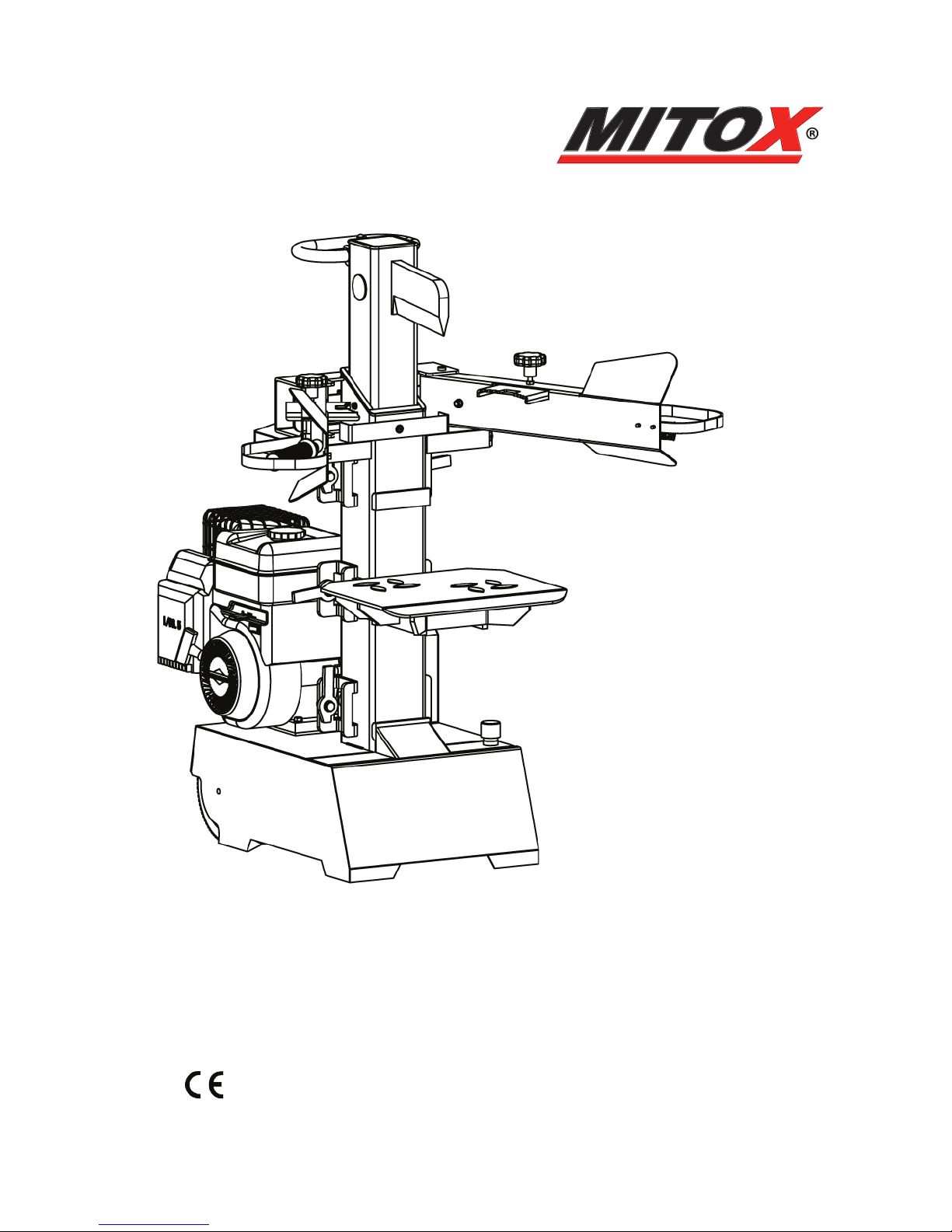

Page 1

Operator’s Manual

user manual, maintenance instructions and spare parts

LS700BS 7 Ton Petrol Logsplitter

www.mitoxgm.co.uk

Read this manual carefully before operating the machine

Original Instructions Version April 13

Page 2

LS700BS 7 Ton Petrol Logsplitter

2

Original Instructions Version April 13

SAFETY WARNINGS & EXPLANATION OF SYMBOLS ON THE MACHINE

UNDERSTAND YOUR LOG SPLITTER

Read and understand the owner’s manual and labels axed to the log splitter. Learn its

application and limitations as well as the specic potential hazards peculiar to it.

DRUGS, ALCOHOL AND MEDICATION

Do not operate the log splitter while under the inuence of drugs, alcohol, or any medication

that could aect your ability to use it properly.

