Page 1

2450 A!amo SE

Albuquerque. NM 87t06

Page 2

PRELIMINARY DOCUMENTATION RELEASE

THE FOLLOWING INFORMATION IS A PRELIMINARY RELEASE ONLY.

THE COMPLETE THEORY OF OPERATION WILL BE ADDED TO THE

ASSEMBLY MANUAL AT A LATER DATE. THE OPERATORS MANUAL

AND DOS DOCUMENTATION WILL BE DEVELOPED IN A SINGLE

MANUAL ALSO. BOTH OF THESE, AND ANY UPDATES TO THIS

ENTIRE SYSTEM DOCUMENTATION WILL BE SENT IMMEDIATELY

UPON THEIR PRINTING DATE.

Page 3

OISK OPERATORS MANUAL

INSCRIPTION OF SYSTEM

A) DISK SPEC SHEET

B) OISK SYSTEM BLOCK DIAGRAM DESCRIPTION

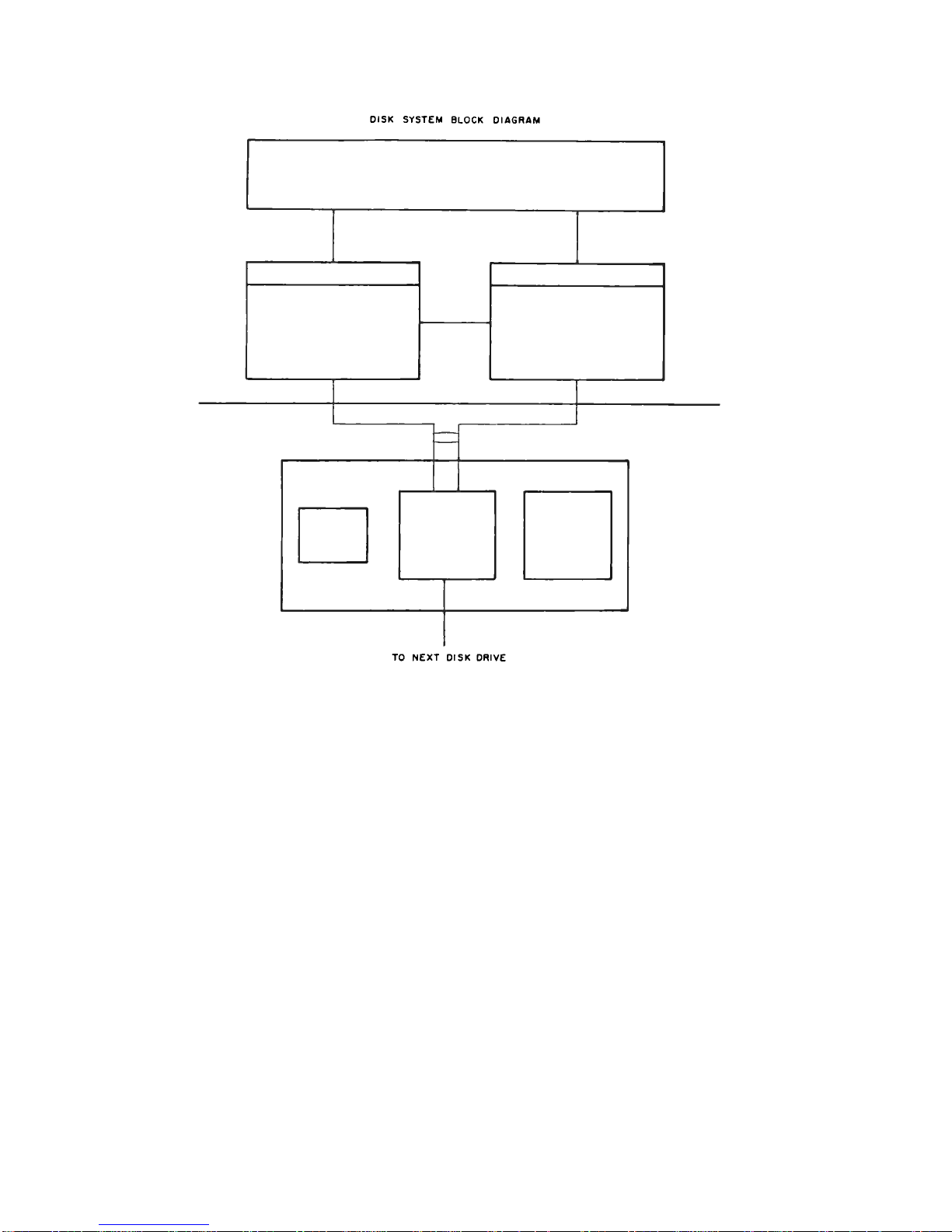

1. CONTROLLER BOARD 1:

Controller Board 1 does all input functions to the ALTAIR

bus (Read Data, Sector Data, Status Information), as well

as Control Addressing of all Disk to ALTAIR I/O.

2. CONTROLLER BOARD 2:

Controller Board 2 performs all output functions from the

ALTAIR bus (Write Data, Disk Control, Disk Enable and

Drive Selection).

3. INTERCONNECT CABLE:

An 18 pair flat cable with two 37 pin connectors, a male

on one end, a female on the other. This cable connects the

Disk Drive to the ALTAIR Disk Controller and "Daisy Chains"

one Disk Drive to another in multiple Disk systems.

4. OISK DRIVE CABINET:

a) POWER SUPPLY:

The Disk Drive Cabinet contains a power supply for powering

the Disk Buffer and Disk Drive.

b) THE DISK BUFFER:

The Disk Buffer board contains the necessary line drivers

and receivers for interconnection with long cables to the

Disk Drive. In addition, it contains the Disk Drive Address

circuitry that allows the Controller to select one of 16

Disk Drives.

The Disk Buffer board also contains the line drivers for

connection of multiple Disk Systems.

c) THE DISK DRIVE:

The Disk Drive, a Pertec F0-400, contains the mechanism and

electronics that actually reads ar.d writes data on the Diskette.

Page 4

CONNECTION OF OISK SYSTEM:

A) CONTROLLER BOARDS:

1. Items Supplied:

a) CONTROLLER BOARD 1 (white vert strips)

b) CONTROLLER BOARD 2 (with short cable wired to it)

c) CONTROLLER CABLE (with 37 pin on one end, 3 Molex connec-

tors on the other end)

d) Connector Mounting Bracket and Hardware

2. Connection of Controller Boards

a) Take cover off ALTAIR (power off!)

b) Feed Molex (flat) connector ends of Controller cable through

hole in back of ALTAIR on connector panel: (37 pin con-

nector outside chassis, molex connectors inside chassis).

c) Lay board 1 flat in front of you on the ALTAIR chassis with

components up and stab connector to your right (as facing

the front of the ALTAIR).

d) Take the short wired cable of board 2 and connect it to the

20 pin connector on board 1 (note polarization key of

connector and missing pin on the PC board).

e) Place board 2 flat, to the left of board 1.

f) Connect 20 pin Molex connector on the Controller cable to

the 20 pin connector on board 2. Note Keying.

g) Take the 10 pin connector on the Controller cable with the

orange and yellow wires connected to it and connect it

to the 10 pin connector on board 2. Note Keying.

h) Take the remaining 10 pin connector on the Controller cable

with white and gray wires on it and connect it to the

10 pin connector on board 1. Note Keying.

i) Take both boards, hold together and slide into slots, with

board 1 on right, board 2 on the left. Be sure wires

from connector go out between card guides, and do not

catch on card guides,

j) Push cards firmly into connector in ALTAIR mother board,

k) Install 37 pin connector in bracket and on back of ALTAIR,

straddling 2 connector holes. Use #4-40 x 5/16 screws,

lockwashers and #4-40 nuts.

B) DISK DRIVE CONNECTION TO ALTAIR:

Take the 6 ft. flat cable with 1 male and 1 female connector;

connect male end to Disk Controller connector on ALTAIR, and

female end to connector on the Oisk Drive marked "To Controller".

Page 5

THE ALTAIR FLOPPY

D!SK SYSTEM

The ALTA/R Disk offers the advantage of nonvolatile memory

plus relatively fast access to datu The AL7A/R Disfc Controffer

consists of tv,o PC boards lover 60 IC s) that fit in [he AL7A1R

nect to the disk through a 37 pin connector mounted on the

back of the ALTAIR Data is transferred to and from the disk

senally at 250K bits sec The disk controller converts the senal

data to and from Sbit parallel words (one word every 32 « sec!

The ALTA/R CPU transfers the data, word by word to and from

memoty. depending on wnether the disk is reading or writing

The disk controller also controls all mechanical functions of the

disk as well as presenting disk status to the computer All timing

tasks Since the /loppy diskette is divided into 32 sectors, a

hardware interrupt system can be enabled to notify the CPU at

The Disk Dnve unit, using a PERTEC FD400 mounted in an

Optima case 15'?" high—same depth and width as computer),

includes a poaer suppfy PC board and a 8u//er Address Line

temperature ior continuous operation The disk dnve cabinet

has two 37 pin connectors on the back panel, one is the input

from the disk controller, the other is the output to additional disk

dnves Up to ]6 dnves may be attached to one controller

The Mb DCDD consists of the disk controller and one disk

dnve with an interconnect cable The

MM

Disk is one disk dnve for

adding storage capability to the

MM

DCDD and includes the inter

The AL7AJR Disk Format allows storage of over 300.000

bytes. Since the disk is hard sectored 132 sectors for each track),

we wnte 137 byies on each sector. 9 of which are used internally

[tracks checksum) leaving 128 data bytes per sector. 4096 per

track One floppy diskette is supplied with each drive: extra flop-

pies are available for purchase A so/Mare driver for the floppy

disk is available at no charge and is supplied with the disk as a

source listing The disk operating system—which has a complete

file structure and utilities for copying, deleting and sorting

files—costs extra Extended BASIC. which uses random and se-

quential tile access for the floppy disk, is also available.

Speed

Access Times

Head Life

Disk Life

Rate

Power

Diskette

Specifications

360 rpm 1166.7 ms/rev)

