Page 1

Mul-ti Mode

www.ponpe.com

Ultrasonic Thickness

Gauge

MT660

User’s Manual

MITECH CO., LTD.

www.mitech-ndt.com

Page 2

mvip@mitech-ndt.com

CONTENTS

sale@ponpe.com

1 Overview...................................................................................................................................................... 4

1.1 Product Features............................................................................................................................... 4

1.2 Measuring Principle...........................................................................................................................4

1.3 Specifications..................................................................................................................................... 4

1.4 Transducer Technical Parameters..................................................................................................5

1.5 Configuration...................................................................................................................................... 6

1.6 Operating Conditions........................................................................................................................ 6

2 Structure Feature.......................................................................................................................................6

2.1 Main Screen....................................................................................................................................... 7

2.2 Keypad Definitions............................................................................................................................ 7

3 Test Preparation.........................................................................................................................................8

3.1 Transducer Selection........................................................................................................................ 8

3.2 Condition and Preparation of Surfaces..........................................................................................9

4 Startup.......................................................................................................................................................... 9

4.1 Power Supply..................................................................................................................................... 9

4.2 Connecting the Probe.....................................................................................................................10

4.3 Starting the Instrument................................................................................................................... 10

4.4 Configuration of the Standby Settings.........................................................................................10

5 Operations.................................................................................................................................................11

5.1 Setting the Work Mode................................................................................................................... 11

5.2 Probe Selection................................................................................................................................11

5.3 Perform Probe Zero........................................................................................................................ 11

5.4 Sound Velocity Calibration.............................................................................................................12

5.5 Making Measurements................................................................................................................... 13

5.6 View Mode Setting.......................................................................................................................... 14

5.7 Nominal Thickness Setting............................................................................................................ 15

5.8 Limit Setting......................................................................................................................................15

5.9 Changing Resolution...................................................................................................................... 16

5.10 Memory Management.................................................................................................................. 16

5.11 Key Sound Setting........................................................................................................................ 17

5.12 Warn Sound Setting......................................................................................................................17

5.13 LCD Brightness Setting................................................................................................................17

5.14 Display Standby Setting...............................................................................................................18

5.15 Auto Poweroff Setting................................................................................................................... 18

5.16 Changing Unit System................................................................................................................. 18

5.17 Date and Time setting.................................................................................................................. 18

5.18 Language Setting.......................................................................................................................... 19

5.19 Product Information...................................................................................................................... 19

5.20 Reset System................................................................................................................................ 19

5.21 Print via Bluetooth.........................................................................................................................19

5.22 USB Communication.................................................................................................................... 20

6. Measuring Technologies......................................................................................................................21

6.1 Measuring Method.......................................................................................................................... 21

Page 3

mvip@mitech-ndt.com

6.2 Wall Measurement.......................................................................................................................... 21

sale@ponpe.com

ponpe.com

7 Servicing....................................................................................................................................................21

8 Transport and Storage...........................................................................................................................21

Appendix A Sound Velocities..................................................................................................................22

Appendix B Applications Notes..............................................................................................................23

User Notes.................................................................................................................................................... 25

Page 4

mvip@mitech-ndt.com

1 Overview

Multi-mode: Pulse-Echo mode (P-E mode) and Echo-Echo mode (E-E mode). In Echo-Echo

Wide measuring range : Pulse-Echo mode: (0.65 ~ 600)mm (in Steel). Echo-Echo mode:

V-Path correction to compensate the nonlinearity of the probe

Color TFT display (320×240 TFT LCD) with adjustable backlight, allow the user to work at

Non-volatile memory can store 100 groups of test thickness. One hundred records max for

Two AA size alkaline batteries as the power source. Continuous operating period of no less

With internal Bluetooth module, it can print test report wirelessly.

USB 2.0 communication port. Online transfer of the measured data to PC via USB.

2

tvH

Multi-mode: Pulse-Echo mode and Echo-Echo mode.

Capable of performing measurements on a wide range of material, including metals, plastic,

Special transducer models are available for special application, including for coarse grain

Probe-Zero function, Sound-Velocity-Calibration function

Two-Point Calibration function.

Three working modes: normal mode, scan mode and diff mode.

Coupling status indicator showing the coupling status.

sale@ponpe.com

The model MT660 is a multi-mode ultrasonic thickness gauge. Based on the same operating

principles as SONAR, the instrument is capable of measuring the thickness of various materials

with accuracy as high as 0.1/0.01 millimeters.

The multi-mode feature of the gauge allows the user to toggle between pulse-echo mode

(flaw and pit detection), and echo-echo mode (eliminate paint or coating thickness).

1.1 Product Features

mode, it can test the wall thickness eliminating paint or coating thickness.

(2.5~100)mm

worksites with low visibility.

each group.

than 100 hours (default brightness setting). Display Standby and Auto Power Off functions to

save power.

1.2 Measuring Principle

The ultrasonic thickness gauge determines the thickness of a part or structure by accurately

measuring the time required for a short ultrasonic pulse generated by a transducer to travel

through the thickness of the material, reflect from the back or inside surface, and be returned to

the transducer. The measured two-way transit time is divided by two to account for the

down-and-back travel path, and then multiplied by the velocity of sound in the material. The result

is expressed in the well-known relationship:

Where: H-Thickness of the test piece.

v-Sound Velocity in the material.

t-The measured round-trip transit time.

1.3 Specifications

ceramics, composites, epoxies, glass and other ultrasonic wave well-conductive materials.

material and high temperature applications.

Page 5

mvip@mitech-ndt.com

Units: Metric and Imperial unit selectable.

Battery information indicates the rest capacity of the battery.

Auto sleep and auto power off function to conserve battery life.

USB2.0 communication port

Bluetooth support.

Size: 120mm×67mm×31mm

Weight: 295g

1.4 Transducer Technical Parameters

Model

Freq

MHz

ΦmmMeasuring

Range

Lower

limit

Description

N02

2.5

14

3.0mm~

300.0mm(In

Steel)

40mm (in Gray

Cast Iron

HT200)

20mm

for thick, highly

attenuating, or

highly scattering

materials

N05510

1mm~

600.0mm

(In Steel)

Φ20mm×

3.0mm

Normal

Measurement

N05

/90°

5

10

1mm~

600.0mm

(In Steel)

Φ20mm×

3.0mm

Normal

Measurement

N0776

0.65mm~

200.0mm

(In Steel)

Φ15mm×

2.0mm

For thin pipe wall

or small curvature

pipe wall

measurement

HT5512

1~600mm

(In Steel)

30mm

For high

temperature

(lower than 300℃)

measurement.

