Page 1

Operator’s Manual

user manual, maintenance instructions and spare parts

435 L/U Brushcutter

www.mitoxgm.co.uk

Read this manual carefully before operating the machine

Original Instructions Version December 12

Page 2

435 L/U Brushcutter

2

Original Instructions Version December 12

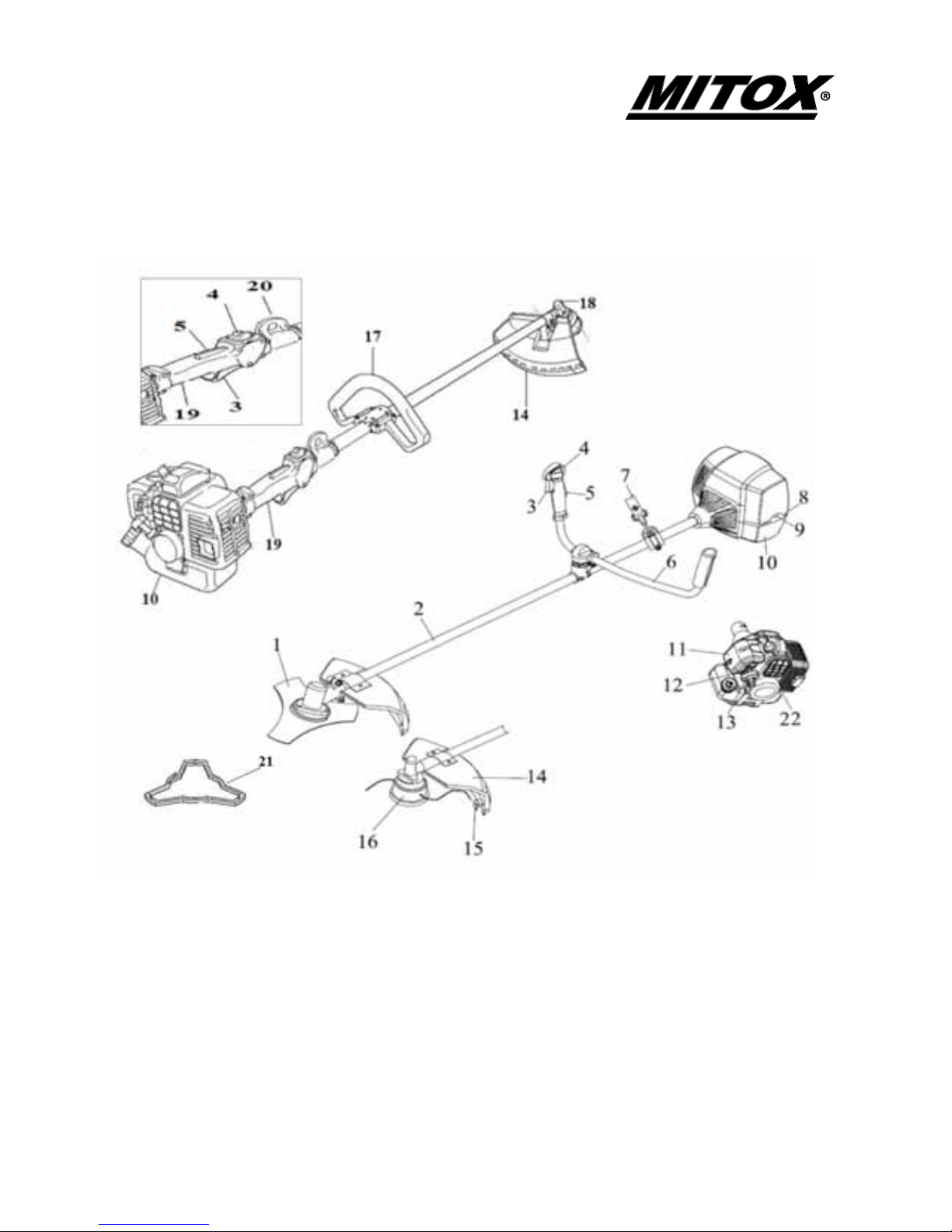

Component Location

PRODUCT DESCRIPTION

This Brushcutter is a 4 stroke fast running power tool and is designed to be used in a

domestic application for trimming grass and light brush.

Page 3

435 L/U Brushcutter

3

Original Instructions Version December 12

Warnings in the Manual

This mark indicates instructions which must be followed in order to prevent accidents which could lead to

serious bodily injury or death.

This mark indicates instructions which must be followed or it leads to mechanical failure, breakdown, or

damage.

This mark indicates hints or useful directions in the use of the product.

IMPORTANT

!

