MITEL MT8812AP, MT8812AC, MT8812AE, SP5659MP1T Datasheet

The SP5659 is a single chip frequency synthesiser designed

for tuning systems up to 2·7GHz.

The RF preamplifier drives a divide-by two prescaler which

can be disabled for applications up to 2GHz, allowing direct

interfacing with the programmable divider, resulting in a step

size equal to the comparison frequency. For applications up

to 2·7GHz the divide-by two is enabled to give a step size of

twice the comparison frequency.

The comparison frequency is obtained either from an onchip crystal controlled oscillator or from an external source.

The oscillator frequency F

REF

or the comparison frequency

F

COMP

may be switched to the REF/COMP output; this feature

is ideally suited to providing the reference frequency for a

second synthesiser such as in a double conversion tuner (see

Fig. 5).

The synthesiser is controlled via an I

2

C bus and responds

to one of four programmable addresses which are selected by

applying a specific voltage to the Address input. This feature

enables two or more synthesisers to be used in a system.

The SP5659 contains four switching ports, P0-P3 and a

5-level ADC, the output of which can be read via the I

2

C bus.

The SP5659 also contains a varactor line disable and

charge pump disable facility.

FEATURES

■ Complete 2·7GHz Single Chip System

■ Optimised for Low Phase Noise

■ Selectable 42 prescaler

■ Selectable Reference Division Ratio

■

Selectable Reference/Comparison Frequency Output

■ Selectable Charge Pump Current

■ Varactor Drive Amplifier Disable

■ 5-Level ADC

■ Variable I

2

C BUS Address for Multi-tuner Applications

SP5659

2·7GHz I2C Bus Low Phase Noise Synthesiser

Preliminary Information

Supersedes March 1996 version, DS4206-1.8 DS4296 - 2.0 June 1998

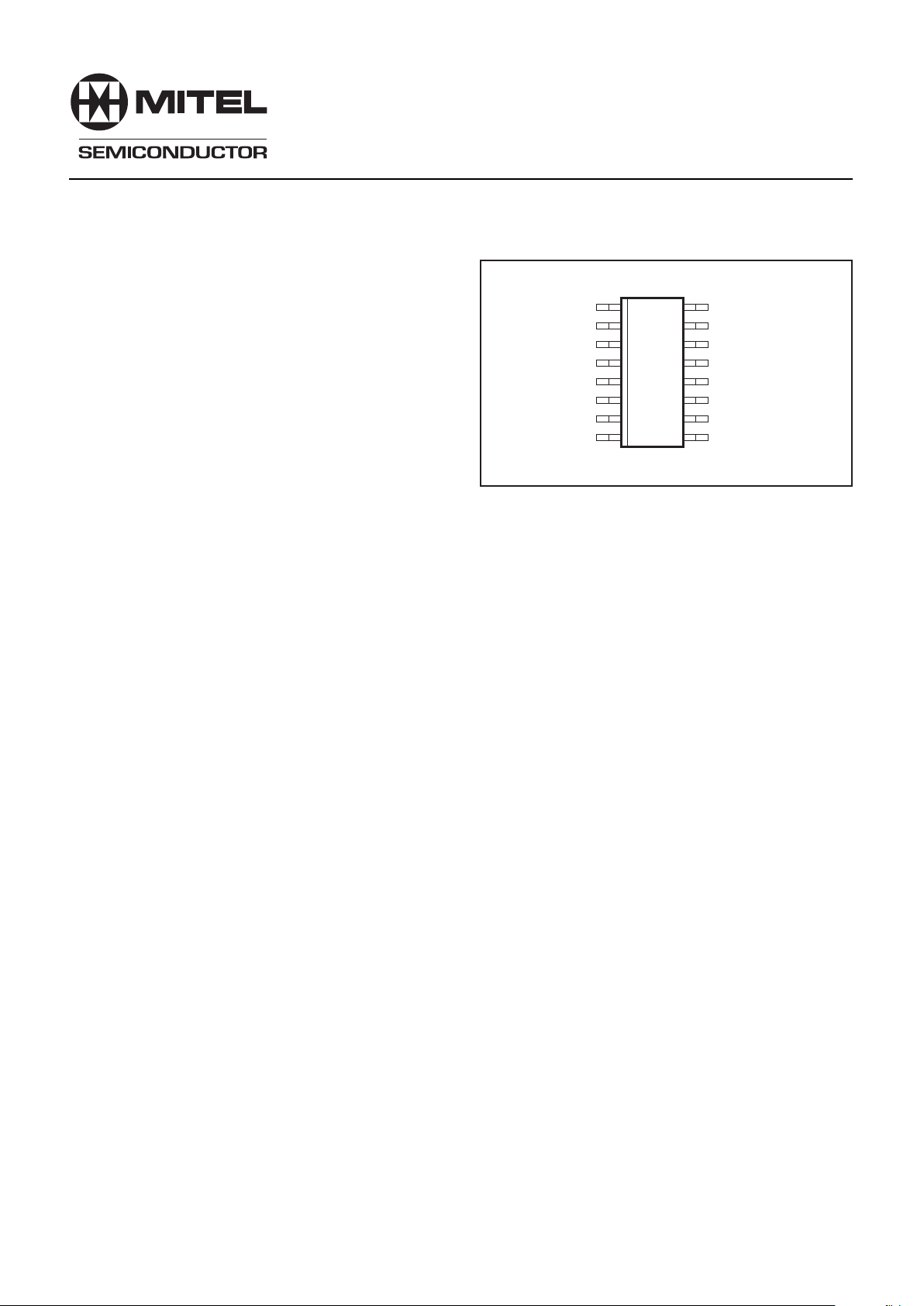

SP5659

1

2

3

4

5

6

7

8

MP16

16

15

14

13

12

11

10

9

CHARGE PUMP

CRYSTAL

REF/COMP

ADDRESS

SDA

SCL

PORT P3

PORT P2

DRIVE

V

EE

RF INPUT

RF INPUT

V

CC

ADC

PORT P0

PORT P1

Fig. 1 Pin connections – top view

■ ESD Protection: 4kV, Mil-Std-883C, Method 3015

(1)

■ Pin Compatible with SP5658

(1) Normal ESD handling precautions should be observed.

APPLICATIONS

■ Satellite TV

■ High IF Cable Tuning Systems

THERMAL DATA

u

JC

= 41°C/W

u

JA

= 111°C/W

ORDERING INFORMATION

SP5659 KG/MP1S (Tubes)

SP5659 KG/MP1T (Tape and reel)