P5EE

5

10

P-E: 2~600mm

E-E: 3~100mm

Φ20mm×

3.0mm

Normal

Measurement

and

trough-coating

thickness testing

sale@ponpe.com

ponpe.com

Table 1.1 Transducer Technical Parameters

Page 6

mvip@mitech-ndt.com

1.5 Configuration

No

Item

Qty.

Note

Standar

d Config.

1

Main body

1

2

Probe P5EE(5MHz)

1

3

Couplant

1

4

Instrument Case

1

5

Operating manual

1

6

Alkaline battery

2

AA size

Optional

Config.

7

Probe N02 (2.5MHz)

8

Probe N05/90°(5MHz)

See Table1.1

9

Probe N05 (5MHz)

10

Probe N07(7MHz)

11

Probe HT5(5MHz)

12

Data Pro Software

1

13

USB Cable

1

14

Portable Bluetooth

thermal printer

1

Including

charger,

manual and

other parts.

1. The Main Body 2. Keypad 3. TFT display

sale@ponpe.com

Table 1.2 Instrument Configurations

1.6 Operating Conditions

Operating Temperature: 0℃~+50℃;

Storage Temperature:-20℃~+70℃

Relative Humidity ≤80%;

The surrounding environment should avoid of vibration, strong magnetic field, corrosive medium

and heavy dust.

2 Structure Feature

4. Battery cover 5.P/R socket 6. Probe zero disc 7.Bluetooth status 8.USB interface 9.

Probe

10. Label

Page 7

mvip@mitech-ndt.com

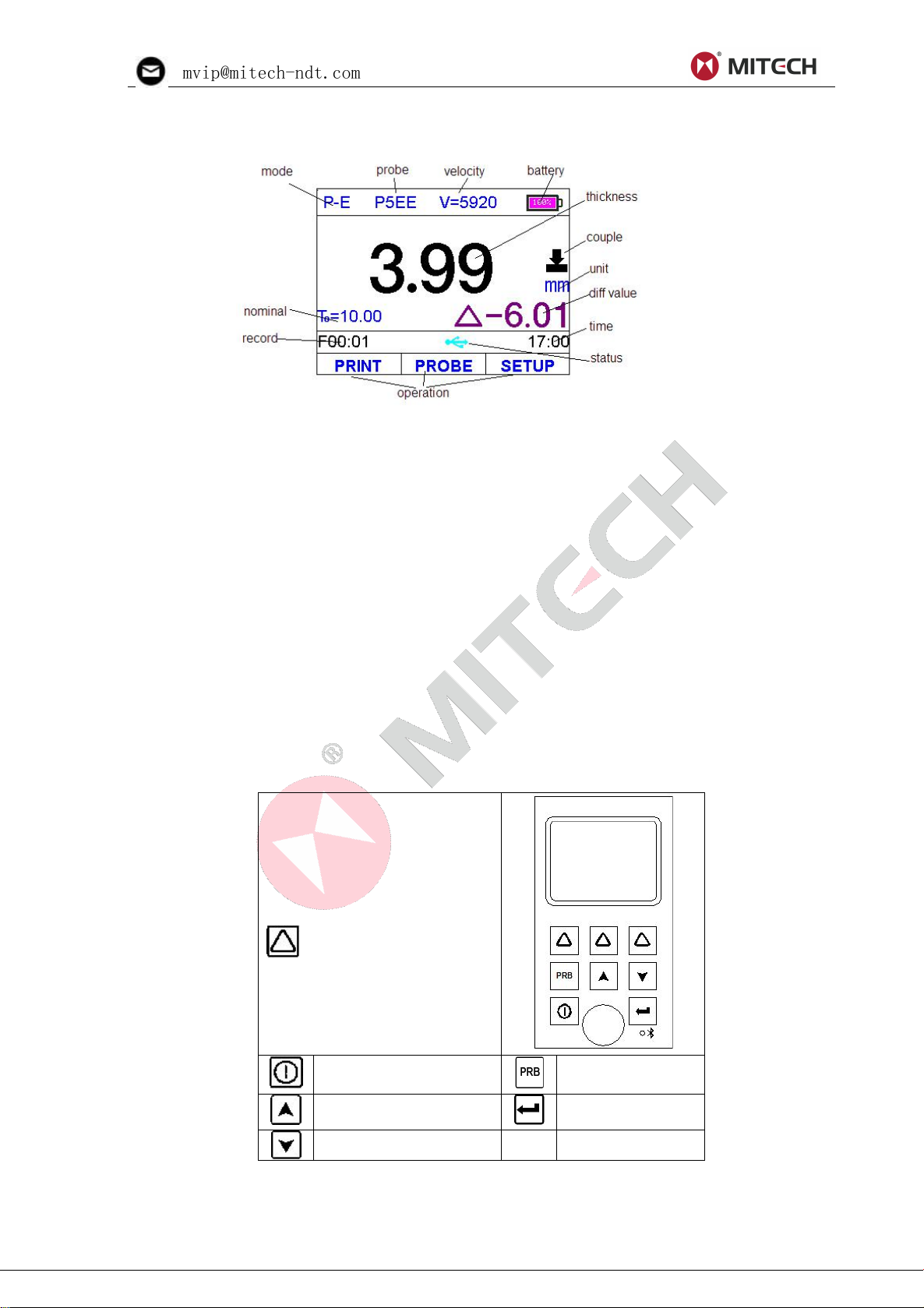

2.1 Main Screen

The instrument is designed to

give the user quick access to

all of the instrument’s

functions. Its easy-to-use menu

system allows any function to

be accessed with several key

presses.

Function keys to select

accordingly the function on the

screen. In the following

sections of this manual, they

are referred to as F1, F2 and

F3 from left to right.

