Page 1

OWNER’S MANUAL

PETROL CHAIN SAW 4518 AND 5020

USER MANUAL, MAINTENANCE INSTRUCTIONS

AND SPARE PARTS

READ THIS MANUAL CAREFULLY BEFORE OPE RATING THE MACHINE

WARNING:

THIS SYMBOL INDICATES IMPORTANT SAFETY PRECAUTIONS

Page 2

Safety Precautions

INTRODUCTION

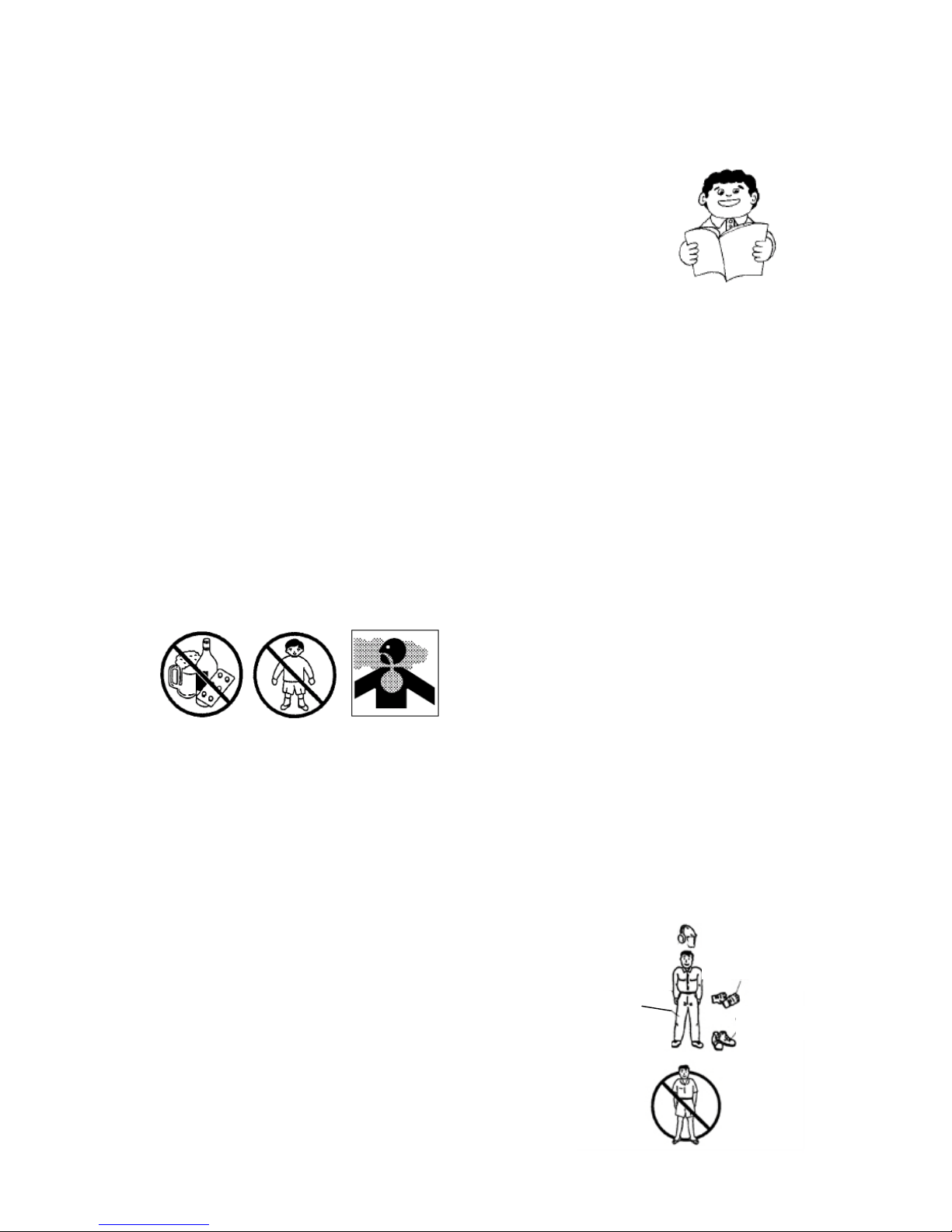

• Read this Owner/Operat or M anual ca r ef ully. B e sure you understand how to operate thi s chainsaw

properly befor e yo u use it. F ailur e to do so could result in serious injury.

• Keep this manual handy so that you may refer to it l ater whenev er any

questions arise. Al so note that you are able to contact the dealer from whom

you purchased the product for assistance.

• Always include this manual when selling, lending, or otherwise transferring

the ownership of this product.

• This product has been designed to be used as a chai n sa w

and it should never be used for any other pur pose, doing so could result in

unforeseen acci dents and injuries occurring.

• This chainsaw is equipped with extremel y sharp saw chain, and when used incorrectly the saw chain

can be dangerous.

• When using this chai nsaw for the first time, take the chain saw to a wide, clear , open space, star t

the engine, and practice handling the chain saw until you are sure that yo u will be able to handle it

properly in actual operation.

• You should never use this chainsaw when under the influence of alcohol, suffering from exhaustion

or lack of sleep, suffering from drowsiness as a result of having taken m edici ne, or at any other time

when your judgment mi ght be impaired or that you might not be able to operate the chain saw

properly and in a safe manner.

• Never allow childr en or anyone unable to fully understand the directions giv en in this manual to use

this chain saw.

