MITEL MT8816AP, MT8816AC, MT8816AE, SA8281, SA8281MP1S Datasheet

...

The SA828 PWM generator has been designed to provide

waveforms for the control of variable speed AC machines,

uninterruptible power supplies and other forms of power

electronic devices which require pulse width modulation as a

means of efficient power control.

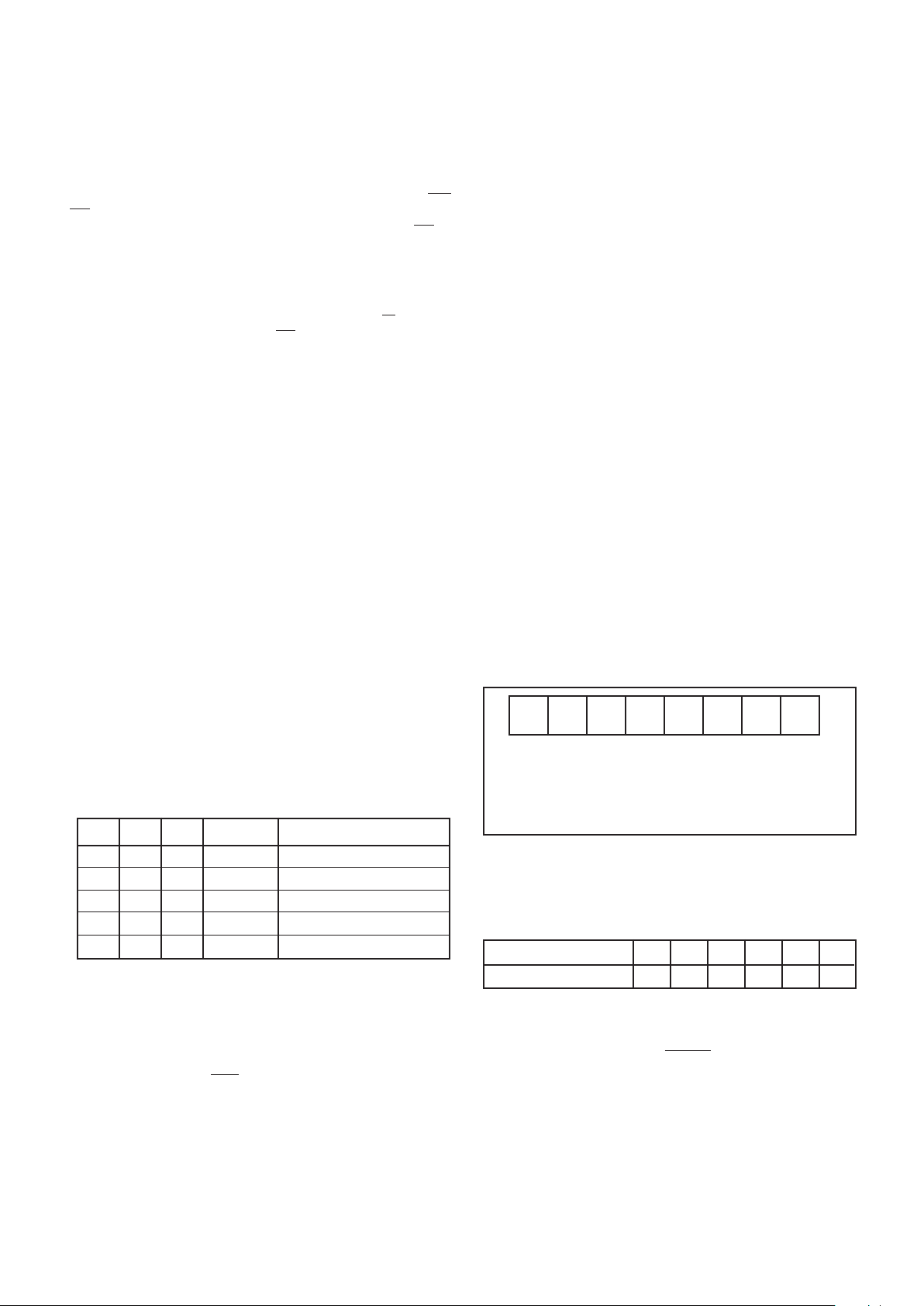

The six TTL level PWM outputs (Fig. 2) control the six

switches in a three-phase inverter bridge. This is usually via an

external isolation and amplification stage.

The SA828 is fabricated in CMOS for low power

consumption.

Information contained within the pulse width modulated

sequences controls the shape, power frequency, amplitude,

and rotational direction (as defined by the red-yellow-blue

phase sequence) of the output waveform. Parameters such as

the carrier frequency, minimum pulse width, and pulse delay

time may be defined during the initialisation of the device. The

pulse delay time (underlap) controls the delay between turning

on and off the two power switches in each output phase of the

inverter bridge, in order to accommodate variations in the turnon and turn-off times of families of power devices.