Track to track. 10 ms

Head settle. 20 tin

Average time to read or

write. 400 nis

Worst case. 1 sac

Over 10.000 hours of head

to disk contact

Over 1 million passes/track

250K bits/sec

117VACH0W

Dysan 101 floppy disk. 77 tacit*

Page 6

DISK SYSTEM BLOCK DIAGRAM

10 NEXT DISK DRIVE

Page 7

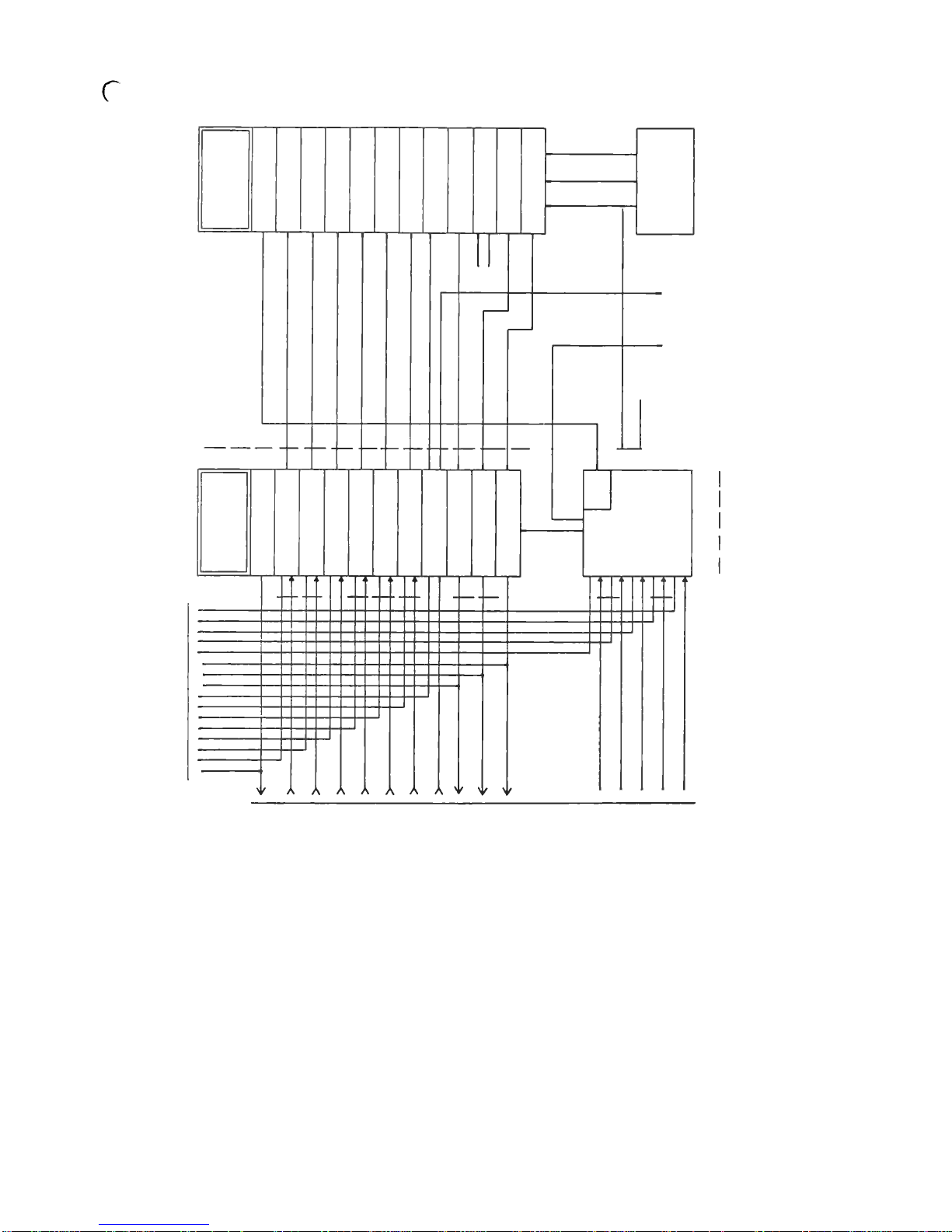

r

Page 8

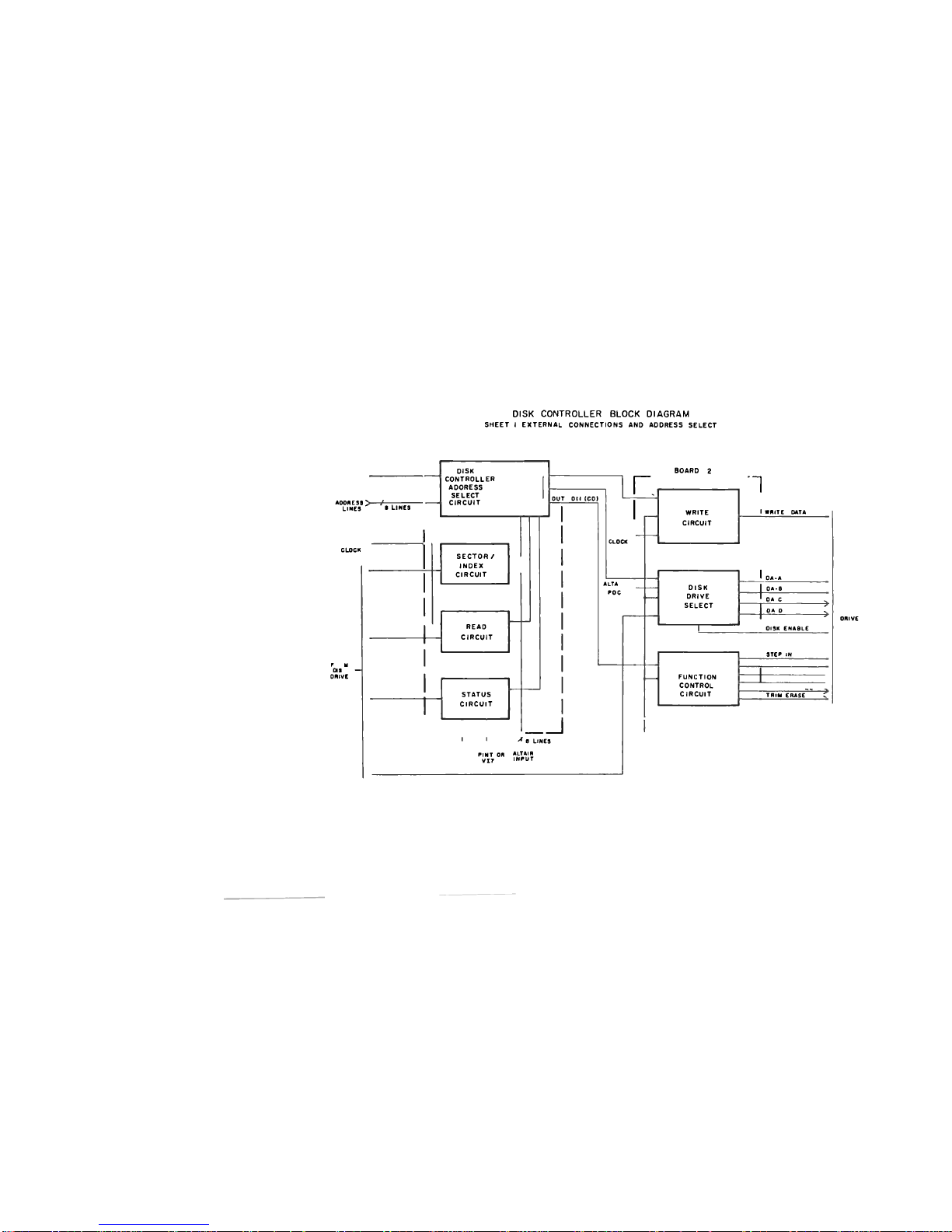

DISK CONTROLLER BLOCK DIAGRAM

SHEET I EXTERNAL CONNECTIONS AND AOORESS SELECT

A00HE99

> /

LIHES < LIWCS

CLOCK

^as" —

ooivt

OISK

CONTROLLER

AOORESS

SELECT

CIRCUIT

READ

CIRCUIT

STATUS

CIRCUIT

SECTOR/

tNOEX

CIRCUIT

ouT on [cot

CLOCK

r

I

[

' ' e LINES

PIMT OH ALTM"

Vt7 IMPUT

ALU

POC

BOARD 2

WRITE

CIRCUIT

1

CIRCUIT

I WHITE MT4

! o*.*

DISK

DRIVE

SELECT

o*.a

DISK

DRIVE

SELECT

o*c ^

DISK

DRIVE

SELECT

0*0 ^

OHK ENA9LE

1

OHK ENA9LE

STEP IX STEP IX

FUNCTION FUNCTION

CONTROL

CIRCUIT

CONTROL

CIRCUIT

TBI* EMSE ?

OHIVE

Page 9

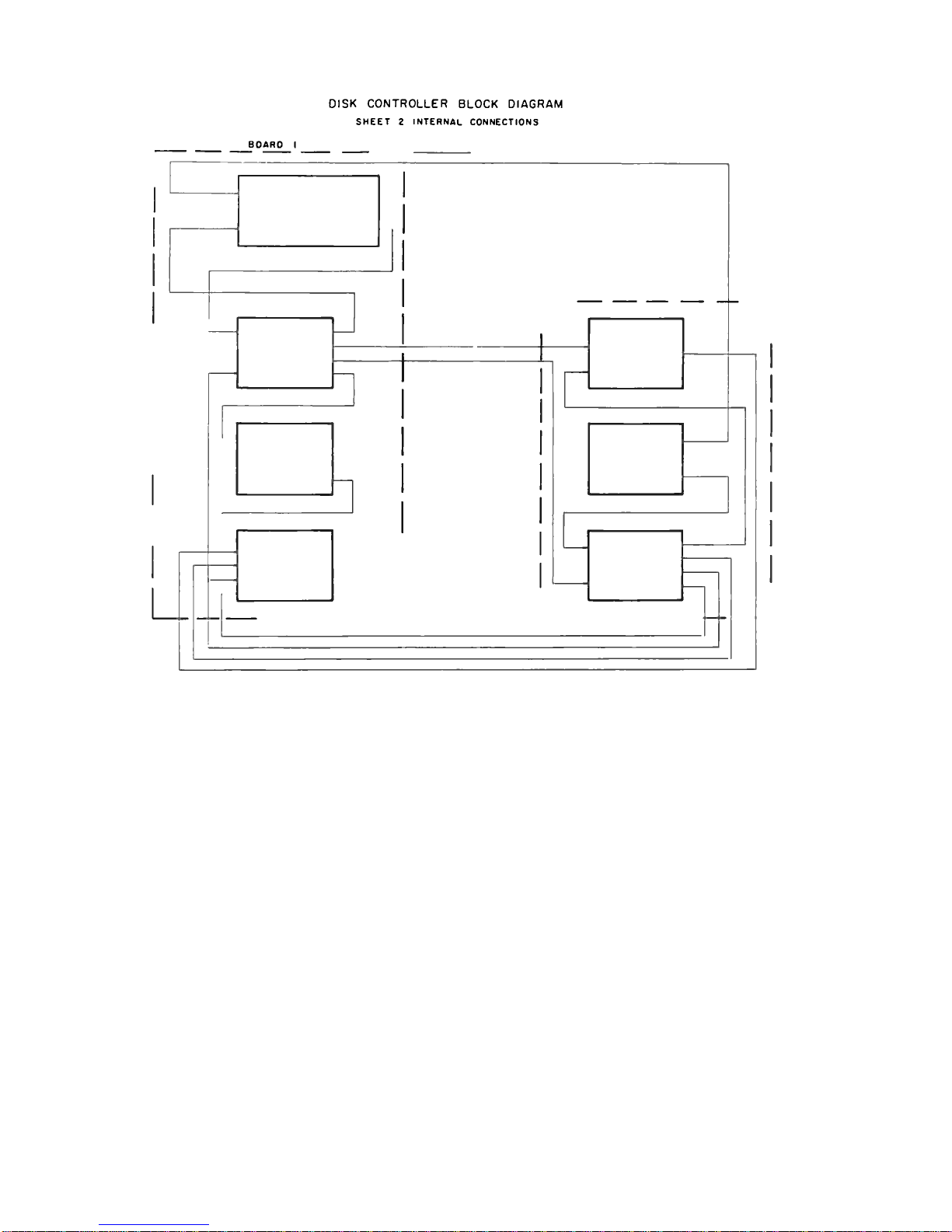

DISK CONTROLLER BLOCK DIAGRAM

SHEET 2 INTERNAL CONNECTIONS

80AR0 I

Page 10

ALTAIR DISK CONTROLLER I/O INFORMATION

A. Address codes for I/O

Address Mode

1.

010

Out Select, latches and enables controller

and disk drive.

010

In

Indicates status of disk drive and controller.

3.

011 Out Controls disk function.

4.

011 In Indicates sector position of disk

5.

012

Out

Write data.

6.

012

In

Read data.

8. Definitions (In order as listed above)

1. Selection of Disk Drive "OUT" on CH #010

D0 LS8 Enables 1 of 16 drives (each drive has a unique ad-

D1 dress, selected by 4 jumper wires) and enables con-

D2 troller (on disk drive buffer P.C. card).

D3 MSB

D4

D5 Not used, don't care.

D6

D7 Clears disk control if set to 1 (D0-D6 don't care).

Disables disk control. Oisk control also cleared

by opening door of disk drive or turning disk drive

power off.

NOTE: a) If disk drive door is open, drive and controller

cannot be enabled.

b) If disk power is off, drive and controller cannot

be enabled.

c) If disk interconnect cable is not connected between

the controller and the drive, drive and controller

cannot be enabled.

Page 11

C) MULIIPLL DISK DRIVE CONNECTION:

1. With multiple Disk Drives, the Disks should have sequential

addresses (i.e., for a .1 drive system you should have Disks

with addresses 0, 1, and 2). They may be connected in any or-

der. There serial # sticker has the Disk Address written on

it. The Disk Address is determined by four jumper wires in

the Disk Buffer P.C. card inside the Drive, and may be changed.

2, Connect the Disks by using the 6 ft. flat cable. Connect the

male connector to the connector marked "From Next Disk" on the

Disk Drive connected to the Controller. The other end of the

cable connects to the next Disk Drive connector marked "To Con-

troller". This procedure is repeated for added Disk Drive.

III. USING THE DISK DRIVE:

A) DISKETTE INFORMATION:

1. Always keep Diskette in envelope when not in use.

2. Keep Diskette away from heat, magnetic fields (flourescent

lights, power transformers, etc.) and dust and dirt.

3. Never touch recording surface of Diskette (opposite label

side).

4. Always mark your Diskette with what is on them. Use adhesive

labels, but don't write on them after they are attached

to the Diskette.

5. The Diskette used is hard Sectored (32 Sector holes, 1 index

hole). Blank Diskettes are available from MITS for $15.00

each. The Diskettes are not IBM compatible.

B) OPERATING THE DISK DRIVE:

1. Open door to Disk Drive by pulling out and down.

2. Insert Diskette into Drive with label side up, making sure

it catches on retaining tab.

3. Close door to Disk Drive.

4. If Disk power is on, wait 10 seconds, after closing door

before activating any programs to access the Disk. Wait

10 seconds after turning power on with Diskette in Drive

before activating any programs to access the Disk. This is

to allow motor speed to stabilize.

5. NEVER: open Disk Drive door or turn power off when Disk Enable

and Head Load lights are on. There would be a good possibili-

ty that you would interrupt the software during a write func-

tion, and destroy data on the Diskette.

6. Consult software documentation on methods used to load basic or

use software. For applications where the user wishes to

write his own software. See last section, "Controller I/O

Information".

Page 12

2. Status (010 - INP) indicates disk status when drive and controller

enabled. Also gives valid "INTE" status (05) from the ALTAIR bus

when controller enabled.

True condition = 0, False = 1.

All false if disk and controller are not enabled, and all false if

no disk in drive.

D0 - ENWO - Enter new Write data - indicates write circuit is ready

for new data byte to be written. It occurs every 32 us and

starts 280 ps after sector true (when Write enabled). It is

reset by outputting to the Write data channel (012).

Dl - Move Head - Indicates head movement allowed when true (step

IN, step OUT,). Goes false for 10 ms, true 1 ms, false 20

ms after step command. May step every 10 ms. Goes false for

40 ms after head load. Goes false during Write and 475 us

after Write to allow completion of trim erase.

D2 - HS - Head Status - True 40 ms after head loaded or step command

Ii*f stepping with head already loaded). Indicates when head

is properly loaded for reading and writing. Also enables sec-

tor position channel when true.

03 - Not Used, = 0.

D4 - Not Used, = 0.

D5 - INTE - Indicates interrupt enabled.

D6 - TRACK 0 - Indicates when head is on outermost track.

D7 - NROA - New read data available - indicates that the read cir-

cuit has 1 byte of data ready to be taken from the read data

channel (012). After the SYNC* bit is detected, it occurs

every 32 ps and is reset by an input instruction on channel

012. The byte containing the SYNC bit is the first byte

read from the disk.

* See "Write Enable"

Page 13

Control (011 - Out) - Controls Disk operations when disk drive

and controller enabled. A true signal, logic 1, on a data line

will control the disk as follows:

00 - Step IN - steps disk head in one position to higher numbered

track.

D1 - Step OUT - steps disk head out one position to lower numbered

track.