• When planning your work schedule, allow plenty of time to perform the work and allow plenty of time

for rest. Limit t he am ount of time yo u co ntinuously use the chain saw to 30~40 minutes per session,

and take 10~20 minutes of r est between work sessions. Also try to keep the total am ount of work

performed in a singl e day to 2 hours.

• Do not climb the tree and operate the chain saw unless you are specially trained to do so.

• Avoid running the engi ne indoor s. The exhaust gases contain harmf ul carbon monoxide.

■ Never use the chain saw in conditions as described below:

• When the ground is slippery or when other co nditions exist which might m ake it difficult to maintain a

steady posture while usi ng the chain saw.

• At night, at times of heavy fog, or at any other times when your field of vision is limited and it would

be difficult t o gain a cl ear view of the area where the chain saw is to be used.

• In heavy rain, during lightning storms, at times of strong or gale-force winds, or at any other times

when weather condi tions might make it unsafe to use this product.

• Lack of sleep, tiredness, or physical exhaustion resul ts in lower attention spans, and this in turn ca n

lead to accident s and injury.

■ WORK CLOTHING AND SAFETY EQUIPMENT

When using the chain saw, we recommend using clot hing

with chainsaw protection:

• Helmet, face protector visor and ear defenders

• Gloves with chainsaw protection.

• Trousers with chainsaw protection.

• Boots with chainsaw protecti on, steel toe caps and non slip

sole.

Boots With

Chainsaw Protection

Chainsaw

Protection

Trousers

Helmet with fac e protector &

ear defenders

Chainsaw

Protection Gloves

Page 3

■ SAFETY AND OPER ATION

• This chain saw is equipped with a very sharp saw chain, and when used incorrectly the saw chain

can be extremely dangerous.

• Improper handling can cause accidents which may in turn lead to serious i njury or death. For this

reason, you should al ways be careful to adhere to the following instructions when using your chain

saw.

• Never hold the chain saw in a way in which the saw chain is poi nted t owards som eone else.

• Never allow the saw chain to come into contact with your body while the engine is in operation.

• Always turn off the engine before adjusting the chainsaw, removing branches which have become

stuck in the saw chain, or at any other time when coming into close proximity with the saw chain.

• Always wear chainsaw safety glov es when adjusti ng the chainsaw.

• Always place the guide bar cover provided over the saw chain when not in use.

• Falling branches may fall onto the operators body or head, resulting in injuries, scratches, and cuts,

and for this reason you should always wear a chainsaw helmet and chainsaw safety clothing when

operating the ch ain saw.

■ SAFE HANDLING OF FUEL

• The engine of the chain saw is designed to run on a two stroke fuel/oil mixture. This fuel is highly

flammable, never store cans of fuel or refill the fuel tank in any pl ace where there is a source of heat

or fire which might ignite the fuel.

• Do not smoke whilst operating the chain saw or refilling, keep lit cigar ettes away

from the chain saw at all times.

• When refilling the fuel tank always stop the engine first and ca r efully make sure

that there are no sparks or open fl am es anywhere near by before refuelling.

• If any fuel spillage occu r s during refuelling, use a dry rag to wipe any fuel which has been spilled

onto the chain saw before starting the engine.

• After refuelling, screw the fuel cap back tightly onto the fuel tank and carry the chain saw to a spot 5

metres or more away f r om where i t was refuelled before starting the engine.

■ BEFORE OP ER ATING THE CHAIN SAW

• Before beginning work, ca r efully check the work area and remove any obstacles and clear a retreat

path from falling trees.

• Within a perimeter of 15 metres of t he work area should be consider ed a haza r dous area into which

no one should enter while the chain saw is being used, and when necessary this area should be

marked with a warning rope, warning signs, or other form s of warning. When work is to be performed

simultaneously by two or more operators, care should also be taken t o constantly look around to

check the presence and l oca tions of other operators within the work area to maintain a safe distance

between each operator.

• Before beginning work, each component of the chain saw should be ch ecked to make sure that it is

in proper working order, make sure that there are no loose screws or bolts, fuel leaks, ruptures, dents,

or any other problems which might interfere with safe operation. Be especially caref ul to check t hat

there is no damage to the saw chain or chain brake.

• Never use the chain saw when the saw chain, gui de bar or sprocket are excessively wo rn, or blunt ,

or when any sort of damage has occurred.

• Keep all parts of your body away from the chai nsaw chain when the engine is running.

■ BEFORE STARTING THE ENGINE

• Carefully check the work area to make sure that no obstacl es exist within a perimeter of 15 metres

around the chain saw before starting the engine.

• To start the engine, place the chainsaw onto the ground in a flat clear area and hold it firmly in place

to ensure that neither the saw chain or the throttle come into contact with any obstacles when the

engine starts.

• After starting the engine, make sure that the saw chain stops m ov ing when the throttle trigger is

released (idl e) . If the saw chain continues to move when the engine is at idl e, adjust t he idle screw on

the carburettor to a point where the saw chain stops movi ng, if this cannot be achieved, take the chain

saw to your authorised servicing dealer for adjustment.

Page 4

■

AVOID NOISE PROBLEMS

• Check and follow the local regulati ons for sound level and hours of operations for garden machinery.

• In general, operate chain saws between 8 am, and 5 pm on week days and 9 am to 5 pm.weekends.

• Avoid using the chain saw late at night and/or early in the morning.

■ SAFETY WHEN USING THE CHAIN SAW

• When using the chain saw, grip the handles firmly with both hands, place your f eet slightly apart so

your weight is distri buted evenly across both legs, and always maintain a steady even posture while

working.

• M aintain full engine speed when cutting.

• Never allow other persons to come within the work area as doing so might expose them to danger.