Turn the instrument

on/off , or Cancel

Probe-Zero

operation

Plus or scroll up

Confirm/Enter

Minus or scroll down

sale@ponpe.com

ponpe.com

Mode: "E-E" indicating the instrument work in the Echo-Echo mode; "P–E” indicating it work in the

Pulse-Echo mode;

Probe: Probe selection

Velocity: Sound velocity

Battery: Indicating the rest capacity of the battery.

Thickness: Last test result

Unit: mm or inch

Diff value: Differential result when working in diff mode.

Time: System time

Status: USB and Bluetooth communication status

Operation: Indicate the information about the ongoing operation;

Record: Shows selected data group name and record count.

Couple: Indicate the coupling status

Nominal thickness: the nominal thickness of the test piece

2.2 Keypad Definitions

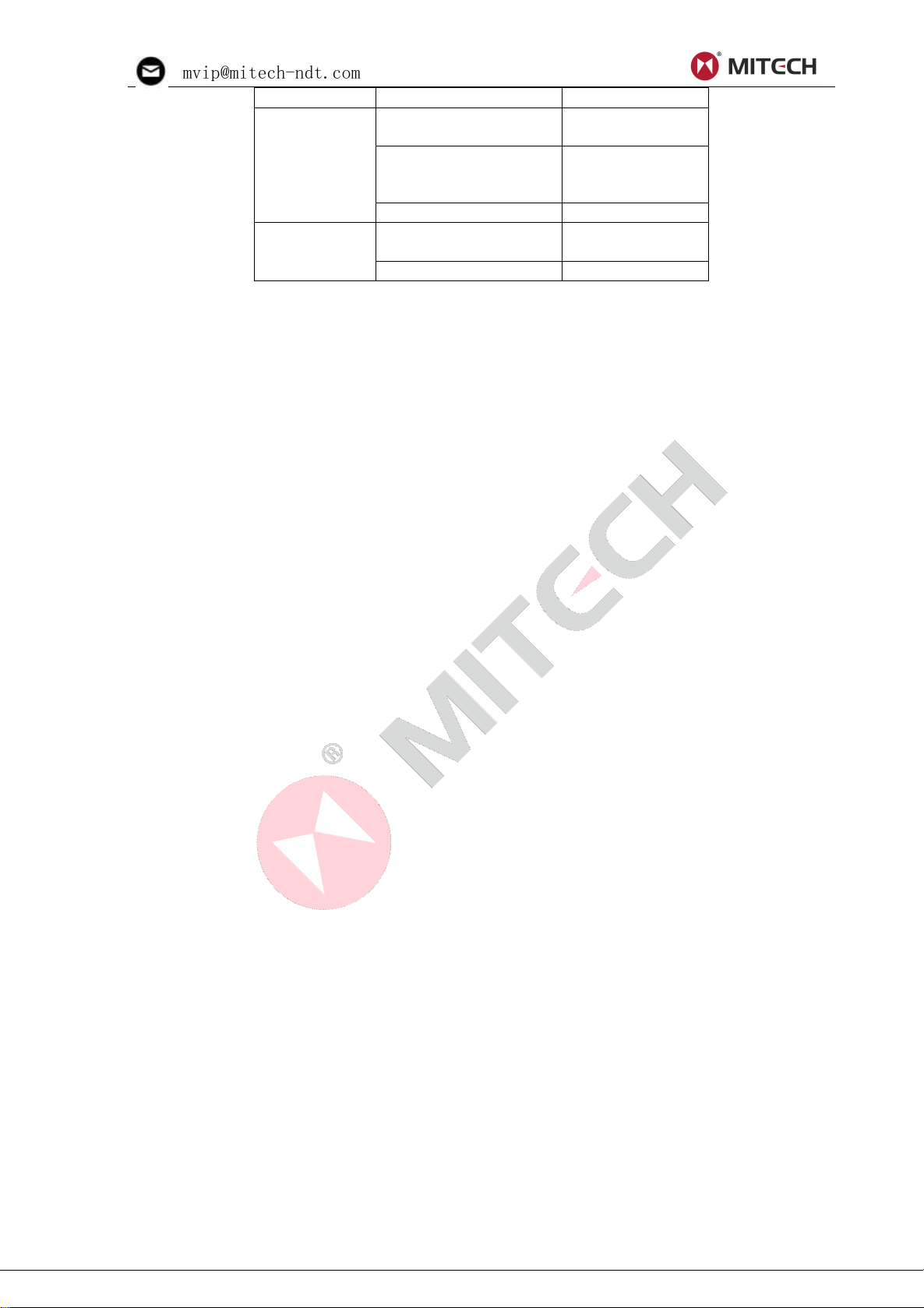

The red LED on the keyboard is used to indicate the Bluetooth communication status as described

in the following table:

Page 8

mvip@mitech-ndt.com

Bluetooth role

LED status

Bluetooth status

Host mode

Fast glittering (150 ms

on, 150 ms turn off)

Searching and

connecting

Fast glittering 5 times

and then turn off after 2

seconds

connecting

Always on

Connected

Slave mode

Slow glittering (800 ms

on, 800 ms turn off)

connecting

Always on

Connected

sale@ponpe.com

3 Test Preparation

3.1 Transducer Selection

The gauge is inherently capable of performing measurements on a wide range of materials,

from various metals to glass and plastics. Different types of material, however, will require the use

of different transducers. Choosing the correct transducer for a job is critical to being able to easily

perform accurate and reliable measurement. The following paragraphs highlight the important

properties of transducers, which should be considered when selecting a transducer for a specific

job.

Generally speaking, the best transducer for a job is one that sends sufficient ultrasonic energy

into the material being measured such that a strong, stable echo is received by the gauge. Several

factors affect the strength of ultrasound as it travels. These are outlined below:

Initial Signal Strength. The stronger a signal is to begin with, the stronger its return echo will

be. Initial signal strength is largely a factor of the size of the ultrasound emitter in the transducer. A

large emitting area will send more energy into the material being measured than a small emitting

area. Thus, a so-called “1/2 inch” transducer will emit a stronger signal than a “1/4 inch”

transducer.