D2 - Head Load - loads head onto disk - enables sector position

status.

D3 - Head Unload - removes head from disk surface, may be unloaded

immediately after "Write Enable" (write and trim erase circuits

hold head loaded until through).

D4 - ^E - Interrupt Enable - enables interrupts to occur when SR0

true (see sector definition).

D5 - H) - Interrupt Disable - disables interrupt circuit. Interrupt

circuit also disabled by clearing disk control.

D6 - HCS - Head Current Switch - must be true when outputting a write

instruction with the head on tracks 43-76. This reduces head

current and optimizes resolution on inner tracks (automatically

reset at end of writing a sector).

D7 - Write Enable - initiates write sequence as follows:

1. Disk selected and enabled, head loaded, enabling sector status.

2. (Sector True) detected for desired sector, write circuit

enabled by software.

3. 200 us from Write Enable, trim erase automatically turned

on. 280 us from start of sector, "ENWD" goes true, sync

byte written by software.

4. First byte written always has most significant (D7) bit A

"1" (SYNC Bit) (most sifnificant bit written first).

5. ENWD goes true every 32 us. MAX. no. of data bytes per

sector 137 (including SYNC).

6. Last or 138th byte written must be a 000. This will be

written for the remainder of the sector. Ignore "ENWD"

from this point to end of sector.

7. At end of sector, the write circuit automatically disabled,

trim erase disabled 475 us later.

Page 14

NOTE: a) Write circuit will continue writing last byte out-

putted on CH #012 to the end of that sector.

b) Head may be unloaded anytime during write cyclr it* no

read or write function is cxpcctcd after current write

cycle. Once Write is enabled, it holds the head loaded

for the required time. (For writing and trim erase).

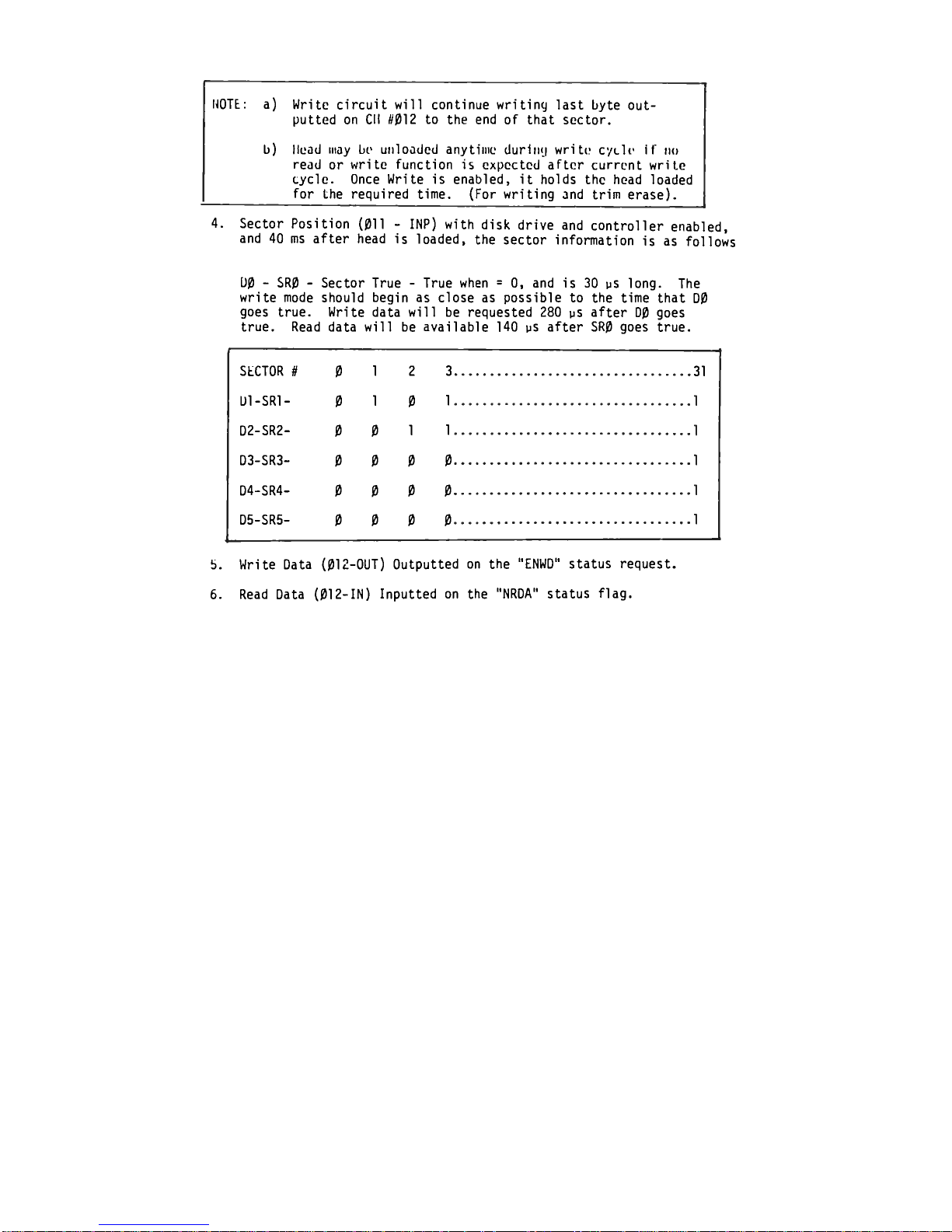

4. Sector Position (011 - INP) with disk drive and controller enabled,

and 40 ms after head is loaded, the sector information is as follows

00 - SR0 - Sector True - True when = 0, and is 30 ps long. The

write mode should begin as close as possible to the time that D0

goes true. Write data will be requested 280 ps after D0 goes

true. Read data will be available 140 ps after SR0 goes true.

SECTOR #

0

1

2 3

31

U1-SR1-

0

1

0

1

1

D2-SR2-

0 0

1 1

1

D3-SR3-

0 0 0

0

1

D4-SR4-

0

0 0

0

1

D5-SR5-

0 0 0 0

1

b. Write Data (012-OUT) Outputted on the "ENWD" status request.

6. Read Data (012-IN) Inputted on the "NRDA" status flag.

Page 15

( )

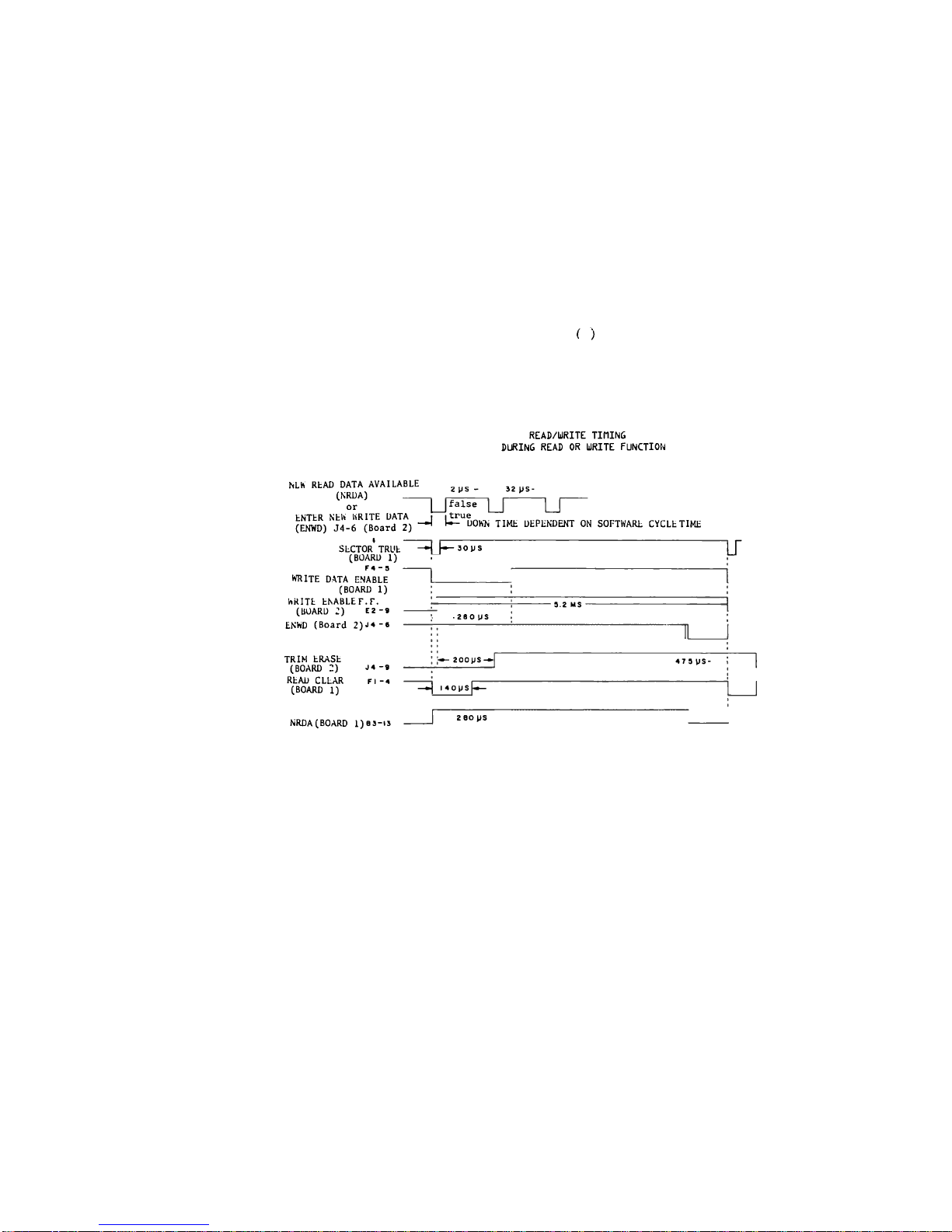

READ/URITE TIMING

DURING READ OR URITE FUNCTION

NLh READ DATA AVAILABLE

(NRDA) ) r^

or

[_]

false

ENTER NEh URtTE DATA

(ENWD) J4-6 (Board 2)

SECTOR* TRUE -^J— soVs

(BOARD 1) .

F4 - S

WHITE DATA ENABLE

(BOARD 1)

WRITE EhABLEF.r.

(BOARD 2) E2

- 9

EKhD (Board 2)^-6

32 ps-

] itrue

—J k- DOWN TIME DEPENDENT ON SOFTWARE CYCLE TIML

TRIM ERASE

(BOARD :)

READ CLEAR

(BOARD 1)

Jl -9

F!

-4

.

2SO

tJS

j—-

200 tJS-*-

—-j ! 40)JS ——

If

5.2 MS

47 5 PS-

NRDA(BOARD l)a:-n

2ao ps

Page 16

*********** ERRATA SHEET ***********

ALTAIR FLOPPY DISK

DRIVE & CONTROLLER - HARDWARE DOCUMENTATION

March 1976

THE FOLLOWING CHANGES HAVE BEEN MADE TO THE ABOVE

TITLED MANUAL ON THE PAGES INDICATED.

PAGE 32: No heat-sink should be used for either XI or X3. Mount both

of these regulators directly to the board.

PAGE 95: Use a length of wire and connect the two pads labeled +8V to-

gether along the bottom edge of the board.

IT IS GENERALLY A GOOD IDEA TO GO THROUGH

YOUR MANUAL AMD MARK THESE CHANGES ON THE

PAGES INDICATED BEFORE BEGINNING THE ACTUAL

PROCESS OF ASSEMBLING YOUR UNIT.

HITS, Inc.

3/16/76

Page 17

^k ccntro^er assembly procedure

Page 18

ASSEMBLY H!MT$

Before beginning the construction of your unit, it is important that you read

the "M!TS Kits Assembly Hints" booklet included with your kit. Pay particular

attention to the section on soldering, because most problems in the Altair

occur as the result of poor soldering. It is essential that you use the cor-

rect type of soldering iron. A 25-30 watt iron with a chisel tip (such as an

Ungar 776 with a 7155 tip) is recommended in the assembly hints booklet.

Some important warnings are also included in the hints booklet. Read them

carefully before you begin work on your unit -- failure to heed these warnings

could cause you to void your warranty.

Check the contents of your kit against the enclosed parts list to make sure

you have all the required components, hardware and parts. The components are

in plastic envelopes; do not open them until you need the components for an

assembly step. You will need the tools called for in the "Kits Assembly

Hints" booklet.

As you construct your kit, follow the instructions in the order they are

presented in the assembly manual. Always complete each section before going

on to the next. Two organizational aids are provided throughout the manual

to assist you: 1) Boxed-off parts identification lists, with spaces provided

to check off the components as they are installed; 2) Reproductions of the

silk screens showing a) previously installed components, b) components being

installed and c) components yet to be installed, (see below)

previously

installed

components

components

yet to be

installed

components

bei

ng

installed

-un inE

Page 19

COMPONENT INSTALLATION METHODS

This section of the manual describes the proper pro-

cedures for installing various types of components

in your kit.

Read these instructions over very carefully and

refer back to than whenever necessary. Failure to

properly install components may cause permanent

damage to the component or the rest of the unit;

it will definitely void your warranty.

More specific instructions, or procedures of a

less general nature, will be included within the

assembly text itself.

Under no circumstances should you proceed with an

assembly step without fully understanding the pro-

cedures involved. A little patience at this stage

will save a great deal of time and potential "head-

aches" later.