• Keep work area cl ear of all persons, particularly small children and pets. Injury may result from flying

debris.

• If a branch or other object gets caught in the saw chain during operat ion, always stop

the engine before r em ov ing the object.

• To protect yourself against injury from falling branches, wear t he r equired safety

equipment.

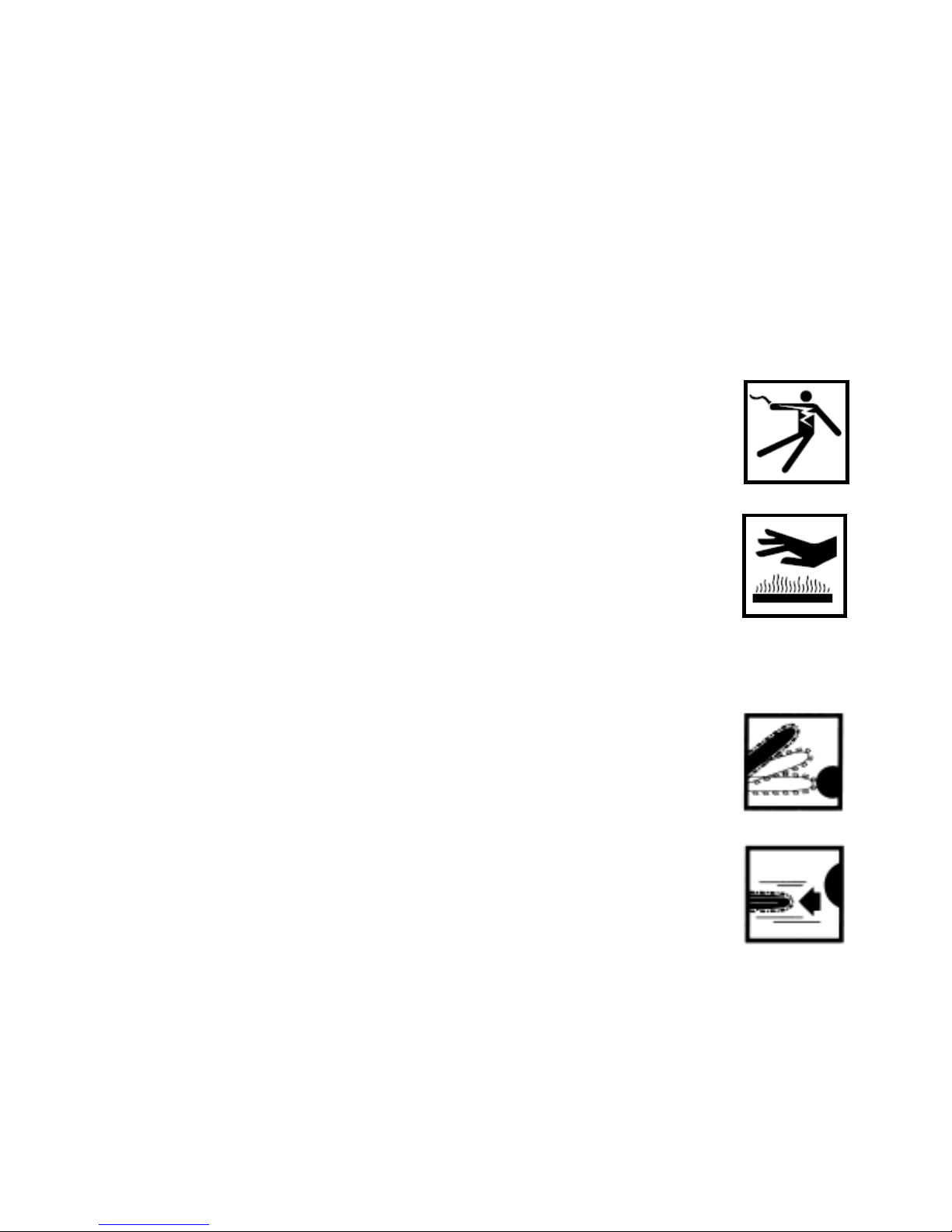

• Never touch the spark pl ug or plug HT cable while the engine is in operation, doing so

may result in an electrical shock.

• Never touch the exhaust, spark plug, or other parts of the engine whil e the engine is in

operation or immediately after shutting down the engine. These parts reach high

temperatures duri ng oper ation and doing so could result in serious burns.

• When you finish cutting in one location and wish to continue work i n another area, stop

the engine, place the protective cover over the guide bar, and t ur n the chain saw so that

the saw chain faces away f r om your body before carrying it to the new location.

• Always remove fuel from the fuel tank before transportati on to prev ent f uel spi llage.

• Never leave the chain saw exposed to direct sunli ght as this can heat the fuel tank and

may cause a discharge of fuel, and flood the engine.

■KICKBACK AND PINCHING SAFETY PRECAUTIONS

■ BEWARE OF KICKBACK

Kickback can occur whenever the tip of the guide bar touches an object when the chain

saw is operating. Kickback may force the guide bar up and back towards the operator at

speed.

■BEWARE OF PINCHING

Pinching the saw chain along the tip of the guide bar may force the guide bar back

rapidly toward the operator. Pinchi ng ca n occur whenever wood closes around the

moving saw chain.

Both kickback and pi nchi ng m ay cause the operator to lose control of the chain saw,

which could result in serious personal injury.

• Understand kickback and pinching.

• Keep a firm grip on the chain saw with both hands whenever the engine is running.

• A firm gri p will help yo u r educe the affects of kickback and pinching as well as maintaining safe

control of the chai n saw.

• Cut at full engine speeds.

