settings, and/or program size.

Design circuits so that the entire system will always operate safely, regardless of the time.

A - 3

[Installation Precautions]

CAUTION

Use the programmable controller in an environment that meets the general specifications in the

QCPU User's Manual (Hardware Design, Maintenance and Inspection).

Failure to do so may result in electric shock, fire, malfunction, or damage to or deterioration of the

product.

To mount the module, while pressing the module mounting lever located in the lower part of the

module, fully insert the module fixing projection(s) into the hole(s) in the base unit and press the

module until it snaps into place.

Incorrect mounting may cause malfunction, failure or drop of the module.

When using the programmable controller in an environment of frequent vibrations, fix the module

with a screw.

Tighten the screw within the specified torque range.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

When using an extension cable, connect it to the extension cable connector of the base unit

securely.

Check the connection for looseness.

Poor contact may cause incorrect input or output.

When using a memory card, fully insert it into the memory card slot.

Check that it is inserted completely.

Poor contact may cause malfunction.

Shut off the external power supply for the system in all phases before mounting or removing the

module. Failure to do so may result in damage to the product.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in

the system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant sections in the QCPU User's Manual (Hardware Design,

Maintenance and Inspection) and in the manual for the corresponding module.

Do not directly touch any conductive parts and electronic components of the module.

Doing so can cause malfunction or failure of the module.

When using a Motion CPU module and modules designed for motion control, check that the

combinations of these modules are correct before applying power.

The modules may be damaged if the combination is incorrect.

For details, refer to the user's manual for the Motion CPU module.

A - 4

[Wiring Precautions]

WARNING

Shut off the external power supply (all phases) used in the system before installation and wiring.

Failure to do so may result in electric shock or damage to the product.

After wiring, attach the included terminal cover to the module before turning it on for operation.

Failure to do so may result in electric shock.

[Wiring Precautions]

CAUTION

Ground the FG and LG terminals to the protective ground conductor dedicated to the programmable

controller.

Failure to do so may result in electric shock or malfunction.

Use applicable solderless terminals and tighten them within the specified torque range. If any spade

solderless terminal is used, it may be disconnected when the terminal screw comes loose, resulting

in failure.

Check the rated voltage and terminal layout before wiring to the module, and connect the cables

correctly.

Connecting a power supply with a different voltage rating or incorrect wiring may cause a fire or

failure.

Connectors for external connection must be crimped or pressed with the tool specified by the

manufacturer, or must be correctly soldered.

Incomplete connections could result in short circuit, fire, or malfunction.

Do not install the control lines or communication cables together with the main circuit lines or power

cables.

Failure to do so may result in malfunction due to noise.

Tighten the terminal screw within the specified torque range.

Undertightening can cause short circuit, fire, or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

Prevent foreign matter such as dust or wire chips from entering the module.

Such foreign matter can cause a fire, failure, or malfunction.

A - 5

[Wiring Precautions]

CAUTION

A protective film is attached to the top of the module to prevent foreign matter, such as wire chips,

from entering the module during wiring.

Do not remove the film during wiring.

Remove it for heat dissipation before system operation.

Mitsubishi programmable controllers must be installed in control panels.

Connect the main power supply to the power supply module in the control panel through a relay

terminal block.

Wiring and replacement of a power supply module must be performed by maintenance personnel

who is familiar with protection against electric shock. (For wiring methods, refer to the QCPU User's

Manual (Hardware Design, Maintenance and Inspection)).

[Startup and Maintenance Precautions]

WARNING

Do not touch any terminal while power is on.

Doing so will cause electric shock or malfunction.

Correctly connect the battery connector.

Do not charge, disassemble, heat, short-circuit, solder, or throw the battery into the fire.

Doing so will cause the battery to produce heat, explode, or ignite, resulting in injury and fire.

Shut off the external power supply (all phases) used in the system before cleaning the module or

retightening the terminal screws, connector screws, or module fixing screws.

Failure to do so may result in electric shock or cause the module to fail or malfunction.

Undertightening can cause drop of the screw, short circuit or malfunction.

Overtightening can damage the screw and/or module, resulting in drop, short circuit, or malfunction.

A - 6

[Startup and Maintenance Precautions]

CAUTION

Before performing online operations (especially, program modification, forced output, and operation

status change) for the running CPU module from the peripheral connected, read relevant manuals

carefully and ensure the safety.

Improper operation may damage machines or cause accidents.

Do not disassemble or modify the modules.

Doing so may cause failure, malfunction, injury, or a fire.

Use any radio communication device such as a cellular phone or PHS (Personal Handy-phone

System) more than 25cm (9.85 inches) away in all directions from the programmable controller.

Failure to do so may cause malfunction.

Shut off the external power supply for the system in all phases before mounting or removing the

module. Failure to do so may cause the module to fail or malfunction.

A module can be replaced online (while power is on) on any MELSECNET/H remote I/O station or in

the system where a CPU module supporting the online module change function is used.

Note that there are restrictions on the modules that can be replaced online, and each module has its

predetermined replacement procedure.

For details, refer to the relevant sections in the QCPU User's Manual (Hardware Design,

Maintenance and Inspection) and in the manual for the corresponding module.

After the first use of the product, do not mount/remove the module to/from the base unit, and the

terminal block to/from the module more than 50 times (IEC 61131-2 compliant) respectively.

Exceeding the limit of 50 times may cause malfunction.

Do not drop or apply shock to the battery to be installed in the module.

Doing so may damage the battery, causing the battery fluid to leak inside the battery.

If the battery is dropped or any shock is applied to it, dispose of it without using.

Before handling the module, touch a grounded metal object to discharge the static electricity from

the human body.

Failure to do so may cause the module to fail or malfunction.

A - 7

[Disposal Precautions]

CAUTION

When disposing of this product, treat it as industrial waste.

When disposing of batteries, separate them from other wastes according to the local regulations.

(For details of the battery directive in EU member states, refer to the QCPU User's Manual

(Hardware Design, Maintenance and Inspection).)

[Transportation Precautions]

CAUTION

When transporting lithium batteries, follow the transportation regulations.

(For details of the regulated models, refer to the QCPU User's Manual (Hardware Design,

Maintenance and Inspection).)

A - 8

CONDITIONS OF USE FOR THE PRODUCT

(1) Mitsubishi programmable controller ("the PRODUCT") shall be used in conditions;

i) where any problem, fault or failure occurring in the PRODUCT, if any, shall not lead to any major

or serious accident; and

ii) where the backup and fail-safe function are systematically or automatically provided outside of

the PRODUCT for the case of any problem, fault or failure occurring in the PRODUCT.

(2) The PRODUCT has been designed and manufactured for the purpose of being used in general

industries.

MITSUBISHI SHALL HAVE NO RESPONSIBILITY OR LIABILITY (INCLUDING, BUT NOT

LIMITED TO ANY AND ALL RESPONSIBILITY OR LIABILITY BASED ON CONTRACT,

WARRANTY, TORT, PRODUCT LIABILITY) FOR ANY INJURY OR DEATH TO PERSONS OR

LOSS OR DAMAGE TO PROPERTY CAUSED BY the PRODUCT THAT ARE OPERATED OR

USED IN APPLICATION NOT INTENDED OR EXCLUDED BY INSTRUCTIONS, PRECAUTIONS,

OR WARNING CONTAINED IN MITSUBISHI'S USER, INSTRUCTION AND/OR SAFETY

MANUALS, TECHNICAL BULLETINS AND GUIDELINES FOR the PRODUCT.

("Prohibited Application")

Prohibited Applications include, but not limited to, the use of the PRODUCT in;

• Nuclear Power Plants and any other power plants operated by Power companies, and/or any

other cases in which the public could be affected if any problem or fault occurs in the PRODUCT.

• Railway companies or Public service purposes, and/or any other cases in which establishment of

a special quality assurance system is required by the Purchaser or End User.

• Aircraft or Aerospace, Medical applications, Train equipment, transport equipment such as

Elevator and Escalator, Incineration and Fuel devices, Vehicles, Manned transportation,

Equipment for Recreation and Amusement, and Safety devices, handling of Nuclear or

Hazardous Materials or Chemicals, Mining and Drilling, and/or other applications where there is a

significant risk of injury to the public or property.

Notwithstanding the above, restrictions Mitsubishi may in its sole discretion, authorize use of the

PRODUCT in one or more of the Prohibited Applications, provided that the usage of the PRODUCT

is limited only for the specific applications agreed to by Mitsubishi and provided further that no

special quality assurance or fail-safe, redundant or other safety features which exceed the general

specifications of the PRODUCTs are required. For details, please contact the Mitsubishi

representative in your region.

A - 9

REVISIONS

*The manual number is given on the bottom left of the back cover.