2

Page 20

PIM t

u

o

PIN I

rr

PIN I

°o

o

PIM I

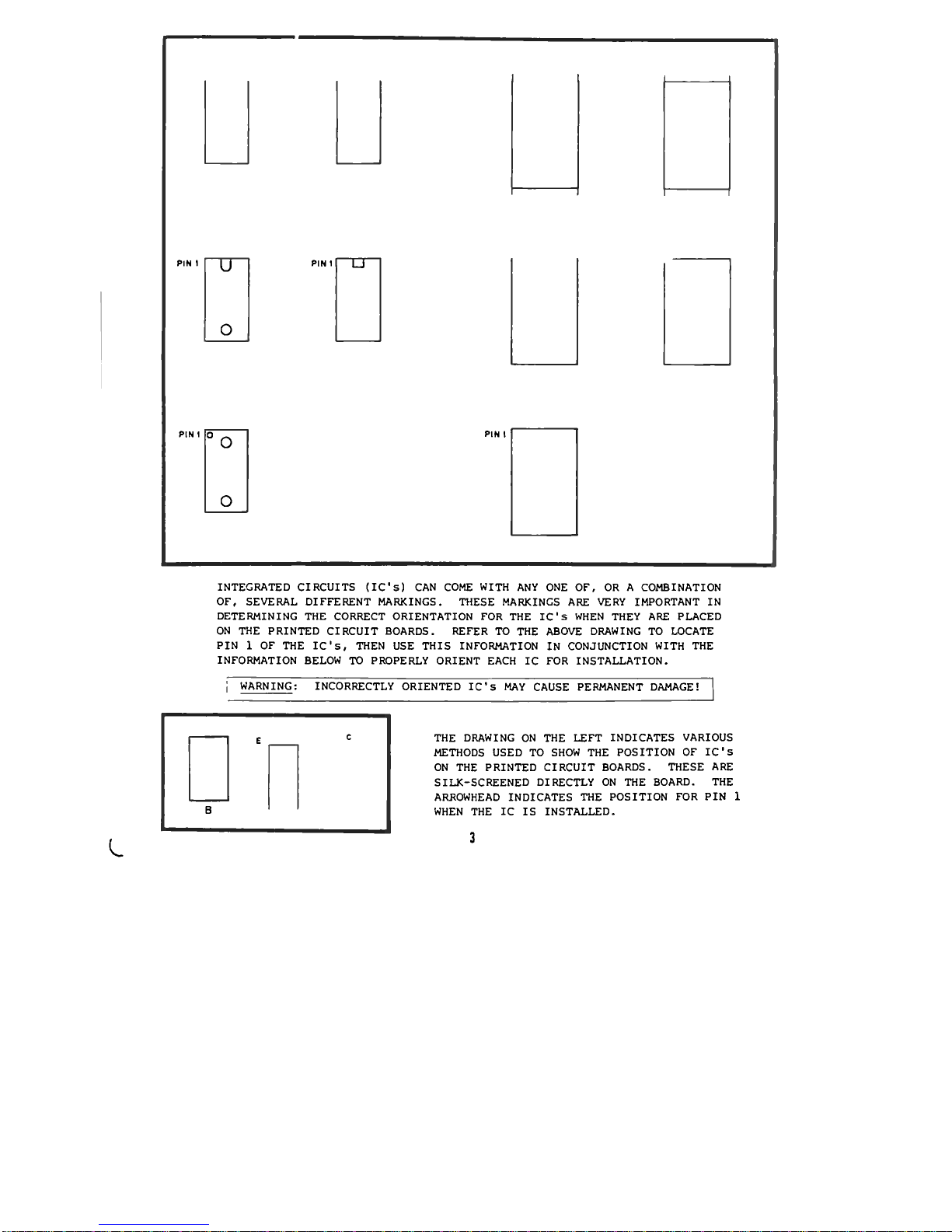

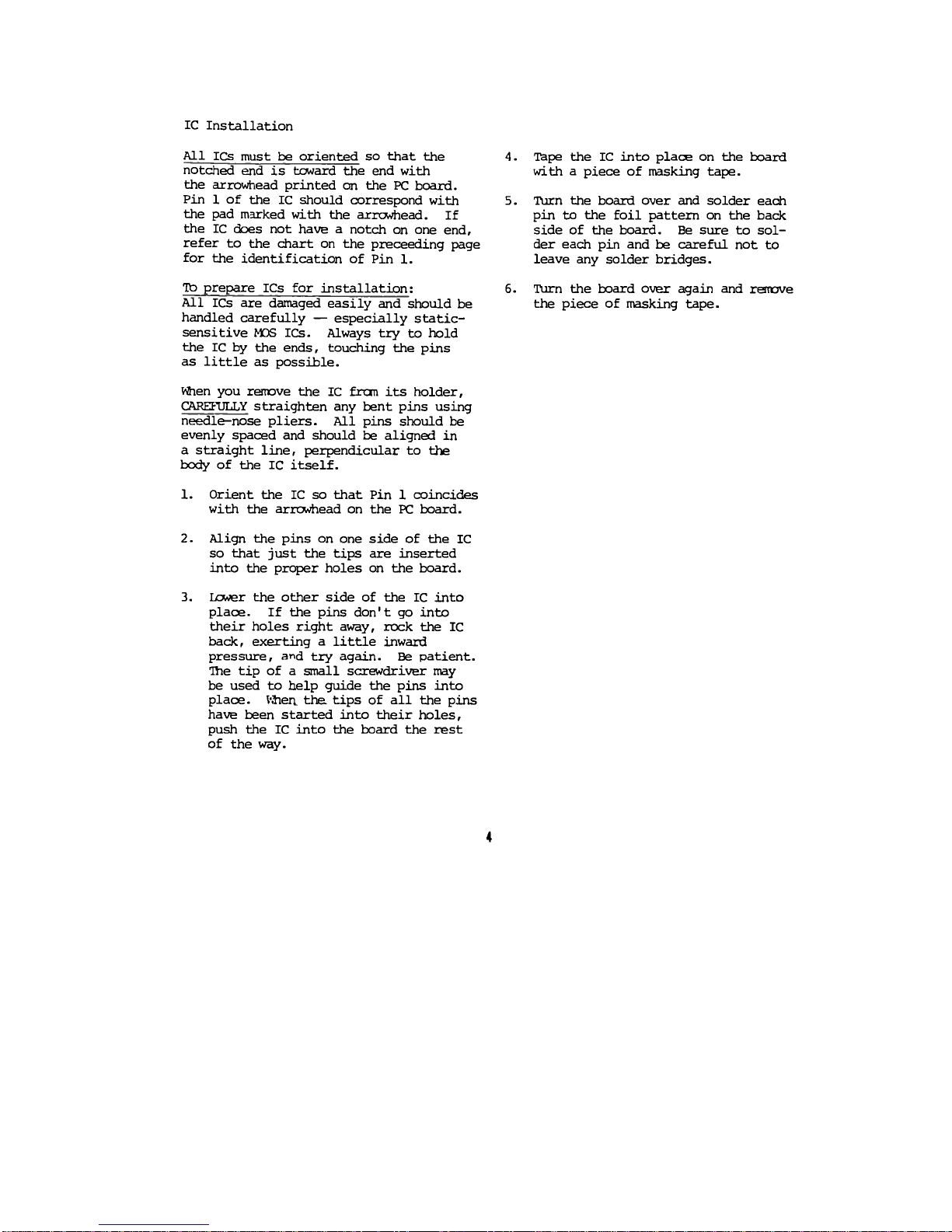

INTEGRATED CIRCUITS (IC's) CAN COME WITH ANY ONE OF, OR A COMBINATION

OF, SEVERAL DIFFERENT MARKINGS. THESE MARKINGS ARE VERY IMPORTANT IN

DETERMINING THE CORRECT ORIENTATION FOR THE IC's WHEN THEY ARE PLACED

ON THE PRINTED CIRCUIT BOARDS. REFER TO THE ABOVE DRAWING TO LOCATE

PIN 1 OF THE IC's, THEN USE THIS INFORMATION IN CONJUNCTION WITH THE

INFORMATION BELOW TO PROPERLY ORIENT EACH IC FOR INSTALLATION.

j WARNINGl INCORRECTLY ORIENTED IC's MAY CAUSE PERMANENT DAMAGE!

L

E C E

B

THE DRAWING ON THE LEFT INDICATES VARIOUS

METHODS USED TO SHOW THE POSITION OF IC's

ON THE PRINTED CIRCUIT BOARDS. THESE ARE

SILK-SCREENED DIRECTLY ON THE BOARD. THE

ARROWHEAD INDICATES THE POSITION FOR PIN 1

WHEN THE IC IS INSTALLED.

3

Page 21

IC Installation

All ICS must be oriented so that the

notched end is toward the end with

the arrowhead printed on the PC board.

Pin 1 of the IC should correspond with

the pad marked with the arrowhead. If

the IC does not have a notch on one end,

refer to the chart on the proceeding page

for the identification of Pin 1.

lb prepare ICs for installation:

All ICs are damaged easily and should be

handled carefully — especially static-

sensitive MOS ICs. Always try to hold

the IC by the ends, touching the pins

as little as possible.

Mien you remove the IC fran its holder,

CAREFULLY straighten any bent pins using

needle-nose pliers. All pins should be

evenly spaced and should be aligned in

a straight line, perpendicular to the

body of the IC itself.

1. Orient the IC so that Pin 1 coincides

with the arrowhead on the PC board.

4. Tape the IC into place on the board

with a piece of masking tape.

5. Turn the board over and solder each

pin to the foil pattern on the back

side of the board. Be sure to sol-

der each pin and be careful not to

leave any solder bridges.

6. Turn the board over again and remove

the piece of masking tape.

2. Align the pins on one side of the IC

so that just the tips are inserted

into the proper holes on the board.

3. Lcwer the other side of the IC into

place. If the pins don't go into

their holes right away, rock the IC

back, exerting a little inward

pressure, and try again. Be patient.

The tip of a small screwdriver may

be used to help guide the pins into

place.

S-3ien the.

tips of all the pins

have been started into their holes,

push the IC into the board the rest

of the way.

4

Page 22

Resistor installation

Resistors have four (or possibly five) color-coded bands

as represented in the chart below. The fourth band is gold or

silver and indicates the tolerance. NOTE: In assembling a

MITS kit, you need only be concerned with the three bands of

color to the one side of the gold or silver (tolerance) band.

These three bands denote the resistor's value in ohms. The

first two bands correspond to the first two digits of the

resistor's value and the third band represents a multiplier.

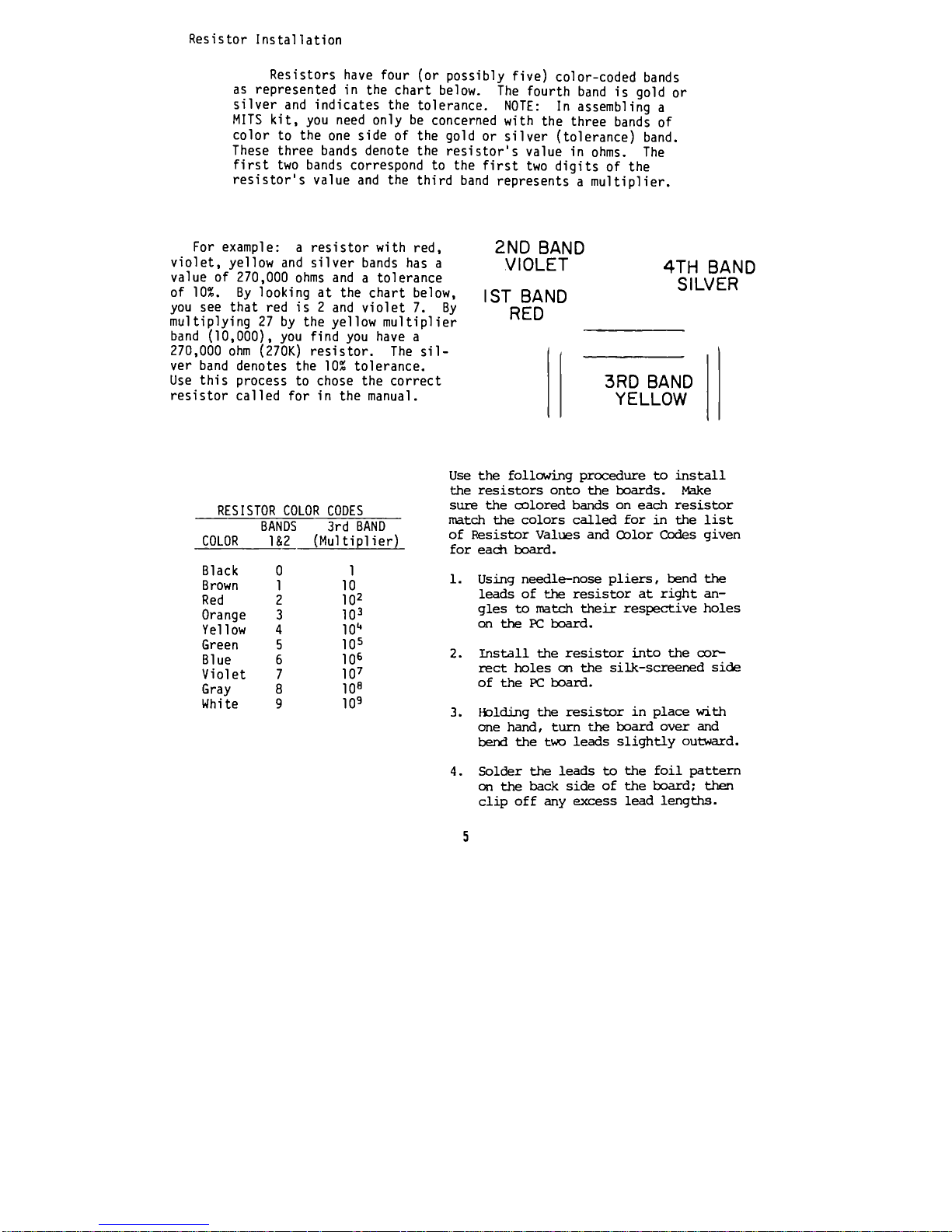

For example: a resistor with red,

violet, yellow and silver bands has a

value of 270,000 ohms and a tolerance

of 10%. By looking at the chart below,

you see that red is 2 and violet 7. By

multiplying 27 by the yellow multiplier

band (10,000), you find you have a

270,000 ohm (270K) resistor. The sil-

ver band denotes the 10% tolerance.