• Follow the manufactur er ' s i nstr uctions for sharpening and maint aining the chain.

• Use only genuine spare parts.

Page 5

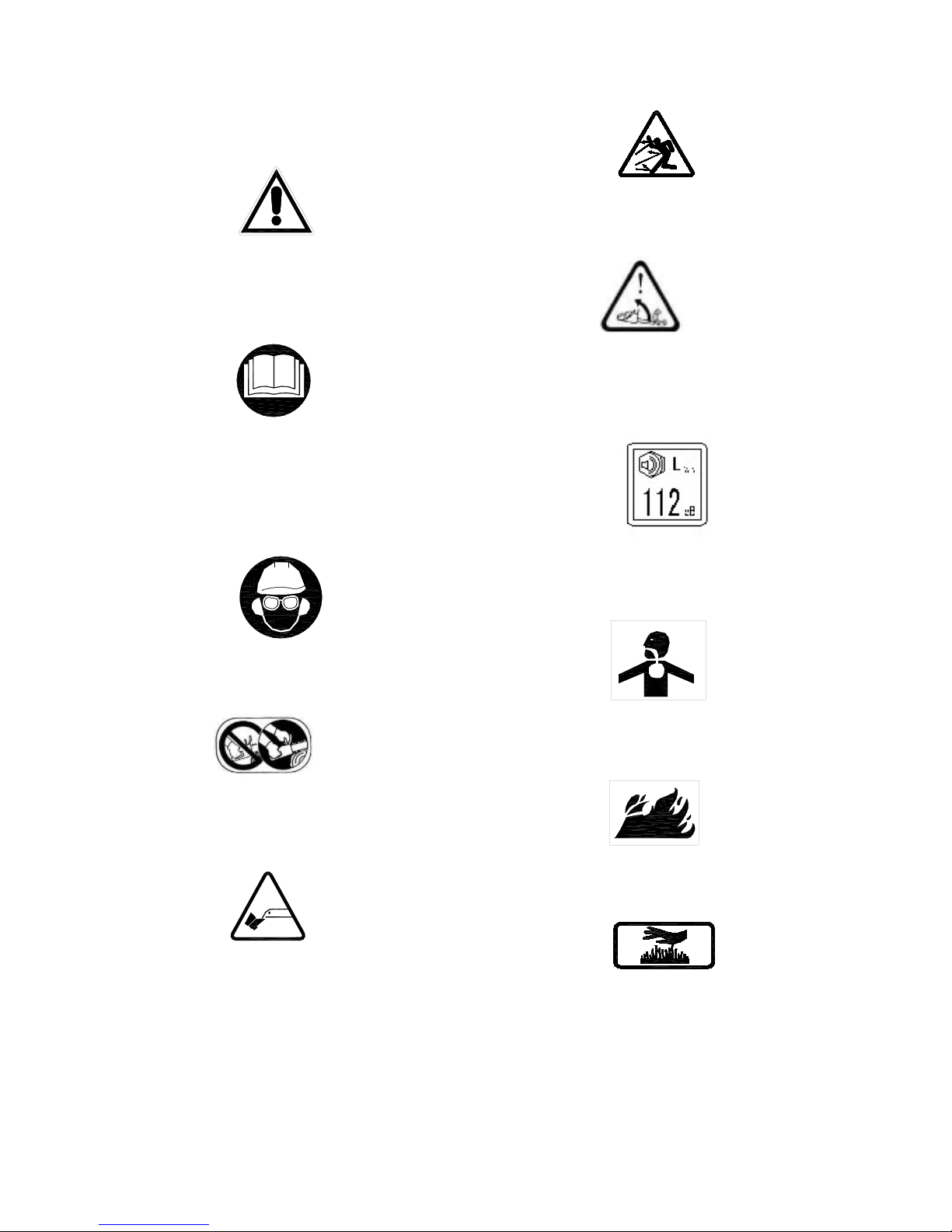

■ SAFETY SYMBOLS

1. Warning, Danger, Caution

2. Read the documentation and safety

instructions which are provided in this

user manual.

3. When oper a ting the chainsaw, use

protective equipment, helmet, visor, ear

defenders, and chainsaw safety

clothing.

4. Use the chain saw with two hands.

5. Keep hands and feet away from moving

parts. Always keep a safe distance from

the saw chain.

6. Beware of objects being throw n from

the operating zone.

7. Warning! Danger of kickback

8. Directive 2000-14/CE. Guaranteed noise

levels.

9. Danger: risk of exhaust fumes

intoxication.

10. Danger: risk of fi re or explosion.

11

. Hot surface, risk of burn.

■

Taking care of warning labels

Always keep warning labels clean and free of scratches, which might make them illegible or difficult to read. If

the warning label s provided with your chain saw become damaged, peel off , or otherwise become illegible or

difficult t o read, or der new labels from the authorised servicing dealer and replace the damaged labels. When

applying new labels, first wipe away any dirt and dry the surface bef or e applying the new label in the same

place as the original label.

Page 6

■ EXPLANATION OF SYMBOLS ON THE MACHINE

For safe operation and main t enan ce, symb ol s are carved i n rel ief on the machine:

FUEL TANK

Fuel tank 2 stroke mix

Position: Fuel ca p

CHAIN OIL

Chain oil tank

Position: oil cap

IGNITION SWITCH

Setting the switch to the “O” position, the engine stops imm ediately.

Position: Left of the rear handle.

CHOKE OPERATION

Starting mode when the engine is hot. (choke off)

Position: Air cleaner cover.

Starting mode when the engine is cold. (choke on)

Position: Air cleaner cover.