NOTE

Component Location

1 BLADE 3 Point blade for grass, weed or brush cutting applications.

2 DRIVE SHAFT Contains the drive shaft.

3 THROTTLE TRIGGER Spring loaded to return to idle when released.

4 IGNITION SWITCH Slide switch, forward to run, back to stop.

5 SAFETY LEVER Prevents accidental operation of the throttle.

6 HANDLE This handle can be adjusted for maximum comfort

7 HARNESS ASSEMBLY Fully adjustable for maximum comfort

8 PETROL CAP

9 PURGE BULB Push the purge bulb to remove the air from the fuel system.

10 FUEL TANK Contains fuel and fuel lter.

11 AIR CLEANER Contains replaceable lter.

12 CHOKE To help in cold starting.

13 STARTER HANDLE Pull to start the engine.

14 DEBRIS SHIELD Helps protect the operator from debris.

15 CUT-OFF KNIFE Cuts the nylon line to the correct length.

16 NYLON CUTTER HEAD Contains replaceable nylon trimming line.

17 FRONT HANDLE This handle can be adjusted for maximum comfort.

18 GEARBOX For attaching a blade or nylon head to.

19 REAR HANDLE Incorporating throttle trigger, switch, and safety lever.

20 HARNESS FIXING POINT Fixing point to attach the harness.

21 BLADE COVER Blade cover for transportation.

22 OIL FILLER Filler for the engine oil.

Page 4

435 L/U Brushcutter

4

Original Instructions Version December 12

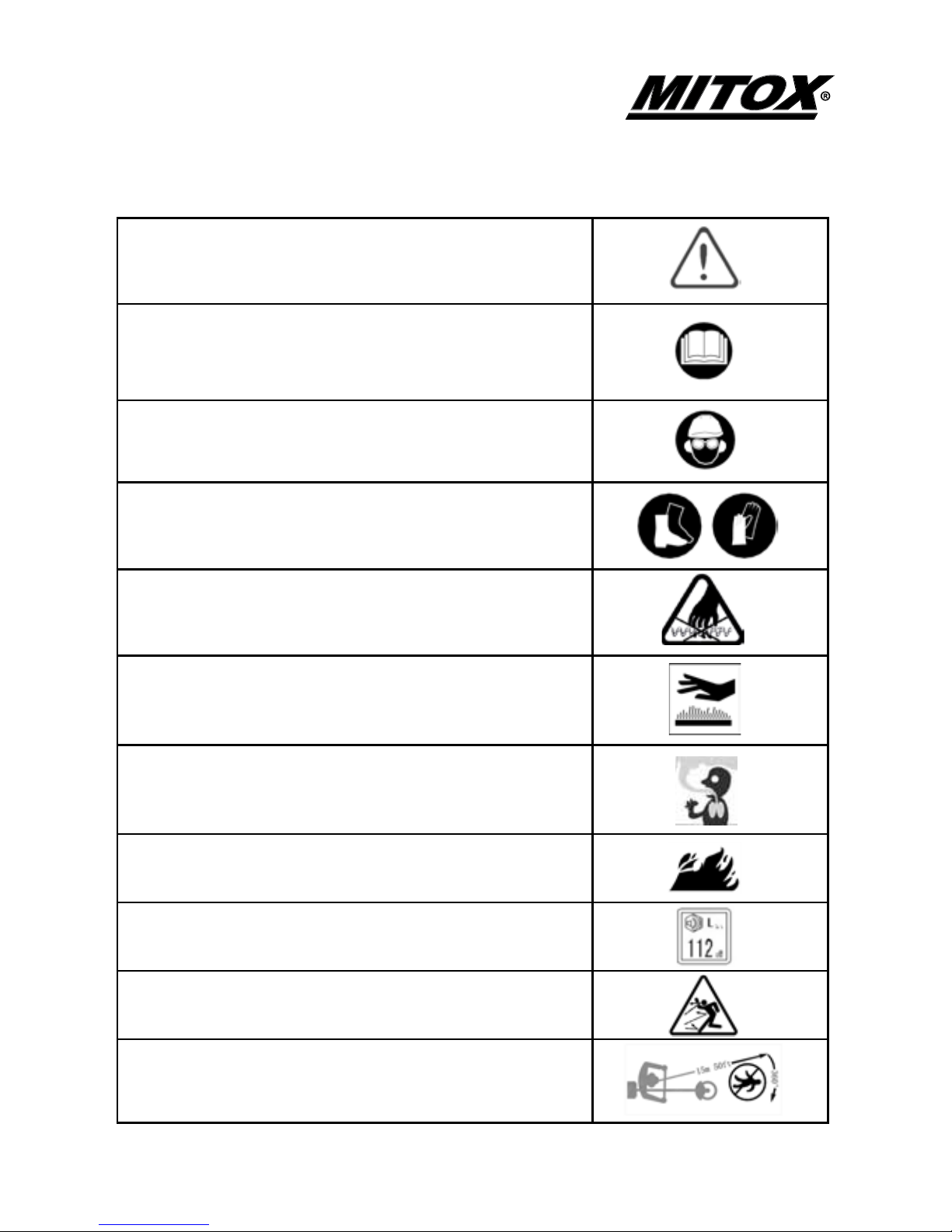

Safety Symbols

Warning: Danger, Caution

Read the documentation and safety instructions which are provided

in this user manual.