Absorption and Scattering. As ultrasound travels through any material, it is partly absorbed. If

the material through which the sound travels has any grain structure, the sound waves will

experience scattering. Both of these effects reduce the strength of the waves, and thus, the

gauge’s ability to detect the returning echo. Higher frequency ultrasound is absorbed and

scattered more than ultrasound of a lower frequency. While it may seem that using a lower

frequency transducer might be better in every instance, low frequencies are less directional than

high frequencies. Thus, a higher frequency transducer would be a better choice for detecting the

exact location of small pits or flaws in the material being measured.

Geometry of the transducer. The physical constraints of the measuring environment

sometimes determine a transducer’s suitability for a given job. Some transducers may simply be

too large to be used in tightly confined areas. Also, the surface area available for contacting with

the transducer may be limited, requiring the use of a transducer with a small wearface. Measuring

on a curved surface, such as an engine cylinder wall, may require the use of a transducer with a

matching curved wearface.

Temperature of the material. When it is necessary to measure on surfaces that are

exceedingly hot, high temperature transducers must be used. These transducers are built using

special materials and techniques that allow them to withstand high temperatures without damage.

Additionally, care must be taken when performing a “Probe-Zero” or “Calibration to Known

Thickness” with a high temperature transducer.

Selection of the proper transducer is often a matter of tradeoffs between various

characteristics. It may be necessary to experiment with a variety of transducers in order to find one

that works well for a given job.

Page 9

mvip@mitech-ndt.com

The transducer is the “business end” of the instrument. It transmits and receives ultrasonic

its use.

sale@ponpe.com

ponpe.com

sound waves that the instrument uses to calculate the thickness of the material being measured.

The transducer connects to the instrument via the attached cable, and two coaxial connectors.

When using transducers, the orientation of the dual coaxial connectors is not critical: either plug

may be fitted to either socket in the instrument.

The transducer must be used correctly in order for the instrument to produce accurate,

reliable measurements. Below is a short description of the transducer, followed by instructions for

Left figure is a bottom view of a typical transducer. The two semicircles of the wearface are

visible, as is the barrier separating them. One of the semicircles is responsible for conducting

ultrasonic sound into the material being measured, and the other semicircle is responsible for

conducting the echoed sound back into the transducer. When the transducer is placed against the

material being measured, it is the area directly beneath the center of the wearface that is being

measured.

Right figure is a top view of a typical transducer. Press against the top with the thumb or index

finger to hold the transducer in place. Moderate pressure is sufficient, as it is only necessary to

keep the transducer stationary, and the wearface seated flat against the surface of the material

being measured.

3.2 Condition and Preparation of Surfaces

In any ultrasonic measurement scenario, the shape and roughness of the test surface are of

paramount importance. Rough, uneven surfaces may limit the penetration of ultrasound through

the material, and result in unstable, and therefore unreliable, measurements. The surface being

measured should be clean, and free of any small particulate matter, rust, or scale. The presence of

such obstructions will prevent the transducer from seating properly against the surface. Often, a

wire brush or scraper will be helpful in cleaning surfaces. In more extreme cases, rotary sanders or

grinding wheels may be used, though care must be taken to prevent surface gouging, which will

inhibit proper transducer coupling.

Extremely rough surfaces, such as the pebble-like finish of some cast iron, will prove

most difficult to measure. These kinds of surfaces act on the sound beam like frosted

glass on light, the beam becomes diffused and scattered in all directions.

In addition to posing obstacles to measurement, rough surfaces contribute to excessive wear

of the transducer, particularly in situations where the transducer is “scrubbed” along the surface.

Transducers should be inspected on a regular basis, for signs of uneven wear of the wearface. If

the wearface is worn on one side more than another, the sound beam penetrating the test material

may no longer be perpendicular to the material surface. In this case, it will be difficult to exactly

locate tiny irregularities in the material being measured, as the focus of the sound beam no longer

lies directly beneath the transducer.

4 Startup

4.1 Power Supply

Two AA size alkaline batteries are needed as the power supply.

The battery compartment is situated at the instrument back. The cover is fastened with two

Page 10

mvip@mitech-ndt.com

screws. To insert the batteries:

1. Loosen the two screws of the battery cover.

2. Lift the cover off upward.

3. Insert the batteries into the battery compartment.

4. Close the battery compartment and fasten the screws.

5. Turn on the instrument to make sure the battery is installed correctly and firmly.

The start display of the

instrument appears as right

figure.

Press F1 key to change to

a different language.

Press F3 key to skip the

booting check process and

enter the measure mode

immediately.

The instrument carries out

a self-check and then

switches over to the measure

mode automatically if there is

no key operation.

The instrument is now

ready for the first

measurement.

sale@ponpe.com

4.2 Connecting the Probe

To prepare the instrument for operation, you have to connect a probe to it. The instrument is

available with the Lemo socket connectors.

When connecting a probe to the instrument, it’s not only important that the physical connection

be properly made. It’s also important that the instrument is properly configured to work with the

installed probe.

4.3 Starting the Instrument

To start the instrument, press down until display activates. While the device is booting a

splash screen, the serial number of the unit, the installed software version, the date and time of the

system appear on the display.

The instrument will automatically reload last settings. It has a special memory that retains all of

its settings even when the power is off.

To shut off the instrument, keep pressing down key until shutting down message appears.

The gauge also has auto power off function to save battery capacity. If there is no operation

during a specified period of time (setting as the Auto Poweroff delay), the gauge will be powered

off automatically.

Note: The instrument will shut off automatically if the battery capacity level is too low.

4.4 Configuration of the Standby Settings

To save battery power, the device supports the following power states:

Run state – The main unit is running at full frequency

Standby state – After 5 seconds (default setting) the brightness of the LCD display is tuned to a

low level and the CPU is running at reduced frequency. This has no effects on the data or the

memories. Pressing any key or performing a measurement sets the unit back to run state and the

brightness is tuned back.

Power off state – After 2 minutes (default setting) the instrument changes from standby state to

Page 11

mvip@mitech-ndt.com

power off state. The main unit and the display is switched off and consumes almost no energy.

To switch between P-E mode

and E-E mode, press in

the Test Settings dialog.

In the Probe Model dialog,

Use the key and the

key to scroll to the probe

model currently being used.