2

SP5659

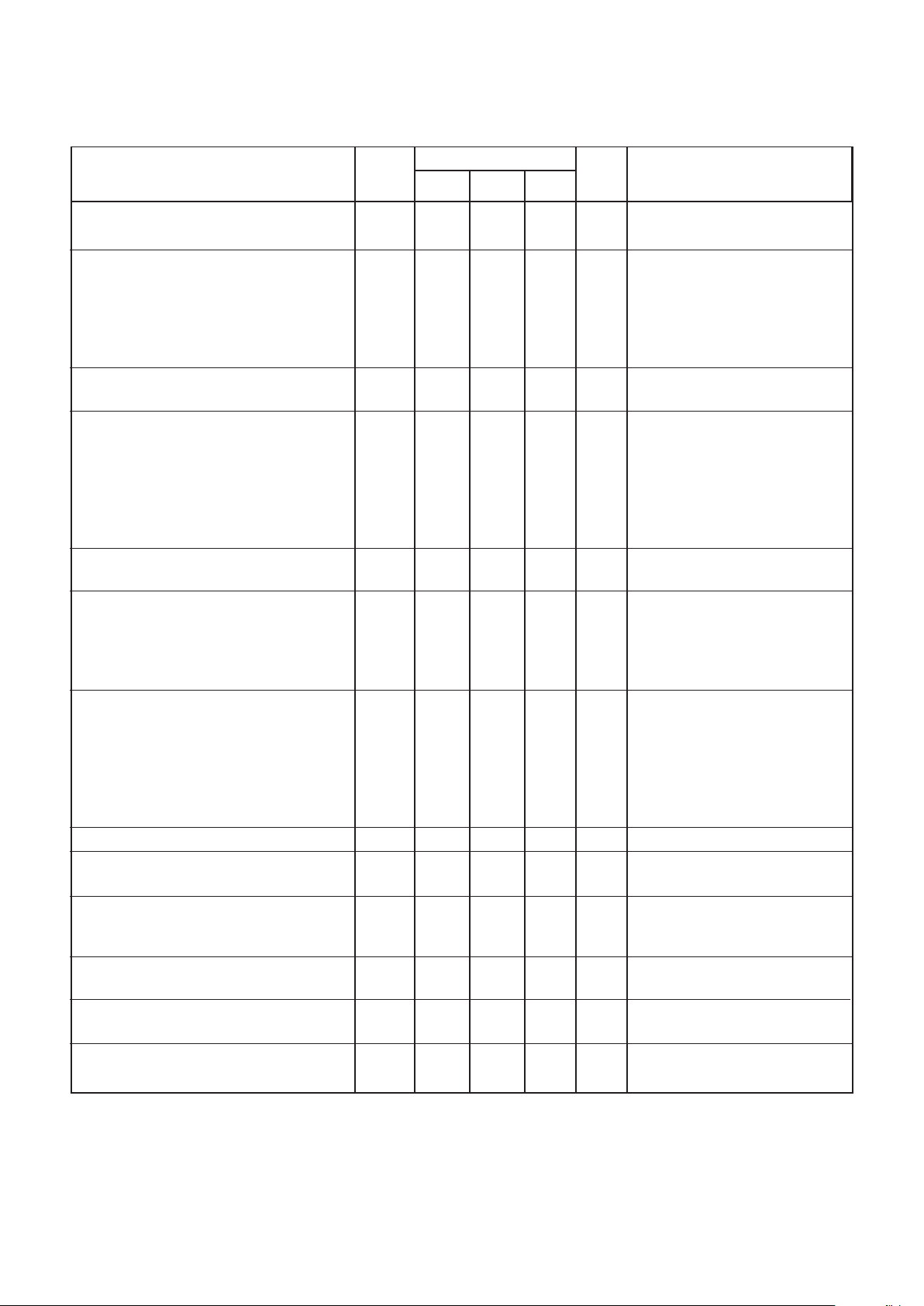

ELECTRICAL CHARACTERISTICS

T

AMB

= 220°C to 180°C, V

CC

= 14·5V to 15·5V, reference frequency = 4MHz.

These Characteristics are guaranteed by either production test or design. They apply within the specified ambient temperature

and supply voltage ranges unless otherwise stated.

Supply current, I

CC

RF input voltage

RF input impedance

RF input capacitance

SDA, SCL

Input high voltage

Input low voltage

Input high current

Input low current

Leakage current

Input hysteresis

SDA

Output voltage

Charge Pump

Output current

Output leakage current

Drive output current

Drive saturation voltage

External reference input frequency

External reference input amplitude

Crystal frequency

Crystal oscillator drive level

Recommended crystal series resistance

Crystal oscillator negative resistance

REF/COMP output voltage, enabled

Comparison frequency

Equivalent phase noise at phase detector

RF division ratio

Reference division ratio

P0, P1, P2, P3 sink current

P0, P1, P2, P3 leakage current

ADC input voltage

ADC input current

Address input current high

Address input current low

Typ.

Value

12

13,14

13,14

13,14

5, 6

5, 6

5, 6

5, 6

5, 6

5, 6

5

1

1

16

16

2

2

2

2

2

3

7,8,9,10

11

11

4

4

50

3

0

1

2

200

4

35

10

400

240

480

10

68

58

50

2

0·8

63

350

2142

85

73

300

5·5

1·5

10

210

10

0·4

610

350

200

20

500

16

200

2

131071

262142

10

610

1

20·5

Min. Max.

mA

mA

mVrms

mVrms

mVrms

Ω

pF

V

V

µA

µA

µA

V

V

nA

mA

mV

MHz

mVp-p

MHz

mVp-p

Ω

Ω

mVp-p

MHz

dBC/Hz

mA

µA

µA

mA

mA

V

CC

= 5V, PE = 1 (note 1)