AVOID DANGEROUS CONDITIONS

Always operate your log splitter on dry, solid, level ground. Never operate your log splitter on

slippery, wet, muddy, or icy surfaces. Keep your work area clean and well lit. Cluttered areas

invite injuries. Do not use the log splitter in wet or damp areas or expose it to rain. Do not

use it in areas where fumes from paint, solvents or ammable liquids pose a potential hazard.

INSPECT YOUR LOG SPLITTER

Check your log splitter before turning it on. Keep guards in place and in working order.

Replace damaged, missing or failed parts before using it. Make sure all nuts, bolts, screws,

hydraulic ttings, hose clamps, etc. are securely tightened. Always check the oil level in the

hydraulic oil tank. Never operate your log splitter when it is in need of repair or is in poor

mechanical condition.

WORK WEAR

Do not wear loose clothing, neckties or jewellery (rings, wrist watches). They can be caught in

moving parts. Protective gloves and safety footwear are recommended when working. Wear

protective hair covering to contain long hair, preventing it from getting caught in machinery.

PROTECT YOUR EYES AND FACE

Any log splitter may throw foreign objects into the eyes. This can cause permanent eye

damage. Always wear safety goggles. Everyday eyeglasses have only impact resistant lenses.

They are not safety glasses.

PREVENT FIRES

Do not smoke or have open ames when operating or refuelling the log splitter. Never

operate the log splitter near a ame or spark. Oil is ammable and can be ignited.

KEEP BYSTANDERS AWAY

Allow only one person to load and operate the log splitter. Always keep bystanders, including

visitors, children and pets away from the work area, especially when the log splitter is under

operation. Only the operator should stand near the machine and only within the safe

operating area of 5 metres. Never use another person to help you with freeing a jammed

log. No one under the age of 16 should be allowed to operate the log splitter. Any individual

under the age of 18 should always be under the supervision of an an adult.

INSPECT YOUR LOG

Never attempt to split logs containing nails, wire or debris. Always make sure that both ends

of the log you are splitting are cut as square as possible. This will prevent the log from sliding

out of position while under pressure. Branches must be cut o ush with the trunk.

Page 3

LS700BS 7 Ton Petrol Logsplitter

3

Original Instructions Version April 13

DON’T OVERREACH

Keep a proper footing and balance at all times. Never stand on the log splitter. Serious injury

could occur if the tool is tipped or if the cutting tool is unintentionally contacted. Do not store

anything above or near the log splitter where anyone might stand on the tool to reach it.

AVOID INJURY FROM UNEXPECTED ACCIDENT

Do not straddle or reach across the splitting area when operating the log splitter. Never pile

logs to be split in a manner that will cause you to reach across the log splitter. Only use your

hands to operate the control levers. Never use your foot, knee, a rope, or any other extension

device. Always pay full attention to the movement of the wedge ram. Never attempt to load

your log splitter while the ram is in motion. Keep hands out of the way of all moving parts.

Never try to split two logs. One of them may y up and hit you.

PROTECT YOUR HANDS

When the ram of the log splitter is in the return mode, keep your hands o the machine – the

log splitter is designed to automatically stop when the cylinder is fully retracted. Keep your

hands away from splits and cracks which open in the log. They may close suddenly and crush

or injure your hands. Do not remove jammed logs with your hands.

INCORRECT USE

The log splitter will do a better and safer job working at its designed rate. Don’t use the log

splitter for a purpose for which it was not intended. Do not, under any circumstances, alter

your log splitter. This equipment was designed and engineered to be used in accordance with

the operating instructions. Altering the equipment, or using the equipment in such a way as

to circumvent its design capabilities and capacities, could result in serious or fatal injury and

will void the warranty. Never try to split logs larger than those indicated in the specications

table. This could be dangerous and may damage the machine.

NEVER LEAVE THE LOG SPLITTER RUNNING UNATTENDED

Don’t leave the tool until it has come to a complete stop.

FOR YOUR SAFETY

Do not remove or tamper with any of the machines protection or safety devices or modify

the log splitter in any way.

PROTECT THE ENVIRONMENT

Take used oil to an authorized collection point or follow the stipulations in the country where

the log splitter is used. Do not discharge into drains, soil or water.

MAINTAIN YOUR LOG SPLITTER WITH CARE

Always clean the unit after each use. Keep the log splitter clean for best and safest performance.

Follow the instructions for lubricating. Inspect all hydraulic seals, hoses and couplers for leaks

prior to use. Control levers and power switch must be kept clean, dry and free from oil and

grease at all times.