CARBURETOR ADJUSTMENTS

The screw under the “H” stamp is High-speed adjustment screw.

Position: Left side of top cover

The screw under the “L” stamp is Slow-speed adjustment screw.

Position: Left side of top cover

The screw the “T” stamp is Idle adjustment screw.

Position: Left side of top cover

CHAIN BRAKE OPERATION

Shows the directions that the chain brake is Released (white arrow) and

Activated (black arrow).

Position: Front of chain brake cover

Page 7

■ INSTALLING THE GUIDE BAR AND C H AIN

■

The chainsaw package contains the items as illustrated.

1. Power unit

2. Guide bar cover

3. Guide bar

4. Saw chain

5. Plug wrench

6. Owner’s manual.

Open the box and install the guide bar and saw chain on the power unit as follows:

The saw chain is very sharp. Use chainsaw prot ective gloves f or safety.

1. Pull the chain brake lev er t owards the front handle to check that the

chain brake is off.

2. Loosen the nuts and remove the chain cover.

3 . Fit the guide bar ov er the bar bolts.

4. Fit the saw chain to the drive sprocket and whil e fit ting t he saw chain around

the guide bar, adjust the position of the chain tensioner located in the

side cover to fit into the tension adjustment hole in the guide bar.

5. Fit the chain cover to the power unit and fasten the nuts finger tight.

6.

While holding up the tip of t he guide bar, adjust the chain tension by turning

the tensioner screw until the chain does not sag from the under si de of the

guide bar.

7. Tighten the bar nut s securel y to 12/15N.M with the bar held upwards, then

check the chain for smooth rotation and proper tension by rotating the

chain by hand in a clockwise direction when viewed from the chain

cover side.

A new chain will expand in length at the beginning of use.

Check and readjust the tensi on f requ ently, as a loose saw chain

can easily derail or cause rapid wear to i t self and the guide bar and sprocket.

It is important to maintain the proper chain tension. Rapid wear of the guide bar or the saw chain becoming

derailed can be caused by improper t ension, especially when using a new saw chain.

Chain tension screw

Plug wrench

Power unit

Guide bar cover

Guide bar

Saw chain

(4)

Cutting direction

(6)

Page 8

■ TWO-STROKE FUEL

WARNING

• Fuel is very flammable. Do not smoke o r bring any fl ame or sparks near fuel.

Always stop the engine and allow it cool before refuelling. Refuel outdoors on

bare ground, restart eng ine at least 5m away from the refuelling stop.

The engine is lubricat ed by oil mixed into petrol. Prepare a mixture of unleaded petrol and semi-synthetic twostroke oil that meet s the specif ications of:

API TC, ISO-L-EGC, JASO FC (Low Smoke) oil.

Recommended mixing ratio is 32:1.

• FUEL WITH NO OIL (RAW PETROL) will cause severe damage to the engine which is not covered by

manufacturers warranty.

• Use fresh, unleaded petrol (95 RON) and semi-synthetic oil specially made for high performance two-stroke

engines. Mix in a ratio of 32 parts p et rol to 1 part of oil.

• By using two-stroke oil specially made for two-stroke engines you will reduce the f ormation of ash and carbon

deposits on the spark plug, piston, exhaust muffler and cylinder as well as reducing emissions of harmful

exhaust gases.

• Oil FOR 4-CYCLE ENGINES should not be used as two stroke lubrication oil as it can cause fouling of

the spark plug, exhaust por t blocking, piston ring sticking and other internal engine damage.

■ FUEL STORAGE

• Mixed two stroke fuel which has been left unused for a period of one month or more may damage the

carburettor and r esul t in the engine failing to start or operate correctly.

• W hen storing the ch ainsaw for a period of more than one month, empty t he fuel tank, and run the engi ne to

empty the carburettor of fuel.

• Two stroke f uel can cause deterioration of rubber and/or pl astic components during prol onged storage.

• It is important to only use good quali ty, fresh fuel mix.

■ FUELLING

• Shake the fuel container to thoroughly mix the two-stroke oil and petrol.

• Clean dirt and sawdust from around t he fuel cap before removing.

• Pour two-stroke fuel int o the fuel tank with a filtered funnel, up to 80% of the fuel tanks capacity.

• Replace the fuel cap and tighten securely. Spilled fuel must be wiped away from the chain saw before

starting the engine.

• Move at least 5m away from the refuelling area before restarting the engine.

■ CHAIN OIL- GUIDE BAR AND SAW CHAIN LUBRICATION

• Chain oil lubricates the saw chain and guide bar during operation,

• We recommend the use of SAE30 grade chain oil with good adhesion (anti-fling) characteristics.

• Fill the chain oil tank every time you fill the fuel tank.

• Failure to lubrica te the guide bar and saw chain will result in overheating of these components resulting in

premature wear or perm anent damage.

•

Do not use waste or regenerated oil that can cause damage to the oil pump and harm the

environment.

Page 9

■ STARTING THE ENGINE

• Keep clear of the saw chain as it will start rotat in g when engine starts.

• Fill fuel and chain oil tanks respect ively, and tighten the caps securely.

z

• Set the ignition switch to “I” position (c).

• Push in the decompressor button (d).

• Pull out the choke lever to the closed position (a). The choke will close and the thr ott le will be set in the starting

position.

• Place the saw on the ground, grip the front handle with your lef t hand, place your ri ght foot through t he rear

handle. Pull the star ter handle with your right hand.

• CAUTION do not pull the start er cord all the way out and do not let go of the starter

handle when the cord is ext ended, this can damage the starter mechani sm.