Print date Manual number Revision

Dec., 2008 SH(NA)-080808ENG-A

Mar., 2009 SH(NA)-080808ENG-B Partial correction

Nov., 2009 SH(NA)-080808ENG-C Partial correction

May, 2010 SH(NA)-080808ENG-D Partial correction

May, 2011 SH(NA)-080808ENG-E Partial correction

Sep., 2011 SH(NA)-080808ENG-F Partial correction

Oct., 2011 SH(NA)-080808ENG-G Partial correction

May, 2012 SH(NA)-080808ENG-H Partial correction

Jan., 2014 SH(NA)-080808ENG-I Partial correction

Jul. 2014 SH(NA)-080808ENG-J Partial correction

First edition

SAFETY PRECAUTIONS, INTRODUCTION, MANUALS, MANUAL PAGE

ORGANIZATION, Section 1.3, 1.6, 2.2.2, 2.2.3, 2.3, 2.3.4, 2.3.5, 3.3, 3.7,

3.8.1, 3.8.2, 4.1.1, 4.1.2, 4.2.2, 4.2.3, 5.1.1, 5.2.1, 5.2.5, 5.2.6, 5.2.8, 6.1,

6.3, 6.5, 6.6.1, 6.6.5, 6.11.3, 6.12.2, 6.13.3, 6.14, 6.15.2, 6.20, 6.22.2, 6.22.4,

CHAPTER 7, Section 7.1.2, 7.2, 8.2, 9.1, 9.2, 9.2.11, 9.3.3, 9.5.2, 9.7.4, 9.10,

10.1.1, 10.1.2, Appendix 1, Appendix 3

SAFETY PRECAUTIONS, Section 4.2.2, 9.2.10, 9.7.4

Addition

CONDITIONS OF USE FOR THE PRODUCT

SAFETY PRECAUTIONS, MANUALS, Section 1.5.1, 1.5.2, 2.1, 2.2.1, 2.2.3,

2.4, 3.7, 4.2.2, 5.1.1, 5.1.4, 5.2.9, 6.2, 6.5, 6.6.2, 6.6.3, 6.6.4, 6.11.2, 6.12.2,

6.13.1, 6.14, 6.17.1, 6.22, 6.24, 7.1.3, 8.1.1, 9.2.9, 9.2.10, 9.3.1, 9.5.1, 9.7,

9.8, 9.9, 9.10.1, 9.11.1, 9.11.2, 9.12.3, 9.13.2, 10.1.2, Appendix 2.1, Appendix 2.2, Appendix 2.3, Appendix 2.4

SAFETY PRECAUTIONS, GENERIC TERMS AND ABBREVIATIONS,

Section 3.1, 3.4, 3.6, 3.8.1, 3.8.2, 5.1.1, 5.1.2, 5.1.5, 5.2.1, 5.2.8, 5.2.9, 6.5,

6.25, 7.2, CHAPTER 8, Section 9.2, 9.2.4, 9.2.10, 9.3.2, 9.3.3, 9.10, 10.1.3

Deletion

CHAPTER 12

SAFETY PRECAUTIONS, INTRODUCTION, MANUAL PAGE ORGANIZATION, Section 2.4.5, 5.2.6, 6.24, 9.2, 9.2.10, 9.12.4

GENERIC TERMS AND ABBREVIATIONS, Section 1.5.2, 3.8, 4.2.2, 6.22.2,

6.22.4, 10.1.2

Section 5.2.8, 6.2, 6.12.3, 8.1.1, 8.1.2, 9.1, 9.2.13, 9.3.2, 9.3.3, 9.7, 9.7.4,

Appendix 1

GENERIC TERMS AND ABBREVIATIONS, Section 4.2.1, 5.2.1, 5.2.5,

5.2.10, 6.12.3, 9.1, 9.7.2, 9.7.6, 10.1.3, Appendix 2.2, 2.3

GENERIC TERMS AND ABBREVIATIONS, Section 1.5.2, 3.8, 4.2.2, 6.22.2,

6.22.4, 10.1.2

Japanese manual version SH-080803-K

This manual confers no industrial property rights or any rights of any other kind, nor does it confer any patent licenses. Mitsubishi Electric Corporation cannot be held responsible for any problems involving industrial property rights which may occur

as a result of using the contents noted in this manual.

© 2008 MITSUBISHI ELECTRIC CORPORATION

A - 10

INTRODUCTION

Remark

This manual describes the memory maps, functions, programs, I/O number assignment, and devices of the Q series CPU

module.

Before using this product, please read this manual and the relevant manuals carefully and develop familiarity with the

functions and performance of the Q series programmable controller to handle the product correctly.

When applying the program examples introduced in this manual to the actual system, ensure the applicability and confirm that

it will not cause system control problems.

Relevant CPU module

CPU module Model

Basic model QCPU Q00JCPU, Q00CPU, Q01CPU

High Performance model QCPU Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, Q25HCPU

Process CPU Q02PHCPU, Q06PHCPU, Q12PHCPU, Q25PHCPU

Redundant CPU Q12PRHCPU, Q25PRHCPU

This manual does not describe the specifications of the power supply modules, base units, extension cables, memory

cards, and batteries.

For details, refer to the following.

QCPU User's Manual (Hardware Design, Maintenance and Inspection)

For multiple CPU systems, refer to the following.

QCPU User's Manual (Multiple CPU System)

For redundant systems, refer to the following.

QnPRHCPU User's Manual (Redundant System)

A - 11

CONTENTS

CONTENTS

SAFETY PRECAUTIONS......................................................................................................................A - 1

CONDITIONS OF USE FOR THE PRODUCT ...................................................................................... A - 9

REVISIONS ...........................................................................................................................................A - 10

INTRODUCTION ...................................................................................................................................A - 11

MANUALS ............................................................................................................................................. A - 18

MANUAL PAGE ORGANIZATION......................................................................................................... A - 20

GENERIC TERMS AND ABBREVIATIONS ..........................................................................................A - 22

CHAPTER1 OVERVIEW 1-1 to 1-20

1.1 Processing Order in the CPU Module....................................................................................1 - 1

1.2 Storing and Executing Programs ........................................................................................... 1 - 2

1.3 Structured Programming ........................................................................................................ 1 - 3

1.4 Devices and Instructions Useful for Programming................................................................. 1 - 6

1.5 Features................................................................................................................................. 1 - 11

1.5.1 Features of the Basic model QCPU ..................................................................................1 - 11

1.5.2 Features of the High Performance model QCPU..............................................................1 - 13

1.5.3 Features of the Process CPU ...........................................................................................1 - 15

1.5.4 Features of the Redundant CPU.......................................................................................1 - 17

1.6 Checking Serial Number and Function Version ..................................................................... 1 - 19

CHAPTER2 SEQUENCE PROGRAMS 2-1 to 2-51

2.1 Sequence Program Overview ................................................................................................ 2 - 1

2.2 Sequence Program Configuration.......................................................................................... 2 - 3

2.2.1 Main routine program ........................................................................................................2 - 4

2.2.2 Subroutine program ..........................................................................................................2 - 5

2.2.3 Interrupt program ..............................................................................................................2 - 6

2.3 Settings When Program is Divided .......................................................................................2 - 14

2.3.1 Initial execution type program ...........................................................................................2 - 19

2.3.2 Scan execution type program ...........................................................................................2 - 22

2.3.3 Low-speed execution type program ..................................................................................2 - 23

2.3.4 Stand-by type program ......................................................................................................2 - 31

2.3.5 Fixed scan execution type program ..................................................................................2 - 36

2.3.6 Changing the program execution type ..............................................................................2 - 40

2.4 Data Used in Sequence Programs ........................................................................................2 - 42

2.4.1 BIN (Binary Code) ............................................................................................................. 2 - 45

2.4.2 HEX (Hexadecimal)...........................................................................................................2 - 46

2.4.3 BCD (Binary-coded Decimal) ............................................................................................2 - 47

2.4.4 Real number (Floating-point data).....................................................................................2 - 48

2.4.5 Character string data.........................................................................................................2 - 51

CHAPTER3 CPU MODULE OPERATION 3-1 to 3-16

3.1 Initial Processing .................................................................................................................... 3 - 1

3.2 I/O Refresh (Refresh Processing with Input/Output Modules) ............................................... 3 - 2

A - 12

3.3 Program Operation ................................................................................................................ 3 - 2

3.4 END Processing..................................................................................................................... 3 - 3

3.5 Operation Processing in the RUN, STOP, or PAUSE Status ................................................. 3 - 4

3.6 Operation Processing during Momentary Power Failure ....................................................... 3 - 6

3.7 Data Clear Processing ........................................................................................................... 3 - 7

3.8 I/O Processing and Response Delay.....................................................................................3 - 9

3.8.1 Refresh mode....................................................................................................................3 - 10

3.8.2 Direct mode.......................................................................................................................3 - 14

CHAPTER4 ASSIGNMENT OF BASE UNIT AND I/O NUMBER 4-1 to 4-17

4.1 Base Unit Assignment............................................................................................................ 4 - 1

4.1.1 Base mode........................................................................................................................4 - 1

4.1.2 Base unit assignment setting ............................................................................................4 - 2

4.2 I/O Number Assignment......................................................................................................... 4 - 4

4.2.1 Concept of I/O number assignment ..................................................................................4 - 5

4.2.2 Setting I/O numbers ..........................................................................................................4 - 8

4.2.3 I/O number setting example ..............................................................................................4 - 14

4.2.4 Checking I/O numbers ......................................................................................................4 - 17

CHAPTER5 MEMORIES AND FILES USED FOR CPU MODULE 5-1 to 5-51

5.1 Memories Used for Basic Model QCPU................................................................................. 5 - 1

5.1.1 Memory composition and storable data ............................................................................5 - 1

5.1.2 Program memory ..............................................................................................................5 - 3

5.1.3 Standard ROM ..................................................................................................................5 - 6

5.1.4 Standard RAM ...................................................................................................................5 - 7