MAKE THE WORKSHOP CHILDPROOF

Lock the shop. Store the log splitter away from children and others not qualied to use it.

Page 4

LS700BS 7 Ton Petrol Logsplitter

4

Original Instructions Version April 13

UNDERSTAND YOUR MACHINE

Read and understand the operator’s manual and labels axed to the machine. Learn its

application and limitations as well as the specic potential hazards peculiar to it.

Be thoroughly familiar with the controls and their proper operation. Know how to stop the

machine and disengage the controls quickly.

Make sure to read and understand all of the instructions and safety precautions as outlined

in the Engine Manual, packed separately with your unit. Do not attempt to operate the

machine until you fully understand how to properly operate and maintain the Engine and

how to avoid accidental injuries and/or property damage.

WORK AREA

Never start or run the engine inside a closed area. The exhaust fumes are dangerous,

containing carbon monoxide, an odorless and deadly gas. Operate this unit only in a well

ventilated outdoor area.

BURN RISK

Take care not to touch the hot muer/exhaust, gear housing and cylinder.

TABLE OF CONTENTS

Safety Warnings & Cautions .….….….….….….….….….….….…………………………………………………………………..........2

Application Conditions ....….….….….…………….….….….….……………………………………………………………….…….....5

Specifications….….….……………………………….….….….….….………………………………………………..........5

Contents of Container …..….….….….….….….….….….….….….…………………………………………………………………. .....6

Set up and Preparation for Operation…….……….….….….….….….….….….…………………………………………………….......6

Delivering Log Splitter to Work Site ..….….….….….….….….….….….….….….….…………………………………......................................7

Log Splitter Operation ...........…….….….….….….….….….….….….….………………………………………………………. ...................8

Replacing Hydraulic Oil ……….….….….….….….….….….….………………......…………………………………………………....9

Sharpening Wedge ............…….….….….….….….….….….….….….………………….............……………………………………….....10

Trouble Shooting ………………….….….….….….….….….….….….……………………………………………….............………....10

Wiring Diagram ………………….….….….….….….….….….….………………………………….……………………………..........10

Hydraulic Plumbing Diagram ………………….….….….….….….….….….….……………………………………………......…….10

Parts Schematic .....…………….….….….….….….….….….….….….….….….……………………………...........................................................11

Declaration of Conformity….….….….….….….….….….….….….….….….……………………………...........................................................14

Page 5

LS700BS 7 Ton Petrol Logsplitter

5

Original Instructions Version April 13

DESCRIPTION OF MACHINE

The log splitter is designed to be used in a domestic application.

The log splitter is designed exclusively for the following applications:

-Splitting freshly cut timber that does not exceed the dimensions specied in the technical data.

The 4-way splitting cross is only to be used on freshly cut wood and not seasoned wood as this type of wood

can splinter and put undue strain on the log splitter.

ENGINE INFORMATION

The Engine Manufacturer is responsible for all engine-related issues with regards to performance, power rating, specications,

warranty and service. Please refer to the Engine Manual, packed separately with your unit, for more information.

APPLICATION CONDITIONS

This log splitter is designed for operating under ambient temperatures between +5ºC and 40ºC. It can be stored or transported under

ambient temperatures between -25ºC and 55ºC.