• When the engine has fired, push in the choke lever in (b) and then pull the starter

handle again to star t t he engine

.

• Allow the engine to warm up; pulling the throttle lever slightly will reset the throttle

control and allow the engi ne to idle.

■ Starting hot engine

• Set the ignition switch to “I” posi tion (c).

• Pull the choke lever to closed position (a), then push the choke lever to the open position (b), this will set the

throttle t o the hot start posi tion.

• Push in the decompressor button (d).

• Pull the starter handle until the engine runs.

• Pulling the throttle lever slightly will reset the throttle contr ol allow the engine to idle.

■ Overchoking

Should the engi ne become flooded due to overch oking, turn the ignition switch of f, unscrew the spark plug, wipe

it dry or replace, pull t he recoil starter several times without the spark plug in pl ace and with choke i n the open

position (b). T his will help clean and ventilate the combustion ch amber.

Two stroke fuel

Saw chain Oil

(a) Choke closed

(b) Choke open

(d) Decompressor

(c) Ignition switch

Page 10

■ CHAIN BRAKE

• The chainsaw is equipped with an automatic chain br ake to stop the saw chain rotation when activ ated, eg

kickback duri ng saw cutting. The brake is automati call y operat ed by inertial force, which acts on the weight fitted

inside the chain brake handle. The brake can also be operated manually when the brake handle is pushed

forward towards the guide bar.

• To release the chain brake, pull back the brake handle toward the fr ont handle until a “click” sound is heard.

The chain brake is now reset and the saw chain is able to rotate.

How to check:

• You must check the chain brake oper ation before each usage by running the chainsaw at full throttle for 1-2

seconds and pushing the chain brake handle forward (b).

• The saw chain should stop imm ediately with the engine at full speed.

• If the saw chain is slow to stop or does not stop, replace the chain brake band or ch ain br ake assembly before

use.

• Disengage the chai n br ake aft er t esting. (a)

■ KICKBACK SAFETY PRECAUTIONS FOR CHAIN SAW USERS

Kickback m ay occur when the nose or tip of the guide bar touches an object, or when the wood being cut closes

in and pinches the saw chain. Top contact of the gui de bar may cause a f ast rever se reacti on, ki cking the guide

bar up and back towards the operator. Pinching the saw chain along the top of the guide bar may push the

guide bar rapidly back towards the operator. Either of these reactions may cause the operator t o l ose control of

the chain saw which could result in serious personal injury.

Do not rely exclusively on the safety devices built into the chainsaw. As a chain saw user you should take

several steps to keep the cutting work free from accident or injury .

• With a basic understanding of kickback you can reduce or eliminate the element of surprise. Sudden surprise

contribut es to accidents.

• Keep a good grip on t he chain saw with both hands, the right hand on the rear handle, and the left hand on the

front handle, when the engine is running. Use a firm grip with thumbs and fingers encircling the chain saw

handles. A firm grip will help you reduce ki ckback and maintain control of t he chainsaw.

• Make certain that the area in which you ar e cutting is f ree from obstructi ons. Do not let the nose of the guide

bar contact a log, branch, or any other obstruction which could be hit whil e yo u ar e operating the chainsaw.

• Cut at high engine speeds.

• Do not overreach or cut above shoulder height.

• Follow manufacturers sharpening and maintenance instructions for sharpening saw chain.

• Only use replacement guide bars and saw chai ns spe ci fied by the manufacturer or the equivalent.

■ BEFORE ST ARTING WORK

Always follow the safety regu lations:

• Before starting work we recomm ended to fi r st pr actice sawing easy logs. This also helps you get accu stomed

to your chainsaw’s operation.

• The chain saw must only be used for cutting wood. It must not be used to cut other types of material.

• The chai nsaw should cut easil y without force . When cutting appl y only light pressure while r unning the engine

at full throttle.

• W hen the saw chain is caught i n the cut, do not attem pt to pull it out by force, turn off the engi ne and use a

wedge or a lever to release the saw chain and guide bar.

(a)

(b)

(a) Chain brake disengaged

(b) Chain brake engaged

Page 11

■ RUNNING IN

During the fir st ten hours of work, avoid running the engine at maximum speed f or a prol onged period until all

the components have bedded in. After the engine has been run in, it will reach its maximum power.

After two hours of work, check that all nuts bolts and screws are securely fastened and tighten if

necessary.

■ STOPPING ENGINE

• Release the throttle lev er and allow the engine to run at idle for half a minute.

• Shift the ignition switch to the STOP position (“0”).

• Except for an emergency, avoid stopping the engine while at full throttle.

■CHECKING THE S AW CHAIN LUBRICATION SUPPLY

After starti ng the engine, run the chainsaw at m edium speed and see if chain

oil is sprayed as shown in the figure.

■ CARE AND MAINTENANCE OF YOUR CHAINSAW

• In order to maintain the chain saw in good working order, perform the maintenance and checking operations

described in this manual at regular intervals. In t he ev ent t hat any par t needs to be replaced, please contact the

nearest authorised service dealer for assistance.

• Al wa ys stop the engine and all ow to cool before performing any maintenance or checking procedures.

• When sharpening, r em ov ing, or r eatt ach ing the saw chain always wear chainsaw safet y gloves and use only

appropriate t ools and equipment to prevent injur y.

• When replacing saw chain or any other part s, use only genuine spare parts and approv ed lubri ca nts.

• Disconnect the spark plug to prevent accidental starting when carrying out routine maintenance.

■ MAINTENANCE AFTER EACH USE

■ AIR FILTER

To clea n dirt in the air filter, split the air f ilter into hal ves and wash with w arm soap y water. When usi ng

compressed air, blow from the inside.