Finally press or F3 to

confirm the selection. Or press

to cancel and exit.

2 Press the key to

activate the probe zero

mode, as right figure.

3 Apply a single droplet of

ultrasonic couplant to the

face of the metal

probe-disc.

6.

sale@ponpe.com

ponpe.com

Pressing any key will stop the unit entering power off state while it prompts out “Idle Timeout!” and

return back to run state.

The change from run state to standby state is controlled by Display standby delay setting. The

time delay can be configured by the user in the Display Standby Delay dialog box. The main unit

can be reset to run state by any user activity while in standby state.

5 Operations

5.1 Setting the Work Mode

Often times users and inspectors in the field are faced with coated materials such as pipes and

tanks. Typically inspectors will need to remove the paint or coating prior to measuring, or allow for

some fixed amount of error introduced by the paint or coating thickness and velocity.

The error can be eliminated with this gauge by using a special Echo-Echo mode to perform

measurements for applications such as this. The gauge gives you this feature in a simple way

eliminating the need to remove the paint or coating.

5.2 Probe Selection

Be sure to set the right probe model to the instrument. Otherwise, there will be erroneous.

5.3 Perform Probe Zero

Note: Probe Zero operation applies only to Pulse-Echo mode. Do not perform Probe Zero in

Echo-Echo mode.

The key is used to “zero” the instrument in much the same way that a mechanical

micrometer is zeroed. If the gauge is not zeroed correctly, all the measurements that the gauge

makes may be in error by some fixed value. When the instrument is “zeroed”, this fixed error value

is measured and automatically corrected for all subsequent measurements. The instrument may

be “zeroed” by performing the following procedure.:

1 Plug the transducer into the instrument. Make sure that the connectors are fully engaged.

Check that the wearface of the transducer is clean and free of any debris.

4 Press the transducer against the probe disc, making sure that the transducer sits flat against

the surface.

Page 12

mvip@mitech-ndt.com

5 When the progress bar shows complete, remove the transducer from the probe disc. If

7. Press while in probe zero mode will stop the probe zero operation and return to the

In the Set Velocity dialog,

press F1/F2 and / keys

to adjust the velocity value

up or down, until it matches

the sound velocity of the

material to be measured.

You can also press the

key to select among the

preset commonly using

velocities.

1 Perform a Probe-Zero on the standard 4.00 mm disc.

2 Apply couplant to the sample piece.

3 Press the transducer against the sample piece, making sure that the transducer sits flat

4 Having achieved a stable reading, remove the transducer. If the displayed thickness

sale@ponpe.com

necessary, repeat this procedure for times.

6 At this point, the instrument has successfully calculated its internal error factor, and will

compensate for this value in any subsequent measurements. When performing a “probe zero”, the

instrument will always use the sound velocity value of the built-in probe-disc, even if some other

velocity value has been entered for making actual measurements. Though the instrument will

remember the last “probe zero” performed, it is generally a good idea to perform a “probe zero”

whenever the gauge is turned on, as well as any time a different transducer is used. This will

ensure that the instrument is always correctly zeroed.

measurement mode.

5.4 Sound Velocity Calibration

In order for the gauge to make accurate measurements, it must be set to the correct sound

velocity for the material being measured. Different types of material have different inherent sound

velocities. If the gauge is not set to the correct sound velocity, all of the measurements the gauge

makes will be erroneous by some fixed percentage.

The One-Point calibration is the simplest and most commonly used calibration procedure

optimizing linearity over large ranges. The Two-point calibration allows for greater accuracy over

small ranges by calculating the probe zero and velocity.

Note: One and Two point calibrations must be performed on material with the paint or coating

removed. Failure to remove the paint or coating prior to calibration will result in a multi material

velocity calculation that may be different from the actual material velocity intended to be

measured.

5.4.1 Calibration to a known velocity

Note: This procedure requires that the operator knows the sound velocity of the material to be

measured. A table of common materials and their sound velocities can be found in Appendix A of

this manual.

5.4.2 Calibration to a known thickness

Note: This procedure requires a sample piece of the specific material to be measured, the

exact thickness of which is known, e.g. from having been measured by some other means.

against the surface of the sample. The display should show some thickness value, and the

coupling status indicator should appear steadily.

Page 13

mvip@mitech-ndt.com

changes from the value shown while the transducer was coupled, repeat step 3.

5 Press the / key

to enter the “Input Nominal

Thickness” dialog. See right

figure.

6 Press F1/F2 and

/ to input the thickness

value, until it matches the

thickness of the sample

piece.

7

8 Press /F3 to confirm the input. The gauge exits from the input dialog and return to the

9 The gauge is now ready to perform measurements.

1 Perform a Probe-Zero on the standard disc.

2 Apply couplant to the sample piece.

3 Press the transducer against the sample piece, at the first/second calibration point,

4 Having achieved a stable reading, remove the transducer. If the displayed thickness

5 Press the / key to enter the “Input Nominal Thickness” dialog. See right figure.

6 Press F1/F2 and

/ to input the thickness

value, until it matches the

thickness of the sample

piece. Then press to

calibrate the second point,

see the following figure.

7

8

9

10 Figure: Testing the

second point during Two

Point Calibration.

11

12

13 Repeat Step 2 to Step 6 on the second calibration point.

14 Finally press the /F3 to complete Two Point Calibration procedure. The gauge is now

sale@ponpe.com

ponpe.com

measurement mode. It is now displaying the sound velocity value it has calculated based on the

thickness value that was input.

5.4.3 Two Point Calibration

Note: This procedure requires that the operator has two known thickness points on the test

piece that are representative of the range to be measured.

making sure that the transducer sits flat against the surface of the sample. The display should

show some (probably incorrect) thickness value, and the coupling status indicator should appear

steadily.

changes from the value shown while the transducer was coupled, repeat step 3.

ready to perform measurements within this range.

5.5 Making Measurements

When the tool is displaying thickness measurements, the display will hold the last value

measured, until a new measurement is made.

Page 14

mvip@mitech-ndt.com

In order for the transducer to do its job, there must be no air gaps between the wear-face and

Three view modes can be

selected to show the

measured value: Normal

Mode, Scan Mode and Diff

Mode.