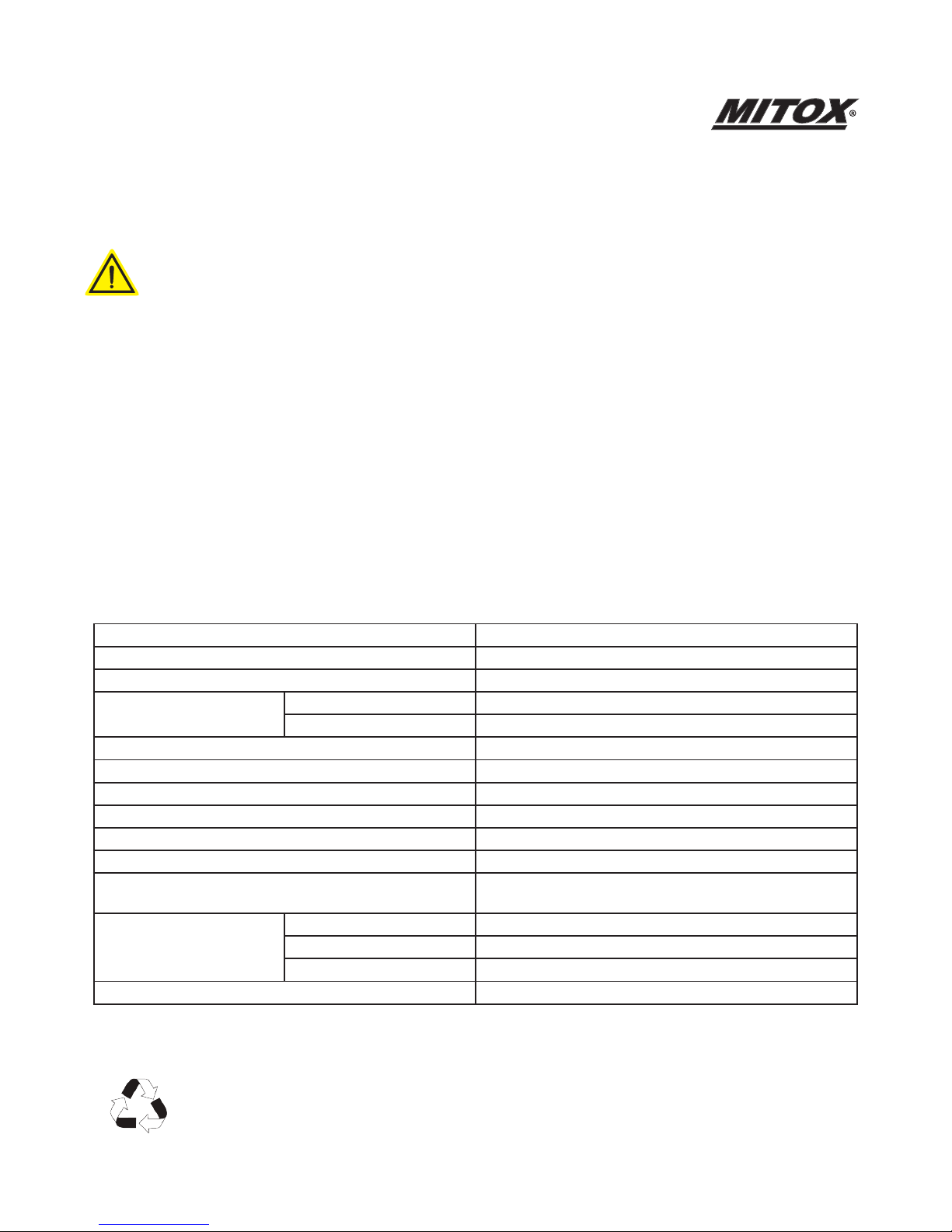

SPECIFICATIONS

Model Number LS700

Motor 196cc, 6.5 HP

Max rpm 3600

Log Capacity Diameter 12cm - 32cm

Length 104cm / 78cm / 52cm

Maximum Force 7 Ton

Hydraulic Pressure 2581 PSI

Hydraulic Oil Capacity 6 L

Ram Travel 475mm

Forward Speed 4.9cm / sec.

Retract Speed 22.3cm / sec

Noise Level 88.1dbA under no load ;

93.0dbA under full load

Overall Sizes Length 107cm

Width 46 cm

Height 103 cm

Weight 125kg

ENVIRONMENTAL INFORMATION

Recycle unwanted materials instead of disposing of them as waste. All tools, hoses and packaging should be

sorted, taken to the local recycling center and disposed of in an environmentally safe way.

Page 6

LS700BS 7 Ton Petrol Logsplitter

6

Original Instructions Version April 13

FUEL SAFETY

Fuel is highly ammable, and its vapours can explode if ignited. Take precautions when using the log splitter to reduce the chance of

serious personal injury.

When relling or draining the fuel tank, use an approved fuel storage container while in a clean, well-ventilated outdoor area. Do not

smoke, or allow sparks, open ames or other sources of ignition near the area while adding fuel or operating the unit. Never ll the

fuel tank indoors.

Keep grounded conductive objects, such as tools, away from exposed, live electrical parts and connections to avoid sparking or

arcing. These events could ignite fumes or vapours.

Always stop the engine and allow it to cool before lling the fuel tank. Never remove the cap of the fuel tank or add fuel while the

engine is running or when the engine is hot. Do not operate a machine with known leaks in the fuel system.

Loosen the fuel tank cap slowly to relieve any pressure in the tank.

Never overll the fuel tank. Fill the tank to no more than 12.5mm (1/2”) below the bottom of the ller neck to provide space for

expansion as the heat of the engine and/or sun causes fuel to expand.

Replace all fuel tank and container caps securely and wipe up spilled fuel. Never operate the unit without the fuel cap securely in

place.