To assemble the air filter halves, press until they click together.

■ OILING PORT

Dismount the gui de bar and check the oiling port for clogging and clean as necessary.

■ GUIDE BAR

When the guide bar is dismount ed, remove sawdust f rom the bar groov e and the oiling

port.

Grease the nose sprocket wit h a sprocke t grease gun (Oregon part number 21939)

1. Guide bar grove (A-1)

2. Oil hole (A-2)

3. Drive sprocket (B-3)

4. Grease point (B-4)

Oiling port

A B 4 3

1

2

Page 12

■OTHERS

Check for fuel leakage, loose fastenings and damage to major parts, especially handle joints, guide bar

mountings and chain brake . If any defects are found, make sure they are repair ed before operating the

chainsaw. Check guide bar and saw chain for excessive wear or dam age, and replace as necessary. Never fit a

new chain on a worn sprocket, or a worn chain on a new sprocket.

■ PERIODICAL SERVICE POINTS

■

CYLINDER FINS

Chainsaw dust clogging between the cylinder fins will cause overheating of the engine.

Periodically check and clean the cylinder fi ns after removing the cylinder cover.

When installing the cylinder cover, make sure that switch wires and gromm ets are fitted correctly.

■ FUEL FILTER

Using a wire hook, take the fuel filter from the fuel t ank and clean or replace with new fuel filter.

■ SPARK PLUG

Reset the gap to 0.65 mm, or repl ace the spark plug with

NGK: BPRM7A as necessary.

■ SPROCKET

Check for cracks and for excessive wear interfering with the chain drive. If the wear is

considerable, r eplace sprocket and saw chain. Nev er fit a new chain on a worn sprocket ,

or a worn chain on a new sprocket.

■ ADJUSTING SAW CHAIN LUBRICATION FLOW RATE

Never fill the oil tank or adjust the saw chain oiler with the engine running.

An increase in the oil flow rate will increase oil consumpti on, requiring more frequent checks of the oil tank. To

ensure sufficient lubrication, it may be necessary to check the oil level more frequently than at fuel tank refill s.

The guide bar and saw chain are lubrica ted automatically by a pump that operates whenever the saw chain

rotates. The pump is set at the factor y to deliv er a minimum flow rate, but it can be adjusted in the to deliver

more oil. A temporary increase in oil fl ow is recommended when cutting hardwood.

■ OIL PUMP ADJUSTMENT

• Stop the engine and make sure the ignition switch is in the OFF

position.

• Place the chainsaw on its side.

• With a screwdriver, adjust the oil flow rate adjusting screw and turn in

the required direction.

• Clockwise-decrease lu brication

• Counter clockwise-increase lubrication.

Page 13

■ SAW CHAIN SHARPENING:

Be sure to wear safety gloves.

■ THE SAW CHAIN NEEDS TO BE SHARPENED WHEN:

• Sawdust becomes like powder.

• You need extra force to cut.

• The cut path does not go straight.

• Vibration increases.

• Fuel consumption increases.

■ SAW CHAIN SHARPENING

• Clamp chain saw guide bar in a vice to

secure. (Dia 1)

• Sharpen chain with a 5/32 file and holder

(Oregon part number 16265)

Place file on the cutter and push straight

forward. Keep the file position as illustrated

(Dia 1). After every cutter has been set, check

the depth gauge and fil e it t o the proper lev el

as illustrated (Dia 2).

• Make sure every cutter has the same length

and edge angles as

illustrated (Di a 3).

(Dia 1) Filing saw chain cut ters

(Dia 2) File saw chain with depth gauge

(Dia 3) Recommended sharpening angles

Dia 2

Dia 3

Dia 1

25O

Page 14

■

ADJUSTING THE CARBURETTOR

The carburett or has been f actory adjusted, but may require fi ne tuning due to a change in operating conditions.

Carburettor adjustments should be made by the supplying dealer usi ng specialist tools as follows.

• Make sure that the air filter and fuel filter are clean, and the fuel is freshly mixed.

• Stop the engine and screw in both the H and L needles until they stop. Never force them. T hen set them back

the initial number of t ur ns as shown below.

H screw: 1 +or-¼

L screw: 1 ¼ +or-¼

1. Start the engine and allow it to warm up at half-throttle with saw chain and gui de bar fit ted.

2. Turn the L screw slowly to find a position where idling speed is at maximum, then set the L adjusting screw

back a quarter (1/ 4) tur n (counter cl ockwise).

3. Turn the idle adjusting screw T counter clockwise so that the saw chain does not tur n. If the idling speed is

too slow, turn the screw clockwise.

4. To check the low speed adjustment pull the throttle fully and the engine should not die, if it tries to die, open

the L screw slightly and re-adjust i dle if necessary.

5. Set the engine to full thr ott le, the H adjusting screw is tur ned clockwise to reduce fuel, as the fuel mix ture is

reduced, the engine will run faster until it sounds as if it is screami ng, at this point, turn the H screw counter

clockwise by quarter (1/4) turn to allow more fuel.

A two stroke engine r elies on the fuel mixture to cool t he engine; a lean fuelled engine will run fast but

can

overheat and lead to engine seizure.