When operating this machine, use protective equipment such as

goggles, helmet and ear defenders.

Wear security shoes and gloves.

Beware: Keep hands and feet away from moving parts. Always keep a

safe distance from the cutting parts.

Hot surface: Risk of burn.

Danger: Risk of intoxication.

Danger: Risk of re or explosion

Directive 2000-14/CE. Guaranteed noise levels

Beware of objects being thrown from the operating zone

Warning: Keep all people, animals and vulnerable objects at least 15

metres from the working area.

Page 5

435 L/U Brushcutter

5

Original Instructions Version December 12

Taking Care of Warning Labels

Always keep warning labels clean and free of scratches, which might make them illegible or

dicult to read. If the warning labels provided with your Brushcutter become damaged, peel

o, or otherwise become illegible or dicult to read, order new labels from the authorised

servicing dealer and replace the damaged labels. When applying new labels, rst wipe away any

dirt and dry the surface before applying the new label in the same place as the original label.

Explanation of Symbols on the Machine

For safe operation and maintenance, symbols are carved in relief on the machine:•

FUEL TANK

Fuel tank

Position: Fuel cap

CHOKE OPERATION

Starting mode when the engine is hot (choke o).

Position: Air cleaner cover.

Starting mode when the engine is cold (choke on).

Position: Air cleaner cover.

Page 6

435 L/U Brushcutter

6

Original Instructions Version December 12

Safety Precautions

Introduction

Read this Owner/Operator Manual carefully. Be sure you understand how to operate this Brushcutter

properly before you use it. Failure to do so could result in serious injury.

Keep this manual handy so that you may refer to it later whenever any questions arise. Also note that you are

able to contact the dealer from whom you purchased the product for assistance.

Always include this manual when selling, lending, or otherwise transferring the ownership of this product.

This product has been designed to be used as a Brushcutter power tool as described previously and it should

never be used for any other purpose; doing so could result in unforeseen accidents and injuries occurring.

Only approved Mitox accessories should be used with this product.

This Brushcutter is equipped with extremely sharp blades, always wear sturdy gloves when handling the

blades and t the safety guards when not in use.

When using this Brushcutter for the rst time, take the Brushcutter to a wide, clear, open space, start the

engine, and practice handling the Brushcutter until you are sure that you will be able to handle it properly in

actual operation.

You should never use this Brushcutter when under the inuence of alcohol, suering from exhaustion or

lack of sleep, suering from drowsiness as a result of having taken medicine, or at any other time when your

judgement might be impaired or that you might not be able to operate the Brushcutter properly and in a

safe manner.

Never allow children or anyone unable to fully understand the directions given in this manual to use this

Brushcutter.

When planning your work schedule, allow plenty of time to perform the work and allow plenty of time for

rest. Limit the amount of time you continuously use the Brushcutter to 30~40 minutes per session and take

10~20 minutes of rest between work sessions. Also, try to keep the total amount of work performed in a

single day to 2 hours.

Never run the engine indoors as the exhaust gases contain harmful carbon monoxide.

Page 7

435 L/U Brushcutter

7

Original Instructions Version December 12

Never use the Brushcutter in conditions as described below:

When the ground is slippery or when other conditions exist which might make it dicult to maintain a

steady posture while using the Brushcutter.

At night, at times of heavy fog, or at any other times when your eld of vision is limited and it would be

dicult to gain a clear view of the area where the Brushcutter is to be used. In heavy rain, during lightning

storms, at times of strong or gale-force winds, or at any other times when weather conditions might make it

unsafe to use this product.

Lack of sleep, tiredness, or physical exhaustion results in lower attention spans, and this in turn can lead to

accidents and injury.

Work Clothing and Safety Equipment

When using the product, you should wear proper clothing and protective equipment.

• Helmet

• Protection goggles or face protector

• Ear protectors

• Thick work gloves

• Non-slip sole work boots

• When using your Brushcutter, always wear strong, durable, work clothing; shirts should be long-

sleeved and trousers should be full-length.

Safety and Operation

This Brushcutter is equipped with a very sharp blade, and when used incorrectly the blades can be extremely

dangerous.

Improper handling can cause accidents which may in turn lead to serious injury or death. For this reason,

you should always be careful to adhere to the following instructions when using your Brushcutter.