Use this process to chose the correct

resistor called for in the manual.

2ND BAND

VIOLET

1ST BAND

RED

4TH BAND

SiLVER

3RD BAND

YELLOW

RESISTOR COLOR CODES

BANDS

3rd BAND

COLOR

1&2

(Multiplier)

Black

0 1

Brown

1

10

Red

2

10^

Orange

3

10^

Yellow

4 10"

Green 5

105

Blue

6

106

Violet 7 10?

Gray 8

10S

White 9

109

Use the following procedure to install

the resistors onto the boards. Make

sure the colored bands on each resistor

match the colors called for in the list

of Resistor Values and Color Codes given

for each board.

1. Using needle-nose pliers, bend the

leads of the resistor at right an-

gles to match their respective holes

on the PC board.

2. Install the resistor into the cor-

rect holes en the silk-screened side

of the PC board.

3. Holding the resistor in place with

one hand, turn the board over and

bend the two leads slightly outward.

4. Solder the leads to the foil pattern

on the back side of the board; then

clip off any excess lead lengths.

5

Page 23

Capacitor Installation

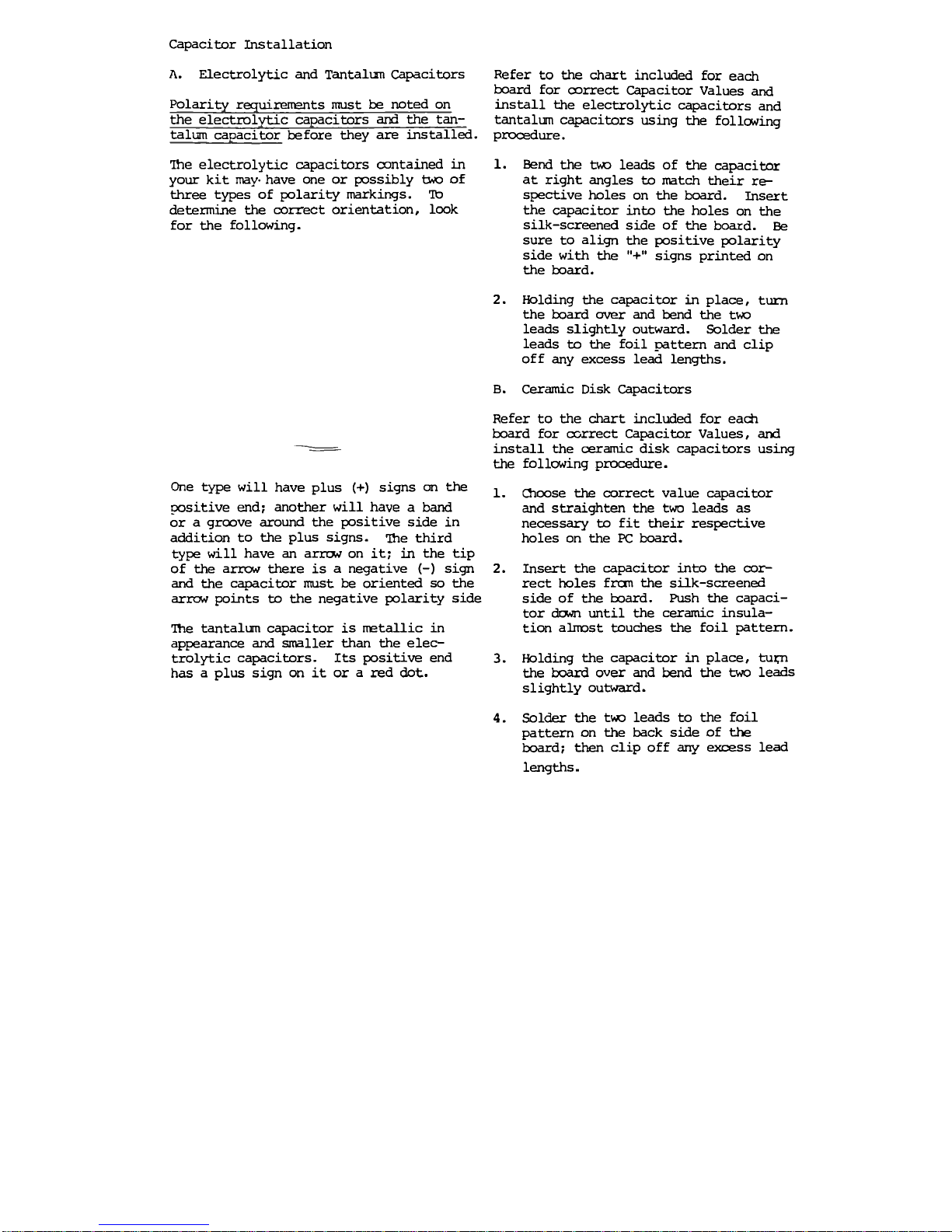

A. Electrolytic and Tantalun Capacitors

Polarity requirements must be noted on

the electrolytic capacitors and the tan-

talum capacitor before they are installed.

The electrolytic capacitors contained in

your kit may- have one or possibly two of

three types of polarity markings, lb

determine the correct orientation, look

for the following.

One type will have plus (+) signs on the

positive end; another will have a band

or a groove around the positive side in

addition to the plus signs. The third

type will have an arrw on it; in the tip

of the arrow there is a negative

(-)

sign

and the capacitor must be oriented so the

arrow points to the negative polarity side

The tantalum capacitor is metallic in

appearance and smaller than the elec-

trolytic capacitors. Its positive end

has a plus sign on it or a red dot.

Refer to the chart included for each

board for correct Capacitor Values and

install the electrolytic capacitors and

tantalum capacitors using the following

procedure.

1. Bend the two leads of the capacitor

at right angles to match their re-

spective holes on the board. Insert

the capacitor into the holes on the

silk-screened side of the board. Be

sure to align the positive polarity

side with the "+" signs printed on

the board.

2. Holding the capacitor in place, tum

the board over and bend the two

leads slightly outward. Solder the

leads to the foil pattern and clip

off any excess lead lengths.

B. Ceramic Disk Capacitors

Refer to the chart included for each

board for correct Capacitor Values, and

install the ceramic disk capacitors using

the following procedure.

1. Choose the correct value capacitor

and straighten the two leads as

necessary to fit their respective

holes on the PC board.

2. Insert the capacitor into the cor-

rect holes fron the silk-screened

side of the board. Push the capaci-

tor dwn until the ceramic insula-

tion almost touches the foil pattern.

3. Holding the capacitor in place, tutrn

the board over and bend the two leads

slightly outward.

4. Solder the two leads to the foil

pattern on the back side of the

board; then clip off any excess lead

lengths.

Page 24

Transistor Installation

Diode Installation

lb install transistors, use the foll-

owing instructions.

NOTE: Always check the part number of

each transistor before you install it.

(See listing of Transistor Part Numbers

for each board.) Sane transistors look

identical but differ in electrical char-

acteristics, according to part number.

If you have received substitute part

numbers for the transistors in you kit,

check the Transistor Identification

Chart which follows these instructions

to be sure you make the correct sub-

stitutions.

NOTE: Always make sure the transistor

is oriented so that the emitter lead is

installed in the hole on the PC board

labeled with an "E." lb determine

which lead is the emitter lead, refer to

the Transistor Identification Chart.

1. After the correct transistor has

been selected and the leads have

been properly oriented, insert the

transistor into the holes on the

silk-screened side of the board.

2. Holding the transistor in place,

tum the board over and bend the

three leads slightly outward.

NOTE: Diodes are marked with a band on

one end indicating the cathode end.

Each diode must be installed so that

the end with the band is oriented towards

the band printed on the PC board. Fail-

ure to orient the diodes oorrectly may

result in permanent damage to your unit.

Use the following prooedure to install

diodes onto the board. Refer to the list

of Diode Part Numbers included for each

board to make sure you install the correct

diode each time.

1. Bend the leads of the diode at right

angles to match their respective

holes on the board.

2. Insert the diode into the correct

holes on the silk screen, making

sure the cathode end is properly

oriented. Tum the board over and

bend the leads slightly outward.

3. Solder the two leads to the foil

pattern on the back side of the

board; then clip off any excess

lead lengths.

3. Solder the leads to the foil pattern

on the back side of the board; then

clip off any excess lead lengths.

7

Page 25

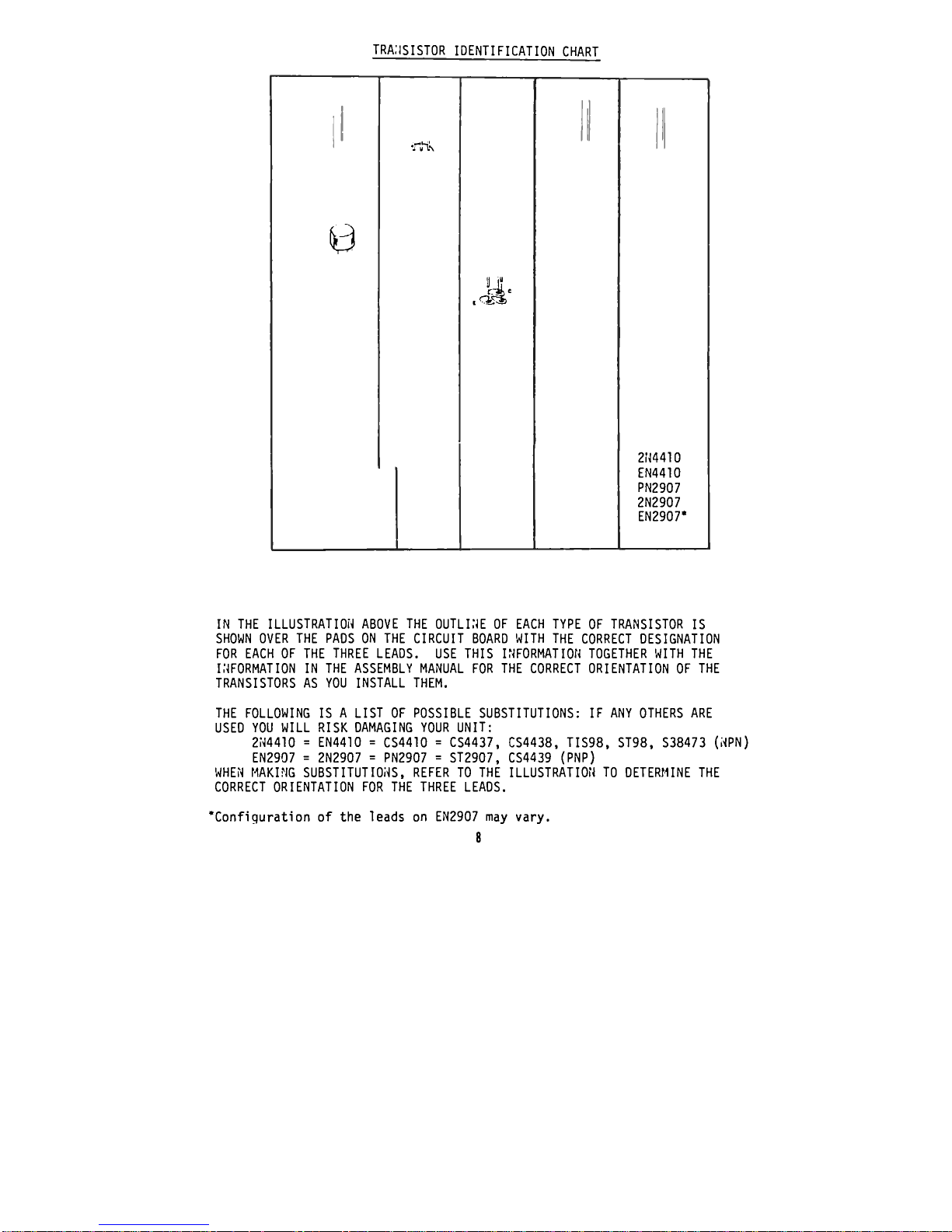

TRA.'iSISTOR IDENTIFICATION CHART

0

-rh-.

.A

2N4410

EN4410

PN2907

2N2907

EN2907*

IN THE ILLUSTRATION ABOVE THE OUTLINE OF EACH TYPE OF TRANSISTOR IS

SHOWN OVER THE PADS ON THE CIRCUIT BOARD WITH THE CORRECT DESIGNATION

FOR EACH OF THE THREE LEADS. USE THIS INFORMATION TOGETHER WITH THE

INFORMATION IN THE ASSEMBLY MANUAL FOR THE CORRECT ORIENTATION OF THE

TRANSISTORS AS YOU INSTALL THEM.

THE FOLLOWING IS A LIST OF POSSIBLE SUBSTITUTIONS: IF ANY OTHERS ARE

USED YOU WILL RISK DAMAGING YOUR UNIT:

2N4410 = EN4410 = CS4410 = CS4437, CS4438, TIS98, ST98, S38473 (NPN)

EN2907 = 2N2907 = PN2907 = ST2907, CS4439 (PNP)

WHEN MAKING SUBSTITUTIONS, REFER TO THE ILLUSTRATION TO DETERMINE THE

CORRECT ORIENTATION FOR THE THREE LEADS.

'Configuration of the leads on EN2907 may vary.

8

Page 26

disk drive assembly procedure

Page 27

t'A.'iK T<)t' M-:W;VAL

Remove the top from the Disk Drive case

by withdrawing the two screws indicated

in the drawing below. Slide the case

top backwards, lifting the back slightly,

to remove it entirely from the chassis.