V

CC

= 5V, PE = 0

300MHz to 2·7GHz, PE = 1

(prescaler enabled) see Fig. 4b

100MHz, PE = 1 (prescaler

enabled) see Fig. 4b

100MHz to 2·0GHz, PE = 0

(prescaler disabled) see Fig. 4b

See Fig. 10

See Fig. 10

Input voltage = V

CC

Input voltage = V

EE

VCC = V

EE

Sink current = 3mA

Drive output disabled

AC coupled sinewave

AC coupled sinewave

Parallel resonant crystal (note 2)

Includes temperature and process

tolerances

AC coupled, RE = 1, see note 3

See note 4

Prescaler disabled, see Table 1

Prescaler enabled, see Table 1

See Table 1

V

PORT

= 0·7V

V

PORT

= 13·2V

See Fig. 3 Table 5

V

CC >VINPUT >VEE

Input voltage = V

CC

Input voltage = V

EE

Characteristic Pin Units Conditions

NOTES

1. Maximum power consumption is 468mW with V

CC

= 5·5V and all ports off.

2. Resistance specified is maximum under all conditions including start up.

3. If the REF/COMP output is not used, it should be left open circuit or connected to V

CC

and disabled by setting RE to logic 0.

4. 6kHz loop bandwidth, phase comparator frequency 250kHZ. Figure measured at 1kHz offset DSB (within loop bandwidth).

3

SP5659

Supply voltage

RF input voltage

RF input DC offset

Port voltage

Total port current

ADC input DC offset

REF/COMP output DC offset

Charge pump DC offset

Drive DC offset

Crystal oscillator DC offset

Address DC offset

SDA, SCL input voltage

Storage temperature

Junction temperature

Port in off state

Port in on state

12

13,14

13, 14

7-10

7-10

7-10

11

3

1

16

2

4

5, 6

ABSOLUTE MAXIMUM RATINGS

All voltages are referred to VEE at 0V

Max.Min.