5.1.5 Operating and writing programs in the standard ROM (boot operation) ...........................5 - 9

5.2 Memories Used for High Performance model QCPU, Process CPU, and Redundant CPU..5 - 13

5.2.1 Memory composition and storable data ............................................................................5 - 13

5.2.2 Program memory ..............................................................................................................5 - 16

5.2.3 Standard ROM ..................................................................................................................5 - 19

5.2.4 Standard RAM ...................................................................................................................5 - 20

5.2.5 Memory card .....................................................................................................................5 - 22

5.2.6 Writing to the standard ROM and Flash card by GX Developer........................................5 - 26

5.2.7 Automatic all data write from memory card to standard ROM...........................................5 - 31

5.2.8 Operating the program in the standard ROM and memory card (boot operation).............5 - 34

5.2.9 Details of written files ........................................................................................................5 - 39

5.2.10 Specifying valid parameters (parameter-valid drive setting)..............................................5 - 40

5.3 Program File Structure ........................................................................................................... 5 - 41

5.4 File Operations by GX Developer and Handling Precautions................................................5 - 43

5.4.1 File operations...................................................................................................................5 - 43

5.4.2 Precautions for handling files ............................................................................................ 5 - 44

5.4.3 File size.............................................................................................................................5 - 45

5.4.4 Units of file sizes ...............................................................................................................5 - 48

A - 13

CHAPTER6 FUNCTIONS 6-1 to 6-151

6.1 Function List........................................................................................................................... 6 - 1

6.2 Constant Scan ....................................................................................................................... 6 - 4

6.3 Latch Function ....................................................................................................................... 6 - 8

6.4 Output Mode at Operating Status Change (STOP to RUN)...................................................6 - 11

6.5 Clock Function ....................................................................................................................... 6 - 14

6.6 Remote Operation.................................................................................................................. 6 - 19

6.6.1 Remote RUN/STOP .......................................................................................................... 6 - 19

6.6.2 Remote PAUSE ................................................................................................................. 6 - 22

6.6.3 Remote RESET.................................................................................................................6 - 25

6.6.4 Remote latch clear ............................................................................................................6 - 29

6.6.5 Relationship between remote operation and RUN/STOP status of the CPU module ....... 6 - 31

6.7 Q Series-compatible Module Input Response Time Selection (I/O Response Time) ............ 6 - 32

6.8 Error Time Output Mode Setting............................................................................................6 - 34

6.9 H/W Error Time PLC Operation Mode Setting ....................................................................... 6 - 35

6.10 Intelligent Function Module Switch Setting ............................................................................ 6 - 36

6.11 Monitor Function .................................................................................................................... 6 - 38

6.11.1 Monitor condition setting ...................................................................................................6 - 39

6.11.2 Local device monitor/test ..................................................................................................6 - 45

6.11.3 External input/output forced on/off ...................................................................................6 - 48

6.12 Writing Programs While CPU Module is in RUN Status......................................................... 6 - 54

6.12.1 Online change (ladder mode)............................................................................................ 6 - 54

6.12.2 Online change (files) ........................................................................................................6 - 58

6.12.3 Precautions for online change........................................................................................... 6 - 60

6.13 Execution Time Measurement ............................................................................................... 6 - 65

6.13.1 Program monitor list ..........................................................................................................6 - 65

6.13.2 Interrupt program monitor list ............................................................................................6 - 69

6.13.3 Scan time measurement ..................................................................................................6 - 70

6.14 Sampling Trace Function ....................................................................................................... 6 - 74

6.15 Debug Function from Multiple GX Developers....................................................................... 6 - 87

6.15.1 Simultaneous monitoring from multiple GX Developers function ......................................6 - 87

6.15.2 Online change function from multiple GX Developers .....................................................6 - 89

6.16 Watchdog Timer (WDT) ......................................................................................................... 6 - 91

6.17 Self-diagnostic Function......................................................................................................... 6 - 93

6.17.1 Interrupt caused by an error..............................................................................................6 - 102

6.17.2 LEDs indicating errors.......................................................................................................6 - 103

6.17.3 Error clear .........................................................................................................................6 - 104

6.18 Error History ........................................................................................................................... 6 - 105

6.18.1 Basic model QCPU ...........................................................................................................6 - 105

6.18.2 High Performance model QCPU, Process CPU, and Redundant CPU ............................6 - 106

6.19 System Protection.................................................................................................................. 6 - 107

6.19.1 Password registration........................................................................................................ 6 - 108

6.19.2 Remote password ............................................................................................................6 - 110

6.20 System Display of CPU Module with GX Developer.............................................................. 6 - 115

6.21 LED Display ........................................................................................................................... 6 - 120

A - 14

6.21.1 Methods for turning off the LEDs.......................................................................................6 - 121

6.21.2 LED indication priority .......................................................................................................6 - 122

6.22 High Speed Interrupt Function ............................................................................................... 6 - 125

6.22.1 High speed interrupt program execution function .............................................................6 - 126

6.22.2 High speed I/O refresh and high speed buffer transfer functions...................................... 6 - 127

6.22.3 Processing time.................................................................................................................6 - 129

6.22.4 Restrictions .......................................................................................................................6 - 131

6.23 Interrupt from Intelligent Function Module .............................................................................6 - 134

6.24 Serial Communication Function ............................................................................................. 6 - 135

6.25 Service Processing ................................................................................................................ 6 - 143

6.25.1 Module service interval time read .....................................................................................6 - 143

6.26 Initial Device Value................................................................................................................. 6 - 144

6.27 Memory Check Function ........................................................................................................ 6 - 149

CHAPTER7 COMMUNICATIONS WITH INTELLIGENT FUNCTION MODULE

7.1 Communications between CPU Module and Intelligent Function Module ............................. 7 - 1

7.1.1 Initial setting and auto refresh setting by GX Configurator................................................7 - 2

7.1.2 Initial setting by initial device value ...................................................................................7 - 5

7.1.3 Communications with the FROM and TO instructions ......................................................7 - 5

7.1.4 Communications using the intelligent function module device..........................................7 - 6

7.1.5 Communications using the intelligent function module dedicated instruction ...................7 - 8

7.2 Access to the AnS/A Series Special Function Modules ......................................................... 7 - 10

7-1 to 7-10

CHAPTER8 PARAMETERS 8-1 to 8-34

8.1 PLC Parameters .................................................................................................................... 8 - 2

8.1.1 Basic model QCPU ...........................................................................................................8 - 2

8.1.2 High Performance model QCPU, Process CPU, and Redundant CPU ............................8 - 14

8.2 Redundant Parameters ......................................................................................................... 8 - 27

8.3 Network Parameters .............................................................................................................. 8 - 29

8.4 Remote Password.................................................................................................................. 8 - 34

CHAPTER9 DEVICES 9-1 to 9-109

9.1 Device List ............................................................................................................................. 9 - 1

9.2 Internal User Devices............................................................................................................. 9 - 5

9.2.1 Input (X) ............................................................................................................................9 - 8

9.2.2 Output (Y)..........................................................................................................................9 - 10

9.2.3 Internal relay (M)...............................................................................................................9 - 11

9.2.4 Latch relay (L) ...................................................................................................................9 - 12

9.2.5 Annunciator (F) .................................................................................................................9 - 14

9.2.6 Edge relay (V) ...................................................................................................................9 - 20

9.2.7 Link relay (B).....................................................................................................................9 - 21

A - 15

9.2.8 Link special relay (SB) ......................................................................................................9 - 23

9.2.9 Step relay (S) ....................................................................................................................9 - 24

9.2.10 Timer (T)............................................................................................................................9 - 25

9.2.11 Counter (C) .......................................................................................................................9 - 34

9.2.12 Data register (D)................................................................................................................ 9 - 40

9.2.13 Link register (W)................................................................................................................9 - 41

9.2.14 Link special register (SW) .................................................................................................9 - 43

9.3 Internal System Devices ........................................................................................................ 9 - 44

9.3.1 Function devices (FX, FY, FD) ..........................................................................................9 - 44

9.3.2 Special relay (SM).............................................................................................................9 - 47

9.3.3 Special register (SD).........................................................................................................9 - 48

9.4 Link Direct Device .................................................................................................................. 9 - 49

9.5 Module Access Devices ......................................................................................................... 9 - 53

9.5.1 Intelligent function module device .....................................................................................9 - 53

9.5.2 Cyclic transmission area device........................................................................................9 - 56

9.6 Index Register (Z) .................................................................................................................. 9 - 57

9.6.1 Index register (Z)...............................................................................................................9 - 57

9.6.2 Switching between the scan execution type and low-speed execution type programs..... 9 - 59

9.6.3 Switching from the scan execution type/low-speed execution type program to the

interrupt/fixed scan execution type program

.......................................................... 9 - 60

9.7 File Register (R)..................................................................................................................... 9 - 64

9.7.1 File register data storage location ..................................................................................... 9 - 65

9.7.2 File register size ................................................................................................................9 - 65

9.7.3 Differences in available accesses by storage memory .....................................................9 - 66

9.7.4 Registration procedure for the file register ........................................................................ 9 - 67

9.7.5 Specification methods of the file register...........................................................................9 - 73

9.7.6 Precautions for using the file register................................................................................9 - 74

9.8 Nesting (N)............................................................................................................................. 9 - 77

9.9 Pointer (P).............................................................................................................................. 9 - 78

9.9.1 Local pointer.....................................................................................................................9 - 79