Avoid creating a source of ignition for spilled fuel. If fuel is spilled, do not attempt to start the engine but move the machine away

from the area of spillage and avoid creating any source of ignition until fuel vapours have dissipated.

Store fuel in containers specically designed and approved for this purpose.

Never store fuel or a machine with fuel in the tank inside a building where fumes may reach a spark, open ame, or any other sources

of ignition. Allow the engine to cool before storing in any enclosure. Drain fuel before transport.

Machines stored and not used for over 30 days need the fuel to be stabilised, or drained of fuel to prevent gum forming in the fuel

system, carburettor, petrol pump etc. We recommend the use of Briggs & Stratton fuel stabiliser (992381). Mix fuel stabiliser with fuel

in the fuel tank, or storage containers, and run the engine for a short time to circulate the stabiliser through the carburettor. Engine

and fuel can then be stored for up to 12 months.

SERVICE

Before cleaning, repair, inspecting, or adjusting, shut o the engine and make certain all moving parts have stopped. Always make

sure the engine’s throttle control is in its “STOP” position.

Disconnect the spark plug wire, and keep the wire away from the plug to prevent accidental starting.

Have your machine serviced by qualied repair personnel using only genuine replacement parts. This will ensure the safety of the

machine is maintained.

Page 7

LS700BS 7 Ton Petrol Logsplitter

7

Original Instructions Version April 13

CONTENTS OF THE CONTAINER

A. Log Splitter Frame …………................................1 set

B. Control Lever and Guard Assy................................2sets

C. Removable Support Table....…...............................1 pc

D. Owner’s Manual ……….....…….….....................1 pc

E. Cross Splitter ……….....…….….............................1 pc

SET UP AND PREPARATION FOR OPERATION

1. Pull Spring Pin (A) to remove the Lock Pin (B). Apply a thin coat of grease to both surfaces of the Control Lever Guard as illustrated.

Insert the Control Lever and Guard Assy and make sure the Control Lever End goes into the slot of Connection Bracket (C). Lock

the Control Lever and Guard Assy down with the Lock Pin (B) and Spring Pin (A). Follow the same steps to install the other Control

Lever and Guard Assy on the other side.

2. 3 installation positions are available for the Support Table for dierent splitting lengths. At every installation position, Lock Down

Hooks (D) are available. Insert the Support Table in the selected Brackets (E). Turn the Lock Down Hooks (D) on both sides by 90

degrees to lock the Support Table down.

A

E

Page 8

LS700BS 7 Ton Petrol Logsplitter

8

Original Instructions Version April 13

3. Familiarize yourself with the controls and features of

this log splitter as shown in the illustrations.

1. Transport Handle

2. Ram Travel Adjusting Rod

3. Split Wedge

4. Ram

5. Control Levers Connection Bracket

6. Top Motor Shield

7. Fuel Tank

8. Wheels

9. Base

10. Oil Tank Cover / Air Bleeder

11. Table Lock Down Hook

12. Support Table

13. Side Bracket for Support Table

14. Front Bracket for Support Table

15. Control Lever

16. Control Lever Guard

17. Adjustable Log Holder

18. Log Holder Adjusting Knob

Bleed the air out of the hydraulic system before starting the log splitter.

The bleed screw should be loosened by two rotations until air can go

in and out of the oil tank smoothly. Air ow through the oil tank ller

should be detectable during the operations. Before moving the log

splitter, make sure the bleed screw is tightened to avoid

oil leaking from this point.

THE FAILURE TO LOOSEN THE BLEED SCREW WILL

RESULT IN DAMAGE TO THE SEALS OF THE

HYDRAULIC SYSTEM AND CAUSE PERMANT

DAMAGE TO THE LOG SPLITTER.

DELIVERING THE LOG SPLITTER TO THE WORK SITE

The log splitter is equipped with 2 wheels for minor moving. To

move the log splitter to the work site. Grip the handle (A) to tilt

the log splitter slightly after making sure the bleed screw is

tightened.

If using a crane, lay hoist sling around the housing. Never try to

lift the log splitter at the Handle (A).

Page 9

LS700BS 7 Ton Petrol Logsplitter

9

Original Instructions Version April 13

LOG SPLITTER OPERATION

1. Plan your work site. Work safely and save eort by planning your work before

hand. Have your logs positioned where they can be easily reached. Have a site

located to stack the split wood or load it onto a nearby truck or other carrier.

2. Prepare the logs for splitting. This splitter accommodates logs up to 104cm

in length. When cutting up limbs and large sections, do not cut sections any

longer than 100cm. The 3 support table positions are for splitting logs up to

52cm, 78cm 104cm in length. Insert the support table in the position nearest to

the log length, and secure the support table with the locking hook.