Normal Mode. As shown in

right figure, it shows the last

test thickness value.

sale@ponpe.com

the surface of the material being measured. This is accomplished with the use of a “coupling” fluid,

commonly called “couplant”. This fluid serves to “couple”, or transfer, the ultrasonic sound waves

from the transducer, into the material, and back again. Before attempting to make a measurement,

a small amount of couplant should be applied to the surface of the material being measured.

Typically, a single droplet of couplant is sufficient.

After applying couplant, press the transducer (wearface down) firmly against the area to be

measured. The coupling status indicator should appear, and a digit number should appear in the

display. If the instrument has been properly “zeroed” and set to the correct sound velocity, the

number in the display will indicate the actual thickness of the material directly beneath the

transducer.

If the coupling status indicator does not appear, not stable, or the numbers on the display seem

erratic, firstly check to make sure that there is an adequate film of couplant beneath the transducer,

and that the transducer is seated flat against the material. If the condition persists, it may be

necessary to select a different transducer (size or frequency) for the material being measured.

While the transducer is in contact with the material that is being measured, the instrument will

perform four measurements every second, updating its display as it does so. When the transducer

is removed from the surface, the display will hold the last measurement made.

Note:Occasionally, a small film of couplant will be drawn out between the transducer and the

surface as the transducer is removed. When this happens, the gauge may perform a

measurement through this couplant film, resulting in a measurement that is larger or smaller than it

should be. This phenomenon is obvious when one thickness value is observed while the

transducer is in place, and another value is observed after the transducer is removed. In addition,

measurements through very thick paint or coatings may result in the paint or coating being

measured rather than the actual material intended. The responsibility for proper use of the

instrument, and recognition of these types of phenomenon, rests solely with the user of the

instrument.

5.6 View Mode Setting

Page 15

mvip@mitech-ndt.com

Scan Mode. Besides the

last test thickness value, it

also shows the minimum

thickness value and the

maximum thickness during

the test.

Press will reset the

minimum and maximum

value.

Diff Mode. Shows both the

last test thickness value

and the differential

thickness value (between

the absolute thickness

value and the nominal

thickness value)

While the gauge excels at making single point measurements, it is sometimes desirable to

Press F1/F2 key to

move the highlight cursor;

Press arrow keys to

increase/decrease the

values.

Press or F3 key to

confirm the setting.

Press key to cancel the

change and exit.

For the gauge, test

results beyond the limits will

be displayed with red color

to alarm the user. To

change the limit setting,

Press F1/F2 key to

move the highlight cursor;

Press arrow keys to

increase/decrease the

values.

Press or F3 key to

confirm the setting.

Press key to cancel the

sale@ponpe.com

ponpe.com

ponpe.com

examine a larger region, searching for the thinnest point. The gauge includes a feature, called

Scan Mode, which allows it to do just that.

In normal mode, the gauge performs and displays ten measurements every second, which is

quite adequate for single measurements. In Scan Mode, however, the gauge performs over ten

measurements every second, and displays the readings while scanning. While the transducer is in

contact with the material being measured, the gauge is keeping track of the minimum and

maximum measurement it finds. The transducer may be “scrubbed” across a surface, and any

brief interruptions in the signal will be ignored.

5.7 Nominal Thickness Setting

In Differential measurement mode, it needs to set the nominal thickness value of the test

piece. The setting method is as below:

5.8 Limit Setting

Page 16

mvip@mitech-ndt.com

change and exit

5.9 Changing Resolution

The gauge has

selectable display

resolution, which is 0.1mm

and 0.01mm.

Activate the Memory

Manager dialog as right

figure.

Press to move the

cursor; Press or F3 key

to open the View Record

Data dialog, see next

figure.

Press to move the

cursor to the desired

record.

Press F3 to delete the

focused record.

Press F2 to clear all the

records of this group.

Press /F1 to exit.

sale@ponpe.com

When the resolution is set to 0.01mm, the tested piece surface should be smooth to get

accurate test result. When measuring rough surface or coarse grained materials, it is suggested to

use low resolution.

5.10 Memory Management

5.10.1 Store a Record

By simply pressing the key after a new measurement reading appears, the measured

thickness value will be saved to current selected data group. It is added as the last record of the

group.

5.10.2 View the Saved Record

This function provides the user with the ability to view the records in a desired data group

previously saved in memory. Following is the steps:

5.10.3 Select As Current Data Group

There are 100 data groups (F00 ~ F99) inside the gauge that can be used to store the

measurement values. At most 100 records (thickness values) can be stored to each group. You

can change the destination data group to store the measured values as following.

Page 17

mvip@mitech-ndt.com

Activate the Memory

Manager dialog. Press

to focus on the desired data

group. Press F2 to prompt

out the commands list.

Then select the command

“Set” and press to

confirm.

After finished the above steps, the new selected data group will be set as current data group to

Activate the Memory

Manager dialog.

Press to focus on

the desired data group.

Press F2 to prompt out

the commands list. Then

select the command

“Clear” and press to

confirm.

The setting can be

changed by scrolling with

F1 (increase) and F2

(decrease) keys, or by

pressing arrow keys.

Press or F3 key to

confirm the setting.

Press key to cancel

the change and close the

dialog box.

sale@ponpe.com

ponpe.com

store the new coming testing results.

5.10.4 Clear Selected Group

The user may require the contents of an entire data group be completely cleared of all

measurements. This would allow the user to start a new list of measurements starting at storage

location No.00. The procedure is outlined in the following steps.

If the “Clear All” command is selected and confirmed, all the data groups of the gauge will be

cleared.

Note: Once cleared, the data is not able to be recovered!

5.11 Key Sound Setting

Key sound can be configured to on or off. When the key sound is set to on, the buzzer inside

the main unit would make a short audible alarm while press the key each time.

5.12 Warn Sound Setting

Warning sound can be configured to on or off. If the warning sound is set to on, the buzzer

inside the main unit would make a long audible alarm when a new measured value appears. When

the main unit gives out some operation warnings it will also give a alarm sound if the setting is on.

5.13 LCD Brightness Setting

The different brightness of the LCD will affect battery standby time and continuously working

time. .

The instrument consumes less current in lower brightness and consequently increases the

operating time.