9.9.2 Common pointer................................................................................................................9 - 81

9.10 Interrupt Pointer (I)................................................................................................................. 9 - 84

9.10.1 List of interrupt pointer numbers and interrupt factors ......................................................9 - 86

9.11 Other Devices ........................................................................................................................ 9 - 93

9.11.1 SFC block device (BL) ......................................................................................................9 - 93

9.11.2 SFC transition device (TR)................................................................................................9 - 93

9.11.3 Network No. specification device (J) .................................................................................9 - 93

9.11.4 I/O No. specification device (U)......................................................................................... 9 - 94

9.11.5 Macro instruction argument device (VD)...........................................................................9 - 95

9.12 Constants ............................................................................................................................... 9 - 96

9.12.1 Decimal constant (K).........................................................................................................9 - 96

9.12.2 Hexadecimal constant (H).................................................................................................9 - 96

9.12.3 Real number (E)................................................................................................................9 - 97

9.12.4 Character string (" ")..........................................................................................................9 - 98

9.13 Convenient Usage of Devices................................................................................................ 9 - 99

9.13.1 Global device ....................................................................................................................9 - 99

9.13.2 Local device ......................................................................................................................9 - 100

A - 16

CHAPTER10 CPU MODULE PROCESSING TIME 10-1 to 10-22

10.1 Scan Time .............................................................................................................................. 10 - 1

10.1.1 Scan time structure ...........................................................................................................10 - 1

10.1.2 Time required for each processing included in scan time .................................................10 - 6

10.1.3 Factors that increase the scan time ..................................................................................10 - 15

10.1.4 Factors that shorten the scan time....................................................................................10 - 20

CHAPTER11 PROCEDURES FOR WRITING PROGRAM TO CPU MODULE

11-1 to 11-15

11.1 Basic Model QCPU................................................................................................................11 - 1

11.1.1 Items to be Considered for Creating Programs................................................................. 11 - 1

11.1.2 Hardware Check ...............................................................................................................11 - 2

11.1.3 Procedure for writing a program........................................................................................11 - 4

11.1.4 Procedure for Boot Operation ...........................................................................................11 - 6

11.2 High Performance Model QCPU, Process CPU, and Redundant CPU .................................11 - 7

11.2.1 Items to be Considered for Creating Programs................................................................. 11 - 7

11.2.2 Hardware Check ...............................................................................................................11 - 8

11.2.3 Procedure for Writing One Program..................................................................................11 - 10

11.2.4 Procedure for Writing Multiple Programs ..........................................................................11 - 12

11.2.5 Procedure for Boot Operation ...........................................................................................11 - 15

APPENDICES APPX-1 to APPX-13

Appendix 1 List of Parameter Numbers ......................................................................................... APPX- 1

Appendix 2 Upgrade by Function Addition..................................................................................... APPX- 5

Appendix 2.1 Upgrade of the Basic model QCPU............................................................... APPX- 5

Appendix 2.2 Upgrade of the High Performance model QCPU.............................................. APPX- 8

Appendix 2.3 Upgrade of the Process CPU.......................................................................APPX- 10

Appendix 2.4 Upgrade of the Redundant CPU................................................................... APPX- 11

Appendix 3 Device Point Assignment Sheet.................................................................................. APPX- 12

INDEX INDEX-1 to INDEX-4

A - 17

MANUALS

To understand the main specifications, functions, and usage of the CPU module, refer to the basic manuals.

Read other manuals as well when using a different type of CPU module and its functions.

Order each manual as needed, referring to the following list.

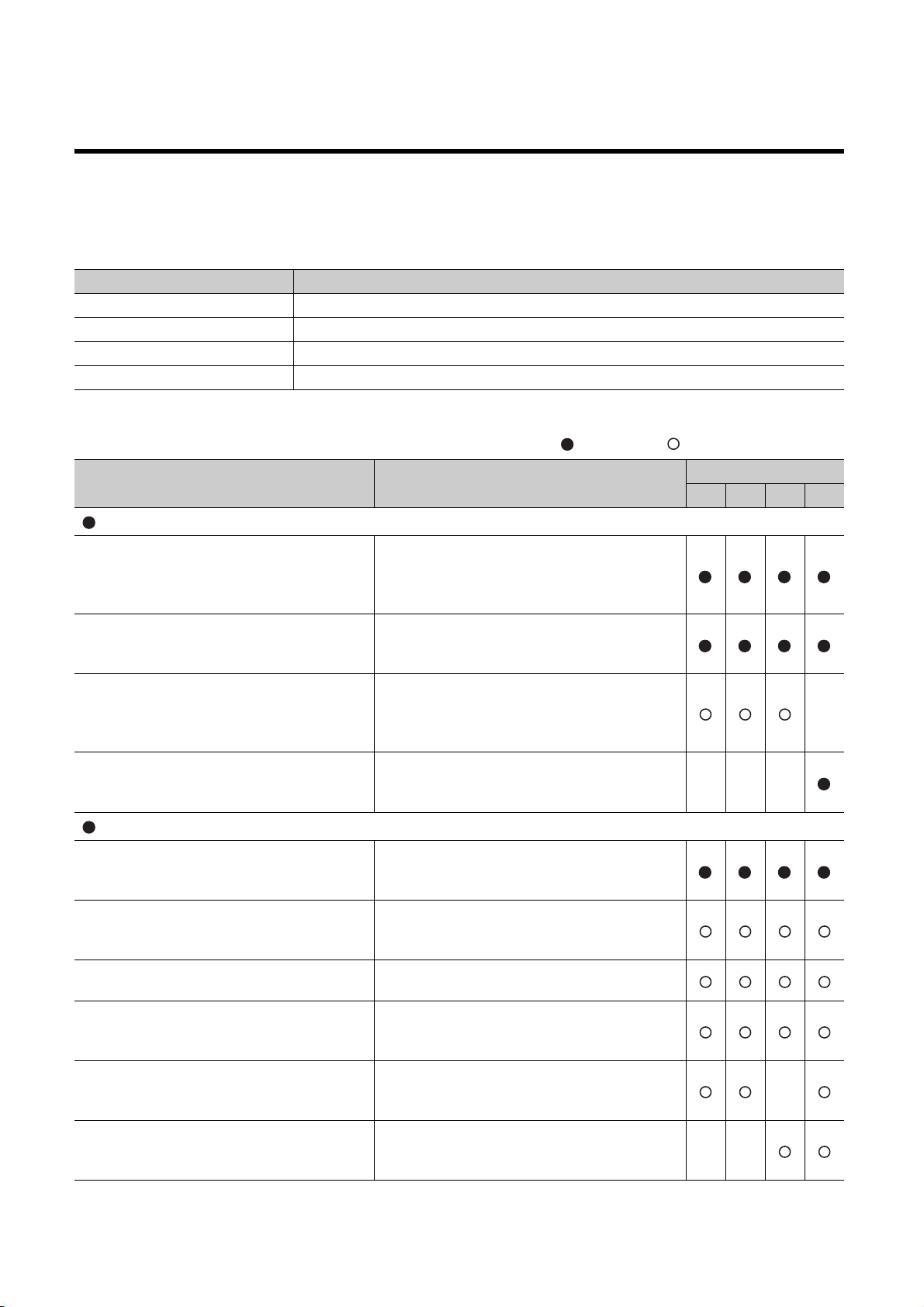

Number (in the list below) CPU module

1) Basic model QCPU

2) High Performance model QCPU

3) Process CPU

4) Redundant CPU

: Basic manual, : Other CPU module manuals

Manual name

< Manual number (model code) >

User's manual

QCPU User's Manual (Hardware Design,

Maintenance and Inspection)

< SH-080483ENG (13JR73) >

Qn(H)/QnPH/QnPRHCPUCPU Users Manual

(Function Explanation, Program Fundamentals)

< SH-080807ENG (13JZ27) >

QCPU User's Manual (Multiple CPU System)

< SH-080485ENG (13JR75) >

QnPRHCPU User's Manual (Redundant System)

< SH-080486ENG (13JR768) >

Description

Specifications of the hardware (CPU modules, power

supply modules, base units, extension cables, and

memory cards), system maintenance and inspection,

troubleshooting, and error codes

Functions, methods, and devices for programming

Information for configuring a multiple CPU system

(system configuration, I/O numbers, communication

between CPU modules, and communication with the

input/output modules and intelligent function modules)

Information on redundant system configuration

(system configuration, functions, communication with

external devices, and troubleshooting)

Manual type

1) 2) 3) 4)

Programming manual

MELSEC-Q/L Programming Manual (Common

Instruction)

< SH-080809ENG (13JW10) >

MELSEC-Q/L/QnA Programming Manual (SFC)

< SH-080041 (13JF60) >

MELSEC-Q/L Programming Manual (MELSAP-L)

< SH-080076 (13JF61) >

MELSEC-Q/L Programming Manual (Structured

Te xt )

< SH-080366E (13JF68) >

MELSEC-Q/L/QnA Programming Manual (PID

Control Instructions)

< SH-080040 (13JF59) >

MELSEC-Q Programming/Structured Programming

Manual (Process Control Instructions)