Do not attempt to split seasoned logs. Green logs split much

more easily, and will not put undue pressure on the splitter.

Seasoned logs can also split violently, which can be dangerous

to the operator.

3. Applying a thin coat of grease to the surfaces of the ram before operation will

lengthen the durability of the ram.

4. Start the engine, following the procedure listed in the Briggs & Stratton engine

manual. The splitting wedge should rise to its highest position automatically.

5. Open the Air Bleed. Loosen the oil tank cover two turns whenever the splitter

is being used. Retighten this cover when you nish.

6. While operating under extremely low temperature, keep the log splitter

running under no load for 15 minutes to preheat the hydraulic oil.

7. Before initial operation, check to be sure the two-handed operation is properly

functioning by following these steps:

(1) Lower both control levers, splitting wedge lowers to approx 5cm

above the highest table position.

(2) Release either of the levers, splitting wedge should remain in the

original position.

(3) Release both levers, the ram should rise to the highest position

automatically.

8. To set the wedge ram stroke, take the following steps:

(1) Move the splitting wedge to desired position. The upper position of

the ram wedge travel should be about 3~5cm over the logs to be split.

(2) Release one control lever and switch o the engine

(3) Release the Setscrew (A) and Raise Adjusting Rod (B) until

Adjusting Rod (B) begins to be stopped by the spring inside. Tighten

the Setscrew (A).

(4) Release both control levers and start the engine

(5) Check upper position of splitting wedge.

Page 10

LS700BS 7 Ton Petrol Logsplitter

10

Original Instructions Version April 13

9. Place log onto splitter. Place the log onto the support table vertically and

sitting at on the support table. Be sure the wedge and support table will

contact the log squarely on the ends. Never attempt to split a log at an angle.

Split log in the direction of its growing grain. Do not

place logs across the log splitter for splitting. It may

be dangerous and may seriously damage the machine.

10. Adjust the Log Holders (A) according to the diameter of the log to obtain

most comfortable Control Levers angle.

11. Hold the log with the clamping brackets. Lower levers to start the

splitting. Releasing either lever stops the motion of the splitting wedge.

Releasing both handles returns the splitting wedge to the upper position.

12. Stack as you work. This will provide a safer work area, by keeping it

uncluttered, and avoid the danger of tripping.

4 WAY SPLITTING CROSS

Mount the 4 way splitting cross over the splitting wedge and secure in

place using the xing screw, ensuring that it is rmly secured.

The 4-way splitting cross is only to be used on freshly

cut wood and not seasoned wood as this type of wood

can splinter and put undue strain on the log splitter.

Accumulated split wood and wood chips can create a

hazardous work environment. Never continue to work in a

cluttered work area which may cause you to slip, trip or fall.

REPLACING HYDRAULIC OIL

The hydraulic system is a closed system with oil tank, oil pump and control

valve. Check oil level regularly with dipstick. Low oil level can damage the

oil pump. Oil Level should measure approx. 1 ~ 2 cm lower than the upper

surface of the oil tank. The oil should be completely changed once a year.

-Make sure moving parts stop and the log splitter is unplugged.

-Make sure that no dirt or debris nds its way into the oil tank

-Collect used oil and responsibly recycle.

-Following an oil change, activate the log splitter a few times without splitting

Hydraulic oil recommended for the log splitter’s hydraulic system:

HLP 22

Use a drain pan to aid in the removal of all used oil and particles.

Remove oil drain plug to drain oil from the hydraulic transmission

system. Examine oil for metal chips as a precaution to future problems.

After oil has been completely drained from the Oil ller, reinstall drain plug.

Fill the hydraulic transmission system with recommended oil through

the ller plug opening, to the correct level.

Page 11

LS700BS 7 Ton Petrol Logsplitter

11

Original Instructions Version April 13

Read dipstick to determine the maximum and minimum oil level.

To check the hydraulic oil, unscrew the oil ller plug and wipe the dip

stick rod with a clean cloth. Next insert the dip stick into oil tank without

screwing it into the tank. The oil should be between the markings Min

and Max. Top up the oil if necessary.

Low oil can damage the oil pump. Overlling can result in

excessive temperature in the hydraulic transmission system.

SHARPENING WEDGE

This log splitter is equipped with a reinforced splitting wedge with a specially treated blade. After long periods of operation, and

when required; sharpen the wedge using a ne-toothed le removing any burrs or at spots on the edge.