The SA828 is easily controlled by a microprocessor and its

fully-digital generation of PWM waveforms gives unprecedented

accuracy and temperature stability. Precision pulse shaping

capability allows optimum efficiency with any power circuitry.

The device operates as a stand-alone microprocessor

peripheral, reading the power waveform directly from an

internal ROM and requiring microprocessor intervention only

when operating parameters need to be changed.

An 8-bit multiplexed data bus is used to receive addresses and

data from the microprocessor/controller. This is a standard

MOTEL

TM

bus, compatible with most microprocessors/controllers.

Rotational frequency is defined to 12 bits for high accuracy

and a zero setting is included in order to implement DC

injection braking with no software overhead.

This family is pin and functionally compatible with the

MA828 PWM generator . Two standard wave shapes are

available to cover most applications. In addition, any

symmetrical wave shape can be integrated on-chip to order.

FEATURES

■ Fully Digital Operation

■ Interfaces with Most Microprocessors

■ Wide Power-Frequency Range

■ 12-Bit Speed Control Accuracy

■ Carrier Frequency Selectable up to 24kHz

■ Waveform Stored in Internal ROM

■ Double Edged Regular Sampling

■ Selectable Minimum Pulse Width and Underlap Time

■ DC Injection Braking

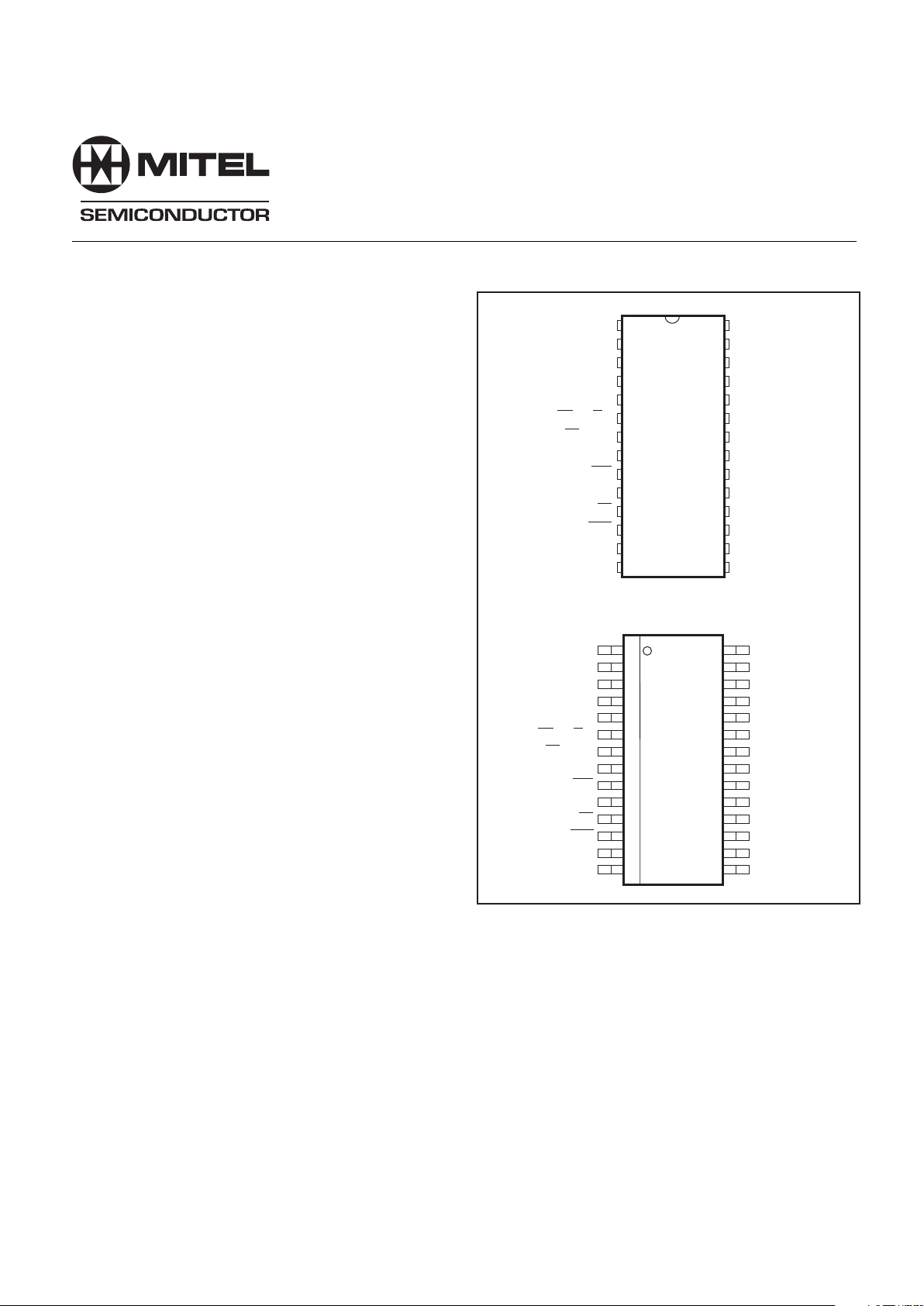

DP28

MP28

Fig. 1 Pin connections – top view (not to scale)

MOTEL is a registered Trademark of Intel Corp. and Motorola Corp.