Page 8

435 L/U Brushcutter

8

Original Instructions Version December 12

Never hold the Brushcutter in a way in which the cutting head is pointing towards someone else.

Never allow the blades to come into contact with your body.

Always turn o the engine before adjusting the Brushcutter, or at any time when coming into close proximity

with the cutting head.

Always wear thick work gloves when adjusting the Brushcutter.

Safe Handling of Fuel

The engine of the Brushcutter is designed to run on unleaded petrol.

This fuel is highly ammable, never store cans of fuel or rell the fuel tank in any place where there is a source

of heat or re, which might ignite the fuel.

Do not smoke whilst operating the Brushcutter or relling, keep lit cigarettes away from the Brushcutter at all

times.

When relling the fuel tank always stop the engine rst and carefully make sure that there are no sparks or

naked ames anywhere nearby before refuelling.

If any fuel spillage occurs during refuelling, use a dry rag to wipe any fuel which has been spilled onto the

Brushcutter before starting the engine.

After refuelling, screw the fuel cap back tightly onto the fuel tank and carry the brushcutter to a spot 5

metres or more away from where it was refuelled before starting the engine.

Page 9

435 L/U Brushcutter

9

Original Instructions Version December 12

Before Operating the Brushcutter

Before beginning work, carefully check the work area and remove any obstacles. Within a perimeter of 15

metres of the work area should be considered a hazardous area into which no-one should enter while the

Brushcutter is being used, and when necessary this area should be marked with a warning rope, warning

signs, or other forms of warning.

When work is to be performed simultaneously by two or more operators, care should also be taken to

constantly look around to check the presence and locations of other operators within the work area to

maintain a safe distance between each operator.

Before beginning work, each component of the Brushcutter should be checked to make sure that it is in

proper working order, make sure that there are no loose screws or bolts, fuel leaks, ruptures, dents, broken

guards or any other problems which might interfere with safe operation.

Keep all parts of your body away from the cutting head when the engine is running.

Before Starting the Engine

Carefully check the work area to make sure that no obstacles exist within a perimeter of 15 metres around

the Brushcutter before starting the engine.

To start the engine, place the Brushcutter onto the ground in a at clear area and hold it rmly in place to

ensure that neither the cutting head nor the throttle come into contact with any obstacles when the engine

starts.

After starting the engine, make sure that the cutting head stops moving when the throttle trigger is

released (idle). If the cutting head continues to move when the engine is at idle, adjust the idle screw on the

carburettor to a point where the cutting head stops moving, if this cannot be achieved, take the Brushcutter

to your authorised service dealer for adjustment.

Page 10

435 L/U Brushcutter

10

Original Instructions Version December 12

Avoid Noise Problems

Check and follow the local regulations for sound levels and hours of operation for garden machinery.

In general, operate Brushcutters between 8 am and 5 pm on weekdays and 9 am to 5 pm at weekends.

Avoid using the Brushcutter late at night and/or early in the morning.

Safety when using the Brushcutter

When using the Brushcutter, grip the handles rmly with both hands, place your feet slightly apart so your

weight is distributed evenly across both legs, and always maintain a steady even posture while working.

Do not use on ladders or if the ground surface is slippery or uneven. Never attempt to cut directly overhead

or with one hand.

• Maintain full engine speed when cutting.

• Never allow other persons to come within the work area as doing so might expose them to

danger.

• Keep work area clear of all persons, particularly small children and pets. Injury may result from

ying debris.

• If grass or other objects get caught in the Brushcutter during operation, always stop the engine

before removing the object.

• Never touch the spark plug or plug HT cable while the engine is in operation,

doing so may result in an electrical shock.

• Never touch the exhaust, spark plug, or any metallic parts while the engine is

in operation or immediately after shutting down the engine. These parts

reach high temperatures during operation and doing so could result in

serious burns.

• When you nish cutting in one location and wish to continue work in another area, stop the

engine.

• Always remove fuel from the fuel tank before transportation to prevent fuel spillage.

• Never leave the Brushcutter exposed to direct sunlight as this can heat the fuel tank and may

cause a discharge of fuel, and ood the engine.

• Be careful not to hit the nylon cutting head against stones or the ground.

Page 11

435 L/U Brushcutter

11

Original Instructions Version December 12

Assembly of the Brushcutter

The blade tted to the guard is sharp and can cause injury, always wear gloves.

Installing the Guard

• Lay the brushcutter on its back with the gearbox shaft facing up.

• Line up the 4 screw holes in the guard with the bracket on the shaft.

• Insert 4 screws through the guard into the captive nuts in the bracket and tighten.

Page 12

435 L/U Brushcutter

12

Original Instructions Version December 12

Installing the Loop Handle Assembly (L model)

• Fix the loop-handle to the shaft over the rubber block provided. Adjust to a comfortable

working position then tighten the xing screws securely.