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE REMEDY SUGGESTED

Engine does not start Engine oil level is low Fill engine with oil to correct level

Ignition switch is OFF Set ignition to ON

Log Splitter does not work while motor

running

Bleed valve is not opened Open bleed valve

Control Levers or Connection parts bent Replace the damaged parts

Low hydraulic oil level Check and rell hydraulic oil

Log Splitter works with

abnormal vibration and noise

Low hydraulic oil level Check and rell hydraulic oil

If the solutions above fail to resolve the problem or the machine is not safe to use then contact the suppying dealer.

HYDRAULIC

PLUMBING DIAGRAM

Page 12

LS700BS 7 Ton Petrol Logsplitter

12

Original Instructions Version April 13

Page 13

LS700BS 7 Ton Petrol Logsplitter

13

Original Instructions Version April 13

ID PART No DESCRIPTION QTY

1 MICCQ01 UPRIGHT TUBE WELDMENT - B&S 1

2 MICCQ62 PUMP GUARD 1

3 MIGG/T93-1987 SPRING WASHER M6 1

4 MIGB/T822-2000 SCREW M6X12 1

5 MIGB3452.1-92 O-RING 23.6X3.55G 1

6 MICCA.00.101 CAP 1

7 MIGB/T95-1985 WASHER M10 26

8 MICCA.00.109 LOCK-OUT LEVER 6

9 MIGB/T5781-2000 BOLT M10X35 8

10 MICCA.00.107 R/H CLAMPING FORK 1

11 MICCQ03.1.1 R/H GUARD ASSY 1

12 MICCA.00.125 KNOB M8X20 2

13 MICBC.40.113 FORK 2

14 MICCA.00.105 CONTROL LEVER SHAFT 2

15 MICCB.05.002 WORK TABLE 2 1

16 MICCA.00.122 PLASTIC INSERT (4) 1

17 MICCA.00.120 PLASTIC INSERT (2) 1

18 MICCA.00.119 PLASTIC INSERT (1) 1

19 MICCA.00.121 PLASTIC INSERT (3) 1

20 MICCA.00.106 L/H CLAMPING FORK 1

21 MICCQ04.1.1 L/H GUARD ASSY 1

22 MIGB/T822-2000 SCREW M6X10 6

23 MIGB/T95-1985 WASHER M6 6

24 MIGB/T802 LOCKNUT M10 6

25 MICFA.00.018 WHEEL A 2

26 MIGB/T894.1-1986 CIRCLIP 16 2

27 MIGB/T5786-2000 BOLT M16X15 1

28 MIJB982-77 WASHER GROUPWARE 16 1

29 MICCA.00.123 SLIDING PLATE 4

30 MICCA.00.126 KNOB 1

31 MICCA.00.129 WEDGE BRACKET ROUND COVER 2

32 MICCA.00.124 ROUND COVER 1

33 MICCA.00.118 SQUARE COVER 1

34 MILS700BS-34 NUT M20 3

35 MICCQ59 HIGH PRESSURE OIL HOSE 24 1

36 MIGB/T93-1987 SPRING WASHER M8 6

37 MILS700BS-37 LOCKNUT M6 1

38 MIGB/T5785-2000 BOLT M8X25 2

39 MIGB/T894.1-1986 CIRCLIP 22 4

40 MICCA.00.102 LOCK SHAFT 1

41 MICCQ02 CCQ CYLINDER 1

42 MIGB/T5781-2000 HEX BOLT 2

43 MICCA.02.104 LEVER HANDLE 2

44 MILS700BS-44 LOCKNUT M8 2

45 MICCD.00.103 PIN D 1

46 MICCA.02.103 OPERATE HANDLE 2

47 MIGB/T41-2000 THIN NUT 6

48 MIGB/T95-1987 WASHER M8 14

49 MICCA.09.001 CONTROL LINK PLATE 1

50 MIGB/T802 NUT 1

51 MICCA.07.109(0) DRAW ROD LOCK COVER 1

52 MILS700BS-52 SUPPORTING RING 1

53 MICCA.00.108 DRAW ROD 1

54 MICCA.09.103(0) DRAW SLEEVE NUT 1

55 MIGB/T6172.1 THIN NUT M16 1

56 MICCA.08.001 DRAW SLEEVE 1

57 MILS700BS-57 HOSE CLAMP 22-28 4

58 MIGB/T5780-2000 BOLT M6X30 1

59 MICCA.16.001 CA VALVE 1

60 MICCB.07.001 WEDGE BRACKET WELDMENT B 1

61 MICCQ43 T-CONNECTOR - TAPE 1

62 MIJ982-1977 WASHER GROUPWARE 20 12

63 MICCQ57 VALVE TUBE NOZZLE 1

64 MICCQ60 HIGH PRESSURE OIL HOSE 24 1

65 MICCQ34 VALVE INJECTION NOZZLE 1

66 MILS700BS-66 OIL RETURN PIPE 1

67 MICCQ61 HIGH PRESSURE OIL HOSE 1

68 MICCQ29 NOZZLE 9/16-18-UNF-2BXM20X1.5 1

69 MICDB2-F203.4ALP GEAR PUMP 1

70 MICCQ46.4 ORIENTATION RING 1

71 MICCQ46.3 JOINING 1

72 MII/C6.5HP ENGINE (B&S) 1

73 MIGB/T5785-2000 BOLT M8X35 4

74 MICCQ68 RUBBER WASHER (UR) 1

75 MIGB/T5786-2000 BOLT M8X30 4

76 MICL090 12.7-19 REV JOINT - CL090 12.7-20 1