Page 18

mvip@mitech-ndt.com

Note: For saving power, lower down the LCD brightness in good light environment.

See right figure of Display

Standby Delay dialog box

for the items of the settings.

Press arrow keys or F2 key

to select the desired item.

Selecting “Disable” item will

forbid the main unit

switching into standby state.

The time delay can be

configured by the user in the

auto shutdown delay dialog

box.

Press arrow keys or F2

key to select the desired item.

Selecting “Disable” item

will forbid the main unit

switching automatically into

power off state.

The instrument supports

both metric and imperial unit

systems.

In the System

Configuration dialog, press

on the Unit System item

to switch back and forth

between imperial and metric

unit system.

sale@ponpe.com

5.14 Display Standby Setting

Standby state lower down the LCD brightness and puts the CPU in a power conserving mode.

The change from run state to standby state is controlled by the setting of the Display standby

delay.

The main unit goes into standby state after a period of time as selected. Carry out a test or

press any key to reactivate the main unit from standby state.

5.15 Auto Poweroff Setting

The change from standby state to power off state is controlled by the setting of automatic

shutdown delay.

Note: If the voltage of the battery is too low, the LCD screen will show “Battery Exhausted!”,

then power off automatically.

5.16 Changing Unit System

5.17 Date and Time setting

For a correct documentation you should always make sure that you are using the correct date

and time setting. Open the system time dialog to set date and time of the instrument system.

The format for date: Year-Month-Date

The format for time: Hour–Minute- Second

Page 19

mvip@mitech-ndt.com

Use F1 and F2 keys to

move the cursor. Use arrow

keys to increase/decrease the

values;

Press /F3 key to confirm

the setting. Press key to

cancel the setting change and

close the dialog box.

Once set, the internal clock of the instrument will maintain the current date and time.

Use the arrow keys and

F2 key to select the operating

language.

Press or F3 key to

confirm the selection.

Press key to cancel

the language change and

close the dialog box.

Information concerning the

instrument model, the

software version and the

serial number of the main unit

is displayed.

Press , , F1 or F3

key to close the dialog box.

Activate the System

Reset function. Then

you will see right dialog.

Press or F3 key to

confirm the reset

operation. Or press F1

key to cancel the reset

operation.

sale@ponpe.com

ponpe.com

5.18 Language Setting

Language of the application software can be selected.

Note: User can also change the operating language on the booting screen during startup.

5.19 Product Information

5.20 Reset System

In case the instrument can no longer be operated, or you need to make a basic initialization

(factory setting), you can reset the instrument to original.

The instrument can be reset by the System Reset function. All the stored data inside the main

unit and user calibration will be cleared during system reset. And the instrument settings will be

reset to default.

To reset the instrument:

NOTE: The effects of resetting the instrument may not be reversed.No key action should be

performed during resetting process.

5.21 Print via Bluetooth

The instrument has Bluetooth function module. It can be connected to a portable Bluetooth

thermal mini-printer for wireless printing. Operating steps to set up the bluetooth connection are as

follows:

1 Start up the Bluetooth mini-printer.

Page 20

mvip@mitech-ndt.com

2 Set the Bluetooth role of

the instrument to Master

mode.

3 The instrument will ask the

operator if need to re-search

nearby Bluetooth printer

shown as right figure.

Select “YES” for the first

time to print. Otherwise,

select “NO”.

The gauge then try to set up a connection with the mini-printer via Bluetooth. Wait for several

Print stored data group

via Bluetooth.

In the memory

manager dialog box, select

“print” will print the

selected data group.

Select “Print All” will print

all data groups stored

inside the instrument.

You can also print out

the test result directly after

each test.

On the main screen,

after each test, simple

press F1 to print out that

test result.

Lift the rubber flaps to uncover the connection port.

Insert the mini-USB end of the USB cable into the USB socket on the upside of main body.

Insert the other end into the USB port of the computer.

sale@ponpe.com

seconds. When the Bluetooth status light on the front panel of the main unit is always on, the

Bluetooth connection between the instrument and the mini-printer is established successfully.

Note: When the instrument is turned off and once again turned on, the Bluetooth

function module will be automatically shut off to save power.

5.22 USB Communication

The instrument is equipped with a USB port on upper left of the instrument.

The PC can be connected with the instrument via the USB cable.

After installing the DataPro software and the USB driver, you can download the stored test data

from the tester.

The DataPro software helps manage and format stored data for high-speed transfer to the PC.

Data can be printed or easily copied and pasted into word processing files and spreadsheets for

further reporting needs. New features include live screen capture mode and database tracking.

Detailed information of the communication software and its usage refer to the software manual.

Page 21

mvip@mitech-ndt.com

6. Measuring Technologies

Keep it away from vibration, strong magnetic field, corrosive medium, dumpiness and dust.

With original packing, transport is allowed on the third grade highway.

sale@ponpe.com

ponpe.com

6.1 Measuring Method

Single point measuring method: Put the probe to any point in the workpiece, the instrument

will show the probe located place thickness.

Two point measuring method: Using the probe to measure two times in the same point of the

tested piece, in two measuring, the probe parting plane keep 90º, the smaller value should be the

thickness of this point.

Multi-point measurement method: Taking times testing in an approximately 30 mm diameter

circular around, the minimum value is the thickness value of the tested piece.

Continuous measurement method: using single point measurement to take continuous

measurement along the specified path with less 5mm interval, the minimum value is the thickness

value of the tested piece.

6.2 Wall Measurement

During measuring, the probe parting plane can be along with the tube axis or vertical tube

axis. If meeting larger tube diameter, you should measure at the vertical axis. And when the tube

diameter is smaller, you should measure in both directions and the minimum value is thickness

value.

7 Servicing

When the gauge appears some other abnormal phenomena, please do not dismantle or adjust

any fixedly assembled parts. Fill in and present the warranty card to us. The warranty service can

be carried on.

8 Transport and Storage

Storage in ordinary temperature.