Upper Handle

Rubber Block

Fixing Screws

Drive Shaft

Lower Handle

To Cutter Head

Page 13

435 L/U Brushcutter

13

Original Instructions Version December 12

Installing the U Handle Assembly (U model)

• Remove the Upper Bracket from the assembly by undoing the Lockscrew.

• Install the handle assembly, Upper Bracket to the assembly and secure using the Lockscrew.

• Ensure that the controls are located on the right and adjust the handle for maximum comfort

before securing.

Lockscrew

Upper Bracket

To Left handle

To Right handle

Lower Bracket

Spring

Drive Shaft

To Gear Case

Page 14

435 L/U Brushcutter

14

Original Instructions Version December 12

Installing the Nylon Head

• Lay the brushcutter on its back with the gearbox shaft facing up.

Rotate the gear box shaft until the hole in

the holder A lines up with the slot in the

plastic guard.

Insert the Allen key into the hole in the

plastic guard and into the holder A.

Screw the nylon head anti-clockwise (turn

left) onto the threaded shaft on the end of

the gearbox.

Make sure that the nylon head is securely

locked in position and remove the Allen key.

A A

Page 15

435 L/U Brushcutter

15

Original Instructions Version December 12

Installing the 3 Tooth Blade

• Lay the brushcutter on its back with the gearbox shaft facing up.

THE BLADE MUST BE CORRECTLY POSITIONED ON THE UPPER BLADE CLAMP

OTHERWISE SERIOUS DAMAGE AND INJURY TO PERSONS AND PROPERTY COULD RESULT.

Rotate the gear

box shaft until

the hole in the

holder A lines

up with the slot

in the plastic

guard.

Insert the Allen

key into the

hole in the gearbox cover and

into holder A.

Place the 3 tooth

blade on the holder

A, centring the

blade on the raised

centre.

Fit the holder

B and then the

washer.

Screw the nut

anti-clockwise (turn

left) and tighten

using the spanner

provided. Fit split

pin. Remove the

Allen key.

A

B

Page 16

435 L/U Brushcutter

16

Original Instructions Version December 12

Replacing the Nylon Cord

Check to see if the nylon head is damaged before replacing the cord. If you can see serious traces of wear or

damage, you must replace the complete nylon head.

1. Stop the engine

2. Open the nylon head by pushing on the catch, (a), and twisting the cover anti-clock wise.

3. Pull the bobbin out of the nylon head and take out the rest of the nylon cords.

4. Cut the cord, 2.4mm Ø and 5 meters long into two equal lengths.

5. Make a loop folded at one end of each of the two nylon cords and insert these into the two holes

provided on the bobbin, (b). Wind the lines clockwise maintaining an even and rm tension onto the

bobbin, being careful not to twist the line.

6. After winding the cord, insert both ends into the notches on the bobbin, (c).

7. Introduce each end of the cords into the holes provided (d). The cords should stick out appx 15 cm

either side.

8. Pull the cords to free them from the notches and ret the spool cover.

Never use a cutting device other than those supplied by the manufacturer. (Steel cord is never allowed)

Always use original spare parts in order to benet from continuous warranty.

(a)

(b)

(c)

(d)

Page 17

435 L/U Brushcutter

17

Original Instructions Version December 12

Fuelling

Fuel is very ammable. Do not smoke or bring any ame or sparks near fuel.

Always stop the engine and allow it to cool before refuelling.

Refuel outdoors on bare ground, restart engine at least 5m away from the refuelling area.

Use fresh, unleaded petrol (95 RON).

Fuel Storage

Fuel which has been left unused for a period of one month or more may damage the carburettor and result

in the engine failing to start or operate correctly.

When storing the brushcutter for a period of more than one month, empty the fuel tank, and run the engine

to empty the carburettor of fuel.

Stale fuel can cause deterioration of rubber and/or plastic components during prolonged storage.

It is important to only use good quality, fresh fuel.

Fuelling

Clean dirt from around the fuel cap before removing.

Pour fuel into the fuel tank with a ltered funnel, up to 80% of the fuel tank’s capacity.

Replace the fuel cap and tighten securely. Spilled fuel must be wiped away from the machine before starting

the engine.

Move at least 5m away from the refuelling area before restarting the engine.

When relling the tank, always turn o the engine and allow it to cool down. Take a careful look around

to make sure that there are no sparks or open ames anywhere nearby before refuelling.

Page 18

435 L/U Brushcutter

18

Original Instructions Version December 12

Engine Oil

This is a 4-stroke engine and is shipped without oil; ll with oil before starting the engine for the

rst time. Failure to ll with oil will cause engine damage and will not be covered by warranty.

Recommended oil

Use 4 stroke oil that meets or exceeds API SG/CF specication.