7

2·5

V

CC

10·3

14

6

50

V

CC

10·3

VCC10·3

V

CC

10·3

V

CC

10·3

VCC10·3

V

CC

10·3

6

1150

1150

Value

20·3

20·3

20·3

20·3

20·3

20·3

20·3

20·3

20·3

20·3

255

V

V p-p

V

V

V

mA

V

V

V

V

V

V

V

°C

°C

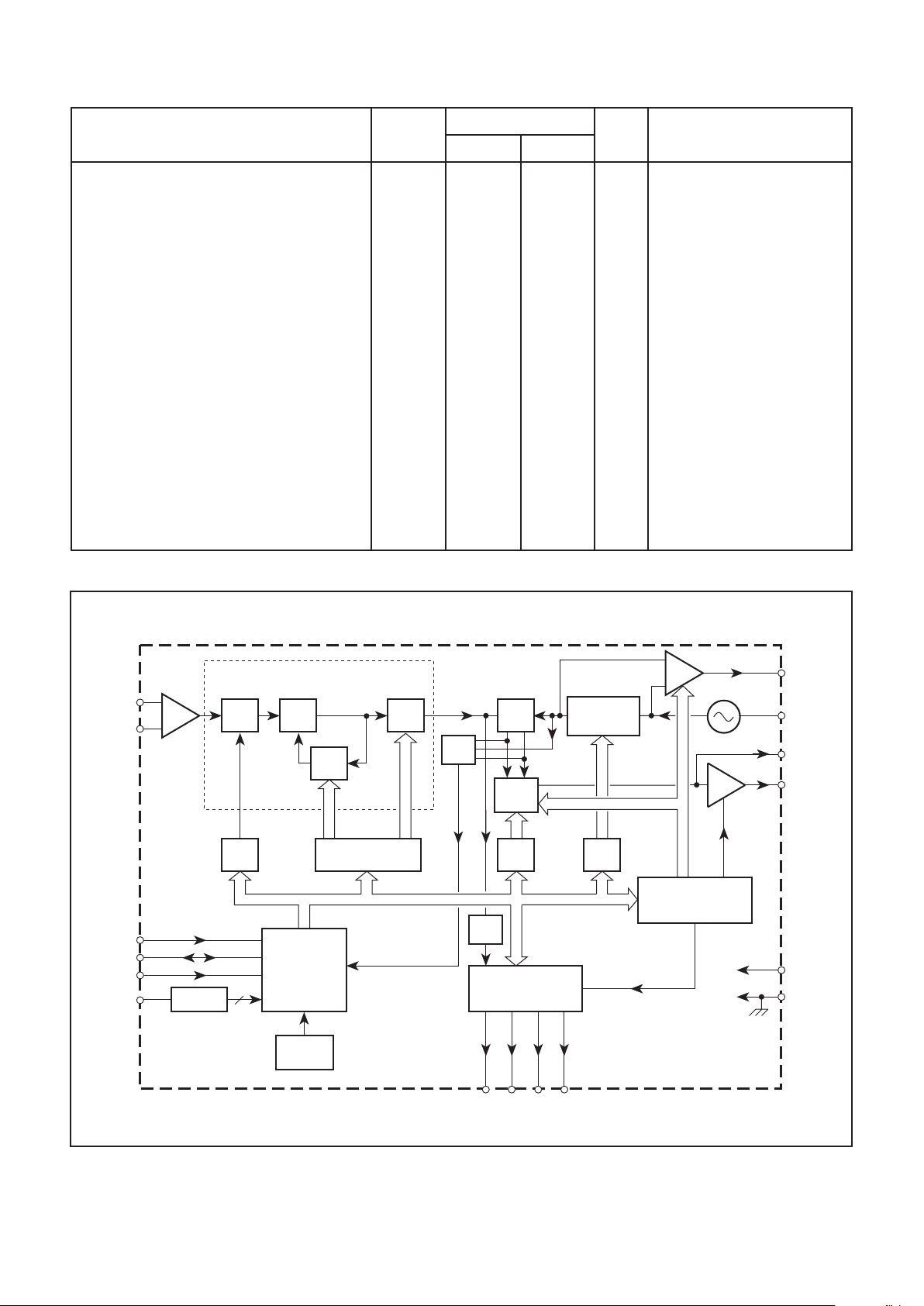

Fig. 2 Block diagram

RF IN

ADDRESS

SDA

LOCK

DET

42/1

13

14

4

5

F

COMP

CHARGE

PUMP

CRYSTAL

2

OSC

789

10

P3 P2 P1 P0

F

PD

416/17

4-BIT

COUNT

13-BIT

COUNT

PROGRAMMABLE DIVIDER

PREAMP

17-BIT LATCH

DIVIDE RATIO

1-BIT

COUNT

PE

PHASE

COMP

I2C

TRANSCEIVER

SCL

6

CHARGE

PUMP

2-BIT

LATCH

FPD/2

3-BIT ADC

ADC

11

3

POWER ON

DETECT

4-BIT LATCH

AND

PORT INTERFACE

REFERENCE

DIVIDER

(SEE TABLE 1)

REF/COMP

3

2-BIT

LATCH

V

CC

V

EE

15

C1, C0

F

L

F

REF

5-BIT LATCH AND

MODE CONTROL LOGIC

(SEE TABLE 6)

DISABLE

DRIVE

16

1

MODE

CONTROL

P0 TEST

CONTROL

12

Parameter Pin Units Conditions

4

SP5659

FUNCTIONAL DESCRIPTION

The SP5659 contains all the elements necessary – with

the exception of a frequency reference, loop filter and external

high voltage transistor – to control a varactor tuned local

oscillator, so forming a complete PLL frequency synthesised

source. The device allows for operation with a high comparison

frequency and is fabricated in high speed logic which enables

the generation of a loop with good phase noise performance.

The block diagram is shown in Fig. 2.

The RF input signal is fed to an internal preamplifier, which

provides gain and reverse isolation from the divider signals.

The output of the preamplifier interfaces with a 17-bit fully

programmable divider via a 42 prescaler. For applications up

to 2·0GHz RF input, the prescaler can be disabled, so

eliminating the degradation in phase noise due to prescaler

action. The divider is of MN1A architecture, where N = 16 or

17, the M counter is 13 bits and the A counter is 4 bits.

The output of the programmable divider, F

PD

, is fed to the

phase comparator where it is compared in phase and frequency

domains with the comparison frequency F

COMP

. This frequency

is derived either from the on-chip crystal controlled oscillator

or from an external reference source. In either case, the

reference frequency F

REF

is divided down to the comparison

frequency by the reference divider, which is programmable to

one of 15 ratios as detailed in Table 1.