AD

2

AD

1

AD

0

VDD

ZPPB

ZPPY

ZPPR

WSS

RPHT

SET TRIP

YPHT

BPHT

V

SS

BPHB

AD

3

AD

4

AD

5

AD

6

AD

7

WR* (R/W†)

RD* (DS†)

ALE* (AS†)

RST

CLK

CS

TRIP

RPHB

YPHB

* = Intel bus format

† = Motorola bus format

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

SA828

SA828

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

AD

2

AD

1

AD

0

VDD

ZPPB

ZPPY

ZPPR

WSS

RPHT

SET TRIP

YPHT

BPHT

V

SS

BPHB

AD

3

AD

4

AD

5

AD

6

AD

7

WR* (R/W†)

RD* (DS†)

ALE* (AS†)

RST

CLK

CS

TRIP

RPHB

YPHB

ORDERING INFORMATION

SA8281/IG/DP1S (28-lead DIL, sine + third harmonic

waveform)

SA8282/IG/DP1S (28-lead DIL, sine waveform)

SA8281/IG/MP1S (28-lead SOIC, Sine + third

harmonic waveform)

SA8382/IG/MP1S (28-lead SOIC, sine waveform)

SA828 Family

Three-Phase PWM Waveform Generator

DS4226 - 2.0 November 1996

SA828

2

>4·5

<0·2

<10

5·0

Input high voltage

Input low voltage

Input leakage current

Output high voltage

Output low voltage

Supply current (static)

Supply current (dynamic)

Supply voltage

V

IN

= VSS or V

DD

IOH = – 12mA

I

OL

= 12mA

All outputs open circuit

f

CLK

= 10MHz

V

IH

V

IL

I

IN

V

OH

V

OL

I

DD (static)

I

DD (dynamic)

V

DD

2

4·0

4·5

0·8

10

0·4

100

20

5·5

Typ. Max.Min.

Value

Characteristic Symbol

ConditionsUnits

ELECTRICAL CHARACTERISTICS

These characteristics are guaranteed over the following conditions (unless otherwise stated):

VDD = +5V ±5%, T

AMB

= +25°C

DC Characteristics

V

V

µA

V

V

µA

mA

V

-

2/f

CLK

2/f

CLK

Clock frequency

Clock duty cycle

SET TRIP = 1 → outputs tripped

→

TRIP = 0

M : S ratio = 1 : 1 ±20%

f

CLK

in MHz

f

CLK

in MHz

f

CLK

D

CLK

t

TRIP

12·5

60

3/f

CLK

3/f

CLK

MHz

%

µs

µs

NOTE 1. For microprocessor interface timings, see Intel and Motorola bus timings (Tables 1 and 2).

Conditions

Typ. Max.

Characteristic Symbol Units

Value

AC Characteristics

ABSOLUTE MAXIMUM RATINGS

Supply voltage, V

DD

Voltage on any pin

Current through any I/O pin

Storage temperature

Operating temperature range

Pin

No.

1

2

3

4

5

6

7

8

9

10

11

12

Name

AD

3

AD

4

AD

5

AD

6

AD

7

Intel: WR

Motorola: R/

W

Intel: RD

Motorola: DS

Intel: ALE

Motorola: AS

RST

CLK

CS

TRIP

Type

I

I

I

I

I

I

I

I

I

I

I

O

Function

Multiplexed Address/Data

Multiplexed Address/Data

Multiplexed Address/Data

Multiplexed Address/Data

Multiplexed Address/Data(MSB)

Intel bus control:

Write Strobe

Motorola bus control: Read/

Write

select

Intel bus control: Read Strobe

Motorola bus control: Data Strobe

Intel bus control: Address Latch

Enable

Motorola bus control: Address

Strobe

Reset internal counters, active low

Clock input

Chip Select input, active low

Output trip status; low = output tripped

Name

RPHB

YPHB

BPHB

V

SS

BPHT

YPHT

SET TRIP

RPHT

WSS

ZPPR

ZPPY

ZPPB

V

DD

AD

0

AD

1

AD

2

Pin

No.