SAE 10W 30 is recommended for general use.

Preparation

1. Place the engine with the fuel tank side downward and horizontally on a level surface.

2. Remove the oil ller cap.

3. Fill with the oil, insert and remove the oil ller cap/dipstick without screwing it into the oil ller neck,

remove it and check the oil level on the dipstick, ensure the oil is up to the full mark on the dipstick.

4. Ret the oil ller cap securely.

Before Operation - Checking the oil

Always check the oil before use or after every 5 hours if operating continuously.

1. Place the engine with the fuel tank side downward and horizontally on a level surface.

2. Remove the oil ller cap.

3. Insert and remove the oil ller cap/dipstick without screwing it into the oil ller neck, remove it and check

the oil level on the dipstick, ensure the oil is up to the full mark on the dipstick.

4. Ret the oil ller cap securely.

Page 19

435 L/U Brushcutter

19

Original Instructions Version December 12

Operation - L models

Keep clear of the cutting head as it may start moving when engine starts.

Starting the Engine

CAUTION do not pull the starter cord all the way out and do not let go of the starter handle when the cord is

extended, this can damage the starter mechanism.

Cold Engine Starting - L models (see page 21 for U models)

Rest the unit on a at, rm surface. Keep the cutting head o the ground and clear of surrounding objects as

it may start moving when starting the engine.

Fig 1 - Push the air purge bulb (a) until fuel Fig 2 - Move the choke lever (c) to the closed

is visible in the clear return fuel line (b). position.

(a)

(b)

(c)

Set the ignition switch (d) to the START

(I) position.

START

STOP

(d)

Hold the safety lever (e) down and squeeze

the throttle control lever (f), push down

the fast idle control (g). Release the throttle

control lever rst and then release your hand.

(e)

(f )

(g)

Page 20

435 L/U Brushcutter

20

Original Instructions Version December 12

• Slowly pull the recoil starter handle until engagement of the pawls with the ywheel is felt.

• While holding the unit, pull out the starter rope rmly until engine res (indicated by a ‘cough’

from the engine).

• Move the choke lever to the open position.

• Pull the starter rope until the engine starts.

• Pull and realease the throttle control lever to return the engine to idle.

• Allow the engine to warm up before use. When cutting, always use the machine on full throttle.

Hot Engine Starting

Set the ignition switch (d) to the start position “I”.

Pull the starter rope until the engine starts.

If the engine does not start after 5 pulls, use the cold start procedure.

Overchoking

Should the engine become ooded due to overchoking, turn the ignition switch o, unscrew the spark plug,

wipe it dry or replace.

Stopping the Engine

Set the engine to idling by releasing the throttle lever.

Set the ignition switch to the o position ‘’O’’ (STOP).

If the engine fails to stop, set the choke lever to the closed position to stall the engine; do not use the

machine until the ignition switch is repaired.

NOTE

Page 21

435 L/U Brushcutter

21

Original Instructions Version December 12

Operation - U models

Keep clear of the blades as they may start moving when engine starts.

Starting the Engine

CAUTION do not pull the starter cord all the way out and do not let go of the starter handle when the cord is

extended, this can damage the starter mechanism.

Cold Engine Starting - U models (see page 19 for L models)

Rest the unit on a at, rm surface. Keep the cutting head o the ground and clear of surrounding objects as

it may start moving when starting the engine.

Fig 1 - Push the air purge bulb (a) until fuel Fig 2 - Move the choke lever (c) to the closed

is visible in the clear return fuel line (b). position.

Set the ignition switch (d) to the START

(I) position.

STOP

(d)

(a)

(b)

(c)

Page 22

435 L/U Brushcutter

22

Original Instructions Version December 12

• Slowly pull the recoil starter handle until engagement of the pawls with the ywheel is felt.

• While holding the unit, pull out the starter rope rmly until engine res (indicated by a ‘cough’

from the engine).

• Move the choke lever to the open position.

• Pull the starter rope until the engine starts.

• Allow the engine to warm up before use. When cutting, always use the machine on full throttle.

Hot Engine Starting

Set the ignition switch (d) to the start position “I”.

Pull the starter rope until the engine starts.

If the engine does not start after 5 pulls, use the cold start procedure.

Overchoking

Should the engine become ooded due to overchoking, turn the ignition switch o, unscrew the spark plug,

wipe it dry or replace.

Stopping the Engine

Set the engine to idling by releasing the throttle lever.

Set the ignition switch to the o position ‘’O’’ (STOP).

If the engine fails to stop, set the choke lever to the closed position to stall the engine; do not use the

machine until the ignition switch is repaired.