< SH-080316E (13JF67) >

A - 18

How to use sequence instructions, basic instructions,

and application instructions

System configuration, performance specifications,

functions, programming, debugging, and error codes

for SFC (MELSAP3) programs

Programming methods, specifications, and functions

for SFC (MELSAP-L) programs

Programming methods using structured languages

Dedicated instructions for PID control

Dedicated instructions for process control

Other relevant manuals

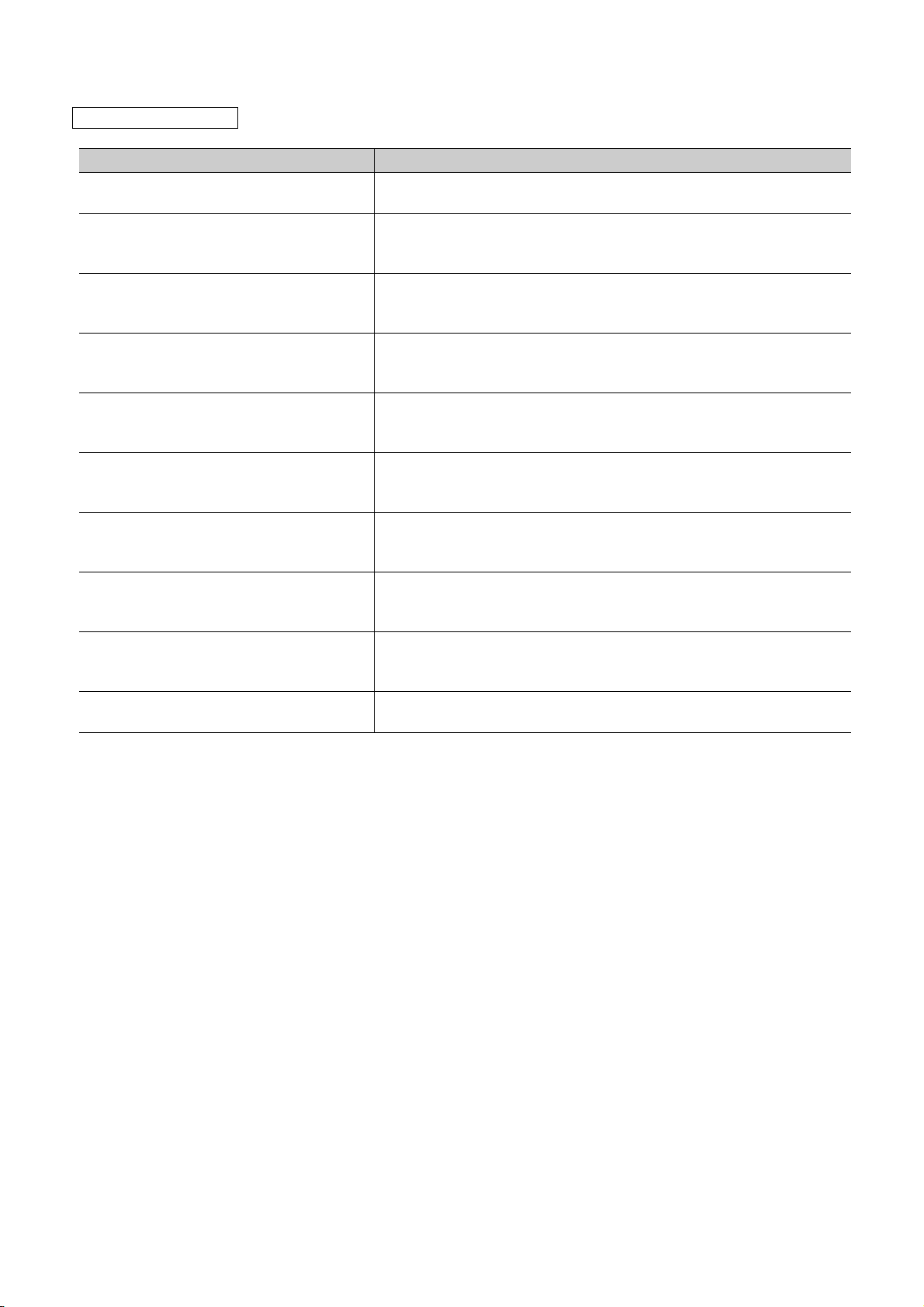

Manual name Description

CC-Link IE Controller Network Reference Manual

< SH-080668ENG (13JV16) >

Q Corresponding MELSECNET/H Network System

Reference Manual (PLC to PLC network)

< SH-080049 (13JF92) >

Q Corresponding MELSECNET/H Network System

Reference Manual (Remote I/O network)

< SH-080124 (13JF96) >

Q Corresponding Ethernet Interface Module User's

Manual (Basic)

< SH-080009 (13JL88) >

Q Corresponding Ethernet Interface Module User's

Manual (Application)

< SH-080010 (13JL89) >

CC-Link System Master/Local Module User's

Manual

< SH-080394E (13JR64) >

Q Corresponding Serial Communication Module

User's Manual (Basic)

< SH-080006 (13JL86) >

MELSEC-Q/L Serial Communication Module User's

Manual (Application)

< SH-080007 (13JL87) >

MELSEC-Q/L MELSEC Communication Protocol

Reference Manual

< SH-080008 (13JF89) >

GX Developer Version 8 Operating Manual

< SH-080373E (13JU41) >

Specifications, procedures and settings before system operation, parameter setting,

programming, and troubleshooting of the CC-Link IE Controller Network module

Specifications, procedures and settings before system operation, parameter setting,

programming, and troubleshooting of a MELSECNET/H network system (PLC to PLC

network)

Specifications, procedures and settings before system operation, parameter setting,

programming, and troubleshooting of a MELSECNET/H network system (remote I/O

network)

Specifications, procedures for data communication with external devices, line

connection (open/close), fixed buffer communication, random access buffer

communication, and troubleshooting of the Ethernet module

E-mail function, programmable controller CPU status monitoring function,

communication via MELSECNET/H or MELSECNET/10, communication using the

data link instructions, and file transfer function (FTP server) of the Ethernet module

System configuration, performance specifications, functions, handling, wiring, and

troubleshooting of the QJ61BT11N

Overview, system configuration, specifications, procedures before operation, basic