Also remove the 4 screws in the side of

the case bottom, and remove the entire

chassis assembly.

Page 28

DISK DRIVE BACK PANEL ASSEMBLY

Remove the back panel from the case by

withdrawing each of the four screws in

the comers of the panel. These four

screws are shown inserted in the draw-

ing below.

Save these four screws for remounting

the back panel later in the assembly

procedure.

Page 29

Terminal Block Installation

Mount the terminal block to the back panel

as shown in the drawing below. Use the

screw sizes and other hardware indicated

in the drawing.

NOTE: Be sure that the back panel is

oriented as shown; be careful

not to mount the terminal block

on the wrong side of the panel.

Tighten all four screws firmly into place.

13

Page 30

Transformer Installation

There are two transformers included in

this kit. The larger of the two will be

refered to as Tl, the smaller as T2.

Wire Preparation

Before mounting these transformers, the

wires must-be cut to the proper length

and screw-mount crimp terminals attached

to each of them. There are also three

wires which will not be used at all, and

will be cut off at the transformer coil.

Refering to the drawing on the opposite

page, cut the wires on transformers Tl

and T2 to the lengths indicated. The

three unused wires should be cut off at

the point where they enter the trans-

former coil itself.

Next, as indicated in the bottom of the

drawing, strip exactly 1/2" of insula-

tion from each of the eleven wires and

bend the exposed portion in half to 1/4".

There are several screw-mount crimp ter-

minals included with this kit. These

have a slot in one end and an insulated

portion on the other end (usually red)

for attaching wires. One of these crimp

terminals must be attached to each of

the eleven transformer wires.

Mounting

Refering to the drawings following the

"Transformer Wire Preparation" drawing,

mount transformers Tl & T2 to the back

panel.

NOTE: For proper orientation, transformer

Tl should have the two yellow wires

towards the top of the panel (with

reference to the drawings), and T2

should have the two black wires to-

wards the top of the panel.

Be sure to install a terminal lug

on transformer Tl as shown in the

drawing. This is a solder type

lug, and not the screw-mount type

used for the transformer wires.

Use the hardware indicated in the drawings

to mount the transformers and tighten the

screws firmly into place.

Insert one of the wires into one of the

terminals as shown in the drawing. Push

the wire in as far as it will go without

distorting it or pushing it all the way

through. NOTE: Save all wires that you cut oM

for later use.

The wire should then be permanently con-

nected to the terminal by either soldering

it in place or crimping. To crimp the

terminal use a crimping tool, if avail-

able, or else flatten the insulated por-

tion of the terminal as tightly as possible

using pliers.

Prepare each of the eleven transformer

wires in the above manner.

14

Page 31

cut off

YELLOW/GREEN

TRANSFORMER WIRE PREPARATION

STRIP

r i

BEND

^

TERMINAL

!5

Page 32

16

Page 33

Fuse Holder Installation

Refering to the drawing below, mount the

fuse holder to the back panel using the

rubber washer and nut provided. Tighten

it firmly into place.

Remove the cap and place the fuse provided

with your kit into the holder, then replace

the cap.

BACK PANEL

RUBBER

WASHER

NUT

17

Page 34

90° ANGLE CLIP INSTALLATION

The drawing below illustrates the hard-

ware and orientation for mounting the

90° angle clip included with this kit.

NOTE: One side of the clip is slightly

shorter than the other. The

shorter side should be mounted

against the back panel with the

longer side extending at 90°.

Install the clip as shown below and tighten

the screws firmly into place. Be sure that

clip remains "square" with the panel when

tightening the screws.

Page 35

Fan Installation

before the cooling fan is installed onto

the back panel, two lengths of wire must

be prepared and connected to it.

There is some black wire included with

the kit; cut two 6 1/2 inch lengths of

this wire. Strip 1/2 inch of insulation

from one end of each of the wires, and

1/4 inch of insulation from the other.

In the same manner as described on page

, attach a screw-mount crimp terminal

to the 1/2" stripped end of each of the

two wires. Tin the 1/4" stripped ends

of the wires by applying a thin coat of

solder.

There are two terminals on the fan in one

of the comers. Solder the ends of the

two wires opposite the crimp terminals to

the terminals on the fan.

Refering to the drawing below, mount the

fan and screen to the back panel using

the hardware indicated. For proper

orientation, the terminals with the two

wires attached should be towards the

bottom on the side nearest the terminal

block. The arrow printed on the fan

to indicate airflow should be facing

towards the screen. The screen itself

has a bump on one side in each of the

four comers. The side with the bumps

should be towards the fan.

(4)^6-32 X 2" FLATHEAD

SCREWS

4) CLIP-ON NUTS

PROTECTIVE

SCREEN

(4)*6 FLATWASHERS

(4)*6 LOCKWASHERS

(4)*6 32 NUTS

19

Page 36

Power Cord Installation

There is a 3-wire power cord included with

this kit which must be prepared as follows

before installation.

1) Strip 4" of the cord casing from the

wires by cutting a circle 4" from the

end and pulling off the black insula-

tion. Be careful not to cut into the

insulation on any of the wires inside.

2) The green wire inside should already

be at the correct length of 4 inches.

Cut the white wire to 3 1/2 inches,

and the black wire to 1 1/4 inches.

Strip 1/4 inch of insulation from the

ends of each of the three wires.

Place the strain relief, included with

the kit, over the power cord. Be sure

that the larger diameter end of the

relief is towards the male plug end of

the cord.

Be sure that there is approximately three

inches of the cord's black insulation

case extending beyond the strain relief*,

then snap it into place on the back panel

as shown below.

* The black wire should reach to the

center of the fuse holder when the

cord & strain relief are in place.

3) Tin the exposed 1/4" of the black

wire by applying a thin coat of

solder.

4) Solder or crimp screw-mount crimp

terminals to the white and green

wires.

20

Page 37

Wtru Preparation

Using the wire supplied with this kit,

and the length of yellow/green wire cut

from transformer Tl, prepare the power

supply interconnect wires according to

the following instructions.

Interconnect Wires

To

avoid confusion, it would be best to

COLOR

LENGTH TAG

prepare these wires one at a time.

Yellow/

2 inches 3

The list on the right indicates the color

Green*

of each wire, the length to which it

should be cut, and a reference "tag".

Black

22 3/4

3

Use the following steps to prepare each Black

17 3/4

9

wire:

Black

17 1/2

10

1)

Cut the specified color wire to the

length indicated.

Black 25

1

2)

Strip 1/2 inch of insulation from

White 18 6

one end and 1/4 inch from the other.

White

17 3/4

8

3) Tin the wire exposed 1/4 inch by ap-

plying a thin coat of solder.

Orange

17 3/4

7

4)

According to the instructions on

Orange

18 1/2

4

page , connect a screw-mount

crimp terminal to the 1/2 inch

Orange

18 1/4

5

stripped end.

5)

Approximately 5 inches from the 1/4

*From transformer Tl,

inch tinned end of the wire label it,

This

wire need not be

using masking tape, with the refer-

labeled.

ence tag indicated.

An additional length of BLACK wire should

be cut to 22 1/2 inches and 1/4 inch of

insulation stripped from each end. Tin

both ends by applying a thin coat of solder.

Label this wire "FUSE".

2)

Page 38

Back Panel Wiring

The disk back panel assembly may now be

completed by connecting all of the wires

to their appropriate locations.

[See drawing page 2 3)

Three solder connections are necessary

and should be made first. These in-

clude the black power cord wire, the

yellow/green wire and the black 22 1/2

inch wire labeled "FUSE".

1) Solder the 1/4 inch tinned end of the

yellow/green wire to the solder lug

on transformer Tl.

2) Solder the black power cord wire to

the center terminal on the fuse

holder.

3) Solder one end of the black "FUSE"

wire to the other fuse holder ter-

minal.

The remaining connections will be made to

the terminal block.

The drawing(P.23) shows the proper orienta-

tion and connections for all of the wires

on the back panel. The "tags" on the wires

you prepared earlier refer to the numbers

shown on the terminal block.

WARNING: The power supply is a critical

part of any electronic system.

Check the wiring here several

times to be sure you have it

correct. Be sure that each of

the wires is in the proper loca-

tion and that all of the screws

on the terminal block are tight.

Use the drawing below for reference and

connect all of the wires as indicated.

Match the "tags" on the wires prepared

earlier with the numbered positions on

the terminal block. There should be

a total of 25 crimp terminal connections

made to the block.

NOTE: Where two terminals are to be con-

nected to the same screw, place

them "back to back". In this posi-

tion they will fit flat together,

and make a much more solid connec-

tion.

The ON-OFF switch may also be soldered in

at this time. Use the free end of the

black "FUSE" wire and the free end of the

wire labeled "1" to connect to the switch

terminals. There are three terminals on

the switch. Use the center terminal and

one to either side of it. (The switch

position towards the side where the con-

nections are made will be its OFF position

Install the 4 tie wraps in the posi-

tions shown in the top drawing on

page 23.

22

Page 39

w[RH Mou'rrm; & tm WRAPS

c

r r

(p

11

W n (P

t:

o)

POWER CORD

0

*TIE WRAPS (4)

AC POWER

CORD

Jll

BACK PANEL WIRING

X

T2

O)

s

OFF ON SW.

23

o

o

o

FAX

Page 40

DISK POWER SUPPLY BOARD ASSEMBLY

NOTE: Save all component leads clipped

off during assembly until the

entire unit is complete. Some

of the leads will be used during

the assembly process.

RESISTOR INSTALLATION

Install the following 2 resistors

according to the instructions listed

on page 5 -

RESISTOR VALUES AND COLOR CODES

( ) R1 is 33 ohm (orange-orange-

black) 1/2 W

( ) R2 is 7.5 ohm, 5 W (this may

be color coded, violet-green-

3rd band white or gold: or it

may be a solid body color, with

the value printed directly on

the resistor itself.

24

Page 41

o !

O

) <

O

o

o

o

o

o

+fo* -y.

! o !

O O O O O O

$ $

f+O

o

o

25

Page 42

CAPACITOR INSTALLATION

CAPACITOR VALUES

Install the following 3 ceramic

disk capacitors according to the

instructions on page 6 .

( ) C2 = .luf, 50V

( ) C5 = .luf, 50V

( ) C8 = .luf, 50V

27

Page 43

CAPACITOR INSTALLATION

Install the following 6 electrolytic

capacitors according to the instruc-

tions listed on page 6 .

CAPACITOR VALUES

J CI = 2200uf, 50V

C3 = 33uf, 50V

Y ) C4 = 3300uf, 16V

\ ) C6 = 33uf, 50V

C7 = lOOOuf, 25V

( ) C9 = 33uf, 50V

43

Page 44

r

M!TS

: o :

D!SK POWER SUPPLY !

R2T

]

C5

<000!

O !

o

C8

C! ) + C3) +

t <

D!

OOOOO

29

o

Page 45

DIODE INSTALLATION

Install the following 2 diodes

according to the instructions

on page 7 -

( ) D1 = 1N4004

( ) D2 = 1N4004

+33"'13

O ;

tO.__Qj

D)

$ 9'

o

o !

-Qi

o o o o o o

3)

Page 46

VOLTAGE REGULATOR INSTALLATION

There are 2 voltage regulators to be

installed on the silk-screened side of

the power supply board, XI & X3.

These are to be installed according

to the following procedure. (see

drawing-right)

(1) Set the regulator in place

over the board so that the

mounting hole in the regu-

lator and the board align.

(2) Use a pencil to mark the point

on each of the regulator's

three leads directly over

its corresponding hole in the

board.

(3) Bend the three leads, using

needle-nose pliers, at right

angles from the printed side

of the component.

NOTE: Use heat-sink grease when in-

stalling this component. Apply

it to the surface where the reg-

ulator & board come in contact.

(4) Referring to the drawing, set

the regulator in place on the

silk-screened side of the board.

Secure it to the board using a

#6-32 nut and screw. Hold the

regulator in place as you

tighten the nut to keep from

twisting the leads.

(5) Tum the board over and solder

the three leads to the foil

pattern on the back side of

the board. Be sure not to

leave any solder bridges.

(6) Clip off any excess lead lengths.

the above procedure to install both

of the regulators, XI & X3.

Page 47

VOLTAGE REGULATOR INSTALLATION

( ) XI = 7824

( ) X3 = 7805

MtTS

D)SK POWER

SUPPLY

11.11itiiiimm rnntmn

C4)+

C6)

+

! !

C9l +

O

X3

B

Ct

33

Page 48

BRIDGE RECTIFIER INSTALLATION

There are two bridge rectifiers, BR1

& BR2, to be installed on the power

supply board.

WARNING: Read the following instruc-

tions closely. Proper

orientation of these two

components is absolutely

critical.

These two components are indicated on

the silk-screen by broken lines. This

is to indicate that they are to be

mounted on the bottom (non-silk-

screened) side of the board.

You will observe a "+" sign printed

near one corner of the rectifier.

The lead nearest this "+" sign is

the positive lead of the rectifier.

This lead must be inserted into the -

hole marked on the silk-screen witF

a "+" sign.

NOTE: There is also a "-" sign

printed on the regulator.

The lead nearest this sign is

the negative lead of the recti-

fier, and should be diagonally

opposite the "+" lead on the board.

BE ABSOLUTELY SURE THAT THE PROPER

ORIENTATION IS USED WHEN INSTALLING

THESE TWO COMPONENTS.

Install the rectifiers according to the

following procedure:

(1) Insert the four leads of the

BR1 rectifier into their res-

pective holes from the non-

silk-screened side of the

board. Be sure the "+" lead

of the rectifier is inserted

in the hole labeled "+" on the

silk-screened side of the

board.