NOTE

Page 23

435 L/U Brushcutter

23

Original Instructions Version December 12

Using the Brush Cutter

Choosing the cutting device

Choose the most suitable cutting device for the job to be done, according to these general indications:

• The cutting line head can eliminate tall grass and non-woody vegetation

• The 3-point blade is suitable for cutting brushwood and small shrubs up to 2 cm in diameter.

Nylon Head

• Cut the grass in 1.5 metre widths, keeping the machine well balanced.

• Avoid engaging stones, piles of earth, small pieces of wood or anything that could be hidden or

dicult to see in the grass. If a large object is accidentally struck, if the cutting head gets blocked,

overloaded or stringy material gets wrapped in the cutting head, reduce the engine speed so the

engine idles. Make sure that the cutting head has stopped rotating switch o the engine and

remove the material.

• Put the brushcutter on the ground and check that the cutting head has not been damaged. If

necessary, change the cutting head. If the head is only wrapped by vegetation, remove by hand

and clean the cutting head.

• Always wear safety gloves for this operation and ensure the engine is switched o and the head is

stationary.

• When the 2 nylon cords become too short, accelerate the engine and bump the nylon head on the

ground. Automatically the 2 nylon cords will feed out and be cut to the correct length. Repeat the

operation if necessary.

3-Point Blade

• Start cutting above the undergrowth and then move down with the blade so as to cut the brush

into small pieces.

• Avoid hitting stones, piles of earth, small pieces of wood or anything that could be hidden or

dicult to see in the grass.

Page 24

435 L/U Brushcutter

24

Original Instructions Version December 12

Running In

During the rst ten hours of work, avoid running the engine at maximum speed for a prolonged period until all

the components have bedded in, after the engine has been run in, it will reach its maximum power.

Transportation

Never transport the brushcutter with the engine running. An engine that is running could be accidently

accelerated causing the blade to engage.

Make sure the blade safety guards are in place when transporting the brush cutter.

When carrying by hand, the cutting head should be pointing backwards.

Ensure the Brushcutter is secure when transporting in a vehicle and the tank is drained of fuel.

Page 25

435 L/U Brushcutter

25

Original Instructions Version December 12

Maintenance

IMPORTANT

After every use, check that all nuts, bolts and screws are securely fastened and tighten if necessary.

In the event of an accident, breakdown or blockage, ensure the engine is turned o before any work is

carried out to rectify this.

Make sure the engine has stopped and is cool before performing any service to the machine. Contact with a

moving cutting head or hot muer may result in a personal injury.

Fuel Filter

Every 15 hours of operation, using a wire hook, take the

fuel lter from the fuel tank and clean or replace with a

new fuel lter.

Oil Change

Running the engine with a low or high oil level will cause damage to the engine which will not be

covered by warranty.

An oil change should be performed after the rst 5 hours of operation, thereafter, change the oil after every

50 hours:

1. Drain the oil when the engine is warm.

2. Check the fuel ller cap is tightened.

3. Remove the cap/dipstick and drain the oil into a container and dispose of this at your local recycling

centre.

4. Fill with fresh 10w30 oil, insert and remove the oil ller cap/dipstick without screwing it into the oil ller

neck, remove it and check the oil level on the dipstick, ensure the oil is up to the full mark on the dipstick.

5. Ret the oil ller cap securely.

Page 26

435 L/U Brushcutter

26

Original Instructions Version December 12

Spark Plug

Poor starting or misring is often caused by a fouled or defective

spark plug, clean and reset the gap to 0.5 - 0.6mm, or replace the

spark plug with NGK: CMR6A as necessary.

Air Filter

Before using the brushcutter, check the air lter (a).

A clogged air lter will reduce the engine performance.

Remove the air lter cover by undoing the cover screw,

clean the lter element in warm, soapy water and

dry completely before installing. If the element is broken

or shrunk, replace with a new one.

Carburettor

The carburettor mixture setting has been set at the factory and will

not need adjusting.

Adjusting the idle speed. If adjustment is necessary turn the T screw

(b) clock wise until the blades start to move, then turn the screw T

anticlockwise until the blades stop.

If the idle speed cannot be adjusted to stop the cutting head

moving at idle, contact your dealer for repair before use.

Safety Lock

The safety lock is to prevent the throttle lever from accidentally

being engaged. The throttle lever (c) can only be pressed in if the

safety lock (d) is held down. Check if the safety lock and throttle

lever returns to its original position and the engine returns to idling

when you release your hand from the handle.

Any defects contact your nearest service agent for repairs

before using the machine.

(a)

STOP

(c)

(d)

(b)

u model

shown

Page 27

435 L/U Brushcutter

27

Original Instructions Version December 12

Storage

• Remove the spark plug, pour a small amount of oil into the cylinder. Rotate the crankshaft several

times using the starting rope in order to distribute the oil. Put the spark plug back in.