data communication method with external devices, maintenance and inspection, and

troubleshooting for using the serial communication module

Special functions (specifications, usage, and settings and data communication

method with external devices of the serial communication module

Communication method using the MC protocol, which reads/writes data to/from the

CPU module via the serial communication module or Ethernet module

Operating methods of GX Developer, such as programming and printout

A - 19

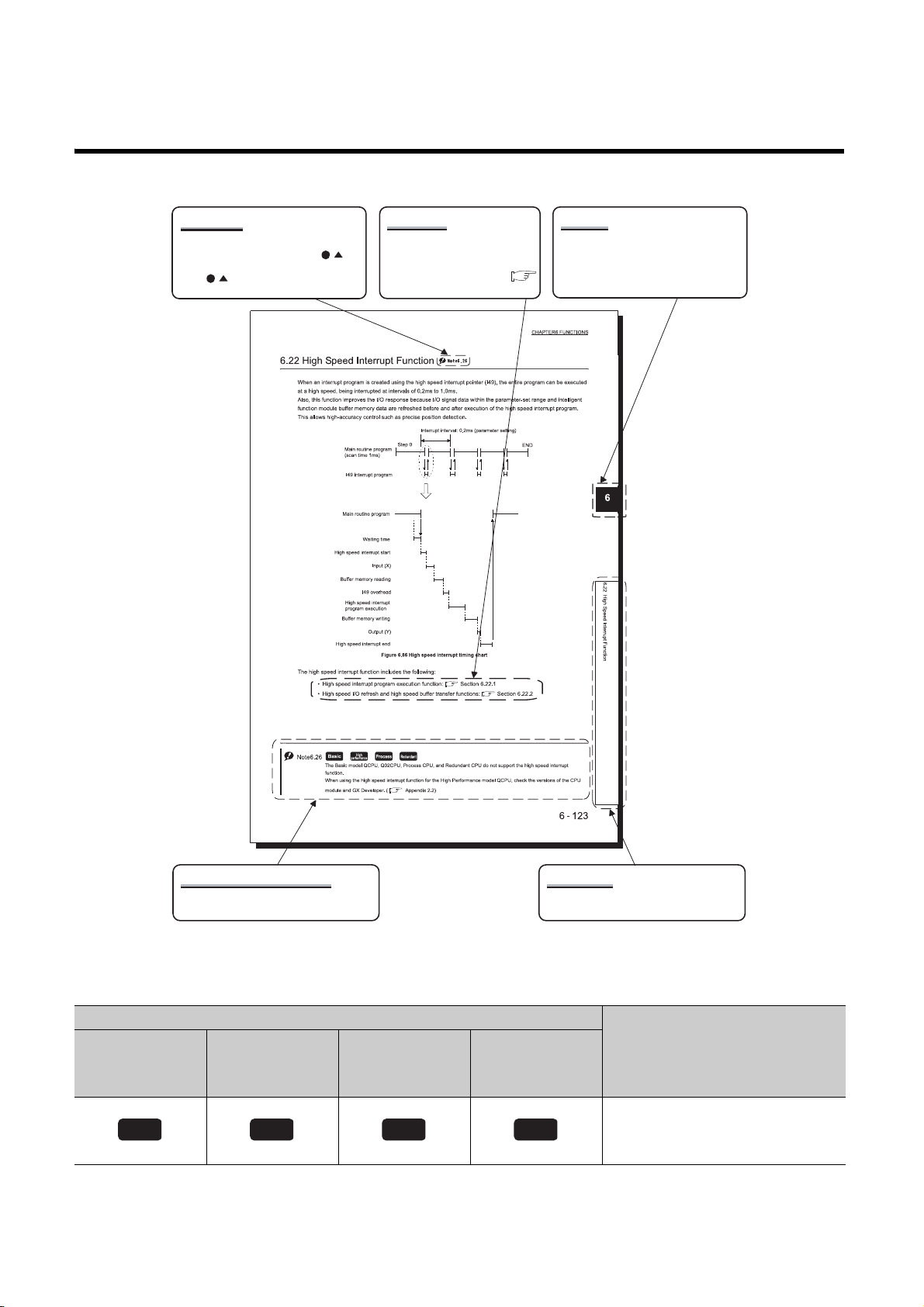

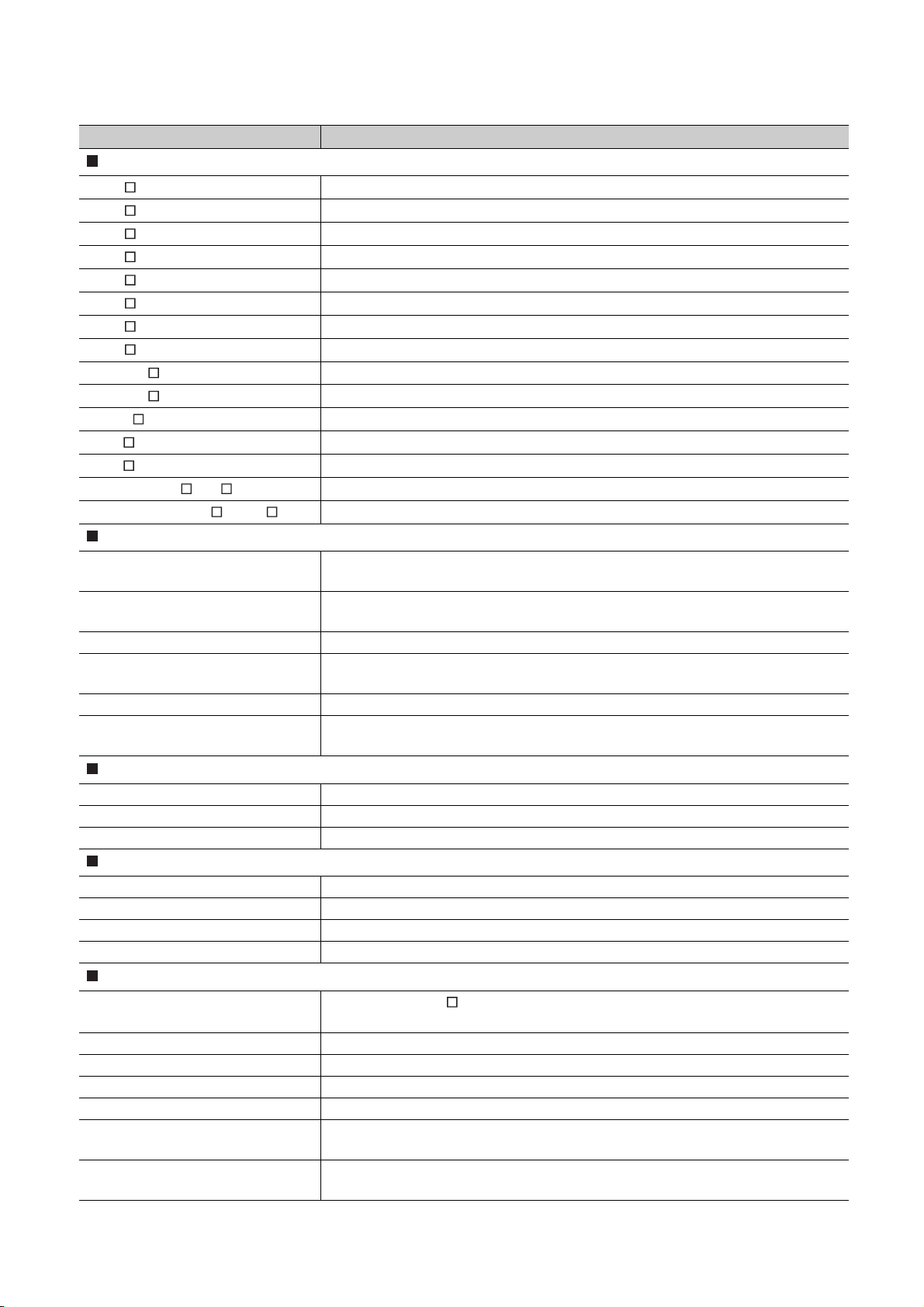

MANUAL PAGE ORGANIZATION

Note (detailed explanation)

ReferenceNote (icon)

The section in this manual or

another relevant manual that can

be referred to is shown with .

The chapter of the current page can be

easily identified by this indication on the

right side.

Chapter

The detailed note corresponding to each icon

is described.

Section title

The section number and title of the current

page can be easily identified.

The detailed explanation of "Note . " is

provided under the corresponding

"Note . " at the bottom of the page.

Basic

*The above page illustration is for explanation purpose only, and is different from the actual page.

Basic model

QCPU

Icons

High

Performance

model QCPU

Process CPU Redundant CPU

Description

A - 20

High

performance

Process

Redundant

Icons indicate that specifications

described on the page contain some

precautions.

In addition, this manual uses the following types of explanations.

Remark

In addition to description of the page, notes or functions that require special attention are described here.

The reference related to the page or useful information are described here.

A - 21

GENERIC TERMS AND ABBREVIATIONS

Unless otherwise specified, this manual uses the following generic terms and abbreviations.

*

indicates a part of the model or version.

(Example): Q33B, Q35B, Q38B, Q312B Q3 B

Generic term/abbreviation Description

Series

Q series Abbreviation for Mitsubishi MELSEC-Q series programmable controller

CPU module type

CPU module

Basic model QCPU Generic term for the Q00JCPU, Q00CPU, and Q01CPU

High Performance model QCPU Generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Process CPU Generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

Redundant CPU Generic term for the Q12PRHCPU and Q25PRHCPU

Motion CPU

PC CPU module

C Controller module Generic term for the Q06CCPU-V, and Q06CCPU-V-B, C Controller modules

CPU module model

QnHCPU Generic term for the Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

Qn(H)CPU Generic term for the Q02CPU, Q02HCPU, Q06HCPU, Q12HCPU, and Q25HCPU

QnPHCPU Generic term for the Q02PHCPU, Q06PHCPU, Q12PHCPU, and Q25PHCPU

QnPRHCPU Generic term for the Q12PRHCPU and Q25PRHCPU

Redundant CPU

Control system Primary system for control and network communication in the redundant system

Standby system Backup system in the redundant system

System A System to which the system A connector of tracking cable is connected

System B System to which the system B connector of tracking cable is connected

Base unit type

Base unit

Main base unit

Extension base unit

Slim type main base unit

Redundant power main base unit

Redundant power extension base unit

Redundant type extension base unit

Multiple CPU high speed main base

unit

Redundant base unit

Redundant power supply base unit

Generic term for the Basic model QCPU, High Performance model QCPU, Process CPU, and

Redundant CPU

Generic term for Mitsubishi motion controllers, Q172CPUN, Q173CPUN, Q172HCPU,

Q173HCPU, Q172CPUN-T, Q173CPUN-T, Q172HCPU-T, and Q173HCPU-T

Generic term for MELSEC-Q series PC CPU modules, PPC-CPU686(MS)-64,

PPC-CPU686(MS)-128, and PPC-CPU852(MS)-512 manufactured by CONTEC Co., Ltd.

Generic term for the main base unit, extension base unit, slim type main base unit, redundant

power main base unit, redundant power extension base unit, and multiple CPU high speed

main base unit

Generic term for the Q3 B, Q3 SB, Q3 RB, and Q3 DB

Generic term for the Q5 B, Q6 B, Q6 RB, Q6 WRB, QA1S5 B, QA1S6 B,

QA1S6ADP+A1S5 B/A1S6 B, QA6 B, and QA6ADP+A5 B/A6 B

Another name for the Q3 SB

Another name for the Q3 RB

Another name for the Q6 RB

Another name for the Q6 WRB

Another name for the Q3 DB

Generic term for the Q3 RB, Q6 RB, and Q6 WRB

Generic term for the Q3 RB and Q6 RB

A - 22

Generic term/abbreviation Description

Base unit model

Q3 B

Q3 SB

Q3 RB

Q3 DB

Q5 B

Q6 B

Q6 RB

Q6 WRB

QA1S5 B

QA1S6 B

QA6 B

A5 B

A6 B

QA6ADP+A5 B/A6 B

QA1S6ADP+A1S5 B/A1S6 B

Power supply module

Power supply module

Q series power supply module

AnS series power supply module Generic term for the A1S61PN, A1S62PN, and A1S63P power supply modules

A series power supply module

Slim type power supply module Abbreviation for the Q61SP slim type power supply module