The output of the phase detector feeds a charge pump and

loop amplifier section which, when used with an external high

voltage transistor and loop filter, integrates the current pulses

into the varactor line voltage. By invoking the device test

modes as described in Fig. 3, Table 6, the varactor drive

output can be disabled, so switching the external transistor

off. This allows an external voltage to be applied to the

varactor line for tuner alignment purposes. Similarly, the

charge can also be disabled to a high impedance state.

The programmable divider output F

PD

/2 can be switched to

port P0 by programming the device into test mode as set out

in Table 6.

PROGRAMMING

The SP5659 is controlled by an I2C Bus. Data and Clock

are fed in on the SDA and SCL lines respectively, as defined

by the I

2

C Bus format. The synthesiser can either accept new

data (write mode) or send data (read mode). The LSB of the

address byte (R/W) sets the device into write mode if it is low

and read mode if it is high. Tables 1 and 2 in Fig. 3 illustrate

the format of the data. The device can be programmed to

respond to several addresses, which enables the use of more

than one synthesiser in an I

2

C Bus system. Table 4 in Fig. 3

shows how the address is selected by applying a voltage to

the address input.

When the device receives a valid address byte, it pulls the

SDA line low during the acknowledge period, and during

following acknowledge periods after further data bytes are

programmed. When the device is programmed into the read

mode, the controller accepting the data must pull the SDA line

low during all status byte acknowledge periods to read another status byte. If the controller fails to pull the SDA line low

during this period, the device generates an internal STOP

condition, which inhibits further reading.

WRITE Mode (Frequency Synthesis)

With reference to Table 2, bytes 2 and 3 contain frequency

information bits 214 to 20 inclusive. Auxiliary frequency bits 2

16

and 215 are in byte 4. For most frequencies, only bytes 2 and

3 will be required. The remainder of byte 4 and byte 5 control

the prescaler enable, reference divider ratio (see Fig. 3),

output ports and test modes (see Table 6).

After reception and acknowledgment of a valid address

(byte 1), the first bit of the following byte determines whether

the byte is interpreted as byte 2 (logic ‘0’) or byte 4 (logic ‘1’);

the next data byte is then interpreted as byte 3 or byte 5,

respectively. After two complete data bytes have been received, additional data bytes can be entered, where byte

interpretation follows the same procedure without readdressing the device. This procedure continues until a STOP condition is received. The STOP condition can be generated after

any data byte; if, however, it occurs during a byte transmission then the previous data is retained.

To facilitate smooth fine tuning, the frequency data bytes are

only accepted by the device after all 17 bits of the data have

been received or after the generation of a STOP condition.

Repeatedly sending bytes 2 and 3 only will not change the

frequency. A frequency change when one of the following

data sequences is sent to an addressed device:

Bytes 2, 3, 4, 5

Bytes 4, 5, 2, 3

or when a STOP condition follows valid data bytes thus:

Bytes 2, 3, 4, STOP

Bytes 4, 5, 2, STOP

Bytes 2, 3, STOP

Bytes 2, STOP

Bytes 4, STOP

It should be noted that the SP5569 must be addressed

initially with both frequency AND control byte data, since the

control byte contains reference divider information which

must be provided before a chosen frequency can be synthesised. This implies that after initial turn on, bytes 2, 3 and 4

must be sent followed by a STOP condition as a minimum

requirement. Alternatively, bytes 2, 3, 4 and 5 must be sent if

port information is also required.

READ Mode

When the device is in read mode the status byte read from

the device on the SDA line takes the form shown in Fig. 3,

Table 3.

Bit 1 (POR) is the power-on reset indicator and is set to a

logic ‘1’ if the V

CC

supply to the device has dropped below 3V

(at 25˚C), for example, when the device is initially turned on.