• Remove the fuel from the machine.

• Check the Brushcutter for damage or problems at the intervals shown in the service schedule.

Gear Case

• Remove the bolt (a) on the gear case, top up the gearbox using Lithium grease and ret the

bolt.

(a)

Page 28

435 L/U Brushcutter

28

Original Instructions Version December 12

Troubleshooting

Engine will not start, power loss:

• Check that the fuel tank is not empty. Fill with unleaded petrol.

• The fuel does not reach the carburettor. Change the fuel lter in the fuel tank.

• There is water in the fuel. Drain and clean the fuel system.

• The air lter is dirty. Clean or replace the air lter.

• There are carbon deposits in the exhaust muer restricting the engine. Clean or change the

muer.

• Spark plug is worn. Replace spark plug.

Page 29

435 L/U Brushcutter

29

Original Instructions Version December 12

Service Schedule

Component Procedure Before

use

Every 15

Hours

Every 25

Hours

Every 50

Hours

Note

Fuel / Oil

leaks / spillage

Wipe up

Fuel tank, lter Inspect /

clean

X

Replace if

necessary

Idle adjust

screw

See above

X X

Adjust

carburettor if

necessary

Spark plug

CMR6A

Clean and

readjust

plug gap

X

GAP .025”

(0.6-0.7mm)

Replace, if

necessary

Cylinder ns,

Intake air cooling vent

Clean

X

Throttle lever,

ignition switch,

safety lock

Check

operation X

Air lter Clean

X

Screws, nuts,

bolts

Tighten /

replace X

Not

adjustment

screws

Grease the gear

box

Check

X

Engine Oil Check

X

Every 5

hours

Engine Oil Change

X

Replace after

rst 5 hours

use

Page 30

435 L/U Brushcutter

30

Original Instructions Version December 12

Specications

MODEL MITOX 435L / 435U

Engine Type Air cooled 4-stroke overhead valve petrol engine

Model 139F-2

Displacement : ( cm3) 33.5 cc

Max. output 0.8 (kw) in accordance with ISO 8893

Idle speed: rpm (min –1) 2800±150

Max rpm 7800

Fuel tank capacity 0.65L

Engine oil capacity 90ml

Fuel Unleaded Petrol

Carburettor Diaphragm type

Spark Plug CMR6A

Transmission Centrifugal clutch, spur gear, cam-crank

Fixation hole diameter: (mm) 25.4

Dry Weight w/o harness & gasoline 7.06kg / 7.16kg

Overall size (LxWxH) 1800mmx380mmx250mm

Reduction ratio 22 :17

Cutting head Cutting

width

3 teeth

blade

255mm

Nylon

head

415mm

3 teeth blade thickness 2.92mm

Cutting line diameter 2.4mm

Max. blade rotation

speed:

7500 rpm (min –1)

Rotation direction Counter Clockwise(as seen from above)

Page 31

435 L/U Brushcutter

31

Original Instructions Version December 12

Page 32

435 L/U Brushcutter

32

Original Instructions Version December 12

CONDITIONS OF WARRANTY

The manufacturer warrants the product against faulty materials and workmanship for a period of 2 years from

the date of rst purchase. The warranty is applicable when the product is used in a “home owner” application.

If products are used for commercial or professional purposes, the warranty period is for 3 months from the

date of rst purchase. Warranty does not extend to failure due to fair wear and tear.

The manufacturer undertakes to replace, any spare parts that are classied as defective by an appointed

Mitox service dealer. The manufacturer will not accept liability for the replacement of the machine, either

partially or wholly, and /or consequential damages and /or interest charges either directly or indirectly.

Warranty does not cover failure due to:

Insucient maintenance.

Incorrect fuel mixture and stale fuel.

Abnormal use or accidental damage.

Incorrect assembly, adjustment or operation of the product.

Spare parts that are subject to wear e.g. safety parts, blades, blade supports, bearings, cables, guards,

deectors, spark plugs, air lters etc.

Neither does warranty extend to:

Freight and packing costs.

Use of non-genuine spare parts i.e. those from another manufacturer.

Use of the machine for any other purpose than that for which it was designed.

Use and maintenance of the machine in a manner not described in the owner’s manual.

As part of our policy of continuous product improvement, we reserve the right to alter or amend this

specication without notice. As a result, the product may dier from the information contained herein but

any alteration will only be implemented without notice if it is classied as an improvement to the above

specication.

READ THE MANUAL CAREFULLY BEFORE OPERATING THE MACHINE

When ordering spare parts, please quote the part number, this can be found in the parts list included in this

manual.

Retain the receipt of purchase without which no warranty can be oered.

Distributed by Mitox Garden Machinery

Wincanton Business Park

Wincanton

Somerset

BA9 9RS

Loading...

Loading...