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

Type

O

O

O

P

O

O

I

O

O

O

O

O

P

I

I

I

Function

Red Phase, Bottom power switch

Yellow Phase, Bottom power switch

Blue Phase, Bottom power switch

Negative power supply (0V)

Blue Phase, Top power switch

Yellow Phase, Top power switch

Set output trip. 120kΩ internal

pull-up resistor

Red Phase, Top power switch

Waveform Sampling Synchronisation

Zero Phase Pulse, Red phase

Zero Phase Pulse, Yellow phase

Zero Phase Pulse, Blue phase

Positive power supply

Multiplexed Address/Data (LSB)

Multiplexed Address/Data

Multiplexed Address/Data

PIN DESCRIPTIONS

The temperature ranges quoted apply to all package types.

Many package types are available and extended temperature

7V

V

SS

–0·3V to VDD +0·3V

±10mA

–65°C to +125°C

–40°C to +85°C

40

ranges can be offered for some. Further information is available

on request.

Stresses above those listed in the Absolute Maximum

Ratings may cause permanent damage to the device. These

are stress ratings only and functional operation of the device at

these conditions, or at any other condition above those indicated

in the operations section of this specification, is not implied.

Exposure to Absolute Maximum Rating conditions for extended

periods may affect device reliability.

3

SA828

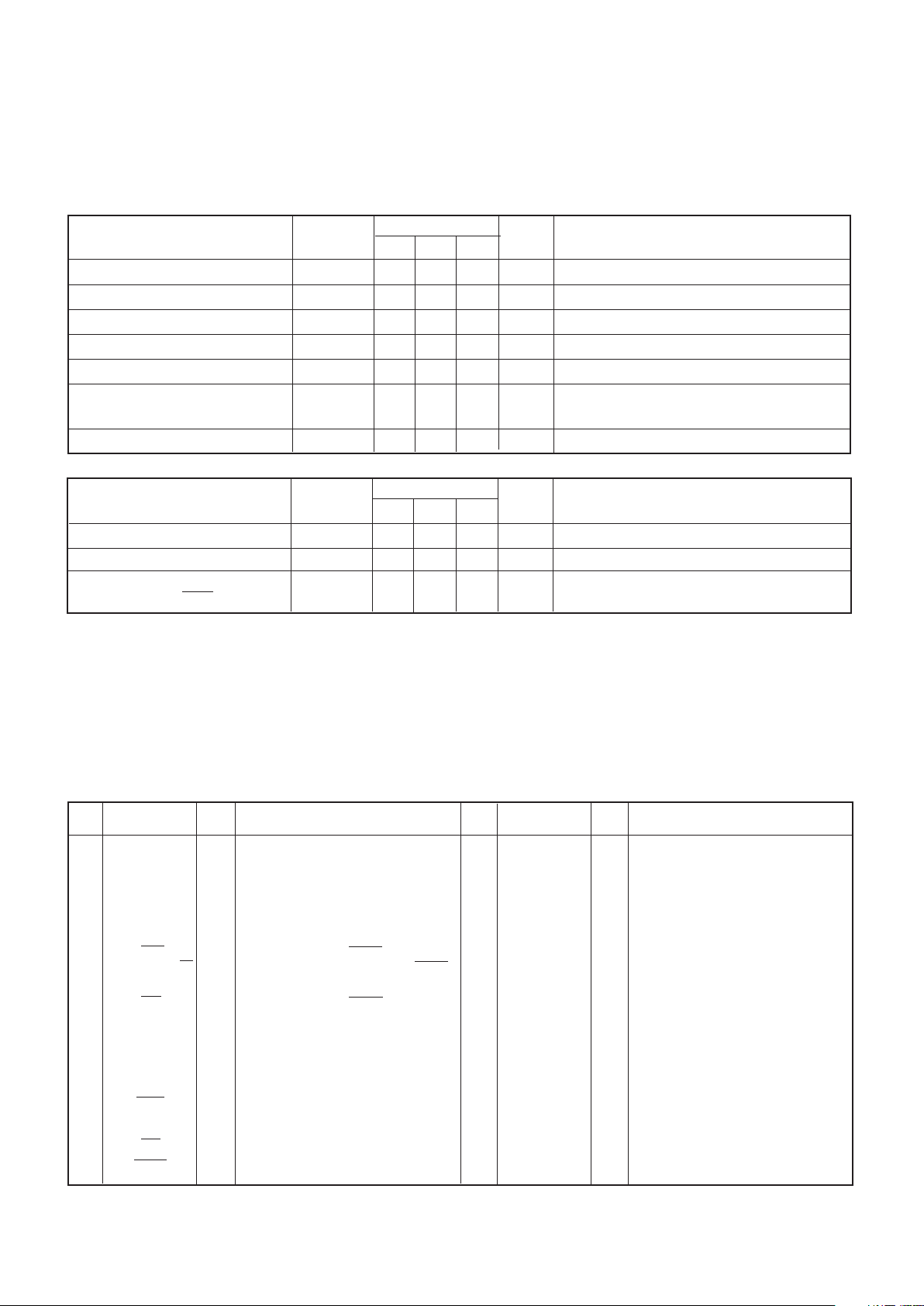

Fig. 2 SA828 internal block diagram

PULSE

DELETION

PULSE

DELAY

CIRCUIT

RPHT

RPHB

PULSE

DELETION

PULSE

DELAY

CIRCUIT

YPHT

YPHB

PULSE

DELETION

PULSE

DELAY

CIRCUIT

BPHT

BPHB

RED PHASE

YELLOW PHASE

BLUE PHASE

PHASING

AND

CONTROL

LOGIC

WAVEFORM

ROM

TRIP

LATCH

ADDRESS

GENERATOR

24-BIT

INITIALISATION

REGISTER

24-BIT

CONTROL

REGISTER

R0

R1

R2

R3

R4

BUS

DEMULTIPLEXER

BUS

CONTROL

CLOCK

DIVIDER

RST

MOTEL

INTERFACE

SYSTEM

BUS

AD

0

-AD

7

8

SET

TRIP

TRIP

CS

CLOCK

ZPP

O/Ps

WSS

FUNCTIONAL DESCRIPTION

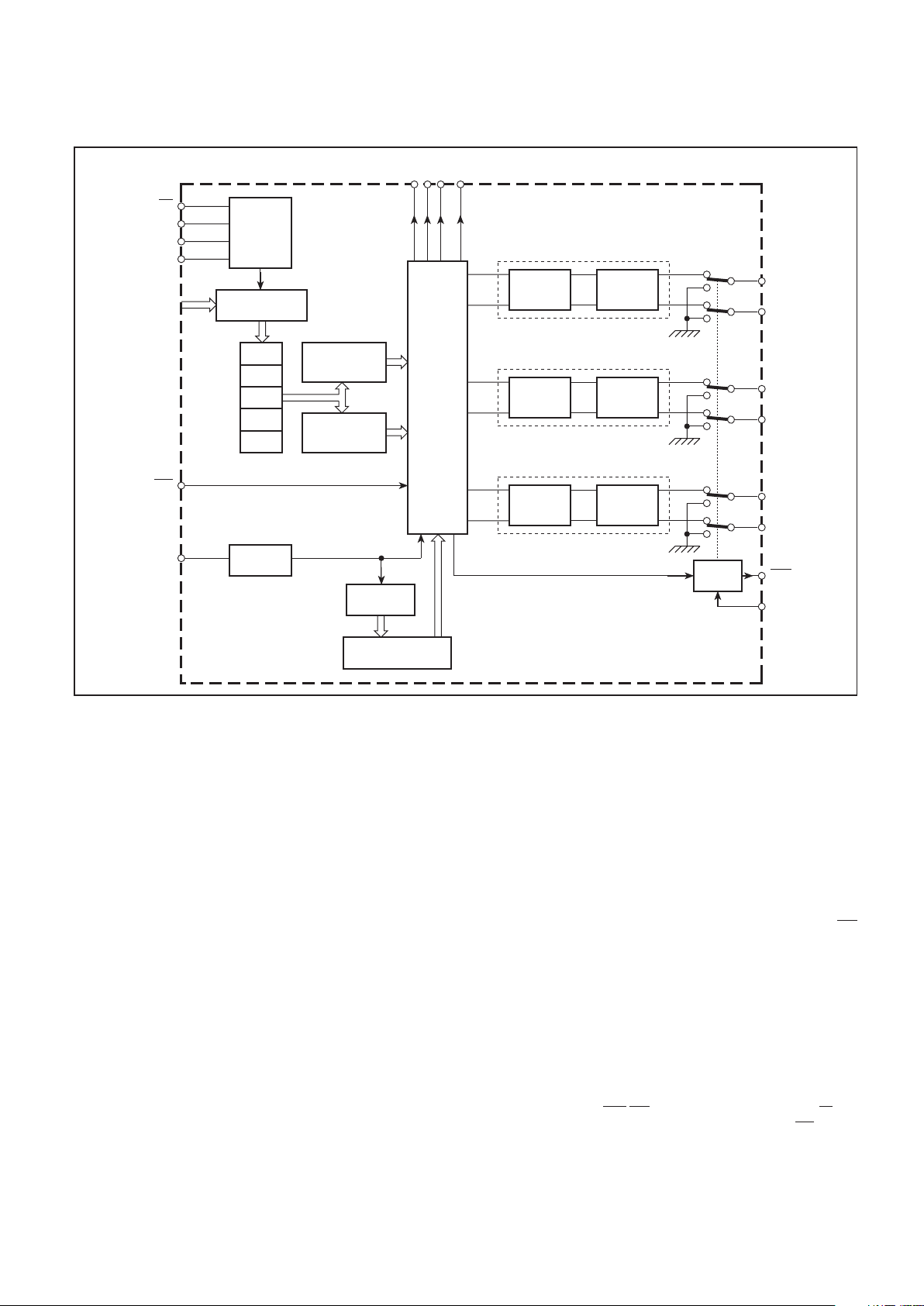

An asynchronous method of PWM generation is used with

uniform or ‘double-edged’ regular sampling of the waveform

stored in the internal ROM as illustrated in Fig. 3.