Redundant power supply module

Network

MELSECNET/H Abbreviation for the MELSECNET/H network system

Ethernet Abbreviation for the Ethernet network system

CC-Link Abbreviation for the Control & Communication Link

Memory card

Memory card Generic term for the SRAM card, Flash card, and ATA card

SRAM card Generic term for the Q2MEM-1MBS, Q2MEM-2MBS, and Q3MEM-4MBS SRAM cards

Flash card Generic term for the Q2MEM-2MBF and Q2MEM-4MBF Flash cards

ATA card Generic term for the Q2MEM-8MBA, Q2MEM-16MBA, and Q2MEM-32MBA ATA cards

Others

GX Developer

QA6ADP Abbreviation for the QA6ADP QA conversion adapter module

QA1S6ADP Abbreviation for the QA1S6ADP(-S1) Q-AnS base unit conversion adapter

Extension cable Generic term for the QC05B, QC06B, QC12B, QC30B, QC50B, and QC100B extension cables

Tracking cable Generic term for the QC10TR and QC30TR tracking cables for redundant systems

Battery

GOT

Generic term for the Q33B, Q35B, Q38B, and Q312B main base units

Generic term for the Q32SB, Q33SB, and Q35SB slim type main base units

Another name for the Q38RB main base unit for redundant power supply system

Generic term for the Q35DB, Q38DB and Q312DB multiple CPU high speed main base units

Generic term for the Q52B and Q55B extension base units

Generic term for the Q63B, Q65B, Q68B, and Q612B extension base units

Another name for the Q68RB extension base unit for redundant power supply system

Another name for the Q65WRB extension base unit for redundant power supply system

Another name for the QA1S51B extension base unit

Generic term for the QA1S65B and QA1S68B extension base units

Generic term for the QA65B and QA68B extension base units

Generic term for the A52B, A55B, and A58B extension base units

Generic term for the A62B, A65B, and A68B extension base units

Abbreviation for A large type extension base unit on which the QA6ADP is mounted

Abbreviation for A small type extension base unit on which the QA1S6ADP is mounted

Generic term for the Q series power supply module, slim type power supply module, and

redundant power supply module

Generic term for the Q61P-A1, Q61P-A2, Q61P, Q61P-D, Q62P, Q63P, Q64P, and Q64PN

power supply modules

Generic term for the A61P, A61PN, A62P, A63P, A68P, A61PEU, and A62PEU power supply

modules

Generic term for the Q63RP and Q64RP power supply modules for redundant power supply

system

Product name for SW D5C-GPPW-E GPP function software package compatible with the Q

series

Generic term for the Q6BAT, Q7BAT, and Q8BAT CPU module batteries, Q2MEM-BAT SRAM

card battery, and Q3MEM-BAT SRAM card battery

Generic term for Mitsubishi Graphic Operation Terminal, GOT-A*** series, GOT-F*** series,

and GOT1000 series

A - 23

CHAPTER1 OVERVIEW

The CPU module performs sequence control by executing programs.

This chapter describes the processing order in the CPU module, locations where the created programs are stored, and

devices and instructions useful for programming.

1.1 Processing Order in the CPU Module

The CPU module performs processing in the following order.

Power-on or reset

Initial processing

Refresh processing with

input/output modules

Program operation processing

Scan time

END processing

Figure 1.1 Processing order in the CPU module

(1) Initial processing ( Section 3.1)

The CPU module performs preprocessing required for program operations.

The preprocessing is performed only once when the module is powered on or reset.

(2) Refresh processing with input and output modules ( Section 3.2)

The CPU module takes on/off data from the input module or intelligent function module and outputs on/off data to

the output module or intelligent function module.

(3) Program operation processing ( Section 3.3)

The CPU module sequentially executes the program stored in the module from the step 0 to the END or FEND

instruction.

(4) END processing ( Section 3.4)

The CPU module performs refresh processing with network modules or communicates with external devices.

1 - 1

CHAPTER1 OVERVIEW

CPU module

The CPU module executes

the programs stored here.

Program memory

Parameter

Program

Device comment

Initial device value

Comments are stored

separately from the program.

Standard

ROM

The CPU module executes the programs

booted from the standard ROM or

a memory card to here.