(2) Insert the BR2 rectifier in the

same manner. Be sure both recti-

fiers are pushed all the way

against the board.

(3) There is a 90° angle bracket

included with your parts. Each

of the two sides has two holes

in it.

Using the side with the two holes

the furthest apart, set the angle

bracket over the two rectifiers.

The holes in the bracket, the rec-

tifiers, and the board should

align.

Temporarily attach the bracket &

rectifiers to the board through

these holes using #6-32 & 5/8"

screws and nuts.

(4) Check the orientation once more,

then solder all four leads of each

rectifier to the board on the

silk-screened side.

(5) Clip off any excess lead lengths.

Leave the angle bracket in place

for the next procedure.

NOTE: Apply heat-sink compound to

all mating surfaces.

34

Page 49

BRIDGE RECTIFIER INSTALLATION

( ) BR1 = VJ048

( ) BR2 = VJ048

BR2{ O {

'tO___Q!

o

D)

D2

BR)'

"01

o O O O O

O

35

Page 50

DISK BUFFER BOARD

ASSEMBLY

IC INSTALLATION

Install the follow-

ing 7 ICs onto the

Disk Buffer Board

according to the

mathod described on

page 4 .

o

o

o

o

o

o

o

o

IC SILK-SCREEN

DESIGNATIONS AND

PART NUMBERS

( ) A, B, D, & E = 8T97

o

o

o

o

( ) c

= 8198

( ) F

= 74L30

( ) G

= 9601

o

o

o

o

lO

o

o

o

o o

r

<ID-

o

o

o

o

o

o

o

o

o

o

o

o

o

O O

o

O o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o °o

o O

o

(1 f)

QO 00

o

00 O

27

Page 51

RESISTOR INSTALLATION

Install

the

following

39

resistors

according

to the

instructions listed

on

page

5 .

RESISTOR VALUES

AND

COLOR CODES

) R9, R7, R5 are 220 ohm

(red-red-brown)

1/2 W

) RIO, R8, R6 are 330 ohm

(orange-orange-brown)

1/2 W

) R12, R14, R16 are 330 ohm

(orange-orange-brown)

1/2 W

) Rll, R13, R15 are 220 ohn

(red-red-brown)

1/2 W

) R33 is 220 ohn

(red-red-brown)

1/2 W

) R34 is 330 ohm

(orange-orange-brcwn)

1/2 W

) R31, R29, R27, R25 are 220 ohn

(red-red-brown)

1/2 W

) R32, R30, R28, R26 are 330 ohn

(orange-orange-brown)

1/2 W

) R36, R35, R37 are 150 ohm

(brown-green-brown)

1/4 W

)

R40 . is /t33iy

ohn

(orang^*orange-brown)

1/2 W

f

(red-red-brown)

1/2 W

) R38 is IX ohm

(brown-black-red)

1/2 W

) R41 is 39K ohn

(orange-v#tite-orange)

1/2 W

) R20, R22, R24 are 330 ohm

(orange-orange-brown)

1/2 W

) R19, R21, R23 are 220 ohm

(red-red-brown)

1/2 W

) R4 & R18 are 330 ohn

(orange-orange-brcwn)

1/2 W

) R3 & R17 are 220 ohn

(red-red-brown)

1/2 W

38

Page 52

!nsert Page

IALTAIR FLOPPY OISKl

Disk Drive Assembly Procedure

Resistor Value Changes, page 38

R39 should be 330 ohms

R40 should be 220 ohms

HITS, Inc.

August, 1976

38*

Page 53

ol

o

o

o

o

o

o

o

o

o o

r

o

o

o

o

o

o

I

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

0

E

O <=

o o

00*^

o

O

o o

is c

o

00

39

o

00 o

Page 54

DIODE INSTALLATION

Install diode D6 according to the

instructions on page 7 -

( ) D6 = 1N914

o

00 o

54)

Page 55

CAPACITOR INSTALLATION

Capacitor C14 is an electrolytic

capacitor. Capacitors CIO, Cll, C12,

and C13 are ceranic disk capacitors.

Install these ccmponents according

to the instructions listed on page 6 .

CAPACITOR VALUES

( Different voltages may be sub-

stituted in some cases.)

( ) C14 = 500 uf, 25V electrolytic

( ) CIO, Cll, C12 & C13 are .1 uf,

12V ceramic disks.

42

Page 56

o o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

<o

o

o

o

a

o

§r

o

o

o

o

o

o

o

o

o

o

o

o

o

o

o

0

o

o

o

o

o

o

o

o

o

t^t

OD s

o

o

o

e O

c

0

o

o

2. —. "

^Dt

o

o

o

o

o

o

o

o

o

o

o

o

o

o

io

o

o

o

o

o

o

00

43

o

00 O

Page 57

DISK DRIVE RIBBON CABLE ASSEMBLY

Ribbon Cable Preparation

There are three ribbon cable as-

semblies to be prepared for installa-

tion in the disk drive unit. A 12'

length of 18-twisted pairs cable has

been provided for this purpose.

First, cut the 12' length of

cable into two 18-inch lengths and

one 25-inch length. The remainder of

the cable should be saved for later

use.

The following two pages contain

diagrams for the proper lengths and

arrangement for the three cable pieces

you have just cut. The two 18" lengths

will be prepared identically.

The cable sheath itself may be cut

using scissors, and can be stripped by

simply pulling it apart. You will note

that the plastic sheath has "welds" ap-

proximately every inch between the twist-

ed pairs. Try not to make any cuts on

the welds themselves.

Each time a 1/4" of insulation is

stripped from the wires themselves, the

bare ends should be tinned by applying

a thin coat of solder.

Study the diagrams on the next two

pages and prepare the three cable as-

semblies as shown. 3e careful to cut

the wires precisely as indicated, and

do not damage the wire insulation when

cutting the cable sheath.

44

Page 58

18 INCH RIBBON CABLES

18"

14"

CUT TO 2" : STRIP 1/8" & TIN

—j*ir

t t

: i

! i

T

r

rt

2 Pr.

STEP CASING EVENLY

APPROX. EVERY INCH

CUT TO 2"

STRIP 1/4" & TIN

45

Page 59

25 INCH RIBBON CABLE

CUT TO 5" : STRIP 1/2" & TIN

4 PAIR

CUT TO 2" : STRIP 1/4" & TIN

2 PAIR

2 PAIR

2 PAIR

1 PAIR

STEP CASING EVENLY

APPROXIMATELY 1 1/2"

STEPS

CUT TO 2 1/4"

STRIP 1/4" & TIN

7

46

Page 60

There arc several 37-pin connectors in

tins kit. One male conncctor and one

temalc conncctor will be used now to

connect onto one end of each of the two

18 inch lengths of ribbon cable that

you have just prepared. The other end

of the two cables will connect directly

to the Disk Buffer board.

Connector Preparation

The two 37-pin connectors must first be

prepared for attaching to the cables.

It may be helpful to solidly mount the

connectors to some steady object dur-

ing this and the following procedures.

1) Place the connector in front of

you with the hollow solder pins

facing upwards.

You will note that the pins on the 37-pin

connectors are all numbered. Note also

that the numbers on the male connector

are the reverse of the female. The male

connector will be wired to the rows of 1

pads on the buffer board labeled "TO"^—^

The female connector will be wired to

the rows of pads labeT^^"FROM". The

numbers on the connector pins corre-

spond directly with the numbers that

label the pads on the buffer board.

2) Using your soldering iron, very

carefully heat each pin one at a

time and fill the hollow space

with solder. The solder should

not quite fill the pin and should

have a slightly concave surface.

Prepare all 37 pins on one male and one

female connector in this manner. Be

sure not to leave any solder bridges

between the pins, and be careful not

to melt any of the nylon insulation

around them.

WARNING

During the following procedure, and

later steps involving ribbon cable,

be sure that you fully understand

all of the instructions before you

begin. These points are the most

likely areas for assembly errors to

occur.

Cable Assembly

The following procedure should be used

for assembling both of the 18 inch

cables. In order to minimize the pos-

sibility of error, the cables will be

attached to the 37-pin connectors and

the Disk Buffer board during the same

procedure. Read this entire procedure

over carefully before beginning.

The following pages contain drawings of

both the 37-pin connectors, and the Disk

Buffer board silk-screen. There is a

space provided to "check-off" each of

the twisted-pair wires as they are con-

nected. Double arrows are also shown

to indicate the connection points for

each of the twisted-pairs.

Orient one of the 18 inch cables so that

the "stepped" edge of the cable casing

is along the rows of pads on the buffer

board labeled "TO". The longest wires

should be near the pads labeled "19 & 37"

and the shortest wires near the pads

labeled "1 & 20". Place the MALE 37-pin

connector near the other end of the

cable.

Begin with the shortest twisted-pair of

wires, nearest the outside edge of the

cable casing, on the buffer board end.

Separate the two wires slightly, then

solder them into the two pads labeled

"1 & 20" on the buffer board. Do this

by inserting the wires from the silk-

screened side of the board and solder-

ing them on the back. Be careful not

to push any of the wire insulation

into the holes. Clip off any excess

wire from the connections and then

check-off the appropriate space on the

silk-screen drawing.

47

Page 61

The same twisted-pair of wires should

now be connected to the pins numbered

"1 & 20" on the 37-pin connector.

Observe the color of the wire now con-

nected to the pad on the buffer board

labeled "1". Be sure to connect this

same wire to the pin numbered "1" on

the connector. Do the same with pad

"20" and pin "20".

Make the connections by re-melting the

solder in the pins and inserting the

-

wires up to their insulation. Remove

the heat from the pins while still

holding the wires in place until the

solder cools. Check-off the appropri-

ate space on ':he connector drawing.

Move to the next twisted-pair of wires

in the ribbon cable and use the same

procedure to connect pads "2 & 21" with

pins "2 & 21". Continue in this manner,

moving across the ribbon cable one pair

at a time, until all 18 twisted-pairs

are in place. Be sure that you do not

connect any wires to pin "12" on the

connector.

NOTE: Take your time and be careful

while soldering the wires to

the connectors. Do not melt

any of the wire insulation or

leave any solder bridges.

Check your work as you go along

and be sure that 1 is connected

to 1, 2 to 2, 3 to 3, etc., be-

cause corrections will be very

difficult later.

Use this procedure to assemble both of

the 18 inch cables. Be sure that the

MALE 37-pin connector goes to the pads

labeled "TO" and the FEMALE connector

to the pads labeled "FROM". Refer to

the drawing on page to get a rough

idea of how these and the next cable

will appear when connected to the board.

( )

( )

Y

"Y

V

)

v

V

fl

-O 20

—O

-o

-<5

—o

Bsaas<

-o

—o

-O 22

-o

-O 23

-o

-O 24

—o

-O 27

-o

IT

9

-O 2.

—o

10

-O 2.

—o

I)

-O ,0

13

-o

3

6

14

-O ,2

—o

15

-O 33

—O

16

-O 34

-^o

)7

-O 3 =

-^O

IS

-lO

-036

-O"

Page 62

37-PIN MALE CONNECTOR

PIN 12 NOT USED

49

Page 63

o

—o

—o

:

-o

-o

50

Page 64

37-PIN FEMALE CONNECTOR

PIN 12 NOT USEO

51

Page 65

Due to it:; complexity, the inch length

of ribbon cablc will be assembled in a

slightly different manner.

The following two pages contain drawings

of one end of -the ribbon cable and the

44-pm edge connector included with this

kit. These connections, on one end of

the ribbon cable only, will be made first.

NOTE: Be sure to observe that

the orientation of the

edge connector is not the

same in all of the drawings.

Use the pin designations

themselves for any reference

when making connections.

Orient the 25 inch ribbon cable as shown

in the drawing on page 46 . The end that

is shown at the top of this drawing will

be attached to the 44-pin edge connector.

The Connection Chart on the following

page also refers to this drawing for the

proper orientation. Twisted-pair #1 is

the pair furthest to the right in the

drawing, and pair #18 is furthest to the

left. It is very important to begin

numbering from the correct side when

making the connections.

For twisted-pair #12, and pair #13, you

will connect both wires of the pair to

a single pin instead of each to a sepa-

rate one.

For twisted-pairs #15 & #16, all four of

the wires should first be twisted together

and then all four attached to both of the

pins A & B. Do the same for pairs #17 &

#18 to connect them to pins D & E. Be

sure that there is a solid electrical con-

nection between both of the pins in each

case. (see drawing below)

A*=pairs #15 & #16

B*=pairs #17 & #18

/ /-HZ

The Connection Chart on the following

page indicates where on the edge con-

nector each twisted-pair should be at-

tached. The pin designations in the

chart and in the drawings refer to those

stamped into the plastic of the connec-

tor itself. Be sure that you connect

the proper wires to the correct pins

according to the designations stamped on

the connector.

In most cases a single wire will connect

to a single pin on the connector. Make

these connections by first making a good

mechanical connection, and then soldering

the wire into place. Be careful not to

leave any solder bridges, or to melt any

insulation.

Be sure to check-off the appropriate

space on the chart as you make each of

the connections.

Use a small piece of ribbon cable wire

to connect pin 18 to pin V on the edge

connector.