The triangle carrier wave frequency is selectable up to 24kHz

(assuming the maximum clock frequency of 12.5MHz is used),

enabling ultrasonic operation for noise critical applications. With

12.5MHz clock, power frequency ranges of up to 4kHz are

possible, with the actual output frequency resolved to 12-bit

accuracy within the chosen range in order to give precise motor

speed control and smooth frequency changing. The output phase

sequence of the PWM outputs can also be changed to allow both

forward and reverse motor operation.

PWM output pulses can be ‘tailored’ to the inverter

characteristics by defining the minimum allowable pulse width

(the SA828 will delete all shorter pulses from the ‘pure’ PWM pulse

train) and the pulse delay (underlap) time, without the need for

external circuitry. This gives cost advantages in both component

savings and in allowing the same PWM circuitry to be used for

control of a number of different motor drive circuits simply by

changing the microprocessor software.

Power frequency amplitude control is also provided with an

overmodulation option to assist in rapid motor braking. Alternatively,

braking may be implemented by setting the rotational speed to

0Hz. This is termed ‘DC injection braking’, in which the rotation of

the motor is opposed by allowing DC to flow in the windings.

A trip input allows the PWM outputs to be shut down immediately,

overriding the microprocessor control in the event of an emergency.

The Waveform Sampling Synchronisation (WSS) output may

be used in conjunction with the ZPP signals to provide feedback

of the actual rotational speed from the rotor. This is of particular

use in slip compensated systems.

Other possible SA828 applications are as a 3-phase waveform

generator as part of a switched-mode power supply (SMPS) or of

an uninterruptible power supply (UPS). In such applications the

high carrier frequency allows a very small switching transformer

to be used.

MICROPROCESSOR INTERFACE

The SA828 interfaces to the controlling microprocessor by

means of a multiplexed bus of the MOTEL format. This interface

bus has the ability to adapt itself automatically to the format and

timing of both MOTorola and IntEL interface buses (hence MOTEL).

Internally, the detection circuitry latches the status of the DS/

RD

line when AS/ALE goes high. If the result is high then the Intel

mode is used; if the result is low then the Motorola mode is used.

This procedure is carried out each time that AS/ALE goes high. In

practice this mode selection is transparent to the user. For bus

connection and timing information refer to the description relevant

to the microprocessor/controller being used.

Industry standard microprocessors such as the 8085, 8088,

etc. and microcontrollers such as the 8051, 8052 and 6805 are all

compatible with the interface on the SA828. This interface consists

of 8 data lines, AD

0

- AD7 (write-only in this instance), which are

multiplexed to carry both the address and data information, 3 bus

control lines, labelled

WR,RD and ALE in Intel mode and R/W, DS

and AS in Motorola mode, and a Chip Select input,

CS, which

allows the SA828 to share the same bus as other microprocessor

peripherals. It should be noted that all bus timings are derived from

the microprocessor and are independent of the SA828 clock

input.

SA828

4

Fig. 3 Asynchronous PWM generation with‘double-edged’ regular sampling as used by the SA828