77 MILS700BS-77 GRUB SCREW 2

78 MILS700BS-78 INTAKE HOSE 1

79 MICCQ51 TIE-IN 20 1

80 MICCQ32 NOZZLE 3/4-16-UNF-2BXM20X1.5 1

81 MI700-79 CROSSCUT WEDGE - VERTICAL 1

82 MI700-80 WEDGE RETAINING BOLT 1

Page 14

LS700BS 7 Ton Petrol Logsplitter

14

Original Instructions Version April 13

EC Declaration of Conformity

We herewith declare

that the following machine complies with the appropriate basic safety and health

requirements of the EC Directive based on its design and type, as brought into circulation

by us.

In case of alteration of the machine, not agreed by us, this declaration will lose its validity.

Description : Log Splitter

Type: 65581 (MITOX LS700BS)

Test report No. 17702004

Applicable EC Directives : EC Directive of Machinery (2006/42/EC)

Applicable Harmonized Standards: EN 609-1:1999 +A2

ZEK 01.4-08/11.11

Name of Company: TIYA International Co., Ltd.

Address: B12B, Shenye Center, 9 Shandong Road,

Qingdao, China

Tel: (532) 8582 3333

Fax: (532) 8582 4444

Name / Title: Yuan Yue/ Director

Singautre:

Place / Date: Qingdao, China / Oct. 23, 2012

Page 15

LS700BS 7 Ton Petrol Logsplitter

15

Original Instructions Version April 13

For more information on the Mitox® range of garden products please visit our website:

www.mitoxgm.co.uk

Page 16

LS700BS 7 Ton Petrol Logsplitter

16

Original Instructions Version April 13

CONDITIONS OF WARRANTY

The manufacturer warrants the product against faulty materials and workmanship for a period of 2 years

from the date of rst purchase. The warranty is applicable when the product is used in a “home owner”

application. If products are used for commercial or professional purposes, the warranty period is for 3 months

from the date of rst purchase. Warranty does not extend to failure due to fair wear and tear.

The manufacturer undertakes to replace any spare parts that are classied as defective by an appointed

Mitox service dealer. The manufacturer will not accept liability for the replacement of the machine, either

partially or wholly, and/or consequential damages, and/or interest charges either directly or indirectly.

Warranty does not cover failure due to:

• Insucientmaintenance.

• Incorrectfuelorstalefuel.

• Abnormaluseoraccidentaldamage.

• Incorrectassembly,adjustmentoroperationoftheproduct.

• Sparepartsthataresubjecttoweare.g.safetyparts,blades,bladesupports,bearings,cables,

guards, deectors, spark plugs, air lters etc.

Neither does warranty extend to:

• Freightandpackingcosts.

• Useofnon-genuinesparepartsi.e.thosefromanothermanufacturer.

• Useofthemachineforanyotherpurposethanthatforwhichitwasdesigned.

• Useandmaintenanceofthemachineinamannernotdescribedintheowner’smanual.

As part of our policy of continuous product improvement, we reserve the right to alter or amend this

specication without notice. As a result, the product may dier from the information contained herein, but

any alteration will only be implemented without notice if it is classied as an improvement to the above

specication.

READ THE MANUAL CAREFULLY BEFORE OPERATING THE MACHINE

When ordering spare parts, please quote the part number, this can be found in the parts list included in this

manual.

Retain the receipt of purchase without which no warranty can be oered.

Distributed by Mitox Garden Machinery

Wincanton Business Park

Wincanton

Somerset

BA9 9RS

www.mitoxgm.co.uk

Loading...

Loading...