R2

0

0

0

0

1

1

1

1

0

0

0

0

1

1

1

1

R3

0

0

0

0

0

0

0

0

1

1

1

1

1

1

1

1

R1

0

0

1

1

0

0

1

1

0

0

1

1

0

0

1

1

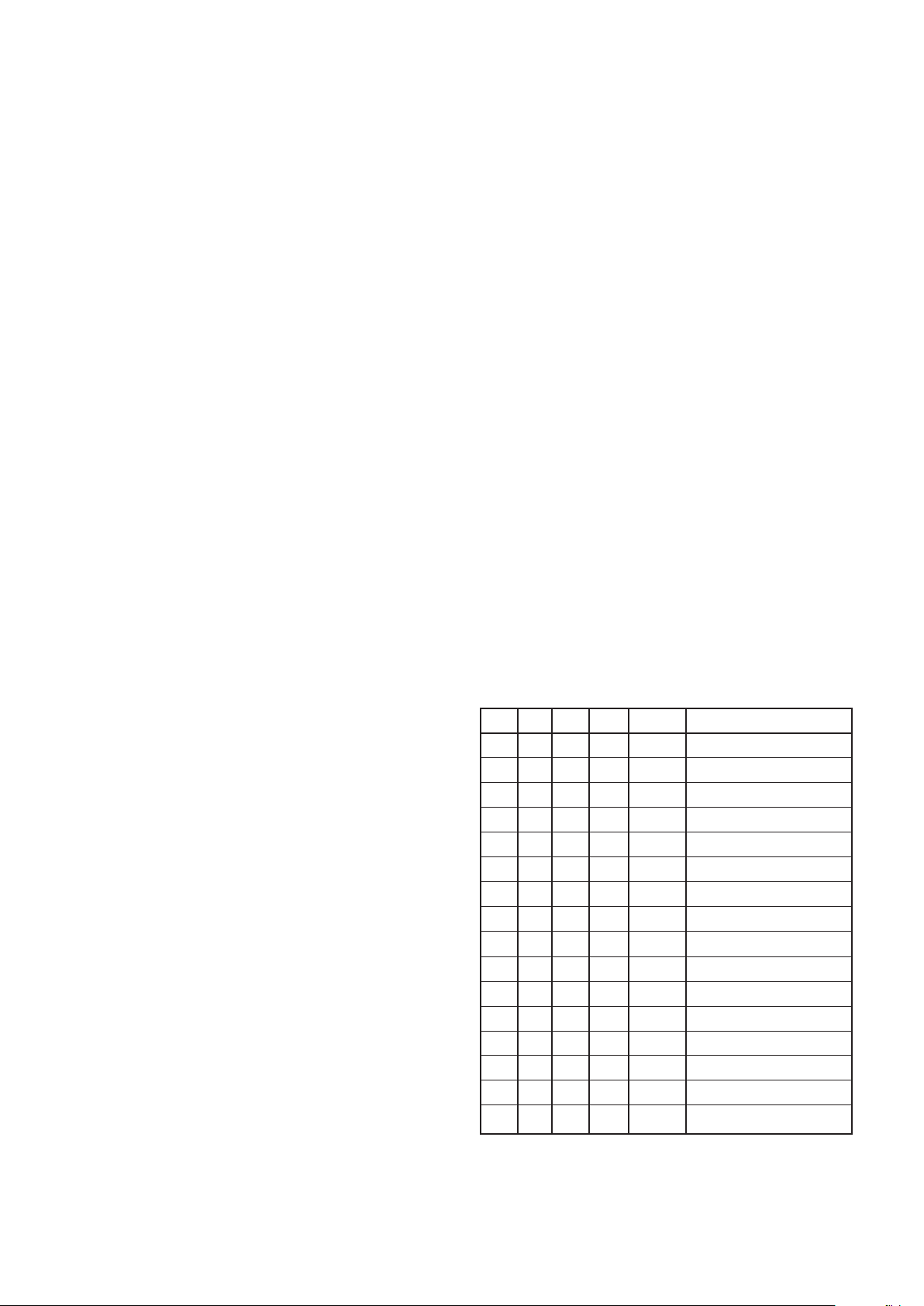

Comparison frequency

2MHz

1MHz

500kHz

250kHz

125kHz

62·5kHz

31·25kHz

15·625kHz

800kHz

400kHz

200kHz

100kHz

50kHz

25kHz

12·5kHz

R0

0

1

0

1

0

1

0

1

0

1

0

1

0

1

0

1

Ratio

2

4

8

16

32

64

128

256

Invalid

5

10

20

40

80

160

320

Table 1 Reference division ratios (4MHz external reference)

Loading...

Loading...