t

1

ALE

t

4

t

3

t

2

t

8

t

10

t

11

t

9

t

12

RD

WR

AD

0

-AD

7

CS

LATCH ADDRESS LATCH DATA

t

15

t

4

t

3

t

8

t

10

t

11

t

9

t

12

DS

R/W

AD

0

-AD

7

CS

LATCH ADDRESS

LATCH DATA

t

1

AS

t

2

t

5

t

6

t

7

t

15

+1

– 1

+1

– 1

RESULTING

PWM

WAVEFORM

0

0

PWM SWITCHING

INSTANTS

TRIANGLE WAVE AT

CARRIER FREQUENCY,

SAMPLING ON +VE AND – VE PEAKS

POWER WAVEFORM

AS READ FROM

INTERNAL ROM

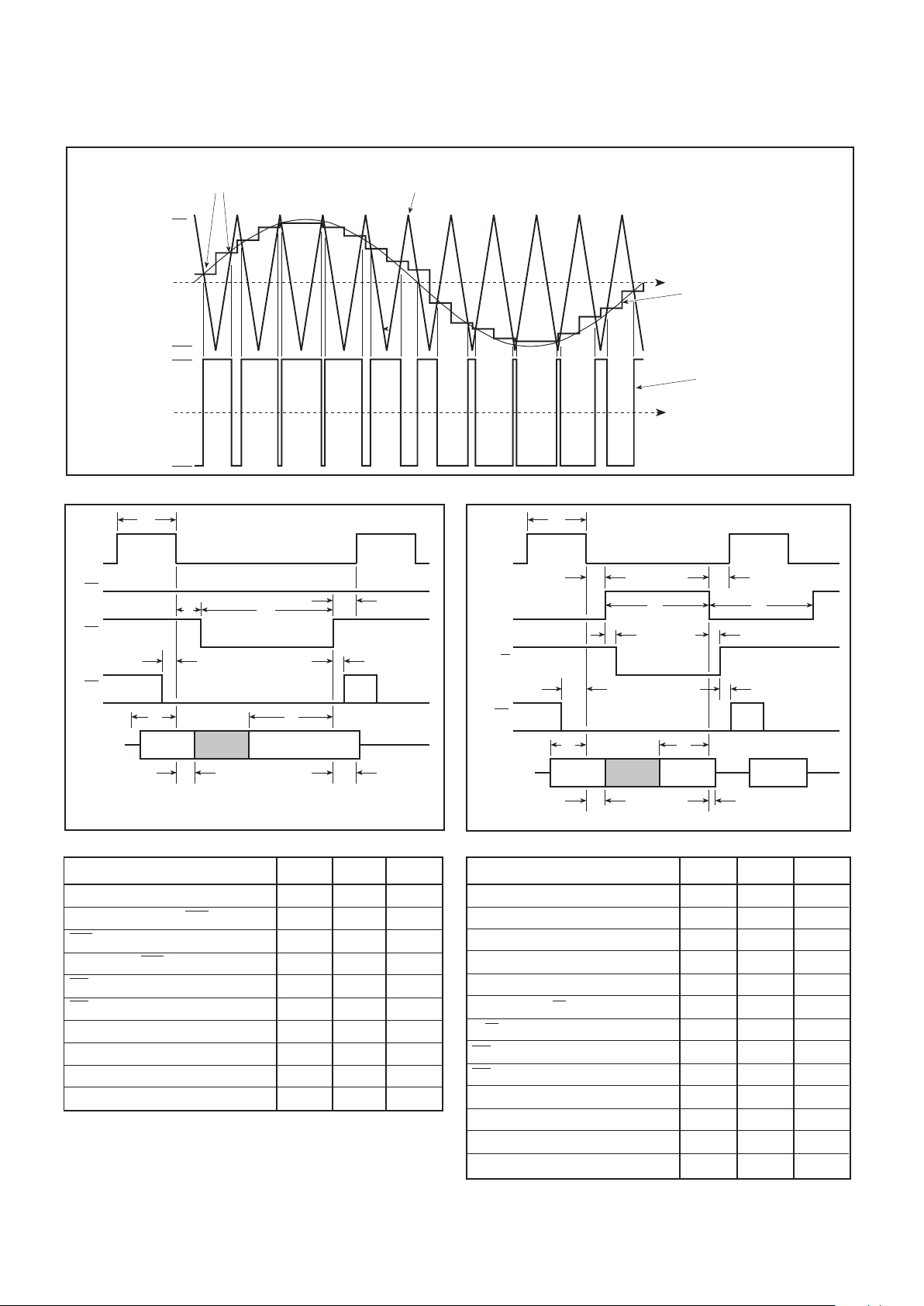

Fig. 5 Motorola bus timing definitions

Parameter

AS high period

Delay time, as low to DS high

DS high period

Delay time, DS low to AS high

DS low period

DS high to R/

W low setup time

R/W hold time

CS setup time

CS hold time

Address setup time

Address hold time

Write data setup time

Write data hold time

Symbol

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

15

t

11

t

12

Min.

90

40

210

40

200

10

10

20

0

30

30

110

30

Table 2 Motorola bus timings at VDD = 5V, T

AMB

= +25°C

Units

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

Fig. 4 Intel bus timing definitions

Parameter

ALE high period

Delay time, ALE to

WR

WR low period

Delay time,

WR high to ALE high

CS setup time

CS hold time

Address setup time

Address hold time

Data setup time

Data hold time

Symbol

t

1

t

2

t

3

t

4

t

8

t

9

t

10

t

15

t

11

t

12

Min.

70

40

200

40

20

0

30

30

100

25

Table 1 Intel bus timings at VDD = 5V, T

AMB

=

+

25°C

Units

ns

ns

ns

ns

ns

ns

ns

ns

ns

ns

5

SA828

Register

R0

R1

R2

R3

R4

Comment

Temporary register R0

Temporary register R1

Temporary register R2

Transfers control data

Transfers initialisation data

AD

1

0

0

1

1

0

Power frequency range

This sets the maximum power frequency that can be carried

within the PWM output waveforms. This would normally be set

to a value to prevent the motor system being operated outside

its design parameters.