Insert the plastic key, packaged with the

edge connector, into the slot between pins

5 & 6 as shown in the drawing on the bot-

tom of page

53

Page 66

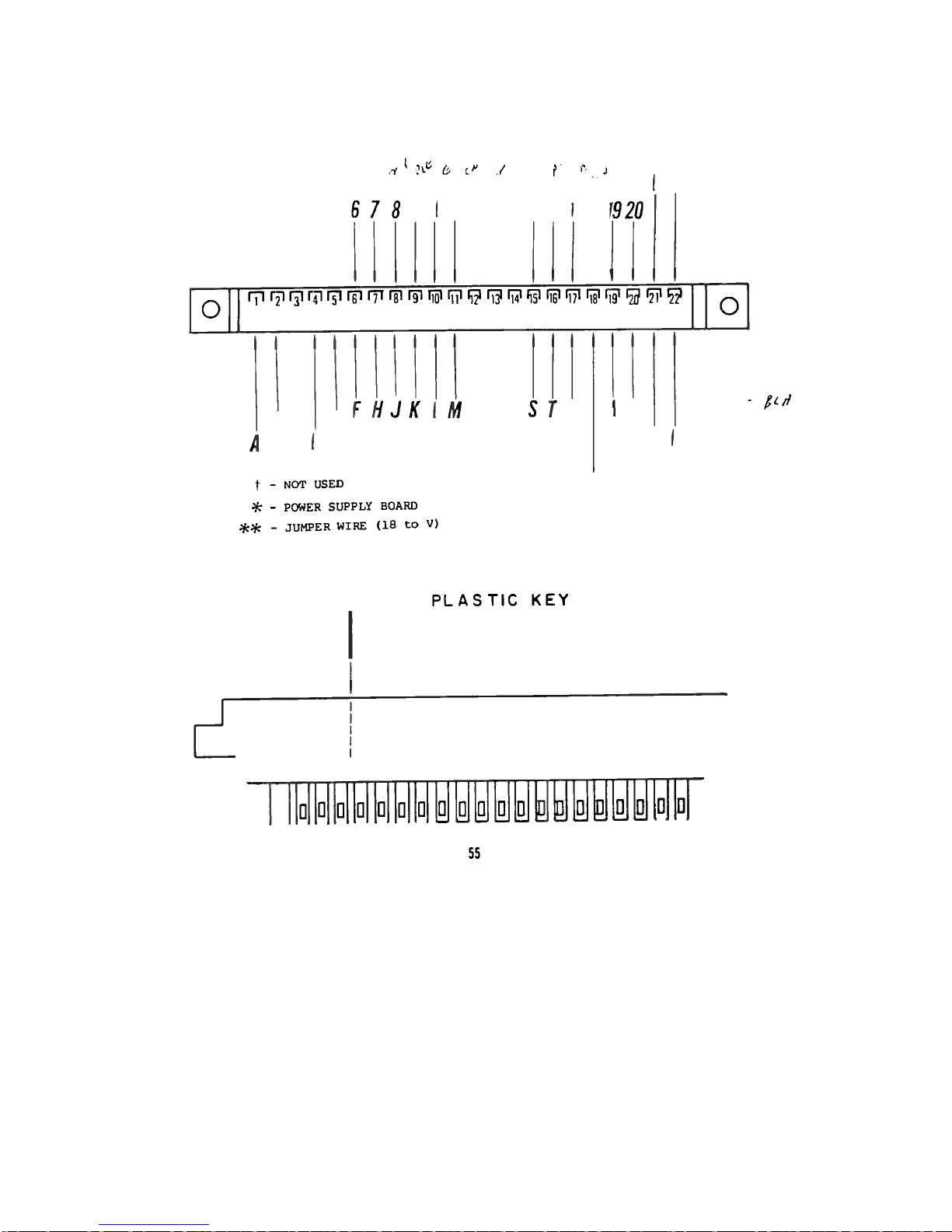

CONNECTION CHART

PAIR # CONNECTOR PIN(S)

PAIR # CONNECTOR PIN(S)

6 S F

7 & H

8 & J

9 & K

10 S L

11 & M

15 S S

16 & T

17 S U

10

11

12

13

14

15

16

17

18

19 & W (

20 & X (

21 (

Y (

22 & Z (

A & B (

D S E ( )

Jumper 18 to V

PIN 22

PIN 1

4 TWISTED PAIRS

(A* & B*)

54

Page 67

/f * ^ & /

6 7 g

^

r< ,

J

920

O

rprprprrtrprprytr^r^t^^if^r^r^f^fip^^f^fg^^

/

F //j/r

M

s r

t - NOT USED

^r - POWER SUPPLY BOARD

^ - JUMPER WIRE (18 to V)

o

- ^C//

PLASTtC KEY

a a a

a a a a^MMMMMto]

0

55

Page 68

The other end of the ribbon cable will

connect to both the Disk Buffer board

and the Power Supply board.

When making these connections, the same

numbering system will be used for the

twisted-pairs as previously. That is,

the pair furthest to the right in the

drawing on page will be refered to

as pair 81.

Page contains silk-screen drawings of

both PC boards, with arrows to indicate

the twisted-pair connections and a space

to check-off each as it is completed.

The first eleven twisted-pairs will con-

nect to the remaining row of pads on the

Disk Buffer board. Make these connec-

tions in the same manner as the previous

ribbon cable connections to this board.

Begin with pair #1 and connect one of its

wires to pad 6 and the other to pad 7 on

the board. Observe the color of the wires

connected to the equivalent pins on the

edge connector. 3e sure you connect pin

6 to pad 6, F to F, etc., as when making

the previous connections. Continue the

connections through the first eleven of

the twisted-pairs in this manner, check-

ing-off the appropriate space as each is

completed.

The next seven twisted-pairs will connect

to the Power Supply board in nearly the

same manner, except that all but two of

the connections involve more than one of

the wires.

The two wires of pair #12 should be twist-

ed together and both connected to pad D.

Pair #13 should connect to pad F in the

same manner.

Twisted-pairs #15 & #16 should have all

four wires (2 each) twisted together and

connected to pad A. Pairs #17 & #18

should be connected to pad B in the same

manner.

Only twisted-pair #14 should be separated

and connected to pads J & H in the same

manner as the first eleven pair.

Make all of the Power Supply board con-

nections as described, checking-off the

appropriate space as you complete each

of them.

Starting approximately 1 inch from the

cable casing, and moving along the Power

Supply cable wires, attach a tie-wrap

approximately every inch until 5 of them

are used. Do these as necessary to make

a neat, tight cable.

There are two other wires which should

be installed at this time. Using the

same wire that you used when making the

connections to the terminal block, cut

one 8 inch length of orange wire and one

8 inch length of black wire. Strip 1/4

inch of insulation from both ends on each

of them and tin the exposed portion.

Connect the orange wire between pad C on

the Power Supply board and pad C on the

buffer board. +5V

Insert the wire from the silk-screened

side of the board and solder it on the

bottom.

Connect the black wire between E and E

in the same manner. GND

56

Page 69

Page 70

SHOULDER WASHER

-40NUT

HEATSINK

COMPOUND

INSULATOR

OXI/2 FLAT HEAD SCREW

VOLTAGE REGULATOR

INSTALLATION

The next two components will be mounted

on the bottom side of the Power Supply

board. These components will also be

mounted to the 90° angle bracket, as with

BR1 & BR2, in the two remaining holes.

Mian installing these components refer

to the drawing above arid orient than

so that the markings on the components

face away from the bracket.

Insert the two regulators from the

bottom side of the board as shewn.

*Use heatsink conpound between all

mating surfaces. Be sure to place

the mica insulating washer between

Q1 and the bracket, and the shoulder

washer between Q1 and the mounting

nut.

Tighten the mounting screws firmly,

being sure not to twist the component

leads as you do so.

Solder all three leads of both ccm-

ponents to the board en the silk-

screened side.

Clip off the excess lead lengths;

then remove the two screws used

earlier to mount BR1 & BR2. The

screws mounting X2 & Q1 should

remain.

\

58

Page 71

VOLTAGE REGULATOR INSTALLATION

( ) X2 = 7805

( ) 01 - TIP 145 (w/Mica insulatinq washer and shoulder

washer)

§

B C E

59

Page 72

DISK CHASSIS ASSEMBLY

The next step in the assembly procedure is to prepare the

chassis itself for mounting the boards and drive unit.

1) Refering to the drawing on the following page,

mount the cross beam as shewn using the exist-

ing screws now holding it in place. Note the

number of holes for proper placement.

2) lb make the following prooedures as simple as

possible, remove the front panels at this time.

Save the screws used to mount the panel to the

chassis.

3) Refering to the same drawing again, mount the

rail as shown in the 2nd hole frcm the front.

Be sure to include the 2 spacers as shewn on

each side.

There are 6 additional screws to be added to the chassis

members, 4 on the beam and 2 on the rail.

4) Install two #6-32 x 3/4" screws onto the rail

in the positions indicated on the sane draw-

ing. Insert them frcm the bottcm and tighten

tfem firmly using #6-32 lockwashers and nuts.

5) Install 4-40 x 1" screws and two 6-32 x 1"

screws on the cross beam as shewn using the

indicated hardware.

60

Page 73

c

c

61

Page 74

BACK PANEL M3UNTIM1

Mount the back panel to the rear of the chassis as shown

below using the same scres^s previously used to mount it.

Be careful not to catch any '.vires between the chassis and

the panel.

BACK PANEL-

(4)EXISTtNG

SCREWS

— CHASStS

63

Page 75

PCMER SUPPLY BOARD MOUNTING

Refering to the drawing on the following page, mount

the PcMer Supply board to the 90° angle clip and bracket

as shown. Study the drawing carefully before beginning.

N3TE: The #4-40 screw shewn are those installed earlier.

Be careful not to disturb the wire connects previously

made between this board and the buffer board and cables.

64

Page 76

Page 77

DISK BUFFER BOARD f-CUNTING

Hefaring to the drawing on the following page, mount the

Disk Buffer board as shown.

Again, study the drawing carefully before beginning. The

screws shewn have already been installed.

The oonnectors on the three cables should faoe towards the

back panel.

66

Page 78

67

Page 79

POWER SUPPLY WIRING

Befering bo the silk-screen drawing be-

low, and the wiring diagram on the fol-

lowing page, connect the wires frtm the

terminal block to the pads cn the Power

Supply board.

Use the following procedure:

1) All of the wires should be

connected to the pads on the

board marked with the same

designation as the tags placed

on them earlier.

2) Insert all of the wires frcnt

the silk-screened side of the

board, alrrost to the insulation.

Add solder from the same side

of the board except wire "3-G",

and then continue applying heat

while pushing the wires down as

far as possible until the insu-

lation just touches the solder.

Be careful not to melt any insu-

lation.

3) Turn the board over to solder

wire "3-G" and then clip off

1 excess lead lengths.

Check this wiring over again carefully,

and then remove the tags fran the wires.

C5

BCE

B C E

+

BR2

HMX2

D!

Page 80

ALTAIR FLOPPY DISK DRIVE

POWER SUPPLY WIRING DIAGRAM

u

Page 81

CONNECTOR MOUNTING

Refering bo the drawing below, mount the two 37-pin connectors

to the back panel as shown.

Be sure to mount the male connector into the slot labeled "TO"

and tha female ccnnector into the slot labeled "FROM".

CH both connectors pin 1 should be towards the top.

CONNECTOR

(TO CONTROLLER)

.214L0CKWASHER

70

Page 82

FRONT PANEL MOUNTING

The front sub panel and dress panel can new be re-installed.

Use the same four screws previously used to mount the sub

panel to re-neunt it to the chassis as shewn in the drawing

belcw.

Note when setting the dress panel in place that it is a

"floating" panel. Installing the pewer switch, as shewn,

at this time will temporarily hold it in place.

Be sure the lettering on the dress panel is facing outwards.

71

Page 83

INSTALLATION

[1) SET THE LED IN PLACE

AND MARK THE LEADS

there are three RL-21 Light-Bnitting-

Diodes (LED's) to be installed cn the

Disk Buffer Board. These LED's have

a cathode and anode lead on each of

them which must be properly oriented

for installation on the board. The

diagram below shows you how to deter-

mine the cathode and anode leads of an

RL-21. Hold the LED up to a light and

you will be able to see inside. The

larger of the tw elsrents inside the

plastic casing is the cathode.

Hie silk-screen on the board itself

has the cathode leads for the three

LED's marked with a "K" The anode

lead is marked with an "A". When you

install these components, make sure that

the cathode leads are in the pads marked

"K" and the anode leads in the pads

marked "A". Improper orientation when

installing LED's may cause permanent

damage to the component.

As is shown in the drawing on this page,

these three components also require

special spacing and bending of the leads

in order to fit the unit properly.

1) Set the LED's in place one

at a tirro and bend as neoes-

sary to fit as shown in draw-

ing [3].

2) Cut the leads as shown in [2]

and place the LED's on the

board properly.

3) Solder them in plaoe from the

bop side of the board. LED's

are very heat sensitive, so

use a minimnn of heat for the

shortest amount of time possible

to make the connection.

Mien properly installed, the LED's should

fit as shown in the drawing below.

BEND

LINE

CUT

[2] CUT THE EXCESS LEAD

TO LEAVE 1/8 INCH

[3] SOLDER TO FIT IN PLACE

AS SHOWN

72

Page 84

WARNING: RL-21 LED's are very sen-

sitive to heat. Use a

minimum application of

heat with your iron when

making these solder con-

nections.

LED Installation

c

( ) D3 = RL-21 LED

( ) D4 = RL-21 LED

( ) D5 = RL-21 LED

O

O

O

o

o

""MM

D!

K

00.

o

o

o

o

o

o

o

o

0

! °

0

o

o o o

o

o

jp O

.oor

o

o

o

t

OS

K

oo,(

73

Page 85

DISK DRIVE UNIT INSTALLATION

The Disk Drive unit itself can now be installed into the chassis.

1) The first step in this process is to set the chassis on

end, with the front panel facing upwards.

2) Remove the screws and rubber feet that were factory in-

stalled on the bottom of the drive unit.

3) Being careful not to catch any of the wires or cables,

slowly lower the drive unit into the chassis. Refer to

the drawing on the following page for the proper orienta-

tion.

4) Refering again to the drawing on the following page, in-

sert the two mounting screws and lockwashers on the front