Component Procedure Before

use

Every

25

Hours

use

Every

50

Hours

use

Every

100

Hours

use

note

Fuel leaks / spillage

Wipe out

X

Fuel tank, filter

Inspect / clean

X

Replace if necessary

Idle adjust screw

See paragraph 3 above

X

Adjust carburettor if

necessary

Spark plug BPMR7A

Clean and r ead j us t plug

gap

X

GAP .025” (0.6-0.7mm)

Replace, if necessary

Cylinder fins,Intake air

cooling vent

Clean

X

Muffler, Spark arrestor,

cylinder exhaust por t

Clean

X

Throttle lever, ignition switch

Check op eration

X

Air filter

Clean

X

Screws, nuts, bolts

Tighten / replace

X

X

Not adjusting screws

Oiling por t

Clean

X

Guide bar

Clean

X

Sprocket

Inspect / replace

X

Saw chain

Inspect / sharpen

X

T idle adjust screw

L low speed adjust screw

H high speed adjust screw

Page 15

TROUBLESHOOTING

Engine will not start, power loss.

- Check that the fuel t ank i s not empty. Fill with mixed fuel.

- The fuel does not reach t he carburettor. Change the fuel filter in the fuel tank.

- There is water in the fuel. Drain and clean the fuel system .

- The air filter is dirt y. Clean the air filter.

- There are carbon deposit s i n the exhaust muffler restricting the engine. Clean or change the muffler.

- Spark plug is worn. Replace spark plug.

- Saw chain will not rotate. Chain brake is activated. Deactivate chain brake.

■ Specifications

MITOX 4518

Power unit :

Displacement (

cm3

): ..………………………………45.0

Fuel: …………....Mixtur e ( petrol 32 : two stroke oil 1)

Fuel tank capacit y (ml): ......……………….……….550

Oil tank capacit y (ml):....…….………….…………..260

Carburettor: .……….....Diaphragm type (Walbro WT)

Ignition system: ……………………...Electronic (CDI)

Spark plug: ...………………………….,NGK:BPRM7A

Chain lubrication system: ....….……Automatic pump

Chain Oil: ..………………………....SAE 30 Anti-fling

Dimensions: power unit ( LxWxH)mm)..425x240x288

Weight Power unit only (kg): ..……………………..6.0

Peak power (kw): …………………..……………1.8kw

Idling speed (r/min): …..………………………….3200

Max cutting speed (r/min): ....…………………..10000

Guide bar :

Type: ……………………………...……Sprocket nose

Size (in): .........……………….…………………...…18”

Oregon Part No: ..……………………...188PXBK095

Saw chain:

Type: ......….……….....Oregon 34SL 72 Drive links

Pitch (in): ....…………………….………………..0.325”

Gauge (in): ..........…………………….………....0.058”

Specifications are subject to change without notice .

■ Specifications

MITOX 5020

Power unit :

Displacement (

cm3

): ...……………………………...49.3

Fuel: …………....Mixtur e ( petrol 32 : two stroke oil 1)

Fuel tank capacit y (ml): ..………………….……….550

Oil tank capacit y (ml): ...…….………….…………..260

Carburettor: .……….....Diaphragm type (Walbro WT)

Ignition system: ....…………………...Electronic (CDI)

Spark plug: ...…………………………..NGK:BPRM7A

Chain lubrication system: ….….……Automatic pump

Chain Oil: ...………………………....SAE 30 Anti-fling

Dimensions: power unit ( LxWxH)mm)..425x240x288

Weight Power unit only (kg): ...……………………..6.0

Specifications are subject to change without notice.

Peak power (w): ....………………..…….………2.2kw

Idling speed (r/min): …..………………………….3200

Max cutting speed (r/min): ...…………………..10000

Guide bar :

Type: ……………………………..…….Sprocket nose

Size (in): ..........……………….…………………… 20”

Oregon Part No: ..……………………...208SLGK095

Saw chain:

Type: ...……………......Oregon 34SL 78 Drive links

Pitch (in): ......…………………………………....0.325”

Gauge (in): .........…………………….……..…..0.058”

Page 16

CONDITIONS OF WA R RA NTY

The manufacturer warrants the product against faulty materials and workmanship for a period of 2 years

from the date of first purchase to the original purchaser. The warranty is applicable when the product is

used in a “home owner” application. If products are used for commercial or professional purposes, the

warranty period is for 3 months from the date of first purchase. Warranty does not extend to failure due to

fair wear and tear.

The manufacturer undertakes to replace any spare parts that are classified as defective by an appointed

Mitox service dealer. The manufacturer will not accept liability for the replacement of the machine, either

partially or wholly , and/or consequential damages.

Warranty does not cover failure due to:

• Insufficient maintenance.

• Incorrect fuel mixture and stale fuel.

• Abnormal use or accidental damage.

• Incorrect assembly, adjustment or operation of the product, including saw chain, guide bar and

sprocket.

• Spare parts that are subject to wear e.g. safety parts, saw chain, guide bar, sprocket, guards,

deflectors, spark plugs, filters etc.

Neither does warranty extend to:

• Freight and packing costs.

• Use of non-genuine spare parts i.e. those from another manufacturer.

• Use of the machine for any other purpose than that for which it was designed.

• Use and maintenance of the machine in a manner not described in the owner’s manual.

As part of our policy of continuou s product improvement, we reserve the right to alter or amend this

specificatio n wit hout no tice. As a result, the product may differ from the information cont ain ed h erein ,

but any alteration will only be implemented without notice if it is classified as an improvement to the

above specificat io n.

READ THE MANUAL CAREFULLY BEFORE OPERATING THE M ACHINE

When ordering spare parts, please quote the part number, this can be found in the parts list included in this

manual

Retain the receipt of purchase without which no warranty can be offered.

Distributed by Mitox Garden Machinery

Wincanton Business Park

Wincanton

Somerset

BA9 9RS

www.mitoxgm.co.uk

Loading...

Loading...