Pulse delay time ('underlap')

For each phase of the PWM cycle there are two control

signals, one for the top switch connected to the positive

inverter DC supply and one for the bottom switch connected to

the negative inverter DC supply. In theory, the states of these

two switches are always complementary. However, due to the

finite and non-equal turn-on and turn- off times of power

devices, it is desirable when changing the state of the output

pair, to provide a short delay time during which both outputs

are off in order to avoid a short circuit through the switching

elements.

Pulse deletion time

A pure PWM sequence produces pulses which can vary in

width between 0% and 100% of the duty cycle. Therefore, in

theory, pulse widths can become infinitesimally narrow. In

practice this causes problems in the power switches due to

storage effects and therefore a minimum pulse width time is

required. All pulses shorter than the minimum specified are

deleted.

Counter reset

This facility allows the internal power frequency counter of

the SA828 to be set to zero, disabling the normal frequency

control and giving a 50% output duty cycle.

Initialisation Register Programming

The initialisation register data is loaded in 8-bit segments into

the three 8-bit temporary registers R0-R2. When all the initialisation

data has been loaded into these registers it is transferred into the

24-bit initialisation register by writing to the dummy register R4.

AD

2

0

0

0

0

1

AD

0

0

1

0

1

0

Table 3 SA828 register addressing

Initialisation Register Function

The 24-bit initialisation register contains parameters which,

under normal operation, will be defined during the power-up

sequence. These parameters are particular to the drive circuitry

used, and therefore changing these parameters during a PWM

cycle is not recommended. Information in this register should

only be modified while

RST is active (i.e. low) so that the PWM

outputs are inhibited (low) during the updating process.

The parameters set in the initialisation register are as follows:

Carrier frequency

Low carrier frequencies reduce switching losses whereas

high carrier frequencies increase waveform resolution and can

allow ultrasonic operation.

Carrier frequency selection

The carrier frequency is a function of the externally applied

clock frequency and a division ratio

n

, determined by the 3-bit

CFS word set during initialisation. The values of

n

are selected

as shown in Table 4.

The carrier frequency,

f

CARR

,

is then given by:

CFS word

Value of n

000

1

001

2

010

4

011

8

100

16

101

32

Table 4 Values of clock division ratio n

FRS2FRS1FRS0X X CFS2CFS2CFS

2

FREQUENCY

RANGE

SELECT WORD

FRS

2

= MSB

FRS0 = LSB

DON’T

CARE

CARRIER

FREQUENCY

SELECT WORD

CFS

2

= MSB

CFS0 = LSB

Fig. 6 Temporary register R1

where k = clock frequency and n = 1, 2, 4, 8, 16 or 32 (as set

by CFS)

Power frequency range selection

The power frequency range selected here defines the maximum

limit of the power frequency. The operating power frequency is

controlled by the 12-bit Power Frequency Select (PFS) word in

the control register but may not exceed the value set here.

k

512 x

n

f

CARR

=

MICROPROCESSOR BUS TIMING

Intel Mode (Fig. 4 and Table 1)

The address is latched by the falling edge of ALE. Data is

written from the bus into the SA828 on the rising edge of

WR.

RD is not used in this mode because the registers in the SA828

are write only. However, this pin must be connected to RD (or

tied high) to enable the SA828 to select the correct interface

format.

Motorola Mode (Fig. 5 and Table 2)

The address is latched on the falling edge of the AS line. Data

is written from the bus into the SA828 (only when R/

W is low) on

the falling edge of DS (providing

CS is low).

CONTROLLING THE SA828

The SA828 is controlled by loading data into two 24-bit

registers via the microprocessor interface. These registers are

the initialisation register and the control register.

The initialisation register would normally be loaded before

motor operation (i.e., prior to the PWM outputs being activated)

and sets up the basic operating parameters associated with the

motor and inverter. This data would not normally be updated

during motor operation.

The control register is used to control the PWM outputs (and

hence the motor) during operation e.g., stop/start, speed,

forward/reverse etc. and would normally be loaded and changed

only after the initialisation register has been loaded.

As the MOTEL bus interface is restricted to an 8-bit wide

format, data to be loaded into either of the 24-bit registers is first

written to three 8-bit temporary registers R0, R1 and R2 before

being transferred to the desired 24-bit register. The data is

accepted (and acted upon) only when transferred to one of the

24-bit registers.

Transfer of data from the temporary registers to either the

initialisation register or the control register is achieved by a write

instruction to a dummy register. Writing to dummy register R3

results in data transfer from R0, R1 and R2 to the control

register, while writing to dummy register R4 transfers data from

R0, R1 and R2 to the initialisation register. It does not matter

what data is written to the dummy registers R3 and R4 as they

are not real registers. It is merely the write instruction to either

of these registers which is acted upon in order to load the

initialisation and control registers.

Loading...

Loading...