Page 22

mvip@mitech-ndt.com

Appendix A Sound Velocities

Material

Sound Velocity

in/µs

m/s

Aluminum

0.250

6340-6400

Steel, common

0.233

5920

Steel, stainless

0.226

5740

Brass

0.173

4399

Copper

0.186

4720

Iron

0.233

5930

Cast Iron

0.173-0.229

4400-5820

Lead

0.094

2400

Nylon

0.105

2680

Silver

0.142

3607

Gold

0.128

3251

Zinc

0.164

4170

Titanium

0.236

5990

Tin

0.117

2960

Epoxy resin

0.100

2540

Ice

0.157

3988

Nickel

0.222

5639

Plexiglass

0.106

2692

Polystyrene

0.092

2337

Porcelain

0.230

5842

PVC

0.094

2388

Quartz glass

0.222

5639

Rubber, vulcanized

0.091

2311

Teflon

0.056

1422

Water

0.058

1473

sale@ponpe.com

Page 23

mvip@mitech-ndt.com

Appendix B Applications Notes

sale@ponpe.com

ponpe.com

Measuring pipe and tube

When measuring a piece of pipe to determine the thickness of the pipe wall, orientation of the

transducers is important. If the diameter of the pipe is larger than approximately 4 inches,

measurements should be made with the transducer oriented so that the gap in the wearface is

perpendicular (at right angle) to the long axis of the pipe. For smaller pipe diameters, two

measurements should be performed, one with the wearface gap perpendicular, another with the

gap parallel to the long axis of the pipe. The smaller of the two displayed values should then be

taken as the thickness at that point.

Measuring hot surfaces

The velocity of sound through a substance is dependant upon its temperature. As materials heat

up, the velocity of sound through them decreases. In most applications with surface temperatures

less than about 100℃, no special procedures must be observed. At temperatures above this point,

the change in sound velocity of the material being measured starts to have a noticeable effect

upon ultrasonic measurement. At such elevated temperatures, it is recommended that the user

perform a calibration procedure on a sample piece of known thickness, which is at or near the

temperature of the material to be measured. This will allow the gauge to correctly calculate the

velocity of sound through the hot material.

When performing measurements on hot surfaces, it may also be necessary to use a specially

constructed high-temperature transducer. These transducers are built using materials which can

withstand high temperatures. Even so, it is recommended that the probe be left in contact with the

surface for as short a time as needed to acquire a stable measurement. While the transducer is in

contact with a hot surface, it will begin to heat up, and through thermal expansion and other effects,

may begin to adversely affect the accuracy of measurements.

Measuring laminated materials

Laminated materials are unique in that their density (and therefore sound-velocity) may vary

considerably from one piece to another. Some laminated materials may even exhibit noticeable

changes in sound-velocity across a single surface. The only way to reliably measure such

materials is by performing a calibration procedure on a sample piece of known thickness. Ideally,

this sample material should be a part of the same piece being measured, or at least from the same

lamination batch. By calibrating to each test piece individually, the effects of variation of

sound-velocity will be minimized.

An additional important consideration when measuring laminates, is that any included air gaps or

pockets will cause an early reflection of the ultrasound beam. This effect will be noticed as a

sudden decrease in thickness in an otherwise regular surface. While this may impede accurate

measurement of total material thickness, it does provide the user with positive indication of air

gaps in the laminate.

Measuring through paint & coatings

Page 24

mvip@mitech-ndt.com

Measuring through paints and coatings are also unique, in that the velocity of the paint/ coating will

sale@ponpe.com

be significantly different form the actual material being measured. A perfect example of this would

be a mild steel pipe with approximately 0.6mm of coating on the surface. Where the velocity of the

pipe is 5920m/s, and the velocity of the paint is 2300m/s. If the user is calibrated for mild steel pipe

and measures through both materials, the actual coating thickness will appear to be 2.5 times

thicker than it actually is, as a result of the differences in velocity. This error can be eliminated by

using a special echo-echo mode to perform measurements for applications such as these. In

echo-echo mode, the paint/ coating thickness will be eliminated entirely and the steel will be the

only material measured.

Suitability of materials

Ultrasonic thickness measurements rely on passing a sound wave through the material being

measured. Not all materials are good at transmitting sound. Ultrasonic thickness measurement is

practical in a wide variety of materials including metals, plastics, and glass. Materials that are

difficult include some cast materials, concrete, wood, fiberglass, and some rubber.

Couplants

All ultrasonic applications require some medium to couple the sound from the transducer to the

test piece. Typically a high viscosity liquid is used as the medium. The sound used in ultrasonic

thickness measurement does not travel through air efficiently.

A wide variety of couplant materials may be used in ultrasonic gauging. Propylene glycol is

suitable for most applications. In difficult applications where maximum transfer of sound energy is

required, glycerin is recommended. However, on some metals glycerin can promote corrosion by

means of water absorption and thus may be undesirable. Other suitable couplants for

measurements at normal temperatures may include water, various oils and greases, gels, and

silicone fluids. Measurements at elevated temperatures will require specially formulated high

temperature couplants.

Inherent in ultrasonic thickness measurement is the possibility that the instrument will use the

second rather than the first echo from the back surface of the material being measured while in

standard pulse-echo mode. This may result in a thickness reading that is TWICE what it should be.

The Responsibility for proper use of the instrument and recognition of these types of phenomenon

rests solely with the user of the instrument.

Page 25

mvip@mitech-ndt.com

User Notes

Damage caused by man-made or improper keeping;

Self-dismantle or non-special repair shop dismantle;

Do not follow the requirement of service registration or warranty expired;

Consumable parts.

MITECH users have lifelong maintenance service

Free maintenance, inspection, software upgrade and etc.

China

Post code:100094

Website:www.mitech-ndt.com

Email:mvip@mitech-ndt.com

Tel:0086-10-58858658

sale@ponpe.com

ponpe.com

Warranty:

The product is guaranteed for one year since purchased. Log www.mitech-ndt.com or follow our

company official public platform to register for maintenance. Please fill the blanks as required, if

the product is not registered for maintenance, it will follow the date of manufacturer.

When applying for maintenance, please visit our official website, www.mitech-ndt.com or official

accounts, submit “online reporting to repair” sheet.

In accordance with the international relevant regulations, the following are not within the scope of

free warranty,

Service promise:

Add:Room E506B, YingChuangDongLi Park, 1# of ShangDi East Road, Haidian District, Beijing,

Loading...

Loading...