Boot

Boot

Parameter Program

Initial device

value

Device

comment

Device

comment

Parameter

Program

Initial device

value

CPU module

Memory card

*1

Program

memory

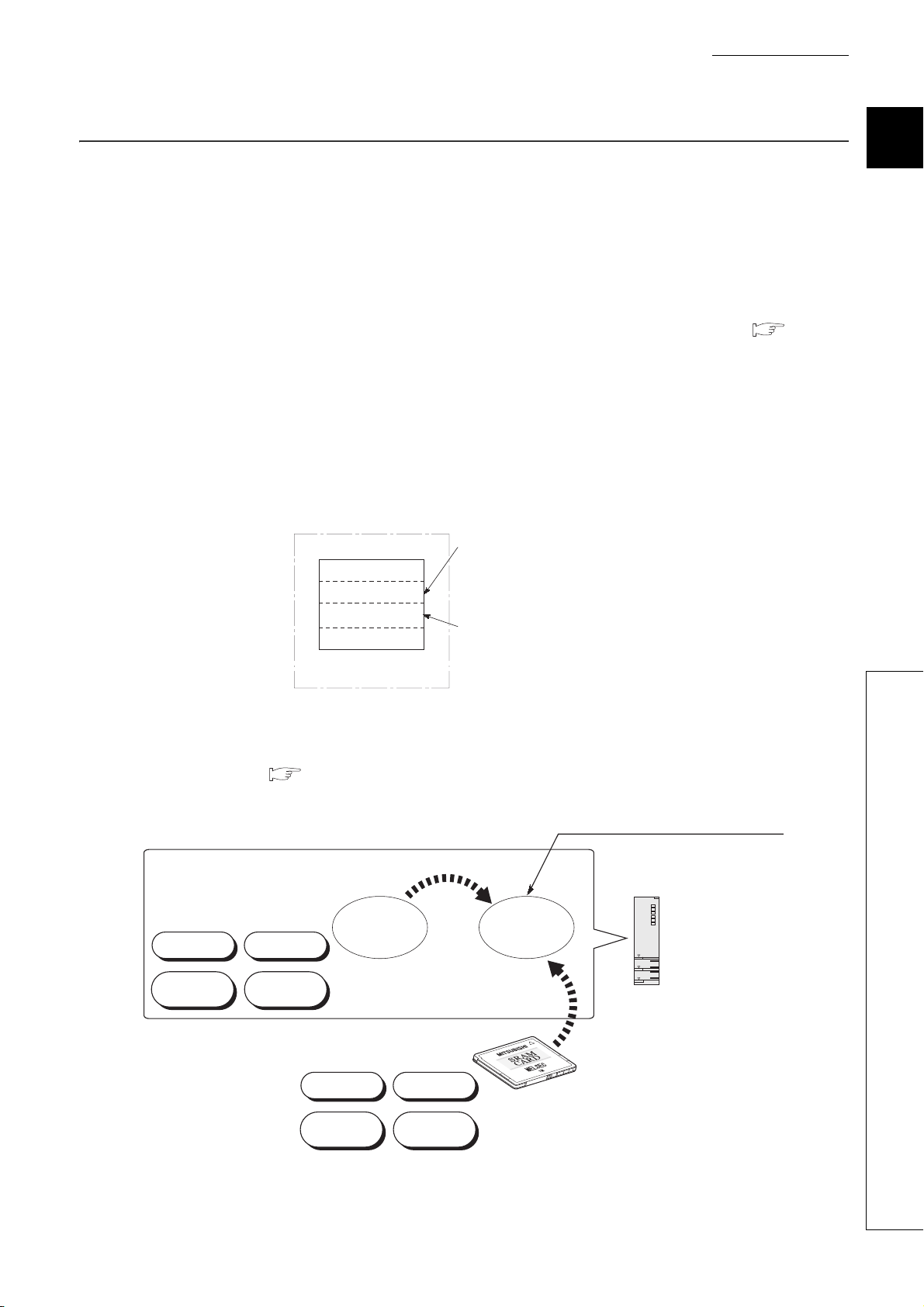

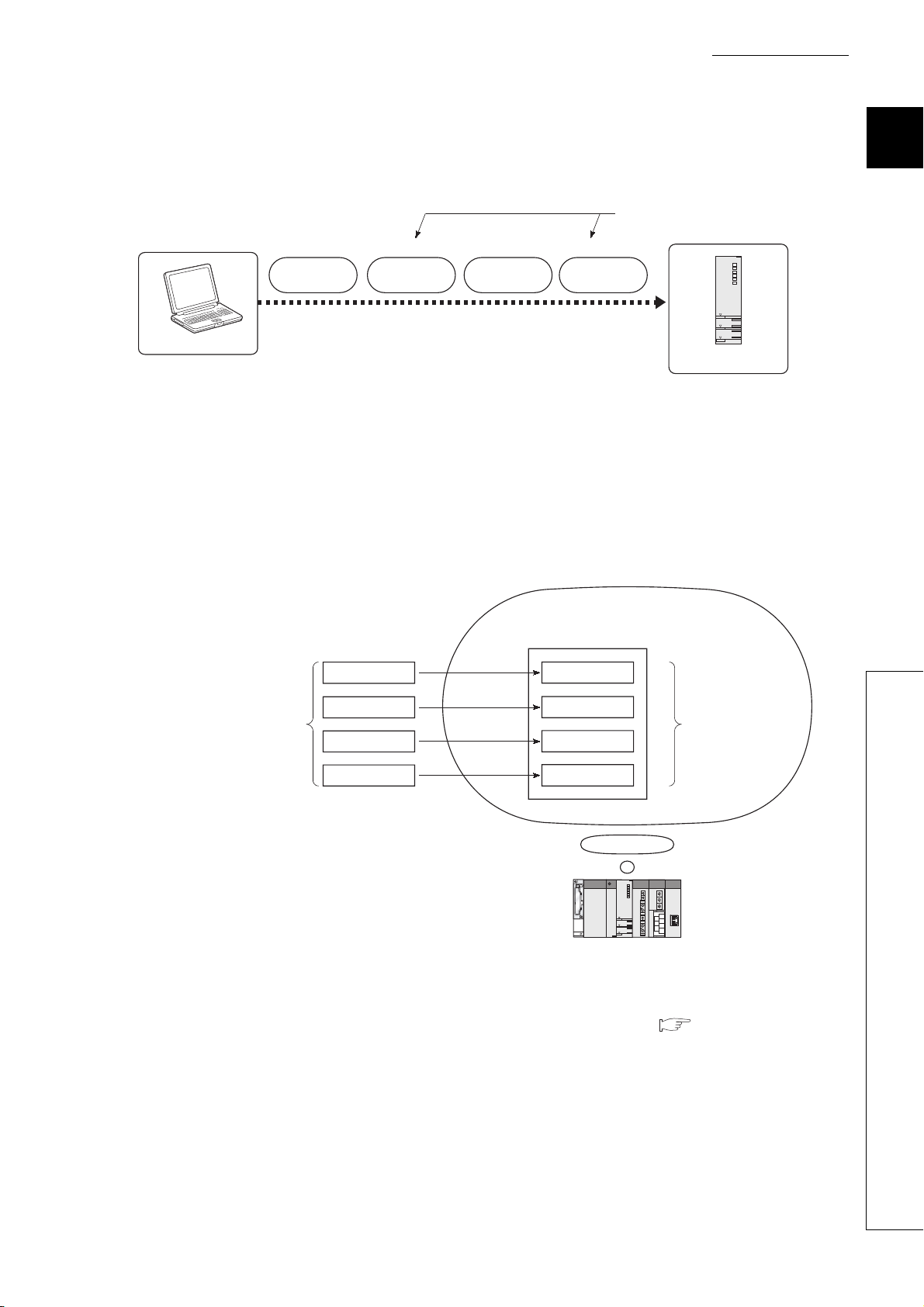

1.2 Storing and Executing Programs

This section describes where to store and how to execute the programs in the CPU module.

(1) Programming

Programs are created with GX Developer.

For details of program configuration and execution conditions, refer to CHAPTER 2.

(2) Storing programs

Created programs and set parameters are stored in the following memories of the CPU module. ( Section

5.1, Section 5.2)

• Program memory

• Standard ROM

• Memory card

(3) Executing programs

The CPU module executes the programs stored in the program memory.

1

Figure 1.2 Executing programs

To execute the programs stored in the standard ROM or a memory card, the programs need to be booted to the

program memory ( Section 5.1.5) when the CPU module is powered off and then on or reset.

1.2 Storing and Executing Programs

Figure 1.3 Executing programs by performing a boot operation

1 - 2

1.3 Structured Programming

Note1.1

The Basic model QCPU cannot store multiple programs, structured programming by dividing into multiple files is not

available.

P8

RET

RET

Y10

Y11

Y12

P1

END

FEND

CALL P1

IRET

I0

Main routine

program

Subroutine

program 1

Subroutine

program 2

Interrupt program

The programs to be executed in the CPU module can be structured in the following two ways.

• In one program

• By dividing into multiple files

(1) Structuring in one program

Structured programming is available by creating one program as a collection of three program sections: main rou-

tine program ( Section 2.2.1), subroutine program ( Section 2.2.2), and interrupt program

( Section 2.2.3)

Note1.1Note1

Note1

1 - 3

Figure 1.4 Structuring in one program

Basic

CHAPTER1 OVERVIEW

GX Developer

CPU module

Multiple programs can be stored

by changing the file name.

File name: PARAM

Parameter Program Program

Device

comment

File name: ABC File name: ABC File name: DEF

Carrying in

Carrying out

Manufacturing

Assembly

Program memory/standard ROM/memory card

Processing contents

are divided according

to the processes.

Program A

Program B

Program C

Program D

Program A to D

will be executed

in the specified

order.

*2

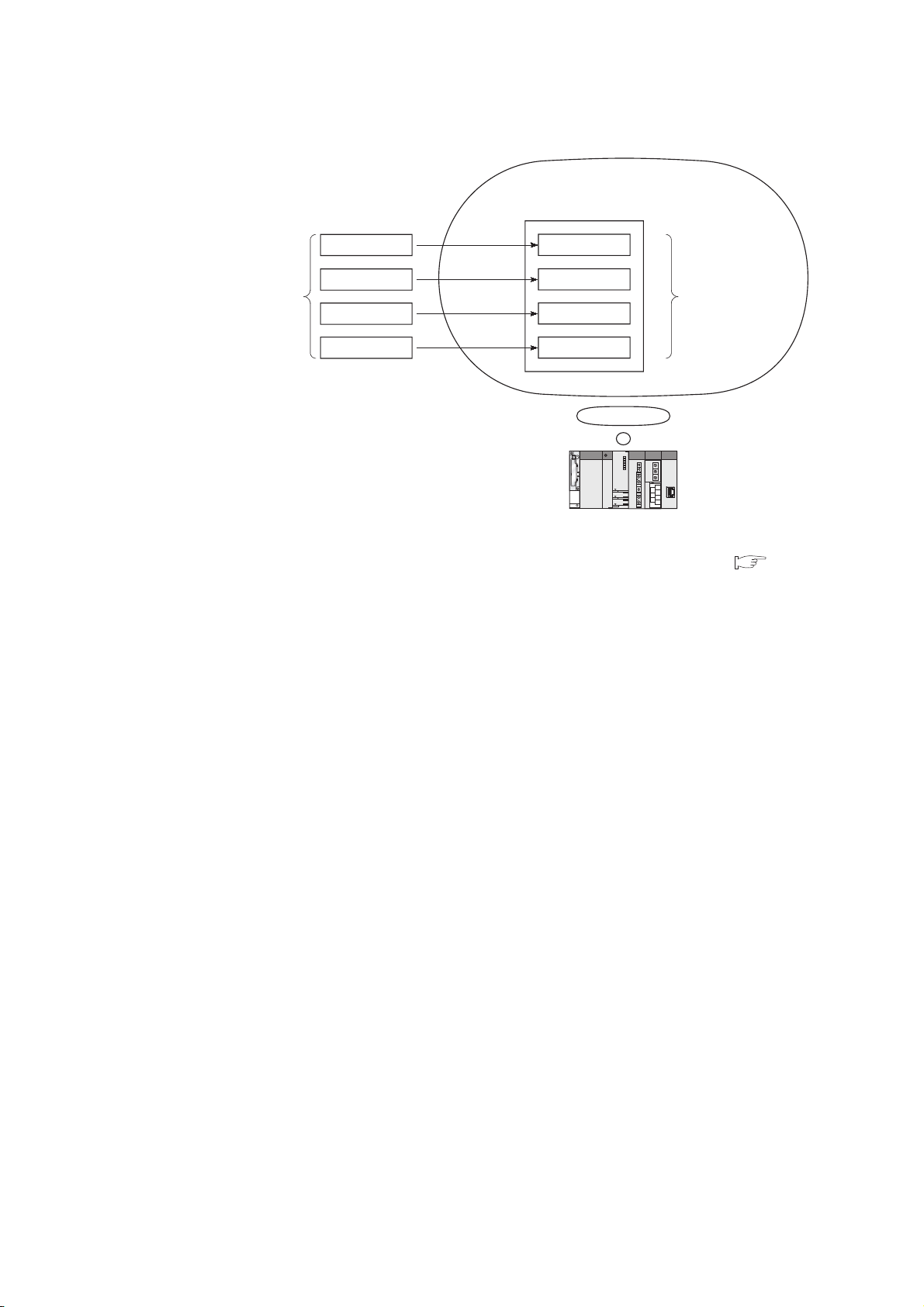

(2) Structuring by dividing into multiple files

A program is stored in a file.

Changing the file name allows the CPU module to store multiple programs.

Figure 1.5 Structuring by dividing into multiple files

Dividing into multiple files according to the processes or functions enables simultaneous programming by two or

more designers. Managing the files separately eases reuse and utilization to other programs.

Structured programming is efficient in this way because only the corresponding file needs to be modified or

debugged in case of change in the specifications.

(a) Dividing into multiple files according to the processes

*1

1

Figure 1.6 Dividing into multiple files according to the processes

*1: The processing contents divided according to the processes can further be divided and managed according to the func-

tions.

*2: The execution order can be set in the Program tab of the PLC parameter dialog box. ( Section 2.3(2))

1.3 Structured Programming

1 - 4

(b) Dividing into multiple files according to the functions

Program memory/standard ROM/memory card

Initial processing

Processing contents

are divided according

to the functions.

Figure 1.7 Dividing into multiple files according to the functions

*1: The execution order and conditions can be set in the Program tab of the PLC parameter dialog box ( Section

2.3(2))

Main processing

Communication

processing

Error processing

Program A

Program B

Program C

Program D

The execution order

and conditions for

program A to D

can be set.

*1

1 - 5

Loading...

Loading...